Datasheet ST72T85A5Q6, ST72E85A5G0, ST7285C, ST7285A5CQ8, ST7285A5CQ6 Datasheet (SGS Thomson Microelectronics)

...Page 1

November 1997 1/117

R

Rev. 1.0

ST7285C

8-BIT MCU FOR RDS WITH 48K ROM, 3K RAM, ADC,

TWO TIMERS, TWO SPIs, I

2

C AND SCI INTERFACES

■

4.5V to 5.5V Supply Operating Range

■ Operates at 8.664MHz Oscillator Frequency for

RDS compatibility

■

Fully Static operation

■

-40°Cto+85°C Maximum Operating

Temperature Range

■

Run, Wait, Slow, Halt and RAM Retention

modes

■

User ROM: 48 Kbytes

■ Data RAM: 3 Kbytes, including 128 byte stack

■

80 pin plastic package

■

62 multifunctional bidirectional I/O lines:

– Programmable Interrupt inputs on some I/Os

– 8 Analog inputs

– EMI filtering

■

Two 16-bit Timers, each featuring:

– 2 Input Captures

– 2 Output Compares

– External Clock input (on Timer A)

– PWM and Pulse Generator modes

■ RDS Radio Data System Filter, Demodulator

and GBS circuits

■

8-bit Analog-to-Digital converter with 8 channel

analog multiplexer

■ Digital Watchdog

■

Two SPI Serial Peripheral Interfaces

■

SCI Serial Communications Interface

■ Full I

2

C multiple Master/Slave interface

■ 2KHz Beep signal generator

■

Master Reset and Power-On Reset

■

8-bit Data Manipulation

■ 63 Basic Instructions

■

17 main Addressing Modes

■

8 x 8 Unsigned Multiply Instruction

■ True Bit Manipulation

■ Complete Development Support on PC/DOS/

WindowsTMReal-Time Emulator

■

Full Software Package (C-Compiler, CrossAssembler, Debugger)

PQFP80

1

Page 2

2/117

Table of Contents

117

ST7285C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1 GENERAL DESCRIPTION . . . . . . . ...............................................5

1.1 INTRODUCTION .........................................................5

1.2 PIN DESCRIPTION .......................................................6

1.3 MEMORYMAP .........................................................10

2 CENTRAL PROCESSING UNIT .................................................13

2.1 INTRODUCTION ........................................................13

2.2 CPU REGISTERS . . . . . . . . ...............................................13

3 CLOCKS, RESET, INTERRUPTS & POWER SAVING MODES ........................15

3.1 CLOCKSYSTEM........................................................15

3.1.1 General Description .................................................15

3.1.2 Crystal Resonator . . . . . . . . ..........................................15

3.1.3 Ceramic Resonator . . . ..............................................16

3.1.4 External Clock . . . . . . . ..............................................16

3.2 MISCELLANEOUS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................17

3.3 RESETS...............................................................18

3.3.1 Introduction . . . . . . . . ...............................................18

3.3.2 External Reset . . . . . . . . . . ...........................................18

3.3.3 Reset Operation . . . . . . . . . . . . . . . .....................................18

3.3.4 Power-on Reset . . . . . . . . . . . . . . . .....................................18

3.4 WATCHDOG TIMER SYSTEM (WDG) . . .....................................19

3.4.1 Introduction . . . . . . . . ...............................................19

3.4.2 Functional Description . . . ............................................19

3.4.3 Watchdog Register . . . ..............................................19

3.5 INTERRUPTS . . . . ......................................................20

3.6 POWER SAVING MODES .................................................22

3.6.1 SlowMode........................................................22

3.6.2 WaitMode ........................................................22

3.6.3 HaltMode.........................................................23

4 ON-CHIP PERIPHERALS . . . ...................................................24

4.1 I/OPORTS.............................................................24

4.1.1 Introduction . . . . . . . . ...............................................24

4.1.2 Generic I/O Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................24

4.1.3 I/O Port Implementation . . . . . . . . . . . . ..................................27

4.2 SERIAL COMMUNICATIONS INTERFACE. . ..................................28

4.2.1 Introduction . . . . . . . . ...............................................28

4.2.2 Features . . . . . . . . . . . . . . . ...........................................28

4.2.3 Serial Data Format . .................................................28

4.2.4 Data Reception and Transmission. . . ...................................28

4.2.5 Receiver Muting and Wake-up Feature . . . . ..............................28

4.2.6 Baud Rate Generation . . . ............................................29

4.2.7 SCI Register Overview . . . ............................................29

4.3 16-BIT TIMER . . . . ......................................................35

4.3.1 Introduction . . . . . . . . ...............................................35

4.3.2 Counter . . . . ......................................................35

Page 3

3/117

Table of Contents

4.3.3 External Clock . . . . . . . ..............................................37

4.3.4 Input Capture . . . ...................................................39

4.3.5 Output Compare . . . . ...............................................40

4.3.6 Timer Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . .........................43

4.4 SERIAL PERIPHERAL INTERFACE . . . . . . . . . . . . . . . . . . . . .....................45

4.4.1 Introduction . . . . . . . . ...............................................45

4.4.2 Features . . . . . . . . . . . . . . . ...........................................45

4.4.3 Functional Description . . . ............................................45

4.4.4 Signal Description . . . . . . . . ..........................................47

4.4.5 Master Out Slave In (MOSI). ..........................................47

4.4.6 Master In Slave Out (MISO) . ..........................................47

4.4.7 Serial Peripheral Control Register (SPCR) ...............................50

4.4.8 Serial Peripheral Status Register (SPSR) . . . . . ...........................51

4.4.9 Serial Peripheral Data I/O Register (SPDR) . . . . . .........................53

4.4.10Single Master And Multimaster Configurations . . . . ........................53

4.5 I2C BUS INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . .........................54

4.5.1 Introduction . . . . . . . . ...............................................54

4.5.2 General Features . . . . ...............................................54

4.5.3 Functional Description . . . ............................................54

4.5.4 EPROM/ROM I C COMPATIBILITY APPLICATION NOTE. . . . ...............56

4.5.5 Re giste r Desc ript ion .................................................57

4.5.6 I2C Stat e Machine: . . . ..............................................61

4.6 A /D CONVERTER (ADC) . .................................................64

4.6.1 Introduction . . . . . . . . ...............................................64

4.6.2 Fu nctio nal De scrip tion . . . ............................................64

4.6.3 Re giste r Desc ript ion .................................................65

4.7 RDS FILTER . . . ........................................................66

4.7.1 Fe atures . . . . . . . . . . . . . . . ...........................................66

4.7.2 Fu nctio nal De scrip tion . . . ............................................67

4.8 RDS DEMODULATOR . . . . . . . . . . . . . . . .....................................68

4.8.1 Fe atures . . . . . . . . . . . . . . . ...........................................68

4.8.2 Fu nctio nal De scrip tion . . . ............................................69

4.9 RDSG.B.S.............................................................72

4.9.1 Introduction . . . . . . . . ...............................................72

4.9.2 Fe atures . . . . . . . . . . . . . . . ...........................................72

4.9.3 Fu nctio nal De scrip tion . . . ............................................74

4.9.4 Ac quisition of Group and Block Synchronization . . . . .......................77

4.9.5 Application Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . .........................77

4.9.6 Block Synchronization Software . . .....................................77

4.9.7 Error Correction s oftwar e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................77

5SOFTWARE ................................................................78

5.1 S T7 ARCHITECTU RE . . . . . . . . . . . . . . . .....................................78

5.2 S T7 ADDRESSING MOD ES ...............................................78

5.3 S T7 INSTRUCT ION SET . .................................................83

6 EL ECT RICAL CHARACTERI STI CS. . . . . . . . . . . . ..................................86

6.1 A BSO LUT E M AXIMUM RATINGS. ..........................................86

6.2 P OWER CONSID ERATIONS . . . . ..........................................87

Page 4

4/117

Table of Contents

117

6.3 DC ELECTRICAL CHARACTERISTICS ......................................88

6.4 AC ELECTRICAL CHARACTERISTICS ......................................89

6.5 CONTROLTIMING ......................................................89

7 GENERAL INFORMATION . . . . . . . . . . ...........................................96

7.1 PACKAGE MECHANICAL DATA. . . . ........................................96

ST72E85

ST72T85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

1 GENERAL DESCRIPTION. . . ...................................................98

1.1 INTRODUCTION ........................................................98

1.2 PIN DESCRIPTION ......................................................99

1.3 MEMORYMAP.........................................................103

1.4 EPROM ERASURE .....................................................105

1.5 EPROM/R OM I C COMPATIBILITY APPLICATION NOTE.......................106

2 ELECTRICAL CHARACTERISTI CS. . . . .........................................107

2.1 ABSOLUTE MAXIMUM RATINGS. . . . . . ....................................107

2.2 POWER CONSIDERATIONS. . . ...........................................108

2.3 DC ELECTRICAL CHARACTERISTICS .....................................109

2.4 AC ELECTRICAL CHARACTERIS TICS. . . ...................................110

2.5 CONTROLTIMING......................................................110

3 GENERAL INFORMATION . . . . . . . . . . ..........................................117

3.1 PACKAGE MECHANICAL DATA. . . . .......................................117

Page 5

5/117

ST7285C

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST7285C HCMOS Microcontroller Unit is a

member of the ST7 family of Microcontrollers dedicated to car radio applications with RDS capability. The device is based on an industry-standard 8bit core and features an enhanced instruction set.

The device is normally operated at an 8.664MHz

oscillator frequency for RDS compatibility but,

thanks to the fully static design, operation is possible down to DC, when RDS functionality is not required. Under software control, theST7285C may

be placed in either WAIT, SLOW or HALT modes,

thus reducing power consumption. The enhanced

instruction set and addressing modes afford real

programming potential. In addition to standard 8bit data management, theST7285C features true

bit manipulation, 8x8 unsigned multiplication and

indirect addressing modes.

The device includes an on-chip oscillator, CPU,

ROM, RAM, 62 I/O lines and the following on-chip

peripherals: Analog-to-Digital converter (ADC),

two industry standard SPI serial interfaces, a Serial Communications Interface, an I2C interface, a

digital Watchdog Timer, two independent 16-bit

Timers, one featuring an External Clock Input, and

both featuring Pulse Generator capabilities, 2 Input Captures and 2 Output Compares. RDS Filter,

Demodulator and GBS circuitry for car radio applications is also included.

NOTE

:

FOR THIS DEVICE, SGS-THOMSON

CAN ONLY RECEIVE MOTOROLA S19 FORMAT

FOR ROM CODES.

