Page 1

1/10September 2002

STD2NM60

STD2NM60-1

N-CHANNEL 600V - 2.8Ω - 2A DPAK/IPAK

Zener-Protected MDmesh™Power MOSFET

(1)ISD<2A, di/dt<400A/µs, VDD<V

(BR)DSS

, TJ<T

JMAX

■ TYPICAL R

DS

(on) = 2.8 Ω

■ HIGH dv/dt AND AVALANCHE CAPABILITIES

■ 100% AVALANCHE TESTED

■ LOW INPUT CAPACITANCE AND GATE

CHARGE

■ LOW GATE INPUT RESISTAN CE

■ TIGHT PROCESS CONTROL AND HIGH

MANUFACTORING YIELDS

DESCRIPTION

The MDmesh™

is a new revolutionary MOSFET

technology that associates the Multiple Drain process with the Company’s PowerMESH™ horizontal

layout. The resulting product has an outstanding low

on-resistance, impressively high dv/dt and excellent

avalanche characteristics. The adoption of the

Company’s proprietary strip technique yields overall

dynamic performance that is significantly better than

that of similar completition’s products.

APPLICATIONS

The MDmesh™ family is very suitable for increase

the power density of high voltage converters allowing system miniaturization and higher efficiencies.

ABSOLUTE MAXIMUM RATINGS

(•)Pu l se width limited by safe operating area

TYPE V

DSS

R

DS(on)

I

D

STD2NM60

STD2NM60- 1

600V

600V

< 3.2 Ω

< 3.2 Ω

2 A

2 A

Symbol Parameter Value Unit

V

DS

Drain-source Voltage (VGS = 0)

600 V

V

DGR

Drain-gate Voltage (RGS = 20 kΩ)

600 V

V

GS

Gate- source Voltage ±30 V

I

D

Drain Current (continuous) at TC = 25°C

2A

I

D

Drain Current (continuous) at TC = 100°C

1.26 A

I

DM

(●)

Drain Current (pulsed) 8 A

P

TOT

Total Dissipation at TC = 25°C

46 W

Derating Factor 0.37 W/°C

V

ESD(G-S)

