Page 1

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 1/27

OPTREX

Type No.

*******

June 20, 2002

Final Revision

First Edition

Checked by Engineering

Checked by Quality Assurance

Approved by Production

Drawn by Engineering

LCD Module Specification

T-51440GL070HU-FW-AC

Table of Contents

1. Application...........................................................................................2

2. Mechanical Specification .....................................................................2

3. Absolute Maximum Ratings................................................................3

4. Environment Condition........................................................................3

5. Optical Characteristics.........................................................................4

6. Electrical Characteristics...................................................................10

7. Product Standard................................................................................19

8. Reliability Test...................................................................................22

9. Code System of Production Lot........................................................24

10. Packing Specification .........................................................................25

11. Product handling Cautions................................................................ 26

12. Condition for Guarantee....................................................................27

Revision History

Rev. Date Page Comment

Page 2

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 2/27

OPTREX

1.Application

This specification applies to 7.0” color TFT -LCD module (T-51440GL070HU-FW-AC).

The applications of the panel are for automotive entertainment and car navigation.

2.Mechanical Specifications

Screen Size : 7 inches (18cm) diagonal

Display Mode : Normally White

Driving Method : a-Si TFT active matrix format

Line Scan/non -interlace Reverse Horizontal Line

Composition : TFT Cell, Driver IC, Timing controller IC, Backlight unit, Inverter

DC/DC Converter, and Video circuit

Input Power Supply : +8V-16V(DC)

Input Signal : Composite Video Signal (NTSC/PAL) or

Specific Analog RGB signal (NTSC/PAL) + Composite or Separate

Synchronized signal

Output Signal : Horizontal/Vertical Synchronized signal (negative)

Resolution : 480(W) x 234(H)

Dot Resolution : 1440(W) x 234(H)

Dot Pitch : 0.3210(W) x 0.3720(H) mm

Pixel Configuration : RGB Stripe

Active Area : 154.08(W) x 87.048(H) mm

Backlight : Triple wavelength L-shaped Cold Cathode Fluorescent Lamp, Dimming

Ratio 1-100%

Viewing Direction : 12 O’clock (Maximum Contrast)

Surface Treatment : AGLR Coating (Low Reflectance)

Outer Dimension : 164.9(W) x 101.9(H) x 23.1(D) mm

Weight : TBD g max.

Attached Drawing : Dimensional Outline UE-210547-00

Page 3

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 3/27

OPTREX

3.Absolute Maximum Ratings

Item Symbol Conditions Min. Max. Unit

Video Circuit VPW Vss–0.2 16.0 V

Power

Supply

Backlight VBL

Ta=25±5?

VSS=0V

Vss–0.2 16.0 V

Composite Video VIDEO

-

1.5 V

P-P

Analog RGB R,G,B

-

1.5 V

P-P

Synchronous

Signals

VSY,HSY – 1.5 V

P-P

Chroma Signal CYSYNC

Ta=25±5?

75O

VPW=VBL=+12.0V

– 1.5 V

P-P

Adjustment

Signals

COLOR,

BRT,CONT,

TINT,DIM

Vss–0.3

VDD+0.3

V

Input

Signal

Switching

Signals

U/D,R/L,

MOD1~3,

N/P,R/CMP,

YC/CMP

Ta=25±5?

Vss=0V

VPW=VBL=+12.0V

Vss–0.3

VDD+0.3

V

Storage Temperature T

stg

-

–40 +85

?

Operating Temperature T

opr

-

–30 +85

?

Note: Absolute maximum ratings should not exceed the limit anytime. If the product

exceeds the limit, it may cause damage. Please be cautious to the changes in supply voltage,

connection parts, surge of signals and ambient temperature.

4.Operating Conditions

Item Conditions Tmperature Range

Remark

LCD Module

w/Backlight

Ambient Temperature

(Panel Surface)

–30~85?

(

–30~85?)

Note4-1,4-2

Operating

Temperature Range

LCD Panel Surface Temperature –30~75?

LCD Module

w/Backlight

Surface Temperature –40~85?

Note4-3

Storage

Temperature Range

LCD Panel Surface Temperature –40~85?

Note4-1: Operating temperature range defines the operation only and the contrast, response time and

other display optical characteristics are set at Ta=+25?.

Note4-2: Panel surface temperature indicates the temperature of the backlight panel surface on the five

points from the four corners and the center. Also note that the panel temperature of backlight

side is 10?(reference value) higher than the other side.

Note4-3: Backlight is not activated.

Page 4

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 4/27

OPTREX

5.Optical Specifications

Conditions Standard Value

Item Symbol

? f C

Min. Typ. Max.

Unit

Method of

Measure

Remark

(1)Brightness

B

0

°

0°

-

(400)

-

Cd/m2

Note5-1

(2)Contrast CR

Optimum

Viewing

60 150

-

-

X

0

°

0° 0.265 0.305 0.345

-

(3)White Chromaticity

Y

0

°

0° 0.300 0.340 0.380

-

(Fig.5-1)

(4)Brightness Uniformity

-

0

°

0° 0.7

-

-

-

(Fig.5-2)

Up

?

U

-

0° ?10

-

(60)

-

Degree

(5)Vertical

Viewing Angle

Down

?

D

-

0° ?10

-

(30)

-

Degree

Left

F

L

0

° - ?

10

-

(60)

-

Degree

(6)Horizontal

Viewing Angle

Right

f

R

0

° - ?

10

-

(60)

-

Degree

(Fig.5-3)

Rise

t r

0

°

0°

-

TBD TBD ms (7)Response

Time Decay

t d

0

°

0°

-

TBD TBD Ms

(Fig.5-4)

Note5-1:Under the condition of tube current 6.0mA

?

Conditions for Measuring

?

Environment: Dark room with no light or close to no light.

?

Temperature:

25±5?

?

Humidity:

40~ 70%RH

?

After backlight has been lit more then 30 minutes, driving voltage is set for optimal contrast to

measure center of display.

?

Measure by the specified inverter or similar product.

?

