Datasheet ST7FSCR1R4, ST7FSCR1E4, ST7SCRDIE, ST7SCR1E4, ST7SCR1R4 Datasheet (SGS Thomson Microelectronics)

...Page 1

Rev. 1.3

March 2003 1/102

ST7SCR

8-BIT LOW-POWER, FULL-SPEED USB MCU WITH 16K

FLASH , 768 RAM, SMARTCARD I/F, TIMER

■ Memories

– Up to 16K of ROM or High Density Flash (HD-

Flash) program memory wi th read/write protection, HDFlash In-Circuit and In-Application

Programming. 100 write/erase cycles guaranteed, data retention: 20 years at 55°C

– Up to 768 bytes of RAM in cluding up to 128

bytes stack and 256 bytes USB buffer

■ Clock , Res et and Supp ly M a nagemen t

– Low Voltage Reset

– 2 power saving modes: Halt and Wait modes

– PLL for generating 48 MHz USB clock using a

4 MHz crystal

■ Interrupt Management

– Nested Interrupt Controller

■ USB (Universal Serial Bus) Interface

– 256-byte buffer for full speed bulk, control and

interrupt transfer types compliant with USB

specification (version 2.0)

– On-Chip 3.3V USB voltage regulator and

transceivers with software power-down

– 7 USB Endpoints:

One 8-byte Bidirectional Control Endpoint

One 64-byte In Endpoint,

One 64-byte Out Endpoint

Four 8-byte In Endpoints

■ 35 or 4 I/O ports:

– Up to 4 LED outputs with software program -

mable constant current (3 or 7 mA).

– 2 General purpose I/Os program mable as in-

terru p ts

– Up to 8 line inputs programmable as interrupts

– Up to 20 Outputs

– 1 line assigned by default as st atic input after

reset

■ ISO7816-3 UART Interface:

– 4 Mhz Clock generation

– Synchronous/Asynchronous protocols (T=0,

T=1)

– Automatic retry on parity error

– Programmable Baud rate from 372 clock puls-

es up to 11.625 clock pulses (D=32/F=372)

– Card Insertion/Removal Detection

■ Smartcard Power Suppl y:

– Selectable card V

CC

1.8V, 3V, and 5V

– Internal Step-up converter for 5V supplied

Smartcards (with a current of up to 55mA) us-

ing only two external components.

– Programmable Smartcard Internal Voltage

Regulator (1.8V to 3.0V) with current overload

protection and 4 KV ESD protection (Human

Body Model) for all Smartcard Interface I/Os

■ One 8-bit Timer

– Time Base Unit (TBU) for generating periodic

interrupts.

■ Development Tools

– Full hardware/software development package

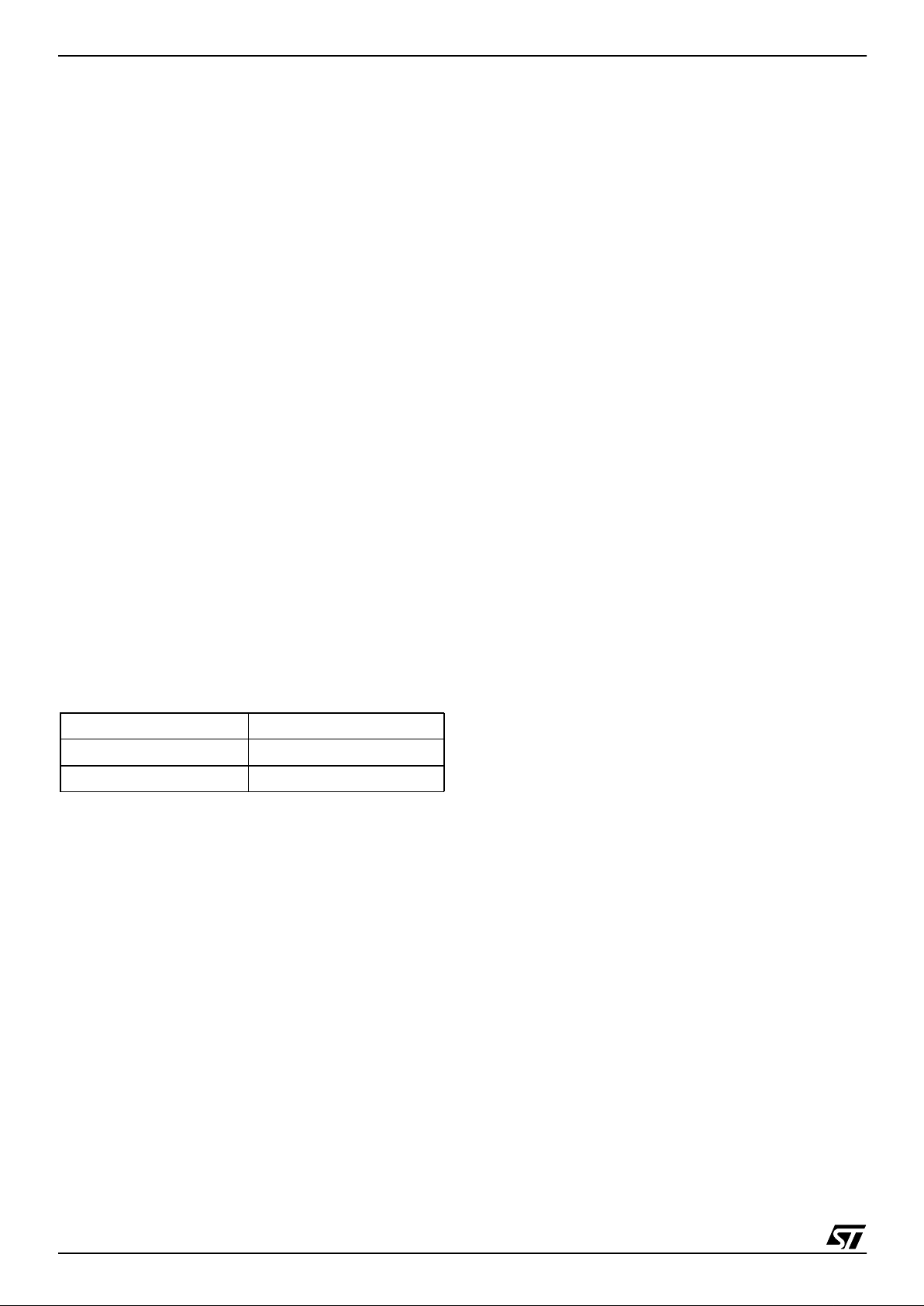

Table 1. Device Summa ry

TQFP64 14x14

SO24

Features ST7FSCR1R4 ST7SCR1R4 ST7FSCR1E4 ST7SCR1E4

Program memory 16K FLASH 16K ROM 16K FLASH 16K ROM

User RAM (stack) - bytes 768 (128)

Peripherals USB Full-Speed (7 Ep), TBU, Watchdog timer, ISO7816-3 Interface

Operating Supply 4.0 to 5.5V

Package TQFP64 SO24

CPU Frequency 4 or 8 Mhz

Operating temperature 0°C to +70°C

1

Page 2

Table of Cont ents

102

2/102

ST7SCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 REGISTER & MEM ORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 ICP (IN-CIRCUIT PR OGRAMMING) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 IAP (IN-APPLICATION PROGRAMMING) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 PROGRAM MEMORY READ-O UT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 CLOCK SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 RESET SEQUENCE MANAGER (RSM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 MASKING AND PROCESSING FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 INTERRUPTS AND LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 CONCURRENT & NESTED MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.5 INTERRUPT REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.3 HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3 I/O PORT IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.4 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10 MISCEL LANEOUS REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12.1 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12.2 TIME BASE UNIT (TBU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12.3 USB INTERFACE (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12.4 SMARTCARD INTERFACE (CRD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1

Page 3

Table of Cont ents

3/102

13 INSTRU CTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

13.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

13.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

14 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

14.1 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

14.2 RECOMMENDED OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14.3 SUPPLY AND RESET CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

14.4 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

14.5 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

14.6 SMARTCARD SUPPLY SUPERVISOR ELECTRICAL CHARACTERISTICS . . . . . . . . 82

14.7 EMC CHARACTERIST ICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

14.8 COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . 89

15 PACKAGE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

15.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . 92

16.1 DEVICE ORDERING INFORMATION AND TRANSFER OF CUSTOMER CODE . . . . . 93

16.2 DEVELOPMENT T OOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

16.3 ST7 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

17 SUMMARY OF CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

ERRAT A SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

18 SILICON IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

19 REFERENCE SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

20 SILICON LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

20.1 UNEXPECTED RESET FETCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

20.2 USB: TWO CO NSECUTIVE SETUP TOKENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

20.3 USB BUFFER SHARED MEMORY ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

20.4 WDG (WATCHDOG) LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

20.5 SUPPLY CURRENT IN HALT MODE (SUSPEND) LIMITATIONS . . . . . . . . . . . . . . . . 100

20.6 START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

20.7 I/O PORT INPUT HIGH LEVEL (VIH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

21 Devic e Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

22 ERRATA SHEET ReVISION History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1

To obtain the most recent version of this datasheet,

please check at www.st.com>products>technical liter ature>datasheet

Please note that an errata sheet can be found at the end of this document on

page 99.

Page 4

ST7SCR

4/102

1 INTRODUCTION

The ST7SCR and ST7FSCR devices are members of the ST7 microcontroller family designed for

USB applications. All devices are based on a common industry-standard 8-bit core, feat uring an enhanced instruction set.

The ST7SCR ROM devices are factory-programmed and are not reprogrammable.

The ST7FSCR versions feature dual-voltage

Flash memory with Flash Programming capability.

They operate at a 4MHz external oscillator frequency.

Under software control, all devices c an be place d

in WAIT or HALT mode, reducing power consumption when the application is in idle or stand-by

state.

The enhanced instruction set and addressing

modes of the ST7 offer both power and flexibility to

software developers, enabling the design of highly

efficient and compact application code. In addition

to standard 8-bit data management, all ST7 microcontrollers feature true bit manipulation, 8x8 un-

signed multiplication and indirect addressing

modes.

The devices include an ST7 Core, up to 16 Kbytes

of program memory, up to 512 bytes of user RAM,

up to 35 I/O lines and the following on-chip peripherals:

– USB full speed interface with 7 endpoints, pro-

grammable in/out configuration and embedded

3.3V voltage regulator and transceivers (no external components are needed).

– ISO7 816-3 UA RT interface with Programmable

Baud rate from 372 clock pulses up to 11.625

clock pulses

– Smartcard Supply Block able to provide pro-

grammable supply voltage and I/O voltage levels

to the smartcards

– Low voltage reset ensuring proper power-on or

power-off of the device (selectable by option)

– Watc hdog Timer

– 8-bit Timer (TBU)

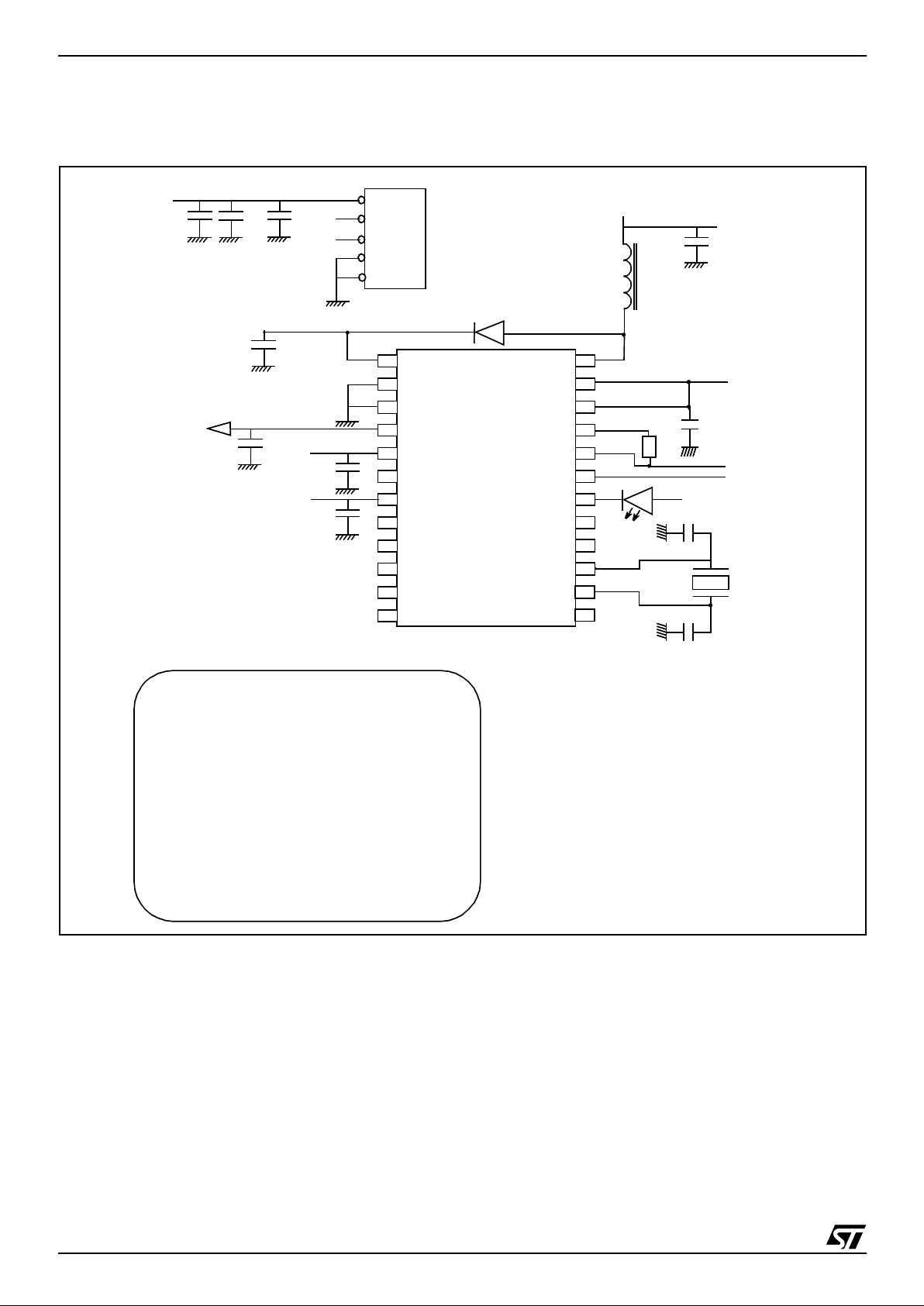

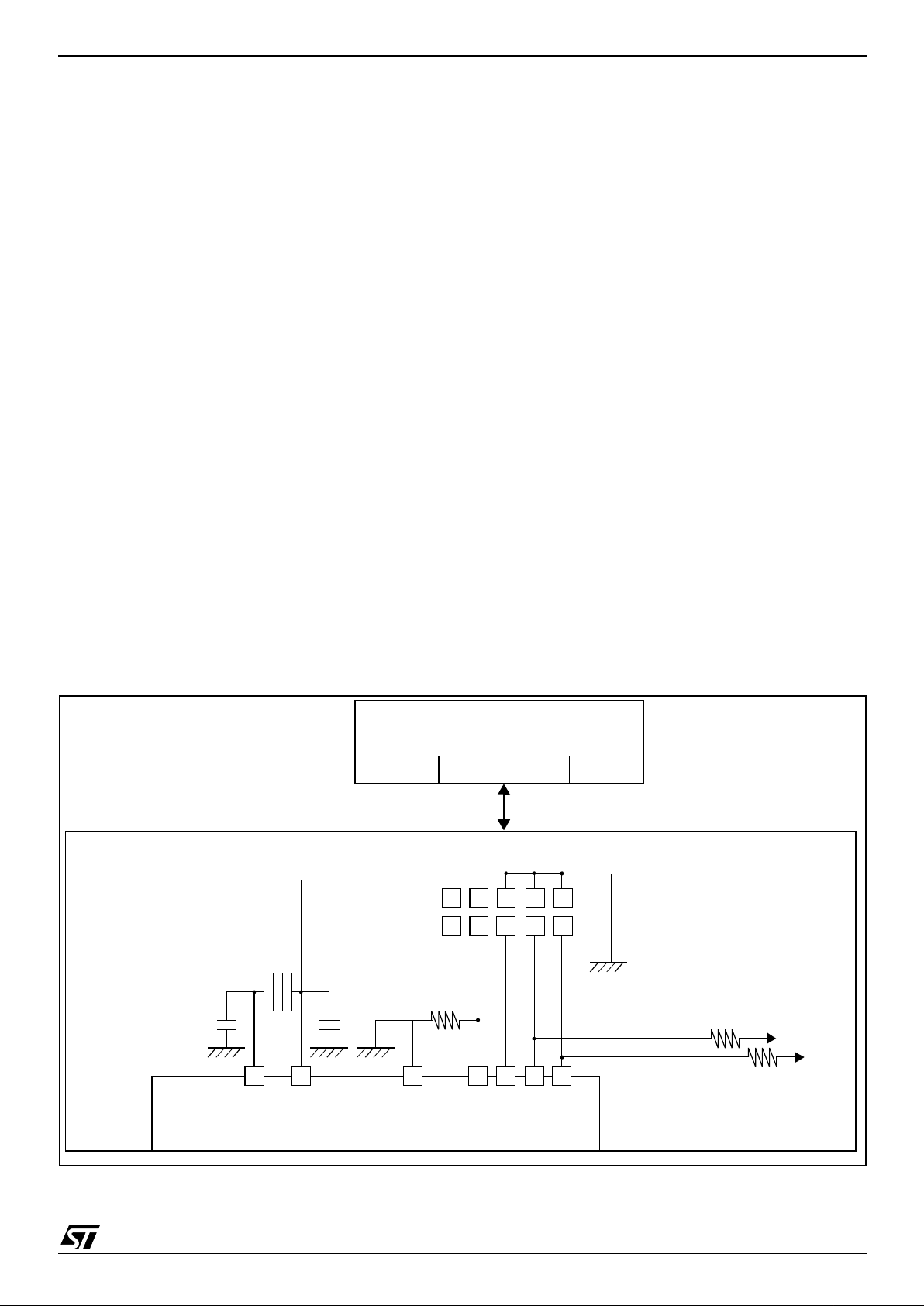

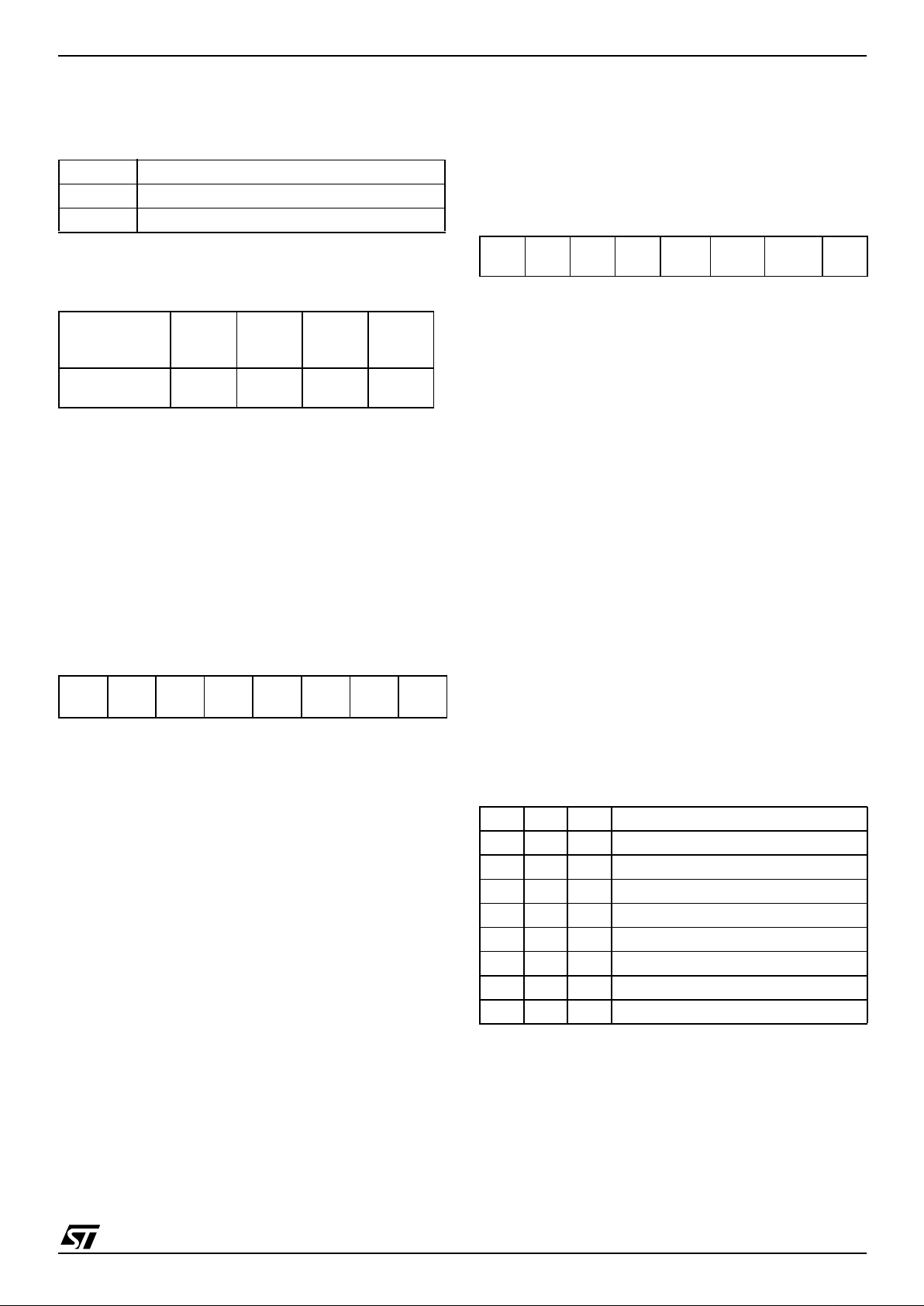

Figure 1. ST7SCR Block Diagram

8-BIT CO RE

ALU

ADDRESS AND DATA BUS

OSCIN

OSCOUT

PA6

4MHz

CONTROL

RAM

(512 Bytes)

PROGRAM

(16K Byt es)

MEMORY

8-BIT TIMER

LVD

V

PP

USBDP

USBDM

USBVCC

PORT C

PC[7:0]

PB[7:0]

PA[5:0]

SUPPLY

MANAG E R

PLL

OSCILLATOR

USB

PORT B

PORT A

USB

DATA

BUFFER

(256 bytes)

DIVIDER

8 MHz

3V/1.8V Vreg

DC/DC

CRDDET

CRDIO

CRDC4

CRDC8

CRDRST

CRDCLK

PD[7:0]

