Page 1

查询ST72734供应商

ST72774/ST72754/ST72734

8-BIT USB MCU FOR MONITORS, WITH UP TO 60K OTP, 1K RAM,

ADC, TIMER, SYNC, TMU, PWM/BRM, H/W DDC & I

■ User ROM/OTP/EPROM : up to 60 Kbytes

■ Data RAM: up to 1 Kbytes (256 bytes stack)

■ 8 MHz Internal Clock Frequency in fast mode,

4 MHz in normal mode

■ Run and Wait CPU modes

■ System protection against illegal address jumps

and illegal opcode execution

■ Sync Processor for Mode Recognition, power

management and composite video blanking,

clamping and free-running frequency

generation

– Corrector mode

– Analyzer mode

■ USB (Universal Serial Bus) for monitor function

– Three endpoints

– Integrated 3.3V voltage regulator

– Transceiver

– Suspend and Resume operations

■ Timing Measurement Unit (TMU) for

autoposition and autosize

■ Fast I

■ DDC Bus Interface with:

2

C Single Master Interface

1

– DDC1/2B protocol implemented in hardware

– Programmable DDC CI modes

– Enhanced DDC (EDDC) address decoding

■ 31 I/O lines

■ 2 lines programmable as interrupt inputs

■ 16-bit timer with 2 input captures and 2 output

■ 8-bit Analog to Digital Converter with 4 channels

1

■ 8 10-bit PWM/BRM Digital to Analog outputs

■ Master Reset and Low Voltage Detector (LVD)

■ Programmable Watchdog for system reliability

■ Fully static operation

■ 63 basic instructions / 17 main addressing

■ 8x8 unsigned multiply instruction

■ True bit manipulation

■ Complete development support on PC/DOS-

■ Full software package (assembler, linker, C-

PSDIP42

compare functions

on port B

reset

modes

Windows: Real-Time Emulator, EPROM

Programming Board and Gang Programmer

compiler, source level debugger)

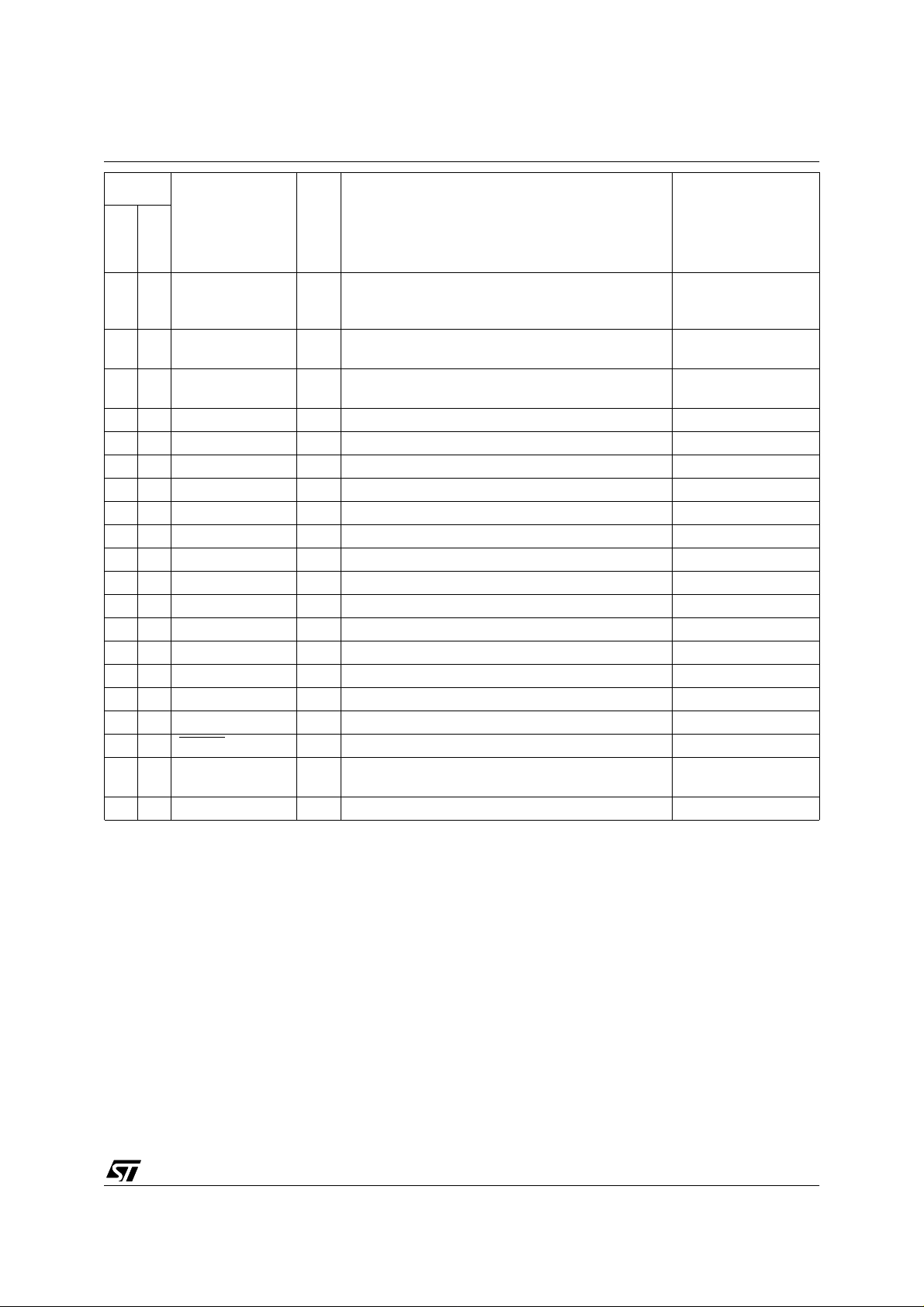

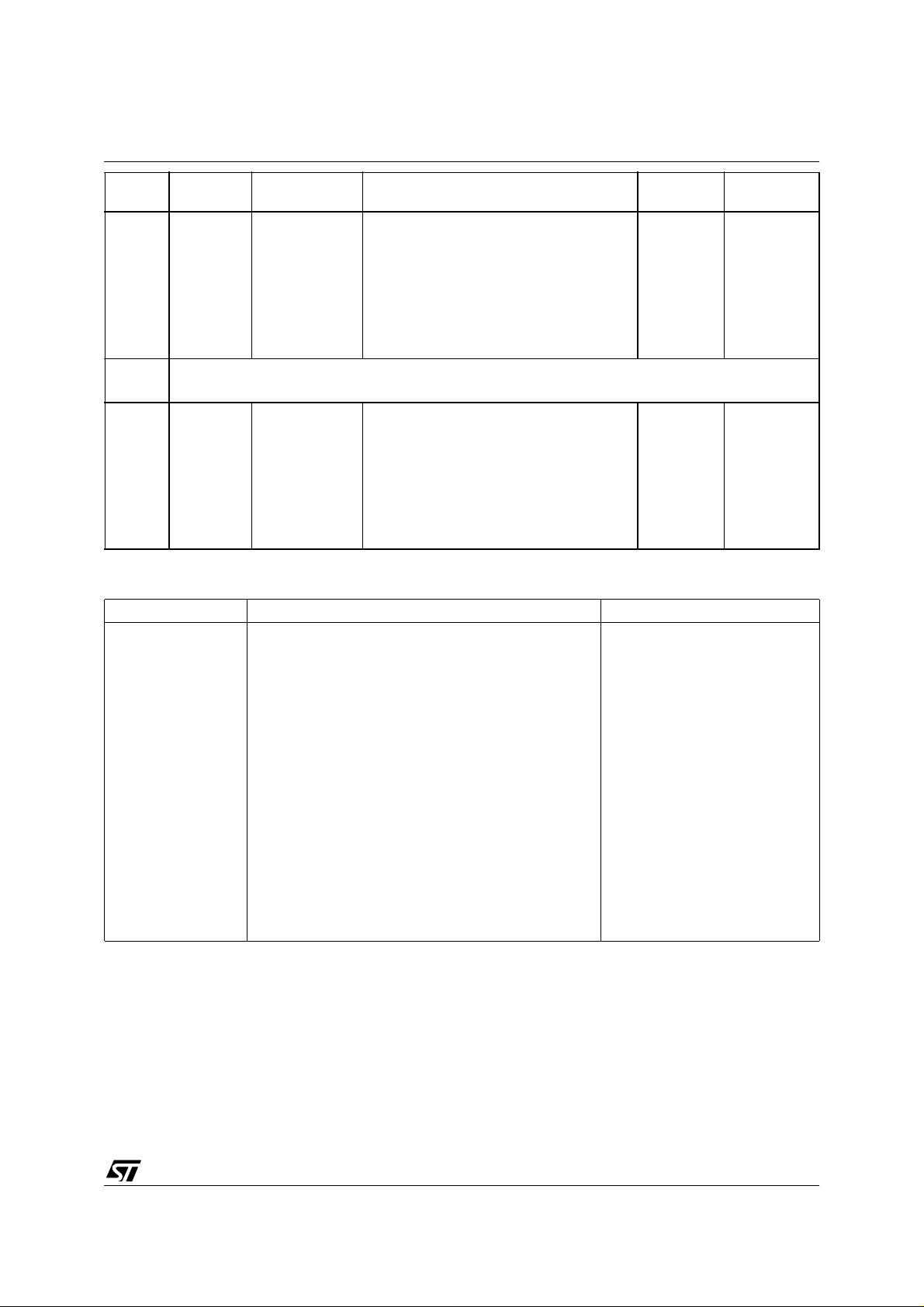

Device Summary

Features ST72(T/E)774 (J/S)9 ST72(T)754(J /S)9 ST72774(J/S)7 ST72754(J/S )7 ST72(T/E)734J6

Program Memory Bytes

RAM (stack) - Bytes 1K (256) 512 (256)

USB No USB USB No USB No USB

Peripherals

Operating Supply 4.0V to 5.5V supply operating range

Oscillator Frequency 12 or 24 MHz

Operating Temperature 0 to +70°C

Package CSDIP42 or PSDIP42 or TQFP44

(1) On some devices only, refer to Device Summ ary; (2) Contact Sales office for availability

(3) 8-bit ±2 LSB A/D converter ; (4) 8-bit ±4 LSB A/D converter.

ADC

3

60K 48K 32K

, 16-bit timer, I2C, DDC, TMU,Sync, PWM, LVD, Watchdog

TQFP44

10 x 10

4

, I2C,LVD,

ADC

DDC,Sync,

16-bit timer,

PWM, Watchdog

PSDIP42

CSDIP42

2

C

October 2003 1/144

1

Page 2

Table of Contents

1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 EXTERNAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 CLOCKS, RESET, INTERRUPTS & LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1 CLOCK SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.2 Crystal Resonator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.3 External Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 LVD and Watchdog Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.2 External Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.3 Illegal Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.4 Illegal Opcode Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.1 WAIT Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.2 HALT Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 MISCELLANEOUS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 7

4.1 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.2 Common Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.3 Port A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.4 Port B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.5 Port C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1.6 Port D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.2 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.4 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3 16-BIT TIMER (TIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4

4.4 SYNC PROCESSOR (SYNC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2/144

2

Page 3

ST72774/ST727754/ST72734

4.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.3 Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.4.4 Input Signal Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.4.5 Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.4.6 Input Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.4.7 Output Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.4.8 Analyzer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.4.9 Corrector Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.4.10Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.5 TIMING MEASUREMENT UNIT (TMU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.5.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.5.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.5.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.6 USB INTERFACE (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.6.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.6.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.6.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.6.5 Programming Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.7 I²C SINGLE MASTER BUS INTERFACE (I2C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.7.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.7.3 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.7.4 Functional Description (Master Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.7.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.8 DDC INTERFACE (DDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.8.2 DDC Interface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.8.3 Sig nal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.8.4 I2C BUS Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.8.5 DDC Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.8.6 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

4.9 PWM/BRM GENERATOR (DAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.9.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.9.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.9.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.108-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

4.10.1 Int roducti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

4.10.2Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

4.10.3 F unct ional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

4.10.4Low Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4.10.5Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4.10.6Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

5.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3/144

Page 4

ST72774/ST727754/ST72734

5.1.1 Inherent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.1.2 Imme diate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.1.3 Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.1.4 Indexed (No Offset, Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.1.5 Indirect (Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.1.6 Indirect Indexed (Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

5.1.7 Relative mode (Direct, Indirect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

5.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

6.1 POWER CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

6.2 AC/DC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

7.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.1 TRANSFER OF CUSTOMER CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4/144

Page 5

Revision follow-up

Changes applied since version 4.0

Version 4.0 March 2001

Page 1:Addition of 72T774 (32KOTP).

Addition of 60K/48K ROM for ST72754

Deletion of table “ device summary”, replaced with cross reference to table 36 on page 147.

page 13 - addition of section 1.4. external connections

Version 4.1 July 2001

Initial format reapplied, text and related figures in the same page.

Table “Device summary” reinserted in cover page and updated.

Update of table 36: ordering information (p143)

Version 4.2 July 2001

Cover - addition of feature about system protection added,

table for device summary: addition of stack values

page 9 - figure 3: replaced 1KByte with 512 Bytes + notes about opcode fetch and HALT

mode

page 10 - table: CR replaced by WDGCR

TIM replaced with Timer and WDG replaced with Watchdog

page 115 - EDF register: addition of “read from RAM”, EDE: few changes

page 135 - Note 1 replaced, note 2 added SUSpend mode limitation..

Whole document: all mentions of HALT mode either deleted or rewritten.

Version 4.3 October 2001

p140, chapter 8, section 8.1code for unused bytes ( FFh) replaced with

page 141- update of table 36 “Ordering information”

page 142 - list of available devices updated

page 114 - DDC DCR register: bit 5 = 1, text “or read from RAM” deleted

Version 4.3 November 2001

page 10, one adddress corrected in the figure 3 “memory map”: 0400h

page 14: addition of mandatory 1K resistor (text and figure)

ST72774/ST727754/ST72734

9Dh (opcode for NOP)

5/144

3

Page 6

ST72774/ST727754/ST72734

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST72774, ST72754 and ST72734 are

HCMOS microcontroller units (MCU) from the

ST727x4 family with dedicated peripherals for

Monitor applications.

They are based around an industry standard 8-bit

core and offer an enhanced instruction set. The

processor runs with an external clock at 12 or 24

MHz with a 5V supply. Due to the fully static design

of this device, operation do wn to DC is possible.

Under software control the ST727x4 can be placed

in WAIT mode thus reducing p ower consumpt ion.

The HALT mode is no longer available.

The enhanced instruction set and addressing

modes afford real programming potential. Illegal

opcodes are patched and lead to a reset.

