Datasheet ST63T73J5B1, ST6373, ST63E73J5D1, ST6373J5B1, ST6373J3B1 Datasheet (SGS Thomson Microelectronics)

...Page 1

R

ST6373

8-BIT ROM/OTP/EPROM MCUs FOR DIGITALLY

CONTROLLED MULTISYNC/MULTISTANDARD MONITORS

■ 4.5V to 6V Operating Supply Voltage Range

■ Low Current Consumption

■

0to+70°C Operating Temperature Range

■

8 MHzclock Oscillator

■ 16K bytes ROM/OTP/EPROM

(8K and 12K ROM versions also available)

■

192 bytes RAM

■ 384 bytes general purpose EEPROM

■ 128 bytes dedicated EEPROM for DDC SPI

■ 22 fully programmable I/O pins, offering direct

LED drive capability, as well as interrupt

generation for keyboard inputs

■ Digital WATCHDOG timer

■ Three Timers, each comprising an 8-bit counter

and a 7- bit Prescaler

■ SYNC Processor:

– 12-bits HSYNC Event Counter

– 12-bits VSYNC Period Counter

– HSYNC and VSYNC Polarity Detection

– HSYNC and VSYNC Outputs

– HFLYBACK and VFLYBACK Inputs

– CLAMP and BLANK Outputs

■ 14-bit (PWM + BRM) D/A Converter

■ Nine 7-bit PWM D/A Converter Outputs

■

8-bit A/D Converter with 8 multiplexed inputs

■ DDC SPI with interrupt and 4 operating modes

■ A further SPI with interrupt and 2 operating

modes

■

Remote Control Signal Input (Non Maskable

Interrupt)

■ VSYNC Interrupt Input

■ Five Interrupt Vectors

■

XOR Register (Instruction Set expansion)

■ MIRROR Register (Instruction Set expansion)

(Refer to end of Document for Ordering Information)

PSDIP42

CSDIP42

February 1998 1/64

ThisisadvanceinformationfromSGS-THOMSON.Detailsaresubject tochangewithoutnotice.

1

Page 2

Table of Contents

ST6373 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1 GENERAL DESCRIPTION . . ....................................................4

1.1 INTRODUCTION . . . . . . . ..................................................4

1.2 PIN DESCRIPTION . . . . . . . ................................................6

1.3 MEMORY SPACES .......................................................8

1.3.1 Stack Space . . . . . . . . . . ..............................................8

1.3.2 Program Space . .. . . ................................................8

1.3.3 Data Space .......................................................10

1.3.4 Data RAM/EEPROM ................................................12

1.3.5 EEPROM Description . . . . . . . . . . . . . ..................................12

1.4 MEMORYPROGRAMMING ...............................................15

1.4.1 Program Memory . . . . . . . . . ..........................................15

1.4.2 Option Byte .......................................................15

1.4.3 Eprom Erasure . . . . . . . ..............................................15

2 CENTRAL PROCESSING UNIT . . . ..............................................16

2.1 INTRODUCTION . . . . . . . .................................................16

2.2 CPU REGISTERS .......................................................16

3 CLOCKS, RESET, INTERRUPTS AND POWER SAVING MODES .....................18

3.1 ON-CHIP CLOCK OSCILLATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . ................18

3.2 RESETS...............................................................19

3.2.1 RESET Input . . . . . . . ...............................................19

3.2.2 Power-on Reset . . . . . . . . . . . . . . . .....................................19

3.2.3 Watchdog Reset . ..................................................20

3.2.4 Application Note . . . . . . . . . . . . . . . .....................................20

3.2.5 MCU Initialization Sequence ..........................................20

3.3 HARDWARE ACTIVATED DIGITAL WATCHDOG FUNCTION . .. . . ...............21

3.4 INTERRUPT . . . . . . . . . . .. . . . .. . . .........................................23

3.4.1 Interrupt Vectors/Sources . ...........................................23

3.4.2 Interrupt Priority . . . . . . . . . . . . . . . .....................................24

3.4.3 Interrupt Option Register . . . . . . . . . . . . . . . . . . . . . ........................24

3.4.4 Interrupt Procedure .................................................25

3.4.5 ST6373 Interrupt Details . . . . . . . . . . . . . . . . . . . . . ........................25

3.5 POWER SAVING MODES. . . ..............................................28

3.5.1 WAIT Mode .......................................................28

3.5.2 STOP Mode . . . . . . . . . . . ............................................28

3.5.3 Exit from WAIT Mode . . . . . . . .........................................28

4 ON-CHIP PERIPHERALS ......................................................29

4.1 I/OPORTS.............................................................29

4.1.1 Details of I/O Ports A and B . . . . . . . . . . . . . . . . . . .........................30

4.1.2 Details of I/O Port C . . . ..............................................31

4.1.3 I/O Port Registers ..................................................34

4.2 TIMERS ...............................................................35

4.2.1 Timer Operating Modes . . . . ..........................................36

4.2.2 Timer StatusControl Registers (TSCR). . . ...............................37

4.2.3 Timer Counter Registers (TCR) . . . . . . . . . . . . . . .. . . . .....................37

64

2/64

Page 3

Table of Contents

4.2.4 Timer Prescaler Registers (PSC). . .....................................37

4.3 A/D CONVERTER (ADC) . . . . . . . . ..........................................38

4.3.1 Application Notes . . . . . . . . . ..........................................38

4.4 SYNC PROCESSOR . . . . . . . ..............................................40

4.4.1 Event Counter . . ...................................................40

4.4.2 Period Counter . . . . . . . ..............................................40

4.4.3 Polarity Detector . ..................................................40

4.4.4 Output Polarity Control ...............................................40

4.4.5 Video Blanking Generator . ...........................................41

4.5 14-BIT PWM D/A CONVERTER ............................................44

4.5.1 Output Details . . ...................................................44

4.5.2 HDA Tuning Cell Registers ...........................................44

4.6 7-BIT PWM D/A CONVERTERS ............................................45

4.6.1 Digital Outputs . . . . . . . ..............................................45

4.7 SERIAL PERIPHERAL INTERFACES. . . . . . . . . . . . . . . . . . . .....................46

4.7.1 SPI Modes ........................................................47

4.8 MIRROR REGISTER . . . . . . . ..............................................51

4.9 XOR REGISTER . . . . . . . .................................................51

5 SOFTWARE . . . . . . . . . .......................................................52

5.1 ST6 ARCHITECTURE . . . . . . . . . . . . . . . .....................................52

5.2 ADDRESSING MODES . . . . . . . . ...........................................52

5.3 INSTRUCTION SET ......................................................53

6 ELECTRICAL CHARACTERISTICS. . . . ..........................................58

6.1 ABSOLUTE MAXIMUM RATINGS. . . . . . . . . . . . . . . . . . .........................58

6.2 RECOMMENDED OPERATING CONDITIONS. . . . .............................58

6.3 DC ELECTRICAL CHARACTERISTICS . . ....................................59

6.4 AC ELECTRICAL CHARACTERISTICS . .....................................60

7 GENERAL INFORMATION . . . . . . . ..............................................61

7.1 PACKAGE MECHANICAL DATA. . . . . . . . .. . . . . . . . . . . . . . . . . . . ................61

7.2 ORDERING INFORMATION . . . . . . . . .. . . . ..................................62

3/64

1

Page 4

ST6373

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

ST6373 Microcontrollers are members of the 8-bit

HCMOS ST637x family, a series of devices specially intended for Digitally Controlled Multi Frequency Monitor applications. All ST637x devices

are based on a building block approach: a common core is surrounded by a combination of onchip peripherals (macrocells) available from a

standard library.

ST6373 devices are available in functionally identical ROM, OTP (ST63T73) and EPROM

(ST63E73) versions, all with the same pinout.

ROM devices are available with 8, 12 or 16K Program memory, whereas OTP and EPROM versions are both available in 16K versions only. For

details relating to sales types, refer to Section 7.2.

Since ROM, OTP and EPROM versions are

functionally identical, the present Datasheet

will refer to the generic ST6373 device, except

where specific versions differ in detail.

The ST6373 devices feature:

– Nine PWM outputs, which can be used as Digital

to Analog converter outputs (withexternal RC filters). These are suitable for tuning and other

functions.

– A PWM output with Bit Rate Multiplier, to which

the above comments apply.

– An Event Counter especially designed to calcu-

late the HSYNC (or HDRIV) Frequency, using

one of the on-chip timers.

– A Period Counter especially designed to calcu-

late the VSYNC Period.

– A Polarity Detector for HSYNC (or HDRIV) and

VSYNC.

– HSYNC and VSYNC outputs with controlled po-

larity.

– Video Blanking and Clamping Outputs.

– Two I/O ports A & B usable for a keyboard wake-

up feature since an interrupt input ored on each

of their pins.

– An Analog to Digital converter connected to port

B which can be used to decode an analog key-

board or for AFC.

– A VSYNC input pin connected to an interrupt

vector and to the DDC SPI for DDC1 protocol.

– An NMI inputwhich canbe used, forexample, as

a Remote Control input for a TV application.

– A hardware DDC SPI able to manage DDC1

(VSYNC as clock), DDC2B and DDC2AB (I2C

BUS Multimaster and Slave). A 128-byte

dedicated EEPROM memory is available for

DDC1 and DDC2B.

– Hardware I2C SPI for internal monitor bus and to

manage, for example, an OSD.

– A Mirror Register and a XOR Register are includ-

ed to complement the basic ST6 instruction set.

