Page 1

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

Copyright 1991, Texas Instruments Incorporated

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

• High-Resolution, Solid-State Image Sensor

for NTSC B/W TV Applications

• 11-mm Image-Area Diagonal, Compatible

With 2/3” Vidicon Optics

• 754 (H) x 244 (V) Active Elements in

Image-Sensing Area

• Low Dark Current

• Electron-Hole Recombination Antiblooming

• Dynamic Range . . . More Than 60 dB

• High Sensitivity

• High Photoresponse Uniformity

• High Blue Response

• Single-Phase Clocking

• Solid-State Reliability With No Image

Burn-in, Residual Imaging, Image

Distortion, Image Lag, or Microphonics

description

The TC241 is a frame-transfer charge-coupled device (CCD) image sensor designed for use in single-chip B/W

NTSC TV applications. The device is intended to replace a 2/3-inch vidicon tube in applications requiring small

size, high reliability, and low cost.

The image-sensing area of the TC241 is configured into 244 lines with 780 elements in each line. Twenty-four

elements are provided in each line for dark reference. The blooming-protection feature of the sensor is based

on recombining excess charge with charge of opposite polarity in the substrate. This antiblooming is activated

by supplying clocking pulses to the antiblooming gate, which is an integral part of each image- sensing element.

The sensor is designed to operate in an interlace mode, electronically displacing the image-sensing elements

by one-half of a vertical line during the charge integration period in alternate fields, effectively increasing the

vertical resolution and minimizing aliasing. The device can also be run as a 754 (H) by 244 (V) noninterlaced

sensor with significant reduction in the dark signal.

A gated floating-diffusion detection structure with an automatic reset and voltage reference incorporated on-chip

converts charge to signal voltage. A low-noise, two-stage, source-follower amplifier buffers the output and

provides high output-drive capability.

The TC241 is built using TI-proprietary virtual-phase technology, which provides devices with high blue

response, low dark current, high photoresponse uniformity, and single-phase clocking.

The TC241 is characterized for operation from –10°C to 45°C.

This MOS device contains limited built-in gate protection. During storage or handling, the device leads should be shorted together

or the device should be placed in conductive foam. In a circuit, unused inputs should always be connected to SUB. Under no

circumstances should pin voltages exceed absolute maximum ratings. Avoid shorting OUTn to ADB during operation to prevent

damage to the amplifier. The device can also be damaged if the output terminals are reverse-biased and an excessive current is

allowed to flow. Specific guidelines for handling devices of this type are contained in the publication

Guidelines for Handling

Electrostatic-Discharge-Sensitive (ESDS) Devices and Assemblies

available from Texas Instruments.

SUB

GND

AMP GND

OUT1

OUT2

OUT3

ADB

TDB

SAG

IAG

SUB

SUB

CDB

IDB

TRG

SRG1

SRG2

SRG3

SAG

IAG

ABG

SUB

22

21

20

19

18

17

16

15

14

13

1211

10

9

8

7

6

5

4

3

2

1

DUAL-IN-LINE PACKAGE

(TOP VIEW)

