Datasheet ST72C171, ST72C171K2M, ST72C171K2B, ST72C171K2 Datasheet (SGS Thomson Microelectronics)

Page 1

Rev. 1.3

May 2000 1/151

This ispreliminary information on anew product in development or undergoing evaluation. Details are subject tochange without notice.

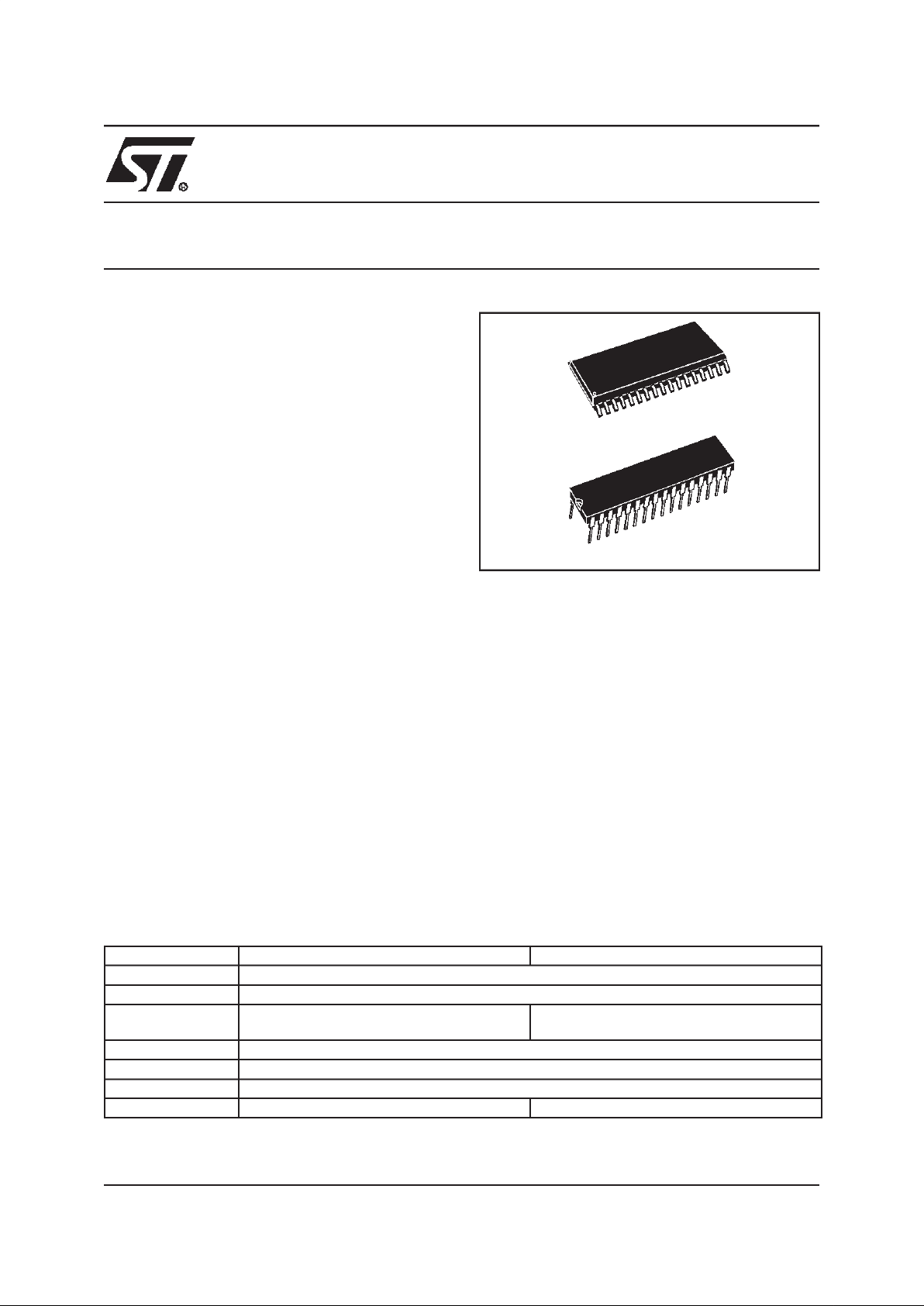

ST72C171

8-BIT MCU with 8K FLASH, ADC, WDG, SPI, SCI, TIMERS

SPGAs (Software Programmable Gain Amplifiers), OP-AMP

PRODUCT PREVIEW

■ Memories

– 8K of single voltage Flash Program memory

with read-out protection

– In-Situ Programming (Remote ISP)

■ Clock, Reset and Supply Management

– Enhanced Reset System

– Low voltage supervisor (LVD) with 3program-

mable levels

– Low consumption resonator or RC oscillators

(internal or external) and by-pass for external

clock source, with safe control capabilities

– 3 Power Savingmodes

■ 22 I/O Ports

– 22 multifunctional bidirectional I/O lines:

– 16 interrupt inputs on 2 independent lines

– 8 lines configurableas analog inputs

– 20 alternate functions

– EMI filtering

■ 2 Timersand Watchdog

– One 16-bit Timer with: 2 Input Captures, 2

Output Compares, external Clockinput, PWM

and Pulse Generator modes

– One 8-bit Autoreload Timer (ART) with: 2

PWM output channels (internally connectable

to the SPGA inputs), 1 Input Capture, external

clock input

– Configurable watchdog (WDG)

■ 2 Communications Interfaces

– Synchronous Serial Peripheral Interface(SPI)

– Serial Communications Interface (SCI)

■ 3 Analog peripherals

– 2 Software Programmable Gain Operational

Amplifiers (SPGAs) with rail-to-rail input and

output, VDDindependent (band gap) and programmable reference voltage (1/8 VDDresolution), Offset compensation, DAC & on/off

switching capability

– 1 rail-to-rail input and output Op-Amp

– 8-bit A/D Converter with up to11 channels(in-

cluding 3 internal channels connected to the

Op-Amp & SPGA outputs)

■ Instruction Set

– 8-bit data manipulation

– 63 basic Instructions

– 17 main addressing modes

– 8 x 8 unsigned multiply instruction

– True bit manipulation

■ Development Tools

– Full hardware/softwaredevelopment package

Device Summary

SO34

PSDIP32

Features ST72C171K2M ST72C171K2B

Flash - bytes 8K Single Voltage

RAM (stack) - bytes 256 (128)

Peripherals

2 SPGAs, 1 Op-Amp,

Watchdog, 3 Timers, SPI, SCI, ADC (11 chan.)

2 SPGAs,

Watchdog, 3 Timers, SPI, SCI, ADC (11 chan.)

Operating Supply 3.2 V to 5.5 V

CPU Frequency Up to 8 MHz (with up to 16 MHz oscillator)

Temperature Range - 40°Cto+85°C

Package SO34 PSDIP32

1

Page 2

Table of Contents

151

2/151

1

ST72C171 . . . . . . . . . . . . . . . . . . . . .......................1

1 GENERAL DESCRIPTION . . . . . . ................................................ 4

1.1 INTRODUCTION . . . . . . . . . . . . . ............................................ 4

1.2 PIN DESCRIPTION . . ..................................................... 5

1.3 MEMORY MAP . . . . . . . . . . ................................................ 8

2 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . ................................. 11

2.1 INTRODUCTION . . . . . . . . . . . . . ...........................................11

2.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . .............................. 11

2.3 STRUCTURAL ORGANISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . 11

2.4 IN-SITU PROGRAMMING (ISP) MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . ...........11

2.5 MEMORY READ-OUT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...........11

3 CENTRAL PROCESSING UNIT . . ............................................... 12

3.1 INTRODUCTION . . . . . . . . . . . . . ...........................................12

3.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . .............................. 12

3.3 CPU REGISTERS . . . .................................................... 12

4 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . ................................15

4.1 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . .............................. 15

4.2 LOW VOLTAGE DETECTOR (LVD) . . . .. . . . . . . . . . ........................... 16

4.3 CLOCK SECURITY SYSTEM (CSS) . . . . . .................................... 21

4.4 CLOCK, RESET AND SUPPLY REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . 23

5 INTERRUPTS . . ............................................................. 24

5.1 NON MASKABLE SOFTWARE INTERRUPT .................................. 24

5.2 EXTERNAL INTERRUPTS . . . . . . . . . . .. . . . . . ............................... 24

5.3 PERIPHERAL INTERRUPTS ............................................... 24

6 POWER SAVING MODES . . . . . . . . . . ........................................... 27

6.1 INTRODUCTION . . . . . . . . . . . . . ...........................................27

6.2 SLOW MODE . . . . . . . .. . . . . . . . . . . . . . . . . . ................................. 27

6.3 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 28

6.4 HALT MODE . . . . . . . . . . . .. . . . . . . ........................................ 29

7 ON-CHIP PERIPHERALS . . . . . . . . . . . ...........................................30

7.1 I/O PORTS . . . .. . . . . . . . . . . . . . ...........................................30

7.2 MISCELLANEOUS REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 OP-AMP MODULE . ...................................................... 38

7.4 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.5 16-BIT TIMER . . . . . . . . . . . . . . . . . . ........................................51

7.6 PWM AUTO-RELOAD TIMER (ART) . . . . . ....................................69

7.7 SERIAL COMMUNICATIONS INTERFACE (SCI) . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.8 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . ...........89

7.9 8-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . .......................... 102

8 INSTRUCTION SET . . . . . . . . . . . . . . . . . . .......................................106

Page 3

Table of Contents

3/151

8.1 ST7 ADDRESSING MODES . . . . . . . . . .. . . . . . .. . .. . . . . . . . . . . . . . . . . . . . . .. . . . 106

8.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . ................................109

9 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . .............................112

9.1 PARAMETER CONDITIONS . . . . . . . . . . . ................................... 112

9.2 ABSOLUTE MAXIMUM RATINGS . . . .......................................113

9.3 OPERATING CONDITIONS . .............................................. 114

9.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . .............. 116

9.5 CLOCK AND TIMING CHARACTERISTICS . . . . . ............................. 119

9.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.7 EMC CHARACTERISTICS . . . . . . . . . . . . . . .................................124

9.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . ................... 129

9.9 CONTROL PIN CHARACTERISTICS ....................................... 132

9.10TIMER PERIPHERAL CHARACTERISTICS .. ................................135

9.11COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . 136

9.128-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . .......................... 139

10 GENERAL INFORMATION ................................................... 143

10.1PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . .......................... 143

10.2THERMAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 144

10.3SOLDERING AND GLUEABILITY INFORMATION .. . . . . . . . . . .. . . . . . ...........145

10.4PACKAGE/SOCKET FOOTPRINT PROPOSAL . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . .. . . . . . . . . . . 146

11.1OPTION BYTES . . ...................................................... 146

11.2DEVICE ORDERING INFORMATION . . . . ................................... 147

11.3DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . ....... 148

11.4ST7 APPLICATION NOTES . . . . . . . .......................................149

11.5TO GET MORE INFORMATION . . . . . . . . ................................... 149

12 SUMMARY OF CHANGES . .................................................. 150

Page 4

ST72C171

4/151

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST72C171 is a member of the ST7 family of

Microcontrollers. All devices are based on a common industry-standard 8-bit core, featuring an enhanced instruction set.

The ST72C171 features single-voltage FLASH

memory with byte-by-byte In-Situ Programming

(ISP) capability.

Under software control, the device can be placed

in WAIT, SLOW, or HALT mode, reducing power

consumption when the application is in idle or

standby state.

The enhanced instruction set and addressing

modes of the ST7 offer bothpower andflexibility to

software developers,enabling the design of highly

efficient and compact application code. In addition

to standard 8-bitdata management, all ST7microcontrollers feature true bit manipulation, 8x8 un-

signed multiplication and indirect addressing

modes The device includes a low consumption

and fast start on-chip oscillator, CPU, Flash program memory, RAM, 22 I/O lines and the following

on-chip peripherals: Analog-to-Digital converter

(ADC) with 8 multiplexed analog inputs, Op-Amp

module, synchronous SPI serial interface, asyncronous serial interface (SCI), Watchdog timer, a

16-bit Timer featuring external Clock Input, Pulse

Generator capabilities, 2 Input Captures and 2

Output Compares, an 8-bit Timer featuring external Clock Input, Pulse Generator Capabilities (2

channels), Autoreload and Input Capture.

The Op-Amp module adds on-chip analog features to the MCU, that usually require using external components.

