Page 1

TECHNICAL INFORMATION

Stereo 90W (4

Digital Power Processing

ADVANCED INFORMATION - December 2000

ΩΩΩΩ

) Class-T Digital Audio Amplifier using

TM

Technology TA2022

General Description

The TA2022 is an 90W continuous average, per channel, Class-T Digital Audio Power

Amplifier IC using Tripath’s proprietary Digital Power Processing

amplifiers offer both the audio fidelity of Class-AB and the power efficiency of Class-D

amplifiers.

Applications

!"DVD Players

!"Mini/Micro Component Systems

!"Home Theater

!"Powered Speakers

Benefits

!"Fully integrated solution with internal

FETs

!"Dramatically improves efficiency versus

Class-AB

!"Signal fidelity equal to high quality linear

amplifiers

!"High dynamic range compatible with

digital media such as CD, DVD, and

internet audio

Features

!"Class-T architecture

!"High Power

!"100W @ 4Ω, 1.0% THD+N

!"90W @ 4Ω, 0.1% THD+N

!"60W @ 8Ω, 0.1% THD+N

!"“Audiophile” Quality Sound

!"0.015% THD+N @ 70W 4Ω

!"0.015% THD+N @ 45W 8Ω

!"0.10% IHF-IM @ 25W 4Ω

!"High Efficiency

!"92% @ 88W 8Ω

!"87% @ 125W 4Ω

!"Dynamic Range = 102 dB

!"Mute Input

!"Over-current protection

!"Over and under-voltage protection

!"Single ended outputs

!"Outputs can be operated in bridged mode

!"32-pin SSIP package

TM

technology. Class-T

1 of 29 TA2022, Rev. 0.90, 12.00

Page 2

TECHNICAL INFORMATION

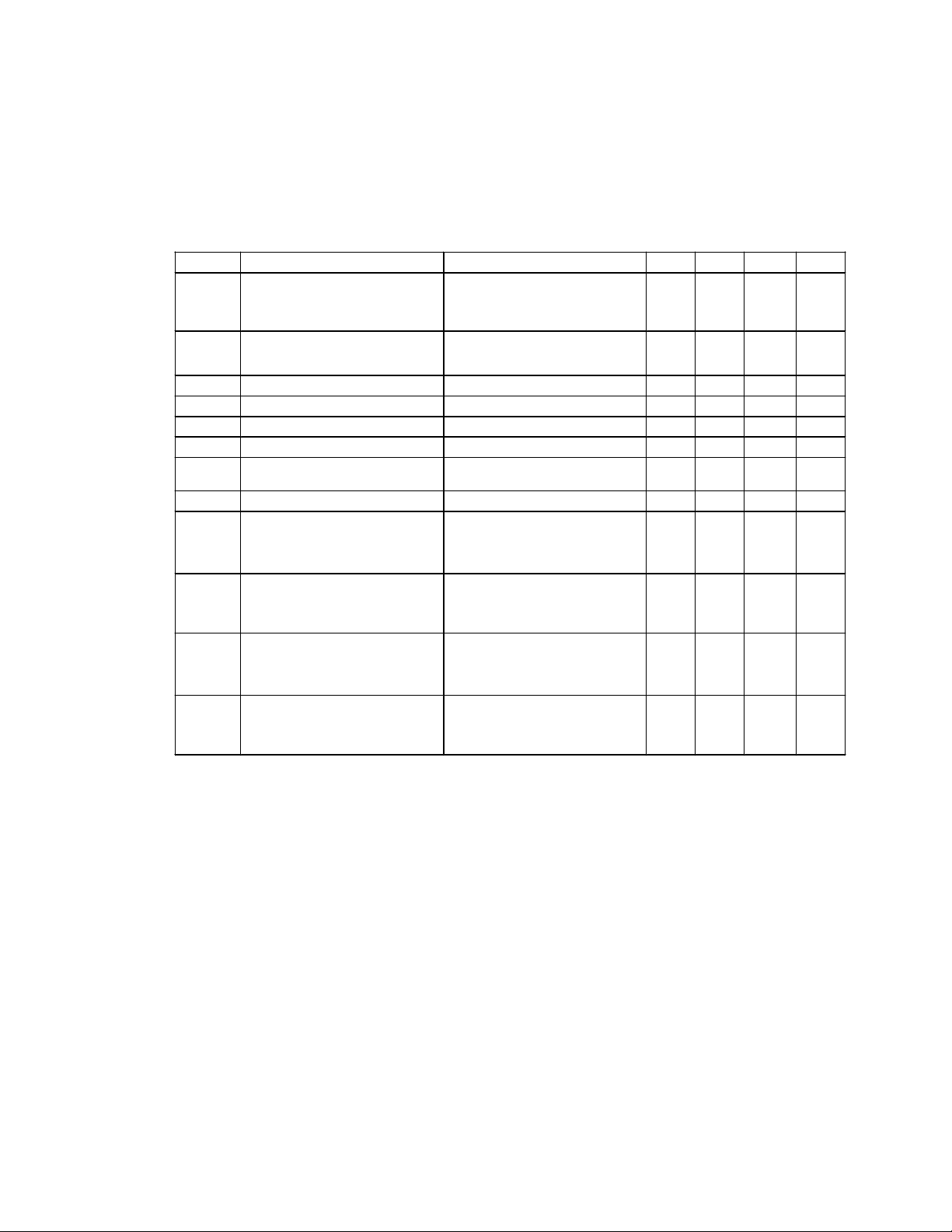

Absolute Maximum Ratings

SYMBOL PARAMETER Value UNITS

VPP, VNN Supply Voltage (VPP1, VPP2, VNN1, VNN2) +/-40 V

V5 Positive 5V Bias Supply

VN10 Voltage for low-side FET drive VNN + 13 V

T

STORE

T

A

T

J

ESDHB ESD Susceptibility – Human Body Model (Note 3)

ESDMM ESD Susceptibility – Machine Model (Note 4)

Voltage at Input Pins (pins 18, 19, 23, 24, 26, 28, 29, 30, 31, 32)

Storage Temperature Range

Operating Free-air Temperature Range (Note 2)

Junction Temperature

All pins (except pin 27)

Pin 27

All pins

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

See the table below for Operating Conditions.

Note 2: This is a target specification. Characterization is still needed to validate this temperature range.

Note 3: Human body model, 100pF discharged through a 1.5KΩ resistor.

Note 4: Machine model, 220pF – 240pF discharged through all pins.

Operating Conditions

SYMBOL PARAMETER MIN. TYP. MAX. UNITS

VPP, VNN Supply Voltage (VPP1, VPP2, VNN1, VNN2) +/-12 +/-31 +/-36 V

V5

VN10

Positive 5V Bias Supply 4.5 5 5.5 V

Voltage for low side FET drive (Volts above VNN) 9 11 12 V

Note 5: Recommended Operating Conditions indicate conditions for which the device is functional.

See Electrical Characteristics for guaranteed specific performance limits.

Thermal Characteristics

SYMBOL PARAMETER Value UNITS

θ

JC

θ

JA

Junction-to-case Thermal Resistance

Junction-to-ambient Thermal Resistance (still air)

(Note 5)

(Note 1)

-55

-40

6

to 150°

°

to 85°

°

150

°

4000

1500

200

-0.3V to (V5 +0.3V)

V

V

C

C

C

V

V

V

1.0

20

°

°

C/W

C/W

2 of 27 TA2022, Rev. 0.90, 12.00

Page 3

TECHNICAL INFORMATION

Electrical Characteristics

(Notes 6, 7)

TA = 25 °C. See Application/Test Circuit on page 7. Unless otherwise noted, the supply voltage is

VPP=|VNN|=31V.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNITS

I

q

I

MUTE

VIH High-level input voltage (MUTE) 3.5 V

VIL Low-level input voltage (MUTE) 1.0 V

VOH High-level output voltage (HMUTE) I

VOL Low-level output voltage (HMUTE) I

V

OFFSET

IOC Over Current Sense Threshold TBD TBD TBD A

I

VPPSENSE

V

VPPSENSE

I

VNNSENSE

V

VNNSENSE

Quiescent Current

(No load, Mute = 0V)

Mute Supply Current

(No load, Mute = 5V)

Output Offset Voltage No Load, MUTE = Logic low

VPPSENSE Threshold Currents Over-voltage turn on (muted)

Threshold Voltages with

R

VPPSENSE

(Note 11)

VNNSENSE Threshold Currents Over-voltage turn on (muted)

Threshold Voltages with

R

VNNSENSE

(Note 11)

= 249KΩ

= 249KΩ

VPP = +31V

VNN = -31V (Note 8)

V5 = 5V (Note 9)

VN10 = 11V (Note 10)

VPP = +31V

VNN = -31V (Note 8)

V5 = 5V (Note 9)

= 3mA 3.5 V

OH

= 3mA 1.0 V

OL

0.1% R

Over-voltage turn off (mute off)

Under-voltage turn off (mute off)

Under-voltage turn on (muted)

Over-voltage turn on (muted)

Over-voltage turn off (mute off)

Under-voltage turn off (mute off)

Under-voltage turn on (muted)

Over-voltage turn off (mute off)

Under-voltage turn off (mute off)

Under-voltage turn on (muted)

Over-voltage turn on (muted)

Over-voltage turn off (mute off)

Under-voltage turn off (mute off)

Under-voltage turn on (muted)

