Page 1

STK512

....................................................................................................................

AVR-based Uni-directional

Radio Starter Kit Featuring

Secure Rolling-Code RF

Transmission Encryption

User Guide

Note: This Radio Starter Kit is not self-contained. It is based on an Atmel® AVR® STK®500

Flash Microcontroller Starter Kit that must be obtained separately.

5170C–AVR–10/09

Page 2

Table of Contents

Section 1

Introduction.................................................................................................................1-1

1.1 Purpose.............................................................................................................................. 1-1

1.2 General Description ........................................................................................................... 1-1

1.3 Evaluation Kit Features......................................................................................................1-1

1.4 Included in the Kit .............................................................................................................. 1-2

Section 2

Getting Started ...........................................................................................................2-1

2.1 Hardware Assembly........................................................................................................... 2-1

2.2 Initial Programming ............................................................................................................ 2-6

2.2.1 Programming the ATmega88 to Control the Receiver......................................... 2-6

2.2.2 Programming the Transmitter(s).......................................................................... 2-7

2.3 Teach the Transmitters to the Receiver............................................................................. 2-8

2.4 The Demonstration ............................................................................................................2-9

Section 3

Programming Notes ...................................................................................................3-1

3.1 Configuration...................................................................................................................... 3-1

3.2 Project Compilation............................................................................................................ 3-2

3.3 EEPROM Image Generation.............................................................................................. 3-2

Section 4

Troubleshooting Guide...............................................................................................4-1

STK512 User Guide i

5170C–AVR–10/09

Page 3

Section 1

Introduction

Congratulations on your purchase of the Atmel® AVR®-based Uni-directional Radio Starter Kit featuring

Secure Rolling Code RF Transmission Encryption. This kit uses an Atmel STK

troller Starter Kit that must be obtained separately.

This User’s Guide describes how to use this Starter Kit. Section 2, Getting Started, describes how to

assemble and program the hardware to demonstrate a wireless link that uses a secure rolling code algo

rithm. Section 3, Programming Notes, describes optional programming for the advanced user.

1.1 Purpose

This starter kit demonstrates a Secure Rolling Code Algorithm transmission protocol for use in a unidirectional wireless communication system. Typical applications for this algorithm are garage door

openers, remote keyless entry, passive entry, and remote car-start systems.

1.2 General Description

This kit demonstrates the transmission protocol with one receiver and a pair of associated transmitters.

However, a typical system can support many more transmitters.

Characteristics of this protocol are:

A transmission-encryption value that is valid only once, preventing interception and re-transmission to

gain unauthorized access,

Message content that is virtually impossible to predict, even if previous messages are known.

®

500 Flash Microcon-

-

For a thorough technical coverage of the hardware, software, and theory, read the application note,

“AVR411: Secure Rolling Code Algorithm for Wireless Link” that is included on the accompanying CD.

1.3 Evaluation Kit Features

Advanced Encryption Standard (AES) and its Cipher-based Message Authentication Code (CMAC)

mode of operation for transmitter authentication:

Multiple transmitters supported

PC command-line tools for cryptographic key management

Up to 256-bit key sizes supported

Less than 30 ms response time

315/434/868 MHz ISM-band frequencies

ATA5771/73/74 and ATA8741/42/43 UHF ASK/FSK transmitters with embedded ATtiny44

microcontroller

STK512 User Guide 1-1

5170C–AVR–10/09

Page 4

Introduction

ATA5723/24/28 and ATA8203/04/05 UHF ASK/FSK receivers

User-programmable transmitters with 6-pin ISP

Sleep modes for minimal power consumption

1.4 Included in the Kit

Note: This Radio Starter Kit is not self-contained. It is based on an Atmel STK500 Flash Microcontroller Starter

Kit that must be obtained separately.