ISO7816 UART

PORT D

CONVERTER

CRDVCC

SELF

WATCHDOG

LED

LED[3:0]

or 4 MHz

48 MHz

DIODE

1

Page 5

ST7SCR

5/102

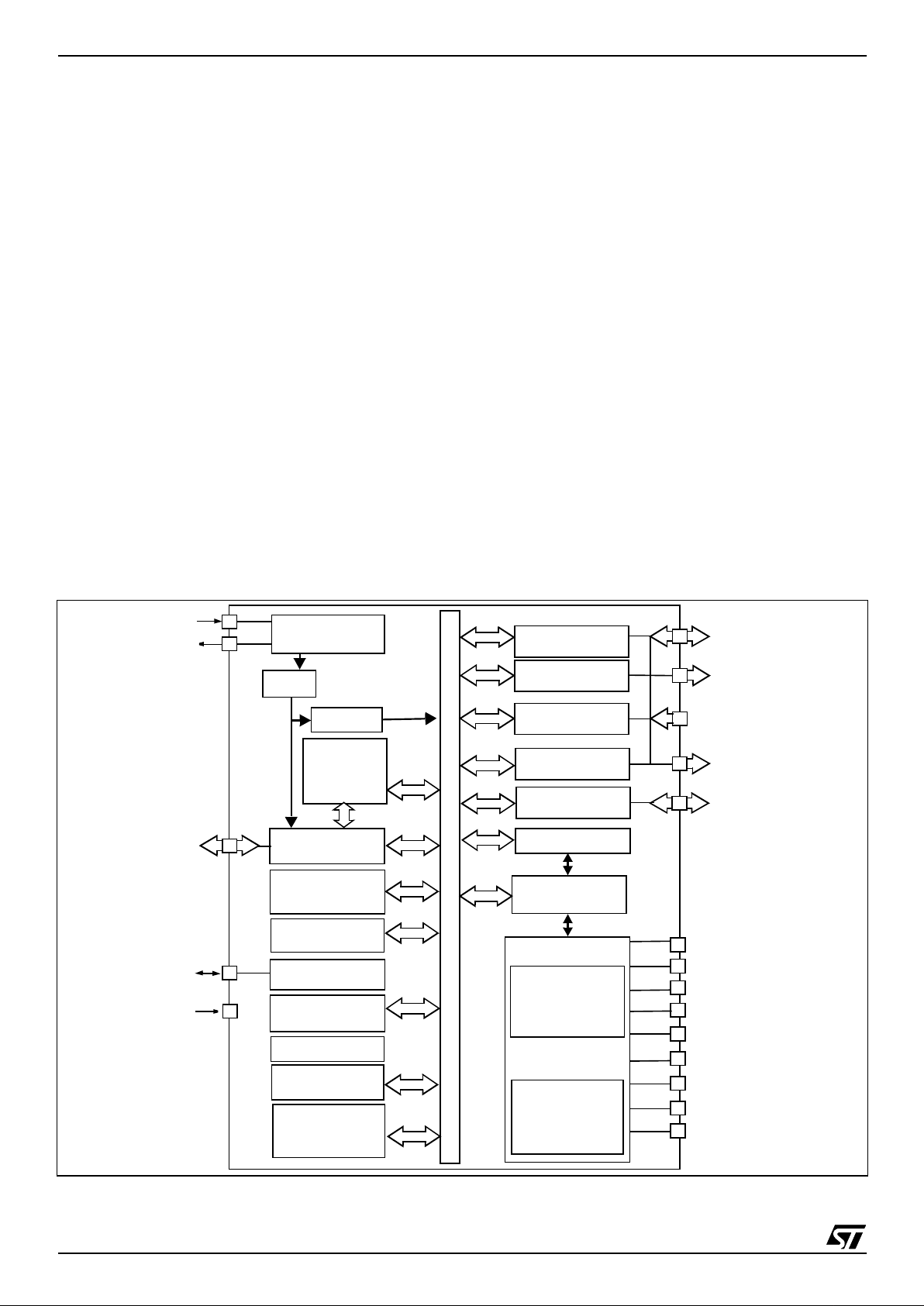

2 PIN DESCRIPTION

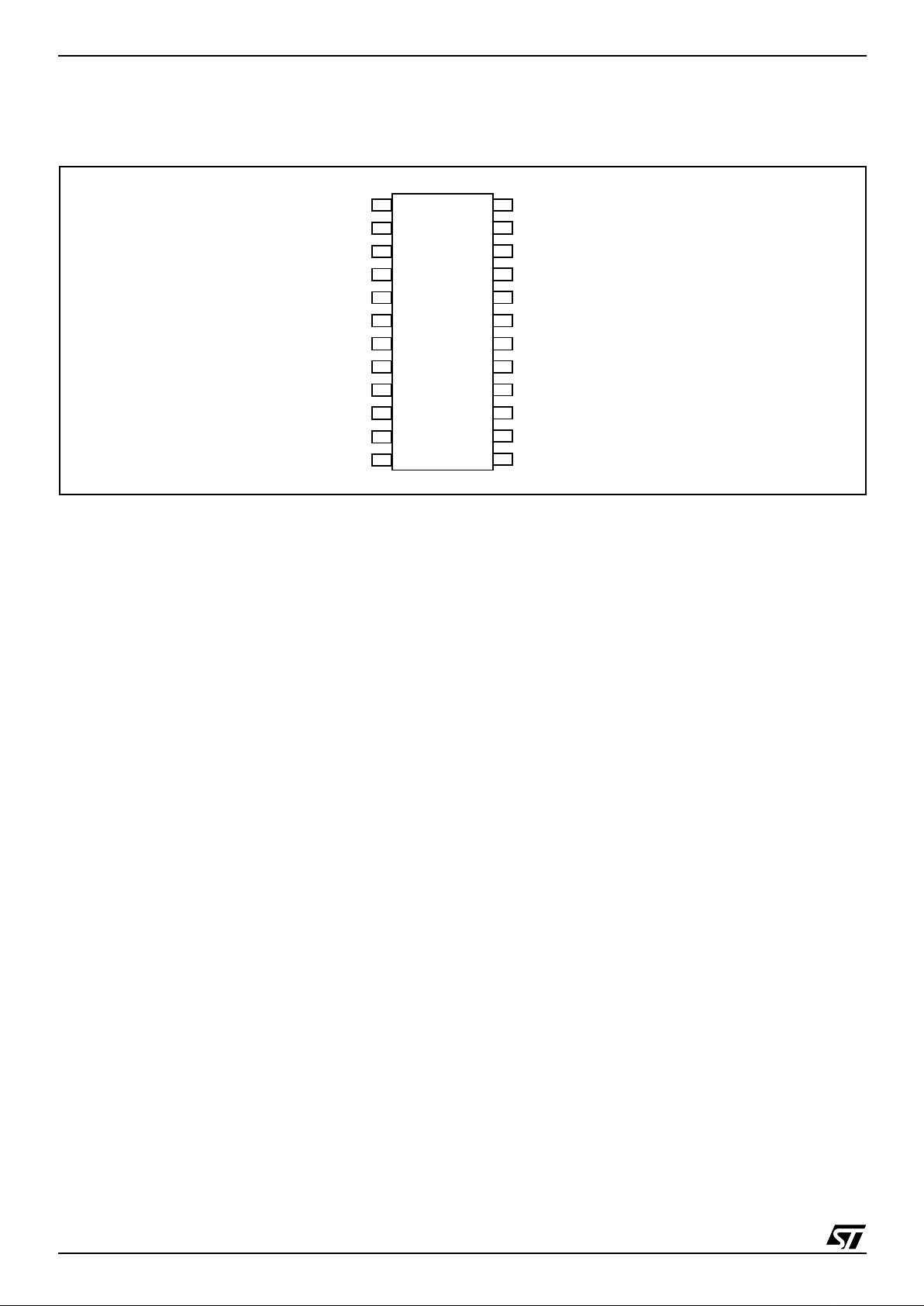

Figure 2. 64-Pin TQFP Package Pinout

WAKUP2/PA2

WAKUP2/PA3

PD0

PD1

PD2

PD3

PD4

PD5

PD6

PD7

OSCIN

OSCOUT

CRDDET

VDD

WAKUP2/ICCDATA/PA0

WAKUP2/ICCCLK/PA1

64 63 62 61 6 0 59 58 57 56 55 54 53 52 51 50 49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

17 18 19 20 21 22 23 24 29 30 31 3225 26 27 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

C4

CRDIO

C8

GND

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

NC

CRDCLK

NC

PA6

V

PP

PC7/WAKUP1

PC6/WAKUP1

PC5/WAKUP1

PC4/WAKUP1

PC3/WAKUP1

PC2/WAKUP1

PC1/WAKUP1

PC0/WAKUP1

GND

VDD

NC

DP

DM

LED0

SELF1

SELF2

PA5

PA4NCNC

LED3

LED2

LED1

VDD

VDDA

USBVcc

CRDVCC

GND

GNDA

DIODE

CRDRST

NC = Not Connected

1

Page 6

ST7SCR

6/102

PIN DESCRIPTION (Cont’d)

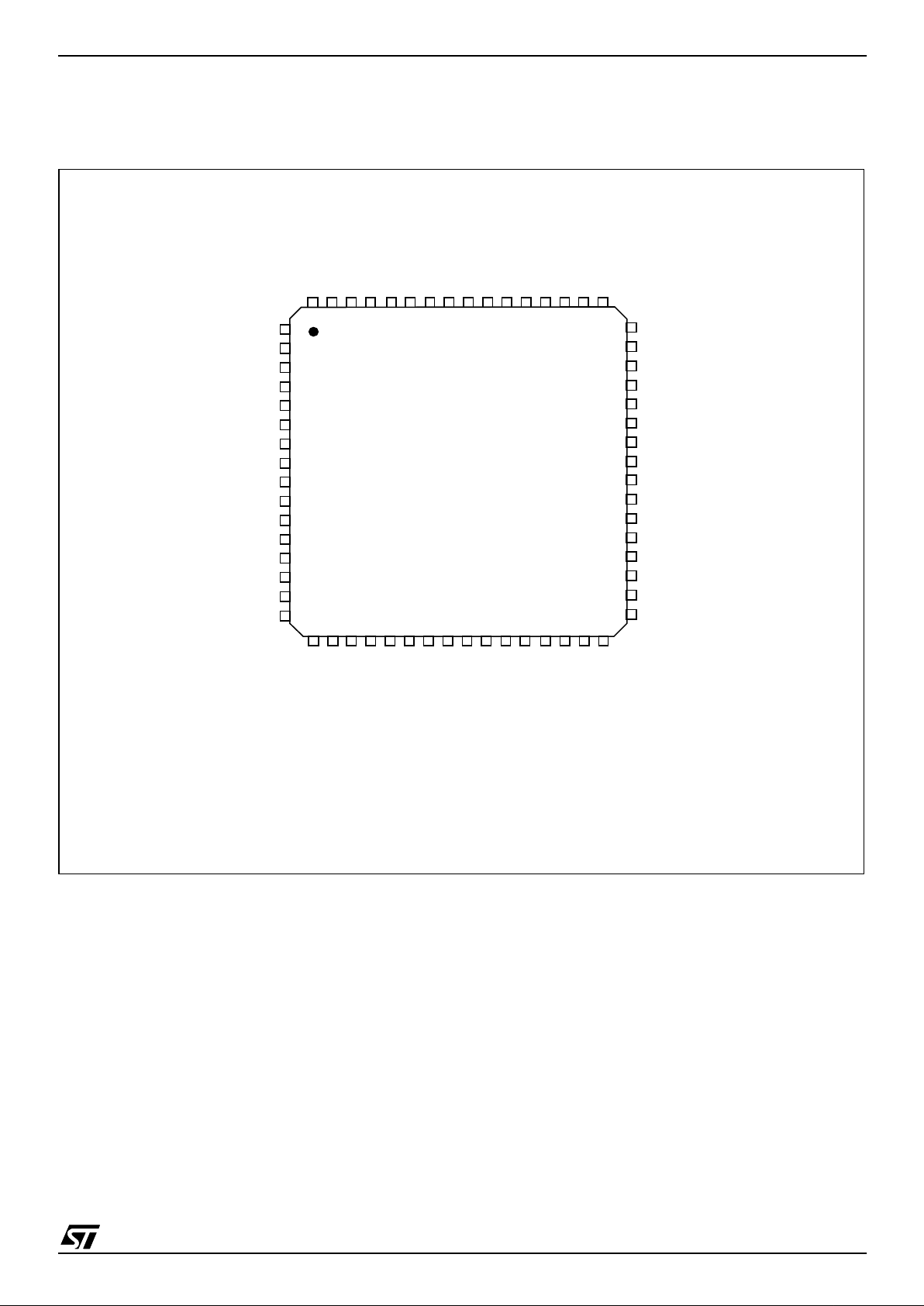

Figure 3. 24-Pin SO Package Pinout

14

13

11

12

15

16

17

18

LED0

DM

DP

USBVcc

OSCIN

OSCOUT

V

PP

1

2

3

4

5

6

7

8

9

10

DIODE

CRDCLK

CRDRST

CRDVCC

PA6

CRDIO

19

20

C8

CRDDET

ICCDATA/WAKUP2/PA0

V

DDA

C4

GNDA

ICCCLK/WAKUP2/PA1

NC

GND

21

22

23

24

V

DD

SELF

1

Page 7

ST7SCR

7/102

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations:

Type: I = input, O = output, S = supply

In/Output level: C

T

= CMOS 0.3VDD/0.7VDD with

input trigger

Output level: HS = 10mA high sink (on N-buffer

only)

Port and control configuration:

– Input:float = floating, wpu = weak pull-up, int = in-

terrupt, ana = analog

– Output : OD = open drain, PP = push-pull

Refer to “I/O PORTS” on page 30 for more det ails

on the software configuration of the I/O ports.

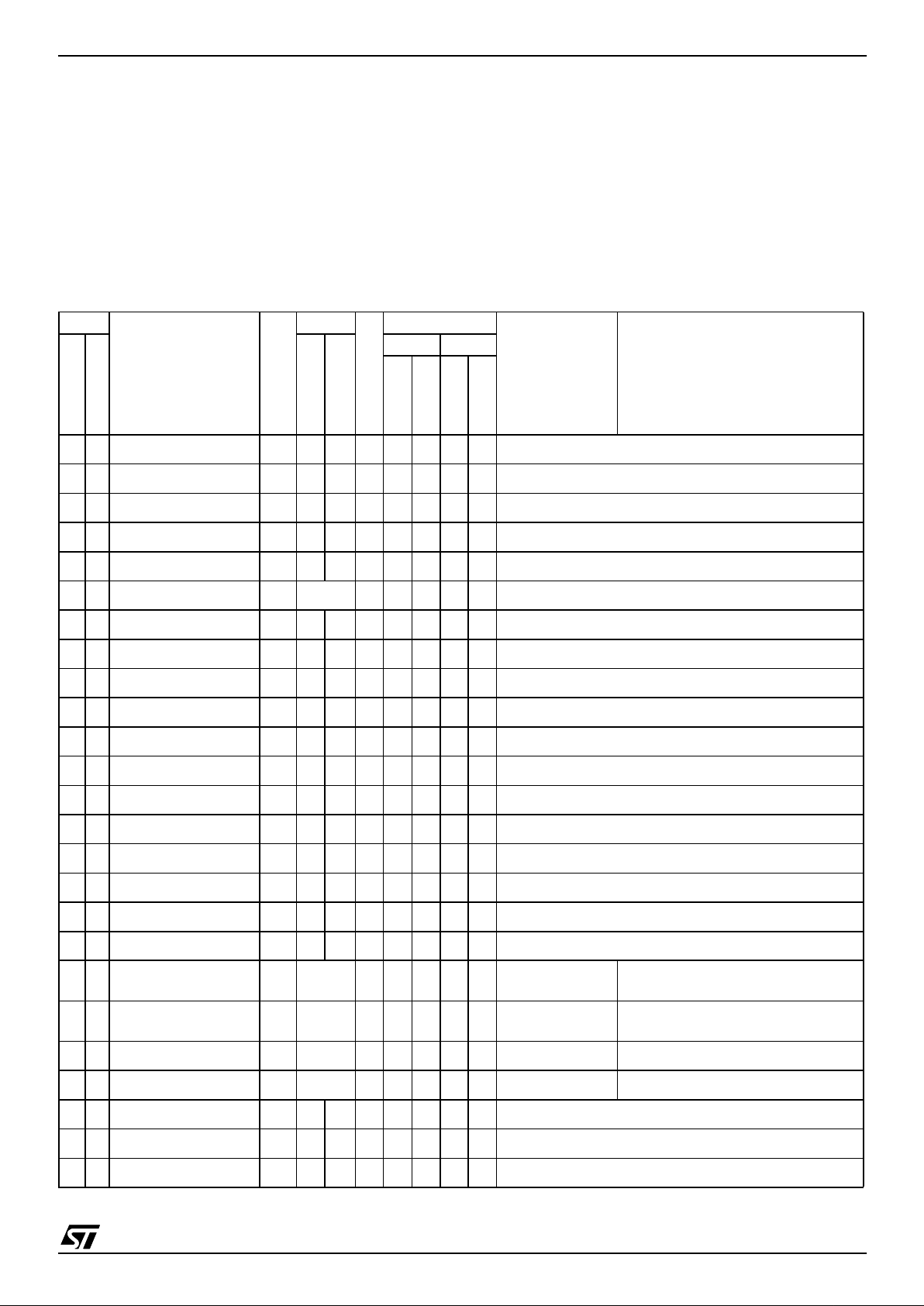

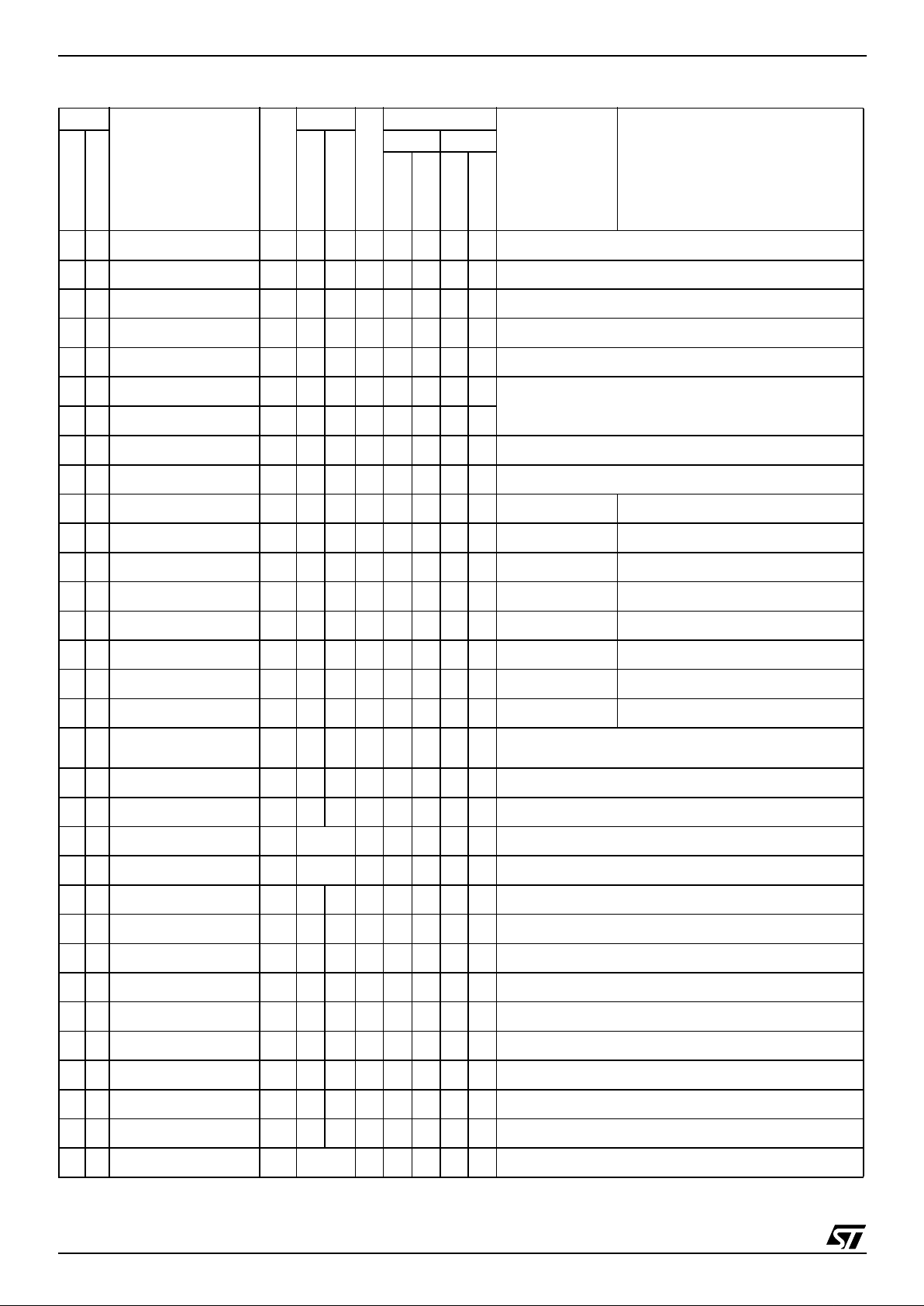

Table 1. Pin Description

Pin n°

Pin Name

Type

Level

V

CARD

supplied

Port / Control

Main

Function

(after reset)

Alternate Function

TQFP64

SO24

Input

Output

Input Output

wpu

int

OD

PP

1 5 CRDRST O CTX X Smartcard Reset

2 NC Not Connected

3 6 CRDCLK O C

T

X X Smartcard Clock

4 NC Not Connected

57C4 O C

T

X X Smartcard C4

6 8 CRDIO I/O C

T

X X X Smartcard I/O

79C8 O C

T

X X Smartcard C8

8 3 GND S Ground

9 PB0 O C

T

X X Port B0

1)

10 PB1 O C

T

X X Port B1

1)

11 PB2 O C

T

X X Port B2

1)

12 PB3 O C

T

X X Port B3

1)

13 PB4 O C

T

X X Port B4

1)

14 PB5 O C

T

X X Port B5

1)

15 PB6 O C

T

X X Port B6

1)

16 PB7 O C

T

X X Port B7

1)

17 10 CRDDET I C

T

X Smartcard Detection

18 VDD S Power Supply voltage 4V-5.5V

19 11

PA0/WAKUP2/

ICCDATA

I/O C

T

X X X X Port A0

Interrupt, In-Circuit Communication

Data Input

20 12

PA1/WAKUP2/

ICCCLK

I/O C

T

X X X X Port A1

Interrupt, In-Circuit Communication

Clock Input

21 PA2/WAKUP2 I/O C

T

X X X X Port A2

1)

Interrupt

22 PA3/WAKUP2 I/O C

T

X X X X Port A3

1)

Interrupt

23 PD0 O C

T

X X Port D0

1)

24 PD1 O C

T

X X Port D1

1)

25 PD2 O C

T

X X Port D2

1)

1

Page 8

ST7SCR

8/102

26 PD3 O C

T

X X Port D3

1)

27 PD4 O C

T

X X Port D4

1)

28 PD5 O C

T

X X Port D5

1)

29 PD6 O C

T

X X Port D6

1)

30 PD7 O C

T

X X Port D7

1)

31 14 OSCIN C

T

Input/Output Oscillator pins. These pins connect a

4MHz parallel-resonant crystal, or an external source

to the on-chip oscillator.

32 15 OSCOUT C

T

33 VDD S Power Supply voltage 4V-5.5V

34 GND S Ground

35 PC0/WAKUP1 I C

T

X X PC0

1)

External interrupt

36 PC1/WAKUP1 I C

T

X X PC1

1)

External interrupt

37 PC2/WAKUP1 I C

T

X X PC2

1)

External interrupt

38 PC3/WAKUP1 I C

T

X X PC3

1)

External interrupt

39 PC4/WAKUP1 I C

T

X X PC4

1)

External interrupt

40 PC5/WAKUP1 I C

T

X X PC5

1)

External interrupt

41 PC6/WAKUP1 I C

T

X X PC6

1)

External interrupt

42 PC7/WAKUP1 I C

T

X X PC7

1)

External interrupt

43 16 V

PP

S

Flash programming voltage. Must be held low in normal operating mode.