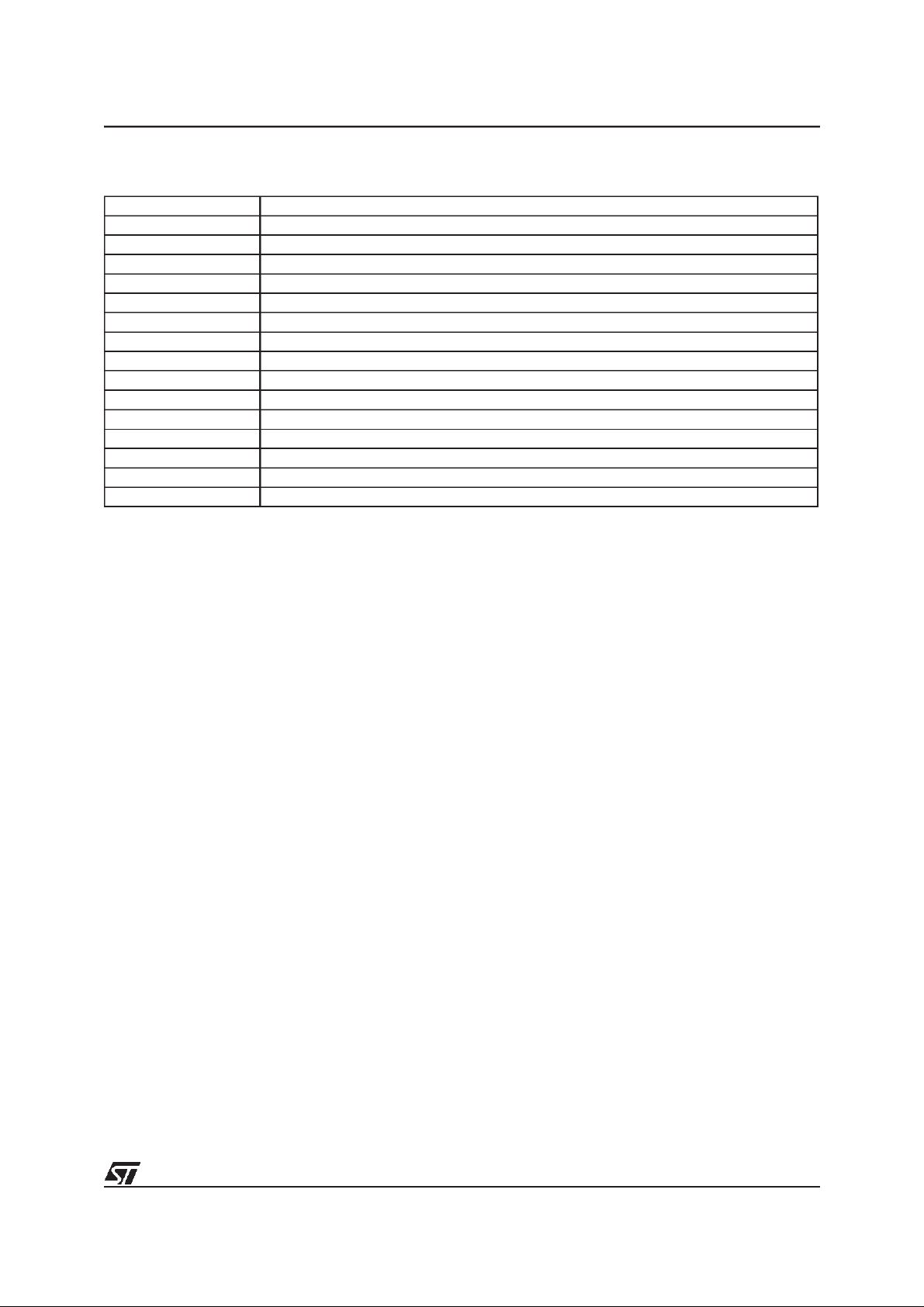

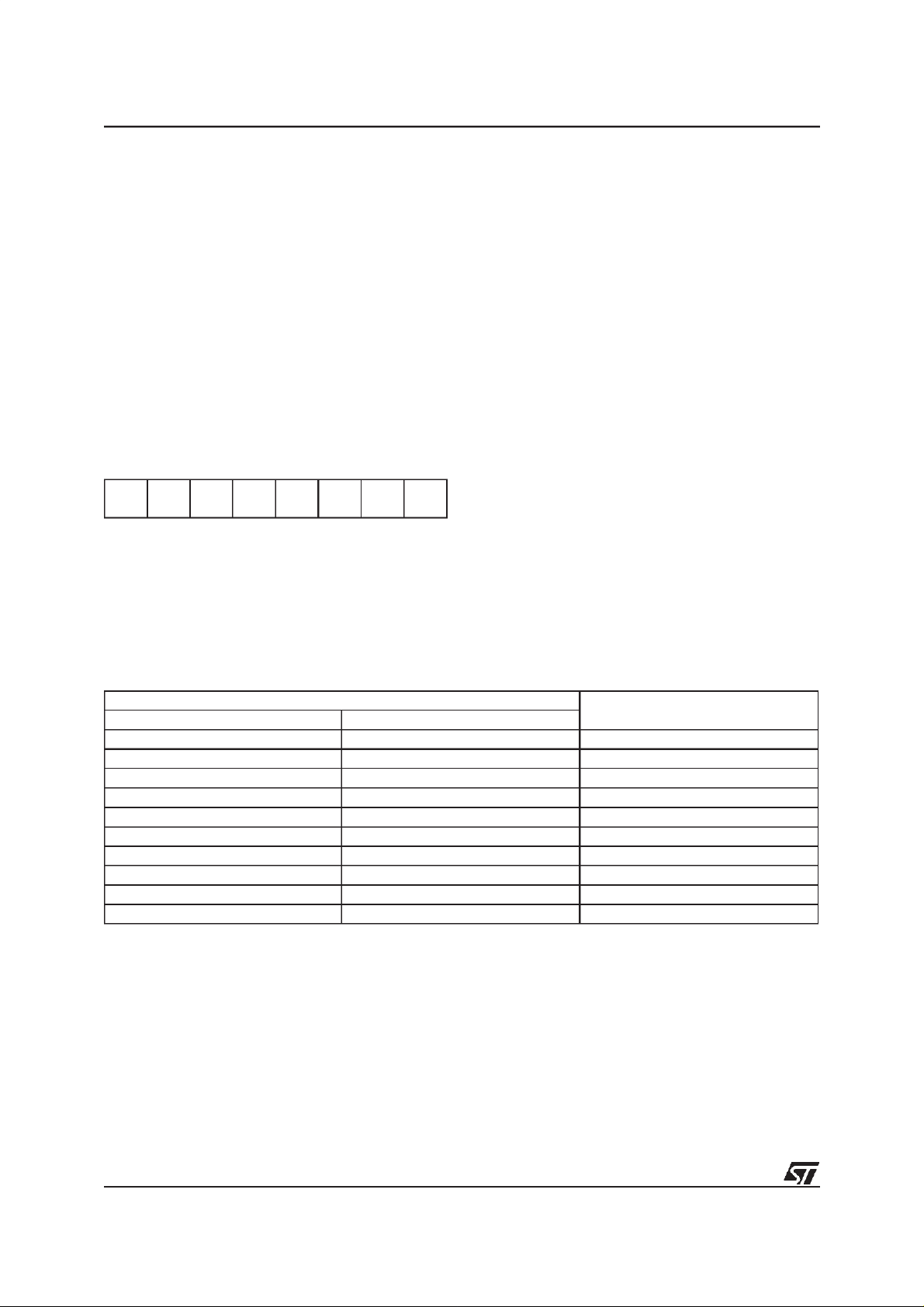

Table 1. ST6373 Device Summary

DEVICE

CONFIGURATION

ST6373

ST63T73 16K OTP 192 512 8 1 9 ST63E73 16K EPROM 192 512 8 1 9 -

Note: See

4/64

Ordering Information in Table 23 at the end of the Datasheet.

Program

Memory

(Bytes)

8K ROM

12K ROM

16K ROM

RAM

(Bytes)

192 512 8 1 9 ST63E73,ST63T73

EEPROM

(Bytes)

A/D

Inputs

14-bit

D/ (PWM)

Output

7-bit

D/A (PWM)

Output

EMULATING

DEVICES

Page 5

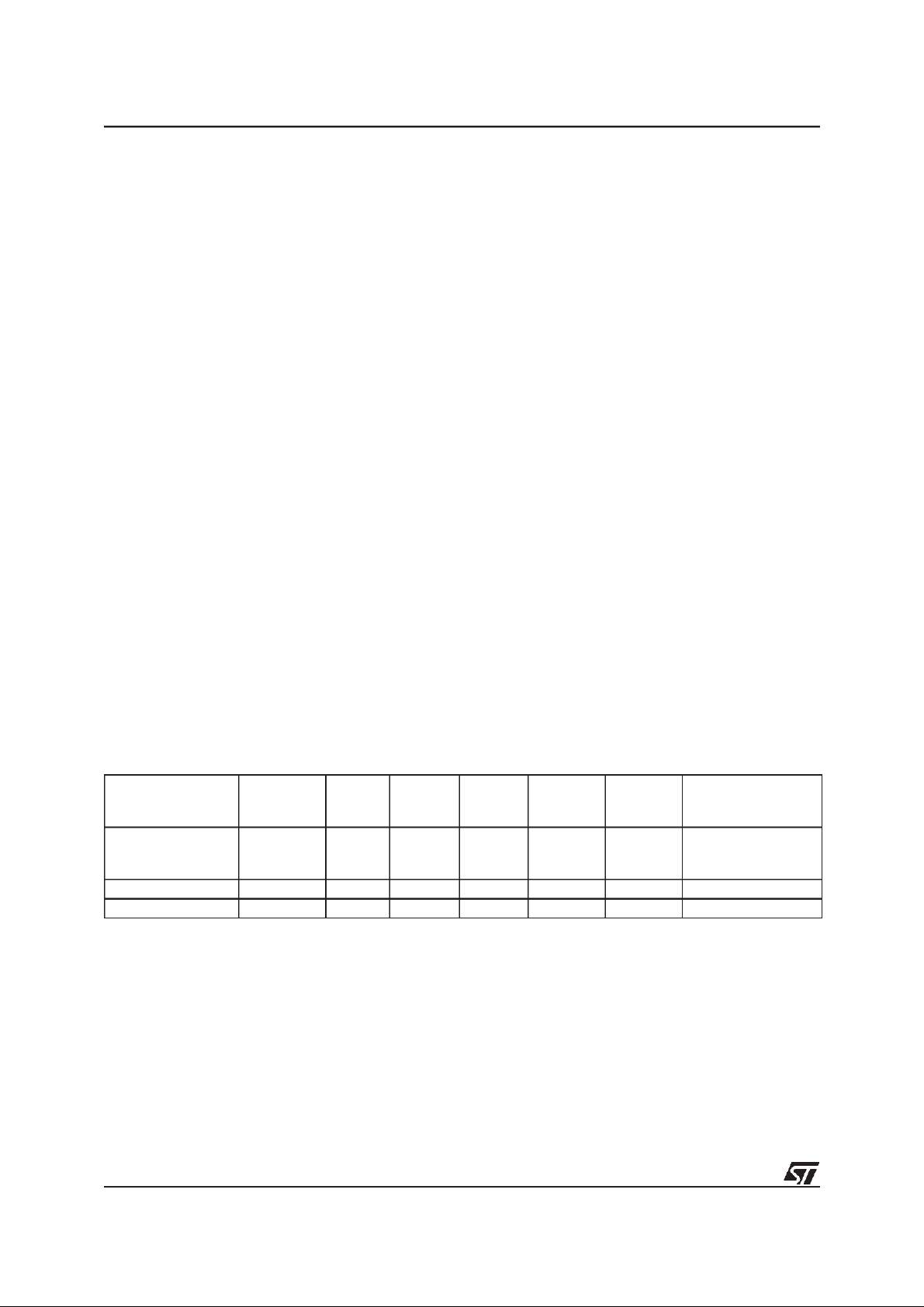

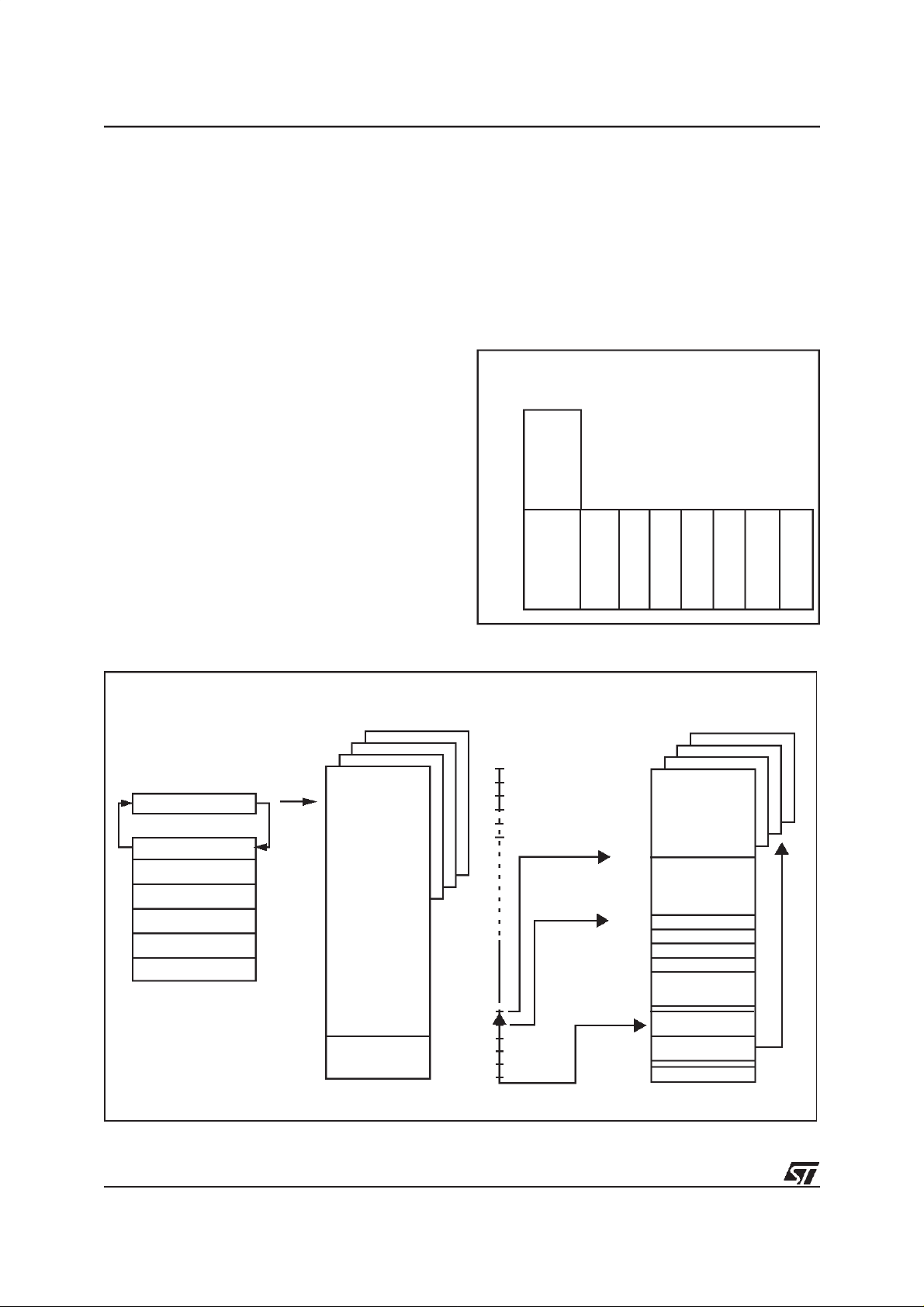

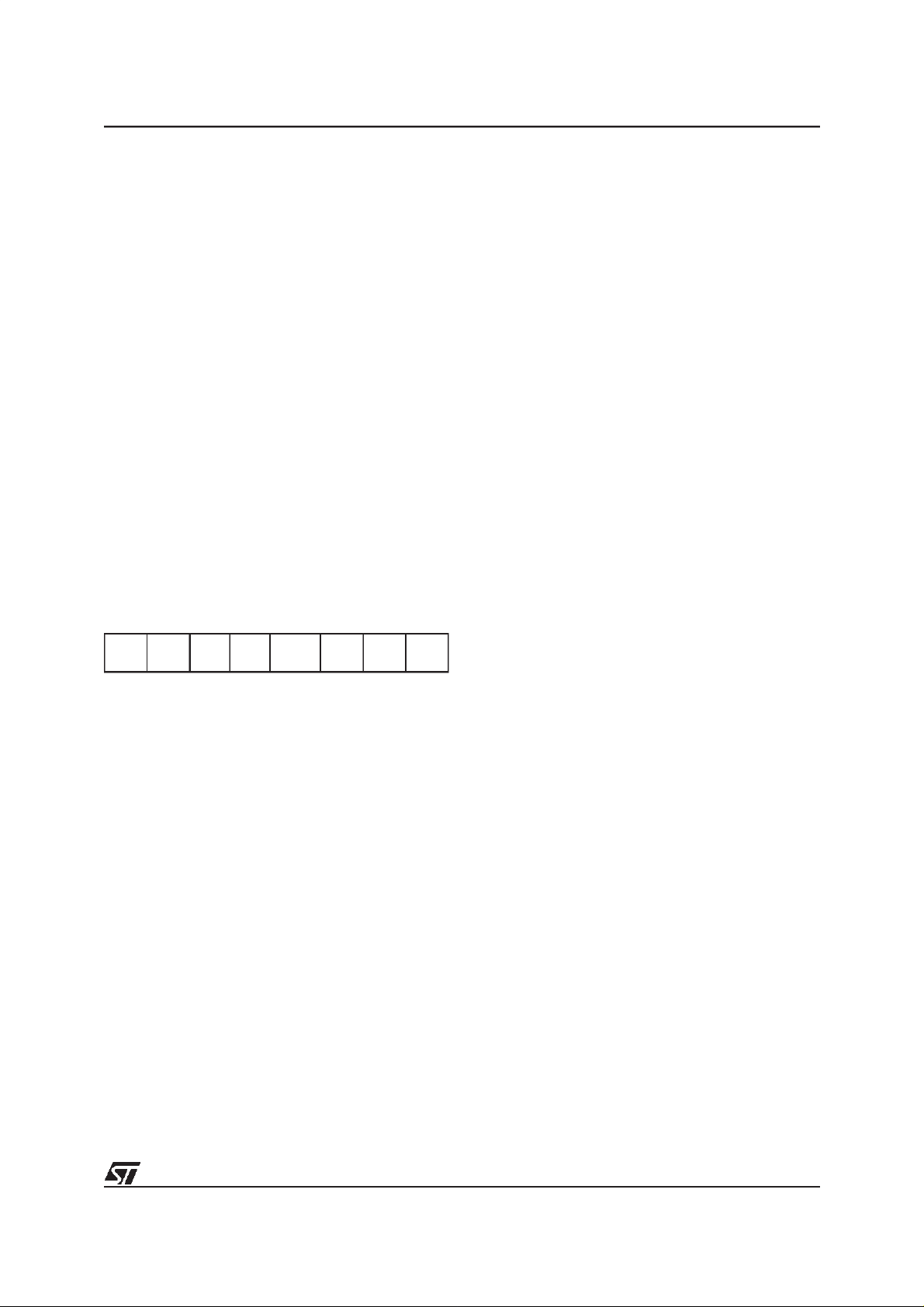

Figure 1. ST6373 Block Diagram

ST6373

TEST/V

(**)

PP

NMI

VSYNC

PWRIN

TEST

INTERRUPT

Inputs

USER PROGRAM

MEMORY

16 KBytes

PC

STACK LEVEL1

STACK LEVEL2

STACK LEVEL3

STACK LEVEL4

STACK LEVEL5

STACK LEVEL6

POWER

SUPPLY

OSCILLATOR

TIMER 1

TIMER 2

DIGITAL

WATCHDOG/TIMER

DATA ROM

USER

SELECTABLE

DATARAM

192 Bytes

DATA EEPROM

384 Bytes

8 BIT CORE

RESET

PORT A

PORT B

PORT C

DDC SPI (1)

EEPROM

128 Bytes (1)

TIMER 3

SYNC

PROCESSOR

I C SPI

D/A Outputs

A/D Inputs

PA0 -> PA7*

PB0 -> PB7*

PC0 -> PC7*

SCLD, SDAD

VSY NC, EXTCLK

HSYNC O, VSYNCO

HSYNC I, VSYNCI

HDRIV

HFLY, VFL Y

CLMPO, BLK O

SCLI, SDAI

HDA, DA0 -> DA8

AD0 -> AD7

V

DDVSS

OSCin OSCout RESET

(*)Refer to Pin Description for Add itional Information

(**)VPPinput for OTP/EPROM deviceprogramming

5/64

Page 6

ST6373

1.2 PIN DESCRIPTION

VDDand V

these two pins. VDDis power and VSSis the

Power is supplied to the MCU using

SS.

ground connection.