Gate source ESD(HBM-C=100pF, R=1.5KΩ) 1kV

dv/dt(1) Peak Diode Recovery voltage slope 15 V/ns

T

stg

Storage Temperature –65 to 150 °C

T

j

Max. Operating Junction Temperature 150 °C

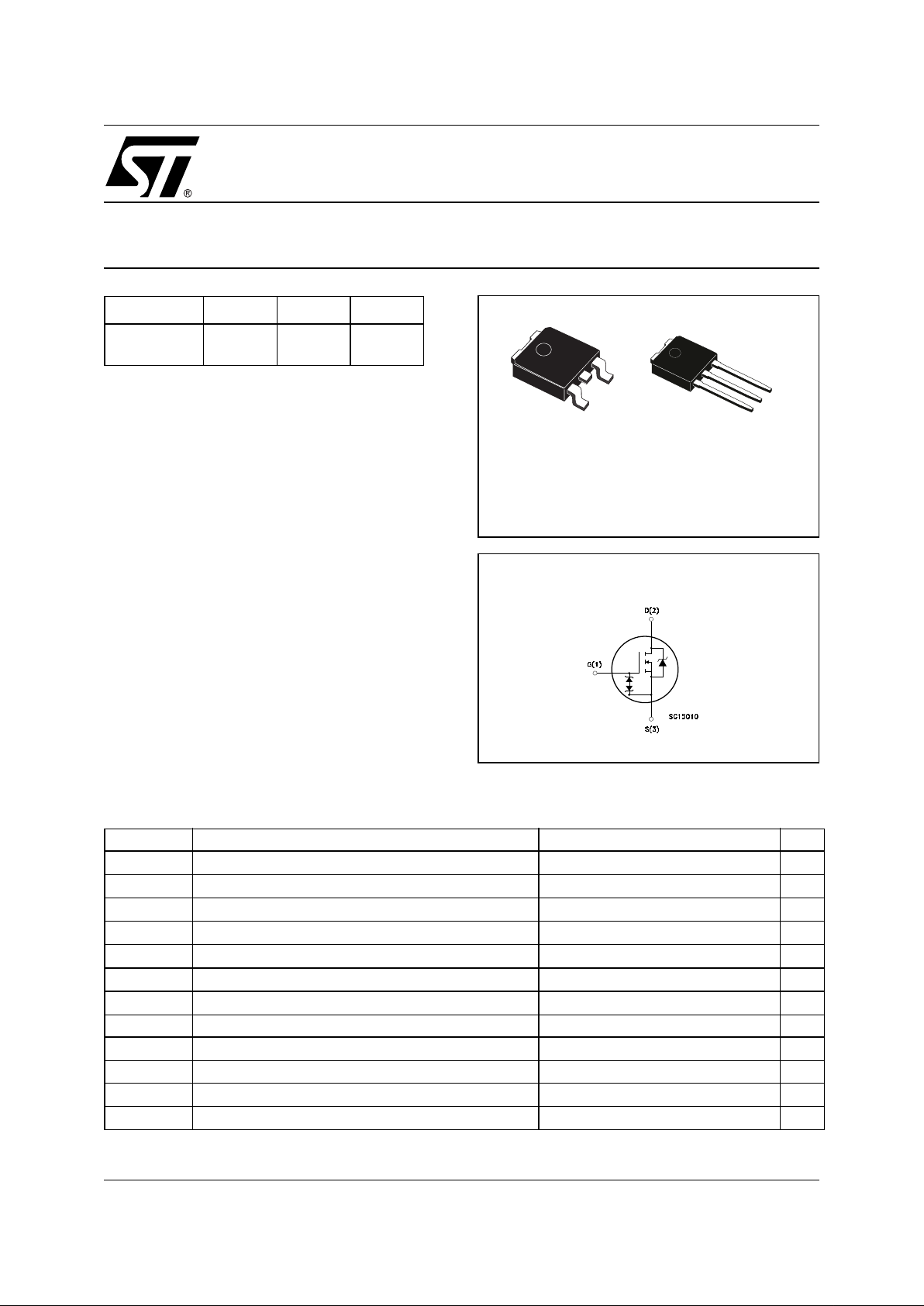

1

3

DPAK

TO-252

3

2

1

IPAK

TO-251

INTERNAL SCHEMATIC DIAGRAM

Page 2

STD2NM60/STD2NM60-1

2/10

THERMA L D ATA

AVALANCHE CHARACTERISTICS

ELECTRICAL CHARACTERISTICS (T

CASE

= 25 °C UNLESS OTHERWISE SPECIFIED)

OFF

ON

(1)

DYNAMIC

Note: 1. Pulsed: Pu l se duration = 300 µs, duty c ycle 1.5 %.

Rthj-case Thermal Resistance Junction-case Max 2.73 °C/W

Rthj-amb Thermal Resistance Junction-ambient Max 62.5 °C/W

T

l

Maximum Lead Temperature For Soldering Purpose 300 °C

Symbol Parameter Max Value Unit

I

AR

Avalanche Current, Repetitive or Not-Repetitive

(pulse width limited by T

j

max)

0.5 A

E

AS

Single Pulse Avalanche Energy

(starting T

j

= 25 °C, ID = IAR, VDD = 50 V)

250 mJ

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

(BR)DSS

Drain-source

Breakdown Voltage

ID = 1 mA, VGS = 0 600 V

I

DSS

Zero Gate Voltage

Drain Current (V

GS

= 0)

V

DS

= Max Rating

1µA

V

DS

= Max Rating, TC = 125 °C

10 µA

I

GSS

Gate-body Leakage

Current (V

DS

= 0)

V

GS

= ± 20V ± 5 µA

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

GS(th)