FBA

, R

FBB

, R

resistors

FBC

20

55

45

65

0.5

2

20

-750 750 mV

62

65

162

154

79

72

42.8

40.9

22.2

20.4

174

169

86

77

-42.1

-40.8

-20.2

-17.9

138

36.5

17.8

152

-36.2

-14.8

60

80

25

178

87

47.3

24.4

191

95

-46.8

-22.6

mA

mA

mA

mA

mA

mA

mA

A

µ

A

µ

A

µ

A

µ

V

V

V

V

A

µ

A

µ

A

µ

A

µ

V

V

V

V

TA2022, Rev. 0.90, 12.00 3 of 27

Page 4

TECHNICAL INFORMATION

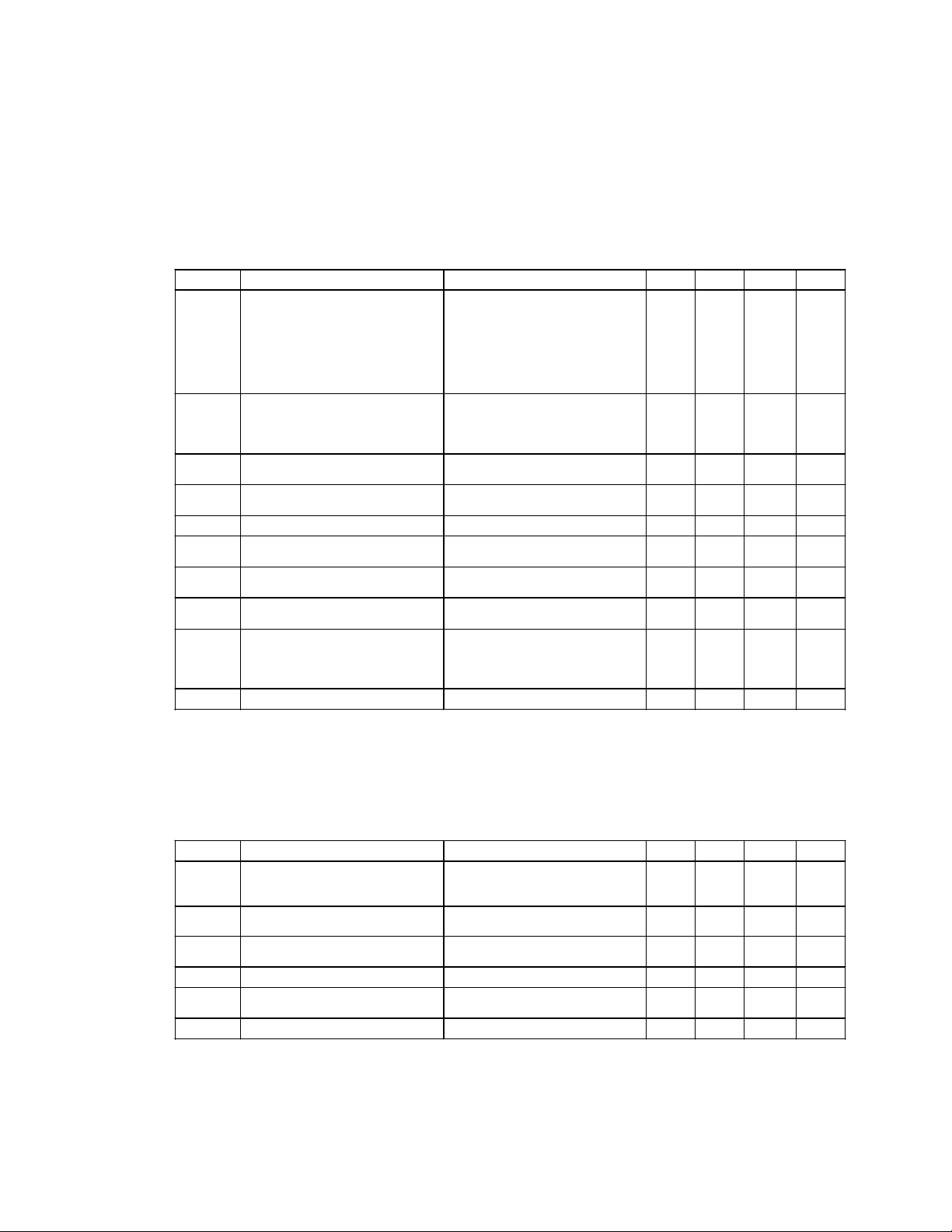

Performance Characteristics – Single Ended

(Notes 6, 7)

TA = 25 °C. Unless otherwise noted, the supply voltage is VPP=|VNN|=31V, the input frequency is

1kHz and the measurement bandwidth is 20kHz. See Application/Test Circuit on page 7.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNITS

P

OUT

THD + N Total Harmonic Distortion Plus

IHF-IM IHF Intermodulation Distortion

SNR Signal-to-Noise Ratio A-Weighted

CS Channel Separation

AV Amplifier Gain

A

VERROR

η

I

SLOAD

e

NOUT

Output Power

(Continuous Average/Channel)

(Note 12)

Noise

Channel to Channel Gain Error

Power Efficiency

Source Current

Output Noise Voltage A-W eighted, input AC grounded 150

VPP = |VNN| = +/-31V, R

THD+N = 0.1%

THD+N = 1.0%

THD+N = 10%

VPP = |VNN| = +/-35V, R

THD+N = 0.1%

THD+N = 10%

= 70W/Channel, RL = 4Ω

P

OUT

VPP = |VNN| = +/-31V

= 45W/Channel, RL = 8Ω

P

OUT

VPP = |VNN| = +/-35V

19kHz, 20kHz, 1:1 (IHF), R

= 25W/Channel

P

OUT

0dB = 90W/Channel, R

0dB = 25W, R

P

OUT

See Application / Test Circuit

P

OUT

See Application / Test Circuit

P

OUT

P

OUT

P

OUT

VPP = +31V

VNN = -31V

V5 = 5V

= 4Ω,

L

= 10W/Channel, RL = 4Ω,

= 10W/Channel, RL = 4Ω

= 88W/Channel, RL = 8

= 125W/Channel, RL = 4Ω

= 125W/Channel, RL = 4

L

L

= 4Ω

L

Performance Characteristics – Bridged Tied Load

TA = 25 °C. Unless otherwise noted, the supply voltage is VPP=|VNN|=30V, the input frequency is

1kHz and the measurement bandwidth is 20kHz.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNITS

P

OUT

THD + N Total Harmonic Distortion Plus

IHF-IM IHF Intermodulation Distortion

η

SNR Signal-to-Noise Ratio

e

NOUT

Output Power

(Continuous Average)

(Note 12)

Noise

Power Efficiency

Output Noise Voltage A-W eighted, input AC grounded 220

VPP = |VNN| = +/-30V, R

THD+N = 0.1%

THD+N = 10%

= 100W, RL = 8Ω

P

OUT

19kHz, 20kHz, 1:1 (IHF), R

= 25W

P

OUT

= 225W, RL = 8Ω

P

OUT

A-Weighted, R

0dB = 150W

L

= 8

Ω

L

= 4Ω

= 8Ω

= 4Ω

L

Ω

Ω

(Notes 6, 7)

= 8Ω

= 8Ω

L

80

90

100

125

0.015

0.1 %

102 dB

83 dB

18.1 V/V

0.5 dB

92

60

88

0.015

87

4.59

4.61

45

%

0.05 %

0.10 %

87 %

104 dB

150

235

W

W

W

W

%

%

%

A

A

mA

V

µ

W

W

V

µ

4 of 27 TA2022, Rev. 0.90, 12.00

Page 5

TECHNICAL INFORMATION

Note 6: Minimum and maximum limits are guaranteed but may not be 100% tested.

Note 7: For operation in ambient temperatures greater than 25°C, the device must be derated based on the

maximum junction temperature and the thermal resistance determined by the mounting technique.

Note 8: This specification includes the current draw from the internal buck regulator.

Note 9: This specification includes the current draw from both the TA2022 and the external feedback biasing.

Note 10: This is the current draw of the VN10 pin if an external “floating” 11V supply is used instead of the

internal buck regulator. If an external floating supply is used, the idle current draw of the VNN supply

will be approximately 20mA.

Note 11: These supply voltages are calculated using the IVPPSENSE AND IVNNSENSE values shown in the

Electrical Characteristics table. The typical voltage values shown are calculated using a

RVPPSENSE and RVNNSENSE value of 249kohm without any tolerance variation. The minimum

and maximum voltage limits shown include either a +1% or –1% (+1% for Over-voltage turn on and

Under-voltage turn off, -1% for Over-voltage turn off and Under-voltage turn on) variation of

RVPPSENSE or RVNNSENSE off the nominal 249kohm value. These voltage specifications are

examples to show both typical and worst case voltage ranges for a given RVPPSENSE and

RVNNSENSE resistor value of 249kohm. Please refer to the Application Information section for a

more detailed description of how to calculate the over and under voltage trip voltages for a given

resistor value.

Note 12: The supply voltage limitation for 4 ohm single ended (+/-31V), or 8 ohm bridged (+/-30V), is based on

the current limit protection circuitry. The current limit circuitry may be activated during large output

excursions if the recommended supply voltage ranges are exceeded. This will result in the amplifier

being muted.