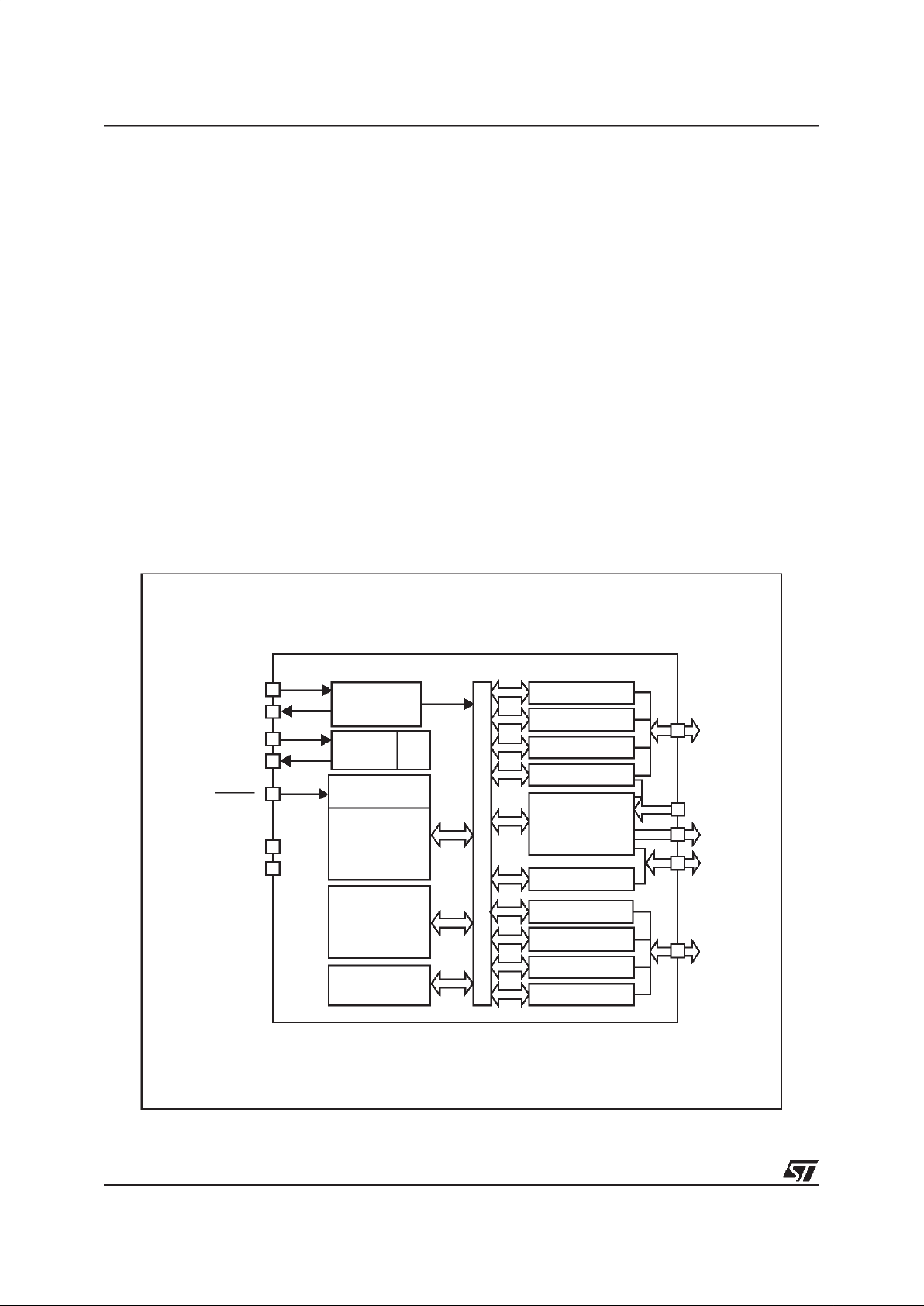

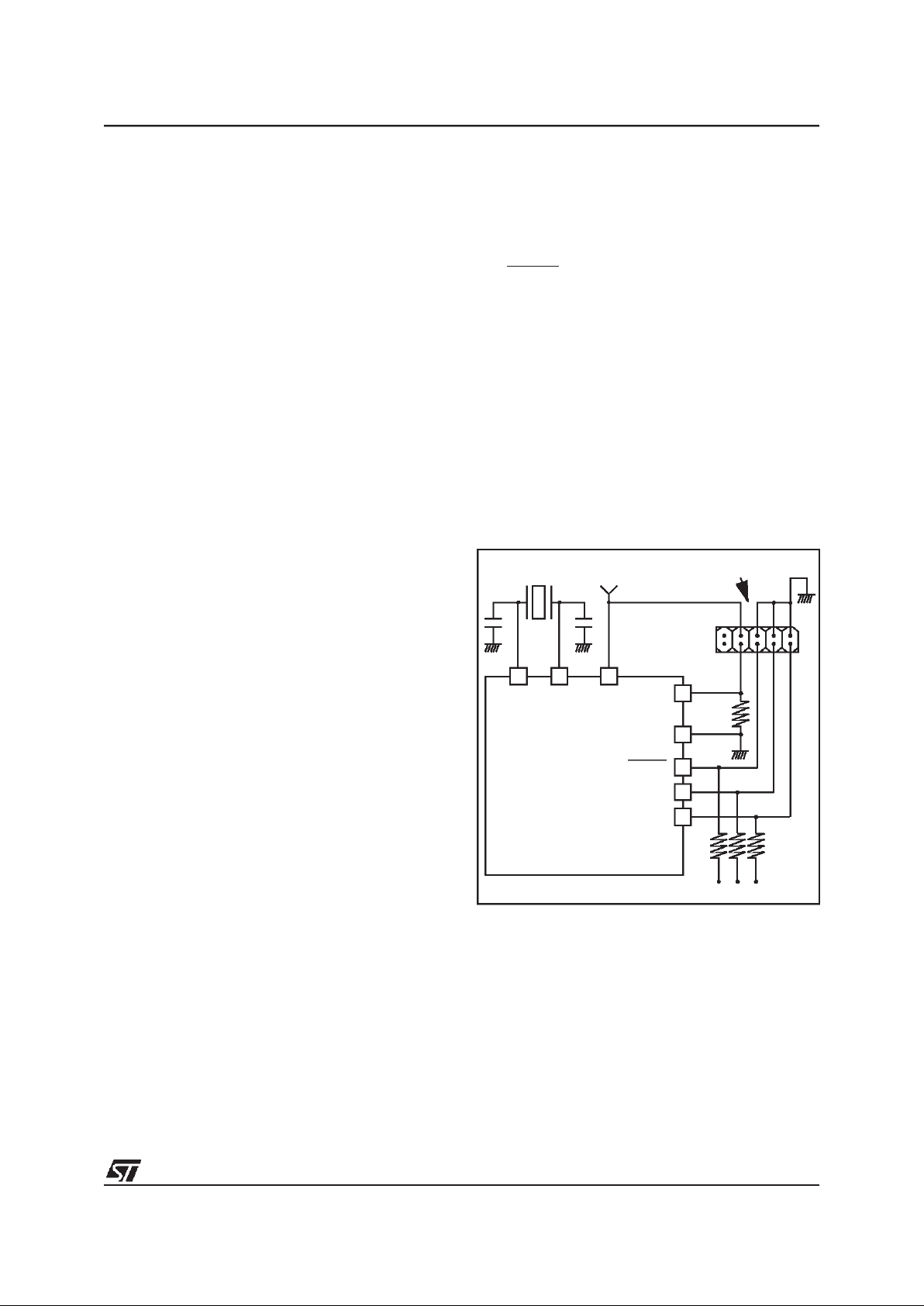

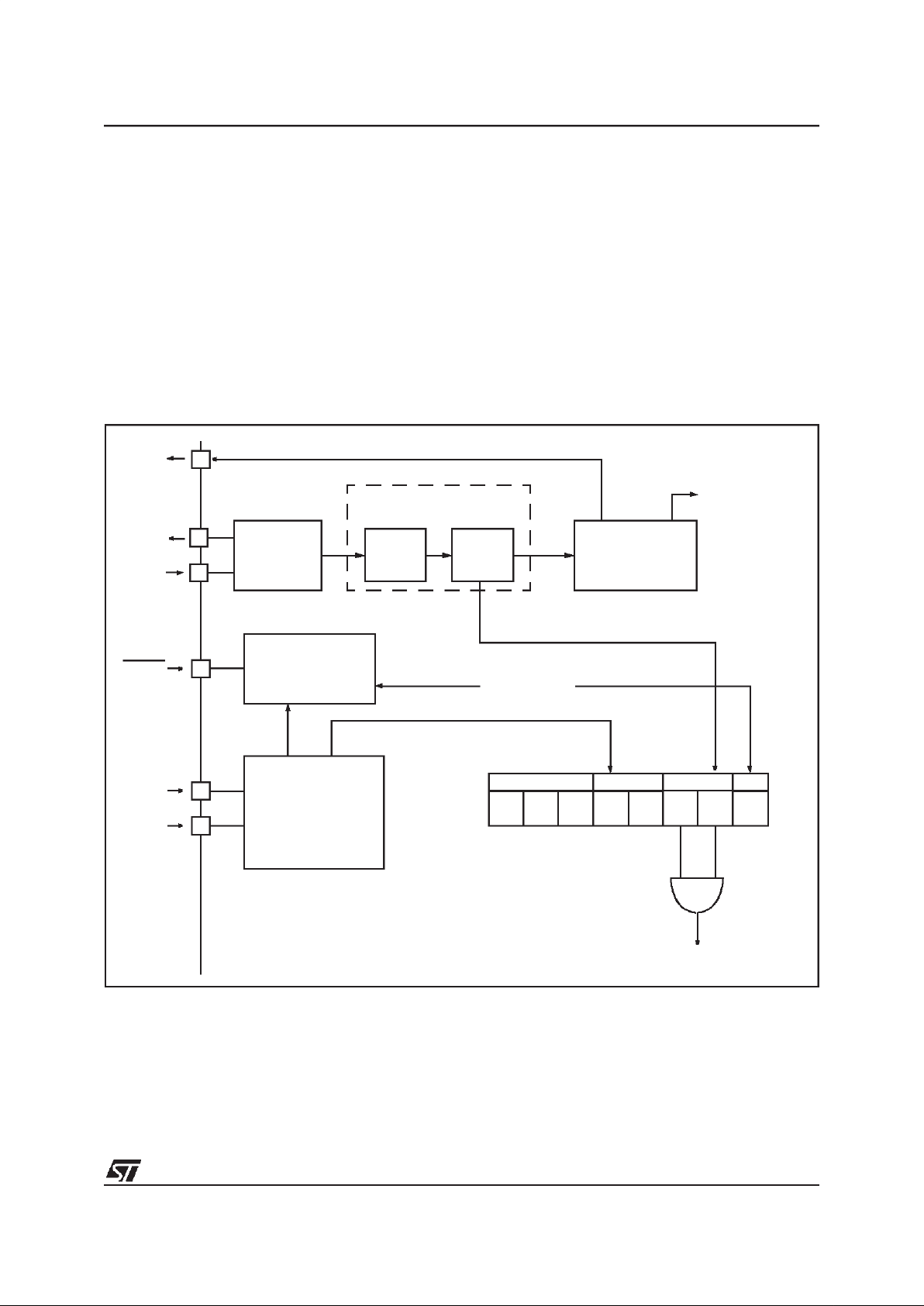

Figure 1. ST72C171 Block Diagram

ADDRESS AND DATA BUS

OSCIN

OSCOUT

RESET

16-BIT TIMER

8-BIT ADC

PORT B

WATCHDOG

Internal

CLOCK

CONTROL

256b-RAM

PA[7:0]

V

SS

V

DD

POWER

SUPPLY

8KFLASH

PORT A

PWM/ART TIMER

SPI

PB[7:0]

LVD

SCI

MULTIOSC

+

CLOCK FILTER

OP-AMP

V

SSA

V

DDA

8-BIT CORE

ALU

PORT C

PC[5:0]

OA1OUT

OA2OUT

MEMORY

OA3OUT*

*only on 34-pin devices

OA3PIN*

Page 5

ST72C171

5/151

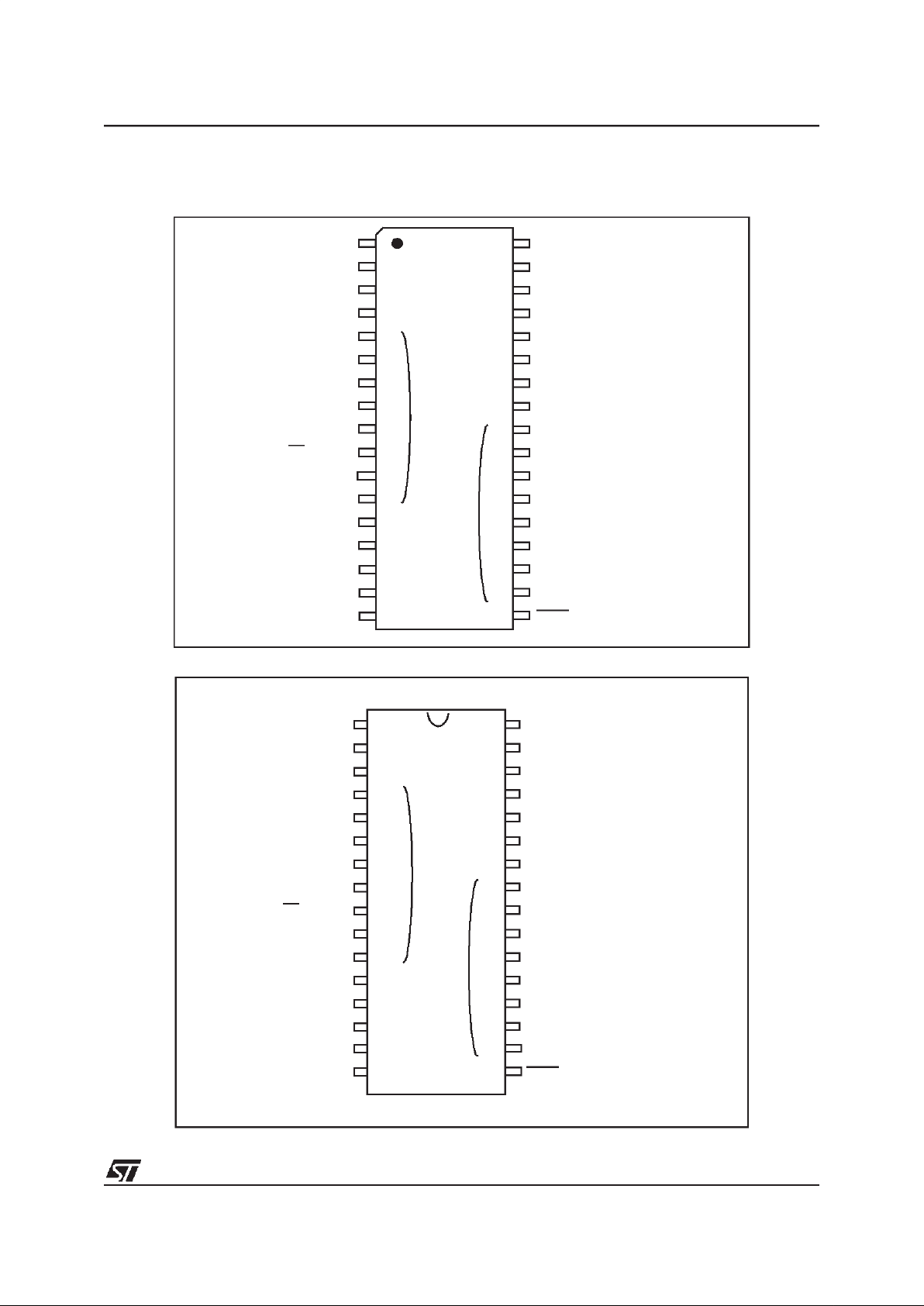

1.2 PIN DESCRIPTION

Figure 2. 34-Pin SO Package Pinout

Figure 3. 32-Pin SDIP Package Pinout

PC2 /OA1PIN / PWM0R

PC3 /OA1NIN

OA1OUT

PC4 /MCO/ OA3NIN

V

DDA

V

SSA

OA3OUT

PC5/ PWM0

PA7 / AIN7/ PWM1

PA6 / AIN6/ ARTICP0

PA5 / AIN5

PA4 / AIN4/ OCMP1

PA3 / AIN3/ OCMP2

PA2 / AIN2/ ICAP1

PA1 / AIN1/ ICAP2

PA0 / AIN0

RESET

21

22

23

24

25

26

34

33

32

31

30

29

28

27

1

2

3

4

5

6

7

8

9

10

11

12

13

14

OA2OUT

PWM1R / OA2PIN / PC1

OA2NIN / PC0

OA3PIN

TDO / PB7

RDI /PB6

ISPDATA / MISO / PB5

MOSI /

(HS)

PB4

ISPCLK / SCK /

(HS)

PB3

SS /

(HS)

PB2

ARTCLK /

(HS)

PB1

EXTCLK /

(HS)

PB0

V

DD

V

SS

OSC2

OSC1

ISPSEL

15

16

17

20

19

18

ei1

ei0

(HS)

20mA high sink capability

OA2OUT

PWM1R / OA2PIN / PC1

OA2NIN / PC0

TDO / PB7

RDI / PB6

ISPDATA / MISO / PB5

MOSI /

(HS)

PB4

ISPCLK / SCK/

(HS)

PB3

SS /

(HS)

PB2

ARTCLK /

(HS)

PB1

EXTCLK /

(HS)

PB0

V

DD

V

SS

OSC2

OSC1

ISPSEL

PC2 / OA1PIN / PWM0R

PC3 / OA1NIN

OA1OUT

PC4 / MCO

V

DDA

V

SSA

PC5 / PWM0

PA7 /AIN7 / PWM1

PA6 /AIN6 /ARTICP0

PA5 /AIN5

PA4 /AIN4 / OCMP1

PA3 /AIN3 / OCMP2

PA2 /AIN2 / ICAP1

PA1 /AIN1 / ICAP2

PA0 /AIN0

RESET

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

ei1

ei0

(HS)

20mA high sink capability

Page 6

ST72C171

6/151

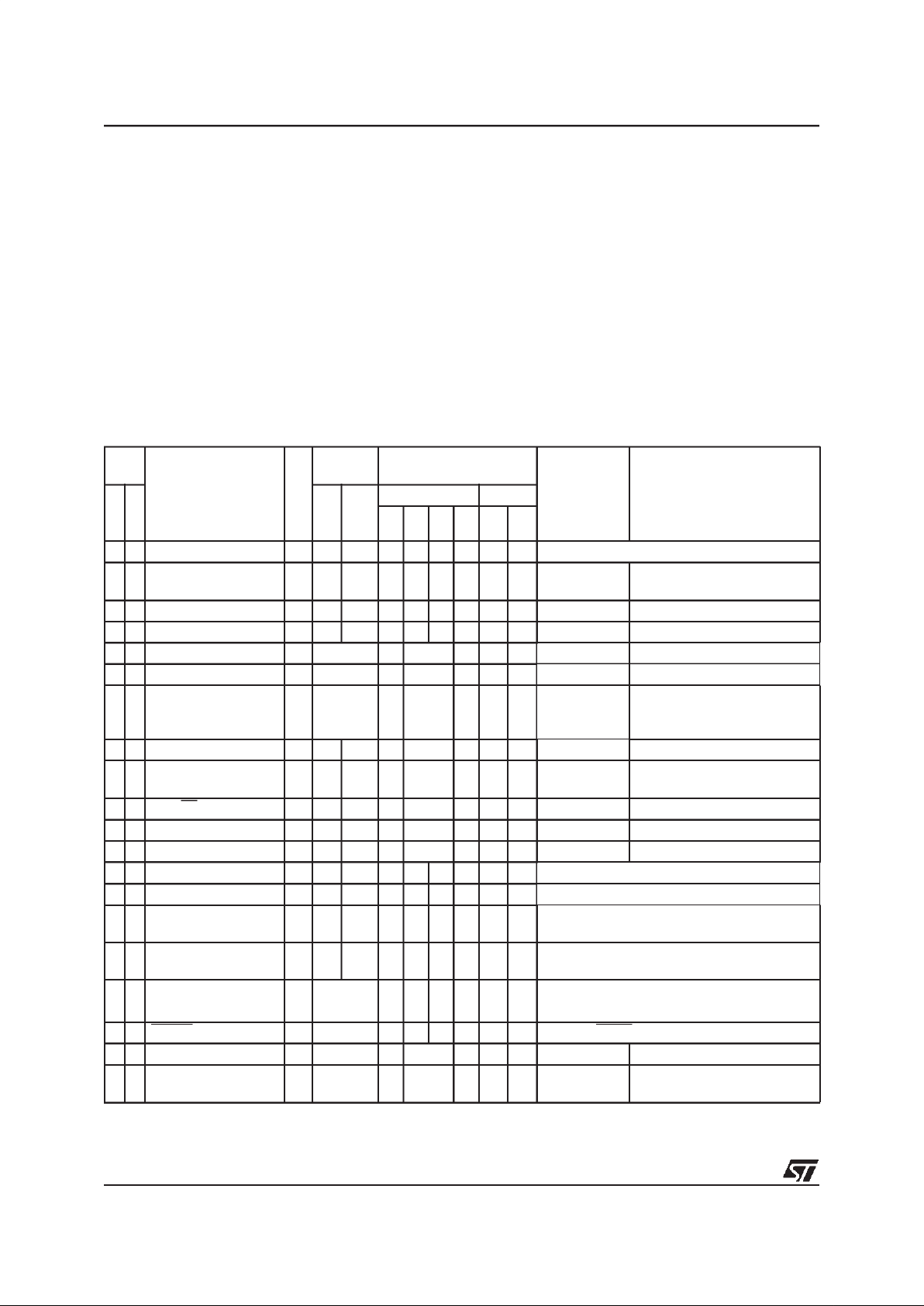

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations:

Type: I = input, O = output, S = supply

In/Output level: C = CMOS 0.3VDD/0.7VDD,

CR= CMOS Levels with resistive output (1K)

A = Analog levels

Output level: HS = high sink (on N-buffer only),

Port configuration capabilities:

– Input:float = floating, wpu = weak pull-up, int = interrupt,ana = analog

– Output: OD = open drain, T = true open drain, PP = push-pull

Note: the Reset configuration of each pin is shown in bold.

