Page 1

CMOS CURRENT MODE PWM CONTROLLER

1

TC170

FEATURES

■ Low Supply Current With

CMOS Technology................................. 3.8mA Max

■ Internal Reference .............................................5.1V

■ Fast Rise/Fall Times (CL = 1000pF) ............. 50nsec

■ Dual Push-Pull Outputs

■ Direct-Power MOSFET Drive

■ High Totem-Pole Output Drive .................... 300mA

■ Differential Current-Sense Amplifier

■ Programmable Current Limit

■ Soft-Start Operation

■ Double-Pulse Suppression

■ Undervoltage Lockout

■ Wide Supply Voltage Operation ...............8V to16V

■ High Frequency Operation ..........................200kHz

■ Available with Low OFF State Outputs

■ Low Power, Pin-Compatible Replacement for UC3846

ORDERING INFORMATION

Temperature

Part No. Package Range

TC170COE 16-Pin SOIC (Wide) 0°C to +70°C

TC170CPE 16-Pin Plastic DIP (Narrow) 0°C to +70°C

GENERAL DESCRIPTION

The TC170 brings low-power CMOS technology to the

current-mode-switching power supply controller market.

Maximum supply current is 3.8 mA. Bipolar current-mode

control integrated circuits require five times more operating

current.

The dual totem-pole CMOS outputs drive power

MOSFETs or bipolar transistors. The 50nsec typical output

rise and fall times (1000pF capacitive loads) minimize

MOSFET power dissipation. Output peak current is 300mA.

The TC170 contains a full array of system-protection

circuits (see features).

Current-mode control lets users parallel power supply

modules. Two or more TC170 controllers can be slaved

together for parallel operation. Circuits can operate from a

master TC170 internal oscillator or an external system

oscillator.

The TC170 operates from an 8V to 16V power supply.

An internal 2%, 5.1V reference minimizes external component count. The TC170 is pin compatible with the Unitrode

UC1846/2846/3846 bipolar controller.

Other advantages inherent in current-mode control include superior line and load regulation and automatic symmetry correction in push-pull converters.

