Page 1

STM8L001J3

SO8N

4.9x6 mm or 150 mils body width

8-bit ultra-low-power microcontroller with up to 8-Kbyte

Flash memory, multifunction timers, comparators, UART, SPI, I2C

Datasheet - production data

Features

• Main microcontroller features

– Supply voltage range 1.8 V to 3.6 V

– Low power consumption (Halt: 0.3 µA,

Active-halt: 0.8 µA, Dynamic Run:

150 µA/MHz)

– STM8 Core with up to 16 CISC MIPS

throughput

– Temp. range: -40 to 125 °C

• Memories

– 8 Kbytes of Flash program including up to

2 Kbytes of data EEPROM

– Error correction code (ECC)

– Flexible write and read protection modes

– In-application and in-circuit programming

– Data EEPROM capability

– 1.5 Kbytes of static RAM

• Clock management

– Internal 16 MHz RC with fast wakeup time

(typ. 4 µs)

– Internal low consumption 38 kHz RC

driving both the IWDG and the AWU

• Reset and supply management

– Ultra-low power POR/PDR

– Three low-power modes: Wait, Active-halt,

Halt

• Interrupt management

– Nested interrupt controller with software

priority control

– Up to 6 external interrupt sources

• I/Os

– Up to 6 I/Os, all mappable on external

interrupt vectors

– I/Os with programmable input pull-ups, high

sink/source capability and one LED driver

infrared output

• Peripherals

– Two 16-bit general purpose timers (TIM2

and TIM3) with up and down counter and 1

channel (used as IC, OC, PWM)

– One 8-bit timer (TIM4) with 7-bit prescaler

– Infrared remote control (IR)

– Independent watchdog

– Auto-wakeup unit

– Beeper timer with 1, 2 or 4 kHz frequencies

– SPI synchronous serial interface

– Fast I2C Multimaster/slave 400 kHz

– UART with fractional baud rate generator

– 2 comparators with 1 input each

• Development support

– Hardware single wire interface module

(SWIM) for fast on-chip programming and

non intrusive debugging

September 2020 DS12153 Rev 4 1/58

This is information on a product in full production.

www.st.com

Page 2

STM8L001J3

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Central processing unit STM8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Development tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Single wire data interface (SWIM) and debug module . . . . . . . . . . . . . . . . 9

3.4 Interrupt controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Low power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.7 Voltage regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.8 Clock control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.9 Independent watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.10 Auto-wakeup counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.11 General purpose and basic timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.12 Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.13 Infrared (IR) interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.14 Comparators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.15 USART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.16 SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.17 I2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Memory and register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Interrupt vector mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Option bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8 Electrical parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.1 Parameter conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.1.1 Minimum and maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.1.2 Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.1.3 Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/58 DS12153 Rev 4

Page 3

STM8L001J3

8.1.4 Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.1.5 Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3.1 General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3.2 Power-up / power-down operating conditions . . . . . . . . . . . . . . . . . . . . 34

8.3.3 Supply current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3.4 Clock and timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.5 Memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3.6 I/O port pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3.7 Communication interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.3.8 Comparator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.3.9 EMC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.4 Thermal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.1 SO8N package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

DS12153 Rev 4 3/58

3

Page 4

List of tables STM8L001J3

List of tables

Table 1. STM8L001J3 device feature summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Legend/abbreviation for table 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. STM8L001J3 pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 4. Flash and RAM boundary addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 5. I/O Port hardware register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6. General hardware register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 7. CPU/SWIM/debug module/interrupt controller registers. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 8. Interrupt mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 9. Option bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 10. Option byte description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 11. Voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 12. Current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 13. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 14. General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 15. Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 16. Total current consumption in Run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 17. Total current consumption in Wait mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 18. Total current consumption and timing in Halt and Active-halt mode at

VDD = 1.8 V to 3.6 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 19. Peripheral current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 20. HSI oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 21. LSI oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 22. RAM and hardware registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 23. Flash program memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 24. I/O static characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 25. Output driving current (High sink ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 26. Output driving current (true open drain ports). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 27. Output driving current (PA0 with high sink LED driver capability). . . . . . . . . . . . . . . . . . . . 43

Table 28. SPI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 29. I2C characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 30. Comparator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 31. EMS data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 32. EMI data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 33. ESD absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 34. Electrical sensitivities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 35. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 36. SO8N – 8-lead 4.9 x 6 mm, plastic small outline, 150 mils body width,

package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 37. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 38. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4/58 DS12153 Rev 4

Page 5

STM8L001J3 List of figures

List of figures

Figure 1. STM8L001J3 device block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2. STM8L001J3 SO8N pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 3. Memory map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4. Pin loading conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 5. Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 6. IDD(RUN) vs. VDD, fCPU = 2 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 7. IDD(RUN) vs. VDD, fCPU = 16 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 8. IDD(WAIT) vs. VDD, fCPU = 2 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 9. IDD(WAIT) vs. VDD, fCPU = 16 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 10. Typ. IDD(Halt) vs. VDD, fCPU = 2 MHz and 16 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 11. Typical LSI RC frequency vs. VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 12. Typical VIL and VIH vs. VDD (High sink I/Os) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 13. Typical VIL and VIH vs. VDD (true open drain I/Os). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 14. Typical pull-up resistance R

Figure 15. Typical pull-up current I

Figure 16. Typ. VOL at VDD = 3.0 V (High sink ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 17. Typ. VOL at VDD = 1.8 V (High sink ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 18. Typ. VOL at VDD = 3.0 V (true open drain ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 19. Typ. VOL at VDD = 1.8 V (true open drain ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 20. Typ. VDD - VOH at VDD = 3.0 V (High sink ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 21. Typ. VDD - VOH at VDD = 1.8 V (High sink ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 22. SPI timing diagram - slave mode and CPHA = 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 23. SPI timing diagram - slave mode and CPHA = 1

Figure 24. SPI timing diagram - master mode

Figure 25. Typical application with I2C bus and timing diagram (1). . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 26. SO8N – 8-lead, 4.9 x 6 mm, plastic small outline, 150 mils body width, package outline . 53

Figure 27. SO8N – 8-lead 4.9 x 6 mm, plastic small outline, 150 mils body width,

package recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 28. Example of SO8N marking (package top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

vs. VDD with VIN=VSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PU

vs. VDD with VIN=VSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PU

(1)

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DS12153 Rev 4 5/58

5

Page 6

Introduction STM8L001J3

1 Introduction

This datasheet provides the STM8L001J3 pinout, ordering information, mechanical and

electrical device characteristics.

For complete information on the STM8L001J3 microcontroller memory, registers and

peripherals, please refer to the STM8L001xx, STM8L101xx microcontroller family reference

manual (RM0013).

The STM8L001J3 devices are members of the STM8L low-power 8-bit family. They are

referred to as low-density devices in the STM8L001xx, STM8L101xx microcontroller family

reference manual (RM0013) and in the How to program STM8L and STM8AL Flash

program memory and data EEPROM programming manual (PM0054).

All devices of the SM8L Series provide the following benefits:

• Reduced system cost

– 8 Kbytes of low-density embedded Flash program memory including up to

2 Kbytes of data EEPROM

– High system integration level with internal clock oscillators and watchdogs.

– Smaller battery and cheaper power supplies.

• Low power consumption and advanced features

– Up to 16 MIPS at 16 MHz CPU clock frequency

– Less than 150 µA/MHz, 0.8 µA in Active-halt mode, and 0.3 µA in Halt mode

– Clock gated system and optimized power management

•

Short development cycles

– Application scalability across a common family product architecture with

compatible pinout, memory map and modular peripherals.

– Full documentation and a wide choice of development tools

•

Product longevity

– Advanced core and peripherals made in a state-of-the art technology

– Product family operating from 1.8 V to 3.6 V supply.

6/58 DS12153 Rev 4

Page 7

STM8L001J3 Description

2 Description

The STM8L001J3 low-power microcontroller features the enhanced STM8 CPU core

providing increased processing power (up to 16 MIPS at 16 MHz) while maintaining the

advantages of a CISC architecture with improved code density, a 24-bit linear addressing

space and an optimized architecture for low power operations.

The family includes an integrated debug module with a hardware interface (SWIM) which

allows non-intrusive in-application debugging and ultra fast Flash programming.

All STM8L001J3 microcontrollers feature low power low-voltage single-supply program

Flash memory. The 8-Kbyte devices embed data EEPROM.

The STM8L001J3 low power microcontroller is based on a generic set of state-of-the-art

peripherals. The modular design of the peripheral set allows the same peripherals to be

found in different ST microcontroller families including 32-bit families. This makes any

transition to a different family very easy, and simplified even more by the use of a common

set of development tools.

All STM8L low power products are based on the same architecture with the same memory

mapping and a coherent pinout.