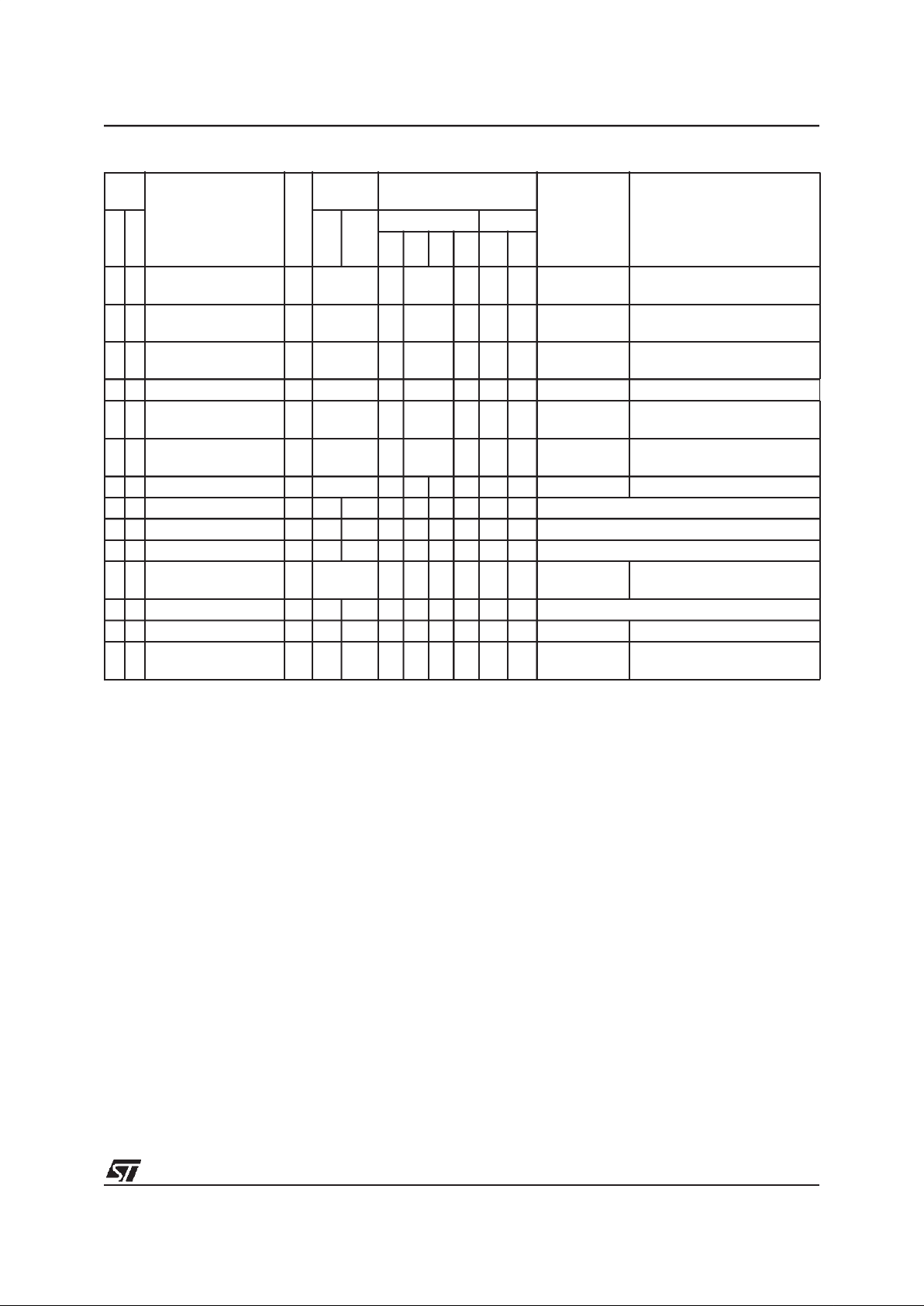

Table 1. Device Pin Description

Pin

n°

Pin Name

Type

Level Port

Main

function

(after

reset)

Alternate function

SDIP32

SO34

Input

Output

Input Output

float

wpu

int

ana

OD

PP

1 1 OA2OUT O A OA2 output

22

PC1/OA2PIN/

PWM1R

I/O C C/C

R

X X X X X Port C1

OA2 noninverting input and/or

ART PWM1 resistive output

3 3 PC0/OA2NIN I/O C/A C X X X X X Port C0 OA2 inverting input

- 4 OA3PIN I A OA3 noninverting input

4 5 PB7/TDO I/O C X ei1 X X Port B7 SCI transmit

5 6 PB6/RDI I/O C X ei1 X X Port B6 SCI receive

6 7 PB5/MISO/ISPDATA I/O C X ei1 X X Port B5

SPI data master in/slaveout or

In Situ Programming Data Input

7 8 PB4/MOSI I/O C HS X ei1 X X Port B4 SPI data master out/slave in

8 9 PB3/SCK/ISPCLK I/O C HS X ei1 X X Port B3

SPI Clock or In Situ Programming Clock Output

9 10 PB2/SS I/O C HS X ei1 X X Port B2 SPI Slave Select (active low)

10 11 PB1/ARTCLK I/O C HS X ei1 X X Port B1 ART External Clock

11 12 PB0/EXTCLK I/O C HS X ei1 X X Port B0 Timer16 External Clock

12 13 V

DD

S Digital Main Supply Voltage

13 14 V

SS

S Digital ground voltage

14 15 OSC2

Resonator oscillator inverter output or capacitor input for RC oscillator

15 16 OSC1

External clock input or Resonator oscillator inverter input or resistor input for RC oscillator

16 17 ISPSEL I C

In Situ Programming Mode Select

Must be tied to V

SS

in user mode

17 18 RESET I/O C X X External Reset

18 19 PA0/AIN0 I/O C X ei0 X X X Port A0 ADC input 0

19 20 PA1/AIN1/ICAP2 I/O C X ei0 X X X Port A1

ADC input 1 orTimer16 input

capture 2

Page 7

ST72C171

7/151

Notes:

1. In the interrupt input column, “eix” defines the associated external interrupt vector. If the weak pull-up

column (wpu) is associated with the interrupt column (int), then the I/O configuration is pull-up interrupt

input, else the configuration is floating interrupt input.

2. OSC1 andOSC2 pins connect a crystal or ceramic resonator, an external RC, or an external source to

the on-chip oscillator see dedicated See “PIN DESCRIPTION” on page 5. for more details.

20 21 PA2/AIN2/ICAP1 I/O C X ei0 X X X Port A2

ADC input 2

or Timer16 input capture 1

21 22 PA3/AIN3/OCMP2 I/O C X ei0 X X X Port A3

ADC input 3 orTimer16 output

compare 2

22 23 PA4/AIN4/OCMP1 I/O C X ei0 X X X Port A4

ADC input 4 orTimer16 output

compare 1

23 24 PA5/AIN5 I/O C X ei0 X X X Port A5 ADC input 5

24 25 PA6/AIN6/ARTICP0 I/O C X ei0 X X X Port A6

ADC input 6 or ARTinput capture

25 26 PA7/AIN7/PWM1 I/O C X ei0 X X X Port A7

ADC input 7 or ART PWM1

output

26 27 PC5/PWM0 I/O C X X X X Port C5 ART PWM0 output

- 28 OA3OUT O A OA3 output

27 29 V

SSA

Analog ground

28 30 V

DDA

Analog supply

29 31 PC4/MCO/OA3NIN I/O C X XXXPortC4

Main Clock Out or OA3 invert-

ing input

30 32 OA1OUT O A OA1 output

31 33 PC3/OA1NIN I/O C/A C X X X X Port C3 OA1 inverting input

32 34

PC2/OA1PIN/

PWM0R

I/O C/A C/C

R

X XXXPortC2

OA1 non-inverting input and/

or ART PWM0 resistive output

Pin

n°

Pin Name

Type

Level Port

Main

function

(after

reset)

Alternate function

SDIP32

SO34

Input

Output

Input Output

float

wpu

int

ana

OD

PP

Page 8

ST72C171

8/151

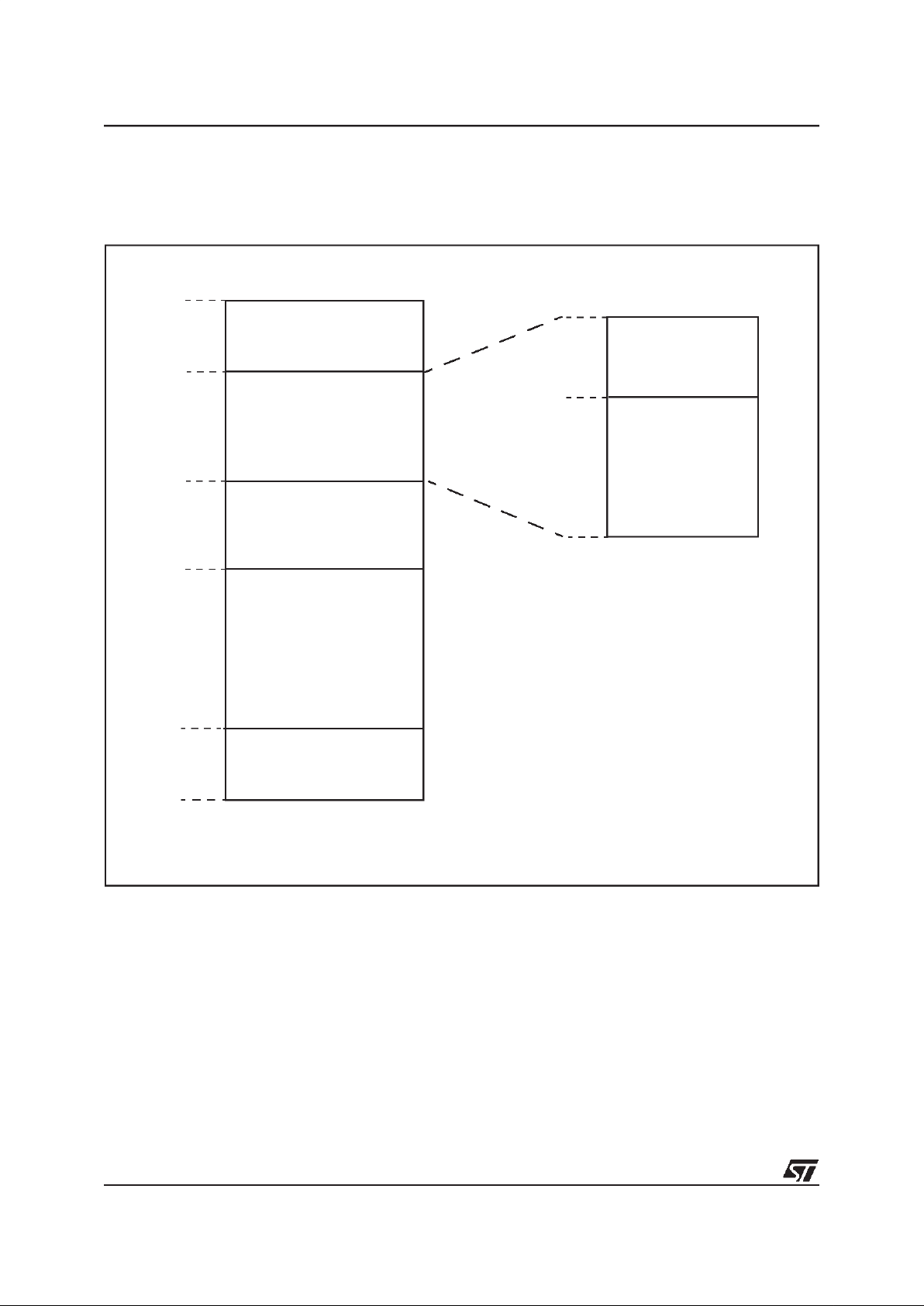

1.3 MEMORY MAP

1.3.1 Introduction

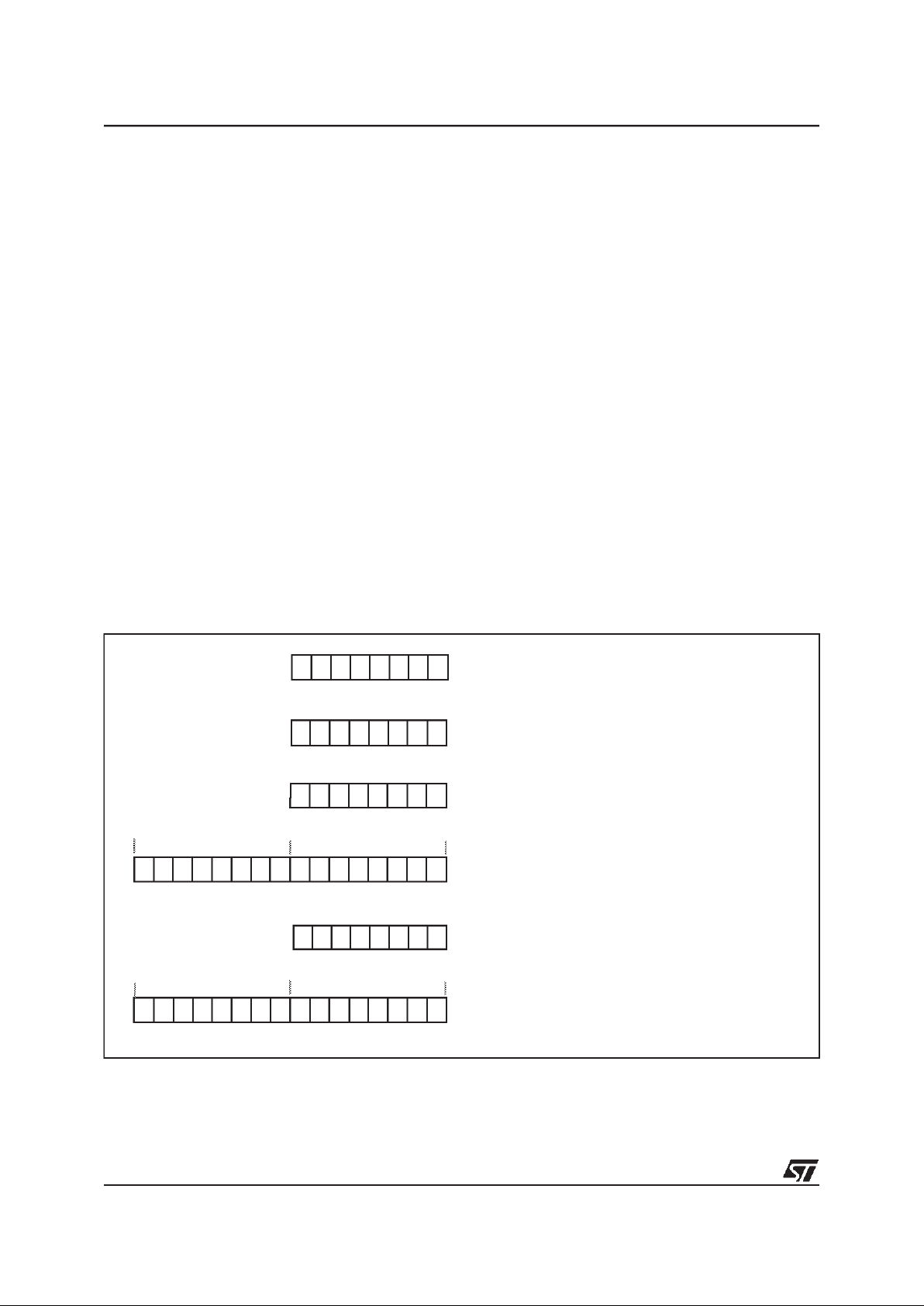

Figure 4. Program Memory Map

Short Addressing

RAM

Stack

0100h

017Fh

0080h

00FFh

0000h

8 Kbytes

Interrupt & Reset Vectors

HW Registers

017Fh

0080h

007Fh

0180h

DFFFh

Reserved

(see

Table 1.3.2)

E000h

FFDFh

FFE0h

FFFFh

(see Table 4)

256 bytes RAM

FLASH

(128 Bytes)

(128 Bytes)

Zero page

Page 9

ST72C171

9/151

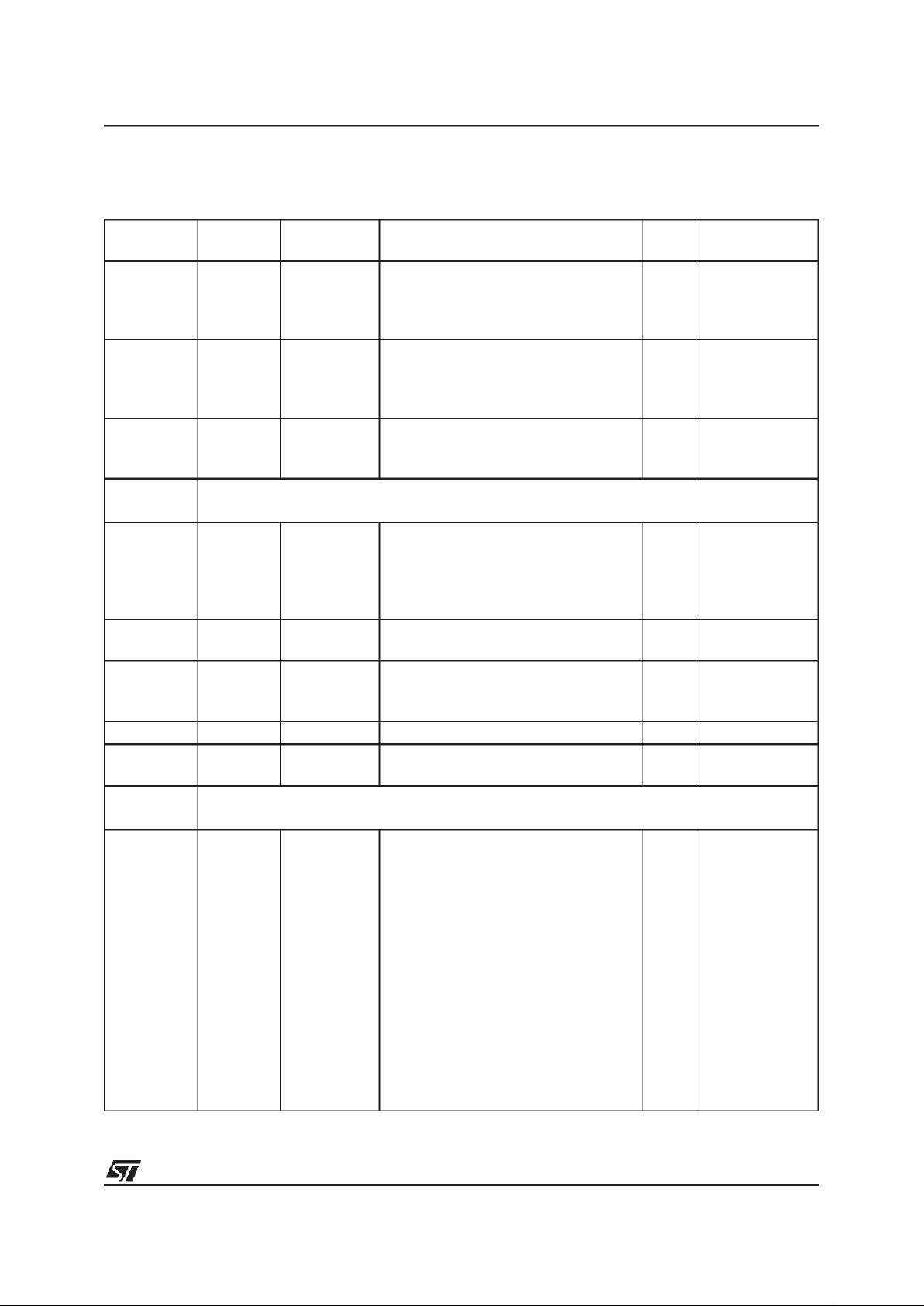

1.3.2 Data Register

Table 2. Hardware Register Memory Map

Address

Block

Name

Register

Label

Register name

Reset

Status

Remarks

0000h

0001h

0002h

0003h

Port A

PADR

PADDR

PAOR

Data Register

Data Direction Register

Option Register

Not Used

00h

00h

00h

R/W

R/W

R/W

Absent

0004h

0005h

0006h

0007h

Port B

PBDR

PBDDR

PBOR

Data Register

Data Direction Register

Option Register

Not Used

00h

00h

00h

R/W

R/W

R/W

Absent

0008h

0009h

000Ah

Port C

PCDR

PCDDR

PCOR

Data Register

Data Direction Register

Option Register

00h

00h

00h

R/W

R/W

R/W

000Bh to

001Ah

Reserved Area (16 Bytes)