2

3

4

5

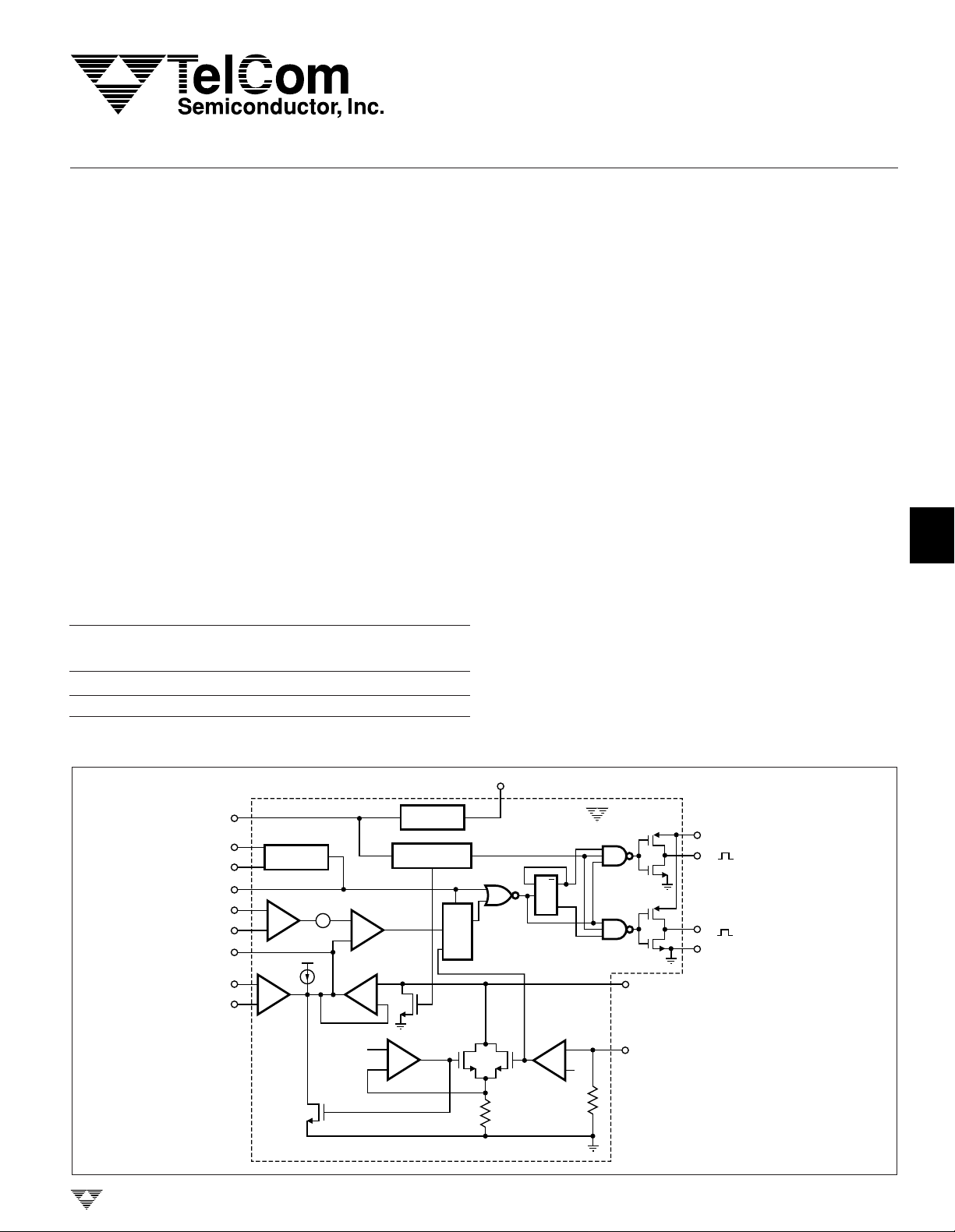

FUNCTIONAL BLOCK DIAGRAM

15

V

IN

9

R

C

SYNC

(–) CURRENT

SENSE INPUT

(+) CURRENT

SENSE INPUT

COMP

(+) ERROR

AMP INPUT

(–) ERROR

AMP INPUT

O

O

8

10

3

4

7

5

6

OSCILLATOR

× 3.15 CURRENT

AMPLIFIER

–

+

V

DD

100µA

+

–

ERROR

AMPLIFIER

TELCOM SEMICONDUCTOR, INC.

–

0.75V

LOCK-UP

AMPLIFIER

Q3

PWM

COMPARATOR

+

+

–

LIMIT BUFFER

AMPLIFIER

350mV

REFERENCE

UNDERVOLTAGE

+

–

Q4

–

+

POSITIVE

FEEDBACK

5.1-VOLT

LOCKOUT

R

S

S

Q

PWM LATCH

Q1

V

REF

Q2

3.5kΩ

2

TC170

DQ

C

Q

SHUTDOWN

COMPARATOR

+

350

–

mV

6kΩ

1

CURRENT LIMIT/

SOFT-START ADJUST

16

SHUTDOWN

NOTE: Outputs low in

OFF state.

13

11

14

12

V

DD

OUTPUT

A ( )

OUTPUT

B ( )

GROUND

6

7

8

TC170-5 10/1/96

4-119

Page 2

TC170

CMOS CURRENT MODE

PWM CONTROLLER

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage ............................................................18V

Output Voltage ................................................ VDD or 18V

Analog Inputs .....................................– 0.3V to VS + 0.3V

Storage Temperature Range ................ – 65°C to +150°C

Lead Temperature (Soldering, 10 sec) ................. +300°C

Maximum Chip Temperature...................................150°C

Plastic Package Thermal Resistance:

θJA (Junction to Ambient)............................. 140°C/W

Operating Temperature Range

Commercial ...........................................0°C to +70°C

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operational sections of the specifications is not implied.

Exposure to Absolute Maximum Rating Conditions for extended periods

may affect device reliability.

