Page 1

STV2000

I2C SINGLE FREQUENCY DEFLECTION PROCESSOR AND

70 MHz RGB PREAMPLIFIER

PRELIMINARY DATA

FEATURES

Horizontal deflection

■ Single frequency, self adaptive oscillator.

■ TTL compatible positive going sync.

2

■ I

C controlled: H-position, Pin Cushion,

Keystone, Parallelogram, Side Pin Balance,Hamplitude.

■ DC East/West feedback.

■ DC controls: H-width breathing compensation.

■ X-Ray protection

Vertical deflection

■ Vertical ramp generator.

■ Wide range AGC loop.

■ TTL compatible positive going sync, no extra

pulses.

2

■ I

C controls: vertical position and S-correction.

■ DC controls: height breathing compensation.

Video preamplifier

■ 3-channel 70MHz bandwidth RGB preamplifier.

■ 5ns typical rise and fall time at 4V

2

■ I

C controls: RGB contrast, cut-off, brightness,

contrast up-date during vertical retrace time.

■ ABL will reduce gain (contrast).

■ 0.514V typical video input signal for normal

display.

I2C Main features

2

■ I

C interface (slave) 100kHz max.

2

■ All I

C controlled DAC are 7bit, except for RGB

gain and cut-off.

■ Power- on- reset at 5 V (V

■ 0.5 to 4 V static DAC output.

DD

).

Supply voltage & power

■ 5 V/10.5 V dual supply.

■ Max power consumption: 1.2W

PP

.

DESCRIPTION

The STV2000 is an I2C-controlled monolithic

integrated circuit assembled in a TQFP44 plastic

package. It combines both a deflection block

(horizontal andvertical, single frequency with very

powerful geometry correction) and a 70MHz RGB

pre-amplifier.

TQFP44

ORDER CODE :

PIN CONNECTIONS

Vin

Vref

VAGCAP

VGND

VCAP

Vout

VBRTHin

VRB

VAVcc

Out1

Cut-off1

FC1

Hin

44 43 42 41 40 39 38 37 36 35 34

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17 18 19

Out2

AGND

Ro

Co

PGDN

Cut-off2

PLL1F

Out3

Cut-off3

FILTER

PLL2C

PVcc

HGND

Hfly

20 21 22

In1

ABLin

In2

Href

Hout

33

32

31

30

29

28

27

26

25

24

23

DAC

LGDN

SAVcc

SCL

SDA

V

(5V)

DD

out

EW

EWFBin

HBRTHin

N.C.

VBDC

In3

Version 3.0

April 2000 1/38

This ispreliminary information on a newproduct now in development. Details are subject tochange without notice.

This ispreliminary information on a new product indevelopment orundergoing evaluation. Details are subject tochange without notice.

1

Page 2

TABLE OF CONTENTS

PIN DESCRIPTION . . . . . . . . . .................................................... 3

BLOCK DIAGRAM .............................................................. 4

ABSOLUTE MAXIMUM RATINGS ................................................. 5

THERMAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .................................. 5

SYNC INPUT .................................................................. 5

I2C READ/WRITE . . . . . . . . . . . . . . . . . . . . . . ......................................... 6

HORIZONTAL SECTION . . . . . . . . . ................................................ 6

VERTICAL SECTION) . . . . . . . . . . . . . . . ............................................ 8

VIDEO PRE-AMP SECTION . . ...................................................11

LOGIC SECTION . ............................................................. 12

I2C BUS ADDRESS TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TYPICAL OUTPUT WAVEFORMS ................................................ 15

OPERATING DESCRIPTION . . . . . . . . . . . . . ........................................19

SCANNING PART . . . . . . . . . . . . . . . . . . . . . . ................................. 19

PRE-AMPLIFIER PART . . . ................................................ 27

STAND-BY MODE AND PROTECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

INTERNAL SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . ................................. 32

PACKAGE MECHANICAL DATA . . . . . . . . . ........................................ 40

2/38

2

2

Page 3

PIN DESCRIPTION

Pin Name Function

1 Vin Vertical Sync Input

2 Vref Vertical Section Reference Voltage

3 VAGCCAP Vertical AGC Loop Capacitor

4 VGND Vertical Section Ground

5 VCAP Vertical Sawtooth Generator Capacitor

6 Vout Vertical Output

7 VBRTHin Vertical Breathing DC Input

8 VRB Vertical Ramp Filter

9 VAVcc Video Section Analog Supply (10.5Vtyp)

10 OUT1 Video Output1

11 Cut-off1 Cut-off1 DAC voltage output pin

12 AGND Video Analog Ground

13 OUT2 Video Output2

14 Cutoff2 Cut-off2 DAC voltage output pin

15 PGND Video Section Power Ground

16 OUT3 Video Output3

17 Cutoff3 Cut-off3 DAC voltage output pin

18 PVcc Video Section Power Supply (10.5V typ)

19 IN1 Video Input 1

20 ABLin Video Automatic Beam Current Compensation Input

21 IN2 Video Input 2

22 DAC 7bits DAC Voltage Output

23 IN3 Video Input 3

24 VBDC Vertical Blanking Output with DC level adjusted by DAC

25 N.C. Not to be connected

26 HBRTHin Horizontal Breathing Compensation DC Input

27 EWFBin EW Correction Feedback Input

28 EWout EW Buffer Output

29 V

30 SDA I

31 SCL I

32 SAVcc Scanning Section Analog Supply (10.5Vtyp)

33 LGND Bus and Scanning Power Ground

34 Hout Horizontal Driver Output, open collector

35 Href Horizontal Section Reference Voltage

36 Hfly Horizontal Flyback Input, Positive

37 HGND Horizontal Section Ground

38 PLL2C PLL2 Loop Filter

39 Filter Horizontal Filter Capacitor (HPOS)

40 PLL1F PLL1 Loop Filter

41 Co Horizontal Oscillator Capacitor

42 Ro Horizontal Oscillator Resistor

43 FC1 PLL1 filter capacitor

44 Hin Horizontal Sync Input

DD

Bus, Scanning Logic and Video Logic Supply (5V typ)

2

C Data Input

2

C Clock Input

STV2000

3/38

3

Page 4

4/38

3

PLL1F Filter FC1 Ro Co HFly PLL2C Hout

40 39 43 42 41 36 38 34

CC

Href

Vref

Hin

Vin

Vout

VRB

SDA

SCL

VDD

IN1

IN2

IN3

32

35

44

37

30

31

29

33

19

21

23

Href

Vref

2

1

4

5

3

7

6

8

Scorr

Hsync

VOSC

RAMP

Generator

2

C BUS

I

DECODER

Clamp

Vpos

Phase

Freq

Comp

Vamp

VCO

Geometry

Tracking

LATCHES & DACs

BrightnessContrast

Phase

Comp

2

X

KeyBal

X

SPB

Drive

Phase

Shifter

X

HFly

Hsync

Vsync

EWPCC

2

KEYST

HOUT

Buffer

+

Blanking

BPCP

Output

Stage

Safety

EW OUTPUT

H Breathing

ABL

DAC

EWout

28

EWFBin

27

HBRTHin

26

20

ABLin

24

VBDC

DAC

22

VAV

9

12

AGND

10

OUT 1

Cut-off 1

11

PV

18

13

OUT 2

Cut-off 2

14

15

PGND

OUT 3

16

Cut-off 3

17

CC

SAV

HGND

VGND

VCAP

VAGCCAP

VBRTHin

LGND

BLOCK DIAGRAM

CC

STV2000

STV2000

Page 5

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

SAVcc Scanning Section Analog Supply Voltage 13.5 V

VAVcc Video Section Analog Supply Voltage 13.5 V

PVcc Supply Voltage for Video Pre-Amp Section 13.5 V

Vdd Logic Section Supply Voltage 5.5 V

V

ESD

Tstg Storage Temperature -40 to 150

Tj Junction Temperature 150

Toper Operating Temperature (Device ambient) 0 to 70

ESD susceptibility HBM model 100pF & 1.5kΩ

EIAJ Norm 200pF & 0Ω

2

300

THERMAL DATA

STV2000

kV

V

o

C

o

C

o

C

Symbol Parameter Value Unit

R

TH(j-a)