TA2022, Rev. 0.90, 12.00 5 of 27

Page 6

TECHNICAL INFORMATION

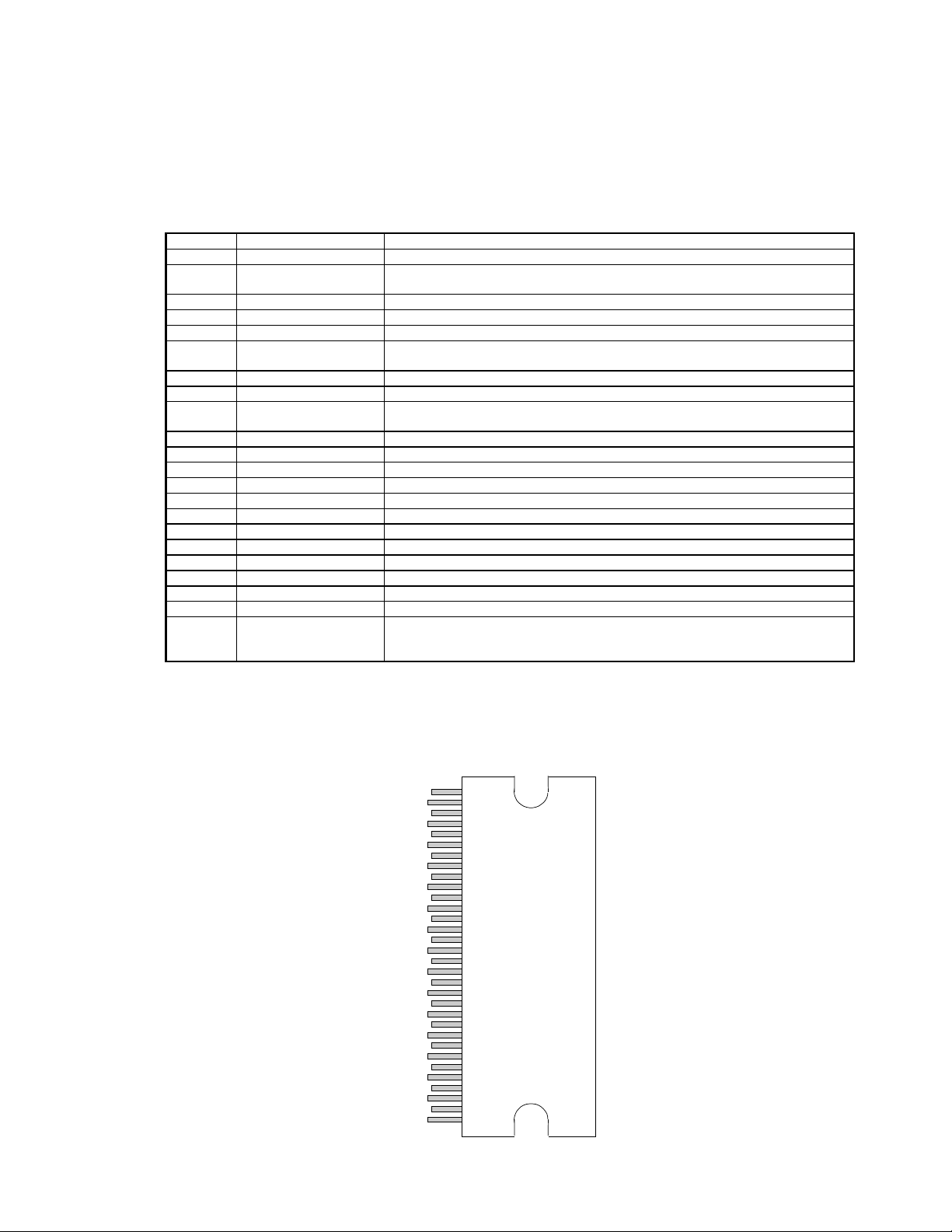

Pin Description

Pin

Function

1, 13 VBOOT2, VBOOT1 Bootstrap voltages for gate drive of high side MOSFET’s

2 VN10 “Floating” supply input. Normally connected to the output of onboard VN10 buck

3 VN10GND Power ground for onboard VN10 generator. Electrically tied to the TA2022 case.

4, 12 VPP2, VPP1 Positive power supply input pins.

5 VN10SW Switching output voltage for onboard VN10 generator (buck converter).

6 NC Not connected internally. May be connected to pin 7 without any loss of

7,10 OUT2, OUT1 Power amplifier outputs.

8, 9 VNN2, VNN1 Negative power supply inputs.

11 NC Not connected internally. May be connected to pin 10 without any loss of

14 VN10FDBK Feedback for onboard VN10 generator (nominally 11V above VNN)

15, 20 AGND Analog Ground.

16, 21 V5 5V power supply input.

17 REF Used to set internal bias. Typically 1.1V

18 VNNSENSE Negative supply voltage sense input.

19 VPPSENSE Positive supply voltage sense input.

22, 25 OAOUT1, OAOUT2 Outputs of Input Stage op amps.

23, 26 INV1, INV2 Inverting inputs of Input Stage op amps.

24 MUTE Logic input. A logic high puts the amplifier in mute mode. Ground if not used.

27 BIASCAP Bandgap reference times two (typically 2.5VDC).

28, 29 FBKGND2, FBKOUT2 Output voltage differential feedback for channel 2.

30,31 FBKGND1, FBKOUT1 Output voltage differential feedback for channel 1.

32 HMUTE Logic Output. A logic high indicates both amplifiers are muted, due to the mute

Description

converter. This voltage must be stable and referenced to VNN.

functionality or performance.

functionality or performance.

pin state, or a “fault” such as an overcurrent, undervoltage, or overvoltage

condition.

32-pin SSIP Package

(Front View)

VBOOT2

VN10

VN10GND

VPP2

VN10SW

OUT2

VNN2

VNN1

OUT1

VPP1

VBOOT1

VN10FDBK

AGND

REF

VNNSENSE

VPPSENSE

AGND

OAOUT1

INV1

MUTE

OAOUT2

INV2

BIASCAP

FBKGND2

FBKOUT2

FBKGND1

FBKOUT1

HMUTE

NC

NC

V5

V5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

6 of 27 TA2022, Rev. 0.90, 12.00

Page 7

TECHNICAL INFORMATION

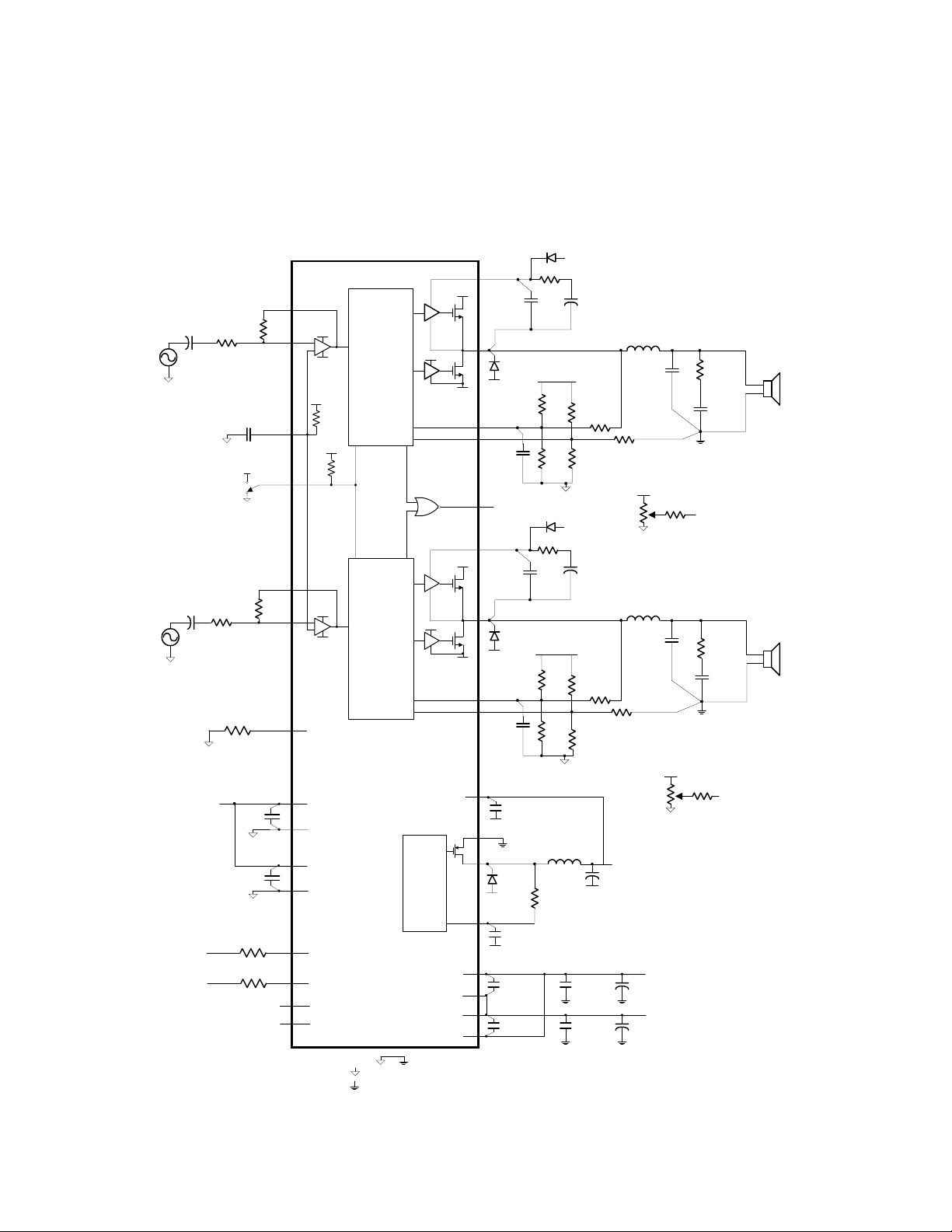

Application / Test Diagram

D

11DQ09

OUT1

D

O

MUR120

C

FB

390pF

AGND (Pin 20)

11DQ09

OUT2

D

O

MUR120

C

FB

560pF

AGND (Pin 20)

C

SW

0.1uF,35V

D

SW

11DQ09

C

SWFB

0.1uF,50V

C

HBR

0.1uF,100V

C

HBR

0.1uF,100V

B

RB 250

C

B

0.1uF

V5 (Pin 21)

R

FBA

1K

R

FBB

1.1K

D

B

RB 250

C

B

0.1uF

V5 (Pin 21)

R

FBA

1K

R

FBB

1.1K

100uH, 1A

R

SWFB

1K

Ω

Ω

Ω

L

VN10

+

Ω

VN10

Ω

+

C

Ω

SW

Ω

C

BAUX

47uF

R

FBA

1K

Ω

R

9.1K

R

FBB

1.1K

Ω

BAUX

47uF

R

FBA

1K

Ω

R

9.1K

R

FBB

1.1K

Ω

+

VNN

C

S

0.1uF, 50V

C

S

0.1uF, 50V

FBC

Ω

FBC

Ω

R

9.1K

C

SW

100uF, 35V

C

3.3uF

3.3uF

VNN

VPP

I

+

C

(Pin 20)