θJC (Junction to Case) ................................... 70°C/W

ELECTRICAL CHARACTERISTICS: V

= 16V, RO = 24kΩ, CO = 1 nF, TA = 25°C, unless otherwise indicated.

IN

Symbol Parameter Test Conditions Min Typ Max Unit

Reference Voltage

V

V

REF

RTC

Output Voltage I

= 1mA 5 5.1 5.3 V

OUT

Line Regulation VIN = 8V to 16V 5 15 mV

Load Regulation I

= 1mA to 10mA 13 20 mV

OUT

Temperature Coefficient Over Operating Temperature Range 0.4 0.5 mV/°C

Oscillator

Oscillator Frequency 35 42 46 kHz

Voltage Stability VIN = 8V to 16V 1.1 1.5 %/V

Temperature Stability Over Operating Temperature Range 5 10 %

Error Amplifier

V

OS

I

B

V

CMRR

A

VOL

BW Unity Gain Bandwidth 1.2 MHz

CMRR Common-Mode Rejection Ratio V

PSRR Power Supply Rejection Ratio VIN = 8V to 16V 60 dB

Input Offset Voltage 630 mV

Input Bias Current 61nA

Common-Mode Input Voltage VIN = 8V to 16V 0 V

Open-Loop Voltage Gain V

= 1V to 6V 70 dB

OUT

0V to 14V 60 dB

CMV

– 2V V

DD

Current Sense Amplifier

Amplifier Gain Pin 3 = 0V to 1.1V 3 3.15 3.3 V/V

Maximum Differential Input Signal V

Common-Mode Input Voltage 0 V

PIN4

– V

PIN3

≤1.1 V

– 3V V

DD

Current Limit Adjust

Current Limit Offset Voltage 0.5 1 V

I

B

Input Bias Current 1nA

Shutdown Terminal

V

TB

V

IN

Threshold Voltage 0.3 0.35 0.4 V

Input Voltage Range 0 V

DD

V

Minimum Latching Current at Pin 1 125 µA

Maximum Nonlatching Current at Pin 1 50 µA

Output Stage

V

DD

V

OL

V

OL

Output Voltage Pin 13 V

Output Low Level I

Output Low Level I

= 20mA 0.4 V

SINK

= 100mA 2 V

SINK

– 0. 5 V

IN

V

IN

+ 0.5 V

IN

4-120

TELCOM SEMICONDUCTOR, INC.

Page 3

CMOS CURRENT MODE

PWM CONTROLLER

1

TC170

ELECTRICAL CHARACTERISTICS (Cont.):

VIN = 16V, RO = 24kΩ, CO = 1nF, TA = 25°C, unless otherwise indicated.