Table 1. STM8L001J3 device feature summary

Features STM8L001J3

Flash

RAM 1.5 Kbytes

Peripheral functions

Timers Two 16-bit timers, one 8-bit timer

Operating voltage 1.8 to 3.6 V

Operating temperature -40 to +125 °C

Packages SO8N

Universal synchronous / asynchronous receiver / transmitter (USART),

8 Kbytes of Flash program memory including up to

2 Kbytes of Data EEPROM

Independent watchdog (IWDG), Auto-wakeup unit (AWU), Beep,

Serial peripheral interface (SPI), Inter-integrated circuit (I2C),

2 comparators, Infrared (IR) interface

DS12153 Rev 4 7/58

16

Page 8

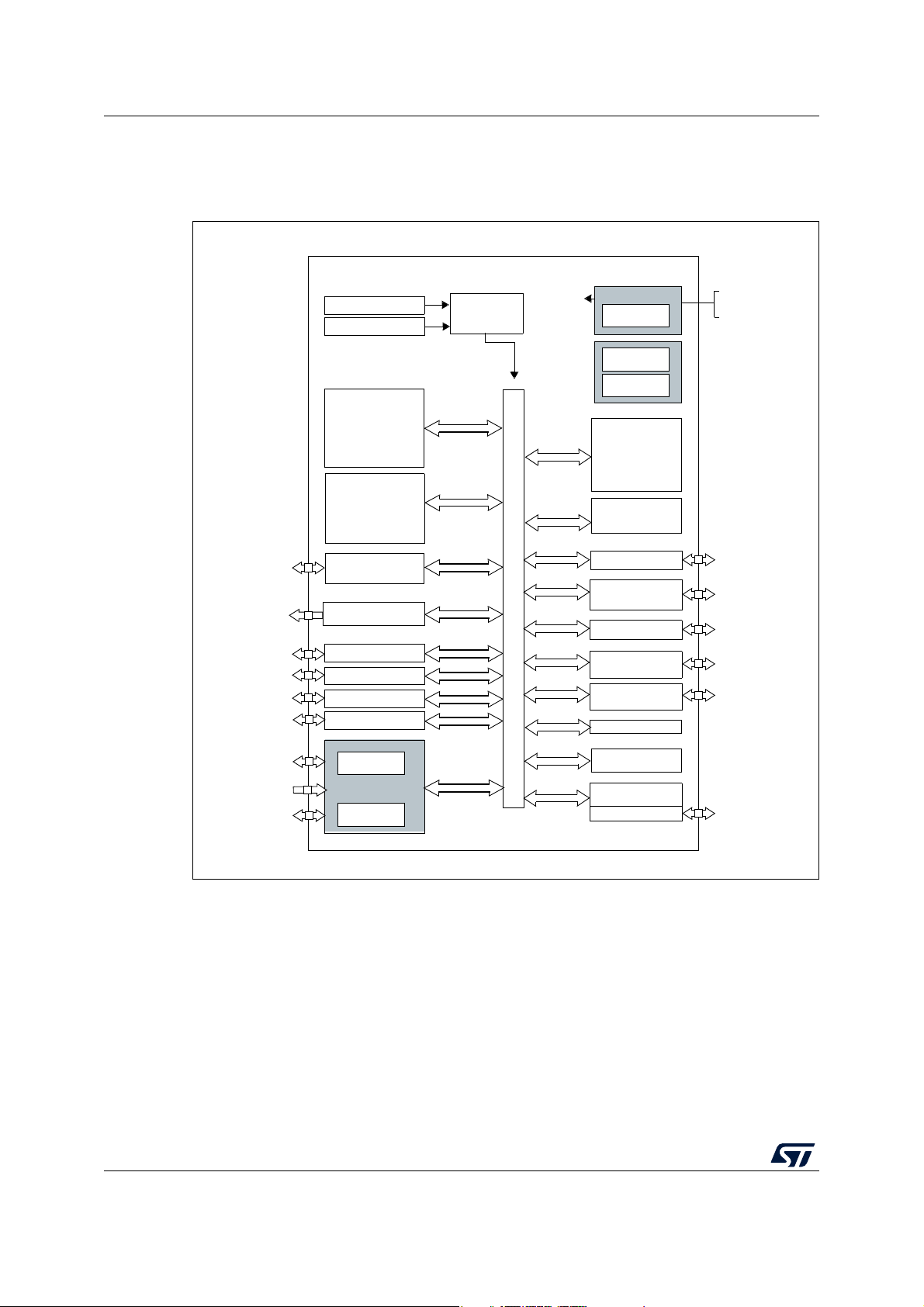

Product overview STM8L001J3

MS32610V1

16 MHz int RC

Clock

controller

Clocks

AWU

Beeper

Address and data bus

38 kHz int RC

Debug module

I²C1

SPI

USART

Up to 8 Kbytes

Flash memory

controller

1.5 Kbytes

to core and

peripherals

IWDG

16-bit Timer 2

(SWIM)

Nested interrupt

up to 6 external

multimaster

8-bit Timer 4

SRAM

interrupts

(including

up to 2 Kbytes

data EEPROM)

Power

Volt. reg.

POR/PDR

Reset

COMP1

COMP2

Port A

Port B

Port C

Port D

RX, TX

SDA, SCL

PA

PB

PC

PD

MOSI, MISO,

SCK

BEEP

SWIM

COMP1_CH3

COMP_REF

Infrared interface

IR_TIM

16-bit Timer 3

IR_TIM

TIM3_CH2

COMP2_CH2

V

DD18

@ V

DD

STM8

Core

up to 16 MHz

V

DD

= 1.8V to 3.6V

V

SS

3 Product overview

Figure 1. STM8L001J3 device block diagram

Legend:

AWU: Auto-wakeup unit

Int. RC: internal RC oscillator

I2C: Inter-integrated circuit multimaster interface

POR/PDR: Power on reset / power down reset

SPI: Serial peripheral interface

SWIM: Single wire interface module

USART: Universal synchronous / asynchronous receiver / transmitter

IWDG: Independent watchdog

8/58 DS12153 Rev 4

Page 9

STM8L001J3 Product overview

3.1 Central processing unit STM8

The 8-bit STM8 core is designed for code efficiency and performance.

It features 21 internal registers, 20 addressing modes including indexed, indirect and

relative addressing, and 80 instructions.

3.2 Development tools

Development tools for the STM8 microcontrollers include:

• The STVD high-level language debugger including C compiler, assembler and

integrated development environment

• The STVP Flash programming software

The STM8 also comes with starter kits, evaluation boards and low-cost in-circuit

debugging/programming tools.

3.3 Single wire data interface (SWIM) and debug module

The debug module with its single wire data interface (SWIM) permits non-intrusive real-time

in-circuit debugging and fast memory programming.

The Single wire interface is used for direct access to the debugging module and memory

programming. The interface can be activated in all device operation modes.

The non-intrusive debugging module features a performance close to a full-featured

emulator. Beside memory and peripherals, also CPU operation can be monitored in realtime by means of shadow registers.

Recommendations for SWIM pin (pin#1)

As the NRST pin is not available on this device, if the SWIM pin should be used with the I/O

pin functionality, it is recommended to add a ~5 seconds delay in the firmware before

changing the functionality on the pin with SWIM functions. This action allows the user to set

the device into SWIM mode after the device power on and to be able to reprogram the

device. If the pin with SWIM functionality is set to I/O mode immediately after the device

reset, the device is unable to connect through the SWIM interface and it gets locked forever.

This initial delay can be removed in the final (locked) code.

If the initial delay is not acceptable for the application there is the option that the firmware

reenables the SWIM pin functionality under specific conditions such as during firmware

startup or during application run. Once that this procedure is done, the SWIM interface can

be used for the device debug/programming.

3.4 Interrupt controller

The STM8L001J3 features a nested vectored interrupt controller:

• Nested interrupts with 3 software priority levels

• 26 interrupt vectors with hardware priority

• Up to 6 external interrupt sources on 6 vectors

• Trap and reset interrupts.

DS12153 Rev 4 9/58

16

Page 10

Product overview STM8L001J3

3.5 Memory

The STM8L001J3 devices have the following main features:

• 1.5 Kbytes of RAM

• The EEPROM is divided into two memory arrays (see the STM8L001xx, STM8L101xx

microcontroller family reference manual (RM0013) for details on the memory mapping):

– 8 Kbytes of low-density embedded Flash program including up to 2 Kbytes of data

EEPROM. Data EEPROM and Flash program areas can be write protected

independently by using the memory access security mechanism (MASS).

– 64 option bytes (one block) of which 5 bytes are already used for the device.

Error correction code is implemented on the EEPROM.

Recommendation for the device's programming:

The device's 8 Kbytes program memory is not empty on virgin devices; there is code loop

implemented on the reset vector. It is recommended to keep valid code loop in the device to

avoid the program execution from an invalid memory address (which would be any memory

address out of 8 Kbytes program memory space).

If the device's program memory is empty (0x00 content), it displays the behavior described

below:

• After the power on, the “empty” code is executed (0x0000 opcodes = instructions: NEG

(0x00, SP)) until the device reaches the end of the 8 Kbytes program memory (the end

address = 0x9FFF).

It takes around 4 milliseconds to reach the end of the 8 Kbytes memory space @2 MHz

HSI clock.

• Once the device reaches the end of the 8 Kbytes program memory, the program

continues and code from a non-existing memory is fetched and executed.

The reading of non-existing memory is a random content which can lead to the execution of

invalid instructions.

The execution of invalid instructions generates a software reset and the program starts

again. A reset can be generated every 4 milliseconds or more.

Only the “connect on-the-fly” method can be used to program the device through the SWIM

interface. The “connect under-reset” method cannot be used because the NRST pin is not

available on this device.

The “connect on-the-fly” mode can be used while the device is executing code, but if there is

a device reset (by software reset) during the SWIM connection, this connection is aborted

and it must be performed again from the debug tool. Note that the software reset occurrence

can be of every 4 milliseconds, making it difficult to successfully connect to the device's

debug tool (there is practically only one successful connection trial for every 10 attempts).

Once that a successful connection is reached, the device can be programmed with a valid

firmware without problems; therefore it is recommended that device is never erased and

that is contains always a valid code loop.

10/58 DS12153 Rev 4

Page 11

STM8L001J3 Product overview

3.6 Low power modes

To minimize power consumption, the product features three low power modes:

• Wait mode: CPU clock stopped, selected peripherals at full clock speed.

• Active-halt mode: CPU and peripheral clocks are stopped. The programmable wakeup

time is controlled by the AWU unit.

• Halt mode: CPU and peripheral clocks are stopped, the device remains powered on.

The RAM content is preserved. Wakeup is triggered by an external interrupt.

3.7 Voltage regulators

The STM8L001J3 embeds an internal voltage regulator for generating the 1.8 V power

supply for the core and peripherals.

This regulator has two different modes: main voltage regulator mode (MVR) and low power

voltage regulator mode (LPVR). When entering Halt or Active-halt modes, the system

automatically switches from the MVR to the LPVR in order to reduce current consumption.

3.8 Clock control

The STM8L001J3 embeds a robust clock controller. It is used to distribute the system clock

to the core and the peripherals and to manage clock gating for low power modes. This

system clock is a 16-MHz High Speed Internal RC oscillator (HSI RC), followed by a

programmable prescaler.

In addition, a 38 kHz low speed internal RC oscillator is used by the independent watchdog

(IWDG) and Auto-wakeup unit (AWU).

3.9 Independent watchdog

The independent watchdog (IWDG) peripheral can be used to resolve processor

malfunctions due to hardware or software failures.

It is clocked by the 38 kHz LSI internal RC clock source, and thus stays active even in case

of a CPU clock failure.

3.10 Auto-wakeup counter

The auto-wakeup (AWU) counter is used to wakeup the device from Active-halt mode.

3.11 General purpose and basic timers

STM8L001J3 devices contain two 16-bit general purpose timers (TIM2 and TIM3) and one

8-bit basic timer (TIM4).

DS12153 Rev 4 11/58

16

Page 12

Product overview STM8L001J3

16-bit general purpose timers

The 16-bit timers consist of 16-bit up/down auto-reload counters driven by a programmable

prescaler. They perform a wide range of functions, including:

• Time base generation

• Measuring the pulse lengths of input signals (input capture)

• Generating output waveforms (output compare, PWM and One pulse mode)

• Interrupt capability on various events (capture, compare, overflow, break, trigger)

8-bit basic timer

The 8-bit timer consists of an 8-bit up auto-reload counter driven by a programmable

prescaler. It can be used for timebase generation with interrupt generation on timer

overflow.