Optimal viewing angle (The angle with best contrast)

12 O’clock

Page 5

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 5/27

OPTREX

(Fig.

5-1)

?

Method of Brightness Measurement

(1)

Measuring Device

TOPCON BM-7? Measuring Field:1°

(2)

Measuring Point

Center of Display

? =0°?f=0°

On condition

? :

A vertical angle from measuring direction to perpendicular.

f :

A horizontal angle from measuring direction to perpendicular.

(3)

Method of Measuring

Apply signal voltage (displayed in white) to maximize brightness and measure brightness B (cd/m2).

The distance between BM-7’s front lens to surface panel is 500mm.

Measured after backlight has been lit for more than 30 minutes.

?

Method of Contrast Measurement

(1)

Measuring Device

TOPCON BM-7? Measuring Field:1°

(2)

Measuring Point

Center of display: same as Method of Brightness Measurement

(3)

Method of Measuring

·

Set LCD module to

? =0°?f=0°

.

·

Change signal voltage to measure maximum brightness Y1 and minimum brightness Y2.

·

Contrast is derived from CR=Y1/Y2.

LCD Module

Distance

:500mm

TOPCON

BM-7

Center

(Pixel)

(X,Y)=

(240,117)

Page 6

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 6/27

OPTREX

(Fig.

5-2)

?

Definition of Brightness Uniformity

Definition is calculated from the four points (S0-S4) on the diagram below.

Minimum Value of S1-S4

Standard Value of Brightness Uniformity=

S0

S1

S2

S3

S4

S0

20mm

20mm

20mm 20mm

Page 7

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 7/27

OPTREX

(Fig.

5-3)

?

Method of Viewing Angle Measurement

(1)

Measuring Device

TOPCON BM-7? Measuring Field:1°

(2)

Measuring Point

Center of display : Same as Method of Brightness Measurement

(3)

Angle of Measuring

? :

An angle vertical to perpendicular line from the viewing direction.

F :

An angle horizontal to perpendicular from the viewing direction.

(4)

Method of Measuring

Set rotation table to

f =0°

and set BM-7 to contrast 10 to measure angle±? for left and right

direction of horizontal viewing anglef. Also set rotation table to

f =90°

and set BM-7 to

contrast 10 to measure angle±?for up and down direction of vertical viewing angle ?.

f

Rotation Table

(θ,φ)

TOPCON BM-7

Comp

uter

Waveform Generator

LCD

Temperature

Control Unit &

?

Page 8

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 8/27

OPTREX

(

Fig.

5-4)

?

Measuring Response Time

(1)

Measuring Device

TOPCON BM-7? Measuring Field:1°

Tektronix Digital Oscilloscope

(2)

Measuring Point

Center of display, same as Method of Brightness Measurement

(3)

Method of Measuring

·

Set LCD panel to

? =0°

,and

f =0°

.

·

Input white?black?white to display by switching signal voltage.

·

If the luminance is 0% and 100% immediately before the change of signal voltage, then

t r

is

optical response time during the change from 90% to 10% immediately after rise of signal voltage,

and

t d

is optical response time during the change from 10% to 90% immediately after decay of

signal voltage.

White Black White

100%

90%

10%

0%

tr

td

Brightness

Page 9

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 9/27

OPTREX

6. Electrical Characteristics

6.1 Recommended Operating Conditions

(Ta=25±5? ? Vss=0V)

Item

Symbol Condition Min. Typ. Max. Unit

System VPW 8.0 12.0 16.0 V Power

Supply

Backlight VBL 8.0 12.0 16.0 V

Composite Video VIDEO 1.0 Vp-p

Analog RGB R,G,B 0.7 Vp-p

Chroma Signal YCSYNC 1.0 Vp-p

Synchronous

Signals

HSY,VSY

75O

0.7 Vp-p

Brightness BRT 2.6 V

Tint TINT 1.0 2.7 V

Color COLOR 2.5 V

Contrast CONT 2.5 V

Backlight DIM 1 100 %

H level 3.0 3.6

Input

Signals

Select Signals

MOD1~3,N/P

U/D,R/CMP

R/L,YC/CMP

L level 0 0.8

V

f

VDN

57.14 59.939 62.86 Hz

f

HDN

NTSC

15.00 15.734 16.50 KHz

f

VDP

48.64 50.00 51.20 Hz

Synchronous Frequency

f

HDP

PAL

15.20 15.625 16.00 KHz

Note: Recommended Operating Conditions defines the guaranteed range of operation and it is out of guarantee

if the product exceeds the range even if within the range of Item3.Absolute Maximum Ratings.

Please use within the range of Recommended Operating Conditions.

6.2 Pixel Alignment

RG B R GB R GB

RG B R GB R GB

RG B

RG BRG B

GB

RG B R GB R GB

RG B R GB R GB

RG B

RG BRG B

RG B

RG B R GB R GB

RG B R GB R GB

RG B

RG BGB

RG B

RG B R GB R GB RGB

RG B R GB R GB

R

R

R

RG

R

B

Page 10

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 10/27

OPTREX

6.3 I/O Terminal Descriptions

No. Symbol

Level

Function

I/O Remark

1 VDD

?

Power Supply

(+5V) Output

2 COLOR

?

Color Adjustment

(0~ 5V)

Input

3 BRT ? Brightness Adjustment

(0~ 5V)

Input

4 CONT

?

Contrast Adjustment

(0~ 5V)

Input

5 VIDEO ? Composite Video Signal Input

(1.0V

P-P

,75O )

Input

6 Vss

?

Signal Ground

?

7 Vss ? Backlight Ground ?

8 Vss

?

Backlight Ground

?

9 VBL ? Power Supply for Backlight

(+8~ 16V)

Input

10 VBL

?

Power Supply for Backlight

(+8~ 16V)

Input

11 U/D

H / L Up/Down Scanning Direction

(Open:Down to Up, GND:Up to Down)

Input

12 R/L H / L

Left/Right Scanning Direction

(Open: Left to Right, GND: Right to Left)

Input

13 DIM

?