I

+

(Pin 20)

R

20K

R

REF

8.25K

R

VNNSENSE

R

VPPSENSE

R

20K

I

5V

I

C

0.1uF

Ω

Ω, 1%

20K

Ω

A

5V

(Pin 20)

R

20K

0.1uF

0.1uF

OAOUT1

R

F

Ω

BIASCAP

OAOUT2

F

Ω

C

S

C

249K

249K

S

INV1

MUTE

INV2

REF

Ω, 1%

Ω, 1%

22

23

2.5V

27

24

25

26

17

21

20

16

15

18

19

6

11

V5

-

+

AGND

200K

Ω

V5

V5

-

+

AGND

V5

AGND

V5

AGND

VNNSENSE

VPPSENSE

NC

NC

TA2022

Processing

&

Modulation

Processing

&

Modulation

VN10

VN10

VN10

Generator

VPP1

VNN1

VNN2

VPP2

VPP1

VNN1

VPP2

VNN2

13

10

31

30

32

1

7

29

28

2

3

5

14

12

9

8

4

VBOOT1

VNN1

(Pin 9)

FBKOUT1

FBKGND1

HMUTE

VBOOT2

VNN2

(Pin 8)

FBKOUT2

FBKGND2

VN10

VNN

VN10GND

VN10SW

VNN

VN10FBK

VNN

L

O

10uH, 10A

0.22uF

R

FBC

9.1K

Ω

V5 (Pin 21)

R

OFA

50K

Ω

AGND (Pin 20)

L

O

10uH, 10A

0.22uF

FBC

Ω

V5 (Pin 21)

R

50K

AGND (Pin 20)

VN10

+

C

S

100uF, 50V

+

C

S

100uF, 50V

VPP

VNN

C

O

R

Z

6.2

2W

Ω,

C

Z

0.22uF

R

OFB

10K

Ω

to FBKGND1

(Pin30)

Offset Trim

Circuit

C

R

O

Z

6.2

Ω,

C

Z

0.22uF

R

OFB

10K

OFA

Ω

Ω

2W

4Ω or 8

to FBKGND2

(Pin28)

Offset Trim

Circuit

R

4Ω or 8

R

L

Ω

L

Ω

Analog Ground

Power Ground

TA2022, Rev. 0.90, 12.00 7 of 27

Page 8

g

TECHNICAL INFORMATION

External Components Description

Components Description

R

Inverting input resistance to provide AC gain in conjunction with RF. This input is

I

RF Feedback resistor to set AC gain in conjunction with RI. Please refer to the Amplifier

CI AC input coupling capacitor which, in conjunction with RI, forms a highpass filter at

R

FBA

R

Feedback divider resistor connected to AGND. This value of this resistor depends

FBB

R

Feedback resistor connected from either the OUT1(2) to FBKOUT1(2) or speaker

FBC

CFB Feedback delay capacitor that both lowers the idle switching frequency and filters

R

Potentiometer used to manually trim the DC offset on the output of the TA2022.

OFA

R

Resistor that limits the manual DC offset trim range and allows for more precise

OFB

R

Bias resistor. Locate close to pin 17 and ground at pin 20.

REF

CA BIASCAP decoupling capacitor. Should be located close to pin 27 and grounded at

CB High frequency bootstrap capacitor, which filters the high side gate drive supply.

C

Bulk bootstrap capacitor that supplements C

BAUX

RB Bootstrap resistor that limits C

DB Bootstrap diode that charges CB, and C

CSW VN10 generator filter capacitors. The high frequency capacitor (0.1uF) must be

LSW VN10 generator filter inductor. This inductor should be sized appropriately so that

D

Flywheel diode for the internal VN10 buck converter. This diode also prevents

SW

C

VN10

SWFB

biased at the BIASCAP voltage (approximately 2.4VDC).

Gain paragraph, in the Application Information section.

)CR2(1f

π=

IIC

Feedback divider resistor connected to V5. This resistor is normally set at 1kΩ.

on the supply voltage setting and helps set the TA2022 gain in conjunction with R

R

F, RFBA,

and R

. Please see the Modulator Feedback Design paragraphs in the

FBC

Application Information Section.

ground to FBKGND1(2). The value of this resistor depends on the supply voltage

setting and helps set the TA2022 gain in conjunction with R

should be noted that the resistor from OUT1(2) to FBKOUT1(2) must have a power

rating of greater than

Design paragraphs in the Application Information Section.

very high frequency noise from the feedback signal, which improves amplifier

performance. The value of C

so that the idle switching difference is greater than 40kHz. Please refer to the

Application / Test Circuit.

adjustment.

pin 20.

This capacitor must be located as close to pin 13 (VBOOT1) or pin1 (VBOOT2) for

reliable operation. The “negative” side of C

(pin 10) or OUT2 (pin 7). Please refer to the Application / Test Circuit.

in a reduction in the average switching frequency.

(bootstrap supply charging).

located close to pin 2 (VN10) to maximize device performance. The bulk capacitor

(100uF) should be sized appropriately such that the VN10 voltage does not

overshoot with respect to VNN during TA2022 turn on.

L

does not saturate, and VN10 does not overshoot with respect to VNN during

SW

TA2022 turn on.

VN10SW from going more than one diode drop negative with respect to VNN.

enerator feedback capacitor. This capacitor, in conjunction with R

(Refer to the Application/Test Circuit)

DISS

2

=

should be offset between channel 1 and channel 2

FB

BAUX

. Please see the Modulator Feedback

)(2RVPPP

FBC

should be connected directly to OUT1

B

during “clipping” events, which result

B

charging current during TA2022 power up

via RB, when the output is low (at VNN).

BAUX

I, RF, RFBA,

, and R

SWFB

. It

FBB

, filters

I,

8 of 27 TA2022, Rev. 0.90, 12.00

Page 9

TECHNICAL INFORMATION

the VN10 feedback signal such that the loop is unconditionally stable.

R

VN10 generator feedback resistor. This resistor sets the nominal VN10 voltage.

SWFB

With R

equal to 1kΩ, the internally VN10 voltage will typically be 11V above

SWFB

VNN.

CS Supply decoupling for the power supply pins. For optimum performance, these

components should be located close to the TA2022 and returned to their respective

ground as shown in the Application/Test Circuit.

R

VNNSNESE

Overvoltage and undervoltage sense resistor for the negative supply (VNN). Please

refer to the Electrical Characteristics Section for the trip points as well as the

hysteresis band.

R

VPPSENSE

Overvoltage and undervoltage sense resistor for the positive supply (VPP). Please

refer to the Electrical Characteristics Section for the trip points as well as the

hysteresis band.

C

Supply decoupling for the high current Half-bridge supply pins. These components

HBR

must be located as close to the device as possible to minimize supply overshoot and

maximize device reliability. These capacitors should have good high frequency

performance including low ESR and low ESL. In addition, the capacitor rating must

be twice the maximum VPP voltage.

CZ Zobel capacitor, which in conjunction with RZ, terminates the output filter at high

frequencies. Use a high quality film capacitor capable of sustaining the ripple current

caused by the switching outputs.

RZ Zobel resistor, which in conjunction with CZ, terminates the output filter at high

frequencies. The combination of R

and CZ minimizes peaking of the output filter

Z

under both no load conditions or with real world loads, including loudspeakers which

usually exhibit a rising impedance with increasing frequency. Depending on the

program material, the power rating of R

may need to be adjusted. The typical

Z

power rating is 2 watts.

DO Fast Recovery diodes that minimize undershoots of the outputs with respect to

power ground during switching transitions as well as output shorts to ground. For

maximum effectiveness, these diodes must be located close to the output pins and

returned to their respective VNN. Please see Application/Test Circuit for VNN return

pin.

LO Output inductor, which in conjunction with CO, demodulates (filters) the switching

waveform into an audio signal. Forms a second order filter with a cutoff frequency

of and a quality factor of

C

O

Output capacitor, which, in conjunction with L

waveform into an audio signal. Forms a second order low-pass filter with a cutoff

frequency of

=

and a quality factor of

π=

)CL2(1f

OOC

.

CLCRQ

OOOL

, demodulates (filters) the switching

O

=

.

Use

CLCRQ

OOOL

a high quality film capacitor capable of sustaining the ripple current caused by the

switching outputs

TA2022, Rev. 0.90, 12.00 9 of 27

Page 10

TECHNICAL INFORMATION

Typical Performance Characteristics – Single Ended

10

f = 1kHz

RL= 4

Ω

5

VPP=|VNN|=31V

AES 17 Filter

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

1 2002 5 10 20 50 100

THD+N vs Output Power

Output Power (W)

THD+N (%)

0.005

10

5

2

1

0.5

0.2

0.1

0.05

0.02

0.01

f = 1kHz

RL= 8

Ω

VPP=|VNN|=35V

AES 17 Filter

1

THD+N vs Output Power

2 1005 10 20 50

Output Power (W)

10

Po = 50W/ch

RL = 4

Ω

5

VPP=|VNN|=31V

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

20 20k50 100 200 500 1k 2k 5k 10k

+0

19kHz, 20kHz 1:1

-10

Po = 25W/ch, 4

0dBr = 10.0Vrms

-20

VPP=|VNN|=31V

BW = 22Hz - 30kHz

-30

-40

-50

-60

-70

-80

Amplitude (dBr)

-90

-100

-110

-120

-130

-140

20 20k50 100 200 500 1k 2k 5k 10k

Ω

THD+N vs Frequency

BW = 30kHz

BW = 22kHz

Frequency (Hz)

Intermodulation Distortion

Frequency (Hz)

