Page 1

STV2001

I2C SINGLE FREQUENCY DEFLECTION PROCESSOR

AND 120 MHz RGB PREAMPLIFIER

TARGET SPECIFICATION

FEATURES

Horizontal deflection

■ Single Frequ enc y, Se lf Adapt ive Os c illa tor.

■ TTL compatible positive going sync.

■ Chip does not accept sync on RGB or any video

signal.

2

■ I

C controlled: H-position, pin cushion,

keystone, parallelogram, side pin balance.

2

■ I

C controlled EW corner : top and bottom

corrections.

2

■ I

C controlled corner: top and bottom phase

corrections.

■ EW output

2

■ I

C controlled H-amplitude

■ DC controlled H-width breath ing comp ensation

■ Xray shut-down on ABL, H output latch, reset by

■ Soft start on H-duty.

Ver tical deflection

■ Vertical ramp generator.

■ Wide range AGC loop.

■ TTL compatible positive going sync, no extra

■ I

■ I

■ DC controlled height breathing compensation

■ Vertical dynamic focus output with fixed

Video preamplifier

■ 3-Channel 120MHz bandwidth video amplifier.

■ 3.5ns typical rise and fall time at 2.5V

■ I

■ I

■ Activation of ABL results in contrast gain

2

with I

C controlled gain (0.5x to 2x).

power OFF/ON.

pulses.

2

C controlled vertical position.

2

C controlled S linearity correction.

2

with I

C controlled gain (0.5X TO 2X).

amplitude (1Vpp).

.

2

C controlled individual RGB contrast

PP

(8bit)>8db

2

C controlled overall brightness.

decrease.

■ Gain window (1.5X) controlled by input pulse

2

and I

C. Pulse height controls the gain variation

from 1x to 1.5x.

■ 0.514V typical video input signal for normal

display.

2

■ I

C controlled contrast (7bits) update during

vertical retrace time.

2

C main features

I

2

■ I

C interface (slave) 100kHz max.

2

■ All I

C controlled DAC are 7 bits, except R GB

gain.

■ Power on reset on 5 V (V

DD

).

Supply voltage & power

■ 5 V/10.5 V dual supply.

■ Max power consumption: 1.2W

DESCRIPTION

The STV2001 is an I2C-controlled monolithic

integrated circuit assembled in a TQF P44 plastic

package. It combines both a deflection block

(horizontal and vertical, single frequency with very

powerful geometry correction) and a 120MHz

RGB pre-amplifier.

TQFP44/SLUG DOWN

ORDER CODE :

Version 1.2

May 2000 1/46

This is preliminary information on a new product now in development. Details are subject to change without notice.

1

Page 2

TABLE OF CONTENTS

1 - PIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 - PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 - BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 - ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 - THERMAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 - SYNC INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 - I2C READ/WRITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8 - HORIZONTAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9 - VERTICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10 - VIDEO PRE-AMP SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11 - LOGIC SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12 - I2C BUS ADDRESS TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13 - TYPICAL OUTPUT WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14 - OPERATING DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1 -GENERAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.1 -Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.2 -I

14.1.3 -Write Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.4 -Read Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.5 -Sync Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.6 -IC Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.7 -Sync Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.1.8 -Sync Processor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.2 -HORIZONTAL PART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.2.1 -Internal Input Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.2.2 -PLL1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.2.3 -PLL2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

14.2.4 -Output Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

14.2.5 -X-RAY Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.3 -VERTICAL PART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.3.1 -Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.3.2 -I2C Control Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.3.3 -Basic Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

14.3.4 -Geometric Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

14.3.5 -E/W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.3.6 -Dynamic Horizontal Phase Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.3.7 -Vertical Dynamic Focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.3.8 -Corner Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.3.9 -Horizontal Breathing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.3.10 -Vertical Breathing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.4 -GENERAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14.4.1 -Input Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2

14.4.2 -Contrast Adjustment (7 bits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14.4.3 -ABL Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14.4.4 -Brightness Adjustment (6 bits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14.4.5 -Drive Adjustment (3 x 8 bits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14.4.6 -Output Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14.4.7 -Bright Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2

C Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3

2/3

2

Page 3

14.4.8 -Blanking Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14.5 -GENERAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.5.1 -POR (Power On Reset) - Subad. 11-D8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.5.2 -Supply Voltage Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.5.3 -Video Off (I2C control) - Subad. 00-D8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.5.4 -Vertical Output Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14.5.5 -X-Ray, Set Operation - Subad. 09-D8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

15 - INTERNAL SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

16 - PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3/3

Page 4

STV2001

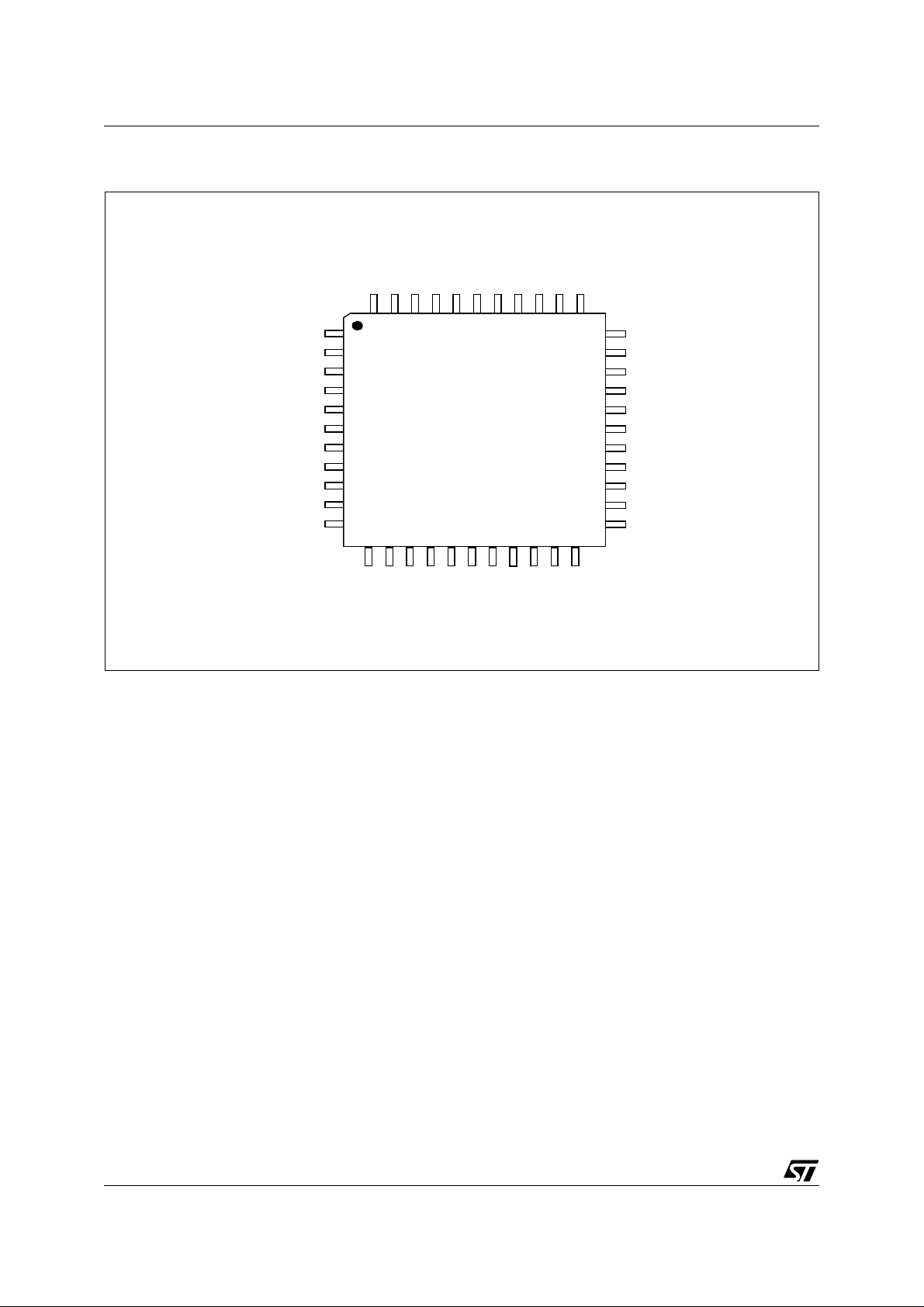

1 - PIN CONNECTIONS

Hin

Vin

Vref

VAGCCAP

VGND

VCAP

Vout

VRB

VAVcc

OUT1

AGND

FC1

FILTER

44 43 42 41 40 39 38 37 36 35 34

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17 18 19 20 21 22

OUT3

OUT2

PGND

Co

Ro

PVCC

PLL1F

VBCAP

PLL2C

HGND

IN1

IN2

ABLin

VBDC

GAINWIN

Hfly

Href

Hout

33

32

31

30

29

28

27

26

25

24

23

HDGND

LGND

SAVcc

SCL

SDA

V

(5V)

DD

EWout

FCAP

HBRTHin

VBRTHin

VFOCUS

IN3

VFLYin

4/46

3

Page 5

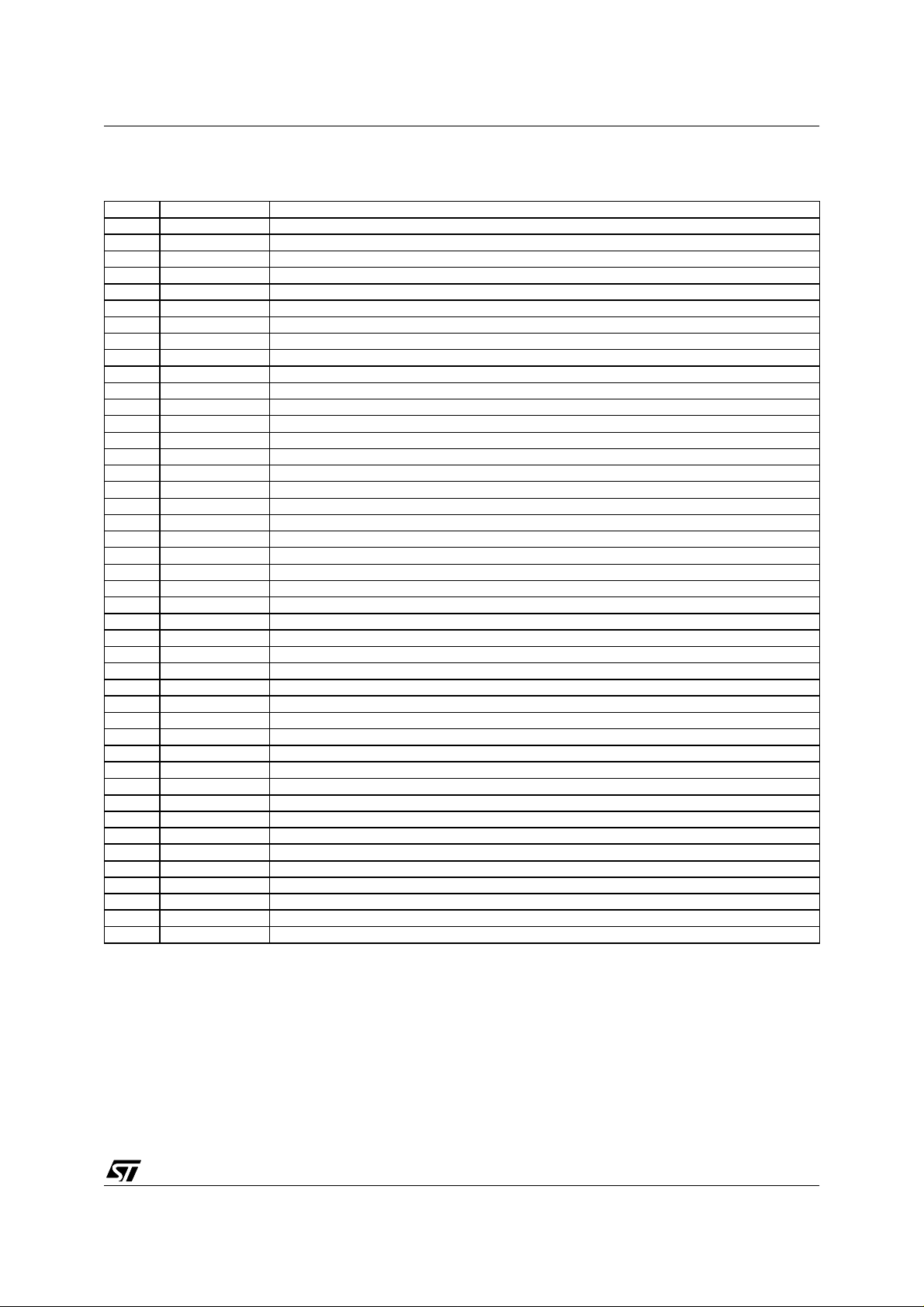

2 - PIN DESCRIPTION

Pin Name Function

1 Hin Horizontal Sync Input

2 Vin Vertical Sync Input

3 Vref Vertical Section Reference Voltage

4 VAGCCAP Vertical AGC Loop Capacitor

5 VGND Vertical Section Ground

6 VCAP Vertical Sawtooth Generator Capacitor

7 Vout Vertical Output

8 VRB Vertical Ramp Filter

9 VAVcc Video Section Analog Supply (10.5V typ)

10 OUT1 Video Output 1

11 AGND Video Analog Ground

12 OUT2 Video Output 2

13 PGND Video Section Power Ground

14 OUT3 Video Output 3

15 PVcc Video Section Power Supply (10.5V typ)

16 GAINWIN Gain Window Input

17 IN1 Video Input 1

18 VBDC Vertical Blanking Output with DC Level adjusted by DAC

19 IN2 Video Input 2

20 ABLin Video Automatic Beam Current Compensation Input

21 IN3 Video Input 3

22 VFLYin Vertical Fly Back Pulse Input

23 VFOCUS Vertical Dynamic Focus Output

24 VBRTHin Vertical Breathing DC Input

25 HBRTHin Horizontal Breathing Compensation DC Input

26 FCAP Filter Capacitor

27 EWout EW Output

28 V

29 SDA I

30 SCL I

31 SAVcc Scanning Section Analog Supply (10.5Vtyp)

32 LGND Bus and Scanning Power Ground

33 HDGND H Driver Output Ground

34 Hout Horizontal Driver Output, open collector

35 Href Horizontal Section Reference Voltage

36 Hfly Horizontal Flyback Input, Positive

37 HGND Horizontal Section Ground

38 PLL2C PLL2 Loop Filter

39 VBCAP PLL2 Top Comparator Filter

40 PLL1F PLL1 Loop Filter

41 Ro Horizontal Oscillator Resistor

42 Co Horizontal Oscillator Capacitor

43 FC1 PLL1 Filter Capacitor

44 FILTER Horizontal Filter Capacitor (HPOS)

DD

Bus, Scanning Logic and Video Logic Supply (5V typ)