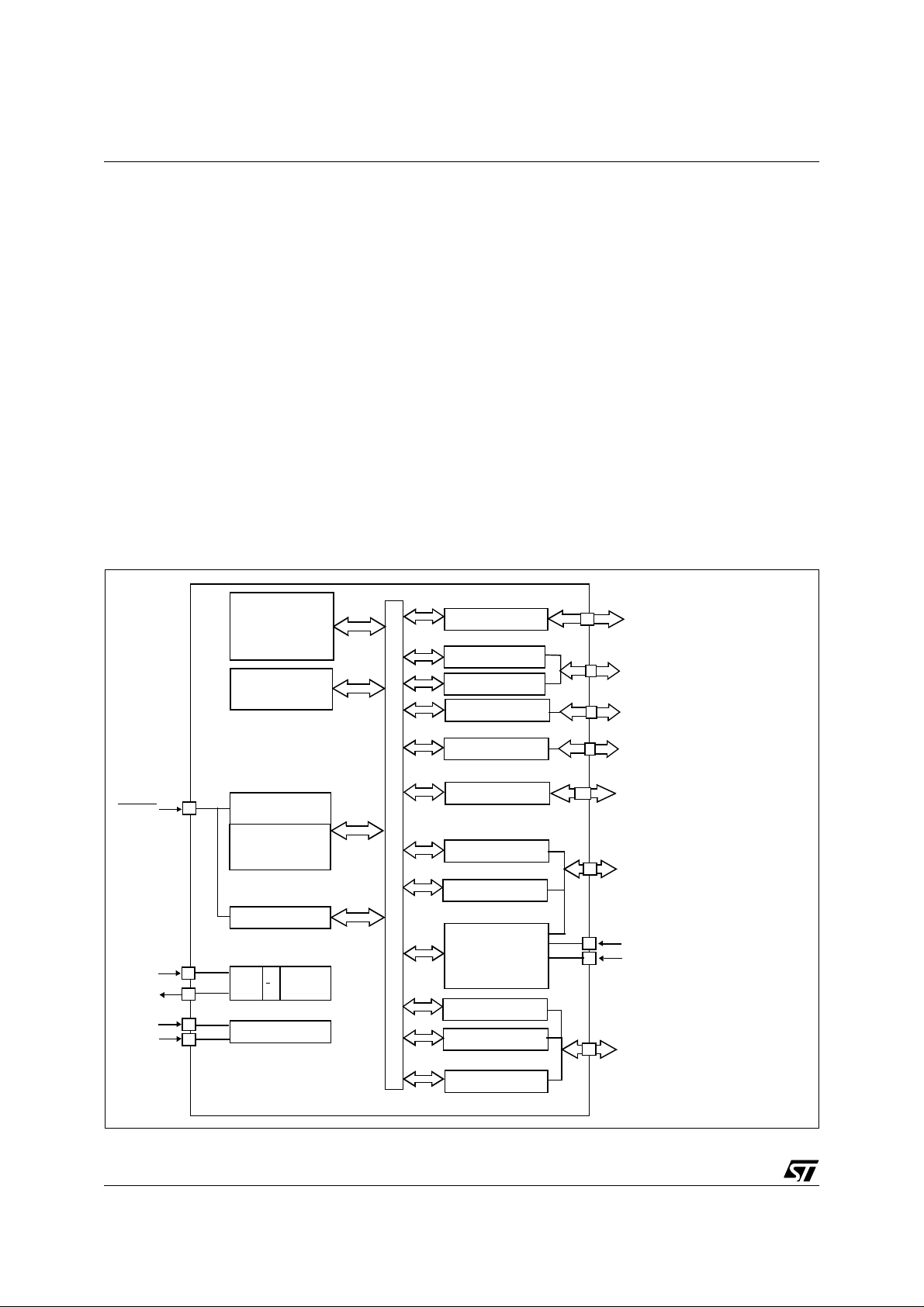

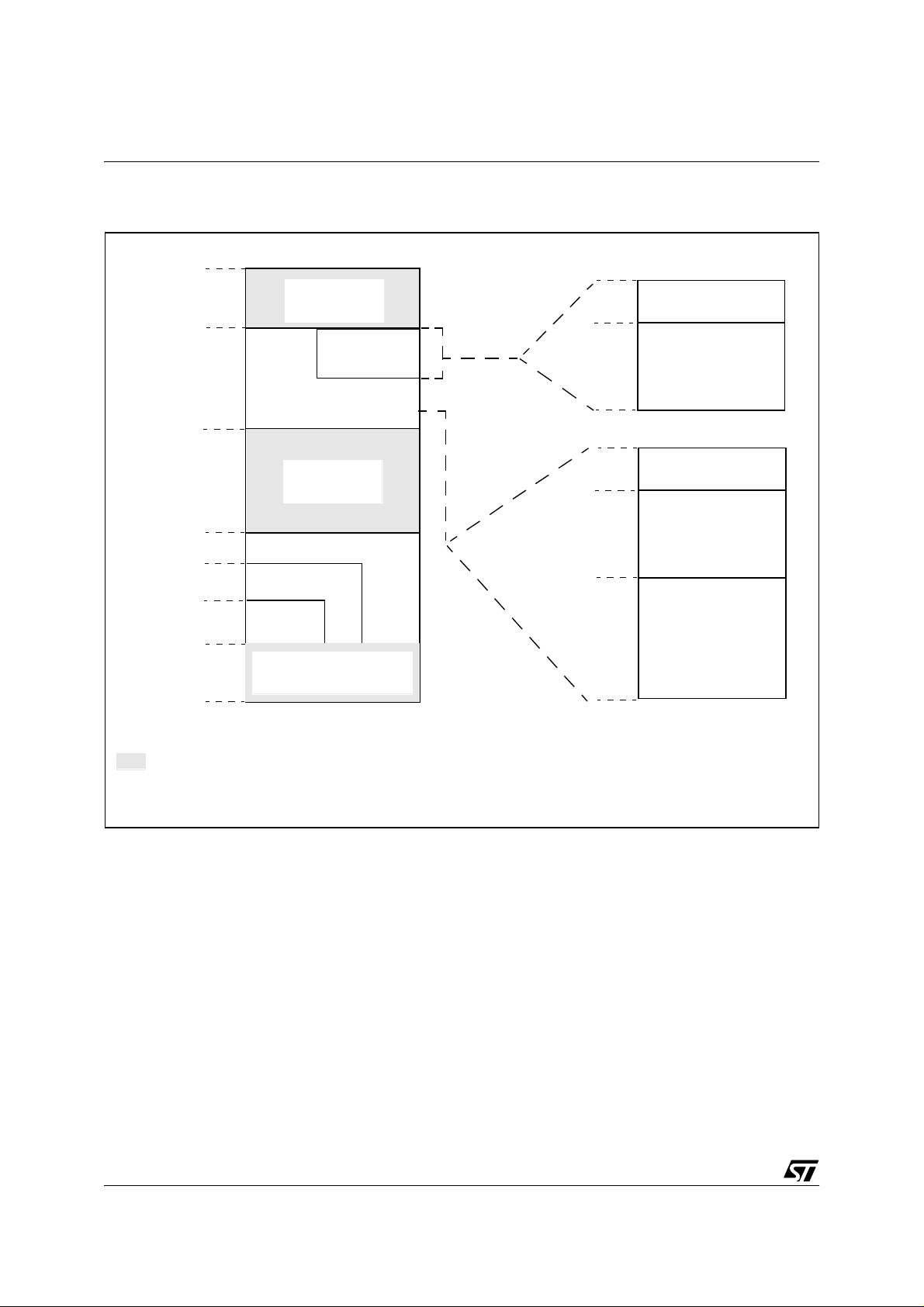

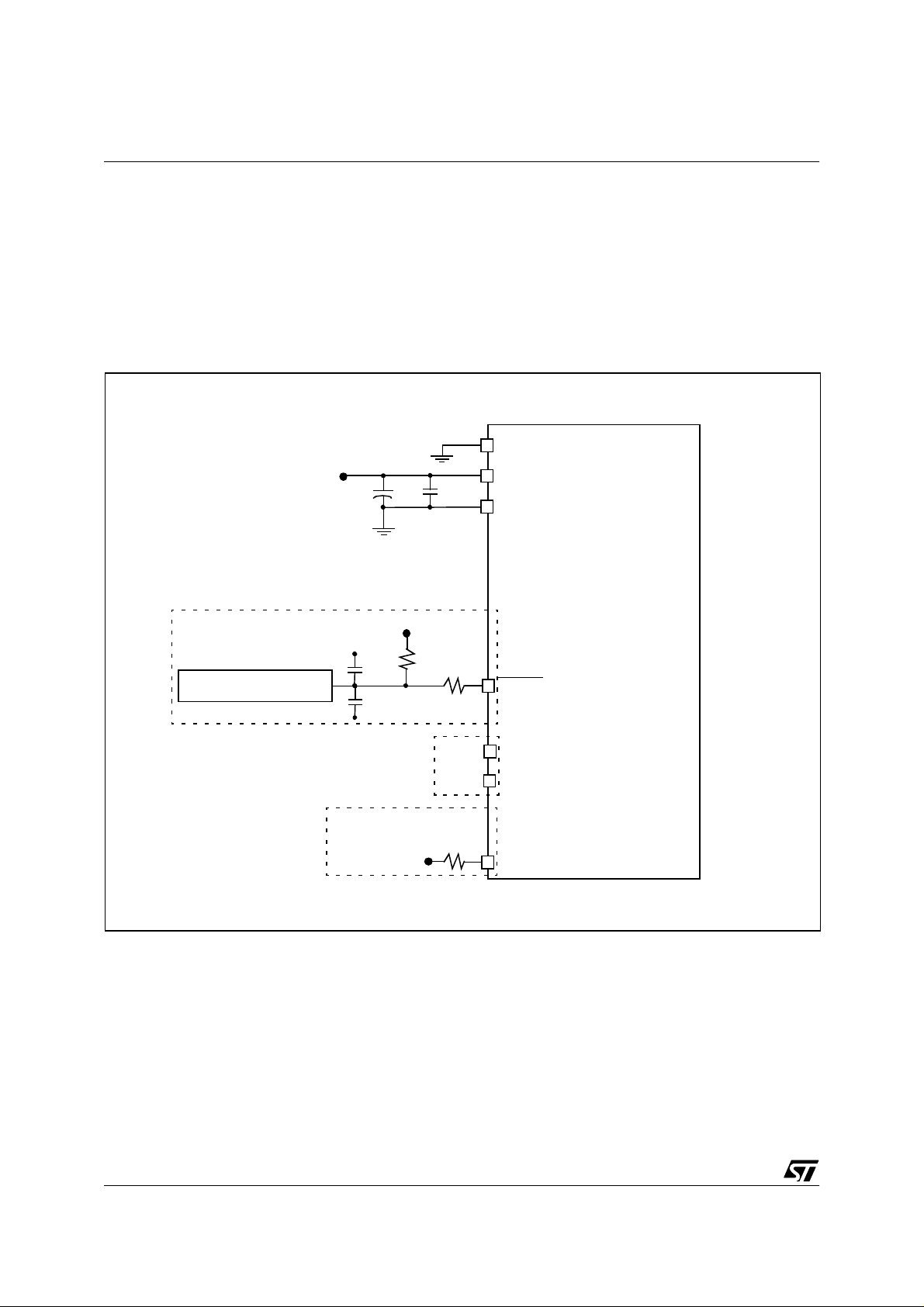

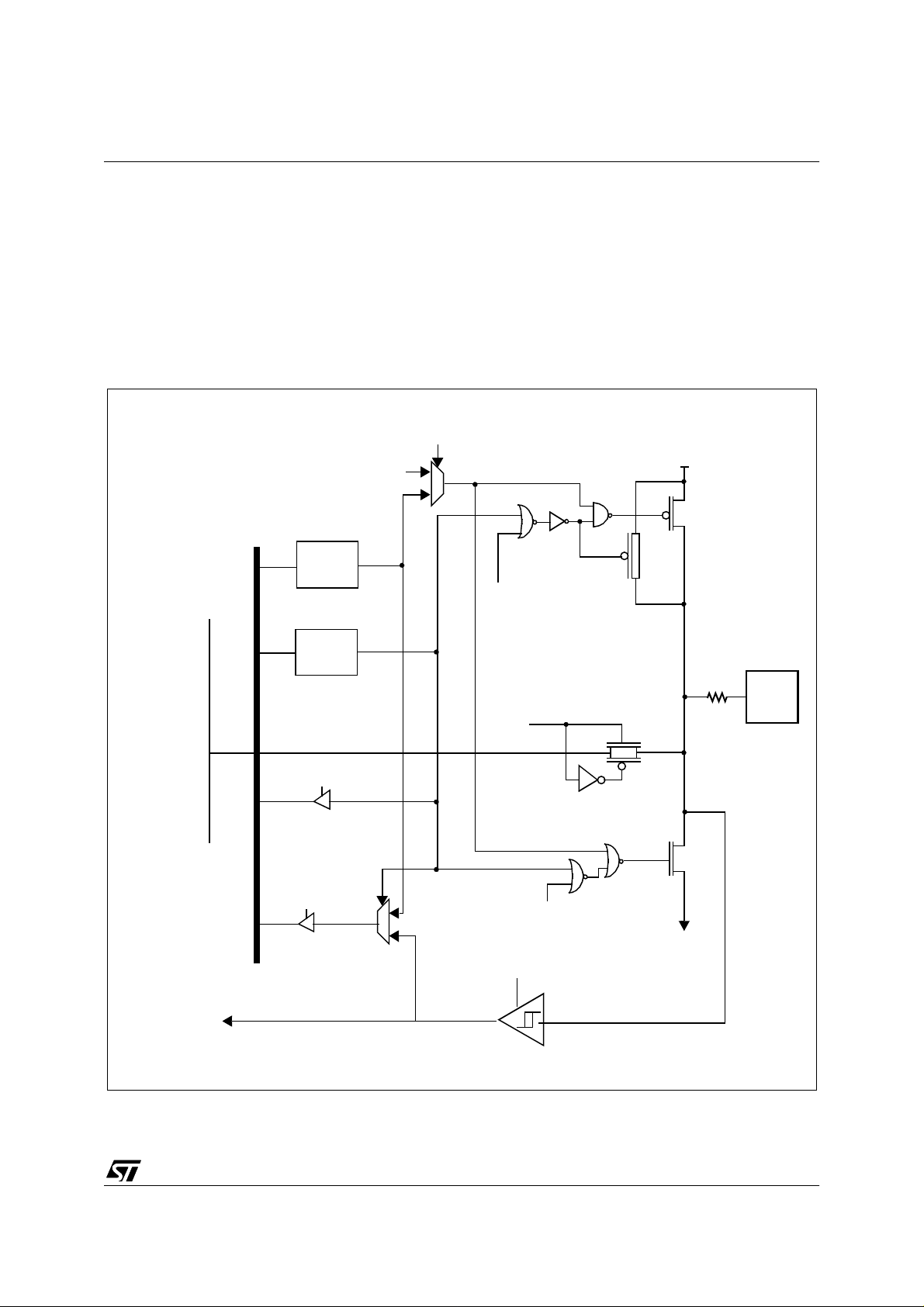

Figure 1. ST727x4 Block Diagram

Up to 60K Bytes

ROM/OTP/EPROM

Up to 1K Bytes

RAM

In addition to standard 8-bit data management the

ST7 features true bit manipulation, 8x8 unsigned

multiplication and indirect addressing modes.

The device includes an on-chip oscillator, CPU,

System protection aga inst illeg al add re ss j umps,

Sync Processor for video timing & Vfback analysis,

up to 60K Program Mem ory, up to 1K RAM, US B/

DMA, a Timing Measurement Unit, I/O, a timer with

2 input captures and 2 output compares, a 4channel Analog to Digital Converter, DDC, I

Single Master, W atchdog Reset, and ei ght 10-bit

PWM/BRM outputs for analog DC control of

external functions.

PA0/OCMP1

PA1

PORT A

PORT B

ADC

I2C

PA2/VSYNCI2

PA3-PA6

PA7/BLANKOUT

PB6-PB7/AIN2-AIN 3/ PWM1- PWM2

PB4-PB5/AIN0-AIN1

PB3/SDAI

PB2/SCLI

2

C

RESET

OSCIN

OSCOUT

V

V

6/144

DD

SS

CONTROL

8-BIT CO RE

ALU

WATCHDOG

Mode

3

:

OSC

Selection

POWER SUPPLY

DDC

ADDRESS AND DATA BUS

USB

PORT D

TIMER

SYNC

PROCESSOR

TMU

PORT C

DAC (PWM)