10

Po = 25W/ch

RL = 8

Ω

5

VPP=|VNN|=35V

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

20 20k50 100 200 500 1k 2k 5k 10k

+0

19kHz, 20kHz 1:1

-10

Po = 12.5W/ch, 8

0dBr = 10.0Vrms

-20

VPP=|VNN|=31V

BW = 22Hz - 30kHz

-30

-40

-50

-60

-70

-80

Amplitude (dBr)

-90

-100

-110

-120

-130

-140

20 20k50 100 200 500 1k 2k 5k 10k

Ω

THD+N vs Frequency

BW = 30kHz

BW = 22kHz

Frequency (Hz)

Intermodulation Distortion

Frequency (Hz)

10 of 27 TA2022, Rev. 0.90, 12.00

Page 11

TECHNICAL INFORMATION

Typical Performance Characteristics – Single Ended

100

VPP=|VNN|=31V

RL = 4

Ω

90

AES 17 Filter

THD+N < 10%

80

70

60

50

40

Efficiency (%)

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100 110 120

10

f = 1kHz

RL= 4

Ω

5

AES 17 Filter

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

1 2002 5 10 20 50 100

-70

VPP=|VNN|=31V

RF=RI=20k

-75

16kFFT

AES 17 Filter

-80

-85

-90

-95

-100

Amplitude (dBr)

-105

-110

-115

-120

20 20k50 100 200 500 1k 2k 5k 10k

Efficiency vs Output Power

Output Power (W)

THD+N vs Output Power

Output Power (W )

Ω

Noise Floor

Frequency (Hz)

+/-27V

+/-23V

+/-31V

100

VPP=|VNN|=35V

RL = 8

Ω

90

AES 17 Filter

THD+N < 10%

80

70

60

50

Efficiency (%)

40

30

20

10

0

0 102030405060 708090

10

f = 1kHz

RL= 8

Ω

5

AES 17 Filter

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

1

-40

VPP=|VNN|=31V

-45

Po = 25W/ch, 4

Po = 12.5W/ch, 8

-50

BW = 22Hz - 22kHz

-55

-60

-65

-70

-75

-80

Channel Separation (dBr)

-85

-90

-95

-100

20 20k50 100 200 50 0 1k 2k 5k 10k

Efficiency vs Output Power

Output Power (W)

THD+N vs Output Power

+/-30V

+/-25V

2 1005 10 20 50

Output Power (W)

Channel Separation

Ω

Ω

RL = 4

Ω

RL = 8

Ω

Frequency (Hz)

+/-35V

TA2022, Rev. 0.90, 12.00 11 of 27

Page 12

TECHNICAL INFORMATION

Typical Performance Characteristics - Bridged

10

f = 1kHz

VPP=|VNN|=30V

5

RL= 8Ω BRIDGED

AES 17 Filter

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

THD+N (%)

0.005

Amplitude (dBr)

10

0.5

0.2

0.1

0.05

0.02

0.01

+0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

-140

2 3005 10 20 50 100 2001

Po = 100W/ch

RL = 8Ω BRIDGED

5

VPP=|VNN|=30V

2

1

20 20k50 100 200 500 1k 2k 5k 10k

19kHz, 20kHz 1:1

Po = 50W/ch, 8Ω BRIDGED

0dBr = 20.0Vrms

VPP=|VNN|=30V

BW = 22Hz - 30kHz

20 20k50 10 0 200 500 1k 2k 5k 10k

THD+N vs Output Power

THD+N vs Frequency

BW = 30kHz

Intermodulation Distortion

Output Power (W )

BW = 22kHz

Frequency (Hz)

Frequency (Hz)

10

f = 1kHz

RL= 8Ω BRIDGED

5

AES 17 Filter

2

1

0.5

0.2

THD+N (%)

0.1

0.05

0.02

0.01

0.005

Efficiency (%)

Amplitude (dBr)

-70

-75

-80

-85

-90

-95

-100

-105

-110

-115

-120

2 3005

1

100

VPP=|VNN|=30V

RL = 8

BRIDGED

Ω

90

AES 17 Filter

THD+N < 10%

80

70

60

50

40

30

20

10

0

0 20 40 60 80 100 120 140 160 180 200 220 240

VPP=|VNN|=30V

RF=RI=20k

Ω

8Ω BRIDGED

16kFFT

AES 17 Filter

20 20k50 100 200 500 1k 2k 5k 10k

THD+N vs Output Power

10 20

Output Power (W )

50 100 200

Efficiency vs Output Power

Output Power (W)

Noise Floor

Frequency (Hz)

+/-27V

+/-23V

+/-30V

12 of 27 TA2022, Rev. 0.90, 12.00

Page 13

TECHNICAL INFORMATION

Application Information

TA2022 Basic Amplifier Operation

The TA2022 has three major operational blocks: the signal processor, the MOSFET driver, and the

power MOSFETs. The signal processor is a 5V CMOS block that amplifies the audio input signal

and converts the audio signal to a switching pattern. This switching pattern is spread spectrum with

a typical idle switching frequency of about 650kHz. The switching patterns for the two channels are

not synchronized and the idle switching frequencies should differ by at least 40kHz to avoid

increasing the audio band noise floor. The idle frequency difference can be accomplished by

offsetting the value of C

560pF for channel 2.

The MOSFET driver level-shifts the signal processor’s 5V switching patterns to the power supply

voltages and drives the power MOSFETs. The MOSFET driver includes a switching power supply

integrated to generate the VN10 supply. Special “bootstrapped” supplies (VBOOT1 and VBOOT2)

are used to power the high side MOSFET drivers. VN10 must be stable (regulated) at 10V to 12V

above VNN. The VN10 circuitry shown in the Application / Test Circuit typically produces 11V

above VNN.

The power MOSFETs are N-channel devices configured in half-bridges and are used to supply

power to the output load. The outputs of the power MOSFETs (OUT1 and OUT2) must be low pass

filtered to remove the high frequency switching pattern. A residual voltage from the switching

pattern will remain on the speaker outputs when the recommended output LC filter is used, but this

signal is outside of the audio band and will not affect audio performance.

Circuit Board Layout

The TA2022 is a power (high current) amplifier that operates at relatively high switching

frequencies. The output of the amplifier switches between VPP and VNN at high speeds while

driving large currents. This high-frequency digital signal is passed through an LC low-pass filter to

recover the amplified audio signal. Since the amplifier must drive the inductive LC output filter and

speaker loads, the amplifier outputs can be pulled above the supply voltage and below ground by

the energy in the output inductance. To avoid subjecting the TA2022 to potentially damaging

voltage stress, it is critical to have a good printed circuit board layout. It is recommended that

Tripath’s layout and application circuit be used for all applications and only be deviated from after

careful analysis of the effects of any changes.

The following components are important to place near their associated TA2022 pins and are ranked

in order of layout importance, either for proper device operation or performance considerations.

- The capacitors C

and will serve to reduce spikes across the supply rails. C

(3mm) of the VNN(8,9) and VPP(4,12) pins. Please note that both VNN1 and VPP1 as

well as VNN2 and VPP2 must be decoupled separately. In addition, the voltage rating for

C

should be 100V as this capacitor is exposed to the full supply range, VPP-VNN.

HBR

- D

, fast recovery PN junction diodes minimize undershoots of the outputs with respect to

O

power ground during switching transitions and abnormal load conditions such as output

shorts to ground. For maximum effectiveness, these diodes must be located close to the

output pins and returned to their respective VNN1(2). Please see Application/Test Circuit

for ground return pin.

for each channel. Typical values of CFB are 390pF for channel 1 and

FB

provide high frequency bypassing of the amplifier power supplies

HBR

should be kept within 1/8”

HBR

TA2022, Rev. 0.90, 12.00 13 of 27

Page 14

TECHNICAL INFORMATION

- C

- C

- C

- D

- To minimize noise pickup and minimize THD+N, R

In general, to enable placement as close to the TA2022, and minimize PCB parasitics, the

capacitors listed above should be surface mount types, located on the “solder” side of the board.

Some components are not sensitive to location but are very sensitive to layout and trace routing.

- To maximize the damping factor and reduce distortion and noise, the modulator feedback

- The output filter capacitor, C

- The modulator feedback resistors, R

TA2022 Grounding

Proper grounding techniques are required to maximize TA2022 functionality and performance.

Parametric parameters such as THD+N, Noise Floor and Crosstalk can be adversely affected if

proper grounding techniques are not implemented on the PCB layout. The following discussion

highlights some recommendations about grounding both with respect to the TA2022 as well as

general “audio system” design rules.

The TA2022 is divided into two sections: the input section, which spans pin 15 through pin 32, and

the output (high power) section, which spans pin 1 through pin 14. On the TA2022 evaluation

board, the ground is also divided into distinct sections, one for the input and one for the output. To

minimize ground loops and keep the audio noise floor as low as possible, the input and output

ground must be only connected at a single point. Depending on the system design, the single point

connection may be in the form of a ferrite bead or a PCB trace.

removes very high frequency components from the amplifier feedback signals and

FB

lowers the output switching frequency by delaying the feedback signals. In addition, the

value of C

is different for channel 1 and channel 2 to keep the average switching

FB

frequency difference greater than 40kHz. This minimizes in-band audio noise.

provides high frequency bypassing for the VN10 (pin 2) and bootstrap supplies. Very

B

high currents are present on these supplies.

filters the feedback signal (VN10FDBK) for the hysteretic VN10 buck converter.

SWFB

The feedback signal is noise sensitive and the trace from C

to VNN should be kept

SWFB

short.

is the flywheel diode for the VN10 buck converter and prevents VN10SW(pin 5) from

SW

going more than one diode drop below VNN.

should be located as close to the

FBC

TA2022 as possible.

connections should be routed directly to the inputs of the output inductors. L

. This was

O

done on the EB-TA2022 board.

, and zobel capacitor, CZ, should be star connected with the

O

load return. The output ground feedback signal should be taken from this star point. This

is suggested by the routing on the Application/Test schematic, but, for space/layout

reasons, this was not fully implemented on the EB-2022.