2

C Data Input

2

C Clock Input

STV2001

5/46

Page 6

6/46

3 - BLOCK DIAGRAM

STV2001

SAV

CC

Href

Vref

Hin

Vin

HGND

VGND

VCAP

VAGCCAP

VRB

Vout

VFOCUS

SDA

SCL

VDD

LGND

IN1

IN2

GAINWIN

IN3

31

35

3

1

2

37

5

6

4

8

7

23

29

30

28

32

17

19

16

21

Href

Scorr

Hsync

Gain

WIndow

PLL1F FILTER FC1 Ro Co HFly PLL2C Hout

40

Vref

Vpos

VOSC

RAMP

Generator

VDF

2

C BUS

I

DECODER

Clamp

44 43 41 42 36 38

Phase

Freq

Comp

Vamp

VCO

Corner

Phase

Geometry

Tracking

EW

Corner

LATCHES & DACs

BrightnessContrast

Phase

Comp

2

X

KeyBal

X

SPB

Drive

VBCAP

39

Phase

Shifter

X

+

HFly

Hsync

Vsync

EWPCC

2

KEYST

34 33

HOUT

Buffer

EW OUTPUT

H Breathing

+

Blanking

BPCP

Output

Stage

HDGND

Safety

VFBack

EHTcomp

AMP

ABL

EWout

27

FCAP

26

22

VFLYin

18

VBDC

25

HBRTHin

VBRTHin

24

VAV

9

OUT 1

10

AGND

11

PV

15

12

OUT 2

ABLin

20

PGND

13

OUT 3

14

CC

CC

STV2001

Page 7

4 - ABSOLUTE MAXIMUM RAT INGS

Symbol Parameter Value Unit

SAVcc Scanning Section Analog Supply Voltage 13.5 V

VAVcc Video Section Analog Supply Voltage 13.5 V

PVcc Supply Voltage for Video Pre-Amp Section 13.5 V

Vdd Logic Section Supply Voltage 5.5 V

V

ESD

Tstg Storage Temperature -40 to 150

Tj Junction Temperature 150

Toper Operating Temperature (Device ambient) 0 to 70

ESD susceptibility HBM model 100pF & 1.5kΩ

EIAJ Norm 200pF & 0Ω

2

300

5 - THERMAL DAT A

STV2001

kV

V

o

C

o

C

o

C

Symbol Parameter Value Unit

R

TH(j-a)

Junction to Ambient Thermal Resistance (MAX) 46

6 - SYNC INPUT

Operating Conditions (V

Symbol Parameter Test Conditions Min Typ Max Unit

HSVR Voltage on Hin 0 5 V

MinD Min Hin pulse duration 0.7 us

Mduty Max Hin Duty Cycle 25 %

VSVR Voltage on Vin 0 5 V

VSW Min Vin pulse duration 5 us

VSD Max Vin Duty Cycle 15 %

Electrical Characteristics (VDD = 5V, T

V

INTH

RIN Horizontal & Vertical Pull-Up Resistor 200 kΩ

Horizontal & Vertical Input Logic Level Low Level

= 5V, T

DD

amb

= 25°C)

= 25°C)

amb

0.8 V

High Level 2.2

o

C/W

V

7/46

Page 8

STV2001

7 - I2C READ /WRITE

Electrical Characteristics (VDD = 5V, T

amb

= 25°C)

Symbol Parameter Test Conditions Min Typ Max Unit

F

T

T

HIGH

V

V

V

SCL

LOW

INL

INH

ACK

Maximum Clock Frequency 100 kHz

Low Period of the SCL Clock 1.3 us

High Period of SCL Clock 0.6 us

SDA & SCL Input Low Level Voltage 1.5 V

SDA & SCL Input High Level Voltage 3 V

Acknowledge Output Voltage on SDA

input with 3mA

0.4 V

8 - HORIZONTAL SECTION

Operating Conditions

Symbol Parameter Test Conditions Min Typ Max Unit

VCO

Ro(min) Minimum Oscillator Resistor 6 kΩ

Co(min) Minimum Oscillator Capacitor 390 pF

Fmax Maximum Oscillator Frequency 150 kHz

OUTPUT SECTION

I

HFB

I

HOUT

Horizontal FlyBack Input Maximum

Current

Horizontal Drive Output Maximum Sink

Current

5mA

15 mA

Electrical Characteristics (VDD = 5V, T

amb

= 25°C)

Symbol Parameter Test Conditions Min Typ Max Unit

SUPPLY AND REFERENCE VOLTAGES

Vcc Supply Voltage 9.5 10.5 11.5 V

Vdd Supply Voltage 4.5 5 5.5 V

Icc Supply Current 30 mA

Idd Supply Current 5 mA

V

HREF

Horizontal Reference Voltag e I=-2mA 7.4 8 8.6 V

VVREF Vertical Reference Voltage I=-2mA 7.4 8 8.6 V

I

HREF

I

VREF

Horizontal Reference Maxim um Source

Current

Vertical Reference Maximum Source

Current

5mA

5mA

8/46

Page 9

STV2001

Operating Conditions

Symbol Parameter Test Conditions Min Typ Max Unit

1st PLL SECTION

V

clamp

V

VCO

A

VCO

H

PHASE

VPMIN

VPTYP

VPMAX

I

PLL1-UL

I

PLL1-L1

I

PLL1-L2

f

O

dfo/dT Free Running Frequency Thermal Drift -150 ppm/

2nd PLL SECTION & HORIZONTAL OUTPUT SECTION

V

THFB

Jitter

H

DC

Vphi2 Internal Clamp Level on PLL2 Filter

VSCinh

Vsat

VCO clamp Voltage range V

VCO clamp Voltage, at POR V

VCO Gain

=8V 3.0 3.8 V

HREF

=8V 3.8 V

HREF

Ro=4868Ω, Co=820pF,

dF/dV=1/11RoCo

23 kHz/V

Horizontal Phase Adjustment Range % of Horizontal Period +/-10 %

Horizontal Phase Setting

Minimum

Typical

Maximum

PLL1 Charge Pump Current

Unlocked

Locked

Locked

Free Running Frequency, no input

at POR, lower clamp voltage at max.

SubAdd 07

X1111111

X1000000

X0000000

2.8

3.4

4.0

Sub-Address 11

+/-40

x1xx xxxx

x0xx xxxx

+/-1

±300

Ro=4868Ω, Co=820pF 86 kHz

Flyback Input Threshold Voltage 0.65 0.75 V

Horizontal Jitter At 80KHz 70 ppm

H

Horizontal Drive Output Duty Cycle

(Ratio of Power Transistor OFF time to

55 %

Period)

Threshold Voltage to Stop H-Out, V-Out,

Reset ABL when Vcc<VSCinh

Horizontal Drive Output Saturatio n

HD

Voltage

Low Level

High Level

Iout=15mA 0.4 V

1.6

4.0

6.9 V

V

V

V

µA

mA

µA

V

V

o

C

9/46

Page 10

STV2001

9 - VERTICAL SECTION

Symbol Parameter Test Conditions Min Typ Max Unit

Electrical Characteristics (VDD = 5V, T

amb

VERTICAL RAMP SECTION

V

RBOT

V

RTOP

V

RTOPF

T

VDIS

F

FRV

Voltage at Ramp Bottom Point V

Voltage at Ramp Top Point with Sync V

Voltage at Ramp Top Point without Sync V

Vertical Sawtooth Discharge Time C

Vertical Free Running Frequency

(S correction inhibited)

ASFR Auto- Sync Frequ ency Range C

RAFD

R

LIN

V

POS

Ramp Amplitude Drift Versus Frequency

at Maximum Vertical Amplitude

Ramp Linearity at Vcap pin

with S Correction inhibited

Vertical Position Adjustment Voltage

with V

mean value

OUT

VOR Vertical Output Peak to Peak Voltage

I

VOUT

V

VRB

Vertical Output Maximum Current +/-5 mA

Vertical Ramp Filter Voltage 2 V

Max Vertical S-Correction Amplitude

dVS

S-Correction inhibited, DV/Vpp at TV/4

S-correction Maximum,

DV/Vpp at 3TV/4

= 25°C)

=8V 2 V

VREF

=8V 5 V

VREF

-

V

=8V

VREF

=150nF 70 µs

OSC

C

=150nF 100 Hz

OSC

=150nF 50 16 5 Hz

OSC

C

=150nF 50Hz -

OSC

165Hz

2.5V < VOSC < 4.5V 0.5 %

Sub-Add=09

X0000000

X1000000

X1111111 3.65

Sub-Add=08

10000000

11000000

11111111 3.5

Sub-Add 0A

0XXXXXXX

11111111

RTOP

0.1

200 ppm/Hz

3.2

3.5

3.8

2.25

3

3.75

-4

+4

V

3.3 V

V

V

2.5 V

V

V

%

%

10/46

Page 11

STV2001

Symbol Parameter Test Conditions Min Typ Max Unit

EAST/WEST FUNCTION (available without feedback connection)

DC Output Voltage with:

EW

DC

TDEW

DC

EW

PARA

EW

track

KeyAdj

KeyTrack

EW Corner

Top

EW Corner

Bottom

-Typical VPOS and Keystone inhibited

-External driver connected as unity gain

buffer

DC Output Voltage Thermal Drift

(Non-test Parameter)

Parabola Amplitude with:

-Max VAMP

-Typ VPOS

-Keystone inhibited

Parabola Amplitude Function of VAMP

Control (tracking between VAMP & EW)

with:

-Typ VPOS=typ.

-Keystone=typ.

-EW Amplitude=typ.

Keystone Adjustment Capa bility with:

-VPOS=typ.

-EW= inhibited

-Vertical Amplitude= Max.

Intrinsic Keystone Function of VPOS

Control (tracking between VPOS and

EW) with :

-EW Amplitude= Max

-Vertical Amplitude=Max

A/B Ratio

B/A Ratio

Corner Adjustment capability with :

-VPS=typ,

-EW = inhibited

-VAMP = max

-HSize = Min

-HBreath>VREF

-Keystone = inhibited

Corner Adjustment capability with :

-VPS=Typ,

-EW = inhibited

-VAMP = Max

-HSize = Min

-HBreath>VREF

-Keystone = inhibited

Sub-add 0C

11111111

11000000

10000000

Sub-address 08

10000000

11000000

11111111

Sub-address 0B

10000000

11111111

Sub-address 09

X0000000

X1111111

Sub-address 04

1111 1111

1100 0000

1000 0000

Sub-address 15

1111 1111

1100 0000

1000 0000

2.0 V

100 ppm/

1.0

0.5

0

0.18

0.35

0.57

0.2

0.2

0.52

0.52

+1.25

0

-1.25

+1.25

0

-1.25

V

V

V

V

V

V

V

pp

V

pp

Vpp

Vpp

Vpp

Vpp

Vpp

Vpp

o

C

11/46

Page 12

STV2001

Symbol Parameter Test Conditions Min Typ Max Unit

INTERNAL DYNAMIC HORIZONTAL PHASE CONTROL

Side Pin Balance Parabola Amplitude

with:

SBPpara

-VAMP=Max,

-VPOS=typ.

-Parallelogram inhibited

Side Pin Balance Parabola Amplitude

function of VAMP Control (tracking be-

SPBtrack

tween VAMP & SPB) with

-SPB=Max

-VPO=typ.