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Page 2

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

functional block diagram

Clearing Drain

Dark-Reference Elements

Amplifiers

OUT2

OUT3

ADB

TDB

SAG

IAG

2

3

4

5

6

7

8

OUT1

9

AMP GND GND

10

SRG3

SRG2

SRG1

TRG

CDB13IDB

14

15

16

17

18

SAG

19

IAG

ABG

20

21

Gates and Serial Registers

Multiplexer, Transfer

Storage Area

Blooming Protection

Image Area With

Top Drain

6 Dummy

Elements

Page 3

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

sensor topology diagram

Area

Image-Storage

Area

Image-Sensing

488

244

251

251

251

One 1/2-Amplitude Element

Columns

6 Dummy

1

3

753

1

24

8

8

7

780

One 1/2-Amplitude Element

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

ABG 21 I Antiblooming gate

ADB 5 I Supply voltage for amplifier-drain bias

AMP GND 9 Amplifier ground

CDB 13 I Supply voltage for clearing-drain bias

GND 10 Ground

IAG

†

2 I Image-area gate

IAG

†

20 I Image-area gate

IDB 14 I Supply voltage for input diode bias

OUT1 8 O Output signal 1

OUT2 7 O Output signal 2

OUT3 6 O Output signal 3

SAG

†

3 I Storage-area gate

SAG

†

19 I Storage-area gate

SRG1 16 I Serial-register gate 1

SRG2 17 I Serial-register gate 2

SRG3 18 I Serial-register gate 3

SUB

†

1 Substrate and clock return

SUB

†

11 Substrate and clock return

SUB

†

12 Substrate and clock return

SUB

†

22 Substrate and clock return

TDB 4 I Supply voltage for top-drain bias

TRG 15 I Transfer gate

†

All pins of the same name should be connected together externally.

Page 4

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description

The TC241 consists of four basic functional blocks: (1) the image-sensing area, (2) the image-storage area,

(3) the multiplexer with serial registers and transfer gates, and (4) the buffer amplifier with charge-detection

nodes. The location of each of these blocks is shown in the functional block diagram.