001Bh

001Ch

001Dh

001Eh

001Fh

OPAMP

OA1CR

OA2CR

OA3CR

OAIRR

OAVRCR

OA1 Control Register

OA2 Control Register

OA3 Control Register

OA Interrupt & Readout Register

OA Voltage Reference Control Register

00h

00h

00h

00h

00h

R/W

R/W

R/W

Section 7.3

R/W

0020h MISC1 MISCR1 Miscellaneous Register 1 00h

see

Section

4.3.5

0021h

0022h

0023h

SPI

SPIDR

SPICR

SPISR

Data I/O Register

Control Register

Status Register

xxh

0xh

00h

R/W

R/W

Read Only

0024h WDG WDGCR Watchdog Control register 7Fh R/W

0025h CRS CRSR

Clock, Reset and Supply Control / Status

Register

00h R/W

0026h to

0030h

Reserved Area (11 Bytes)

0031h

0032h

0033h

0034h0035h

0036h0037h

0038h0039h

003Ah003Bh

003Ch003Dh

003Eh003Fh

TIMER16

TACR2

TACR1

TASR

TAIC1HR

TAIC1LR

TAOC1HR

TAOC1LR

TACHR

TACLR

TAACHR

TAACLR

TAIC2HR

TAIC2LR

TAOC2HR

TAOC2LR

Control Register2

Control Register1

Status Register

Input Capture1 High Register

Input Capture1 Low Register

Output Compare1 High Register

Output Compare1 Low Register

Counter High Register

Counter Low Register

Alternate Counter High Register

Alternate Counter Low Register

Input Capture2 High Register

Input Capture2 Low Register

Output Compare2 High Register

Output Compare2 Low Register

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

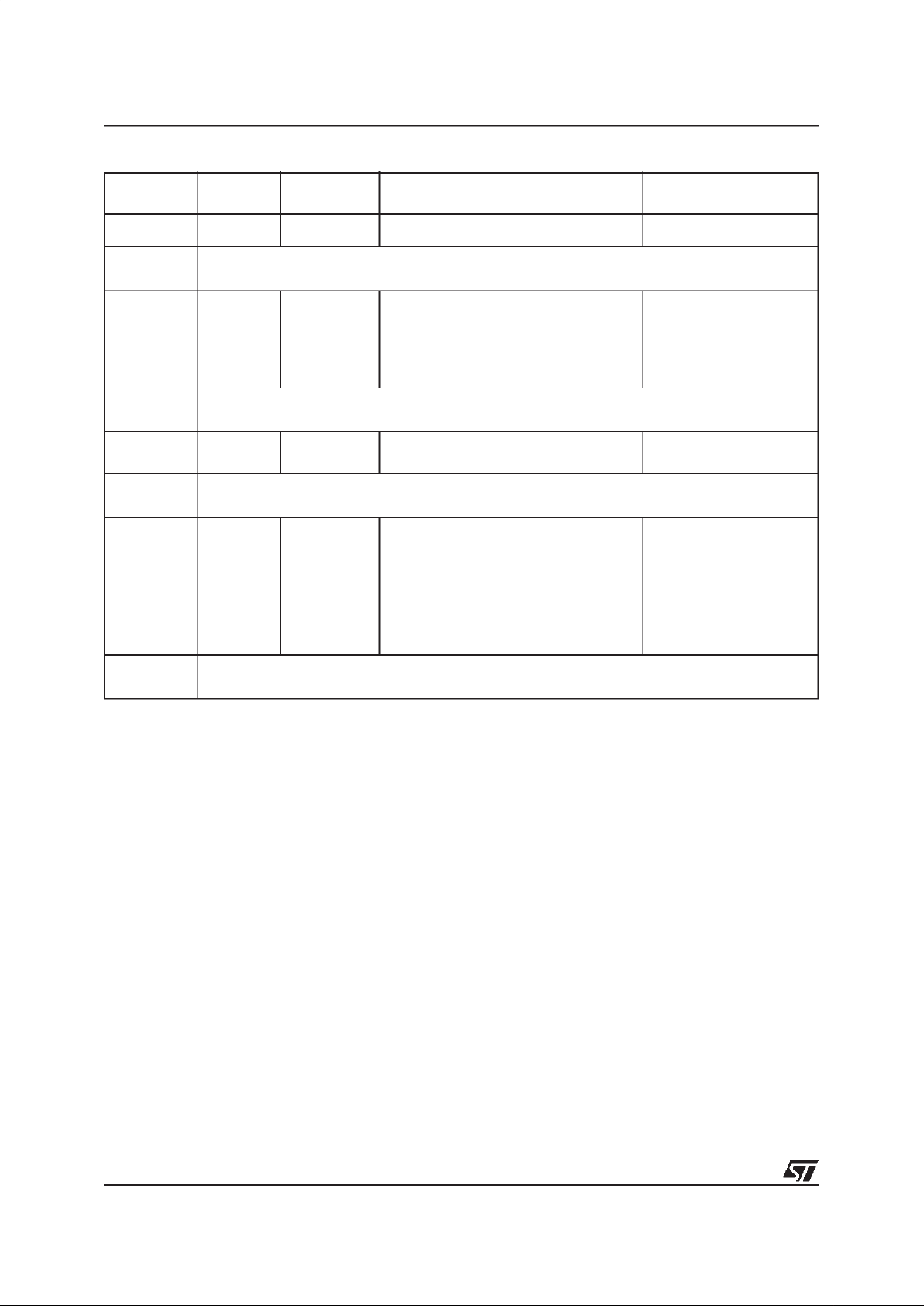

Page 10

ST72C171

10/151

0040h MISC2 MISCR2 Miscellaneous Register2 00h

see

Section

7.2.2

0041h to

004Fh

Reserved Area (15 Bytes)

0050h

0051h

0052h

0053h

0054h

SCI

SCISR

SCIDR

SCIBRR

SCICR1

SCICR2

Status Register

Data Register

Baud Rate Register

Control Register 1

Control Register 2

0C0h

0xxh

0Xxh

0xxh

00h

Read Only

R/W

R/W

R/W

R/W

0055h to

006Fh

Reserved Area (27 Bytes)

0070h

0071h

ADC

ADCDR

ADCCSR

Data Register

Control/Status Register

00h

00h

Read Only

R/W

0072h

0073h

Reserved Area (2 Bytes)

0074h

0075h

0076h

0077h

0078h

0079h

007Ah

007Bh

ART/PWM

PWMDCR1

PWMDCR0

PWMCR

ARTCSR

ARTCAR

ARTARR

ARTICCSR

ARTICR1

PWM Duty Cycle Register 1

PWM Duty Cycle Register 0

PWM Control Register

Control/Status Register

Counter Access Register

Auto Reload Register

Input Capture Control Status Register

Input Capture Register 1

00h

00h

00h

00h

00h

00h

00h

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

007Ch to

007Fh

Reserved Area (4 Bytes)

Address

Block

Name

Register

Label

Register name

Reset

Status

Remarks

Page 11

ST72C171

11/151

2 FLASH PROGRAM MEMORY

2.1 INTRODUCTION

FLASH devices have a single voltage non-volatile

FLASH memory that may be programmed in-situ

(or plugged in a programming tool) on a byte-bybyte basis.

2.2 MAIN FEATURES

■ Remote In-Situ Programming (ISP) mode

■ Up to 16 bytes programmedin the same cycle

■ MTP memory (Multiple Time Programmable)

■ Read-out memory protection against piracy

2.3 STRUCTURAL ORGANISATION

The FLASH program memory is organised in a

single 8-bit wide memory block which can be used

for storing both code and data constants.

The FLASH program memory is mappedin the upper part ofthe ST7 addressing space and includes

the reset and interrupt user vector area .

2.4 IN-SITU PROGRAMMING (ISP) MODE

The FLASH program memory canbe programmed

using Remote ISP mode. This ISP mode allows

the contentsoftheST7program memory to be updated usingastandard ST7 programming tools after the device is mounted on the application board.

This feature can be implemented with a minimum

number of added components and board area impact.

An exampleRemote ISP hardware interface to the

standard ST7 programming tool is described below. For more details on ISP programming, refer to

the ST7 Programming Specification.

Remote ISP Overview

The Remote ISP mode is initiatedby a specific sequence on the dedicated ISPSEL pin.

The Remote ISP is performedin three steps:

– Selection of the RAM execution mode

– Download of Remote ISP codein RAM

– Execution ofRemote ISP code in RAM to pro-

gram the user program into the FLASH

Remote ISP hardware configuration

In Remote ISP mode, the ST7 has to be supplied

with power (VDDand VSS) and a clock signal (oscillator and application crystal circuit for example).

This mode needs five signals (plus the VDDsignal

if necessary) to be connected to the programming

tool. This signals are:

– RESET: device reset

–VSS: device ground power supply

– ISPCLK: ISP outputserial clock pin

– ISPDATA: ISP input serial data pin

– ISPSEL: Remote ISP modeselection. Thispin

must be connected to VSSon the application

board through a pull-down resistor.

If any of thesepins areused for other purposeson

the application, a serial resistor has to be implemented to avoid a conflict ifthe other deviceforces

the signal level.

Figure 5 shows a typical hardware interface to a

standard ST7 programming tool. For more details

on the pin locations, refer to the device pinout description.

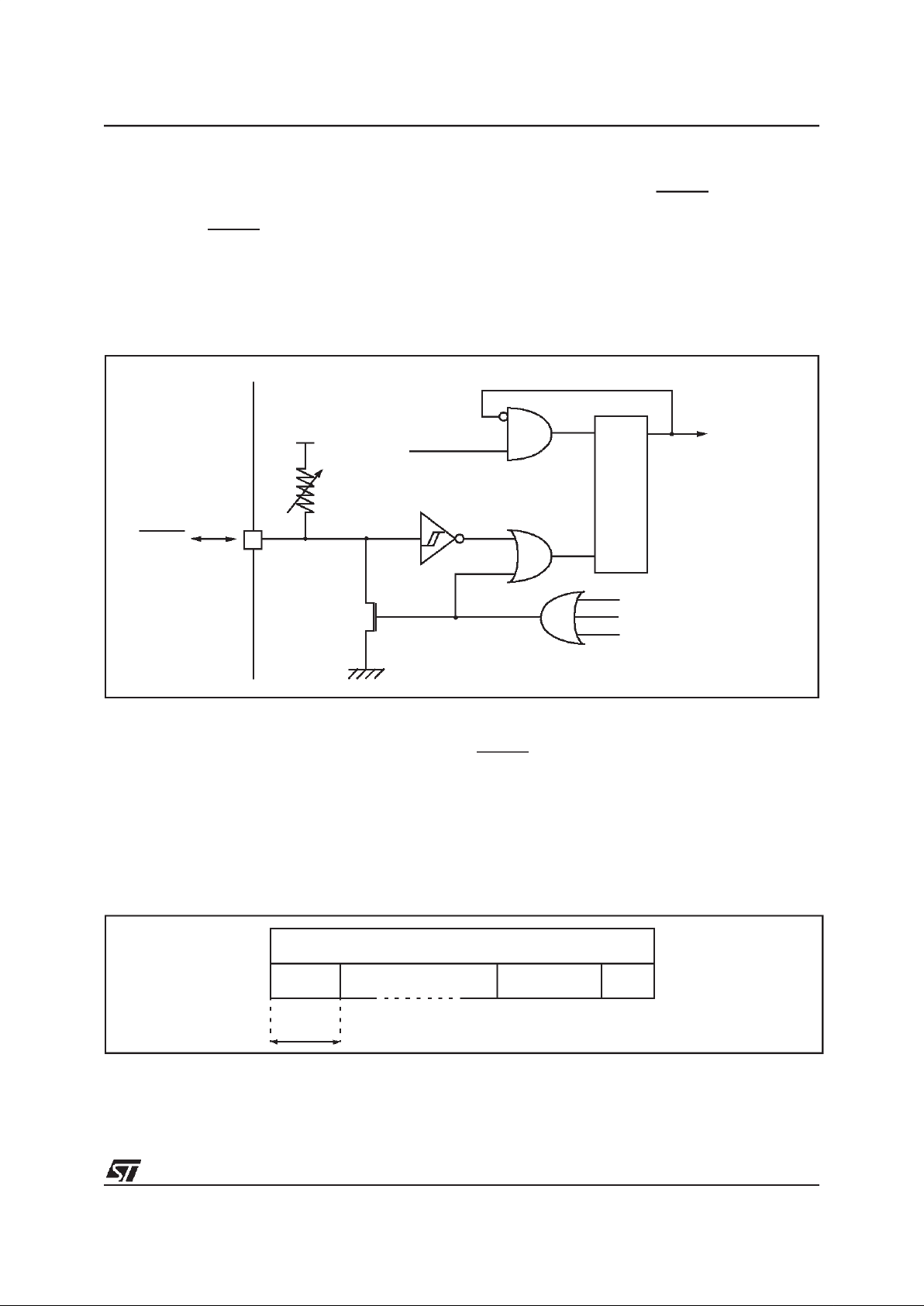

Figure 5. Typical Remote ISP Interface

2.5 MEMORY READ-OUT PROTECTION

The read-out protection is enabled through an option bit.

For FLASH devices, when this option is selected,

the program and data stored in the FLASH memory are protected against read-out piracy (including

a re-write protection). When this protection option

is removed the entire FLASH program memory is

first automatically erased. However, the E2PROM

data memory (when available) can be protected

only with ROM devices.

ISPSEL

V

SS

RESET

ISPCLK

ISPDATA

OSC1

OSC2

V

DD

ST7

HE10 CONNECTOR TYPE

TO PROGRAMMINGTOOL

10KΩ

C

L0

C

L1

APPLICATION

47KΩ

1

XTAL

Page 12

ST72C171

12/151

3 CENTRAL PROCESSING UNIT

3.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

3.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

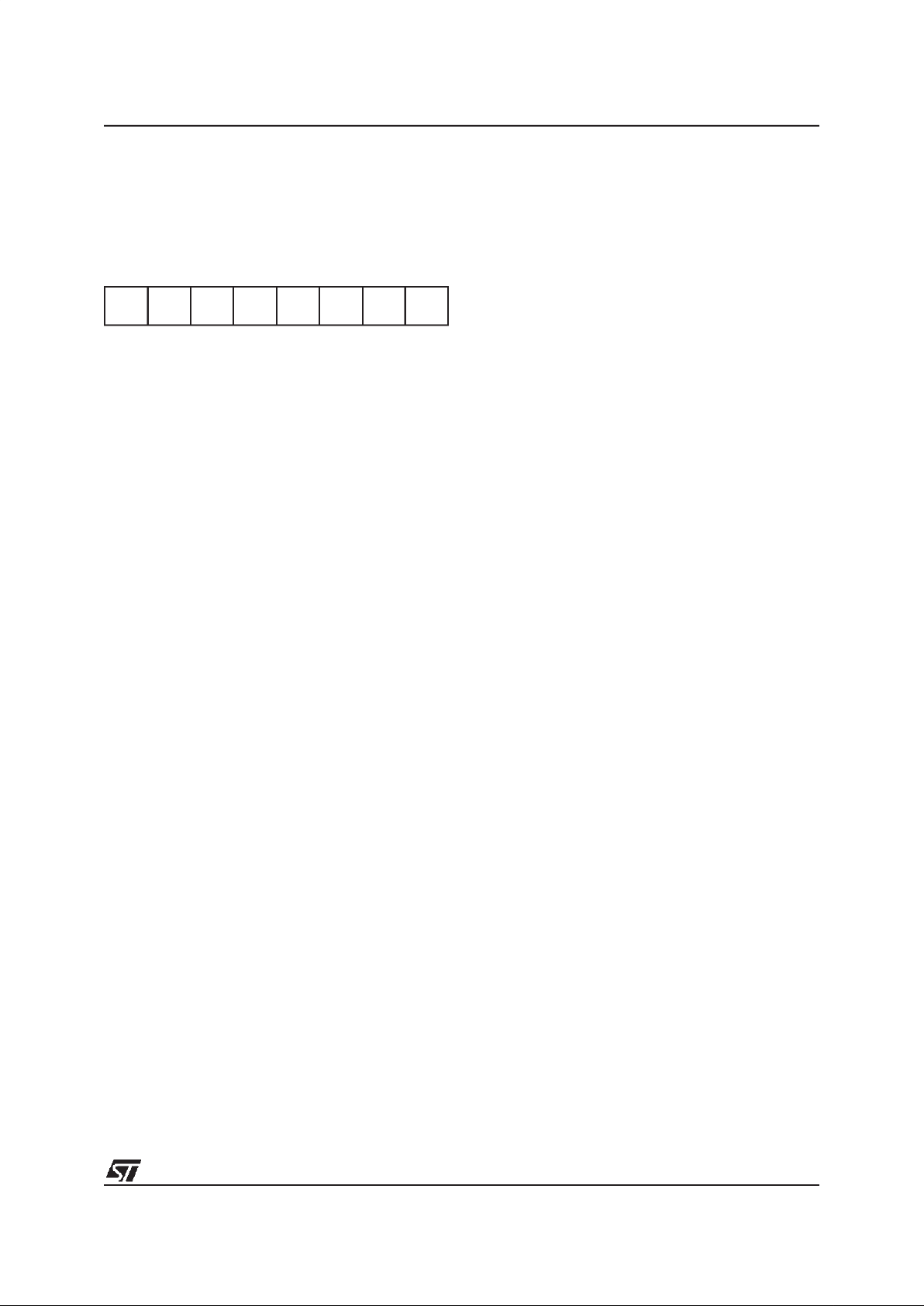

3.3 CPU REGISTERS

The 6 CPU registers shown in Figure 6 are not

present in the memory mapping and are accessed

by specific instructions.

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bitregisters

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y registeris not affectedby the interrupt automatic procedures (notpushed to and popped from

the stack).

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) andPCH

(Program CounterHigh which is the MSB).

Figure 6. CPU Registers

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

STACK POINTER

CONDITION CODE REGISTER

PROGRAM COUNTER

70

1C11HI NZ

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

70

70

70

0

7

15 8

PCH

PCL

15

87 0

RESET VALUE = STACKHIGHER ADDRESS

RESET VALUE =

1X11X1XX

RESET VALUE = XXh

RESET VALUE = XXh

RESET VALUE= XXh

X = Undefined Value

Page 13

ST72C171

13/151

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

The 8-bit Condition Code register contains the interrupt mask and four flags representative of the

result ofthe instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

Bit 4 = H

Half carry

.

This bit is set by hardware whena carryoccursbetween bits 3 and 4 of the ALU during an ADD or

ADC instruction. It is resetby hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines.