-Parallelogram= inhibi ted

Parallelogram Adjustment Capability

with:

ParAdj

-VAMP=Max

-POS =Typ

-SPB=Max

Intrinsic Parallelogram Function of

VPOS Control (tracking between VPOS

and DHPC) with

Partrack

-VAMP=Max

-SPB=Max

-Parallelogram= inhibi ted

A/B Ratio

B/A Ratio

VERTICAL BREATHING COMPENSATION

VBRrng Input DC Breathing Control Range 1 10.5 V

Vertical Size Compensation

VSC

Variation of V output vs full range of

VBRrng

VERTICAL DYNAMIC FOCUS OUTPUT

VDF

DC Output Level RL=10kΩ 4V

DC

VDF Parabola Amplitude with:

VDFamp

Vamp = typ

VPOS = typ.

V

FOCPOL

Parabola Polarity at Output =

Inverted “U”

VERTICAL FLYBACK INPUT

V

FLYTH

V

FLYINH

Vertical Flyback Threshold 1 V

Inhibition of Vertical Flyback input

(id pulse in action instead of VFlyback)

HORIZONTAL SIZE CONTROL

Hsize Hsize output DC voltage

sitting on top of EWDC=2.0V

Sub-add 0E

11111111

10000000

Sub-add 08

10000000

11000000

11111111

Sub-add 0F

11111111

10000000

Sub-add 09

X0000000

X1111111

Sub-address 14

XX00 0000

X100 0000

XX11 1111

sub-add 0D

X0000000

X1111111

+1.4

-1.4

0.5

0.9

1.4

+1.4

-1.4

0.52

0.52

-5

-20

1 Vpp

6.5 V

0

2.4

%T

%T

%T

%T

%T

%T

%T

%

%

%

H

H

H

H

H

H

H

V

V

12/46

Page 13

STV2001

Symbol Parameter Test Conditions Min Typ Max Unit

HORIZONTAL BREATHING COMPENSATION

HBRrng Breathing input DC Control Range 1 10.5 V

Horizontal size compensation, EW DC

HSC

voltage variation under full range of

HBRrng

CORNER PHASE CORRECTION

Corner Phase Top Adjustment with:

Corner

Phase Top

Vamp = max

Vpos = Typ.

SPB = OFF

Parrallelogram = OFF

Corner Phase Bottom Adjustment with:

Corner

Phase

Bottom

Vamp = max

Vpos = Typ.

SPB = OFF

Parrallelogram = OFF

Sub-address 12

X000 0000

X100 0000

X111 1111

Sub-address 05

1000 0000

1111 1111

Sub-address 06

0000 0000

0111 1111

0.2

0.8

-2.8

+2.8

-2.8

+2.8

V

V

%

%

%

%

10 - VIDEO PRE-A MP SECTION

Symbol Parameter Test Conditions Min Typ Max Unit

DC Electrical Characteristics (VAV

VAV

cc

Video Section Analog Supply Voltage

PVcc Power Section Supply Voltage 9.5 10.5 11.5 V

IS Supply Current of VAVcc & PVcc 63 mA

V

V

V

IN

OUT

Black

Video Input Voltage Amplitude 0.7 1 Vpp

Typical Output Voltage Range 0.5 7 V

Output (Black level) 1.5 V

AC Electrical Characteristics (VAVCC = PV

Symbol Parameter Condition Min Typ Max Unit

AV Maximum Gain

CAR Contrast Attenuation Range

DAR Drive Attenuation Range 30 dB

GM Gain Match

BW Large Signal Bandwidth

CC

= PV

= 10.5V, Tamb = 25oC)

CC

9.5 10.5 11.5 V

= 10.5V, CL = 5pF, RL = 1KΩ, Tamb = 25oC)

CC

Max Contrast and Drive

2

I

C Gainwin = 1

V

= 0.7Vpp

IN

Contrast and Drive at

18 dB

30 dB

POR

V

= 0.7Vpp,

IN

V

= 4Vpp, Contrast

OUT

+-0.1 dB

and Drive= 0.87Max

V

=0.7Vpp,

IN

= 2.5Vpp, Contrast

V

OUT

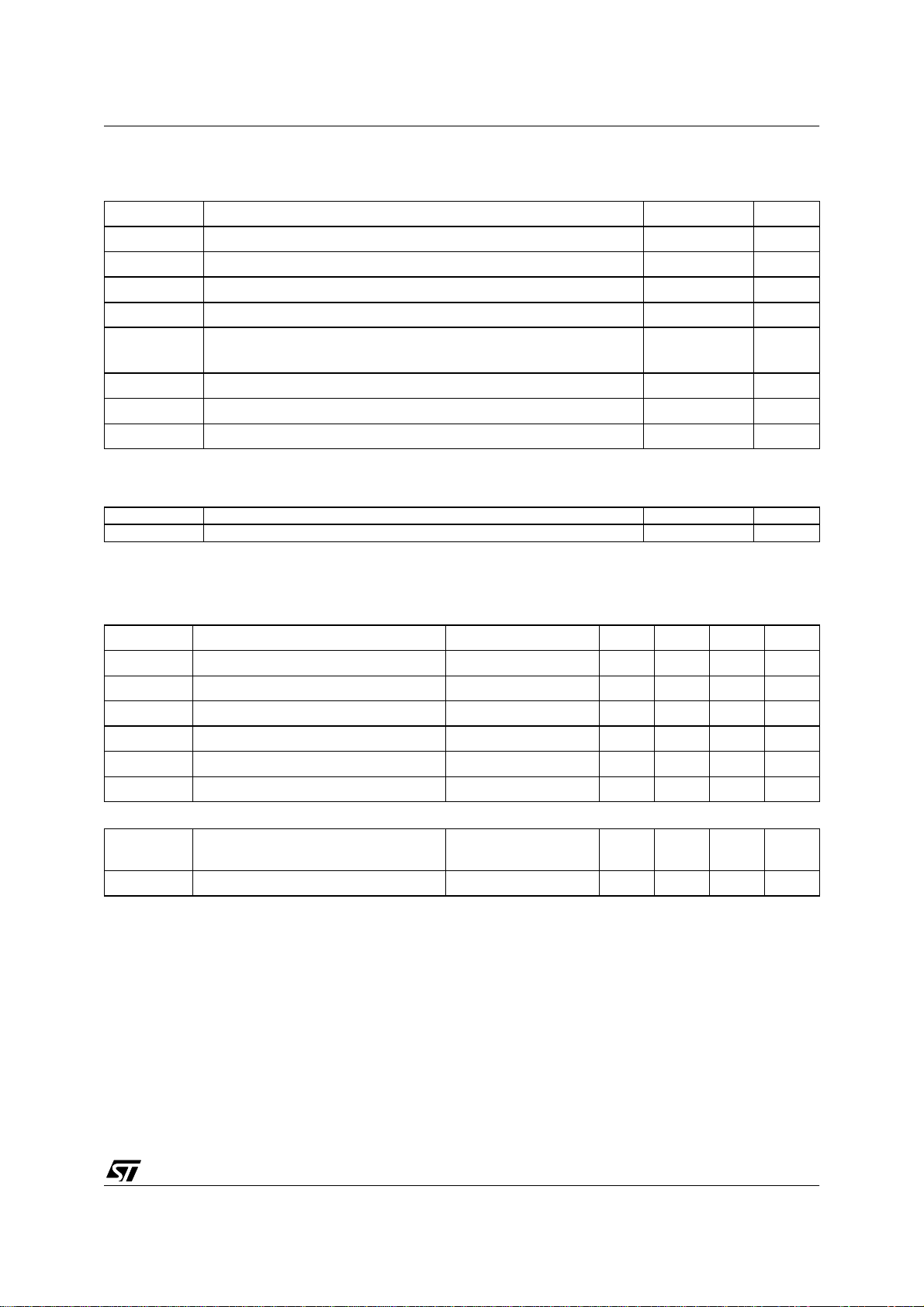

and Drive = 0.87Max

120 MHz

At -3dB

13/46

Page 14

STV2001

Symbol Parameter Test Conditions Min Typ Max Unit

DIS Video Output Distortion f=1MHz, VIN=1Vpp,

V

= 1Vpp

OUT

= 0.7Vpp,

V

, t

t

R

Video Output Rise and Fall Time

F

IN

V

=2.5Vpp,Contrast

OUT

and Drive=0.87Max

dVo Overshoot of output with respect to

actual output amplitude

=5pF 5 7 %

C

LOAD

BRT Brightness max DC level

Brightness min DC level

R

L

Equivalent Load on Video Output Tj<Tj

MAX

Tsample Hold time 100 ms

Thold Sample time 1 µs

V

= 0.7Vpp,

CT Crosstalk Between Video Channels

IN

V

= 2.5Vpp,

OUT

Contrast and

44 dB

Drive=0.7Max

f=1MHz

ABL COMPENSATION

R

G

TH

ABL

ABL

ABL

ABL Input resistor 10 kΩ

ABL minimum Attenuation

ABL maximum Attenuation

ABL latch function activation threshold

(High beam current detection)

V

=5.3V

ABL

V

=2.8V

ABL

01V

GAIN WINDOW

V

INL

V

INH

Input Low Level Voltage 0.7 V

Input High Level Voltage 1.5 V

Contrast Gain Increase during High

Gain

Input

VIN = 1.5V

VIN = 5.0V

T

D

Total Delay Time 100 ns

0.3 %

3.5 4 ns

2.5

0

1kΩ

0

12

1

1.5

V

V

dB

dB

V/V

V/V

14/46

Page 15

11 - LOGIC SECTION

STV2001

DC Electrical Characteristics (VAV

Symbol Parameter Condition Min Typ Max Unit

VBDC OUTPUT SECTI ON

Blanking output high voltage 7 V

VBDC

I

BLK

T

BLK

SUPPLY VOLTAGE THRESHOLD

V

THPD1

V

THPD2

Blanking output low voltage

I2C adjustable

Output sink current 0.3 mA

Vertical blanking time

(start by VSync 2 and by VFly)

Supply first threshold voltage 8.5 V

Supply second threshold voltage 6.9 V

CC

= PV

= 10.5V, Tamb = 25oC)

CC

sub-add10

1X000000

1X111111

1

4.5

V

V

15/46

Page 16

STV2001

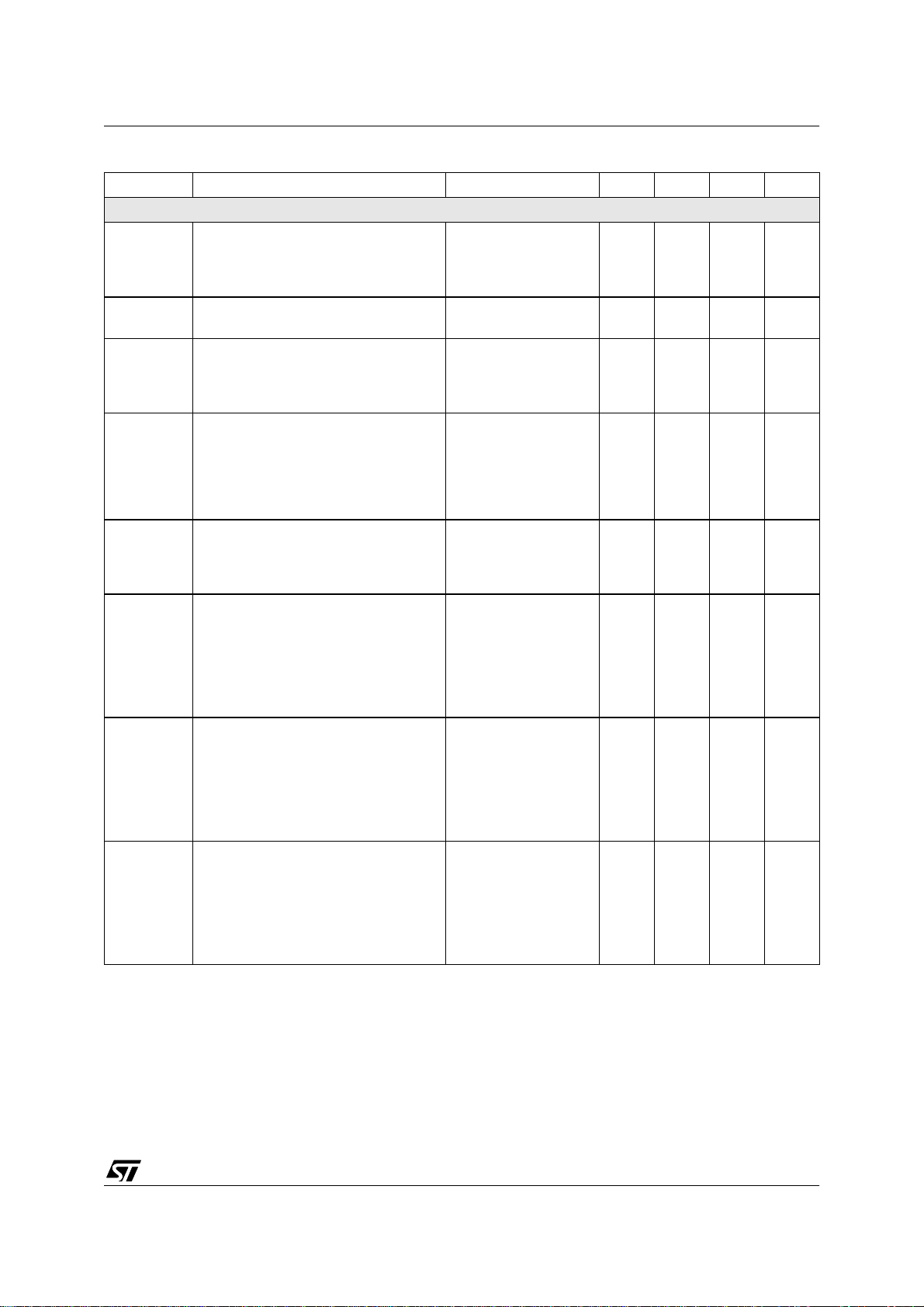

12 - I2C BUS ADDRESS TABLE

[0] denotes POR value, X denotes unused data bit and must be set to 0.