PB1/SDAD

PB0/SCLD

USBVCC

USBDP

USBDM

PD0/VSYNCO

PD1/HSYNCO

PD2/CSYNCI

PD3/ITA/VFBACK

PD4/ITB

PD5/HFBACK

PD6/CLAMPOUT

VSYNCI

HSYNCI

PC0/HSYNCDIV

PC1/AV

PC2-PC7/PWM3-PWM8

3

Page 7

1.2 PIN DESCRI PTION

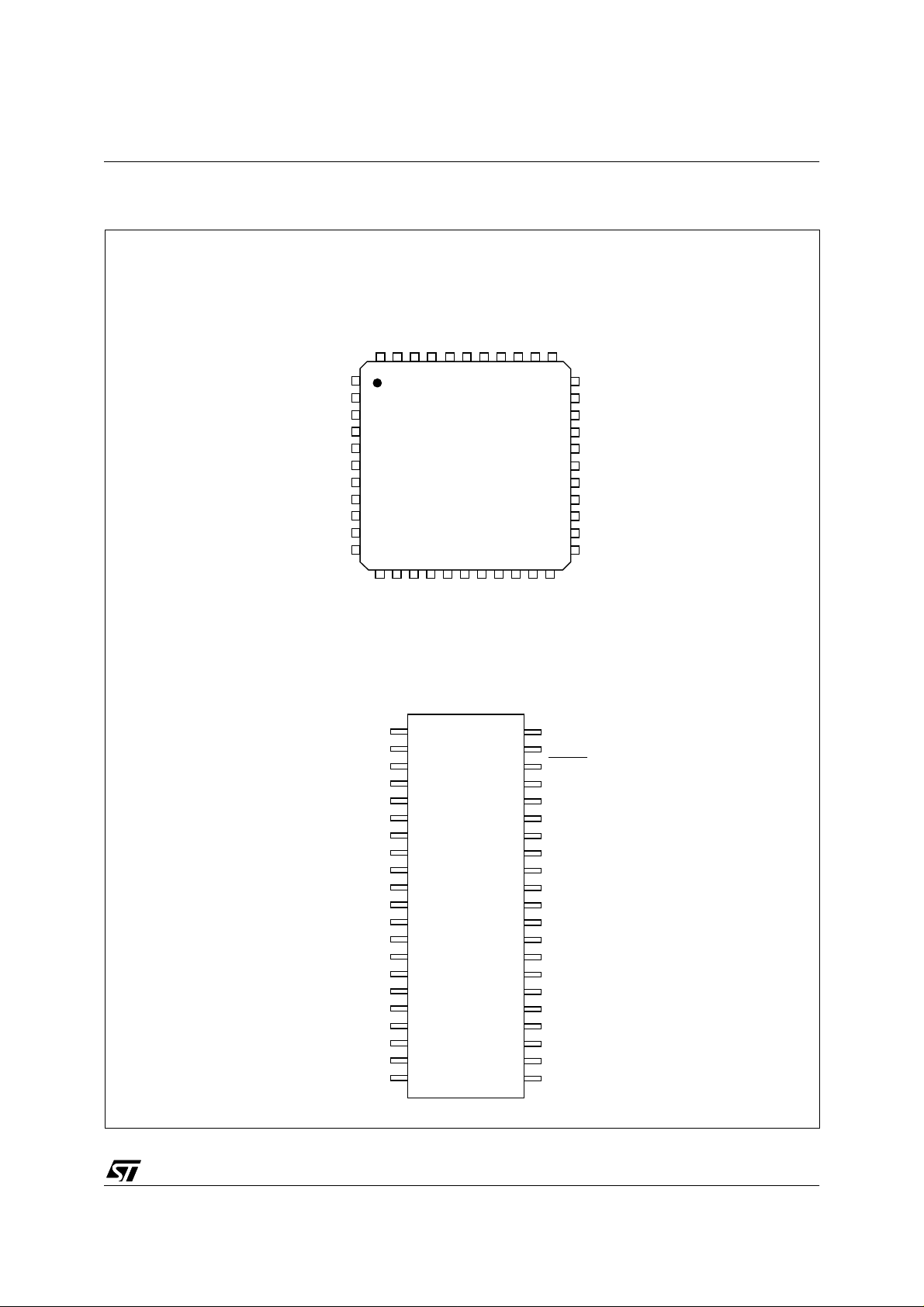

Figure 2. 44-pin TQFP and 42-Pin SDIP Package Pinouts

PC1 / AV

PC0 / HSYNCDIV

PA0 / O C MP1

PWM7 / PC6

PWM8 / PC7

PWM2 / AIN3 / PB7

PWM1 / AIN2 / PB6

AIN1 / PB5

AIN0 / PB4

NC

V

DD

USBVCC

USBDM

USBDP

PC5 / PWM6

PC4 / PWM5

PC3 / PWM4

PC2 / PWM3

44 43 42 41 40 39 38 37 36 35 34

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17 18 19 20 21 22

ss

V

TEST / VPPRESET

PA1

ST72774/ST727754/ST72734

PA2/VSYNCI2

PA3

33

PA4

32

PA5

31

PA6

30

OSCIN

29

OSCOUT

28

PA7 / BLANKO UT

27

PB3 / SDAI

26

PB2 / SCLI

25

PB1 / SDAD

24

NC

23

HSYNCDIV / PC0

AV / PC1

PWM3 / PC2

PWM4 / PC3

PWM5 / PC4

PWM6 / PC5

PWM7 / PC6

PWM8 / PC7

PWM2 / AIN3 / PB7

PWM1 / AIN2 / PB6

AIN1 / PB5

AIN0 / PB4

V

DD

USBVCC

USBDM

USBDP

V

SS

HSYNCI

VSYNCI

VSYNCO / PD0

HSYNCO / PD1

VSYNCI

HSYNCI

VSYNCO / PD0

HSYNCO / PD1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

ITB / PD4

CSYNCI / PD2

VFBACK / IT A /PD3

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

SCLD / PB0

HFBACK / PD5

CLAMPOUT / PD6

PA0 / OCMP1

TEST / V

RESET

PA1

PA2/VSYNCI2

PA3

PA4

PA5

PA6

OSCIN

OSCOUT

PA7 / BLANKOUT

PB3 / SDAI

PB2 / SCLI

PB1 / SDAD

PB0 / SCLD

PD6 / CLAMPOUT

PD5 / HFBACK

PD4 / ITB

PD3 / ITA / VFBACK

PD2 / CSYNCI

PP

NC = Not connected

7/144

3

Page 8

ST72774/ST727754/ST72734

PIN DESCRIPTION (Cont’d)

RESET:

Bidirectional. This active low signal forces

the initialization of the MCU. This event is the top

priority non maskable interrupt. This pin is

switched low when the Watchdog has triggered or

V

is low. It can be used to reset external

DD

peripherals.

OSCIN/OSCOUT: Input/Output Oscillator pin.

These pins connect a pa rallel-resonant crystal, or

an external sou rc e to the on -c h ip o s cilla t o r.

TEST/V

: Input. EPROM programming voltage.

PP

This pin must be held low during normal operating

modes.

V

: Power supply voltage (4.0V-5.5V)

DD

V

: Digital Ground.

SS

Alter nate Funct ions: several pins of the I/O ports

assume software programmable alternate

functions as shown in the pin description

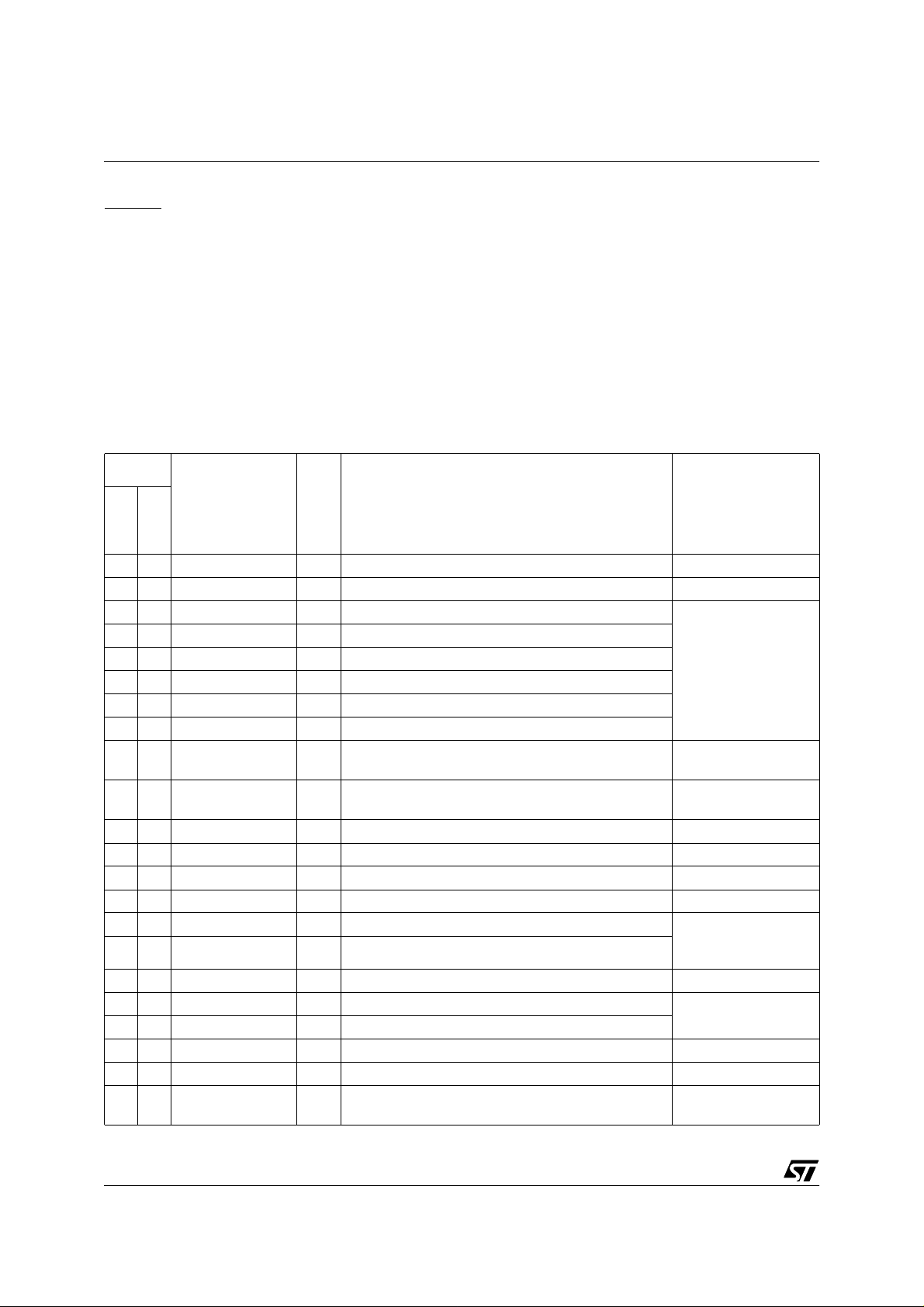

Table 1. ST727x4 Pin Description

Pin No.

Pin Name

SDIP42

TQFP44

39 1 PC0/HSYNCDIV I/O Port C0 or HSYNCDIV output (HSYNCO divided by 2)

40 2 PC1/AV I/O Port C1 or “Active Video” input

41 3 PC2/PWM3 I/O Port C2 or 10-bit PWM/BRM output 3

42 4 PC3/PWM4 I/O Port C3 or 10-bit PWM/BRM output 4

43 5 PC4/PWM5 I/O Port C4 or 10-bit PWM/BRM output5

44 6 PC5/PWM6 I/O Port C5 or 10-bit PWM/BRM output 6

1 7 PC6/PWM7 I/O Port C6 or 10-bit PWM/BRM output 7

2 8 PC7/PWM8 I/O Port C7 or 10-bit PWM/BRM output 8

3 9 PB7/AIN3/PWM2 I/O

4 10 PB6/AIN2/PWM1 I/O

5 11 PB5/AIN1 I/O Port B5 or ADC analog input 1

6 12 PB4/AIN0 I/O Port B4 or ADC analog input 0

813V

9 14 USBVCC S USB power supply (output 3.3V +/- 10%)

10 15 USBDM I/O USB bidirectional data Must be tied to ground

11 16 USBDP I/O USB bidirectional data

12 17 V

13 18 HSYNCI I SYNC horizontal synchronisation input

14 19 VSYNCI I SYN C vertical synch ronis ation input

15 20 PD0/VSYNCO I/O Port D0 or SYNC vertical synchronisation output

16 21 PD1/HSYNCO I/O Port D1 or SYNC horizontal synchronisation output

17 22 PD2/CSYNCI I/O Port D2 or SYNC composite synchronisation input

DD

SS

Type

Port B7 or ADC analog input 3 or 10-bit PWM/BRM

output 2

Port B6 or ADC analog input 2 or 10-bit PWM/BRM

output 1

S Supply (4.0V - 5.5V)

S Ground 0V

Description Remarks

For analog controls,

after external filtering

for devices without

USB peripheral

TTL levels

Refer to Figure 16

TTL levels with pull-up

(SYNC input)

8/144

3

Page 9

Pin No.

ST72774/ST727754/ST72734

Pin Name

SDIP42

TQFP44

18 23 PD3/VFBACK/ITA I/O

19 24 PD4/ITB I/O Port D4 or Interrupt falling edge detector input B

20 25 PD5/HFBACK I/O Port D5 or SYNC horizontal flyback input

21 26 PD6/CLAMPOUT I/O Port D6 or SYNC clamping/ MOIRE output

22 27 PB0/SCLD I/O Port B0 or DDC serial clock

24 28 PB1/SDAD I/O Port B1 or DDC serial data

25 29 PB2/SCLI I/O Port B2 or I2C serial clock

26 30 PB3/SDAI I/O Port B3 or I2C serial data

27 31 PA7/BLANKOUT I/O Port A7 or SYNC blanking output

28 32 OSCOUT O Oscillator output

29 33 OSCIN I Oscillator input

30 34 PA6 I/O Port A6

31 35 PA5 I/O Port A5

32 36 PA4 I/O Port A4

33 37 PA3 I/O Port A3

34 38 PA2/VSYNCI2 I/O Port A2 or SYNC vertical synchronisation input 2 DDC1 only

35 39 PA1 I/O Port A1

36 40 RESET

37 41 TEST/V

38 42 PA0/OCMP1 I/O Port A0 or TIMER output compare 1

PP

Type

Port D3 or SYNC Vertical flyback input or interrupt falling edge detector input A

I/O Reset pin Active low

Test mode pin or EPROM programming voltage. This

S

pin should be tied low in user mode.

Description Remarks

Refer to Figure 16 and

Table 11 Port D Description

Refer to Table 11 Port

D Description

TTL levels with pull-up

(SYNC input)

9/144

Page 10

ST72774/ST727754/ST72734

1.3 MEMORY MA P

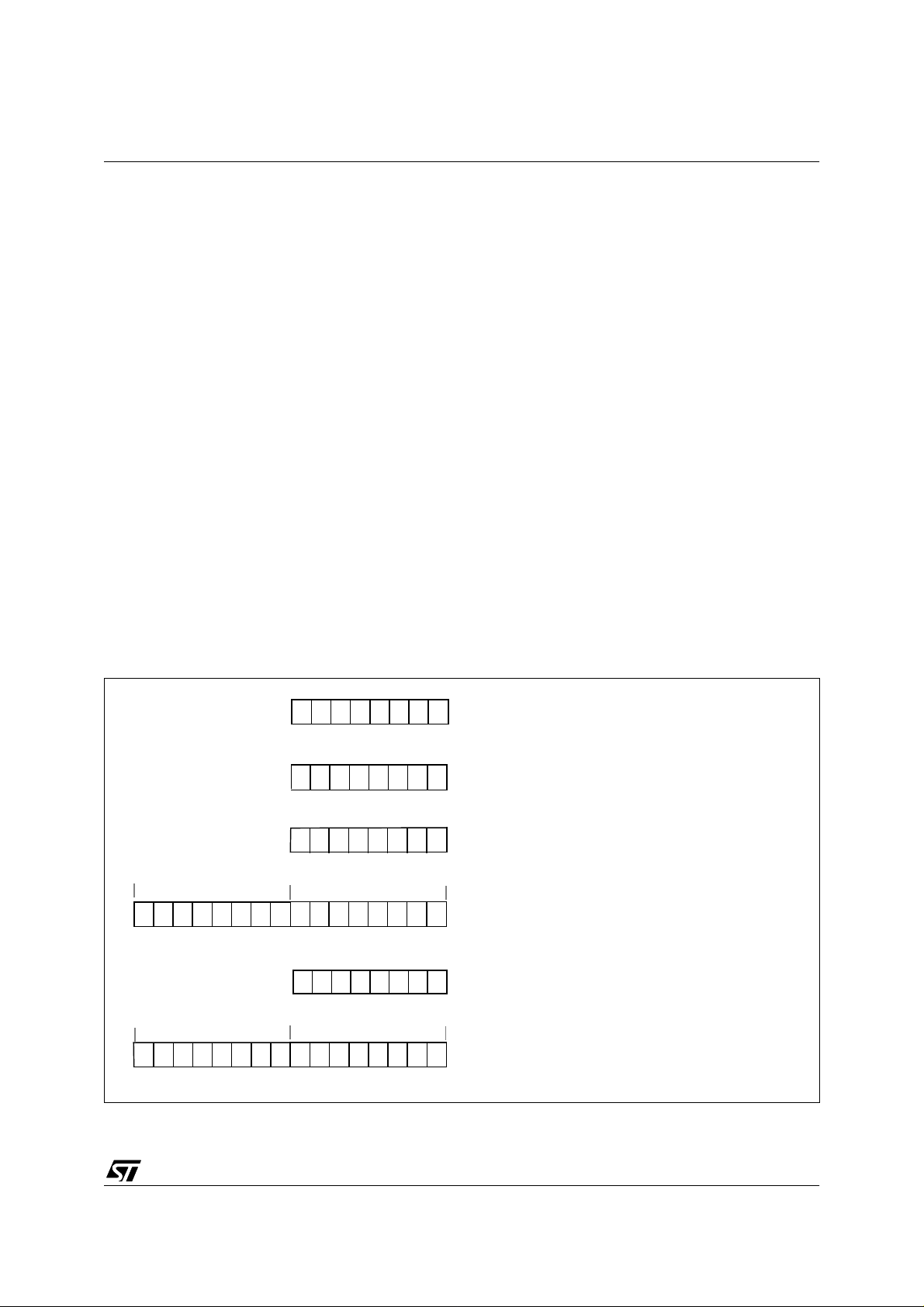

Figure 3. Me m ory Map

0000h

005Fh

0060h

03FFh

0400h

0FFFh

1000h

4000h

8000h

FFDFh

FFE0h

FFFFh

HW Registers

(see Table 2)

512 Bytes RAM

1 Kbyte RAM

Reserved

60 Kbytes

ROM/EPROM

48 Kbytes

32 Kbytes

Interrupt & Reset Vectors *

(see Table 3)

0060h

0100h

01FFh

0060h

0100h

01FFh

0200h

03FFh

Short Addressing

RAM (zero page)

256 Bytes Stack/

16-bit Addressing RAM

Short Addressing

RAM (zero page)

256 Bytes Stack/

16-bit Addressing RAM

16-bit Addressing

RAM

512 Bytes

any opcode fetch in those areas is considered as illegal and generates a reset

(*) this block only contains addresses of interrupts and reset routines, no opcode is run from this block

10/144

Page 11

MEMORY MAP (Cont’d)