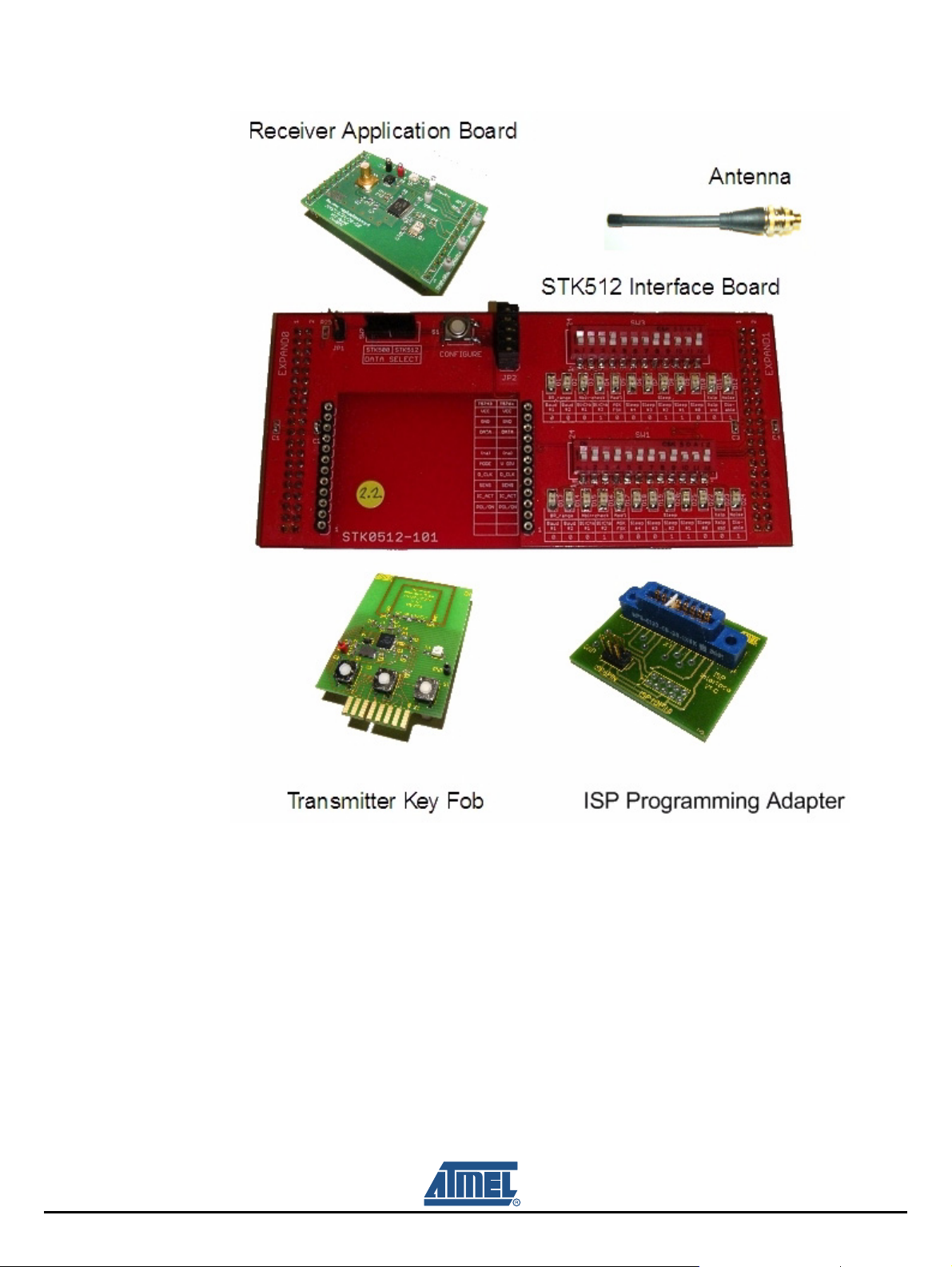

This starter kit includes all the essential components needed to demonstrate an AVR-based uni-directional radio that features a Secure Rolling-Code RF Transmission Encryption protocol. Contents of this

kit are listed and shown in

Transmitter application board

ISP programming adapter for Transmitter

Receiver application board with external antenna

STK512 Interface Board

ATMega88 microcontroller (not shown)

CDROM containing software, Data Sheets, and other documentation (not shown)

Figure 1-1.

1-2 STK512 User Guide

5170C–AVR–10/09

Page 5

Figure 1-1. Kit Contents

Introduction

For investigating further capabilities of this kit, the following are optional:

JTAGICE mkII for debugging

IAR Embedded Workbench

®

AVR C compiler for changing and recompiling the source code without

porting it to another compiler (precompiled source code with default configuration is provided on the

CDROM).

STK512 User Guide 1-3

5170C–AVR–10/09

Page 6

This section contains the steps required to get a simple system with a receiver and two transmitters up

and running. Hardware assembly, initial programming of the components, teaching the transmitters to

the receiver, and demonstrating the transmission protocol are described in the following subsections.

2.1 Hardware Assembly

The kit hardware must be interfaced to the STK500.