D8 D7 D6 D5 D4 D3 D2 D1

WRITE MODE (SLAVE ADDRESS= 8C)

Video

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D x

0E

0F

10

1, on

[0], off

EWCorner

Top/Bottom

0 off

[1], on

Corner phase

Top/Bottom

1, on

[0],off

Ipump2

1, high

[0], low

Hout

0, off

[1], on

Vramp

0, off

[1], on

Xray

1, reset

S Select

1, on

[0], off

EW Key

0, off

[1], on

EW Select

0, off

[1], on

SPB Sel

0, off

[1], on

Parallelog

0, off

[1], on

VBDC

1, on

[0], off

[1] [0] [1] [1] [0] [1] [0]

[1] [0] [1] [1] [0] [1] [0] [0]

[1] [0] [1] [1] [0] [1] [0] [0]

[1] [0] [1] [1] [0] [1] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0 ] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

Horizontal Phase Adjustment

[1] [0] [0] [0] [0] [0] [0]

Vertical Ramp Amplitude Adjustment

[1] [0] [0] [0] [0] [0] [0]

Vertical Position Adjustment

[0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

Gainwin

[0], 1X

1, 1.5X

[1] [1] [1] [1] [1] [1]

Contrast

Drive 1

Drive 2

Drive 3

EW Corner Top

Corner Phase Top

Corner Phase Bottom

S Correction

Keystone

EW Amplitude

Horizontal Amplitude

Side Pin Balance

Parallelogram

Vertical Blanking DC level

16/46

Page 17

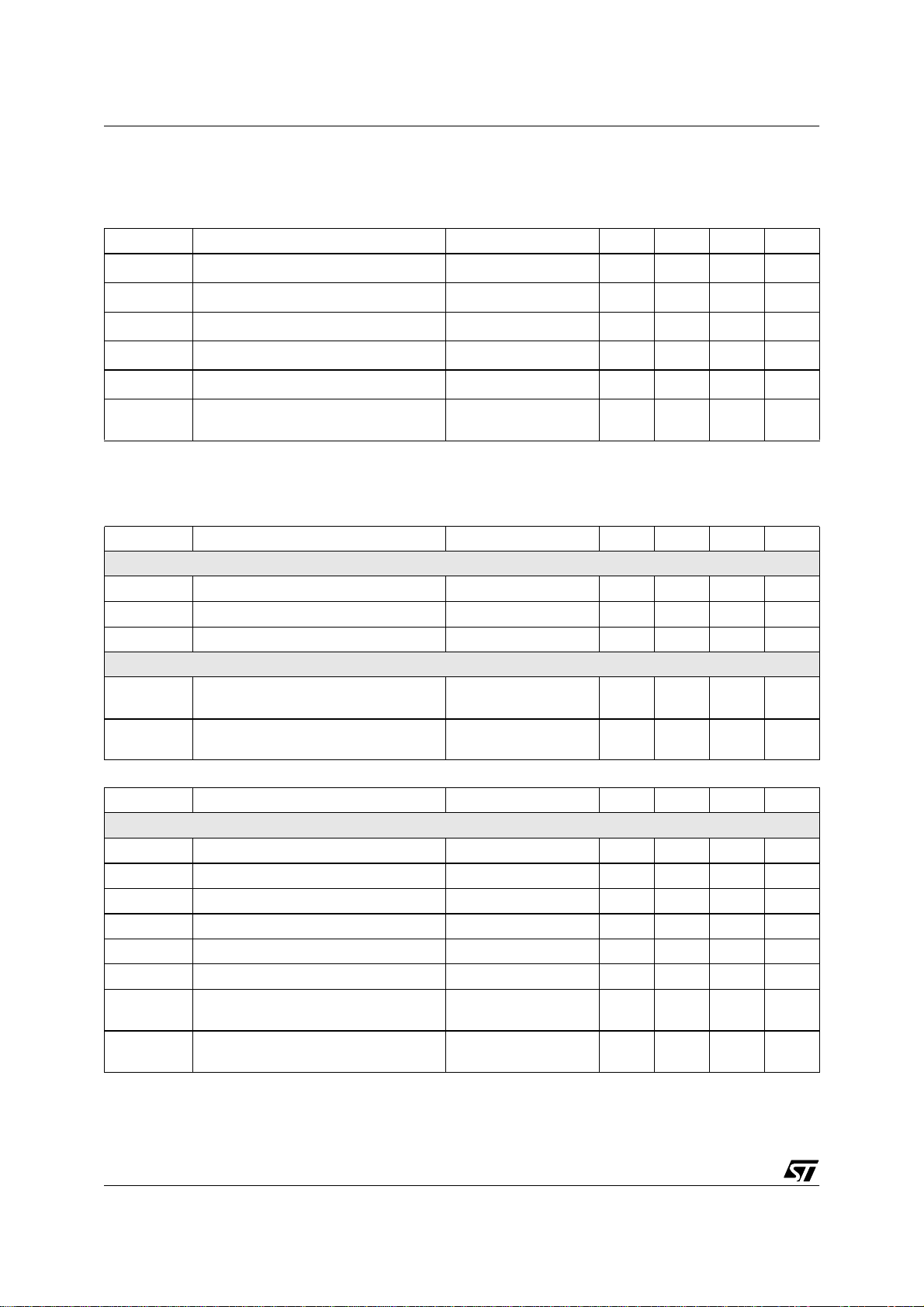

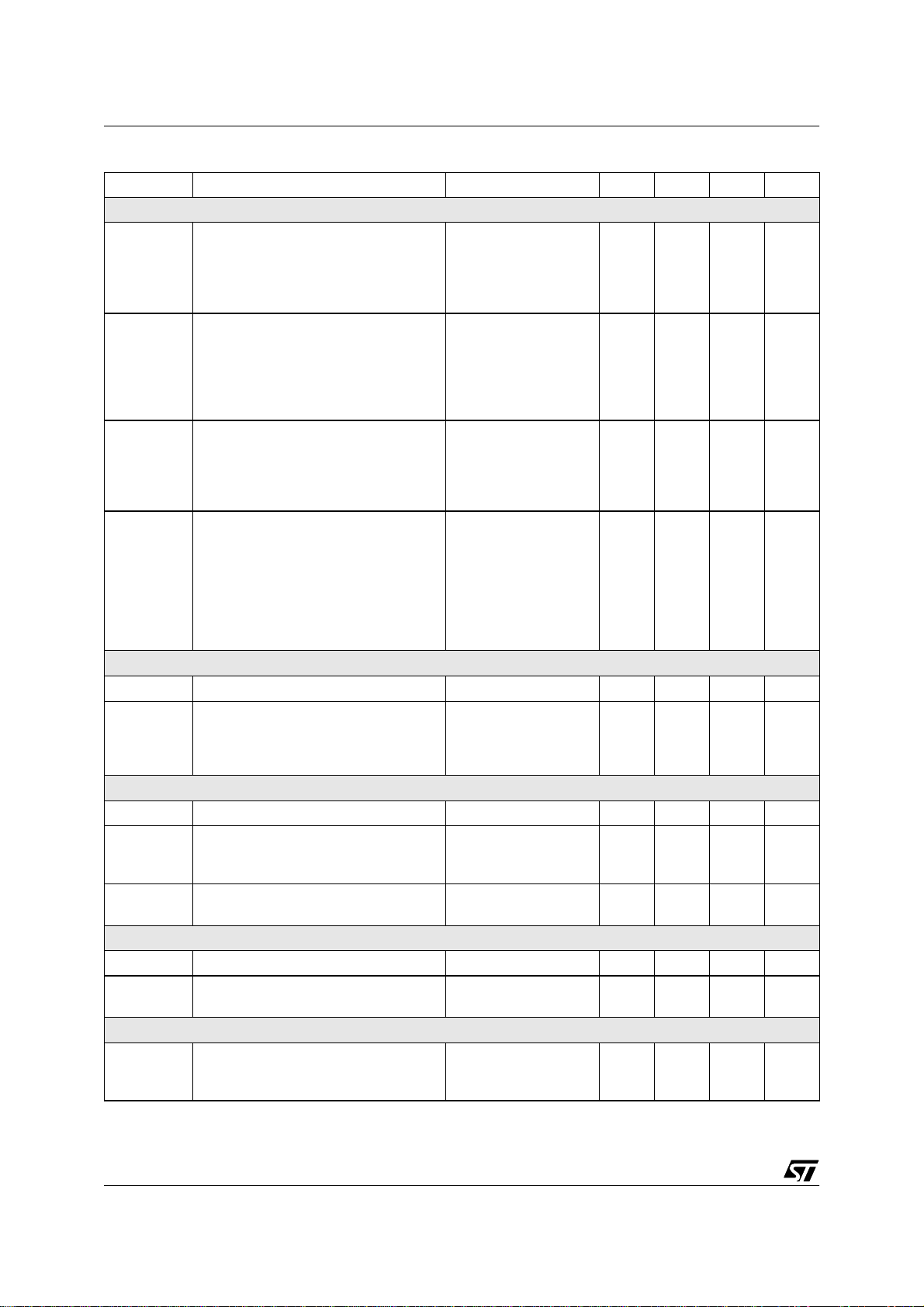

D8 D7 D6 D5 D4 D3 D2 D1

POR

11

12

13 x x x x

14

15

READ MODE (SLAVE ADDRESS = 8D)

Note: Both EW Corner Top and EW Corner Bottom are switched ON/OFF by reg (sub-address 04/D8).

[0], off

1, reset

Hlock

0, lock

[1], unlock

Ipump

1, 1mA

[0], 0.3mA

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [1] [1] [0] [1]

HEHT Comp Gain

[1] [0] [0] [0] [0] [0]

EWCorner Bottom

Xray

1, on

[0], off

Brightness

PLL1 filter voltage clamp (FVC)

[0] [0] [0] [0]

VEHT Comp Gain

STV2001

17/46

Page 18

STV2001

Figure 1. EW Output Referred Voltage

A

EW

DC

Figure 2. Dynamic Horizontal Phase Control Output

EW

B

PARA

EW

A

DHPC

DC

SPB

Figure 3. Keystone Effect on EW Output (PCC Inhibited)