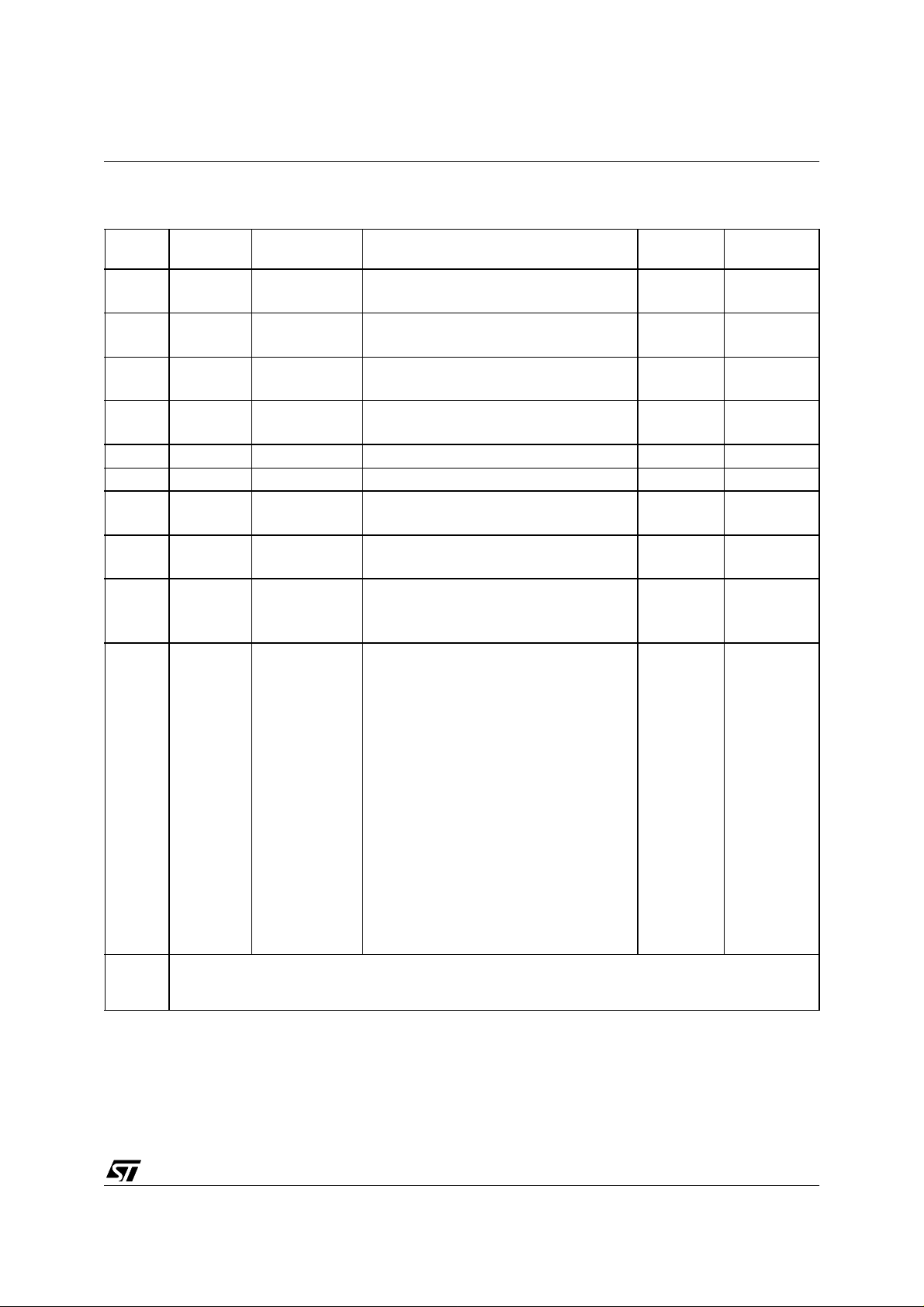

Table 2. Hardware Register Mem ory Map

ST72774/ST727754/ST72734

Address Block Register Label Register Name

0000h

0001h

0002h

0003h

0004h

0005h

0006h

0007h

0008h Watchdog WDGCR Watchdog Control Register 7Fh R/W

0009h MISCR Miscellaneous Register 10h R/W

000Ah

000Bh

000Ch

000Dh

000Eh

000Fh

00010h

0011h

0012h

0013h

0014h

0015h

0016h

0017h

0018h

0019h

001Ah

001Bh

001Ch

001Dh

001Eh

001Fh

0020h

to

0024h

ADC

DDC1/2B

TMU

Timer

PADR

PADDR

PBDR

PBDDR

PCDR

PCDDR

PDDR

PDDDR

ADCDR

ADCCSR

DDCDCR

DDCAHR

TMUCSR

TMUT1CR

TMUT2CR

TIMCR2

TIMCR1

TIMSR

TIMIC1HR

TIMIC1LR

TIMOC1HR

TIMOC1LR

TIMCHR

TIMCLR

TIMACHR

TIMACLR

TIMIC2HR

TIMIC2LR

TIMOC2HR

TIMOC2LR

Port A Data Register

Port A Data Direction Register

Port B Data Register

Port B Data Direction Register

Port C Data Register

Port C Data Direction Register

Port D Data Register

Port D Data Direction Register

ADC Data Register

ADC Control Status register

DDC1/2B Control Register

DDC1/2B Address Pointer High Register

TMU control status register

TMU T1 counter register

TMU T2 counter register

Timer Control Register 2

Timer Control Register 1

Timer Status Register

Timer Input Capture 1 High Register

Timer Input Capture 1 Low Register

Timer Output Compare 1 High Register

Timer Output Compare 1 Low Register

Timer Counter High Register

Timer Counter Low Register

Timer Alternate Counter High Register

Timer Alternate Counter Low Register

Timer Input Capture 2 High Register

Timer Input Capture 2 Low Register

Timer Output Compare 2 High Register

Timer Output Compare 2 Low Register

Reserved Area (5 bytes)

Status

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

xxh

FCh

FFh

FFh

00h

00h

00h

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

Reset

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read only

R/W

R/W

R/W

R/W

Read only

Read only

R/W

R/W

Read only

Read only

Read only

R/W

R/W

Read only

R/W

Read only

R/W

Read only

Read only

R/W

R/W

Remarks

11/144

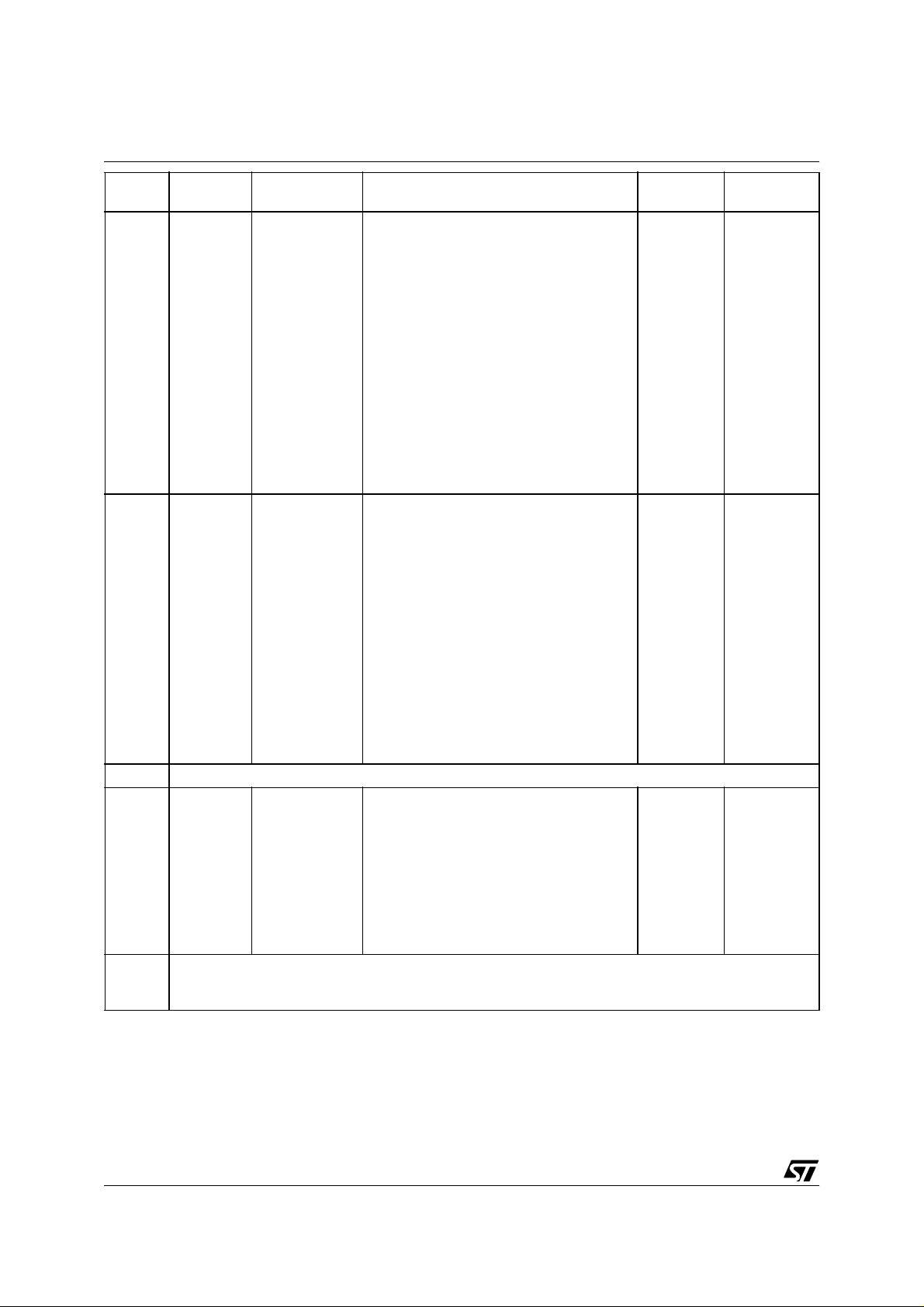

Page 12

ST72774/ST727754/ST72734

Address Block Register Label Register Name

0025h

0026h

0027h

0028h

0029h

002Ah

002Bh

002Ch

002Dh

002Eh

002Fh

0030h

0031h

0032h

0033h

0034h

0035h

0036h

0037h

0038h

0039h

003Ah

003Bh

003Ch

003Dh

003Eh

003Fh Reserved Area (1 byte)

0040h

0041h

0042h

0043h

0044h

0045h

0046h

0047h

0048h

to

004Fh

USB

PWM

SYNC

USBPIDR

USBDMAR

USBIDR

USBISTR

USBIMR

USBCTLR

USBDADDR

USBEP0RA

USBEP0RB

USBEP1RA

USBEP1RB

USBEP2RA

USBEP2RB

PWM1

BRM21

PWM2

PWM3

BRM43

PWM4

PWM5

BRM65

PWM6

PWM7

BRM87

PWM8

PWMCR

SYNCCFGR

SYNCMCR

SYNCCCR

SYNCPOLR

SYNCLATR

SYNCHGENR

SYNCVGENR

SYNCENR

USB PID Register

USB DMA address Register

USB Interrupt/DMA Register

USB Interrupt Status Register

USB Interrupt Mask Register

USB Control Register

USB Device Address Register

USB Endpoint 0 Register A

USB Endpoint 0 Register B

USB Endpoint 1 Register A

USB Endpoint 1 Register B

USB Endpoint 2 Register A

USB Endpoint2 Register B

10 BIT PWM / BRM

PWM output enable register

SYNC Configuration Register

SYNC Multiplexer Register

SYNC Counter Register

SYNC Polarity Register

SYNC Latch Register

SYNC H Sync Generator Register

SYNC V Sync Generator Register

SYNC Processor Enable Register

Reserved Area (8 bytes)

Reset

Status

XXh

XXh

XXh

00h

00h

xxxx 0110

00h

0000 xxxx

80h

0000 xxxx

0000

xxxx0000

0000

xxxx0000

80h

00h

80h

80h

00h

80h

80h

00h

80h

80h

00h

80h

00h

00h

20h

00h

08h

00h

00h

00h

C3h

Remarks

Read only

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

12/144

Page 13

ST72774/ST727754/ST72734

Address Block Register Label Register Name

0050h

0051h

0052h

0053h

0054h

0055h

0056h

0057h

0058h

0059h

005Ah

005Bh

005Ch

005Dh

005Eh

005Fh

DDC/CI

I2C

DDCCR

DDCSR1

DDCSR2

DDCOAR

DDCDR

I2CDR

I2CCCR

I2CSR2

I2CSR1

I2CCR

DDC/CI Control Register

DDC/CI Status Register 1

DDC/CI Status Register 2

Reserved

DDC/CI (7 Bits) Slave address Register

Reserved

DDC/CI Data Register

Reserved Area (2 bytes)

I2C Data Register

Reserved

Reserved

2

C Clock Control Register

I

2

C Status Register 2

I

2

C Status Register 1

I

2

C Control Register

I

Reset

Status

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

Table 3. Interrupt Vector Map

Vector Address Description Remarks

FFE0-FFE1h

FFE2-FFE3h

FFE4-FFE5h

FFE6-FFE7h

FFE8-FFE9h

FFEA-FFEBh

FFEC-FFEDh

FFEE-FFEFh

FFF0-FFF1h

FFF2-FFF3h

FFF4-FFF5h

FFF6-FFF7h

FFF8-FFF9h

FFFA-FFFBh

FFFC-FFFDh

FFFE-FFFFh

Timer Overflow interrupt vector

Timer Output Compare interrupt vector

Timer Input Capture interrupt vector

ITA falling edge interrupt vector

ITB falling edge interrupt vector

DDC1/2B interrupt vector

USB End Suspend interrupt vector

TRAP (software) interrupt vector

Not used

Not used

Not used

USB interrupt vector

Not used

I2C interrupt vector

DDC/CI interrupt vector

RESET vector

Internal Interrupts

External Interrupts

Internal Interrupt

CPU Interrupt

Remarks

R/W

Read only

Read only

R/W

R/W

R/W

R/W

Read only

Read only

R/W

13/144

Page 14

ST72774/ST727754/ST72734

1.4 External connections

The following figure shows the recom mended external connections for the device.

The V

pin is only used for programming OTP

PP

and EPROM devices and must be tied to ground in

user mode.

The 10 nF and 0. 1 µF decoupling capacitors on

the power supply lines are a suggested EMC performance/cost tradeoff.

Figure 4. Recommended Extern al Connec tions

V

DD

EXTERNAL RESET CIRCUIT

10nF

V

DD

0.1µF

0.1µF

+

4.7K

The external reset network (including the mandatory 1K serial resistor) is inten ded to protect the

device against parasitic resets, espec ially in noisy

environments.

Unused I/Os shoul d be t ied hi gh to av oid any unnecessary power consumption on floating lines.

An alternative solution is to program the unused

ports as inputs with pull-up.

V

PP

V

0.1µF

1K

DD

V

SS

RESET

14/144

See

Clocks

Section

Or configure unused I/O ports

by software as input with pull-up

V

10K

DD

OSCIN

OSCOUT

Unused I/O

Page 15

2 CENTRAL PRO CESSING UNIT

ST72774/ST727754/ST72734

2.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

2.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

2.3 CPU REGISTERS

The 6 CPU registers shown in Figure 5 are not

present in the memory mapping and are accessed

by specific instructions.

Accumulator (A)

Figure 5. CPU Registers

70

RESET VALUE = XXh

70

RESET VALUE = XXh

70

RESET VALUE = XXh

The Accumulator is an 8-bit general purpose

register used to hold operands and the results of

the arithmetic and logic calculations and to

manipulate data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bit registers

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede

instruction (PRE) to indicate that the following

instruction refers to the Y register.)

The Y register is not affected by the interrupt

automatic procedures (not pushed to and pop ped

from the stack).

Program Cou nt er (P C )

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

15 8

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

15

RESET VALUE = STACK HIGHER ADDRESS

PCH

RESET VALUE =

7

70

1C11HI NZ

1X11X1XX

70

8

PCL

0

PROGRAM COUNTER

CONDITION CODE REGISTER

STACK POINTER

X = Undefined Value

15/144

Page 16

ST72774/ST727754/ST72734

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

70

enter it and reset by the IRET instruction at the end

of the interrupt routine. If the I bit is cleared by

software in the interrupt routine, pending interrupts

are serviced regardless of the pri ority level of the

current interrupt routine.

111HINZC

The 8-bit Condition Code register contains the

interrupt mask and four flags representative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP

instructions.

These bits can be individually tested and/or

controlled by specific instructions.

Bit 4 = H

Half carry

.

This bit is set by hardware when a carry occurs

between bits 3 and 4 of the ALU during an ADD or

ADC instruction. It is reset by hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH

instruction. The H bit is useful in B CD arithmetic

subroutines.

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is

representative of the result sign of the last

arithmetic, logical or data manipulation. It is a copy

of the 7

th

bit of the result.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit is accessed by the JRMI and JRPL

instructions.

Bit 1 = Z

Zero

.

This bit is set and cleared by hardware. This bit

indicates that the result of the last arithmetic,

logical or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 3 = I

Interrupt mask

.

This bit is set by hardware when entering in

interrupt or by software to disable all interrupts

except the TRAP software interrupt. This bit is

cleared by software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlled by the RIM, SIM and IRET

instructions and is tested by the JRM and JRNM

instructions.

Note: Interrupts requested while I is set are

latched and can be processed whe n I is cleared.

By default an interrupt routine is not in terruptable

because the I bit is set by hardware when you

16/144

Bit 0 = C

Carry/borrow.

This bit is set and cleared by hardware and

software. It indicates an overflow or an underflow

has occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.

This bit is driven by th e SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

Page 17

ST72774/ST727754/ST72734

CPU REGISTERS (Cont’d)

Stack Pointer (SP)

Read/Write

Reset Value: 01 FFh

15 8

00000001

70

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD

instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit,

without indicating the stack overflow. The

previously stored information is then overwritten

and therefore lost. The stack also wraps in case of

an underflow.

SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0

The Stack Pointer is a 16-bit register which is

always pointing to the next free location in the

stack. It is then decremented after data has been

pushed onto the stack and incremented before

data is popped from the stack (see Figure 6).

Since the stack is 256 bytes deep, the most

significant byte is forced by ha rd ware. Fol lowing

an MCU Reset, or after a Reset Stack Pointer

instruction (RSP), the Stack Pointer contains its

reset value (the SP7 to SP0 bits are set) which is

the stack higher address.

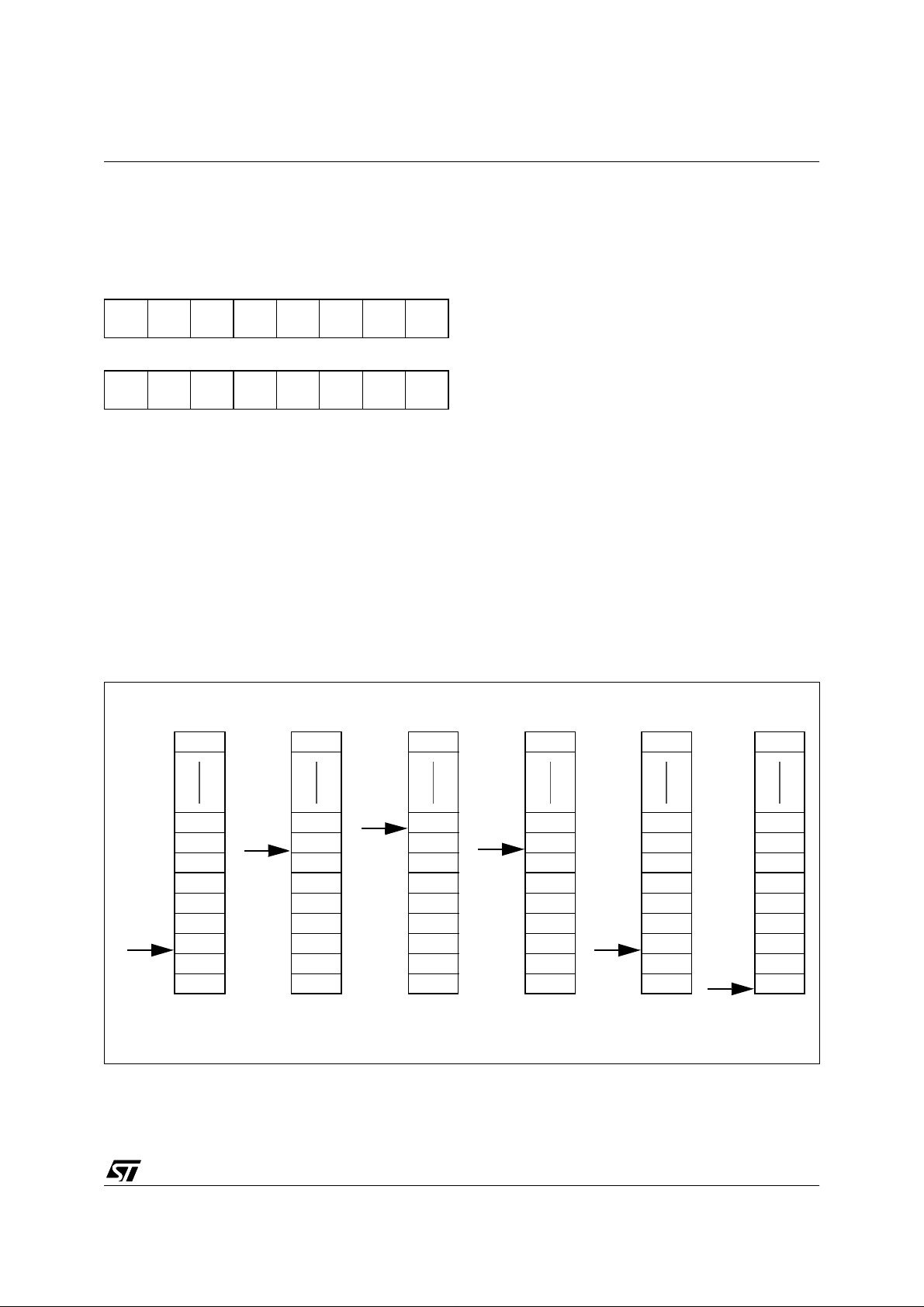

Figure 6. Stack Manipulation Example

@ 0100h

SP

@ 01FFh

CALL

Subroutine

PCH

PCL

Interrupt

event

SP

SP

CC

A

X

PCH

PCL

PCH

PCL

PUSH Y POP Y IRET

Y

CC

A

X

PCH

PCL

PCH

PCL

The stack is used to save the return address

during a subroutine call and the CPU context

during an interrupt. The user may also directly

manipulate the stack b y means of the PU SH and

POP instructions. In the case of an in terrupt, the

PCL is stored at the first location pointed to by the

SP. Then the other registers are stored in the next

locations as shown in Figure 6.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an

interrupt five locations in the stack area.

RET

or RSP

SP

CC

A

X

PCH

PCL

PCH

PCL

SP

PCH

PCL

SP

Stack Higher Address = 01FFh

Stack Lower Address =

0100h

17/144

Page 18

ST72774/ST727754/ST72734

3 CLOCKS, RESET, INTERRUPTS & LOW POWER MODES

3.1 CLOCK SYSTEM

3.1.1 General Description

The MCU accepts either a cry stal or an external

clock signal to drive the internal oscillator. The

internal clock (CPU CLK running at f

CPU

) is

derived from the external oscillator frequency

), which is divided by 3. Depending on the

(f

OSC

external quartz or clock frequency, a division factor

of 2 is optionally added to generate the 12 MHz

clock for the Sync Processor (clamp function) as

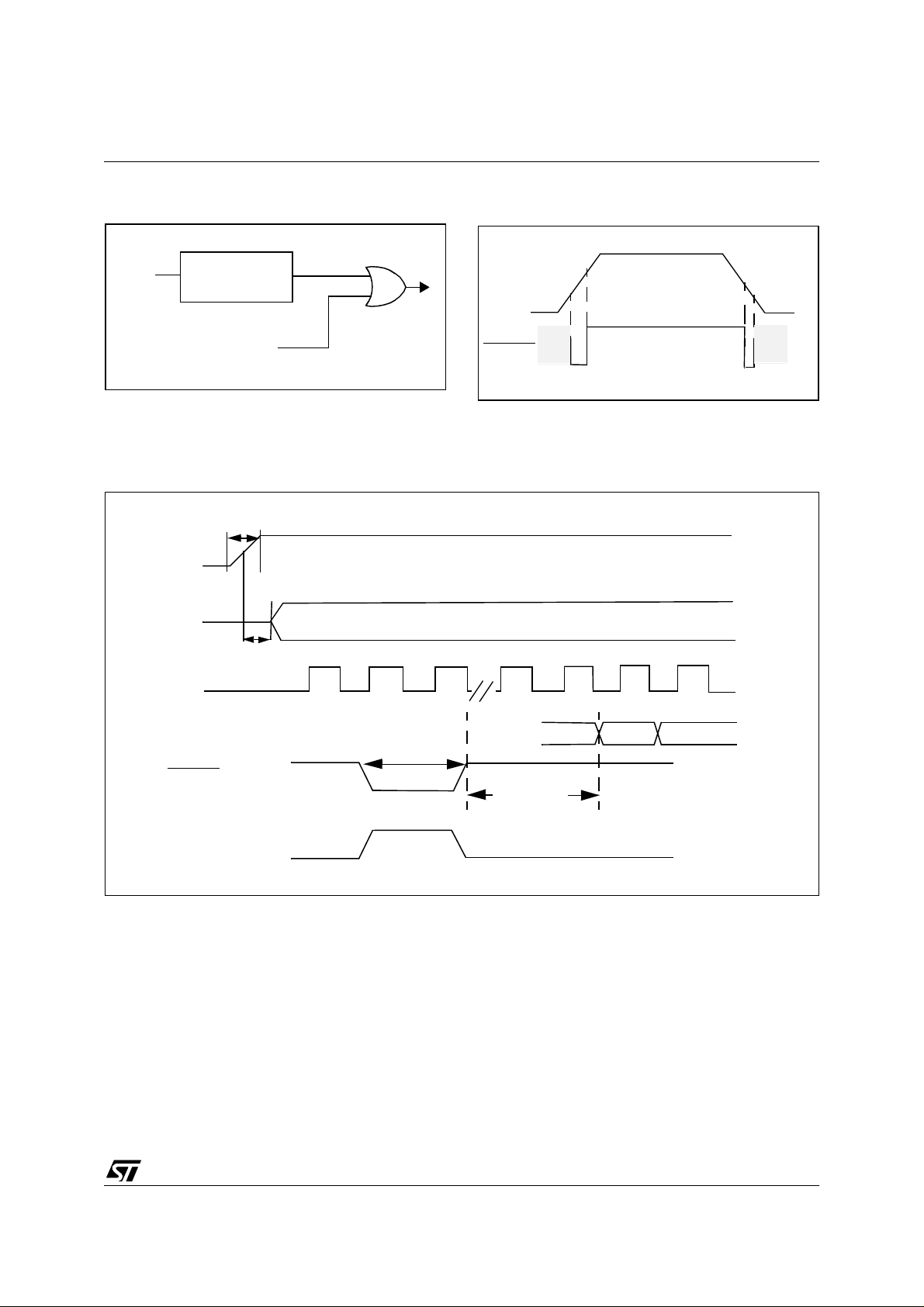

Figure 7. Clock divider chain

OSC

12 MHz

or

%2

FAST

24MHz

shown in Figure 7 and a second divider by 2 for the

6MHz USB clock.

The CPU clock is used also as clock for the

ST727x4 peripherals.

Note: In the Sync processor, an additional divider

by two is added in fast mode (same external timing

for this peripheral).

f

: 4 or 8 MHz

%3

CPU

(CPU and peripherals)

12 MHz

(Sync processor Clampout signal)

%2

6 MHz

(USB)

FAST=1 for 24 M H Z os c illator FAST=0 for 12 MHz osc il lat o r

18/144

12 MHz

or

24MHz

(TMU)

4

Page 19

CLOCK SYSTEM (Cont’d)

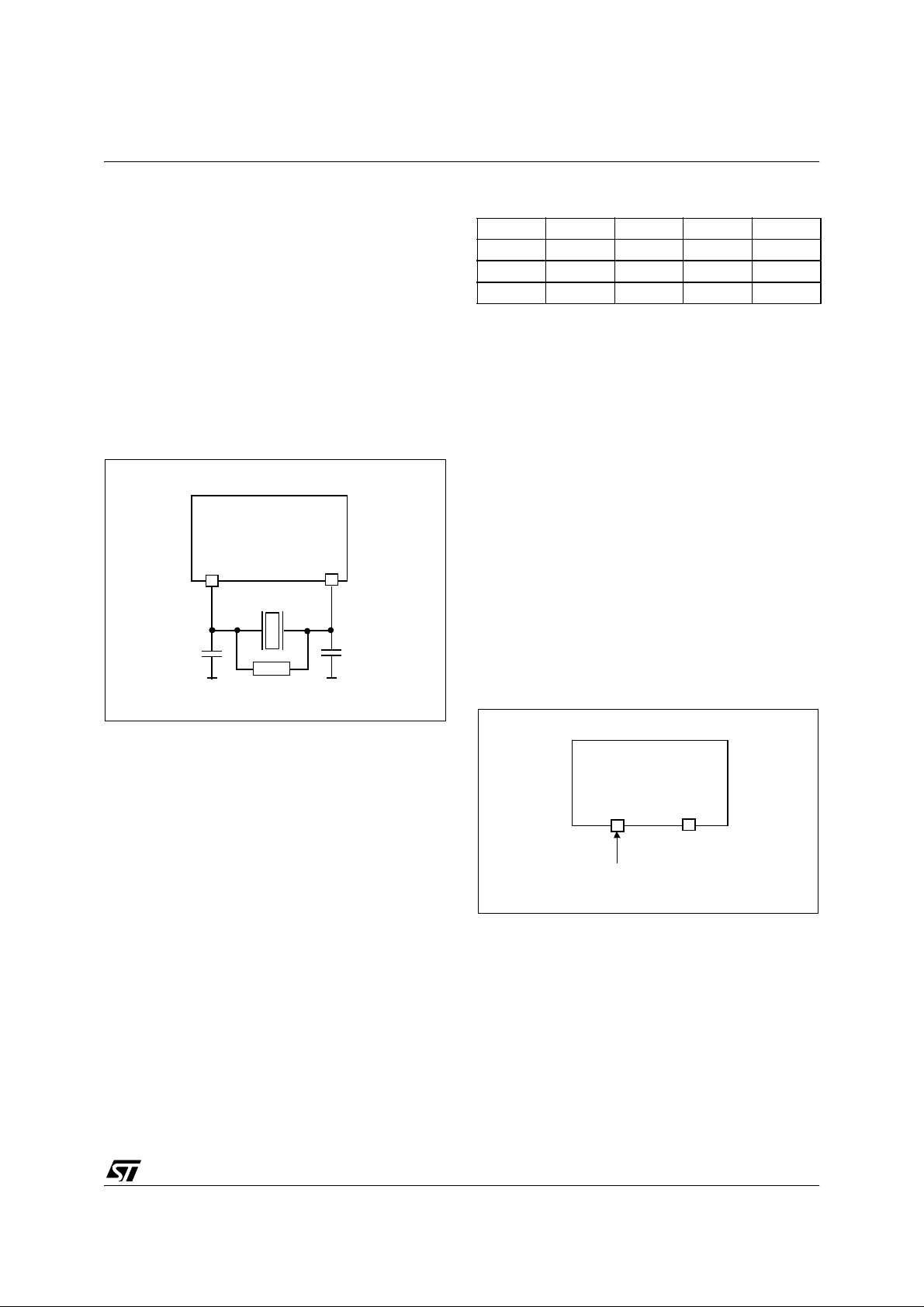

3.1.2 Crystal Resonator

The internal oscillat or is designed to operate with

an AT-cut parallel resonant quartz crystal

resonator in the frequency range specified for f

osc

The circuit shown in Figure 8 is recommended

when using a crystal, and Table 4, “.

Recommended Crystal Values,” on page 19 lists

the recommended capacitance and feedback

resistance values. The crystal and associated

components should be mounted as close as

possible to the input pins in order to minimize

output distortion and start-up stabilization time.

Figure 8. Crystal/Ceramic Resonator

CRYSTAL CLOCK

OSCIN OSCOUT

C

L1

C

L2

ST72774/ST727754/ST72734

Table 4

.

Legend:

C

OSCIN and OSCOUT (the value includes the

external capacitance tied to the pin plus the

parasitic capacitance of the board and of the

device).

R

the quartz allowed.

Note: The tables are relative t o the quart z crystal

only (not ceramic resonator).

3.1.3 External Clock

An external clock should be appli ed to t he O SCIN

input with the OSCOUT pin not connected as

shown in Figure 9. The Crystal clock specifications

do not apply when using an external clock input.

The equivalent spe cification of the external clock

source should be used.

. Recomm en de d Crystal Values

24 Mhz Unit

R

SMAX

C

L1

C

L2

, CL2 = Maximum total capacitance on pins

L1

= Maximum series parasitic resistance of

SMAX

70 25 20 Ohms

22 47 56 pf

22 47 56 pf

*Recommended for oscillator stability

1M*

Figure 9. External Clock Source Connections

OSCIN

EXTERNAL

CLOCK

OSCOUT

NC

19/144

Page 20

ST72774/ST727754/ST72734

3.2 RESET

The Reset procedure is used to provide an orderly

software start-up or to quit low powe r modes.

Five conditions generate a reset:

■ LVD,

■ watchdog,

■ external pulse at the RESET pin,

■ illegal address,

■ illegal opcode.

A reset causes the reset vector to be fetched from

addresses FFFEh and FFFFh in order to be loaded

into the PC and with program execution starting

from this point.

An internal circuitry provides a 4096 CPU clock

cycle delay from the time that the oscillator

becomes active.

3.2.1 LVD and Watchdog Reset

The Low Voltage Detector (LVD) generates a reset

when V

when

is active only when V

is below V

DD

is falling (refer to Figure 11). This circuitry

VDD

when VDD is ri sing or V

TRH

is above V

DD

TRM.

TRL

During LVD Reset, the RESET pin is held low, thus

permitting the MCU to reset other devices.

When a watchdog reset occurs, the RESET

pin is

pulled low permitting the MCU to reset other

devices as when Power on/off (Figure 10).

3.2.2 External Reset

The external reset is an active low input signal

applied to the RESET pin of the MCU.

As shown in Figure 12, the RESET

signal must

remain low for 1000ns.

An internal Schmitt trigger at the RESET

pin is

provided to improve noise immunity.

3.2.3 Illegal Address Detection

An opcode fetch from an illegal address (refer to

Figure 3) generates an illegal address reset.

Program execution at those addresses is

forbidden (especially to protect page 0 registers

against spurious accesses).

3.2.4 Illegal Opcode Detection

Illegal instructions corresponding to no valid

opcode generate a reset. Refer to ST7

Programming Manual.