Junction to Ambient Thermal Resistance (MAX) 46

SYNC INPUT

Operating Conditions (VDD= 5V, T

Symbol Parameter Test Conditions Min Typ Max Unit

HSVR Voltage on Hin Pin 44 0 5 V

MinD Min Hin pulse duration Pin 44 0.7 us

Mduty Max Hin Duty Cycle Pin 44 25 %

VSVR Voltage on Vin Pin 1 0 5 V

VSW Min Vin pulse duration Pin 1 5 us

VSD Max VinDuty Cycle Pin 1 15 %

Electrical Characteristics (VDD= 5V, T

V

INTH

RIN Horizontal & Vertical Pull-Up Resistor 200 kΩ

Horizontal & Vertical Input Logic Level Low Level

amb

=25°C)

=25°C)

amb

0.8 V

High Level 2.2

o

C/W

V

5/38

4

Page 6

STV2000

I2C READ/WRITE

Electrical Characteristics (VDD= 5V, T

Symbol Parameter Test Conditions Min Typ Max Unit

F

T

T

HIGH

V

V

V

SCL

LOW

INL

INH

ACK

Maximum Clock Frequency 100 kHz

Low Period of the SCL Clock 1.3 us

High Period of SCLClock 0.6 us

SDA & SCL Input Low Level Voltage 1.5 V

SDA & SCL Input High Level Voltage 3 V

Acknowledge Output Voltage on SDA

input with 3mA

amb

=25°C)

0.4 V

HORIZONTAL SECTION

Operating Conditions

Symbol Parameter Test Conditions Min Typ Max Unit

VCO

Ro(min) Minimum Oscillator Resistor 6 kΩ

Co(min) Minimum Oscillator Capacitor 390 pF

Fmax Maximum Oscillator Frequency 150 kHz

OUTPUT SECTION

I

HFB

I

HOUT

Electrical Characteristics (VDD= 5V, T

Symbol Parameter Test Conditions Min Typ Max Unit

SUPPLY AND REFERENCE VOLTAGES

Vcc Supply Voltage 9.5 10.5 11.5 V

Vdd Supply Voltage 4.5 5 5.5 V

Icc Supply Current 30 mA

Idd Supply Current 5 mA

V

HREF

VVREF Vertical Reference Voltage I=-2mA 7.4 8 8.6 V

I

HREF

I

VREF

Horizontal FlyBack Input Maximum

Current

Horizontal Drive Output Maximum Sink

Current

=25°C)

amb

Horizontal Reference Voltage I=-2mA 7.4 8 8.6 V

Horizontal Reference Maximum Source

Current

Vertical Reference Maximum Source

Current

5mA

15 mA

5mA

5mA

6/38

4

Page 7

STV2000

Operating Conditions

Symbol Parameter Test Conditions Min Typ Max Unit

1st PLL SECTION

V

clamp

V

VCO

A

VCO

H

PHASE

VPMIN

VPTYP

VPMAX

I

PLL1-UL

I

PLL1-L

f

O

VCO clamp Voltage range V

VCO clamp Voltage, at POR V

VCO Gain

Horizontal Phase Adjustment Range % of Horizontal Period +/-10 %

Horizontal Phase

Minimum

Typical

Maximum

PLL1 Charge Pump Current

Free Running Frequency, no input

at POR, lower clamp voltage at max.

dfo/dT Free Running Frequency Thermal Drift -150 ppm/

2nd PLL SECTION & HORIZONTAL OUTPUT SECTION

V

THFB

Jitter

Flyback Input Threshold Voltage 0.65 0.75 V

Horizontal Jitter At 60KHz 70 ppm

H

Horizontal Drive Output Duty Cycle

H

DC

(Ratio of Power TransistorOFF time to

Period)

Vphi2 Internal Clamp Level on PLL2 Filter

VSCinh

Vsat

Threshold Voltage to Stop H-Out, V-Out,

Reset ABL when Vcc<VSCinh

Horizontal Drive Output Saturation

HD

Voltage

=8V 3.0 3.8 V

HREF

=8V 3.8 V

HREF

Ro=6490Ω, Co=820pF,

dF/dV=1/11RoCo

17.1 kHz/V

SubAdd 07

X1111111

X1000000

X0000000

Unlocked

Locked

2.8

3.4

4.0

+/-140

+/-1

Ro=6490Ω, Co=820pF 65 kHz

48 %

Low Level

High Level

1.6

4.0

6.9 V

Iout=15mA 0.4 V

V

V

V

µA

mA

V

V

o

C

7/38

4

Page 8

STV2000

VERTICAL SECTION

Symbol Parameter Test Conditions Min Typ Max Unit

Electrical Characteristics (VDD= 5V, T

VERTICALRAMP SECTION

V

RBOT

V

RTOP

V

RTOPF

T

VDIS

F

FRV

ASFR Auto-Sync Frequency Range C

RAFD

R

LIN

V

POS

VOR Vertical Output Peak to Peak Voltage

I

VOUT

V

VRB

dVS

EAST/WEST FUNCTION (output is internal, can be checked at EWFB pin indirectly)

EW

DC

TDEW

EW

PARA

Voltage at Ramp Bottom Point V

Voltage at Ramp Top Point with Sync V

Voltage at Ramp Top Point without Sync V

Vertical Sawtooth Discharge Time C

Vertical Free Running Frequency

(S correction inhibited)

Ramp Amplitude Drift Versus Frequency

at Maximum Vertical Amplitude

Ramp Linearity at Vcap pin

with S Correction inhibited

Vertical Position Adjustment Voltage

with V

mean value

OUT

Vertical Output Maximum Current +/-5 mA

Vertical Ramp Filter Voltage 2 V

Max Vertical S-Correction Amplitude

S-Correction inhibited, DV/Vpp at TV/4

S-correction Maximum,

DV/Vpp at 3TV/4

DC Output Voltage with Typical VPOS

and Keystone inhibited

With external driver connected as unity

gain buffer

DC Output Voltage Thermal Drift

DC

(Non-test Parameter)

Parabola Amplitude with Max VAMP,

Typ VPOS, Keystone inhibited

amb

=25°C)

=8V 2 V

VREF

=8V 5 V

VREF

V

-

=8V

VREF

=150nF 70 µs

OSC

=150nF 100 Hz

C

OSC

=150nF 50 165 Hz

OSC

=150nF 50Hz -

C

OSC

165Hz

2.5V < VOSC < 4.5V 0.5 %

Sub-Add=09

X0000000

X1000000

X1111111 3.65

Sub-Add=08

10000000

11000000

11111111 3.5

Sub-Add 0A

0XXXXXXX

11111111

Sub-add 0C

11111111

11000000

10000000

RTOP

0.1

200 ppm/Hz

3.2

3.5

3.8

2.25

3

3.75

-4

+4

2.0 V

100 ppm/

1.0

0.5

0

3.3 V

2.5 V

V

V

V

V

V

%

%

o

C

V

V

V

8/38

4

Page 9

STV2000

Symbol Parameter Test Conditions Min Typ Max Unit

Parabola Amplitude Function of VAMP

EW

track

Control (tracking between VAMP & EW)

with Typ VPOS, Keystone, Typ EW

Amplitude.