Figure 4. Vertical Dynamic FOcus Outpu t

4Vdc

PARA

PARA

B

Keyadj

18/46

Page 19

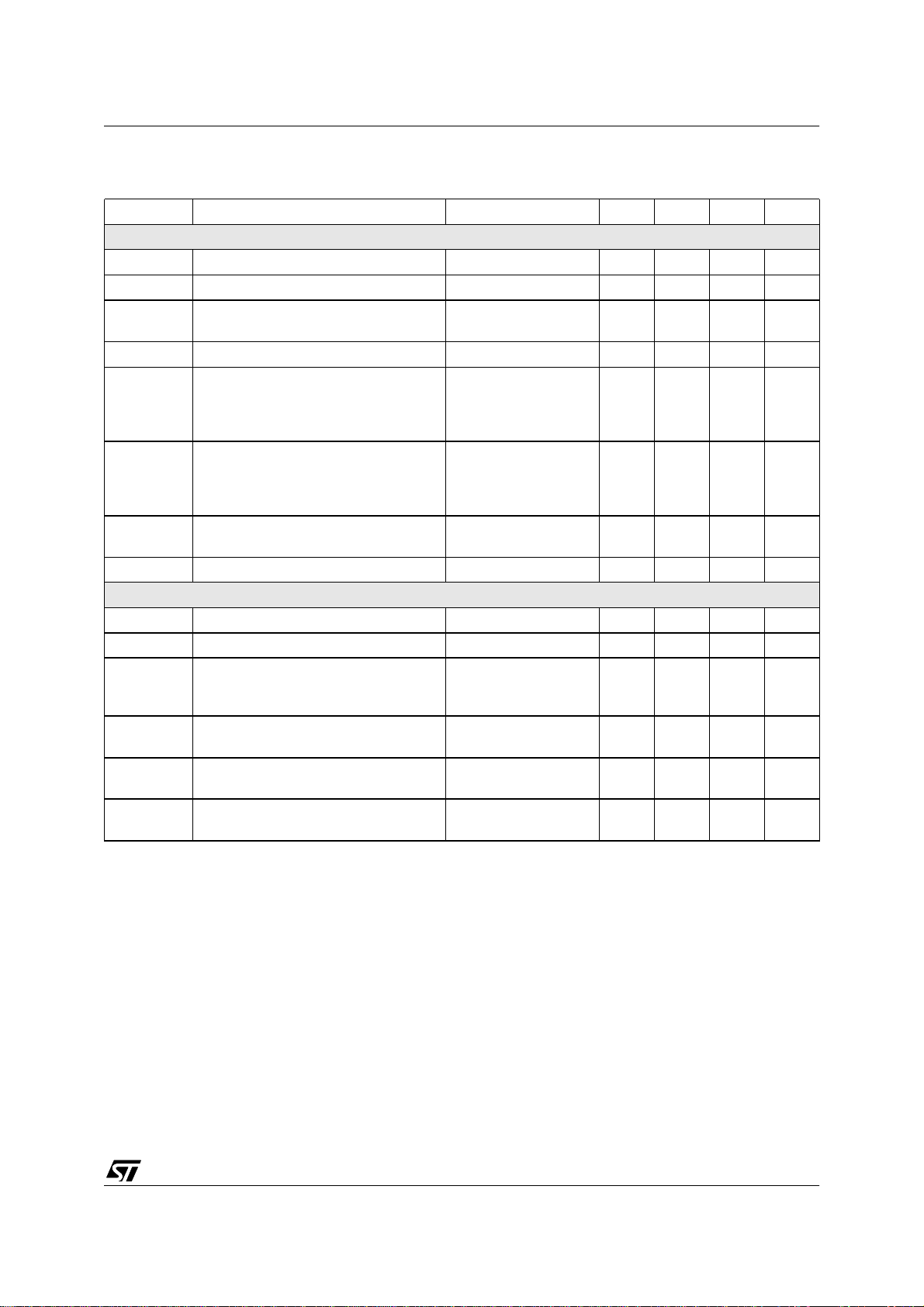

13 - TYPICAL OUTPUT WAVEFORMS

STV2001

Function

Vertical Size

Vertical

Position

Vertical

S

Linearity

Sub

Address

Pin Byte Specification Effect on Screen

1000 0000

1111 1111

x000 0000

x100 0000

x111 1111

0000 0000

Inhibited

1111 1111

V

OUTDC

V

OUTDC

V

OUTDC

= 3.2 V

= 3.5 V

= 3.8 V

∆V

2.25V

3.75V

Vpp

EW Corner

Top

(Symmetri-

cal)

Keystone,

EW Inhibited

1000 0000

1111 1111

1.25Vpp

1.25Vpp

2V

2V

19/46

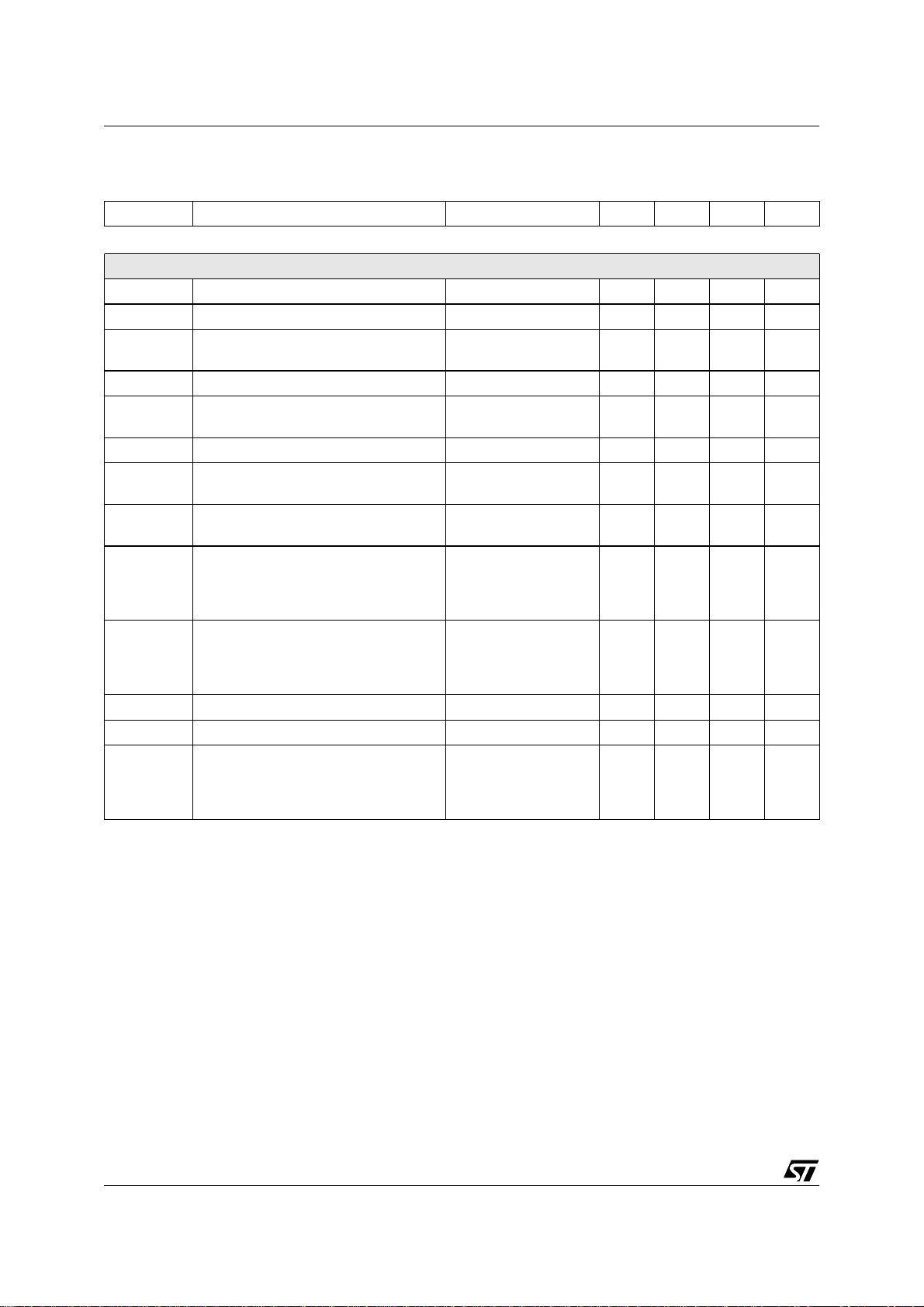

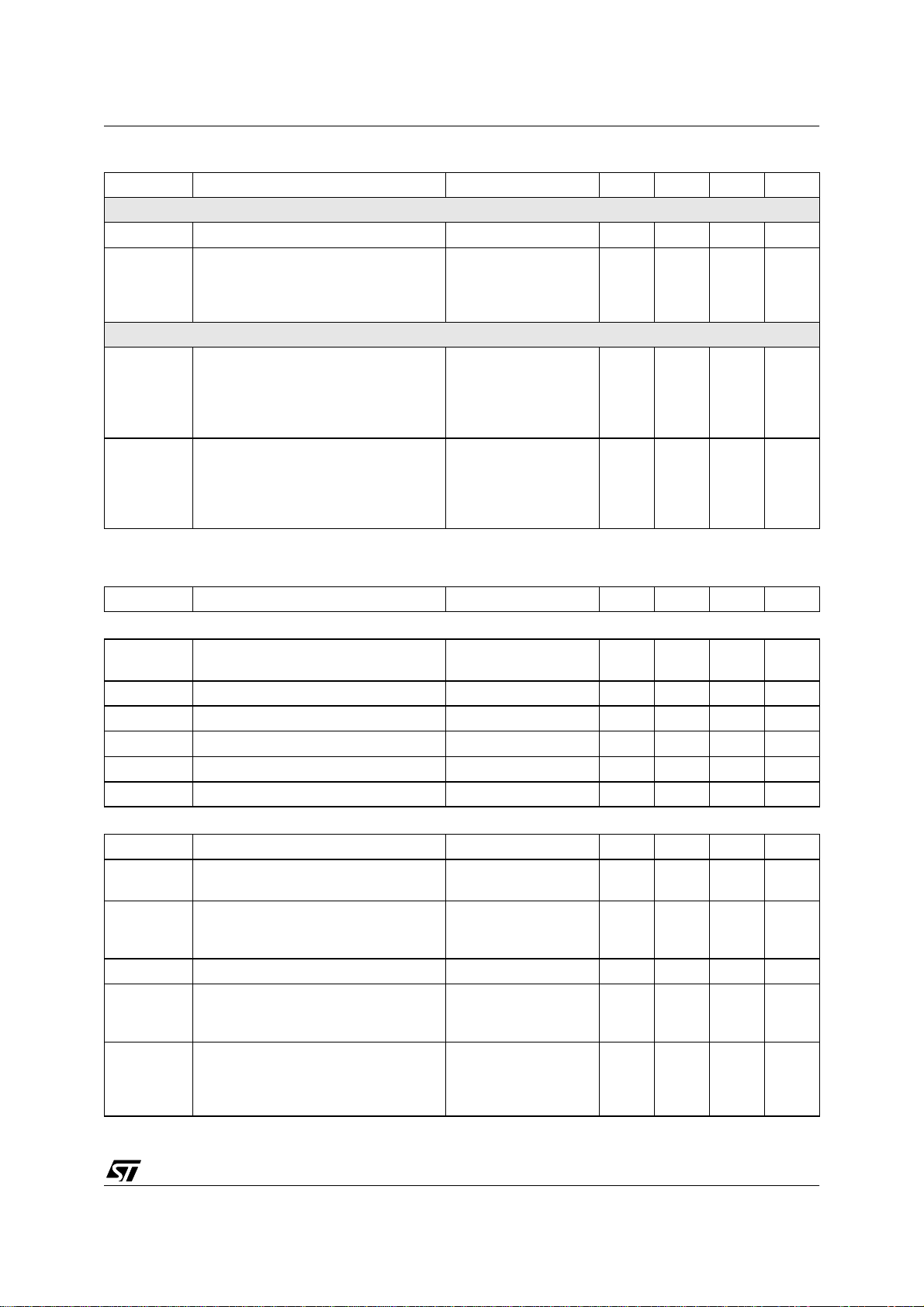

Page 20

STV2001

Function

EW Corner

Bottom

(Sym-

metrical)

Corner

Phase

Bottom

(Asym-

metrical)

Sub

Address

Pin Byte Specification Effect on Screen

Keystone,

EW Inhibited

2V

1000 0000

1111 1111

1.25Vpp

1.25Vpp

2V

Keystone,

EW Inhibited

2V

2V

2.8%TH

2.8%TH

1000 0000

1111 1111

Corner

Phase

Top

(Asym-

metrical)

Keystone

Keystone,

EW Inhibited

1000 0000

1111 1111

EW

Inhibited

1000 0000

1111 1111

2.0V

2.0V

2.8%TH

2.8%TH

2V

2V

0.2Vpp

0.2Vpp

20/46

Page 21

STV2001

Function

EW

Pin Cushion

H Amplitude

H Phase

Sub

Address

Pin Byte Specification Effect on Screen

EW

Inhibited

1000 0000

2.0 V

2.0 V

1.0 V

1111 1111

1000 0000

1111 1111

0000 0000

2.5V

Side Pin

Ballance

Control

Parallelo-

gram

Control

0111 1111

Parallelogram

Inhibited

1000 0000

1111 1111

SPB

Inhibited

1000 0000

1111 1111

2.5V

3.7 V

3.7 V

3.7 V

3.7 V

1.4%

1.4%

1.4%

1.4%

21/46

Page 22

STV2001

Contrast Register (Video IN = 0.5VPP, Drive at maximum, I2C Gainwin=1)

Hex b7 b6 b5 b4 b3 b2 b 1 b0 Vpp G(dB) POR

000000000 -

000000010.015-30

000000100.031-24

000001000.062-18

000010000.125-12

000100000.25-6

001000000.50

01000000212

010110102.81215 X

01111111418

Brightness Register (Drive at maximum)

