Datasheet ST63T87B1, ST63T85B1, ST63E87D1, ST6367B1, ST6367B Datasheet (SGS Thomson Microelectronics)

...Page 1

December 1997 1/84

This is preliminary information on a new product in development or undergoing evaluation. Details are subject to change without noti ce.

R

Rev. 2.2

ST6365, ST6375, ST 6385

ST6367, ST6377, ST 6387

8-BIT MCUs WITH

ON-SCREEN-DISPLAY FOR TV TUNING

■

4.5 to 6V supply operating range

■

8MHz Maximum Clock Frequency

■

User Program ROM: up to 20140 bytes

■

Reserved Test ROM: up to 340 bytes

■

Data ROM: user selectable size

■

Data RAM: 256 bytes

■

Data EEPROM: 384 bytes

■

42-Pin Shrink Dual in Line Plastic Package

■

Up to 22 software programmable general

purpose Inputs/Outpu ts, including 2 direct LED

driving Outputs

■

Two Timers each including an 8-bit counter with

a 7-bit programmable prescaler

■

Digital Watchdog Function

■

Serial Peripheral Interface (SPI) supporting SBUS/ I 2 C BUS and standard serial protocols

■

SPI for external frequency synthesis tuning

■

14 bit counter for voltage synthesis tuning

■

Up to Six 6-Bit PWM D/A Conve r ters

■

AFC A/D converter with 0.5V resolution

■

Five interrupt vectors (IRIN/NMI, Timer 1 & 2,

VSYNC, PWR INT.)

■

On-chip clock oscillator

■

5 Lines by 15 Characters On-Screen Display

Generator with 128 Characters

■

All ROM types are supported by pin-to-pin

EPROM and OTP versions.

■

The development tool of the ST6365, ST 6375,

ST6385, ST6367, ST6377, ST6387 micr ocontrollers consists of the ST638X-EMU2 emulation and development system to be connected

via a standard RS232 serial line to an MS-DOS

Personal Computer.

DEVICE SUMMARY

DEVICE

ROM

(Bytes)

D/A Converter

ST6365 8K 4

ST6367 8K 6

ST6375 14K 4

ST6377 14K 6

ST6385 20K 4

ST6387 20K 6

PSDIP42

(Refer to end of Document for Ordering Information)

1

Page 2

2/84

Table of Contents

84

1

ST6365, ST 6375, ST6385 , ST6367, ST6377, ST6387 . . . . . . . . 1

1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 MEMORY SPACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Stack Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Program Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 Data Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.4 Data RAM/EEPROM/OSD RAM Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 CLOCKS, RESET, INTERRUPTS AND POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . 18

3.1 ON-CHIP CLOCK OSCILLATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 RESETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.1 RESET Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.2 Power-on Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.3 Watchdog Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.4 Application Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.5 MCU Initialization Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 HARDWARE ACTIVATED DIGITAL WATCHDOG FUNCTION . . . . . . . . . . . . . . . . . . . . 21

3.4 INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.1 Interrupt Vectors/Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.2 Interrupt Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.3 Interrupt Option Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.4 Int errupt Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.5 ST 638x Interrupt Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5.1 W AIT M ode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5.2 ST OP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5.3 Ex it from WAIT M ode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.1 Details of I/O Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.2 I/O Pin Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.3 Input/Output Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.4 I/O Port Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 TIMERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.1 Timer Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.2 Timer Status Control Registers (TSCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.3 Timer Counter Registers (TCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.4 Timer Prescaler Registers (PSCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Page 3

3/84

Table of Contents

1

4.3 SERIAL PERIPHERAL INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.1 S-BUS /I

2

C BUS Protocol Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.2 S-BUS /I

2

C BUS Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3.3 Compatibility S-BUS/I

2

C BUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3.4 STD SPI Protocol (Shift Register) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.5 SPI Data/Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4 14-BIT VOLTAGE SYNTHESIS TUNING PERIPHERAL . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.1 Output Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.4.2 VS Tuning Cell Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5 6-BIT PWM D/A CONVERTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.6 AFC A/D COMPARATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.6.1 A/D Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.7 DEDICATED LATCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.8 ON-SCREEN DISPLAY (OSD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.8.1 Format Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5 SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.1 ST6 ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.1 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.2 RECOMMENDED OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.3 DC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 AC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.2 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.3 CUSTOMER EEPROM INITIAL CONTENTS: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.4 OSD TEST CHARACTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.5 ORDERING INFORMATION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page 4

4/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

ST63E85, T85, ST63E87, T87 . . . . . . . . . . . . . . . . . . . . . . . . . . 71

1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1.2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1.3 EPROM/OTP DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.4 POWER ON RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.5 EPROM ERASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.1 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.2 RECOMMENDED OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.3 DC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2.4 AC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.1 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2 CUSTOMER EEPROM INITIAL CONTENTS: FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.3 OSD TEST CHARACTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.4 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.5 ORDERING INFORMATION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Page 5

5/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST6365,67,75,77,85,87 microcontrollers are

members of the 8-bit HCMOS ST638x family, a

series of devices specially oriented to TV applications. Different ROM size and peripheral configurations are available to give the maximum application and cost flexibility. All ST638 x members are

based on a building block approach: a common

core is surrounded by a combination of on-chip peripherals (macrocells) available from a standard library. These peripherals are designed with the

same Core technology providing full compatibility

and short design time. Many of these macrocells

are specially dedicated to TV applications. The

macrocells of the ST638x family are: two Timer

peripherals each including an 8-bit counter with a

7-bit software programmable prescaler (Timer), a

digital hardware activated watchdog function (DHWD), a 14-bit voltage synthesis tuning pe ripheral,

a Serial Peripheral Interface (SPI), up to six 6-bit

PWM D/A converters, an AFC A/D converter with

0.5V resolution, an on-screen display (OSD) with

15 characters per line and 128 characters (in two

banks each of 64 characters). In addition the f ollowing memory resources are available: program

ROM (up to 20K), data RAM (256 bytes), EEPROM (384 bytes). Refer to pin configurations figures and to ST638x device summary (Table 1) for

the definition of ST638x family members and a

summary of differences among the different types.