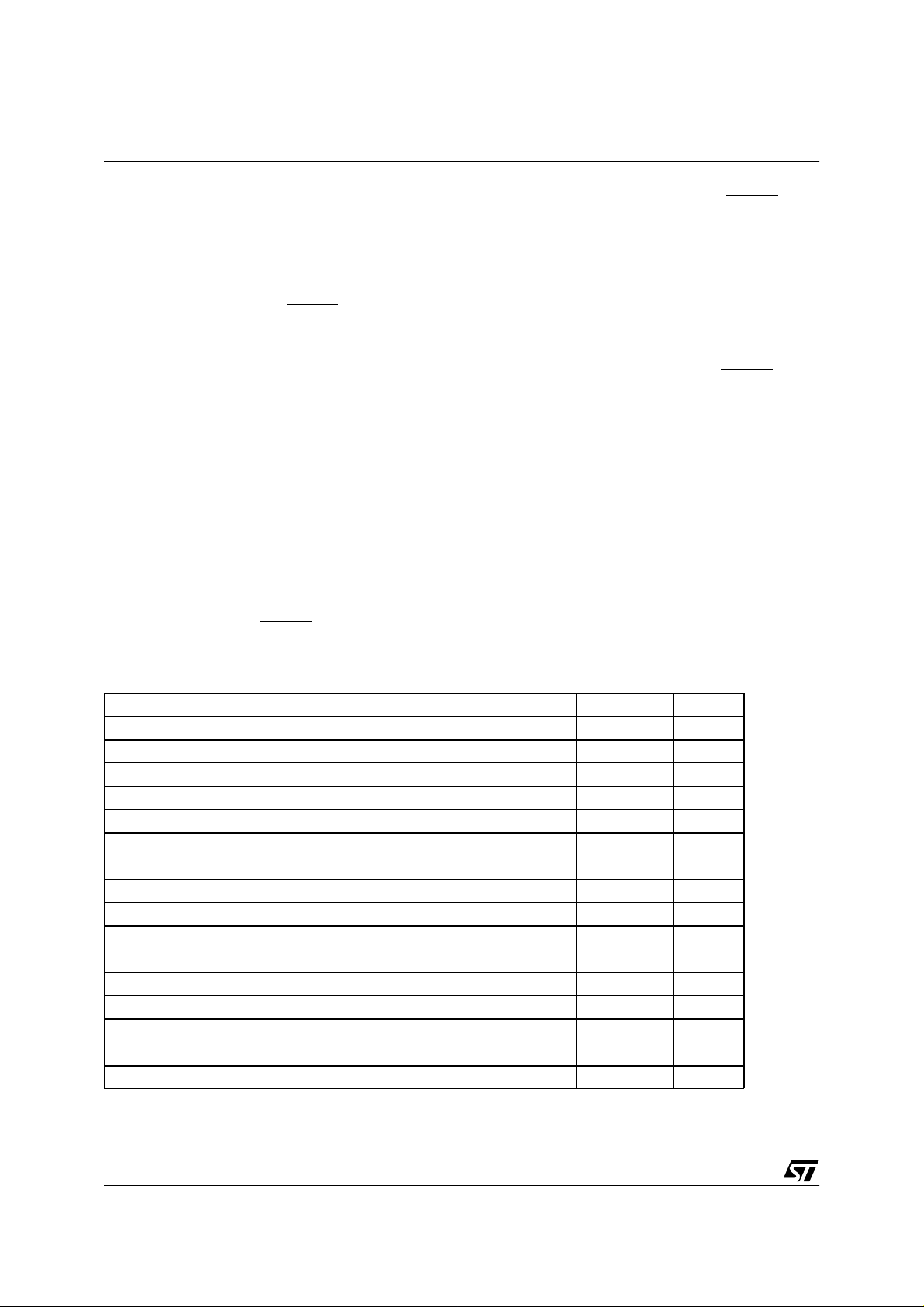

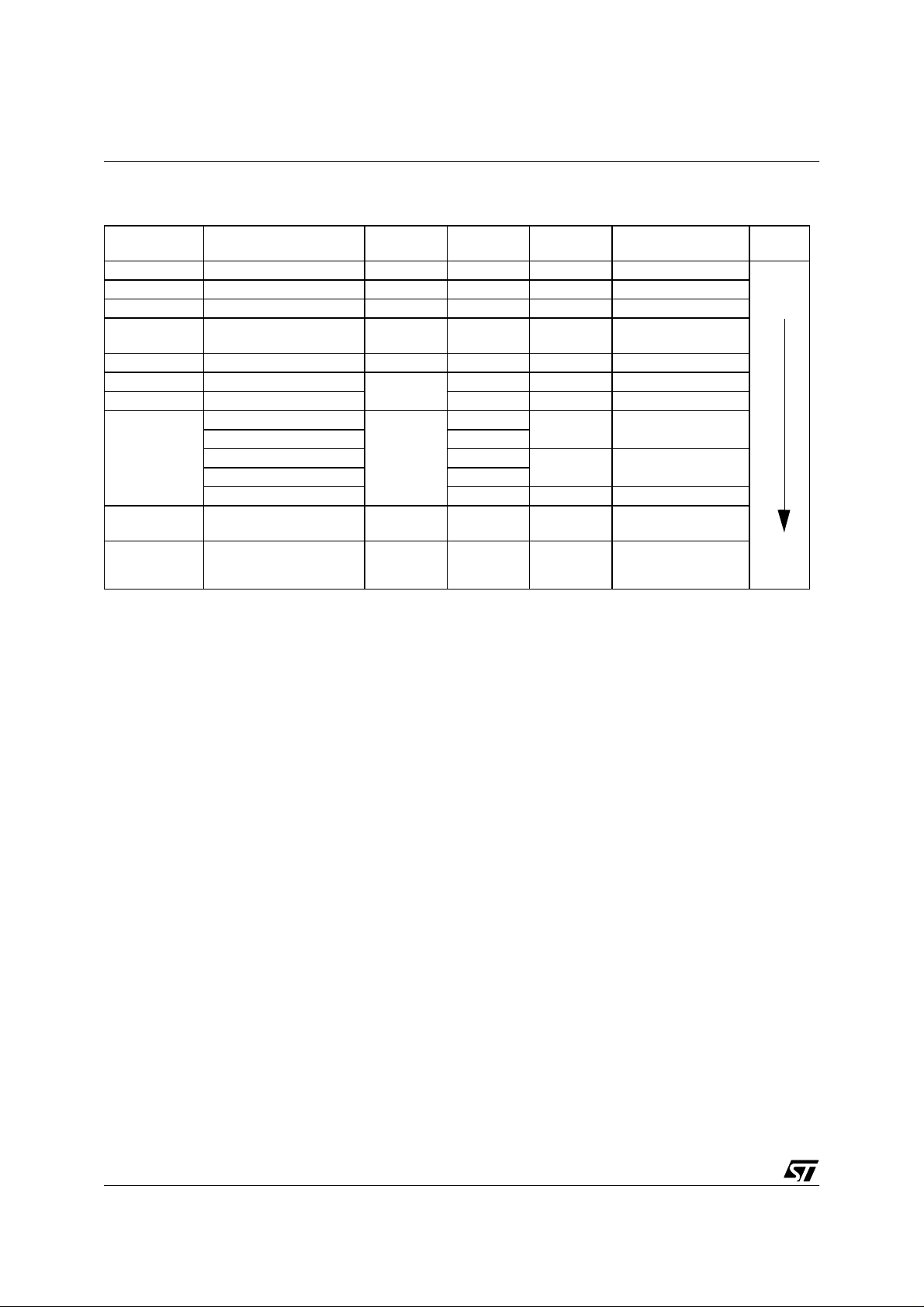

Table 5. List of sections affected by RESET and WAIT (Refer to 3.6 for Wait Mo de)

Section RESET WAIT

Fast bit of the miscellaneous register set to one (24 MHz as external clock) X

Timer Prescaler reset to zero X

Timer Counter set to FFFCh X

All Timer enable bits set to 0 (disabled) X

Data Direction Registers set to 0 (as Inputs) X

Set Stack Pointer to 01FFh X

Force Internal Address Bus to restart vector FFFEh, FFFFh X

Set Interrupt Mask Bit (I-Bit, CC) to 1 (Interrupt disable) X

Set Interrupt Mask Bit (I-Bit, CC) to 0 (Interrupt enable) X

Reset WAIT latch X

Disable Oscillator (for 4096 cycles) X

Set Timer Clock to 0 X

Watchdog counter reset X

Watchdog register reset X

Port data registers reset X

Other on-chip peripherals: registers reset X

20/144

Page 21

RESET (Cont’d)

ST72774/ST727754/ST72734

Figure 10. Low Voltage Detector Functional Diagram

V

DD

LVD

RESET

FROM

WATCHDOG

RESET

RESPOF

INTERNAL

RESET

Figure 11. LVD Reset Signal Output

Note: See electrical characteristics section for

values of V

Figure 12. Reset Timing Diagram

t

DDR

V

DD

OSCIN

t

OXOV

V

V

DD

RESET

TRM

V

TRH

TRH, VTRL

and V

TRM

V

TRL

V

TRM

f

CPU

PC

t

RL

RESET

WATCHDOG RESET

Note: Refer to Electrical Characteristics for values of t

4096 CPU

CLOCK

CYCLES

DELAY

, t

OXOV and

DDR

FFFE

t

FFFF

RL

21/144

Page 22

ST72774/ST727754/ST72734

3.3 INTERRUPTS

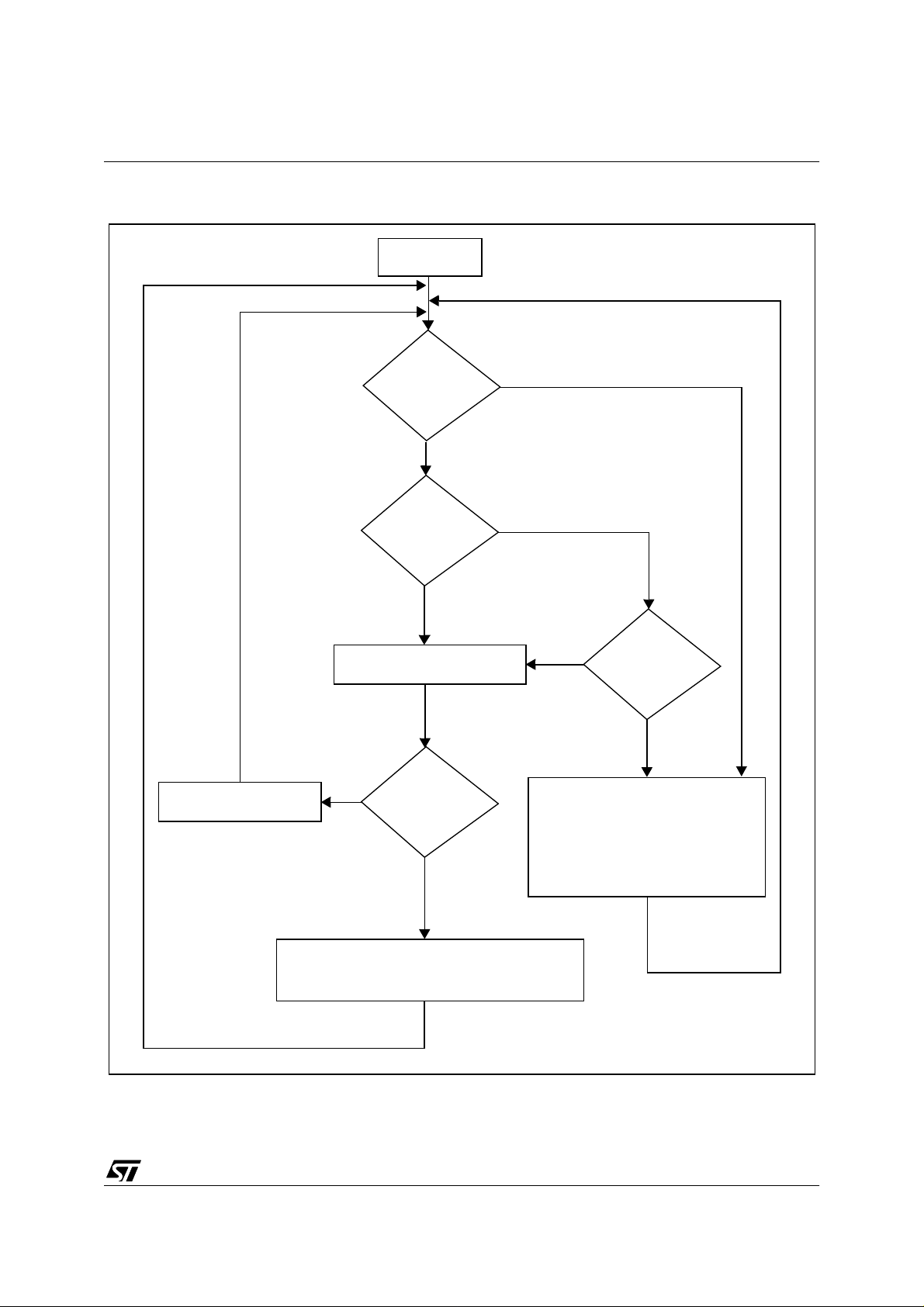

The ST727x4 may be interrupted by one of two

different methods: maskable hardware interrupts

as listed in T able 6 and a non-maskab le software

interrupt (TRAP). The Interrupt processing

flowchart is shown in Figure 13.

The maskable interrupts must be enabled in order

to be serviced. However, disabled interrupts can

be latched and processed when they are enabled.

When an interrupt has to be serviced, the PC, X, A

and CC registers are saved onto the stack and the

interrupt mask (I bit of the Condition Code

Register) is set to prevent additional interrupts.

The Y register is not automatically saved.

The PC is then load ed with the interrupt vector of

the interrupt to service and the interrupt service

routine runs (refer to Table 6, “Interrupt Mapping,”

on page 24 for vector addresses). The interrupt

service routine should finish with the IRET

instruction which causes the contents of the

registers to be recovered from the stack and

normal processing to resume. Note that the I bit is

then cleared if and only if the corresponding bit

stored in the stack is zero.

Though many interrupts can be simultaneously

pending, a priority order is defined (see Table 6,

“Interrupt Mapping,” on page 24). The RESET

pin

has the highest priority.

If the I bit is set, only the TRAP interrupt is enabled.

All interrupts allow the processor to leave the

WAIT low power mode.

Software Interrupt. The software interrupt is the

executable instruction TRAP. The interrupt is

recognized when the TRAP instruction is

executed, regardless of the state of the I bit. When

the interrupt is recognized, it is serviced according

to the flowchart on Figure 13.

ITA, ITB interrupts. The ITA (PD3), ITB (PD4),

pins can generate an interrupt when a falling edge

occurs on these pins, if these interrupts are

enabled with the ITAITE, ITBITE bits respectively

in the miscellaneous register and the I bit of the CC

register is reset. When an enabled interrupt

occurs, normal processing is suspended at the

end of the current instruct ion execution. It is then

serviced according to the flowchart on Figure 13.

Software in the ITA or ITB service routine must

reset the cause of this interrupt by clearing the

ITALAT, ITBLAT or ITAITE, ITBITE bits in the

miscellaneous register.

Peripheral Interrupts. Different peripheral

interrupt flags are able to cause an interrupt when

they are active if both the I bit of the CC register is

reset and if the corresponding enable bit is set. If

either of these conditions is false , the interrupt is

latched and thus remains pending.

The interrupt flags are located in the status

register. The Enable bits are in the control register.

When an enabled interrupt occurs, normal

processing is suspended at the end of the current

instruction execution. It is then serviced according

to the flowchart on Figure 13.

The general sequence for clearing an interrupt is

an access to the status register while the flag is set

followed by a read or write of an associated

register. Note that the clearing sequence resets

the internal latch. A pending interrupt (i.e. waiting

for being ena b led ) w ill therefore be los t if the clea r

sequence is executed.