Hexb5b4b3b2b1b0VppPOR

0000000

0 0 0 0 0 1 0.010

0 0 0 0 1 0 0.020

0 0 0 1 0 0 0.040

0 0 1 0 0 0 0.08

0 1 0 0 0 0 0.16

1 0 0 0 0 0 0.32

0 0 0 0 0 0 0.64

0 0 0 0 0 0 1.28

1011011.8X

1 1 1 1 1 1 2.56

Drive1, Drive2, Drive3 Registers (Video IN = 0.5V

Hex b7 b6 b5 b4 b3 b2 b 1 b0 Vpp G(dB) POR

00000000000 -

01000000010.015-30

02000000100.031-24

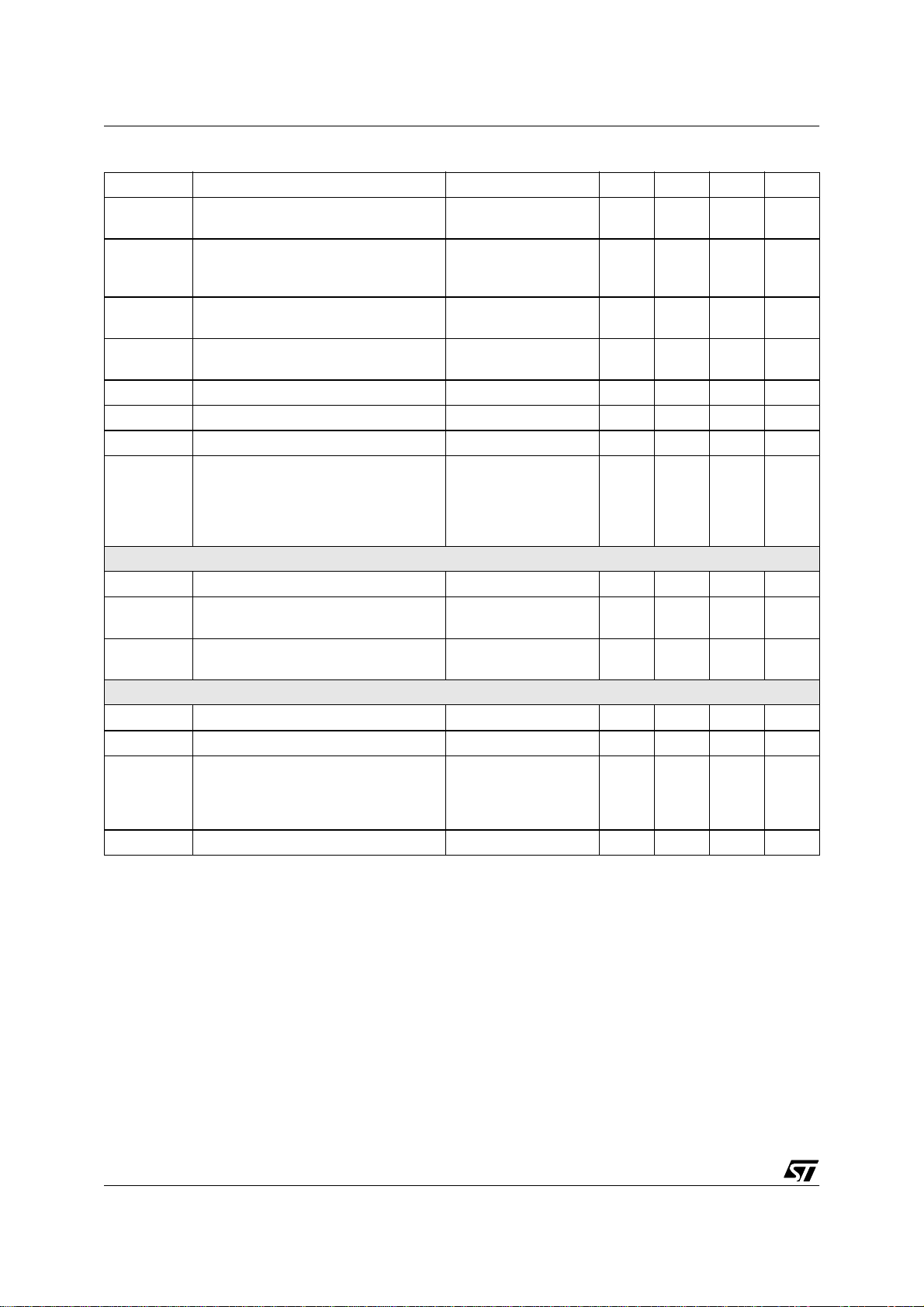

04000001000.062-18

08000010000.125-12

10000100000.25-6

20001000000.50

40010000001 6

8010000000212

B4101101002.81215 X

FF11111111418

, Contrast at maximum, I2C Gainwin=1)

PP

22/46

4

Page 23

Vertical Blanking Output DC voltage

Hex b5 b4 b3 b2 b1 b0 Output dc POR

0000001.0

000001

000010

000100

001000

010000

100000

000000

000000

110100

1111114.5X

STV2001

23/46

Page 24

STV2001

14 - OPERATING DESCRIPTION

SCANNING PART

14.1 - GENERAL CONSIDERATIONS

14.1.1 - Power Supply

Typical power supply voltages are 10.5 V for the

Deflection and Preamplifier sections (SAV

VAV

(Vdd). Optimum operation is obtained

and 11.5 for V

V

V

and PVCC) and 5.0 V for the logic section

CC

, and between 4.5 and 5.5 V for

.

DD

is monitored during the transient phase whe n

CC

CC

between 9.5

switched either on or off, to avoid erratic operation

of the circuit. If V

is inferior to 5.0 V typ., the cir-

CC

cuit outputs are inhibited. Similarly, before V

reaches 4 V, all the I2C registers are reset to their

default value (see I

2

C Control Table).

The circuit is internally supplied by several voltage

references (typ. value: 8 V) to ensure a good power supply rejection. Two of these voltage references are externally accessible respectively for the

vertical and horizont al part s. They c an be used to

bias external circuitry if I

is in ferior to 5 mA.

LOAD

To minimize the noise and consequently the "jitter"

on vertical and horizontal output signals, the reference voltages must be filtered by ex ternal capacitors connected to the ground.

To further improve the jitter on both vertical and

horizontal sections, FCAP and FILTER pins are

used to filter the internal 5V regulator wi th exte rnal

decoupling capacitors.

14.1.2 - I

STV2001 belongs to the I

2

C Control

2

C-controlled device

family. Each adjustment can be mad e via the I

Interface, instead of being controlled by DC voltages on dedicated control pins. The I

2

C bus is a serial bus with a clock and a data input. General

function and bus protocol are specified in the

Philips-bus data sheets. The interface (Data an d

Clock) is TTL-compatible. Spikes u p to 50 ns are

filtered by an integrator and the maximum clock

speed is limited to 100 kHz.

The data line (SDA) can be used bidirectionally. In

read mode, the IC sends reply information (1 byte)

to the micro-processor.

The bus protocol prescribes a full-byte transmission in all cases. T he first by te af ter t he start condition is used to transm it t he IC a ddres s (hex a 8 C

for write, 8D for read).

CC

DD

2

All bytes are sent MSB bit first and the write data

transfer is closed by a stop.

14.1.3 - Write Mode

,

In write mode, the second byte contains the subaddress of the selected function to adjust (or controls to effect) and the third byte the corresponding

data byte. More than one data byte can be sent to

the IC. If after the third byte no stop or start condition is detected, the circuit automatically increments the momentary subaddress in the subaddress counter (auto-increment mode) by one.

Thus it is poss ible to immediately transm it the following data bytes without sending the IC address

or subaddress. This can be us eful for reinitializing

all the controls very quickly (flash manner). This

procedure is ended with a stop condition.

There are 22 adjustment capabilities for the circuit:

3 for the horizontal part, 3 for the vertical, 3 for the

E/W correction, 2 for the dynamic horizontal phase

control, 5 for the pream plifier, 4 for the c orners, 2

for EHT compen sa tion a nd 1 for the blanking DC.

14 bits are also dedicated to several controls (ON/

OFF).

14.1.4 - Read Mode

In the read mode the second byte transmits the reply information. The reply byte contains t he horizontal and vertical lock/unlock status, the XRAY

activation status. A stop condition always stops all

the activities of the bus decoder and switches both

the data and clock line (SDA and SCL) to high im-

C

pedance. See I

2

C subaddress and control tables.

14.1.5 - Sync Processor

The internal sync processor allows the device to

receive separate horizontal & vertical TTL-compatible sync signals.

14.1.6 - IC Status

The IC informs the MCU about both the 1st horizontal PLL (locked or not) and t he XRAY protection (activated or not). The XRAY internal la tch is

reset either directly via the I

creasing the V

CC

supply.

2

C interface or by de-

14.1.7 - Sync Inputs

Both HIN and VIN inputs are TTL compatible triggers with hysterisis to avoid erratic detection. Both

inputs include a pull-up resistor connected to V

Synchro pulses must be positive.

DD

.

24/46

5

Page 25

STV2001

14.1.8 - Sync Processor Output

The sync processor indicates whether 1st PLL is

locked to an incomi ng horizont al sync or not. This

is indicated on the D8 bit of the status register .

PLL1 level is low when locked.

14.2 - HORIZONTAL PART

14.2.1 - Internal Input Conditions

A digital signal (horizontal sync pulse) is sent by

the sync processor to the horizontal input. It must

be positive (see Figure 5).

Synchronization occurs on the leading edge of the

internal sync signal.

The minimum value of Z is 0.7 µs.

Vertical synchro extraction is not allowed.

Figure 5.

Z

T

(VCO). The phase comparator is a "phase frequency" type designed i n CM OS t echnolo gy . This

kind of phase detector avoids locking on wrong

frequencies. It is followed by a "charge pump",

composed of two current sources: sunk and

sourced (typically I =1 mA when locked and

I=40µA when unlocked). This difference be-

tween lock/unlock allows smooth catching o f the

horizontal frequency by PLL1. This effect is reinforced by an internal original slow down system

when PLL1 is locked, preventing the horizontal frequency from changing too quickly. The dynamic

behaviour of PLL1 is fixed by an external filter

which integrates the current of the charge pump. A

"CRC" filter is generally used (see Figu re 6 ). One

2

C Ipump is used to set the pump current to

bit I

1mA or 0.3mA in locked condition.

Figure 6.

PLL1F

40

1.8kΩ

10nF

14.2.2 - PLL1

The PLL1 consists of a phase comparator, an external filter and a voltage-controlled oscillator

Figure 7. Block Diagram ²&

LOCKDET

High

1

COMP1

Low

Lock/Unlock

Status

Ipump

CHARGE

PUMP

2

I

4.7µF

C

44 FILTER

PHASE

ADJUST

PLL1F R0 C0

40 41 42

VCO

OSC

2

C

I

HPOS

Adj.

FC1

43

25/46

Page 26

STV2001

Figure 8. Det ai ls of VCO

PLL1F

(Loop Filter)

(1.4V<V

40

7

<6.4V)

41

R0

I

0

I

2

0

4 I

0

42

6.4V

1.6V

C0

6.4V

1.6V

0

FLIP FLOP

0.875T

RS

T

H

H

The VCO uses an external RC network. It delivers

a linear sawtooth resulting from the capacitor

charge and discharge . The current is proportional

to the one in the resistor. Typical thresholds for the

sawtooth are 1.6 V and 6.4 V.

The VCO control voltage varies between 3.0 V

and 3.8 V (see Figure 8). This VCO frequency

range is very small. The small effective frequency

is due to clamp intervention on the lowest filter value. The PLL1F filter voltage is set by a 4-bit DA C

with a voltage range of 3.0 to 3.8 V.

The sync frequency must always be hig her than

the free running frequency. For example, when using a 60 kHz synchro range, the suggested free

running frequency is 56 kHz.

Figure 9. PLL1 Timing Diagram

HO

SC

Sawtooth 7/8 TH

Phase REF1

1/8 TH

PLL1 ensures the coincidence between the leading edge of the sync signal and a phase reference

resulting from the comparison of:

– the VCO sawtooth

– an internal DC voltage I2C adjustable within the

range of 2.9V to 4.2V (corresponding to ±10%)

(see Figure 9 ).

A Lock/Unlock identification block, also included,

detects in real time whether PLL1 is locked on the

incoming horizontal sync signal or not.

The lock/unlock information is available through

2

the I

C read.

The FC1 Pin (Pin 43) is used for decoupling the internal 6.4 V reference by a capacitor.

6.4V

3.4V (Reference for H Position)

Vb

(2.8V<Vb<4.2V)

1.6V

HSynchro

Phase REF1 is obtained by comparison between the sawtooth and a DC voltage adjustable between 2.9 V and 4.2 V.

The PLL1 ensures the exact coincidence between the signal phase REF and HSYNC.

A ±10% T

26/46

phase adjustment is possible around the 3.5V point.

H

Page 27

STV2001

14.2.3 - PLL2

PLL2 ensures a constan t position of the shape d

flyback signal in comparison with th e sawtooth of

the VCO, taking into account the saturation t ime

Ts (see Figure 10).

Figure 10. PLL2 Timing Diagram

H Osc

Sawtooth

7/8T

H

1/8T

H

6.4V

4.0V

1.6V

Flyback

Internally

Shaped

Flyback

H Drive

Ts

set) is 85% in order to avoid having too long a conduction period of t he horizontal scanning transistor.

The maximum storage time (Ts Max.) is :

- T

0.44T

H

Typically, T

FLY

FLY/TH

/2).

corresponds to around 20 %

which means that Ts max represents approxim

tively 34 % of T

.

H

14.2.4 - Output Section

The H-drive signal is sent to the output through a

shaping stage which also controls the fixed Hdrive duty cycle (see Figure 10). In order to secure

the scanning power part operation, the output is inhibited in the following cases :

-when V

is too low,

CC

-when the ABL protection is activated,

-during the Horizontal flyback,

-when the HDrive I

2

C bit control is off.

The output stage con sists of a NPN bipolar transistor. Only the collecto r is ac cessible

(see Figure 12). E mitter is connected directly to a

separate ground pin.

Figure 12.

V

CC

Duty Cycle

The phase comparator of PLL2 (phas e type com parator) is followed by a charge pump (typical output current: 0.5 mA).

VBCAP pin is used to filter noise on PLL2 top comparator via an external capacitor.