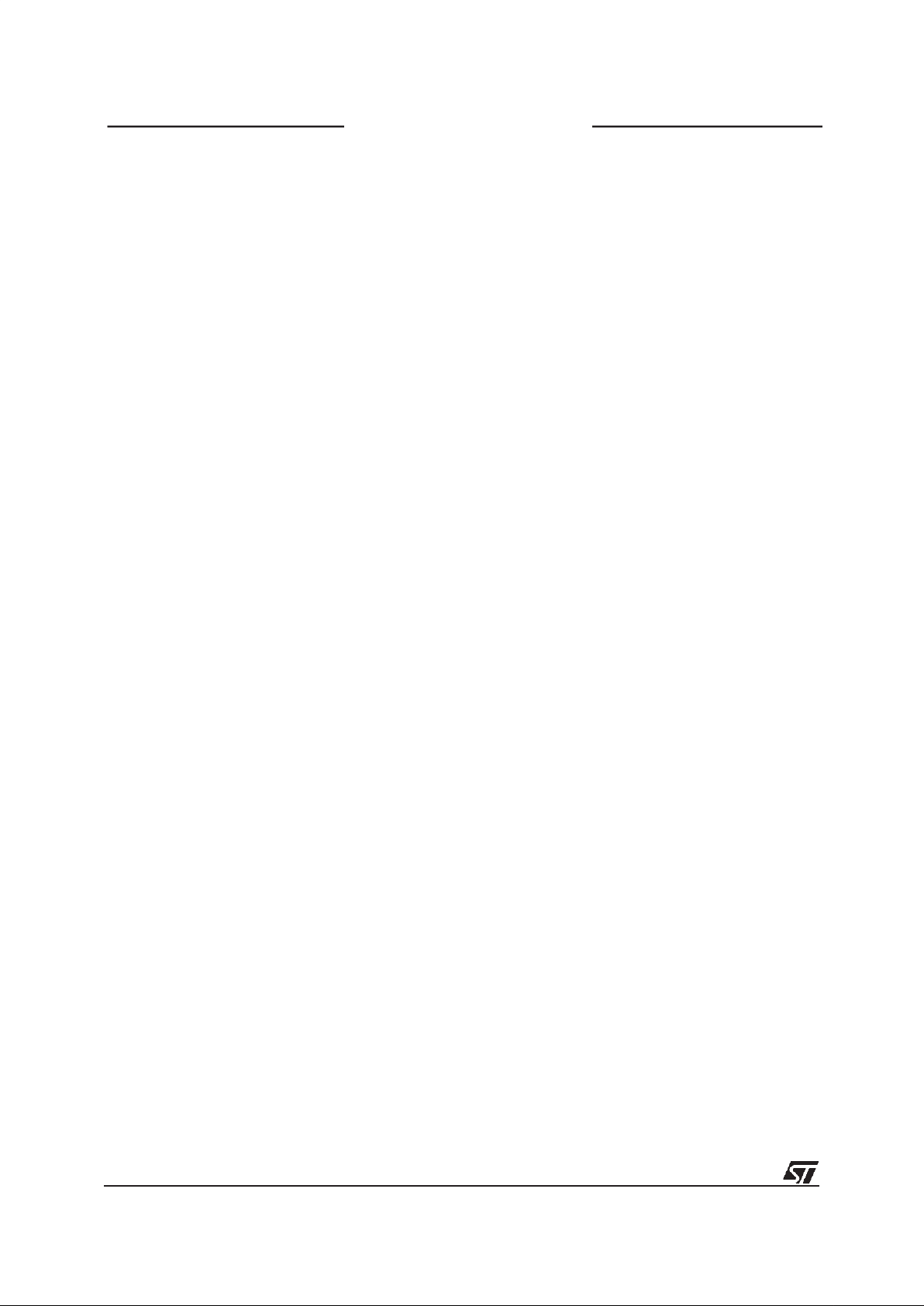

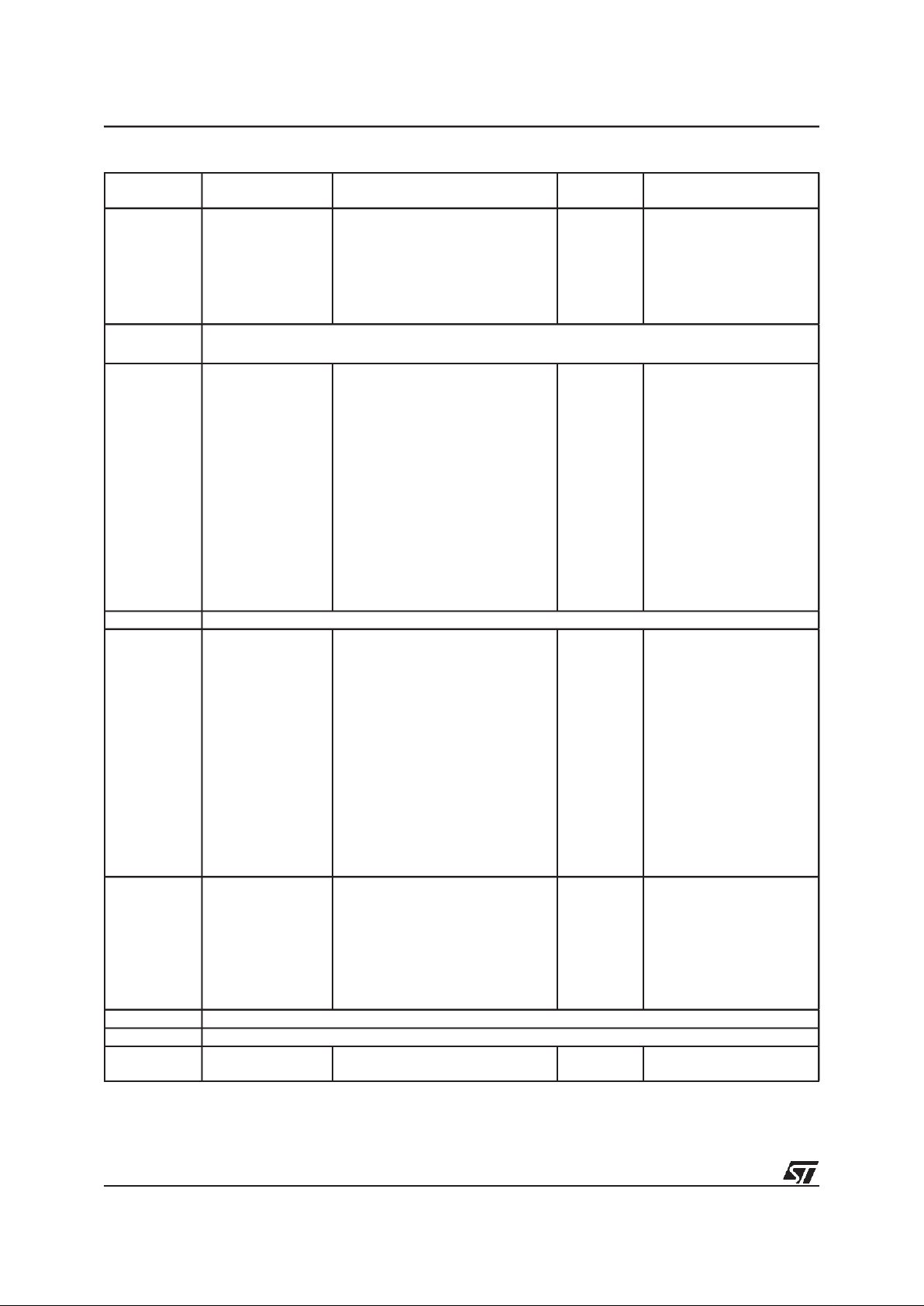

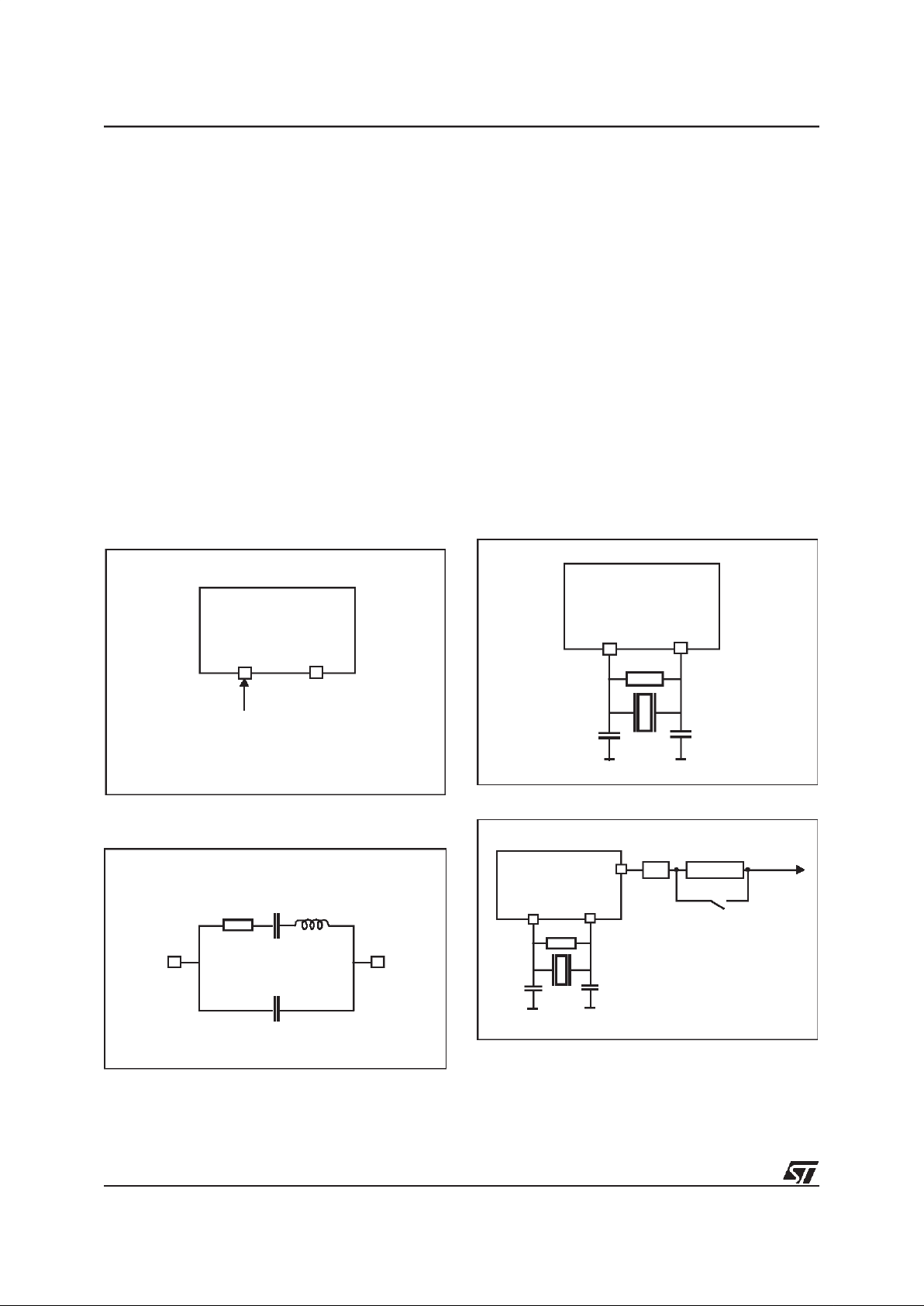

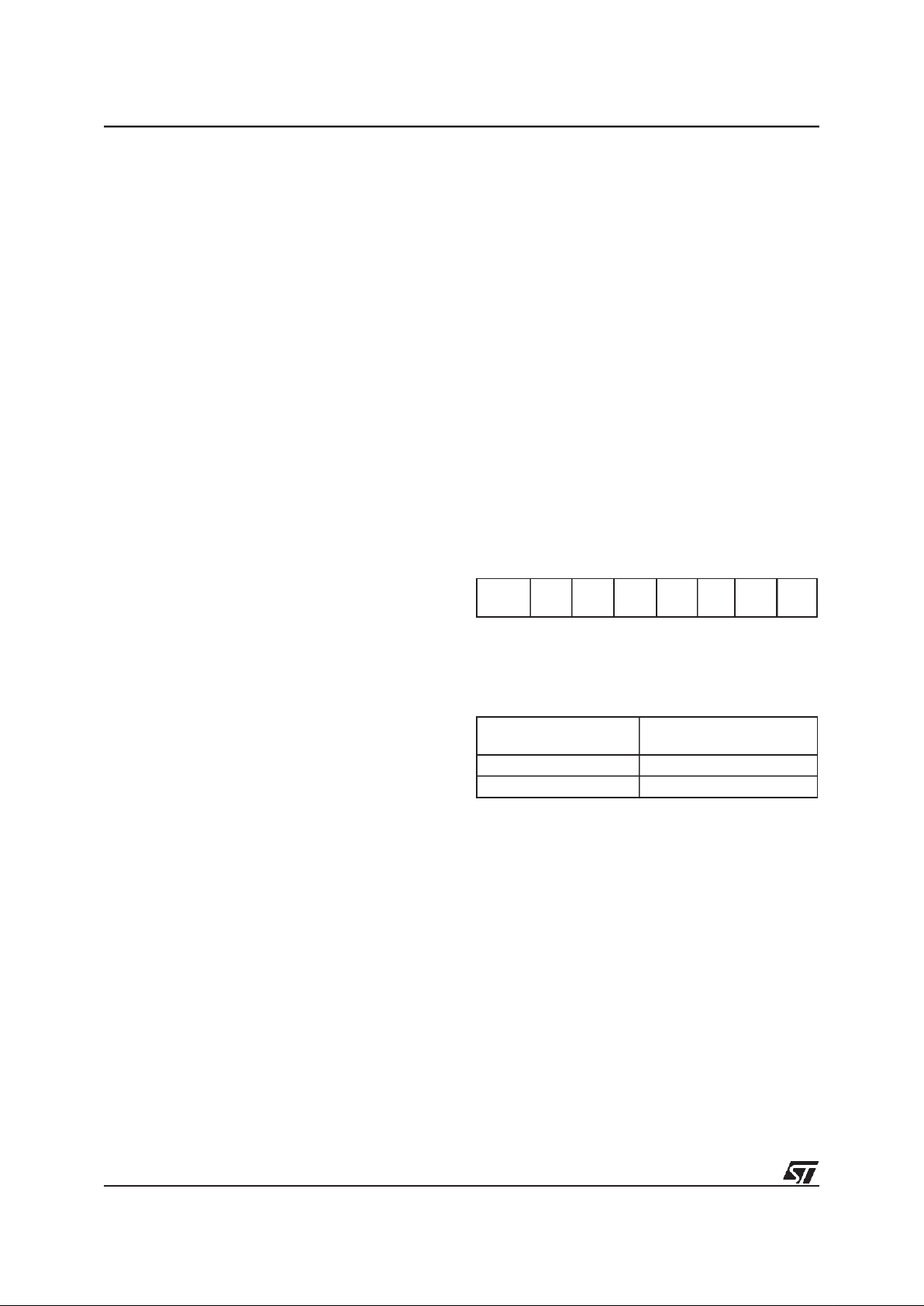

Figure 1. ST7285C Block Diagram

*On EPROM or OTP versions only.

Power on Reset

PA0 - PA7

Pin 65..72

PB0 - PB7

Pin 73..80

OSCin

OSCout

RESET

V

PP

/ TEST

OSC

8 -BIT CORE

ALU

VR01735P

Internal

CLOCK

ADDRESSand DATA BUS

TimerA

PORT A

PORT B

A/D Converter

8

4

SPI B

PORT C

PC0 - PC7

Pin 5..12

SPI A

PORT D

I

2

C

SCI

8

RAM

3k

RDS

FILTER,DEMOD,GBS

8

8

8

TimerB

4

4

2

PD0 - PD7

Pin 13..20

2

PORT E

PE0 - PE7

Pin 25..32

8

PORT F

PF0 - PF7

Pin 33..40

8

PORT H

PORT G

PH0 - PH5

Pin 53..58

6

PG0 - PG7

Pin 45..52

8

ROMor EPROM*

48k

Watchdog

RDScomp

MPX

RDS fil

RDS ref

ARS

AINT

V

DD

V

SS

V

DDPVSSPVDDAVSSA

2

2

Page 6

6/117

ST7285C

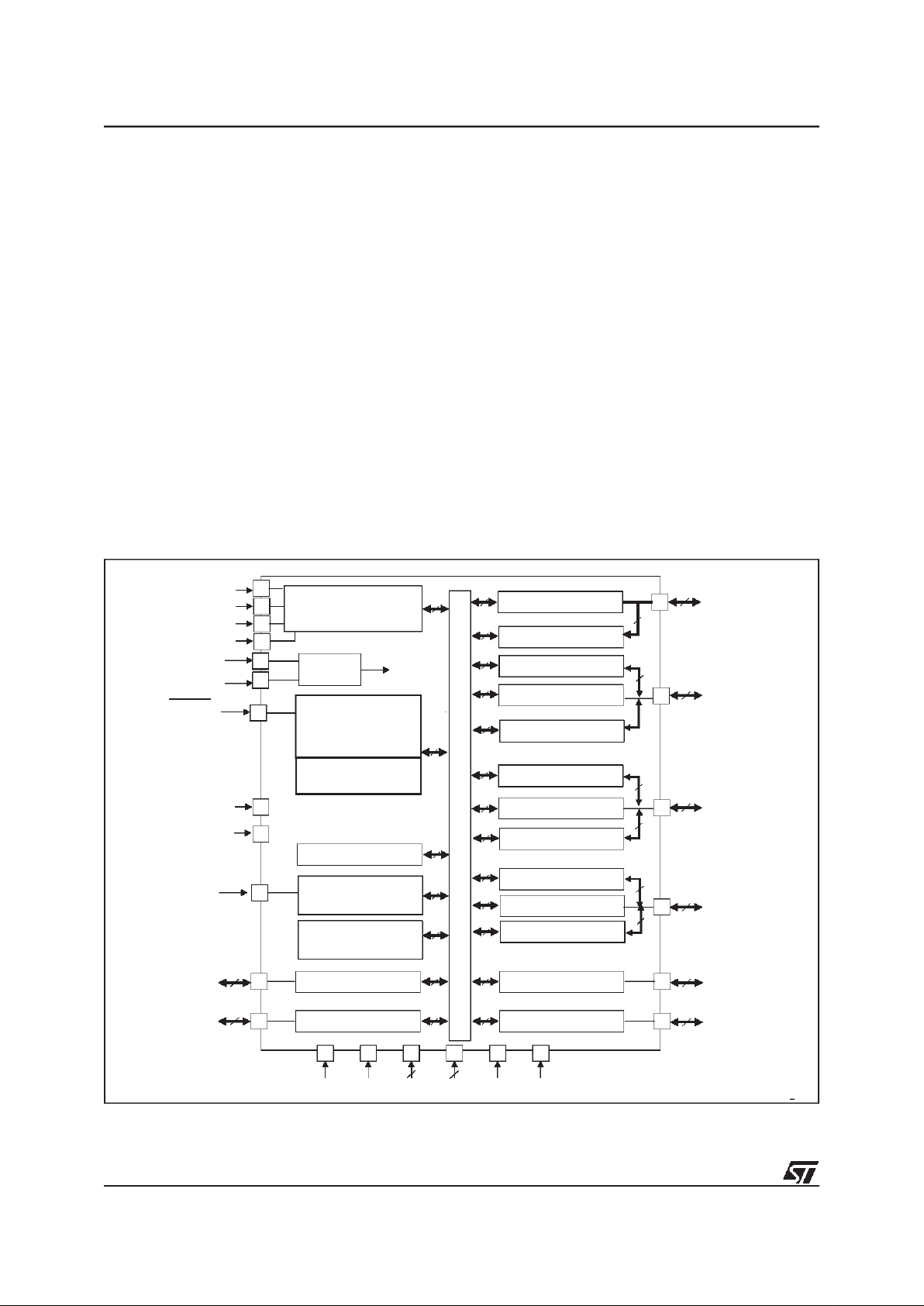

1.2 PIN DESCRIPTION

All I/Os from Port A to Port D, as well as PH0, 1

and 2, feature alternate function compatibility.

Software selectable input pull-ups are available on

ports featuring interrupt capability (PC4, PC5,

PD4, PD5, PF0-PF3, PG3).

VSSA

VDDA

MPX

RDSREF

RDSFIL

RDSCOMP

PH5

PH4

PH3

PH2/RDSDATA

PH1/RDSCLKOUT

PH0/RDSQUAL

PG7

PG6

PG5

PG4

PG3

PG2

PG1

PG0

ARS

AINT

VDDP

VSSP

VSSP

VDDP

OSCOUT

OSCIN

PC0/MISO_B

PC1/MOSI_B

PC2/SCK_B

PC3/SS_B

PC4/OC2_B

PC5/OC1_B

PC6/IC2_B

PC7/IC1_B

PD0/MISO_A

PD1/MOSI_A

PD2/SCK_A

PD3/SS_A

PD4

PD5

PD6/SCL

PD7/SDA

RESET

VPP*/TEST

VDD

VSS

1

2

3

4

5

6

7

8

9 (I10)

10 (I10)

11

12

13

14

15

16

17 (I9)

18 (I9)

19

20

21

22

23

24

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

(I1) 48

47

46

45

44

43

42

41

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65

25 26 27 28 29 30 31 32 37 38 39

40

PB7/BEEP/

CLKOUT

PB6/CLKEXT

PB5/OC2_A

PB4/OC1_A

PB3/IC2_A

PB2/IC1_A

PB1/RDI

PB0/TDO

PA7/AIN7

PA6/AIN6

PA5/AIN5

PA4/AIN4

PA3/AIN3

PA2/AIN2

PA1/AIN1

PA0/AIN0

PE0

PE1

PE2

PE3

PE4

PE5

PE6

PE7

PF0

PF1

PF2

PF3

PF4

PF5

PF6

PF7

33 34 35 36

*) On EPROM/OTPversions only

(I2)(I2)(I2)(I2)

Page 7

7/117

ST7285C

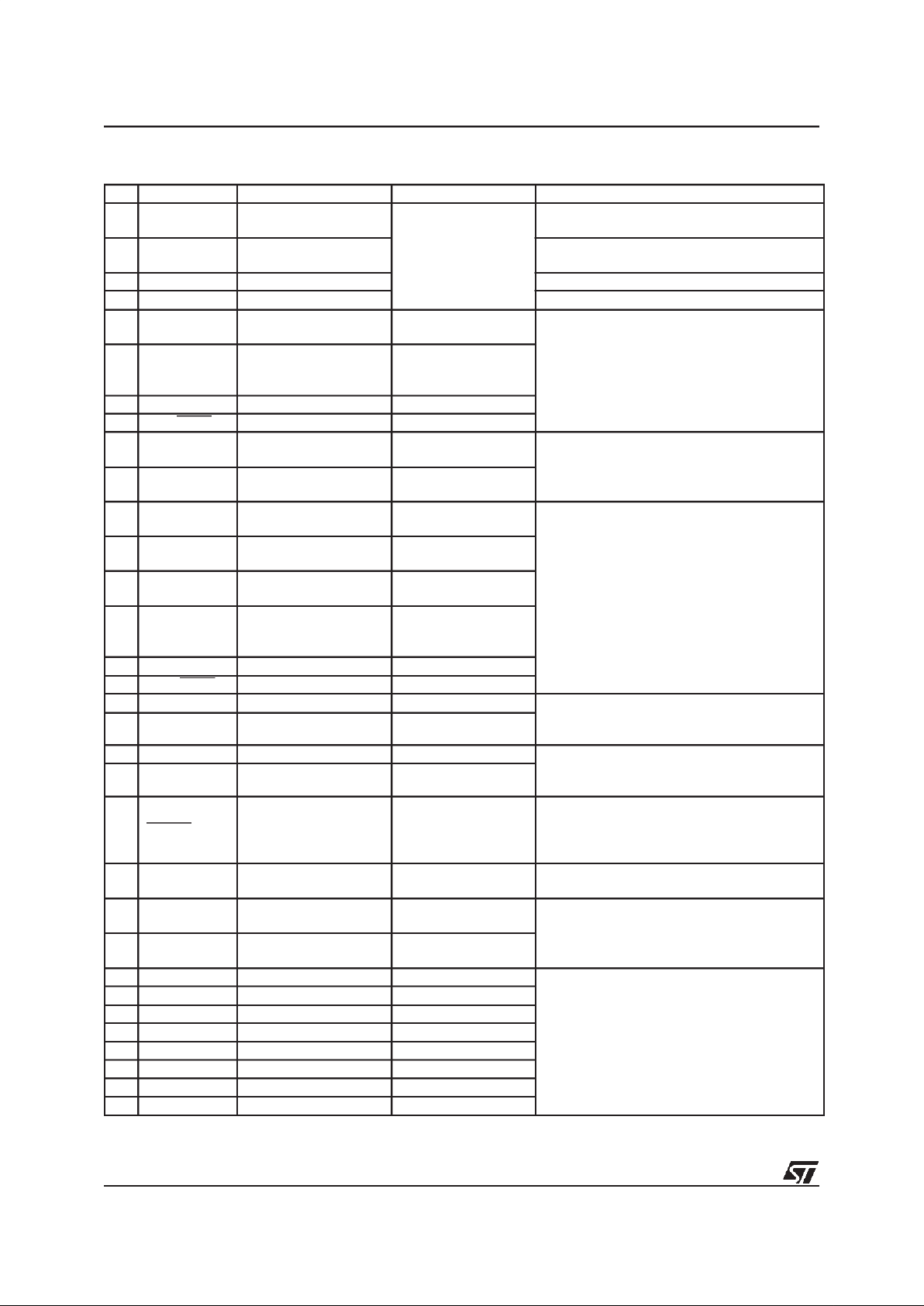

Pin Pin Name(s) Basic Function Alternate Function Remarks

1V

SSP

Ground for Output Buffers

-

This pin is connected to pin 41

2V

DDP

Power Supply for Output Buffers

This pin is connected to pin 42

3 OSCOUT Oscillator Output pin.

4 OSCIN Oscillator Input pin.

5 PC0/MISO_B I/O Port PC0

SPI B master in/slave

out data input/output

Alternate function or I/O. The I/O configuration

is software selectable as triggered input or

push pull output.

6 PC1/MOSI_B I/O Port PC1

SPI B Master Out/

Slave In Data Input/

Output

7 PC2/SCK_B I/O Port PC2 SPI B Serial Clock

8 PC3/SS_B I/O Port PC3 SPI B Slave Select

9 PC4/OC2_B I/O Port PC4

Output Compare 2

on Timer B

Alternate function or I/O. Software selectable

as triggered input, push pull output, or triggered interrupt input with pull up (Interrupt I10).

10 PC5/OC1_B I/O Port PC5

Output Compare 1

on Timer B

11 PC6/IC2_B I/O Port PC6

Input Capture 2

on Timer B

Alternate function or I/O. The I/O configuration

is software selectable as triggered input or

push pull output.

12 PC7/IC1_B I/O Port PC7

Input Capture 1

on Timer B.

13 PD0/MISO_A I/O Port PD0

SPI A Master In/Slave

Out Data Input/Output

14 PD1/MOSI_A I/O Port PD1

SPI A Master Out/

Slave In data Input/

Output

15 PD2/SCK_A I/O Port PD2 SPI A Serial Clock

16 PD3/SS_A I/O Port PD3 SPI A Slave Select

17 PD4 I/O Port PD4 - Software selectable as triggered input, push

pull output, open drain output or triggered interrupt input with pull up (Interrupt I9).