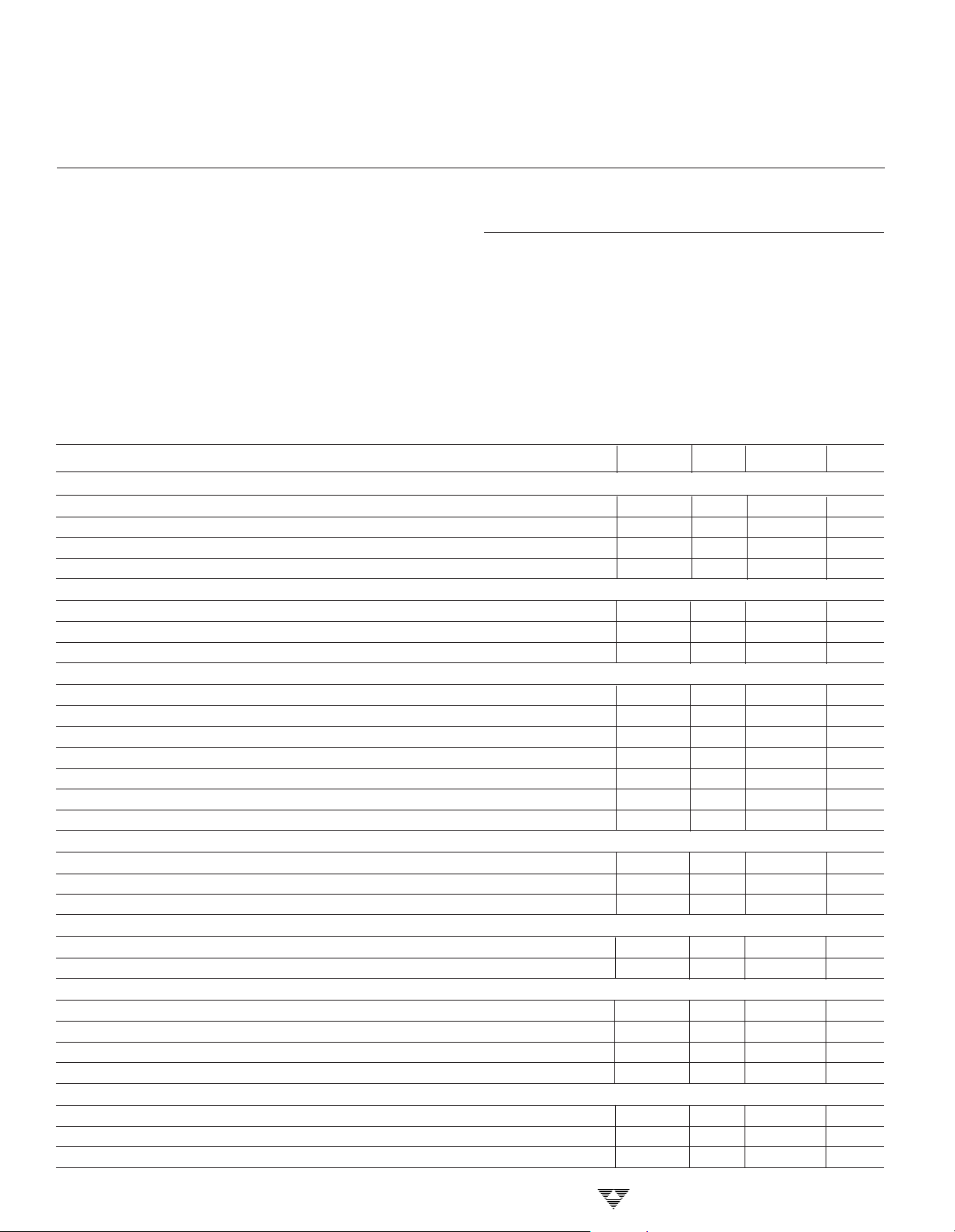

Symbol Parameter Test Conditions Min Typ Max Unit

Output Stage (Cont.)

V

OH

V

OL

t

R

t

F

Output High Level I

Output High Level I

= 20mA V

SOURCE

= 100mA V

SOURCE

– 1V V

DD

– 4V V

DD

Output Rise Time CL = 1000pF 50 150 nsec

Output Fall Time CL = 1000pF 50 150 nsec

Undervoltage Lockout

Start-Up Threshold 7.15 7.7 8.25 V

Threshold Hysteresis 0.5 0.75 1 V

Supply

ISStandby Supply Current 2.7 3.8 mA

PIN DESCRIPTION

Pin No.

(16-Pin PDIP) Symbol Description

1 SOFT START/I

2V

3– I

4+ I

OUT Reference supply output of 5.1 volts. It can supply a minimum of 10mA.

REF

IN – Current Sense Input. Inverting input for sensing peak current of the pass transistor

SENSE

IN + Current Sense Input. Non-inverting input used in conjunction with pin 3. This senses the

SENSE

5 + ERROR AMP IN + Error Amp In. Non-inverting input for output voltage regulation.

6 – ERROR AMP IN – Error Amp In. Inverting input of the amplifier for the reference voltage.

7 CMPTR For compensation of the feedback loop response.

8C

9R

O

O

10 SYNC For PWM controller oscillator synchronization of two or more controllers. or as a clock input

11 OUTPUT A A output drive of phase A from push pull transistors.

12 GND Ground return for all input and output pins.

13 V

DD

14 OUTPUT B Output of phase B from push pull transistors.

15 V

IN

16 SHUTDOWN Input pin to disable both output drives to 0V OFF.

Soft Start Adjust / Current Limit. For setting the peak current threshold of sense inputs (pins

LIM

3 and 4). Second function of this pin is Soft-Start Adjust.

through series sense current monitor resistor.

positive end of current monitor resistor.