3.12 Beeper

The STM8L001J3 devices include a beeper function used to generate a beep signal in the

range of 1, 2 or 4 kHz when the LSI clock is operating at a frequency of 38

kHz.

3.13 Infrared (IR) interface

The STM8L001J3 devices contain an infrared interface which can be used with an IR LED

for remote control functions. Two timer output compare channels are used to generate the

infrared remote control signals.

3.14 Comparators

The STM8L001J3 features two zero-crossing comparators (COMP1 and COMP2) sharing

the same current bias and voltage reference. The voltage reference can be internal

(comparison with ground) or external (comparison to a reference pin voltage).

Each comparator is connected to 4 channels, which can be used to generate interrupt, timer

input capture or timer break. Their polarity can be inverted.

3.15 USART

The USART interface (USART) allows full duplex, asynchronous communications with

external devices requiring an industry standard NRZ asynchronous serial data format. It

offers a very wide range of baud rates.

3.16 SPI

The serial peripheral interface (SPI) provides half/ full duplex synchronous serial

communication with external devices. It can be configured as the master and in this case it

provides the communication clock (SCK) to the external slave device. The interface can

also operate in multi-master configuration.

12/58 DS12153 Rev 4

Page 13

STM8L001J3 Product overview

3.17 I2C

The inter-integrated circuit (I2C) bus interface is designed to serve as an interface between

the microcontroller and the serial

I2C bus-specific sequencing, protocol, arbitration and timing. It manages standard and fast

speed modes.

I2Cbus. It provides multi-master capability, and controls all

DS12153 Rev 4 13/58

16

Page 14

Pin description STM8L001J3

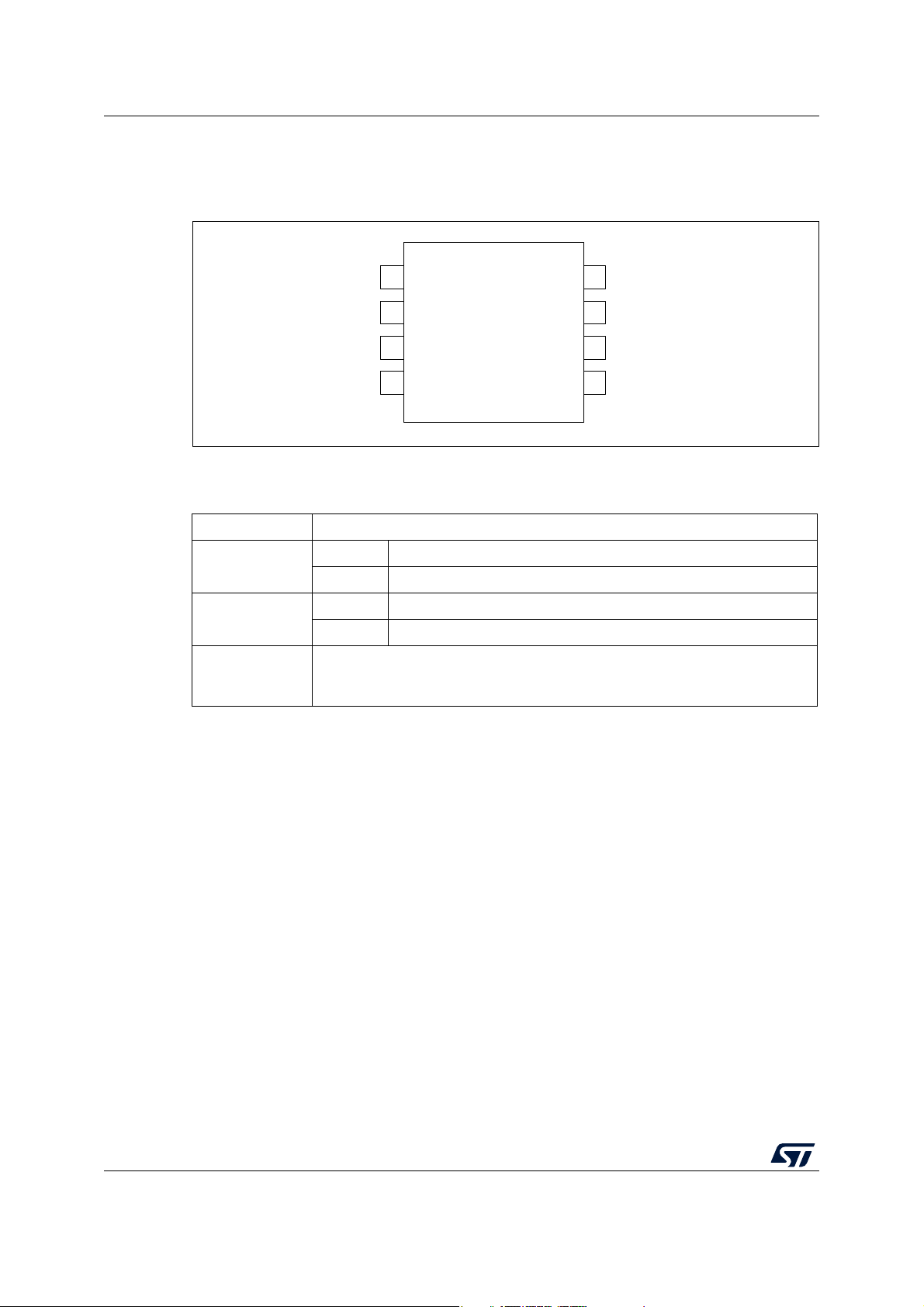

MSv46315V1

1

2

3

4

8

7

6

5

PC1/I2C_SCL/

PC2/USART_RX

PB7/SPI_MISO/

PC0/I2C_SDA

PB6/SPI_MOSI

PB3/TIM2_ETR/COMP2_CH2/

PB5/SPI_SCK/

PD0/TIM3_CH2/COMP1_CH3

PA0/SWIM/BEEP/IR_TIM/

PC3/USART_TX/

PC4/USART_CK/CCO

PA2/

PA4/TIM2_BKIN/

PA6/COMP_REF

VSS

VDD

STM8L

4 Pin description

Figure 2. STM8L001J3 SO8N pinout

Table 2. Legend/abbreviation for table 4

Type I= input, O = output, S = power supply

Input CM = CMOS

Level

Output HS = high sink/source (20 mA)

Port and control

configuration

Input float = floating, wpu = weak pull-up

Output T = true open drain, OD = open drain, PP = push pull

Bold X (pin state after reset release).

Reset state

Unless otherwise specified, the pin state is the same during the reset phase (i.e.

“under reset”) and after internal reset release (i.e. at reset state).

14/58 DS12153 Rev 4

Page 15

STM8L001J3 Pin description

Pin

number

SO8N

1

Table 3. STM8L001J3 pin description

Input Output

Main

Pin name

Type

OD

Floating

WPU

function

PP

(after

reset)

Alternate function

Ext. interrupt

High sink / source

(1)

PA0

IR_TIM

/SWIM/BEEP/

(2)

I/O X X

(1)

HS

C

XXPort A0

(2)

SWIM input and

output / Beep

output/ Timer

infrared output

(1)

PC3/USART_TX I/O X

X X HS X X Port C3 USART transmit

USART

PC4/USART_CK/

CCO

I/O X

(1)

XXHSXXPort C4

synchronous clock /

Configurable clock

output

PA2 I/O X XXHSXXPort A2-

2

PA4/TIM2_BKIN I/O X XXHSXXPort A4

PA6/COMP_REF I/O X XXHSXXPort A6

3V

4V

SS

DD

PD0/TIM3_CH2/

COMP1_CH3

5

PB3/TIM2_ETR/

COMP2_CH2

S - ----- -Ground

S - ----- -Power supply

I/O X XXHSXXPort D0

I/O X XXHSXXPort B3

Timer 2 - break

input

Comparator

external reference

Timer 3 - Channel 2

/ Comparator 1 -

Channel 3

Timer 2 - trigger /

Comparator 2 -

Channel 2

PB5/SPI_SCK I/O X X X HS X X Port B5 SPI clock

6 PB6/SPI_MOSI I/O X XXHSXXPort B6

PB7/SPI_MISO I/O X XXHSXXPort B7

7

(3)

PC0/I2C_SDA I/O X -X-T

PC1/I2C_SCL I/O X -X-T

- Port C0 I2C data

(3)

- Port C1 I2C clock

SPI master out /

slave in

SPI master in /

slave out

8

PC2/USART_RX I/O X X X HS X X Port C2 USART receive

DS12153 Rev 4 15/58

16

Page 16

Pin description STM8L001J3

1. The PA0 pin is in input pull-up during the reset phase and after internal reset release. This PA0 default state influences all

the GPIOs connected in parallel on pin number 1 (PC3, PC4).

2. High sink LED driver capability available on PA0.

3. In the open-drain output column, ‘T’ defines a true open-drain I/O (P-buffer, weak pull-up and protection diode to V

not implemented). Although PC0/PC1 itself is a true open drain GPIO with its respective internal circuitry and

characteristics, V

also bonded to the same pin number.

maximum of the pin number 7 and pin number 8 is limited by the standard GPIO (PB7 or PC2) which is

IN

DD

are

Slope control of all GPIO pins can be programmed except true open drain pins which by

default is limited to 2 MHz.

Note: The PA1, PA3, PA5, PB0, PB1, PB2, PB4, PC5, PC6, PD1, PD2, PD3, PD4, PD5, PD6 and

PD7 GPIOs should be configured after device reset, by user software into the in output

push-pull mode with output-low state to reduce device consumption and to improve EMC

immunity. Those GPIOs are not connected to pins and after device reset are in input floating

mode. To configure PA1 pin in output push-pull mode refer to Section “Configuring

NRST/PA1 pin as general purpose output” in the STM8L001xx, STM8L101xx

microcontroller family reference manual (RM0013).

Note: As several pins provide a connection to multiple GPIOs, the mode selection for any of those

GPIOs impacts all the other GPIOs connected to the same pin. The user is responsible for

the proper setting of the GPIO modes in order to avoid conflicts between GPIOs bonded to

the same pin (including their alternate functions). For example, pull-up enabled on PA0 is

also seen on PC3 and PC4. Push-pull configuration of PA2 is also seen on PA4 and PA6,

etc.