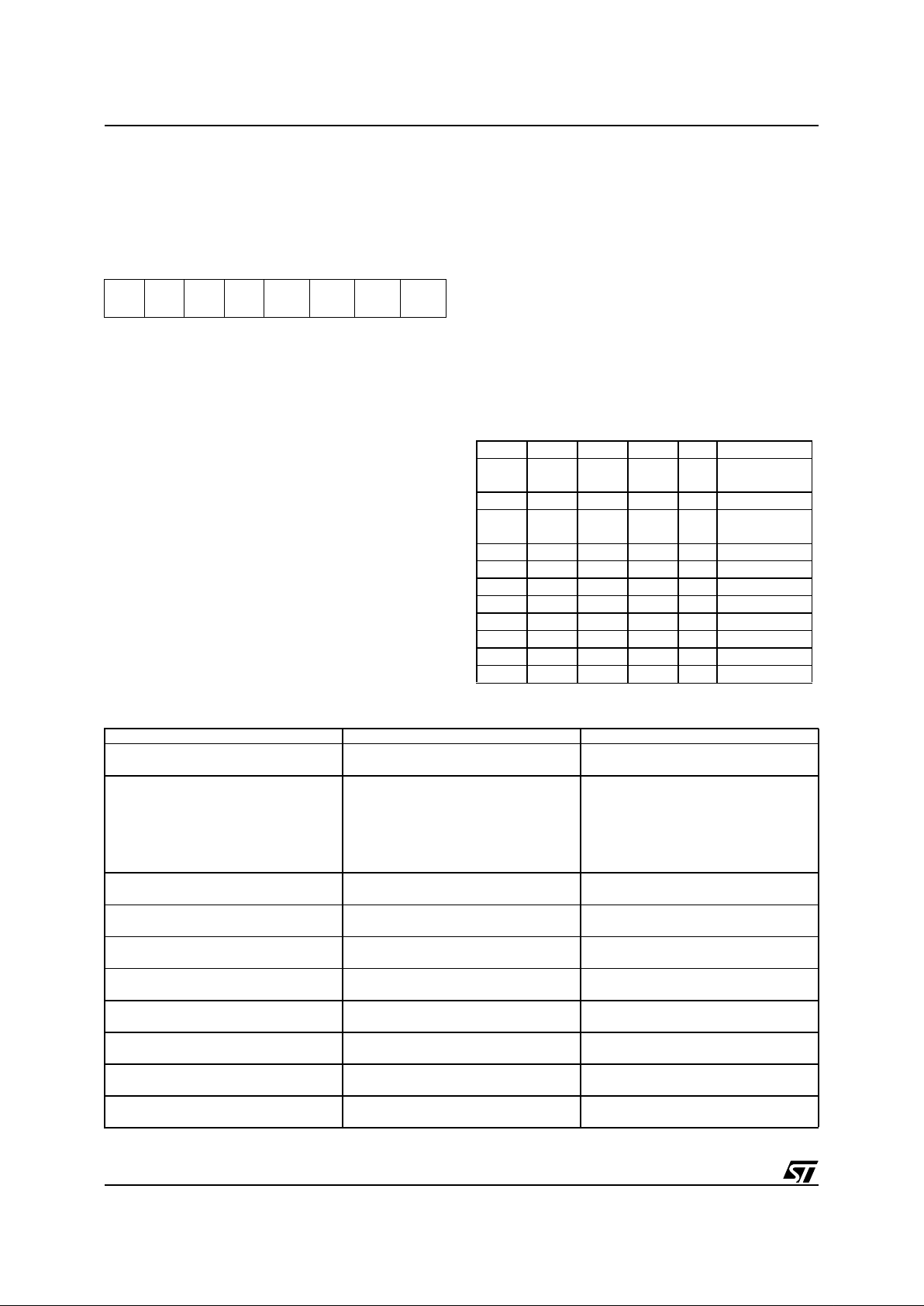

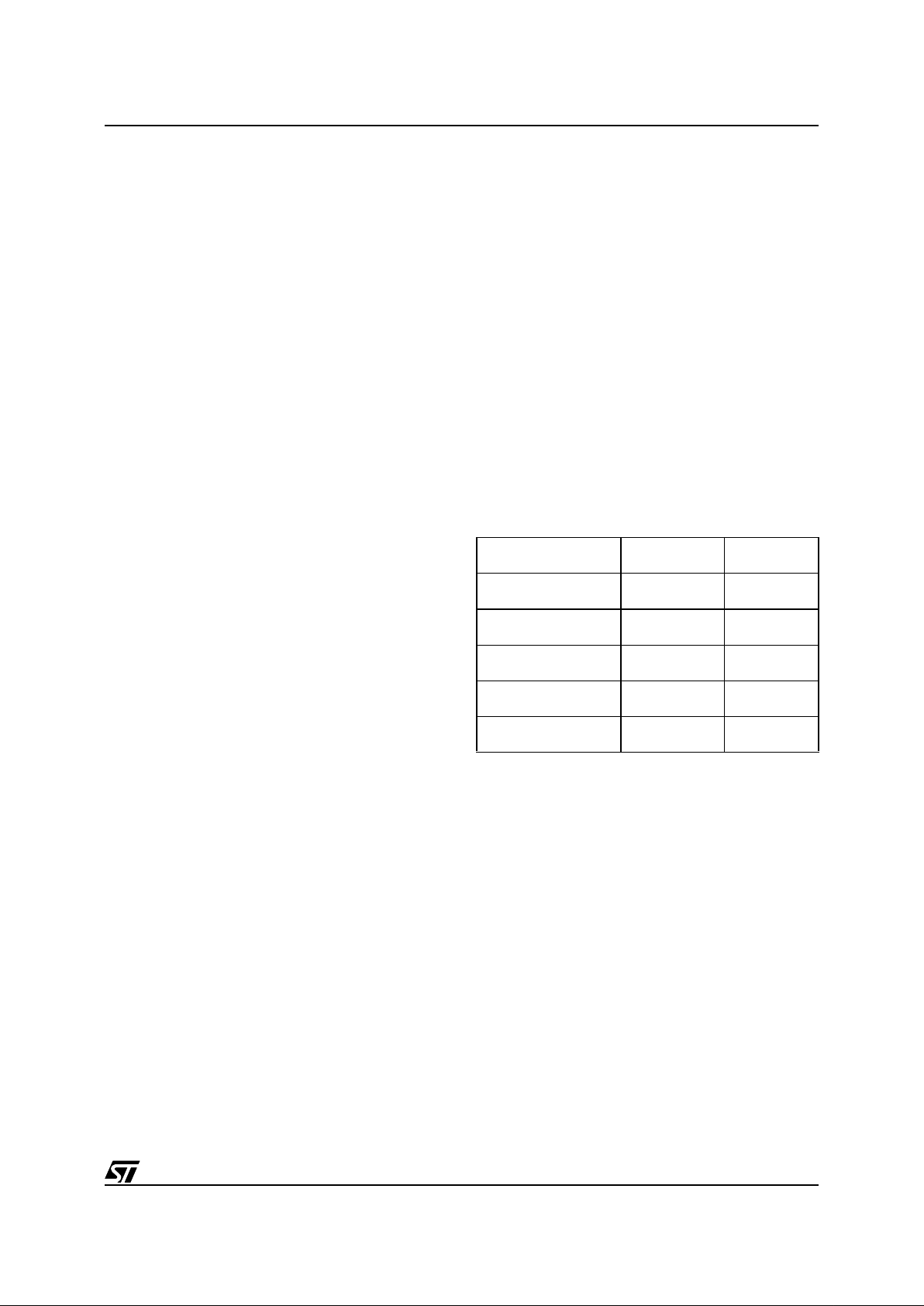

Table 1. Device Summary

Device

ROM

(Bytes)

RAM

(Bytes)

EEPROM

(Bytes)