Timing capacitor (CO) input to set oscillator frequency in conjunction with pin 9, RO, resistor

input. Second function is for setting crossover dead time of pin 11and 14 outputs.

Timing resistor (RO) input to set oscillator frequency by setting constant current charge rate

to charge capacitor CO.

to sync oscillator from external signal.

Supplies power to operate the output drivers only.

Voltage bias supply for all TC170 circuits except the output transistors.

2

3

4

5

6

PIN CONFIGURATIONS (DIP and SOIC)

SOFT START/

I

LIM

OUT

V

REF

– I

SENSE

+ I

SENSE

+ ERROR AMP IN

– ERROR AMP IN

CMPTR

C

1

2

IN

3

IN

4

TC170

5

CPE

6

7

8

O

SHDN

16

V

15

14

OUTPUT B

V

13

12

GND

11

OUTPUT A

10

SYNC

R

9

IN

DD

O

TELCOM SEMICONDUCTOR, INC.

C

INT

V

SS

C

AZ

BUF

ACOM

–

C

REF

+

C

REF

–

V

REF

1

2

3

4

TC170COE

5

6

7

8

16

15

14

13

12

11

10

9

V

DD

DIGITAL GND

CMPTR OUT

B

A

+

V

IN

–

V

IN

+

V

REF

NOTE: Outputs LOW in "OFF" state.

7

8

4-121

Page 4

TC170

CMOS CURRENT MODE

PWM CONTROLLER

Peak Current Limit Setup

Resistors R1 and R2 at the current limit input (pin 1)

set the TC170 peak current limit (Figure 1). The potential at

pin 1 is easily calculated:

V1 = V

REF

R1 should be selected first. The shutdown circuit feature is not latched for (V

latched for currents greater than 125µA.

The error amplifier output voltage is clamped from

going above V1 through the limit buffer amplifier. Peak

current is sensed by RS and amplified by the current

amplifier which has a fixed gain of 3.15.

I

, the peak current limit, is the current that causes

PCL

the PWM comparator noninverting input to exceed V1, the

potential at the inverting input. Once the comparator trip

point is exceeded, both outputs are disabled.

I

is easily calculated:

PCL

I

=

PCL

where:

V1 = V

V

REF

3.15 = Gain of current-sense amplifier

0.75V = Current limit offset

Both driver outputs (pins 11 and 14) are OFF (LOW)

when the peak current limit is exceeded. When the sensed

current goes below I

R2

R1 + R2

– 0.35)/R1 < 50µA and is

REF

V1 – 0.75V

3.15 (RS)

REF

R2

R1 + R2

= Internal voltage reference = 5.1V

, the circuit operates normally.

PCL

The input pulse to pin 16 should be at least 500 nsec

wide and have an amplitude of at least 1V in order to get the

minimum propagation delay from input to output. If these

parameters are met, the delay should be less than

600nsec at 25°C; however, the delay time will increase as

the device temperature rises.

Soft Restart From Shutdown

A soft restart can be programmed if nonlatched shutdown operation is used.

A capacitor at pin 1 will cause a gradual increase in

potential toward V1. When the voltage at pin 1 reaches

0.75V, the PWM latch set input is removed and the circuit

establishes a regulated output voltage. The soft-start operation forces the PWM output drivers to initially operate with

minimum duty cycle and low peak currents.

Even if a soft start is not required, it is necessary to

insert a capacitor between pin 1 and ground if the current I

is greater than 125µA. This capacitor will prevent "noise

triggering" of the latch, yet minimize the soft-start effect.

Soft-Start Power-Up

During power-up, a capacitor at R1, R2 initiates a softstart cycle. As the input voltage (pin 15) exceeds the

undervoltage lockout potential (7.7V), Q4 is turned OFF,

ending undervoltage lockout. Whenever the PWM comparator inverting input is below 0.5V, both outputs are

disabled.