22/144

Page 23

INTERRUPTS (Cont’d)

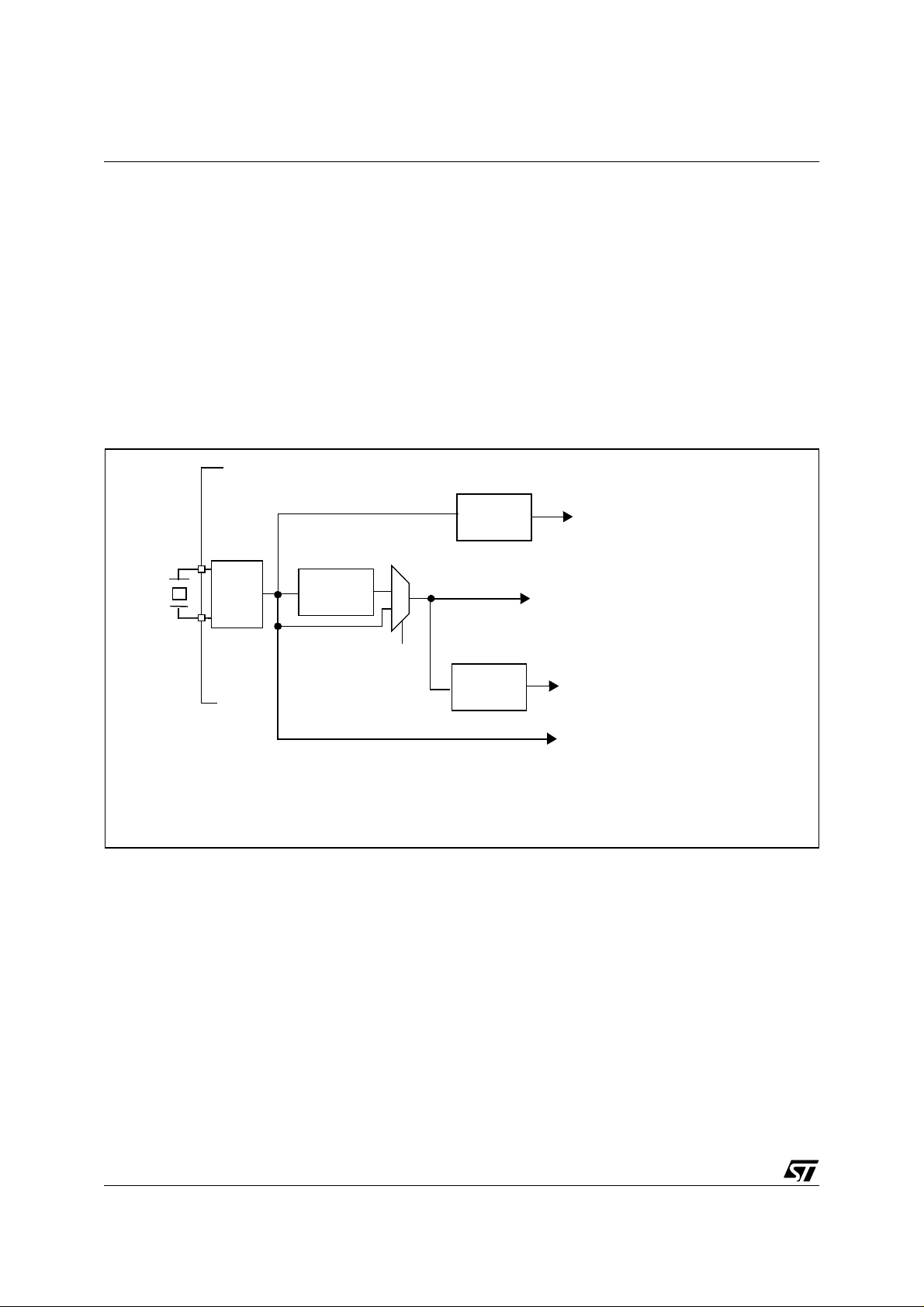

Figure 13. I nt errupt Processin g Fl owchart

FROM RESET

ST72774/ST727754/ST72734

EXECUTE INSTRUCTION

TRAP?

N

N

I BIT SET?

Y

FETCH NEXT INSTRUCTION

N

IRET?

Y

N

INTERRUPT?

Y

STACK PC, X, A, CC

SET I BIT

LOAD PC FROM INTERRUPT VECTOR

Y

RESTORE PC, X, A, CC FROM STACK

THIS CLEARS I BIT BY DEFAULT

VR01172D

23/144

Page 24

ST72774/ST727754/ST72734

INTERRUPTS (Cont’d)

Table 6. Int errupt Mappin g

Source

Block

RESET Reset N/A N/A no FFFEh-FFFFh

TRAP Software N/A N/A no FFFCh-FFFDh

USB End Suspend Interrupt USBISTR ESUSP yes FFFAh-FFFBh

DDC/CI DDC/CI Interrupt

DDC1/2B DDC1/2B Interrupt DDCDCR EDF yes FFF6h-FFF7h

Port D bit 4 External Interrupt ITB

Port D bit 3 External Interrupt ITA ITALAT yes FFF2h-FFF3h

TIM

I2C

USB USB Interrupt USBISTR ** yes FFE6h-FFE7h

Description

Input Capture 1

Input Capture 2 ICF2

Output Compare 1 OCF1

Output Compare 2 OCF2

Timer Overflow TOF yes FFECh-FFEDh

I2C Peripheral Inter-

rupts

Register

Label

DDCSR1

DDCSR2

MISCR

TIMSR

I2CSR1

I2CSR2

Flag

** yes FFF8h-FFF9h

ITBLAT yes FFF4h-FFF5h

ICF1

** yes FFEAh-FFEBh

Maskable

by I-bit

yes FFF0h-FFF1h

yes FFEEh-FFEFh

Vector Address

Priority

Order

Highest

Priority

Lowest

Priority

** Many flags can cause an interrupt, see peripheral interrupt status register description.

24/144

Page 25

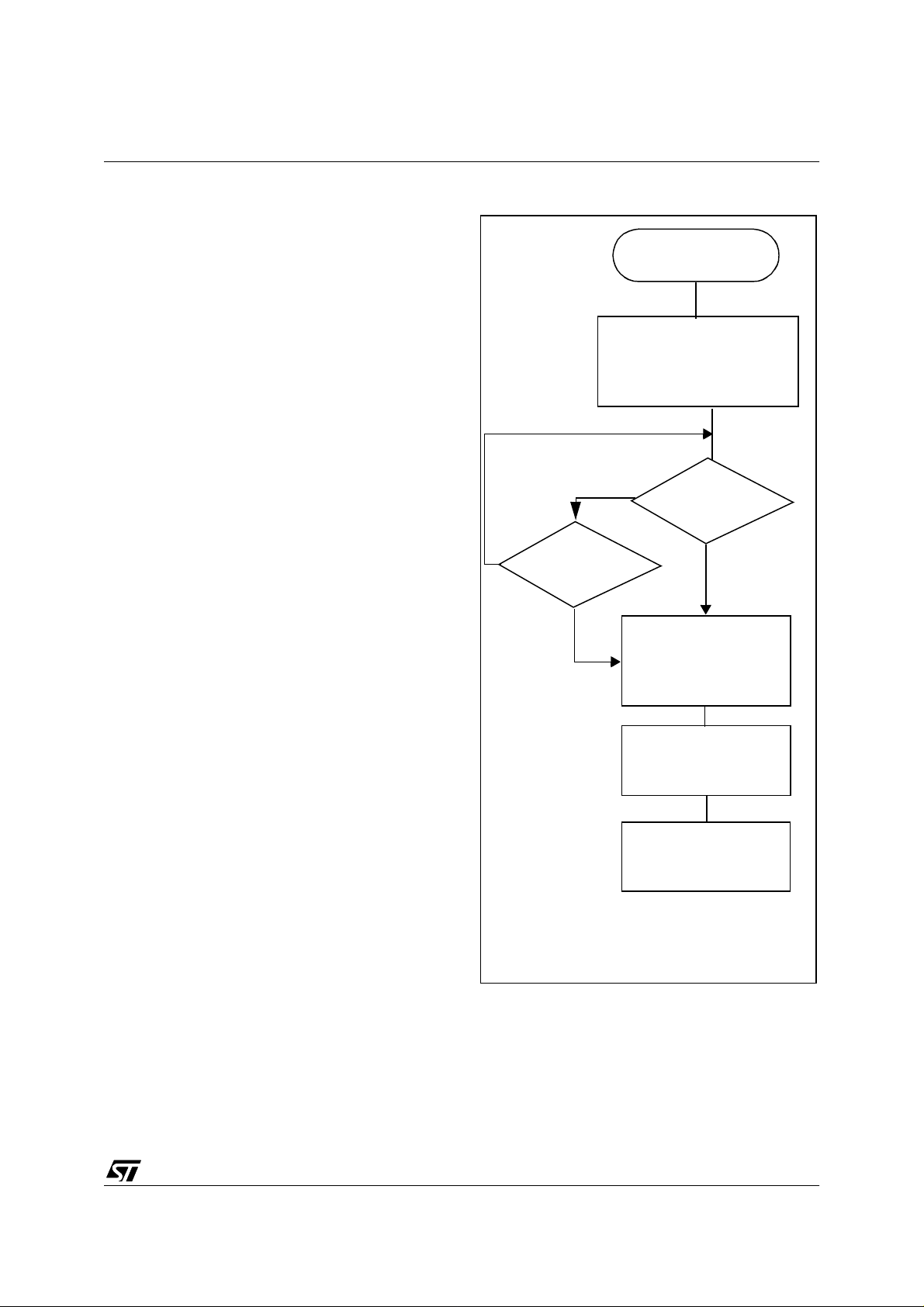

3.4 POWER SAVI NG MO DE S

ST72774/ST727754/ST72734

3.4.1 WAIT Mode

This mode is a low power consumption mode. The

WFI instruction places the MCU in WAIT mode:

The internal clock remains active but all CPU

processing is stopped; however, all other

peripherals are still running.

Note: In WAIT mode, DMA accesses (DDC, USB)

are possible.

During WAIT mode, the I bit in the condition code

register is cleared to enable all interrupts, whi ch

causes the MCU to exit WAIT mode, causes the

corresponding interrupt vector to be fetched, th e

interrupt routine to be executed and normal

processing to resume. A reset causes the program

counter to fetch the reset vector and processing

starts as for a normal reset.

Table 5 gives a list of the different sections

affected by the low power modes. For detailed

information on a particular device, please refer to

the corresponding part.

Figure 14. WAIT Flow Chart

WFI INSTRUCTION

OSCILLATOR

PERIPH. CLOCK

CPU CLOCK

I-BIT

N

N

INTERRUPT

Y

OSCILLATOR

PERIPH. CLOCK

CPU CLOCK

I-BIT

ON

ON

OFF

CLEARED

RESET

Y

ON

ON

ON

SET

3.4.2 HALT Mode

The HALT mode is the MCU lowest power

consumption mode. Meanwhile, the HALT mode

also stops the oscillator stage comple tely which is

the most critical condition in CRT monitors.

For this reason, the HALT mode has been disabled

and its associated HALT instruction is now

considered as illegal and will generate a reset.

IF RESET

4096 CPU CLOCK

CYCLES DELAY

FETCH RESET VECTOR

OR SERVICE INTERRUPT

Note: Before servicing an interrupt, the CC register is

pushed on the sta ck. T he I-Bit is s et d uring the inte rrupt routine and cleared when the CC register is

popped.

25/144

Page 26

ST72774/ST727754/ST72734

3.5 MISCELLANEOUS REGISTER

MISCELLANEOUS REGISTER (MISCR)

Address: 0009h — R ea d/W rite

Reset Value: 0001 0000 (10h)

70

VSYNC

FLY_SYNHSYNC

SEL

FAST ITBLAT ITALAT ITBITE ITAITE

DIVEN

Bit 4= FAST

Fast Mode.

This bit is set and cleared by software. It is used to

select the external cloc k frequ ency . If th e exte rnal

clock frequency is 12 M Hz, this bit must be at 0,

else if the external frequency is 24 MHz, this bit

must be at 1.

Bit 7= VSYNCSEL

DDC1 VSYNC Selection.

This bit is set and cleared by software. It is used to

choose the VSYNC signal in DDC1 mode.

0: VSYNCI selected

1: VSYNCI2 selected

Note: VSYNCI 2 is only available for the DDC cell,

not for the SYNC processor cell.

Bit 6= FL Y _SY N

Flyback or Synchro Switch.

This bit is set and cleared by software. It is used to

choose the signals the Timing Measureme nt Unit

(TMU) will analyse.

0: horizontal and vertical synchro outputs analysis

1: horizontal and vertical Flyback inputs analysis

Bit 5= HS YNCDIVEN

HSYNCDIV Enable.

This bit is set and cleared by software. It is used to

enable the output of the HSYNCO output on PC0.

0: HSYNCDIV disabled

1:HSYNCDIV enabled

Bit 3= ITBLAT

Falling Edge Detector Latch.

This bit is set by hardware when a falling edge

occurs on pin ITB/PD4 in Port D. An interrupt is

generated if ITBITE=1and the I bit in the CC

register = 0. It is cleared by software.

0: No falling edge detected on ITB

1: Falling edge detected on ITB

Bit 2= ITALAT

Falling Edge Detector Latch.

This bit is set by hardware when a falling edge

occurs on pin ITA/PD3 in Port D. An interrupt is

generated if ITAITE=1and the I bit in the CC

register = 0. It is cleared by software.

0: No falling edge detected on ITA

1: Falling edge detected on ITA

Bit 1= ITBITE

ITB Interrupt Enable

.

This bit is set and cleared by software.

0: ITB interrupt disabled

1: ITB interrupt enabled

Bit 0= ITAITE

ITA Interrupt Enable

.

This bit is set and cleared by software.

26/144

0: ITA interrupt disabled

1: ITA interrupt enabled

Page 27

4 ON-CHIP PERIPHERALS

4.1 I/O PORTS

ST72774/ST727754/ST72734

4.1.1 Introd uct i on

The I/O ports allow the transfer of data through

digital inputs and outputs, and, for specific pins,

the input of analog s ignals or the Input/Output of

alternate signals for on-chip peripherals (DDC,

TIMER...).

Figure 15. I/O Pin Typical Cir cuit

Alternate enable

Alternate

1

output

0

DR

latch

Data Bus

DDR

latch

Each pin can be programmed independently as

digital input or digital output. E ach pin can be an

analog input when an analog switch is connected

to the Analog to Digital Converter (ADC).

V

DD

P-BUFFER

(if required)

PULL-UP (if required)

Alternate enable

PAD

Analog Enable

(ADC)

Common Analog Rail

DDR SEL

Analog

Switch (if required)

N-BUFFER

DR SEL

1

Alternate Enable

0

Digital Enable

V

SS

Alternate Input

Note: This is the typical I/O pin configuration. For cost optimization, each port is customized with a specific configuration.

27/144

5

Page 28

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

Table 7. I/O Pin Functions

DDR MODE

0 Input

1 Output

4.1.2 Common Functional Description

Each port pin of the I/O Ports can be individual ly

configured under software control as either i nput

or output.

Each bit of a Data Direction Register (DDR)

corresponds to an I/O pin of the associated p ort.

This corresponding bit must be set to configure its

associated pin as output and must be cleared to

configure its associated pin as input (Table 7, “. I/O

Pin Functions,” on page 28). The Data Direction

Registers can be read and written.

The typical I/O circuit is shown on Figure 15. Any

write to an I/O port updates the port data register

even if it is configured as input. Any read of an I/O

port returns either the data latched in the port data

register (pins configured as output) or the value of

the I/O pins (pins configured as input).

Remark: when an I/O pin does not exist inside an

I/O port, the returned value is a logic one (pin

configured as input).

At reset, all DDR registers are cleared, which

configures all port’s I/Os as inputs with or without

pull-ups (see Table 8 to Table 12 I/O Ports

Register Map). The Data Registers (DR) are also

initialized at reset.

4.1.2.1 Input mode

When DDR=0, the corresponding I/O is configured

in Input mode.

In this case, the output buffer is switched off, the

state of the I/O is readable through the Data

Register address, but the I/O state comes directly

from the CMOS Schmitt Trigger output and not

from the Data Register output.

4.1.2.2 Output mode

When DDR=1, the corresponding I/O is configured

in Output mode.

In this case, the output buffer is activated

according to the Data Register’s content.

A read operation is directly performed from the

Data Register output.

4.1.2.3 Analog input

Each I/O can be used as analog input by adding an

analog switch driven by the ADC.

The I/O must be configured in Input before using it

as analog input.

The CMOS Schmitt trigger is OFF and the analog

value directly input through an analog switch to the

Analog to Digital Converter, when the analog

channel is selected by the ADC.

4.1.2.4 Alternate mode

A signal coming from a on-chip peripheral can be

output on the I/O.

In this case, the I/O is automaticall y configured in

output mode.

This must be controlled directly by the peripheral

with a signal coming from the peripheral which

enables the alternate signal to be output.

A signal coming from an I/O can be inpu t in a onchip peripheral.

Before using an I/O as Alternate Input, it must be

configured in Input mode (DDR=0). So both

Alternate Input configuration and I/O Input

configuration are the same (with or without pullup). The signal to be input in the peripheral is taken

after the CMOS Schmitt trigger or TTL Schmitt

trigger for SYNC.

The I/O state is readable as in Input mode by

addressing the corresponding I/O Data Register.