Keystone Adjustment Capability with

KeyAdj

Typ VPOS, EW inhibited and Max

Vertical Amplitude

Intrinsic Keystone Function of VPOS

Control (tracking between VPOS and

KeyTrack

EW) with Max EW Amplitude and

Max Vertical Amplitude

A/B Ratio

B/A Ratio

INTERNAL DYNAMIC HORIZONTAL PHASE CONTROL

Side Pin Balance Parabola Amplitude

SBPpara

with Max VAMP, Typ VPOS and

Parallelogram inhibited

Side Pin Balance Parabola Amplitude

SPBtrack

function of VAMP Control (tracking between VAMP & SPB) with Max SPB,

Typ VPOS and Parallelogram inhibited

Parallelogram Adjustment Capability

ParAdj

with Max VAMP, Typ VPOS and

Max SPB

Intrinsic Parallelogram Function of

VPOS Control (tracking between VPOS

Partrack

and DHPC) with Max VAMP, Max SPB

and Parallelogram inhibited

A/B Ratio

B/A Ratio

VERTICALBREATHING COMPENSATION

VBRrng Input DC Breathing Control Range 1 10.5 V

VBRadj

Vertical Output Variation versus DC

Breathing Control

HORIZONTAL SIZECONTROL

Hsize

Hsize output DC voltage

sitting on top of EWDC=2.0V

EW OUTPUT BUFFER

Iewout EWout pin max sourcecurrent 3.0 mA

EWFB EWoutput referred DC voltage 2.0 V

Sub-address 08

10000000

11000000

11111111

Sub-address 0B

10000000

11111111

Sub-add 09

X0000000

X1111111

Sub-add 0E

11111111

10000000

Sub-add 08

10000000

11000000

11111111

Sub-add 0F

11111111

10000000

Sub-add 09

X0000000

X1111111

Vbrin>V

VREF

Vbrin=4V

sub-add 0D

X0000000

X1111111

0.2

0.2

0.52

0.52

+1.4

-1.4

0.5

0.9

1.4

+1.4

-1.4

0.52

0.52

0

-10

0

2.4

V

V

%T

%T

%T

%T

%T

%T

%T

%

%

V

V

V

pp

pp

H

H

H

H

H

H

H

V

V

9/38

4

Page 10

STV2000

Symbol Parameter Test Conditions Min Typ Max Unit

HORIZONTAL BREATHING COMPENSATION

HBRdc Breathing input DC Control Range 1 10.5 V

Horizontal size compensation, EW DC

HSC

voltage variation under full range of

0.4 V

HBRdc

VIDEO PRE-AMP SECTION

Symbol Parameter Test Conditions Min Typ Max Unit

DC Electrical Characteristics (VAVCC=PVCC= 10.5V, Tamb = 25oC)

VAV

cc

Video Section Analog Supply Voltage

PVcc Power Section Supply Voltage 9.5 10.5 11.5 V

IS Supply Current of VAVcc & PVcc 60 mA

Video Input Voltage Amplitude 0.7 1 Vpp

Typical Output Voltage Range 0.5 7 V

Output DC level (Black level) 1.5 V

V

V

V

IN

OUT

DC

AC Electrical Characteristics (VAVCC=PVCC= 10.5V, CL = 12pF, RL = 1KΩ, Tamb = 25oC)

Symbol Parameter Condition Min Typ Max Unit

AV Maximum Gain

CAR Contrast Attenuation Range

DAR Drive Attenuation Range 30 dB

GM Gain Match

BW Large Signal Bandwidth

DIS Video Output Distortion f=1MHz, V

t

R,tF

Video Output Rise and Fall Time

dVo Overshoot of output with respect to

actual output amplitude

BRT Brightness max DC level

Brightness min DC level

R

L

Equivalent Load on Video Output Tj<Tj

Tsample Hold time 100 ms

Max Contrast and Drive

2

C Gainwin = 1

I

= 0.7Vpp

V

IN

Contrast and Drive at

POR

= 0.7Vpp,

V

IN

= 4Vpp, Contrast

V

OUT

and Drive= 0.87Max

V

=0.7Vpp,

IN

= 4Vpp, Contrast

V

OUT

and Drive = 0.87Max

At -3dB

=1Vpp,

IN

= 1Vpp

V

OUT

V

= 0.7Vpp,

IN

=4Vpp,Contrast

V

OUT

and Drive=0.87Max

=5pF 5 7 %

C

LOAD

MAX

9.5 10.5 11.5 V

18 dB

30 dB

+-0.1 dB

70 MHz

0.3 %

5ns

2.5

0

1kΩ

V

V

10/38

4

Page 11

STV2000

Symbol Parameter Test Conditions Min Typ Max Unit

Thold Sample time 1 µs

= 0.7Vpp,

V

IN

= 2.5Vpp,

CT Crosstalk Between Video Channels

CUTOFF

V

CUTOFF

I

CUTOFF

CUTOFF DAC output voltage

Output sink current

Output source current 2

ABL COMPENSATION

V

OUT

Contrast and

Drive=0.7Max

f=1MHz

00000000

10000000

11111111

44 dB

0.5

2.5

4.5

100 µA

V

V

V

mA

R

G

TH

ABL

ABL

ABL

ABL Input resistor 10 kΩ

ABL minimum Attenuation

ABL maximum Attenuation

ABL latch function activation threshold

(High beam current detection)

V

=5.3V

ABL

=2.8V

V

ABL

01V

0

12

DAC

sub-add 12

VDAC I

LOAD

=100uA

00000000

01000000

01111111

0.5

2.25

4.0

IDAC Source current 1.5 2 mA

LOGIC SECTION

DC Electrical Characteristics (VAVCC=PVCC= 10.5V, Tamb = 25oC)

Symbol Parameter Condition Min Typ Max Unit

V BLANKING OUTPUT SECTION

Blanking output high voltage 7 V

VBDC

Blanking output low voltage

I2C adjustable

I

T

BLK

BLK

Output sink current 0.3 mA

Vertical blanking time

(gated with Hflyback)

SUPPLY VOLTAGE THRESHOLD

V

THPD1

V

THPD2

Supply first threshold voltage 8.5 V

Supply second threshold voltage 6.9 V

sub-add10

1X000000

1X111111

1

4.5

22 H cycle

dB

dB

V

V

V

V

V

11/38

4

Page 12

STV2000

I2C BUS ADDRESS TABLE

[0] denotes POR value, X denotes unused data bit and must be set to 0.

D8 D7 D6 D5 D4 D3 D2 D1

WRITE MODE (SLAVE ADDRESS= 8C)

Video: 1, on

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D x

0E

0F

10

11

12

13x xxx

[0], off

[1] [0] [1] [1] [0] [1] [0] [0]

[1] [0] [1] [1] [0] [1] [0] [0]

[1] [0] [1] [1] [0] [1] [0] [0]

[0] [0] [0] [0] [1] [0] [0] [0]

[0] [0] [0] [0] [1] [0] [0] [0]

[0] [0] [0] [0] [1] [0] [0] [0]

Hout

0, off

[1], on

Vramp

0, off

[1], on

Xray

1, reset

[0]

S Select

1, on

[0], off

EW Key

0, off

[1], on

EW Select

0, off

[1], on

SPB Sel

0, off

[1], on

Parallelog

0, off

[1], on

VBDC

1, on

[0], off

POR

[0], off

1, reset

[1] [0] [1] [1] [0] [1] [0]

Cut off 1

Cut off 2

Cut off 3

Horizontal Phase Adjustment

[1] [0] [0] [0] [0] [0] [0]

Vertical Ramp Amplitude Adjustment

[1] [0] [0] [0] [0] [0] [0]

Vertical Position Adjustment

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

[1] [0] [0] [0] [0] [0] [0]

Gainwin

[0], 1X

1, 1.5X

Powsav

1, on

[0], off

[1] [0] [0] [0] [0] [0] [0]

[1] [1] [1] [1] [1] [1]

[1] [0] [1] [1] [0] [1]

Contrast

Drive 1

Drive 2

Drive 3

S Correction

Keystone

EW Amplitude

Horizontal Amplitude

Side Pin Balance

Parallelogram

Vertical Blanking DC level

Brightness

DAC

PLL1 filter voltage clamp (FVC)

[0] [0] [0] [0]

12/38

4

Page 13

D8 D7 D6 D5 D4 D3 D2 D1

READ MODE (SLAVE ADDRESS = 8D)

Hlock

0, lock

[1], unlock

Xray

1, on

[0], off

Figure 1. EW Output Referred Voltage

A

EW

DC

Figure 2. Dynamic Horizontal Phase Control Output

EW

STV2000

B

PARA

EW

A

DHPC

DC

SPB

Figure 3. Keystone Effect on EW Output (PCC Inhibited)