OSCin, OSCout.

These pins are internally connected to the on-chip oscillator circuit. A quartz

crystal or a ceramic resonator can be connected

between these two pins in order to allow the correct operation of the MCU with various stability/cost trade-offs. The OSCin pin is the input pin,

the OSCout pin is the output pin.

RESET. The active lowRESETpin is used to start

the microcontroller to the beginning of its program.

Additionally the quartz crystal oscillator will be disabled when theRESET pin is low toreduce power

consumption during reset phase.

TEST

. The TEST pin mustbe held at VSS for nor-

mal operation.

PA0, PA1, PA2/HSYNCO, PA3/VSYNCO,

PA4/CLMPO, PA5/BLKO, PA6/SCLI, PA7/SDAI

Port A.

–

Software configurable as push-pull output, open-drain output, Schmitt trigger input with

or without pull-up. Port A inputs can be also

ORed into the INT1 interrupt. Port A outputs

have a LED drive capability (10 mA). Pins PA2

and PA3 can be configured respectively as

HSYNC and VSYNC outputs.Pins PA4 and PA5

can be configured respectively as CLAMP and

BLANK Outputs.Pins PA6 and PA7 can be configurated as the I2C SPI pins SCLI and SDAI.The

push-pull output and the input pull-up options do

not exist for these two pins. After reset the PA0

to PA5 pins are configured as inputs with pull-up.

PB0/AD0, PB1/AD1, PB2/AD2, PB3/AD3,

PB4/AD4, PB5/AD5/HFLY, PB6/AD6/VFLY,

PB7/AD7

Port B

–

. Each pin can be software configured as

push-pull output, open-drain output, Schmitt trigger inputwith or without pull-up.Port B inputs can

be also ored into the INT1 interrupt. Pins PB5

and PB6 can be configured as HFLY and VFLY

inputs. In addition, any pin of port B can be software selected as the Analog-to-Digital converter

input. Only one pin should be selected at a time,

otherwise a conflict would result. After reset the

port B pins are configured as inputs with pull-up.

PC0/SCLD, PC1/SDAD, PC2, PC3/EXTCLK,

PC4/PWRIN, PC5, PC6/HSYNC, PC7/HDRIV

– Port C. Software configurable as open-drain out-

puts or Schmitt trigger inputs with or without pullups. When configured as outputs, pins PC0 to

PC3 are configured as 5V open-drain. Pins PC4

to PC7 are configured as open-drain 12V; the input pull-up option does not exist for these four

pins. Pins PC0, PC1 and PC3 can be configured

as the DDCSPI pins SCLD, SDADand EXTCLK.

The input pull-up option does not exist for PC0

and PC1. Pins PC6 and PC7 can be configured

as HSYNC and HDRIV inputs.After reset: PC3 is

configured as input with pull-up. PC0, PC1 &

PC4 to PC7 are configured in input without pullup. PC2 is in output mode with the value 1 (high

impedance).

DA0-DA8. These pins are the nine PWM D/A outputs of the on-chip D/A converters. These lines

have push-pull outputs with 5V drive. The output

repetition rate is 31.25KHz (with 8MHz clock).

VSYNC. This is the Vertical Synchronization pin.

This pin is connected to an internal interrupt and is

configured as input with pull-up and Schmitt trigger.

HDA. This is the output pin of the on-chip 14-bit

PWM D/A Converter. This line is a push-pull output with standard drive.

NMI

. This pin is the Non-Maskable interrupt input

and is configured as input withpull-up and Schmitt

trigger.

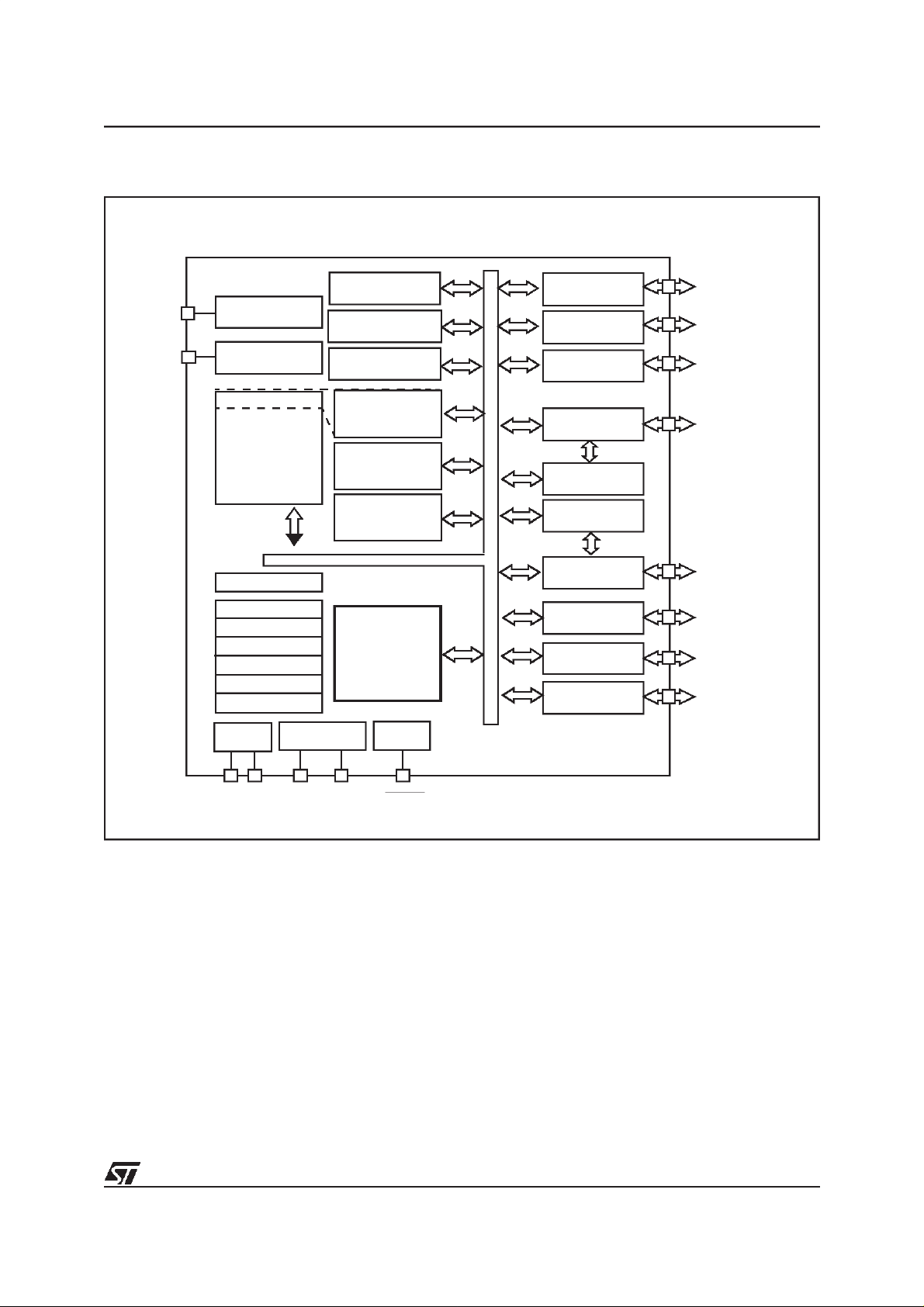

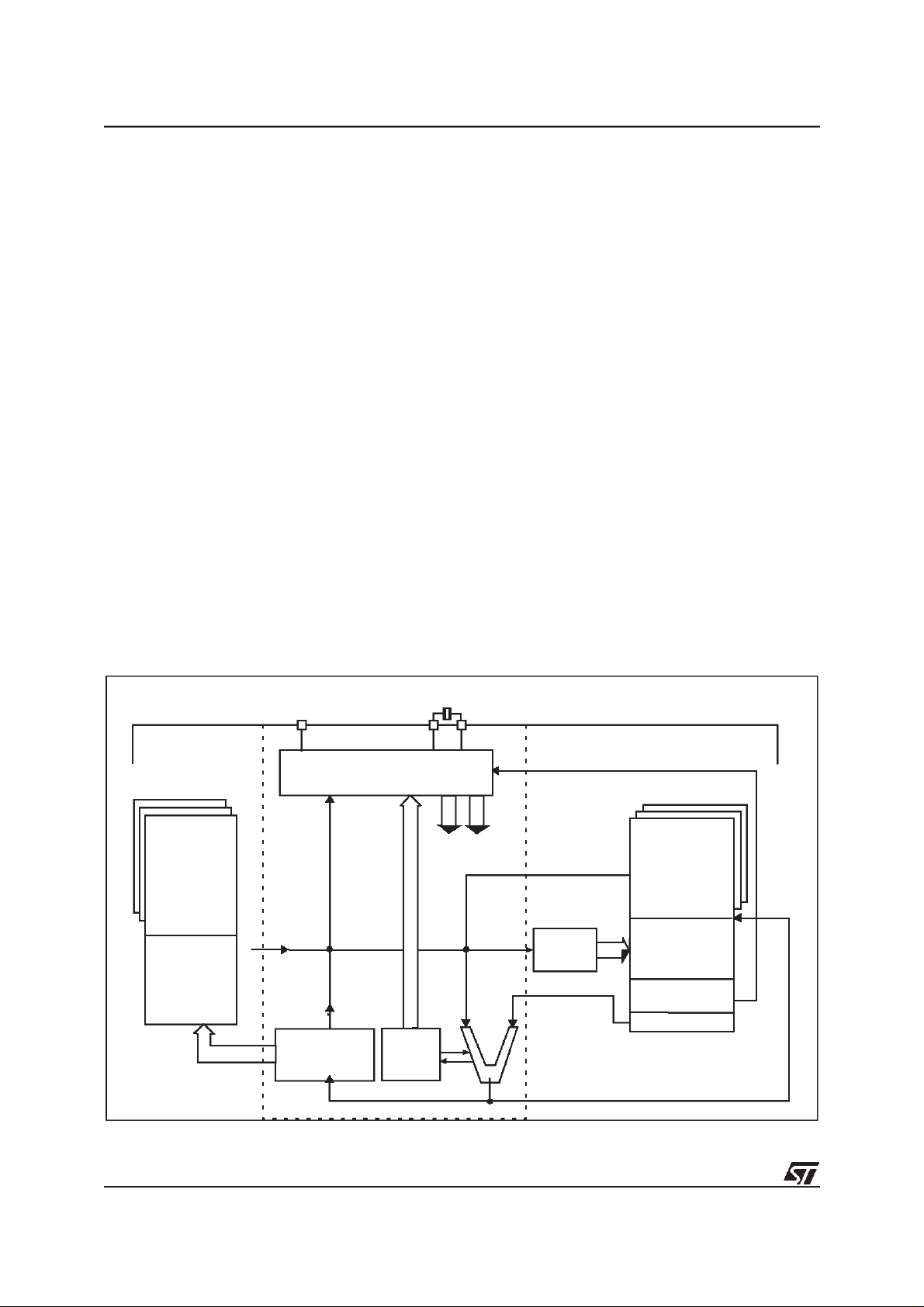

Figure 2. ST6373 Pin configuration

V

DD

O0/DA0

O1/DA1

O2/DA2

O3/DA3

AD0/PB0

AD1/PB1

AD2/PB2

AD3/PB3

AD4/PB4

HFLY/AD5/PB5

VFLY/AD6/PB6

AD7/PB7

PA0

PA1

HSYNCO/PA2

VSYNCO/PA3

CLMPO/PA4

BLKO/PA5

SCLI/PA6

SDAI/PA7

(1) This pin is also the VPPinput for OTP/EPROM devices

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

V

SS

21

42

PC0/SCLD

41

PC1/SDAD

40

PC2

39

PC3/EXTCLK

38

PC4/PWRIN

37

PC5

36

PC6/HSYNC

35

PC7/HDRIV

34

HDA

33

RESET

32

OSCout

31

OSCin

30

TEST/V

29

28

VSYNC

27

NMI

26

DA4/O4

25

DAR/O5

24

DA6/O6

23

DA7/O7

22

DA8/O8

PP

(1)

6/64

Page 7

Table 2. Pin Summary

Pin Function Description

DA0 to DA8 Output, Push-Pull

HDA Output, Push-Pull

NMI Input, Pull-up, Schmitt Trigger Input

VSYNC Input, Pull-up, Schmitt Trigger

TEST Input, Pull-Down

OSCin Input, Resistive Bias, SchmittTrigger to Reset Logic Only

OSCout Output, Push-Pull

RESET Input, Pull-up, Schmitt Trigger Input

PA0-PA5 I/O, Push-Pull/Open Drain, Software Input Pull-up, Schmitt Trigger Input

PA6-PA7 I/O, Open-Drain, No Input Pull-up, Schmitt Trigger Input

PB0-PB7 I/O, Push-Pull/Open Drain, Software Input Pull-up, Schmitt Trigger Input, Analog Input

PC0-PC1 I/O, Open-Drain, No Input Pull-up, Schmitt Trigger Input

PC2-PC3 I/O, Open-Drain, 5V, Software Input Pull-up, Schmitt Trigger Input

PC4-PC7 I/O, Open-Drain, 12V, No Input Pull-up, Schmitt Trigger Input

V

DD,VSS

Power Supply Pins

ST6373

7/64

Page 8

ST6373

1.3 MEMORY SPACES

The MCU operates in three different memory

spaces: Stack Space, Program Space and Data

Space.

1.3.1 Stack Space

The stackspace consists of six 12bit registers that

are used for stacking subroutine and interrupt return addresses plus the current program counter

register.