28/144

Page 29

ST72774/ST727754/ST72734

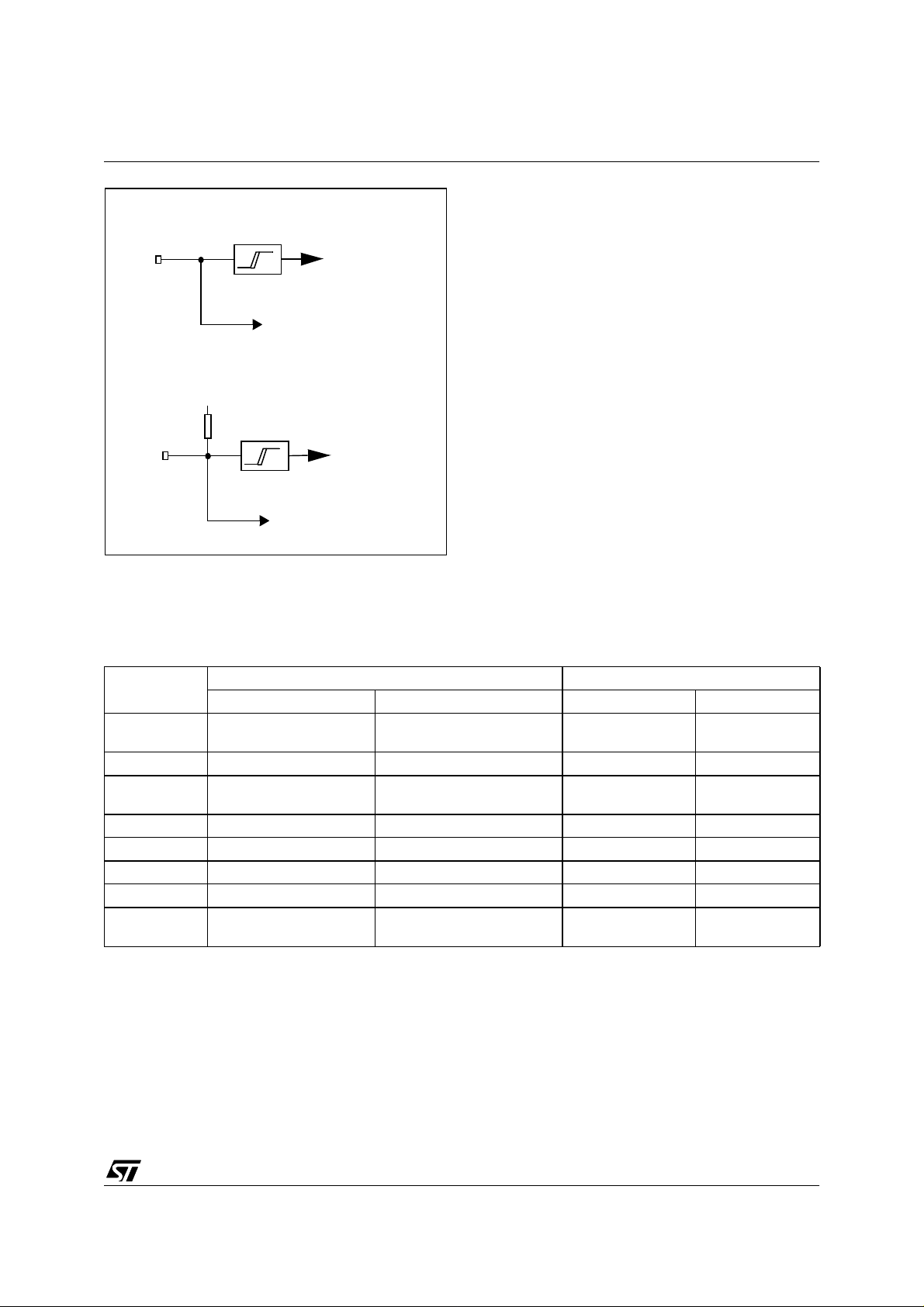

Figure 16. Input Structure for SYNC signals

TTL trigger

Pin

HSYNCI Input

VSYNCI Input

(no pull-up)

I/O logic (if existing)

V

DD

TTL trigg erpull-up

CSYNCI Input

Pin

HFBACK Input

VFBACK Input

I/O logic (if existing)

4.1.3 Port A

PA7 and PA[2:0] can be defined as Input lines

(with pull-up) or as Push-pull Outputs.

PA [6:3] can be defined as Input lines (without pullup) or as Output Open drain lines.

PA7 and PA[2:0] can be defined as Input lines

(with pull-up) or as Push-pull Outputs.

PA [6:3] can be defined as Input lines (without pullup) or as Output Open drain lines.

Table 8. Port A Description

PORT A

PA0 With pull-up push-pull OCMP1

PA1 With pull-up push-pull - PA2 With pull-up push-pull VSYNCI2

PA3 Without pull-up open-drain - -

PA4 Without pull-up open-drain - PA5 Without pull-up open-drain - PA6 Without pull-up open-drain - -

PA7 With pull-up push-pull BLANKOUT

*Reset State

Input* Output Signal Condition

I / O Alternate Function

OC1E =1

(CR2[TIMER])

VSYNCSEL=1

(MISCR)

BLKEN = 1

(ENR[SYNC])

29/144

Page 30

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

Figure 17. PA0 to PA2, PA7

Alternate

output

Alternate enable

1

V

DD

DATA BUS

Figure 18. PA3 to PA6

DR

latch

DDR

latch

DDR SEL

DR SEL

DR

latch

DDR

latch

0

PULL-UP

OC1E

P-BUFFER

N-BUFFER

PAD

1

OC1E

V

SS

0

CMOS Schmitt Trigger

Alternate enable

Alternate

output

1

0

PAD

30/144

DATA BUS

Alternate input

DDR SEL

DR SEL

N-BUFFER

1

0

Alternate enable

CMOS Schmitt Trigger

V

SS

Page 31

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

4.1.4 Port B

The alternate functions are the I/O pins of the onchip DDC SCLD & SCDAD for PB0:1, the I/O pins

of the on-chip I2C SCLI & SCDAI for PB2:3, and 4

bits of port B bit can be used as the Analog source

to the Analog to Digital Converter.

Only one I/O line must be configured as an analog

input at any time. The user must avoid any

situation in which more than one I/O pin is selected

as an analog input simultaneously to av oid de vice

malfunction.

When the analog function is selected for an I/O pin,

the pull-up of the respective pin of Port B is

disconnected and the digital input is off.

Table 9. Port B Description

PORT B I/O Alternate Function

Input* Output Signal Condition

All unused I/O lines should be tied to an

appropriate logic level (either V

Since the ADC is on the same chip as the

microprocessor, the user should not switch heavily

loaded signals during conversion, if high precision

is required. S uch switching will affec t the supply

voltages used as analog references . the a ccuracy

of the conversion depends on the quality of the

power supplies (V

and VSS). The user must take

DD

special care to ensure that a well regulated

reference voltage is present on the V

pins (power supply variations must be less than

5V/ms). T his impli es, in particul ar, that a su itable

decoupling capacitor is used at the V

or VSS)

DD

DD

DD

and V

pin.

SS

PB0 Without pull-up Open-drain

PB1 Without pull-up Open-drain

PB2 Without pull-up Open-drain

PB3 Without pull-up Open-drain

PB4 With pull-up Push-pull Analog input (ADC) (without pull-up) CH[2:0]=000 (ADCCSR)

PB5 With pull-up Push-pull Analog input (ADC) (without pull-up) CH[2:0]=001 (ADCCSR)

PB6 With pull-up Push-pull

PB7 With pull-up Push-pull

*Reset state

SCLD (input with CMOS schmitt trigger or

open drain output)

SDAD (input with CMOS schmitt trigger or

open drain output)

SCLI (input with CMOS schmitt trigger or

open drain output)

SDAI (input with CMOS schmitt trigger or

open drain output)

Analog input (ADC) (without pull-up) CH[2:0]=010 (ADCCSR)

10-bit output 1 (PWM) OE0=1 (PWMOE)

Analog input (ADC) (without pull-up) CH[2:0]=011 (ADCCSR)

10-bit output 2 (PWM) OE1=1 (PWMOE)

DDC enable

DDC enable

I2C enable

I2C enable

31/144

Page 32

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

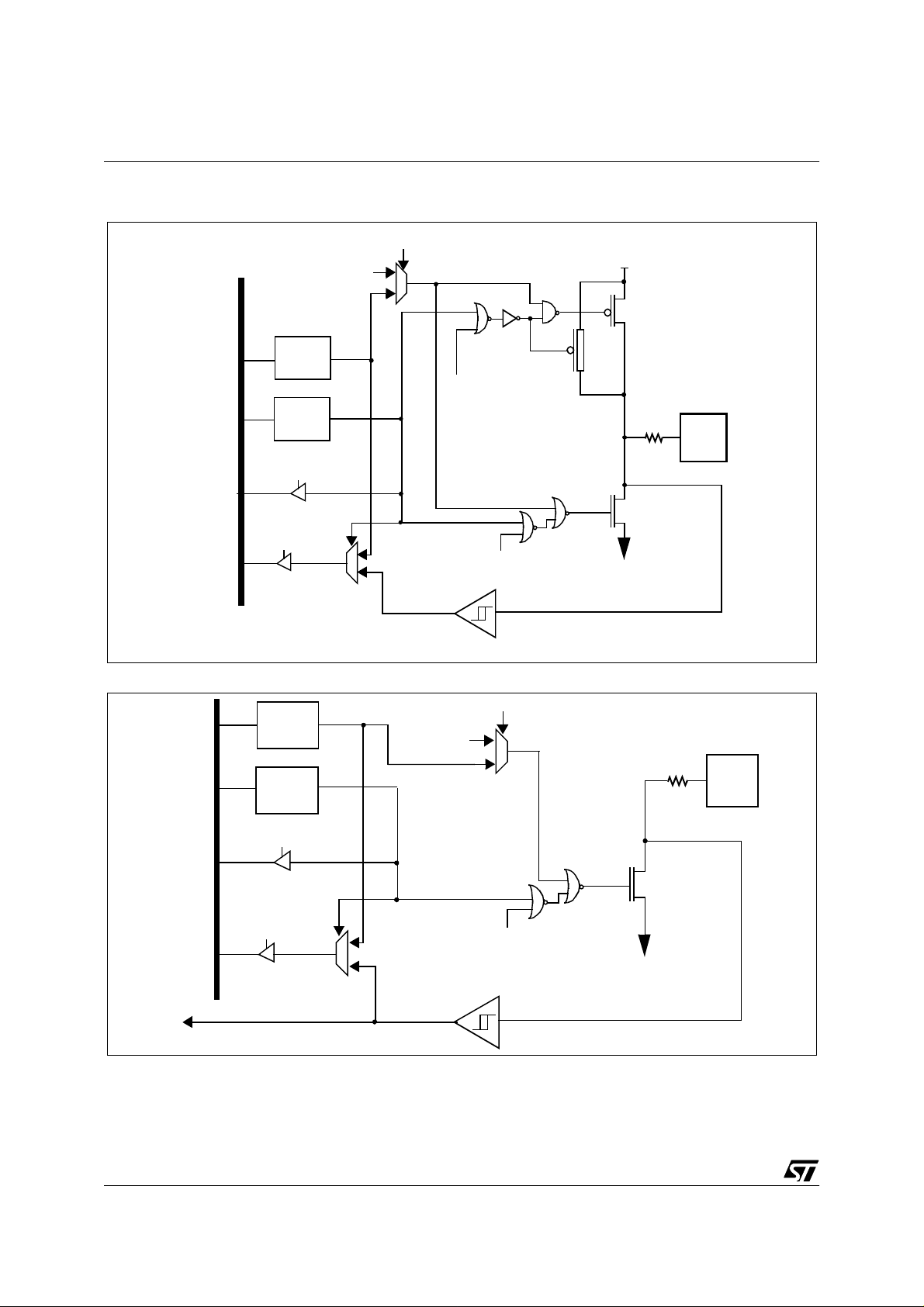

Figure 19. PB0 to PB3

DR

latch

DDR

latch

DDR SEL

Alternate

output

Alternate enable

1

0

PAD

N-BUFFER

DATA BUS

DR SEL

Alternate input

Figure 20. PB4 to PB7

DATA BUS

Common Analog Rail

DR

latch

DDR

latch

DDR SEL

1

0

CMOS Schmitt Trigger

Alternate enable

Analog enable

(ADC)

V

PULL-UP

Analog

switch

SS

V

DD

P-BUFFER

PAD

32/144

DR SEL

DR SEL

N-BUFFER

1

1

V

0

0

CMOS Schmitt Trigger

SS

Page 33

I/O PORTS (Cont’d)

4.1.5 Port C

The available port pins of port C may be used as

general purpose I/O.

Table 10. Port C Description

ST72774/ST727754/ST72734

The alternate functions are the PWM outputs for

PC2:7, HSYNCDIV (HSYNCO divided by 2) for

PC0 and the TMU input for PC1.

PORT C

PC0 With pull-up Push-pull HSYNCDIV (push-pull)

PC1 With pull-up Push-pull AV (active video) input (TMU) PC2 With pull-up Push-pull 10-bit output 3 (PWM)

PC3 With pull-up Push-pull 10-bit output 4 (PWM)

PC4 With pull-up Push-pull 10-bit output 5 (PWM)

PC5 With pull-up Push-pull 10-bit output 6 (PWM)

PC6 With pull-up Push-pull 10-bit output 7 (PWM)

PC7 With pull-up Push-pull 10-bit output 8 (PWM)

* Reset State

I / O Alternate Function

Input* Output Signal Condition

HSYNCDIVEN

=1

(MISCR)

OE2=1

(PWMOE)

OE3=1

(PWMOE)

OE4=1

(PWMOE)

OE5=1

(PWMOE)

OE6=1

(PWMOE)

OE7=1

(PWMOE)

33/144

Page 34

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

Figure 21. PC0, PC2 to PC7

Alternate

output

Alternate enable

1

V

DD

Figure 22. PC1

DATA BUS

DR

latch

DDR

latch

DDR SEL

DR SEL

DR

latch

0

PULL-UP

OC1E

1

0

OC1E

CMOS Schmitt Trigger

P-BUFFER

N-BUFFER

V

SS

P-BUFFER

PAD

V

DD

34/144

AV

DDR

latch

DDR SEL

DATA BUS

DR SEL

1

0

CMOS Schmitt Trigger

PULL-UP

V

SS

PAD

N-BUFFER

Page 35

I/O PORTS (Cont’d)

4.1.6 Port D

The Port D I/O pins are normally used for the input

and output of video synchronization signals of the

Sync Processor, but are set to I/O Input with pullup upon reset. The I/O mode can be set

individually for each port bit to Input with pull-up

and output push-pull through the Port D DDR.

The configuration to supp ort the Sync Processor

requires that the SYNOP (bit7) and CLMPEN (bit6)

of the ENR (Enable Register of SYNC) is reset.

SYNOP enables port D bits 0,1 and CLMPEN

enables Port D bit 6 to the sync outputs.

Port D, bit 4:3 are the alternate inputs ITA, ITB, (for

the interrupt falling edge detector).

When a falling edge occurs on these inputs, an

interrupt will be generated depending on the status

of the INTX (ITAITE & ITBITE) bit s in the MISCR

Register.

Table 11. Port D Description

ST72774/ST727754/ST72734

Port D, bit 6 is switched to the alternate

(CLAMPOUT) by reset ting the CLMPEN bit of the

ENR Register inside SYNC block.

If the SYNC function is selected, Port D bit 5 and 3

MUST be set as input to enable the HFBACK or

VFBACK timin g in p uts.

Note: As these inputs are switched from normal

I/O function ality, the v ideo sync hronization signals

may also be mo nitored dire ctly through the Port D

Data Register for such tasks as checking for the

presence of video signals or checking the polarity of

Horizontal and Vertical synchronization signals

(when the Syn c Inputs are s witched dire ctly to the

outputs usin g the m ultip lexers of the Sync Proc essor).

PORT D

PD0 With pull-up Push-pull

PD1 With pull-up Push-pull

PD2 With pull-up Push-pull

PD3 With pull-up Push-pull

PD4 With pull-up Push-pull

PD5 With pull-up Push-pull

PD6 With pull-up Push-pull

* Reset state

Input* Output Signal Condition

I / O Alternate Function

VSYNCO

(push pull output)

HSYNCO

(push pull output)

CSYNCI (input with TTL Schmitt

trigger & pull-up)

ITA (input with CMOS Schmitt

trigger & pull-up)

VFBACK (input with TTL Schmitt

trigger & pull-up)

ITB (input with CMOS Schmitt

trigger & pull-up)

HFBACK (input with TTL Schmitt

trigger & pull-up)

CLAMPOUT

(push pull output)

SYNOP=0

(ENR [SYNC])

SYNOP=0

(ENR [SYNC])

-

-

-

-

CLMPEN=0

(ENR [SYNC])

35/144

Page 36

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

Figure 23. PD2 to PD5

DR

DATA BUS

latch

DDR

latch

DDR SEL

PULL-UP

V

DD

P-BUFFER

PAD

N-BUFFER

CSYNCI Input

HFBACK Input

VFBACK Input

Figure 24. PD0 to PD1

DATA BUS

DR SEL

alternate input

Alternate

output

DR

latch

DDR

latch

DDR SEL

1

0

CMOS Schmitt Trigger

TTL Schmitt Trigger

Alternate enable

1

0

Alternate enable

V

SS

VDD

PULL-UP

P-BUFFER

PAD

36/144

Alternate input

DR SEL

N-BUFFER

1

0

Alternate enable

CMOS Schmitt Trigger

V

SS

Page 37

I/O PORTS (Cont’d)

Figure 25. PD6

Alternate

output

ST72774/ST727754/ST72734

Alternate enable

1

0

VDD

P-BUFFER

Alternate input

VSYNCI2 input

DATA BUS

DR

latch

DDR

latch

DDR SEL

DR SEL

PULL-UP

Alternate enable

PAD

N-BUFFER

1

0

Alternate enable

CMOS Schmitt Trigger

TTL Schmitt Trigger

V

SS

37/144

Page 38

ST72774/ST727754/ST72734

I/O PORTS (Cont’d)

4.1.7 Register Description

Data Registers (PxDR)

Read/Write

Reset Value: 0000 0000 (00h)

70

MSB LSB

Table 12. I/O Ports Register Map