, R

FBA

, and R

FBB

should all be grounded and

FBC,

attached to 5V together. These connections will serve to minimize common mode noise

via the differential feedback. Please refer to the EB-TA2022 evaluation board for more

information.

14 of 27 TA2022, Rev. 0.90, 12.00

Page 15

TECHNICAL INFORMATION

The analog grounds, pin 15 and pin 20 must be connected locally at the TA2022 for proper device

functionality. On the TA2022 evaluation board, Tripath has used an analog ground plane to

minimize the impedances between pin 15 and pin 20 as well as the other analog ground

connections, such as V5 supply bypassing, and feedback divider networks. The ground for the V5

power supply should connect directly to pin 20. Additionally, any external input circuitry such as

preamps, or active filters, should be referenced to pin 20.

For the power section, Tripath has traditionally used a “star” grounding scheme. Thus, the load

ground returns and the power supply decoupling traces are routed separately back to the power

supply. In addition, any type of shield or chassis connection would be connected directly to the

ground star located at the power supply. These precautions will both minimize audible noise and

enhance the crosstalk performance of the TA2022.

The TA2022 incorporates a differential feedback system to minimize the effects of ground bounce

and cancel out common mode ground noise. As such, the feedback from the output ground for

each channel needs to be properly sensed. This can be accomplished by connecting the output

ground “sensing” trace directly to the star formed by the output ground return, output capacitor, C

and the zobel capacitor, C

Pin 3, VN10GND, is used for the VN10 buck converter. Pin 3 can be connected to the main power

supply decoupling ground trace (or plane) without any loss in functionality or reduction of

performance. This pins is electrically shorted to the copper heat sink (case) of the TA2022. Even if

the internal VN10 regulator is not being used, VN10GND should still be connected to PGND.

TA2022 Amplifier Gain

The gain of the TA2022 is the product of the input stage gain and the modulator gain. Please refer

to the sections, Input Stage Design, and Modulator Feedback Design, for a complete explanation of

how to determine the external component values.

=

A

VTA2022

−≈

. Refer to the Application / Test Circuit for a schematic description.

Z

A* AA

MODULATORV EVINPUTSTAG TA2022V

R

F

R

I

+

R*R

FBBFBA

)R(R*R

FBBFBAFBC

1

+

,

O

For example, using a TA2022 with the following external components,

R

R

R

Input Stage Design

The TA2022 input stage is configured as an inverting amplifier, allowing the system designer

flexibility in setting the input stage gain and frequency response. Figure 1 shows a typical

TA2022, Rev. 0.90, 12.00 15 of 27

= 20kΩ

I

R

= 20kΩ

F

R

= 1kΩ

FBA

= 1.13kΩ

FBB

= 9.09kΩ

FBC

A

VTA2022

20k

Ω

Ω

1.13k Ω*1.0k Ω

−≈

20k

)1.13k(1.0k Ω*9.09k Ω

Ω+

18.13 1

=

+

V

V

Page 16

A

TECHNICAL INFORMATION

application where the input stage is a constant gain inverting amplifier. The input stage gain should

be set so that the maximum input signal level will drive the input stage output to 4Vpp.

TA2022

OAOUT1

V5

-

+

INPUT1

CI

RF

RI

INV1

INPUT2

BIASCAP

INV2

RF

RICI

OAOUT2

GND

V5

+

-

AGND

Figure 1: Input Stage

The gain of the input stage, above the low frequency high pass filter point, is that of a simple

inverting amplifier:

R

F

A

EVINPUTSTAG

−=

R

I

Modulator Feedback Design

The modulator converts the signal from the input stage to the high-voltage output signal. The

optimum gain of the modulator is determined from the maximum allowable feedback level for the

modulator and maximum supply voltages for the power stage. Depending on the maximum supply

voltage, the feedback ratio will need to be adjusted to maximize performance. The values of RFBA,

RFBB and RFBC (see explanation below) define the gain of the modulator. Once these values are

chosen, based on the maximum supply voltage, the gain of the modulator will be fixed even with as

the supply voltage fluctuates due to current draw.

For the best signal-to-noise ratio and lowest distortion, the maximum modulator feedback voltage

should be approximately 4Vpp. This will keep the gain of the modulator as low as possible and still

allow headroom so that the feedback signal does not clip the modulator feedback stage.

Figure 2 shows how the feedback from the output of the amplifier is returned to the input of the

modulator. The input to the modulator (FBKOUT1/FBKGND1 for channel 1) can be viewed as

inputs to an inverting differential amplifier. R

2.5V and R

scales the large OUT1/OUT2 signal to down to 4Vpp.

FBC

FBA

and R

bias the feedback signal to approximately

FBB

16 of 27 TA2022, Rev. 0.90, 12.00

Page 17

TECHNICAL INFORMATION

1/2 TA2022

V5

RFBA

RFBA

RFBB

RFBC

RFBC

OUT1

OUT 1 GROUND

Processing

&

Modulation

FBKOUT1

FBKGND1

RFBB

AGND

Figure 2: Modulator Feedback

The modulator feedback resistors are:

FBA

VPP*R

R

FBA

FBB

=

1Ktypically specified, UserR

Ω=

4)-(VPP

VPP*R

R

FBA

FBC

=

4

A

MODULATOR-V

≈

+

R*R

FBBFBA

1

+

)R(R*R

FBBFBAFBC

The above equations assume that VPP=|VNN|.

For example, in a system with VPP

=36V and VNN

MAX

MAX

=-36V,

R

R

R

= 1kΩ, 1%

FBA

= 1.125kΩ, use 1.13kΩ, 1%

FBB

= 9.0kΩ, use 9.09kΩ, 1%

FBC

The resultant modulator gain is:

)1.13k(1.0k Ω*9.09k Ω

A

MODULATOR-V

≈

Ω+

18.13V/V 1

=+

1.13k Ω*1.0k Ω

Input Capacitor Selection

C

can be calculated once a value for RI has been determined. CI and RI determine the input low

I

frequency pole. Typically this pole is set below 10Hz. C

1

C

I

=

Rf2

IP

π

is calculated according to:

I

TA2022, Rev. 0.90, 12.00 17 of 27

Page 18

TECHNICAL INFORMATION

where:

I

R

= Input resistor value in ohms.

P

f

= Input low frequency pole (typically 10Hz or below).

Mute Control

The mute pin must be driven to a logic low or logic high state for proper operation. The state of the

mute pin is “latched in” to minimize the effects of noise on this pin, which could cause the TA2022

to switch state unintentionally. Controlling the mute pin with a push-pull output from a

mircocontroller, or a physical switch between V5 and AGND, works well as both solutions have low

impedance drive capability. In some cases, it may be desirable to drive the mute pin with an

alternative approach. When the device is in mute, the pin must be “pulled low” via approximately

1kohm to overcome the internal latch and change the TA2022 state (i.e. out of mute). When the

device is not in mute, the mute pin must be “pulled high” via approximately 2kohm to overcome the

internal latch and change the TA2022 state (i.e. into mute). Figure 3 shows a simple control circuit

that buffers a Mute Control signal that is not capable of driving the Mute pin of the TA2022 directly.

When the Mute Control signal is high, the Mute pin will be driven low and theTA2022 will be on. If

the Mute Control signal is low, the 2k resistor will pull the Mute pin high and the TA2022 will be

muted.

V5

2k

TO MUTE

(Pin 24)

MUTE

CONTROL

10k

AGND

Figure 3: Low impedance drive for Mute Pin

To ensure proper device operation, including minimization of turn on/off transients that can result in

undesirable audio artifacts, Tripath recommends that the TA2022 device be muted prior to power

up or power down of the 5V supply. The “sensing” of the V5 supply can be easily accomplished by

using a “mircocontroller supervisor” or equivalent to drive the TA2022 mute pin high when the V5

voltage is below 4.5V. This will ensure proper operation of the TA2022 input circuitry. A microcontroller supervisor such as the MCP101-450 from Microchip Corporation has been used by

Tripath to implement clean power up/down operation.

If turn-on and/or turn-off noise is still present with a TA2022 amplifier, the cause is may be other

circuitry external to the TA2022. While the TA2022 has circuitry to suppress turn-on and turn-off

transients, the combination of power supply and other audio circuitry with the TA2022 in a particular

application may exhibit audible transients. One solution that will completely eliminate turn-on and

turn-off pops and clicks is to use a relay to connect/disconnect that amplifier from the speakers with

that appropriate timing during power on/off.

18 of 27 TA2022, Rev. 0.90, 12.00

Page 19

TECHNICAL INFORMATION

TA2022 Output Capability

The TA2022 can output 100 watts into a 4ohm load at 1% THD+N. The maximum amplifier output

power is determined by a number of factors including the TA2022 junction temperature, the load

impedance and the power supply voltage.

Tripath does not recommend driving loads below 4 ohm as the amplifier efficiency will be seriously

reduced and the amplifier may prematurely current limit.

Bridging the TA2022

The TA2022 is can be bridged by returning the signal from OAOUT1 to the input resistor at INV2.

OUT1 will then be a gained version of OAOUT1, and OUT2 will be a gained and inverted version of

OAOUT1 (see Figure 3). When the two amplifier outputs are bridged, the apparent load impedance

seen by each output is halved, so the minimum recommended impedance for bridged operation is 8

ohms. Due to the internal current limit setting, the maximum supply voltage recommended for

bridged operation is +/-30V. Bridged operation into loads below 8ohms is possible, but, as

mentioned above, the amplifier efficiency will be reduced and the amplifier may prematurely current

limit.

TA2022

OAOUT1

V5

-

+

INPUT

CI

INV1

RF

RI

BIASCAP

20k

INV2

20k

OAOUT2

AGND

V5

+

-

AGND

Figure 4: Input Stage Setup for Bridging

The switching outputs, OUT1 and OUT2, are not synchronized, so a common inductor may not be

used with a bridged TA2022. For this same reason, individual zobel networks must be applied to

each output to load each output and lower the Q of each common mode differential LC filter.