Backlight Dimming

(1~ 100% Adjustable)

Input

14 MOD1 H / L Display Mode 1 Input

15 MOD2 H / L Display Mode 2 Input

16 MOD3 H / L Display Mode 3 Input

17 N/P H / L NTSC/PAL Select

(Open : NTSC, GND : PAL)

Input

18 TINT

?

Tint Adjustment

(1~ 5V)

Input

19 R/CMP H / L

RGB/Composite Select

(Open: RGB, GND:Composite)

Input

20 YC/CMP H / L

Synchronous Signal Select

(Open: YC Separate, GND: Composite)

Input

21 YCSYNC

?

Chroma Signal

(0.7V

P-P

,75O )

Input

22 VSY ? Vertical Sync.

(0.7V

P-P

,75O , Active Low)

Input

23 HSY

?

Horizontal Sync.

(0.7V

P-P

,75O , Active low)

Input

24 Vss

?

Signal Ground

?

25 G

?

Green Color Video Signal

(1.0V

P-P

,75O )

Input

26 B

?

Blue Color Video Signal

(1.0V

P-P

,75O )

Input

27 R

?

Red Color Video Signal

(1.0V

P-P

,75O )

Input

28 VPW ? System Power Supply

(+8~ 16V)

Input

29 VSYO

?

Vertical Sync.Output

(0.7V

P-P

,75O,Active Low)

Output

30 HSYO

?

Horizontal Sync.Output

(0.7V

P-P

,75O ,Active Low)

Output

Mating Connector : SHDR-30V -S-B (JST)

Page 11

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 11/27

OPTREX

6.4 Block Diagram

OEV

FX

7 inch Wide TFT

LCD Module

VBL

DIM

V

COM

Video Controller

Timing

Controller

Inverter

COLOR

VSY

HSY

R/CMP

YCSYNC

U/D

YC/CMP

VIDEO

R,G,B

MOD1~3

CLK

OE

R/L

BRT

HSYO

VSYO

CONT

TINT

N/P

Brightness

Control

DC/DC

Converter

+18.5V

-12.0V

+5V

+3.3V

+3.3V +5V

-5V +7V

V

PW

Dip SW

HOT

GND

Page 12

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 12/27

OPTREX

6.5 Signal Definition

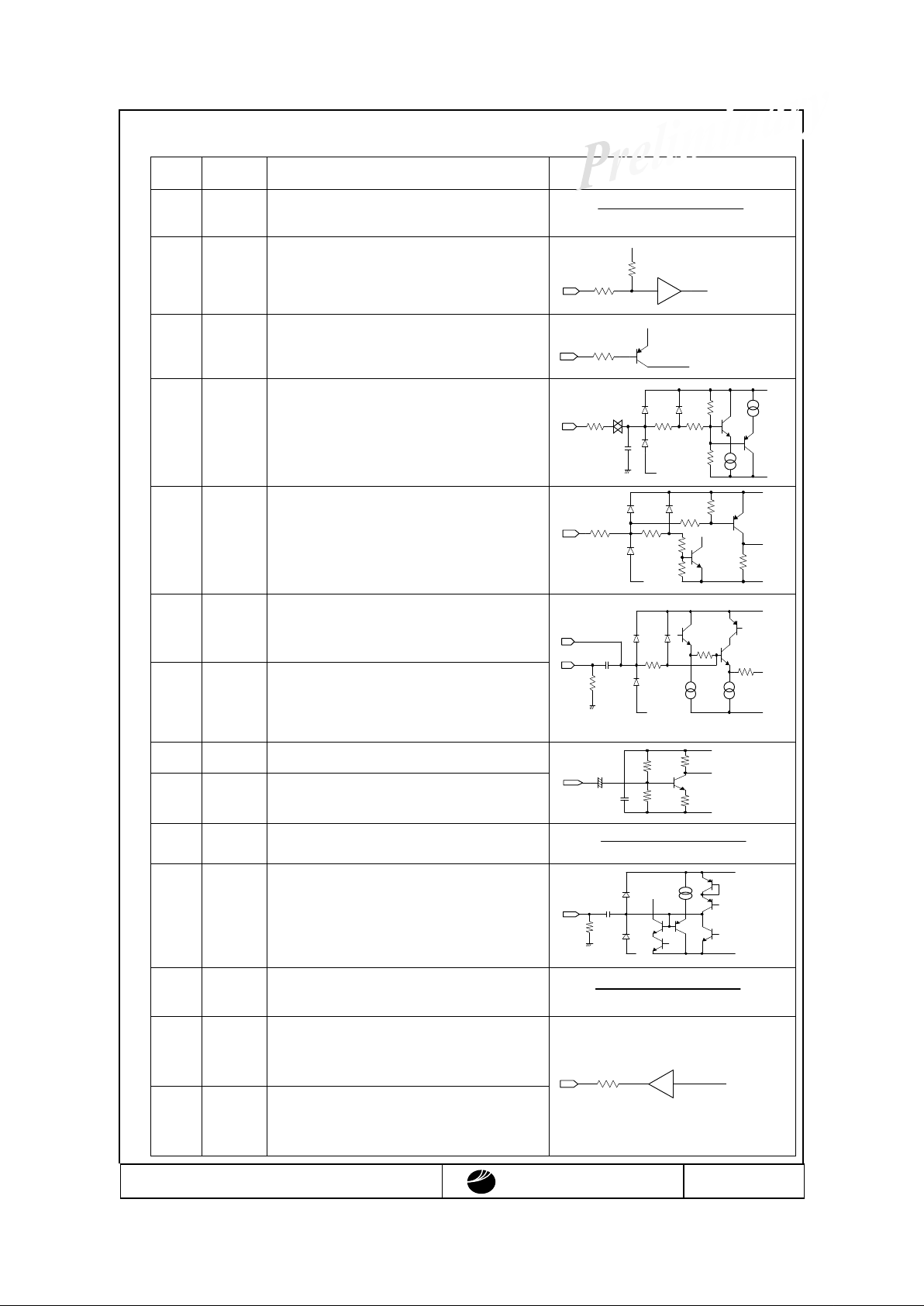

Pin No. Symbol Function I/O Intermal Equivalent Circuit

1 VDD 5V output terminal

Please use this for each adjustable

terminal (2 ~ 4, 18 pin)

Output Current(Idd) = Less than 10mA

2 COLOR Color adjustment input terminal.

Can be selected to change anywhere

between 0 ~ 5V.

