Page 1

October 2001 1/179

Rev. 1.7

ST92141

8/16-BIT MCU FOR 3-PHASE AC MOTOR CONTROL

■ Register File based 8/16 b it Core Architecture

with RUN, WFI, SLOW, HALT and STOP

modes

■ 0-25 MHz Operation (internal clock) @ 5V±10%

voltage range

■ -40°C to +85°C Operating Temperature Range

■ Fully Programmable PLL Clock Generator, with

Frequency Multiplication and low frequency,

low cost external crystal (3-5 MHz)

■ Minimum Instruction Cycle time: 160 ns - (@ 25

MHz internal clock frequency)

■ Internal Memory:

– EPROM/OTP/FA STR OM 16K bytes

– RAM 512 bytes

■ 224 general purpose registers available as RAM,

accumulators or index pointers (register file)

■ 32-pin Dual Inline and 34-pin Small Outline

Packages

■ 15 programmable I/O pins wi th Schmitt Trigger

input, including 4 high sink outputs (20mA @

V

OL

=3V)

■ 4 Wake-up Interrupts (one usable as Non-

Maskable Interrupt) for emergency event

management

■ 3-phase Induction Motor Controller (IMC)

Peripheral with 3 pairs of PWM outputs and

asynchronous emergency stop

■ Serial Peripheral Interface (SPI) with Master/

Slave Mode capability

■ 16-bit Timer with 8-bit Prescaler usable as a

Watchdog Timer

■ 16-bit Standard Timer with 8-bit Prescaler

■ 16-bit Extended Function Timer with Prescaler, 2

Input Captures and 2 Output Compares

■ 8-bit Analog to Di gital Converter allow ing up to

6 input channels with autoscan and watchdog

capabili ty

■ Low Voltage Detector Reset

■ Rich Instruction Set with 14 Addressing Modes

■ Division-by-Zero trap generation

■ Versatile Development Tools, including

Assembler, Linker, C-compiler, Archiver,

Source Level Debugger and Hardware

Emulators with Real-Time Operating System

available from Third Parties

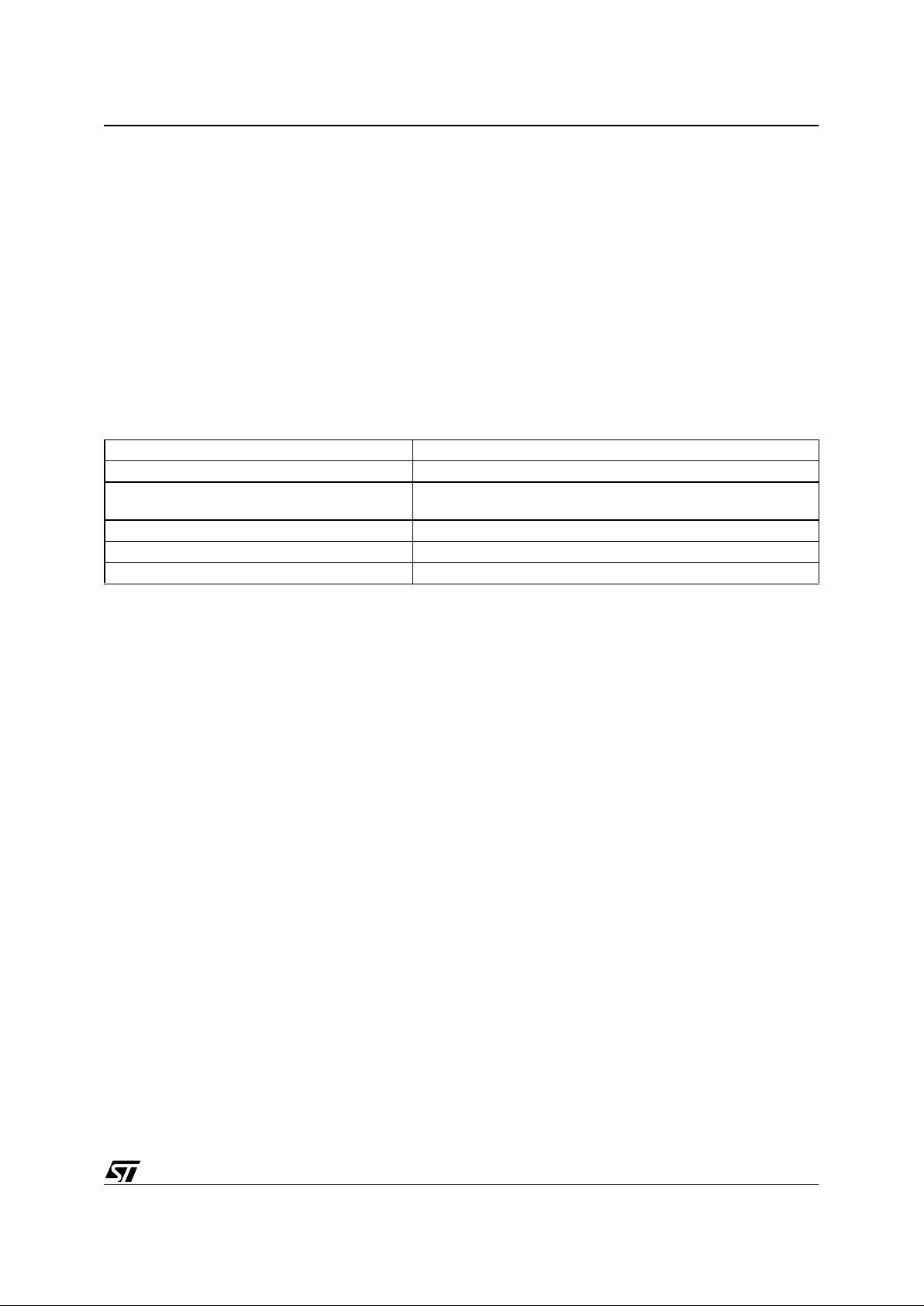

DEVICE SUMMARY

DEVICE

Program

Memory

(Bytes)

RAM

(Bytes)

PACKAGE

ST92P141 16K FASTROM 512

PSDIP32/

SO34

ST92E141 16K EPROM 512 CSDIP32W

ST92T141 16K OTP 512

PSDIP32/

SO34

PSDIP32

SO34 Shrink

CSDIP32W

9

Page 2

2/179

Table of Contents

179

1

1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 ST9+ Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Power Saving Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.3 System Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.4 Low Voltage Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.5 I/O Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.6 3-ph ase Induction Motor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.7 Watchdog Timer (WDT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.8 Standard Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.9 Ex tended Funct ion Time r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.10 Serial Peripheral Interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.11 Analog/Digital Converter (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 I/O Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2.2 I/O Port Reset State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.1 Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.2 EPROM Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 REGISTER MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 DEVICE ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1 CORE ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2 MEMORY SPACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.1 Register File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.2 Register Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 SYSTEM REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.1 Central Interrupt Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.2 Flag Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3.3 Reg ister Pointing Techn iques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3.4 Paged Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3.5 Mode Regi ster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3.6 Stack Pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.4 MEMORY ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.5 MEMORY MANAGEMENT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.6 ADDRESS SPACE EXTENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.6.1 Addressing 16-Kbyte Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.6.2 Addressing 64-Kbyte Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.7 MMU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.7.1 DPR[ 3:0]: Data Page Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.7.2 CSR: Code Segment Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.7.3 ISR: Interrupt Segment Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.7.4 DMASR: DMA Segment Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.8 MMU USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.8.1 Normal Program Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.8.2 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.8.3 DMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Page 3

3/179

Table of Contents

3.2 INTERRUPT VECTORING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.1 Divide by Zero trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.2 Segment Paging During Interrupt Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3 INTERRUPT PRIORITY LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4 PRIORITY LEVEL ARBITRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.1 Priority level 7 (Lowest) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.2 Maximum depth of nesting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.3 Sim ultaneou s Inte rrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.4 Dynamic Priority Level Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.5 ARBITRATION MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.5.1 Concurrent Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.5.2 Nested Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.6 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.7 TOP LEVEL INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.8 ON-CHIP PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.9 NMI/WKP0 LINE MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.9.1 NMI/Wake-Up Event Handling in Run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.9.2 NMI/Wake-Up Event Handling in STOP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.9.3 Unused Wake Up Management Unit lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.10INTERRUPT RESPONSE TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.11INTERRUPT REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.12WAKE-UP / INTERRUPT LINES MANAGEMENT UNIT (WUIMU) . . . . . . . . . . . . . . . . . . 55

3.12.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.12.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.12.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.12.4 Programming Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.12.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4 EM CONFIGURATION REGISTERS (EM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5 RESET AND CLOCK CONTROL UNIT (RCCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2 CLOCK CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2.1 Clock Control Unit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3 CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.3.1 PLL Clock Multiplier Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.3.2 CPU Clock Prescaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.3.3 Peripheral Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.3.4 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.3.5 Interrupt Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.4 CLOCK CONTROL REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.5 OSCILLATOR CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.6 RESET/STOP MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.6.1 Reset Pin Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.7 STOP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.8 LOW VOLTAGE DETECTOR (LVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.2 SPECIFIC PORT CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Page 4

4/179

Table of Contents

179

6.3 PORT CONTROL REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.4 INPUT/OUTPUT BIT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.5 ALTERNATE FUNCTION ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.5.1 Pin Declared as I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.5.2 Pin Declared as an Alternate Function Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.5.3 Pin Declared as an Alternate Function Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.6 I/O STATUS AFTER WFI, HALT AND RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.1 TIMER/WATCHDOG (WDT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.1.2 F unctional Desc ription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.1.3 Watchdog Timer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.1.4 WDT Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.2 STANDARD TIMER (STIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.2 F unctional Desc ription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.2.3 Interrupt Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.2.4 Register Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.2.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.3 EXTENDED FUNCTION TIMER (EFT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.3.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.3.3 F unctional Desc ription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.3.4 Inte rrupt Managem ent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.3.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.4 3-PHASE INDUCTION MOTOR CONTROLLER (IMC) . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.4.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.4.3 F unctional Desc ription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.4.4 T acho Count er Operating mod e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.4.5 IMC Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.4.6 IMC Output selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7.4.7 NM I manage men t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.4.8 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7.5 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.5.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.5.3 G eneral Descript ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.5.4 F unctional Desc ription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

7.5.5 Inte rrupt Managem ent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

7.5.6 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

7.6 ANALOG TO DIGITAL CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.6.2 F unctional Desc ription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7.6.3 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

7.6.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

8 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Page 5

5/179

Table of Contents

9 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

9.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

9.2 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

9.3 TRANSFER OF CUSTOMER CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

10 SUMMARY OF CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Page 6

6/179

ST92141 - GENER AL DESCRIPTION

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST92141 microcontroller is developed and

manufactured by STMicroelec tronics using a proprietary n-well HCMOS process. Its performance

derives from the use of a flexible 256-register programming model for ultra-fast context switching

and real-time event response. The intelligent onchip peripherals offload the ST9 core from I/O and

data management processing tasks al lowing critical application tasks to get the m aximum use of

core resources. The new-generation ST9 MCU

devices now also support low power co nsump tion

and low voltage operation for power-efficient and

low-cost embedded systems.

1.1.1 ST9+ Core

The advanced Core consists of the Central

Processing Unit (CPU), the Register File, the Interrupt controller, and the Memory Management Unit.

The MMU allows addressing of up to 4 Megabytes

of program and data mapped into a sing le linear

space.

Four independent buses are controlled by the

Core: a 16-bit memory bus, an 8 -bit register data

bus, an 8-bit register address bus and a 6-bit interrupt bus which connects the interrupt controllers in

the on-chip peripherals with the core.

Note: The DMA features of the ST9+ core are not

used by the on-chip peripherals of the ST92141.

This multiple bus architecture makes the ST9 family devices highly efficient for accessing on and offchip memory and fast exchange of data with the

on-chip peripherals.

The general-purpose registers can be used as accumulators, index registers, or address pointers.

Adjacent register pairs make up 16-bit registers for

addressing or 16-bit processing. Although the ST9

has an 8-bit ALU, the chip handles 16-bit operations, including arithmetic, loads/stores, and memory/register and memory/memory exchanges.

1.1.2 Power Savin g Modes

To optimize performance versus power consumption, a range of operating modes can be dynamically selected by software according to the requirements of the application.

Run Mode. This is the f ull s pee d execution mod e

with CPU and peripherals running at the maximum

clock speed delivered either by the Phase Locked

Loop controlled by the RCCU (Reset and Clock

Control Unit), directly by the oscillator or by an ex-

ternal source (dedicated Pin or Alternate Function).

Slow Mode. Power consumption can be significantly reduced by running the CPU and the peripherals at reduced clock speed using the CPU Prescaler and RCCU Clock Divider.

Wait For Interrupt Mode. The Wait For Interrupt

(WFI) instruction suspends program execution until an interrupt request is acknowledged. During

WFI, the CPU clock is halted while the peripheral

with interrupt capability and interrupt controller are

kept running at a frequency that can be programmed by software in the RCCU registers. In

this mode, the power consumption of t he device

can be reduced by more than 95% (Low Power

WFI).