image-sensing storage areas

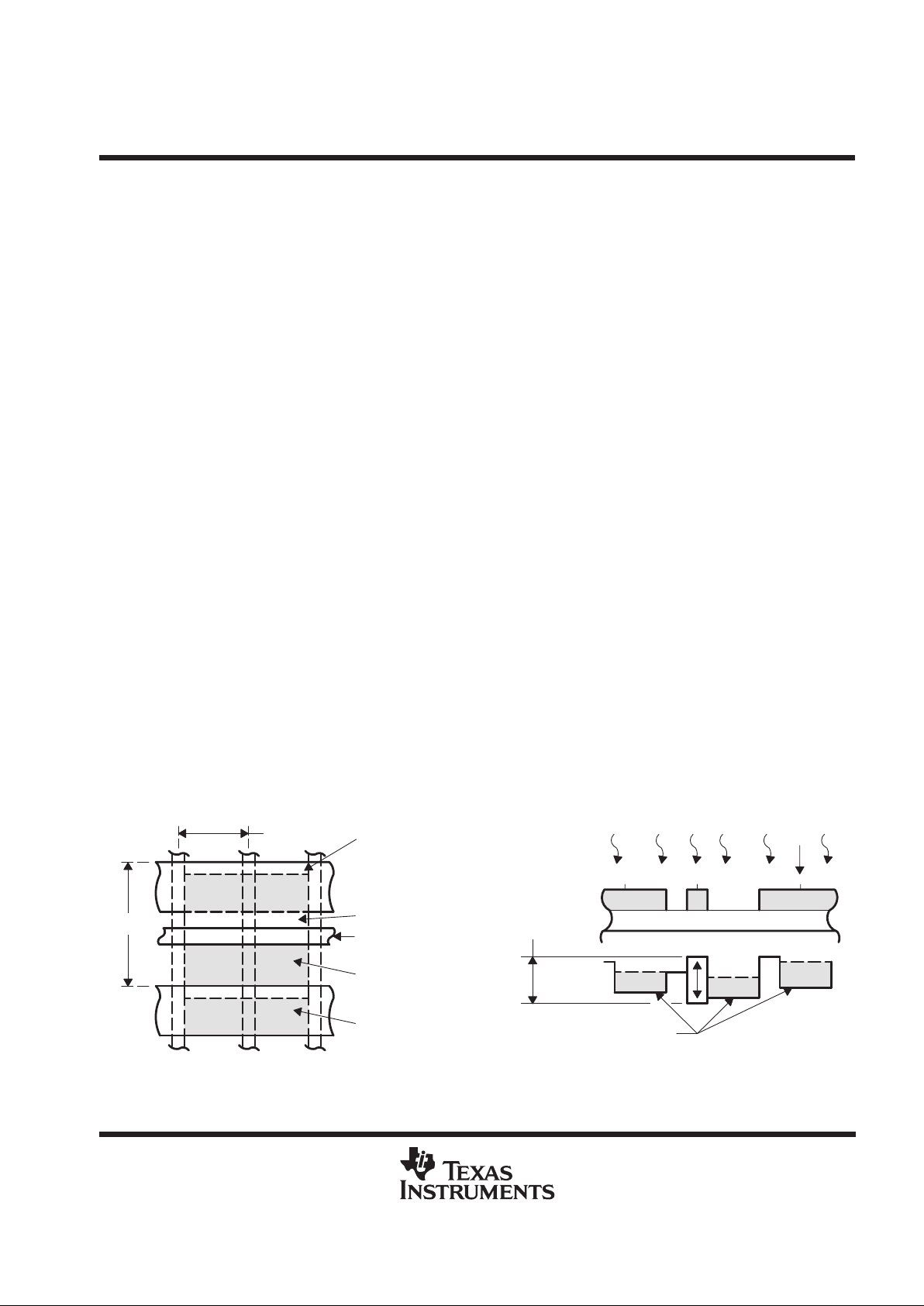

Cross sections with potential-well diagrams and top views of image-sensing and storage-area elements are

shown in Figure 1 and Figure 2. As light enters the silicon in the image-sensing area, free electrons are

generated and collected in the potential wells of the sensing elements. During this time, the antiblooming gate

is activated by the application of a burst of pulses every horizontal-blanking interval. This prevents blooming

caused by the spilling of charge from overexposed elements into neighboring elements. After the completion

of integration, the signal charge is transferred into the storage area. T o generate the dark reference necessary

in subsequent video-processing circuits for restoration of the video-black level, 23 full columns and one

half-column of elements at the left edge of the image-sensing area are shielded from incident light. Two full

columns and one half-column of elements at the right of the image-sensing area are also shielded from incident

light. The total number of elements per row is 780 (753 active elements plus 25 shielded elements and 2

transitional elements).

multiplexer with transfer gates and serial registers

The multiplexer and transfer-gates transfer charge line by line from the image-element columns into the

corresponding serial register and prepare it for readout. Multiplexing is activated during the horizontal-blanking

interval by applying appropriate pulses to the transfer gates and serial registers. The required pulse timing is

shown in Figure 3. A drain is included in this area to provide the capability to quickly clear the image-sensing

and storage areas of unwanted charge. Such charge can accumulate in the imager during the start-up of

operation or under special circumstances when nonstandard TV operation is desired.

buffer amplifier with charge-detection nodes

The buffer amplifier converts charge into a video signal. Figure 4 shows the circuit diagram of a charge-detection

node and one of the three amplifiers. As charge is transferred into the detection node, the potential of this node

changes in proportion to the amount of signal received. This change is sensed by an MOS transistor and, after

proper buffering, the signal is supplied to the output terminal of the image sensor . After the potential change has

been sensed, the node is reset to a reference voltage supplied by an on-chip reference generator. The reset

is accomplished by a reset gate that is connected internally to the serial register. The detection nodes and

corresponding amplifiers are located some distance from the edge of the storage area; six dummy elements

are used to span this distance. The location of the dummy elements is shown in the functional block diagram.

ABG

IAG

11.5 µm

Clocked Barrier

Virtual Barrier

Antiblooming Gate

Virtual Well

Clocked Well

Light

Antiblooming

Clocking Levels

Accumulated Charge

27 µm

Figure 1. Charge-Accumulation Process

Page 5

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SAG

Channel Stops

Virtual Phase

Clocked Phase

Figure 2. Charge-Transfer Process

Page 6

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Composite

Blanking

SRG3

SRG2

SRG 1

TRG

SAG

IAG

ABG

Blanking Interval

Horizontal

Expanded

Figure 3. Timing Diagram

Page 7

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

OUTn

ADB

SRGn

Two-Stage

Source-

Follower

Amplifier

Reset Gate

and

Output Diode

Detection Node

CCD Register

Virtual

Gate

Clocked

Gate

Reference Generator

Figure 4. Buffer Amplifier and Charge-Detection Node

Page 8

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

spurious-nonuniformity specification

The spurious-nonuniformity specification of the TC241 CCD grades –10, –20, –30, and –40 is based on several

sensor characteristics:

• Amplitude of the nonuniform pixel

• Polarity of the nonuniform pixel

– Black

– White

• Location of the nonuniformity (see Figure 5)

– Area A

– Element columns near horizontal center of the area

– Element rows near vertical center of the area

– Area B

– Up to the pixel or line border

– Up to area A

– Other

– Edge of the imager

– Up to area B

• Nonuniform pixel count

• Distance between nonuniform pixels

• Column amplitude

The CCD sensors are characterized in both an illuminated condition and a dark condition. In the dark condition,

the nonuniformity is specified in terms of absolute amplitude as shown in Figure 6. In the illuminated condition,

the nonuniformity is specified as a percentage of the total illumination as shown in Figure 7.