AFC VS D/A

Colour

Pins

EPROM Devices

ST6365 8K 256 384 Yes Yes 4 3 ST63E85

ST6367 8K 256 384 Yes Yes 6 3 ST63E87

ST6375 14K 256 384 Yes Yes 4 3 ST63E85

ST6377 14K 256 384 Yes Yes 6 3 ST63E87

ST6385 20K 256 384 Yes Yes 4 3 ST63E85

ST6387 20K 256 384 Yes Yes 6 3 ST63E87

Page 6

6/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

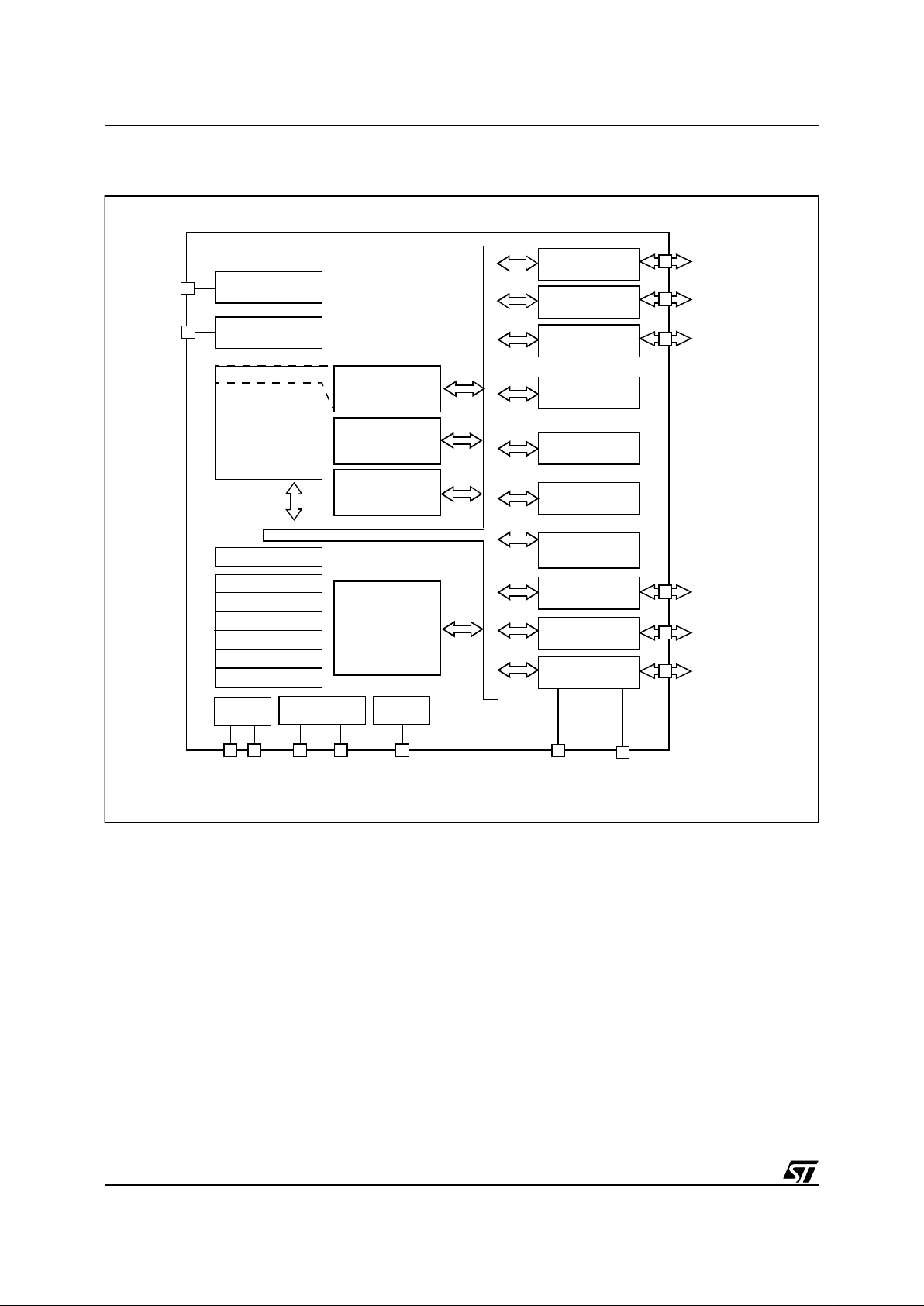

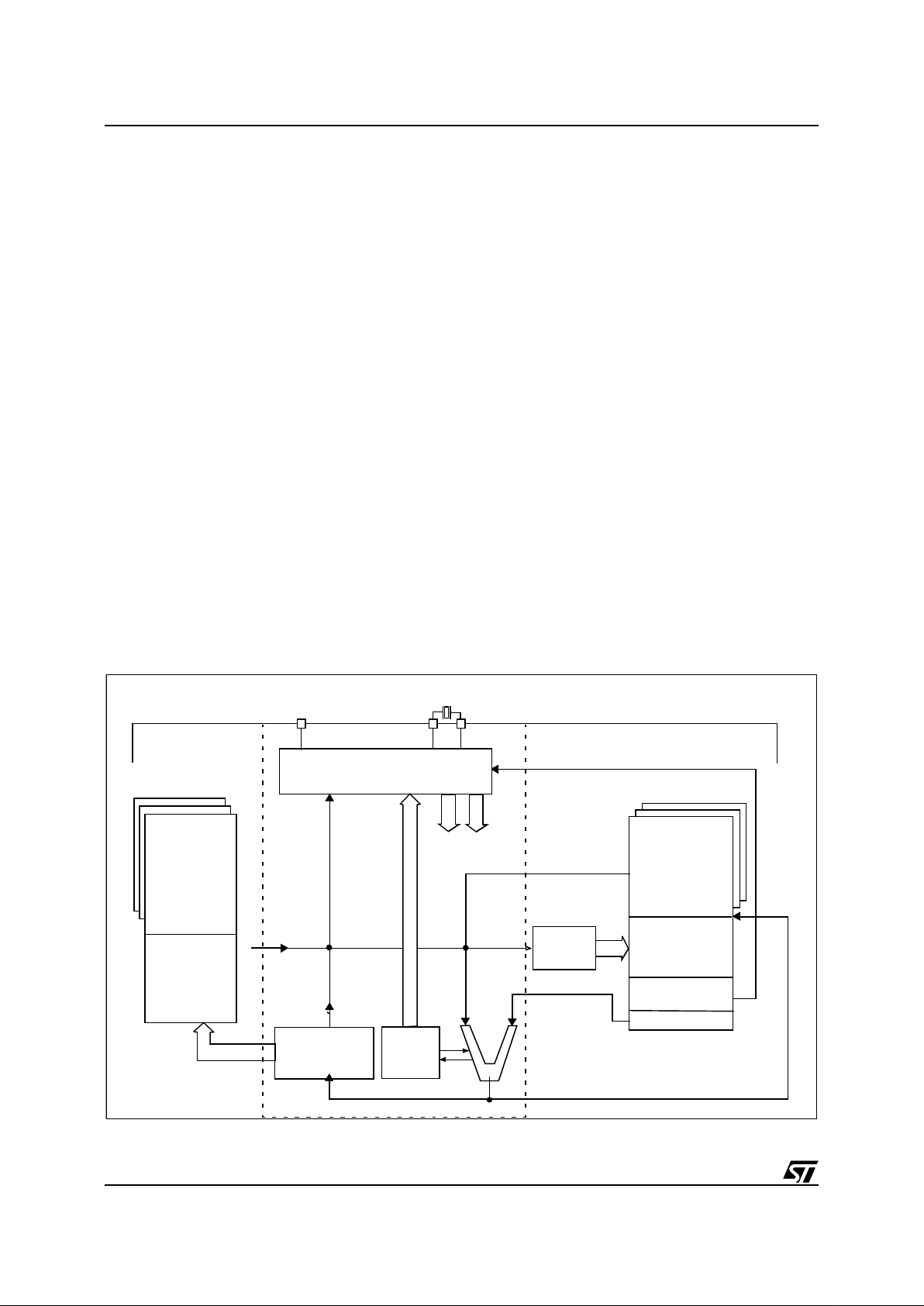