Halt Mode. When executing the HALT instruction,

and if the Watchdo g is not enab led, the CP U and

its peripherals stop operating. If however the

Watchdog is enabled, the HALT instruction has no

effect. The main difference between Halt mode

and Stop mode is that a reset is necessary to exit

from Halt mode which causes the system to be

reinitialized.

Stop Mode. When Stop mode is requested by executing the STOP sequenc e (see Wake-up Management Unit section), the CPU and the peripherals stop operating. Operations resume after a

wake-up line is activated. The difference between

Stop mode and Halt mode is in the way the CPU

exits each state: when the STO P sequence is executed, the status of the registers is recorded, and

when the system exits from Stop mo de the CPU

continues execution with the s am e status, without

a system reset.

The Watchdog count er, if enable d, is stop ped. A fter exiting Stop mode it restarts counting from

where it left off.

When the MCU exits from STOP mode, the oscillator, which was also s leeping, requi res a start-up

time to restart working properly. An internal counter is present to guarantee that, after e xiting Stop

Mode, all operations take place with the clock stabilised.

1.1.3 System Clock

A programmable PLL Clock Generator allows

standard 3 to 5 MHz crystals to be used to obtain a

large range of internal frequencies up to 25MHz.

9

Page 7

7/179

ST92141 - GENERAL DESCRIPTION

1.1.4 Low Voltage Reset

The on-chip Low Voltage Detector (LVD) generates a static reset when the supply voltage is below a reference value. The LVD works both during

power-on as well as when the power supply drops

(brown-out). The reference value for the voltage

drop is lower than the reference value for p oweron in order to avoid a parasitic reset when the

MCU starts running and sinks current on the supply (hysteresis).

1.1.5 I/O Ports

The I/O lines are grouped into two I/O Ports and

can be configured on a bit basis to provide timing,

status signals, an address/data bus for timer inputs and outputs, analog inputs, external wake-up

lines and serial or parallel I/O.

1.1.6 3-phase Induction Motor Controll er

The IMC controller is designed f or variable spee d

motor control applications. Three pairs of PWM

outputs ar e availa ble fo r contro lling a three-ph as e

motor drive. Rotor speed feedba ck is provided by

capturing a tachogenerator input signal. Emergency stop is provided by putting the PWM outputs in

high impedance m ode upon asynchronous faulty

event on NMI pin.

1.1.7 Watchdog Timer (WDT)

The Watchdog timer can be used to m onitor system integrity. When enabled, it generates a reset

after a timeout period unless the counter is refreshed by the application software. For additional

security, watchdog function can be enabled by

hardware using a specific pin.

1.1.8 Standard Timer

The standard timer includes a programmable 16bit down-counter and an associated 8-bit prescaler

with Single and Continuous counting modes.

1.1. 9 E x tended Function Timer

The Extended Func tion Timer can be used for a

wide range of standard timing tasks. It has a 16-bit

free running counter with programmable prescaler. Each timer can have up to 2 input capture and

2 output compare pins wi th associated registers.

This allows applications to measure pulse intervals or generate pulse waveforms. Timer overflow

and other events are f lagged in a status register

with optional interrupt generation.

1.1.10 Serial Peripheral Interface (SPI)

The SPI bus is used to communicate with external

devices via the SPI, or I²C bus communication

standards.

1.1.11 Analog/Digital Converter (ADC)

The ADC provides up to 6 an alog inputs with onchip sample and hold. The analo g watchdog generates an interrupt when the i nput voltage moves

out of a preset threshold.

9

Page 8

8/179

ST92141 - GENER AL DESCRIPTION

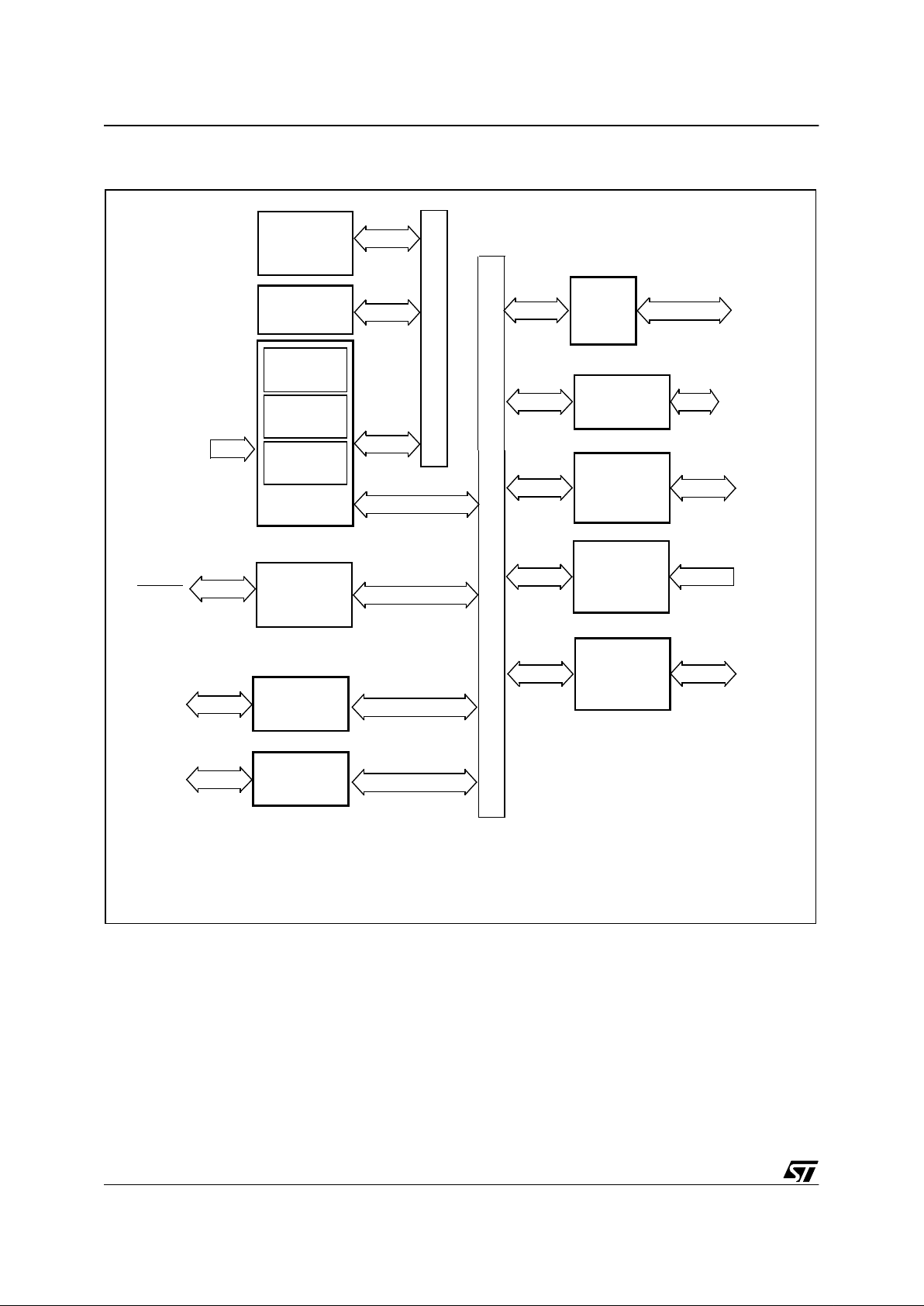

Figure 1. ST92141 Block Diagram

Register File

256 bytes

ST9+ CORE

8/16-bit

CPU

Interrupt

Management

MEMORY BUS

RCCU + LVD

REGISTER BUS

WATCHDOG

MISO

MOSI

SCK

SSN

EF TIMER

SPI

IMC

TACHO

UH

UL

VH

VL

WH

WL

STIN

STOUT

All alternate functions (

Italic characters

) are mapped on Port3 and Port5

Fully Prog.

I/Os

P3[6:0]

P5[7:0]

NMI

WKUP[3:0]

INT0

INT6

OSCIN

OSCOUT

RESET

INTCLK

CK_AF

RAM

512 bytes

EPROM/

FASTROM

16K

A/D Converter

with analog

watchdog

AIN[7:2]

EXTRG

WDIN

WDOUT

STIM TIMER

ICAP1

OCMP1

ICAP2

OCMP2

EXTCLK

9

Page 9

9/179

ST92141 - GENERAL DESCRIPTION

1.2 PIN DESCRI PTION

ST92E141

134

1817

V

SS

TACHO

VH

VL

WH

WL

UH

UL

N.C.

V

PP

P5.0/WKUP1/ICAP2

P5.1/NMI/WKUP0

RESET

OSCOUT

OSCIN

V

SS

V

DD

PSDIP32/CSDIP32W Package

SO34 Package

ST92E141

132

17

16

V

SS

TACHO

VH

VL

WH

WL

UH

UL

V

PP

P5.0/WKUP1/ICAP2

P5.1/NMI/WKUP0

RESET

OSCOUT

OSCIN

V

SS

V

DD

V

DD

MOSI/P3.0

MISO/P3.1

SCK/STIN/WKUP3/P3.2

STOUT/SSN/P3.3

EXTRG/OCMP2/P3.4

INT6/OCMP1/P3.5

ICAP1/WKUP2/P3.6

AV

DD

AV

SS

INTCLK/AIN7/P5.7

CK_AF/AIN6/P5.6

AIN5/P5.5

AIN4/P5.4

AIN3/EXTCLK/WDO UT/ P5.3

AIN2/INT0/WDIN/P5.2

V

DD

MOSI/P3.0

MISO/P3.1

SCK/STIN/WKUP3 /P 3.2

STOUT/SSN/P3.3

EXTRG/OCMP2/P3.4

INT6/OCMP1/P3.5

ICAP1/WKUP2/P3.6

N.C.

AV

DD

AV

SS

INTCLK/AIN7/P5.7

CK_AF/AIN6/P5.6

AIN5/P5.5

AIN4/P5.4

AIN3/EXTCLK/W DO UT/P5.3

AIN2/INT0/WDIN/P5.2

9

Page 10

10/179

ST92141 - GENER AL DESCRIPTION

9

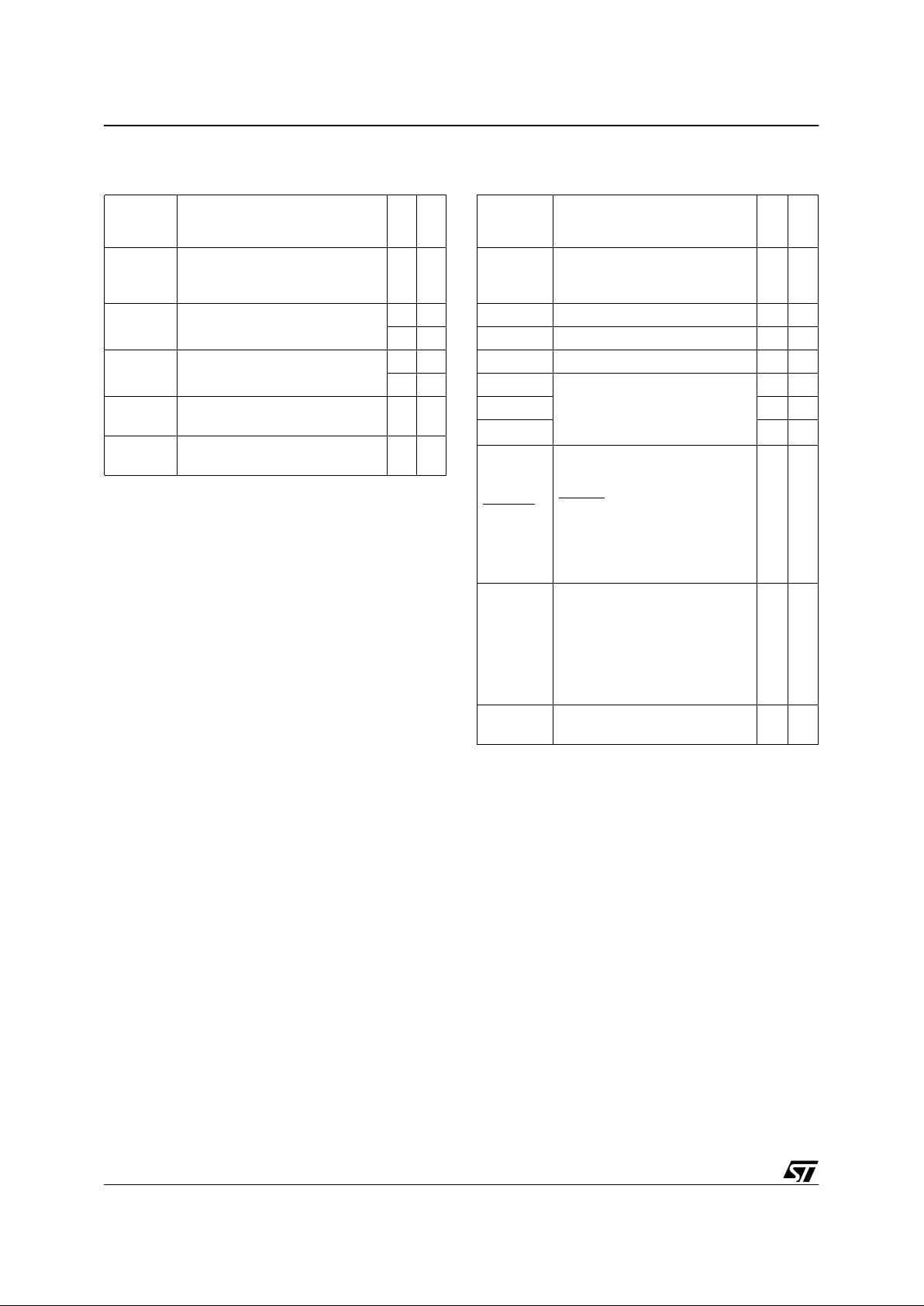

Table 1. Power Supply Pins Table 2. Primary Function pins

Name Function

SDIP32

SO34

V

PP

Programming voltage for

EPROM/OTP devices. Must be

connected to V

SS

in user mode.