PARA

PARA

B

Keyadj

13/38

4

Page 14

STV2000

TYPICAL OUTPUT WAVEFORMS

Function

Vertical Size

Vertical

Position

Vertical

S

Linearity

Sub

Address

Pin Byte Specification Effect on Screen

2.25 V

10000000

3.75 V

11111111

x0000000

x1000000

x1111111

V

V

V

OUTDC

OUTDC

OUTDC

= 3.2 V

= 3.5 V

= 3.8 V

00000000

Inhibited

11111111

V

PP

Keystone

EW

Pin Cushion

14/38

EW

Inhibited

10000000

11111111

EW

Inhibited

10000000

11111111

2.0V

2.0V

2.0 V

2.0 V

0.2Vpp

0.2Vpp

1.0 V

4

Page 15

STV2000

Function

H Amplitude

H Phase

Side Pin

Ballance

Control

Sub

Address

Pin Byte Specification Effect on Screen

10000000

11111111

5V

00000000

01111111

5V

Parallelogram

Inhibited

10000000

11111111

3.7 V

1.4%

1.4%

3.7 V

Parallelo-

gram

Control

SPB

Inhibited

10000000

11111111

3.7 V

3.7 V

1.4%

1.4%

15/38

4

Page 16

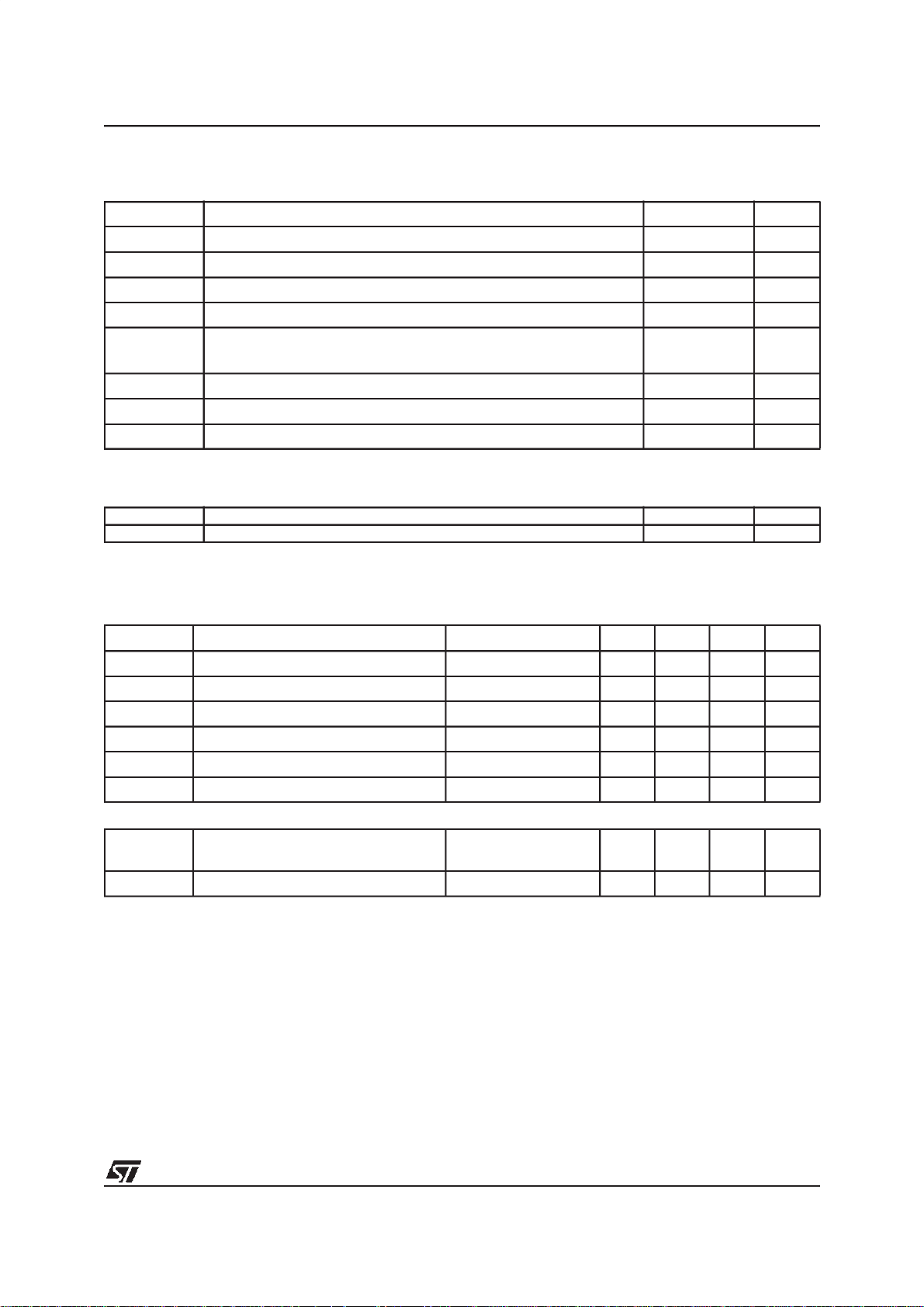

Contrast Register (Video IN = 0.5VPP, Drive at maximum, I2C Gainwin=1)

Hex b7 b6 b5 b4 b3 b2 b1 b0 Vpp G(dB) POR

000000000 -

000000010.015-30

000000100.031-24

000001000.062-18

000010000.125-12

0 0 0 1 0 0 0 0 0.25 -6

001000000.50

01000000212

010110102.81215 X

01111111418

Brightness Register (Drive at maximum)

Hexb5b4b3b2b1b0VppPOR

0000000

0000010.010

0000100.020

0001000.040

0010000.08

0100000.16

1000000.32

0000000.64

0000001.28

1011011.8X

1111112.56

Drive1, Drive2, Drive3 Registers (Video IN = 0.5VPP, Contrast at maximum, I

Hex b7 b6 b5 b4 b3 b2 b1 b0 Vpp G(dB) POR

00000000000 01 0 0 0 0 0 0 0 1 0.015 -30

02 0 0 0 0 0 0 1 0 0.031 -24

04 0 0 0 0 0 1 0 0 0.062 -18

08 0 0 0 0 1 0 0 0 0.125 -12

10 0 0 0 1 0 0 0 0 0.25 -6

20001000000.50

40010000001 6

8010000000212

B4101101002.81215 X

FF11111111418

2

C Gainwin=1)

16/38

5

Page 17

STV2000

Cutoff1, Cutoff2, Cutoff3 Output values

Hexb7b6b5b4b3b2b1b0FBpinPOR

00000000000.5

0100000001

0200000010

0400000100

08000010000.625 X

1000010000

2000100000

4001000000

8010000000

B410110100

FF111111114.5

DAC Output DC voltage

Hex b6 b5 b4 b3 b2 b1 b0 Output dc POR

00000000.5

0000001

0000010

0000100

0001000

0010000

0100000

1000000

10000002.25 X

0110100

11111114.0

Vertical Blanking Output DC voltage

Hex b5 b4 b3 b2 b1 b0 Output dc POR

0000001.0

000001

000010

000100

001000

010000

100000

000000

000000

110100

1111114.5X

17/38

5

Page 18

STV2000

OPERATING DESCRIPTION

A SCANNING PART

1. GENERAL CONSIDERATIONS

1.1 Power Supply

Typical power supply voltages are 10.5 V for the

Deflection and Preamplifier sections (SAVCC,

VAVCCand PVCC) and 5.0 V for the logic section

(Vdd). Optimumoperation is obtainedbetween 9.5

and 11.5 for VCC, and between 4.5 and 5.5 V for

VDD.

VCCis monitored during the transient phase when

switched either on or off, to avoid erratic operation

of the circuit. If VCCis inferior to 6.9 V typ., the circuit outputs are inhibited. Similarly, before V

reaches 4 V, all the I2C registers are reset to their

default value (see I2C Control Table).