44 17 PA6 I C

T

PA6

45 18 LED0 O HS X Constant Current Output

46 19 DM I/O C

T

USB Data Minus line

47 20 DP I/O C

T

USB Data Plus line

48 NC Not Connected

49 21 USBVCC O C

T

3.3 V Output for USB

50 22 V

DDA

S power Supply voltage 4V-5.5V

51 23 V

DD

S power Supply voltage 4V-5.5V

52 LED1 O HS X Constant Current Output

53 LED2 O HS X Constant Current Output

54 LED3 O HS X Constant Current Output

55 NC Not Connected

56 NC Not Connected

57 PA4 I/O C

T

X X X X Port A4

Pin n°

Pin Name

Type

Level

V

CARD

supplied

Port / Control

Main

Function

(after reset)

Alternate Function

TQFP64

SO24

Input

Output

Input Output

wpu

int

OD

PP

1

Page 9

ST7SCR

9/102

Note 1 : Keyboard interface

58 PA5 I/O C

T

X X X X Port A5

59 24 SELF2 O C

T

An External inductance must be connected to these

pins for the step up converter (refer to Figure 4 to

choose the right capacitance)

60 24 SELF1 O C

T

61 1 DIODE S C

T

An External diode must be connected to this pin for

the step up converter (refer to Figure 4 to choose the

right component)

62 2 GNDA S

Ground

63 3 GND S

64 4 CDRVCC O C

T

X Smartcard Supply pin

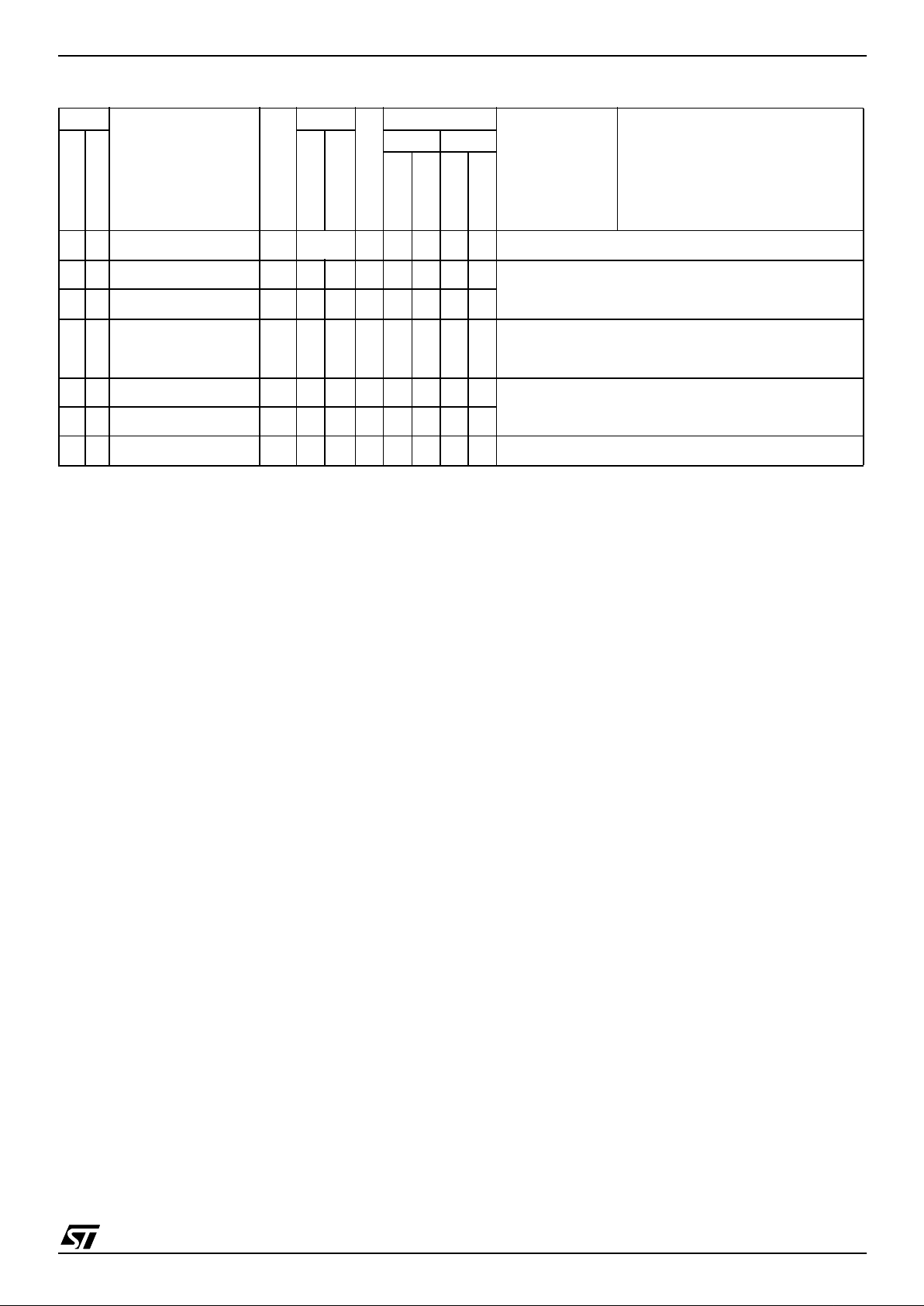

Pin n°

Pin Name

Type

Level

V

CARD

supplied

Port / Control

Main

Function

(after reset)

Alternate Function

TQFP64

SO24

Input

Output

Input Output

wpu

int

OD

PP

Page 10

ST7SCR

10/102

PIN DESCRIPTION (Cont’d)

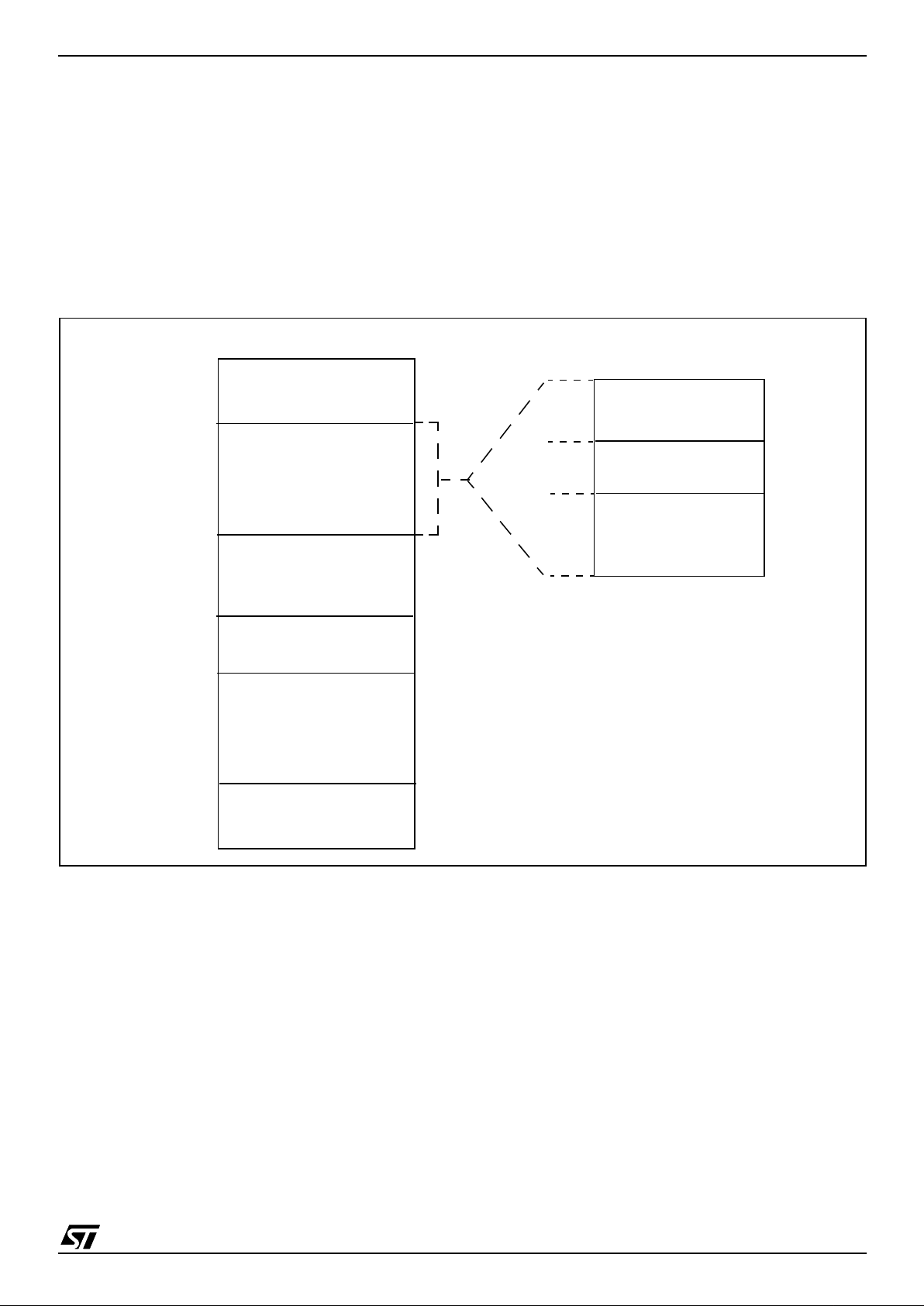

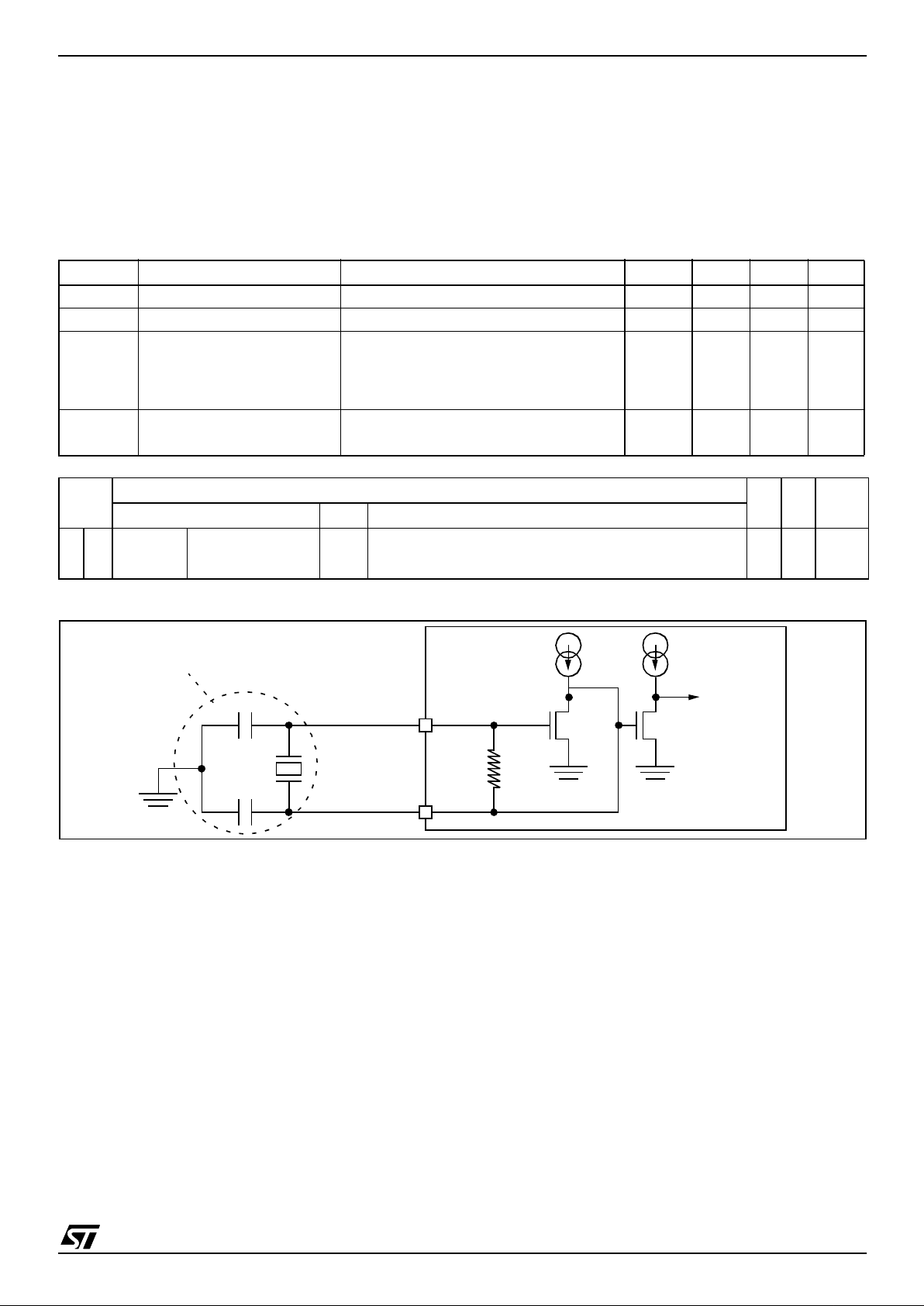

Figure 4. Smartcard Interface Reference A pplication

Note 1: Refer to Section 6 on page 20.

LED0

DM

DP

USBVcc

OSCIN

OSCOUT

V

PP

DIODE

CRDCLK

CRDRST

CRDVCC

PA6

CRDIO

C8

CRDDET

PA0

V

DDA

C4

GNDA

PA1

NC

GND

V

DD

SELF

V

DD

C

L1

C

L2

C7

C8

C9

V

DD

L1

C5

D1

R

LED

C4

VBUS

D-

D+

GND

SHIELD

C2C1 C3

C6

V

DD

V

DD

D+

D-

Mandatory values for the external components :

C2 : 4.7 µF,ESR 0. 5 Ohm

L1 : 10 µH, 2 Ohm

C7 : 4.7 µF,ESR 0.5 Ohm

C5 : 1 nF

Crystal 4.0 MHz, Impedance m ax100 Ohm

Cl1 , C l2

1)

D1: BAT42 SHOTTKY

C6 : 10 0 nF

C8 : 470 pF

C9 :

100 pF

C1 : 100nF

C3 : 1 µF

C4 : 4.7 µF

R : 1.5kOhm

1

Page 11

ST7SCR

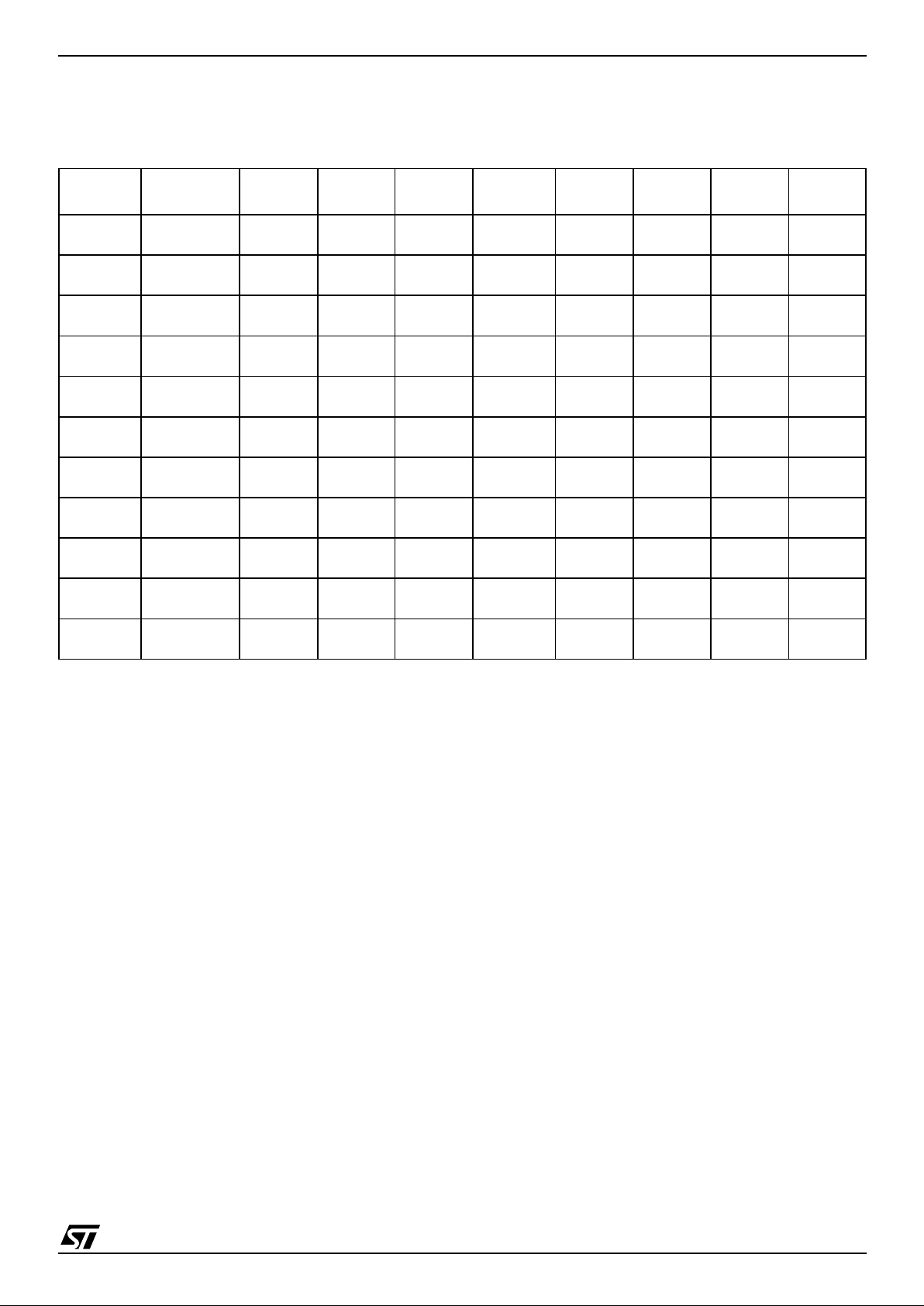

11/102

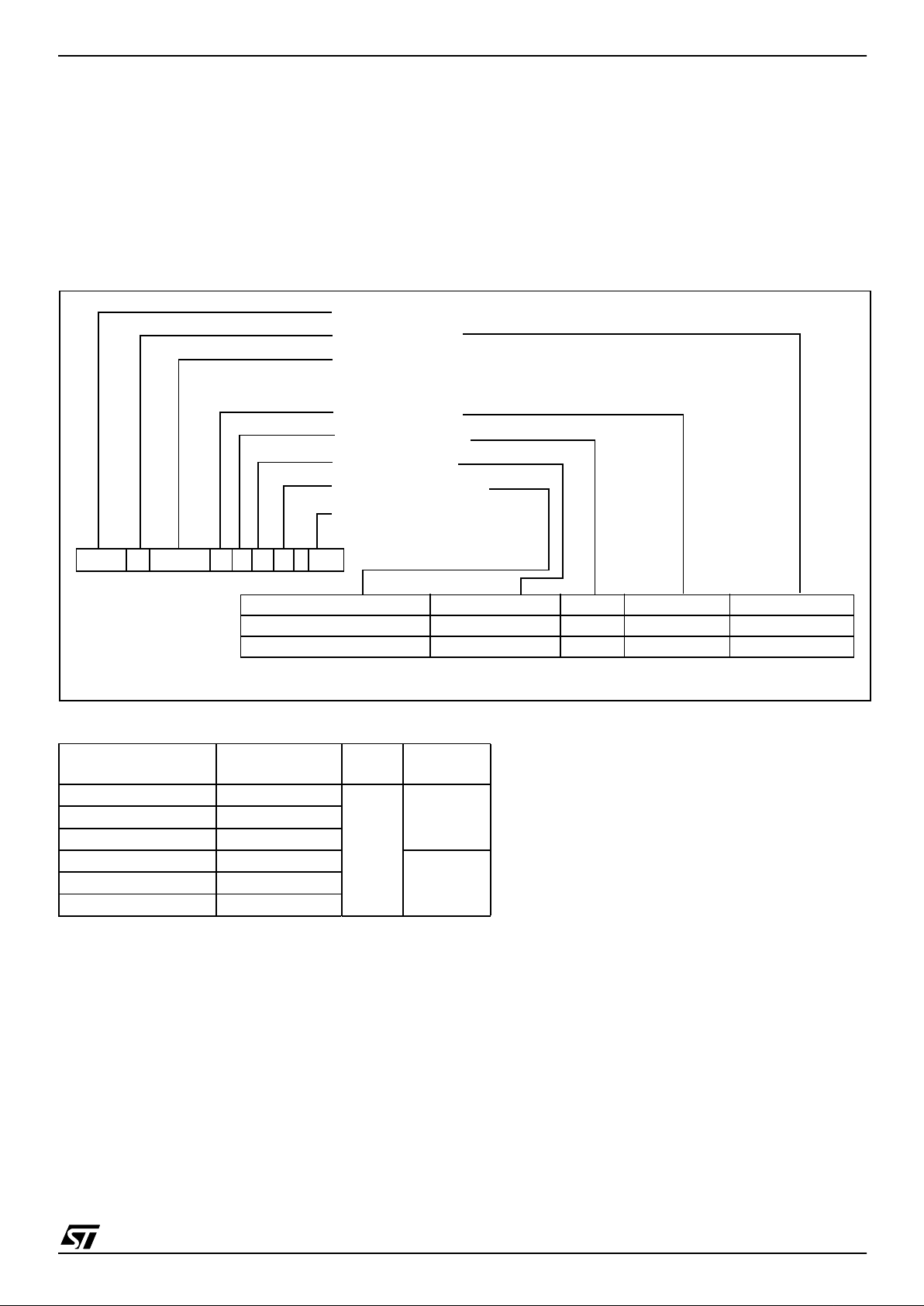

3 REGISTER & MEMORY MAP

As sho wn i n Figure 5, the MCU is capable of ad-

dressing 64K bytes of memories and I/O registers.

The available memory locations consist of 40

bytes of register locations, up to 512 bytes of RAM

and up to 16K bytes of user program memory. The

RAM space includes u p to 128 by t es fo r the stack

from 0100h to 017Fh.

The highest address bytes contain the user re set

and interrupt vectors.

IMPORTANT: Memory locations noted “Reserved” must ne ver be accessed. Ac cessing a reserved area can have unpredictable effects on the

device.