When the undervoltage lockout level is passed, the

capacitor begins to charge. The PWM duty cycle increases

until the operating output voltage is reached. Soft-start

operation forces the PWM output drivers to initially operate

with minimum duty cycle and low peak current.

L

Output Shutdown

The TC170 outputs can be turned OFF quickly through

the shutdown input (pin 16). A signal greater than 350 mV

at pin 16 forces the shutdown comparator output HIGH.

The PWM latch is held set, disabling the outputs.

Q2 is also turned ON. If V

positive feedback through the lock-up amplifier and Q1

keeps the inverting PWM comparator inverting input below

0.75V. Q3 remains ON even after the shutdown input

signal is removed, because of the positive feedback. The

state can be cleared only through a power-up cycle. Outputs will be disabled whenever the potential at pin 1 is

below 0.75V.

The shutdown terminal gives a fast, direct way to disable the TC170 output transistors. System protection and

remote shutdown applications are possible.

4-122

/R1 is greater than 125µA,

REF

Current-Sense Amplifier

The current-sense amplifier operates at a fixed gain of

3.15. Maximum differential input voltage (V

1.1V. Common-mode input voltage range is 0V to VIN – 3V.

Resistive-sensing methods are shown in Figure 2. In

Figure 2(A), a simple RC filter limits transient voltage spikes

at pin 4, caused by external output transistor-collector

capacitance. Transformer coupling (Figure 3) offers isolation and better power efficiency, but cost and complexity

increase.

In order to minimize the propagation delay from the input

to the current amplifier to the output terminals, the current

ramp should be in the order of 1 µs in width (min). Typical

time delay values are in the 300 to 400nsec region at 25°C.

The delay time increases with device temperature so that at

50°C, the delay times may be increased by as much as

100nsec.

TELCOM SEMICONDUCTOR, INC.

PIN4

– V

PIN3

) is

Page 5

CMOS CURRENT MODE

(B)

g

PWM CONTROLLER

1

TC170

SWITCH

CURRENT

4

3

RS

7

5

6

3.15 CURRENT-SENSE

×

AMPLIFIER

+

–

ERROR

AMPLIFIER

+

–

–

0.75V

V

DD

+

100 Aµ

Q3

350mV

V1

PWM COMPARATOR

+

–

Q4

+

LIMIT

BUFFER

AMPLIFIER

–

+

–

LOCK-UP

AMPLIFIER

POSITIVE

FEEDBACK

FROM

UNDERVOLTAGE

LOCKOUT

Q1

Q2

10

R

Q

S

S

PWM LATCH

SHUTDOWN

COMPARATOR

+

–

"A" = 1

OUTPUT

OFF (LOW)

V

REF

6k

5.1V

2

R1

1

R2

16

2

3

V1

4

×

3.15 CURRENTSENSE

AMPLIFIER

TC170

(A) Ground Reference

TC170

4

+

–

3

*OPTIONAL RC FILTER

I

L

Figure 1. R1 and R2 Set Maximum Peak Output Current

I

R*

C

RS

Figure 2. Resistive Sensing

3.5k

I

×

3.15 CURRENTSENSE AMPLIFIER

4

+

–

3

TC170

Above-Ground Resistive Sensin

350mV

RS

V

5

6

OUT

7

TELCOM SEMICONDUCTOR, INC.

8

4-123

Page 6

TC170

MASTER

R

O

SYNC CMPTR

SLAVE

9

8

9

8

210 7

7

1/2 TC4427

V

DD

TC170

10

C

O

V

REF

C

O

R

O

CMPTRSYNC

TC170

×

3.15 CURRENT–

SENSE AMPLIFIER

4

+

–

TC170

Figure 3 Transformer Isolated Current Sense

+

V

S

–

3

IS • RS

=

V

S

N

Undervoltage Lockout

The undervoltage lockout circuit forces the TC170 outputs OFF (low) if the supply voltage is below 7.7V. Threshold

hysteresis is 0.75V and guarantees clean, jitter-free turn-on

and turn-off points. The hysteresis also reduces capacitive

filtering requirements at the PWM controller supply input

(pin 15).