Step A: Assemble the STK500 Board

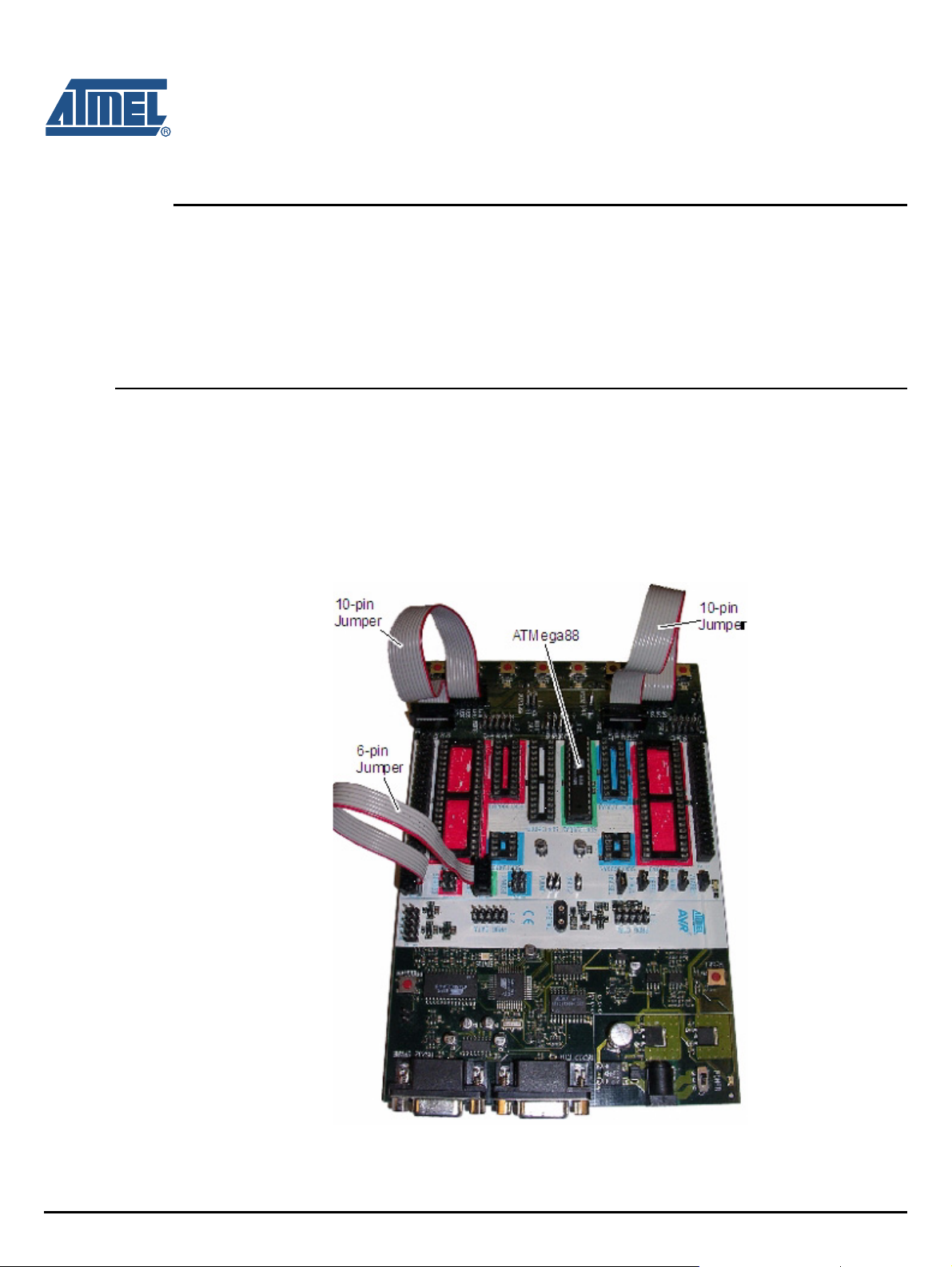

The STK500 Board must be set up properly before mounting the STK512 Interface Board. The assembled STK500 Board is shown in Figure 2-1.

Figure 2-1. STK500 Board with Ribbon Cables and Microcontroller

Section 2

Getting Started

STK512 User Guide 2-1

5170C–AVR–10/09

Page 7

Getting Started

1. Carefully remove any ICs in the green “SCKT3200A2” socket.

2. Insert the furnished ATMega88 into the “SCKT3200A2” socket.

Note: The orientation of the red stripe in the cable is not critical in the following steps as long as pin 1 is con-

nected to pin 1.

3. Using a 6-pin jumper cable supplied with the STK500;

connect the two male headers “ISP6PIN” and “SPROG2”.

4. Using a 10-pin jumper cable supplied with the STK500;

connect the two male headers “PORTC” and “LEDS”.

5. Using a 10-pin jumper cable supplied with the STK500;

connect the two male headers “PORTD” and “SWITCHES”.

6. Place jumpers on the following headers as shown in Figure 2-2.

–VTARGET

–AREF

– RESET

–XTAL1

– OSCEL (a 3-pin header. Place a jumper next to the “1” printed on the board).