Figure 5. Me m ory M a p

0000h

Interrupt & Reset Vectors

HW Registers

0040h

003Fh

(see Table 2)

FFDFh

FFE0h

FFFFh

(see Table 7)

C000h

033Fh

Program Memory

RAM

USB RAM

(16K Bytes)

Short Addressing

Stack (128 Bytes)

0100h

0180h

023Fh

0040h

00FFh

017Fh

16-bit Addressing RAM

RAM (192 Bytes)

( 192 Bytes)

023Fh

0240h

256 Bytes

(512 Bytes)

Unused

1

Page 12

ST7SCR

12/102

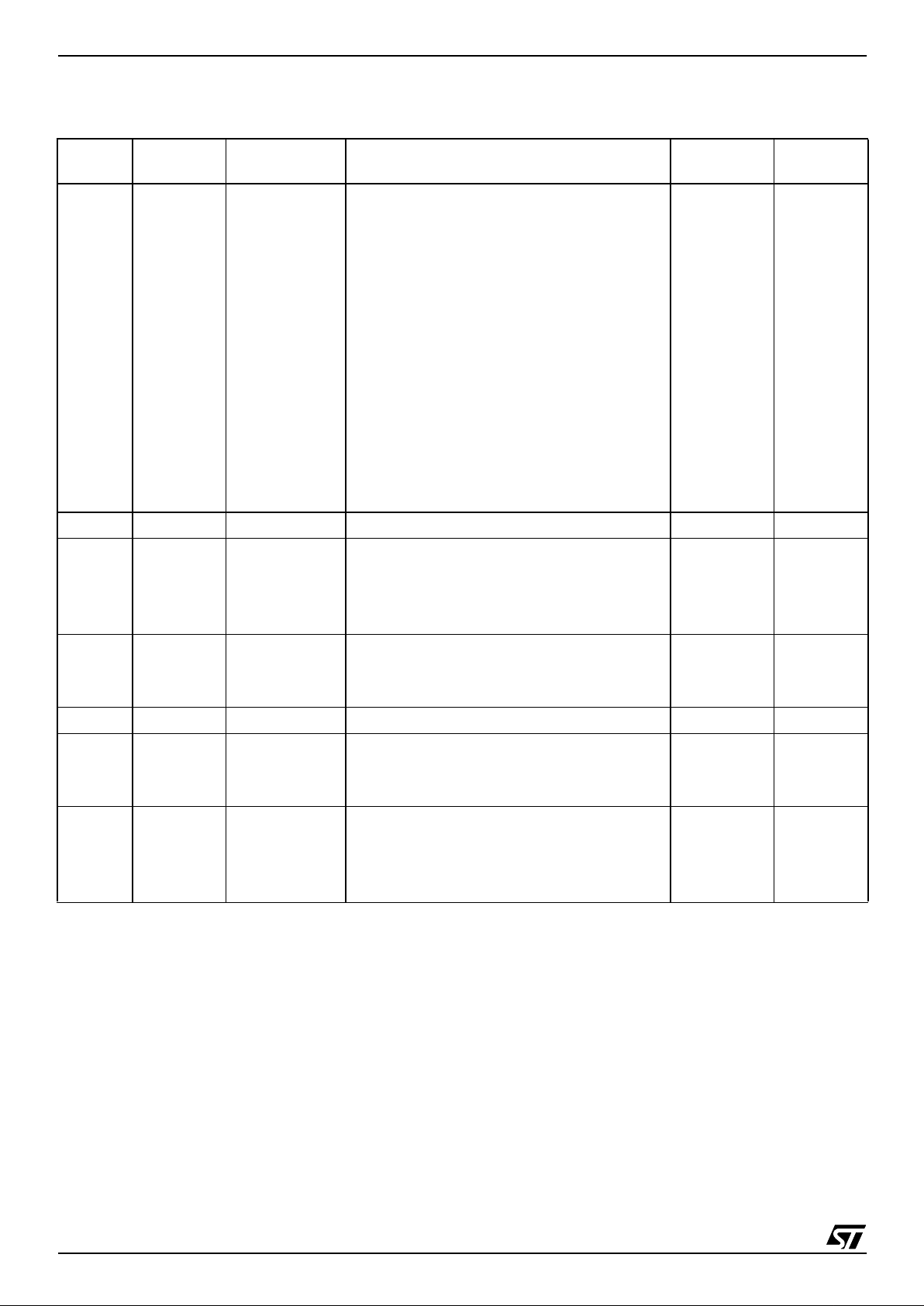

Table 2. Hardware Regist er Memo ry Ma p

Address Block

Register

Label

Register

name

Reset Status Remarks

0000h

0001h

0002h

0003h

0004h

0005h

0006h

0007h

0008h

0009h

000Ah

000Bh

000Ch

000Dh

CRD

CRDCR

CRDSR

CRDCCR

CRDETU1

CRDETU0

CRDGT1

CRDGT0

CRDWT2

CRDWT1

CRDWT0

CRDIER

CRDIPR

CRDTXB

CRDRXB

Smartcard Interface Control Register

Smartcard Interface Status Register

Smartcard Contact Control Register

Smartcard Elementary Time Unit 1

Smartcard Elementary Time Unit 0

Smartcard Guard time 1

Smartcard Guard time 0

Smartcard Character Waiting Time 2

Smartcard Character Waiting Time 1

Smartcard Character Waiting Time 0

Smartcard Interrupt Enable Register

Smartcard Interrupt Pending Register

Smartcard Transmit Buffer Register

Smartcard Receive Buffer Register

00h

80h

xxh

01h

74h

00h

0Ch

00h

25h

80h

00h

00h

00h

00h

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R

R/W

R

000Eh Watchdog WDGCR Watchdog Control Register 00h R/W

0011h

0012h

0013h

0014h

Port A

PADR

PADDR

PAOR

PAPUCR

Port A Data Register

Port A Data Direction Register

Option Register

Pull up Control Register

00h

00h

00h

00h

R/W

R/W

R/W

R/W

0015h

0016h

0017h

Port B

PBDR

PBOR

PBPUCR

Port B Data Register

Option Register

Pull up Control Register

00h

00h

00h

R/W

R/W

R/W

0018h Port C PCDR Port C Data Register 00h R/W

0019h

001Ah

001Bh

Port D

PDDR

PDOR

PDPUCR

Port D Data Register

Option Register

Pull up Control Register

00h

00h

00h

R/W

R/W

R/W

001Ch

001Dh

001Eh

001Fh

MISC

MISCR1

MISCR2

MISCR3

MISCR4

Miscellaneous Register 1

Miscellaneous Register 2

Miscellaneous Register 3

Miscellaneous Register 4

00h

00h

00h

00h

R/W

R/W

R/W

R/W

1

Page 13

ST7SCR

13/102

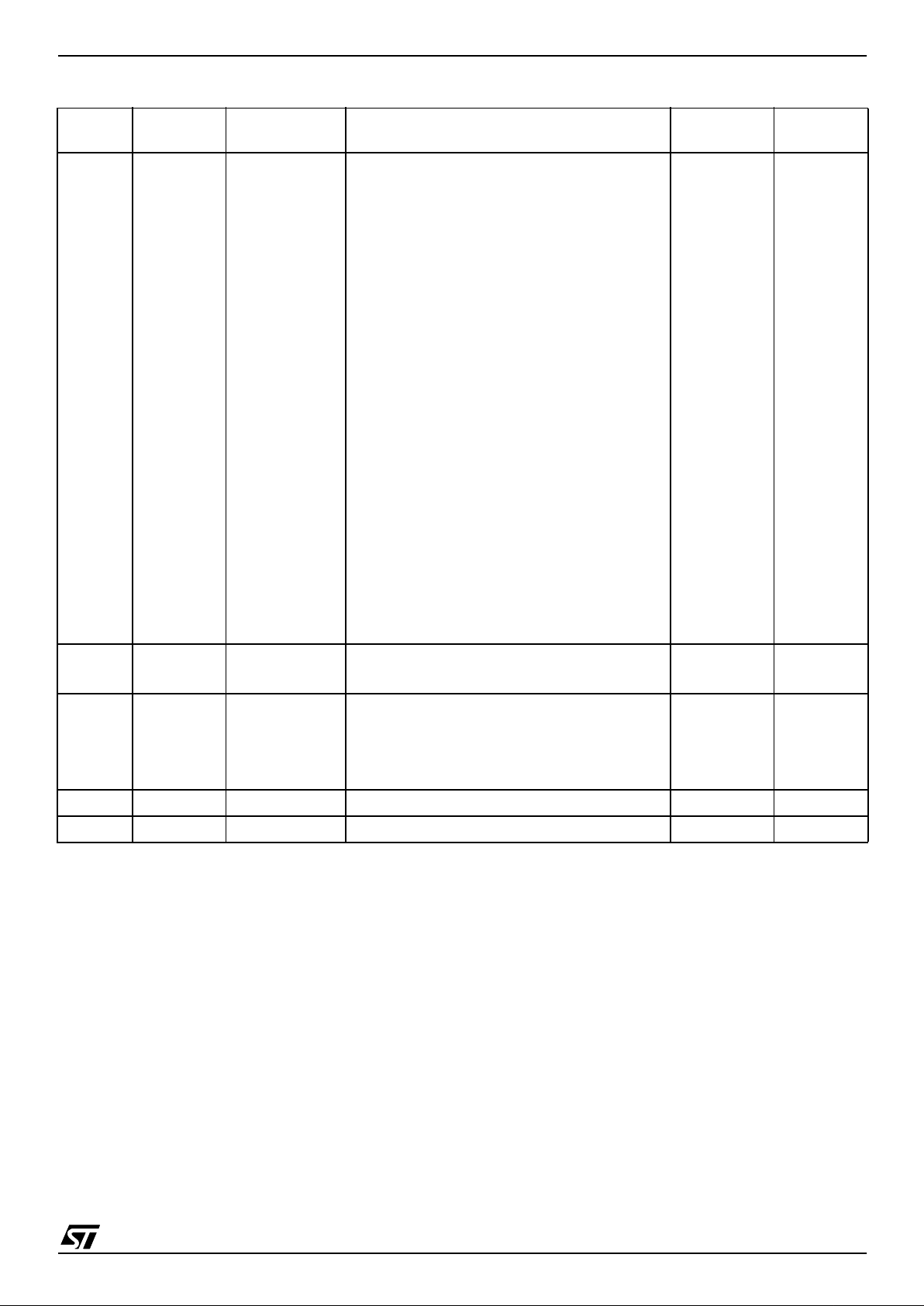

0020h

0021h

0022h

0023h

0024h

0025h

0026h

0027h

0028h

0029h

002Ah

002Bh

002Ch

002Dh

002Eh

002Fh

0030h

0031h

0032h

0033h

0034h

USB

USBISTR

USBIMR

USBCTLR

DADDR

USBSR

EPOR

CNT0RXR

CNT0TXR

EP1TXR

CNT1TXR

EP2RXR

CNT2RXR

EP2TXR

CNT2TXR

EP3TXR

CNT3TXR

EP4TXR

CNT4TXR

EP5TXR

CNT5TXR

ERRSR

USB Interrupt Status Register

USB Interrupt Mask Register

USB Control Register

Device Address Register

USB Status Register

Endpoint 0 Register

EP 0 ReceptionCounter Register

EP 0 Transmission Counter Register

EP 1 Transmission Register

EP 1 Transmission Counter Register

EP 2 Reception Register

EP 2 Reception Counter Register

EP 2 Transmission Register

EP 2 Transmission Counter Register

EP 3 Transmission Register

EP 3 Transmission Counter Register

EP 4 Transmission Register

EP 4 Transmission Counter Register

EP 5 Transmission Register

EP 5 Transmission Counter Register

Error Status Register

00h

00h

06h

00h

00h

0xh

00h

00h

00h

00h

00h

0xh

00h

00h

00h

00h

00h

00h

00h

00h

00h

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0035h

0036h

TBU

TBUCV

TBUCSR

Timer counter value

Timer control status

00h

00h

R/W

R/W

0037h

0038h

0039h

003Ah

ITC

ITSPR0

ITSPR1

ITSPR2

ITSPR3

Interrupt Software Priority Register 0

Interrupt Software Priority Register 1

Interrupt Software Priority Register 2

Interrupt Software Priority Register 3

FFh

FFh

FFh

FFh

R/W

R/W

R/W

R/W

003Bh Flash FCSR Flash Control Status Register 00h R/W

003Eh LED_CTRL LED Control Register 00h R/W

Address Block

Register

Label

Register

name

Reset Status Remarks

1

Page 14

ST7SCR

14/102

4 FLASH PROGRAM MEMORY

4.1 Introduction

The ST7 dual voltage High Density Flash (HDFlash) is a non-volatile memory that can be electrically erased as a single block or by individual sectors and programmed on a Byte-by-Byte basis using an external V

PP

supply.

The HDFlash devices can be programmed and

erased off-board (plugge d in a programm ing tool)

or on-board using ICP (In-Circuit Programming) or

IAP (In-Application Programming).

The array matrix organ isation allows each sector

to be erased and reprogramm ed without affecting

other sectors.

4.2 Main Features

■ Three Flash programming modes :

– Insertion in a programming tool. In this m ode,

all sectors including option bytes can be programmed or erased.

– ICP (In-Circuit Programming). In this mode, all

sectors including option bytes can be programmed or erased without removing the device from the application board.

– IAP (In-Application Programming) In this

mode, all sectors except Sector 0, can be programmed or erased without removing the device from the application board a nd wh ile the

application is running.

■ ICT (In-Circuit Testing) for downloading and

executing user application test patterns in RAM

■ Read-out protection against piracy

■ Register Access Security System (RASS) to

prevent accidental programming or erasing

4. 3 S truct u re

The Flash memory is organised in sectors and can

be used for both code and data storage.

Depending on the overall FLASH memory size i n

the microcontroller device, there are up to three

user sectors (see Table 3). Each of these sec tors

can be erased independently to avoid unnecessary erasing of the whole Flash memory when only

a partial erasing is required.

The first two sectors have a fixed siz e of 4 Kby tes

(see Figure 6). They are mapped in the upper part

of the ST7 addressing space so t he reset and interrupt vectors are located in Sector 0 (F000hFFFFh).

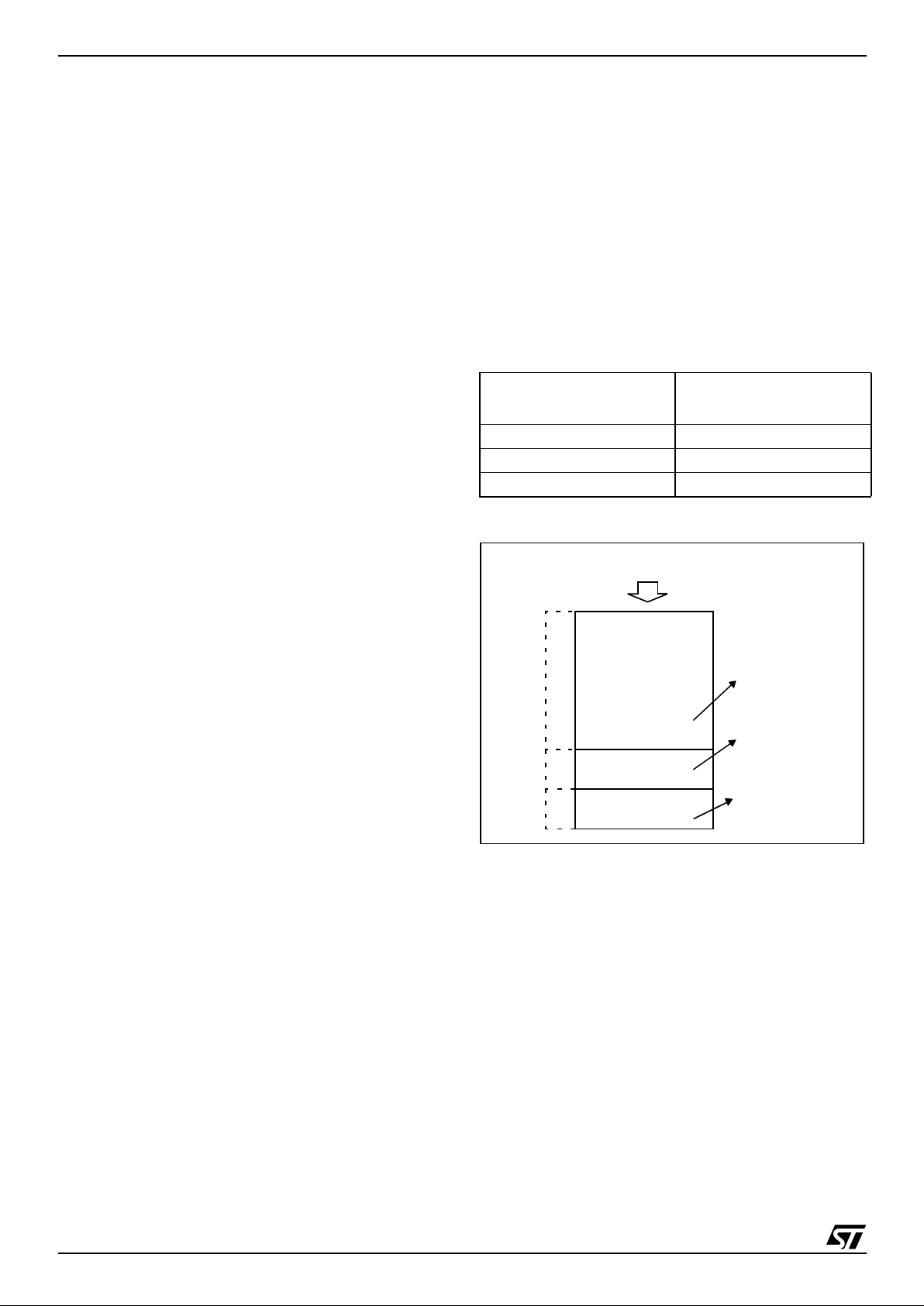

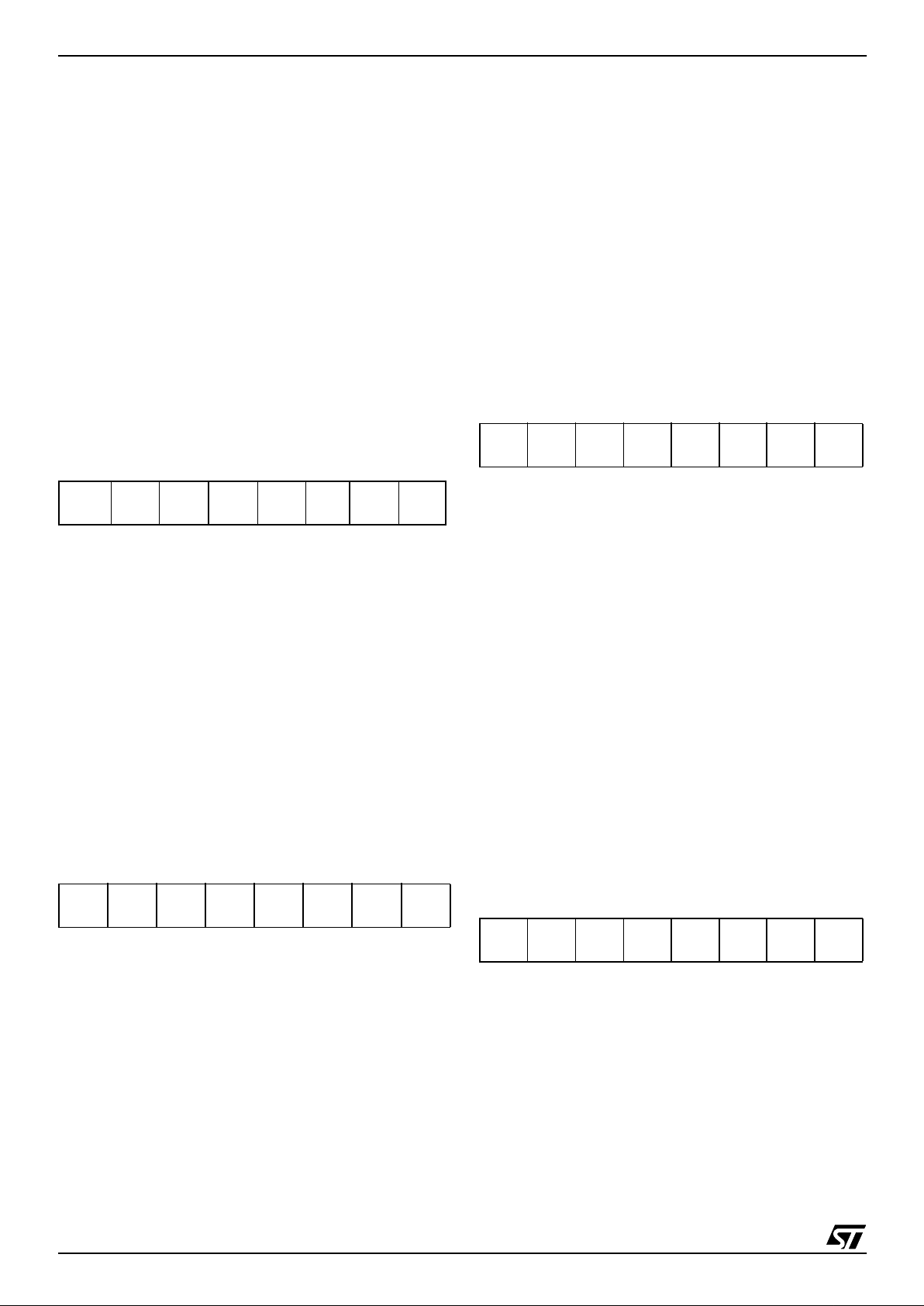

Table 3. Sectors available in FLASH devices

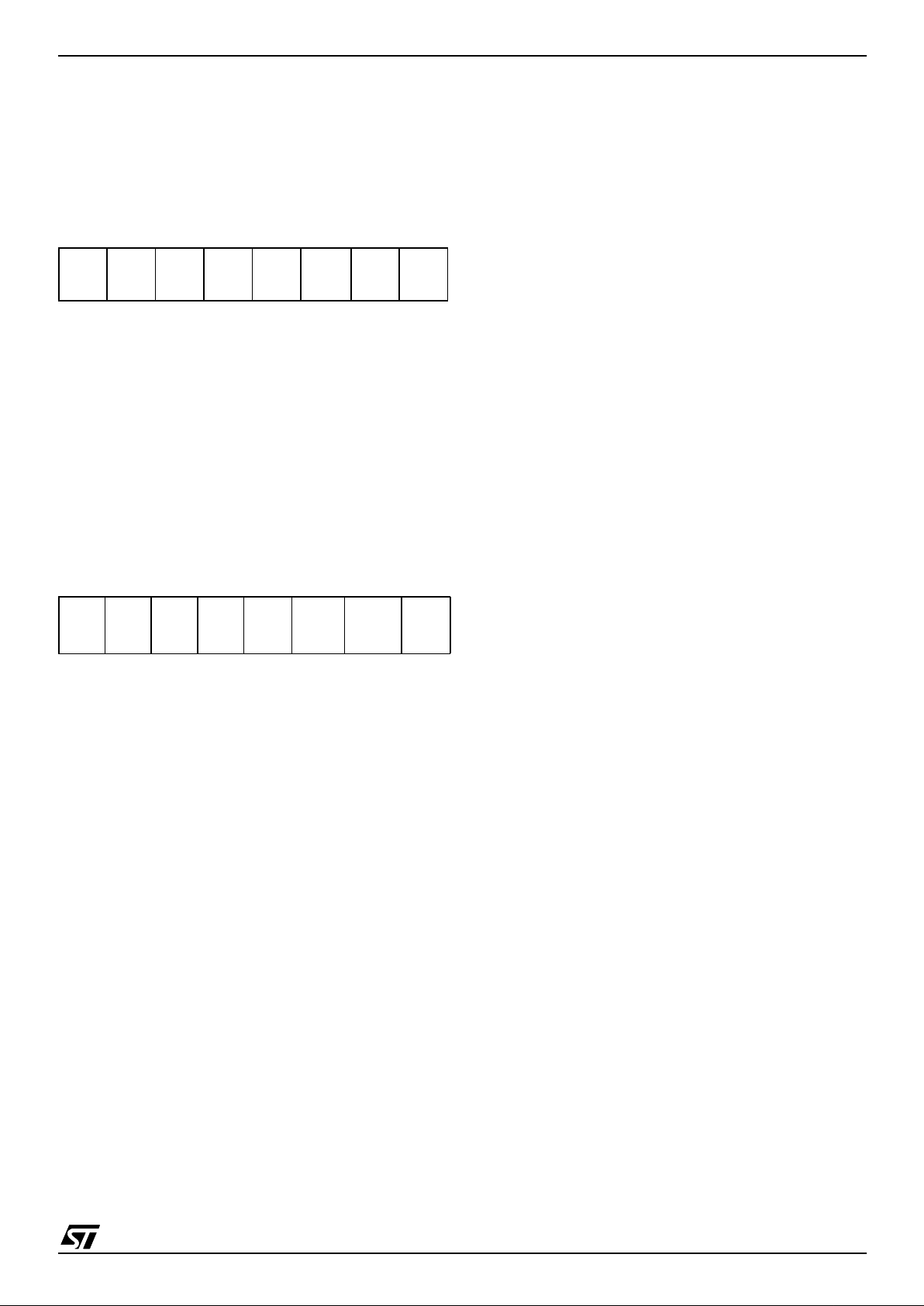

Figure 6. Memory map and sector address

Flash Memory Size

(bytes)

Available Sectors

4K Sector 0

8K Sectors 0,1

> 8K Sectors 0,1, 2

4 Kbytes

4 Kbytes

SECTOR 1

SECTOR 0

SECTOR 2

16K USER FLASH MEMORY SIZE

FFFFh

F000h

EFFFh

E000h

DFFFh

C000h

8Kbytes

ex.: user program

ex.: user data

ex.: user system library

+ IAP BootLoader

+ libra ry

1

Page 15

ST7SCR

15/102

FLASH PROGRAM MEMORY (Cont’d)

4.4 ICP (In-Circuit Programming)

To perform ICP the microcontroller must be

switched to ICC (In-Circuit Communication) mode

by an external controller or programming tool.