24 25

V

DD

Main power supply voltage (5V ±

10% (2 pins internally connected)

17 18

11

V

SS

Digital Circuit Ground (2 pins internally connected)

18 19

32 34

AV

DD

Analog V

DD

of the Analog to Digit-

al Converter

910

AV

SS

Analog V

SS

of the Analog to Digit-

al Converter

10 11

Name Function

SDIP32

SO34

TACHO

Signal input from a tachogenerator to the IMC controller for

measuring the rotor speed

31 33

UH U-phase PWM output signal 26 28

VH V-phase PWM output signal 30 32

WH W-phase PWM output signal 28 30

UL The complemented UH, VH, WH

output signals with added dead

time to avoid crossover conduction from the power driver

25 27

VL 29 31

WL 27 29

RESET

Reset (input, active low). The

ST9+ is initialised by the Reset

signal. With the deactivation of

RESET

, program execution begins from the memory location

pointed to by the vector contained in memory locations 00h

and 01h

21 22

OSCIN

OSCIN is the input of the oscillator inverter and internal clock

generator. OSCIN and OSCOUT

connect a parallel-resonant crystal (3 to 5 MHz), or an external

source to the on-chip clock oscillator and buffer

19 20

OSCOUT

OSCOUT is the output of the oscillator inverter

20 21

Page 11

11/179

ST92141 - GENERAL DESCRIPTION

1.2.1 I/O Port Configuration

All ports can be individually configured as input, bidirectional, output, or alternate function. Refer t o

the Port Bit Configuration Table in the I/O Port

Chapter.

All I/Os are implemented with a High Hysteresis or

Standard Hysteresis Schmitt trigger function (See

Electrical Characteristics).

Weak Pull-Up = This column indicat es if a weak

pull-up is present or not (refer to Table 3).

– If WPU = yes, then the WPU can be enabled/dis-

able by software

– If WPU = no, then enabling the WPU by software

has no effect

All port output configurations can be software selected on a bit basis to provide push-pull or open

drain driving capabilities. For all ports, when configured as open-drain, the voltage on the pin must

never exceed the V

DD

power line value (refer to

Electrical characteristics section).

1.2.2 I/O Port Reset State

I/Os are reset asynchronously as soon as the RESET pin is asserted low.

All I/Os are forced by the Reset in "floating input"

configuration mode.

WARNING

When a com mon p in is de clared to be connect ed

to an alternate function input and to an alternate

function output, the user must be aware of the fact

that the alternate function output signal always inputs to the alternate funct ion module declared as

input.

When any given pin is declared to be connected to

a digital alternate function input, the user must be

aware of the fact that the alternate function input is

always connected to the pin. When a given pin is

declared to be connected to an analog alternate

function input (ADC input for example) and if this

pin is programmed in the "AF-OD" mode, the digital input path is disconnected from the pin t o prevent any DC consumption.

Table 3. I/O Port Characteristics

Legend: OD = Open Drain; HC= High current

Input Output Weak Pull-Up Reset State

Port 3[4:0]

Port 3[6:5]

Schmitt trigger (High Hysteresis)

Schmitt trigger (High Hysteresis)

Push-Pull/OD

Push-Pull/OD (HC)

Yes

Yes

Floating input

Floating input

Port 5.0

Port 5.1

Port 5.2

Port 5[7:3]

Schmitt trigger (High Hysteresis)

Schmitt trigger (High Hysteresis)

Schmitt trigger (Standard Hysteresis)

Schmitt trigger (Standard Hysteresis)

Push-Pull/OD (HC)

Push-Pull/OD

Push-Pull/OD (HC)

Push-Pull/OD

Yes

Yes

Yes

Yes

Floating input

Floating input

Floating input

Floating input

9

Page 12

12/179

ST92141 - GENER AL DESCRIPTION

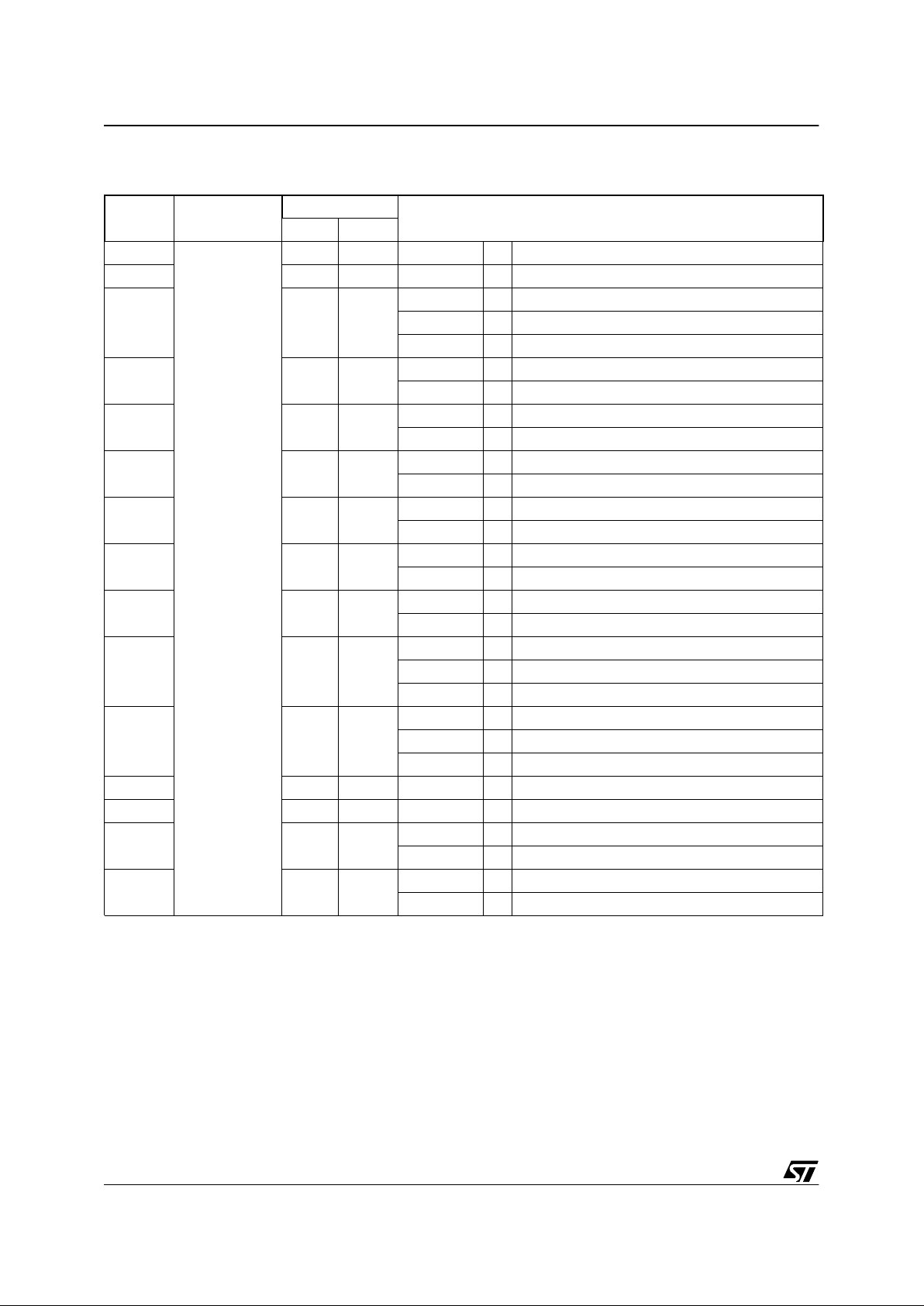

Table 4. ST92141 Alternate functions

How to confi gure the I/O por ts

To configure the I/O ports, use the information in

Table 3 and Table 4 and the Port Bit Configuration

Table in the I/O Ports Chapter on page 81.

I/O no te = The hardware characteristics fixed for

each port line in Table 3.

All I/O inputs have Sch mitt trigger fixed by hardware so selecting CMOS or TTL input by software

has no effect, the input will always be Schmitt Trigger. In particular, the Schmitt Triggers present on

the P5[7:2] pins have a standard hysteresis

whereas the remaining pins have Schmitt Triggers

with High Hysteresis (refer to Electrical Specifications).

Alternate Functions (AF) = More than one AF

cannot be assigned to an external pin at the same

time:

Port

Name

General

Purpose I/O

Pin No.

Alternate Functions

SDIP32 PSO34

P3.0

All ports useable

for general purpose I/O (input,

output or bidirectional)

2 2 MOSI I/O SPI Master Output/Slave Input Data

P3.1 3 3 MISO I/O SPI Master Input/Slave Output Data

P3.2 4 4

WKUP3 I Wake-up line 3

STIN I Standard Timer Input

SCK I/O SPI Serial Clock Input/Output

P3.3 5 5

SSN I SPI Slave Select

STOUT O Standard Timer Output

P3.4 6 6

EXTRG I A/D External trigger

OCPM2 O Ext. Timer Output Compare 2

P3.5 7 7

INT6 I External Interrupt 6

OCMP1 O Ext. Timer - Output Compare 1

P3.6 8 8

ICAP1 I Ext. Timer - Input Capture 1

WKUP2 I Wake-up line 2

P5.0 23 2 4

ICAP2 I Ext. Timer - Input Capture 2

WKUP1 I Wake-up line 1

P5.1 22 2 3

NMI I Not maskable Int.

WKUP0 I Wake-up line 0

P5.2 16 1 7

AIN2 I Analog Data Input 2

INT0 I External Interrupt 0

WDIN I Watchdog input

P5.3 15 16

AIN3 I Analog Data Input 3

EXTCLK I Ext. Timer - Input Clock

WDOUT O Watchdog Output

P5.4 14 15 AIN4 I Analog Data Input 4

P5.5 13 14 AIN5 I Analog Data Input 5

P5.6 12 13

AIN6 I Analog Data Input 6

CK_AF I Clock Alternative Source

P5.7 11 12

AIN7 I Analog Data Input 7

INTCLK O Internal Main Clock

9

Page 13

13/179

ST92141 - GENERAL DESCRIPTION

An alternate function can be selected as follows.

AF Inputs:

– AF is selected implicitly by enabling the corre-

sponding peripheral. Exceptions to this are ADC

analog inputs which must be explicitly selected

as AF by software.

AF Outputs or Bidirectional Lines:

– In the case of Outputs or I/Os, AF is selected ex-

plicitly by sof twar e.

Example 1: Standard Timer input

AF: STIN, Port: P3.2, I/O Note: Schmitt trigger.

Write the port configuration bits:

P3C2.2=1

P3C1.2=0

P3C0.2=1

or P3C2.2=0

P3C1.2=0

P3C0.2=1

Enable the Standard T imer input by softw are as

described in the STIM chapter.

Example 2: Standard Timer output

AF: STOUT, Port: P3.3

Write the port configuration bits (for AF output

push-pull):

P3C2.3=0

P3C1.3=1

P3C0.3=1

Example 3: ADC analog input

AF: AIN2, Port: P5.2, I/O Note: doe s not apply to

analog inputs

Write the port configuration bits:

P5C2.2=1

P5C1.2=1

P5C0.2=1

9

Page 14

14/179

ST92141 - GENER AL DESCRIPTION

1.3 MEMORY MA P

1.3.1 Memory Configuration

The Program memory space of the ST92141, 16K

bytes of directly addressable on-chip m emory, is

fully available to the user.

The first 256 memory locat ions from address 0 to

FFh hold the Reset Vector, the Top-Level (Pseudo

Non-Maskable) interrupt, the Divide by Zero Trap

Routine vector and, optionally, the interrupt vector

table for use with the on-chip peripherals and the

external interrupt sources. Apart from this case no

other part of the Program memory has a predetermined function except segm ent 21h which is reserved for use by STMicroelectronics.

1.3.2 EPROM Programming

The 16K bytes of EPROM memory of the

ST92E141 may be programmed by using the

EPROM Programming Boards (EPB) or gang programmers available from STMicroelectronics.

EPROM Erasing

The EPROM of the windowed package of the

ST92E141 may be erased by exposure to Ultra-Violet light.