The flyback input consists of an NPN transistor.

This input must be current driven. The maximum

recommended input current is 5 mA

(see Figure 11).

Figure 11. Flyback Input Electrica l Diagram

400Ω

HFLY

36

20kΩ

GND 0V

Q1

The duty cycle is fixed at 55%. For a safe start-up

operation, the initial duty cycle (after power-on re-

Hout

34

HDGND

33

This output stage is intended for "reverse" base

control, where setting the output NPN in off-state

will control the power scanning transistor in offstate.

The maximum output current is 15 mA, and the

corresponding voltage drop of the output V

CEsat

is

0.4 V Max.

Obviously, the power scanning transistor cannot

be directly driven by the integrated circuit. An interface either bipolar or MO S type has to be added

between the circuit and the power transistor.

27/46

Page 28

STV2001

14.2.5 - X-RAY Protection

X-Ray protection is activated when the ABL input (1 V on Pin 20) is at a low level. It inhibits both H-Drive,

and Vout while Video goes into off-mode.

This activation is internally delayed by 2 lines to avoid erratic detection (short parasitics).

This protection is latched; it may be reset either by switching V

Figure 13. Safety Functions Block Diagram

Checking

V

CC

V

+1V

CC

VSCinh

off or by I2C (see Figure 13).

CC

2

C Drive on/off

I

HORIZONTAL

OUTPUT

INHIBITION

XRAY Protection

+

20

ABL

VCC off or I2C Reset

Horizontal Flyback

0.7V

14.3 - VERTICAL PART

14.3.1 - Function

When the synchronization pulse is not present, an

internal current source sets the free runni ng frequency. For an external capacitor, C

OSC

= 150nF,

the typical free running frequency is 100Hz.

The typical free running frequency can be calculat-

ed according to:

fo(Hz) = 1.5

.

10

-5 .

1

C

OSC

A positive TTL level pulse applied on Pin 2 (Vin) is

used to synchronize the ramp in t he range [fmin,

fmax] (see Figure 14). This frequency range depends on the external capacitor connected on

Pin 6 (VCAP). A 150nF (

± 5%) capacitor is recom-

mended for 50 Hz to 165 Hz applications.

The typical maximum and minimum frequency, at

o

25

C and without any correction (S correction),

can be calculated as follows:

f(Max.) = 3.5 x f

and f(Min.) = 0.33 x f

o

o

When an S correction is applied, these values are

slightly modified.

With a synchronization p ulse, the internal oscillator is synchonized immediately but its amplitude

2

I

C Ramp on/off

S

Q

R

VERTICAL

OUTPUT

INHIBITION

Video-off

changes. An internal correc tion then adjusts it in

less than half a second. The ramp top value (P in 6)

is sampled on the AGC capacitor (Pin 4) at each

clock pulse. A transconductance amplifier modifies the charge current of the capacitor so as t o

make the amplitude constant again. We recommend using an AGC cap acitor with a low leakage

current. A value lower than 100nA is mandatory.

A good level of stability for the internal closed loop

is obtained by a 470nF

± 5% capacitor value on

Pin 4 (VAGC).

VRB (Pin 8) is used for decoupling the internal 2V

reference voltage by a capacitor.

14.3.2 - I

2

C Control Adjustments

S correction shapes can then be added to this

ramp. This frequency -independent S correction is

generated internally. Its amplitudes is adjustable

via the I

2

C. S correction can be inhibited by apply-

ing the selected bits.

Finally, the amplitude of the S corrected ramp is

adjustable via the verti cal ramp amplitude cont rol

register.The adjusted ramp is a vailable on Pin 7

) to drive an external power stage.

(V

OUT

28/46

Page 29

STV2001

The gain of this stage can be adjusted (± 25%) depending on its register value.

The mean value of this ramp is driven by its own

2

C register (vertical position) with :

I

VPOS = 7/16 x

V

REF-V

= ± 300 m V.

Figure 14. AGC Loop Block Diagram

DISCH.

VSYNCIN

2

SYNCHRO OSCILLATOR

Usually V

is sent through a resistive divider to

OUT

the inverting input of the booster. Since VPOS derives from V

the bias voltage sent to the non-

REF-V,

inverting input of the booster should also derive

from V

to optimize the accuracy

REF-V

(see Figure 14).

TRANSCONDU CTANCE

CHARGE CURR ENT

6

OSC

CAP

Vlow

Sawth

Disch

VPOSITION

SUB09/7bits

SAMPLING

.

VERT AMP

SUB08/7bits

AMPLIFIER

REF

4

SAMPLING

CAPACITANCE

S CORRECTION

VS AMP

SUB0A/7bits

24

BREATH

I2C

sub14

/6bits

VOUT

7

14.3.3 - Basic Equations

As a first approximation, the amplitude of the ramp

on Pin 7 (VOUT) is calculated as follows:

V

- VPOS = (V

OUT

OSC

- V

) x (1 + 0.25 (V

DCMID

AMP

))

where :

V

DCMID

= 7/16 x V

(middle value of the ramp on

REF

Pin 5, typically 3.6V)

= V5 (ramp with fixed amplitude)

V

OSC

= -1 as minimum vertical amplitude register

V

AMP

value and +1 as maximum value.

VPOS is calculated according to:

VPOS = V

where V

P

+ (0.4 x VP )

DCMID

= -1 and +1 as respectively minimum

and maximum vertical position register value.

The current available on Pin 6 is:

3

= x V

I

OSC

where

C

OSC

8

= capacitor connected on Pin 6

REF

x C

OSC

x f

f = synchronization frequency.

14.3.4 - Geometric Corrections

The principle is represented in Figure 15.

Starting from the vertical ramp, a parabola-shaped

current is generated for E/W correction (also

known as Pin Cushion correction), dynamic horizontal phase control correction.

The parabola generator consists of an analog multiplier, the output current of which is equal to :

∆I = k x (V

where V

- V

OUT

is the vertical output ramp (typically

OUT

between 2 and 5 V) and V

(for V

ly centered on 3.6 V. By c hanging the v ertical po-

= 8.2V). The VOUT sawtooth is typical-

REF-V

sition, the sawtooth shifts by

DCMID

)

2

DCMID

±0.4 V.

is 3.6 V

The "geometry tracking" feature ensures a correct

screen geometry for any end user adjustment. It

generates non-symmetric parab ola dependent on

the vertical position. To avoid Vertical EHT compensation (VBreathing) from affecting the geometry correction, an additional Buffer Amplifier is

used for VBreathing.

29/46

Page 30

STV2001

Due to the large output stage voltage ran ge (E/W

Pin Cushion, Keystone), the combination of the

tracking function, maximum vertical amplitude,

maximum or minimum vertical position and max imum gain on the DAC control may lead to output

stage saturation. This m us t be avoided by li miting

the output voltage with appropriate I

2

C register

values. For the E/W part and the dynamic horizontal phase control part, a sawtooth-shaped differential current in the following form is generated:

.

(V

∆I’ = k’

OUT

- V

DCMID

).

Then ∆I and ∆I’ are added and converted into voltage for the E/W part.

Each of the two E/W comp onents or the two dynamic horizontal phase control components may

be inhibited by their own I

2

C select bit.

EW output voltage is available at EWout pin directly. External buffer circuit is required to drive Darlington pair transistor, which is sinking the DI ODE

MODULATOR current in order to achieve EW correction. Additionally, an I

2

C contro lled DC sh ift is

used for H-width.

The dynamic horizontal phase control drives the

H-position internally, moving the HFLY position on

the horizontal sawtooth in the range of

± 2.8 %T

both for side pin balance and parallelogram.

H

30/46

Page 31

Figure 15. Geometric Corrections Principle

V

VOSC

3.5V

V

DCMID

V

POS

AMP

V

OUT

From VB r e ath

STV2001

V

OUT

7

VDFocus

3.5V

3.5V

I - V

EW

2

1

X

AMP

23

R

Keystone

3.5V

EW

EWDC

2

1

X

Corner Top

+

I - V

OUT

27

R

Corner Bot.

Corner Top

3.5V

2

1

X

Corner Bot.

R

S.P.B.

+

To Horizontal Phase

Parallelog.

3.5V

31/46

Page 32

STV2001

14.3.5 - E/W

EWOUT = EW

+ K1 (V

DC

OUT

- V

DCMID

) +K2 (V

OUT

- V

K1 is adjustable via the keystone I2C register. K2 is adjustable via the E/W amplitude I2C register.

14.3.6 - Dynamic Horizontal Phase Control

I

OUT

= K4 (V

OUT

- V

DCMID

) + K5 (V

OUT

- V

DCMID

2

)

K4 is adjustable via the parallelogram I2C register.

2

K5 is adjustable via the side pin balance I

C register.

14.3.7 - Vertical Dynamic Focus

Vertical Dynamic Focus waveform is available on

Pin 23. It is the parabolic waveform with downwards concavity, at vertical frequency . Its amplitude is fixed at 1 Vpp.

14.3.8 - Corner Correction

There are 4 types of corner correction in the device: EW Corner Top, EW Corner Bottom, Corner

Phase Top and Corner Phase Bottom. EW Corner

Top and EW Corner Bottom are used to modu late

the EW amplitude. Corner P has e To p and Corner

Phase Bottom are used to modulate the Horizontal

Phase. These 4 types of correction are used to

compensate the distortion appearing at the corners of the CRT.

EW Corner Top and EW Corner Bottom corrections add a half parabola current to the EW voltage. Since the E/W output voltage range is limited,

it was necessary to add EW Corner Correction to

decrease both EW amplitude and Keystone by

2

C.

I

2

)

DCMID

Corner Phase Top and Corner Phase Bottom corrections add a half parab ola current to the Horizontal Phase. Top and Bottom Corrections can be

adjusted separately by I

2

C with 7 Bits DAC.

14.3.9 - Horizontal Breathing

Horizontal breathing is performed through the E W

stage with V-I Converter and an I

2

C controlled variable gain stage. This DC controlled input provides

the Horizontal Width correction required to offset

width changes due to EHT variat ion. Gain attenuation is set by a 7 bits DAC with I

2

C.

14.3.10 - Vertical Breathing

Vertical breathing compensation is performed

through gain modulat ion o f the ve rtical ramp . This

DC-controlled input allows the vertical height corrections needed to offset height cha nges due to

EHT variations. Input is received at the output of

the EHT compensation Amplifier. Gain attenuation

is set by 6 Bits DAC via I

2

C.

PRE-AMPLIFIER PART

14.4 - GENERAL CONSIDERATIONS

14.4.1 - Input Stage

The R, G and B signal s must be supplied to the

three inputs through coupling capacitors (100nF).

The maximum input peak-to-peak video amplitude

is 1 V.

Figure 16. .

HSYNC

BPCP

Internal pulse width is fixed at 1µs

In both cases, BPCP width is fixed.

32/46

The input stage includes a clamping function. This

clamp uses the i nput serial capacitor a s "memory

capacitor" and is gated by an internally generated

"Back-Porch-Clamping-Pulse (BPCP)".

The BPCP is synchronized on the second edge of

the horizontal pulse HIN inputs on Pin 1.

Page 33

STV2001

14.4.2 - Contrast Adjustment (7 bits)

The contrast adjustment is made by simultaneously controlling the gain of three internal variable

gain amplifiers through the I

2

C bus interface. The

contrast adjustment allows covering a range higher than 40 dB. This adjustment is refreshed during

the vertical retrace time.

14.4.3 - ABL Control

The STV2001 has an A BL input (automatic beam

limitation) to attenuate RGB v ideo signal s ac cording to beam intensity.

The operating range is typically 2.5 V, from 5 .3 V

to 2.8 V. A typical 12 dB Max. at tenuation is applied to the signal whatever the current gain. Refer

to Figure 16 for ABL input attenuation range.

In the case of software control, the ABL input must

be pulled to AV

through a resistor to limit power

CC

consumption.

ABL input voltage must not exceed V AV

resistor is 10k

Ω.

CC

. Input

Figure 17.

Attenuation (dB)

2

0

-2

-4

-6

-8

-10

-12

-14

12345678

VIN (V)

9

14.4.4 - Brightness Adjustment (6 bits)

As with contrast adjustment, brightness is controlled by I

2

C.

The brightness function consists of adding the

same DC offset to the three R, G, B signals after

contrast amplification. This DC-Offset is present

only outside the blanking pulse (see Figure 19).

The DC output level is forced to "INFRA-BLACK"

level (V

) during the blanking pulse.

DC

14.4.5 - Drive Adjustment (3 x 8 bits)

To adjust the white bal ance, th e device offers t he

possibility of separately ad justing the overall g ain

of each complete video channel. Each channel

gain is controlled by I

2

C (8 bits each). The very

large drive adjustment range (48dB ) allows different standard or custom color temperatures.

The drive adjustment is also used to adjust the

output voltages at the optimum am plitude to drive

the C.R.T drivers, keeping the whole contrast control for end-users only. The drive adjustment is

made after the contrast and brightness so that the

white balance remains correct when BRT is adjusted.