Figure 2-2. Detail of Jumper Placement on the STK500

2-2 STK512 User Guide

5170C–AVR–10/09

Page 8

Getting Started

Step B: Assemble and Attach the STK512 Interface Board

The STK512 Interface Board must be assembled and mounted on the STK500 Board. The completed

assembly is shown in

Figure 2-3.

Figure 2-3. Assembled STK512 Interface Board

1. Orient the STK500 as shown in the Figure 2-3.

Caution: After the next step, whenever the interface board is removed from the STK500 sockets, use

caution if a tool is used for leverage. It is easy to bend pins or otherwise damage the STK500 and/or the

interface board. Use a rocking motion while steadily pulling (not prying) it straight from the sockets.

2. Insert the STK512 Interface Board into the EXPANDx sockets, oriented with the LEDs and red DIP

switches to the left-hand side. To verify the orientation, check that the EXPAND0 pins on the Interface Board plug into the EXPAND0 socket on the STK500 Board. Press firmly so that the board pins

seat well.

3. Install jumpers on all five pairs of pins (JP2, next to the “configure” button) as shown in Figure 2-4.

STK512 User Guide 2-3

5170C–AVR–10/09

Page 9

Getting Started

Figure 2-4. STK512 Jumper Placement

2-4 STK512 User Guide

5170C–AVR–10/09

Page 10

Getting Started

Step C: Mount the Receiver Application Board

The Receiver Application Board must be mounted on the STK512 Interface Board. The completed

assembly is shown in

Figure 2-5.

Figure 2-5. Completed Receiver Assembly

Caution: After the next step, if the receiver board is removed from the interface board sockets, use

EXTREME caution! The pins on the receiver board are very easily bent and broken! Use a rocking

motion to lift the board straight (perpendicular) out of the socket.

1. Orient the receiver board above the Interface Board as shown in Figure 2-5. Carefully insert the

Receiver Application Board into the STK512 Interface Board sockets.

2. Install the antenna onto the SMB connector.

3. Supply the STK500 with +12 V power by connecting it to a PC using the RS232 port.

STK512 User Guide 2-5

5170C–AVR–10/09

Page 11

Getting Started

2.2 Initial Programming

After setting-up the hardware, insert the accompanying CD into the computer’s CDROM drive.

Note: If you want to use something other than the pre-compiled demonstration software and EEPROM files

included on the CD, there is additional programming information in Section 3, Programming Notes.

1. Apply power to the STK500 by moving the power switch toward the edge of the board.

2. If not already done, install and/or open AVR Studio.

3. When the first box appears entitled, “Welcome to AVR Studio 4,” click “Cancel” (to program the

devices doesn't require that a “Project” be used).

4. Click on the black IC icon with “AVR” -- it is in one of the top rows of the AVR Studio screen.

(Note: When hovering over this symbol with the mouse pointer, “connect to the selected AVR programmer” appears. This indicates that this is the correct icon).

A pop-up window labeled “STK500” appears.

5. AVR Studio is now ready to program the transmitter(s) and receiver.

2.2.1 Programming the ATmega88 to Control the Receiver

1. Select the “Program” tab and then select ATmega88 from the pull down menu.

2. Select the “Advanced” tab and then select “read signature” to ensure that communication with the

device is functioning properly. If the read attempt is successful, a number will show in the window. If

not, a pop-up will appear describing the failure. Consult the STK500 documentation to handle any

failures.

3. Select the “Fuses” tab and ensure that the Fuses are set as shown in Table 2-1

Table 2-1. Receiver ATmega88 Fuse Settings

Fuse Name Setting

Boot Flash section size = 1024…

Brown-out detection disabled

Int RC Osc 8 MHz: … +64 ms

Divide clock by 8 internally

Watchdog Timer always on

Checked

Checked

Checked

Not Checked

Not checked

4. From the CD, in the folder “software\IAR\RX\Release\Exe,” program the flash of the ATMega88 with

“RX_fffMHz.a90.” (Note: “fff” is 315, 434, 868 or 915, the frequency specified for this kit).

5. From the CD, in the folder “software\Precompiled,” program the EEPROM of the ATMega88 with

“RX_EEPROM_AES128.hex.”

The ATMega88 is now programmed to control the receiver.

Note: About receiver programming: the two rows of DIP switches on the interface board provide the capability to

set the OPMODE and LIMIT registers of the receiver IC. These DIP switches are NOT used by this demonstration software, as the receiver is programmed by the ATmega88. More can be found about how these

switches work by consulting the appropriate Data Sheets for the receiver ICs used in this kit. To avoid accidental misprogramming of the receiver IC when using this demonstration kit, avoid pushing the white

“CONFIGURE” button when the black slide switch is in the “STK512” position!