18 PD5 I/O Port PD5 19 PD6/SCL I/O Port PD6 I

2

C Serial Clock Alternate function or I/O. The I/O configuration

is software selectable as triggered input or

open drain output.

20 PD7/SDA I/O Port PD7 I

2

C Serial Data

21 RESET General Reset -

Bidirectional. An active low signal forces MCU

initialization. This event is the top priority nonmaskable interrupt. As an output, it can be

used to reset external peripherals.

22 TEST RESERVED -

Input. This pin MUST be tied directly to V

SS

during normal operation.

23 V

DD

Power Supply forall logic circuitry

Except for output buffers and pull-ups.

24 V

SS

Ground for all logic circuitry

-

25 PE0 I/O Port PE0 -

Software selectable as triggered input or push

pull output.

26 PE1 I/O Port PE1 27 PE2 I/O Port PE2 28 PE3 I/O Port PE3 29 PE4 I/O Port PE4 30 PE5 I/O Port PE5 31 PE6 I/O Port PE6 32 PE7 I/O Port PE7 -

Page 8

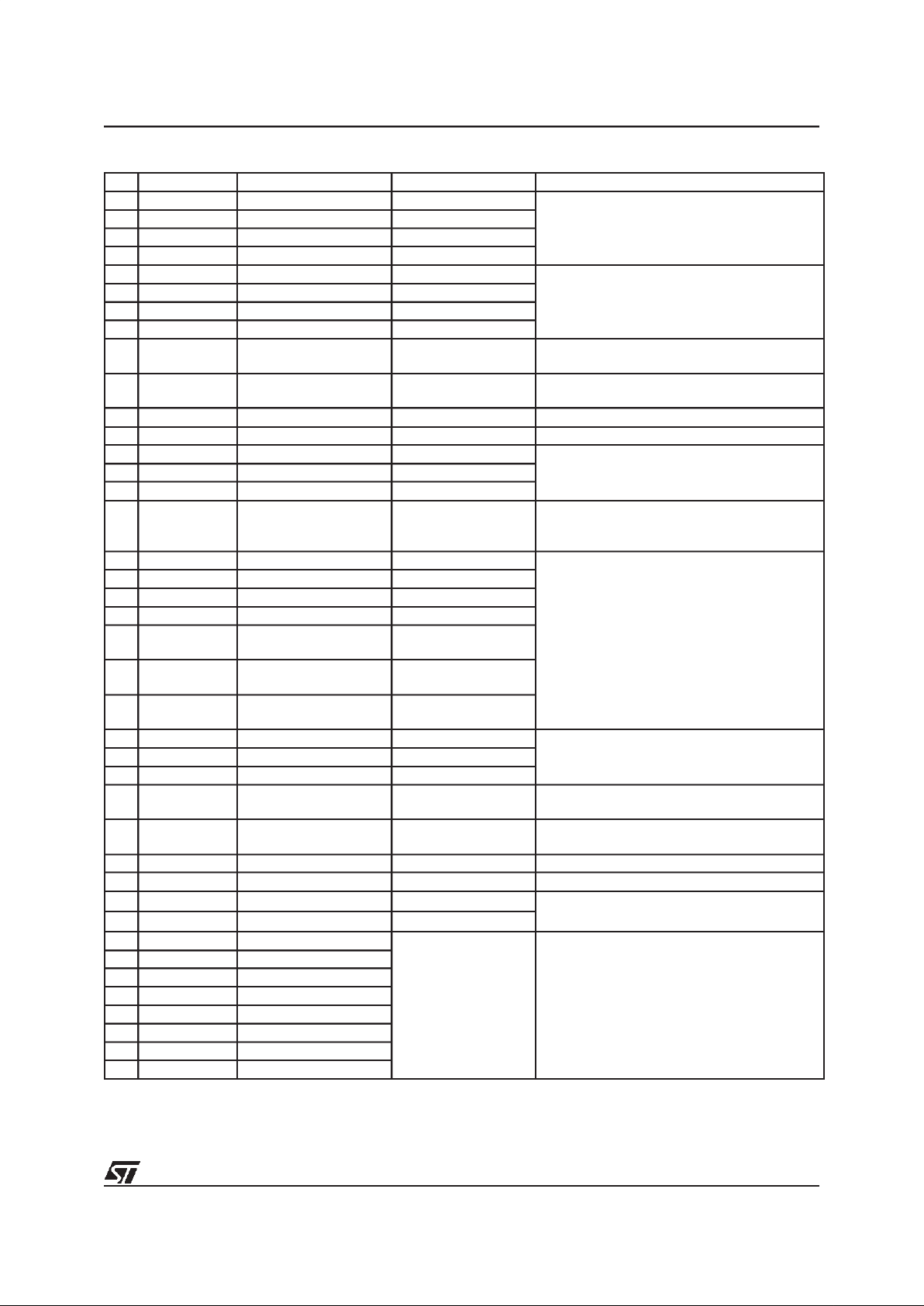

8/117

ST7285C

33 PF0 I/O Port PF0 -

Software selectable as triggered input, a push

pull output, open drain output, or triggered interrupt input with pull up (Interrupt I2).

34 PF1 I/O Port PF1 35 PF2 I/O Port PF2 36 PF3 I/O Port PF3 37 PF4 I/O Port PF4 -

Software selectable as a triggered input or as

a push pull output.

38 PF5 I/O Port PF5 39 PF6 I/O Port PF6 40 PF7 I/O Port PF7 -

41 V

SSP

Ground for Output Buffers.

- This pin is connected to pin 1.

42 V

DDP

Power Supply for Output Buffers

- This pin is connected to pin 2.

43 AINT Reserved - Must be tied to 5V

44 ARS Reserved - Must be tied to 5V

45 PG0 I/O Port PG0 -

Software selectable as triggered input or push

pull output.

46 PG1 I/O Port PG1 47 PG2 I/O Port PG2 -

48 PG3 I/O Port PG3 -

Software selectable as triggered input, a push

pull output, open drain output, or triggered interrupt input with pull up (Interrupt I1).

49 PG4 I/O Port PG4 -

Software selectable as triggered input or push

pull output. Note that PH0, 1, 2 offer alternate

function capabilities for test purposes.

50 PG5 I/O Port PG5 51 PG6 I/O Port PG6 52 PG7 I/O Port PG7 -

53

PH0/

RDSQUAL

I/O Port PH0 RDS Quality signal

54

PH1/

RDSCLKOUT

I/O Port PH1

RDS GBS Clock Out

signal

55

PH2/

RDSDATA

I/O Port PH2 RDS GBS Data signal

56 PH3 I/O Port PH3 -

Software selectable as triggered input or high

voltage (10V max) open drain output.

57 PH4 I/O Port PH4 58 PH5 I/O Port PH5 -

59 RDSCOMP RDS Comp Input signal

Used to feed theDemodulator froman external

filter when the internal filter is switched off.

60 RDSFIL

RDS Filtered Output

signal

Used for Demodulator test purposes.

61 RDSREF RDS Input Reference

62 MPX RDS input signal

63 V

DDA

Analog Power Supply

For RDS and ADC circuits

64 V

SSA

Analog Ground

65 PA0/AIN0 I/O Port PA0

Analog input to ADC

Alternate function or I/O. The I/O configuration

is software selectable as triggered input or

push pull output. Note that when a pin is used

as Analog input it must not be configured as an

output to avoid conflicts with the analog voltage to be measured.

66 PA1/AIN1 I/O Port PA1

67 PA2/AIN2 I/O Port PA2

68 PA3/AIN3 I/O Port PA3

69 PA4/AIN4 I/O Port PA4

70 PA5/AIN5 I/O Port PA5

71 PA6/AIN6 I/O Port PA6

72 PA7/AIN7 I/O Port PA7

Pin Pin Name(s) Basic Function Alternate Function Remarks

Page 9

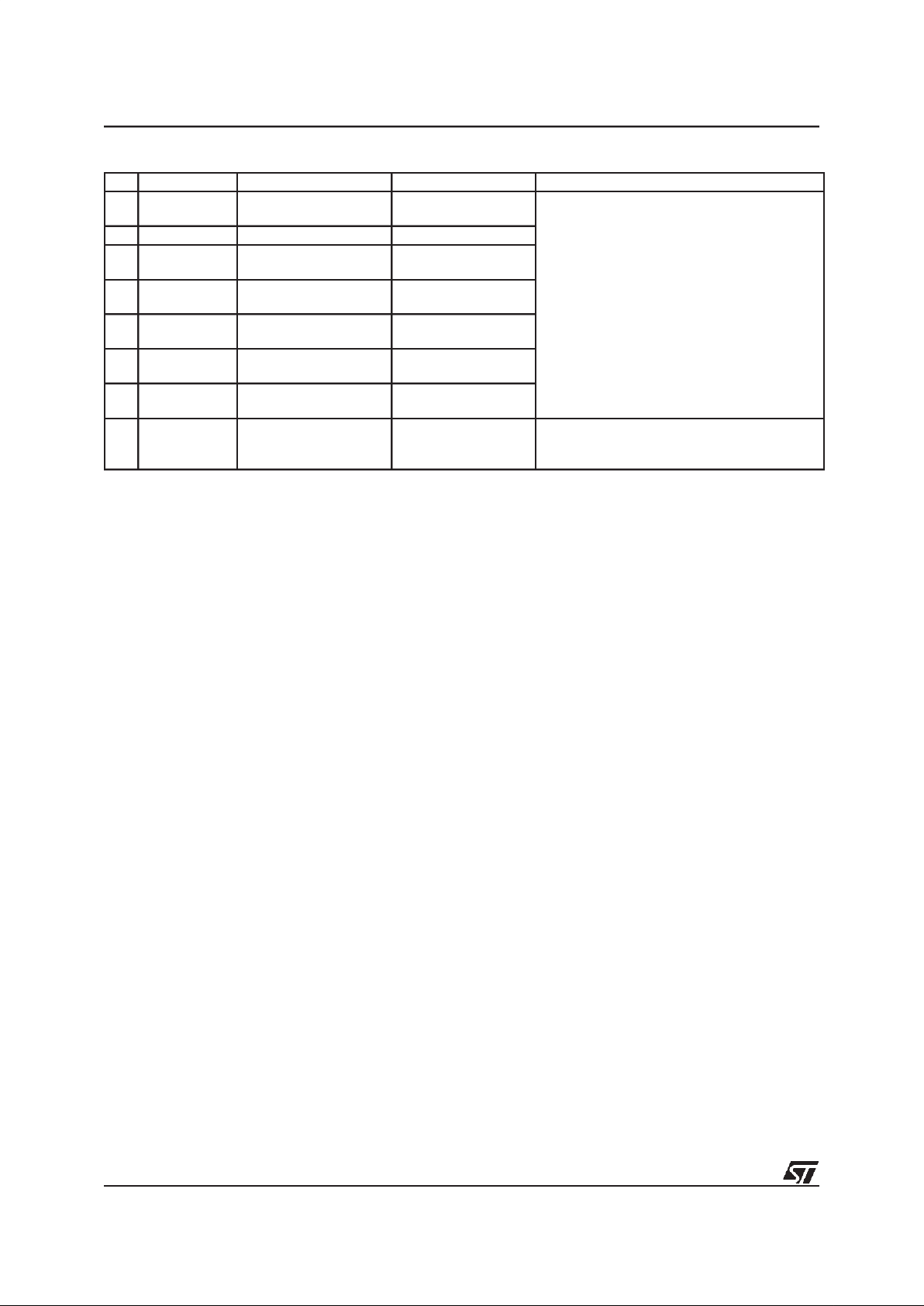

9/117

ST7285C

73 PB0/TDO I/O Port PB0

SCI Transmit Data

Out

Alternate function or I/O. The I/O configuration

is software selectable as triggered input or

push pull output.

74 PB1/RDI I/O Port PB1 SCI Receive Data In

75 PB2/IC1_A I/O Port PB2

Input capture 1

on Timer A

76 PB3/IC2_A I/O Port PB3

Input capture 2

on Timer A

77 PB4/OC1_A I/O Port PB4

Output compare 1

on Timer A

78 PB5/OC2_A I/O Port PB5

Output compare 2

on Timer A

79 PB6/CLKEXT I/O Port PB6

External Clock on

Timer A

80

PB7/BEEP/

CLKOUT

I/O Port PB7 BEEP or CPU Clock.

This pin can be a push pull output delivering

the Beep signal (2KHz) or the CPU clock, according to the miscellaneous register settings.