BA

20 Pixels

Lines

11

15 Pixels

Lines

7

Pixels

360

Lines

233

Figure 5. Sensor-Area Map

Page 9

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

mV

Amplitude

t

Illumination

% of Total

t

Figure 6. Pixel-Nonuniformity, Figure 7. Pixel-Nonuniformity,

Dark Condition Illuminated Condition

The grade specification for the TC241 is as follows (CCD video-output signal is 50 mV ±10 mV):

Pixel-nonuniformity:

DARK CONDITION ILLUMINATED CONDITION

DISTANCE

NONUNIFORM PIXEL TYPE

SEPARATION

PART

PIXEL

WHITE BLACK W/B

†

% OF TOTAL

TOTAL

‡

NUMBER

AMPLITUDE, x

(

mV

)

AREA AREA AREA

ILLUMINATION

AREA A

AREA B

COUNT

‡

X Y AREA

()

A B A B A B

TC241-20 x > 3.5 0 0 0 0 0 0 x > 5 0 0 — — — —

2.5 < x ≤ 3.5 2 5 2 5 2 5 5.0 < x ≤ 7.5 2 5

TC241-30

x > 3.5 0 0 0 0 0 0 x > 7.5 0 0

12

10080A

3.5 < x ≤ 7 3 7 3 7 3 7 7.5 < x ≤ 15 3 7

TC241-40

x > 7 0 0 0 0 0 0 x > 15 0 0

15

— — —

†

White and black nonuniform pixel pair

‡

The total spot count is the sum of all nonuniform white, black, and white/black pairs in the dark condition added to the number of nonuniform black

pixels in the illuminated condition. The sum of all nonuniform combinations do not exceed the total count.

Column nonuniformity:

PART

COLUMN

WHITE BLACK

PART

NUMBER

AMPLITUDE, x

AREAS AREAS

NUMBER

(mV)

A AND B A AND B

TC241-20 x > 0.3 0 0

TC241-30 x > 0.5 0 0

TC241-40 x > 0.7 0 0

Page 10

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Supply voltage range, V

CC

: ADB, CDB, IDB, TDB (see Note 1) 0 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, V

I

: ABG, IAG, SAG, SRG, TRG –15 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

–10°C to 45°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

STG

–30°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to the substrate terminal.

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

CC

ADB, CDB, IDB, TDB 11 12 13 V

Substrate bias voltage 0 V

High level 1.5 2 2.5

IAG

Intermediate level

§

–5

Low level –10 –9 –8

High level 1.5 2 2.5

SRG1, SRG2, SRG3

Low level –10 –9 –8

High level 2 4 6

I

nput voltage,

V

I

‡

ABG

Intermediate level

§

–2.5

V

Low level –7

High level 1.5 2 2.5

SAG

Low level –10 –9 –8

High level 1.5 2 2.5

TRG

Low level –10 –9 –8

IAG, SAG 2.05

Clock frequency, f

clock

SRG1, SRG2, SRG3, TRG 4.77

MHz

ABG 2.05

Load capacitance OUT1, OUT2, OUT3 8 pF

Operating free-air temperature, T

A

–10 45 °C

‡

The algebraic convention, in which the least-positive (most negative) value is designated minimum, is used in this data sheet for clock voltage

levels.

§

Adjustment is required for optimal performance.