3 BRT Brightness Adjustment for RGB signal.

Can be selected to change anywhere

between 0 ~ 5V.

4 CONT Contrast adjustment terminal.

Can be selected to change anywhere

between 0 ~ 5V.

5 VIDEO Composite video signal input terminal.

Please use standard input level 1 Vp-p

of composite video signal. When using

composite video input signal fix

YCSYNC(21pin) to GND .

6 Vss Signal Ground terminal.

Connect to GND.

7 Vss Backlight grounding terminal.

Connect to GND.

8 Vss Backlight grounding terminal.

Connect to GND.

9 VBL Power supply input terminal for ba

cklight.

Use standard 12V.

10 VBL

Power supply input terminal for backlight.

Use standard 12V.

11 U/D Up/Down scanning direction select

terminal.

When open, it will scan down to up.

When connected to GND, it will scan

up to down.

12 R/L Left/Right scanning direction select

terminal.

When open, it will scan left to right.

When connected to GND, it will scan

right to left.

40k

40k

60k

24k200100

-5V

+5V

GND

10k

75k200

100

-5V

+5V

GND

+5V

50k

40k

20k

200100

-5V

GND

+5V

-5V

1uF

GND

75

100

Page 13

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 13/27

OPTREX

Pin No.

Symbol Function I/O Intermal Equivalent Circuit

13 DIM Backlight Dimming Terminal.

Input 3.3V square wave PWM format

14

15

16

MOD 1

MOD 2

MOD 3

Display mode select input terminal

See Table 6.1

17 N/P NTSC/PAL select terminal.

Open : NTSC

GND : PAL

18 TINT Tint adjustment input terminal.

Can be selected between 1~5V

19 R/CMP Video signal input select terminal.

Open: Analog RGB

GND: Composite Video

20 YC/CMP Synchronous signal input select terminal.

Open: YC seperate input

GND: Composite

21 YCSYNC Chroma input terminal.

Use Chroma signal 0.7Vp-p.

When using composite video, connect to

GND.

22 VSY Vertical synchronous signal input terminal.

23 HSY Horizontal synchronous signal input terminal.

24 Vss Signal Ground terminal.

Connect to GND.

25

26

27

G

B

R

Analog RGB signal input terminal.

Use Analog RGB signal standard level

0.7Vp-p.

28 PWR System power supply input terminal.

Use standard 12V.

29 VSYO Vertical synchronous signal output terminal.

Please use for UOS(under on screen) to adjust

the screen position.

30 HSYO Horizontal synchronous signal output

terminal.

Please use for UOS(under on screen) to adjust

the screen position.