N

1

I

S

CMOS CURRENT MODE

PWM CONTROLLER

Circuit Synchronization

Current-mode-controlled power supplies can be operated in parallel with a common load. Paralleled converters

will equally share the load current. Voltage-mode controllers unequally share the load current, decreasing system

reliability.

Two or more TC170 controllers can be slaved together for parallel operation. Circuits can operate from a

master TC170 internal oscillator with an external driver

(Figure 4). Devices can also be slaved to an external

oscillator (Figure 5). Disable internal slave device oscillators by grounding pin 8. Slave controllers derive an oscillator from the bidirectional synchronization output signal at

pin 10.

Pin 10 is bidirectional in that it is intended to be both a

sync output and input. This is accomplished by making the

output driver "weak." This is advantageous in that it eliminates an additional pin from the package but does not

enable the device to directly drive another device. In order

to make it an effective driver, a buffer is required (Figure 4).

In order to use pin 10 as a sync input, it is necessary to

overcome the internal driver. This requires a pulse with an

amplitude equal to VIN. Since VIN must be above 8.25V for

the undervoltage lockout to be disabled, a CMOS or opencollector TTL driver should be used.

Figure 4. Master/Slave Parallel Operation

EXTERNAL*

OSCILLATOR

*PULSE WIDTH OF

OSCILLATOR IS = T

Figure 5. External Clock Synchronization

V

DD

TC4427

D

1/2

10

10

15

V

IN

TC170

SYNC

V

REF

29

+

V

S

15

V

IN

SYNC

TC170

V

REF

29

8

C

O

R

O

C

O

R

O

4-124

TELCOM SEMICONDUCTOR, INC.

Page 7

CMOS CURRENT MODE

PWM CONTROLLER

1

TC170

V

2.3V

R

O

9

R

O

Figure 6 . Oscillator Circuit

10

SYNC

DISCHARGE

CURRENT

2.3V 4.3V

1 mA

I

CHARGE

8

C

O

Oscillator Frequency and Output Dead Time

The oscillator frequency for RO = 24kΩ and

CO= 1000pF is:

1.27 2800 C

FO =

[

ROC

where: RO = Oscillator Resistor (Ω)

The oscillator resistor can range from 5 kΩ to 50 kΩ.

Oscillator capacitor can range from 250 pF to 1000 pF.

Figure 7 shows typical operation for various resistance and

capacitance values.

During transitions between the two outputs, simultaneous conduction is prevented. Oscillator fall time controls

the output off, or dead time (Figure 6).

Dead time is approximately:

TD =

2000 [CO]

1 –

–

2

R

O

CO = Oscillator Capacitor (F)

FO = Oscillator Frequency (Hz)

2.3

(

R

O

]

COCO + 150 × 10

O

)

O

–12

DD

1

F

PIN 8

+

2.3V

–

PIN 10

50

45

40

35

30

25

20

15

10

OSCILLATOR RESISTANCE (kΩ)

5

0 20 40 60 80 100 120 140 160 180 200

OSCILLATOR FREQUENCY (kHz)

Figure 7. Oscillator Frequency vs Oscillator Resistance

where: RO = Oscillator Resistor (kΩ)

CO = Oscillator Capacitor (pF)

TD = Output Dead Time (sec)

O

ON-TIME

OUTPUT DEAD TIME (TD)

TA= +25°C

250pF

750pF1000pF

500pF

2

3

4

5

6

7

TELCOM SEMICONDUCTOR, INC.

Maximum possible duty cycle is set by the dead time.