The erasure characteristic of the ST92E141 is

such that erasure begins when the memory is exposed to light with a wave lengths shorter than ap-

proximately 4000Å. It should be noted that sunlight

and some types of fluorescent lam ps have wavelengths in the range 3000-4000Å. It is thus recommended that the window of the ST92E141 packages be covered by an opaque label to prevent unintentional erasure problems when testing the application in such an environment.

The recommended erasure procedure of the

EPROM is the exposure to short wave ultraviolet

light which have a wave-lengt h 2537Å. The integrated dose (i.e. U.V. intensity x exposure time) for

erasure should be a minimum of 15W-sec/cm2.

The erasure time with this dosage is approximately 30 minutes using an ultraviolet lamp with

12000mW/cm2 power rating. The ST92E141

should be placed within 2.5cm (1 inch) of the lamp

tubes during erasure.

Table 5. First 6 Bytes of Program Space

Figure 2. Me m ory Map

0 Address high of Power on Reset routine

1 Address low of Power on Reset routine

2 Address high of Divide by zero trap Subroutine

3 Address low of Divide by zero trap Subroutine

4 Address high of Top Level Interrupt routine

5 Address low of Top Level Interrupt routine

SEGMENT 0

64 Kbytes

00FFFFh

00C000h

00BFFFh

008000h

007FFFh

004000h

000000h

003FFFh

PAGE 0 - 16 Kb y tes

PAGE 1 - 16 Kb y tes

PAGE 2 - 16 Kb y tes

PAGE 3 - 16 Kb y tes

SEGMENT 20h

64 Kbytes

200000h

21FFFFh

20C000h

20BFFFh

208000h

207FFFh

204000h

203FFFh

PAGE 80 - 16 Kbytes

PAGE 81 - 16 Kbytes

PAGE 82 - 16 Kbytes

PAGE 83 - 16 Kbytes

200000h

200200h

RAM

512 bytes

Internal

Reserved

SEGMENT 21h

64 Kbytes

20FFFFh

220000h

210000h

Internal ROM

Reserved

Reserved

Reserved

max. 64 Kbytes

000000h

004000h

FASTROM/EPROM

16 Kbytes

003FFFh

9

Page 15

15/179

ST92141 - GENERAL DESCRIPTION

1.4 REGISTER MAP

The following pages contain a list of ST92141 registers, grouped by peripheral or function.

Be very careful to correctly program both:

– The set of registers dedicated to a particular

function or peripheral.

– Registers common to other functions.

– In particular, double-check that any registers

with “undefined” reset values have been correct-

ly initial is ed.

WARNING: Note that in the EIVR and each IVR

register, all bits are significant. Take care when

defining base vector ad dresses that en tries in the

Interrupt Vector table do not overlap.

Table 6. Common Registers

Function or Peripheral Common Registers

ADC CICR + NICR + I/O PORT REGISTERS

WDT

CICR + NICR + EXTERNAL INTERRUPT REGISTERS +

I/O PORT REGISTERS

I/O PORTS I/O PORT REGISTERS + MODER

EXTERNAL INTERRUPT INTERRUPT REGISTERS + I/O PORT REGISTERS

RCCU INTERRUPT REGISTERS + MODER

9

Page 16

16/179

ST92141 - GENER AL DESCRIPTION

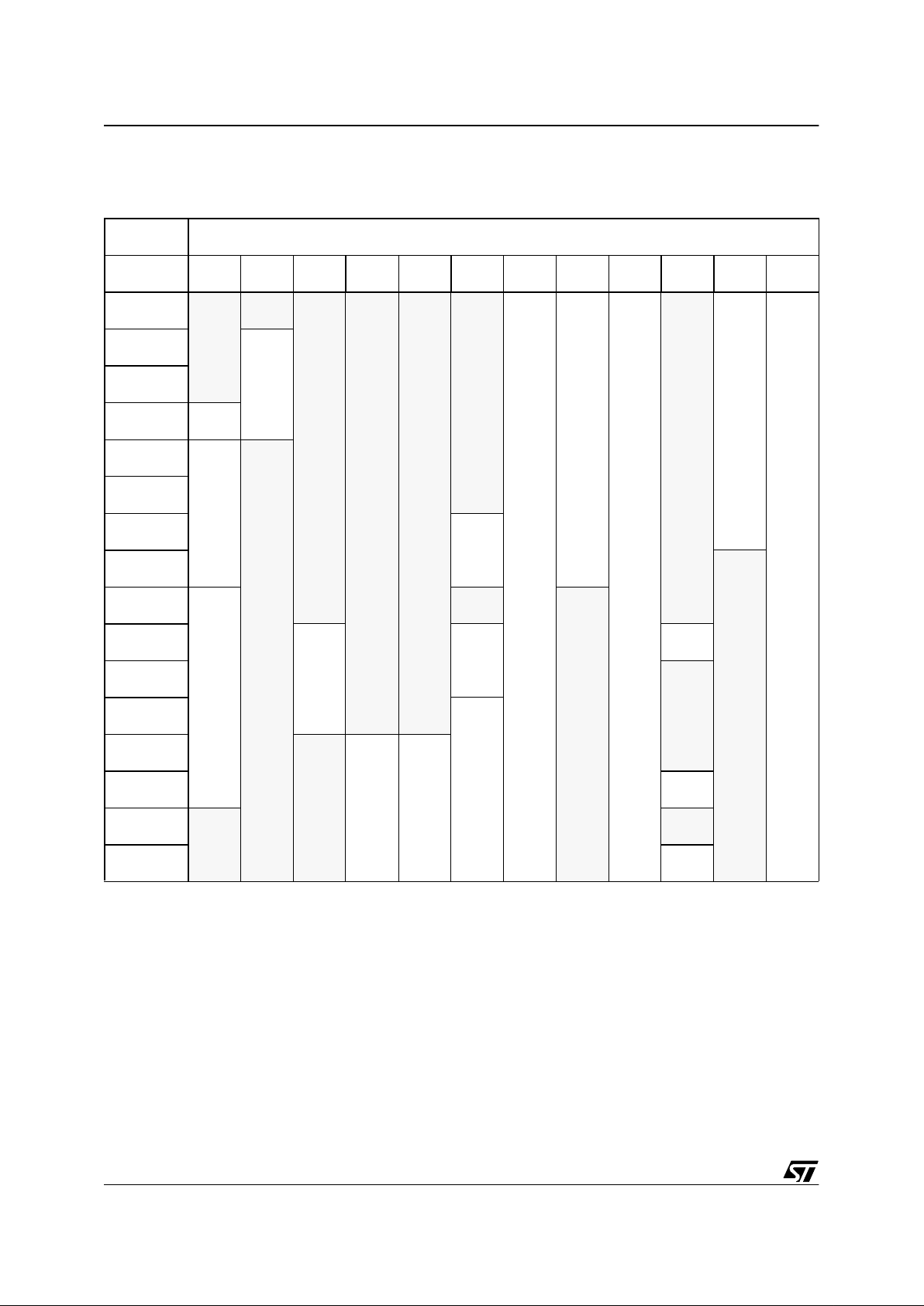

Table 7. G roup F Pages

Resources available on the ST92141 devices:

Register Page

0 2 3 7 11 21 28 48 51 55 57 63

R255

Res.

Res.

Res.

Res. Res.

Res.

EFT0

IMC

IMC

Res.

WU

A/D0

R254

PORT

3

R253

R252

WCR

R251

WDT

Res.

R250

R249

MMU

R248

Res.

R247

EXT

INT

Res.

Res.

R246

PORT

5

EM

RCCU

R245

Res.R244

MMU

R243

Res. SPI0 STIM0

R242

RCCU

R241

Res.

Res.

R240

RCCU

9

Page 17

17/179

ST92141 - GENERAL DESCRIPTION

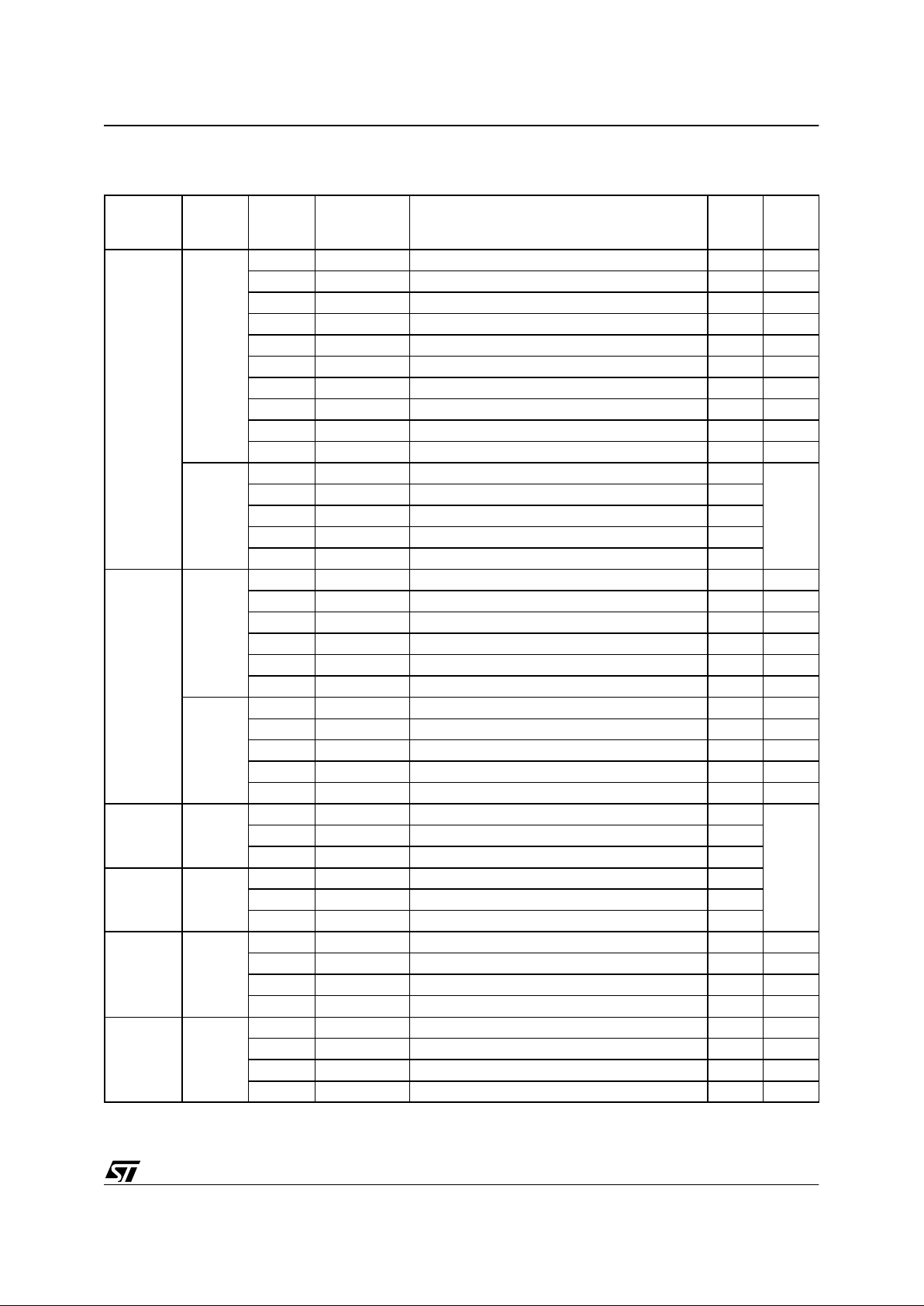

Table 8. Detailed Register Map

Page

(Decimal)

Block

Reg.

No.

Register

Name

Description

Reset

Value

Hex.

Doc.