16/58 DS12153 Rev 4

Page 17

STM8L001J3 Memory and register map

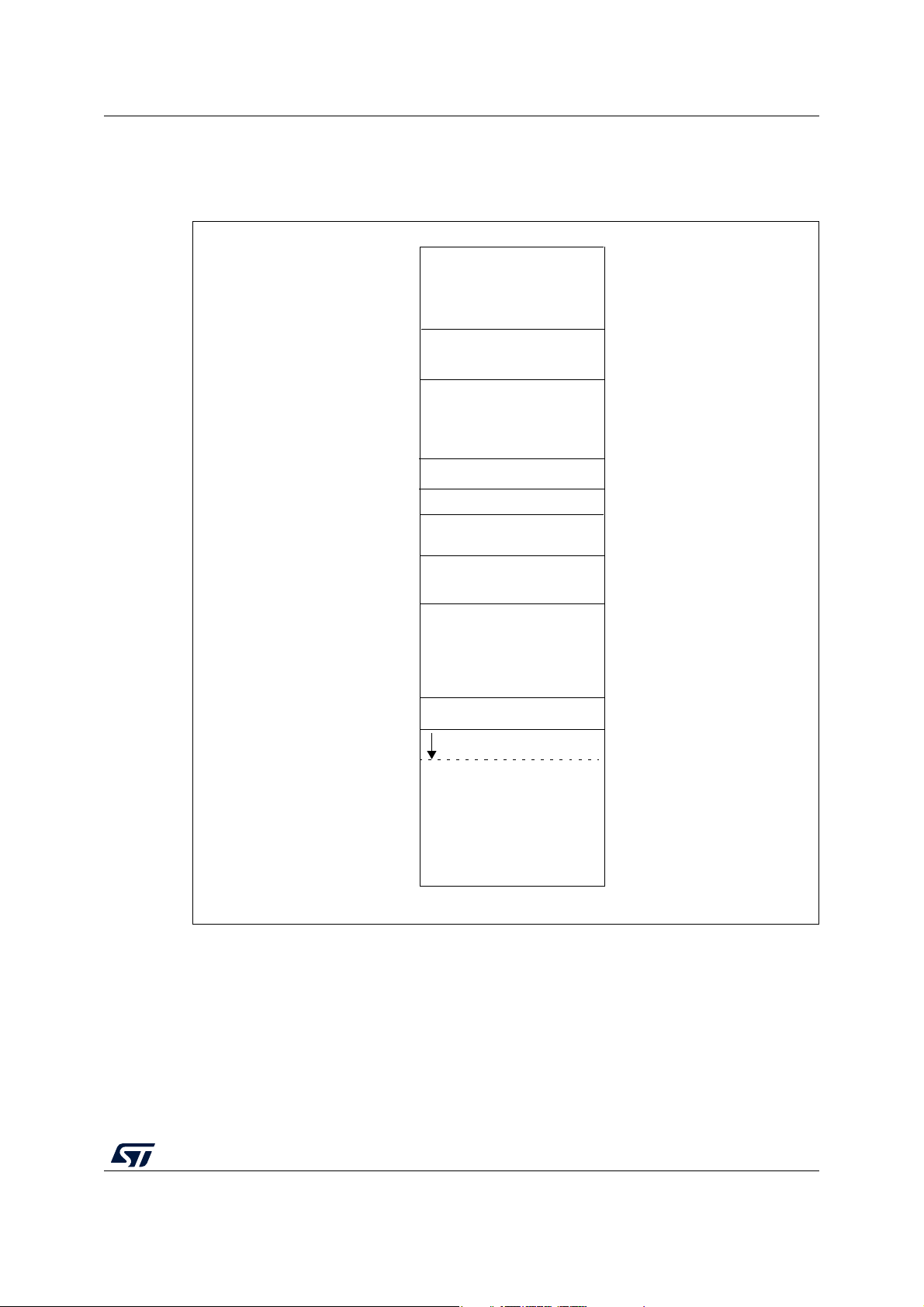

GPIO and peripheral registers

(2)

0x00 0000

Reserved

Flash program memory

(up to 8 Kbytes)

(1)

Interrupt vectors

0x00 4800

0x00 48FF

RAM

0x00 05FF

(1.5 Kbytes)

(1)

(up to 513 bytes)

(1)

0x 004900

Option bytes

0x00 5000

0x00 57FF

0x00 5800

0x00 7FFF

0x00 8000

0x00 9FFF

0x00 0600

0x00 47FF

0x00 49FF

0x00 7EFF

0x00 8080

0x00 807F

CPU/SWIM/Debug/ITC

Registers

0x00 7F00

Reserved

Reserved

including

Stack

including

Data EEPROM

(up to 2 Kbytes)

0x 004925

0x 004931

0x 004924

0x 004930

Unique ID

Reserved

Low-density

MS32621V1

5 Memory and register map

Figure 3. Memory map

1. Table 4 lists the boundary addresses for each memory size. The top of the stack is at the RAM end

address.

2. Refer to Table 6 for an overview of hardware register mapping, to Table 5 for details on I/O port hardware

registers, and to Table 7 for information on CPU/SWIM/debug module controller registers.

DS12153 Rev 4 17/58

27

Page 18

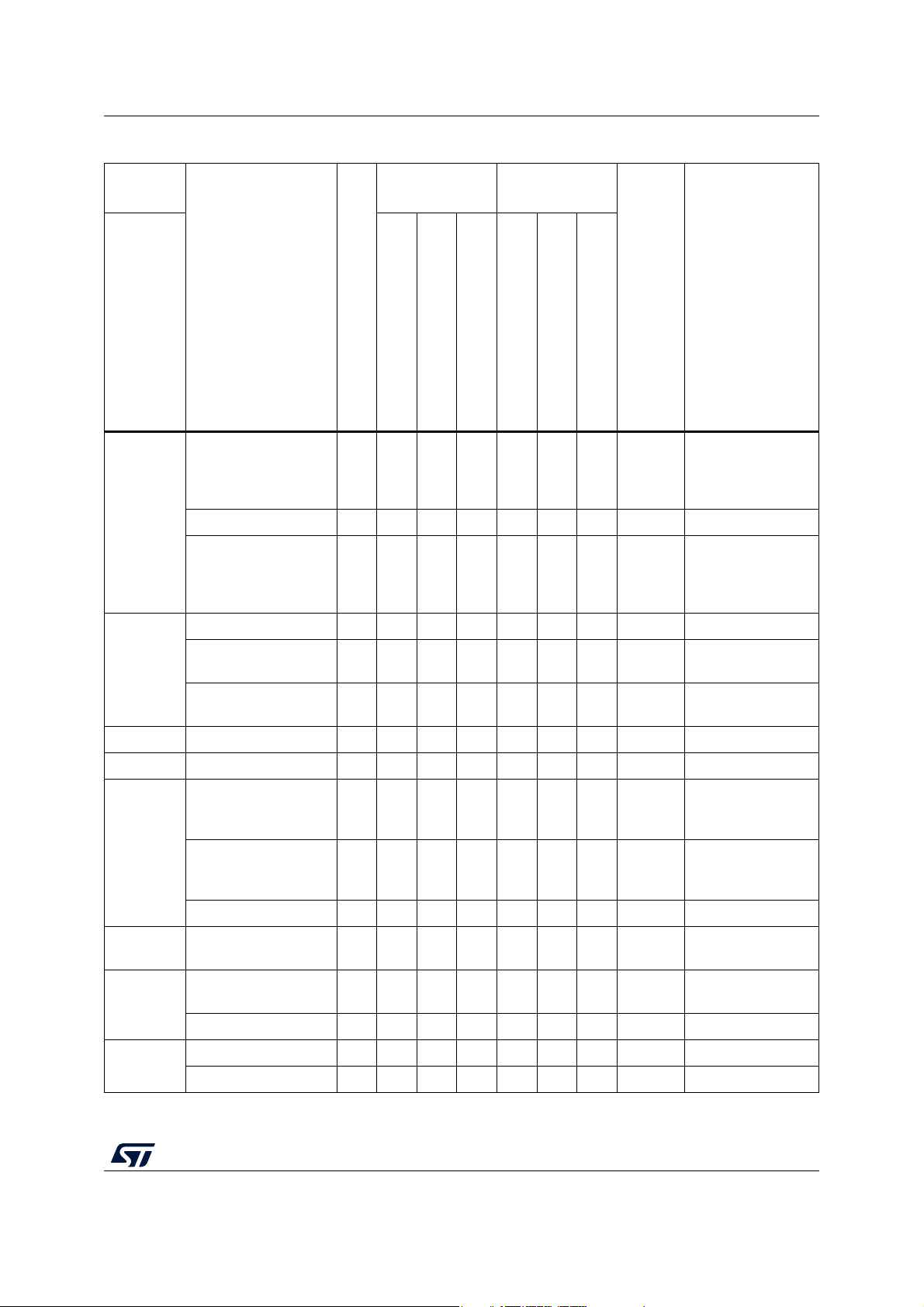

Memory and register map STM8L001J3

Table 4. Flash and RAM boundary addresses

Memory area Size Start address End address

RAM 1.5 Kbytes 0x00 0000 0x00 05FF

Flash program memory 8 Kbytes 0x00 8000 0x00 9FFF

Address Block Register label Register name

0x00 5000

Table 5. I/O Port hardware register map

Reset

status

PA_ODR Port A data output latch register 0x00

0x00 5001 PA_IDR Port A input pin value register 0xxx

0x00 5002 PA_DDR Port A data direction register 0x00

Port A

0x00 5003 PA_CR1 Port A control register 1 0x00

0x00 5004 PA_CR2 Port A control register 2 0x00

0x00 5005

PB_ODR Port B data output latch register 0x00

0x00 5006 PB_IDR Port B input pin value register 0xxx

0x00 5007 PB_DDR Port B data direction register 0x00

Port B

0x00 5008 PB_CR1 Port B control register 1 0x00

0x00 5009 PB_CR2 Port B control register 2 0x00

0x00 500A

PC_ODR Port C data output latch register 0x00

0x00 500B PC_IDR Port C input pin value register 0xxx

0x00 500C PC_DDR Port C data direction register 0x00

Port C

0x00 500D PC_CR1 Port C control register 1 0x00

0x00 500E PC_CR2 Port C control register 2 0x00

0x00 500F

PD_ODR Port D data output latch register 0x00

0x00 5010 PD_IDR Port D input pin value register 0xxx

0x00 5011 PD_DDR Port D data direction register 0x00

Port D

0x00 5012 PD_CR1 Port D control register 1 0x00

0x00 5013 PD_CR2 Port D control register 2 0x00

18/58 DS12153 Rev 4

Page 19

STM8L001J3 Memory and register map

Address Block Register label Register name

0x00 5050

Table 6. General hardware register map

Reset

status

FLASH_CR1 Flash control register 1 0x00

0x00 5051 FLASH_CR2 Flash control register 2 0x00

0x00 5052 FLASH _PUKR

Flash

Flash Program memory unprotection

register

0x00

0x00 5053 FLASH _DUKR Data EEPROM unprotection register 0x00

0x00 5054 FLASH _IAPSR

Flash in-application programming status

register

0x00 5055

to

Reserved area (75 bytes)