2-6 STK512 User Guide

5170C–AVR–10/09

Page 12

2.2.2 Programming the Transmitter(s)

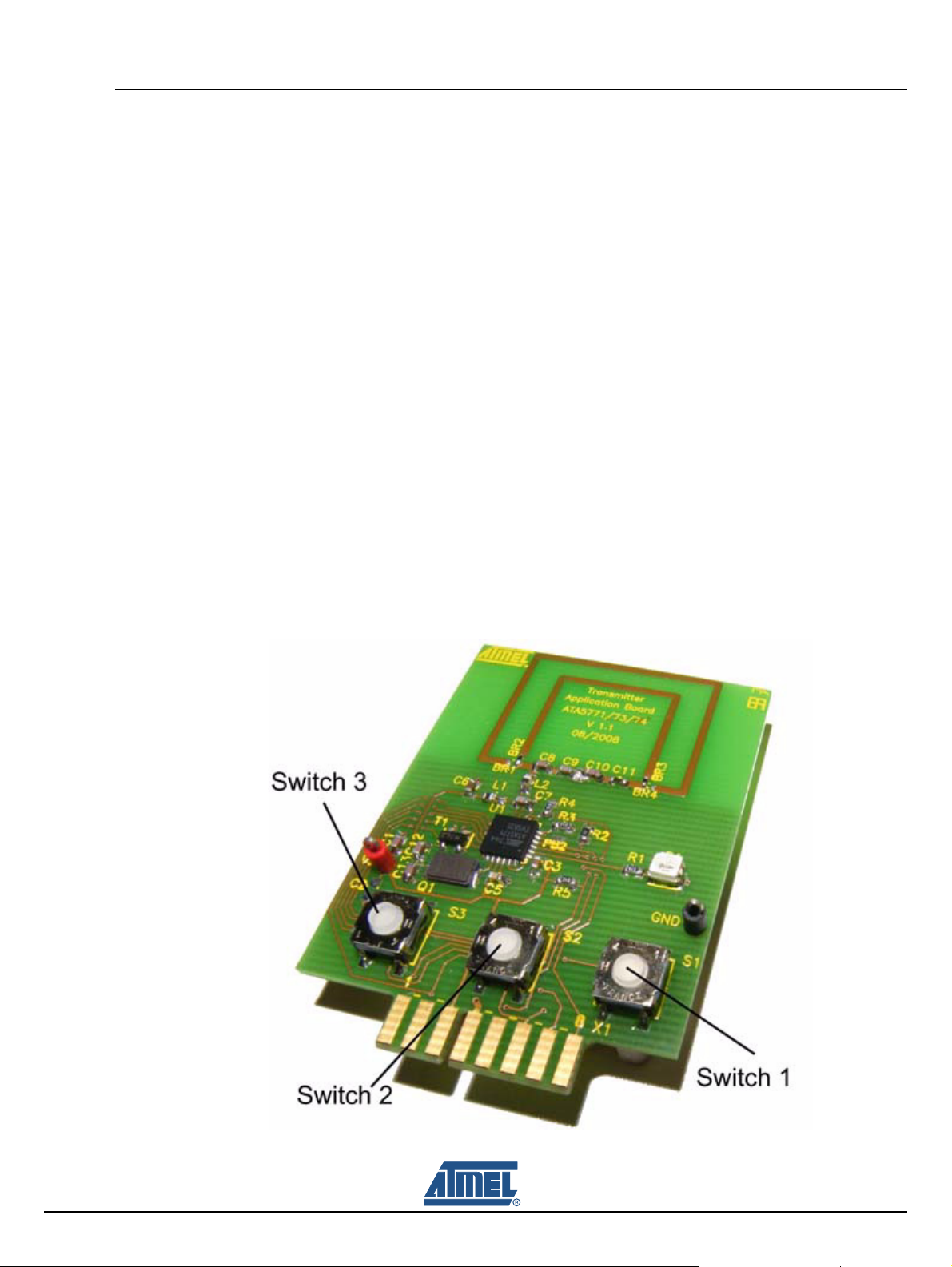

1. On the STK500, remove the 6-pin cable from the “SPROG2” header, plug it into the ISP programming adapter. Next, insert the transmitter application board into the adapter, as shown in Figure 2-6.

Figure 2-6. Transmitter Key Fob with 6-pin Cable

Getting Started

2. On the “Program” tab of the “STK500” pop-up window, select the ATtiny44 from the pull-down list.

3. In the “Advanced” tab select “read signature” to ensure that communication with the device is functioning properly. If the read attempt is successful, a number will show in the window. If not, a pop-up

will appear, describing the failure. Consult the STK500 documentation to handle any failures.