The circuit is internally supplied by several voltage

references (typ. value: 8 V) to ensure a good power supply rejection. Two of these voltage references are externally accessible respectively for the

vertical and horizontal parts. They can be used to

bias external circuitry if I

To minimize the noiseand consequently the ”jitter”

on vertical and horizontal output signals, the reference voltages must be filtered by external capacitors connected to the ground.

1.2 I2C Control

STV2000 belongs to the I2C-controlled device

family. Each adjustment can be made via the I2C

Interface, insteadof being controlled by DC voltages on dedicated control pins. The I2C bus is a serial bus with a clock and a data input. General

function and bus protocol are specified in the

Philips-bus data sheets. The interface (Data and

Clock) is TTL-compatible. Spikes up to 50 ns are

filtered by an integrator and the maximum clock

speed is limited to 100 kHz.

The data line (SDA) can be used bidirectionally. In

read mode, the IC sends reply information (1 byte)

to the micro-processor.

The bus protocol prescribes a full-byte transmission in all cases. The first byte after the start condition is used to transmit the IC address (hexa 8C

for write, 8D for read).

All bytes are sent MSB bit first and the write data

transfer is closed by a stop.

is inferior to 5 mA.

LOAD

DD

1.3 Write Mode

In write mode, the second byte contains the subaddress of the selected function to adjust (or controls to effect)and the third byte the corresponding

data byte. More than one data byte can be sent to

the IC. If after the third byte no stop or start condition is detected, the circuit automatically increments the momentary subaddress in the subaddress counter (auto-increment mode) by one.

Thus it is possible to immediately transmit the following data bytes without sending the IC address

or subaddress. This can be useful for reinitializing

all the controls very quickly (flash manner). This

procedure is ended with a stop condition.

There are 19 adjustment capabilitiesfor the circuit:

3 for the horizontal part, 3 for the vertical, 3 for the

E/W correction, 2 for the dynamic horizontal phase

control, 7 for the preamplifier and 1 for the blanking DC. 14 bits are also dedicated to several controls (ON/OFF).

1.4 Read Mode

In the read mode the second byte transmitsthe reply information. The reply byte contains the horizontal and vertical lock/unlock status, the XRAY

activation status. A stop condition always stops all

the activities of the bus decoder and switches both

the data and clock line (SDA and SCL) to high impedance. See I2C subaddress and control tables.

1.5 Sync Processor

The internal sync processor allows the device to

receive separate horizontal & vertical TTL-compatible sync signals.

1.6 IC Status

The IC informs the MCU about both the 1st horizontal PLL (locked or not) and the XRAY protection (activated or not). The XRAY internal latch is

reset either directly via the I2C interface or by decreasing the VCCsupply.

1.7 Sync Inputs

Both HIN and VIN inputs are TTL compatible triggers with hysterisis to avoid erratic detection. Both

inputs include a pull-up resistor connected to VDD.

Synchro pulses must be positive.

18/38

6

Page 19

STV2000

OPERATINGDESCRIPTION (continued)

1.8 Sync Processor Output

The sync processor indicates whether 1st PLL is locked to an incoming horizontal sync or not. This is indicated on the D8 bit of the status register . PLL1 level is low when locked.

2. HORIZONTAL PART

2.1 Internal Input Conditions

A digital signal (horizontal sync pulse) is sent by

the sync processor to the horizontal input. It must

be positive (see Figure 4).

Synchronization occurs on the leading edge of the

internal sync signal.

The minimum value of Z is 0.7 µs.

Vertical synchro extraction is not allowed.

Figure 4.

Z

T

2.2 PLL1

The PLL1 consists of a phase comparator, an external filter and a voltage-controlled oscillator

(VCO). The phase comparator is a ”phase frequency” type designed in CMOS technology. This

kind of phase detector avoids locking on wrong

Figure 6. Block Diagram

frequencies. It is followed by a ”charge pump”,

composed of two current sources: sunk and

sourced (typically I =1mA when locked and

I = 140 µA when unlocked). This difference between lock/unlock allows smooth catching of the

horizontal frequency by PLL1. This effect is reinforced by an internal original slow down system

when PLL1is locked, preventing the horizontal frequency from changing too quickly. The dynamic

behaviour of PLL1 is fixed by an external filter

which integrates the current of the charge pump. A

”CRC” filter is generally used (see Figure 5).

Figure 5.

PLL1F

40

1.8kΩ

10nF

4.7µF

H/HVIN

44

LOCKDET

COMP1

High

Low

Lock/Unlock

Status

CHARGE

PUMP

39 Filter

PHASE

ADJUST

PLL1F R0 C0

40 42 41

VCO

OSC

2

C

I

HPOS

Adj.

FC1

43

19/38

6

Page 20

STV2000

OPERATINGDESCRIPTION (continued)

Figure 7. Details of VCO

I

0

PLL1F

(Loop Filter)

(1.4V<V7<6.4V)

40

42

4I

R0

I

0

2

0

41

6.4V

1.6V

C0

6.4V

1.6V

0 0.875T

RS

FLIP FLOP

T

H

H

The VCO uses an external RC network. It delivers

a linear sawtooth resulting from the capacitor

charge and discharge . The current is proportional

to the one in the resistor. Typical thresholds for the

sawtooth are 1.6 V and 6.4 V.

The VCO control voltage varies between 3.0 V

and 3.8V (see Figure 7). This VCO frequency

range is very small. The small effective frequency

is dueto clamp intervention on the lowest filter value. The PLL1F filter voltage is set by a 4-bit DAC

with a voltagerange of 3.0 to 3.8 V.

The sync frequency must always be higher than

the freerunning frequency. For example, whenusing a 60 kHz synchro range, the suggested free

running frequency is 56 kHz.

Figure 8. PLL1 Timing Diagram

HO

SC

Sawtooth 7/8 TH

Phase REF1

1/8 TH

PLL1 ensures the coincidence between the leading edge of the sync signal and a phase reference

resulting from the comparison of:

– the VCO sawtooth

– an internal DC voltage I2C adjustable within the

range of 2.9V to 4.2V (corresponding to ±10%)

(see Figure 8).

A Lock/Unlock identification block, also included,

detects in real time whether PLL1 is locked on the

incoming horizontal sync signal or not.

The lock/unlock information is available through

the I2C read.

The FC1 Pin (Pin 43) is used for decoupling the internal 6.4 V reference by a capacitor.

6.4V

3.4V (Reference for H Position)

Vb

(2.8V<Vb<4.2V)

1.6V

HSynchro

Phase REF1 is obtained by comparison between the sawtooth and a DC voltage adjustable between 2.9 V and 4.2 V.

The PLL1 ensures the exact coincidence between the signal phase REF and HSYNC.

A ±10% T

20/38

phase adjustment is possible around the 3.5V point.

H

6

Page 21

OPERATINGDESCRIPTION (continued)

STV2000

2.3 PLL2

PLL2 ensures a constant position of the shaped

flyback signal in comparison with the sawtooth of

the VCO, taking into account the saturation time

Ts (see Figure 9).

Figure 9. PLL2 Timing Diagram

H Osc

Sawtooth

7/8T

H

1/8T

H

6.4V

4.0V

1.6V

Flyback

Internally

Shaped

Flyback

H Drive

Ts

duction period of the horizontal scanning transistor.

The maximum storage time (Ts Max.) is :

0.44TH-T

Typically, T

FLY

FLY/TH

/2).

corresponds to around 20 %

which means that Ts max represents approxim

tively 34 % of TH.

2.4 Output Section

The H-drive signal is sent to the output through a

shaping stage which also controls the fixed Hdrive duty cycle (see Figure 9). In order to secure

the scanning power part operation, the output is inhibited in the following cases :

-when VCCis too low,

-when the ABL protection is activated,

-during the Horizontal flyback,

-when the HDrive I2C bit control is off.

The output stage consists of a NPN bipolar tran-

sistor. Only the collector is accessible

(see Figure 11).