Page

N/A

Core

R230 CICR Central Interrupt Control Register 87 52

R231 FLAGR Flag Register 00 24

R232 RP0 Pointer 0 Register xx 26

R233 RP1 Pointer 1 Register xx 26

R234 PPR Page Pointer Register xx 28

R235 MODER Mode Register E0 28

R236 USPHR User Stack Pointer High Register xx 30

R237 USPLR User Stack Pointer Low Register xx 30

R238 SSPHR System Stack Pointer High Reg. xx 30

R239 SSPLR System Stack Pointer Low Reg. xx 30

I/O

Port

5:4,2:0

R224 P0DR Port 0 Data Register FF

79

R225 P1DR Port 1 Data Register FF

R226 P2DR Port 2 Data Register FF

R228 P4DR Port 4 Data Register FF

R229 P5DR Port 5 Data Register FF

0

INT

R242 EITR External Interrupt Trigger Regis ter 00 52

R243 EIPR External Interrupt Pending Reg. 00 53

R244 EIMR External Interrupt Mask-bit Reg. 00 53

R245 EIPLR External Interrupt Priority Level Reg. FF 53

R246 EIVR External Interrupt Vector Regis ter x6 54

R247 NICR Nested Interrupt Control 00 54

WDT

R248 WDTHR Watchdog Timer High Register FF 90

R249 WDTLR Watchdog Timer Low Register FF 90

R250 WDTPR Watchdog Timer Prescaler Reg. FF 90

R251 WDTCR Watchdog Timer Control Register 12 90

R252 WCR Wait Control Register 7F 91

2

I/O

Port

3

R252 P3C0 Port 3 Configuration Register 0 00

79

R253 P3C1 Port 3 Configuration Register 1 00

R254 P3C2 Port 3 Configuration Register 2 00

3

I/O

Port

5

R244 P5C0 Port 5 Configuration Register 0 FF

R245 P5C1 Port 5 Configuration Register 1 00

R246 P5C2 Port 5 Configuration Register 2 00

7SPI

R240 SPDR SPI Data Register 00 145

R241 SPCR SPI Control Register 00 145

R242 SPSR SPI Status Register 00 146

R243 SPPR SPI Prescaler Register 00 146

11 STIM

R240 STH Counter High Byte Register FF 95

R241 STL Counter Low Byte Register FF 95

R242 STP Standard Timer Prescaler Register FF 95

R243 STC Standard Timer Control Register 14 95

9

Page 18

18/179

ST92141 - GENER AL DESCRIPTION

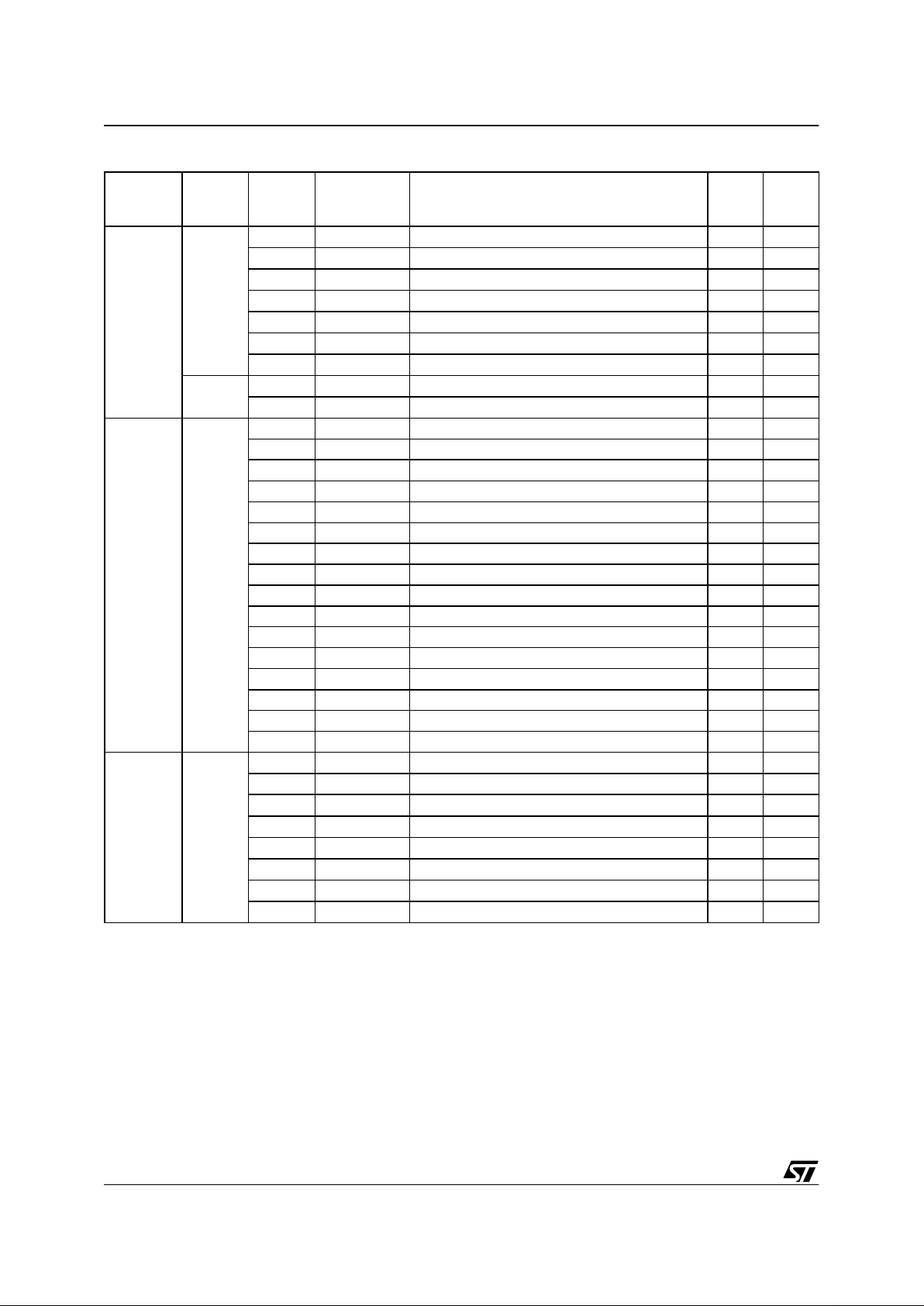

21

MMU

R240 DPR0 Data Page Register 0 xx 35

R241 DPR1 Data Page Register 1 xx 35

R242 DPR2 Data Page Register 2 xx 35

R243 DPR3 Data Page Register 3 xx 35

R244 CSR Code Segment Register 00 36

R248 ISR Interrupt Segment Register xx 36

R249 DMASR DMA Segment Register xx 36

EM

R245 EMR1 EM Register 1 80 62

R246 EMR2 EM Register 2 0F 62

28 EFT

R240 IC1HR Input Capture 1 High Register xx 108

R241 IC1LR Input Capture 1 Low Register xx 108

R242 IC2HR Input Capture 2 High Register xx 108

R243 IC2LR Input Capture 2 Low Register xx 108

R244 C HR Counter High Register FF 109

R245 C LR Counter Low Register FC 109

R246 ACHR Alternate Counter High Register FF 109

R247 ACLR Alternate Counter Low Register FC 109

R248 OC1HR Output Compare 1 High Register 80 110

R249 OC1LR Output Compare 1 Low Register 00 110

R250 OC2HR Output Compare 2 High Register 80 110

R251 OC2LR Output Compare 2 Low Register 00 110

R252 CR1 Control Register 1 00 111

R253 CR2 Control Register 2 00 112

R254 SR Status Register 00 113

R255 CR3 Control Register 3 00 113

48 IMC

R248 PCR0 Peripheral Control Register 0 80 130

R249 PCR1 Peripheral Control Register 1 00 130

R250 PCR2 Peripheral Control Register 2 00 131

R251 PSR Polarity Selection Register 00 131

R252 OPR Output Peripheral Register 00 132

R253 IMR Interrupt Mask Register 00 132

R254 DTG Dead Time Generator Register 00 133

R255 IMCIVR IMC Interrupt Vector Register xx 133

Page

(Decimal)

Block

Reg.

No.

Register

Name

Description

Reset

Value

Hex.

Doc.

Page

9

Page 19

19/179

ST92141 - GENERAL DESCRIPTION

Note: xx denotes a byte with an undefined value, however some of the bits may have defined values. Refer to register description for details.

51 IMC

R240 TCPTH Tacho Capture Register High xx 125

R241 TCPTL Tacho Capture Register Low xx 125

R242 TCMP Tacho Compare Register xx 125

R243 ISR Interrupt Status Register 3F 36

R244 TPRSH Tacho Prescaler Register High 00 127

R245 TPRSL Tacho Prescaler Register Low 00 127

R246 CPRS PWM Counter Prescaler Register 00 127

R247 REP Repetition Counter Register 00 127

R248 CPWH Compare Phase W Preload Register High 00 128

R249 CPWL Compare Phase W Preload Register Low 00 128

R250 CPVH Compare Phase V Preload Register High 00 128

R251 CPVL Compare Phase V Preload Register Low 00 128

R252 CPUH Compare Phase U Preload Register High 00 129

R253 CPUL Compare Phase U Preload Register Low 00 129

R254 CP0H Compare 0 Preload Register High 00 129

R255 CP0L Compare 0 Preload Register Low 00 129

55 RCCU

R240 CLKCTL Clock Control Register 00 69

R242 CLK_FLAG Clock Flag Register 48, 28 70

R246 PLLCONF PLL Configuration Register xx 71

57 WUIMU

R249 WUCTRL Wake-Up Control Register 00 59

R250 WUMRH Wake-Up Mask Register High 00 60

R251 WUMRL Wake-Up Mask Register Low 00 60

R252 WUTRH Wake-Up Trigger Register High 00 61

R253 WUTRL Wake-Up Trigger Register Low 00 61

R254 WUPRH Wake-Up Pending Register High 00 61

R255 WUPRL Wake-Up Pending Register Low 00 61

63 ADC

R240 D0R Channel 0 Data Register xx 151

R241 D1R Channel 1 Data Register xx 151

R242 D2R Channel 2 Data Register xx 151

R243 D3R Channel 3 Data Register xx 151

R244 D4R Channel 4 Data Register xx 151

R245 D5R Channel 5 Data Register xx 151

R246 D6R Channel 6 Data Register xx 151

R247 D7R Channel 7 Data Register xx 151

R248 LT6R Channel 6 Lower Threshold Reg. xx 152

R249 LT7R Channel 7 Lower Threshold Reg. xx 152

R250 UT6R Channel 6 Upper Threshold Reg. xx 152

R251 UT7R Channel 7 Upper Threshold Reg. xx 152

R252 CRR Compare Result Register 0F 153

R253 CLR Control Logic Register 00 154

R254 ICR Interrupt Control Register 0F 155

R255 IVR Interrupt Vector Register x2 155

Page

(Decimal)

Block

Reg.

No.

Register

Name

Description

Reset

Value

Hex.

Doc.

Page

9

Page 20

20/179

ST92141 - DEVICE ARCHITECTURE

2 DEVICE ARCHITECTURE

2.1 CORE ARCHITECTURE

The ST9 Core or Central Processing Unit (CPU)

features a highly optimised instruction set, capable

of handling bit, byte (8-bit) and word (16-bit) data,

as well as BCD and Boolean formats; 14 addressing modes are available.

Four independent buses are controlled by the

Core: a 16-bit Memory bus, an 8-bi t Registe r data

bus, an 8-bit Register ad dress bus an d a 6-bit Interrupt/DMA bus which connect s th e in terrupt an d

DMA controllers in the on-chip peripherals with the

Core.

This multiple bus architecture affords a high degree of pipelining and parallel operation, thus making the ST9 family devices highly efficient, both for

numerical calculation, data handling and with regard to communication with on-chip peripheral resources.

2.2 MEMORY SPACES

There are two separate memory spaces:

– The Register File, which comprises 240 8-bit

registers, arranged as 15 groups (Group 0 to E),

each containing sixteen 8-bit registers plus up to

64 pages of 16 registers mapped in Group F,

which hold data and control bits for the on-chip

peripherals and I/Os.

– A sing le linear memory space acc ommodating

both program and data. All of the physically sep-

arate memory areas, including the internal ROM,

internal RAM and ex ternal memory are mapped

in this common address space. The total ad-

dressable memory space of 4 Mbytes (limited by

the size of on-chip memory and the number of

external address pins) is arranged as 64 seg-

ments of 64 Kbytes. Each segment is further

subdivided into four pages of 16 Kbytes, as illus-

trated in Figure 3. A Memory Man agement Unit

uses a set of pointer registers to address a 22-bit

memory field using 16-bit address-based instruc-

tions.