4. Select the “fuses” tab and ensure that the Fuses are set as shown in Table 2-2.

Table 2-2. Transmitter ATtiny44 Fuse Settings

Fuse Name Setting

Preserve EEPROM memory…

Brown-out detection disabled

Int RC Osc 8 MHz: … +64 ms

Divide clock by 8 internally

Watchdog Timer always on

Checked

Checked

Checked

Not Checked

Not checked

5. From the CD, in the folder “software\IAR\TX\Release\Exe,” program the flash of the ATtiny45 with

“TX.a90.”

6. From the CD, in the folder “software\Precompiled,” program the EEPROM of the Tiny45 with

“TX_EEPROM_AES128_ID1.”

7. Repeat this process for the second transmitter, except with the file “TX_EEPROM_AES128_ID2.”

The transmitters are now programmed and ready for use.

STK512 User Guide 2-7

5170C–AVR–10/09

Page 13

Getting Started

2.3 Teach the Transmitters to the Receiver

In order for the rolling code to work, each transmitter must convey to (teach) the receiver three data elements: its unique serial number, its secret key, and its sequence counter value. The “learn mode” is

physically activated at the receiver during which time authorized transmitters can transmit their specific

information. This teaching and learning process is accomplished by the following steps.

For security purposes, when the receiver enters the learn mode, all previous data concerning transmitters should be erased. This is discussed in further detail in section 3.2 of the “AVR411: Secure Rolling

Code Algorithm for Wireless Link Application Note” that is furnished on the CDROM. This requirement

has not been implemented in this starter kit in order to allow further investigation into this mode.

Familiarize yourself with the following instructions before beginning the teaching process.

Also, keep your transmitter key fobs readily available. The default timeout to teach a transmitter is 10

seconds before the receiver will exit the learn mode.

1. Enter learn mode on the receiver by pressing the SW5 button on the STK500. The LED marked

LED5 illuminates, indicating that the receiver is in learn mode.

2. Within 10 seconds, press Switch 1 on the transmitter key fob you want the receiver to recognize.

Inadvertently pressing any other button or combination of buttons will transmit an ordinary message

that will be ignored by the receiver since the receiver is expecting a longer “teach” message. Once

the receiver receives the “teach” message, the learn-mode LED5 blinks off once, and you have

another 10 seconds to teach the next transmitter. If LED5 does not blink, the message was not

received correctly, perhaps due to interference or an incorrect button combination. Repeat steps 1

and 2 until successful.

Figure 2-7. Transmitter Key Fob Button Numbering

2-8 STK512 User Guide

5170C–AVR–10/09

Page 14

3. Repeat steps 1 and 2 for to teach additional transmitters.

4. When the last transmitter has been taught to the receiver, wait for the 10-second learn-mode timeout

to expire. At this Point, LED5 goes off and the receiver is ready to accept regular messages from the

transmitters.

Note: Whenever the maximum number of transmitters is reached, LED5 blinks to indicate that a transmitter has

been learned, but there is not another 10-second delay. LED5 goes off immediately after blinking.

2.4 The Demonstration

On the STK500, LED0 through LED4 represent a sequential circular counter (i.e., LEDs 0 through 4 illuminate in sequence and then LEDs 0 through 4 again illuminate in sequence, etc.). Pressing Switch 3 on

a learned transmitter key fob increments the code counter and the illuminated LED; pressing Switch 2,

the counter and the illuminated LED de-increments.

Since the rolling code is transparent (embedded in the transmitted message) to the end user of a system, by default, the software provided in this starter kit is designed to simply demonstrate the reliable

receipt of transmissions originating from the transmitter key fobs.

A necessary component of this secure encryption algorithm is synchronization between the transmitter

and receiver. To demonstrate synchronization feature, a situation must be created to cause a transmitter

key fob’s counter to become out of sequence with the receiver’s respective counter. With the source

code provided, the window of acceptance defaults to a value of 100. That is, the transmitter key fob must

increment its counter 100 times above the count the receiver remembers for that transmitter key fob.

This can be done by moving the transmitter key fob out of range of the receiver and pressing either

Switch 2 or 3 more than 100 times. When the transmitter key fob is again brought within range of the

receiver; note that the receiver will not respond to that transmitter key fob because the counters are out

of sequence more than 100. This synchronization feature is further explained in section 3.1.1 of the

“AVR411: Secure Rolling Code Algorithm for Wireless Link Application Note” that is furnished on the

CDROM.

Getting Started

To simplify demonstrating the out-of-sync situation, the size of the “rolling window of acceptance” variable can be reduced. This reduces the number of times the transmitter key fob switches must be

pressed to cause an out of sync condition.

Similar to the above approach, incremented counter values can be changed through manipulation of the

counter value variable directly in software. Atmel recommends appropriate variable monitoring capabili

ties be available before attempting this approach.