Depending on the ICP code dow nloaded in RAM,

Flash memory programming can be fully customized (number of bytes to prog ram, program locations, or selection serial communication interface

for downloading).

When using an STMicroelectronics or third-party

programming tool that supp orts ICP and the specific microcontroller device, the user needs only to

implement the ICP hardware interface on the application board (see Figure 7). For more details on

the pin locations, refer to the device pinout description.

ICP needs six signals to be connec ted to the programming tool. These signals are:

–V

SS

: device power supply ground

–V

DD

: for re s e t by LV D

– OSCIN: to force the clock during power-up

– ICCCLK: ICC output serial clock pin

– ICCDATA: ICC input serial data pin

–V

PP

: ICC mode selection and programming

voltage.

If ICCCLK or ICCDATA are used for other purposes in the application, a serial resistor has to be implemented to avoid a conflict in case one of the

other devices forces the signal level.

Note: To develop a c usto m program mi ng tool, refer to the ST7 FLASH Programmin g and I CC Re ference Manual which gives full details on the ICC

protocol hardware and software.

4.5 IAP (In-Application Programming)

This mode uses a BootLoader program previously

stored in Sector 0 by the user (in ICP mode or by

plugging the device in a programming tool).

This mode is fully controlled by user software. This

allows it to be adapted to the user application, (user-defined strategy for entering programming

mode, choice of communications protocol us ed to

fetch the data to be stored, etc.). For example, it is

possible to download code from the USB interface

and program it in the Flash. IAP mode can be used

to program any of the Flash sectors except Sector

0, which is write/erase protected to allow recovery

in case errors occur during the programming operation.

Figure 7. Typical ICP Interface

ICP PROGRAMMING TOOL CONNECTOR

10k

Ω

C

L2

C

L1

ICCDATA

ICCCLK

V

SS

V

PP

OSCIN

OSCOUT

ST7

HE10 CONNECTOR TYPE

T

OT

HE A

PP

L

ICA

TION

V

DD

4.7k

Ω

APPLICATION BOARD

1

246810

975 3

PROGRAMMING TOOL

ICC CONNECTOR

ICC C a ble

1

Page 16

ST7SCR

16/102

FLASH PROGRAM MEMORY (Cont’d)

Note: If the ICCCLK or ICCDATA pins are only

used as outputs in the application, no signal isolation is necessary. As soon as the Programming

Tool is plugged to the boa rd, even if an ICC session is not in progress, the ICCCLK and ICCDATA

pins are not available for the application. If they

are used as inputs by the application, isolation

such as a serial resistor has to implemented in

case another device forces the signal. Refer to the

Programming Tool documentation for recommended resistor values.

4.6 Program Memo ry Read-out P rotection

The read-out protection is enabled through an option bit.

For Flash devices, when this option is selected,

the program and data stored in the F lash m em ory

are protected ag ainst rea d-out piracy (i ncluding a

re-write protection). When this protection is removed by reprogramming the Option Byte, the en-

tire Flash program memory is first automatically

erased.

Refer to the Option By te description for more details.

4.6.1 Register Description

FLASH CONTROL/STATUS REGISTER (FCSR)

Read/Write

Reset Value: 0000 0000 (00h)

This register is reserved for use by Programming

Tool software. It controls the FLASH programming

and erasing operations. For details on customizing

FLASH programming methods and In-Circuit Testing, refer to the ST7 FLASH Programming and

ICC Reference Manual.

70

00000000

1

Page 17

ST7SCR

17/102

5 CENTRAL PRO CESSING UNIT

5.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

5.2 MAIN FEATURES

■ Enable executing 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes (with indirect

addressing mode)

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power HALT and WAIT modes

■ Priority maskable hardware interrupts

■ Non-maskable software/hardware interrupts

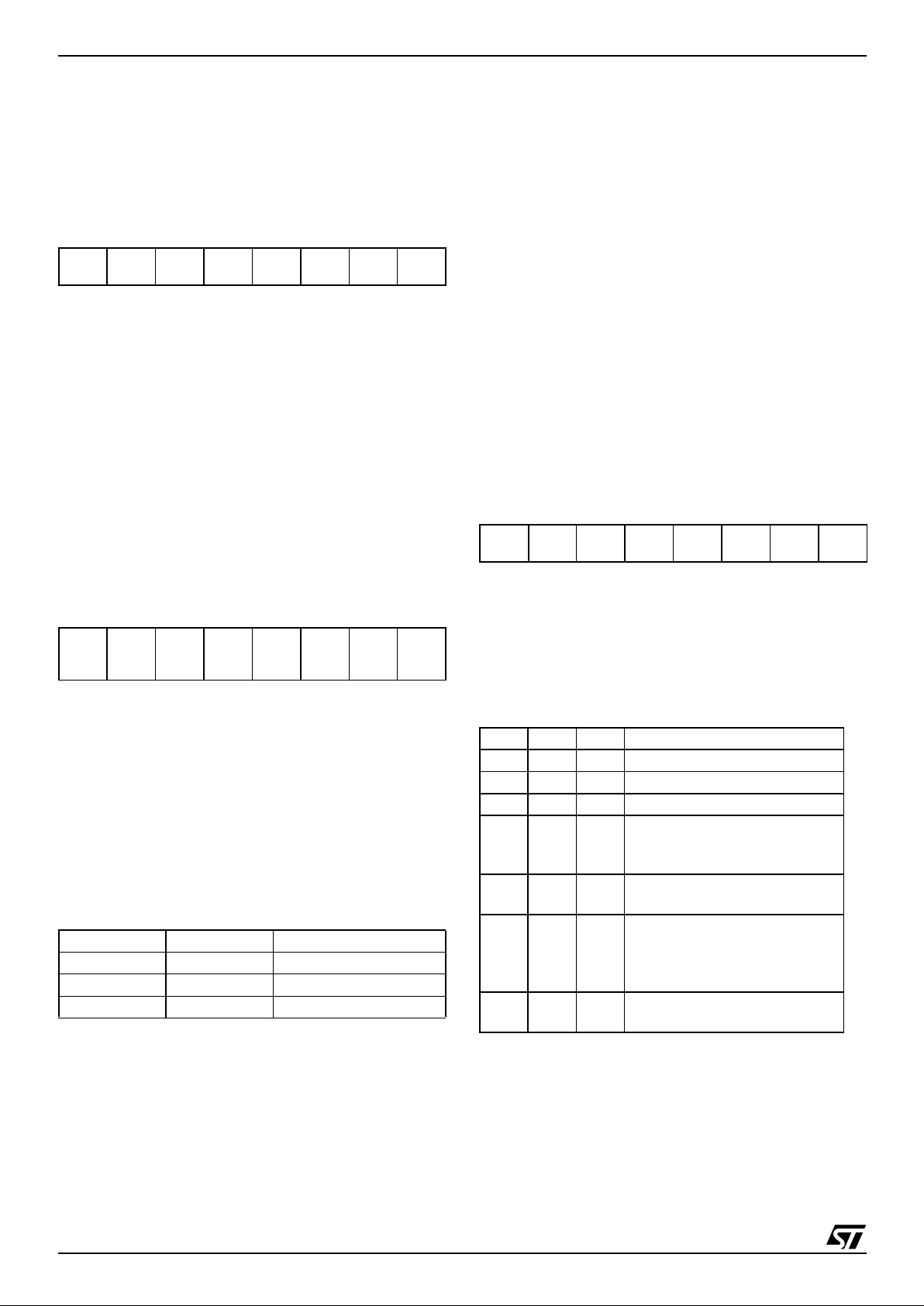

5.3 CPU REGISTERS

The 6 CPU registers shown in Figure 8 are not

present in the memory mapping and are accessed

by spec ifi c ins t ru c tio n s .

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the res ults of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

These 8-bit registers are used to create effective

addresses or as tempo rary storage areas f or data

manipulation. (The Cross -Assembler generates a

precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y register is not affected by the interrupt automatic procedures.

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

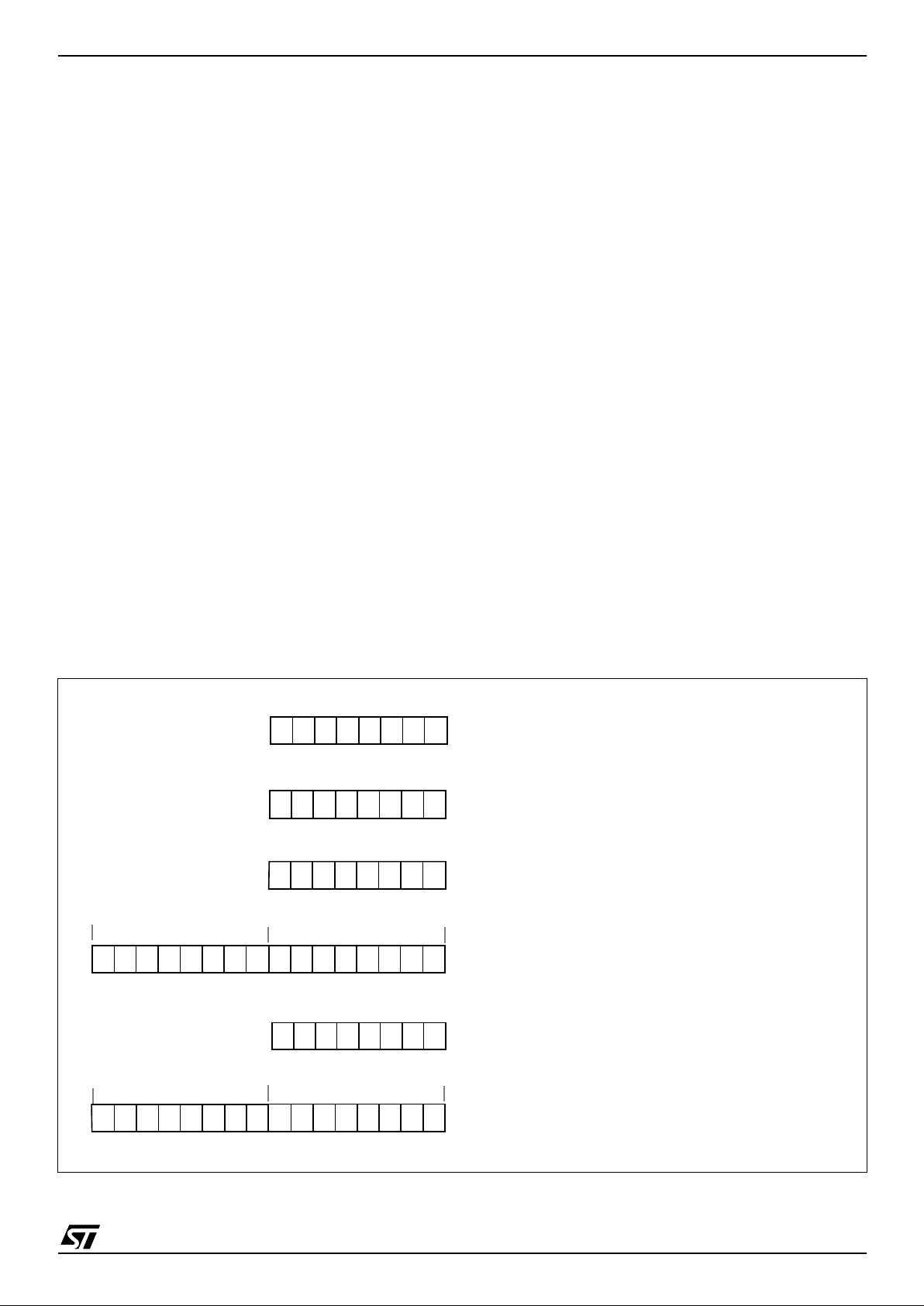

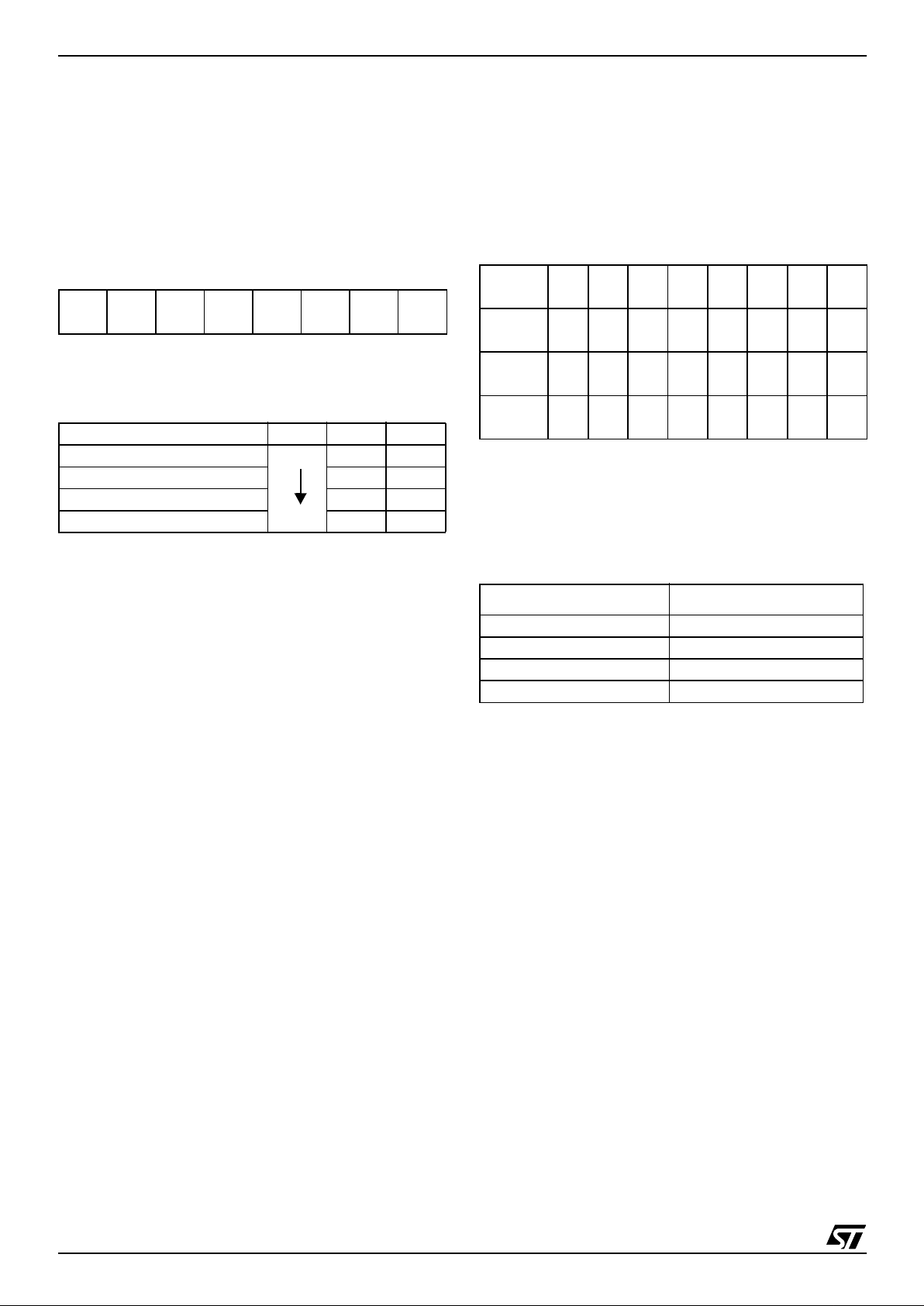

Figure 8. CPU Registers

ACCUMULA TOR

X INDEX REGISTER

Y INDEX REGISTER

STACK POINTER

CONDITION CODE REGISTER

PROGRAM COUNTER

70

1C1I1HI0NZ

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

70

70

70

0

7

15 8

PCH

PCL

15

8

70

RESET VALUE = STACK HIGHER ADDRESS

RESET VALUE =

1X11X1XX

RESET VALUE = XXh

RESET VALUE = XXh

RESET VALUE = XXh

X = Undefined Value

1

Page 18

ST7SCR

18/102

CENTRAL PROC ESSING UNIT (Cont’d)

Condition Code Reg ister (CC)

Read/Write

Reset Value: 111x1xxx

The 8-bit Condition Code regist er contains the i nterrupt masks and four flags representative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

Arithmetic Management Bits

Bit 4 = H

Half carry

.

This bit is set by hardware when a carry occurs between bits 3 and 4 of t he ALU during an ADD or

ADC instructions. It is reset by hardware during

the same instructio n s.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH in struction. The H bit is useful in BCD arithmetic subroutine s .

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is representative of the result sign of the last arithmetic,

logical or data manipulation. I t’s a copy of the result 7

th

bit.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit is accesse d by the JRMI and JRPL instructions.

Bit 1 = Z

Zero

.

This bit is set and cleared by hardware. This bit indicates that the result of the last arithme tic, logical

or data manipulation is zero.

0: The result of the last operation is dif ferent from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 0 = C

Carry/borrow.

This bit is set and cleared b y hardware and software. It indicates an overflow or an un derflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.

This bit is driven by th e SCF and RCF instructions

and tested by the JRC and JRNC instructions. It i s

also affected by the “bit test and branch”, shift and

rotate instructions.

Interrupt Managem ent B i ts

Bit 5,3 = I1, I0

Interrupt

The combination of the I1 and I0 bits gives the current interrupt software priority.

These two bits are set/cleared by hardware when

entering in interrupt. The loaded value is given by

the corresponding bits in the interrupt software priority registers (IxSPR). They can be also set/

cleared by software with the RIM, SIM, IRET,

HALT, WFI and PUSH/POP instructions.

See the interrupt management chapter for more

details.

70

11I1HI0NZ

C

Interrupt Software Priorit y I1 I0

Level 0 (main) 1 0

Level 1 0 1

Level 2 0 0

Level 3 (= interrupt disable) 1 1

1

Page 19

ST7SCR

19/102

CENTRAL PROC ESSING UNIT (Cont’d)

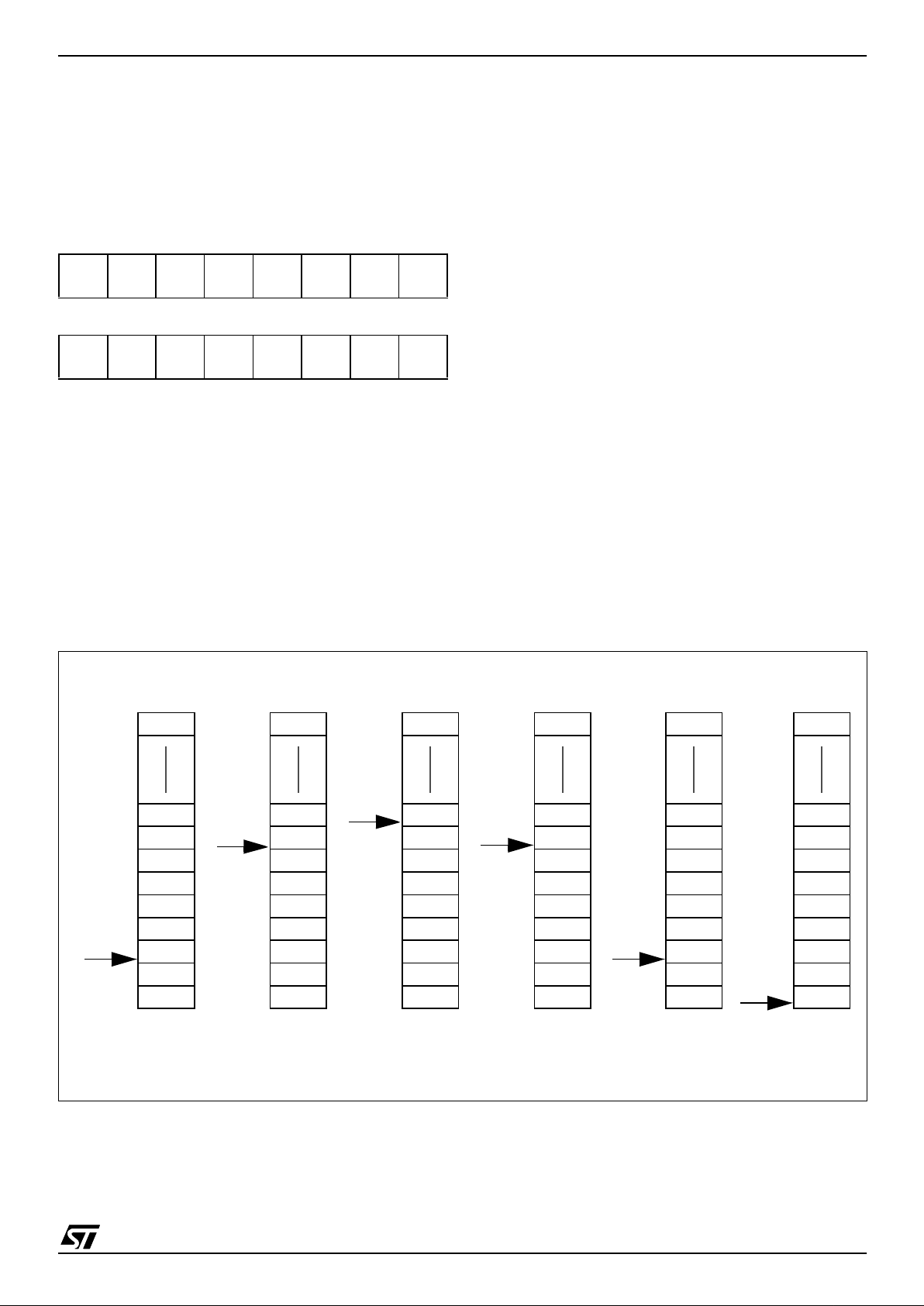

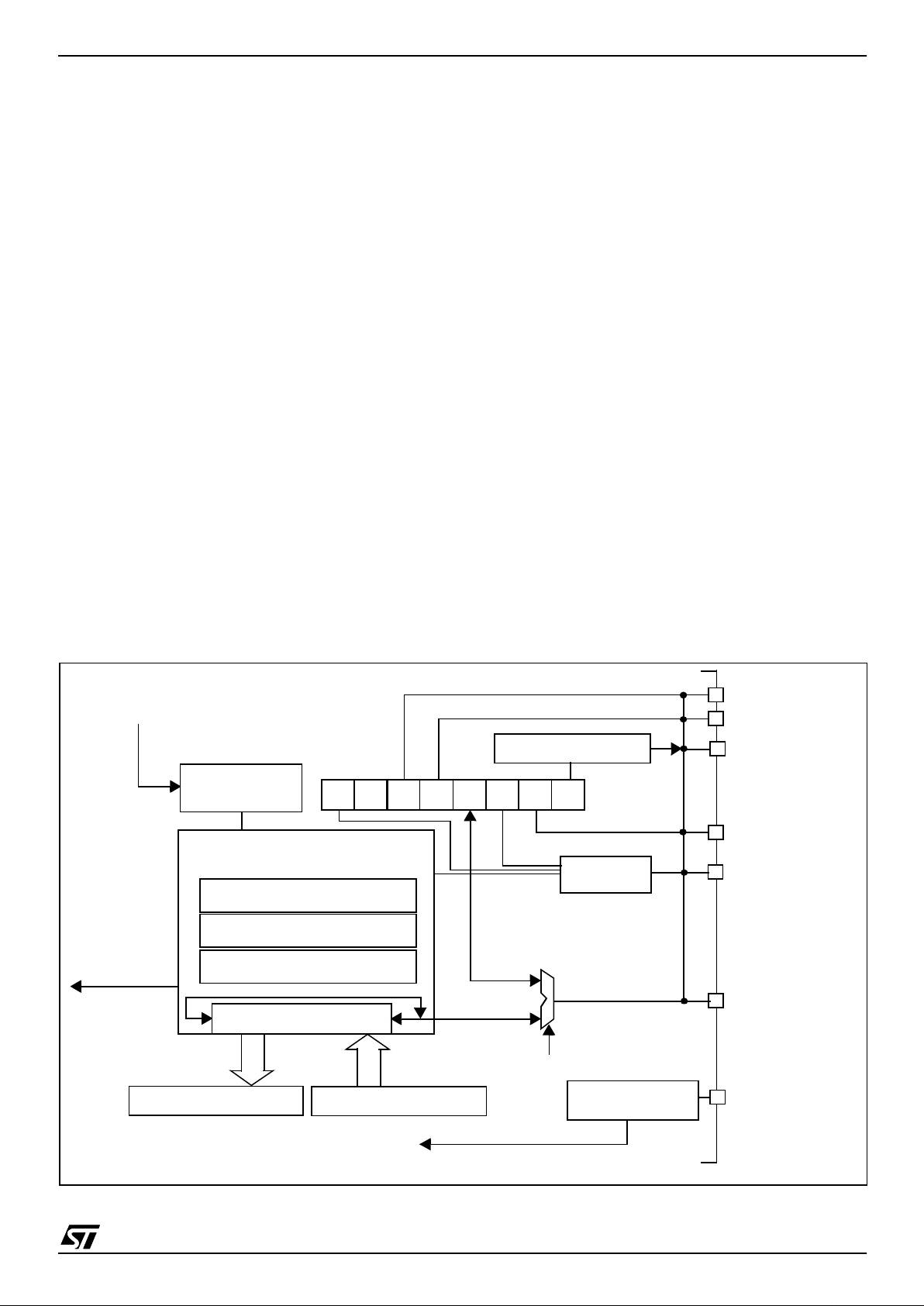

Stack Poi nter (SP)

Read/Write

Reset Value: 017Fh

The Stack Pointer is a 16-bit register which is always pointing to the next free location in the stack.