Bit 3 = I

Interrupt mask

.

This bit is set by hardware when entering in interrupt or by software to disable all interrupts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlledby the RIM, SIM and IRET instructions and is tested by the JRM and JRNM instructions.

Note: Interrupts requested while I is set are

latched and can be processed when I is cleared.

By default an interrupt routine is not interruptable

because the I bit is set by hardware when you en-

ter it and reset by the IRET instruction at the end of

the interrupt routine. If the I bit is cleared by software in the interrupt routine, pending interruptsare

serviced regardless of the priority level of the current interrupt routine.

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is representative of the result sign of the last arithmetic,

logical or data manipulation. It is a copy of the 7

th

bit of the result.

0:Theresultof the last operation is positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit isaccessed bythe JRMI andJRPL instructions.

Bit 1 = Z

Zero

.

This bit is set and cleared by hardware. Thisbit indicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 0 = C

Carry/borrow.

This bit is set and cleared by hardware and software. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow hasoccurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

70

111HINZC

Page 14

ST72C171

14/151

CENTRAL PROCESSING UNIT (Cont’d)

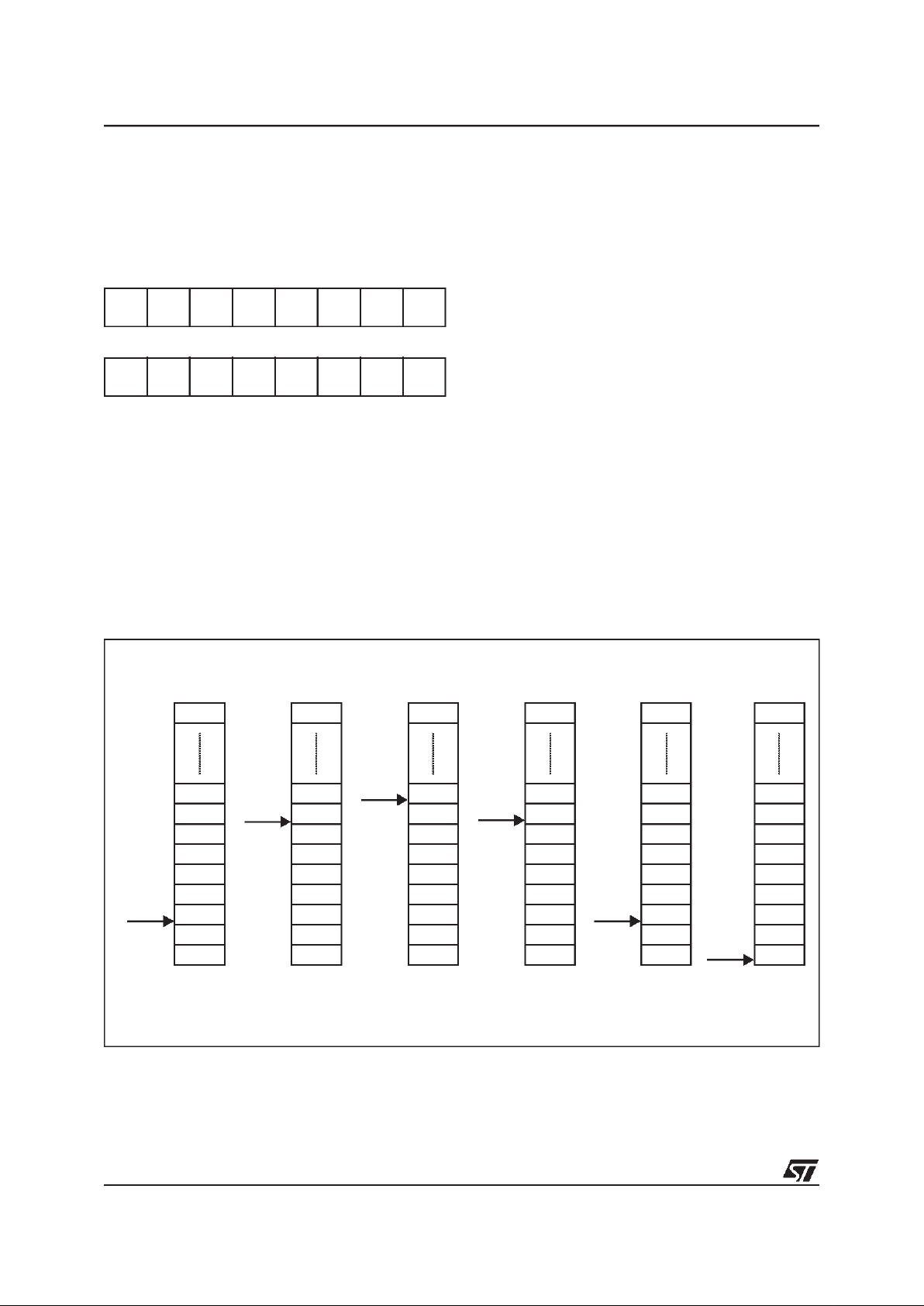

Stack Pointer (SP)

Read/Write

Reset Value: 01 7Fh

The Stack Pointer is a 16-bit register which is always pointingto the next free location in the stack.

It isthen decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 7).

Since the stack is 128 bytes deep, the10 most significant bits are forced by hardware. Following an

MCU Reset, orafter a Reset Stack Pointer instruction (RSP),the Stack Pointer contains its reset value (the SP5 to SP0 bits are set) which is the stack

higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, without indicating the stack overflow. The previously

stored information is then overwritten and therefore lost. The stack also wrapsin case of anunderflow.

The stack is used to save the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by meansof the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location pointed to by the SP. Then the

other registers are stored in the next locations as

shown in Figure 7.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from thestack.

A subroutine call occupies twolocations and an interrupt five locations in the stack area.

Figure 7. Stack Manipulation Example

15 8

00000001

70

0 1 SP5 SP4 SP3 SP2 SP1 SP0

PCH

PCL

SP

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

SP

Y

CALL

Subroutine

Interrupt

Event

PUSH Y POP Y IRET

RET

or RSP

@ 017Fh

@ 0100h

Stack Higher Address = 017Fh

Stack Lower Address =

0100h

Page 15

ST72C171

15/151

4 SUPPLY, RESET AND CLOCK

MANAGEMENT

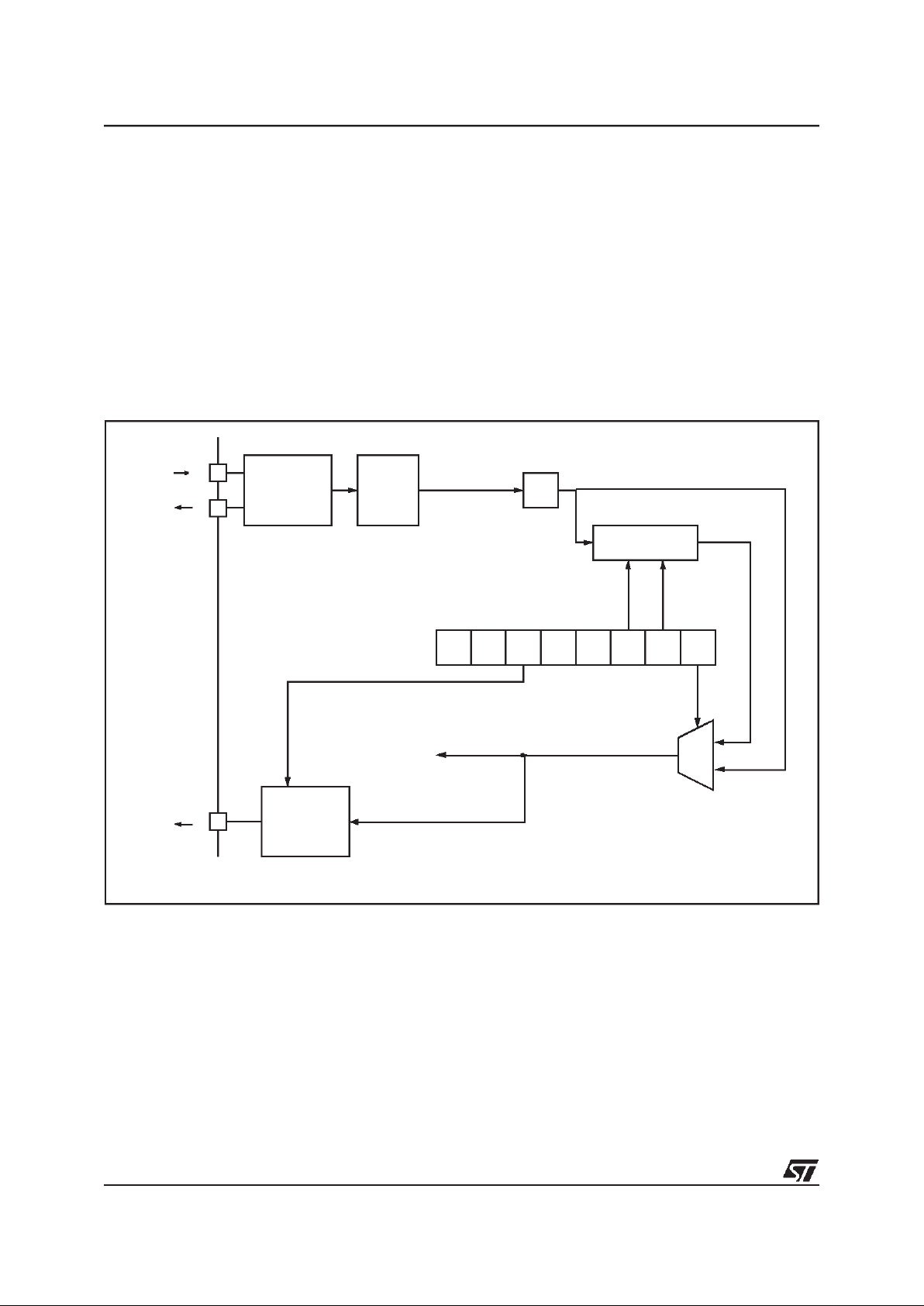

The device includes a range of utility features for

securing the application in critical situations (for

example in case of a power brown-out), and reducing the number of external components. An

overview is shown in Figure 8.

4.1 Main Features

■ Supply Manager

– Main supply Low voltage detection (LVD)

– Global power down

■ Reset Sequence Manager (RSM)

■ Multi-Oscillator (MO)

– 4 Crystal/Ceramic resonator oscillators

– 2 External RC oscillators

– 1 Internal RC oscillator

■ Clock Security System (CSS)

– Clock Filter

– Backup Safe Oscillator

■ Main Clock controller (MCC)

Figure 8. Clock, Reset and Supply Block Diagram

IE SOD0- - - RF RF

CRSR

CSS- WDG

f

OSC

MAIN CLOCK

CONTROLLER

(MCC)

CF INTERRUPT

LVD

LOW VOLTAGE

DETECTOR

(LVD)

MULTI-

OSCILLATOR

(MO)

f

CPU

FROM

WATCHDOG

PERIPHERAL

MCO

OSCOUT

OSCIN

RESET

V

DD

V

SS

RESET SEQUENCE

MANAGER

(RSM)

CLOCK

FILTER

SAFE

OSC

CLOCK SECURITY SYSTEM

(CSS)

Page 16

ST72C171

16/151

4.2 LOW VOLTAGE DETECTOR (LVD)

To allow the integration of power management

features in the application, the Low Voltage Detector function (LVD) generates a static reset when

the VDDsupply voltage is below a V

IT-

reference

value. This means that it secures the power-up as

well as the power-down keeping the ST7 in reset.

The V

IT-

referencevalue fora voltage drop is lower

than the V

IT+

referencevalue forpower-on in order

to avoid a parasitic reset when theMCUstarts running and sinks current on the supply (hysteresis).

The LVD Reset circuitry generates a reset when

VDDis below:

–V

IT+

when VDDis rising

–V

IT-

when VDDis falling

The LVD function is illustrated in the Figure .

Provided the minimum VDDvalue (guaranteed for

the oscillator frequency) is above V

IT-

, the MCU

can only be in two modes:

– under full software control

– in static safe reset

In these conditions, secure operation is always ensured for the application without the need for external reset hardware.

During aLow Voltage Detector Reset, the RESET

pin is held low, thus permitting the MCU to reset

other devices.

Notes:

1. The LVD allows the device to be used without

any external RESET circuitry.

2. Three different reference levels are selectable

through the option byte according to the application requirement.

LVD application note

Application software can detect a reset caused by

the LVD by reading the LVDRF bit in the CRSR

register.

This bit is set by hardware when a LVD reset is

generated and cleared by software (writing zero).

Figure 9. Low Voltage Detector vs Reset

V

DD

V

IT+

RESET

V

IT-

V

hyst

Page 17

ST72C171

17/151

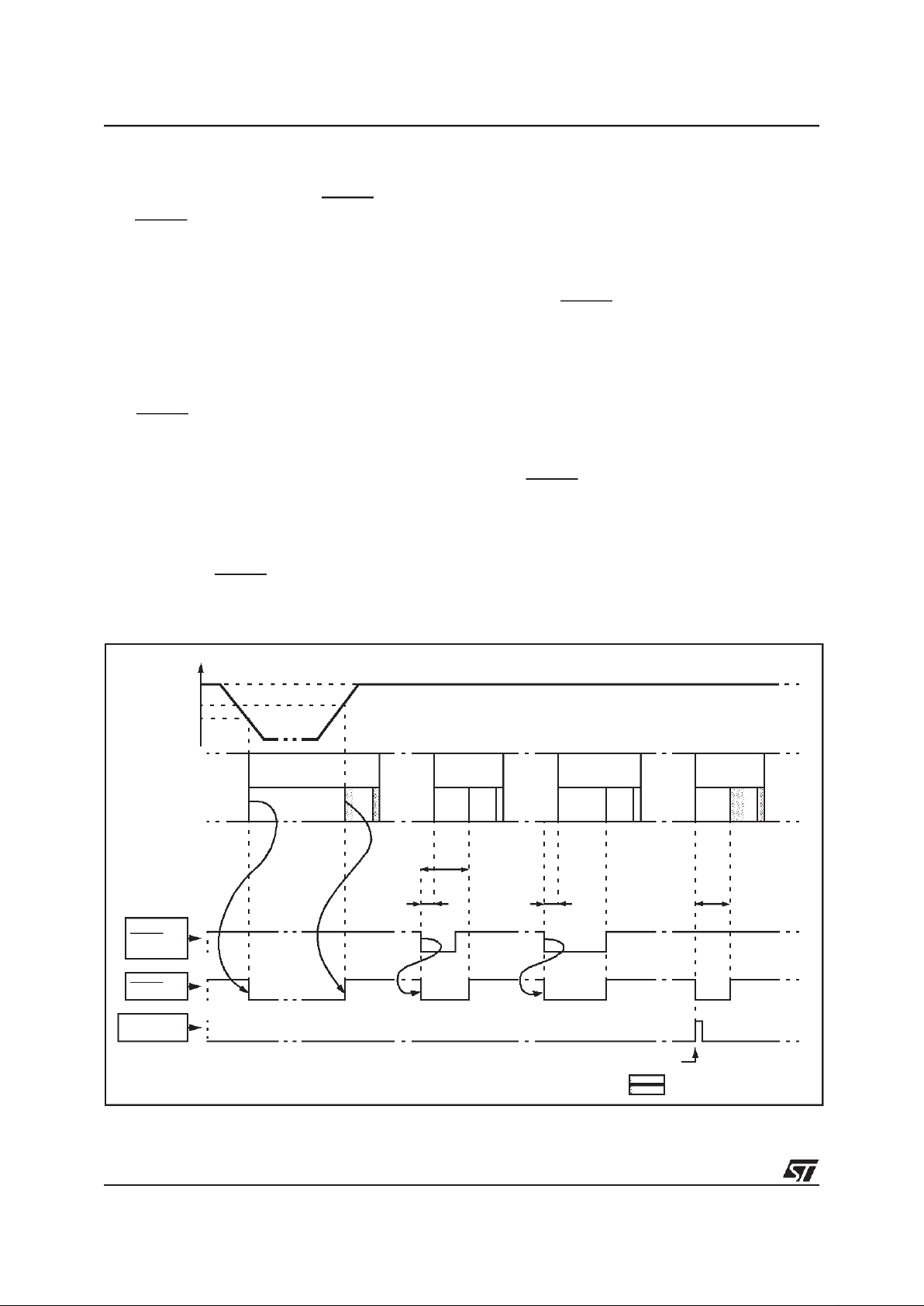

4.2.1 Reset Sequence Manager (RSM)

The RSM block of the CROSS Module includes

three RESET sources as shown in Figure 10:

■ EXTERNAL RESETSOURCE pulse

■ Internal LVD RESET (Low Voltage Detection)

■ Internal WATCHDOG RESET

These sources act on the RESET PIN and it is always kept low during the READ OPTION RESET

phase.

The RESET service routine vector is fixed at the

FFFEh-FFFFh addresses in the ST7 memory

map.