Whichever approach is used, the transmitter key fob and receiver counter can be resynchronized by

having the receiver relearn the transmitter key fob.

-

STK512 User Guide 2-9

5170C–AVR–10/09

Page 15

The following describes optional programming that is not necessary to use the kit to demonstrate the rolling code algorithm over an RF link. In addition to the information below, the accompanying CD contains

a “readme.html” file that documents user programming of both the receiver and transmitter.

This information is included for the advanced user who wishes to experiment with the kit and its

expanded capabilities.

3.1 Configuration

There are numerous options for the system, e.g., cryptographic key sizes, message field sizes etc. The

parameters are given as #define macros in the config.h files in both the transmitter and receiver source

code folder. The most important parameters are given in. It is important that the parameters for the trans

mitter and receiver code are the same.

The configuration file contains several other advanced parameters. Parameter usage is explained in

comment blocks in the files themselves and should not be altered. Always keep a backup copy of the

original default configuration.

Section 3

Programming Notes

-

Table 3-1. Basic Configuration Parameters

Default

Parameter Name

KEY_BITS 128

SERIAL_NO_BYTES 4

COMMAND_CODE_BYTES 1

SEQ_COUNTER_BYTES 4

MAC BYTES - 4

MAX_TRANSMITTERS 5

WINDOW SIZE - 100 The size of the rolling window of acceptance.

Note: 1. Serial number, command code and sequential counter value fields must not exceed 16 bytes. A compile

error will occur if the total size exceeds this limit.

Value Description

Size of the AES cipher key in bits. Allowed values are 128, 192 and 256

bits, where 256 bits is the most secure option.

Size in bytes of the message field containing a transmitter's serial

number. Allowed values are 1, 2, and 4 bytes

Size in bytes of the message field containing the requested command.

Allowed values are 1, 2, and 4 bytes

Size in byte of the message field containing the sequential counter

value. Allowed values are 1, 2, and 4 bytes

Size in bytes of the message field containing the MAC. The value must

not be larger than 16 bytes. More bytes give a more secure

authentication.

Maximum number of transmitters that one receiver can learn. This

number is limited by the amount of free EEPROM memory. A compile

error will occur of the number is chosen too large.

(1)

.

(1)

.

(1)

.

STK512 User Guide 3-1

5170C–AVR–10/09

Page 16

Programming Notes

3.2 Project Compilation

This step can be skipped if you only want to use the precompiled source code with default settings. If

not, compile projects for both the transmitter and the receiver. Detailed compilation instructions and fuse

settings are giving in the source code documentation.

3.3 EEPROM Image Generation

Allocate serial numbers and secret and shared keys for the system components. Then use the supplied

command line tools to generate one HEX file for every unit. The secret key for the transmitters should be

discarded after generating the HEX file. They are not needed and could compromise system security if

they get into the wrong hands.

Make sure that all transmitters that will be associated with a receiver have the same shared key as the

receiver.

Note: 1. The supplied tools are only meant for prototyping and evaluation. For full production use, a secure key

management infrastructure should be established.

3-2 STK512 User Guide

5170C–AVR–10/09

Page 17

Table 4-1. Troubleshooting Solutions

Problem Reason Solution

Power is not applied or is less than 5V

LED on Receiver

Application Board

not active

LED(s) on STK512

Interface Board not

active

Registers in the

receiver do not

appear to be

programming

DATA Selector switch was not set to the STK511

position when power was applied

Receiver in permanent sleep mode because Sleep

mode of all 1s selected in OPMODE register

Receiver Application Board rotated 180° when mounted

on the STK512 Interface Board

Power not applied

Corresponding DIP Switch bit(s) not set

Bias resistor(s) damaged

Incorrect firmware loaded into the STK512 Interface

Board where I/O port of the onboard microcontroller

programmed to logic high

Power supplied is too low Verify that the power being supplied is 5V

DATA Selector switch was not set to the STK511

position when Configure button pressed

STK512 Interface Board firmware has become

corrupted

Registers may be programming correctly with no visible

signs of change Some external source may be holding

the Data line low

Section 4

Troubleshooting Guide

Verify that 5V is supplied to the Receiver Application

Board via on-board pins or through the STK512 Interface

Board connection to the STK 500 (VTG jumper).

Set DATA Selector switch to STK511 and re-apply 5V

supply

Select different polling rate and re-program OPMODE

register

Verify that Receiver Application Board signal test points

are placed toward the DIP switches.

Verify that Power is supplied to the STK512 Interface

Board through either the Receiver Application Board or

the STK500 Board (VTG jumper).

Set the corresponding bit(s) to ON on the DIP Switch for

that register.

Replace the corresponding bias resistor(s) on the back of

the STK512 Interface Board with 1 k

Reload the STK512 Interface Board Firmware as

described in Section 2.2.