Page 11

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating ranges of supply voltage and operating

free-air temperature (unless otherwise noted)

PARAMETER MIN TYP

†

MAX UNIT

Dynamic range (see Note 2) Antiblooming disabled (see Note 3) 60 dB

Charge-conversion factor 1.4 1.6 1.8 µV/e

Charge-transfer efficiency (see Note 4) 0.9999 0.99995

Signal-response delay time, τ (see Note 5 and Figure 11) 18 20 22 ns

Gamma (see Note 6) 0.97 0.98

Output resistance 700 800 Ω

1/f noise (5 kHz) 0.13

Noise voltage

Random noise (f = 100 kHz) 0.11

µ

V/√H

z

Noise-equivalent signal 120 electrons

ADB (see Note 7) 20

Rejection ratio at 4.77 MHz SRG1, SRG2, SRG3 (see Note 8) 40 dB

ABG (see Note 9) 20

Supply current 5 mA

IAG 12000

SRG1, SRG2, SRG3 120

Input capacitance, C

i

ABG 4000 pF

TRG 350

SAG 14000

†

All typical values are at TA = 25 °C

NOTES: 2. Dynamic range is –20 times the logarithm of the mean-noise signal divided by the saturation-output signal.

3. For this test, the antiblooming gate must be biased at the intermediate level.

4. Charge-transfer efficiency is one minus the charge loss per transfer in the output register. The test is performed in the dark using

an electrical input signal.

5. Signal-response delay time is the time between the falling edge of the SRG clock pulse and the output-signal valid state.

6. Gamma (γ) is the value of the exponent in the equation below for two points on the linear portion of the transfer-function curve (this

value represents points near saturation):

ǒ

Exposure (2)

Exposure (1)

Ǔ

g

+

ǒ

Output signal (2)

Output signal (1)

Ǔ

7. ADB rejection ratio is –20 times the logarithm of the ac amplitude at the output divided by the ac amplitude at ADB.

8. SRGn rejection ratio is –20 times the logarithm of the ac amplitude at the output divided by the ac amplitude at SRGn.

9. ABG rejection ratio is –20 times the logarithm of the ac amplitude at the output divided by the ac amplitude at ABG.

Page 12

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

optical characteristics, TA = 40°C (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

No IR filter

Measured at V

150

Sensitivit

y

With IR filter

U

(see Notes 10 and 11)

19

mV/l

x

Saturation signal, V

sat

(see Note 12) Antiblooming disabled, interlace off 320 400 mV

Maximum usable signal, V

use

Antiblooming enabled, interlace on 180 360 mV

Interlace on 100

Blooming-overload ratio (see Note 13)

Interlace off 200

Image-area well capacity 200 x 10

3

electrons

Smear (see Note 14) See Note 15 0.00072

Dark current Interlace off TA = 21°C 0.027 nA/cm

2

TC241-30 15

Dark signal (see Note 16)

TC241-40 20

mV

p

TC241-30 3.5

Pixel uniformit

y

Output signal

= 50 mV

±10 mV

TC241-40 5

mV

p

TC241-30 0.5

Column uniformit

y

Output signal

= 50 mV

±10 mV

TC241-40 0.7

mV

Shading Output signal = 100 mV 15%

NOTES: 10. Sensitivity is measured at an integration time of 16.667 ms with a source temperature of 2856 K. A CM-500 filter is used.

11. VU is the output voltage that represents the threshold of operation of antiblooming. VU ≈ 1/2 saturation signal.

12. Saturation is the condition in which further increase in exposure does not lead to further increase in output signal.

13. Blooming-overload ratio is the ratio of blooming exposure to saturation exposure.

14. Smear is a measure of the error induced by transferring charge through an illuminated pixel in shutterless operation. It is equivalent

to the ratio of the single-pixel transfer time during a fast dump to the exposure time using an illuminated section that is 1/10 of the

image-area vertical height with recommended clock frequencies.

15. Exposure time is 16.67 ms and the fast-dump clocking rate during vertical timing is 2.05 MHz.

16. Dark-signal level is measured from the dummy pixels.

Page 13

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

DR (dynamic range)

+

camera white-clip voltage

V

n

(light input)

Lux

Enabled

With Antiblooming

Blooming Point

Well Capacity

Dependent on

Disabled

With Antiblooming

Blooming Point

Gate High Level

Upon Antiblooming

Level Dependent

DR

V

n

V

sat (min)

V

use (typ)

V

use (max)

V

O

NOTES: A. V

use (typ)

is defined as the voltage determined to equal the camera white clip. This voltage must be less than V

use

(max)

.