Figure 11.

V

CC

Duty Cycle

The phase comparator of PLL2 (phase type comparator) is followed by a charge pump (typical output current: 0.5 mA).

The flyback input consists of an NPN transistor.

This input must be current driven. The maximum

recommended input current is 5 mA

(see Figure 10).

Figure 10. Flyback Input Electrical Diagram

400Ω

HFLY 36

20kΩ

GND 0V

Q1

The duty cycle is fixed at 48%. For a safestart-up

operation, the initial duty cycle (after power-on reset) is 85% in order to avoid having too long a con-

Hout

34

This output stage is intended for ”reverse” base

control, where setting the output NPN in off-state

will control the power scanning transistor in offstate.

The maximum output current is 15 mA, and the

corresponding voltage drop of the output V

0.4 V Max.

CEsat

Obviously, the power scanning transistor cannot

be directly driven by the integrated circuit. An interface either bipolar or MOS type has to be added

between the circuitand the power transistor.

is

21/38

6

Page 22

STV2000

OPERATINGDESCRIPTION (continued)

2.5 X-RAYProtection

X-Ray protection is activated when the ABL input (1 V on Pin 20) is at a low level. It inhibits both H-Drive,

and Vout while Video goes into off-mode.

This activation is internally delayed by 2 lines to avoid erratic detection (short parasitics).

This protection is latched; it may be reset eitherby switching VCCoff or by I2C (see Figure 12).

Figure 12. Safety Functions Block Diagram

VCCChecking

V

+1V

CC

VSCinh

XRAYProtection

+

20

ABL

VCCoff or I2C Reset

Horizontal Flyback

0.7V

3. VERTICAL PART

3.1 Function

When the synchronization pulse is not present, an

internal current source sets the free running frequency. For an external capacitor, C

OSC

= 150nF,

the typical free running frequency is 100Hz.

The typical freerunning frequency can be calculat-

ed according to:

fo(Hz) = 1.5.10

-5 .

C

1

OSC

A positive TTL level pulse applied on Pin 1(Vin) is

used to synchronize the ramp in the range [fmin,

fmax] (see Figure 13). This frequency range depends on the external capacitor connected on Pin

5. A 150nF (± 5%) capacitor is recommended for

50 Hz to 165 Hz applications.

The typical maximum and minimum frequency, at

25oC and without any correction (S correction),

I2C Drive on/off

HORIZONTAL

OUTPUT

INHIBITION

I2C Ramp on/off

S

Q

R

VERTICAL

OUTPUT

INHIBITION

Video-off

can be calculated as follows:

f(Max.) = 3.5 x foand f(Min.) = 0.33 x f

o

When an S correction is applied, these values are

slightly modified.

With a synchronization pulse, the internal oscillator is synchonized immediately but its amplitude

changes. An internal correction then adjusts it in

less than half asecond. The ramp top value (Pin 5)

is sampled on the AGC capacitor (Pin 3) at each

clock pulse. A transconductance amplifier modifies the charge current of the capacitor so as to

make the amplitude constant again. We recommend using an AGC capacitor with a low leakage

current. A value lower than 100nA is mandatory.

A good level of stability forthe internal closed loop

is obtained by a 470nF ± 5% capacitor value on

Pin 3 (VAGC).

VRB (Pin 8) is used for decoupling the internal 2V

reference voltage by a capacitor.

22/38

6

Page 23

OPERATINGDESCRIPTION (continued)

STV2000

3.2 I2C Control Adjustments

S correction shapes can then be added to this

ramp. This frequency-independent S correction is

generated internally. Its amplitudes is adjustable

via the I2C. Scorrection can beinhibited by applying the selected bits.

Finally, the amplitude of the S corrected ramp is

adjustable via the vertical ramp amplitude control

register.The adjusted ramp is available on Pin 6

(V

) to drive an external power stage.

OUT

Figure 13. AGC Loop Block Diagram

DISCH.

VSYNCIN

1

SYNCHRO OSCILL ATOR

The gain of this stage can be adjusted (± 25%) depending on its register value.

The mean value of this ramp is driven by its own

I2C register (vertical position) with :

VPOS = 7/16 x V

Usually V

is sent through a resistive divider to

OUT

REF-V

= ± 300 mV.

the inverting input of the booster. Since VPOS derives from V

inverting input of the booster should also derive

from V

REF-V

,the bias voltage sent tothenon-

REF-V

to optimize the accuracy

(see Figure 13).

TRANSCONDUCTANCE

CHARGECURRENT

5

OSC

CAP

Vlow

Sawth

Disch

VERTAMP

SUB08/7bits

VPOSITION

SUB09/7bits

SAMPLING

.

AMPLIFIER

REF

3

SAMPLING

CAPACITANCE

SCORRECTION

VSAMP

SUB07/7bits

7

BREATH

6VOUT

3.3 Basic Equations

As a first approximation, the amplitude of the ramp

on Pin 6 (VOUT) is calculated as follows:

V

- VPOS = (V

OUT

OSC-VDCMID

) x (1 + 0.25 (V

AMP

))

where :

V

DCMID

=7/16xV

(middle value of the ramp on

REF

Pin 5, typically 3.6V)

V

OSC=V5

V

AMP

(ramp with fixed amplitude)

= -1 as minimum vertical amplitude register

value and +1 as maximum value.

VPOS is calculated according to:

VPOS = V

DCMID

+ (0.4x VP)

where VP= -1 and +1 as respectively minimum

and maximum vertical position register value.

The current available on Pin 5 is:

I

OSC

where

C

OSC

3

=xV

8

REFxCOSC

xf

= capacitor connected on Pin 5

f = synchronization frequency.

23/38

6

Page 24

STV2000

OPERATINGDESCRIPTION (continued)

3.4 Geometric Corrections

The principle is represented in Figure 14.

Starting from thevertical ramp, a parabola-shaped

current is generated for E/W correction (also

known as Pin Cushion correction), dynamic horizontal phase control correction.

The parabola generator consists of an analog multiplier, the output current of which is equal to :

∆I=kx(V

where V

- V

OUT

is the vertical output ramp (typically

OUT

between 2 and 5 V) and V

(for V

= 8.2V). The VOUT sawtooth is typical-

REF-V

DCMID

)

2

DCMID

is 3.6 V

ly centered on 3.6 V. By changing the vertical position, the sawtooth shifts by ±0.4 V.

The ”geometry tracking” feature ensures a correct

screen geometry for any end user adjustment. It

generates non-symmetric parabola dependent on

the vertical position.

Due to the large output stage voltage range (E/W

Pin Cushion, Keystone), the combination of the

tracking function, maximum vertical amplitude,

maximum or minimum vertical position and maxi-

Figure 14. Geometric Corrections Principle

mum gain on the DAC control may lead to output

stage saturation. This must be avoided by limiting

the output voltage with appropriate I2C register

values. For the E/W part and the dynamic horizontal phase control part, a sawtooth-shaped differential current in the following form is generated:

∆I’= k’.(V

OUT

- V

DCMID

).

Then ∆I and ∆I’ are added and converted into voltage for the E/W part.

Each of the two E/W components or the two dynamic horizontal phase control components may

be inhibited by their own I2C select bit.

Internal EW correction voltage is not available directly on the output pin. The EW correction is obtained with the feedback voltage (Pin 27: EWBin)

which generates a modulating current in the diode

(Pin 28). In addition, the horizontal width is I2Ccontrolled.

The dynamic horizontal phase control drives the

H-position internally, moving theHFLY position on

the horizontal sawtooth in the range of ± 2.8 %T

both for side pin balance and parallelogram.

H

3.5 E/W

EWOUT = EWDC+K1(V

OUT

- V

DCMID

) +K2 (V

OUT

- V

DCMID

2

)

K1 is adjustable via the keystone I2C register. K2 is adjustable via the E/W amplitude I2C register.

24/38

6

Page 25

OPERATINGDESCRIPTION (continued)

3.6 Dynamic Horizontal Phase Control

I

OUT

=K4(V

OUT

- V

DCMID

) + K5 (V

OUT

- V

DCMID

2

)

K4 is adjustable via the parallelogram I2C register.