Set DATA Selector switch to STK512 and re-press button

Reload the STK512 Interface Board Firmware as

described in Section 2.2.

Monitor the Data Test point with an oscilloscope to check

for presence of the acknowledge bit.

Receiver Application Board rotated 180° when mounted

on the STK512 Interface Board

STK512 User Guide 4-1

Verify that Receiver Application Board signal test points

are toward the DIP switches.

5170C–AVR–10/09

Page 18

Troubleshooting Guide

Table 4-1. Troubleshooting Solutions (Continued)

Problem Reason Solution

STK512 Interface Board not correctly connected to

STK500

ISP ribbon cable not connected properly

Unable to load

STK512 Interface

Board firmware

Transmitter not

responding to

button press

No activity on

Tr a ns m i t te r

Application Board

LED(s)

Tr a ns m i t te r

Application Board

LED(s) constantly lit

Unable to program

Tr a ns m i t te r

Application board

through ISP header

Demo not working

(STK500 LED(s) not

responding to

transmitted signal)

Incorrect device selected

Device present in STK500 sockets

ISP jumper not shorted on STK512 Interface Board Connect shunt

Power and serial cable not connected to STK500 Verify setup of the STK500 hardware

Battery dead

Demo Software corrupted Reload the desired software according to Section 2.2.

Switch contact not made

Low Battery voltage Replace coin cell battery

Transmitter is in sleep mode Press button to wake from sleep mode

Demo Software corrupted Reload the desired software according to Section 2.2.

Demo Software corrupted Reload the desired software according to Section 2.2.

Incorrect orientation of the ribbon cable connecting the

ISP header to the STK500

Power not supplied to transmitter on-board

microcontroller

Wrong device selected in the STK500 software

Power and serial cable not connected to STK500 Verify setup of the STK500 hardware

Incorrect orientations of the Receiver Application Board

or STK512 Interface Board

Power not properly supplied to all boards See the troubleshooting section for each board.

Data Selector switch not set to STK500 position Set the switch to the proper position and re-run the demo

Microcontroller socket on STK500 not populated

Corrupted software in the STK500 microcontroller

10-pin ribbon cable not connected properly

Incompatible modulation used on the transmitter and

receiver

Receiver set to permanent sleep Check for Sleep bits in the OPMODE register set for all 1s

Receiver limits incorrect Verify correct register settings as given in Section 2.

Receiver antenna not connected

Verify EXPANDO and EXPAND1 are properly oriented

Ensure ribbon cable connected between ISP6PIN header

and SPROG3 header

Check orientation of pin 1 on headers

Select ATmega8515 from the Device menu. Verify that the

signature byte matches in the Advanced tab

Remove all devices from the programming sockets of the

STK500

Open Transmitter Application Board case and replace

coin cell battery

Ensure proper contact of the button to the Transmitter

Application Board

Verify the orientation of both sides of the ribbon cable

Supply 3 volts to the transmitter microcontroller through

the coin cell battery or via the STK500

Select ATtinyl3 from the Device menu. Verify that the

signature We matches in the Advanced tab

Verify the hardware is assembled correctly as shown in

Section 2.

The demo uses an ATmega88 microcontroller in the

STK500 to decode the received signal

Reload the Receiver Decode software as shown

in Section 2.

Verify that the 10-pin ribbon cable is properly connected

to the LEDS header from the PORTC header on the

STK500

Verify that transmitter and receiver are both set for the

same modulation type (ASK versus FSK)

Connect external whip antenna to Receiver Application

Board

4-2 STK512 User Guide

5170C–AVR–10/09

Page 19

Headquarters International

Atmel Corporation

2325 Orchard Parkway

San Jose, CA 95131

USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Atmel Asia

Unit 1-5 & 16, 19/F

BEA Tower, Millennium City 5

418 Kwun Tong Road

Kwun Tong, Kowloon

Hong Kong

Tel: (852) 2245-6100

Fax: (852) 2722-1369

Product Contact

Web Site

www.atmel.com

Literature Requests

www.atmel.com/literature

Atmel Europe

Le Krebs

8, Rue Jean-Pierre Timbaud

BP 309

78054 Saint-Quentin-enYvelines Cedex

France

Tel: (33) 1-30-60-70-00

Fax: (33) 1-30-60-71-11

Technical Support

avr@atmel.com

Atmel Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Sales Contact

www.atmel.com/contacts

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF

THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© 2009 Atmel Corporation. All rights reserved. Atmel®, logo and combinations thereof, AVR®, AVR Studio®, STK® and others are registered

trademarks or trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

5170C–AVR–10/09

/xM

Page 20

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Atmel:

ATASTK512-EK1-AUT

Loading...

Loading...