Gate Threshold Voltage

V

DS

= VGS, ID = 250µA

345V

R

DS(on)

Static Drain-source On

Resistance

VGS = 10V, ID = 1 A

2.8 3.2 Ω

Symbol Parameter Test Conditions Min. Typ. Max. Unit

g

fs

(1) Forward Transconductance VDS > I

D(on)

x R

DS(on)max,

I

D

=2 A

1.4

S

C

iss

Input Capacitance

V

DS

= 25V, f = 1 MHz, VGS = 0

160 pF

C

oss

Output Capacitance 67 pF

C

rss

Reverse Transfer

Capacitance

4pF

R

G

Gate Input Resistance f=1 MHz Gate DC Bias = 0

Test Signal Level = 20mV

Open Drain

3.5 Ω

Page 3

3/10

STD2NM60/STD2NM60-1

ELECTRICAL CHARACTERISTICS (CONTINUED)

SWITCHING ON

SWITCHING OFF

SOURCE DRAIN DIODE

Note: 1. Pulsed: Pu l se duration = 300 µs, duty c ycle 1.5 %.

2. Pulse width li mited by safe operating area.

GATE-SOURCE ZENER DIODE

PROTECTION FEATURES OF GATE-TO-SOURCE ZENER DIODES

The built-in back-to-back Zener diodes have specif ically been designed to enhanc e not only t he dev ice’s

ESD capability, but also to make them safely absorb possible voltage transients that may occasionally be

applied from gate to source. In this respect the Zener voltage is approp riate to achieve an efficient and

cost-effective intervention to protect the device’s int egrity. These integrated Zener diode s th us av oi d the

usage of external components.

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

d(on)

t

r

Turn-on Delay Time

Rise Time

VDD = 300V, ID = 1 A

RG= 4.7Ω VGS = 10V

(see test circuit, Figure 3)

13

8

ns

ns

Q

g

Total Gate Charge

V

DD

= 480V, ID = 2 A,

VGS = 10V

6 8.4 nC

Q

gs

Gate-Source Charge 1.8 nC

Q

gd

Gate-Drain Charge 3.3 nC

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

r(Voff)

Off-voltage Rise Time

V

DD

= 480 V, ID = 2 A,

RG=4.7Ω, V

GS

= 10V

(see test circuit, Figure 5)

12 ns

t

f

Fall Time 25 ns

t

c

Cross-over Time 30 ns

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

SD

Source-drain Current 2 A

I

SDM

(2)

Source-drain Current (pulsed) 8 A

VSD (1)

Forward On Voltage

ISD = 2 A, VGS = 0

1.5 V

t

rr

Q

rr

I

RRM

Reverse Recovery Time

Reverse Recovery Charge

Reverse Recovery Current

I

SD

= 2 A, di/dt = 100A/µs,

VDD = 100 V, Tj = 25°C

(see test circuit, Figure 5)

516

516

2

ns

nC

A

t

rr

Q

rr

I

RRM

Reverse Recovery Time

Reverse Recovery Charge

Reverse Recovery Current

I

SD

= 2 A, di/dt = 100A/µs,

V

DD

= 100 V, Tj = 150°C

(see test circuit, Figure 5)

808

890

2.2

ns

nC

A

Symbol Parameter Test Conditions Min. Typ. Max. Unit

BV

GSO

Gate-Source Breakdown

Voltage

Igs=± 1mA (Open Drain) 30 V

Page 4

STD2NM60/STD2NM60-1

4/10

Output Characteristics

Safe Operating Area

Transfer Characteristics

Transconductanc e

Static Drain-source On Resistance

Ther m al Impeda n c e

Page 5

5/10

STD2NM60/STD2NM60-1

Normalized BVDSS vs. Temperature

Normalized On Resistance vs Temperatur eNormalized Gate Thereshold Voltage vs Temp.