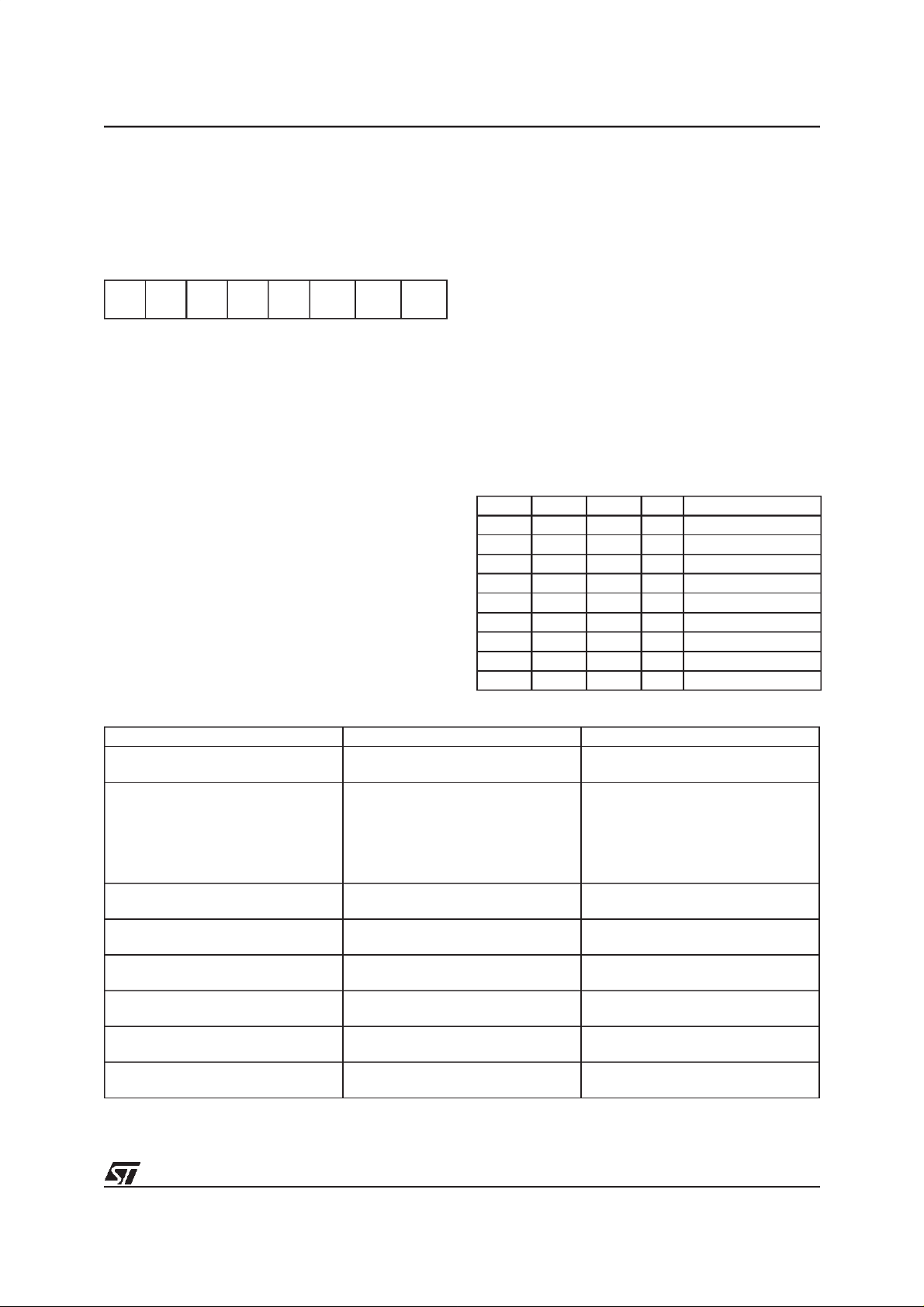

1.3.2 Program Space

The program space is physically implemented in

the ROM and includes all the instructions that are

to be executed, as well as the data required for the

immediate addressing mode instructions, the reserved test area and user vectors. It is addressed

thanks to the 12-bit Program Counter register (PC

register) and theST6 Corecan directly address up

to 4K bytes of Program Space. Nevertheless, the

Program Space can be extended by the addition

of 2-Kbyte memory banks as it is shown inFigure

2, in which the 16K bytes memory is described.

These banks are addressed by pointing to the

000h-7FFh locations of the Program Space thanks

to the Program Counter, and by writing the appropriate code in the Program ROM Page Register

(PRPR) located at address CAh in the Data

Space. Because interrupts and common subrouroutines should be available all the time only the

Figure 4. Memory Addressing Diagram

lower 2K byte of the 4K program space are bank

switched while the upper 2K byte can be seen as

static space. Table 3 gives the different codesthat

allows the selection of the corresponding banks.

Note that,from thememory point ofview, the Page

1 and the Static Page represent the same physical

memory: it is only a different way ofaddressing the

same location.

Figure 3.16K-Byte Program Space Addressing

Program

counter

space

0FFFh

0800h

07FFh

0000h

0000h

Static

Page

Page 1

Page 0

Page1

Static

Page

Page

Page Page Page Page Page

2345 67

1FFFh

PROGRAM COUNTER

STACK LEVEL 1

STACK LEVEL 2

STACK LEVEL 3

STACK LEVEL 4

STACK LEVEL 5

STACK LEVEL 6

0000h

0FF0h

RESET VECTORS

0FFFh

PROGRAM SPACE

ROM

INTERRUPT&

0-63

000h

03Fh

040h

07Fh

080h

081h

082h

083h

084h

0C0h

0FFh

DATA SPACE

RAM / EEPROM

BANKING AREA

DATA ROM

WINDOW

X REGISTER

Y REGISTER

V REGISTER

W REGISTER

RAM

DATA ROM

WINDOW SELECT

DATA RAM

BANK SELECT

ACCUMULATOR

8/64

Page 9

MEMORY SPACES (Cont’d)

Program ROM Page Register (PRPR)

Address: CAh - Write only

Reset Value: XXh

70

- - - - - PRPR2 PRPR1 PRPR0

Care is required when handling the PRPR as it is

write only. For this reason, it is not allowed to

change the PRPR contents while executing interrupts drivers, asthe driver cannotsaveand thanrestore its previous content. Anyway, this operation

may be necessary if the sum of common routines

and interrupt drivers will take more than 2K bytes;

in this case could be necessary to divide theinterrupt driver in a (minor) partin the static page (start

D7-D3. These bits are not used but have to be

written to “0”.

PRPR2-PRPR0.

These are the program ROM

banking bits and the value loaded selects the corresponding page to be addressed in the lower part

of 4Kprogram address space as specified inTable

3.This register is undefined on reset.

Note:

Only the lower part of address space has been

bankswitched because interrupt vectors and common subroutines should be available all the time.

The reason of this structure is due to the fact that it

is not possible to jump from a dynamic page to another, unless jumping back to the static page,

changing contents of PRPR, and, then, jumping to

a different dynamic page.

and end), and in thesecond (major) part in one dynamic page.Ifitis impossible to avoid the writingof

this register in interrupts drivers, an image of this

register mustbesavedina RAM location, andeach

time the program writes the PRPR bit writes also

the image register. The image register must be

written first, so if an interrupt occurs between the

two instructions the PRPR is not affected.

Table 3.ProgramMemoryPageRegisterCoding

PRPR2 PRPR1 PRPR0 PC11 Memory Page

X X X 1 Static Page (Page 1)

0000Page0

0 0 1 0 Page 1 (Static Page)

0100Page2

0110Page3

1000Page4

1010Page5

1100Page6

1110Page7

ST6373

Table 4. ST6373 Program Memory Map

Program Memory Page Device Address Description

PAGE 0

PAGE 1

“STATIC”

PAGE 2

PAGE 3

PAGE 4

PAGE 5

PAGE 6

PAGE 7

0000h-007Fh

0080h-07FFh

0800h-0F9Fh

0FA0h-0FEFh

0FF0h-0FF7h

0FF8h-0FFBh

0FFCh-0FFDh

0FFEh-0FFFh

0000h-000Fh

0010h-07FFh

0000h-000Fh

0010h-07FFh

0000h-000Fh

0010h-07FFh

0000h-000Fh

0010h-07FFh

0000h-000Fh

0010h-07FFh

0000h-000Fh

0010h-07FFh

User ROM (End of 12K)

User ROM (End of 16K)

Note*): all reserved areas must be set to FFh in the ROM code.

*)

Reserved

User ROM

User ROM

Reserved

Interrupt Vectors

Reserved

NMI Vector

Reset Vector

Reserved

User ROM

Reserved

User ROM (End of 8K)

Reserved

User ROM

Reserved

Reserved

User ROM

Reserved

9/64

Page 10

ST6373

MEMORY SPACES (Cont’d)

1.3.3 Data Space

The ST6 Coreinstruction set operates on a specific space, referred to as the Data Space, which

contains all the data necessary for the program.

Figure 5. Data Space

DATA RAM/EEPROM

BANK AREA

DATA ROM

WINDOWAREA

X REGISTER 080h

Y REGISTER 081h

V REGISTER 082h

W REGISTER 083h

DATA RAM

PORT A DATA REGISTER 0C0h

PORT B DATA REGISTER 0C1h

PORT C DATA REGISTER 0C2h

RESERVED 0C3h

PORT A DIRECTIONREGISTER 0C4h

PORT B DIRECTIONREGISTER 0C5h

PORT C DIRECTION REGISTER 0C6h

RESERVED 0C7h

INTERRUPT OPTIONREGISTER 0C8h

DATA ROM WINDOW REGISTER 0C9h

PROGRAM ROM PAGEREGISTER 0CAh

I C SPI DATA REGISTER 0CBh

DDC SPI DATA REGISTE R 0CCh

PORT A OPTION REGISTER 0CDh

PORT B OPTION REGISTER 0CEh

RESERVED 0CFh

ADC RE SULT REGISTER 0D0h

ADC CONTROL REGISTER 0D1h

TIMER 1 PRESCALERR EGISTER 0D2h

TIMER 1 COUNTER REGISTER 0D3h

TIMER 1 STATUS/CONTROL REGISTER 0D4h

TIMER 2 PRESCALERR EGISTER 0D5h

TIMER 2 COUNTER REGISTER 0D7h

WATCHDOG REGISTER 0D8h

000h

03Fh

040h

07Fh

084h

0BFh

*)

*)

The Data Space allows the addressing of RAM

(192 bytes), EEPROM (384 bytes plus 128 bytes

for the DDC SPI), ST6 Core and peripheral registers, as well as read-only data such as constants

and look-up tables.

MIRROR REGISTER 0D9h

TIMER 3 PRESCALERREGISTER 0DAh

TIMER 3 COUNTER REGISTER 0DBh

TIMER 3 STATUS/CONTROL REGISTER 0DCh

EVE NT COUNTER DATA REGISTER 1 0DDh

EVE NT COUNTER DATA REGISTER 2 0DEh

SYNC PROCESSOR CONTROL REGISTE R 0DFh

D/A 0/4 DATA CONTROL REGISTER 0E0h

D/A 1/5 DATA CONTROL REGISTER 0E1h

D/A 2/6 DATA CONTROL REGISTER 0E2h

D/A 3/7 DATA CONTROL REGISTER 0E3h

D/A 8 DATA CONTROL REGISTER 0E4h

I C SPI CONTROL REGISTE R 1 0E5h

I C SPI CONTROL REGISTE R 2 0E6h

D/A BA NK REGISTER 0E7h

DATA RAM BANK REGISTER 0E8h

DDC EEPROM CONTROL REGISTER 0E9h

EEPROM CO NTROL R EGISTER 0EAh

DDC SPI CONTROL REGISTER 1 0EBh

DDC SPI CONTROL REGISTER 2 0ECh

NMI/PWRIN/VSYNC INTERRU PT REGISTER 0EDh

HDA DATA REGISTER 1 0EEh

HDA DATA REGISTER 2 0EFh

PERIOD COUNTER DATA REGISTER 0F0h

PERIOD COUNTER 1 AND BLANK CTRLREG. 0F1h

AUTO-COU NTER REGISTER 0F2h

SCL LATCHAND DDC2B ADDRESSCTRL REG. 0F3h

XOR REGISTER 0F4h

RESERVED

ACCUMULATOR 0FFh

*)

*)

*)

*)

*)

*)

*)

*)

*)

*)

*)

*)

*)

0F5h

0FEh

*) These registers contain write only bits, in which

case the bit operation instructions are not possible.

10/64

Page 11

MEMORY SPACES (Cont’d)

Data ROM Addressing.All the read-only data are

physically implemented in the ROM in which the

Program Space is also implemented. The ROM

therefore contains theprogram tobe executedand

also the constants and the look-up tables needed

for the program. The locations of Data Space in

which the different constants and look-up tables

are addressed by the ST6 Core can be considered

as being a 64-byte window through which it is possible to access to the read-only data stored in the

ROM. This window is located from the 40h address to the 7Fh address in the Dataspace and allows the direct reading of the bytes from the 000h

address to the 03Fh address in the ROM. All the

bytes of the ROM can be used to store either instructions or read-only data. Indeed, the window

can be moved by step of 64 bytes along the ROM

in writing the appropriate code in the Write-only

Data ROM Window register (DRWR, location

C9h). The effective address of the byte to be read

as a data in the ROM is obtained by the concatenation ofthe 6 less significant bits of the address in

the Data Space (as less significant bits) and the

content of the DRWR (as most significant bits). So

when addressing location 40h of data space, and

0 is loaded in the DRWR, the physical addressed

location in ROM is 00h.