0x00 509F

0x00 50A0

EXTI_CR1 External interrupt control register 1 0x00

0x00 50A1 EXTI_CR2 External interrupt control register 2 0x00

0x00 50A2 EXTI_CR3 External interrupt control register 3 0x00

ITC-EXTI

0x00 50A3 EXTI_SR1 External interrupt status register 1 0x00

0x00 50A4 EXTI_SR2 External interrupt status register 2 0x00

0x00 50A5 EXTI_CONF External interrupt port select register 0x00

0xX0

0x00 50A6

WFE_CR1 WFE control register 1 0x00

WFE

0x00 50A7 WFE_CR2 WFE control register 2 0x00

0x00 50A8

to

Reserved area (8 bytes)

0x00 50AF

0x00 50B0

RST_CR Reset control register 0x00

RST

0x00 50B1 RST_SR Reset status register 0x01

0x00 50B2

to

Reserved area (14 bytes)

0x00 50BF

0x00 50C0

CLK_CKDIVR Clock divider register 0x03

0x00 50C1

to

0x00 50C2

CLK

Reserved area (2 bytes)

0x00 50C3 CLK_PCKENR Peripheral clock gating register 0x00

0x00 50C4 Reserved (1 byte)

0x00 50C5 CLK_CCOR Configurable clock control register 0x00

0x00 50C6

to

Reserved area (25 bytes)

0x00 50DF

DS12153 Rev 4 19/58

27

Page 20

Memory and register map STM8L001J3

Table 6. General hardware register map (continued)

Address Block Register label Register name

0x00 50E0

0x00 50E1 IWDG_PR IWDG prescaler register 0x00

0x00 50E2 IWDG_RLR IWDG reload register 0xFF

0x00 50E3

to

0x00 50EF

0x00 50F0

0x00 50F1 AWU_APR

0x00 50F2 AWU_TBR AWU timebase selection register 0x00

0x00 50F3 BEEP BEEP_CSR BEEP control/status register 0x1F

0x00 50F4

to

0x00 51FF

0x00 5200

0x00 5201 SPI_CR2 SPI control register 2 0x00

0x00 5202 SPI_ICR SPI interrupt control register 0x00

0x00 5203 SPI_SR SPI status register 0x02

0x00 5204 SPI_DR SPI data register 0x00

0x00 5205

to

0x00 520F

0x00 5210

IWDG

AWU

SPI

IWDG_KR IWDG key register 0xXX

Reserved area (13 bytes)

AWU_CSR AWU control/status register 0x00

AWU asynchronous prescaler buffer

register

Reserved area (268 bytes)

SPI_CR1 SPI control register 1 0x00

Reserved area (11 bytes)

I2C_CR1 I2C control register 1 0x00

Reset

status

0x3F

0x00 5211 I2C_CR2 I2C control register 2 0x00

0x00 5212 I2C_FREQR I2C frequency register 0x00

0x00 5213 I2C_OARL I2C own address register low 0x00

0x00 5214 I2C_OARH I2C own address register high 0x00

0x00 5215 Reserved area (1 byte)

0x00 5216 I2C_DR I2C data register 0x00

0x00 5217 I2C_SR1 I2C status register 1 0x00

0x00 5218 I2C_SR2 I2C status register 2 0x00

0x00 5219 I2C_SR3 I2C status register 3 0x00

0x00 521A I2C_ITR I2C interrupt control register 0x00

0x00 521B I2C_CCRL I2C Clock control register low 0x00

0x00 521C I2C_CCRH I2C Clock control register high 0x00

0x00 521D I2C_TRISER I2C TRISE register 0x02

20/58 DS12153 Rev 4

I2C

Page 21

STM8L001J3 Memory and register map

Table 6. General hardware register map (continued)

Address Block Register label Register name

Reset

status

0x00 521E

to

Reserved area (18 bytes)

0x00 522F

0x00 5230

USART_SR USART status register 0xC0

0x00 5231 USART_DR USART data register 0xXX

0x00 5232 USART_BRR1 USART baud rate register 1 0x00

0x00 5233 USART_BRR2 USART baud rate register 2 0x00

USART

0x00 5234 USART_CR1 USART control register 1 0x00

0x00 5235 USART_CR2 USART control register 2 0x00

0x00 5236 USART_CR3 USART control register 3 0x00

0x00 5237 USART_CR4 USART control register 4 0x00

0x00 5238

to

Reserved area (18 bytes)

0x00 524F

DS12153 Rev 4 21/58

27

Page 22

Memory and register map STM8L001J3

Table 6. General hardware register map (continued)

Address Block Register label Register name

0x00 5250

0x00 5251 TIM2_CR2 TIM2 control register 2 0x00

0x00 5252 TIM2_SMCR TIM2 slave mode control register 0x00

0x00 5253 TIM2_ETR TIM2 external trigger register 0x00

0x00 5254 TIM2_IER TIM2 interrupt enable register 0x00

0x00 5255 TIM2_SR1 TIM2 status register 1 0x00

0x00 5256 TIM2_SR2 TIM2 status register 2 0x00

0x00 5257 TIM2_EGR TIM2 event generation register 0x00

0x00 5258 TIM2_CCMR1 TIM2 capture/compare mode register 1 0x00

0x00 5259 TIM2_CCMR2 TIM2 capture/compare mode register 2 0x00

0x00 525A TIM2_CCER1 TIM2 capture/compare enable register 1 0x00

TIM2

0x00 525B TIM2_CNTRH TIM2 counter high 0x00

0x00 525C TIM2_CNTRL TIM2 counter low 0x00

0x00 525D TIM2_PSCR TIM2 prescaler register 0x00

0x00 525E TIM2_ARRH TIM2 auto-reload register high 0xFF

0x00 525F TIM2_ARRL TIM2 auto-reload register low 0xFF

0x00 5260 TIM2_CCR1H TIM2 capture/compare register 1 high 0x00

TIM2_CR1 TIM2 control register 1 0x00

Reset

status

0x00 5261 TIM2_CCR1L TIM2 capture/compare register 1 low 0x00

0x00 5262 TIM2_CCR2H TIM2 capture/compare register 2 high 0x00

0x00 5263 TIM2_CCR2L TIM2 capture/compare register 2 low 0x00

0x00 5264 TIM2_BKR TIM2 break register 0x00

0x00 5265 TIM2_OISR TIM2 output idle state register 0x00

0x00 5266

to

0x00 527F

Reserved area (26 bytes)

22/58 DS12153 Rev 4

Page 23

STM8L001J3 Memory and register map

Table 6. General hardware register map (continued)

Address Block Register label Register name

0x00 5280

TIM3_CR1 TIM3 control register 1 0x00

Reset

status

0x00 5281 TIM3_CR2 TIM3 control register 2 0x00

0x00 5282 TIM3_SMCR TIM3 slave mode control register 0x00

0x00 5283 TIM3_ETR TIM3 external trigger register 0x00

0x00 5284 TIM3_IER TIM3 interrupt enable register 0x00

0x00 5285 TIM3_SR1 TIM3 status register 1 0x00

0x00 5286 TIM3_SR2 TIM3 status register 2 0x00

0x00 5287 TIM3_EGR TIM3 event generation register 0x00

0x00 5288 TIM3_CCMR1 TIM3 capture/compare mode register 1 0x00

0x00 5289 TIM3_CCMR2 TIM3 capture/compare mode register 2 0x00

0x00 528A TIM3_CCER1 TIM3 capture/compare enable register 1 0x00

TIM3

0x00 528B TIM3_CNTRH TIM3 counter high 0x00

0x00 528C TIM3_CNTRL TIM3 counter low 0x00

0x00 528D TIM3_PSCR TIM3 prescaler register 0x00

0x00 528E TIM3_ARRH TIM3 auto-reload register high 0xFF

0x00 528F TIM3_ARRL TIM3 auto-reload register low 0xFF

0x00 5290 TIM3_CCR1H TIM3 capture/compare register 1 high 0x00

0x00 5291 TIM3_CCR1L TIM3 capture/compare register 1 low 0x00

0x00 5292 TIM3_CCR2H TIM3 capture/compare register 2 high 0x00

0x00 5293 TIM3_CCR2L TIM3 capture/compare register 2 low 0x00

0x00 5294 TIM3_BKR TIM3 break register 0x00

0x00 5295 TIM3_OISR TIM3 output idle state register 0x00

0x00 5296

to

Reserved area (74 bytes)

0x00 52DF

0x00 52E0

TIM4_CR1 TIM4 control register 1 0x00

0x00 52E1 TIM4_CR2 TIM4 control register 2 0x00

0x00 52E2 TIM4_SMCR TIM4 Slave mode control register 0x00

0x00 52E3 TIM4_IER TIM4 interrupt enable register 0x00

0x00 52E4 TIM4_SR1 TIM4 Status register 1 0x00

TIM4

0x00 52E5 TIM4_EGR TIM4 event generation register 0x00

0x00 52E6 TIM4_CNTR TIM4 counter 0x00

0x00 52E7 TIM4_PSCR TIM4 prescaler register 0x00

0x00 52E8 TIM4_ARR TIM4 auto-reload register low 0xFF

DS12153 Rev 4 23/58

27

Page 24

Memory and register map STM8L001J3

Table 6. General hardware register map (continued)

Address Block Register label Register name

0x00 52E9

to

0x00 52FE

0x00 52FF IRTIM IR_CR Infra-red control register 0x00

0x00 5300

0x00 5301 COMP_CSR Comparator status register 0x00

0x00 5302 COMP_CCS Comparator channel selection register 0x00

COMP

COMP_CR Comparator control register 0x00

Reserved area (23 bytes)