Output Voltage Offset

The output offset voltage of the TA2022 is largely determined by the matching of the respective

R

, R

FBA

, and R

FBB

networks for FBKOUT1(2) and FBKGND1(2). Thus, the intrinsic offset of the

FBC

TA2022 can be altered by the external feedback network resistor matching. To minimize the

nominal untrimmed offset voltage, 1% tolerance resistors are recommended.

In most applications, the output offset voltage will need to be trimmed via an external circuit (either

passive or active). The output offset voltage of the TA2022 can be nulled by modifying the

TA2022, Rev. 0.90, 12.00 19 of 27

Page 20

TECHNICAL INFORMATION

modulator feedback as shown in Figure 4. Potentiometer R

resistance seen by the output ground, and therefore the output offset. ROFB limits the trim range.

1/2 TA2022

V5

RFBA

RFBA

is used to trim the effective

OFA

ROFA

50K

ROFB

10K

RFBC

RFBC

OUT1

OUT 1 GROUND

Processing

&

Modulation

FBKOUT1

FBKGND1

RFBB

RFBB

AGND

Figure 5: Manual Output Offset Trim Circuit

A DC servo can also be used to automatically null any offset voltage. Please see the EB-2022

documentation.

Output Filter Design

Tripath amplifiers generally have a higher switching frequency than PWM implementations allowing

the use of higher cutoff frequency filters, reducing the load dependent peaking/drooping in the

20kHz audio band. This is especially important for applications where the end customer may attach

any speaker to the amplifier (as opposed to a system where speakers are shipped with the

amplifier), since speakers are not purely resistive loads and the impedance they present changes

over frequency and from speaker model to speaker model. An RC network, or “zobel” (R

should be placed at the filter output to control the impedance “seen” by the TA2022. The TA2022

works well with a 2

nd

order, 80kHz LC filter with LO = 10uH and CO = 0.22uF and RZ = 6ohm and CZ

, CZ)

Z

= 0.22uF.

Output inductor selection is a critical design step. The core material and geometry of the output

filter inductor affects the TA2022 distortion levels, efficiency, power dissipation and EMI output.

The inductor should have low loss at 700kHz with 80Vpp. Tripath has used:

- Micrometals (www.micrometals.com) type-2 toroidal iron powder cores, which have low

loss, good linearity and low EMI radiation. The specific core was a T106-2 wound to

11uH with 16AWG wire. Tripath has also used T94-2 cores wound to 11uH with good

success.

- JW Miller 5502 10uH rod core inductors, which have excellent linearity, approximately 1

watt of core loss and high EMI radiation.

- ISI RPC-100-10 10uH vertical rod core inductors, which have good linearity, medium core

loss and high EMI radiation.

20 of 27 TA2022, Rev. 0.90, 12.00

Page 21

TECHNICAL INFORMATION

Power Supplies

The TA2022 requires the split supply rails VPP1(VPP2) and VNN1(VNN2), and V5. It also uses

some additional voltages, VN10, VBOOT1 and VBOOT2 that are generated internally. The

selection of components for the switching regulator is shown in the Application / Test Diagram.

Minimum and Maximum Supply Voltage Operating Range

The TA2022 can operate over a wide range of power supply voltages from +/-12V to +/-36V. In

order to optimize operation for either the low or high range, the user must select the proper values

for R

VNNSENSE

, R

VPPSENSE

, R

FBA

, R

, and R

FBB

. Please refer to the Modulator Feedback Design and

FBC

Over/Under-voltage Protection sections for more additional information.

VN10 (Pin 2)

The TA2022 has an internal hysteretic buck converter, which, in conjunction with a handful of

passive components, generates the necessary floating power supply for the mosfet driver stage

(nominally 11V with the external components shown in Application / Test Circuit). The performance

curves shown in the data sheet as well as efficiency measurements were done using the internal

VN10 generator. Tripath recommends that the internal VN10 generator be used.

In some cases, though, a designer may wish to use an external VN10 generator. The specification

for VN10 quiescent current (65mA typical, 80mA maximum) in the Electrical Characteristics section

states the amount of current needed when an external floating supply is used. If the internal VN10

generator is not used, Tripath recommends shorting VN10SW(pin 5) to VN10GND(pin 3) and

VN10FDBK(pin 14) to VN10GND(pin 3). VN10GND should still be connected to the system power

(high current) ground star for noise reasons.

The external VN10 supply must be able to source a maximum of 80mA into the VN10 pin. Thus, a

positive supply must be used. In addition, this supply must be referenced to the VNN rail. If the

external VN10 supply does not track fluctuations in the VNN supply or is not able to source current

into the VN10 pin, the TA2022 will, at the very least, not work, but more likely, be permanently

damaged.

Figure 6 shows a simple circuit for an external VN10 supply. Though simple, there is one problem

with this circuit; the maximum input voltage of the 7810. If the maximum input voltage of the 7810

is exceeded (typically this voltage is 35V), then the 7810 will be damaged which will likely cause

damage to the TA2022. Thus, this circuit should only be used where the VNN power supply is well

regulated even under heavy load conditions (including the effects of power supply pumping).

TO POWER SUPPLY

"STAR" GND

VIN

0.1uF 0.1uF10uF

7810

"GND"

TO VNN (PIN 8,9)

VOUT

TO VN10 (PIN 2)

10uF

Figure 6: Simple External VN10 Supply

TA2022, Rev. 0.90, 12.00 21 of 27

Page 22

TECHNICAL INFORMATION

Figure 7 shows a much more robust VN10 supply. In this case, the maximum supply differential the

LM317 experiences is the input voltage minus the output voltage. The maximum differential

specification is 40V for the LM317. W hen used as the VN10 supply for the TA2022, the maximum

differential the LM317 will experience is 25V, even at maximum operating voltage of 36V for the

TA2022. As configured, VOUT will be about 10.63V above VNN.

TO POWER SUPPLY

"STAR" GND

10uF

0.1uF

VIN

ADJ

1.8k

TO VNN (PIN 8,9)

LM317

10uF

VOUT

240

0.1uF

TO VN10 (PIN 2)

10uF

Figure 7: Robust External VN10 Supply

It should be noted that the maximum power dissipation for either Figure 6 or Figure 7 is:

MAX

1.6W80mA(max.)11V)(31VIOUTVOUT)(VINPD

=×−≈×−=

Thus, the LM7810 or LM317 must be sufficiently heat sinked to sustain 80mA in the system

ambient temperature. In the case where multiple TA2022’s are run off the same VN10 generator,

the power dissipation may be prohibitively large for the linear regulator in conjunction with allowable

heat sink. In these cases, a more sophisticated scheme using an additional transformer secondary

winding referenced to VNN may be necessary to minimize the linear regulator power dissipation.

Protection Circuits

The TA2022 is guarded against over-current, over / under-voltage and over-temperature conditions.

If the device goes into an over-current or over / under-voltage condition, the HMUTE goes to a logic

HIGH indicating a fault condition. When this occurs, the amplifier is muted, all outputs are TRISTATED, and will float to approximately 2.5VDC.

Over-current Protection

An over-current fault occurs if more than approximately 8 amps of current flows from any of the

amplifier output pins. This can occur if the speaker wires are shorted together or if one side of the

speaker is shorted to ground. An over-current fault sets an internal latch that can only be cleared if

the MUTE pin is toggled or if the part is powered down. See the over-current curves in the Typical

Characteristics section for more information.

Over / Under-voltage Protection

The TA2022 has built-in over and under voltage protection for both the VPP and VNN supply rails.

The nominal operating voltage will typically be chosen as the supply “center point.” This allows the

supply voltage to fluctuate, both above and below, the nominal supply voltage.

22 of 27 TA2022, Rev. 0.90, 12.00

Page 23

TECHNICAL INFORMATION

VPPSENSE (pin 19) performs the over and undervoltage sensing for the positive supply, VPP.

VNNSENSE (pin 18) performs the same function for the negative rail, VNN. In the simplest

implementation, the supply is done via a single, external resistor per sense pin. When the current

through R

VPPSENSE

(or R

VNNSENSE

) goes below or above the values shown in the Electrical

Characteristics section (caused by changing the power supply voltage), the TA2022 will be muted.

VPPSENSE is internally biased at 2.5V and VNNSENSE is biased at 1.25V. For the single resistor

sense case (as shown in the Application / Test Diagram), these bias points must be taken into

consideration when calculating the R

VPPSENSE

or R

VNNSENSE

resistor.

Once the supply comes back into the supply voltage operating range (as defined by the supply

sense resistors), the TA2022 will automatically be unmuted and will begin to amplify. There is a

hysteresis range on both the VPPSENSE and VNNSENSE pins. If the amplifier is powered up in

the hysteresis band the TA2022 will be muted. Thus, the usable supply range is the difference

between the over-voltage turn-off and under-voltage turn-off for both the VPP and VNN supplies. It

should be noted that there is a timer of approximately 200mS with respect to the over and under

voltage sensing circuit. Thus, the supply voltage must be outside of the user defined supply range

for greater than 200mS for the TA2022 to be muted.

The equation for calculating R

VPPSENSE

is as follows:

2.5V - VPP

R

VPPSENSE

=

I

VPPSENSE

The equation for calculating R

VNNSENSE

is as follows:

R

VNNSENSE

=

I

VNNSENSE

VNN-1.25V

where I

VPPSENSE

or I

VNNSENSE

can be any of the currents shown in the Electrical

Characteristics table for VPPSENSE and VNNSENSE, respectively.

Example: Nominal supply voltage – +/-32.5V +/-10%

From this information, a value of R

VPPSENSE

and R

VNNSENSE

can be calculated using the above

formulas.