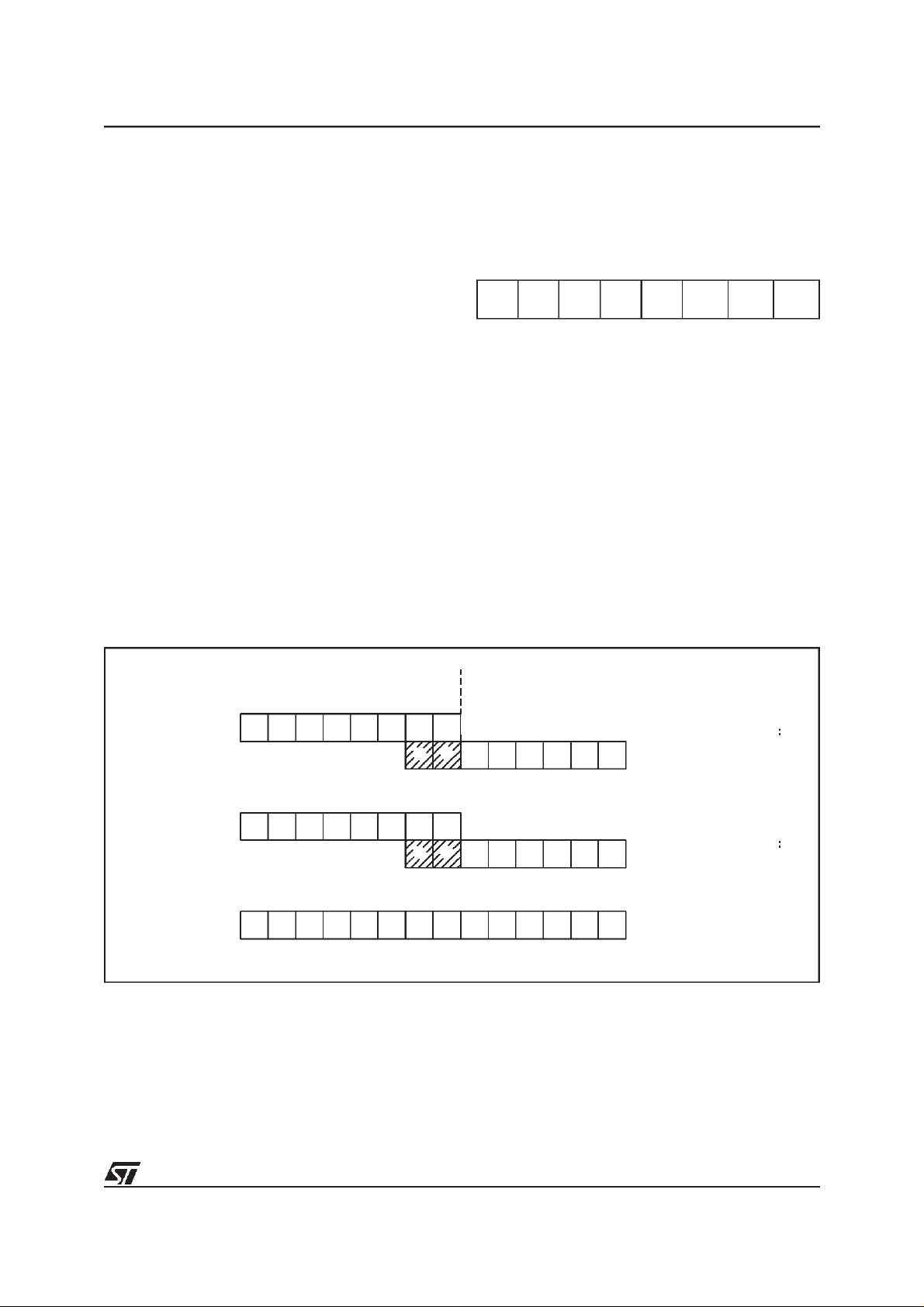

Figure 6. Data ROM Window Memory Addressing

ST6373

Data ROM Window Register (DWR)

Address: C9h - Write only

Reset Value: XXh

70

DWR7 DWR6 DWR5 DWR4 DWR3 DWR2 DWR1 DWR0

DWR7-DWR0. These are the Data Rom Window

bits that correspond to the upper bits of data ROM

program space. Thisregister is undefined after reset.

Note:

Care is required when handling the DRWR as it is

write only. For this reason, it is not allowed to

change the DRWR contents while executing interrupts drivers, as the driver cannot save and than

restore its previous content. If it is impossible to

avoid the writing of this register in interrupts drivers, an image of this register must be saved in a

RAM location, and each time the program writes

the DRWR it writes also the image register. The

image register must be written first, so if an interrupt occurs between the two instructions the

DRWR register is not affected.

DATA ROM

WINDOW REGISTER

CONTENTS

(DWR)

Example:

DWR=28h

ROM

ADDRESS:A19h

13

12

7

65432 0

0

0

00000000

11

11

1

01

0

01

543210

67891011

543210

0000

1

1

0

11

00

1

PROGRAM SPACE ADDRESS

READ

DATA SPACE ADDRESS

40h-7Fh

IN INSTRUCTION

DATA SPACE ADDRESS

1

59h

VR01573B

11/64

Page 12

ST6373

MEMORY SPACES (Cont’d)

1.3.4 Data RAM/EEPROM

In the ST6373, 64 bytes of data RAM are directly

addressable in the data space from 80h to BFh addresses. The additional 128 bytes of RAM, and the

384 + 128 bytes of EEPROM can be addressed

using the 64-byte banks located between addresses 00H and 3Fh. Bank selection is carried out by

programming the Data RAM Bank Register (DRBR) located at address E8h of the Data Space. In

this way each bank of RAM or EEPROM can select 64 bytes at a time. No more than one bank

should be set at a time.

Data RAM Bank Register (DRBR)

Address: E8h - Write only

Reset Value: XXh

70

DRBR7DRBR6DRBR5DRBR4DRBR3DRBR2DRBR1DRBR

DRBR6

. This bit is reserved and must be held at

0

“0”.

DRBR5, DRBR4

. Each of these bits,when set,will

select one page of the EEPROM dedicated to the

DDC SPI.

DRBR3, DRBR2

. Each of these bits,when set,will

select oneRAM page.

DRBR7, DRBR1, DRBR0. These bits select the

EEPROM pages.

This register isundefined after reset.

Table 5 summarizes how to set the Data RAM

Bank Register in order to select the various banks

or pages.

Note:

Care is required when handling the DRBR as it is

write only. For this reason, it is not allowed to

change the DRBR contents while executing interrupts drivers, as the driver cannot save and than

restore its previous content. If it is impossible to

avoid the writing of this register in interrupts drivers, an image of this register must be saved in a

RAM location, and each time the program writes

the DRBRit writes also the image register. The image register must be written first, so if an interrupt

occurs between the two instructions the DRBR is

not affected.

1.3.5 EEPROM Description

The data space of ST6373 devices, from 00h to

3Fh, is paged as described in Table 5. The 512

bytes of EEPROM are located in eight pages of 64

bytes (see Table 3 below).

Table 5. Data RAM Bank Register Set-up

DRBR Value

Hex. Binary

01h 0000 0001 EEPROM Page 0

02h 0000 0010 EEPROM Page 1

03h 0000 0011 EEPROM Page 2

04h 0000 0100 RAM Page 2

08h 0000 1000 RAM Page 3

10h 0001 0000 DDC EEPROM Page 0

20h 0010 0000 DDC EEPROM Page 1

81h 1000 0001 EEPROM Page 3

82h 1000 0010 EEPROM Page 4

83h 1000 0011 EEPROM Page 5

Selection

12/64

Page 13

MEMORY SPACES (Cont’d)

By programming the Data RAM Bank Register,

DRBR, the user can select the bank or page leaving unaffected the means of addressing the static

registers. The way to address the “dynamic” page

is to set the DRBR as described in Table 5 (e.g. to

select EEPROM page 0,the DRBR has tobe loaded with content 01h, see Data RAM/EEPROM addressing for additional information). Bits 0,1 and

4,5,7 of the DRBR are dedicated to the standard

EEPROM and DDC EEPROM respectively.

The EEPROM pages do not require dedicated instructions to be accessed in reading or writing.

The standard EEPROM is controlled by the EEPROM Control Register, EECR, the DDC EEPROM

is controlled by the DDC EPROM Control Register

DEECR, in the same way. Any EEPROM location

can be read just like any other data location, also

in terms of access time.

To write an EEPROM location takes an average

time of 5ms and during this time the EEPROM is

not accessible by the Core. A busy flag can be

read by the Core to know the EEPROM status before trying any access. In writing the EEPROM can

work in two modes: Byte Mode (BMODE) and Parallel Mode (PMODE). TheBMODE is the normal

way to use the EEPROM and consists in accessing one byteat a time. The PMODE consists in accessing 8 bytes per time.

SB. WRITE ONLY. If this bit is setthe EEPROM is

disabled (any access will be meaningless) and the

power consumption of theEEPROM is reduced to

the leakage values.

D5, D4. Reserved for testing purposes, they must

be set to zero.

PS

. SET ONLY. Once in Parallel Mode, as soon

as the user software sets the PS bit the parallel

writing of the 8 adjacent registers will start. PS is

internally reset at the end of the programming procedure. Note that less than 8 bytes can be written;

after parallel programming the remaining undefined bytes will have no particular content.

PE. WRITEONLY. This bit must be setbythe user

program in order to perform parallel programming

(more bytes per time). IfPE is setand the “parallel

start bit” (PS) is low, up to 8 adjacent bytes can be

written at the maximum speed, the content being

stored in volatile registers. These 8 adjacent bytes

can be considered as row, whose A7, A6, A5, A4,

A3 are fixed while A2, A1 and A0 are the changing

bytes. PE is automatically reset at the end of any

parallel programming procedure. PE can be reset

by the user software before starting the programming procedure, leaving unchanged the EEPROM

registers.

BS. READ ONLY.This bit willbe automatically set

by the CORE when the user program modifies an

EEPROM register. The user program has to test it

EEPROM Control Register (EECR)

Address: EAh - Read/Write

Reset Value: 00h

70

Re-

-SB

served

Re-

served

PS PE BS EN

DDC EEPROM Control Register (DDCEECR)

Address: E9h - Read/Write

Reset Value: 00h

70

Re-

-SB

D7

. Not used

served

Re-

served

PS PE BS EN

before any read or write EEPROM operation; any

attempt to access the EEPROM while “busy bit” is

set will be aborted and the writing procedure in

progress completed.

EN

. WRITE ONLY. This bit MUST be set to one in

order to write any EEPROM register. If the user

program will attempt to write the EEPROM when

EN= “0” the involved registers will be unaffected

and the “busy bit” will not be set.

Notes

:

When the EEPROM is busy (BS = “1”) the EECR

cannot be accessed in write mode, it is only possible to read BS status.This implies that, as long as

the EEPROM is busy, it is not possible to change

the status of the EEPROM control register. EECR

bits 4 and 5 are reserved for test purposes, and

must never be set.

ST6373

13/64

Page 14

ST6373

MEMORY SPACES (Cont’d)

Additional Notes on Parallel Mode. If the user

wants to perform a parallel programming the first

action should be the setting of the PE bit; from this

moment, the first time the EEPROM will be addressed in writing, the ROW address will be

latched and it will be possible to change it only at

the end of the programming procedure or by resetsetting PE without programming the EEPROM.

After the ROW address latching the Core can

“see” just one EEPROM row (the selected one)

and any attempt to write or read other rows will

produce errors. Do not read the EEPROM while

PE is set.

As soon as PE bit is set, the 8 volatile ROW latches are cleared. From this moment the user can

load data in the wholeROW or just in a subset. PS

setting will modify the EEPROM registers corresponding to the ROW latches accessed after PE.

For example, ifthe software sets PE and accesses

EEPROM in writing at addresses 18h,1Ah,1Bh

and then sets PS, these three registers will be

modified at thesame time;the remaining bytes will

have no particular content. Note that PE is internally reset at the end of the programming procedure. This implies that the user must set PE bit between two parallel programming procedures. Anyway the user can set and then reset PE without

performing any EEPROM programming. PS is a

set only bit and is internally resetat the end of the

programming procedure. Note that if the user tries

to set PS while PE is not set there will not be any

programming procedure and the PS bit will be unaffected. Consequently PS bit can not be set if EN

is low. PS can be affected by the user set if, and

only if, EN and PE bits are also set to one.

14/64

Page 15

1.4 MEMORY PROGRAMMING

ST6373

1.4.1 Program Memory

The ST6373 OTP and EPROM MCUs can be programmed with a range of EPROM programming

tools available from SGS-THOMSON.

EPROM/OTP programming mode is set by a

+12.5V voltage applied to the TEST/VPPpin. The

programming flow is described in the User Manual

of the EPROM Programming Tool.

1.4.2 Option Byte

The Option Byte allows OTP and EPROM versions to be configured to offer the same features

available as mask options in ROM devices. The

Option Byte’s content is automatically read, and

the selected options enabled on Reset.

The Option Byte can onlybe accessed during programming mode. Access is either automatic (copy

from a master device) or by selecting the OPTION

BYTE PROGRAMMING mode ofthe programmer.

The option byte is located in a non-user map. No

address needs to be specified.

Option Byte

0 = 100KHz (default)

1 = 400KHz

All other bits must be programmed asshown in the

register table above.

The Option byte is written during programming ei-

ther by using the PC menu (PC driven Mode) or

automatically (stand-alone mode).

1.4.3 Eprom Erasure

Thanks to the transparent window present in the

EPROM package, its memory contents may be

erased by exposure to UV light.

Erasure begins when thedevice is exposed to light

with a wavelength shorter than 4000Å. It should be

noted that sunlight, as well as some types of artificial light, includes wavelengths in the 3000-4000Å

range which, on prolonged exposure, can cause

erasure of memory contents. It is thus recommended that EPROM devices be fitted with an

opaque label over the window area in order to prevent unintentional erasure.

The recommended erasure procedure forEPROM

devices consists of exposure to short wave UV

light having a wavelength of 2537Å. The minimum

70

recommended integrated dose (intensity x exposure time) for complete erasure is 15Wsec/cm2.

0000X 010

This is equivalent to an erasure time of 15-20 minutes using a UV source having an intensity of

12mW/cm2at a distance of 25mm (1 inch) from

bit 3 =

I2C Clock Speed

:

the device window.

15/64

Page 16

ST6373

2 CENTRAL PROCESSING UNIT

2.1 INTRODUCTION

The CPU Core ofST6devicesisindependent ofthe

I/O or Memory configuration. As such, it may be

thought of as an independent central processor

communicating with on-chip I/O, Memory and Peripherals via internal address, data, and control

buses. In-core communication is arranged as

shown in Figure 1; the controller being externally

linked to both the Reset and Oscillator circuits,

while thecore islinked to the dedicatedon-chip peripherals via the serial data bus and indirectly, for

interrupt purposes, through the control registers.

2.2 CPU REGISTERS

The ST6 Family CPU core features six registers

and three pairs of flags available to the programmer. These are described in the following paragraphs.

Accumulator (A)

. The accumulator is an 8-bit

general purpose register used in all arithmetic calculations, logical operations, and data manipulations. The accumulator can be addressed in Data

space as a RAMlocation at address FFh. Thus the

ST6 can manipulate the accumulator just like any

other register in Data space.