K5 is adjustable via the side pin balance I2C register.

3.7 Horizontal Breathing

Horizontal breathing compensation is performed

through the EW stage with the Voltage-Current

Converter. This DC-controlled input provides the

required horizontal width corrections to offset

width changes arising from EHT variations.

B PRE-AMPLIFIER PART

1. GENERAL CONSIDERATIONS

STV2000

3.8 Vertical Breathing

Vertical breathing compensation is performed

through the gain modulation of the vertical ramp.

This DC-controlled input provides the vertical

height corrections required to offset height changes arising from EHT variations.

1.1 Input Stage

The R, G and B signals must be supplied to the

three inputs through coupling capacitors (100nF).

The maximum input peak-to-peak video amplitude

is 1 V.

Figure 15. .

HSYNC

BPCP

Internal pulse width is fixed at 1µs

In both cases, BPCP width is fixed.

1.2 Contrast Adjustment (7 bits)

The contrast adjustment is made bysimultaneously controlling the gain of three internal variable

gain amplifiers through the I2C bus interface. The

contrast adjustment allows covering a range higher than 40 dB. This adjustment is refreshed during

the vertical retrace time.

1.3 ABL Control

The STV2000 has an ABL input (automatic beam

limitation) to attenuate RGB video signals according to beam intensity.

The inputstage includes a clamping function. This

clamp uses the input serial capacitor as ”memory

capacitor” and is gated by an internally generated

”Back-Porch-Clamping-Pulse (BPCP)”.

The BPCP is synchronized on the second edge of

the horizontal pulse HIN inputs on Pin 44.

The operating range is typically 2.5 V, from 5.3V

to 2.0 V. A typical 12 dB Max. attenuation is applied to the signal whatever the current gain. Refer

to Figure 16 for ABL input attenuation range.

In the case of software control, the ABL input must

be pulled to AVCCthrough a resistor to limit power

consumption.

ABL input voltage must not exceed VAVCC. Input

resistor is 10kΩ.

25/38

6

Page 26

STV2000

OPERATINGDESCRIPTION (continued)

Figure 16.

Attenuation (dB)

2

0

-2

-4

-6

-8

-10

-12

-14

123456789

V

(V)

IN

1.4 Brightness Adjustment (6 bits)

As with contrast adjustment, brightness is controlled by I2C.

The brightness function consists of adding the

same DC offset to the three R, G, B signals after

contrast amplification. This DC-Offset is present

only outside the blanking pulse (see Figure 18).

The DC output level is forced to ”INFRA-BLACK”

level (VDC) during the blanking pulse.

1.5 Drive Adjustment (3 x 8 bits)

To adjust the white balance, the device offers the

possibility of separately adjusting the overall gain

of each complete video channel. Each channel

gain is controlled by I2C (8 bits each). The very

large drive adjustment range (48dB) allows different standard or custom color temperatures.

The drive adjustment is also used to adjust the

output voltages at the optimum amplitude to drive

the C.R.T drivers, keeping the whole contrastcontrol for end-users only. The drive adjustment is

made after the contrast and brightness so that the

white balance remains correct when BRT is adjusted.

1.6 Output Stage

The three output stages (see Figure 17) incorporate three functions:

• The blanking stage: when the internal

generated blanking pulse is high, the three

outputs are switched to a voltage which is

400 mV lower than the BLACK level. The

black level is the output voltage with minimum

brightness when the input signal video

amplitude is equal to ”0”.

• The output stage itself: a large bandwidth

output amplifier which can deliver up to 5V

PP

on the three outputs (for 0.7 V video signal on

the inputs).

• The output CLAMP: the IC also incorporates

three internal output clamps (sample and hold

system) used for the DC to shift the three

output signals. The DC output voltage is fixed

at 1.5 V.

The overall waveforms of the output signal according to the different adjustments are shown in

Figure 18.and Figure 19.

Figure 17.

26/38

6

Cut-off

DAC

8 bits

S/H

1.5V

10

11

Vout

Cut-off

CRTDriver

STV2000

Page 27

OPERATINGDESCRIPTION (continued)

Figure 18. Waveforms VOUT,BRT, CONT

HSYNC

BPCP

BLK

Video IN

V

OUT1,VOUT2,VOUT3

(4)

V

CONT

STV2000

(3)

V

BRT

(2)

V

BLACK

(1)

V

DC

Note : 1. VDC= 1.5V

2. V

BLACK=VDC

3. V

BRT=VBLACK

4. V

CONT=VBRT

+ 0.4V

+ BRT (with BRT = 0 to 2.5V)

+ CONT with CONT = k x video (CONT = 5VPPmax. for VIN= 0.7VPP)

Figure 19. Waveforms (DRIVE adjustment)

HSYNC

BPCP

BLK

Video IN

,

V

OUT1VOUT2

, V

OUT3

CONT

BRT

0.4V fixed

V

CONT

V

BRT

V

BLACK

V

DC

twoexamples of

driveadjustment

(1)

Note : 1. Driveadjustment modifiesthe followingvoltages : V

Driveadjustment does not modify the followingvoltages : V

DC

.

andV

CONT,VBRT

.

BLACK

.

27/38

6

Page 28

STV2000

OPERATINGDESCRIPTION (continued)

1.7 Cutoff DAC Output

Three Cutoff DACs (8 bits) with output buffers are

incorporated to drive the external cutoff circuit.

Output voltage range is from 0.5 V to 4.5 V.

1.8 Blanking Generator

A vertical blanking pulse is generated

(see Figure 20). The output level is a positive going pulse of 8V. The vertical blanking is started by

the vertical sync pulse and the duration is determined by counting 22horizontal periods. If there is

Figure 20. VBDC (Pin 24) Output Voltage Waveform

22Hlines

DClevelcontrolledby

6-bit DAC

1.9 DAC Output

This is a 7-bit DAC with 1 output pin. An output

buffer is used to enhance load capability with an

Imax(source) of 2 mA.

no vertical sync pulse the vertical blanking start

coincides with the beginning of the vertical capacitor discharge time.

The blanking output generates a superimposed

variable DC voltage. The 6-bit adjustment range is

1 V to 4.5 V. This is used to allow brightness control through G1. Additionally, this pin is used for

spot killer suppression. The 0.8 V of Vcc threshold

will trigger the output into a high level state resulting from the Vcc decay.

8V

4.5V

1.0V

Table1: Logic Table

Conditions Hout Vout Video-off Low Power

at 0 to 6.9 V (PD2 mode) no no video-off NA (1)

V

cc

at 6.9 V to 8.5 V (PD1 mode) yes yes video-off NA(1)

V

cc

2

C DPMS bit=1, (default=0) no no video-off yes

I

Hlock/unlock detection = unlock yes yes video-off no

Video ABL input pin < 1 V no no video-off no

5VPORorI

2

C Houton/off, (default=1=on) on/off yes on/off no

I

2

C Vout on/off, (default=1=on) yes on/off on/off no

I

2

C Video on/off, (default=0=video-off) yes yes on/off no

I

at >8.5 V yes yes video-on (2) NA (1)

V

cc

at >8.5 V, I2C video=1=on yes yes video-on (2) no

V

cc

Note 1 NA= Not applicable.

Note 2 I

2

C POR=1, (default=0) yes yes video-off no

2

C video=on will be reset by I2CDPMS/Low Vcc.

28/38

6

Page 29

OPERATINGDESCRIPTION (continued)

C STAND-BY MODE AND PROTECTIONS

1. GENERAL CONSIDERATIONS

STV2000

1.1 POR (Power On Reset) - Subadress 11- D8

POR is activated on 5 V with default values for

each adjustment and in addition video off (see

1.3). It can be activated via the I2C command.