B. A system trade-off is necessary to determine the system light sensitivity versus the signal/noise ratio. By lowering

the V

use (typ)

, the light sensitivity of the camera is increased; however, this sacrifices the signal/noise ratio of the

camera.

Vn = noise-floor voltage

V

sat (min)

= minimum saturation voltage

V

use (max)

= maximum usable voltage

V

use (typ)

= typical user voltage (camera white clip)

Figure 8. Typical V

sat

, V

use

Relationship

Page 14

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

Slew rate between 10% and 90% = 70 to 120 V/µs

Ratio t1 : t2 at 2 MHz = 4:3

Ratio t1 : t2 at 1 MHz = 1:1

0%

VIL max

Intermediate Level

VIH min

100%

t1 t2

Figure 9. Typical Clock Waveform for ABG, IAG, and SAG

Slew rate between 10% and 90% = 300 V/µs

Ratio t1 : t2 = 1:1

0%

VIL max

10%

VIH min

100%

t1 t2

Figure 10. T ypical Clock Waveform for SRG1, SRG2, SRG3, and TRG

Hold

and

Sample

100%

90%

OUT

SRG

– 8 V

0%

– 8 V to –10 V

1.5 V to 2.5 V

CCD Delay

τ

15 ns10 ns

Figure 11. SRG and CCD Output Waveforms

Page 15

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

VERTICAL MODULATION

TRANSFER FUNCTION

(BARS PARALLEL TO SERIAL REGISTER)

0.4

0.2

0

0 0.2 0.4 0.6

MTF

0.6

0.8

Normalized Spatial Frequency

1

0.8 1

0

3.7 7.4 11.1 14.8 18.5

Spatial Frequency – Cycles/mm

λ = 400 to 700-nm Monochromatic Light

HORIZONTAL MODULATION

TRANSFER FUNCTION

(BARS PERPENDICULAR TO SERIAL REGISTER

)

0.4

0.2

0

0 0.2 0.4 0.6

MTF

0.6

0.8

Normalized Spatial Frequency

1

0.8 1

0

8.7 17.4 26.1 34.8 43.5

Spatial Frequency – Cycles/mm

λ = 400 to 700-nm Monochromatic Light

V

ADB

= 12 V

TA = 25°C

V

ADB

= 12 V

TA = 25°C

Figure 12 Figure 13

1

Noise –

10

f – Frequency – Hz

AMPLIFIER NOISE VOLTAGE

vs

FREQUENCY

100

1000

V

ADB

= 12 V

nV/ Hz

10

3

10

4

10

5

10

6

10

7

0.1

0.01

1

400 600 800 1000 1200

Responsivity – A/W

Incident Wavelength – nm

RESPONSIVITY

vs

WAVELENGTH OF INCIDENT LIGHT

Quantum Efficiency

70%

50%

30%

20%

10%

7%

5%

3%

2%

100%

V

ADB

= 12 V

TA = 25°C

TA = 25°C

Figure 14 Figure 15

Page 16

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

TMS3471C

TL1593

TC241

TMS3472A

4.7 µF

+

+

+

+

100 Ω

OUT1

OUT2

OUT3

GT3

GT1

GT2

15 pF

14.3-MHz

Oscillator

20 pF

4443424140393837363534

1

2

3

4

5

6

7

8

9

10

11

33

32

31

30

29

28

27

26

25

24

23

V

CC

1213141516171819202122

L

10

11

16

15

14

13

12

1

2

3

4

5

6

7

8

ADB

10

22

21

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

9

V

ABG–

ABLVL

V

ABG+

V

TMS3473B

IALVL

V

SS

19

18

17

16

15

14

13

12

11

1

2

3

4

5

6

7

8

9

9

8

7

6

5

4

3

2

1

11

12

13

14

15

16

17

18

19

47 kΩ

47 kΩ

100 Ω

100 Ω

100 Ω

4.7 µF

4.7 µF

4.7 µF

100 Ω

100 Ω

100 Ω

9

SC (90)