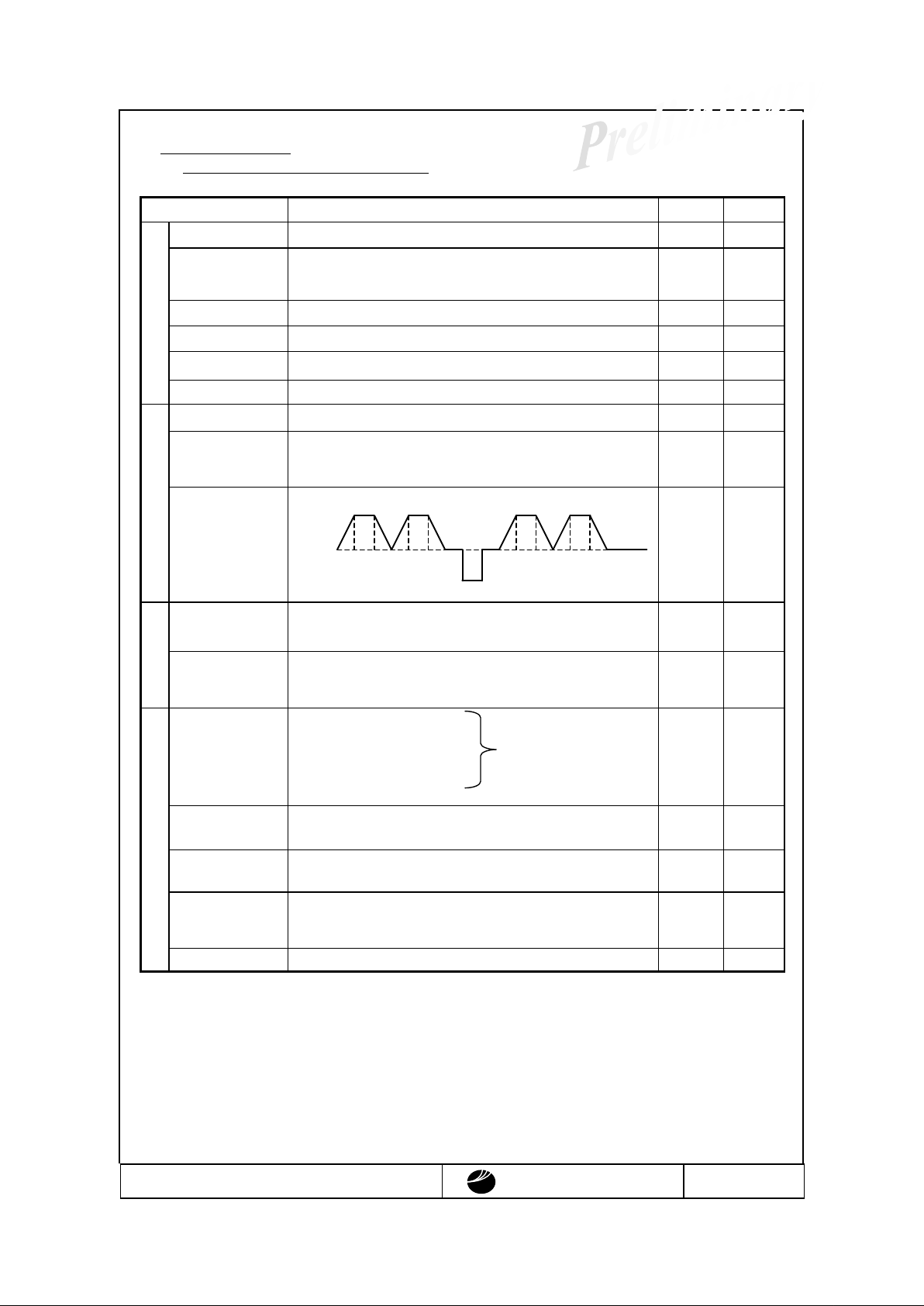

22k

+3.3V

100

+3.3V

22k

40k

25k

35k200

100

-5V

+5V

GND

36k

4.7k

30k

1k

200100

-5V

+5V

GND

4.7k

5k

0.1uF 200

75

-5V

+5V

GND

YC/CMP

YCSYNC

22k

2k

10uF

22k

100

0.1uF

+3.3V

GND

+

0.1uF

75

-5V

+5V

GND

100

Page 14

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 14/27

OPTREX

Table 6.1 : Display Mode

Mode

Display Image

(4:3 Signal Input)

MOD1

(14pin)

MOD2

(15pin)

MOD3

(16pin)

Remark

Full

GND GND GND

Input Signal is displayed fully

on screen.

Normal Center

OPEN GND GND

4:3 Image displayed in center

of

display.

Wide

GND OPEN GND

4:3 Signal has been extended

sideways from center of

display.

Zoom 1

OPEN OPEN GND

Display is fixed on top and

then

zoomed.

Zoom 2

GND GND OPEN

The time for gate is adjusted

from Zoom1 mode.

Normal Left

OPEN GND OPEN

4:3 image shifted to left.

Normal Right

GND OPEN OPEN

4:3 image shifted to right.

Unfixed

OPEN OPEN OPEN

Unfixed

Page 15

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 15/27

OPTREX

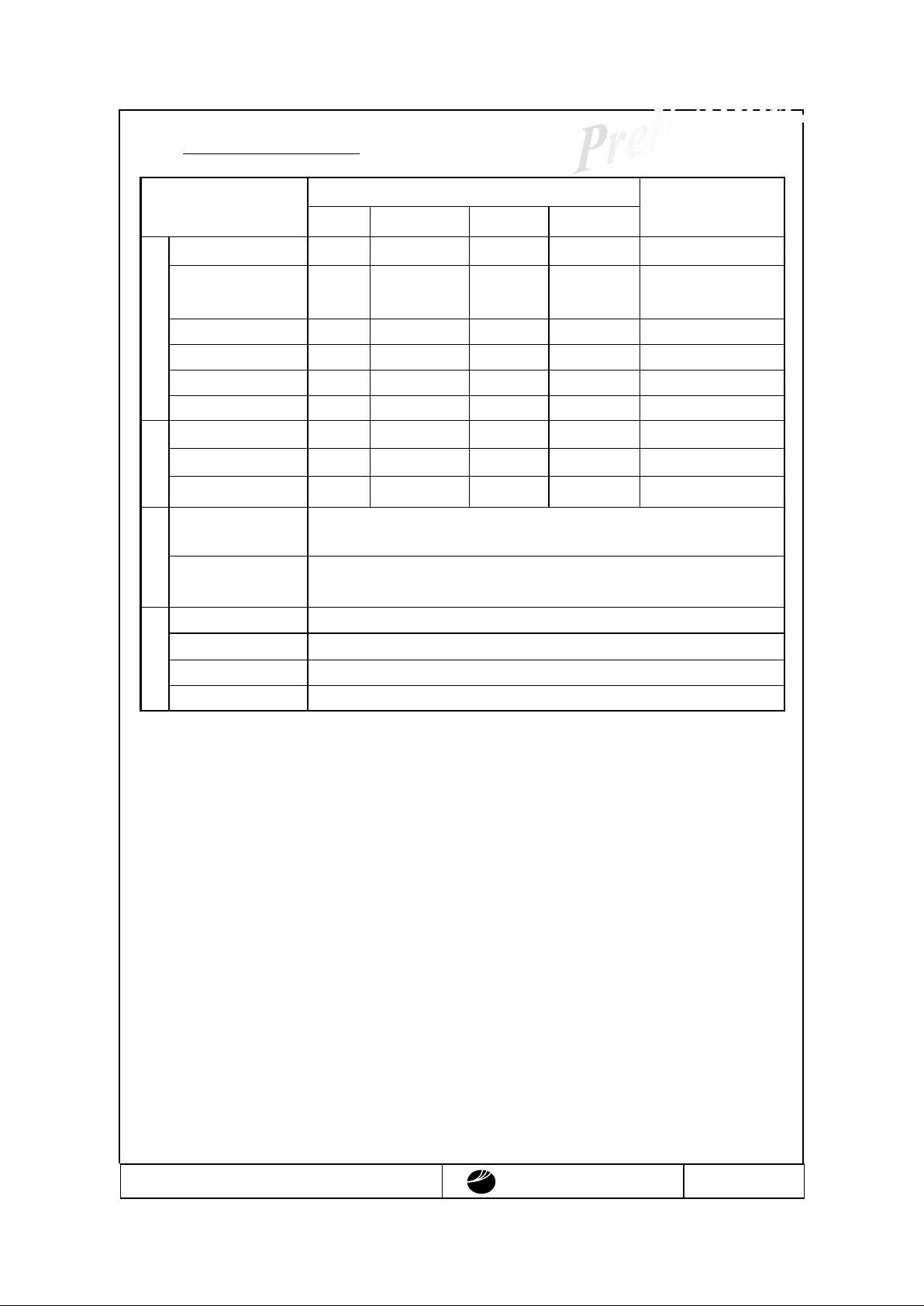

6.6 Timing specification (Analog RGB)

Fig.6-1 Full/Wide/Zoom1,2 mode

Note: Display mode and DipSW setting can change non-display lines and display lines.