Capacitance Variations

Gate Charge vs Gate-source Voltage

Source-drain Diode Forward Characteristics

Page 6

STD2NM60/STD2NM60-1

6/10

Fig. 5: Test Circuit For Inductive Load Switching

And Diode Recovery Times

Fig. 4: Gate Charge test Circuit

Fig. 2: Unclamped Inductive WaveformFig. 1: Unclamped Inductive Load Test Circuit

Fig. 3: Switching Times Test Circuit For

Resistive Load

Page 7

7/10

STD2NM60/STD2NM60-1

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.20 2.40 0.087 0.094

A1 0.90 1.10 0.035 0.043

A2 0.03 0.23 0.001 0.009

B 0.64 0.90 0.025 0.035

B2 5.20 5.40 0.204 0.213

C 0.45 0.60 0.018 0.024

C2 0.48 0.60 0.019 0.024

D 6.00 6.20 0.236 0.244

E 6.40 6.60 0.252 0.260

G 4.40 4.60 0.173 0.181

H 9.35 10.10 0.368 0.398

L2 0.8 0.031

L4 0.60 1.00 0.024 0.039

V2 0

o

8

o

0

o

0

o

P032P_B

TO-252 (DPAK) MECHANICAL DATA

Page 8

STD2NM60/STD2NM60-1

8/10

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.2 2.4 0.086 0.094

A1 0.9 1.1 0.035 0.043

A3 0.7 1.3 0.027 0.051

B 0.64 0.9 0.025 0.031

B2 5.2 5.4 0.204 0.212

B3 0.85 0.033

B5 0.3 0.012

B6 0.95 0.037

C 0.45 0.6 0.017 0.023

C2 0.48 0.6 0.019 0.023

D 6 6.2 0.236 0.244

E 6.4 6.6 0.252 0.260

G 4.4 4.6 0.173 0.181

H 15.9 16.3 0.626 0.641

L 9 9.4 0.354 0.370

L1 0.8 1.2 0.031 0.047

L2 0.8 1 0.031 0.039

A

C2

C

A3

H

A1

D

L

L2

L1

1 3

= =

B3

B

B6

B2

E

G

= =

= =

B5

2

TO-251 (IPAK) MECHANICAL DAT A

0068771-E

Page 9

9/10

STD2NM60/STD2NM60-1

TAPE AND REEL SHIPMENT (suffix ”T4”)*

TUBE SHIPMENT (no suffix)*

DPAK FOOTPRINT

* on sales type

DIM.

mm inch

MIN. MAX. MIN. MAX.

A 330 12.992

B 1.5 0.059

C 12.8 13.2 0.504 0.520

D 20.2 0.795

G 16.4 18.4 0.645 0.724

N 50 1.968

T 22.4 0.881

BASE QTY BULK QTY

2500 2500

REEL MECHANICAL DATA

DIM.

mm inch

MIN. MAX. MIN. MAX.

A0 6.8 7 0.267 0.275

B0 10.4 10.6 0.409 0.417

B1 12.1 0.476

D 1. 5 1.6 0.059 0.063

D1 1.5 0.059

E 1.65 1.85 0.065 0.073

F 7.4 7.6 0.291 0.299

K0 2.55 2.75 0.100 0.108

P0 3.9 4.1 0.153 0.161

P1 7.9 8.1 0.311 0.319

P2 1.9 2.1 0.075 0.082

R 40 1.574

W 15.7 16.3 0.618 0.641

TAPE MECHANICAL DATA

All dimensions

are in millimeters

All dimensions are in millimeters

Page 10

STD2NM60/STD2NM60-1

10/10

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibi lity f or the

consequences of use of su ch in formation nor for any in fringement of patents or other rights of third parties w hich may result from

its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previously suppli ed. STMi croelect ronics pr oducts are not author ized for use as cr itical component s in li fe suppo rt devi ces or

systems without express written approval of STMicroelectronics.

© The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

© http://www.st.com

Loading...

Loading...