1.2 Supply Voltage Threshold.

Two built-in thresholds (see figure 21) are used to

enter the following modes:

• PDI mode:

– Activated for Vcc < 8.5V

– Video off (see 1.13)

• PD2 mode:

– Activated for Vcc < 6.9V

– Video off (see 1.13)

–H

1.3 Video Off (I2C control) - Subadress 00 - D8

Activates blanking of the 3 video output stages.

During this time the outputs are switched to

ground level, regardless of the presence of Hsync

or Hflyback. Activation time is inferior to 1µs.

OUT

and V

OUT

disabled

This also activates the blanking output generating

a positive going signal at pin 24 as long as “video

off” is activated.

1.4 Vertical Output Off

This command will switch off output VAMP. The

vertical output swing is reduced to 0V.

During power saver mode, the total vertical section

is disabled.

1.5 Power Saver On - Subadress 11 - D7

This I2C command activates the PD1 and PD2

mode regardless of the scanning Vcc value. Internal scanning and pre-amp voltage are off. During

“power saver” mode, the device power consumption will be reduced to below 20mA for all supply

pins. Vdd, I2C interface and DAC data are not affected by this command.

1.6 X-Ray, Set Operation - Subadress 09 - D8

When ABL voltage is below 1 V threshold, Xray

latch will be activated. This I2C command will reset

the Xray latch. Activation time below 100ms.

29/38

Page 30

STV2000

INTERNAL SCHEMATICS

Figure 21.

Figure 22.

Vref

1+

44

2

V

DD

SAV

CC

200Ω

Ω

200k

22k

Figure 24.

SAV

CC

4

Vgnd

Figure 25.

SAV

CC

5

VCAP

Ω

Figure 23.

VAGCCAP 3

30/38

7

SAV

CC

Figure 26.

SAV

VOUT 6

CC

Page 31

INTERNAL SCHEMATICS (continued)

STV2000

Figure 27.

BREATH

V

Figure 28.

VAV

Figure 30.

VAV

CC

IN

Agnd

Agnd

7

SAV

CC

Pins

19

21

23

Figure 31.

10k

Internal

5V

Ω

VAV

CC

CC

9

12V

BIPSWITCH

20

Figure 29.

PV

Pgnd

CC

AGND

VAV

Agnd

CC

Pins 10, 13, 16

Figure 32.

Pin 11

14

17

VAV

Agnd

Agnd

CC

10k

Ω

31/38

7

Page 32

STV2000

INTERNAL SCHEMATICS (continued)

Figure 33.

Agnd

Figure 34.

12

Pgnd

15

VAV

CC

Figure 36.

DAC

Figure 37.

VBDC

VAV

24

VAV

22

CC

AGND

CC

50

Ω

Figure 35.

32/38

7

PV

VAV

CC

CC

18

Figure 38.

HBreath

SAV

26

CC

60K

Vref

Page 33

INTERNAL SCHEMATICS (continued)

STV2000

Figure 39.

EWFB

Figure 40.

EWout

SAV

SAV

27

28

CC

CC

10k

1.5k

Vref

Vref

Figure 42.

SDA

Figure 43.

SCL

30

31

5V

5V

10K

10k

V

DD

V

DD

Figure 41.

Figure 44.

V

29

DD

5V

BIPSWITCH

SAV

CC

32

12V

BIPSWITCH

33/38

7

Page 34

STV2000

INTERNAL SCHEMATICS (continued)

Figure 45.

Figure 46.

Lgnd

HOUT

34

33

SAV

CC

Figure 48.

HFLY

Figure 49.

SAV

36

Hgnd

CC

37

Href

35

Figure 47.

SAV

Href

34/38

7

cc

35

22kΩ

Figure 50.

38PLL2C

SAV

CC

Href

Page 35

INTERNAL SCHEMATICS (continued)

STV2000

Figure 51.

Figure 52.

PLL1F

SAV

40

CC

SAV

39Filter

CC

Href

Href

Figure 54.

Figure 55.

FC1

SAV

43

SAV

42

CC

CC

Href

1K

_

3

4K

_

3

Href

35

Figure 53.

SAV

41

CC

Href

35

Figure 56.

VRB

SAV

CC

Vref

R1

8

R2

35/38

7

Page 36

STV2000

Figure 57. STV2000 Demonstration Board Schematics

Vcc

47K

C11

100n10u

C10

MC14528

C12

47K

R37

Vcc

HFLY

R38

16

VCC

TA1

1

47p

C9

47p

TB1

TA2

2

Delay

Width

14

TB2

CDA

3

Vcc

R16 10K

13

CDB

1A

4

121511

1B

N1A

5

Vcc

N1B

QA

6

10

QB

NQA

7

9

NQB

GND

8

R15 10K

C7 33p

Vcc

C6 10u

R13 1K

Hout

D1 1N4148

R12 560

R17

Vcc

5V

SDA

SCL

GND

C5

R11 100

C4

22p

22p

+5V

R8 4K7

R9 4K7

R10 100

EW

1K

BD677

C8 33p

R14 10K

C37

C36

4u7

HIN

1K8

HREF

47u

100n

22n

C35

C32

820p

6490

100n

C33

R36

VIN

C34

10n

C31

C30

R35

2K

100u

C21

OUT2

R1 10K

R2 1K

R4 1K

R6 10K

47

R20

47

R21

R22

47

100n

C22

OUT3

CUTOFF2

R23

75

R24

R25

L1

10uH

CUTOFF3

R3 10K

R5 10K

IN3

IN1 IN2

75 75

Vcc

C3

R18 25K

23

IN3

DAC

IN2

ABLIN

IN1

PVCC

CUTOFF3

OUT3

PGND

CUTOFF2

OUT2

CUTOFF1

AGND

11

100u

100n

200p

Vcc

100n

C17

R19

DAC

2221201918171615141312

C24

C23

OUT1

100n

C19

100n

C20

CUTOFF1

+5V

Vcc

100u

C16

C15

100n

31

32

33

SCL

LGND

HREF

SAVCC

HFLY

HGND

PLL2C

44 43 42 41 40 39 38 37 36 35 34

Vcc

C0

R0

FC1

HIN HOUT

VIN

1

100n

C28

R32

FILTER

PLL1F

2

47u

C29

1K

VREF

470n

C27

VAGCCAP

3

R33

1u

30

SDA

VGND

4

10K

C14

100u

C13

100n

28

29

VDD

EWOUT

STV2000

VCAP

VOUT

5

6

150n

C26

R31 12K

VOUT

27

EWFBIN

VBRTHIN

7

R31 10K

26

HBRTH

VRB

8

1u

C39

C25

100n

24

25

NC

VBDC

VAVCC

OUT1

9

10

L3 10uH

Vcc

36/38

Page 37

PACKAGE MECHANICAL DATA

44-Pin Thin Quad Flat Package

STV2000

Dimensions

D

D1

D3

33

34

44

23

22

E3

12

PIN1

IDENTIFICATION

1

11

e

L1

L

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

0.10m

m

.004

EE1

K

A

A2

A1

b

c

A 1.60 0.063

A1 0.05 0.15 0.002 0.006

A2 1.35 1.40 1.45 0.053 0.055 0.057

b 0.30 0.37 0.45 0.012 0.015 0.018

c 0.09 0.20 0.004 0.008

D 12.00 0.472

D1 10.00 0.394

D3 8.00 0.315

E 12.00 0.472

E1 10.00 0.394

E3 8.00 0.315

e 0.80 0.031

K0°3.5° 7°

L 0.45 0.60 0.75 0.018 0.024 0.030

L1 1.00 0.039

Number of Pins

N44

37/38

8

Page 38

STV2000

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no

responsibility for the consequences of use of such information nor for any infringement of patents or other

rights ofthird parties which may result from its use. No license is granted by implication or otherwise under any

patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject tochange

without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or

systems without the express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved.

Purchase of I

components in an I

2

C Components bySTMicroelectronics conveys a license under the Philips I2C Patent. Rights to use these

2

C system is granted provided that the system conforms to the I2C Standard Specification as defined

by Philips.

STMicroelectronics Group of Companies

Australia - Brazil - China -Finland - France - Germany -Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

38/38

Loading...

Loading...