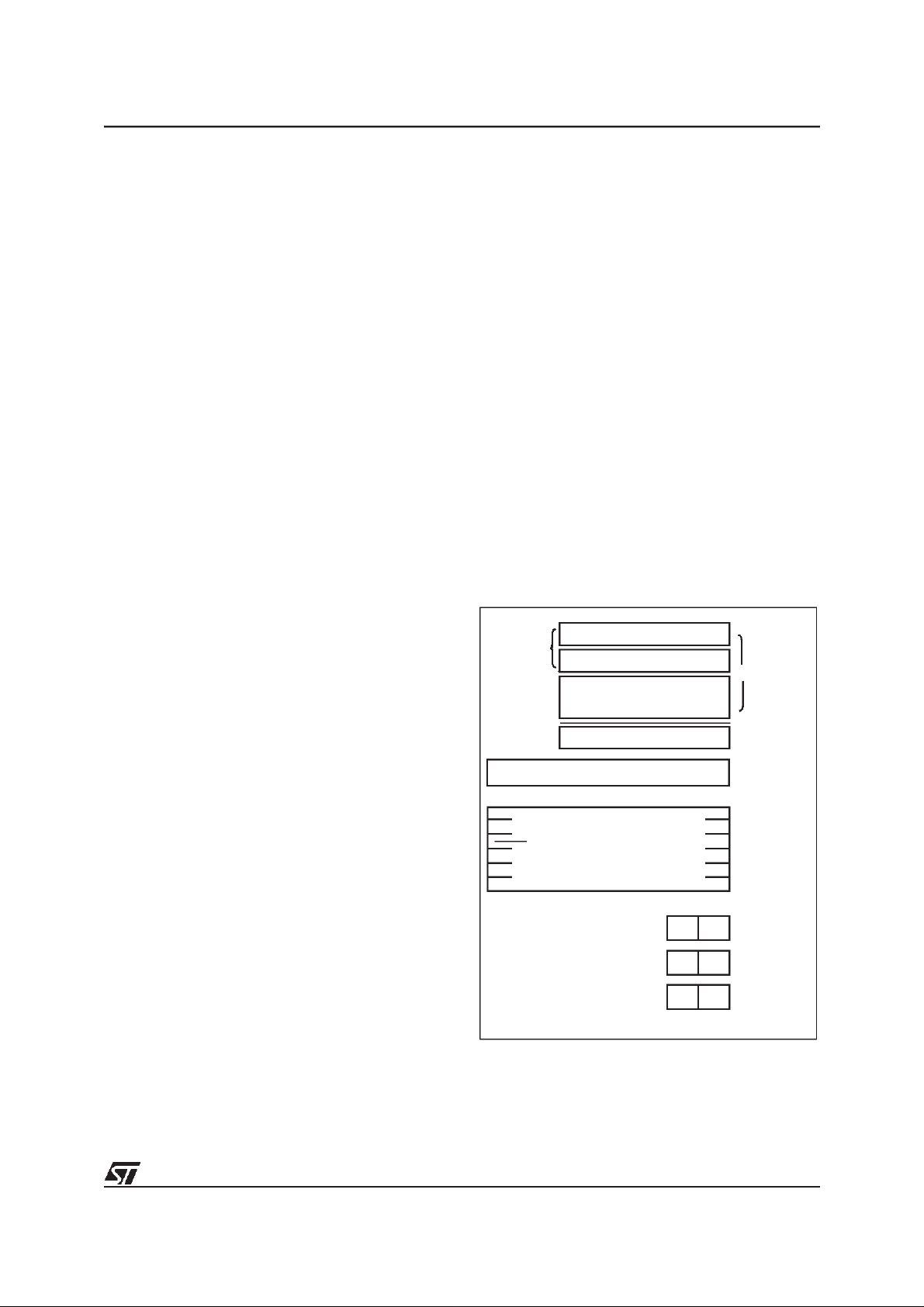

Figure 7. ST6 Core Block Diagram

0,01 TO 8MHz

RESET

OSCin

Indirect Registers (X, Y).

These two indirect registers are used as pointers to memory locations in

Data space. They are used in the register-indirect

addressing mode. These registers can be addressed in thedata space as RAM locations at addresses 80h (X) and 81h (Y). They can also be accessed with the direct, short direct, or bit direct addressing modes. Accordingly, the ST6 instruction

set can use theindirect registers as any other register of the data space.

Short Direct Registers (V, W).

These two registers are used to save a byte in short direct addressing mode. They can be addressed in Data

space as RAM locations at addresses 82h (V) and

83h (W). They can also be accessed using the direct and bit direct addressing modes. Thus, the

ST6 instruction set can use the short direct registers as any other register of the data space.

Program Counter (PC). The program counter is a

12-bit register which contains the address of the

next ROM location to be processed by the core.

This ROM location may be an opcode, an operand, or the address of an operand. The 12-bit

length allows the direct addressing of 4096 bytes

in Program space.

OSCout

16/64

PROGRAM

ROM/EPROM

12

CONTROLLER

OPCODE

Program Counter

and

6 LAYER STACK

FLAG

VALUES

2

FLAGS

CONTROL

SIGNALS

A-DATA

ADDRESS/READ LINE

ADDRESS

DECODER

B-DATA

ALU

RESULTS TO DATA SPACE(WRITE LINE)

INTERRUPTS

256

DATA SPACE

DATA

RAM/EEPROM

DATA

ROM/EPROM

DEDICATIONS

ACCUMULATOR

VR01811

Page 17

CPU REGISTERS (Cont’d)

However, if the program space contains more than

4096 bytes, the additional memory in program

space can be addressed by using the Program

Bank Switch register.

The PC value is incremented after reading theaddress ofthe current instruction. To executerelative

jumps, the PC and the offset are shifted through

the ALU, where they are added; the result is then

shifted back into the PC. The program counter can

be changed in the following ways:

- JP (Jump) instruction. . . . . PC=Jump address

- CALL instruction . . . . . ....PC=Calladdress

- Relative Branch Instruction. PC= PC +/- offset

- Interrupt . . . . . . . . . . . . . .PC=Interrupt vector

- Reset . ................PC=Reset vector

- RET & RETI instructions . .. . PC= Pop (stack)

- Normal instruction . . . . . . .......PC=PC+1

Flags (C, Z). The ST6 CPU includes three pairs of

flags (Carry and Zero), each pair being associated

with one of the three normal modes of operation:

Normal mode, Interrupt mode and Non Maskable

Interrupt mode. Each pair consists of a CARRY

flag and a ZERO flag. One pair (CN, ZN) is used

during Normal operation, another pair is used during Interrupt mode (CI, ZI),and a third pair is used

in the Non Maskable Interrupt mode (CNMI, ZNMI).

The ST6 CPU uses the pair of flags associated

with the current mode: as soon as an interrupt (or

a Non Maskable Interrupt) is generated, the ST6

CPU uses the Interrupt flags (resp. the NMI flags)

instead of the Normal flags. When the RETI instruction is executed, the previously used set of

flags is restored. It should be noted that each flag

set can only be addressed in its own context (Non

Maskable Interrupt, Normal Interrupt or Main routine). The flags are not cleared during context

switching andthus retain their status.

The Carry flag is set when a carry or a borrow occurs during arithmetic operations; otherwise it is

cleared. The Carry flag is also set to the value of

the bit tested in a bit test instruction; it also participates in the rotate left instruction.

The Zero flag is set if the result of the lastarithmetic or logical operation was equal to zero; otherwise it is cleared.

Switching between the three sets of flags is performed automatically when an NMI, an interrupt or

a RETI instructions occurs. As the NMI mode is

ST6373

automatically selected after the reset of the MCU,

the ST6 core uses at first the NMIflags.

Stack.

ware stack which eliminates the need for a stack

pointer. The stack consists of six separate 12-bit

RAM locations that do not belong to the data

space RAM area. When a subroutine call (or interrupt request) occurs,the contents ofeach level are

shifted into the next higher level, while the content

of the PC is shifted into the first level (the original

contents of the sixth stack level are lost). When a

subroutine or interrupt return occurs (RET or RETI

instructions), the first level register is shifted back

into the PC and the value of each level is popped

back into the previous level. Since the accumulator, in common with all other data space registers,

is not stored in this stack, management of these

registers should be performed within the subroutine. The stack will remain in its “deepest” position

if morethan 6 nested calls or interrupts areexecuted, and consequently the last return address will

be lost. It will also remain in its highest position if

the stack is empty and a RET or RETI is executed.

In this case the next instruction will be executed.

Figure 8. ST6 CPU Programming Mode

l

The ST6 CPU includes a true LIFO hard-

X REG. POINTER

INDEX

REGISTER

INTERRUPTFLAGS

NMI FLAGS

b7

b7

b7

b7

b7

PROGRAMCOUNTER

SIX LEVELS

STACKREGISTER

YREG.POINTER

VREGISTER

WREGISTER

ACCUM ULATOR

b0

b0

b0

b0

b0

b0b11

CZNORMAL FLAGS

CZ

CZ

SHORT

DIRECT

ADDRESSING

MODE

VA000 423

17/64

Page 18

ST6373

3 CLOCKS, RESET, INTERRUPTS AND POWERSAVING MODES

3.1 ON-CHIP CLOCK OSCILLATOR

The internal oscillator circuit is designed to require

a minimum of external components. A crystal

quartz, a ceramic resonator, or an external signal

(provided to the OSCin pin) may be used to generate a system clockwith various stability/cost tradeoffs. The typical clock frequency is 8MHz. Please

note that different frequencies will affect the operation of those peripherals (D/As, SPI) whose reference frequencies are derived from the system

clock.

The different clock generator connection schemes

are shown inFigure 1 and 2. One machine cycle

takes 13 oscillator pulses; 12 clock pulses are

needed to increment the PC while and additional

13th pulse is needed to stabilize the internal latches during memory addressing. This means that

with a clock frequency of 8MHz the machine cycle

is 1.625µSec.

The crystal oscillator start-up time is a function of

many variables: crystal parameters (especially

RS), oscillator load capacitance (CL), IC parameters, ambient temperature, and supply voltage.It

must be observed thatthe crystal or ceramic leads

and circuit connections must be as short as possible. Typical values for CL1 and CL2 are in the

range of 15pF to 22pF but these should be chosen

based on the crystal manufacturers specification.

Typical input capacitance for OSCin and OSCout

pins is 5pF.

The oscillatoroutput frequency is internally divided

by 13 to produce the machine cycle and by 12 to

produce the Timers and the Watchdog clock. A

byte cycle is the smallest unit needed to execute

any operation (i.e., increment the program counter). An instruction may need two, four, or five byte

cycles to be executed (SeeTable 1).

Table 6. Instruction Timing with 8MHz Clock

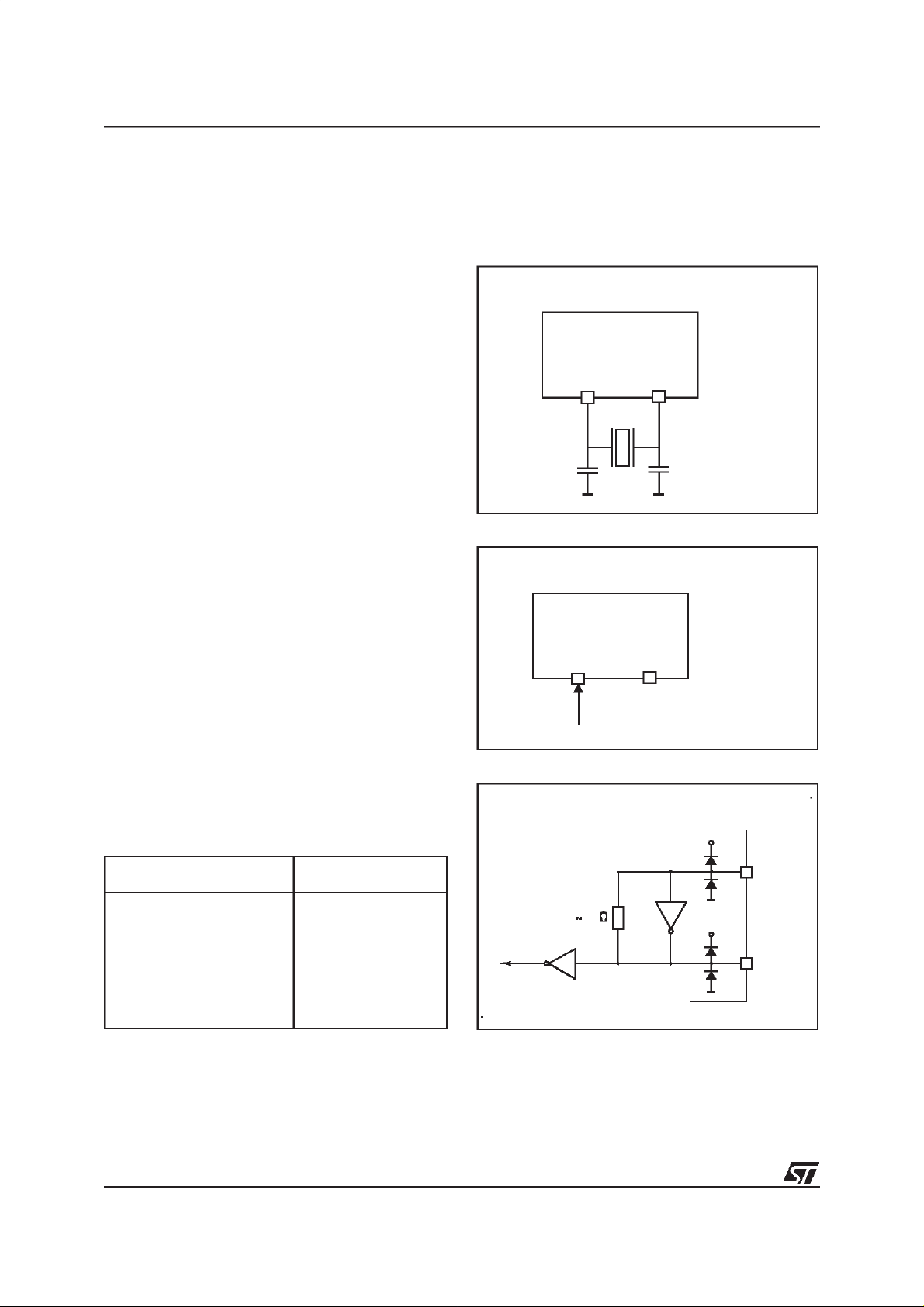

Figure 9. Clock Generator Option 1

CRYSTAL/RESONATOR CLOCK

ST6xxx

OSC

C

L1

OSC

in

out

C

L2

VA0016B

Figure 10. Clock Generator Option 2

EXTERNAL CLOCK

ST6xxx

OSC

OSC

in

out

NC

VA0015C

Figure 11. OSCin, OSCout Diagram

OSCin, OSCout (QUARTZ PINS)

V

DD

Instruction Type Cycles

Branch if set/reset 5 Cycles 8.125µs

Branch & Subroutine Branch 4 Cycles 6.50µs

Bit Manipulation 4 Cycles 6.50µs

Load Instruction 4 Cycles 6.50µs

Arithmetic & Logic 4 Cycles 6.50µs

Conditional Branch 2 Cycles 3.25µs

Program Control 2 Cycles 3.25µs

18/64

Execution

Time

OSCin

1M

In

V

DD

OSCout

VA00462

Page 19

3.2 RESETS

ST6373

The MCU can be reset in three ways:

– by the external Reset input being pulled low;

– by Power-on Reset;

– by the digital Watchdog peripheral timing out.

3.2.1 RESET Input

The RESET pin may be connected to a device of

the application board in order to reset the MCU if

required. The RESET pin may be pulled low in

RUN, WAIT or STOP mode. This input can be

used to reset the MCU internal state and ensure a

correct start-up procedure. The pin is active low

and features a Schmitt trigger input. The internal

Reset signal is generated by adding a delay to the

external signal. Therefore even short pulses on

the RESET pin are acceptable, provided VDDhas

completed its rising phase and that the oscillatoris

running correctly (normal RUN or WAIT modes).

The MCU is kept in the Reset state as long as the

RESET pin is held low.

If RESET activation occurs in RUN or WAIT

modes, processing of the user program isstopped

(RUN mode only), theInputs and Outputs are configured as inputs with pull-up resistors if available.

When the level on the RESET pin then goes high,

the initialization sequence is executed following

expiry of the internal delay period.