Fig6-2 4:3 mode (Center/Right/Left)

Note: Normal left/right has same value as Normal center values as above.

*( ) values are for PAL mode

Dot clock : 9.59MHz (9.53MHz)

R,G,B 3Sub-pixles =1clock

262.5 Line

(312.5Line)

Non-display Line

234

Line

(281

Line

50.01µs(50.36µs)

DipSW

Selectabl

e

63.56µs(64.00µs)

VSY

HSY

262.5 Line

(312.5 Line)

Non-display line

234

Line

(281

Line)

50.01µs(50.36µs)

DipSW

S

electable

63.56µs(64.00µs)

VSY

HSY

* ( ) values are for PAL mode

Dot clock : 7.20MHz (7.15MHz)

R,G,B 3sub-pixels =1clock

Page 16

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 16/27

OPTREX

Fig. 6-3 (Horizontal Timing (NTSC/PAL)

Note : All values are set at typical.

Values within ( ) are values for PAL mode.

Fh=15.734(15.625) kHz

HSY

4.7µs

R,G,B

1.0Vp-p

0.7Vp-p

1 LINE=63.56(64.00)µs

50.01(50.36)µs

Display Area

DipSW

Selectable

Page 17

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 17/27

OPTREX

Fig.6-4 Vertical Timing (NTSC: Full/4:3mode)

Note: Wide/Zoom mode has different starting location

525 1 2

11

8

4

30

10

Display Area

0.7

Vp-p

DipSW Selectable

524

5 6 7

3

9

20

29

26 22

28

23 24 25

21

27

Display Area

262 263 264

273

270

266

272 274

267 268 269

265

271

285

275

255

245 246

284

254

0.7

Vp-p

DipSW Selectable

DipSW Selectable

0.7

Vp-p

1.0 Vp-p

VSY

Line No.

R,G,B

HSY

VSY

Line No.

HSY

R,G,B

(12 ~ 19H)

Page 18

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 18/27

OPTREX

6.7 Video Board Adjustment

6.7.1

Dip Switch (SW 1,2)

Dip Switch Number Contents Remark

Horizontal Display Starting Position Adjust(From

HSY

)

Vertical Display Starting Position Adjust(From VSY)

SW1

SW1-8:Display Image Adjustment Select

ON:Internal by Pots. OFF:External by level

Default Set

SW1-1 : ON

SW1-2 : OFF

SW1-3 : ON

SW1-4 : OFF

SW1-5 : OFF

SW1-6 : OFF

SW1-7 : OFF

SW1-8 : ON

SW2-1:ON(Default)

SW2-2:ON(Default)

SW2-3:UOS(Under On Screen) Display Select

ON:Active OFF:Non Active

SW2

SW2-4:Synchronous Signal Select

ON:Composite OFF:Analog RGB

Default Set

SW2-1 : ON

SW2-2 : ON

SW2-3 : OFF

SW2-4 : ON

6.7.2 Potentiometers for Display Image Adjustment

Symbol Contents Remark

VR301 TINT:Tint Adjustment

VR302 COLOR:Color Adjustment

VR305 CONT:Contrast Adjustment

VR312 BRT:Brightness Adjustment

ON ON ON

ON OFF OFF OFF OFF OFF

OFF ON ON OFF OFF ON

OFF ON OFF

ON OFF ON

ON ON OFF

12H(24H)

13H(25H)

14H(26H)

15H(27H)

16H(28H)

17H(29H)

18H(30H)

19H(31H)

SW1 7 6 5 Start Line=12H

ON ON ON

ON OFF OFF OFF OFF OFF

OFF ON ON OFF OFF ON

OFF ON OFF

ON OFF ON

ON ON OFF

7.3000uS(8.5000uS)

6.9875uS(8.1875uS)

6.6750uS(7.8750uS)

6.3625uS(7.5625uS)

6.0500uS(7.2500uS)

5.7375uS(6.9375uS)

5.4250uS(6.6250uS)

5.1125uS(6.3125uS)

SW1 4 3 2 1 Wait Time

ON ON ON

ON OFF OFF OFF OFF OFF

OFF ON ON OFF OFF ON

OFF ON OFF

ON OFF ON

ON ON OFF

4.8000uS(6.0000uS)

4.4875uS(5.6875uS)

4.1750uS(5.3750uS)

3.8625uS(5.0625uS)

3.5500uS(4.7500uS)

3.2375uS(4.4375uS)

2.9250uS(4.1250uS)

2.6125uS(3.8125uS)

ON

ON ON OFF OFF

OFF

OFF ON OFF OFF

OFF ON

ON OFF

ON

ON

( ) values are for PAL mode, at zoom add31H(35H)

( ) values are for PAL mode, other values at side black

Page 19

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 19/27

OPTREX

7.Product Standard

7.1.Mechanical Testing

7.1.1.External appearance

Inspection Area Item Criteria Remark

Surface

Linear

Scratches

Thickness

Disregard under 0.05mm

Between 0.05mm-0.15mm, total length must be within 50mm

Greater then 0.15mm is not acceptable

Surface

Sport

Scratches

Disregard under 1 sub-pixel

Penalized for 1-3 sub-pixels

Shall not exceed 3 sub-pixels

Back

Scratches

Observe from surface and judge based on criteria of surface

Chipped It must not influence surface

Dirt Must be removable

TFT Cell Section

Discoloration

No irregular discoloration on screen

Note1

Note2

Linear

Scratches

Thickness

Disregard under 3.0mm

Greater then 3.0mm must have less then 90mm total

Spot

Scratches

Diameter

Less then 3.0mmf,only 3 is allowed

Greater then 3.0mmf is not accepted

Dirt Must be removable

Deformation

Not allowed

Metal

Shield case

(Applies to all

surface)

Fingerprint

Remove as much as possible

Crack No crack or disconnection

Distortion No noticeable distortion

Note2

Input Output

Section

(FPC w/B/L Cable)

FPC tape The FPC should not be coming off for more then 10mm Note3

Note1: Cell section’s area subject to quality display area. Quality display area is specified in the external

appearance drawing.