It is then decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 9).

Since the stack is 256 bytes deep, the 8 most significant bits are forced by hard ware. Following a n

MCU Reset, or after a Reset Stack Pointer instruction (RSP), the Stack Pointer contains its reset value (the SP7 to SP0 bits are set) which is the stack

higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, without indicating the stack overflow. The previously

stored information is then o verwritten and therefore lost. The stack also wraps in case of an underflow.

The stack is used to sav e the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by means of the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location po inted t o by t he SP. Th en t he

other registers are stored in the next locations as

shown in Figure 9

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an interrupt five locat ion s i n the stack ar ea.

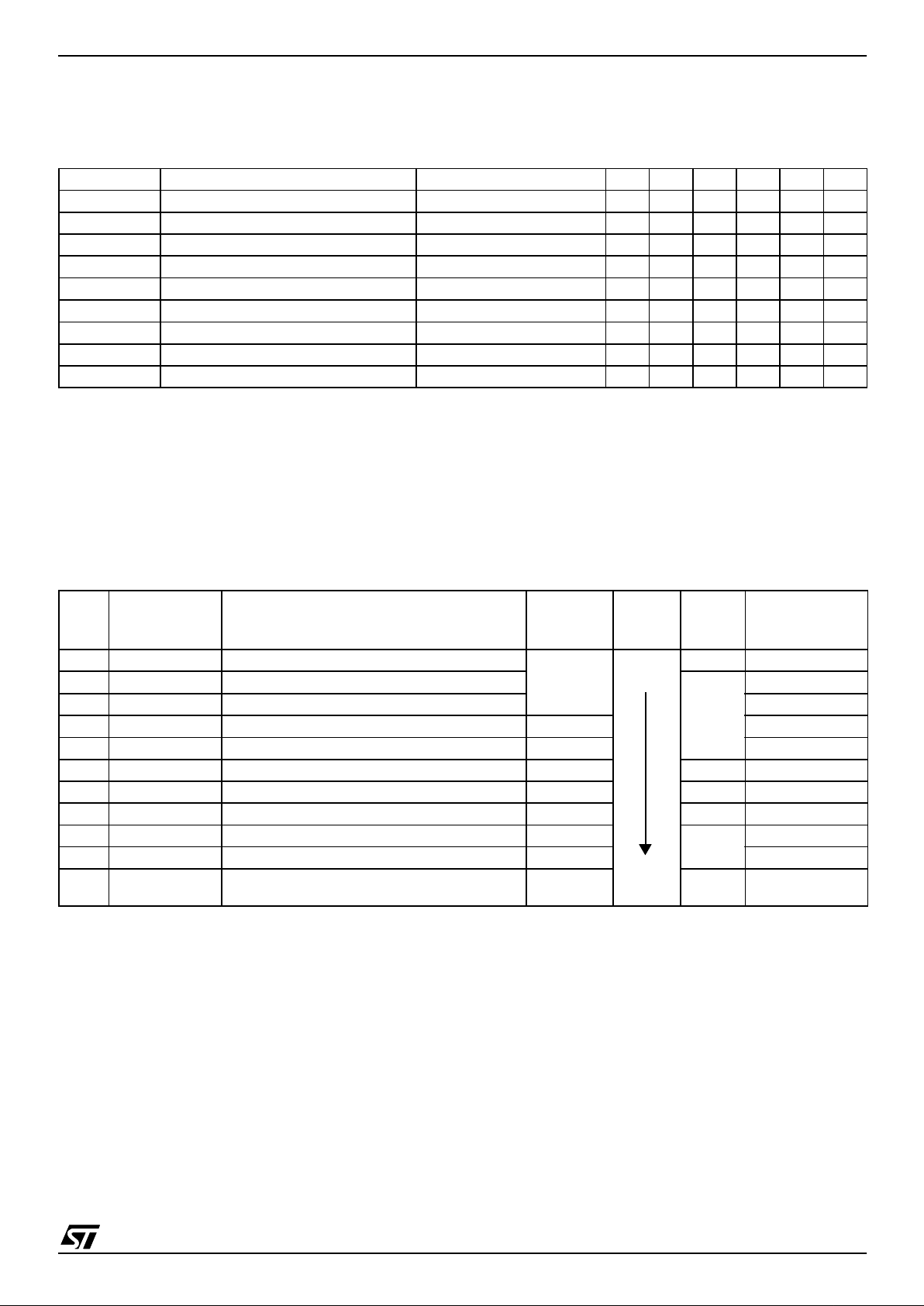

Figure 9. Stack Manipulation Example

15 8

00000001

70

SP7 SP6 SP5 SP4 SP3 SP2 SP1

SP0

PCH

PCL

SP

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

SP

Y

CALL

Subroutine

Interrupt

Event

PUSH Y POP Y IRET

RET

or RSP

@ 017Fh

@ 0100h

Stack Higher Address = 017Fh

Stack Lower Address =

0100h

1

Page 20

ST7SCR

20/102

6 SUPPLY, RESET AND CLOCK MANAGEMENT

6.1 CLOCK SYSTEM

6.1.1 General Description

The MCU accepts either a 4MHz crystal or an external clock signal to drive the internal oscillator.

The internal clock (f

CPU

) is derived from the inter-

nal oscillat o r freq uency (f

OSC

), which is 4 Mhz .

After reset, the internal clock (f

CPU

) is provided by

the internal oscillator (4Mhz frequency).

To activate the 48-MHz clock for the USB inter-

face, the user mus t turn on the PLL by setting the

PLL_ON bit in the MISCR4 register. When the PLL

is locked, the LOCK bit is set by hardware.

The user can then select an internal frequency

(f

CPU

) of either 4 MHz or 8MHz by programming

the CLK_SEL bit in t he MISCR4 register (refer to

MISCELLANEOUS REGISTERS section on page

37).

The PLL provides a signal with a duty cycle of 50

%.

The internal clock signal (f

CPU

) is also routed to

the on-chip peripherals. The CPU clock signal

consists of a square wave with a duty cycle of

50%.

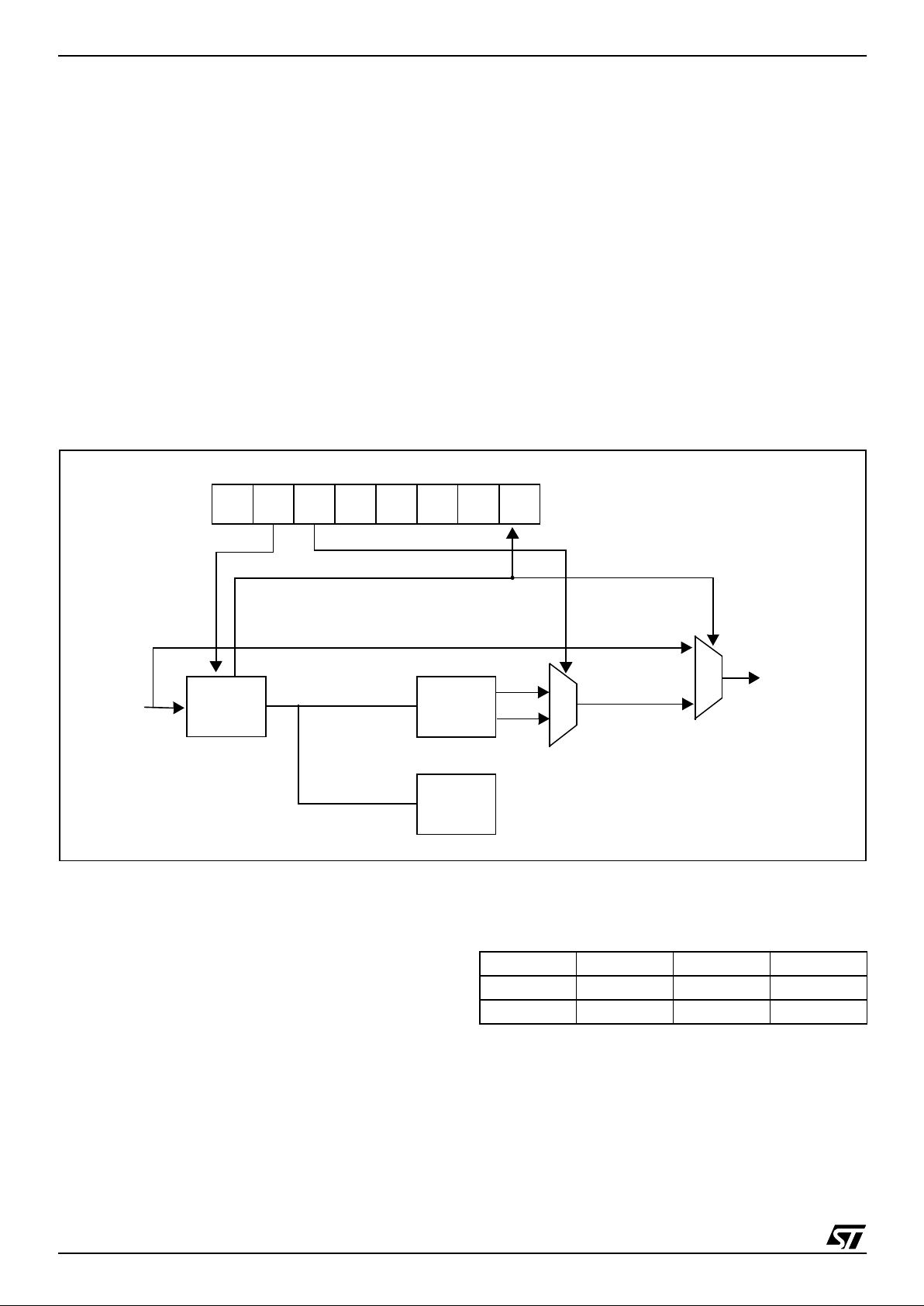

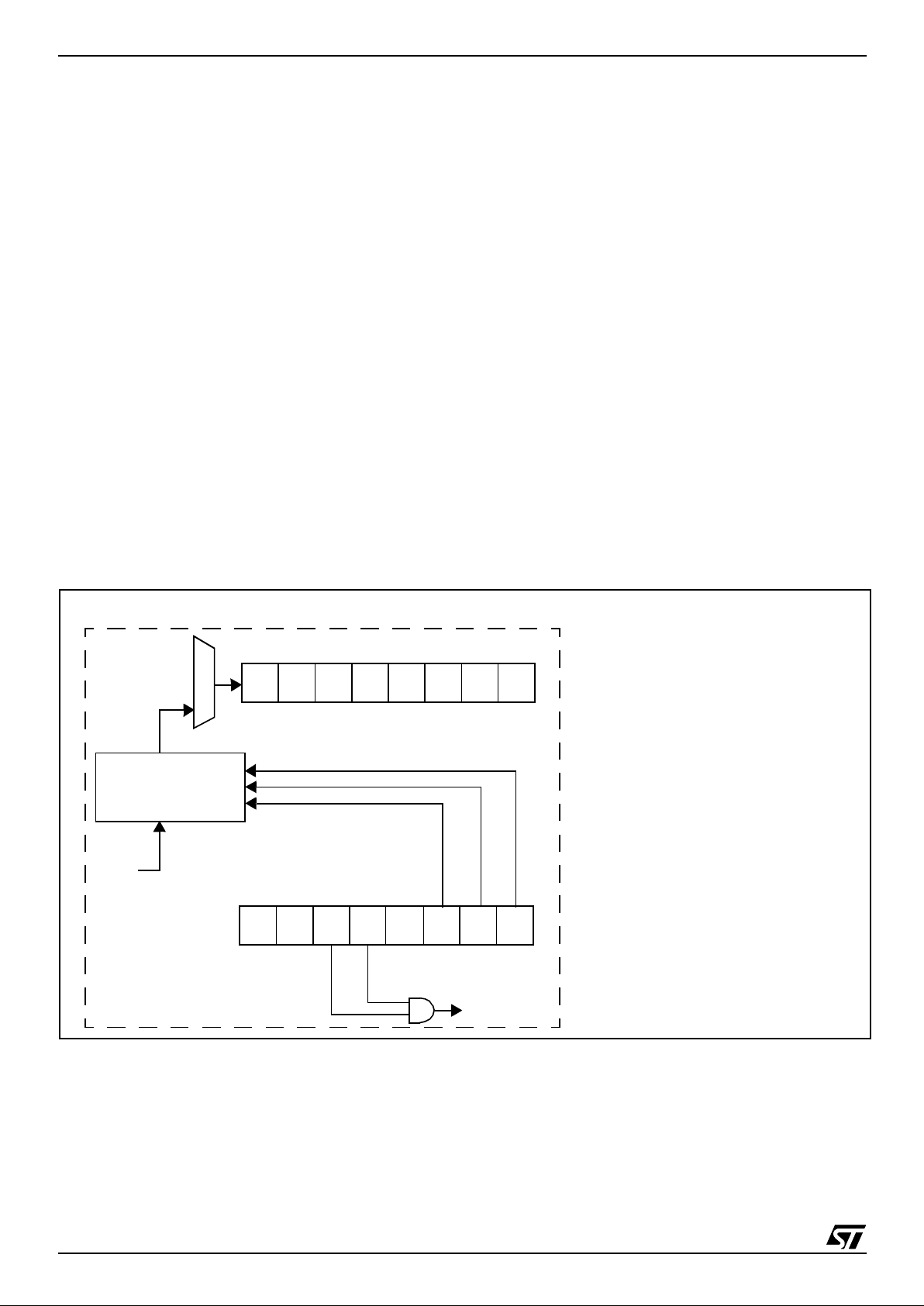

Figure 10. Clock, Reset and Supply Block Diagram

The internal oscillat or is designed to operate with

an AT-cut parallel resonant quartz in the frequency range specified for f

osc

. The circuit shown in

Figure 12 is recommend ed when using a crystal,

and Table 4 lists the recommended capacitance.

The crystal and associated components should be

mounted as close as p ossible to the input pins i n

order to minimize output distortion and start-up

stabilisation time. The LOCK bit in the MISCR4

register can also be used to generat e the f

CPU

di-

rectly from f

OSC

if the PLL and the US B interface

are not active.

Table 4. Recommended Values for 4 MHz

Crystal Resonator

Note: R

SMAX

is the equivalent serial resistor of the

crystal (see crystal specification).

PLL_

MISCR4

ON

-

-

----

LOCK

4 Mhz

INTERNAL

8 Mhz

CLOCK (f

CPU

)

4 MHz

PLL

X 12

48 MHz

USB

48 MHz

DIV

(f

OSC

)

CLK_

SEL

R

SMAX

20

Ω

25

Ω

70

Ω

C

OSCIN

56pF 47pF 22pF

C

OSCOUT

56pF 47pF 22pF

1

Page 21

ST7SCR

21/102

CLOCK SYSTEM (Cont’d)

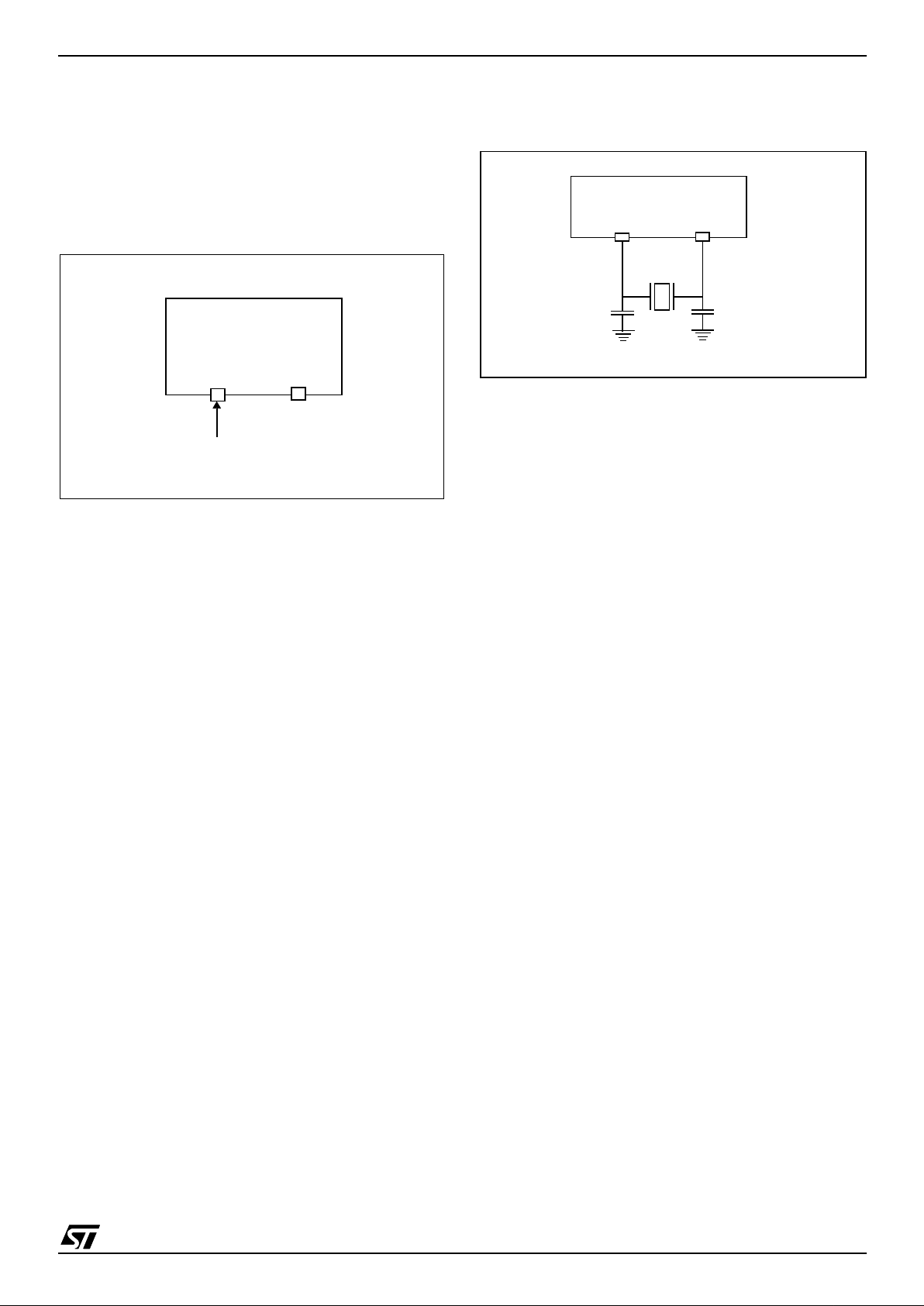

6.1.2 External Clock

An external clock may be applied to the OSCIN input with the OSCOUT pin not connected, as

shown on Figure 11.

Figure 11. .External Clock Source Connections

Figure 12. Crystal Resonator

OSCIN OSCOUT

EXTERNAL

CLOCK

NC

OSCIN OSCOUT

C

OSCIN

C

OSCOUT

1

Page 22

ST7SCR

22/102

6.2 RESET SEQUENCE MANAGER (RSM)

6.2.1 Introd uc tion

The reset sequence manager has two reset sources:

■ Internal LVD reset (Low Voltage Detection)

which includes both a power-on and a voltage

drop reset

■ Internal watchdog reset generated by an

internal watchdog counter unde rflow as shown

in Figure 14.

6.2.2 Functional Description

The reset service routine vector is fixed at addresses FFFEh-FFFFh in the ST7 memory map.

The basic reset sequence consists of 3 phases as

shown in Figure 13:

■ A first delay of 30µs + 127 t

CPU

cycles during

which the internal reset is maintained.

■ A second delay of 512 t

CPU

cycles after the

internal reset is generated. It allows the

oscillator to stabilize and ens ures that recovery

has taken place from the Reset state.

■ Reset vector fe tch (duration: 2 clock cycles)

Low Voltage Detector

The low voltage detector gene rates a reset when

V

DD<VIT+

(rising edge) or VDD<V

IT-

(falling edge),

as shown in Figure 13.

The LVD filters spikes on V

DD

larger than t

g(VDD)

to

avoid para siti c rese ts. Se e “ SUP PLY AND RESET

CHARACTERISTICS” on page 79.