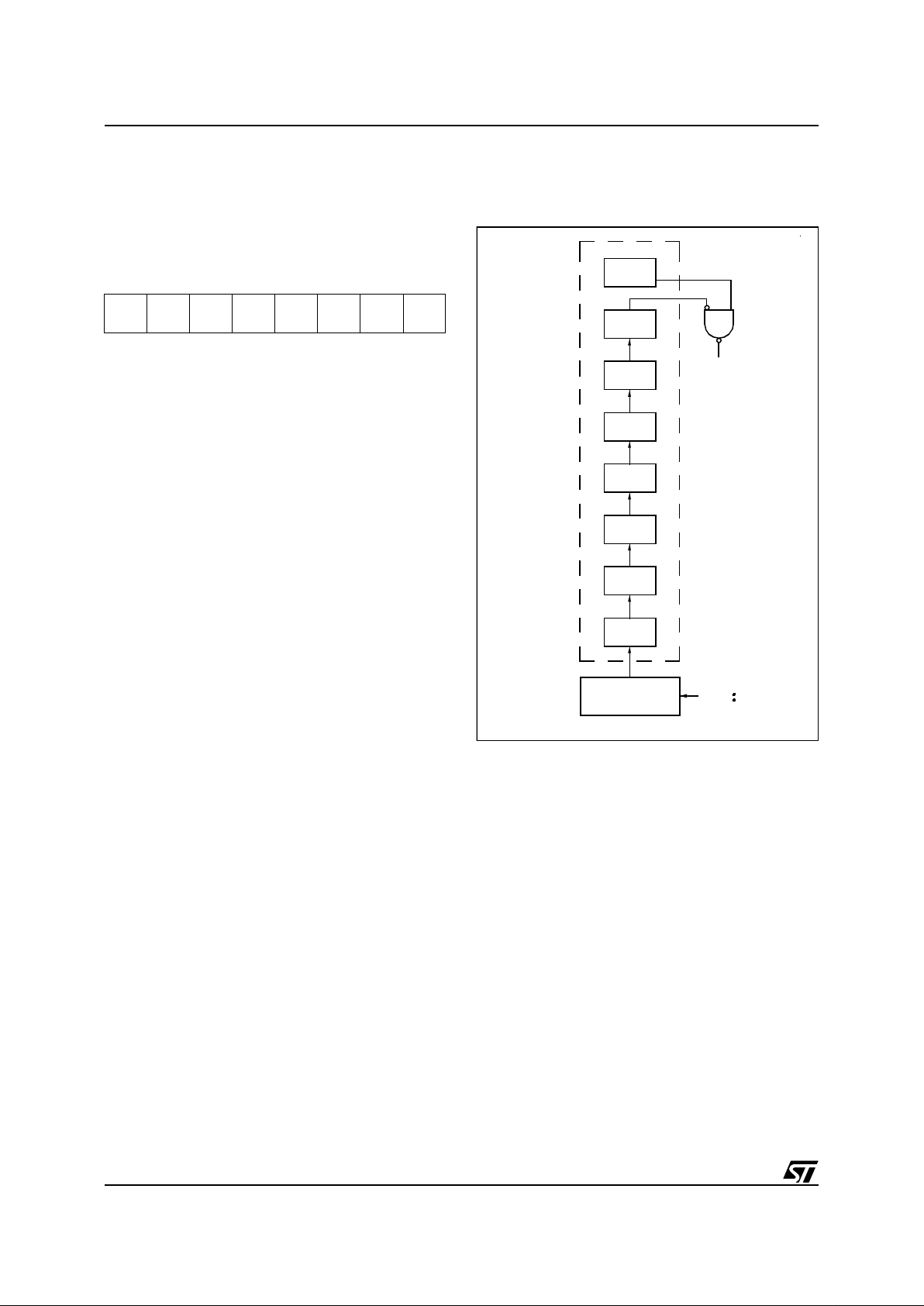

Figure 1. Bloc k D ia gram

TEST

IRIN/PC6

INTERRUPT

UP TO 20KBytes

PC

STACK LEVEL 1

STACK LEVEL 2

STACK LEVEL 3

STACK LEVEL 4

STACK LEVEL 5

STACK LEVEL 6

POWER

SUPPLY

OSCILLATOR

RESET

DATA RO M

USER

SELECTABLE

DATA RAM

256 Bytes

PORT A

PORT B

PORT C

8 BIT CORE

TEST

TIMER 1

PA0 - PA7*

VDDVSSOSCin OSCout RESET

USER PROGRAM

MEMORY

TIMER 2

Inputs

DATA EEPROM

384 Bytes

PC2, PC4 - PC7*

D/A Outputs

AFC & VS*

R, G, B, BLANK

VS Output &

On-Screen

Digital

Watchdog

DA0 - DA5

*Refer to Pin Description for Additional Information

Serial Pe ri pheral

PC0/SCL

PC1/SDA

PC3/SEN

Timer

AFC Outputs

Display

Interface

HSYNC, VSYNC

VR01753

OSDOSCout

OSDOSCin

PB0 - PB2, PB4 PB6*

Page 7

7/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

1.2 PIN DESCRIPTION

V

DD

and VSS.