8

4-125

Page 8

TC170

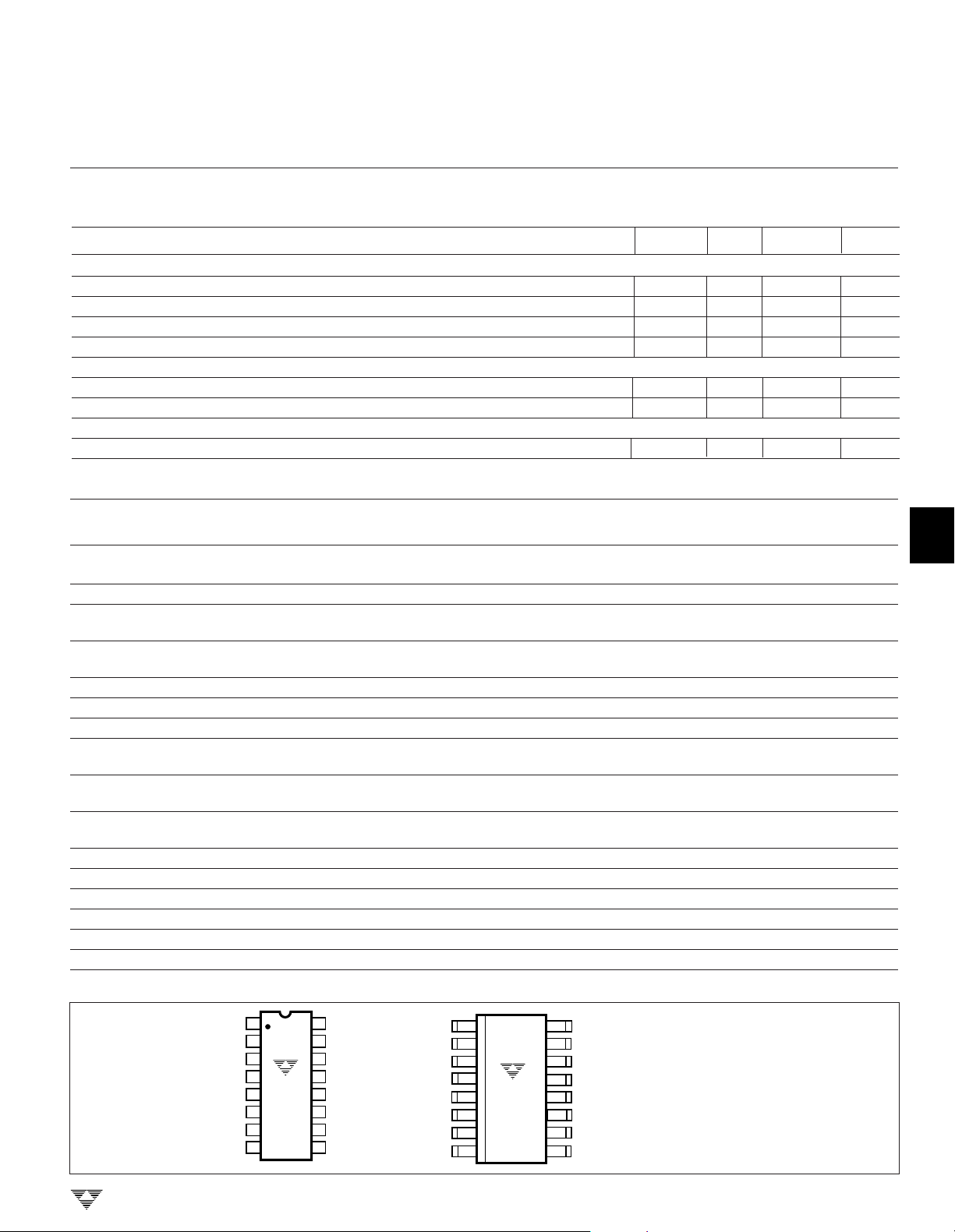

TYPICAL CHARACTERISTICS

CMOS CURRENT MODE

PWM CONTROLLER

Output Rise and Fall Times

TA = +25°C

C

VS = 16V

LOAD

= 500pF

DIV

5V

50nsec

DIV

Output Rise and Fall Times

TA = +25°C

C

VS = 16V

LOAD

= 1800pF

5V

DIV

5 nsec

DIV

Output Rise and Fall Times

TA = +25°C

C

VS = 16V

LOAD

= 1000pF

5V

DIV

50nsec

DIV

4-126

TELCOM SEMICONDUCTOR, INC.

Loading...

Loading...