Reset

status

Table 7. CPU/SWIM/debug module/interrupt controller registers

Address Block Register label Register name

0x00 7F00

0x00 7F01 PCE Program counter extended 0x00

0x00 7F02 PCH Program counter high 0x80

0x00 7F03 PCL Program counter low 0x00

0x00 7F04 XH X index register high 0x00

0x00 7F05 XL X index register low 0x00

0x00 7F06 YH Y index register high 0x00

CPU

A Accumulator 0x00

Reset

status

0x00 7F07 YL Y index register low 0x00

0x00 7F08 SPH Stack pointer high 0x05

0x00 7F09 SPL Stack pointer low 0xFF

0x00 7F0A CC Condition code register 0x28

0x00 7F0B

to

0x00 7F5F

0x00 7F60 CFG CFG_GCR Global configuration register 0x00

0x00 7F61

0x00 7F6F

0x00 7F70

0x00 7F71 ITC_SPR2 Interrupt Software priority register 2 0xFF

0x00 7F72 ITC_SPR3 Interrupt Software priority register 3 0xFF

0x00 7F73 ITC_SPR4 Interrupt Software priority register 4 0xFF

0x00 7F74 ITC_SPR5 Interrupt Software priority register 5 0xFF

0x00 7F75 ITC_SPR6 Interrupt Software priority register 6 0xFF

0x00 7F76 ITC_SPR7 Interrupt Software priority register 7 0xFF

0x00 7F77 ITC_SPR8 Interrupt Software priority register 8 0xFF

ITC-SPR

(1)

ITC_SPR1 Interrupt Software priority register 1 0xFF

Reserved area (85 bytes)

Reserved area (15 bytes)

24/58 DS12153 Rev 4

Page 25

STM8L001J3 Memory and register map

Table 7. CPU/SWIM/debug module/interrupt controller registers (continued)

Address Block Register label Register name

Reset

status

0x00 7F78

to

Reserved area (2 bytes)

0x00 7F79

0x00 7F80 SWIM SWIM_CSR SWIM control status register 0x00

0x00 7F81

to

Reserved area (15 bytes)

0x00 7F8F

0x00 7F90

DM_BK1RE Breakpoint 1 register extended byte 0xFF

0x00 7F91 DM_BK1RH Breakpoint 1 register high byte 0xFF

0x00 7F92 DM_BK1RL Breakpoint 1 register low byte 0xFF

0x00 7F93 DM_BK2RE Breakpoint 2 register extended byte 0xFF

0x00 7F94 DM_BK2RH Breakpoint 2 register high byte 0xFF

0x00 7F95 DM_BK2RL Breakpoint 2 register low byte 0xFF

DM

0x00 7F96 DM_CR1 Debug module control register 1 0x00

0x00 7F97 DM_CR2 Debug module control register 2 0x00

0x00 7F98 DM_CSR1 Debug module control/status register 1 0x10

0x00 7F99 DM_CSR2 Debug module control/status register 2 0x00

0x00 7F9A DM_ENFCTR Enable function register 0xFF

1. Refer to Table 6: General hardware register map on page 19 (addresses 0x00 50A0 to 0x00 50A5) for a list

of external interrupt registers.

DS12153 Rev 4 25/58

27

Page 26

Interrupt vector mapping STM8L001J3

6 Interrupt vector mapping

IRQ

No.

Source

block

Description

Table 8. Interrupt mapping

Wakeup

from Halt

mode

Wakeup

from

Active-halt

mode

Wakeup

from Wait

(WFI

mode)

Wakeup

from Wait

(WFE

mode)

Vector

address

- RESET Reset Yes Yes Yes Yes 0x00 8000

- TRAP Software interrupt - - - - 0x00 8004

0 - Reserved - - - - 0x00 8008

1 FLASH EOP/WR_PG_DIS - - Yes Yes

(1)

2-3-Reserved ----

4 AWU Auto wakeup from Halt - Yes Yes Yes

(1)

0x00 800C

0x00 8010

-0x00 8017

0x00 8018

5 - Reserved - - - - 0x00 801C

6 EXTIB External interrupt port B Yes Yes Yes Yes 0x00 8020

7 EXTID External interrupt port D Yes Yes Yes Yes 0x00 8024

8 EXTI0 External interrupt 0 Yes Yes Yes Yes 0x00 8028

9 EXTI1 External interrupt 1 Yes Yes Yes Yes 0x00 802C

10 EXTI2 External interrupt 2 Yes Yes Yes Yes 0x00 8030

11 EXTI3 External interrupt 3 Yes Yes Yes Yes 0x00 8034

12 EXTI4 External interrupt 4 Yes Yes Yes Yes 0x00 8038

13 EXTI5 External interrupt 5 Yes Yes Yes Yes 0x00 803C

14 EXTI6 External interrupt 6 Yes Yes Yes Yes 0x00 8040

15 EXTI7 External interrupt 7 Yes Yes Yes Yes 0x00 8044

16 - Reserved - - - - 0x00 8048

17 - Reserved - - - -

18 COMP Comparators - - Yes Yes

19 TIM2

Update

/Overflow/Trigger/Break

- - Yes Yes 0x00 8054

(1)

0x00 804C

-0x00 804F

0x00 8050

20 TIM2 Capture/Compare - - Yes Yes 0x00 8058

21 TIM3 Update /Overflow/Break - - Yes Yes

22 TIM3 Capture/Compare - - Yes Yes

23-

24

-Reserved ----

25 TIM4 Update /Trigger - - Yes Yes

26 SPI End of Transfer Yes Yes Yes Yes

(1)

(1)

(1)

(1)

0x00 805C

0x00 8060

0x00 8064-

0x00 806B

0x00 806C

0x00 8070

26/58 DS12153 Rev 4

Page 27

STM8L001J3 Interrupt vector mapping

Table 8. Interrupt mapping (continued)

IRQ

Source

No.

block

27 USART

Description

Transmission

complete/transmit data

Wakeup

from Halt

mode

Wakeup

from

Active-halt

mode

--YesYes

Wakeup

from Wait

(WFI

mode)

Wakeup

from Wait

(WFE

mode)

(1)

Vector

address

0x00 8074

register empty

28 USART

Receive Register DATA

FULL/overrun/idle line

--YesYes

(1)

0x00 8078

detected/parity error

29 I2C I2C interrupt

1. In WFE mode, this interrupt is served if it has been previously enabled. After processing the interrupt, the processor goes

back to WFE mode. Refer to Section Wait for event (WFE) mode in the STM8L001xx, STM8L101xx microcontroller family

reference manual (RM0013).

2. The device is woken up from Halt or Active-halt mode only when the address received matches the interface address.

(2)

Yes Yes Yes Ye s

(1)

0x00 807C

DS12153 Rev 4 27/58

27

Page 28

Option bytes STM8L001J3

7 Option bytes

Option bytes contain configurations for device hardware features as well as the memory

protection of the device. They are stored in a dedicated row of the memory.

All option bytes can be modified only in ICP mode (with SWIM) by accessing the EEPROM

address. See

Refer to the How to program STM8L and STM8AL Flash program memory and data

EEPROM programming manual (PM0054) and the STM8 SWIM communication protocol

and debug module user manual (UM0470) for information on SWIM programming

procedures.

Tab le 9 for details on option byte addresses.

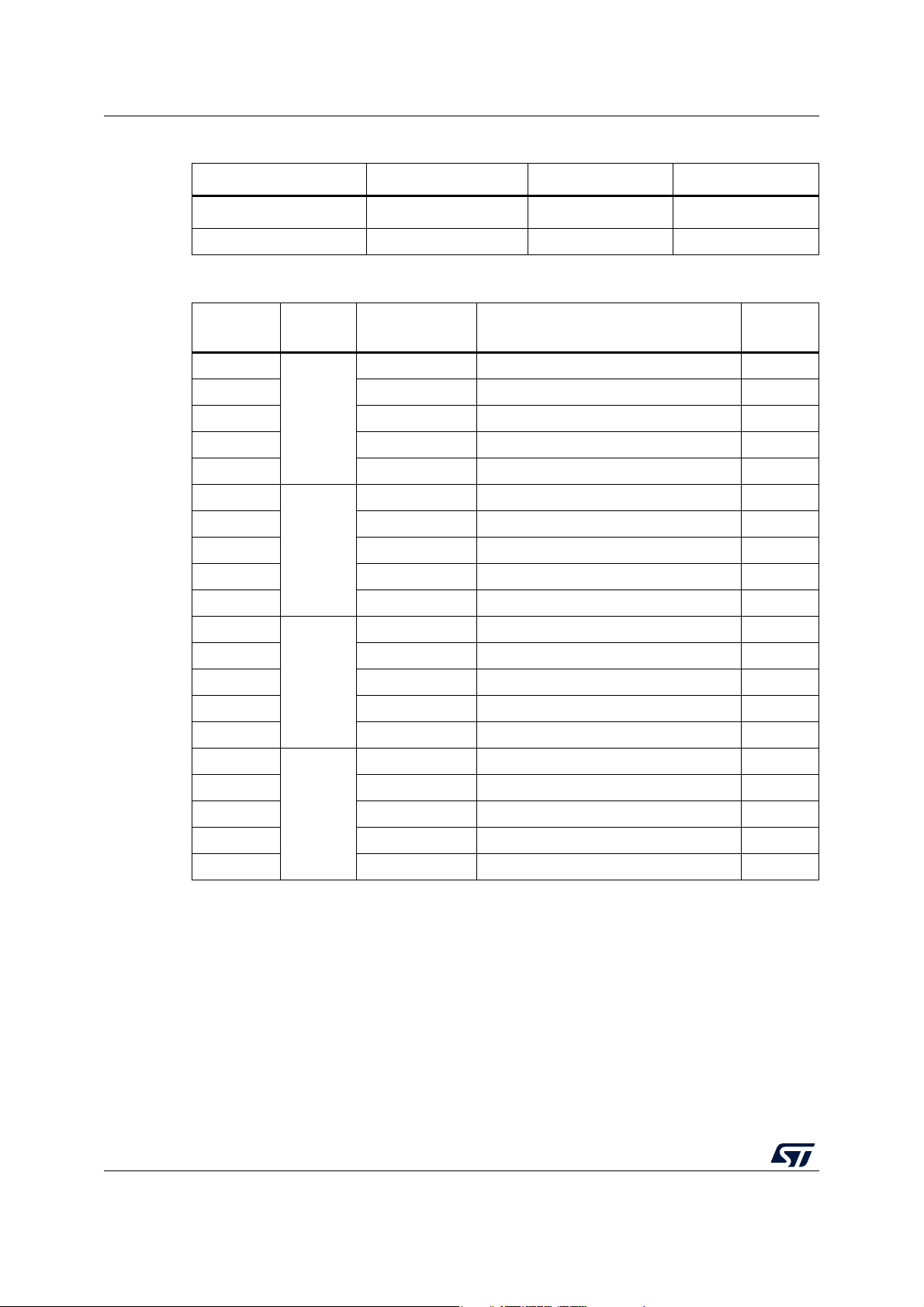

Table 9. Option bytes

Option

Addr. Option name

Read-out

0x4800

0x4807 - - Reserved 0x00

0x4802

0x4803 DATASIZE OPT3 DATASIZE[7:0] 0x00

0x4808

protection

(ROP)

UBC (User

Boot code size)

Independent

watchdog

option

OPT1

OPT2

byte

No.