Power is supplied to the MCU using

these two pins. V

DD

is power and VSS is the

ground connection.

OSCin, OSCout.

These pins are internally connected to the on-chip oscillator circuit. A quartz

crystal or a ceramic resonator can be connected

between these two pins in order to allow the correct operation of the MCU with various stability/

cost trade-offs. The OSCin pin is the input pin, the

OSCout pin is the output pin.

RESET

. The act ive low RESET pi n i s used to s tart

the microcontroller to the beginning of its program.

Additionally the quartz crystal oscillator will be disabled w h en the RESET

pin is low to reduce power

consumption during reset phase.

TEST

. The TEST pin m ust be h eld at V

SS

for nor-

mal operation.

PA0-PA7

. These 8 lines are organized as one I /O

port (A). Each line may be configured as either an

input with or without pull-up resistor or as an output under software control of the data direction

register. Pins PA4 to PA7 are configured as opendrain outputs (12V drive). On PA4-PA7 pins the input pull-up option is not available while PA6 and

PA7 have additional current driving capability

(25m A, V

OL

:1V). PA0 to PA3 pins are configured

as push-pull.

PB0-PB2, PB4-PB6

. These 6 lines are organized

as one I/O port (B). Each line may be conf igured

as either an input with or without internal pull-up

resistor or as an output under software control of

the data direction register.

PC0-PC7

. These 8 lines are organized as one I /O

port (C). Each line may be configured as either an

input with or without internal pull-up resi stor or as

an output under software control of the data direction register. Pins PC0 to PC3 are configured as

open-drain (5V drive) in output mode while PC4 to

PC7 are open-drain with 12 V drive and the input

pull-up options d oes not exist o n these four pins.

PC0, PC1 and PC3 lines when in output mode are

“ANDed” with the SPI control signals and are all

open-drain. PC0 is connected to the SPI clock signal (SCL), PC1 with the SPI data signal (SDA)

while PC3 is connected with SPI enable signal

(SEN, used in S-BUS protocol). Pin PC4 and PC6

can also be inputs to software programmable edge

sensitive latches which can generate interrupts;

PC4 can be connected to Power Interrupt while

PC6 can be connected to the IRIN/NMI interrupt

line.

DA0-DA5

. These pins are the six PWM D /A outputs of the 6-bit on-chip D/A converters. These

lines have open-drain outputs with 12V drive. The

output repetition rate is 31.25KHz (with 8MHz

clock).

AFC

. This is the input of the on-chip 10 levels

comparator that can be used to implement the

AFC function. This pin is an high imped ance input

able to withstand signals with a peak amplitude up

to 12V.

OSDOSCin, OSDOSCout

. These are the On

Screen Display oscillator termin als. An oscillation

capacitor and coil network have to be connected to

provide the right signal to the OSD.

HSYNC, VSYNC

. These are the horizontal and

vertical synchronization pins. The active polarity of

these pins to the OSD macrocel l can be selected

by the user as ROM mask option. If the device is

specified to have negative logic inputs, then these

signals are low the OSD oscillator stops. If the device is specified to have positive logic inputs, then

when these signals are high the OSD oscillator

stops. VSYNC is also connected to the VSYNC interrupt .

R, G, B, BLANK

. Outputs from the OSD. R, G and

B are the co lor outputs while BLA NK i s t he blanking output. All outputs are push-pull. The active

polarity of these pins can be selected by the user

as ROM mask option.

VS

. This is the output pin of the on-chip 14-bit voltage synthesis tuning cell (VS). The tuning sign al

present at this pin gives an approximate resolution

of 40KHz per step over the UHF band. This line is

a push-pull output with standard drive.