Pin Pin Name(s) Basic Function Alternate Function Remarks

Page 10

10/117

ST7285C

1.3 MEMORY MAP

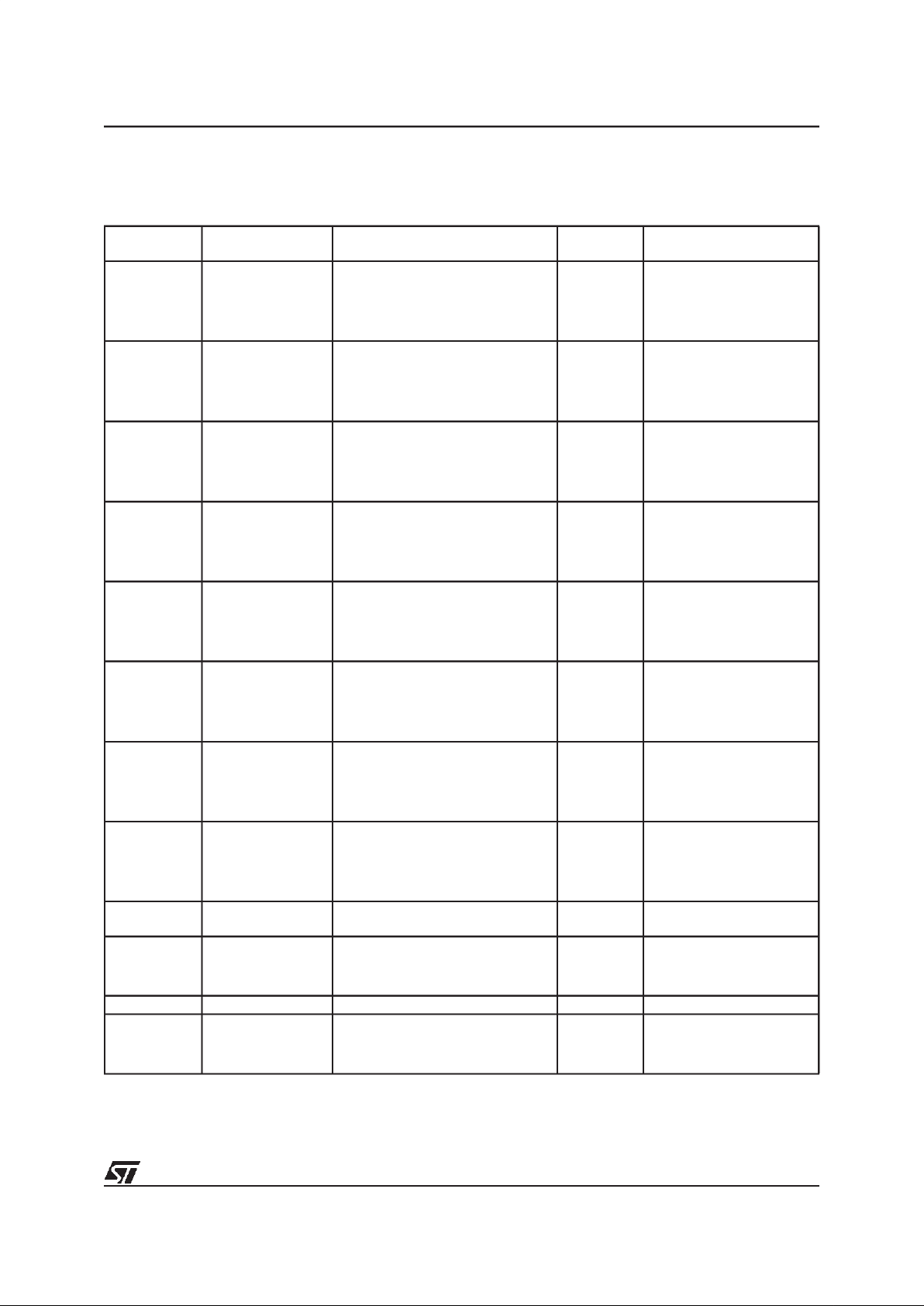

Table 1. Memory Map

Address Block Register name

Reset

Status

Remarks

0000h

0001h

0002h

0003h

Port A

Data Reg

Data Direction Reg

Not Used

Not Used

00h

00h

R/W Register

R/W Register

Absent

Absent

0004h

0005h

0006h

0007h

Port B

Data Reg

Data Direction Reg

Not Used

Not Used

00h

00h

R/W Register

R/W Register

Absent

Absent

0008h

0009h

000Ah

000Bh

Port C

Data Reg

Data Direction Reg

Option Reg

Not Used

00h

00h

--00----b

R/W Register

R/W Register

R/W Register

Absent

000Ch

000Dh

000Eh

000Fh

Port D

Data Reg

Data Direction Reg

Option Reg

Not Used

00h

00h

--00----b

R/W Register

R/W Register

R/W Register

Absent

0010h

0011h

0012h

0013h

Port E

Data Reg

Data Direction Reg

Not Used

Not Used

00h

00h

R/W Register

R/W Register

Absent

Absent

0014h

0015h

0016h

0017h

Port F

Data Reg

Data Direction Reg

Option Reg

Not Used

00h

00h

----0000b

R/W Register

R/W Register

R/W Register

Absent

0018h

0019h

001Ah

001Bh

Port G

Data Reg

Data Direction Reg

Option Reg

Not Used

00h

00h

----0---b

R/W Register

R/W Register

R/W Register

Absent

001Ch

001Dh

001Eh

001Fh

Port H

Data Reg

Data Direction Reg

Not Used

Not Used

00h

00h

R/W Register

R/W Register

Absent

Absent

0020h

Miscellaneous Reg-

ister

00h see register description

0021h

0022h

0023h

SPI A

Data I/O Reg

Control Reg

Status Reg

XXh

0xh

00h

R/W Register

R/W Register

Read Only Register

0024h WDG Watchdog register 7Fh see register description

0025h

0026h

0027h

SPI B

Data I/O Reg

Control Reg

Status Reg

XXh

0xh

00h

R/W Register

R/W Register

Read Only Register

Page 11

11/117

ST7285C

0028h

0029h

002Ah

002Bh

002Ch

002Dh

002Eh

I

2

C

CR: Control Register

SR1: Status Register 1

SR2: Status Register 2

CCR: Clock Control Register

OAR1: Own Address Register 1

OAR2: Own Address Register 2

DR: Data Register

00h

00h

00h

00h

00h

00h

00h

R/W Register

Read Only Register

Read Only Register

R/W Register

R/W Register

R/W Register

R/W Register

002Fh

0030h

RESERVED

0031h

0032h

0033h

0034h

0035h

0036h

0037h

0038h

0039h

003Ah

003Bh

003Ch

003Dh

003Eh

003Fh

Timer A

Control Reg2

Control Reg1

Status Reg

Input Capture1 High Register

Input Capture1 Low Register

Output Compare1 High Register

Output Compare1 Low Register

Counter High Register

Counter Low Register

Alternate Counter High Register

Alternate Counter Low RegisteR

Input Capture2 High Register

Input Capture2 Low Register

Output Compare2 High Register

Output Compare2 Low Register

00h

00h

XXh

XXh

XXh

XXh

XXh

FFh

FCh

00h

00h

XXh

XXh

XXh

XXh

R/W Register

R/W Register

Read Only Register

Read Only Register

Read Only Register

R/W Register

R/W Register

Read Only Register

Read Only Register

Read Only Register

Read Only Register

Read Only Register

Read Only Register

R/W Register

R/W Register

0040h RESERVED

0041h

0042h

0043h

0044h

0045h

0046h

0047h

0048h

0049h

004Ah

004Bh

004Ch

004Dh

004Eh

004Fh

Timer B

Control Reg2

Control Reg1

Status Reg

Input Capture1 High Register

Input Capture1 Low Register

Output Compare1 High Register

Output Compare1 Low Register

Counter High Register

Counter Low Register

Alternate Counter High Register

Alternate Counter Low Register

Input Capture2 High Register

Input Capture2 Low Register

Output Compare2 High Register

Output Compare2 Low Register

00h

00h

XXh

XXh

XXh

XXh

XXh

FFh

FCh

00h

00h

XXh

XXh

XXh

XXh

R/W Register

R/W Register

Read Only Register

Read Only Register

Read Only Register

R/W Register

R/W Register

Read Only Register

Read Only Register

Read Only Register

Read Only Register

Read Only Register

Read Only Register

R/W Register

R/W Register

0050h

0051h

0052h

0053h

0054h

0055h

0056h

0057h

SCI

SCI Prescaler

SCSR: Status Register

SCDR: Data Register

SCBRR: Baud Rate Register

SCCR1: Control Register 1

SCCR2: Control Register 2

PSCBRR: Receive Baud Rate Reg

Reserved

PSCBRT: Transmit Baud Rate Reg

1100000xb

XXh

00x----xb

XXh

00h

00h

---

00h

Read Only Register

R/W Register

R/W Register

R/W Register

R/W Register

R/W Register

Reserved ST use

R/W Register

0058h RESERVED

0059h RESERVED

005Ah

005Bh

RDS Filter

RDS FI1

RDS FI2

R/W Register

R/W Register

Address Block Register name

Reset

Status

Remarks

Page 12

12/117

ST7285C

005Ch

005Dh

005Eh

005Fh

RDS Demodulator

RDS DE1

RDS DE2

RDS DE3

RDS DE4

see register description

0060h

0061h

0062h

0063h

0064h

0065h

0066h

0067h

0068h

0069h

006Ah

006Bh

006Ch

006Dh

006Eh

006Fh

RDS GBS

SR0 -Shift Reg 0

SR1 -Shift Reg 1

SR2 -Shift Reg 2

SR3 -Shift Reg 3

SY0 -Polynomial Reg 0

SY1 -Polynomial Reg 1

GS_CNT Count Reg

GS_INT Interrupt Reg

DR0 -RDSDAT Reg 0

DR1 -RDSDAT Reg 1

DR2 -RDSDAT Reg 2

DR3 -RDSDAT Reg 3

QR0 -QUALITY Reg 0

QR1 -QUALITY Reg 1

QR2 -QUALITY Reg 2

QR3 -QUALITY Reg 3

see register description

0070h

0071h

ADC

Data Reg

Control/Status Reg

XXh

00h

Read Only Register

R/W Register

0072h to

007Fh

RESERVED

0080h to

0BFFh

0C00h to

0C7Fh

RAM 3K Bytes

of which

STACK 128 Bytes

User variables and subroutine nesting

0C80h to

3FFFh

RESERVED

4000h to

FFDFh

ROM 48K bytes

(49120 bytes)

User application code and data

FFE0h to

FFFFh

User vectors Interrupt and Reset Vectors

Address Block Register name

Reset

Status

Remarks

Page 13

13/117

ST7285C

2 CENTRAL PROCESSING UNIT

2.1 INTRODUCTION

The CPU has a full 8-bit architecture. Six internal

registers allow efficient 8-bit data manipulation.

The CPU is capable of executing 63 basic instructions and features 17 main addressing modes.

2.2 CPU REGISTERS

The 6 CPU registers are shown in the programming model inFigure 2. Following an interrupt, all

registers except Y are pushed onto the stack in the

order shown in Figure 3. They are popped from

stack in the reverse order.

Accumulator (A). The Accumulator is an 8-bit

general purpose register used to hold operands

and the results of the arithmetic and logic calculations as well as data manipulations.

Index Registers (X and Y).These 8-bit registers

are used to create effective addresses or as temporary storage areas for data manipulation. The

Cross-Assembler generates a PRECEDE instruction (PRE) to indicate that the following instruction

refers to the Y register. The Y register is never automatically stacked. Interrupt routines must push

or pop it by using the PUSH and POP instructions.

Program Counter (PC).The program counter is a

16-bit register containing the address of the next

instruction to be executed by the CPU.

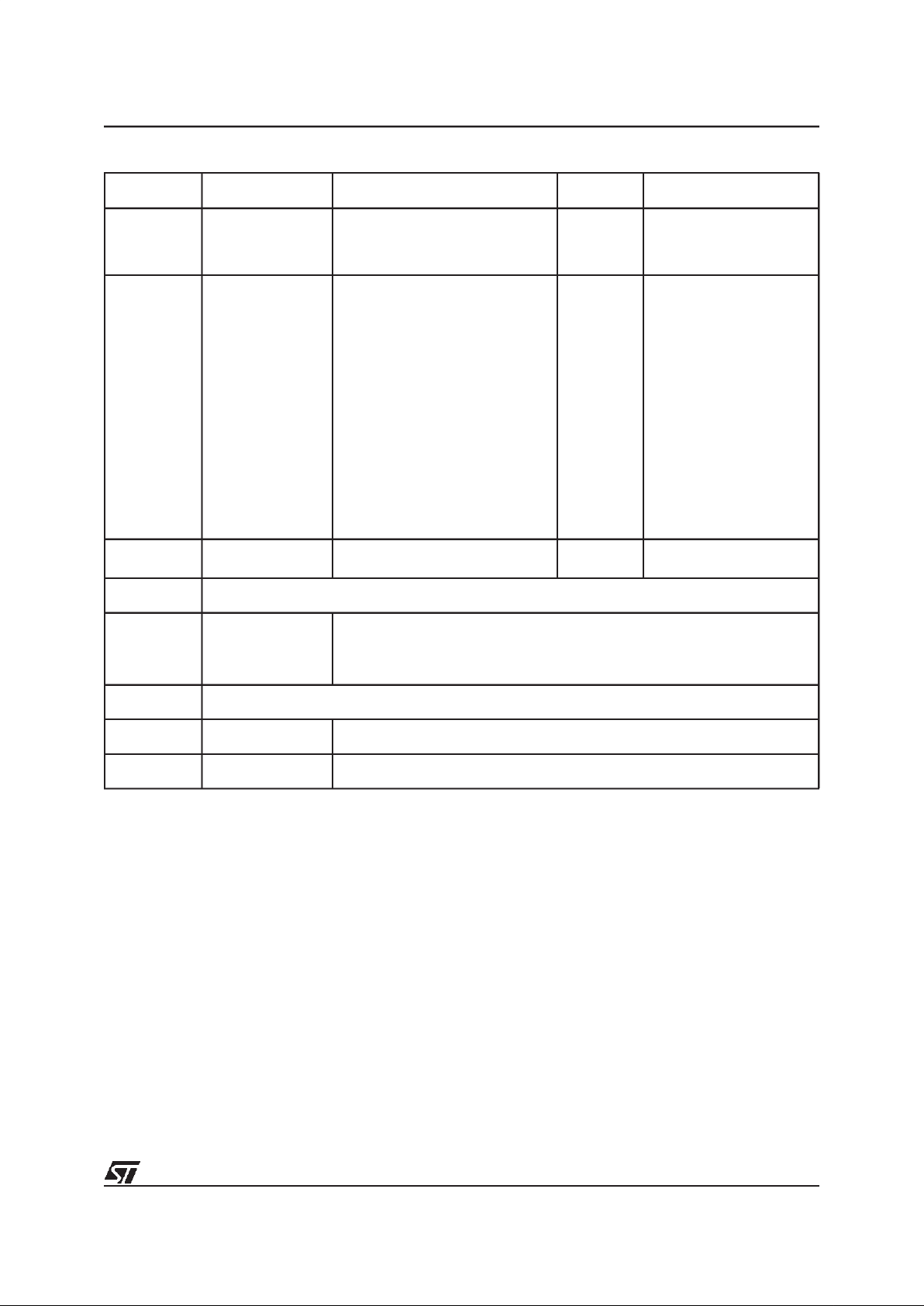

Figure 2. Organization of Internal CPU Registers

ACCUMULATOR:

X INDEX REGISTER:

Y INDEX REGISTER:

PROGRAM COUNTER:

STACKPOINTER:

CONDITION CODE REGISTER:

X = Undefined

RESET VALUE:

70

XXXXXXXX

RESET VALUE:

70

XXXXXXXX

RESET VALUE:

70

XXXXXXXX

15

70

RESET VALUE = DEVICE DEPENDENT,SEE MEMORY MAP

RESET VALUE:

70

XXXXXXXX

15

70

RESET VALUE = DEVICE DEPENDENT,SEE MEMORY MAP

Page 14

14/117

ST7285C

CPU REGISTERS(Cont’d)

Stack Pointer (SP) The Stack Pointer is a 16-bit

register. Since the stack size can vary from device

to device, the appropriate number of most significant bits are forced so as to map the stack as defined in the Memory Map. The number of least significant digits thus available tothe user will depend

on the stack size, for example in the case of a 128

byte stack, 7 bits will be available whereas in the

case of a64 byte stack, only 6 bits will beavailable.

The stack is used to save the CPU context during

subroutine calls or interrupts. The user may also

directly manipulate the stack by means of the

PUSH and POP instructions.

Following an MCU Reset, or after a Restore following a Reset Stack Pointer instruction (RSP),

the StackPointer is set to point to thehighest location in the stack. It is then decremented after data

has been pushed onto the stack and incremented

after data is popped from the stack. When the lower limit is exceeded, the Stack Pointer wraps

around to the stack upper limit. The previously

stored information is then overwritten and therefore lost. The upper and lower limits of the stack

area are shown in the Memory Map.

A subroutine call occupies two locations and an interrupt five locations in the stack area.

Condition Code Register (CC) The Condition

Code register is a 5-bit register which indicates the

result of the instruction just executed as wellas the

state of the processor. These bits can be individually tested by a program and specified action taken

as a result of their state. The following paragraphs

describe each bit of the CC register in turn.

Half carry bit (H)The H bit is set to 1 when acarry

occurs between bits 3 and 4 of the ALU during an

ADD or ADC instruction. The H bit is useful in BCD

arithmetic subroutines.

Interrupt mask (I) When the I bit is set to 1, all interrupts except the TRAP software interrupt are

disabled. Clearing this bit enables interrupts to be

passed to the processor core. Interrupts requested

while I is set are latched and can be processed

when I is cleared (only one interrupt request per interrupt enable flag can be latched).

Negative (N)

When set to 1, this bit indicates that

the result of the last arithmetic, logical or data manipulation is negative (i.e. the most significant bit is

a logic 1).

Zero (Z)

When set to 1, this bit indicates that the

result of the last arithmetic, logical or data manipulation is zero.

Carry/Borrow (C) When set, C indicates that a

carry or borrow out of the ALU occured during the

last arithmetic operation. This bit is also affected

during execution of bit test, branch, shift, rotate

and store instructions.

Figure 3. Stacking Order

INCREASING

MEMORY

UNSTACK

ACCUMULATOR

X INDEX REGISTER

PCH

PCL

(PUSH)

DECREASING

MEMORY

111

VR000074

07

ADDRESSES

ADDRESSES

STACK

(POP)

CONDITION CODE

RETURN

INTERRUPT

Page 15

15/117

ST7285C

3 CLOCKS, RESET, INTERRUPTS & POWER SAVING MODES

3.1 CLOCK SYSTEM

3.1.1 General Description

The MCU accepts either a Crystal or Ceramic resonator, or an external clock signal to drive the internal oscillator. The internal clock (CPU CLK running at f

CPU

) is derived from the external oscillator

frequency (f

OSC).

The external Oscillator clock is

first divided by 2, and an additional division factor

of 2, 4, 8, or 16 can be applied, in Slow Mode, to

reduce the frequency of the CPU clock (see

note 1); this clock signal is also routed to the onchip peripherals. The CPU clock signal consists of

a square wave with a duty cycle of 50%.

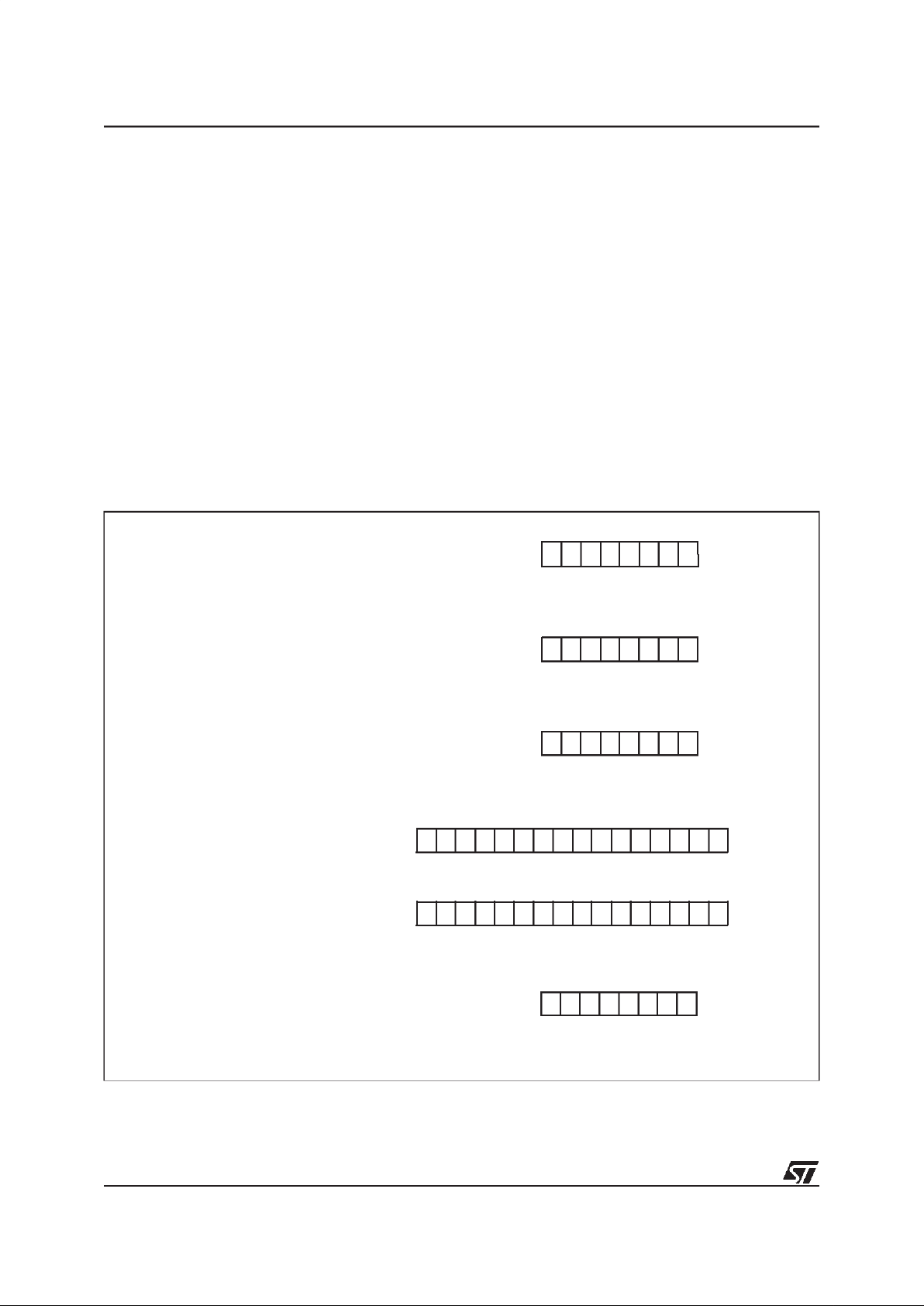

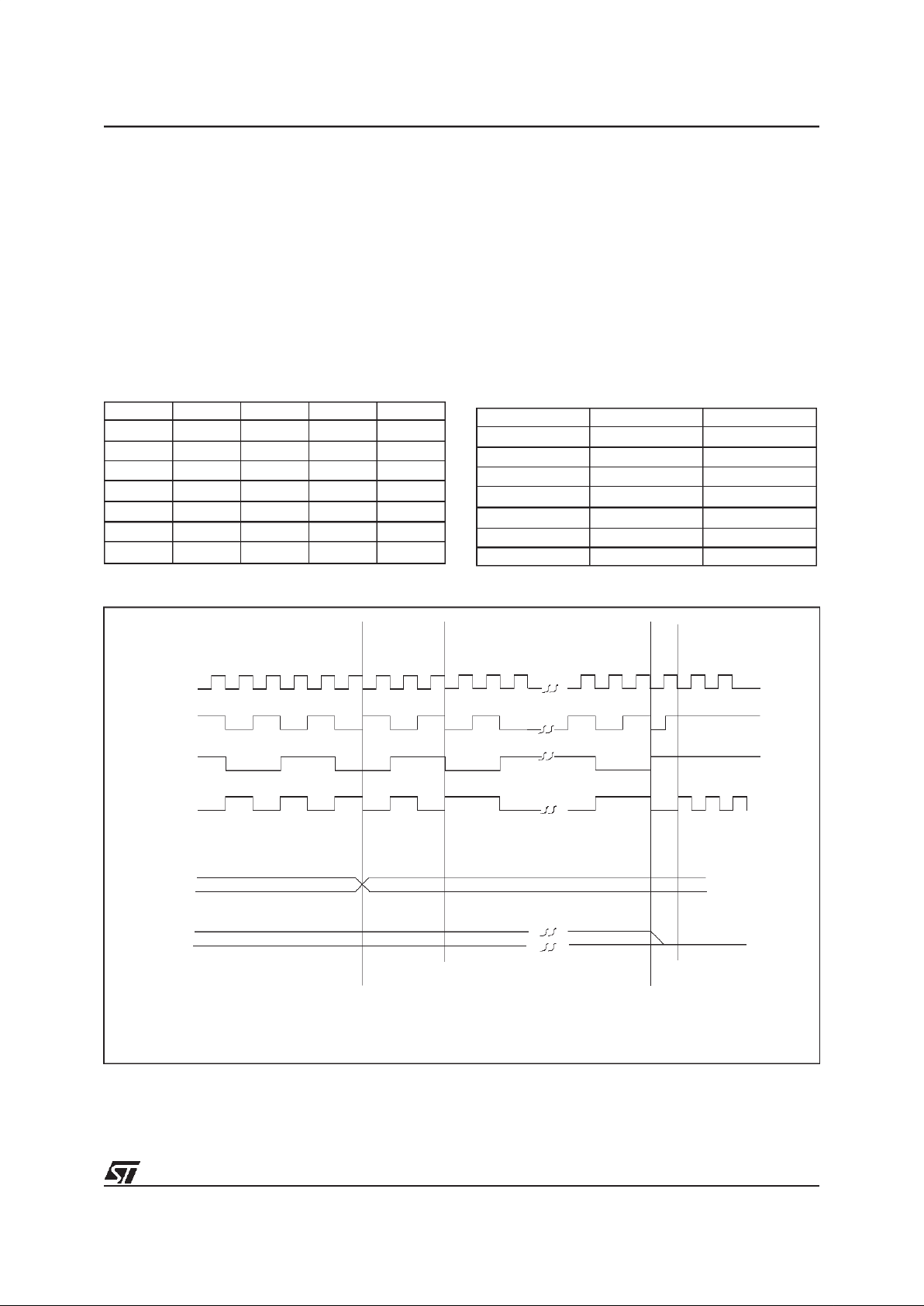

Figure 4. External Clock Source Connections

Figure 5. Equivalent Crystal Circuit

3.1.2 Crystal Resonator

The internal oscillator is designed to operate with

an AT-cut parallel resonant quartz crystal resonator in the frequency range specified for f

osc

.The

circuit shown in Figure 6 is recommended when

using a crystal, andTable 2 lists the recommended capacitance and feedback resistance values.