If RESET pin activation occurs in the STOP mode,

the oscillator starts up and all Inputs and Outputs

are configured as inputs with pull-up resistors if

available. When the level of theRESET pin then

goes high, the initialization sequence is executed

following expiry of the internal delay period.

3.2.2 Power-on Reset

The function of the POR circuit consists in waking

up the MCU at an appropriate stage during the

power-on sequence. At the beginning of this sequence, the MCU is configured in the Reset state:

all I/O ports are configured as inputs with pull-up

resistors and noinstruction is executed. When the

power supply voltage rises to a sufficient level, the

oscillator starts to operate, whereupon an internal

delay is initiated, in order to allow the oscillator to

fully stabilize before executing the first instruction.

The initialization sequence is executed immediately following the internal delay.

The internal delay is generated by an on-chip

counter. Theinternal reset line is released 2048internal clock cycles after release of the external reset.

The internal POR device is a static mechanism

which forces the reset state when VDDis below a

threshold voltage in the range 3.4 to 4.2Volts (see

Figure 1).The circuit guarantees that the MCU will

exit or enter the reset state correctly, without spurious effects, ensuring, for example, that EEPROM

contents are not corrupted.

Note

: This featureisnot available on OTP/EPROM

Devices.

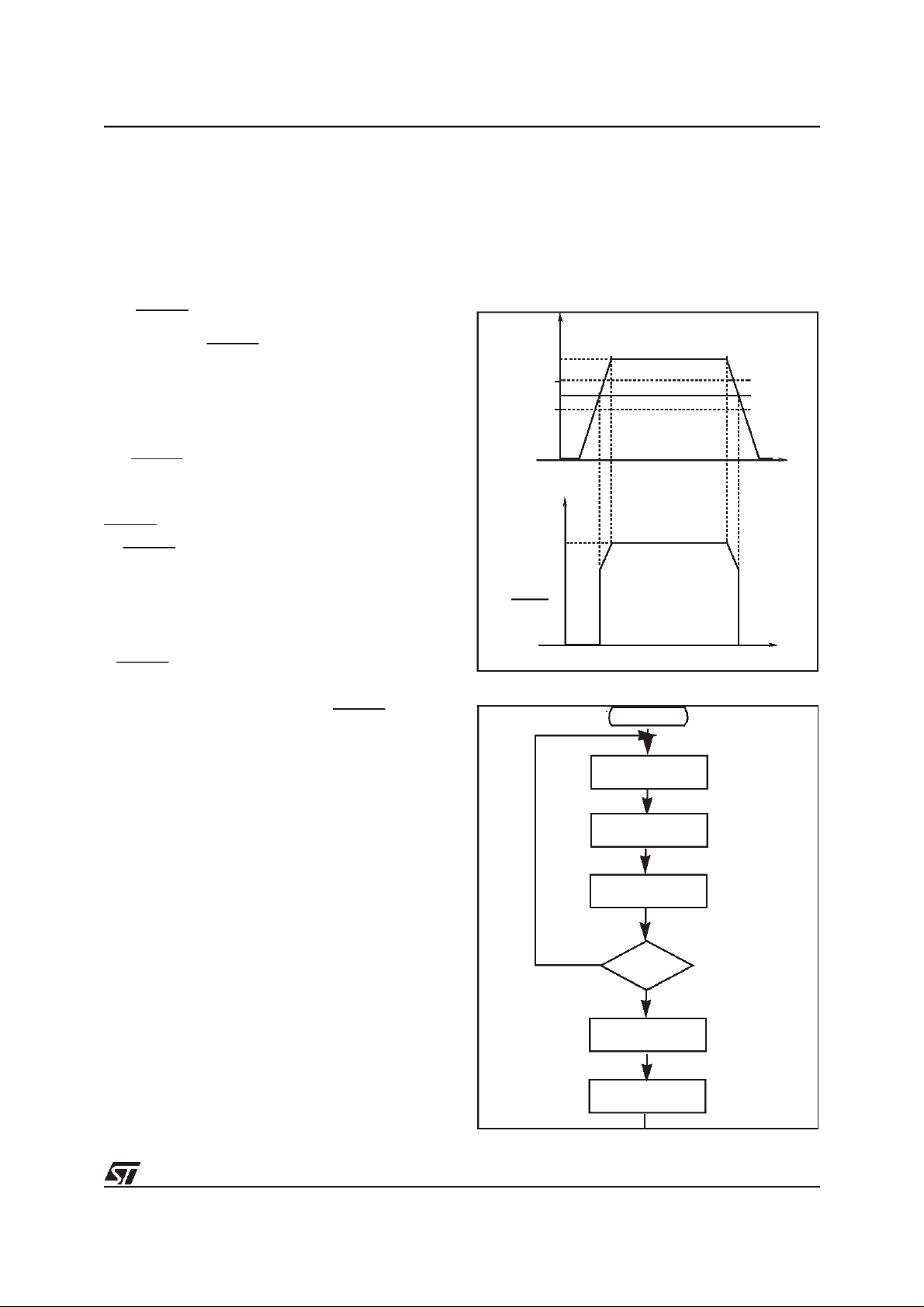

Figure 12. Power ON/OFF Reset operation

V

DD

4.2

Threshold

3.4

t

V

DD

POWER

ON/OFF

RESET

t

VR02037

Figure 13. Reset and Interrupt Processing

RESET

NMI MASK SET

INT LATCH CLEARED

( IF PRESENT )

SELECT

NMI MODE FLAGS

PUT FFEH

ON A DDRESSBUS

YES

IS RESET STILL

PRESENT?

NO

LOAD PC

FROM RESET LOCATION S

FFE/FFF

FETCH INSTRUCTION

VA000427

19/64

Page 20

ST6373

RESETS (Cont’d)

3.2.3 Watchdog Reset

The MCU provides a Watchdog timer function in

order to ensure graceful recovery from software

upsets. If the Watchdog register is not refreshed

before an end-of-count condition is reached, the

internal reset will be activated. This, amongst other things, resets the watchdog counter.

The MCU restarts just as though the Reset had

been generated by theRESET pin, including the

built-in stabilisation delay period.

3.2.4 Application Note

No external resistor is required between VDDand

the Reset pin, thanks to the built-in pull-up device.

3.2.5 MCU Initialization Sequence

When a reset occurs the stack is reset, the PC is

loaded with the address of the Reset Vector (located in program ROMstarting at address 0FFEh). A

jump to the beginning of theuser program mustbe

coded at this address. Following a Reset, the Interrupt flag is automatically set, so that the CPU is

in Non Maskable Interrupt mode; this prevents the

initialisation routine from being interrupted. The initialisation routine should therefore be terminated

by a RETI instruction, in order to revert to normal

mode andenable interrupts. Ifno pending interrupt

is present at theend of the initialisation routine, the

MCU will continue by processing the instruction

immediately following the RETI instruction. If, however, a pending interrupt is present, it will be serviced.

Figure 14. Reset and Interrupt Processing

RESET

JP:2 BYTES/4CYCLES

RESET

VECTOR

INITIALIZATION

ROUTINE

JP

RETI: 1 BYTE/2 CYCLES

RETI

VA00181

Figure 15. Reset Circuit

RESET

(ACTIVE LOW)

OSCILLATOR

SIGNAL

1k

V

DD

300k

TO ST6

ST6

INTERNAL

RESET

COUNTER

RESET

WATCHDOG RESET

POWER ON/OFFRESET

VA0200E

20/64

Page 21

3.3 HARDWARE ACTIVATED DIGITAL WATCHDOG FUNCTION

ST6373

The hardware activated digital watchdog function

consists of a down counter that is automatically initialized after reset so that this function does not

need to be activated by the user program. As the

watchdog function is always activated this down

counter can not be used as a timer. The watchdog

is using one data space register (HWDR location

D8h). The watchdog register is set to FEh on reset

and immediately starts to count down, requiring no

software start. Similarly the hardware activated

watchdog can not be stopped or delayed by software.

The watchdog time can be programmed using the

6 MSBs in the watchdog register, this gives the

possibility to generate a reset in a time between

3072 to 196608 oscillator cycles in 64 possible

steps. (With a clock frequency of 8MHzthis means

from 384ms to 24.576ms). The reset is prevented

if the register is reloaded with the desired value

before bits 2-7 decrement from all zeros to all

ones.

The presence of the hardware watchdog deactivates the STOP instruction and a WAIT instruction

is automatically executed instead of a STOP. Bit 1

of the watchdog register (set to one at reset) can

be used to generate a software reset if cleared to

zero). Figure 1shows the watchdog block diagram

while Figure 2shows its working principle.

Figure 16. Hardware Activated Watchdog Block Diagram

RESET

S

Q

RSFF

R

-2

DB1.7 SETLOAD

7

-2

SET

8

-12

DB0

8

WRITE

DATA BUS

OSCILLATOR

CLOCK

RESET

VA00010

21/64

Page 22

ST6373

HARDWARE ACTIVATED DIGITAL WATCHDOG FUNCTION (Cont’d)

Hardware Activated Watchdog Register

(HWDR)

Address: D8h - Read/Write

Reset Value: 0FEh

70

Figure 17. Hardware Activated Watchdog

Working Principle

D0

BIT7

T1 T2 T3 T4 T5 T6 SR C

T1-T6. These are the watchdog counter bits. It

should be noted that D7 (T1) is the LSB of the

counter and D2 (T6) is the MSB of the counter,

these bits are in the opposite order to normal.

SR. This bit is set to one during the reset phase

and will generate a software reset if cleared to zero.

C. This is the watchdog activation bit that is hardware set. The watchdog function is always activated independently of changes of value of this bit.

The register reset value is FEh (Bit 1-7 set to one,

Bit 0 cleared).

D1

D2

D3

D4

D5

D6

D7

BIT6

BIT5

BIT4

BIT3

BIT2

WATCHDOG CONTROL REGISTER

BIT1

BIT0

8-BIT

DOWN COUNTER

RESET

OSC-12

VA00190

22/64

Page 23

3.4 INTERRUPT

ST6373

The MCU Core can manage 4 different maskable

interrupt sources, plus one non-maskable interrupt

source (top priority level interrupt). Each source is

associated with a particular interrupt vector that

contains a Jump instruction tothe related interrupt

service routine. Each vector is located in the Program Space at a particular address (see Table 7).

When a source provides an interrupt request, and

the request processing is also enabled by the

MCU Core, then the PC register is loaded with the

address of the interrupt vector (i.e. of theJump instruction). Finally, the PC executes the Jump instruction and the interrupt routine is processed.

The relationship between vector and source and

the associated priority is hardware fixed for

ST6373 devices. For some interrupt sources it is

also possible to select by software the kind of

event that will generate the interrupt.

All interrupts can bedisabled by writing tothe GEN

bit (global interrupt enable) of the interrupt option

register (address C8h). Following a reset, the

ST6373 is in non maskable interrupt mode, so no

interrupts will be accepted and NMI flags will be

used, until a RETI instruction is executed. If aninterrupt is executed, one special cycle is made by

the core, during that the PC is set to the related interrupt vector address. A jump instruction at this

address has to redirect program execution to the

beginning of the related interrupt routine. The interrupt detecting cycle, also resets the related interrupt flag (not available to the user), so that another interrupt can be stored for this current vector,

while its driver is under execution.

If additional interrupts arrive from the same

source, they will be lost. NMI can interrupt other interrupt routines at any time, while other interrupts

cannot interrupt each other. If more than one interrupt is waiting for service, they are executed according to their priority. The lower the number, the

higher the priority. Priority is, therefore, fixed. Interrupts are checked during the last cycle of an in-

struction (RETI included). Level sensitive interrupts have to be valid during this period.

Table 7 details the different interrupt vectors/sources relationships.

3.4.1 Interrupt Vectors/Sources

The MCU Core includes 5 different interrupt vectors in order to branch to 5 different interrupt routines. The interrupt vectors are located in the fixed

(or static) page of the Program Space.

Table 7. Interrupt Vectors/Sources

Relationships

Interrupt Source

NMI pin

Timer 3

I/O Port A, I/O Port B

Timer 2

ADC

I2C

SPI

VSYNC,

Timer 1

DDC SPI

PWRIN

Associated

Vector

Interrupt

Vector # 0 (NMI)

Interrupt

Vector # 1

Interrupt

Vector #2

Interrupt

Vector #3

Interrupt

Vector #4

Vector

Address

0FFCh-0FFDh

0FF6h-0FF7h

0FF4h-0FF5h

0FF2h-0FF3h

0FF0h-0FF1h

The interrupt vector associated with the nonmaskable interrupt source is named interrupt vector #0. Itis located at the (FFCh, FFDh) addresses

in the Program Space. This vector is associated

with the NMI pin.

The interrupt vectors located at addresses

(FF6h,FF7h), (FF4h,FF5h), (FF2h,FF3h),

(FF0h,FF1h) are named interrupt vectors #1, #2,

#3 and #4 respectively. These vectors are associated with TIMER 3, Port A and Port B interrupts

(#1), Timer 2, VSYNC and I2C SPI (#2), TIMER 1

and the DDC SPI (#3) and the ADC and PC4

(PWRIN) (#4).

23/64

Page 24

ST6373

INTERRUPTS(Cont’d)

3.4.2 Interrupt Priority

The non-maskable interrupt request has the highest priority and can interrupt any other interrupt

routines at any time, nevertheless the other interrupts cannot interrupt each other. If more than one

interrupt request is pending, they are processed

by the MCU Core according to their priority level:

vector #1 has the higher priority while vector #4

the lower. The priority of each interrupt source is

hardware fixed.

3.4.3 Interrupt Option Register

The Interrupt Option Register (IOR register, location C8h) is used to enable/disable the individual

interrupt sources and to select the operating mode

of the external interrupt inputs. This register is addressed in the Data Space as a RAM location at

address C8h, nevertheless it is write-only register

that can not be accessed with single-bit operations. The operating modes of the external interrupt inputs associated to interrupt vectors #1 and

#2 are selected through bits 4 and 5 of the IOR

register.

Interrupt Option Register (IOR)

Address: (C8h) - Write only

Reset Value: XX00XXXXb

70

-

EL1 ES2 GEN ----

D7

. Not used.

EL1. This is the Edge/Level selection bit of interrupt #1. When set to one, the interrupt is generated on low level of the related signal; when cleared

to zero, the interrupt is generated on falling edge.

The bit is cleared tozero after reset.

ES2

. This is the edge selection bit on interrupt #2.

This bit is used in ST6373 devices for VSYNC detection, the interrupt for Timer 2 and the I2CSPI.It

is cleared to zero on reset (falling edge), and must

be maintained at 0 ifthe Timer 2 and I2C interrupts

are to be used. The VSYNC interrupt may be configured to act on the falling edge (ES2=0) or rising

edge (ES2=1) according to the system design.

GEN

. This is the global enable bit. When set to

one all interrupts are globally enabled; when this

bit is cleared to zeroall interrupts are disabled (excluding NMI) independently to the individual interrupt enable bitof each peripheral.

D3 - D0

. These bits are not used.