Figure 10. Reset Block Diagram

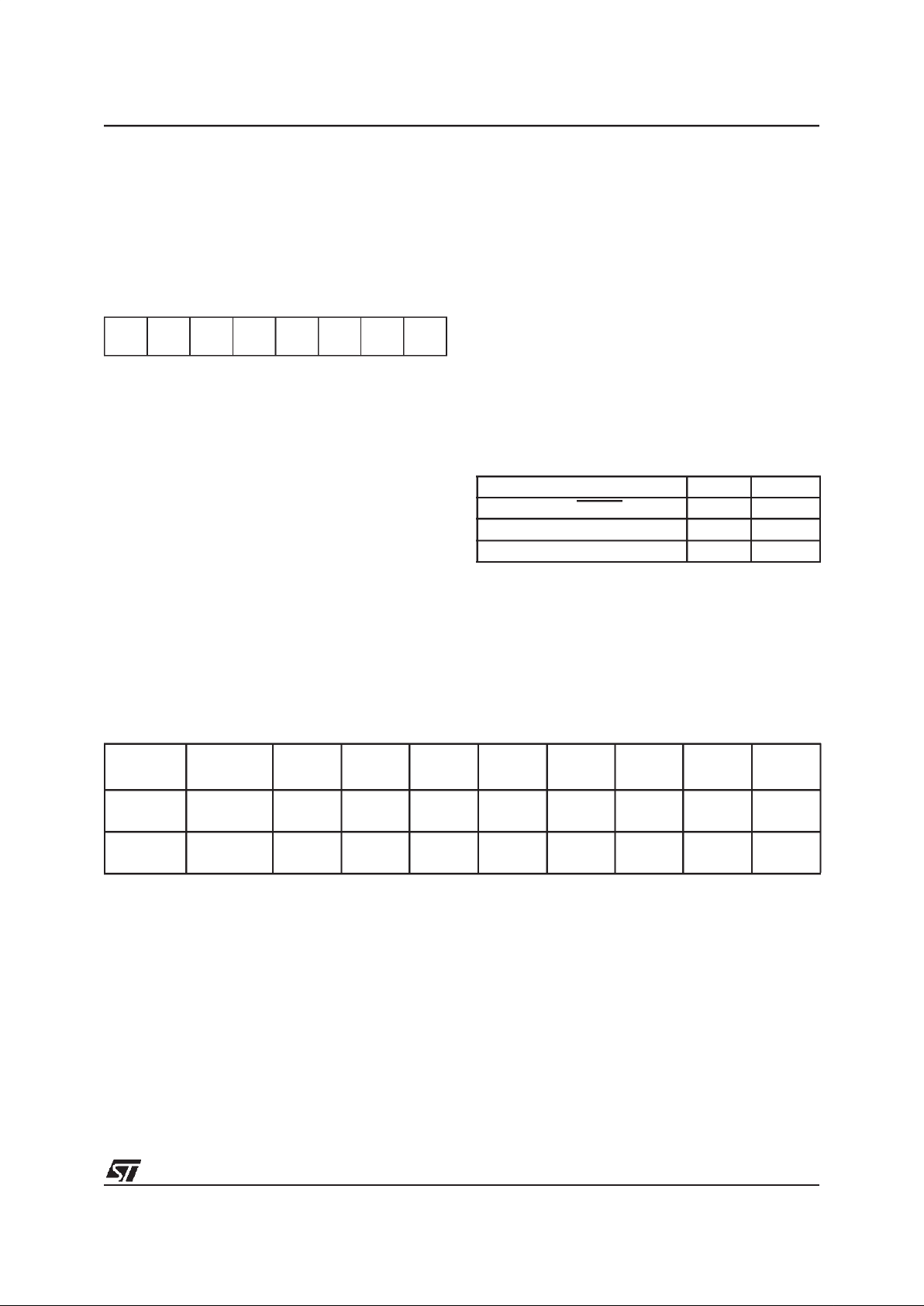

The basic RESET sequence consists of 4 phases

as shown in Figure 11:

■ OPTION BYTE reading to configure the device

■ Delay depending on the RESET source

■ 4096 cpu clock cycle delay

■ RESET vector fetch

The duration of the OPTION BYTE reading phase

(t

ROB

) is defined in the Electrical Characteristics

section. This first phase is initiated by an external

RESET pin pulse detection, a Watchdog RESET

detection, or when VDDrises up to V

LVDopt

.

The 4096 cpu clock cycledelay allows the oscillator to stabilise and to ensure thatrecovery has taken place from the Reset state.

The RESET vector fetch phase duration is 2 clock

cycles.

Figure 11. RESET Sequence Phases

f

CPU

COUNTER

RESET

R

ON

V

DD

WATCHDOG RESET

LVD RESET

INTERNAL

RESET

READ OPTION RESET

RESET

READ

OPTION BYTE

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

DELAY

t

ROB

Page 18

ST72C171

18/151

RESET SEQUENCE MANAGER (Cont’d)

4.2.2 Asynchronous External RESET pin

The RESETpin is both an input andan open-drain

output with integrated RONweak pull-up resistor.

This pull-up has no fixed value but varies in accordance with the input voltage. It can be pulled

low by external circuitry to reset the device. See

electrical characteristics section for more details.

A RESET signal originating from an external

source must have a duration of at least t

h(RSTL)in

in

order to be recognized. This detection is asynchronous and therefore the MCU can enter reset state

even in HALT mode.

The RESET pin is an asynchronous signal which

plays a major role in EMS performance. In a noisy

environment, it is recommended to follow the

guidelines mentioned in the electrical characteristics section.

Two RESET sequences can be associated with

this RESET source: short or long external reset

pulse (see Figure 12).

Starting from the external RESET pulse recognition, the device RESET pin acts as an output that

is pulled low during at least t

w(RSTL)out

.

4.2.3 Internal Low Voltage Detection RESET

Two different RESET sequences caused by the internal LVD circuitry can be distinguished:

■ Power-On RESET

■ Voltage Drop RESET

The device RESET pin acts as an output that is

pulled low when VDD<V

IT+

(rising edge) or

VDD<V

IT-

(falling edge) as shown in Figure 12.

The LVD filters spikes on VDDlarger than t

g(VDD)

to

avoid parasitic resets.

4.2.4 Internal Watchdog RESET

The RESET sequence generated by a internal

Watchdog counter overflow is shown in Figure 12.

Starting from the Watchdog counter underflow, the

device RESET pin acts as an output that is pulled

low during at least t

w(RSTL)out

.

Figure 12. RESET Sequences

V

DD

RUN

RESET PIN

EXTERNAL

WATCHDOG

DELAY

V

IT+

V

IT-

t

h(RSTL)in

t

w(RSTL)out

RUN

DELAY

t

h(RSTL)in

DELAY

WATCHDOG UNDERFLOW

t

w(RSTL)out

RUN RUN

DELAY

RUN

RESET

RESET

SOURCE

SHORT EXT.

RESET

LVD

RESET

LONG EXT.

RESET

WATCHDOG

RESET

INTERNAL RESET (4096T

CPU

)

FETCH VECTOR

Page 19

ST72C171

19/151

4.2.4.1 Multi-Oscillator (MO)

The Multi-Oscillator (MO) block is the main clock

supplier of the ST7. To insure an optimum integration in the application, it is based on an external

clock source and six different selectable oscillators.

The main clock of the ST7 can be generated by 8

different sources comming from the MO block:

■ an External source

■ 4 Crystal or Ceramic resonator oscillators

■ 1 External RC oscillators

■ 1 Internal High Frequency RC oscillator

Each oscillator is optimized for a given frequency

range in term of consumption and is selectable

through the Option Byte.

External Clock Source

The defaultOption Byte value selects the External

Clock in the MO block. In this mode, a clock signal

(square, sinus or triangle) with ~50% duty cycle

has to drive the OSCin pin while the OSCout pin is

tied to ground (see Figure 13).

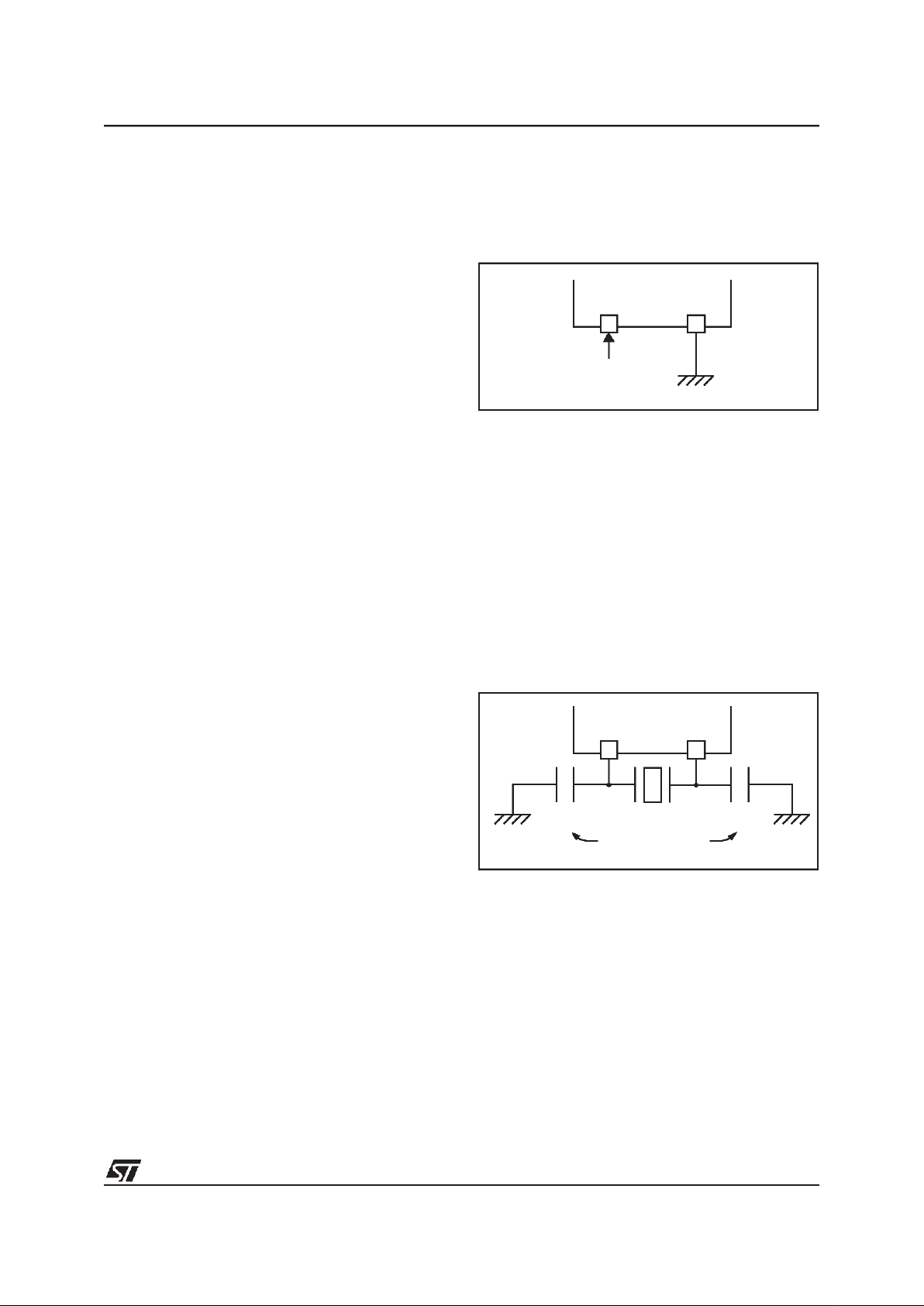

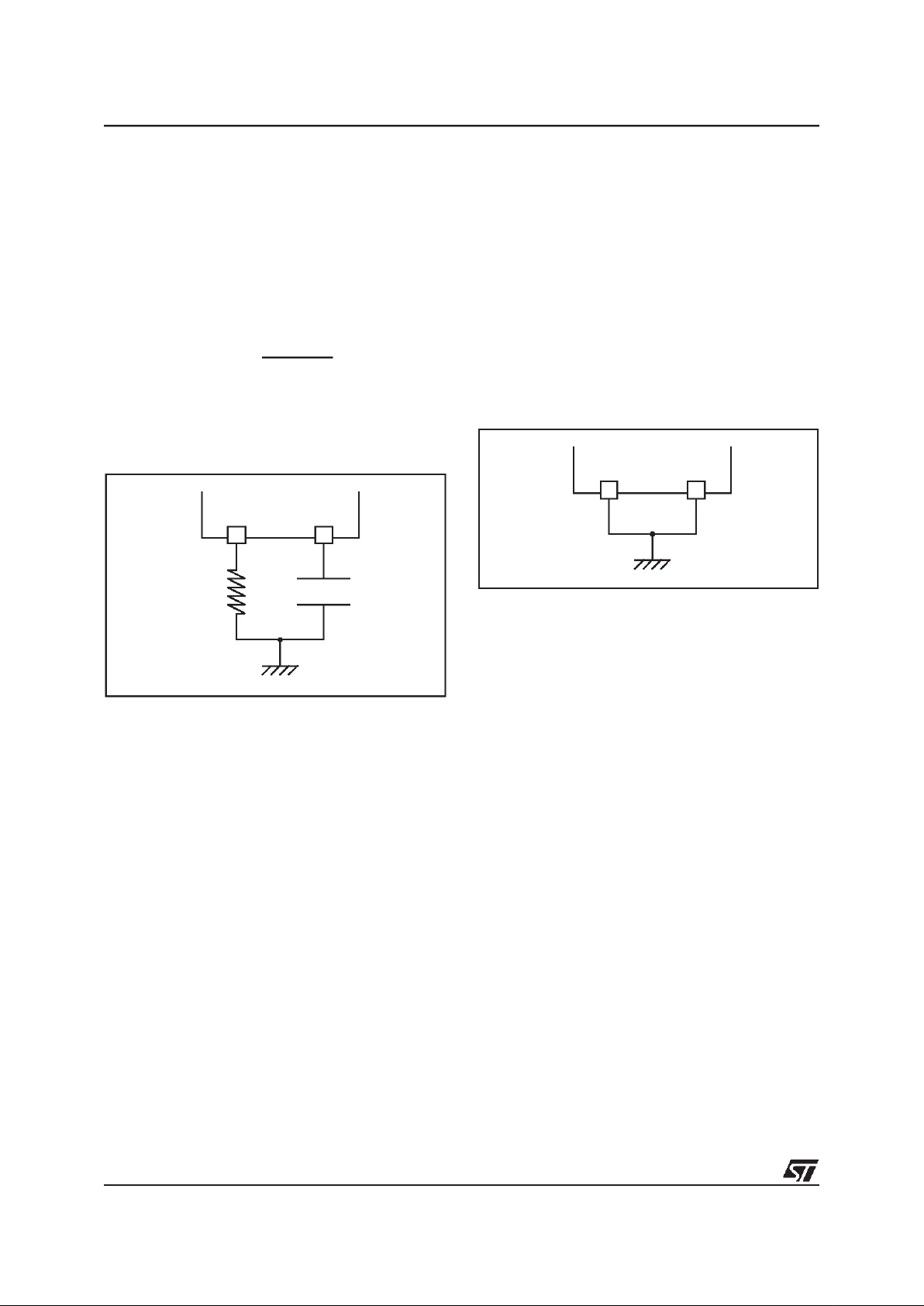

Figure 13. MO External Clock

Crystal/Ceramic Oscillators

This family of oscillators allows a high accuracy on

the main clockof the ST7.The selection withinthe

list of 4 oscillators has to be done by Option Byte

according to the resonator frequency in order to

reduce the consumption. In this mode of the MO

block, the resonator and the load capacitors have

to be connected as shown in Figure 14 and have

to be mounted as close aspossible to the oscillator pins in order to minimize output distortion and

start-up stabilization time.

These oscillators, when selected via the Option

Byte, are not stopped during the RESET phase to

avoid losing time in the oscillator starting phase.

Figure 14. MO Crystal/Ceramic Resonator

OSCin OSCout

EXTERNAL

ST7

SOURCE

OSCin OSCout

LOAD

CAPACITORS

ST7

C

L1

C

L0

Page 20

ST72C171

20/151

MULTIOSCILLATOR (MO) (Cont’d)

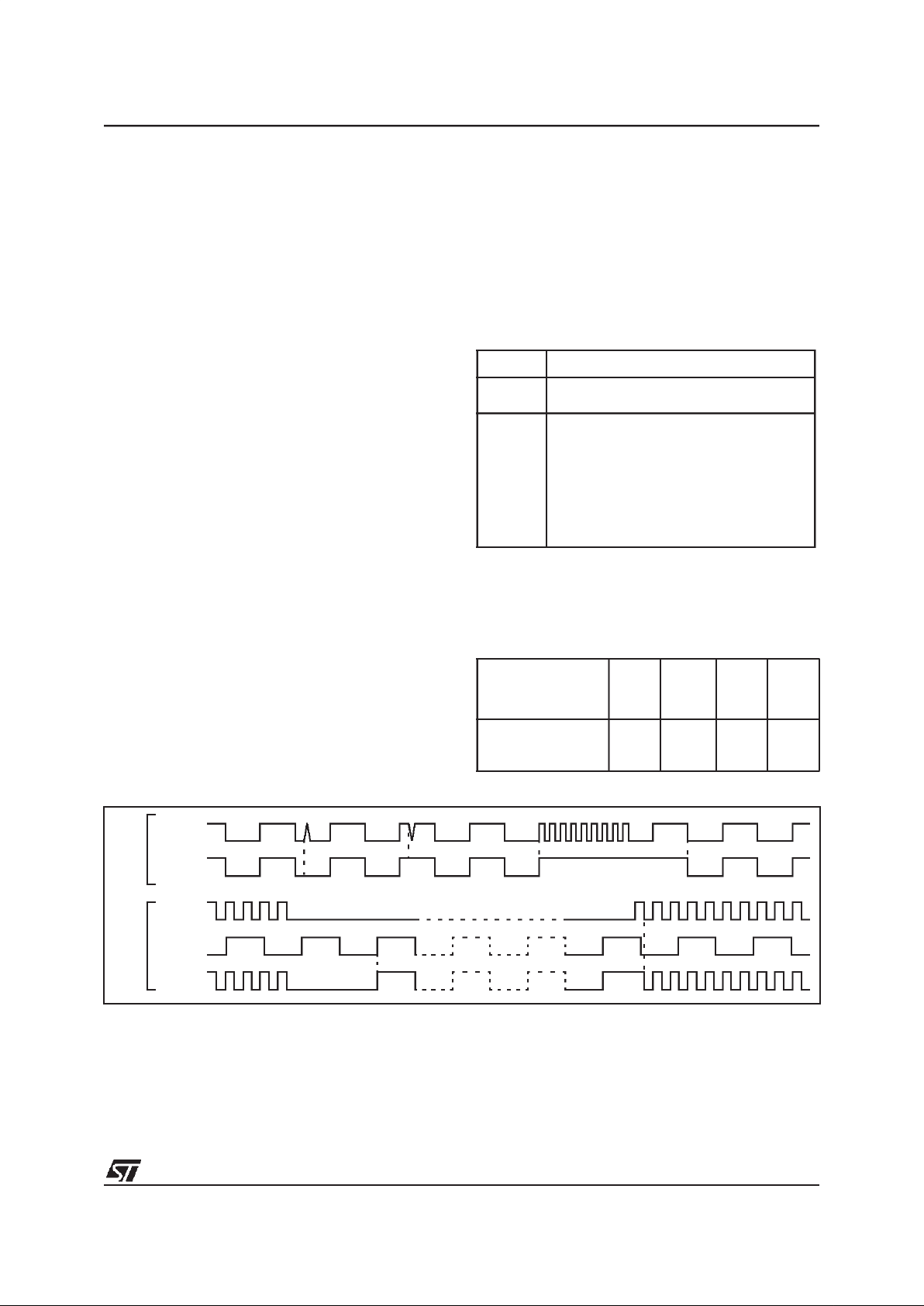

External RC Oscillator

This oscillator allows a low cost solution on the

main clockof the ST7 using only an external resistor and an external capacitor (see Figure 15). The

selection of the external RC oscillator has to be

done by Option Byte.