The crystal and associated components should be

mounted as close as possible to the input pins in

order to minimize output distortion and start-up

stabilisation time.

Use of an external CMOS oscillator is recommended when crystals outside the specified frequency ranges are to be used.

Figure 6. Crystal/Ceramic Resonator

Figure 7. Clock Prescaler Block Diagram

Note 1: Additional division factor of CPU clock is only available on L5/L6.

OSC

in

OSC

out

EXTERNAL

CLOCK

NC

OSC

in

OSC

out

R

S

L

1

C

1

C

0

OSC

in

OSC

out

C

OSCin

C

OSCout

R

P

OSC

in

OSC

out

C

OSCin

C

OSCout

R

P

%2 %2,4,8,16

CPUCLK

to CPU and

Peripherals

Page 16

16/117

ST7285C

CLOCK SYSTEM (Cont’d)

3.1.3 Ceramic Resonator

A ceramic resonator may be used as an alternative to a crystal in low-cost applications. The circuit

shown in Figure 6 is recommended when using a

ceramic resonator. Table 3 lists the recommended

feedback capacitance and resistance values. The

manufacturer of the particular ceramic resonator

being considered should be consulted for specific

information.

Table 2. Recommended Values for Crystal

Resonator

3.1.4 External Clock

An external clock may be applied to the OSCin input with the OSCout pin not connected, as shown

on Figure 4. The t

OXOV

and t

ILCH

specifications do

not apply when using an external clock input. The

equivalent specification of the external clock

source should be used instead of t

OXOV

or t

ILCH

.

See CONTROL TIMING SECTION.

Table 3.Recommended Values for Ceramic

Resonator

Figure 8. Timing Diagram for Internal CPU Clock Frequency transistions

2MHz 4MHz 8MHz Unit

R

SMAX

400 75 60 Ω

C

0

5 7 10 pF

C

1

81215fF

C

OSCin

15-40 15-30 15-25 pF

C

OSCout

15-30 15-25 15-20 pF

R

P

10 10 10 MΩ

Q304060

10

3

2-8MHz Unit

R

SMAX

10 Ω

C

0

40 pF

C

1

4.3 pF

C

OSCin

30 pF

C

OSCout

30 pF

R

P

1-10 MΩ

Q 1250

MISCELLANEOUS REGISTER

00 10

1

10

VR02062B

New frequency

requested

New frequency

active when

f

OSC

/4 & f

OSC

/8 = 0

Normalmode

active

Normalmode

requested

PSM1:PSM0

SMS

f

OSC

/2

f

OSC

/4

f

OSC

/8

f

CPU

Page 17

17/117

ST7285C

3.2 MISCELLANEOUS REGISTER

The Miscellaneous register allows one to select

the SLOW operating mode and to set the clock division prescaler factor. Bits 3 and 4 allow one to

set PB7 functionality (I/O, CPU Clock o/p or Beep

signal o/p), while bits 6 and 7 determine the signal

conditions which will trigger an interrupt request on

I/O pins having interrupt capability.

Register Address: 0020h — Read/Write

Reset Value: 00h

b7, b6 -

EI1, EI0

:

External Interrupt Option

0 0 - Negative edge and low level (Reset state)

1 0 - Negative edge only

0 1 - Positive edge only

1 1 - Positive and negative edge

This selection applies globally to the four external

interrupts: I1, I2, I9 and I10.

b6 and b7 can be written only when the Interrupt

Mask (I) of the CC (Condition Code) register is set

to 1.

b5- Reserved

b4, b3 - SK1, CK0

:

Clock/Beep Output

0 0 - I/O port (Reset state)

1 0 - I/O port

0 1 - CPU Clock output to pin PB7

1 1 - 2KHz Beep signal output to pin PB7

(at 8.664 MHz oscillator frequency)

b2, b1 - SM1,SM0:

CPU clock prescaler for Slow

Mode

0 0 - Oscillator frequency / 4

1 0 - Oscillator frequency / 8

0 1 - Oscillator frequency / 16

1 1 - Oscillator frequency / 32

b0 - SMS:

Slow Mode Select

0- Normal mode - Oscillator frequency / 2

(Reset state)

1- Slow mode (Bits b1 and b2 define the prescaler

factor)

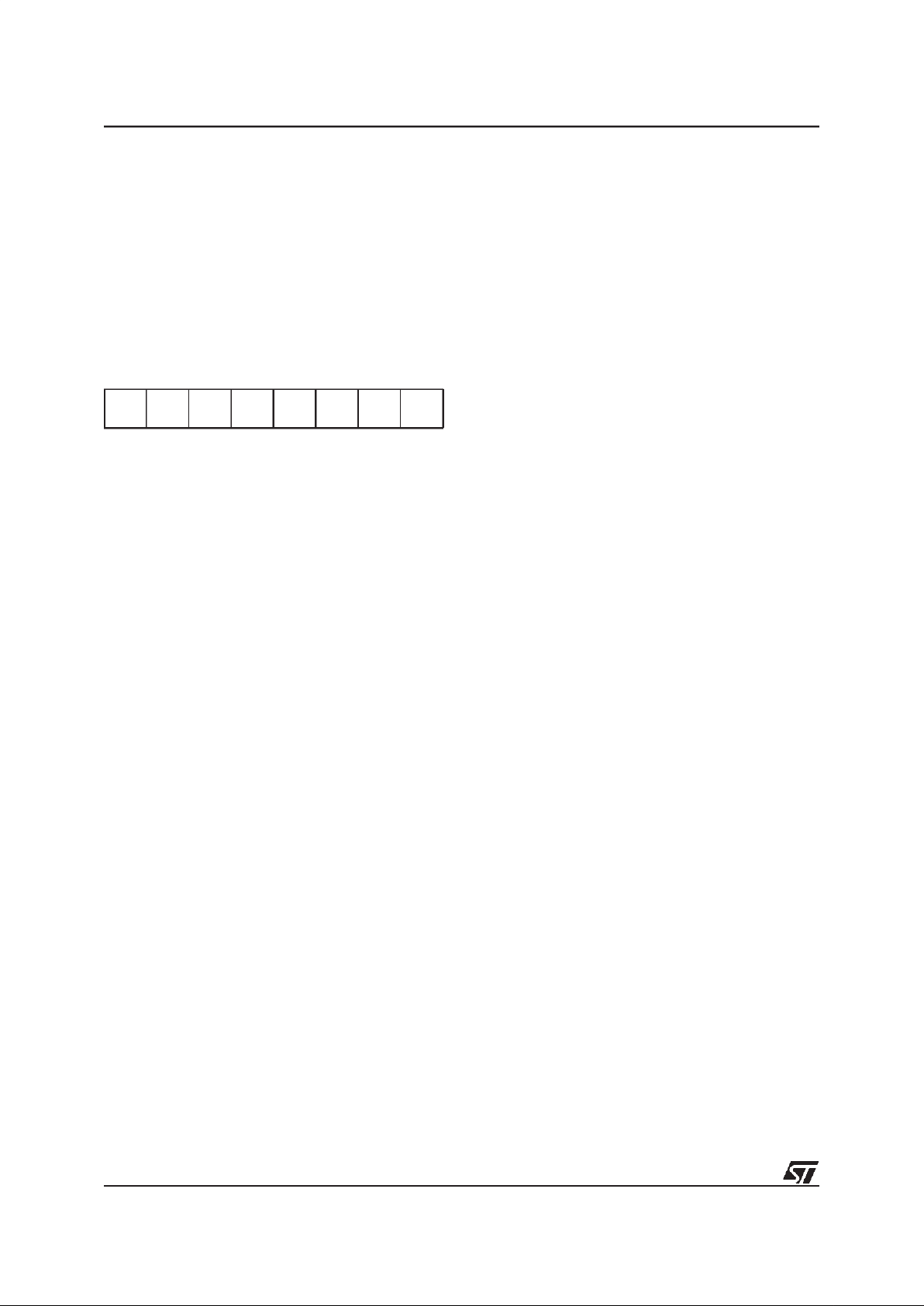

70

EI1 EI0 b5 SK1 CK0 SM1 SM0 SMS

Page 18

18/117

ST7285C

3.3 RESETS

3.3.1 Introduction

There are four sources of Reset:

– RESET pin (external source)

– Power-On Reset (Internal source)

– WATCHDOG (Internal Source)

The Reset Service Routine vector is located at ad-

dress FFFEh-FFFFh.

3.3.2 External Reset

The RESET pin is both an input and an open-drain

output with integrated pull up resistor. When one

of the internal Reset sources is active, the Reset

pin is driven low to reset the whole application.

3.3.3 Reset Operation

The duration of the Reset condition, which is also

reflected on the output pin, is fixed at4096 internal

CPU Clock cycles. A Reset signal originating from

an external source must have a duration of at least

1.5 internal CPU Clock cycles in order to be recognised. At the end of the Power-On Reset cycle, the

MCU may be held in the Reset condition by an External Reset signal. The RESET pin may thus be

used to ensure VDDhas risen to a point where the

MCU can operate correctly before the User program is run. Following a Reset event, or after exit-

ing Halt mode, a 4096 CPU Clock cycle delay period is initiated in order to allow the oscillator to

stabilise and to ensure that recovery has taken

place from the Reset state.

During the Reset cycle, the device Reset pin acts

as an output that is pulsed low for 3 machine cycles (6 oscillator cycles). In its high state, an internal pull-up resistor of about 300KΩ is connected to

the Reset pin. This resistor can be pulled low by

external circuitry to reset the device.

3.3.4 Power-on Reset

This circuit detects the ramping up of VDD,and

generates a pulse thatis used to reset the application (at approximately VDD= 2V).

Power-On Reset is designed exclusively to cope

with power-up conditions, and should not be used

in order to attempt to detect a drop in the power

supply voltage.

Caution:

to re-initialize the Power-On Reset, the

power supply must fall below approximately 0.8V

(Vtn), prior to rising above 2V. If this condition is

not respected, on subsequent power-up the Reset

pulse may not be generated. An external pulse

may be required to correctly reactivate the circuit.

Figure 9. Reset Block Diagram

VDD

COUNTER

RESET

to ST7

VR2062C

300K

WATCHDOG RESET

OR DLPSS

RESET

OSCILLATOR

SIGNAL

INTERNAL

RESET

Page 19

19/117

ST7285C

3.4 WATCHDOG TIMER SYSTEM (WDG)

3.4.1 Introduction

The Watchdog timer is used to detect the occurence of a software fault, usually generated by

external interference or by unforeseen logical conditions, which causes the application program to

abandon its normal sequence. The Watchdog circuit generates an MCU reset on expiry of a programmed time period, unless the program refreshes the counter’s contents before it is decremented

to zero.

3.4.2 Functional Description

The counter is decremented every 12,288 machine cycles, and the length of the timeout period

can be programmed by the user in 64 increments,

ranging from 12,288 machine cycles to 786,432

machine cycles, depending on the value loaded in

bits 0-5 of the Watchdog register. The application

program must be written so that the Watchdog

register is reloaded at regular intervals during normal operation.

The Watchdog is not activated automatically on

Reset, and must be activated by the user program

if required. Once activated it cannot be disabled,

save by a Reset.

During the Reset cycle, the device Reset pin acts

as an output that is pulsed low for 3 machine cycles (6 oscillator cycles). In its high state, an internal pull-up resistor of about 100KΩis connected to

the Reset pin.

This resistor can be pulled low by external circuitry

to reset the device.

The Watchdog delay time is defined by bits 5-0 of

the Watchdog register; bit 6 must always be set in

order to avoid generating an immediate reset.

Conversely, this can be used to generate a software reset (bit 7 = 1, bit 6 = 0).

Once bit 7 is set, it cannot be cleared by software:

i.e. the Watchdog cannot be disabled by software

without generating a Reset. The Watchdog timer

mustbe reloaded before bit 6 is decremented to ”0”

to avoid a Reset. Following a Reset, the Watchdog

register will contain 7Fh (bits 0-6 = 1, bit 7 = 0).

If the Watchdog is activated, the HALT instruction

will generate a Reset.

If the circuit is not used as a Watchdog (i.e. bit 7 is

never set), bits 6 to 0 may be used as a simple 7bit timer, for instance as a real time clock. Since no

interrupt will be generated under these conditions,

the Watchdog register must be monitored by software.

3.4.3 Watchdog Register

Register Address: 0024h — Read/Write

Reset Value: 0111 1111 (7Fh)

b7 = WDGA: Activation bit (is active if set)

b6-0 =

T6-T0

: 7-bit timer counter (Msb to Lsb)

Table 4. Watchdog Timing (f

OSC

= 8 MHz)

70

WDGA T6 T5 T4 T3 T2 T1 T0

WDG Register initial

value

WDG timeout period (ms)

FF 197

C0 3

Page 20

20/117

ST7285C

3.5 INTERRUPTS

A list of interrupt sources is given inTable 5below,

together with relevant details for each source. Interrupts are serviced according to their order ofpriority, starting with I0, which has the highest priority, and so to I11, which has the lowest priority.

The following list describes the origins for each interrupt level:

– I0 connected to Software Interrupt (TRAP)

– I1 connected to Port G3

– I2 connected to Port F0, F1, F2, F3

– I3 connected to SPI A

– I4 connected to Timer A

– I5 connected to GBS interrupt

– I6 connected to Timer B

– I7 connected to SPI B

– I8 connected to SCI

– I9 connected to Ports D4, D5

– I10 connected to Ports C4, C5

– I11 connected to I2C

Exit from HALT mode may only be triggered by an

External Interrupt on one of the following ports:

C4(I10), C5(I10), D4(I9), D5(I9), F0(I2), F1(I2),

F2(I2), F3(I2) and G3(I1).

If more than one input pin of a group connected to

the same interrupt line is selected simultaneously,

these will be logically ORed.

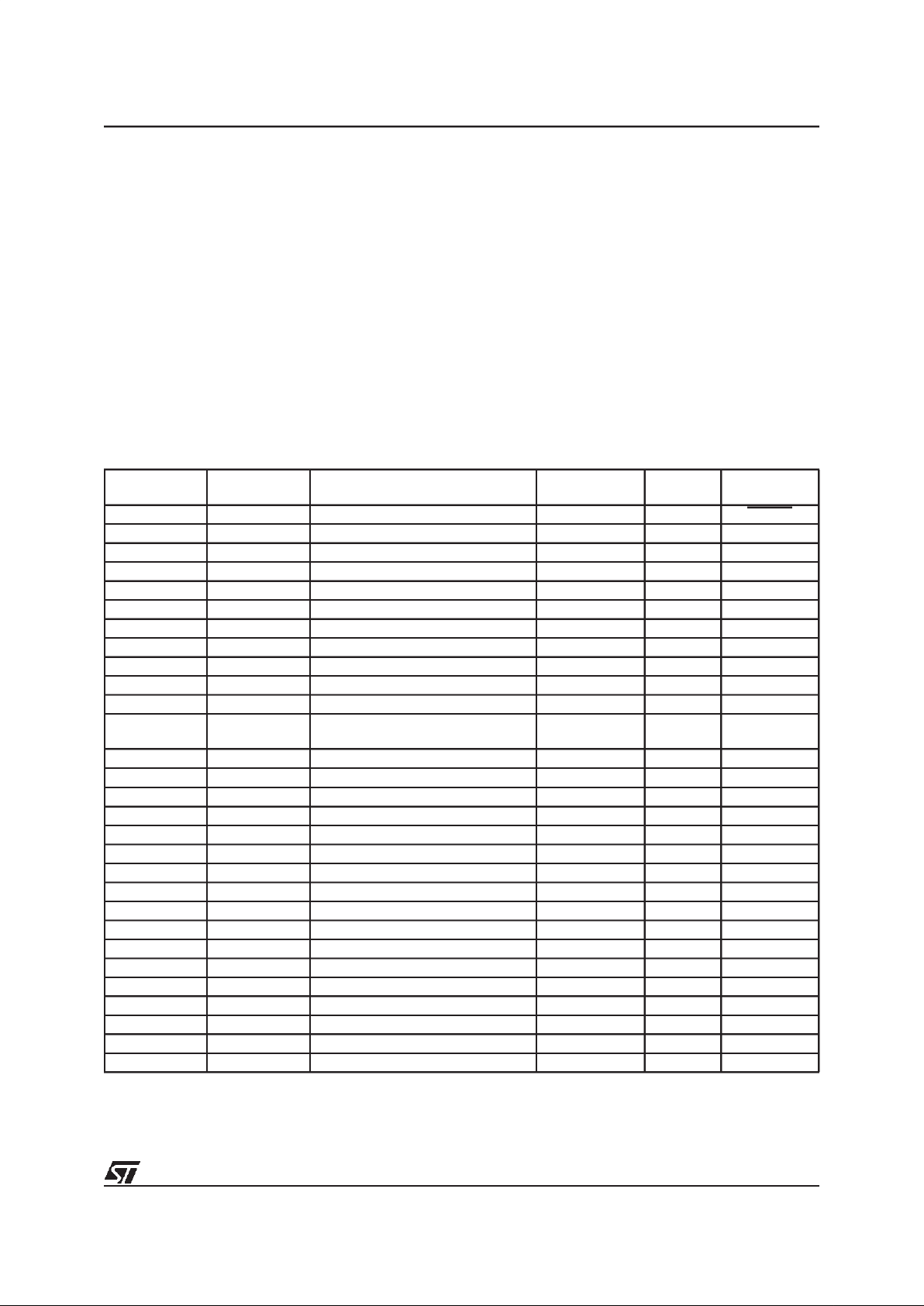

Table 5. Interrupt Mapping

Interrupt

source

Vector

Address

Interrupts Register

Flag

name

CPU

interrupts

- FFFEh-FFFFh Reset N/A N/A RESET

I0 FFFCh-FFFDh Software N/A N/A TRAP

I1 FFFAh-FFFBh Ext. Interrupt (Port G3) N/A N/A INT1

I2 FFF8h-FFF9h Ex. Interrupt (Ports F0, F1, F2, F3) N/A N/A INT2

I3 FFF6h-FFF7h Transfer Complete SPI A Status SPIF1_A SPI_A

“ “ Mode Fault “ MODF1_A “

I4 FFF4h-FFF5h Input Capture 1 Timer A Status ICF1_A TIMER_A

“ “ Output Compare 1 “ OCF1_A “

“ “ Input Capture 2 “ ICF2_A “

“ “ Output Compare 2 “ OCF2_A “

“ “ Timer Overflow “ TOF_A “

I5 FFF2h-FFF3h RDS Block Interrupt. RDS GRP

VSI

CNI

GBS

I6 FFF0h-FFF1h Input Capture 1 Timer B Status ICF1_B TIMER_B

“ “ Output Compare 1 “ OCF1_B “

“ “ Input Capture 2 “ ICF2_B “

“ “ Output Compare 2 “ OCF2_B “

“ “ Timer Overflow “ TOF_B “

I7 FFEEh-FFEFh Transfer Complete SPI B Status SPIF2_B SPI_B

“ “ Mode Fault “ MODF1_B “

I8 FFECh-FFEDh Transmit Buffer Empty SCI Status TDRE SCI

“ “ Transmit Complete “ TC “

“ “ Receive Buffer Full “ RDRF “

“ “ Idle Line Detect “ IDLE “

“ “ Overrun “ OR “

I9 FFEAh-FFEBh Ext. Interrupt (Ports D4,D5) N/A N/A INT9

I10 FFE8h-FFE9h Ext. Interrupt (Port C4, C5) N/A N/A INT10

I11 FFE6h-FFE7h Byte Transmission Finished I

2

C Status BTF I2C

“ “ Bus Error “ BERR I2C

“ “ Stop Detection “ SSTOP I2C

Page 21

21/117

ST7285C

INTERRUPTS (Cont’d)