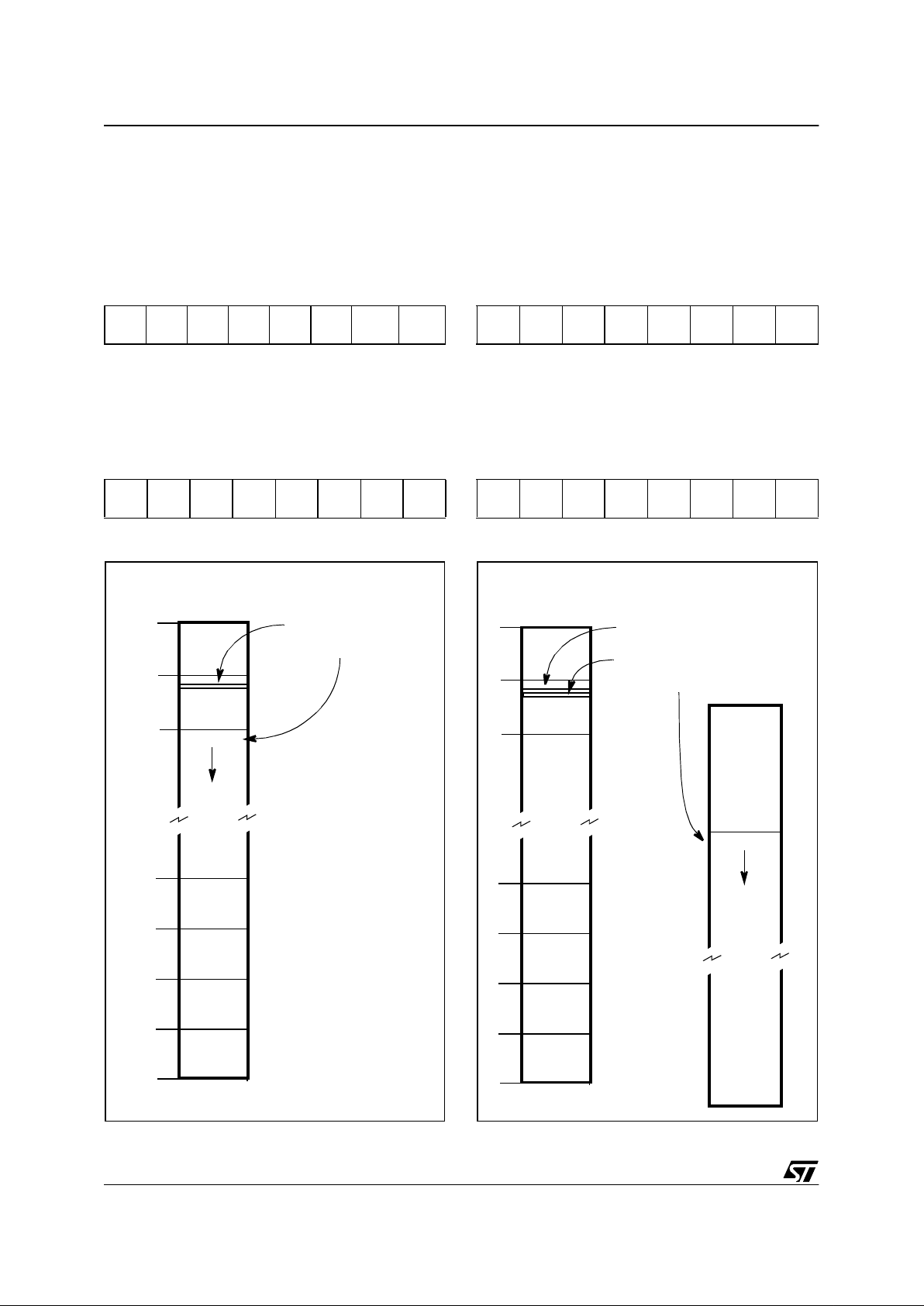

2.2.1 Reg ister File

The Register File consists of (see Figure 4):

– 224 general purpose registers (Group 0 to D,

registers R0 to R223)

– 6 system registers in the System Group (Group

E, registers R224 to R239)

– Up to 64 pages, depending on device configura-

tion, each containing up to 16 registers, mapped

to Group F (R240 to R255), see Figure 5.

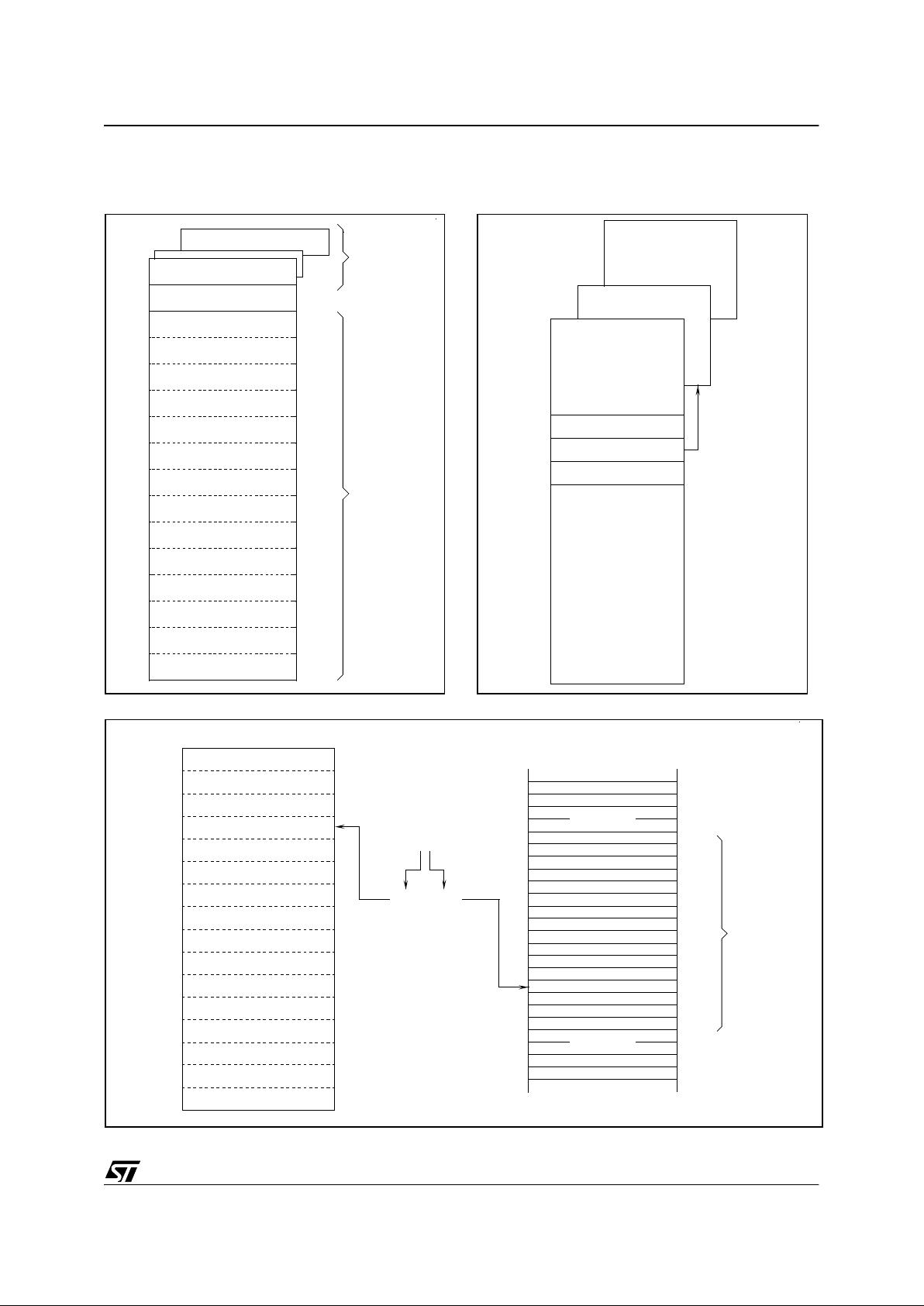

Figure 3. Single Program and Data Memory Address Spac e

3FFFFFh

3F0000h

3EFFFFh

3E0000h

20FFFFh

02FFFFh

020000h

01FFFFh

010000h

00FFFFh

000000h

8

7

6

5

4

3

2

1

0

63

62

2

1

0

Address 16K Pages 64K Segments

up to 4 Mbytes

Data

Code

255

254

253

252

251

250

249

248

247

9

10

11

21FFFFh

210000h

133

134

135

33

Reserved

132

9

Page 21

21/179

ST92141 - DEVICE ARCHITECTURE

MEMORY SPACES (Cont’d)

Figure 4. Regis te r Gr oups Figure 5. Pag e Pointer for Group F m apping

Figure 6. Addressing the Register File

F

E

D

C

B

A

9

8

7

6

5

4

3

PAGED REGISTERS

SYSTEM REGISTER S

2

1

0

00

15

255

240

239

224

223

VA00432

UP TO

64 PAGES

GENERAL

REGISTERS

PURPOSE

224

PAGE 63

PAGE 5

PAGE 0

PAGE POINT ER

R255

R240

R224

R0

VA00433

R234

REGISTER FILE

SYSTEM REGISTER S

GROU P D

GROUP B

GROUP C

(1100)

(0011)

R192

R207

255

240

239

224

223

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

15

VR000118

00

R195

R195

(R0C3h)

PAGED REGISTERS

9

Page 22

22/179

ST92141 - DEVICE ARCHITECTURE

MEMORY SPACES (Cont’d)

2.2.2 Register Addressing

Register File registers, including Group F paged

registers (but excluding Group D), may be addressed explicitly by means of a decimal, hexadecimal or binary address; thus R231, RE7h and

R11100111b represent the same register (see

Figure 6). Group D registers can only be ad-

dressed in Working Register mode.

Note that an upper case “R” is used to denote this

direct addressing mode.

Working Re gi st ers

Certain types of instruction require that registers

be specified in the form “rx”, where x is in the

range 0 to 15: these are known as Working Registers.

Note that a lower case “r” is used to denote this indirect addressing mode.

Two addressing schemes are av ailable: a single

group of 16 working registers, or two separately

mapped groups, each consisting of 8 working registers. These groups may be mapped starting at

any 8 or 16 byte boundary in the register file by

means of dedicated pointer registers. This technique is described in more detail in Section 2.3.3

Register Pointing Techniques, and illustrated in

Figure 7 and in Figure 8.

System Registers

The 16 registers in Group E (R224 to R239) are

System registers and may be addressed using any

of the register addressing modes. Thes e registers

are described in greater detail in Section 2.3 SYSTEM REGISTER S.

Paged Registers

Up to 64 pages, each containing 16 registers, may

be mapped to G roup F. These are add ressed using any register addressing mode, in conjunctio n

with the Page Pointer register, R234, which is one

of the System registers. This register selects the

page to be mapped to Group F and, once set,

does not need to be changed if two or more registers on the same page are to be addressed in succession.

Therefore if the Page Pointer, R234, is set to 5, the

instructions:

spp #5

ld R242, r4

will load the contents of working register r4 into the

third register of page 5 (R242).

These paged registers hold data and control information relating to the on-chip peripherals, each

peripheral always being associated with the sam e

pages and registers to ensure code com patibility

between ST9 devices. The number of these registers therefore depends on the peripherals which

are present in the s pecific ST9 family device. In

other words, pages only exist if the relevant peripheral is present.

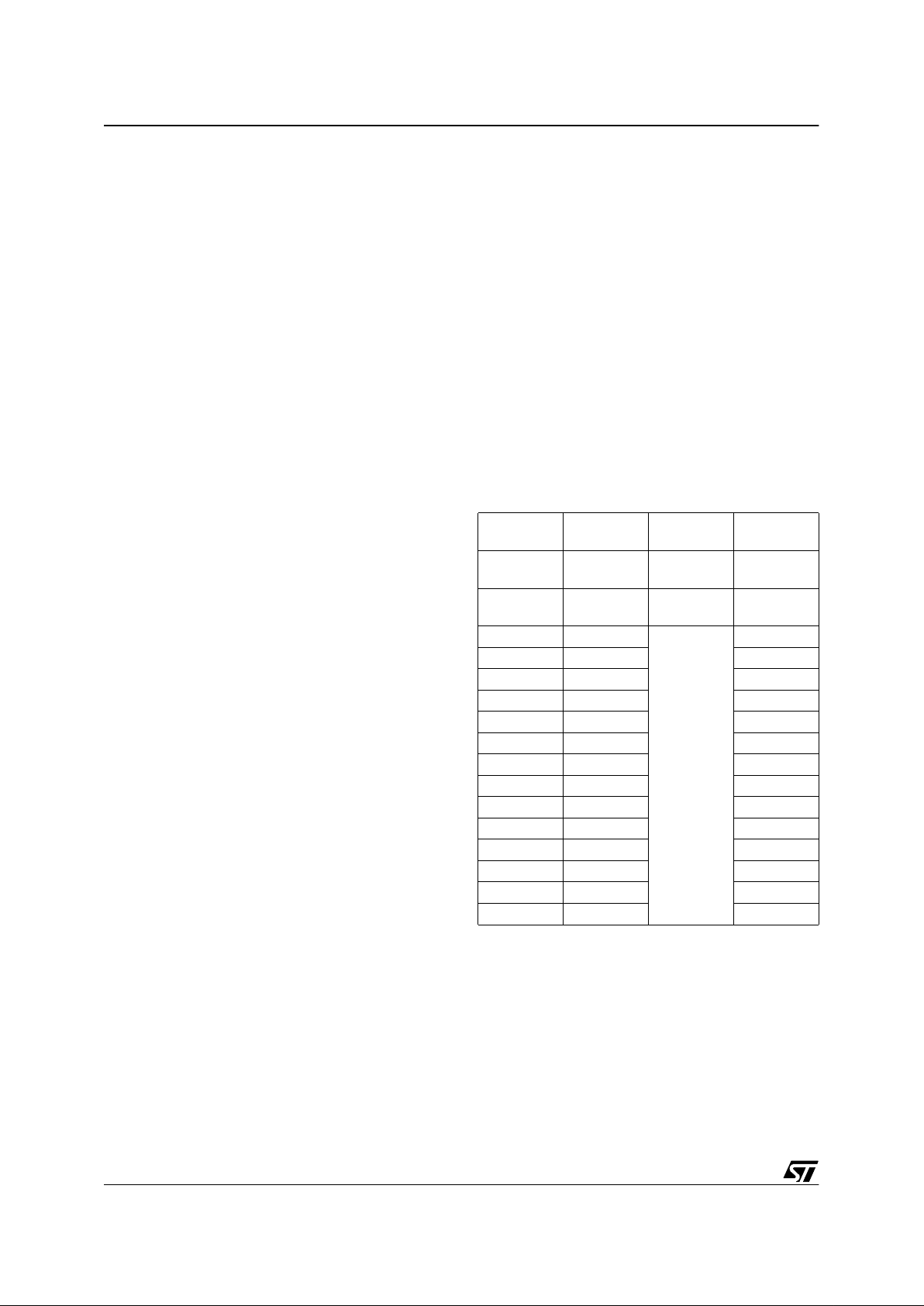

Table 9. Register File Organization

Hex.