The frequency of the external RCoscillator is fixed

by the resistor and the capacitor values:

The previousformula shows that in this MO mode,

the accuracy of the clock is directly linked to the

accuracy of the discrete components.

Figure 15. MO External RC

Internal RC Oscillator

The Internal RC oscillator mode is based on the

same principle as the External RC one including

the an on-chip resistor andcapacitor. This mode is

the most cost effective one with the drawback of a

lower frequency accuracy. Its frequency is in the

range of several MHz.

In this mode, the two oscillator pins have to be tied

to ground as shownin Figure 16.

The selection of the internal RC oscillator has to

be done by Option Byte.

Figure 16. MO InternalRC

f

OSC

~

N

REX.C

EX

OSCin OSCout

ST7

C

EX

R

EX

OSCin OSCout

ST7

Page 21

ST72C171

21/151

4.3 CLOCK SECURITY SYSTEM (CSS)

The Clock Security System (CSS) protects the

ST7 against main clock problems. To allow the integration of the security features in the applications, itis based on a clock filter control and anInternal safe oscillator. The CSS can be enabled or

disabled by option byte.

4.3.1 Clock Filter Control

The clock filter is based on a clock frequency limitation function.

This filter function is able to detect and filter high

frequency spikes on the ST7 main clock.

If the oscillator is not working properly (e.g. working at a harmonic frequency of the resonator), the

current active oscillator clock can be totally filtered, and then no clock signal is available for the

ST7 from this oscillator anymore. If the original

clock source recovers, the filtering is stopped automatically and the oscillator supplies the ST7

clock.

4.3.2 Safe Oscillator Control

The safe oscillator of the CSS block is a low frequency back-up clock source (see Figure 17).

If the clock signal disappears (due to a broken or

disconnected resonator...) during a safe oscillator

period, the safe oscillator delivers a low frequency

clock signalwhich allows the ST7 to perform some

rescue operations.

Automatically, theST7 clock sourceswitches back

from the safe oscillator if the original clock source

recovers.

Limitation detection

The automatic safe oscillator selection is notified

by hardware setting the CSSD bit of the CRSR

register. An interrupt can be generated if the CSSIE bit has been previously set.

These two bits are described in the CRSR register

description.

4.3.3 Low Power Modes

4.3.4 Interrupts

The CSS interrupt event generates an interrupt if

the corresponding Enable Control Bit (CSSIE) is

set and the interrupt mask in the CC register is reset (RIM instruction).

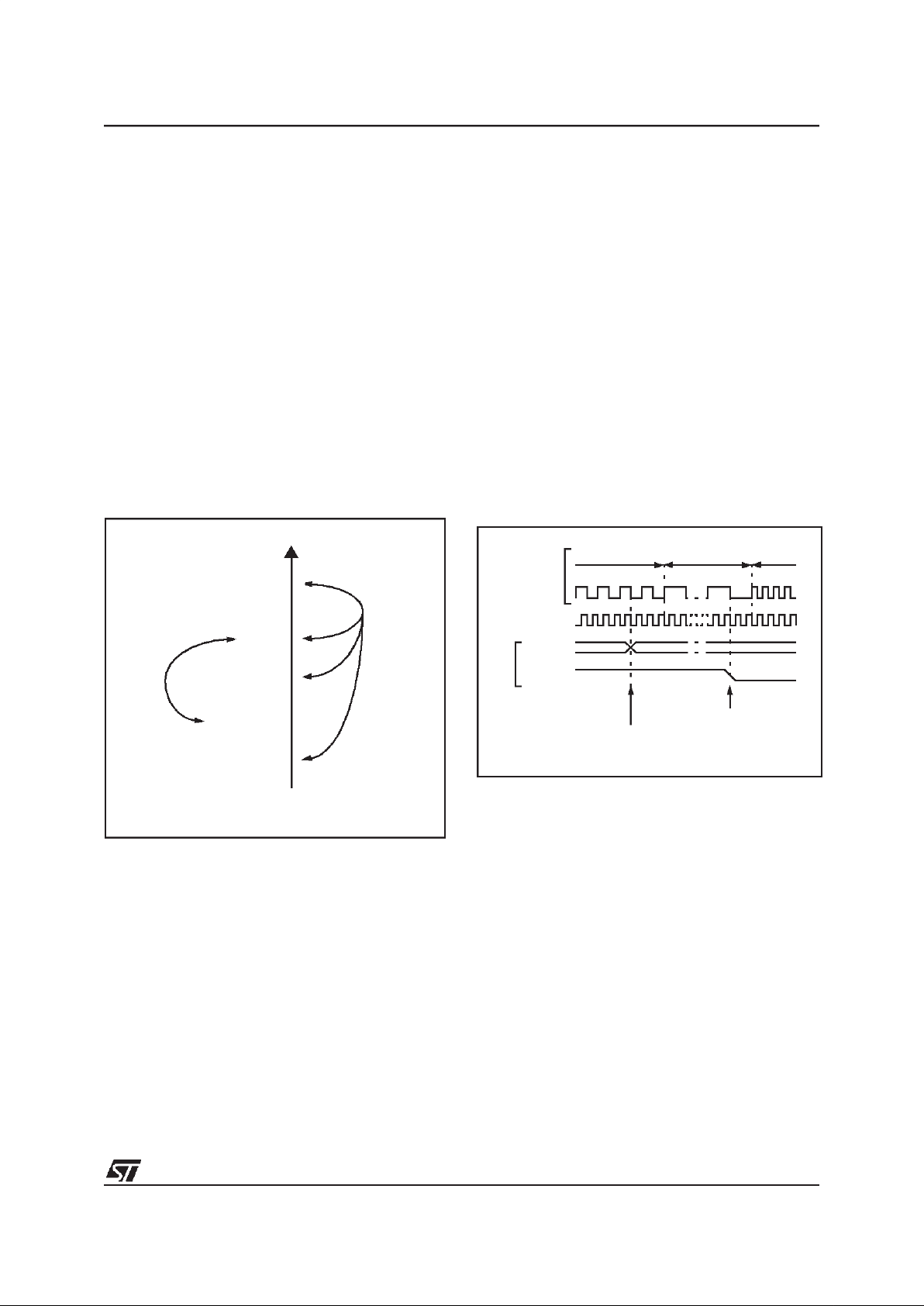

Figure 17. Clock Filter Function and Safe Oscillator Function

Mode Description

WAIT

No effect on CSS. CSS interrupt cause the

device to exit from Wait mode.

HALT

The CRSR register is frozen. The CSS (including the safe oscillator) is disabled until

HALT mode is exited.The previous CSS

configuration resumes when the MCU is

woken up by aninterrupt with “exit from

HALT mode” capability or from the counter

reset value when the MCU is woken up by a

RESET.

Interrupt Event

Event

Flag

Enable

Control

Bit

Exit

from

Wait

Exit

from

Halt

CSS event detection

(safe oscillator activated as main clock)

CSSD CSSIE Yes No

f

OSC

/2

f

CPU

f

OSC

/2

f

CPU

f

SFOSC

SAFE OSCILLATOR

FUNCTION

CLOCK FILTER

FUNCTION

Page 22

ST72C171

22/151

4.3.5 Main Clock Controller (MCC)

The MCC block supplies the clock for the ST7

CPU anditsinternal peripherals. It allows the power saving modes such as SLOW mode to be managed by the application.

All functions are managed by the Miscellaneous

Register 1 (MISCR1).

The MCC block consists of:

– a programmable CPU clock prescaler

– a clock-out signalto supply external devices

The prescaler allows the selection of the main

clock frequency and is controlled with three bits of

the MISCR1: CP1, CP0 and SMS.

The clock-out capability is anAlternate Function of

an I/O port pin, providing the f

CPU

clock as an output for driving external devices. It is controlled by

the MCO bit in the MISCR1 register.

Figure 18. Main Clock Controller (MCC) Block Diagram

DIV 2, 4, 8, 16

DIV 2

SMSCP1 CP0

CPU CLOCK

MISCR1

TO CPU AND

PERIPHERALS

f

OSC

MCO

PORT

FUNCTION

ALTERNATE

OSCOUT

OSCIN

MULTI-

OSCILLATOR

(MO)

CLOCK

FILTER

(CF)

MCO

f

CPU

Page 23

ST72C171

23/151

4.4 CLOCK, RESET AND SUPPLY REGISTER DESCRIPTION

CLOCK RESET AND SUPPLY REGISTER

(CRSR)

Read/Write

Reset Value: 000x 000x (00h)

Bit 7:5 = Reserved.

Bit 4 = LVDRF

LVD Reset Flag

This bit indicates when set that the last Reset was

generated by the LVD block. It is set by hardware

(LVD reset) and cleared by software (writing zero)

or a Watchdog Reset. See WDGRF flag description for more details.

Bit 3 = Reserved.

Bit 2 = CSSIE

CSS Interrupt Enable

This bit allows to enable the interrupt when a distrurbance is detected by the Clock Security System (CSSD bit set). It is set and cleared by software.

0: Clock Filter interrupt disable

1: Clock Filter interrupt enable

Bit 1 = CSSD

CSS Safe Osc. Detection

This bit indicates that the safe oscillator of the CSS

block has been selected. It is set by hardware and

cleared by reading the CRSR register when the

original oscillator recovers.

0: Safe oscillator is not active

1: Safe oscillator has been activated

Bit 0 = WDGRF

WatchDog Reset Flag

This bit indicates when set that the last Reset was

generated by the Watchdog peripheral. It isset by

hardware (watchdog reset) and cleared by software (writing zero) or an LVD Reset.

Combined with the LVDRF flag information, the

flag description is given by the following table.

Table 3. Supply, Reset and Clock Register Map and Reset Values

70

---

LVD

RF

-

CSSIECSSDWDG

RF

RESET Sources LVDRF WDGRF

External RESET pin 0 0

Watchdog 0 1

LVD 1 X

Address

(Hex.)

Register

Label

76543210

0020h

MISCR

Reset Value

PEI3

0

PEI2

0

MCO

0

PEI1

0

PEI0

0

CP1

0

CP0

0

SMS

0

0025h

CRSR

Reset Value

-

0

-

0

-

0

LVDRF

x

-

0

CSSIE0CSSD0WDGRF

x

Page 24

ST72C171

24/151

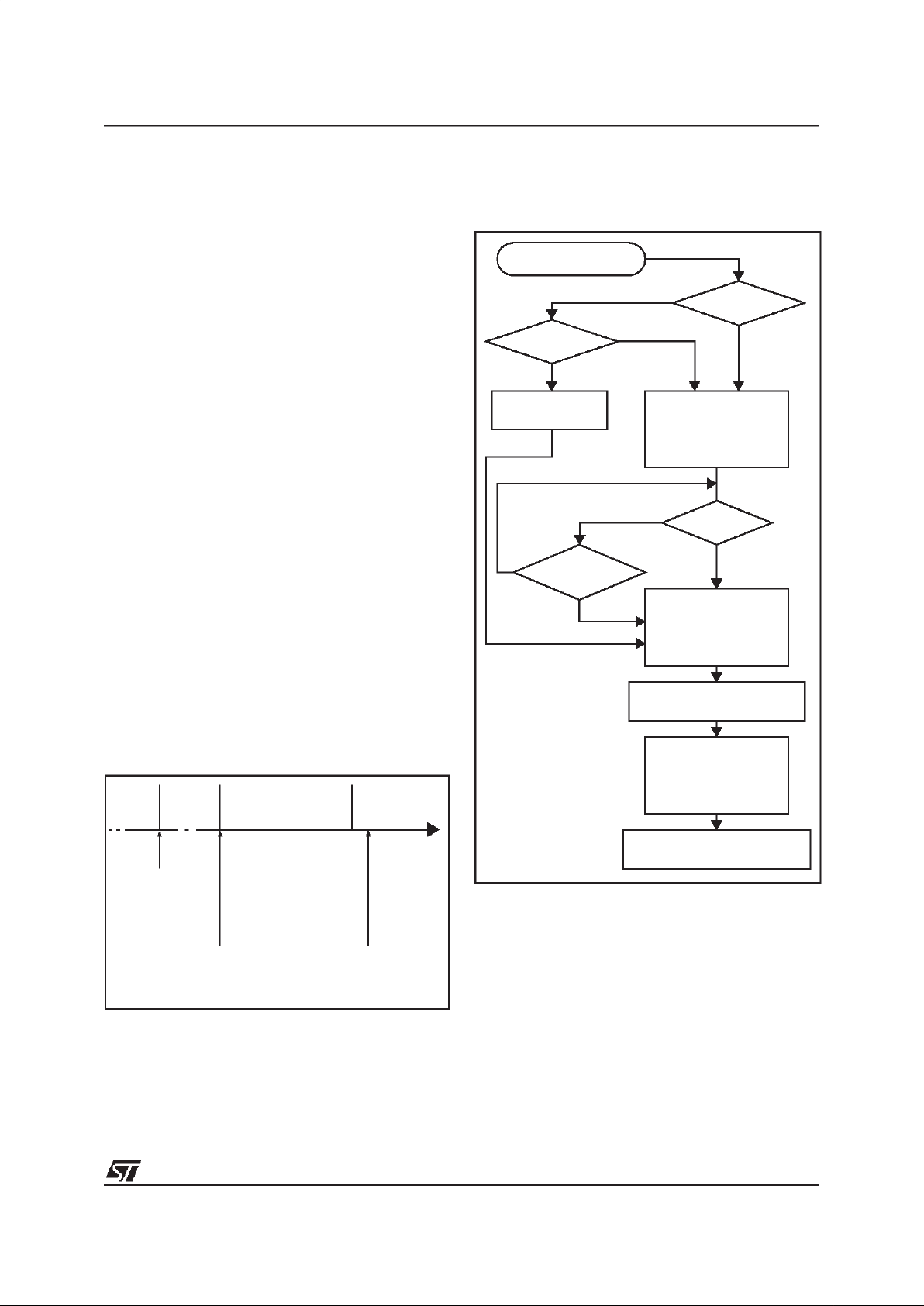

5 INTERRUPTS

The ST7 core may be interruptedby one oftwo different methods: maskable hardware interrupts as

listed in the Interrupt Mapping Table and a nonmaskable software interrupt (TRAP). The Interrupt

processing flowchart is shown in Figure 19.

The maskableinterrupts must be enabled clearing

the I bit in order to be serviced. However, disabled

interrupts may be latched and processed when

they are enabled (see external interrupts subsection).

When an interrupt has to be serviced:

– Normal processing is suspended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– The I bit of the CC register is set to prevent addi-

tional interrupts.

– ThePC isthenloaded with the interrupt vectorof

the interruptto service and the first instruction of

the interrupt service routine is fetched (refer to

the Interrupt Mapping Tablefor vector addresses).

The interrupt service routine should finish with the

IRET instruction which causes the contents of the

saved registers to be recovered from thestack.

Note: As a consequence of the IRET instruction,

the I bit will be cleared and the main program will

resume.

Priority management

By default, a servicing interrupt cannot be interrupted because the I bit is set by hardware entering in interrupt routine.

In the case when several interrupts are simultaneously pending, an hardware priority defines which

one will be serviced first (see the Interrupt Mapping Table).

Interrupts and Low power mode

All interrupts allow the processor to leave the

WAIT low power mode. Only external and specifically mentioned interrupts allow the processor to

leave the HALT low power mode (refer to the “Exit

from HALT“ column in the Interrupt Mapping Table).

5.1 NON MASKABLE SOFTWARE INTERRUPT

This interrupt is entered when the TRAP instruction is executed regardless of the stateof theI bit.

It will be serviced according to the flowchart on

Figure 19.

5.2 EXTERNAL INTERRUPTS

External interrupt vectors can be loaded into the

PC register if the corresponding external interrupt

occurred and if the I bit is cleared. Theseinterrupts

allow the processor to leave the Halt low power

mode.

The external interrupt polarity is selected through

the miscellaneous register or interrupt register (if

available).

An external interrupt triggered on edge will be

latched and the interrupt request automatically

cleared upon entering the interrupt serviceroutine.

If several input pins, connected to the same interrupt vector, are configured as interrupts, their signals are logically ANDed before entering the edge/

level detection block.

Caution:The type of sensitivitydefinedin the Miscellaneous or Interrupt register (if available) applies to the ei source. In case of an ANDedsource

(as described on the I/O ports section), a low level

on an I/O pin configured as input with interrupt,

masks the interrupt requesteven in case of risingedge sensitivity.

5.3 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the status

register are able to cause an interrupt when they

are active if both:

– The I bit of the CC register is cleared.

– Thecorresponding enable bit is setin thecontrol

register.

If any of these two conditions is false, the interrupt

is latched and thus remains pending.

Clearing an interrupt request is done by:

– Writing “0”to the corresponding bit in the status

register or

– Access tothe status registerwhile the flag isset

followed by a read or write of an associated register.

Note: the clearing sequence resets the internal

latch. A pending interrupt (i.e. waiting for being enabled) will therefore be lost ifthe clear sequence is

executed.

Page 25

ST72C171

25/151

INTERRUPTS (Cont’d)

Figure 19. Interrupt Processing Flowchart

I BIT SET?

Y

N

IRET?

Y

N

FROM RESET

LOAD PC FROM INTERRUPT VECTOR

STACK PC, X, A, CC

SET I BIT

FETCH NEXT INSTRUCTION

EXECUTEINSTRUCTION

THIS CLEARS I BIT BY DEFAULT

RESTORE PC,X, A,CC FROM STACK

INTERRUPT

Y

N

PENDING?

Page 26

ST72C171

26/151

INTERRUPTS (Cont’d)

Table 4. Interrupt Mapping

Source

Block

Description

Register

Label

Flag

Exit from

HALT

Vector

Address

Priority

Order

RESET Reset N/A N/A yes FFFEh-FFFFh

TRAP Software N/A N/A no FFFCh-FFFDh

ei0 Ext. Interrupt ei0 N/A N/A yes FFFAh-FFFBh

ei1 Ext. Interrupt ei1 N/A N/A yes FFF8h-FFF9h

CSS Clock Filter Interrupt CRSR CSSD no FFF6h-FFF7h

SPI

Transfer Complete

SPISR

SPIF

no FFF4h-FFF5h

Mode Fault MODF

TIMER 16

Input Capture 1

TASR

ICF1_1

no FFF2h-FFF3h

Output Compare 1 OCF1_1

Input Capture 2 ICF2_1

Output Compare 2 OCF2_1

Timer Overflow TOF_1

ART/PWM

Input Capture 1 ARTICCSR ICF0

yes

FFF0h-FFF1h

Timer Overflow ARTCSR OVF FFEEh-FFEFh

OP-AMP

OA1 Interrupt

OIRR

OA1V

yes

FFECh-FFEDh

OA2 Interrupt OA2V FFEAh-FFEBh

NOT USED FFE6-FFE9

SCI SCI Peripheral Interrupts no FFE4-FFE5

NOT USED FFE0h-FFE3h

Highest

Priority

Priority

Lowest

Page 27

ST72C171

27/151

6 POWER SAVING MODES

6.1 INTRODUCTION

To give a large measure of flexibilitytotheapplication in terms of power consumption, three main

power saving modes are implemented in the ST7

(see Figure 20).