Note2: If there are any other problems please follow “Precautions under operation”.

Note3: This is provisional standard and applies to limited sample (Optrex standards)

7.1.2.Dimensional Outline

All standards follow the measurement designated by the dimensional outline drawing.

Page 20

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 20/27

OPTREX

7.2.

Quality of Display

7.2.1.Conditions for Common Inspection

Unless specified, the conditions below will be applied.

Ta=25±5

? ?

Humidity=65%?VPW=VBL=+12.0V?VSS=0V?Backlight inverter=Our standard

inverter or equivalent, measured after backlight bas been lit for more then 30 minutes.

7.2.2.Quality Display Standard and Criteria for Judgement

(A)Quality Display Standard

Item

Description Criteria

Line defect Black, white and colored line

Not

accepted

Quality

Display

Spot defect

Lighting irregularities due to sub-pixels by the TFT and CF.

White spots

:

Any pixel that can be seen through ND(Neutral Density)

filter when black signal(V

sig

=4V) is inputted under

specified condition.

Black sports:Any pixel that is below 50% of maximum luminance

when white signal(V

sig

=0V) is inputted.

Refer to

next

section

Note 2

Stain Luminance irregularities and discoloration spots.

Irregularity Same as stain with more area.

Line Same as stain but in linear shape.

Stripe Same as stain, but in arc, spirals, or moiré shape.

Quality

Screen

Reverse Others that are formed from concentration of irregular patterns.

Note 1,2

Note1: The quality of screen is set at V

sig

=0V(white),2V(middle),4V(black)screen display and it may not be

seen through 2.5% ND filter. However, for few exceptions, Sample under Optrex standard will be

used for inspection.

Note2: When questions arise concerning this specifications or new problems that are not specified, it will be

discussed for solution.

Page 21

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 21/27

OPTREX

(B)

Spot Defect Inspection Standards and Criteria.

White spots inspection criteria

7.2.1.Include below with the common inspection condition

· Luminance: 200~ 250 [lx]

· Distance: 45~ 50 [cm] (Perpendicular from panel surface)

· Time: 5 [S] (After ND filter has been placed)

· Surface Brightness : 300~ 320 [cd/m2]

Standard

Type

Acceptable

No.

Criteria

Level 1

White Spots

0

Visible through 0.3%ND filter

Level 1-

2

White Spots

3

Visible through 1.0%ND filter, and not visible through 0.3%ND filter

Level 1-

3

White Spots

5

Visible through 2.5%ND filter, and not visible through 1.0%ND filter

Black spots

6

Any visible black spots on V

sig

=1V(All white cluster)

Total

7

Total white and black spots in level 1-3

Any spots that are not visible through 2.5% ND filters and not within level 1-3 is disregarded.

?

Density:

Only up to 2(white or black) are allowed for diameter withinf10mm.

If it is continuos, then continuos spot is applied.

?

Continuos spot :

Any spot that continues for more then 3 pixels is not acceptable.

For 2 continuos white spots, treat as one spot for the table above.

For 2 continuos black spots, treat as two spots for the table above.

For 2 continuos white and black spot, treat as one each.

?

White & black spot:

If the pixel holds both white and black spot (level 1-3), treat as white spot for the table above.

?

Foreign Substance(within Cell):

Foreign substance shall not be more then 3-pixel size.

If the size of substance is 2 to 3-pixel, then count as 2 in acceptable value.

If the size of substance is 1 to 2-pixel, then count as 2 in acceptable value.

If the size of substance is smaller then 1 pixel, then disregard.

Page 22

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 22/27

OPTREX

8.Reliability Test

8.1.Mechanical and Environmental Test

Item Condition Test hour Remark

High temp operation

Ta=65±2?,45%RH Below

192 hrs Note1

High temp & high

humidity operation

Ta=65±2?,90±2%RH, No Condensation

192 hrs Note1

Low temp operation

Ta=-30±3?

192 hrs Note1

High temp storage

Ta=85±2?,45%RH below

192 hrs

Note1

Low temp storage Ta=-40

±3?

192 hrs Note1

Endurance

Light resistance Sunshine carbon arc Ta=63

±2?

360 hrs

Drastic temp change

-30?(60min)?25?(15min)?80?(60min), No electric path

20 cycle Note2

Condensation

-30?(30min non-operating),25?/95%RH(10min

operating)

Dried after specified cycle and confirm operation

10cycle

Heat

Humidity cycle

1cycle=48hrs non-operational

5cycle

Static resistance

C=200pF,R=0

O ,V=±

150V

3 discharge on electric and other terminal, non-operational

-

Electrical

Electric discharge

C=150pF,R=150

O ,V=±

15kV

Discharge ±chrages 5 times each on panel and earth, nonoperational

-

Vibration

5~10Hz,width 25mm

10~30Hz,3.7×9.8m/s2 X,Y,Z all dir

30~50Hz,1.6×9.8m/s2 8min×2sweep

50~80Hz,0.7×9.8m/s

2

non-operational

80~100Hz,0.3×9.8m/s2

All dir

96 hrs

Shock

980m/s

2

,

t=6ms,X,Y,Z all dir2,semi-sine-wave, non-

operational

-

Terminal durability

Apply 500g of weight perpendicular to end of terminal

Onon-operational

-

External durability

Apply pressure on the center of the screen by push/pull gauge.

head diameter isf12mm?pressured apply 5×9.8N(=5kgf)

once, non-opreatioal

-

Mechanical

Pressure resistance

5×104 Pa(=0.5Pressure)?non-operational

2 hrs

Note 1: High temperature operation, high temperature & high humidity operation, low temperature operation,

high temperature storage and low temperature storage will test it’s ability for 1000 hours to confirm.