Page 8

8/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

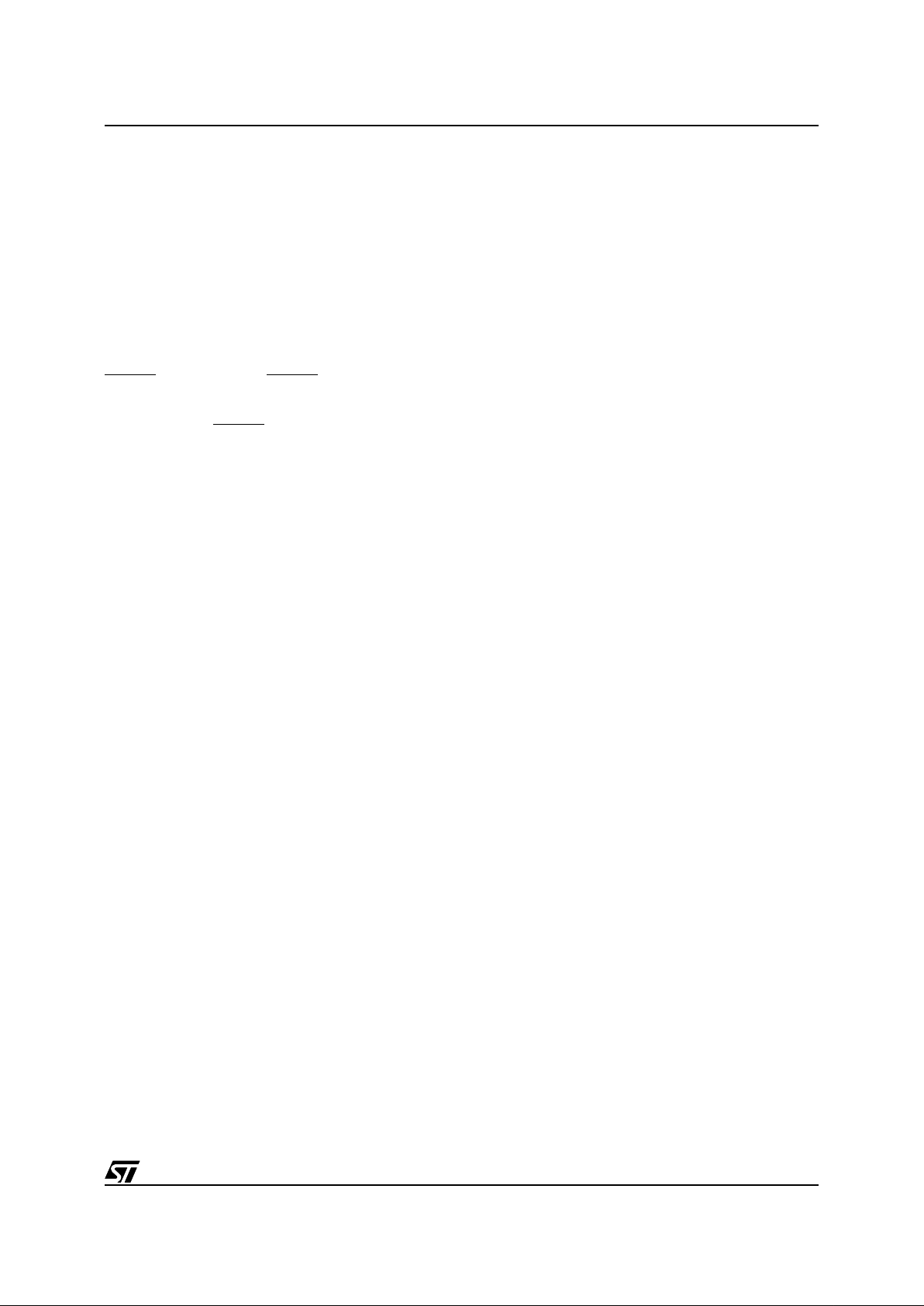

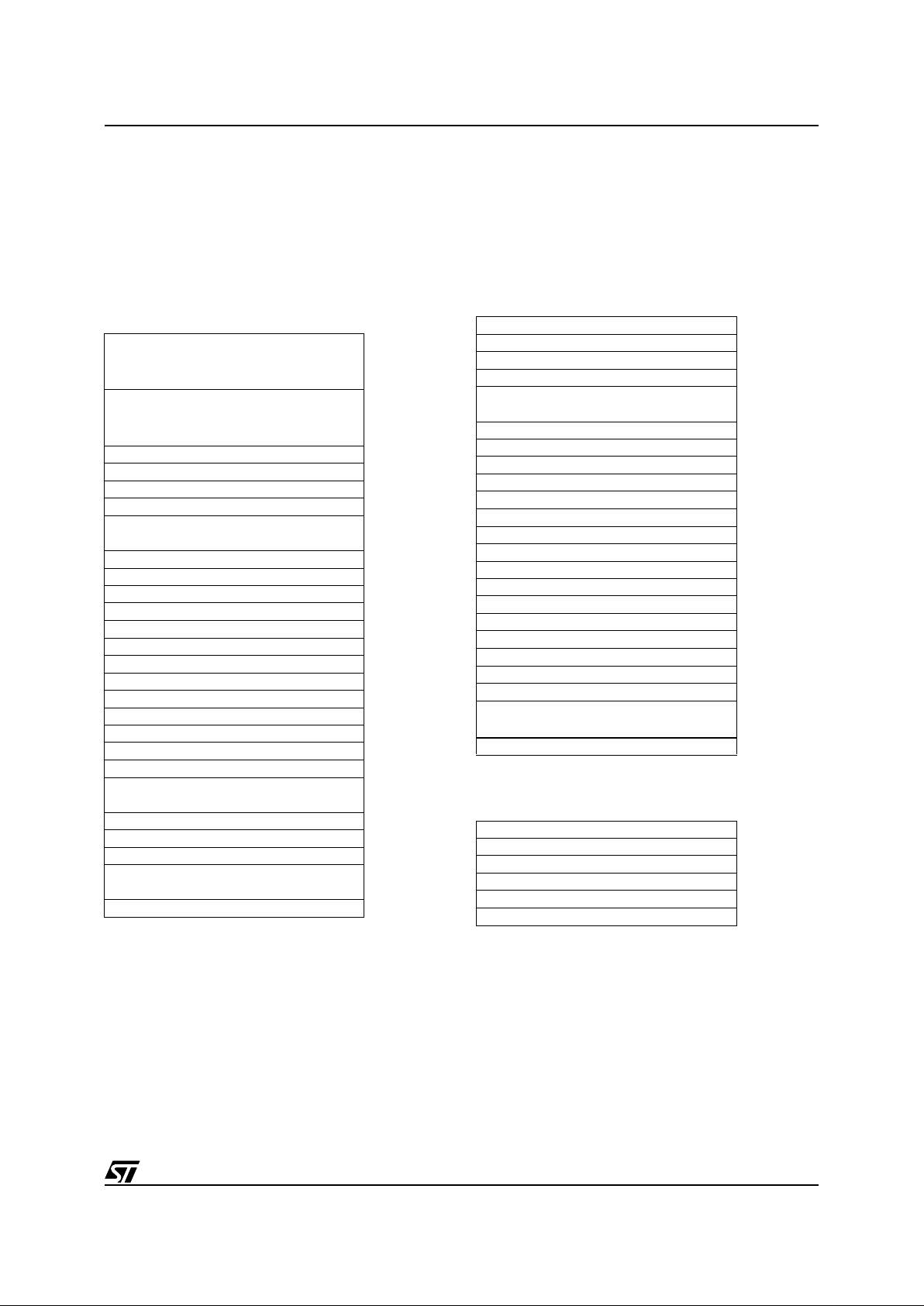

Figure 2. ST6365, 75, 85 Pin configuration Figure 3. ST6367, 77, 87 Pin configuration

Table 2. Pin Summary

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

VS

DA1

DA2

DA3

DA4

PB0

PB1

PB2

AFC

PB4

PB5

PB6

PA0

PA1

PA2

PA3

PA4

PA5

PA6 (HD0)

PA7 (HD1)

V

SS

V

DD

PC0/SCL

PC1/SDA

PC2

PC3/SEN

PC4/PWRIN

PC5

PC7

OSCin

OSCout

TEST/V

PP

(1)

VSYNC

BLANK

B

G

R

PC6/IRIN

(1) This pi n is al s o the VPP input for OTP/EPROM devices

RESET

HSYNC

OSDOSCin

OSDOSCout

VR01375

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

DA0

DA1

DA2

DA3

DA4

DA5

PB1

PB2

AFC

PB4

PB5

PB6

PA0

PA1

PA2

PA3

PA4

PA5

PA6 (HD0)

PA7 (HD1)

V

SS

V

DD

PC0/SCL

PC1/SDA

PC2

PC3/SEN

PC4/PWRIN

PC5

VS

OSCin

OSCout

TEST/V

PP

(1)

VSYNC

BLANK

B

G

R

PC6/IRIN

(1) This pin is also the VPP input for OTP/EPROM devices

RESET

HSYNC

OSDOSCin

OSDOSCout

VR01375E

Pin Function Description

DA0 to DA5 Output, Open- Drain, 12V

AFC Input, High Impedance, 12V

VS Output, Push- Pull

R, G, B, BLANK Output, Push- Pull

HSYNC, VSYNC Input, Pull- up, Schmitt Trigger

OSDOSCin Input, High Impedance

OSDOSCout Output, Push- Pull

TEST Input, Pull- Down

OSCin Input, Resistive Bias, Schmitt Trigger to Reset Logic Only

OSCout Output, Push- Pull

RESET Input, Pull- up, Schmitt Trigger Input

PA0- PA3 I/ O, Push- Pull, Software Input Pull- up, Schmitt Trigger Input

PA4- PA5 I/ O, Open- Drain, 12V, No Input Pull- up, Schmitt Trigger Input

PA6- PA7 I/ O, Open- Drain, 12V, No Input Pull- up, Schmitt Trigger Input, High Drive

PB0- PB2 I/ O, Push- Pull, Software Input Pull- up, Schmitt Trigger Input

PB4- PB6 I/ O, Push- Pull, Software Input Pull- up, Schmitt Trigger Input

PC0- PC3 I/ O, Open- Drain, 5V, Software Input Pull- up, Schmitt Trigger Input