SC

BF

CBLK

CSYNC

CP1

CP2

BCP2

CP2

47 kΩ

47 kΩ

100 pF

11

12

1 kΩ

SH2, 3

SH1

1 kΩ

SH2, 3

SH1

V

CC

4.7 kΩ

V

CC

ABS2

ABS1

ABS0

ADB

V

CC

V

SS

V

ABLVL

IALVL

V

ABG+

V

ABG–

12 V

5 V

–10 V

2 V

–2.5 V

–5 V

4 V

–6 V

DC VOLTAGES

10

20

V

SS

V

AGB+

GND

PD

SAIN

MIDSEL

ABIN

IAIN

I

/N

IALVL

V

AGB–

V

CC

SAOUT

ABOUT

IAOUT

ABLVL

V

CC

ABSR

IASR

V

SS

DLADJ

GND

PD

SRG2,3IN

SRG1IN

TRGIN

2,3PC1

2,3PC2

SSR

10

V

SS

20

V

SS

1PC2

1PC1

V

CC

SRG3OUT

SRG2OUT

SRG1OUT

TRGOUT

V

CC

TSR

SUB

ABG

IAG

SAG

SRG3

SRG2

SRG1

TRG

IDB

CDB

SUB

SUB

IAG

SAG

TDB

ADB

OUT3

OUT2

OUT1

AMPGND

GND

SUB

ANLGV

CC

AIN1

CIN1

IAN2

CIN2

AIN3

CIN3

ANLG GND

S/H

1

S/H

2

S/H3

DGTL V

CC

OUT1

OUT2

OUT3

DGTL GND

V

CC

CLK2M

HGATE

VGATE

WHTB

WHTA

VDGPSB

I/N

HIGH

PD

PS

GT

ABIN

PI

SH2, 3

SH1

GND

T

S1

S2, 3

X2

GT1

GT2

GT3

BCPS0

BCPS1

VDS

E/LFIBCP1

X1

‡

‡

‡

SUPPORT CIRCUITS

DEVICE PACKAGE APPLICATION FUNCTION

TMS3471CFS 44 pin flatpack Timing generator NTSC timing generator

TMS3472ADW 20 pin flatpack with tabs Serial driver Driver for SRG1, SRG2, SRG3, and TRG

TMS3473BDW 20 pin small outline Parallel driver Driver for ABG, IAG, and SAG

TL1593CNS 16 pin small outline (EIAJ) Sample and hold Three-channel sample-and-hold IC

Figure 16. Typical Application Circuit Diagram

†

Decoupling capacitors are not shown.

‡

TI recommends designing AC coupled systems.

Page 17

TC241

780- × 488-PIXEL CCD IMAGE SENSOR

SOCS006C – AUGUST 1986 – REVISED DECEMBER 1991

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

The package for the TC241 consists of a ceramic base, a glass window, and a 22-lead frame. The glass window is

sealed to the package by an epoxy adhesive. The package leads are configured in a dual in-line organization and

fit into mounting holes with 2.54 mm (0.10 in) center-to-center spacings.

(0.217 ± 0.030)

5,50 ± 0,76

3,86 (0.152) MAX

Optical Center

27,81 (1.095) MAX

8,00 (0.315)

23,39 (0.921)

0,25 (0.010)

10,16 (0.400) TYP

2,79 (0.110)

MAX

(0.730)

18,54

2,01 (0.079)

Index Dot

9,35 (0.368)

REF

0,46 (0.018)

2,54 (0.100)

(see Note D)

18,24

(0.718)

2,01 x 2,39

(0.079 x 0.094)

ALL LINEAR DIMENSIONS ARE IN MILLIMETERS AND PARENTHETICALLY IN INCHES

C

L

TC241 (22 pin)

Optical

(see Note B)

7/94

NOTES: A. Single dimensions are nominal.

B. The center of the package and the center of the image area are not coincident.

C. The distance from the top of the glass to the image-sensor surface is typically 1,46 mm (0.057 in). The glass is 0,95 ±0,08 mm thick

and has an index of refraction of 1.53.

D. Each pin centerline is located within 0,25 mm (0.010 in) of its true longitudinal position.

Page 18

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...