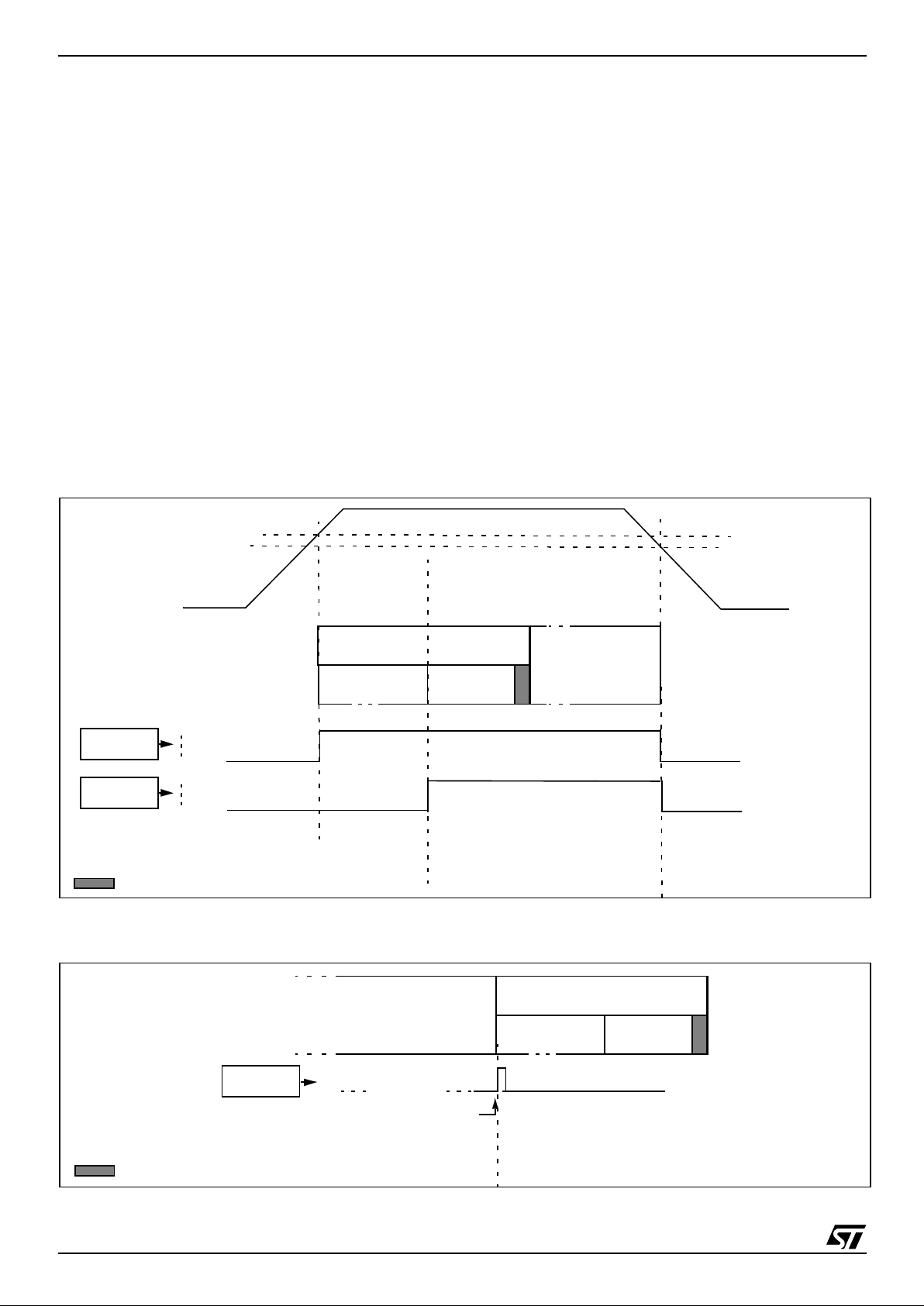

Figure 13. LVD RESET Sequence

Figure 14. Watchd og RESET Seque nce

DELAY 1

RUN

LVD

RESET

FETCH VECTOR (2 t

CPU

)

DELAY 2

LVD

RESET

INTERNAL

RESET

DELAY 1 = 30µs + 127 t

CPU

DELAY 2 = 512 t

CPU

V

DD

V

IT+

V

IT-

WATCHDOG

WATCHDOG UN DE RFL OW

RESET

FETCH VECTOR (2 t

CPU

)

DELAY 1

WATCHDOG

RESET

DELAY 2

DELAY 1 = 30µs + 127 t

CPU

DELAY 2 = 512 t

CPU

RUN

1

Page 23

ST7SCR

23/102

7 INTERRUP T S

7.1 INTRODUCTION

The ST7 enhanced interrupt management provides the following features:

■ Hardware interrupts

■ Software interrupt (TRAP)

■ Nested or concurrent interrupt management

with flexible interrupt priority and level

management:

– Up to 4 software programmable nesting levels

– Up to 16 interrupt vectors fixed by hardware

– 3 non maskable events: TLI, RESET, TRAP

This interrupt management is based on:

– Bit 5 and bit 3 of the CPU CC register (I1:0),

– Interrupt software priority registers (ISPRx),

– F ixed interrupt vecto r addresses locat ed at the

high addresses of the memory map (FFE0h to

FFFFh) sorted by hardware priority order.

This enhanced interrupt cont roller guarantees full

upward compatibility with the standard (not nested) ST7 interrupt controller.

7.2 MASKI N G AND PRO C ESSING FLOW

The interrupt masking is managed by the I1 and I0

bits of the CC register and the ISPRx registers

which give the interrupt software priority level of

each interrupt vector (see Table 5 ). The processing flow is shown in Figure 15 .

When an interrupt request has to be serviced:

– Normal processing is suspended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– I1 and I0 bits of CC register are set according to

the corresponding values in the ISPRx registers

of the serviced interrupt vector.

– The PC is then loaded with the interrupt vector of

the interrupt to service and the first instruction of

the interrupt service routine is fetched (refer to

“Interrupt Mapping” table for vector addresses).

The interrupt service routine should end with the

IRET instruction which c auses the contents of the

saved registers to be recovered from the stack.

Note: As a cons equence of the IRET instruction,

the I1 and I0 bits will be restored from the stack

and the program in the previous level will resume.

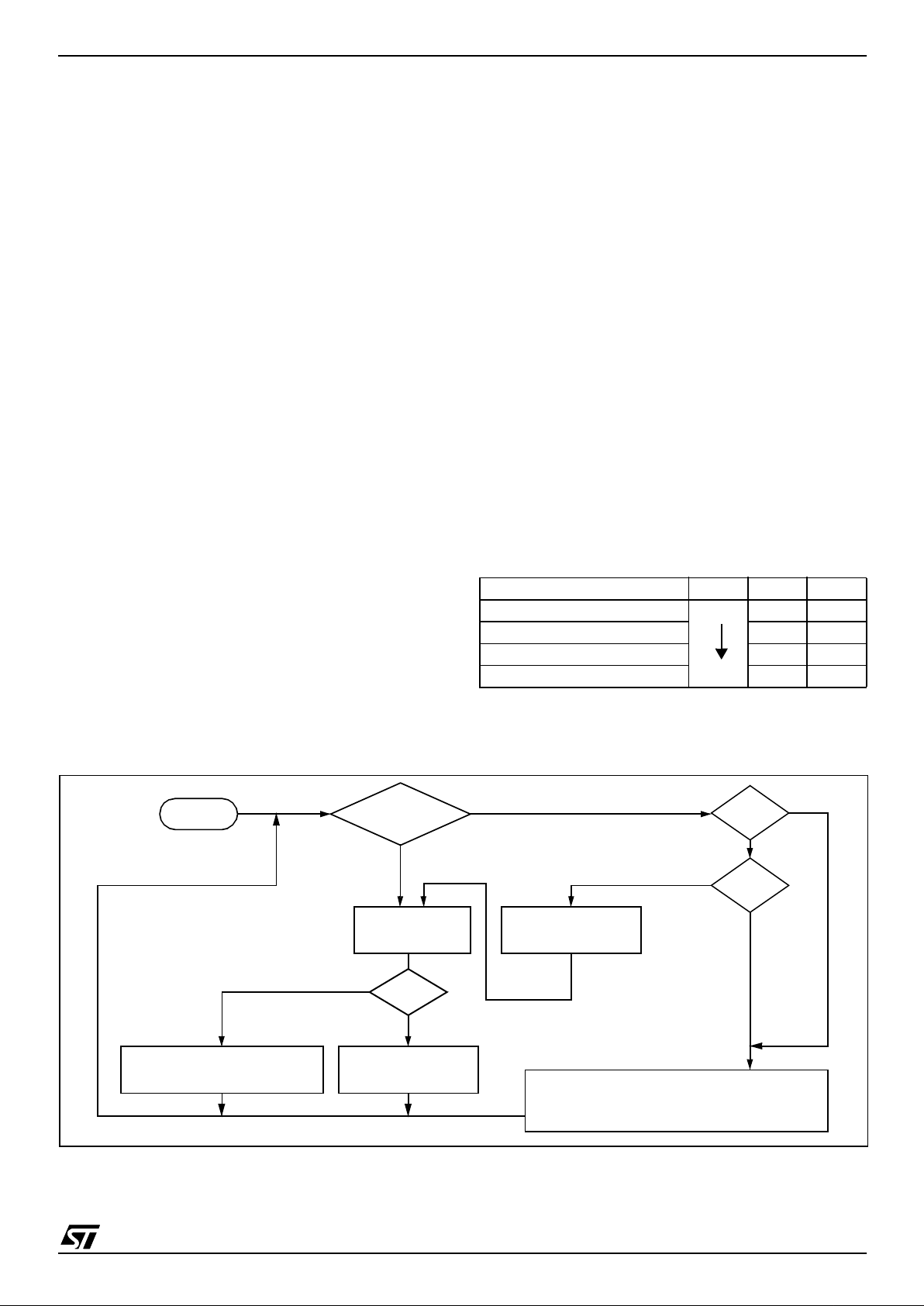

Table 5. Interrupt Software Priority Levels

Figure 15. Int errupt Processing Flow c hart

Interrupt software priority Le vel I1 I0

Level 0 (main) Low

High

10

Level 1 0 1

Level 2 0 0

Level 3 (= interrupt disable) 1 1

“IRET”

RESTORE PC, X, A, CC

STACK PC, X, A, CC

LOAD I1:0 FROM INTERR UPT SW REG.

FETCH NEX T

RESET

TLI

PENDING

INSTRUCTION

I1:0

FROM STACK

LOAD PC FROM INTERRUPT VECTOR

Y

N

Y

N

Y

N

Interrupt has the same or a

lower software priority

THE INTERRUPT

STAYS PENDING

than c u rrent one

Interrupt has a higher

softwarepr iority

than current one

EXECUTE

INSTRUCTION

INTERRUPT

1

Page 24

ST7SCR

24/102

INTERRUPTS (Cont’d)

Servicing Pending In te rrup t s

As several interrupts can b e pen ding at the s ame

time, the interrupt to be taken into account is determined by the following two-step process:

– the highest software priority interrupt is serviced,

– i f several interrupts have the same software pri-

ority then the interrupt with the highest hardware

priority is serviced first.

Figure 16 describes this decision process.

Figure 16. Priority Decision Process

When an interrupt request is not serviced immediately, it is latched and then processed when its

software priority combined with the hardware priority becomes the highest one.

Note 1: The hardware priority is exclusive while

the software one i s not. This allows the prev ious

process to succeed with only one interrupt.

Note 2: RESET, TRAP and TLI are non maskable

and they can be considered as havin g the highest

software priority in the decision process.

Different Interrupt Vector Sources

Two interrupt source types are managed by the

ST7 interrupt controller: the non-maskable type

(RESET, TLI, TRAP) and the maskable type (external or from internal peripherals).

Non-Maskable Sources

These sources are processed regardless of the

state of the I1 and I0 bits of the CC register (see

Figure 15). After stacking the PC, X, A and CC

registers (except for RESET), the corresponding

vector is loaded in the PC register and t he I1 and

I0 bits of the CC are set to disable interrupts (level

3). These sources allow the processor to exit

HALT mode.

■ TLI (Top Level Hardware Interrupt)

This hardware interrupt occurs when a specific

edge is detected on the dedicated TLI pin.

Caution: A TRAP instruction must not be used in a

TLI service routine.

■ TRAP (Non Maskable Software Interrupt)

This software interrupt is serviced when the TRAP

instruction is executed. It will be serviced according to the flowchart in Figure 15 as a TLI.

Caution: TRAP can be interrupted by a TLI.

■ RESET

The RESET source has the highe st priority in the

ST7. This means that the first current routine has

the highest software priority (level 3) and the highest hardware priority.

See the RESET chapter for more details.

Maskable Sources

Maskable interrup t vector sourc es can be servi ced

if the corresponding in terrupt is enabled and if its

own interrupt software priority (in ISPRx registers)

is higher than the one currently being serviced (I1

and I0 in CC register). If any of these two co nditions is false, the interrupt is la tched and thus remains pending.

■ External Interrupts

External interrupts allow the processor to exit from

HALT low power mode.

External interrupt sensitivity is software selectable

through the External Interrupt Control register

(EICR).

External interrupt triggered on edge will be latched

and the interrupt request automatically cleared

upon entering the interrupt service routine.

If several input pins of a group connected to the

same interrupt line are selected simultaneously,

these w ill be log i cally NANDed.

■ Peripheral Interrupts

Usually the peripheral interrupts cause the MCU to

exit from HALT mode except thos e mentioned in

the “Interrupt Mapping” table.

A peripheral interrupt occurs when a specific flag

is set in the peripheral status registers and if the

corresponding enable bit is set in the peripheral

control register.

The general sequence for clearing an interrupt is

based on an access to the status register followed

by a read or write to an associated register.

Note: The clearing sequence resets the internal

latch. A pending interrupt (i.e. waiting for being

serviced) will therefore be lost if the clear sequence is executed.

PENDING

SOFTWARE

Different

INTERRUPTS

Same

HIGHEST HARDWARE

PRIORITY SERVICED

PRIORITY

HIGHEST SOFTWARE

PRIORITY SERVICED

1

Page 25

ST7SCR

25/102

INTERRUPTS (Cont’d)

7.3 INTERRUPTS AND LOW POWER MODES

All interrupts allow the processor to exit the WAIT

low power mode. On the contrary, only external

and other specified interrupt s allow the processor

to exit from the HALT modes (see column “Exit

from HALT” in “Interrupt Mapping” table). When

several pending interrupts are present whi le exiting HALT mode, the first one serviced can only be

an interrupt with e xit from HALT mode c apability

and it is selected through the same decision proc ess shown in Figure 16.

Note: If an interrupt, that is not able to Exit from

HALT mode, is pending with the highest priority

when exiting HALT mode, this interrupt is serviced

after the first one serviced.

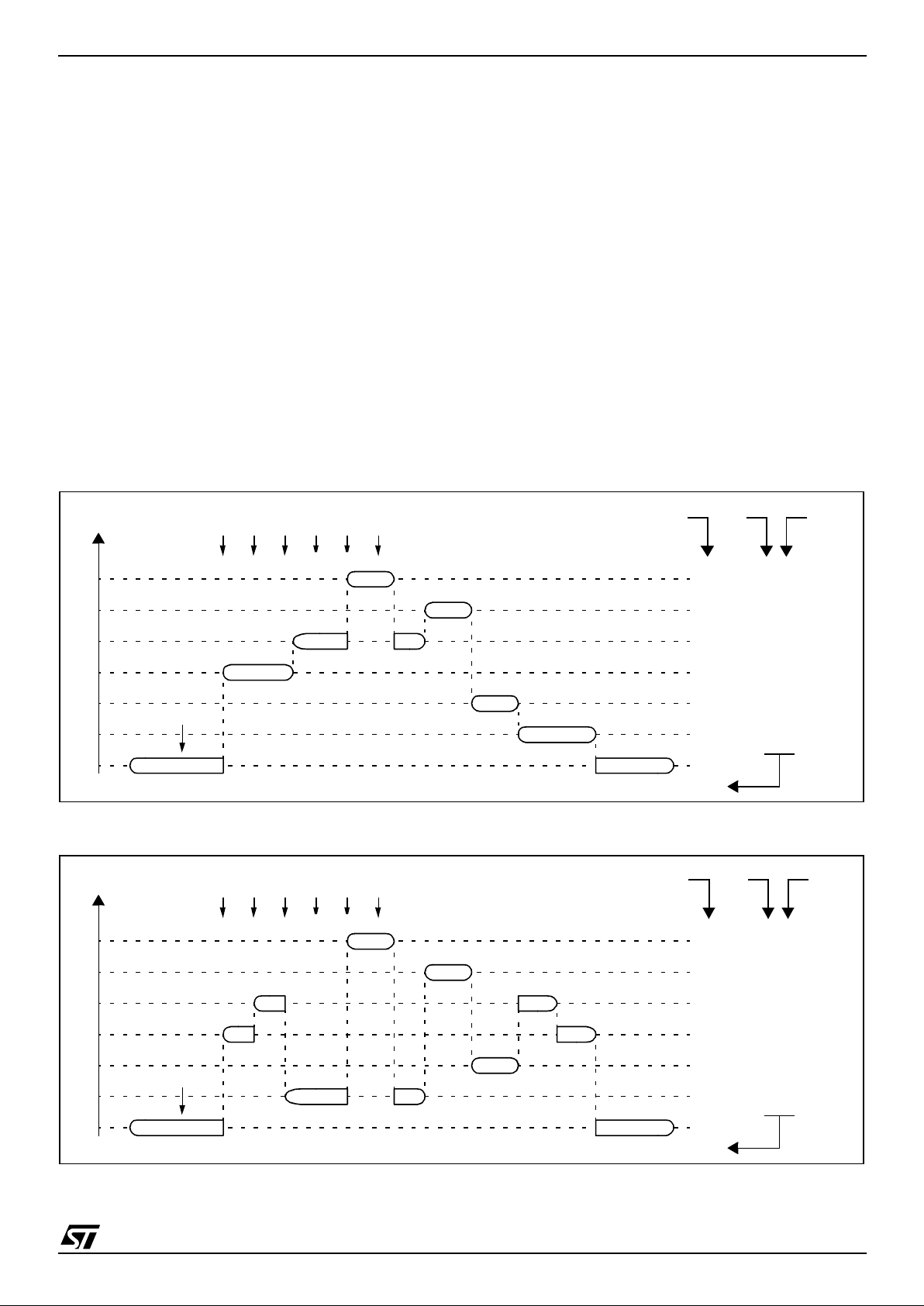

7.4 CONCURRENT & NESTED MANAGEMENT

The following Figure 17 and Figure 18 show two

different interrupt management modes. The first is

called concurrent mode and do es not allow an interrupt to be interrupted, unlike the nested mode in

Figure 18. The interrupt hardware priority is given

in this order from the l owes t to the hi ghest: M A IN,

IT4, IT3 , IT2, IT1, IT0, TLI. The software priority is

given for each interrupt.

Warning: A stack overflow may occur without notifying the software of the failure.

Figure 17. Concurrent Interrupt Managem ent

Figure 18. Nested Interrupt Management

MAIN

IT4

IT2

IT1

TLI

IT1

MAIN

IT0

I1

HARDWARE PRIORITY

SOFTWARE

3

3

3

3

3

3/0

3

11

11

11

11

11

11 / 10

11

RIM

IT2

IT1

IT4

TLI

IT3

IT0

IT3

I0

10

PRIORITY

LEVEL

USED STACK = 10 BYTES

MAIN

IT2

TLI

MAIN

IT0

IT2

IT1

IT4

TLI

IT3

IT0

HARDWARE PRIORITY

3

2

1

3

3

3/0

3

11

00

01

11

11

11

RIM

IT1

IT4

IT4

IT1

IT2

IT3

I1 I0

11 / 10

10

SOFTWARE

PRIORITY

LEVEL

USED STACK = 20 BYTES

1

Page 26

ST7SCR

26/102

INTERRUPTS (Cont’d)

7.5 INTERRUPT REGISTER DESCRIPTION

CPU CC REGISTER INTERRUPT BITS

Read/Write

Reset Value: 111x 1010 (xAh)

Bit 5, 3 = I1, I0

Soft w a re In te r r u p t Priority

These two bits indicate the current interrupt software priority.

These two bits are set/cle ared by hardware whe n

entering in interrupt. The loaded value is given by

the corresponding bits in the interrupt software priority registers (ISPRx).

They can be also s et/cleared by s oft ware wi th the

RIM, SIM, HALT, WFI, IRET and PUSH/POP instructions (see “Interrupt Dedicated Instruction

Set” table).

*Note: TLI, TRAP and RESET events are non

maskable sources and can interrupt a level 3 program.

INTERRUPT SOFTWARE PRIORITY REGISTERS (ISPRX)

Read/Write (bit 7:4 of ISPR3 are read only)

Reset Value: 1111 1111 (FFh)

These four registers contain the interrupt software

priority of each interrupt vector.

– Each interrupt vector (except RESET and TRAP)

has corresponding bits in these registers where

its own software priority is stored. This correspondance is shown in the following table.

– Each I1_x and I0_x bit value in the ISPRx regis-

ters has the same meaning as the I1 and I0 bits

in the CC register.

– Level 0 can not be written (I1_x=1, I0_x=0). In

this case, the previously stored value is kept. (example: previous=CFh, write=64h, result=44h)

The RESET, TRAP a nd TLI vectors have no s oftware priorities. When one is serviced, the I1 and I0

bits of the CC register are both set.

*Note: Bits in the ISPRx registers which correspond to the TLI can be read and written but they

are not significant in the interrupt process management.

Caution: If the I1_x and I0_x bits are modified

while the interrupt x is execu ted the following behaviour has to be considered: If the interrupt x is

still pending (new interrupt or flag not cleared) and

the new software priority is highe r than the previous one, the interrupt x is re-ent ered. Otherwise,

the software priority stays unchanged up to the

next interrupt request (after the IRET of the interrupt x).

70

11I1 H I0 NZC

Interrupt Software Priority Level I1 I0

Level 0 (main)

Low

High

10

Level 1 0 1

Level 2 0 0

Level 3 (= interrupt disable*) 1 1

70

ISPR0 I1_3 I0_3 I1_2 I0_2 I1_1 I 0_1 I1_0 I0_0

ISPR1 I1_7 I0_7 I1_6 I0_6 I1_5 I 0_5 I1_4 I0_4

ISPR2 I1_11 I0_11 I1_10 I0_10 I1_9 I0_9 I1_8 I0_8

ISPR3 1 1 1 1 I1_13 I0_13 I1_12 I0_12

Vector address ISPRx bits

FFFBh-FFFAh I1_0 and I0_0 bits*

FFF9h-FFF8h I1_1 and I0_1 bits

... ...

FFE1h-FFE0h I1_13 and I0_13 bits

1

Page 27

ST7SCR

27/102

INTERRUPTS (Cont’d)

Table 6. Dedicated Interrupt Instruc tion Set

Note: During the execut ion of an interrupt routine, the HALT, POPCC, RI M, SIM and WFI instructions

change the current software priority up to the next IRET instruction or one of the previously mentioned

instructions.

In order not to lose the current software priority level, the RIM, SIM, HALT, WFI and POP CC instructions

should never be used in an interrupt routine.

Table 7. I nte rrupt Mapping

Note 1: This interrupt can be used to exit from USB suspend mode.

Instruction New Description Function/Example I1 H I0 N Z C

HALT Entering Halt mode 1 0

IRET Interrupt routine return Pop CC, A, X, PC I1 H I0 N Z C

JRM Jump if I1:0=11 I1:0=11 ?

JRNM Jump if I1:0<>11 I1:0<>11 ?

POP CC Pop CC from the Stack Mem => CC I1 H I0 N Z C

RIM Enable interrupt (level 0 set) Load 10 in I1:0 of CC 1 0

SIM Disable interrupt (level 3 set) Load 11 in I1:0 of CC 1 1

TRAP Software trap Software NMI 1 1

WFI Wait for interrupt 1 0

N°

Source

Block

Description

Register

Label

Priority

Order

Exit

from

HALT

Address

Vector

RESET Reset

N/A

Highest

Priority

Lowest

Priority

yes FFFEh-FFFFh

TRAP Software Interrupt

no

FFFCh-FFFDh

0 ICP FLASH Start programming NMI interrupt FFFAh-FFFBh

1 UART ISO7816-3 UART Interrupt UIC FFF8h-FFF9h

2 USB USB Communication Interrupt USBISTR FFF6h-FFF7h

3 WAKUP1 External Interrupt Port C yes FFF4h-FFF5h

4 WAKUP2 External Interrupt Port A yes FFF2h-FFF3h

5 TIM TBU Timer Interrupt TBUSR no FFF0h-FFF1h

6 CARDDET

1)

Smartcard Insertion/Removal Interrupt

1)

USCUR

yes

FFEEh-FFEFh

7 ESUSP End suspend Interrupt USBISTR FFECh-FFEDh

8 Not used no FFEAh-FFEBh

1

Page 28

ST7SCR

28/102

8 POWER SAVING MODES

8.1 INTRODUCTION

To give a large measure of flexibility to the application in terms of power consumption, two main power saving modes are implemented in the ST7.