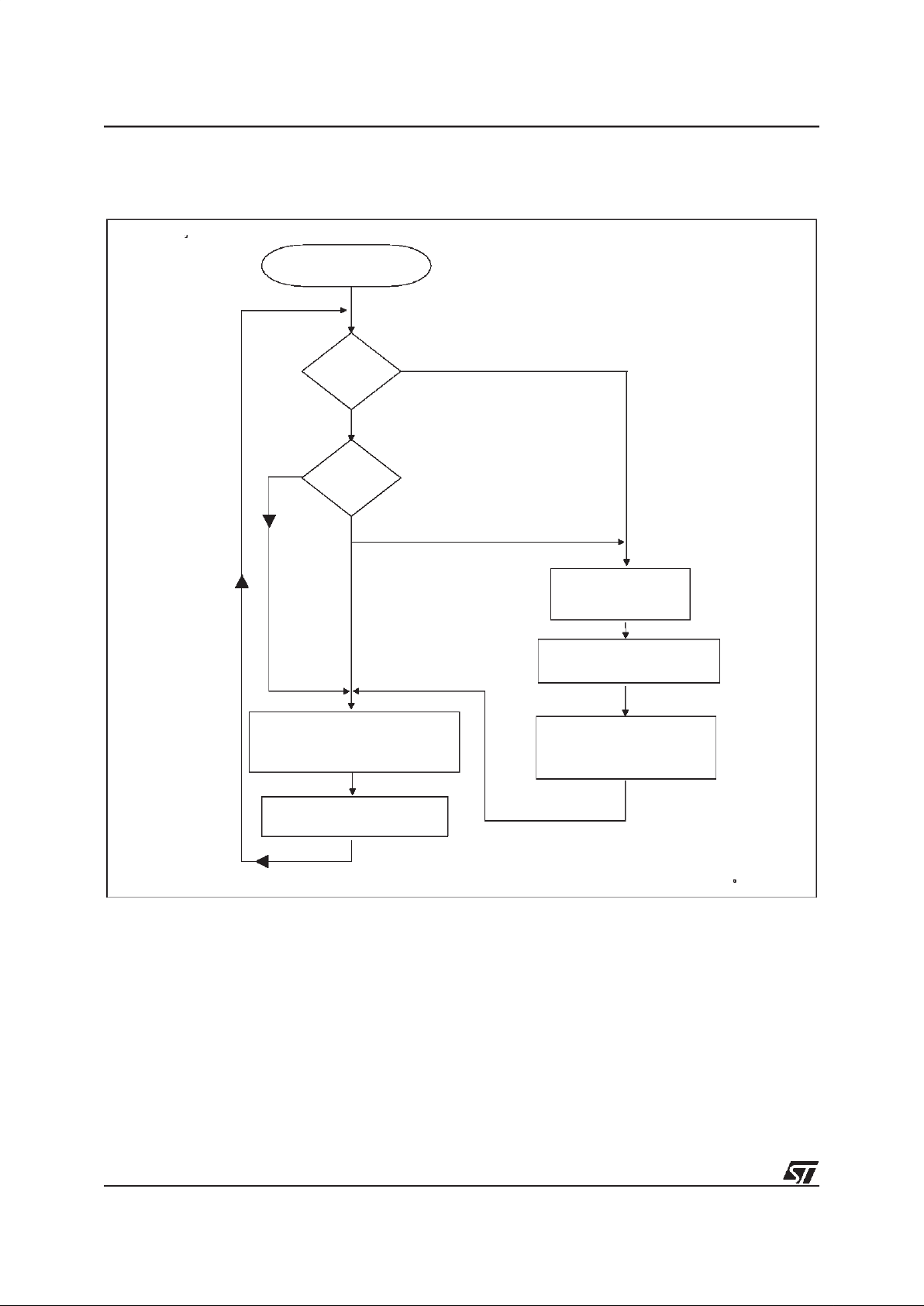

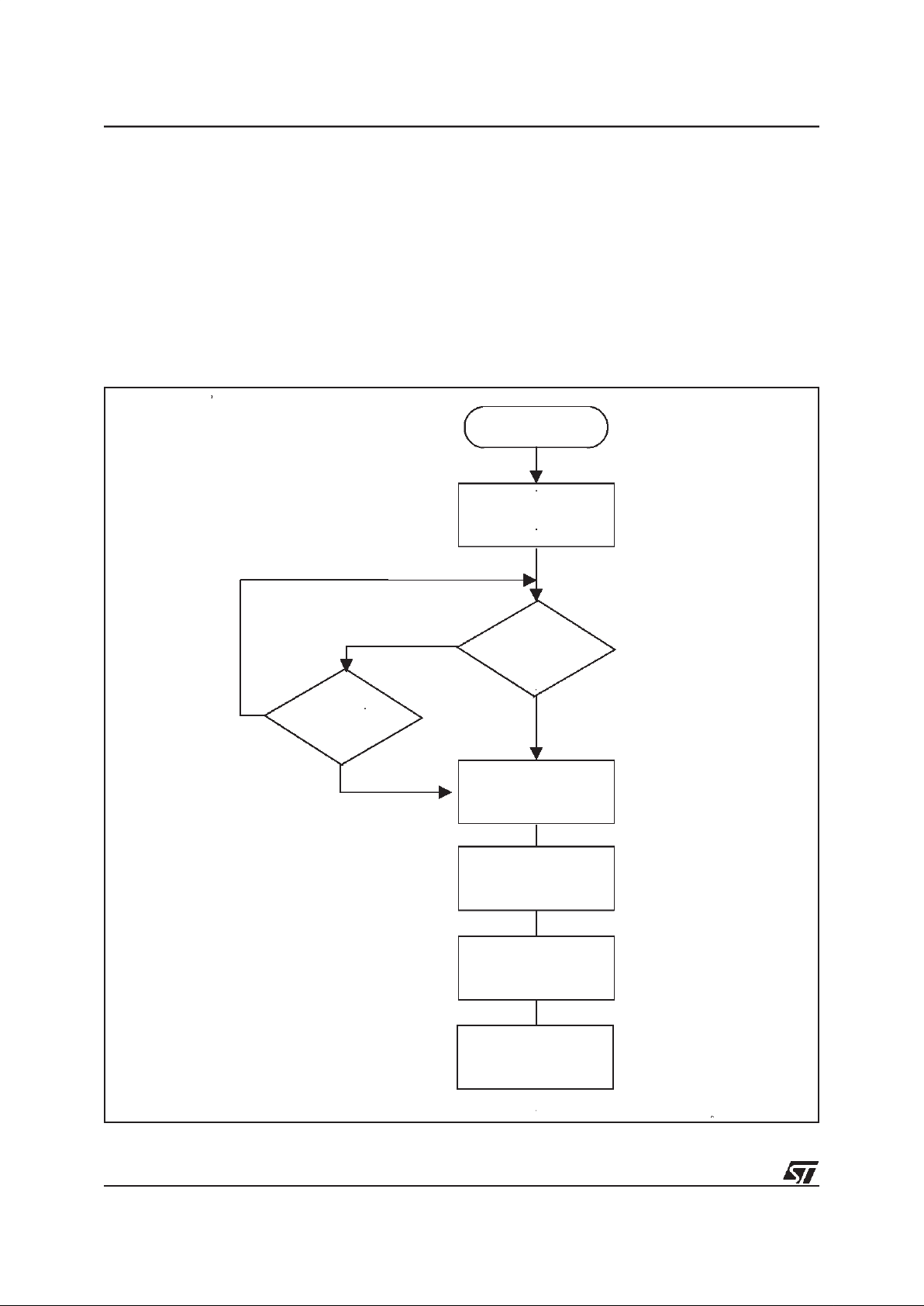

Figure 10. Interrupt Processing Flowchart

Note 1. See Table 5 . Interrupt Mapping

FROM RESET

TRAP

FETCH NEXT

INSTRUCTION

OF APPROPRIATE INTERRUPT

SERVICEROUTINE

EXECUTE INSTRUCTION

PUSH

PC,X,A,CC

SET I BIT TO 1

VR01172B

N

Y

LOAD PC

WITH APPROPRIATE

INTERRUPT VECTOR

(1)

I BIT = 1

N

Y

ONTO STACK

Page 22

22/117

ST7285C

3.6 POWER SAVING MODES

3.6.1 Slow Mode

The following Power Saving mode may be selected by setting the relevant bits in the Miscellaneous

register as detailed in Section3.2.

In Slow Mode, the oscillator frequency can be divided by 4, 8, 16 or 32 rather than by 2. The CPU

and peripherals are clocked at this lower frequency, and therefore the RDS filter cannot operate

correctly in this mode. SLOW mode is used to reduce power consumption, and enables the user to

adapt clock frequency to available supply voltage.

3.6.2 Wait Mode

WAIT mode places the MCU in a low power consumption mode by stopping the CPU. All peripherals remain active. During WAIT mode, the I bit (CC

Register) is cleared, so as to enable all interrupts.

All other registers and memory remain unchanged. The MCU will remain in WAIT mode until

an Interrupt or Reset occurs, whereupon the Program Counter branches to the starting address of

the Interrupt or Reset Service Routine.

Refer to Figure 11 below.

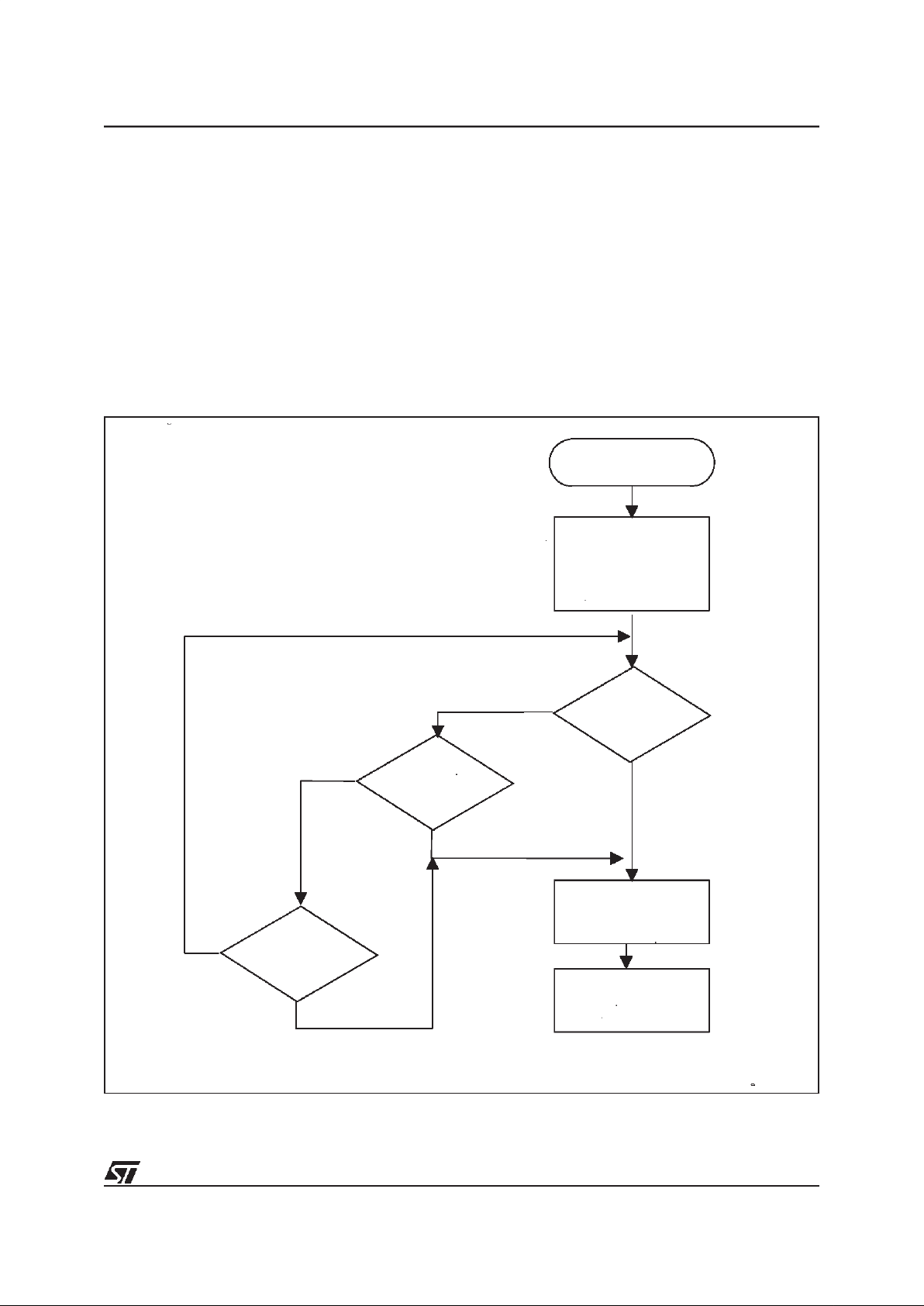

Figure 11. Wait Mode Flow Chart

WAIT

WAIT

Y

VR02062D

N

Y

Y

N

EXTERNAL

INTERRUPT

RESET

RESTART

PROCESSORCLOCK

FETCHRESET

VECTOROR

SERVICEINTERRUPT

PERIPHERAL

INTERRUPT

N

ACTIVE OSCILLATOR

AND PERIPHERALS

CLOCKSACTIVE

PROCESSORCLOCK

STOPPED

Page 23

23/117

ST7285C

POWER SAVING MODES(Cont’d)

3.6.3 Halt Mode

The HALT instruction places the MCU in its lowest

power consumption mode. In HALT mode the internal oscillator is turned off, causing all internal

processing to be halted. During HALT mode, the I

bit in the CC Register is cleared so as to enable

External Interrupts.

All other registers and memory remain unaltered

and all Input/Output lines remain unchanged. This

state will endure until an External Interrupt (I1, I2,

I9, I10) or a Reset is generated, whereupon the internal oscillator is restarted. A delay of 4096 CPU

clock cycles is initiated prior to restarting the application, in order to allow the oscillator to stabilize.

The External Interrupt or Reset causes the Program Counter to be set to the address of the corresponding Interrupt or Reset Service Routine.

Figure 12. Halt Mode Flow Chart

N

Y

VR02062E

N

EXTERNAL

INTERRUPT

WAIT

HALT

Y

STOP OSCILLATOR

ANDALL CLOCKS

CLEARI-BIT

RESET

OSCILLATOR

IN SLOW MODE

TURN ON

OSCILLATOR

WAIT FOR 4096 CPU

CLOCK TIME DELAY

FETCH RESET

VECTOROR

SERVICEINTERRUPT

Page 24

24/117

ST7285C

4 ON-CHIP PERIPHERALS

4.1 I/O PORTS

4.1.1 Introduction

Each I/O Port can contain up to 8 individually programmable I/Os. The MCU features seven 8-bit

Ports (A, B, C,... G) and one 6-bit-port (H). Each I/

O pin is dedicated to its main functionality, thus reducing and simplifying its programmability.

The current chapter describes the generic I/O

structure used in the MCU.

All I/Os are based on a generic circuit, of which a

block diagram is given inFigure 13. In most cases

the functions are simplified, and several subblocks may be missing (such as, for instance, the

analog switch on ports B to H or pull-up and interrupt logic for most of the I/O ports). Some registers

may also be absent where their functionality is redundant: it is therefore advisable to consult the

Memory Map in section1.3 and the pin description

in section 1.2 for proper use of any particular I/O.

Only ports C4, C5, D4, D5, F0,F1, F2, F3, G3 feature interrupt capability.

The following sub-section 4.1.2 contains generic

information on ST7 I/O ports. For information specific to this device, please refer to sub-section

4.1.3.

4.1.2 Generic I/O Features

The I/O ports offer the following generic features:

– inputs with Schmitt trigger

– analog inputs, when connected via internal mul-

tiplexer

– interrupt generation, maskable by software

– EMI compliance thanks to reduced noise radia-

tion due to lowered cross-current in push pull

mode and reduced input susceptibility. This fea-

ture is particularly relevant in RDS applications.

Each

generic

I/O pin may be individually program-

mable by software as:

– input: no pull-up, no interrupt generation

– input: pull-up, no interrupt generation

– input: pull-up, interrupt generation

– input: pull-down, no interrupt generation

– output: push-pull

– output: open-drain, no pull-up

– output: open-drain, with pull-up

4.1.2.1 Port Registers

Each port may be associated with up to four registers:

–

DATA REGISTER

(DR)

Address 0000 0000 000x xx00b; always present.