OPT1 ROP[7:0] 0x00

OPT2 UBC[7:0] 0x00

OPT4

[1:0]

7654 3 2 1 0

Reserved

Table 10. Option byte description

ROP[7:0] Memory readout protection (ROP)

0xAA: Enable readout protection (write access via SWIM protocol)

Refer to Read-out protection section in the STM8L001xx, STM8L101xx

microcontroller family reference manual (RM0013) for details.

UBC[7:0] Size of the user boot code area

0x00: no UBC

0x01-0x02: UBC contains only the interrupt vectors.

0x03: Page 0 and 1 reserved for the interrupt vectors. Page 2 is available to

store user boot code. Memory is write protected

...

0x7F - Page 0 to 126 reserved for UBC, memory is write protected

Refer to User boot area (UBC) section in the STM8L001xx, STM8L101xx

microcontroller family reference manual (RM0013) for more details.

UBC[7] is forced to 0 internally by HW.

Option bits Factory

default

setting

IWDG

_HALT

IWDG

_HW

0x00

28/58 DS12153 Rev 4

Page 29

STM8L001J3 Option bytes

Table 10. Option byte description (continued)

DATASIZE[7:0] Size of the data EEPROM area

0x00: no data EEPROM area

0x01: 1 page reserved for data storage from 0x9FC0 to 0x9FFF

0x02: 2 pages reserved for data storage from 0x9F80 to 0x9FFF

OPT3

OPT4

...

0x20: 32 pages reserved for data storage from 0x9800 to 0x9FFF

Refer to Data EEPROM (DATA) section in the STM8L001xx, STM8L101xx

microcontroller family reference manual (RM0013) for more details.

DATASIZE[7:6] are forced to 0 internal by HW.

IWDG_HW: Independent watchdog

0: Independent watchdog activated by software

1: Independent watchdog activated by hardware

IWDG_HALT: Independent window watchdog reset on Halt/Active-halt

0: Independent watchdog continues running in Halt/Active-halt mode

1: Independent watchdog stopped in Halt/Active-halt mode

Caution: After a device reset, read access to the program memory is not guaranteed if address

0x4807 is not programmed to 0x00.

DS12153 Rev 4 29/58

29

Page 30

Electrical parameters STM8L001J3

50 pF

STM8L PIN

MS32617V1

8 Electrical parameters

8.1 Parameter conditions

Unless otherwise specified, all voltages are referred to VSS.

8.1.1 Minimum and maximum values

Unless otherwise specified the minimum and maximum values are guaranteed in the worst

conditions of ambient temperature, supply voltage and frequencies by tests in production on

100% of the devices with an ambient temperature at T

the selected temperature range).

Data based on characterization results, design simulation and/or technology characteristics

are indicated in the table footnotes and are not tested in production. Based on

characterization, the minimum and maximum values refer to sample tests and represent the

mean value plus or minus three times the standard deviation (mean±3

8.1.2 Typical values

= 25 °C and TA = TA max (given by

A

∑).

Unless otherwise specified, typical data are based on TA = 25 °C, V

only as design guidelines and are not tested.

8.1.3 Typical curves

Unless otherwise specified, all typical curves are given only as design guidelines and are

not tested.

8.1.4 Loading capacitor

The loading conditions used for pin parameter measurement are shown in Figure 4.

Figure 4. Pin loading conditions

= 3 V. They are given

DD

30/58 DS12153 Rev 4

Page 31

STM8L001J3 Electrical parameters

MS32618V1

V

IN

STM8L PIN

8.1.5 Pin input voltage

The input voltage measurement on a pin of the device is described in Figure 5.

Figure 5. Pin input voltage

8.2 Absolute maximum ratings

Stresses above the absolute maximum ratings listed in Tab le 11: Voltage characteristics,

Tab le 12: Current characteristics and Table 13: Thermal characteristics may cause

permanent damage to the device. These are stress ratings only and functional operation of

the device at these conditions is not implied. Exposure to maximum rating conditions for

extended periods may affect device reliability. The device mission profile is compliant with

the JEDEC JESD47 qualification standard; extended mission profiles are available on

demand.

Table 11. Voltage characteristics

Symbol Ratings Min Max Unit

- V

V

DD

SS

V

IN

External supply voltage -0.3 4.0

Input voltage on any pin

(1)

VSS-0.3 VDD+0.3

see Absolute maximum

V

ESD

Electrostatic discharge voltage

ratings (electrical sensitivity)

on page 51

1. I

must never be exceeded. This is implicitly insured if VIN maximum is respected. If VIN maximum

INJ(PIN)

cannot be respected, the injection current must be limited externally to the I

injection is induced by V

while a negative injection is induced by VIN<VSS.

IN>VDD

value. A positive

INJ(PIN)

V

-

DS12153 Rev 4 31/58

52

Page 32

Electrical parameters STM8L001J3

Table 12. Current characteristics

Symbol Ratings Max. Unit

I

VDD

I

VSS

I

IO

Total current into V

Total current out of V

Output current sunk by IR_TIM pin (with high sink LED

driver capability)

power line (source) 80

DD

ground line (sink) 80

SS

80

Output current sunk by any other I/O and control pin 25

Output current sourced by any I/Os and control pin -25

I

INJ(PIN)

ΣI

INJ(PIN)

1. I

2. When several inputs are submitted to a current injection, the maximum ΣI

must never be exceeded. This is implicitly insured if VIN maximum is respected. If VIN maximum

INJ(PIN)

cannot be respected, the injection current must be limited externally to the I

injection is induced by VIN>VDD while a negative injection is induced by VIN<VSS.

positive and negative injected currents (instantaneous values). These results are based on characterization

with ΣI

INJ(PIN)

Injected current on any pin

Total injected current (sum of all I/O and control pins)

maximum current injection on four I/O port pins of the device.

Table 13. Thermal characteristics

(1)

(2)

value. A positive

INJ(PIN)

is the absolute sum of the

INJ(PIN)

±5

±25

Symbol Ratings Value Unit

T

STG

T

Storage temperature range -65 to +150

Maximum junction temperature 150

J

mA

° C

32/58 DS12153 Rev 4

Page 33

STM8L001J3 Electrical parameters

8.3 Operating conditions

Subject to general operating conditions for VDD and TA.

8.3.1 General operating conditions

Table 14. General operating conditions

Symbol Parameter Conditions Min Max Unit

(1)

f

MASTER

V

DD

(2)

P

D

T

A

T

J

1. f

2. To calculate P

= f

MASTER

Θ

JA

CPU

in table “Thermal characteristics”

Master clock frequency 1.8 V ≤ V

Standard operating voltage - 1.8 3.6 V

Power dissipation at TA= 125 °C

for suffix 3 devices

Temperature range

Junction temperature range

) use the formula given in thermal characteristics P

Dmax(TA

1.8 V ≤ V

(3 suffix version)

-40 °C ≤ T

(3 suffix version)

< 3.6 V 0 16 MHz

DD

SO8N - 49 mW

< 3.6 V

DD

A

Dmax

≤ 125 °C

=(T

-TA)/ΘJA with T

Jmax

− 40 125 °C

- 40 130 °C

in this table and

Jmax

DS12153 Rev 4 33/58

52

Page 34

Electrical parameters STM8L001J3

8.3.2 Power-up / power-down operating conditions

Table 15. Operating conditions at power-up / power-down

Symbol Parameter Conditions Min Typ Max Unit

t

VDD

t

TEMP

V

POR

V

PDR

1. Guaranteed by characterization results.

2. Correct device reset during power on sequence is guaranteed when t

circuit is recommended to ensure correct device reset during power down, when V

3. Tested in production.

VDD rise time rate - 20 - 1300 µs/V

Reset release delay VDD rising - 1 - ms

Power on reset

(1)(2)

threshold

Power down reset

(1)(2)

threshold

8.3.3 Supply current characteristics

Total current consumption

The MCU is placed under the following conditions:

• All I/O pins in input mode with a static value at VDD or VSS (no load)

• All peripherals are disabled except if explicitly mentioned.

- 1.35 - 1.65

(3)

- 1.40 - 1.60 V

is respected. External reset

VDD[max]

< VDD < V

PDR

DD[min]

.

V

Subject to general operating conditions for VDD and TA.

34/58 DS12153 Rev 4

Page 35

STM8L001J3 Electrical parameters

1. Based on characterization results, unless otherwise specified.

2. All peripherals off, VDD from 1.8 V to 3.6 V, HSI internal RC osc., f

3. Maximum values are given for TA = − 40 to 125 °C.

4. CPU executing typical data processing.

5. An approximate value of I

6. Tested in production.

Figure 6. I

Table 16. Total current consumption in Run mode

Symbol Parameter Conditions

Code executed from

RAM

Supply

I

DD (Run)

I

DD(Run)

DD(RUN)

current in

Run

mode

= f

MASTER

vs. V

(4) (5)

Code executed from

can be given by the following formula:

DD(Run)

x 150 µA/MHz +215 µA.

DD, fCPU

= 2 MHz Figure 7. I

Flash

(2)

f

MASTER

f

MASTER

f

MASTER

f

MASTER

f

MASTER

f

MASTER

f

MASTER

f

MASTER

(1)

Typ M ax

= 2 MHz 0.39 0.60

= 4 MHz 0.55 0.70

= 8 MHz 0.90 1.20

= 16 MHz 1.60 2.10

= 2 MHz 0.55 0.70

= 4 MHz 0.88 1.80

= 8 MHz 1.50 2.50

= 16 MHz 2.70 3.50

CPU=fMASTER

DD(RUN)

vs. VDD, f

= 16 MHz

CPU

(3)

(6)

Unit

mA

1. Typical current consumption measured with code executed from Flash.

DS12153 Rev 4 35/58

52

Page 36

Electrical parameters STM8L001J3

I

1. Based on characterization results, unless otherwise specified.

2. Maximum values are given for TA = -40 to 125 °C.

Figure 8. I

Table 17. Total current consumption in Wait mode

(1)

Symbol Parameter Conditions Typ Max

= 2 MHz 245 400

= 4 MHz 300 450

= 8 MHz 380 600

= 16 MHz 510 800

DD(WAIT)

vs. VDD, f

= 16 MHz

CPU

DD (Wait)

DD(WAIT)

Supply

current in

Wait mode

vs. VDD, f

CPU not clocked,

all peripherals off,

HSI internal RC osc.