After a RESET the normal operating mode is selected by default (RUN mode). This mode drives

the device (CPU and embedded peripherals) by

means of a master clock which is based on the

main oscillator frequency divided by 2 (f

CPU

).

From Run mode, the different power saving

modes may be selected by setting the relevant

register bits or by calling the specific ST7 software

instruction whose action depends on the the oscillator status.

Figure 20. Power Saving Mode Transitions

6.2 SLOW MODE

This mode has two targets:

– To reduce powerconsumption bydecreasingthe

internal clock in the device,

– To adapt the internal clock frequency (f

CPU

)to

the available supply voltage.

SLOW mode is controlled by three bits in the

MISCR1 register: the SMS bit which enables or

disables Slow modeand two CPx bits which select

the internal slow frequency (f

CPU

).

In this mode, the oscillator frequency can bedivided by 4, 8, 16 or 32 instead of 2 in normal operating mode. The CPU and peripherals are clocked at

this lower frequency.

Note: SLOW-WAIT mode is activated when enterring the WAIT mode while the device is already in

SLOW mode.

Figure 21. SLOW Mode Clock Transitions

POWER CONSUMPTION

WAIT

SLOW

RUN

HALT

High

Low

SLOW WAIT

00 01

SMS

CP1:0

f

CPU

NEW SLOW

NORMAL RUN MODE

MISCR1

FREQUENCY

REQUEST

REQUEST

f

OSC

/2

f

OSC

/4 f

OSC

/8 f

OSC

/2

Page 28

ST72C171

28/151

POWER SAVING MODES (Cont’d)

6.3 WAIT MODE

WAIT mode places the MCU in a low power consumption mode by stopping the CPU.

This power saving mode is selectedby calling the

“WFI” ST7 software instruction.

All peripherals remain active. During WAIT mode,

the I bit of the CC register are forced to 0, to enable all interrupts. All other registers and memory

remain unchanged. The MCU remains in WAIT

mode until an interrupt or Reset occurs, whereupon the Program Counter branches to the starting

address of the interrupt or Reset serviceroutine.

The MCU will remain in WAIT mode until a Reset

or an Interrupt occurs, causing it to wake up.

Refer to Figure22.

Figure 22. WAIT Mode Flow-chart

Note: Before servicing an interrupt, the CC regis-

ter is pushed on the stack. The Ibit of the CC register is set during the interrupt routine and cleared

when the CC register is popped.

WFI INSTRUCTION

RESET

INTERRUPT

Y

N

N

Y

CPU

OSCILLATOR

PERIPHERALS

IBIT

ON

ON

0

OFF

FETCH RESET VECTOR

OR SERVICE INTERRUPT

CPU

OSCILLATOR

PERIPHERALS

IBIT

ON

OFF

1

ON

CPU

OSCILLATOR

PERIPHERALS

I BIT(see note)

ON

ON

1

ON

4096 CPU CLOCK CYCLE

DELAY

Page 29

ST72C171

29/151

POWER SAVING MODES (Cont’d)

6.4 HALT MODE

The HALT mode is the lowest power consumption

mode of the MCU. It is entered by executing the

ST7 HALT instruction (see Figure 24).

The MCU can exit HALT mode on reception of either an specific interrupt (see Table 4, “Interrupt

Mapping,” on page 26) or a RESET. When exiting

HALT mode by means of a RESET or an interrupt,

the oscillator is immediately turned on and the

4096 CPU cycle delay is used to stabilize the oscillator. After the start up delay, the CPU resumes

operation by servicing the interrupt or by fetching

the reset vector which woke it up (see Figure 23).

When entering HALT mode, the I bit in the CC register is forced to 0 to enable interrupts. Therefore,

if an interrupt is pending, the MCU wakes immediately.

In the HALT mode the main oscillator is turned off

causing all internal processing to be stopped, including the operation of the on-chip peripherals.

All peripherals are not clocked except the ones

which get their clock supply from another clock

generator (such as an external or auxiliary oscillator).

The compatibility of Watchdog operation with

HALT mode is configured by the “WDGHALT” option bit of the option byte. The HALT instruction

when executed while the Watchdog system is enabled, can generate a Watchdog RESET (see

Section 11.1 OPTION BYTES for more details).

Figure 23. HALT Mode Timing Overview

Figure 24. HALT Mode Flow-chart

Notes:

1. WDGHALTis anoption bit. See option byte sec-

tion for more details.

2. Peripheral clocked with an external clock source

can still be active.

3. Only some specific interrupts can exit the MCU

from HALT mode (such as external interrupt). Refer to Table 4, “Interrupt Mapping,” on page 26 for

more details.

4. Before servicing an interrupt, the CC register is

pushed on the stack. The I bit of the CCregister is

set during the interrupt routine and cleared when

the CC register is popped.

HALTRUN RUN

4096 CPU CYCLE

DELAY

RESET

OR

INTERRUPT

HALT

INSTRUCTION

FETCH

VECTOR

HALT INSTRUCTION

RESET

INTERRUPT

3)

Y

N

N

Y

CPU

OSCILLATOR

PERIPHERALS

2)

IBIT

OFF

OFF

0

OFF

FETCH RESET VECTOR

OR SERVICE INTERRUPT

CPU

OSCILLATOR

PERIPHERALS

IBIT

ON

OFF

1

ON

CPU

OSCILLATOR

PERIPHERALS

IBIT

4)

ON

ON

1

ON

4096 CPU CLOCK CYCLE

DELAY

WATCHDOG

ENABLE

DISABLE

WDGHALT

1)

0

WATCHDOG

RESET

1

Page 30

ST72C171

30/151

7 ON-CHIP PERIPHERALS

7.1 I/O PORTS

7.1.1 Introduction

The I/O ports offer different functional modes:

– transferof datathrough digital inputsandoutputs

and for specific pins:

– analog signal input (ADC)

– alternate signal input/output for the on-chip pe-

ripherals.

– external interrupt generation

An I/O port is composed of up to 8 pins. Each pin

can be programmed independently as digital input

(with or without interrupt generation) or digital output.

7.1.2 Functional Description

Each port is associated to 2 mainregisters:

– Data Register (DR)

– Data Direction Register (DDR)

and some of them to an optional register (see reg-

ister description):

– Option Register (OR)

Each I/Opin may be programmed using thecorre-

sponding registerbits in DDR and ORregisters:bit

X corresponding topinXof the port. The samecorrespondence is used for the DR register.

The following description takes into account the

OR register, for specific ports whichdo notprovide

this register refer to the I/O Port Implementation

Section 7.1.2.5. The generic I/O block diagram is

shown on Figure 26.

7.1.2.1 Input Modes

The input configuration is selected by clearing the

corresponding DDR register bit.

In this case, reading the DR register returns the

digital value applied to the external I/O pin.

Different input modes can beselected bysoftware

through the OR register.

Notes:

1. All the inputs are triggered by a Schmitt trigger.

2. When switching from input mode to output

mode, the DR register should be written first to

output the correct value as soon as the port isconfigured as an output.

Interrupt function

When an I/O is configured in Input with Interrupt,

an event on this I/O can generate an external Interrupt request to the CPU. The interrupt sensitivity is given independently according to the description mentioned in the Miscellaneous register or in

the interrupt register (where available).

Each pin can independently generate an Interrupt

request.

Each external interrupt vector is linked to a dedicated group of I/O port pins (see Interrupts section). If more than one input pin is selected simultaneously as interrupt source, this is logically

ORed. For this reason if one of the interrupt pins is

tied low, it masks the other ones.

7.1.2.2 Output Mode

The pin is configured inoutput mode by setting the

corresponding DDR register bit.

In this mode, writing “0” or “1” to the DR register

applies this digital value to the I/O pin through the

latch. Then reading the DR register returns the

previously stored value.

Note: In this mode, the interrupt function is disabled.

7.1.2.3 Digital Alternate Function

When an on-chip peripheral is configured to use a

pin, the alternate function is automatically selected. This alternate function takes priority over

standard I/O programming. When the signal is

coming from an on-chip peripheral, the I/O pin is

automatically configured in outputmode (push-pull

or open drain according to the peripheral).

When the signal is going to an on-chip peripheral,

the I/O pin has to be configured in input mode. In

this case, the pin’s state is also digitally readable

by addressing the DR register.

Notes:

1. Input pull-up configuration can cause an unexpected value at the input of the alternate peripheral input.

2. When the on-chip peripheral uses a pin asinput

and output, this pinmust beconfigured as an input

(DDR = 0).

Warning

: The alternate function must not beacti-

vated as long as the pin is configured as input with

interrupt, in order to avoid generating spurious interrupts.

Page 31

ST72C171

31/151

I/O PORTS (Cont’d)

7.1.2.4 Analog Alternate Function

When the pin is used as an ADC input theI/O must

be configured as input, floating. The analog multiplexer (controlled by the ADC registers) switches

the analog voltage present on the selected pin to

the common analog rail which is connected to the

ADC input.

It is recommended not to change the voltage level

or loading on any port pin while conversion is in

progress. Furthermore it is recommended not to

have clocking pins located close to a selected analog pin.

Warning

: The analog input voltage level must be

within the limits stated in the Absolute Maximum

Ratings.

7.1.2.5 I/O Port Implementation

The hardware implementation on each I/O port depends on the settings in the DDR and OR registers

and specific feature of the I/O port such as ADCInput (see Figure 26) or true open drain. Switching

these I/O ports from one state to another should

be done in a sequence that prevents unwanted

side effects. Recommended safe transitions are illustrated in Figure 25. Other transitions are potentially risky and should be avoided, since they are

likely to present unwanted side-effects such as

spurious interrupt generation.

Figure 25. Recommended I/O StateTransition Diagram

with interrupt

INPUT

OUTPUT

no interrupt

INPUT

push-pullopen-drain

OUTPUT

Page 32

ST72C171

32/151

I/O PORTS (Cont’d)

Figure 26. I/O Block Diagram

Table 5. Port Mode Configuration

Legend:

0 - present, not activated

1 - present and activated

Notes:

– No OR Register on some ports (see register map).

– ADC Switch on ports with analog alternate functions.

DR

DDR

LATCH

LATCH

DATA BUS

DR SEL

DDR SEL

V

DD

PAD

ANALOG

SWITCH

ANALOG ENABLE

(ADC)

M

U

X

ALTERNATE

ALTERNATE

ALTERNATE ENABLE

COMMON ANALOG RAIL

ALTERNATE

M

U

X

ALTERNATE INPUT

PULL-UP(S

EE TABLE BELOW)

OUTPUT

P-BUFFER

(S

EE TABLE BELOW)

N-BUFFER

1

0

1

0

OR

LATCH

ORSEL

FROM

OTHER

BITS

EXTERNAL

PULL-UP

CONDITION

ENABLE

ENABLE

GND

(S

EE TABLE BELOW)

(S

EE NOTE BELOW)

CMOS

SCHMITT TRIGGER

SOURCE (EIx)

INTERRUPT

SENSITIVITY

SEL

Configuration Mode Pull-up P-buffer

Floating 0 0

Pull-up 1 0

Push-pull 0 1

True Open Drain not present not present

Open Drain (logic level) 0 0

Page 33

ST72C171

33/151

I/O PORTS (Cont’d)

7.1.2.6 Device Specific Configurations

Table 6. Port Configuration

*Reset state.

Port Pin name

Input(DDR =0) Output (DDR=1)

OR = 0 OR = 1 OR = 0 OR = 1

Port A PA7: PA0 floating* pull-up with interrupt open drain push-pull

Port B

PB0:PB4 floating* pull-up with interrupt

open drain

high sink capability

push-pull

PB5:PB7 floating* pull-up with interrupt open drain push-pull

Port C PC0:PC5 floating* pull-up open drain push-pull

Page 34

ST72C171

34/151

I/O PORTS (Cont’d)

7.1.3 Register Description

DATA REGISTERS

Port A Data Register (PADR)

Port B Data Register (PBDR)

Port C DataRegister (PCDR)

Read/Write

Reset Value: 0000 0000 (00h)

Bit 7:0 = D[7:0]

Data Register 8 bits.

The DR register has a specific behaviour according to the selectedinput/output configuration. Writing the DR register is always taken in account

even if the pin is configured as an input. Reading

the DRregisterreturns either theDR register latch

content (pin configured as output) or the digital value applied to the I/O pin (pin configured as input).

DATA DIRECTION REGISTERS

Port A Data Direction Register (PADDR)

Port B Data Direction Register (PBDDR)

Port C DataDirection Register (PCDDR)

Read/Write

Reset Value: 0000 0000 (00h) (input mode)

Bit 7:0 = DD[7:0]

Data Direction Register 8 bits.

The DDR register gives the input/output direction

configuration of the pins. Each bits is set and

cleared by software.

0: Input mode

1: Output mode

OPTION REGISTERS

PORT A Option Register (PAOR)

PORT B Option Register (PBOR)

PORT C Option Register (PCOR)

Read/Write

Reset Value: 0000 0000 (00h) (no interrupt)

Bit 7:0 = O[7:0]

Option Register 8 bits.

The PAOR, PBOR and PCOR registers are used

to select pull-up or floating configuration in input

mode.

Each bit is set and cleared by software.

Input mode:

0: Floating input

1: Input pull-up (with or without interrupt see Table

6)

70

D7 D6 D5 D4 D3 D2 D1 D0

70

DD7 DD6 DD5 DD4 DD3 DD2 DD1 DD0

70

O7 O6 O5 O4 O3 O2 O1 O0

Page 35

ST72C171

35/151

I/O PORTS (Cont’d)

Table 7. I/O Port Register Map andReset Values

Address

(Hex.)

Register

Label

76543210

0000h

PADR

Reset Value

D7

0

D6

0

D5

0

D4

0

D3

0

D2

0

D1

0

D0

0

0001h

PADDR

Reset Value

D7

0

D6

0

D5

0

DD4

0

DD3

0

DD2

0

DD1

0

DD0

0

0002h

PAOR

Reset Value

D7

0

D6

0

D5

0

O4

0

O3

0

O2

0

O1

0

O0

0

0004h

PBDR

Reset Value

D7

0

D6

0

D5

0

D4

0

D3

0

D2

0

D1

0

D0

0

0005h

PBDDR

Reset Value

DD7

0

DD6

0

DD5

0

DD4

0

DD3

0

DD2

0

DD1

0

DD0

0

0006h

PBOR

Reset Value

O7

0

O6

0

O5

0

O4

0

O3

0

O2

0

O1

0

O0

0

0008h

PCDR

Reset Value

D7

0

D6

0

D5

0

D4

0

D3

0

D2

0

D1

0

D0

0

0009h

PCDDR

Reset Value

DD7

0

DD6

0

DD5

0

DD4

0

DD3

0

DD2

0

DD1

0

DD0

0

000Ah

PCOR

Reset Value

O7

0

O6

0

O5

0

O4

0

O3

0

O2

0

O1

0

O0

0

Page 36

ST72C171

36/151

7.2 MISCELLANEOUS REGISTERS

7.2.1 Miscellaneous Register 1 (MISCR1)

Miscellaneous register 1 isused select SLOW operating mode.Bits 3, 4, 6, and 7 determine the polarity of external interrupt requests.

Register Address: 0020h — Read/Write

Reset Value: 0000 0000 (00h)

Bit 7:6 = PEI[3:2]

Polarity Options of External In-

terrupt ei1. (Port B)

.

These bits are set and cleared by software. These

bits determine which event causes the external interrupt (ei1) on port B according to Table 8.

Table 8. ei1Ext. Int. Polarity Options

Bit 5 = MCO

Main clock out selection

This bit enablesthe MCO alternatefunction on the

I/O port. It is set and cleared by software.

0: MCO alternate function disabled

(I/O pin free for general-purpose I/O)

1: MCO alternate function enabled

(f

OSC

/2 on I/O port)

This bit is set and cleared by software. When set it

can beused to output the internal clock to the dedicated I/O port.

Bit 4:3 = PEI[1:0]

Polarity Options of External In-

terrupt ei0. (Port A)

These bits determine which event causes the external interrupt (ei0) on port A according to Table

9.

Table 9. ei0 Ext. Int. Polarity Options

Bit 2:1 = CP[1:0]

CPU clock prescaler

These bits are set and cleared by software. They

determine the CPU clock when the SMS bit is set

according to the following table.

Table 10. f

CPU

Value in Slow Mode

Bit 0 = SMS

Slow Mode Select

This bit is set andcleared by software.

0: Normal Mode - f

CPU=fOSC

/2

1: Slow Mode-the f

CPU

valueis determinedbythe

PC[1:0] bits.

70

PEI3 PEI2 MCO PEI1 PEI0 CP1 CP0 SMS

MODE PEI3 PEI2

Falling edge and low level

(Reset state)

00

Rising edge only 0 1

Falling edge only 1 0

Rising and falling edge 1 1

MODE PEI1 PEI0

Falling edge and low level

(Reset state)

00

Rising edge only 0 1

Falling edge only 1 0

Rising and falling edge 1 1

f

CPU

Value CP1 CP0

f

OSC

/4 0 0

f

OSC

/8 1 0

f

OSC

/16 0 1

f

OSC

/32 1 1

Page 37

ST72C171

37/151

7.2.2 Miscellaneous Register 2 (MISCR2)

Miscellaneous register 2 is used to configure of

SPI and the output selection of thePWMs.

Register Address: 0040h — Read/Write

Reset Value: 0000 0000 (00h)

Bit 7:5 = not used

Bit 4 = SPIOD

SPI output disable

This bit isusedto disable the SPI output onthe I/O

port (in both master or slave mode).

0: SPI output enabled

1: SPI output disabled

(I/O pin free for general-purpose I/O)

Bit 3 = P1OS

PWM1 output select

This bit is used to select the output for the PWM1