NMI/PWR/VSync Interrupt Register (NPVIR)

70

D7 D6 D5 D4 D3 D2 D1 D0

b7: VSYNCST: (Read & Write, 0 written on Reset)

VSYNCEN

b6:

: (Read & Write, 0 written on Reset)

b5:PWRFLAG:(Read&Write,UndefinedonReset)

b4: PWINTEN: (Write Only, 0 written on Reset)

PWREDGE

b3:

: (Write Only, 0 written on Reset)

b2:NMIFLAG:(Read &Write,UndefinedonReset)

b1: NMINTEN: (Write Only, 0 written on Reset)

b0: NMIEDGE: (Write Only, 0 written onReset)

Note thatNObit operation instructionsare possible.

The input latch is activatedoneither the positive or

negative edge of the NMI (respectively PWRIN)

signal: if NMIEDGE (resp. PWREDGE) is high the

latch will be triggered onthe rising edge of the signal at NMI (resp. PWRIN); if thisbit is low the latch

will be triggered on the falling edge.

An interrupt can be generated if it is enabled: if

NMINTEN (resp. PWINTEN) is high, then the output of the latch may generate an interrupt on vector #0 (resp. vector #4); if this bit is low the interrupt is disabled.

The status of the latch is read with NMIFLAG (resp. PWRFLAG): if NMIFLAG (resp. PWRFLAG) is

high, a signal has been latched. The latch can be

reset by setting NMIFLAG (resp. PWRFLAG).

The VSYNC input is linked to the interrupt vector#

2 through a latch.

If 1 is written in VSYNCST the latch will be triggered on the rising edge of the signal at VSYNC, if

VSYNCST is low the latch will be triggered on the

falling edge (0 written on Reset).

An interrupt can be generated only if VSYNCEN is

at 1. Writing a 1 in VSYNCEN will also reset the

latch (0 written on Reset).

The status of the latch is read through the bit

VSYNCEN; reading a 1 means that a signal has

been latched.

The status of the VSYNC pin is read with the

VSYNCST bit.

24/64

Page 25

INTERRUPTS(Cont’d)

3.4.4 Interrupt Procedure

The interrupt procedure is very similar toa call procedure; the user can consider the interrupt as an

asynchronous call procedure. As this is an asynchronous event the user does not know about the

context and the time at which it occurred. As a result the user should save all the data space registers which will be used inside the interrupt routines. There are separate sets of processor flags

for normal, interrupt and non-maskable interrupt

modes which are automatically switched and so

these do not need to be saved.

The following list summarizes the interrupt procedure (refer also to Figure 20. Interrupt Processing

Flow Chart):

– Interrupt detection

– The flags C and Z of the main routine are ex-

changed with the flags C and Z of the interrupt

routine (resp. the NMI flags)

– The value of the PC is stored in the first level of

the stack - The normal interrupt lines are inhibit-

ed (NMI still active)

– The edge flip-flop is reset

– The related interrupt vector is loaded in the PC.

– User selected registers are saved inside the in-

terrupt service routine (normally on a software

stack)

– The source of the interrupt is found by polling (if

more than one source is associated to the same

vector)

– Interrupt servicing

– Return from interrupt (RETI)

– Automatically the MCU Core switches back to

the normal flags (resp. the interrupt flags) and

pops the previous PC value from the stack

The interrupt routine begins usually by the identifi-

cation of the device that has generated the interrupt request. The user should save the registers

which are used inside the interrupt routine (that

holds relevant data) into asoftware stack.

After the RETI instruction execution, the Core carries out the previous actions and the main routine

can continue.

ST6373

Figure 18. Interrupt Processing Flow-Chart

INSTRUCTION

FETCH

INSTRUCTION

EXECUTE

INSTRUCTION

WAS

THE INSTRUCTION

A RETI

YES

YES

NO

?

NO

CLEAR

INTERRUPT MASK

SELECT

PROGRAM FLAGS

” POP ”

THE STACKED PC

?

YES

3.4.5 ST6373 Interrupt Details

Interrupt #0. The NMI Interrupt is connected to the

first interrupt #0 (NMI, Pin 27). If the NMIinterrupt

is disabled at the latch circuitry, then it willbe high.

The #0 interrupt input detects a high to low level.

Note that once #0 has been latched, then the only

way to remove the latched #0 signal is to service

the interrupt. #0 can interrupt the other interrupts.

NO

IS THE CORE

ALREADY IN

NORMAL MODE ?

INTERNAL MODE FLAG

CHECK IF THERE IS

AN INTERRUPT REQUEST

AND INTERRUPT MASK

LOAD PC FROM

INTERRUPT VECTOR

( FFC / FFD )

SET

INTERRUPT MASK

PUSH THE

PC INTO THE STACK

SELECT

VA000014

25/64

Page 26

ST6373

INTERRUPTS(Cont’d)

Interrupt #1. The TIMER 3 Interrupt and the Port

A and B interrupts are connected by a logical AND

function to interrupt #1 (0FF6h). The TIMER 3 interrupt generates a low level (which is latched in

the timer) requiring that the Interrupt 1 Edge/Level

bit is set to 1. The I/O Port A and B interrupts may

be set to generate an interrupt on the falling edge

or low level state of the input (EL1 = 1 or EL1 = 0

respectively) according to the external connections.Note that if a low level is maintained on an

I/O bit configured as acting on a Low Level after

the interrupt is generated, the MCU will return to

the interrupt state after exiting the RETI instruction

from the first interrupt service.

Interrupt #2.The VSYNC, Timer 2 and I2C SPI In-

terrupt areconnected by a logical AND function to

interrupt #2. Bit 5 of the interrupt option register

C8h is used to select the negative edge (ES2=0)

or the positive edge (ES2=1) to trigger the interrupt #2.For the correct operation of the Timer 2

and I2C SPI interrupts, the falling edge should be

selected (ES2 = 0).For theVSYNC interrupt, either

edge can be selected, depending on the operation

required. For example if the rising edge on VSYNC

is the trigger, and after receiving the interrupt

edge, the VSYNC trigger level is switched to the

falling edge, the time between the risingand falling

edge (e.g. the display time)to be determined. The

VSYNC interrupt is controlled in Register NPVIR

at address EDh.

Note that once an edge has beenlatched, then the

only way to remove the latched signalis to service

the interrupt. Care must be taken not to generate

spurious interrupts. For example, changing the

edge selection bit from falling edge to rising edge

when the VSYNC input is high (or disabled in NP-

VIR) will cause a spurious interrupt.(see Interrupt

Circuit Diagram)

Interrupt #3

. The TIMER 1 and DDCSPI Interrupt

are connected by a logical AND function to interrupt #3. This interrupt is triggered ondetection of a

low level latched in the timer and DDC SPI.

Interrupt #4

. The PWRIN and Analog to Digital

Converter Interrupts are connected by a Logical

AND to interrupt #4 (0FF0h). The PWRINinterrupt

is controlled through the NPVIR Register at address EDh, and the Phase Unlock interrupt is controlled through SPCR at address DFh. The #4 interrupt input detects a low level. A simple latch is

provided from the PC4 (PWRIN) pin in order to

generate the PWRINT signal. This latch can be

triggered by either the positive or negative edge of

the PWRIN signal (bit 3, PWREDGE, of register

NPVIR EDh). The latch isreset by software.

Notes

:

Global disable does not reset edge sensitive interrupt flags.These edge sensitive interrupts become

pending again when global disabling is released.

Moreover, edge sensitive interrupts are stored in

the related flags also when interrupts are globally

disabled, unless each edge sensitive interrupt is

also individually disabled before the interrupting

event happens. Global disable is done by clearing

the GEN bit of Interrupt option register, while any

individual disable is done in the control register of

the peripheral. The on-chip Timer peripherals

have an interrupt request flag bit (TMZ), this bit is

set to one when the device wants to generate an

interrupt request and a mask bit (ETI) that must be

set to one to allow the transfer of the flag bit to the

Core.

26/64

Page 27

INTERRUPTS(Cont’d)

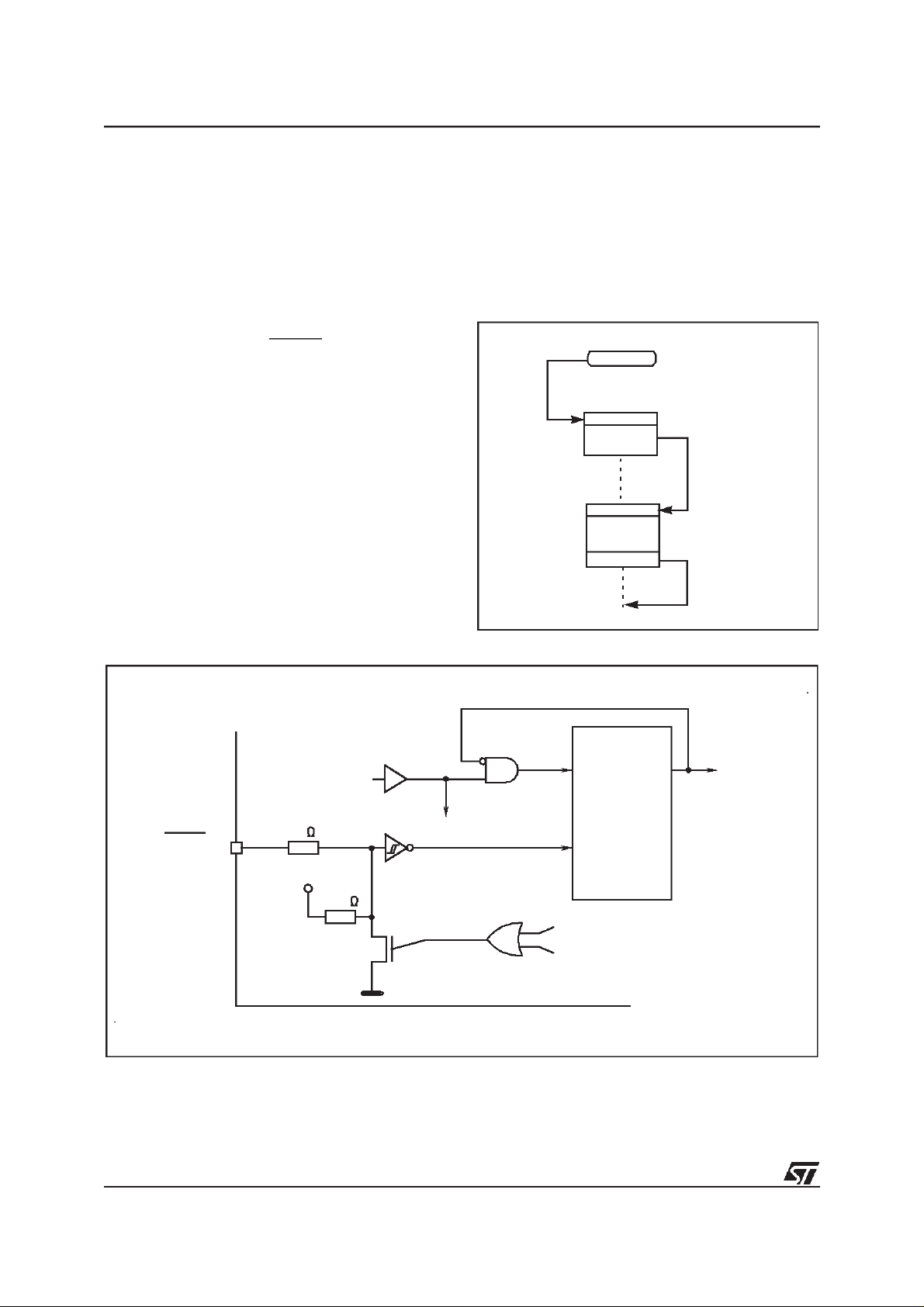

Figure 19. Interrupt Circuit Diagram

START FROM

RE

ST6373

IT

VA0426Q

STOP/WA

(FF2,3)

INT #3

Start

2

I

IORREG.C8H,bit5

FF

INT #2 (FF4,5)

CLR

CLK Q

INT #1 (FF6,7)

INT #0 - NMI (FFC,D)

Start

0

I

FF

CLR

CLK Q

FF

NPVIR Bit 2

CLR

CLK Q

NPVIR Bit 0

NPVIR BIT 1

FF

0

QCLK

CLR

1

MUX

IORREG.C8H,bit6

Start

1

I

INT #4 (FF0,1)

h, bit 4 : GEN

IOR REGC

ADC

ADCR Bit 7SLACR Bit 1

NPVIR Bit 4

QCLK

NPVIR Bit 5

FF

CLR

V

DD

DD

V

2

I C SPI

PBE

SINGLE BIT ENABLE

FROM REGISTER PORT A,B

NMI

PBEPBE

A,B

PORT

TIMER 3

TSCR3 Bit 6

DD

V

Bits

TIMER 2

NPVIR Bit 6

SYNC

V

SCR1 Bit 5

TSCR2 Bit 6

PI

TIMER 1

DDC S

SCR1 Bit 5

TSCR1 Bit 6

DD

V

NPVIR Bit 3

PC4/PWRIN

27/64

Page 28

ST6373

3.5 POWER SAVING MODES

STOP and WAIT modes have been implemented

in the ST638x in order to reduce the current consumption of the device during idle periods. These

two modes are described in the following paragraphs. Since the hardware activated digital

watchdog function is present, the STOP instruction is de-activated and any attempt to execute it

will cause the automatic execution of a WAIT instruction.

3.5.1 WAIT Mode

The configuration of the MCU in the WAIT mode

occurs as soon as the WAIT instruction is executed. The microcontroller can also be considered as

being in a “software frozen” state where the Core

stops processing the instructions of the routine,

the contents of the RAM locations and peripheral

registers are saved as long as the power supply

voltage is higher than the RAM retention voltage

but where the peripherals are still working. The

WAIT mode is used when the user wants to reduce the consumption of the MCU when it is in

idle, while not losing count of time or monitoring of

external events. The oscillator is not stopped in order to provide clock signal to the peripherals. The

timers counting may be enabled (writing the PSI

bit in TSCR1 register) and the timer interrupt may

be also enabled before entering the WAIT mode;

this allows the WAIT mode to be left when timer interrupt occurs. If the exit from the WAIT mode is

performed with a general RESET (either from the

activation of the external pin or by watchdog reset)

the MCU will enter a normal reset procedure as

described in the RESET chapter. If an interrupt is

generated during WAIT mode the MCU behaviour

depends on the state of the MCU Core before the

initialization ofthe WAIT sequence, but also of the

kind of the interrupt request that is generated. This

case will be described in the following paragraphs.

In any case, the MCU Core does not generate any

delay afterthe occurrence of the interrupt because

the oscillator clock is still available.

3.5.2 STOP Mode

Since the hardware activated watchdog is present

on the ST638x, the STOP instruction has been deactivated. Any attempt to execute a STOP instruction will cause a WAIT instruction to be executed

instead.

3.5.3 Exit from WAIT Mode

The following paragraphs describe the output procedure of the MCU Core from WAIT mode when