–

DATA DIRECTION REGISTER

(DDR)

Address 0000 0000 000x xx01b; always present.

–

OPTION REGISTER

(OR)

Address 0000 0000 000x xx10b; depending on

I/O dedication.

– PULL-UP REGISTER(PUR)

Address 0000 0000 000x xx11b; depending on

I/O dedication.

These are not internal CPU registers and must be

accessed by reading and writing to the relevant

memory locations. Refer toTable 1- Memory Map

for the respective addresses and reset values.

4.1.2.2 Functional Description

Each I/O pin may be programmed independently

as an analog input if the port features analog capabilities, as a digital input or a digital output with various variants, using the corresponding register

bits. When programmed as a digital input, a pull-up

or a pull-down resistor can, if present, be activated

by software. Only when enabling the pull-up, can

an interrupt function be programmed by software.

When programmed as an output, the I/O pin can

be programmed to operate either in push-pull or in

open-drain mode.

The interrupts generated by a port (active low) are

“ORed” to a single interrupt line that can be routed

to a CPU interrupt.

Page 25

25/117

ST7285C

I/O PORTS (Cont’d)

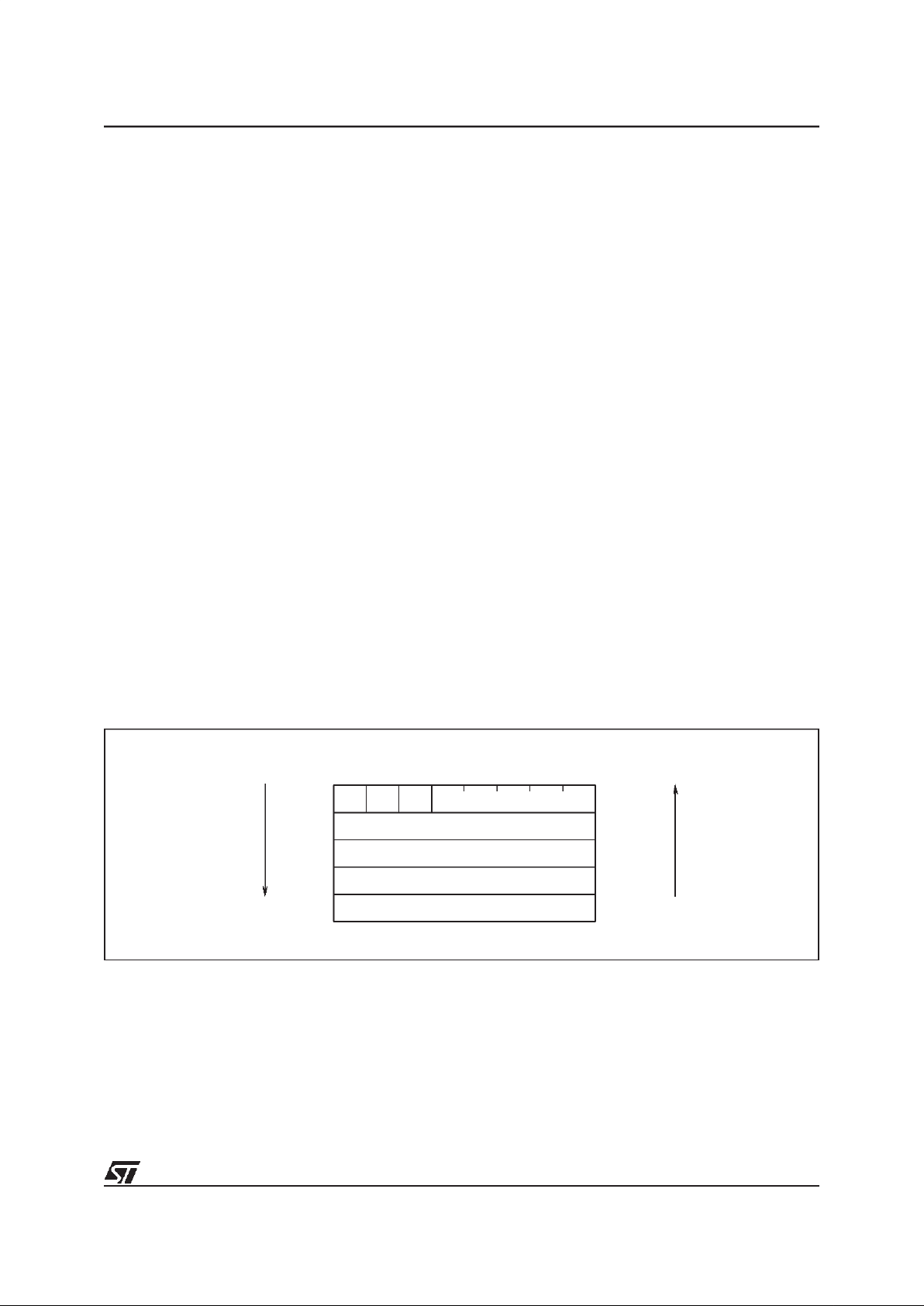

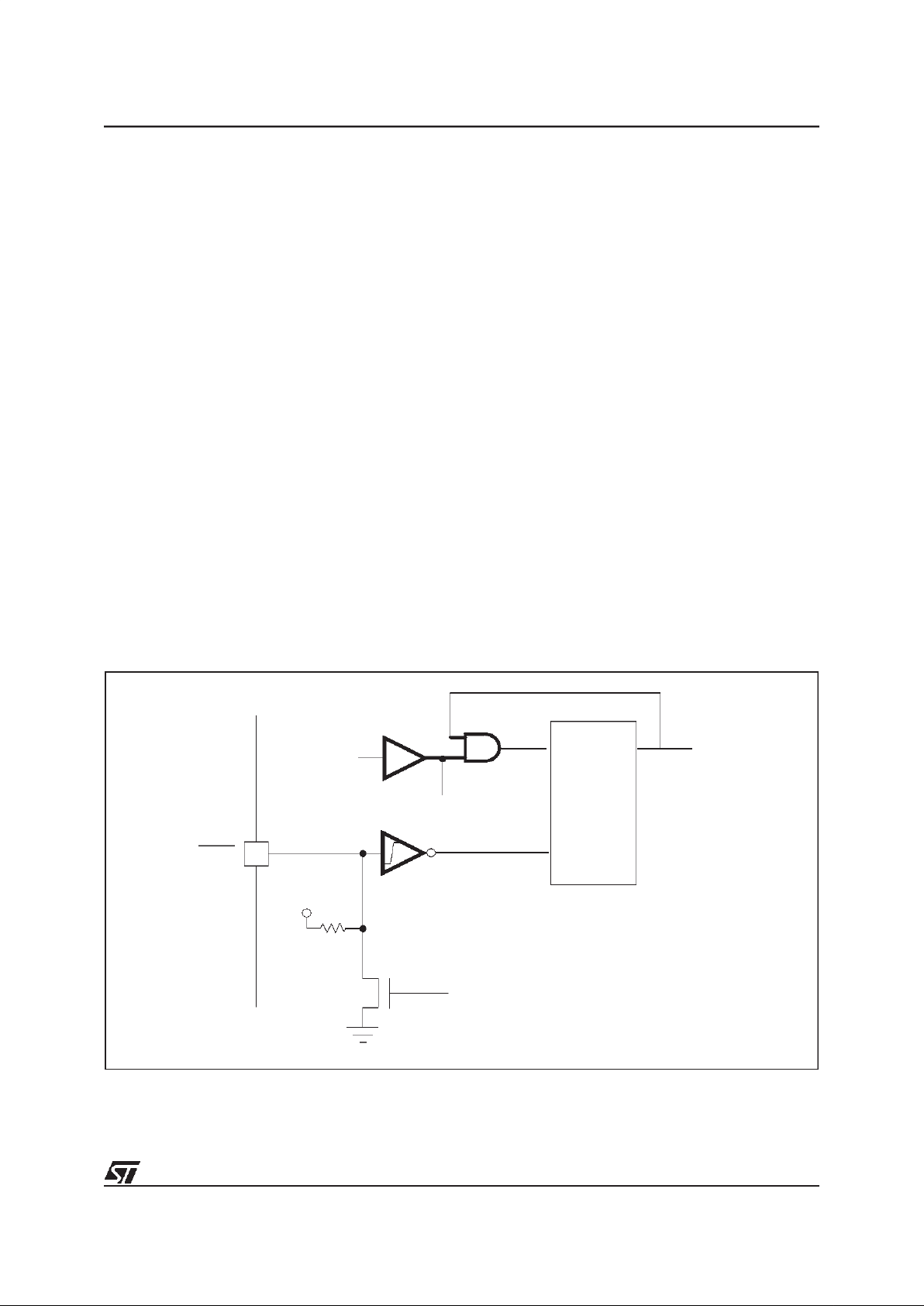

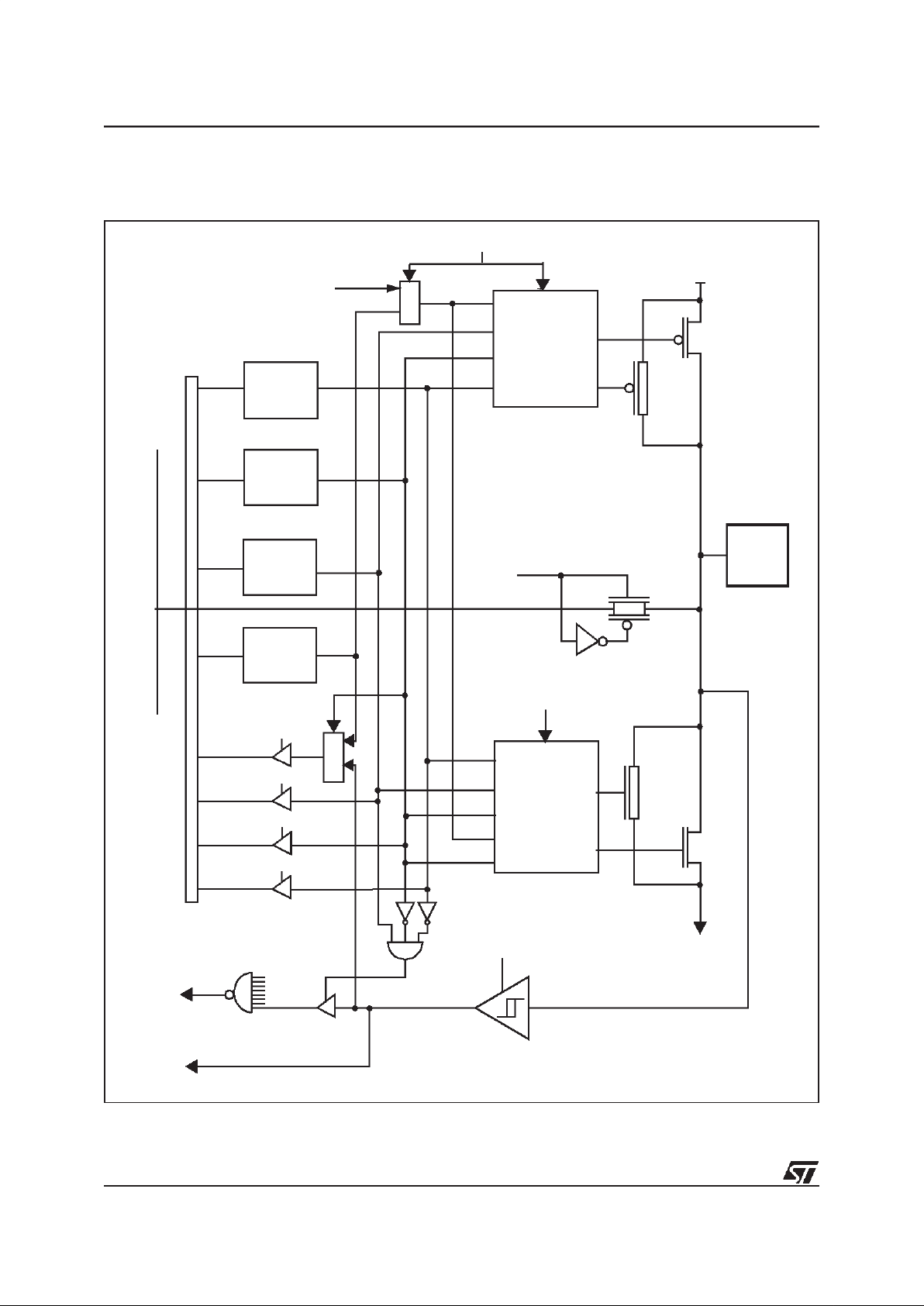

Figure 13. Generic I/O Circuitry

V

DD

PAD

FROM

OTHER

BITS

DR SEL

OR SEL

DDR SEL

PUR SEL

PUR

DDR

OR

DR

DAT A BUS

INTERRUPT

M

U

X

SIGNAL FROM ALTERNATE

TRIGGER ENABLE

PAD_TRIG

ANALOG

SWITCH

ANALOG ENABLE

COMMON ANALOG RAIL

from

ADC

M

U

X

ALTERNATE FUNCTION ENABLE

CONFIGURATION

DECODER

ALTERNATE FUNCTION ENABLE

CONFIGURATION

DECODER

FUNCTION

Page 26

26/117

ST7285C

I/O PORTS (Cont’d)

4.1.2.3 Operating Modes

All I/O pins may be configured as inputs or outputs

by programming the corresponding bits of the DR,

DDR, OR and PUR memory-mapped registers.

Table 6 illustrates the available operating modes.

During Reset, DR, DDR, OR and PUR are initialized to a Low level.

Table 6. I/O Operating Modes

Note:

(1) This state can add static current consumption.

– Input Mode

In input mode, both the analog multiplexer and the

port buffer are switchedto a high impedance state.

To avoid ringing with slowly rising or falling input

signals and to increase noise immunity, the inputs

are equipped with Schmitt-triggers.

The state of the pin is readable through the Data

Register. The pin state is read directly from the

Schmitt Trigger’s output and not from the Data

Register.

There are four different input modes, as illustrated

in Table 6.

Note: Pull-up and pull-down devices are not implemented by means of linear resistors, but by means

of resistive transistors.

– Interrupt function

The interrupt signals of all activated bits are

NANDed together, so that whenever at least one

of the activated inputs goes low, the port’s common interrupt output will go high in order to activate the CPU interrupt input.

– Output Mode

In output mode, the port output buffer is activated

and drives the output according to the content of

the data register, DR. In this mode, the analog

multiplexer, when present, is switched to high impedance and the interrupt is disabled.

Data written to the DR is directly copied to the output pins. A read operation of DR will be directly

performed from the DR register, so that the output

data stored in DR is readable, regardless of the

logic levels at the output pin due to output loading.

There are three different output modes for the

standard I/O pins as illustrated inTable 6.

– Alternate function

Alternate functions take priority over standard I/O

programming; if a peripheral needs to use a pad,

the alternate function is automatically activated.

The signal from the peripheral is output to the pad

(automatically configured in this case in push-pull

or open drain modes without pull-up and pulldown), and controlled directly by the peripheral.

The signal to be input to the peripheral from the

pad is taken after the schmitt trigger and is controlled directly by the peripheral. In this case, the pin’s

state is readable as in Input Mode by addressing

the Data Register and by configuring the PAD in

Input Mode (DDR=0).

– Analog Input Mode

In analog input mode (activated by the ADC), the

analog multiplexer is activated and switches the

analog voltage present on the selected pin (pins

PA0 to PA7) to the common analog rail. The common analog rail is connected to the Analog to Digital converter (see Section4.6) input. It is not recommended to change the voltage level or loading

on any port pin while conversion is in progress.

Furthermore it is not recommended to have clocking pins located close to a selected analog pad.

WARNING: Before activating the Analog Input

Mode, the I/O state must be set to:

INPUT, NO PULL-UP, NO INTERRUPT

(DDR = 0, OR = 0, PUR = 1)

The alternate function must not be activated as

long as the pad is configured as Input with Interrupt, in order to avoid generating spurious interrupts.

Analog input mode is only implemented for pins

PA0 to PA7. The analog input voltage level must

be within the limits stated in the Absolute Maximum Ratings.

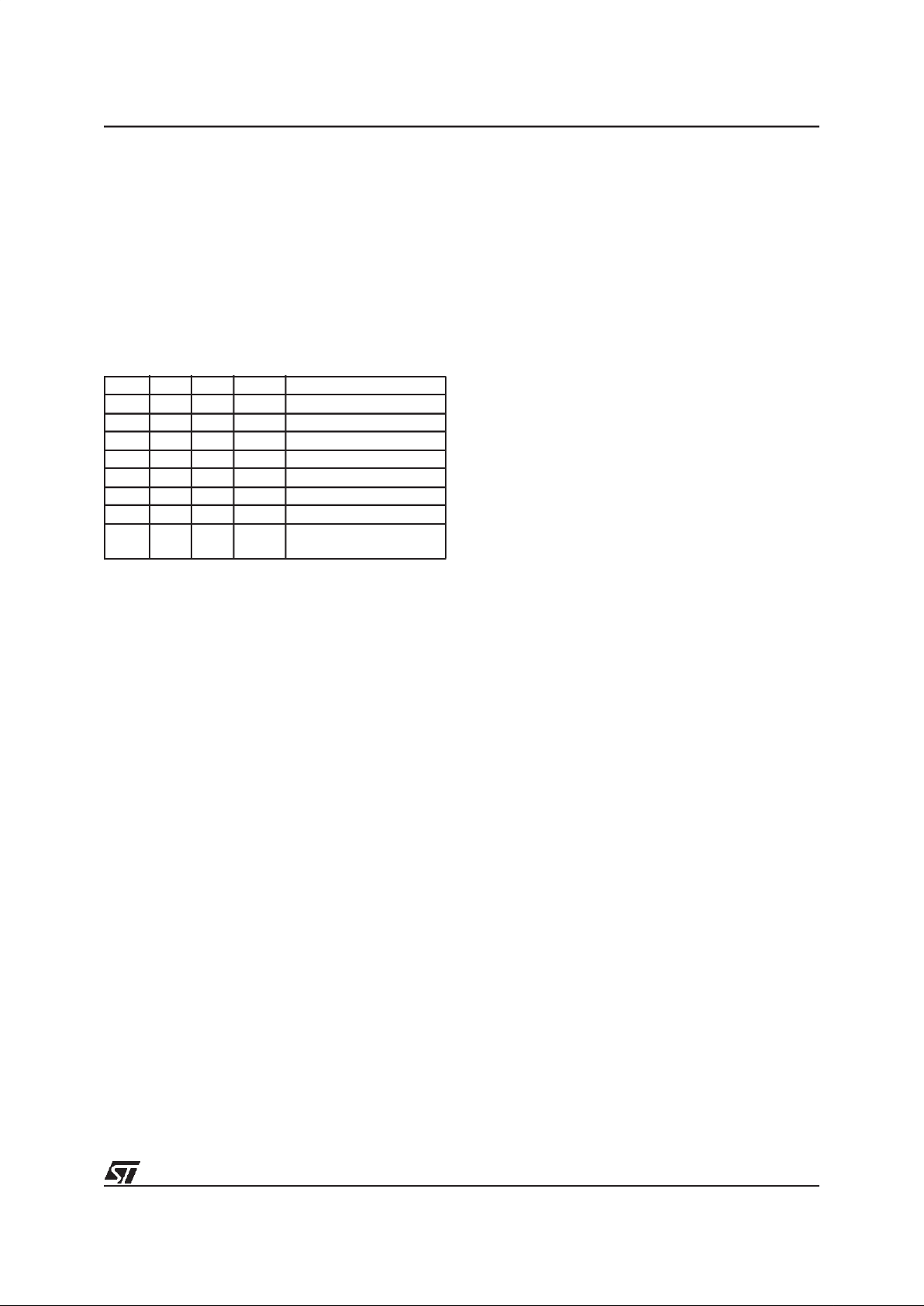

DDR OR PUR Mode Option

0 0 0 input pull-up, no interrupt

0 0 1 input no pull-up, no interrupt

0 1 0 input pull-up, interrupt

0 1 1 input pull-down, no interrupt

1 0 0 output open-drain, pull-up

1 0 1 output open-drain, no pull-up

1 1 0 output RESERVED

(1)

1 1 1 output

push-pull, nopull-up, no

pull-down

Page 27

27/117

ST7285C

I/O PORTS (Cont’d)

4.1.3 I/O Port Implementation

On the ST7285C, the pull down is always absent,

the pull up exists only where an interrupt facility is

present (Ports C4, C5, D4, D5, F0, F1, F2, F3,

G3). On port A, the analog inputs are directly controlled by the ADC.The I/O port register configurations are reduced to the following.