MAX

=×=

36V use35.75V1.132.5VVPP

MAX

−=×−=

36V- use35.75V1.132.5VVNN

R

where I

VPPSENSE

VPPSENSE

2.5V -36V

A138

µ

kΩ

%1,k243use242.75

Ω==

is the minimum over-voltage turn off current for VPPSENSE.

R

where I

VNNSENSE

VNNSENSE

36V- -1.25V

A152

µ

kΩ

%1,k249use245.1

Ω==

is the minimum over-voltage turn off current for VNNSENSE.

TA2022, Rev. 0.90, 12.00 23 of 27

Page 24

TECHNICAL INFORMATION

Using the resistor values from above, the actual minimum over voltage turn off points will be:

N_OFFMIN_OV_TUR

N_OFFMIN_OV_TUR

µ

A

36.03V2.5V138kΩ243VPP

=+×=

36.60V-A152kΩ4921.25VVNN

=×−=

µ

The other three trip points can be calculated using the same formula but inserting the appropriate

I

VPPSENSE

(or I

VNNSENSE

) current value. As stated earlier, the usable supply range is the difference

between the minimum overvoltage turn off and maximum under voltage turn-off for both the VPP

and VNN supplies.

=

=

VPP-VPPVPP

VNN-VNNVNN

N_OFFMAX_UV_TURN_OFFMIN_OV_TUR RANGE

N_OFFMAX_UV_TURN_OFFMIN_OV_TUR RANGE

Using the resistor values from above, and the maximum under voltage trip currents shown in the

Electrical Characteristics table, the maximum under voltage turn off points will be:

N_OFFMAX_UV_TUR

N_OFFMAX_UV_TUR

µ

A

µ

23.64V2.5V87kΩ243VPP

=+×=

22..41V-A95kΩ4921.25VVNN

=×−=

and the resultant supply ranges will be:

RANGE

RANGE

12.39V23.64V03.36VPP

=−=

14.19V-22.41V60.36VNN

=−−−=

It should also be noted that the tolerance of the R

VPPSENSE

(or R

VNNSENSE

voltages and thus, the usable supply range. To minimize the additional variance Tripath

recommends 1% tolerance resistors.

As a matter of completeness, the formulas below include the effect of resistor tolerance assuming a

known value of R

VPPSENSE

or R

VNNSENSE

.

TRIPVPPSENSE N_OFFMIN_OV_TUR

TRIPVPPSENSE N_OFFMAX_UV_TUR

TRIPVNNSENSE N_OFFMIN_OV_TUR

TRIPVNNSENSE N_OFFMAX_UV_TUR

+÷×−=

+××−=

Using a value of 243kΩ for R

VPPSENSE

along with the appropriate value of I

and a value of 249kΩ for R

, the trip voltages and supply ranges can be calculated.

TRIP

VNNSENSE

N_OFFMIN_OV_TUR

N_OFFMAX_UV_TUR

RANGE

=−=

µ

AkΩ

µ

Ak Ω

9.74V24.70V44.34VPP

) resistors will effect the trip

2.5V)100/TOL1()IR(VPP

++÷×=

2.5V)100/TOL1()IR(VPP

++××=

)100/TOL1()IR(25.1VNN

)100/TOL1()IR(25.1VNN

, assuming 5% tolerance,

34.44V 2.5V)100/51()138243(VPP

=++÷×=

24.70V 2.5V)100/51()87243(VPP

=++××=

24 of 27 TA2022, Rev. 0.90, 12.00

Page 25

TECHNICAL INFORMATION

(

)

N_OFFMIN_OV_TUR

N_OFFMAX_UV_TUR

RANGE

=−−−=

µ

µ

11.21V-23.59V80.34VNN

−=+××Ω−=

80.34)100/51()152492(25.1VNN

−=+÷×Ω−=

59.23)100/51()95492(25.1VNN

VAk

VAk

Thus, by using 5% resistors, the supply range for the VPP has been reduced by 2.65V while the

VNN range has been reduced by approximately 3.0V (as compared to resistors with no tolerance

variation). In actuality, if a 5% resistor was to be used, then the initial value of R

R

VNNSENSE

would have had to be adjusted such that the minimum over voltage turn off points would

VPPSENSE

and

have never been less than +/-36V as defined by the supply voltage and tolerance specification.

It should be noted that the values for V

VPPSENSE

Characteristics table were calculated using a value of 249kΩ for both R

and V

VNNSENSE

shown in the Electrical

VPPSENSE

and R

VNNSENSE

. In

addition, for the maximum and minimum values, as opposed to the typical ones, a 1% tolerance

resistor value around 249kΩ was chosen to show the effect on supply range. Thus, the minimum

and maximum values would be “worst case” assuming a supply voltage of 5V for the input section

of the TA2022.

Over-temperature Protection

An over-temperature fault occurs if the junction temperature of the part exceeds approximately

165°C. The thermal hysteresis of the part is approximately 30°C, therefore the fault will

automatically clear when the junction temperature drops below 135°C.

HMUTE (pin 32)

The HMUTE pin is a 5V logic output that indicates various fault conditions within the device. These

conditions include: over-current, overvoltage and undervoltage. The HMUTE output is capable of

directly driving an LED through a series 2k

resistor.

Ω

Heat Sink Requirements

In most applications it will be necessary to fasten the TA2022 to a heat sink. The determining factor

is that the 150°C maximum junction temperature, T

(max) cannot be exceeded, as specified by the

J

following equation:

TT

−

P

DISS

=

θ

A)MAX(J

JA

where:

P

= maximum power dissipation

DISS

T

= maximum junction temperature of TA2022

JMAX

T

= operating ambient temperature

A

= junction-to-ambient thermal resistance

θ

JA

=

θ

θ

JA

JC + θCS + θSA

TA2022, Rev. 0.90, 12.00 25 of 27

Page 26

(

)

TECHNICAL INFORMATION

Example:

What size heat sink is required to operate the TA2022 at 80W per channel continuously in a 70ºC

ambient temperature?

P

Efficiency =

Thus, P

The

θ

(assuming a

music source (as opposed to a continuous sine wave) and regulatory agency testing requirements

will determine the size of the heat sink required.

is determined by:

DISS

P

OUT

η

=

P

IN

(per channel) =

P

DISS

for two channels = 28.24W

DISS

TT

−

DISS

A)MAX(J

=

=

θ

JA

P

of the TA2022 is 1.0°C/W, so a heat sink of 1.63°C/W is required for this example

JC

= 0.2°C/W). In actual applications, other factors such as the average P

θ

CS

P

70150

−

24.28

P

=

OUT

P

η

= 2.83°C/W

OUT

−

OUT

PP

DISSOUT

80

85.0

14.12W80

=−=−

with a

DISS

26 of 27 TA2022, Rev. 0.90, 12.00

Page 27

TECHNICAL INFORMATION

Performance Measurements of the TA2022

The TA2022 operates by generating a high frequency switching signal based on the audio input.

This signal is sent through a low-pass filter (external to the Tripath amplifier) that recovers an

amplified version of the audio input. The frequency of the switching pattern is spread spectrum in

nature and typically varies between 100kHz and 1MHz, which is well above the 20Hz – 20kHz

audio band. The pattern itself does not alter or distort the audio input signal, but it does introduce

some inaudible components.

The measurements of certain performance parameters, particularly noise related specifications

such as THD+N, are significantly affected by the design of the low-pass filter used on the output as

well as the bandwidth setting of the measurement instrument used. Unless the filter has a very

sharp roll-off just beyond the audio band or the bandwidth of the measurement instrument is limited,

some of the inaudible noise components introduced by the TA2022 amplifier switching pattern will

degrade the measurement.

One feature of the TA2022 is that it does not require large multi-pole filters to achieve excellent

performance in listening tests, usually a more critical factor than performance measurements.

Though using a multi-pole filter may remove high-frequency noise and improve THD+N type

measurements (when they are made with wide-bandwidth measuring equipment), these same

filters degrade frequency response. The TA2022 Evaluation Board uses the Application/Test

Circuit of this data sheet, which has a simple two-pole output filter and excellent performance in

listening tests. Measurements in this data sheet were taken using this same circuit with a limited

bandwidth setting in the measurement instrument.

TA2022, Rev. 0.90, 12.00 27 of 27

Page 28

TECHNICAL INFORMATION

Package Information

32-pin SSIP Package:

28 of 27 TA2022, Rev. 0.90, 12.00

Page 29

TECHNICAL INFORMATION

ADVANCED INFORMATION – This is a product in development. Tripath Technology Inc. reserves

the right to make any changes without further notice to improve reliability, function or design.

Tripath and Digital Power Processing are trademarks of Tripath Technology Inc. Other trademarks,

which are referenced in this document, are owned by their respective companies

Tripath Technology Inc. reserves the right to make changes without further notice to any products

herein to improve reliability, function or design. Tripath does not assume any liability arising out of

the application or use of any product or circuit described herein; neither does it convey any license

under its patent rights, nor the rights of others.

TRIPATH’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN

LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN CONSENT OF

THE PRESIDENT OF TRIPATH TECHNOLOGY INC. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical

implant into the body, or (b) support or sustain life, and whose failure to perform, when properly

used in accordance with instructions for use provided in this labeling, can be reasonably

expected to result in significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to

perform can be reasonably expected to cause the failure of the life support device or system, or

to affect its safety or effectiveness.

For more information on Tripath products, visit our web site at:

World Wide Sales Offices

Western United States: Jim Hauer jhauer@tripath.com 408-567-3089

Taiwan, HK, China: Jim Hauer jhauer@tripath.com 408-567-3089

Japan: Osamu Ito ito@tripath.com 81-42-334-2433

Europe: Steve Tomlinson stomlinson@tripath.com 44-1672-86-1020

www.tripath.com

.

B

TRIPATH TECHNOLOGY, INC.

3900 Freedom Circle, Suite 200

Santa Clara, California 95054

408-567-3000

TA2022, Rev. 0.90, 12.00 29 of 27

Loading...

Loading...