Address

Decimal

Address

Function

Register

File Group

F0-FF 240-255

Paged

Registers

Group F

E0-EF 224-239

System

Registers

Group E

D0-DF 208-223

General

Purpose

Registers

Group D

C0-CF 192-207 Group C

B0-BF 176-191 Group B

A0-AF 160-175 Group A

90-9F 144-159 Group 9

80-8F 128-143 Group 8

70-7F 112-127 Group 7

60-6F 96-111 Group 6

50-5F 80-95 Group 5

40-4F 64-79 Group 4

30-3F 48-63 Group 3

20-2F 32-47 Group 2

10-1F 16-31 Group 1

00-0F 00-15 Group 0

1

Page 23

23/179

ST92141 - DEVICE ARCHITECTURE

2.3 SYSTEM REGISTERS

The System registers are listed in Table 10 Sy s-

tem Registers (Group E). They are used to per-

form all the important system settings. Their purpose is described in the following pages. Refer t o

the chapter dealing with I/O for a description of the

PORT[5:0] Data registers.

Table 10. System Registers (Group E)

2.3.1 Central Interrupt Control Register

Please refer to the ”INTERRUPT” chapter for a detailed description of the ST9 interrupt philosophy.

CENTRAL INTERRUPT CONTROL REGISTER

(CICR)

R230 - Read/Write

Register Group: E (System)

Reset Value: 1000 0111 (87h)

Bit 7 = GCEN:

Global Counter Enable

.

This bit is the Global Counter Enable of the Multifunction Timers. The GCEN bit is ANDed with the

CE bit in the TCR Register (only in devices featuring the MFT Multifunction Timer) in order to enable

the Timers when both bits are set. This bit is set after the Reset cycle.

Note: If an MFT is not included in the ST9 device,

then this bit has no effect.

Bit 6 = TLIP:

Top Level Interrupt Pending

.

This bit is set by hardware when a Top Level Interrupt Request is recognized. This bit can also be

set by software to simulate a Top Level Interrupt

Request.

0: No Top Level Interrupt pending

1: Top Level Interrupt pending

Bit 5 = TLI:

Top Level Interrupt bit

.

0: Top Level Interrupt is acknowledged depending

on the TLNM bit in the NICR Register.

1: Top Level Interrupt is acknowledged depending

on the IEN and TLNM bits in the NICR Register

(described in the Interrupt chapter).

Bit 4 = IEN:

Interrupt Enable .

This bit is cleared by interrupt acknowledgement,

and set by interrupt return (iret). IEN is modified

implicitl y by iret, ei and di instructions or by an

interrupt acknowledge cycle. It can also be explicitly written by the user, but only when no i nterrupt

is pending. Therefore, the user should execute a

di instruction (or guarantee by other means that

no interrupt request can arrive) before a ny write

operation to the CICR register.

0: Disable all interrupts except Top Level Interrupt.

1: Enable Interrupts

Bit 3 = IAM:

Interrupt Arbitration Mode

.

This bit is set and cleared by software to select the

arbitration mode.

0: Concurrent Mode

1: Nested Mode.

Bits 2:0 = CPL[2:0]:

Current Priority Level

.

These three bits record the priority level of the routine currently running (i.e. the Current Priority Level, CPL). The highest priority level is represented

by 000, and the lowest by 111. The CPL bits can

be set by hardware or software and provide the

reference according to which subsequent interrupts are either left pending or are allowed to interrupt the current interrupt service routine. When the

current interrupt is replaced by one of a higher priority, the current priority value is automatically

stored until required in the NICR register.

R239 (EFh) SSPLR

R238 (EEh)

SSPHR

R237 (EDh)

USPLR

R236 (ECh)

USPHR

R235 (EBh)

MODE REGISTER

R234 (EAh)

PAGE POINTER REGISTER

R233 (E9h)

REGISTER POINTER 1

R232 (E8h)

REGISTER POINTER 0

R231 (E7h)

FLAG REGISTER

R230 (E6h)

CENTRAL INT. CNTL REG

R229 (E5h)

PORT5 DATA REG.

R228 (E4h)

PORT4 DATA REG.

R227 (E3h)

PORT3 DATA REG.

R226 (E2h)

PORT2 DATA REG.

R225 (E1h)

PORT1 DATA REG.

R224 (E0h)

PORT0 DATA REG.

70

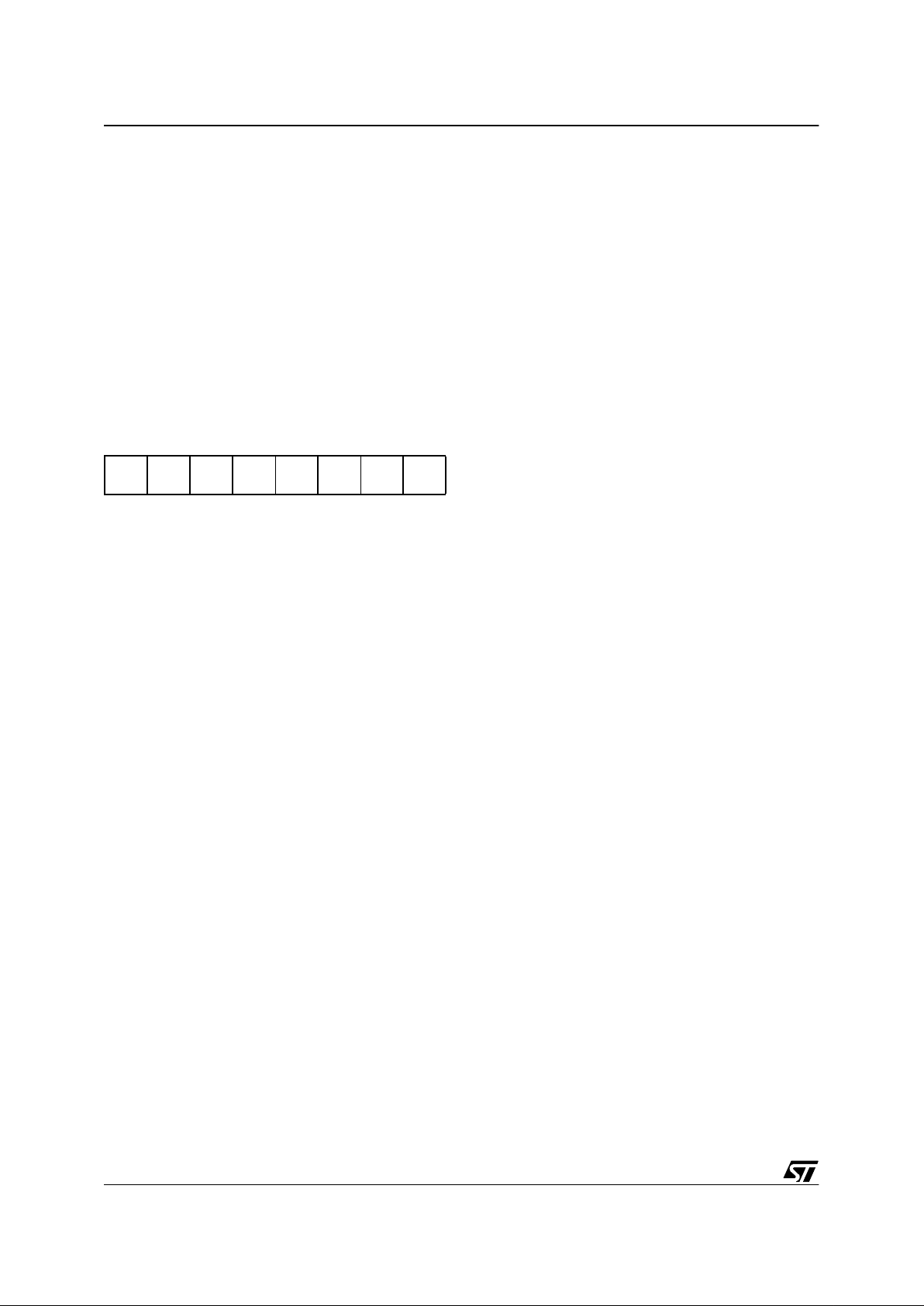

GCEN TLIP TLI IEN IAM CPL2 CPL1 CPL0

1

Page 24

24/179

ST92141 - DEVICE ARCHITECTURE

SYSTEM REGI STE R S (Cont’d)

2.3.2 Flag Register

The Flag Register contains 8 flags which indicate

the CPU status. During an interrupt, the flag register is automatically stored in the system stack area

and recalled at the end of the interrupt service routine, thus returning the CPU to its original status.

This occurs for all interrupts and, wh en operating

in nested mode, up to seven versions of the flag

register may be stored.

FLAG REGISTER (FLAGR)

R231- Read/Write

Register Group: E (System)

Reset value: 0000 0000 (00h)

Bit 7 = C :

Carry Flag

.

The carry flag is affected by:

Addition (add, addw, adc, adcw),

Subtraction (sub, subw, sbc, sbcw),

Compare (cp, cpw),

Shift Right Arithmetic (sra, sraw),

Shift Left A r ith me t ic (sla, slaw),

Swap Nibbles (swap),

Rotate (rrc, rrcw, rlc, rlcw, ror,

rol),

Decimal Adjust (da),

Multiply and Divide (mul, div, divws).

When set, it generally indicates a carry out of the

most significant bit position of the register being

used as an accumulator (bit 7 for byte operations

and bit 15 for word operations).

The carry flag can be set by the S et Carry Flag

(scf ) instruction, cleared by the Reset Carry Flag

(rcf) instruction, and complemented by the Complement Carry Flag (ccf) instruction.

Bit 6 = Z:

Zero Flag

. The Zero flag is affected by:

Addition (add, addw, adc, adcw),

Subtraction (sub, subw, sbc, sbcw),

Compare (cp, cpw),

Shift Right Arithmetic (sra, sraw),

Shift Left A r ith me t ic (sla, slaw),

Swap Nibbles (swap),

Rotate (rrc, rrcw, rlc, rlcw, ror,

rol),

Decimal Adjust (da),

Multiply and Divide (mul, div, divws),

Logical (and, andw, or, orw, xor,

xorw, cpl),

Increment and Decrement (inc, incw, dec,

decw),

Test (tm, tmw, tcm, tcmw, btset).

In most cases, the Zero flag is set when the contents

of the register being used as an accumulator become zero, following one of the above operations.

Bit 5 = S:

Sign Flag

.

The Sign flag is affected by the same instructions

as the Zero flag.

The Sign flag is set when bit 7 (for a byte operation) or bit 15 (for a word operation) of the register

used as an accumulator is one.

Bit 4 = V:

Overflow Flag

.

The Overflow flag is affected by t he sa me instructions as the Zero and Sign flags.

When set, the Overflow flag indicates that a two'scomplement number, in a result register, is in error, since it has exceeded the largest (or is less

than the smallest), number that can be represented in two’s-complement notation.

Bit 3 = DA:

Decimal Adjust Flag

.

The DA flag is used f or BCD arithm et ic. Si nce t he

algorithm for correcting BCD operations i s different for addition and subtraction, this flag is used to

specify which type of instruction was executed

last, so that the subsequen t Decimal Adjust (da)

operation can perform its function correctly. The

DA flag cannot normally be u sed as a test condition by the programmer.

Bit 2 = H:

Half Carry Flag.

The H flag indicates a carry out of (or a borrow into) bit 3, as the resu lt of addin g or subt racti ng tw o

8-bit bytes, each representing two BCD digits. The

H flag is used by the Dec imal Adjust (da) instruc-

tion to convert the binary result of a previous addition or subtraction into the correct BCD result. Like

the DA flag, this flag is not norma lly accessed by

the user.

Bit 1 = Reserved bit (must be 0).

Bit 0 = DP:

Data/Program Memory Flag

.

This bit indicates the memory area addressed . Its

value is affected by the Set Data Memory (sdm)

and Set Program Mem ory (spm) instructions. Refer to the Memory Management Unit for further details.

70

C Z S V DA H - DP

1

Page 25

25/179

ST92141 - DEVICE ARCHITECTURE

SYSTEM REGI STE R S (Cont’d)

If the bit is set, dat a is accessed using the Data

Pointers (DPRs registers), otherwise it is pointed

to by the Code Pointer (CSR regist er); therefore,

the user initialization routine must include a Sdm

instruction. Note that code is always poi nted to by

the Code Pointer (CSR).

Note: In the current ST9 devices, the DP flag is

only for co mpatibility wit h software d eveloped for

the first generation of ST9 devices. With the single

memory addressing space, its us e is now redundant. It must be kept to 1 w ith a Sdm instruction at

the beginning of the program to ens ure a normal

use of the different memory pointers.