After a RESET the normal operat ing mode is selected by default (RUN mode). This mode drives

the device (CPU and embedded peripherals) by

means of a master clock which is based on the

main oscillator frequency.

From Run mode, the different power saving

modes may be selected by setting the relevant

register bits or by calling the specific ST7 software

instruction whose action depends on the oscillator

status.

8.2 WAIT MODE

WAIT mode places the MCU in a low power c onsumption mode by stopping the CPU.

This pow e r s a v ing mo de is selected by calling the

“WFI” ST7 software instruction.

All peripherals remain active. During WAIT mode,

the I bit of the CC register is forced to 0, to enable

all interrupts. All other registers and memory remain unchanged. The MCU remains in WAIT

mode until an interrupt or Res et oc curs, where upon the Program Counter branches to the starting

address of the interrupt or Reset service routine.

The MCU w ill re mai n in W AIT mo de unt il a Res et

or an Interrupt occurs, causing it to wake up.

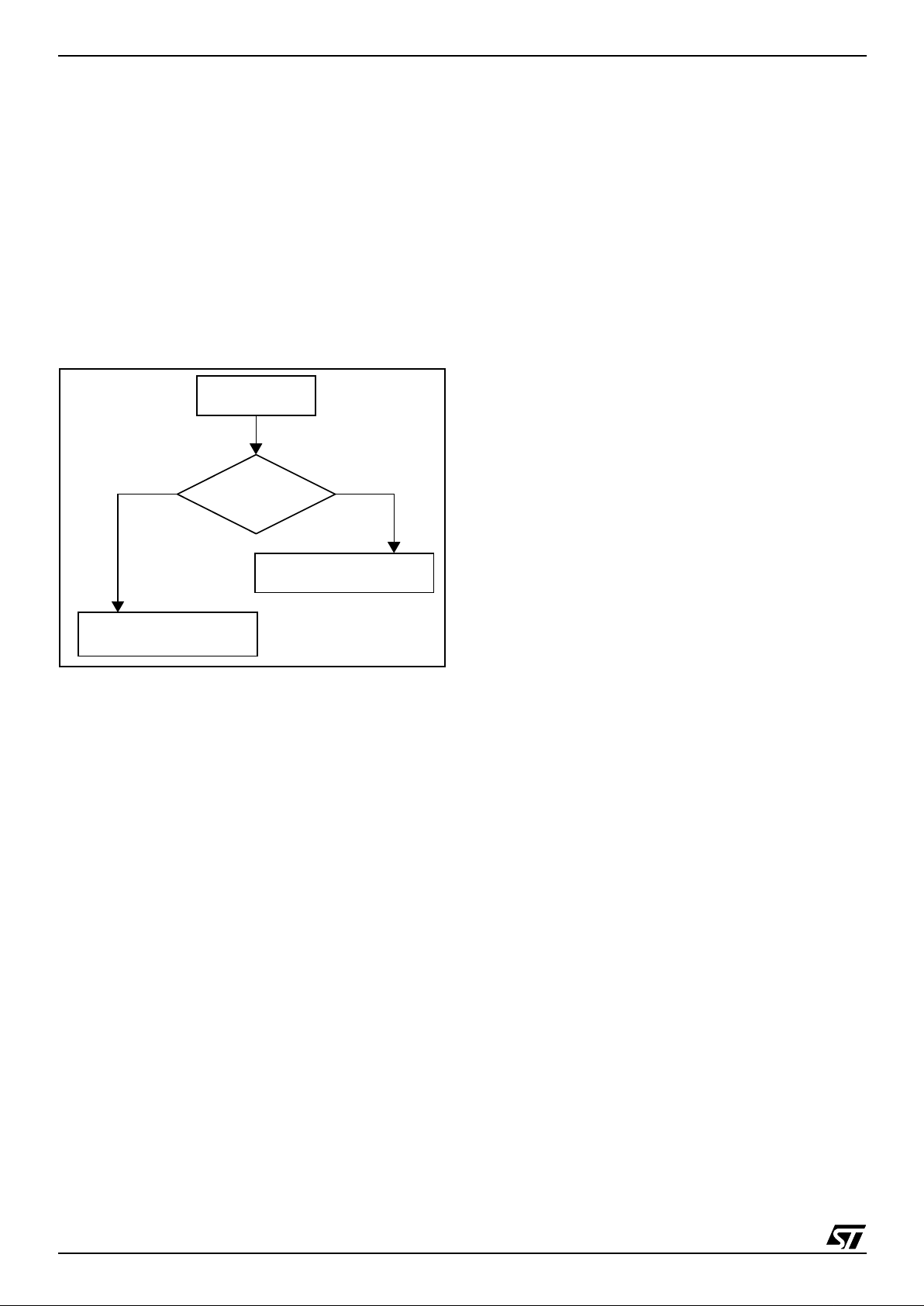

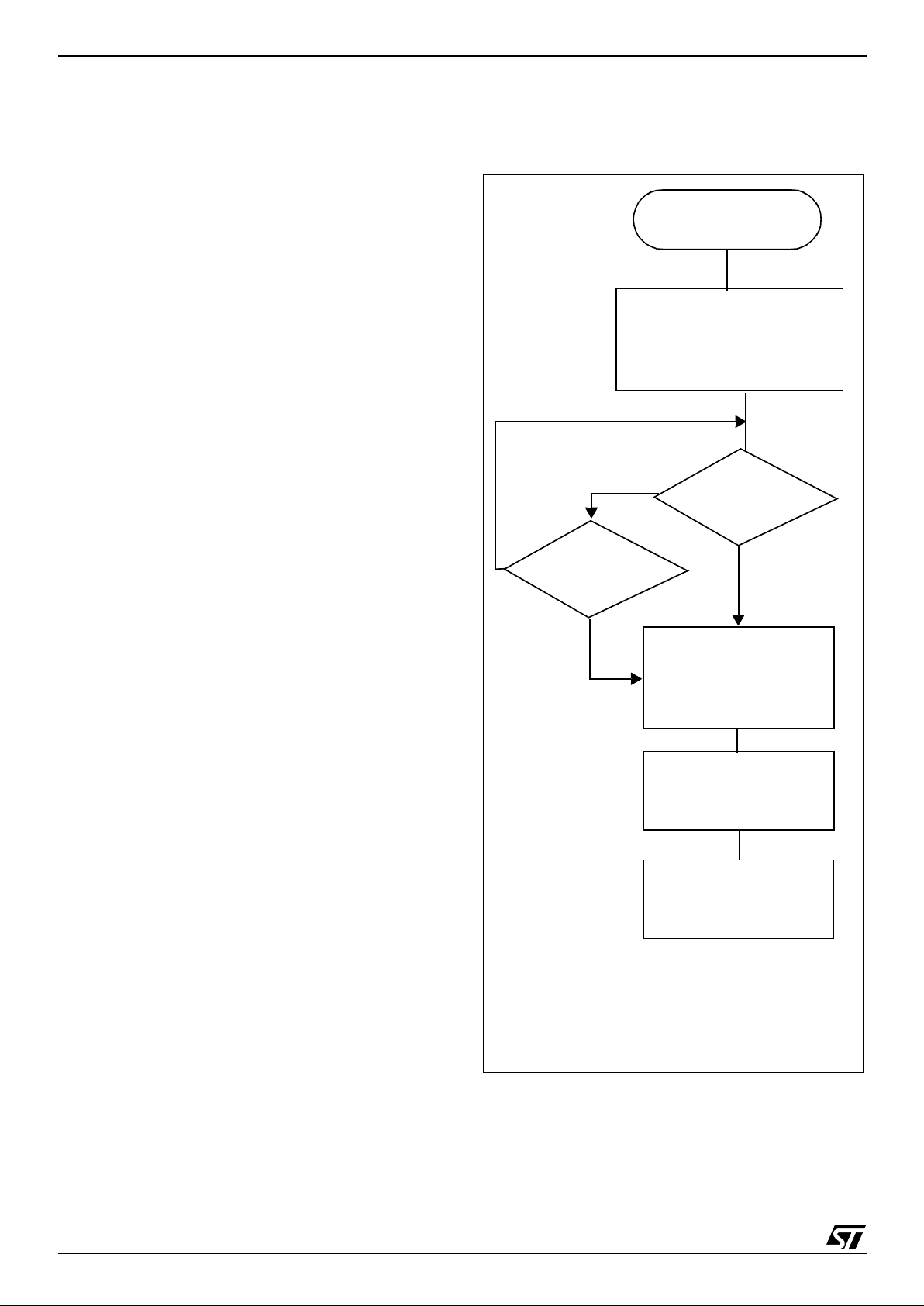

Refer to Figure 19.

Figure 19. WAIT Mode Flow Chart

WFI INSTRUCTION

RESET

INTERRUPT

Y

N

N

Y

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

CLEARED

OFF

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

SET

ON

FETCH RESET VECTOR

OR SERVICE INTERRUPT

512 CPU CLOCK

CYCLES DELAY

IF RESET

Note: Before servicing an interrupt, the CC

register is pushed on the stack. The I-Bit is set

during the interrupt routine and cleared when

the CC register is popped.

1

Page 29

ST7SCR

29/102

POWER SAVING MODES (Cont’d)

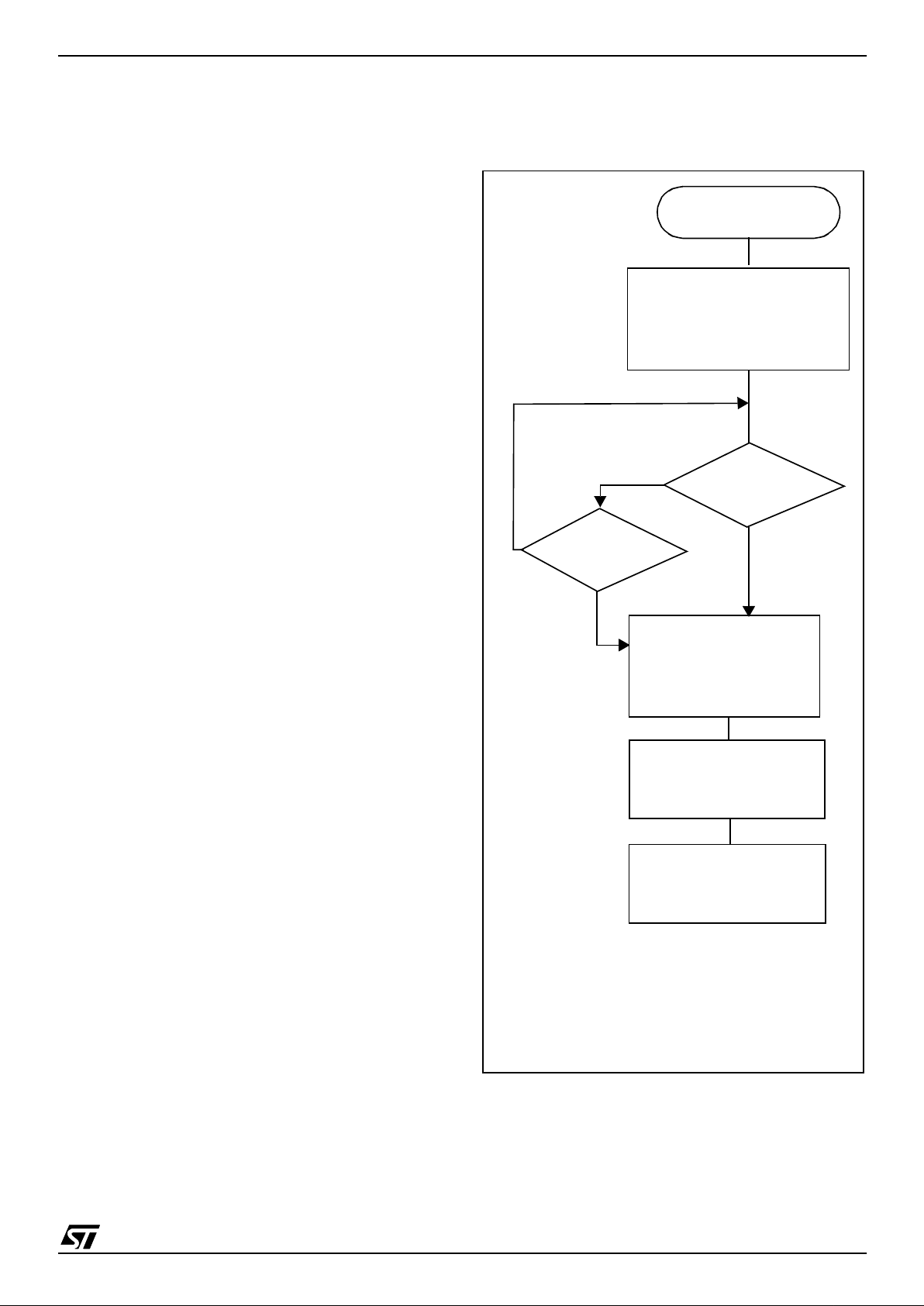

8.3 HALT MODE

The HALT mode is the MCU lowest power consumption mode. The HALT mode is entered by executing the HALT instruction. The internal oscillator is then turned off, causing all internal processing to be stopped, including the operation of the

on-chip peripherals.

Note: Th e PL L must be disabled before a HALT

instruction.

When entering HALT mode, the I bit in the Condition Code Register is cleared. Thus, any of the external interrupts (ITi or US B end suspend mode),

are allowed and if an interrupt occurs, the CPU

clock becomes active.

The MCU can e xit HAL T mode on reception of either an external interrupt on ITi, an end suspen d

mode interrupt coming from USB peripheral, or a

reset. The osc illato r is t hen t ur ned on and a stabilization time is provided before rele as ing CPU operation. The stabilization time is 512 CPU clock cycles.

After the start up delay, the CPU continues operation by servicing the interrupt which wakes it up or

by fetching the reset vector if a reset wakes it up.

Figure 20. HALT Mod e Flo w C hart

N

N

EXTERNAL

INTERRUPT*

RESET

HALT INSTRUCTION

512 CPU CLOCK

FETCH RESET VECTOR

OR SERVICE INTERRUPT

CYCLES DELAY

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

SET

ON

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

OFF

OFF

CLEARED

OFF

Y

Y

Note: Before servicing an interrupt, the CC

register is pushed on the stack. The I-Bit is set

during the interrupt routine and c leared when

the CC register is popped.

1

Page 30

ST7SCR

30/102

9 I/O PORTS

9.1 Introduction

The I/O ports offer different functional modes:

– transfer of data through digital inputs and outputs

and for specific pins:

– alternate signal input/output for the on-chip pe-

ripherals.

– external interrupt detection

An I/O port i s c om posed of up to 8 pins. E ach pin

can be programmed independently as digital input

(with or without interrupt generation) or digital output.

9.2 Functional description

Each port is associated to 4 main registers:

– Data Register (DR)

– Data Direction Register (DDR)

– Option Register (OR)

– Pull Up Register (PU)

Each I/O pin may be programmed using the corre-

sponding register bits in DDR register: bit X corresponding to pin X of the port. The same correspondence is used for the DR register.

Table 8. I /O Pi n Fu nc ti ons

Input Modes

The input configuration is s ele cted by clearing the

corresponding DDR register bit.

In this case, reading the DR register returns the

digital value applied to the external I/O pin.

Note 1: All the inputs are triggered by a Schmitt

trigg er.

Note 2: When switching from input mode to output

mode, the DR register should be written first to

output the correct value as soon as the port is configured as an output.

Interrupt function

When an I/O is configured in Input with Interrupt,

an event on this I/O can generate an external In-

terrupt request to the CPU. The interrupt sensitivity is given independently according to the description mentioned in the ITRFRE interrupt register.

Each pin can independently generate an I nterrupt

request.

Each external interrupt vecto r is linked to a dedicated group of I/O port pins (see Interrupts section). If more than one input pin is selected sim ultaneously as interrupt source, this is logically

ORed. For this reason if one of the interrupt pins is

tied low, it masks the other ones.

Output Mode

The pin is configured in output mode by setting the

corresponding DDR register bit (see Table 7).

In this mode, writing “0” or “1” to the DR register

applies this digital value to the I/O pin throu gh the

latch. Then reading the DR register returns the

previously stored value.

Note: In thi s mo de, th e interrupt function is disabled.

Digital A lternate Func ti on

When an on-chip peripheral is configured to use a

pin, the alternate function is au tomatically selected. This alternate function takes priority over

standard I/O programming. When the signal is

coming from an on-chip peripheral, the I/O pin is

automatically configured in output mode (push-pull

or open drain according to the peripheral).

When the signal is goi ng t o an on-c hip pe ripheral,

the I/O pin ha s to be configured in input m ode. In

this case, the pin’s state is also digitally reada ble

by addressing the DR register.

Notes:

1. Input pull-up conf iguration can cause a n unexpected value at the input of the alternate peripheral input.

2. When the on-chip peripheral uses a pin as input

and output, this pin must be configured as an input

(DDR = 0).

Warning

: The alternate f uncti on m ust not be acti-

vated as long as the pin is configured as input with

interrupt, in order to avoid generating spurious interrupts.

DDR MODE

0 Input

1 Ou tput

1

Page 31

ST7SCR

31/102

I/O PORTS (Cont’d)

9.3 I/O Port Implementation

The hardware implementation on each I/O port depends on the settings in the DDR register and specific feature of the I/O port such as true open drain.

9.3.1 Port A

Table 9. Port A Description

Figure 21. PA0, PA1, PA2, PA3, PA4, PA5 Configuration

Figure 22. P A 6 Conf i guration

PORT A

I / O

Input Output

PA[5:0] without pull-up * push-pull or open drain with software selectable pull-up

PA6 without pull-up *Reset State

DR

DDR

LATCH

LATCH

DR SEL

DDR SEL

V

DD

PAD

ALTERNATE ENABLE

ALTERNATE ENABLE

ALTERNATE ENABLE

ALTERNATE

ALTERNATE INPUT

PULL-UP

1)

OUTPUT

P-BUFFER

N-BUFFER

1

0

1

0

CMOS SCHMITT TRIGGER

V

SS

V

DD

DIODES

DATA BUS

Note 1: selectable by PAPUCR register

DR SEL

PAD

V

DD

DIODES

DATA BUS

CMOS SCHMITT TRIGGER

1

Page 32

ST7SCR

32/102

I/O PORTS (Cont’d)

9.3.2 Ports B and D

Table 10. Port B and D Description

Figure 23. Port B and D Configuration

PORTS B AND D Output *

PB[7:0]

push-pull or open drain with software selectable pull-up

PD[7:0]

*Reset State = open drain

DR

LATC H

DR SEL

V

DD

PAD

ALTERNATE ENABLE

ALTERNATE ENABLE

ALTERNATE ENABLE

ALTERNATE

PULL-UP

1)

OUTPUT

P-BUFFER

N-BUFFER

1

V

SS

V

DD

DIODES

DATA BUS

OM

LATCH

PULL_UP

LATCH

0

1

0

‘0’

Note 1: selectable by PAPUCR register

1

Page 33

ST7SCR

33/102

I/O PORTS (Cont’d)

9.3.3 Port C

Table 11. Port C Description

Figure 24. P ort C C onfi guration

PORT C Input

PC[7:0] with pull-up

DR SEL

PAD

ALTERNATE INPUT

V

DD

DIODES

CMOS SCHMITT TRIGGER

DATA BUS

PULL-UP

V

DD

1

Page 34

ST7SCR

34/102

I/O PORTS (Cont’d)

9. 4 Register Description

DATA REGISTERS (PxDR)

Port A Data Register (PADR): 0011h

Port B Data Register (PBDR): 0015h

Port C Data Register (PCDR): 0018h

Port D Data Register (PCDR): 0019h

Read/Write

Reset Value Port A: 0000 0000 (00h)

Reset Value Port B: 0000 0000 (00h)

Reset Value Port C: 0000 0000 (00h)

Reset Value Port D: 0000 0000 (00h)

Bits 7:0 = D[7:0]

Data Register 8 bits.

The DR register has a specific behaviour according to the selected input/output configuration. Writing the DR register is always taken in account

even if the pin is configured as an input. Reading

the DR register ret urns either t he DR register latch

content (pin configured as output) or the digital value applied to the I/O pin (pin configured as input).

DATA DIRECTION REGISTER (PADDR)

Port A Data Direction Register (PADDR): 0012h

Read/Write

Reset Value Port A: 0000 0000 (00h)

Bits 7:0 = DD7-DD0

Data Direction Register 8 bits.

The DDR register gives the inp ut/output directio n

configuration of the pins. Each bits is set and

cleared by software.

0: Input mode

1: Output mode

OPTION REGISTER (PxOR)

Port x Option Register

PxOR with x = A, B, or D

Port A Option Register (PAOR): 0013h

Port B Option Register (PBOR): 0016h

Port D Option Register (PDOR): 001Ah

Read/Write

Reset Value: 0000 0000 (00h)

Bits 7:0 = OM[7:0]

Option register 8 bits.

The OR register allows to distinguish in output

mode if the push-pull or open drain configuration is

selected.

Each bit is set and cleared by software.

0: Output open drain

1: Output push-pull

PULL UP CONTROL REGISTER (PxPUCR)

Port x Pull Up Registe r

PxPUCR w ith x = A, B, or D

Port A Pull up Register (PAPUCR): 0014h

Port B Pull up Register (PBPUCR): 0017h

Port D Pull up Register (PDPUCR): 001Bh

Read/Write

Reset Value: 0000 0000 (00h)

Bits 7:0 = PU[7:0]

Pull up register 8 bits.

The PU register is used to control the pull up.

Each bit is set and cleared by software.

0: Pull up inactive

1: Pull up active

70

D7 D6 D5 D4 D3 D2 D1 D0

70

DD7 DD6 DD5 DD4 DD3 DD2 DD1 DD0

70

OM7 OM6 OM5 OM4 OM3 OM2 OM1 OM0

70

PU7 PU6 PU5 PU4 PU3 PU2 PU1 PU0

1

Page 35

ST7SCR

35/102

I/O PORTS (Cont’d)

Table 12. I/O Ports Register Map

Address

(Hex.)

Register

Label

76543210

11

PADR

Reset Value

MSB

0000000

LSB

0

12

PADDR

Reset Value

MSB

0000000

LSB

0

13

PAOR

Reset Value

MSB

0000000

LSB

0

14

PAPUCR

Reset Value

MSB

0000000

LSB

0

15

PBDR

Reset Value

MSB

0000000

LSB

0

16

PBOR

Reset Value

MSB

0000000

LSB

0

17

PBPUCR

Reset Value

MSB

0000000

LSB

0

18

PCDR

Reset Value

MSB

0000000

LSB

0

19

PDDR

Reset Value

MSB

0000000

LSB

0

1A

PDOR

Reset Value

MSB

0000000

LSB

0

1B

PDPUCR

Reset Value

MSB

0000000

LSB

0

1

Page 36

ST7SCR

36/102

10 MISCELLANEOUS REGISTERS

MISCELLAN EOUS REGISTER 1 (MISCR1)

Reset Value : 0000 0000 (00h)

Read/Write

Writing the ITIFREC register enables or disables

external interrupt on Port C. Each bit can be

masked independantly. The ITMx bit masks the

external interrupt on PC.x.

Bits[7:0 ] = ITM [7:0]

Interrupt Mask

0: external interrupt disabled

1: external interrupt enabled

MISCELLANEOUS REGISTER 2 (MISCR2)

Reset Value : 0000 0000 (00h)

Read/Write

Writing the ITIFREA register enab les or disables

external interrupt on port A.

Bit 7 = Reserved.

Bit 6 = CRDIRM

CRD Insertion/Removal Interrupt

Mask

0: CRDIR interrupt disabled

1: CRDIR interrupt enabled

Bits [5:0] = ITM [14:9]