14.4.6 - Output Stage

The three output stages (see Figure 18) incorporate three functions:

• The blanking stage: when the internal

generated blanking pulse is high, the three

outputs are switched to a voltage which is

400 mV lower than the BLACK level. The

black level is the output voltage with minimum

brightness when the input signal video

amplitude is equal to "0".

• The output stage itself: a large bandwidth

output amplifier which can deliver up to 5V

PP

on the three outputs (for 0.7 V video signa l on

the inputs).

• The output CLAMP: the I C also incorporates

three internal output clamps (sample and hold

system) to fix the "INFRA-BLACK" level

(VDC) at 1.1V during blanking.

The overall waveforms of the output signal according to the different adjustments are shown in

Figure 19. and Figure 20.

33/46

Page 34

STV2001

Figure 18.

10

S/H

1.5V

Figure 19. Waveforms VOUT, BRT, CONT

HSYNC

BPCP

BLK

Video IN

V

, V

OUT2

, V

OUT3

V

CONT

OUT1

(4)

Vout

CRT Driver

STV2001

34/46

(3)

V

BRT

(2)

V

BLACK

(1)

V

DC

Note : 1. VDC = 1.5V

BLACK

= V

BRT

CONT

= V

= VDC + 0.4V

2. V

3. V

4. V

CONT

BRT

0.4V fixed

+ BRT (with BRT = 0 to 2.5V)

BLACK

+ CONT with CONT = k x video (CONT = 5VPP max. for VIN = 0.7VPP)

BRT

Page 35

Figure 20. Waveforms (DRIVE adjustment)

HSYNC

BPCP

HFly

Video IN

,

V

V

Note :

OUT1

V

BRT

V

BLACK

V

DC

1. Drive adjustment modifies the following voltages : V

Drive adjustment does not modify the following voltages : V

OUT2

,

V

OUT3

two examples of

drive adjustment

(1)

CONT

V

CONT

, V

DC

.

BRT

and V

STV2001

.

.

BLACK

14.4.7 - Bright Window

Contrast Gain can be increased by 1.5X when the

I2C command “GainWin” is issued or GWIN (Pin

16) pulse value reaches its Turn-ON threshold.

Bright Window gain can be controlled separately

2

C command or pulse voltage at “GAINWIN”

by I

pin. Although both controls are independent, max

gain is still limited to 1.5x, not 1.5x + 1.5x.

14.4.8 - Blanking Generator

A vertical blanking pulse is generated

(see Figure 21). The output level is a positive going pulse of 9.5V. The vertical blanking is started

Figure 21. VBDC (Pin 18) Output Voltage Waveform

DC level controlled by

6-bit DAC

by the vertical sync pulse and by the falling edge of

VFly pulse. If there is no VFly pulse (VFly>6.5V ),

the vertical blanking the vertical blanking start coincides with the beginning of the vertical capacitor

discharge time.

The blanking output generates a superimposed

variable DC voltage. The 6-bit adjustment range is

1 V to 4.5 V. T his is used t o allow brightness control through G1. Addi tionally, this pin is used for

0.8 V

spot killer suppression. The

of Vcc threshold

will trigger the output into a high level sta te resulting from the Vcc decay.

9.5V

4.5 V

1.0 V

35/46

Page 36

STV2001

Table 1: Logic Table

Conditions Hout Vout Video-o ff Low Power

at 0 to 6.9 V (PD2 mode) no no video-off NA (1)

V

cc

at 6.9 V to 8.5 V (PD1 mode) yes yes video-off NA(1)

V

cc

Hlock/unlock detection = unlock yes yes video-off no

Video ABL input pin < 1 V no no video-off no

5 V POR or I

2

C Hout on/off, (default=1=on) on/off yes on/off no

I

2

C Vout on/off, (default=1=on) yes on/off on/off no

I

2

C Video on/off, (default=0=video-off) yes yes on/off no

I

at >8.5 V yes yes video-on (2)NA (1)

V

cc

at >8.5 V, I2C video=1=on yes yes video-on (2)no

V

cc

Note 1 NA= Not applicable.

Note 2 I

2

C POR=1, (default=0) yes yes video-off no

2

C video=on will be reset by Low Vcc.

STAND-BY MODE AND PROTECTIONS

14.5 - GENERAL CONSIDERATIONS

2

14.5.1 - POR (Power On Reset) - Subad. 11-D8

POR is activated on 5 V with default values for

each adjustment and in addition video off (see

1.3). It can be activated via the I

2

C command.

14.5.2 - Supply Voltage Threshold.

Two built-in thresholds (see figure 21) are used to

enter the following modes:

• PDI mode:

– Activated for Vcc < 8.5V

– Video off (see 1.13)

• PD2 mode:

– Activated for Vcc < 5.0V

– Video off (see 1.13)

– H

OUT

and V

OUT

disabled

14.5.3 - Video Off (I

Activates blanking of the 3 video output stages.

During this time the outputs are s witched to VDC

level, regardless of the presence of Hsync or Hflyback. Activation time is inferior to 1µs.

This also ac tivates the blanking outpu t at pin 18

into a high level state close to 9.5V as long as

“video off” is activated. When the device enters the

“Video-off” mode, voltage on pin 8 is 8V.

14.5.4 - Vertical Output Off

This command will switch of f output VAMP. The

vertical output swing is reduced to 0V.

14.5.5 - X-Ray, Set Operation - Subad. 09-D8

When ABL voltage is below 1 V threshold, Xray

latch will be activated. This I

the Xray latch. Activation time below 100ms.

C control) - Subad. 00-D8

2

C command will reset

36/46

Page 37

15 - INTERNAL SCH EM ATI CS

STV2001

Figure 22.

Figure 23.

Vref

1,2

3

V

DD

SAV

CC

200

Figure 25.

SAV

CC

Ω

200k

Ω

Vgnd

5

Figure 26.

SAV

CC

6

VCAP

22k

Ω

Figure 24.

VAGCCAP

4

SAV

CC

Figure 27.

SAV

VOUT

7

CC

37/46

6

Page 38

STV2001

INTERN AL SCH E M ATICS (continued)

Figure 28.

VRB

Figure 29.

VAV

SAV

CC

9

Figure 31.

CC

Vref

R1

8

AGND

11

VAV

CC

R2

Figure 32.

12V

BIPSWITCH

PGND

13

Figure 30.

PV

CC

Pgnd

AGND

VAV

Agnd

CC

Pins 1 0, 12, 14

Figure 33.

VAV

PV

CC

CC

15

38/46

Page 39

INTERN AL SCH E M ATICS (continued)

STV2001

Figure 34.

Figure 35.

Pins

17

19

21

Agnd

IN

16GainWin

VAV

VAV

CC

CC

Figure 37.

ABLin

Figure 38.

V

FLYIN

20

SAV

22

VAV

Agnd

CC

CC

10k

Internal

Ω

5V

10k

V

8V

CC

Figure 36.

VBDC

Agnd

VAV

18

CC

Agnd

Figure 39.

SAV

V

FOCUS

23

LGND

AGND

8V

CC

20 k

39/46

Page 40

STV2001

INTERN AL SCH E M ATICS (continued)

Figure 40.

BREATH

V

Figure 41.

HBreath

SAV

25

24

SAV

CC

CC

60K

Figure 43.

SAV

CC

Vref

1.5k

27

EWout

10k

Figure 44.

Ω

V

28

DD

Vref

5V

BIPSWITCH

Figure 42.

SAV

CC

F

CAP

26

LGND

40/46

Internal 5V

Figure 45.

SDA

29

5V

10K

V

DD

Page 41

INTERN AL SCH E M ATICS (continued)

STV2001

Figure 46.

SCL

Figure 47.

30

SAV

CC

31

5V

10k

12V

Bipswitch

Figure 49.

SAV

CC

V

DD

HOUT 34

HDGND

33

Figure 50.

SAV

CC

Href

35

22kΩ

Figure 48.

Figure 51.

Href

35

SAV

CC

32Lgnd

36

HFLY

41/46

Page 42

STV2001

INTERN AL SCH E M ATICS (continued)

Figure 52.

Figure 53.

PLL2C

SAV

38

Hgnd

CC

37

Href

Figure 55.

PLL1F

Figure 56.

SAV

CC

42

SAV

40

CC

Href

Href

35

Figure 54.

VBCAP

42/46

39

Lgnd

SAV

CC

Figure 57.

Href Href

SAV

CC

41

35

Page 43

INTERN AL SCH E M ATICS (continued)

Figure 58. Figure 59.

SAV

CC

1K

_

3

43

FC1

4K

_

3

STV2001

HrefSAV

CC

44FILTER

43/46

Page 44

STV2001

Figure 60. Demonstration board schematic

Vcc

5V

SDA

SCL

GND

47K

C34

100n

C33

10u

TA1

MC1452 8

C32

47K

R36

Vcc

HFLY

C30 33p

R35 10K

Width

R39

C35

47p

14

13

16

TB1

VCC

121511

1B

TB2

CDB

9

10

QB

N1B

NQB

R38 10K

CDA

TA2

1A

QA

NQA

2

1

N1A

3

4

5

GND

7

6

8

+5V

R40 4K7

C36 33p

C38

22p

22p

C37

R41 4K7

R43 100

R42 100

47p

Vcc

Vcc

R37 10K

Delay

Hout

C9

C8

4u7

HIN

Vcc

C31 10u

R33 1K

R34 560 D1 1N4148

Vcc (10.5V)

100u100n

C29

+5V

C28

28

29

30

31

32

33

SCL

SDA

HREF

47u

100n

22n

C7

C5

C4

R2

1K8

6490

820p

100n

1u

C3

VIN

Hout

LGND

HDGND

SAVCC

Href

Hfly

Hgnd

PLL2C

VBCAP

1n*

C6

10n

R1

C1

C2

PLL1F

R0

C0

FC1

44 43 42 41 40 39 38 37 36 35 34

FILTER

Vref

Hin

Vin

3

1

2

100n

47u

C10

C11

VDD

STV2001

Vgnd

VCAP

VAGCCAP

4

5

6

470n

150n

C13

C12

R32 10K

EW

C27

100u

C26

100n

C25 1u

26

24

25

27

FCAP

EWout

Vout

7

VBRTHin

HBRTHin

VAVCC

Out1

VRB

8

9

10

100n

C19

C14

C18

L3 10uH

R5 12K

Vfly in

R29 10K

R30 10K

R31 10K

R28 1K

R27 10K

R26 10K

VFOCUS

R24 1K

Vcc

R22 1K

R25 10K

R23 10K

R21 10K

23

Agnd

2221201918171615141312

VFLYIN

VFOCUS

IN3

ABLin

In2

VBDC

In1

GANWIN

PVCC

Out3

PGND

Out2

11

100n

47

R19

R16

C24

100n

R18

C23

R20 25K

100n

C22

75

47

47

R17

IN2 IN3

75

R15

IN1

R14

75

R13 75

100u

C21

C20

Vcc

10uH

L1

100n

R12 1K

R11 1K

100n

OUT1

OUT2

R10 1K

OUT3

100u

44/46

Vcc

VOUT

Page 45

16 - PACKAGE MECHANICAL DATA

TQFP 44 L SLUG DOWN BODY

A

A2

STV2001

A1

B

Slug down

C

K

D

D1

L

L1

D3

34

S1

44

Pin 1

Identification

33

H

1

S

23

22

E

E3

E1

12

11

e

Dimensions Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 1.420 1.540 0.056 0.061

A1 0.065 0.100 0.135 0.003 0.004 0.005

A2 1.360 1.400 1.440 0.054 0.055 0.057

B 0.325 0.350 0.375 0.013 0.014 0.015

c 0.165 0.006

D 11.900 12.000 12.100 0.469 0.472 0.476

D1 9.975 10.000 10.025 0.393 0.394 0.395

D3 7.950 8.000 8.050 0.313 0.315 0.317

e 0.750 0.800 0.850 0.030 0.031 0.033

E 11.900 12.000 12.100 0.469 0.472 0.476

E1 9.975 10.000 10.025 0.393 0.394 0.395

E3 7.950 8.000 8.050 0.313 0.315 0.317

H 5.840 5.890 5.940 0.230 0.232 0.234

L 0.450 0.018

L1 0.938 1.000 1.063 0.037 0.039 0.042

S 6.000 6.100 0.236 0.240

S1 6.000 6.100 0.236 0.240

K 1.5d 3.5d 5.5d 1.5d 3.5d 5.5d

45/46

7

Page 46

STV2001

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the con sequences of use of suc h informatio n nor for any infringeme nt of patents or other right s of

third parties whi ch ma y res ult fro m its u se. N o licen se is grant ed by implic ation or oth erwi se und er an y patent

or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supe rsedes and repl aces all informa tion previously s upplied. STMicr oelectronics

products are not auth orized for use as critical componen ts in lif e support devices or syst ems with out the e xpress written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved.

Purchase of I2C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use the se compone nt s i n an

Australi a - Brazil - China - Finland - Fr ance - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malt a - Mo rocco - Singa pore - Spain

2

C system is granted pro vi ded that the sy stem confo rm s to the I2C Standard Specification as defined by Philips.

I

STMicroelectronics Grou p of Companie s

Sweden - Switzerland - United K ingdom - U.S .A.

http://www.st.co m

46/46