4.1.3.1 Ports A0-A7, B0-B7, C0-C3, C6, C7, D0D3, D6, D7,E0-E7, F4-F7, G0-G2, G4-G7, H0-H5

These ports do not offer interrupt capabilities.

Note: Open drain I/O is implemented on I2C pins

(pins 19 and 20) and high voltage pins (PH3/4/5).

The design uses special I/O devices without P

channel, thus forbidding the push pull configuration.

In this case there is neither pull up register nor option register. These registers do not exist and so

cannot be read or written to.

4.1.3.2 Ports C4, C5, D4, D5, F0-F3, G3

These ports offer interrupt capabilities.

In this case there is no pull up register since the

pull-up is present only when the interrupt feature is

selected. This register does not exist and so cannot be read or written to.

Switching these I/O ports from one state to another should be done in such a sequence as to prevent unwanted side effects. Recommended safe

transitions are illustrated inFigure 14. Other transitions are potentially risky and should be avoided,

since they are likely to present unwanted side-effects such as spurious interrupt generation.

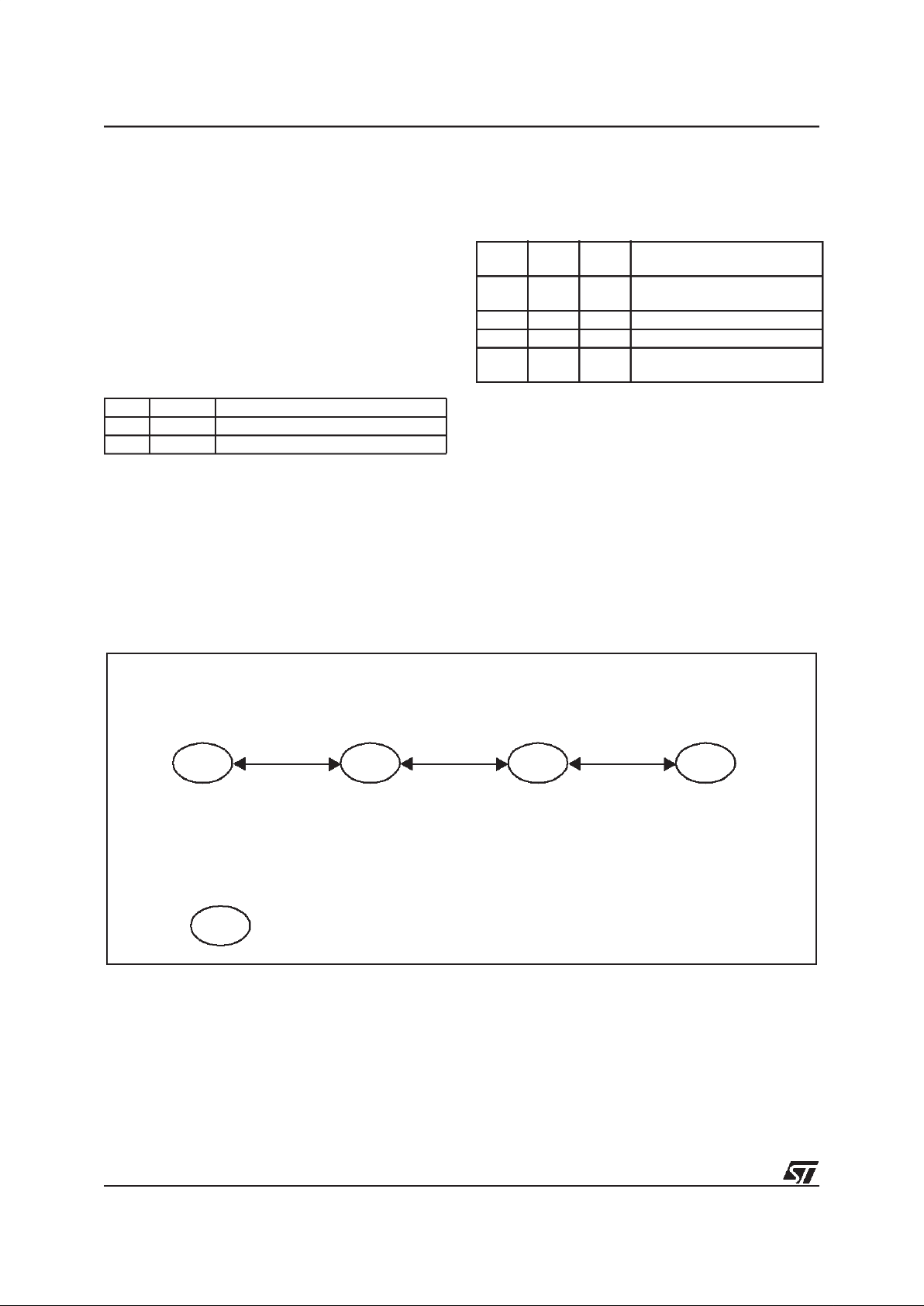

Figure 14. Recommended I/O State Transition Diagram

DDR MODE OPTION

0 input no pull-up, no pull-down, no interrupt

1 output push-pull (or open drain: see note)

DDR OR

MOD

E

OPTION

0 0 input

no pull-up, no pull-down,

no interrupt

0 1 input interrupt, pull-up

1 0 output open-drain, no pull-up

1 1 output

push-pull, no pull-up,

no pull-down

110001

Interrupt

pull-up

push-pull

no pull-up

open-drain

no pull-up

no pull-down

INPUT

OUTPUT

OUTPUT

10

no pull-up

no interrupt

INPUT

no pull-down

(Reset state)

XX

= DDR, OR

Page 28

28/117

ST7285C

4.2 SERIAL COMMUNICATIONS INTERFACE

4.2.1 Introduction

The Serial Communications Interface (SCI) offers

a flexible means of full-duplex data exchange with

external equipment requiring an industry standard

NRZ asynchronous serial data format. The SCI offers a very wide range of Baud rates thanks to the

presence of two Baud rate generator systems: the

first is of conventional type and yields common

communications Baud rates with standard oscillator frequencies; the second features a programmable prescaler capable of dividing the input frequency by any factor from 1 to 255, thus offering a

very wide range of Baud rates even with nonstandard oscillator frequencies. Transmitter and

Receiver circuits are independent and can operate

at different Baud rates; indeed, each can select either type of Baud rate generator. External connections are by means of two I/O pins: TDO (Port

PB0) for the Transmit Data output and RDI (Port

PB1) for the Receive Data input.

4.2.2 Features

– Full duplex, asynchronous communications

– NRZ standard format (Mark/Space)

– Dual Baud rate generator systems

– Independently programmable transmission and

reception Baud rates

– Separate Transmit and Receive Baud rates

– Programmable word length (8 or 9 bits)

– Receive buffer full, Transmit buffer empty and

End of Transmission flags

– Receiver wake-up function by the most signifi-

cant bit or by idle line

– Muting function for multiprocessor configurations

–Separate enable bitsforTransmitter andReceiver

– Noise, Overrun and Frame Error detection

– Four interrupt sources with flags

– Overall accuracy better than 1% of Baud rate.

4.2.3 Serial Data Format

Serial data is transmitted and received as frames

comprising the following elements:

– An Idle Line in the ”high” state prior to transmis-

sion or reception.

– A Start bit inthe ”low” state, denoting the start of

each character.

– Character dataword (8 or 9 bits), least significant

bit first.

– A Stop bit in the ”high” state, indicating that the

frame is complete.

Word length may be selected as being either 8 or 9

bits by programming the M bit in the SCCR1 control register.

An Idle Line condition is interpreted on receiving

an entire frame of ”ones”.

A Break is interpreted on receiving ”zeros” for

some multiple of the frame period.

4.2.4 Data Reception and Transmission

The following description is best read with reference to the SCI Block Diagram illustrated in Figure

1, where it will be noted that the SCDR data register is shown as two separate registers, one for

transmitted data and the other for received data.

The Serial Communications Data Register (SCDR)

performs a dual function (Read And Write),since it

accesses two separate registers, one for transmission (TDR) and one for reception (RDR). The TDR

register provides the data interface between the internal bus and the output shiftregister for data to be

transmitted, while the RDR register provides an interface between the input shift register and the internal bus for incoming data.

When the SCDR is read, the RDR is accessed and

its contents are transferred to the data bus. The

RDRF (RDR Full Flag) in the SCSR register is set

to ”1” as soon as the word in the receiver shift register is transferred to the RDR register.

When the SCDR is written to, the data word is

transferred to the TDR register. The TDRE flag

(TDR empty) in the SCSR register is set to ”1” as

soon as the word in the TDR is transferred to the

transmit shift register.

Incoming data is received in a serial shift register

and then transferred to a parallel Receive Data

Register (RDR) as a complete word, thus allowing

the next incoming character to be received in the

shift register while the current character is still in

the RDR.

Oversampling techniques are used for data recovery by discriminating between valid incoming data

and noise.

4.2.5 Receiver Muting and Wake-up Feature

In multiprocessor configurations it is often desirable that only the intended message recipient

should actively receive the full message contents,

thus reducing redundant SCI service overheads

for all non addressed receivers. Communications

protocols in such configurations generally issue

the recipient address as a message header.

Page 29

29/117

ST7285C

SERIAL COMMUNICATIONS INTERFACE(Cont’d)

Each receiving device decodes this address header under program control and all non addressed

receivers may be placed in a sleep mode by

means of the Muting function, thus avoiding the

message contents from generating unnecessary

requests for service. This is achieved by inhibiting

all reception flags and interrupt generation when

Muting is enabled. A muted receiver may be reawakened in one of two ways: by Idle Line detection or by Address Mark detection. The wake-up

method may be programmed by programming the

WAKE bit in the SCCR1 register.

Receiver wake-up by Idle Line detection takes

place as soon as the Receive line is recognised as

being idle. An Idle Line condition is detected upon

receiving 10 or 11 consecutive ”ones”, depending

on whether a word has been defined as comprising 8 or 9 data bits. This wake-up method is selected by programming the WAKE bit to ”0”.

Receiver wake-up by Address Mark detection

takes place on receiving a ”1” as the most significant bit of a word, thus indicating that the message

is an address. This wake-up method is selected by

programming the WAKE bit to ”1”.

4.2.6 Baud Rate Generation

The following description is best read with reference to the SCI Baud Rate and External Prescaler

Diagram illustrated in Figure 2.

The CPU Clock is first divided by 16 by the first divisor block, then again divided by the division factor selected for the first prescaler, indicated by PR.

This division factor can be selected to be 1, 3, 4 or

13, depending on the setting of the SCP0 and

SCP1 bits (bits 6 and 7) in the SCBRR register (refer to the register description). The output from the

first prescaler will thus be the CPU Clock frequency divided by 16, 48, 64 or 208. This master clock

is available both to the conventional Baud Rate

Generator and to the External Prescaler.

The conventional Baud Rate Generator is enabled

by setting the relevant section (RX or TX) of the

External Prescaler to 00h. In this case the master

clock frequency is further divided by 1, 2, 4, 8, 16,

32, 64 or 128, depending on the settings of bits

SCT0, SCT1 and SCT2 in the case of the transmitter, and SCR0, SCR1 and SCR2 in the case of the

receiver (refer to the SCBRR register description).

If the External Prescaler Receive or Transmit

Baud Rate Register, PSBRT or PSBRR is set to a

value other than zero, that section of the prescaler

will be operational in place of the conventional

Baud Rate Generator. The output clock rate sent

to the transmitter or to the receiver will be the output from the first prescaler divided by a factor

ranging from 1 to 255 set in the External Prescaler

Receive or Transmit Baud Rate Register. As can

be seen the External Prescaler option gives a very

fine degree of control on the Baud rate, whereas

the conventional Baud Rate Generator retains industry standard software compatibility.

4.2.7 SCI Register Overview

The registers described in the following paragraphs allow full control of the various features

and parameters of the Serial Communications Interface. Refer also to the Memory Map.

4.2.7.1 Data Register (SCDR)

Address: 0051h — Read/Write

Reset Value: XXh

Contains the Received or Transmitted data char-

acter, depending on whether it is read or written to.

4.2.7.2 Control Register 1 (SCCR1)

Address: 0053h — Read/Write

Reset Value: XXh

Contains bits to select the desired word length and

the wake-up mode.

Bit-7 = R8

Receive Data Bit 8

If bit M is set at one, R8 will be used to store the

9th bit on reception.

Bit-6 = T8

Transmit Data Bit 8

Used to store the 9th data bit of the transmitted

word, when 9-bit word length is selected (bit M set

to ”1”).

Bit-4 = M

Word Length

Determines the word length:

0 = 1 Start bit, 8 Data bits, 1 Stop bit

1 = 1 Start bit, 9 Data bits, 1 Stop bit

Bit-3 = WAKE

Wake-Up Method

1 = Address Mark

0 = Idle Line

76543210

R8 T8 - M WAKE - - -

Page 30

30/117

ST7285C

SERIAL COMMUNICATIONS INTERFACE(Cont’d)

4.2.7.3 Control Register 2 (SCCR2)

Address: 0054h — Read/Write

Reset Value: 00h

Contains four control bits which allow interrupts

generated by TDR Empty, Transmit Complete,

RDR Full and Idle Line to be enabled or disabled.

Also contains four control bits to enable or disable

Transmission, Reception, Receiver Wake-Up and

Send Break.

Bit-7 =

TIE

Transmitter Interrupt Enable

Authorizes an interrupt when set at one and when

the TDRE (transmission register empty) flag is set

to “1” indicating that the last word has been transmitted. When TIE is at zero this interrupt is disabled.

Bit-6 = TCIE

Transmission Complete Interrupt En-

able

This bit setto “1” enables an interrupt when theTC

flag (transmission competed) changes to “1”.

When TCIE is at “0” this interrupt is disabled.

Bit-5 = RIE

Receiver Interrupt Enable

Authorizes an interrupt when set to “1” and when

either the RDRF (Receive Data Register Full) flag

or the OR (Overspeed on Reception) flag is set to

“1”, indicating that the last word has been transmitted. When TIE is set to “0”, this interrupt is disabled.

Bit-4 = ILIE

Idle Line Interrupt Enable

This bit at “1” enables an interrupt if the IDLE flag

changes to “1” (which corresponds to an idle line

on reception). The interrupt cannot occur if the

IDLE bit is at “0”.

Bit-3 =

TE

Transmitter Enable

This bit at “1” enables the transmitter. At start-up,

the transmitter sends a preamble (ten or eleven

ones). During transmission, a “0” pulse on the TE

bit (“0” followed by “1”) sends a preamble after the

current word. Setting the TE bit to “0” switches the

output line to a high impedance state at the end of

the word currently being transmitted.

Bit-2 = RE

Receiver Enable

The RE bit at “1” enables the receiver which begins searching for a START bit. The RE bit at “0”

disables the receiver and resets the associated

status bits to “0” (RDRF, IDLE, OR, NF and FE).

Bit-1 = RWU

Receiver Wake-Up

The RWU bit at “1” mutes the receiver. The wakeup mode is determined by the WAKE bit (bit 3 in

SCCR1). As long as RWU remains at “1”, the flags

relating to the receiver cannot rise to “1”.

Writing “0” to RWU forces an exit from the muted

state.

As soon as the wake-up sequence is recognized,

the RWU bit is forced to “0”. If the wake-up selected mode corresponds to the reception of a preamble, the RWU bit cannot be set to “1” as long as the

reception remains idle. If the selected wake-up

mode corresponds to the reception of a “1” on the

most significant bit, the reception of this particular

word wakes up the receiver and sets the RDRF

flag to “1”, which allows the receiver to receive this

word normally and to use it as an address word.

Bit-0 = SBK

Send Break

This bit set to “1” tells the transmitter to send a

whole number of BREAKS (all bits at “0” including

the stop bit). At the end of the last BREAK the

transmitter inserts an extra “1” bit in order to acknowledge the START bit. If the SBK bit is set to

“1” and then to “0”, the transmitter will send a

BREAK word at the end of the current word.

4.2.7.4 Status Register (SCSR)

Address: 0050h — Read Only

Reset Value: 1100 0000b

Contains four flags which denote conditions which

can lead to interrupts if the corresponding bits of

SCCR2 are set: TDR Empty, Transmit Complete,

RDR Full and Idle Line. These flags are used for

management of the SCI interrupt system.

Also contains three flags which indicate error conditions due to Overrun, Noise and Framing.

Bit-7 =TDRE

Transmit Data Register Empty

Indicates that the content of the transmission data

register has been transferred into the shift register.

If the TDRE bit is at “0”, it indicates that the transmission has not yet occurred and that a write operation into the data register would overwrite previous data. The TDRE bit is reset to “0” by an SCSR

access followed by a write operation into the transmission data register. Data will not be transferred

to the shift register as long as the TDRE bit is not

reset to “0”.

Bit-6 =

TC

Transmission Complete

76543210

TIE TCIE RIE ILIE TE RE RWU SBK

76543210

TDRE TC RDRF IDLE OR NF FE -

Page 31

31/117

ST7285C

SERIAL COMMUNICATIONS INTERFACE(Cont’d)

The TC bit is automatically set to “1” when transmission of a frame containing Data, a Preamble or

a Break is complete, if:

– TE = ”1”, TDRE = ”1”, no word is currently being

transmitted and no preamble or BREAK is await-

ing transmission.

– TE = ”0” and the current word or preamble or

BREAK has been transmitted

The TC bit is aflag indicating that one of the above

sequences has occurred. This bit is reset to “0” by