2.3.3 Register Pointing Techniques

Two registers within the System register group,

are used as pointers to the working registers. Register Pointer 0 (R232) may be used on its own as a

single pointer to a 16-register working space, or in

conjunction with Register Pointer 1 (R233), to

point to two separate 8-register spaces.

For the purpose of register pointing, the 16 register

groups of the register file are subdivided into 32 8register blocks. The values specified with the Set

Register Pointer instructions refer to the blocks to

be pointed to in twin 8-register mode, or to the lower 8-register block location in single 16-register

mode.

The Set Registe r Pointer instructions srp, srp0

and srp1 automatically inform the C PU whether

the Register File is to operate in single 16-register

mode or in twin 8-register mode. The srp instruction selects the single 16-register group mode and

specifies the location of the lower 8-register block,

while the srp0 and srp1 instructions automatically select the twin 8-register group mode and specify the locations of each 8-register block.

There is no limitation on the order or position of

these register groups, other than that they must

start on an 8-register boundary i n twin 8-register

mode, or on a 16-register boundary in single 16register mode.

The block number should always be an even

number in single 16-re gister mode. The 16-register group will always start at the block whose

number is the nearest even number equal to or

lower than the block number specified in the srp

instruction. Avoid using odd block numbers , since

this can be confusing if twin mode is subsequently

selected.

Thus:

srp #3 will be interpreted as srp #2 and will al-

low using R16 ..R31 as r0 .. r15.

In single 16-register mode , the working registers

are referred to as r0 to r15. In twin 8-register

mode, registers r0 to r7 are in the block pointed

to by RP0 (by means of the srp0 instruction),

while registers r8 to r15 are in the block pointed

to by RP1 (by means of the srp1 instructio n).

Caution:

Group D registers can only be accessed

as working registers using the Register Pointers,

or by means of the Stack Pointers. They cannot be

addressed explicitly in the form “Rxxx”.

1

Page 26

26/179

ST92141 - DEVICE ARCHITECTURE

SYSTEM REGI STE R S (Cont’d)

POINTER 0 REGIST ER (RP0)

R232 - Read/Write

Register Group: E (System)

Reset Value: xxxx xx00 (xxh)

Bits 7:3 = RG[4:0]:

Register Group number.

These bits contain the num ber (in the range 0 to

31) of the register block s pecified in the srp0 or

srp instructions. In single 16-register mode the

number indicates the lower of the two 8-register

blocks to which the 16 working registers are to be

mapped, while in twin 8-register mode it indicates

the 8-register block to which r0 to r7 are to be

mapped.

Bit 2 = RPS:

Register Pointer Selector

.

This bit is set by the instructions srp0 and srp1 to

indicate that the twin register po inting m ode is s elected. The bit is reset by the srp instruction to indicate that the single register pointing mode is selected.

0: Single register pointing mode

1: Twin register pointing mode

Bits 1:0: Reserved. Forced by hardware to zero.

POINTER 1 REGISTER (RP1)

R233 - Read/Write

Register Group: E (System)

Reset Value: xxxx xx00 (xxh)

This register is only used in the twin register pointing mode. W hen us ing t he sin gle regist er pointing

mode, or when using only one of the twin regi ster

groups, the RP1 register must be considered as

RESERVED and may NOT be us ed as a general

purpose register.

Bits 7:3 = RG[4:0]:

Register Group number.

These bits contain the n umber (in the range 0 to

31) of the 8-register block specified in the srp1 instruction, to which r8 to r15 are to be mapped.

Bit 2 = RPS:

Register Pointer Selector

.

This bit is set by the srp0 and srp1 instructions to

indicate that the twin registe r pointing mod e is s elected. The bit is reset by the srp instruction to indicate that the single register pointing mode i s selected.

0: Single register pointing mode

1: Twin register pointing mode

Bits 1:0: Reserved. Forced by hardware to zero.

70

RG4 RG3 RG2 RG1 RG0 RPS 0 0

70

RG4 RG3 RG2 RG1 RG0 RPS 0 0

1

Page 27

27/179

ST92141 - DEVICE ARCHITECTURE

SYSTEM REGI STE R S (Cont’d)

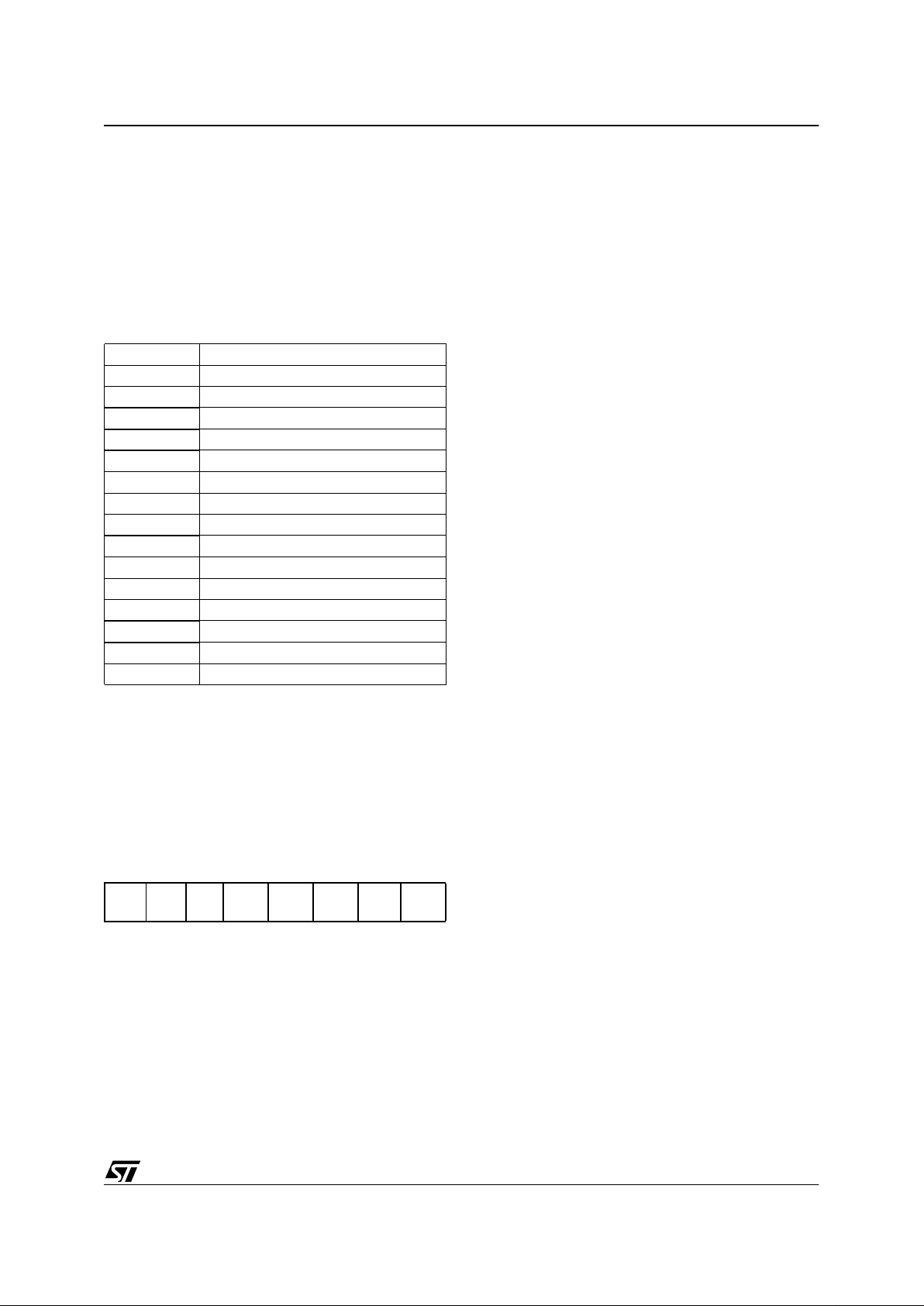

Figure 7. Pointing to a single group of 16

registers

Figure 8. Pointing to two groups of 8 registers

31

30

29

28

27

26

25

9

8

7

6

5

4

3

2

1

0

F

E

D

4

3

2

1

0

BLOCK

NUMBER

REGISTER

GROUP

REGISTER

FILE

REGISTER

POINTER 0

srp #2

set by:

instruction

points to:

GROUP 1

addressed by

BLOCK 2

r15

r0

31

30

29

28

27

26

25

9

8

7

6

5

4

3

2

1

0

F

E

D

4

3

2

1

0

BLOCK

NUMBER

REGISTER

GROUP

REGISTER

FILE

REGISTER

POINTER 0

srp0 #2

set by:

instructions

point to:

GROUP 1

addressed by

BLOCK 2

&

REGISTER

POINTER 1

srp1 #7

&

GROUP 3

addressed by

BLOCK 7

r7

r0

r15

r8

1

Page 28

28/179

ST92141 - DEVICE ARCHITECTURE

SYSTEM REGI STE R S (Cont’d)

2.3.4 Paged Registers

Up to 64 pages, each containing 16 registers, may

be mapped to Group F. These paged registers

hold data and control information relating to the

on-chip peripherals, each peripheral a lways being

associated with the same pages and registers to

ensure code compa tibility bet ween ST9 devices.

The number of these registers depends on the peripherals present in the specific ST9 device. In other words, pages only exist if the relevant peripheral is present.

The paged registers are addressed using the normal register addressing modes, in conjunction with

the Page Pointer register, R234, which is on e of

the System registers. This register selects the

page to be mapped to Group F and, once set,

does not need to be changed if two or more registers on the same page are to be addressed in succession.

Thus the instructions:

spp #5

ld R242, r4

will load the contents of working register r4 into the

third register of page 5 (R242).

Warning: During an interrupt, the PPR register is

not saved automatically in the stack. If needed, it

should be saved/restored by the user within the interrupt routine.

PAGE POINTER REGIST ER ( PPR)

R234 - Read/Write

Register Group: E (System)

Reset value: xxxx xx00 (xxh)

Bits 7:2 = PP[5:0]:

Page Pointer

.

These bits contain the num ber (in the range 0 to

63) of the page specified in the spp instruction.

Once the page pointer has been set , there is no

need to refresh it unless a different page is required.

Bits 1:0: Reserved. Forced by hardware to 0.

2.3.5 Mode Regi ster

The Mode Register allows control of the following

operating parameters:

– Selection of internal or external System and User

Stack areas,

– Management of the clock frequency,

– Enabl ing of Bus request and Wait s ignals when

interfacing to external memory.

MODE REGISTER (MODER)

R235 - Read/Write

Register Group: E (System)

Reset value: 1110 0000 (E0h)

Bit 7 = SSP:

System Stack Point er

.

This bit selects an internal or external System

Stack area.

0: External system stack area, in memory space.

1: Internal system stack area, in the Register File

(reset state).

Bit 6 = USP:

User Stack Pointer

.

This bit selects an internal or external User S tack

area.

0: External user stack area, in memory space.

1: Internal user stack area, in the Register File (re-

set state).

Bit 5 = DIV2:

Crystal Oscillator Clock Divided by 2

.

This bit controls the divide-by-2 circuit operating

on the crystal oscillator clock (CLOCK1).

0: Clock divided by 1

1: Clock divided by 2

Bits 4:2 = PRS[2:0]:

CPUCLK Prescaler

.

These bits load the prescaler division factor for the

internal clock (INTCLK). The prescaler factor selects the internal clock frequency, which can be divided by a factor from 1 to 8. Refer to the Re set

and Clock Control chapter for further information.

Bit 1 = BRQEN:

Bus Request Enable

.

0: External Memory Bus Request disabled

1: External Memory Bus Request enabled on

BREQ

pin (where available).

Note: Disregard this bit if BREQ

pin is not availa-

ble.

Bit 0 = HIMP:

High Impedance Enable

.

When any of Po rts 0, 1, 2 or 6 d epending on device configuration, are programmed as Address

and Data lines to interface external Memory, these

lines and the Memory interface control lines (AS,

DS, R/W) can be forced into the High Impedance

70

PP5 PP 4 PP3 PP2 PP1 P P0 0 0

70

SSP USP DIV2 PRS2 PRS1 PRS0 BRQEN HIMP

1

Page 29

29/179

ST92141 - DEVICE ARCHITECTURE

SYSTEM REGI STE R S (Cont’d)

state by setting the HIMP bit. When this bit is reset,

it has no effect.

Setting the HIMP bit is recommended for noise reduction when only internal Memory is used.

If Port 1 and/or 2 are declared as an address AND

as an I/O port (for example: P10... P14 = Address,

and P15... P17 = I/O), the HIMP b it has no effect

on the I/O lines.

2.3.6 Stack Pointers

Two separate, double-register stack pointers are

available: the System Stack Pointer and the User

Stack Pointer, both of which can address registers

or memor y .

The stack pointers point to the “bottom” of the

stacks which are filled us ing the pus h comma nds

and emptied using the pop command s. The stack

pointer is automatically pre-decremented when

data is “pushed” in and post-incremented when

data is “popped” out.

The push and pop commands used to manage the

System Stack may be addressed to the User

Stack by adding the suffix “u”. To use a stack in-

struction for a word, the suffix “w” is added. These

suffixes may be combined.