= 2 MHz Figure 9. I

CPU

f

MASTER

f

MASTER

f

MASTER

f

MASTER

(2)

Unit

µA

1. Typical current consumption measured with code executed from Flash.

36/58 DS12153 Rev 4

Page 37

STM8L001J3 Electrical parameters

Table 18. Total current consumption and timing in Halt and Active-halt mode at

V

= 1.8 V to 3.6 V

DD

Symbol Parameter Conditions Typ Max Unit

I

DD(AH)

I

DD(WUFAH)

t

WU(AH)

I

DD(Halt)

I

DD(WUFH)

Supply current in Active-halt

mode

Supply current during

wakeup time from Active-halt

mode

Wakeup time from Active-

(3)

halt mode to Run mode

Supply current in Halt mode

Supply current during

wakeup time from Halt mode

LSI RC osc.

(at 37 kHz)

--2-mA

= 16 MHz 4 6.5 μs

f

CPU

TA = -40 °C to 25 °C 0.35 1.2

T

= 55 °C 0.6 1.8 μA

A

= 85 °C 1 2.5

T

A

= 105 °C 2.5 6.5 μA

T

A

T

= 125 °C 5.4 12

A

(1)(2)

T

= -40 °C to 25 °C 0.8 2 μA

A

= 55 °C 1 2.5 μA

T

A

= 85 °C 1.4 3.2 μA

T

A

T

= 105 °C 2.9 7.5 μA

A

= 125 °C 5.8 13 μA

T

A

(4)

(4)

(4)

2-mA

μA

μA

μA

Wakeup time from Halt mode

t

1. T

2. Guaranteed by characterization results.

3. Measured from interrupt event to interrupt vector fetch.

4. Tested in production.

(3)

WU(Halt)

= -40 to 125 °C, no floating I/O, unless otherwise specified.

A

To get tWU for another CPU frequency use tWU(FREQ) = tWU(16 MHz) + 1.5 (T

The first word of interrupt routine is fetched 5 CPU cycles after t

to Run mode

Figure 10. Typ. I

DD(Halt)

= 16 MHz 4 6.5 μs

f

CPU

.

WU

vs. V

DD, fCPU

= 2 MHz and 16 MHz

FREQ-T16 MHz

).

1. Typical current consumption measured with code executed from Flash.

DS12153 Rev 4 37/58

52

Page 38

Electrical parameters STM8L001J3

Current consumption of on-chip peripherals

Measurement made for f

MASTER

Table 19. Peripheral current consumption

= from 2 MHz to 16 MHz

Symbol Parameter Typ. V

I

DD(TIM2)

I

DD(TIM3)

I

DD(TIM4)

I

DD(USART)

I

DD(SPI)

I

DD(I2C1)

I

DD(COMP)

1. Data based on a differential IDD measurement between all peripherals off and a timer counter running at

16 MHz. The CPU is in Wait mode in both cases. No IC/OC programmed, no I/O pin toggling. not tested in

production.

2. Data based on a differential IDD measurement between the on-chip peripheral when kept under reset and

not clocked and the on-chip peripheral when clocked and not kept under reset. The CPU is in Wait mode in

both cases. No I/O pin toggling. Not tested in production.

TIM2 supply current

TIM3 supply current

TIM4 timer supply current

USART supply current

SPI supply current

I2C supply current

Comparator supply current

(1)

(1)

9

(1)

(2)

(2)

(2)

8.3.4 Clock and timing characteristics

Internal clock sources

= 3.0 V Unit

DD

9

4

µA/MHz

7

4

4

(2)

20 µA

Subject to general operating conditions for VDD and TA.

High speed internal RC oscillator (HSI)

Table 20. HSI oscillator characteristics

Symbol Parameter Conditions Min Typ Max Unit

f

Frequency VDD = 3.0 V - 16 - MHz

HSI

= 3.0 V, TA = 25 °C -5 - 5 %

V

ACC

Accuracy of HSI

HSI

oscillator

(factory calibrated)

I

DD(HSI)

1. V

2. Guaranteed by characterization results.

HSI oscillator power

consumption

= 3.0 V, TA = -40 to 125 °C unless otherwise specified.

DD

DD

1.8 V ≤ V

-40 °C ≤ T

≤ 3.6 V,

DD

≤ 125 °C

A

- - 70 100

-7.5

(1)

(2)

-7.5

(2)

(2)

µA

%

38/58 DS12153 Rev 4

Page 39

STM8L001J3 Electrical parameters

Low speed internal RC oscillator (LSI)

Table 21. LSI oscillator characteristics

Symbol Parameter Conditions Min Typ Max Unit

(1)

f

f

drift(LSI)

1. V

2. For each individual part, this value is the frequency drift from the initial measured frequency.

Frequency - 26 38 56 kHz

LSI

LSI oscillator frequency

(2)

drift

= 1.8 V to 3.6 V, TA = -40 to 125 °C unless otherwise specified.

DD

Figure 11. Typical LSI RC frequency vs. V

8.3.5 Memory characteristics

0 °C ≤ TA ≤ 85 °C -12 - 11 %

DD

TA = -40 to 125 °C unless otherwise specified.

Table 22. RAM and hardware registers

Symbol Parameter Conditions Min Typ Max Unit

V

RM

1. Minimum supply voltage without losing data stored in RAM (in Halt mode or under Reset) or in hardware

registers (only in Halt mode). Guaranteed by characterization results.

Data retention mode

(1)

Halt mode (or Reset) 1.65 - - V

Flash memory

Symbol Parameter Conditions Min Typ

V

Operating voltage

DD

(all modes, read/write/erase)

Programming time for 1- or 64-byte (block)

erase/write cycles (on programmed byte)

t

prog

Programming time for 1- to 64-byte (block)

write cycles (on erased byte)

Table 23. Flash program memory

f

MASTER

DS12153 Rev 4 39/58

= 16 MHz 1.8 - 3.6 V

--6-ms

--3-ms

Max

(1)

Unit

52

Page 40

Electrical parameters STM8L001J3

Table 23. Flash program memory (continued)

Symbol Parameter Conditions Min Typ

TA=+25 °C, VDD = 3.0 V -

I

t

N

1. Guaranteed by characterization results.

2. Retention guaranteed after cycling is 10 years at 55 °C.

3. Retention guaranteed after cycling is 1 year at 55 °C.

4. Data based on characterization performed on the whole data memory (2 Kbytes).

Programming/ erasing consumption

prog

Data retention (program memory)

after 10k erase/write cycles

= +85 °C

at T

A

Data retention (data memory)

after 10k erase/write cycles

RET

at T

= +85 °C

A

Data retention (data memory)

after 300k erase/write cycles

= +125 °C

at T

A

Erase/write cycles (program memory) See notes

RW

Erase/write cycles

(data memory) See notes

=+25 °C, VDD = 1.8 V - -

T

A

100

100

(1)

(1)

(1)

(1)

(1)(4)

T

= 55 °C 20

RET

T

= 55 °C 20

RET

T

= 85 °C 1

RET

(1)(2)

(1)(3)

8.3.6 I/O port pin characteristics

Max

(1)

Unit

-

0.7

mA

--

--

years

--

- - cycles

- - kcycles

General characteristics

Subject to general operating conditions for VDD and TA unless otherwise specified. All

unused pins must be kept at a fixed voltage: using the output mode of the I/O for example or

an external pull-up or pull-down resistor.

Table 24. I/O static characteristics

Symbol Parameter Conditions Min Typ

V

V

V

Input low level voltage

IL

Input high level voltage

IH

Schmitt trigger voltage hysteresis

hys

(2)

(2)

All I/Os VSS-0.3 - 0.3 x V

All I/Os 0.70 x V

Standard I/Os - 200 -

(3)

True open drain I/Os - 250 -

V

≤ VIN ≤ V

SS

DD

Standard I/Os

V

≤ VIN ≤ V

Input leakage current

I

lkg

(4)

SS

True open drain I/Os

V

≤ VIN ≤ V

SS

DD

DD

PA0 with high sink LED

driver capability

R

C

Weak pull-up equivalent resistor

PU

(7)

I/O pin capacitance - - 5

IO

(6)

V

= V

IN

SS

(1)

DD

-VDD+0.3 V

- - 50

- - 200

- - 200

30 45 60 kΩ

(8)

Max Unit

V

DD

mV

(5)

(5)

nA

(5)

-pF

40/58 DS12153 Rev 4

Page 41

STM8L001J3 Electrical parameters

1. VDD = 3.0 V, TA = -40 to 85 °C unless otherwise specified.

2. Guaranteed by characterization results.

3. Hysteresis voltage between Schmitt trigger switching levels. Guaranteed by characterization results.

4. The max. value may be exceeded if negative current is injected on adjacent pins.

5. Not tested in production.

pull-up equivalent resistor based on a resistive transistor (corresponding I

6. R

PU

Figure 14).

7. Guaranteed by design.

8. Capacitance per one GPIO on pin. Complete pin capacitance depends on how many GPIOs are connected on a given pin

(see Table 3). Total pin capacitance is then N x C

(where N = number of GPIOs on a given pin).

IO

current characteristics described in

PU

Figure 12. Typical VIL and V

Figure 13. Typical V

and V

IL

vs. VDD (High sink I/Os)

IH

vs. VDD (true open drain I/Os)

IH

DS12153 Rev 4 41/58

52

Page 42

Electrical parameters STM8L001J3

Figure 14. Typical pull-up resistance RPU vs. VDD with VIN=V

Figure 15. Typical pull-up current IPU vs. VDD with VIN=V

SS

SS

42/58 DS12153 Rev 4

Page 43

STM8L001J3 Electrical parameters

Output driving current

Subject to general operating conditions for V

I/O

Symbol Parameter Conditions Min Max Unit

Type

(1)

V

OL

Standard

(2)

V

OH

1. The IIO current sunk must always respect the absolute maximum rating specified in Table 12 and the sum

of I

(I/O ports and control pins) must not exceed I

IO

2. The IIO current sourced must always respect the absolute maximum rating specified in Table 12 and the

sum of I

(I/O ports and control pins) must not exceed I

IO

Table 25. Output driving current (High sink ports)

Output low level voltage for an I/O pin

Output high level voltage for an I/O pin

and TA unless otherwise specified.

DD

= +2 mA,

I

VSS

.

VDD

.

IO

V