The deteriortion of plarizer is disregarded.

Note 2: Drastic tempertaure change test will continue the inspection under same condition consecutiely to

confirm it’s ability. Test will be done mounted in your request kit.

65?

25?

0?

2.5 2.5 2.5 2.5

2.5 2.5

2.5 2.5 2.5 2.5

3 3 3 3 3

8 hrs

90~ 95%RH

Page 23

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 23/27

OPTREX

8.2.Reliability Test Standard

Optical & Electrical Characteristics

Item

Contrast

Surface luminance

Response

Circuit

Quality of Screen

High temp operation*

>30

within±20% within±20% Within+40%

Not to be conspicious

High temp & high humidity

operation*

>25

?

?

?

?

Low temp operation*

>30

?

?

?

?

High temp storage*

?

?

?

?

?

Low temp storage*

?

?

?

?

?

Endurance

Light resistance*

?

?

?

?

?

Drastic temp change*

?

?

?

?

?

Condensation?

>25

?

?

?

?

Heat

Temp.& Humidity cycle?

?

?

?

?

?

Static resistance

No abnormalities in system and display.

Electrical

Electric discharge

No damage should be done

Vibration

No abnormalities in system and display.

Shock

No abnormalities in system and display.

Exterior durability

No abnormalities in system and display.

Mechanical

Pressure durability

No abnormalities in system and display.

Note

: *

indicates that test was performed in room teperature, more then 2 hours after it was taken out from

chamber.

?indicates that test was performed after 24 hours after it has been taken out from chamber.

Luminance, circuit, response time changes are compared from the initial standard values.

Page 24

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 24/27

OPTREX

9.Code System of Production Lot

9.1.Production Lot Number

Module’s production Lot Number will be indicated as below.

?

? ? ? ? ?

Factory Number (number)

Factory Code (Alphabet & Number)

Week of Manufacture

(1~ 5)

Month of Manufacture

(1~ 9,X,Y,Z)

Year of Manufacture(Lower 2 digits)

9.2.Type Number

The type number of module is specified on the back of module as follows;

T -51440GL070H U - FW- A-A

C

Silk Screen Print

9.3.Precautions under Operation

When questions arise concerning this specifcations or new problems not specified in this specifications

arise, problems related to the specification is to be discussed for solution.

Page 25

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 25/27

OPTREX

10.Packing Specification

T B D

Page 26

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 26/27

OPTREX

11.Product Handling Cautions

In order to use the products properly please note the following precautions.

1) For LCD screen

?

LCD particles used in LCD module is made into form of glass board. Do not apply any strong

physical shock.

If it cracks, handle with extra caution to avoid any harm.

?

The polarizer attached on the surface of LCD particles are composed by soft materials. Please do

not scratch them.

2) Handling LCD module (static electricity countermeasure)

?

Please ground all human bodies and electrical facilities. Also on the operation line, anti-static

electricity mat (rubber) is recommended to avoid electric shock in case of accident.

?

Working uniform should avoid synthetic fiber and recommend the use of cotton or non-electrical

conducting fiber.

?

When removing protective film from LCD panel, please remove it slowly to avoid development of

static electricity.

3) For Storing Single LCD module for long term

?

Do not store under high temperature and high humidity.

?

Do not expose the module to direct sunlight or intensive ultraviolet rays for many hours.

?

Avoid any force applied from external environment.

4) LCD module does not have circuit for over current protection. For in case of accident, please use

power supply with over current protection.

5) If LCD panel breaks, it is possible that the liquid crystal leaks from the panel. Avoid putting it into

eyes or mouth. When liquid crystal sticks on hands, clothes, or feet. Wash it out immediately with

soap.

6) When using product with metal holder, if metal holder and the body are not soldered, sooth electric

flow is not guaranteed. To secure the flows of electricity, please consult.

7) For products that requires the use of

CFL

?

On the connection of CFL cable more then 1000 v high voltage is applied. Please handle with

care to avoid any burn upon contact.

?

Please be careful if overcoat of CFL cable is in the status of abrasion by the contact with the system.

?

Continuous use of CFL at low temperature, will shorten longevity of CFL compared to it’s use at

room temperature.

8) For products that uses touch panel

?

Do not stack panel on top of each other. There may be possibility of harm caused by the edge of

panel.

?

Do not place any heavy objects above panel.

Page 27

T-51440GL070HU-FW-AC OPTREX CORPORATION Page 27/27

OPTREX

9) For product that uses COG, TAB, and COF

?

The back side of IC hip is exposed and has low intensity. Upon handling, do not apply powerful

pressure to the IC chip.

?

IC chip backside is exposed and should not be equipped with any setup that releases electrical

contact to prevent electrical damage. Also to prevent unintentional function by light and to keep

it’s electrical characteristics, set up to avoid exposure to light.

10) For product that uses FPC, heal seal and TAB

?

To maintain reliability, do not hold onto connection section.

Do not bend or pull lines with strong power. It could snap the lines.

12.Condition for Guarantee.

Our product is designed and manufactured by your specification requirement as a part for final electrical

products. We will guarantee the product has no sign of defect and meet all qualifications of your

request. However, if the final product was not for common household use, but instead used for medical,

nuclear controller, aviation, disaster prevention or any other products that require extreme reliability, we

can not be held responsible for any quality guarantee issue.

If the product was placed for any of the use above, we ask for revision on our contract for manufacturing

this product.

1) After delivery, any modification (including restructure and taking apart) of the product we can not

hold any responsibility for quality guarantee issue.

2) Any damage caused by the outside force, we can not hold any responsibility for quality guarantee

issue.

3) After completing all product inspection and after delivery from the factory, any static electricity

applied on product, we can not hold any responsibility for quality guarantee issue.

4) Upon using product with CFL, longevity and luminance may altar by the performance of inverter or

leakage. We can not hold any responsibility for quality guarantee issue by performance or

reliability of final product.

5)

Any product that uses our product within, we will not hold any responsibility for any problems that

has no relationship with the structure or performance of our product.

Loading...

Loading...