PC4- PC7 I/ O, Open- Drain, 12V, No Input Pull- up, Schmitt Trigger Input

V

DD

,

V

SS

Power Supply Pins

Page 9

9/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

1.3 MEMORY SPACES

The MCU operates in three different memory

spaces: Stack Space, Program Space and Data

Space .

1.3.1 Stack Space

The stack space consists of six 12 bit registers that

are used for stacking subroutine and interrupt return addresses plus the current program counter

regi ster.

1.3.2 Program Space

The program space is physically implemented in

the ROM and includes all the instructions that are

to be executed, as well as the data required for the

immediate addressing mode instructions, the reserved test area and the user vectors. It is addressed thanks to the 12-bit Program Counter register (PC register) and the ST6 Core can directly

address up to 4K bytes of Program Space. Nevertheless, the Program Space can be extende d by

the addition of 2Kbyte memory banks as it is

shown in Figure 4, in which the 20K bytes memory

is described. These banks are addressed by pointing to the 000h-7FFh locations of the Program

Space thanks to the Program Counter, and by writing the appropriate code in the Program ROM

Page Register (PRPR) located at address CAh in

the Data Space. Because interrupts a nd common

subroutines should be available all the time only

the lower 2K byte of the 4K program space are

bank switched while the upper 2K byte can be

seen as static space. Table 3 gives the dif ferent

codes that allows the selection of the c orresponding banks. Note that, from the memory point of

view, the Page 1 and the Static Page represent

the same physical memory: it is only a different

way of addressing the same location. On the

ST6385 and ST6387, a total of 20480 bytes of

ROM have been implemented; 20140 bytes are

available as User ROM while 340 bytes are reserved for testing.

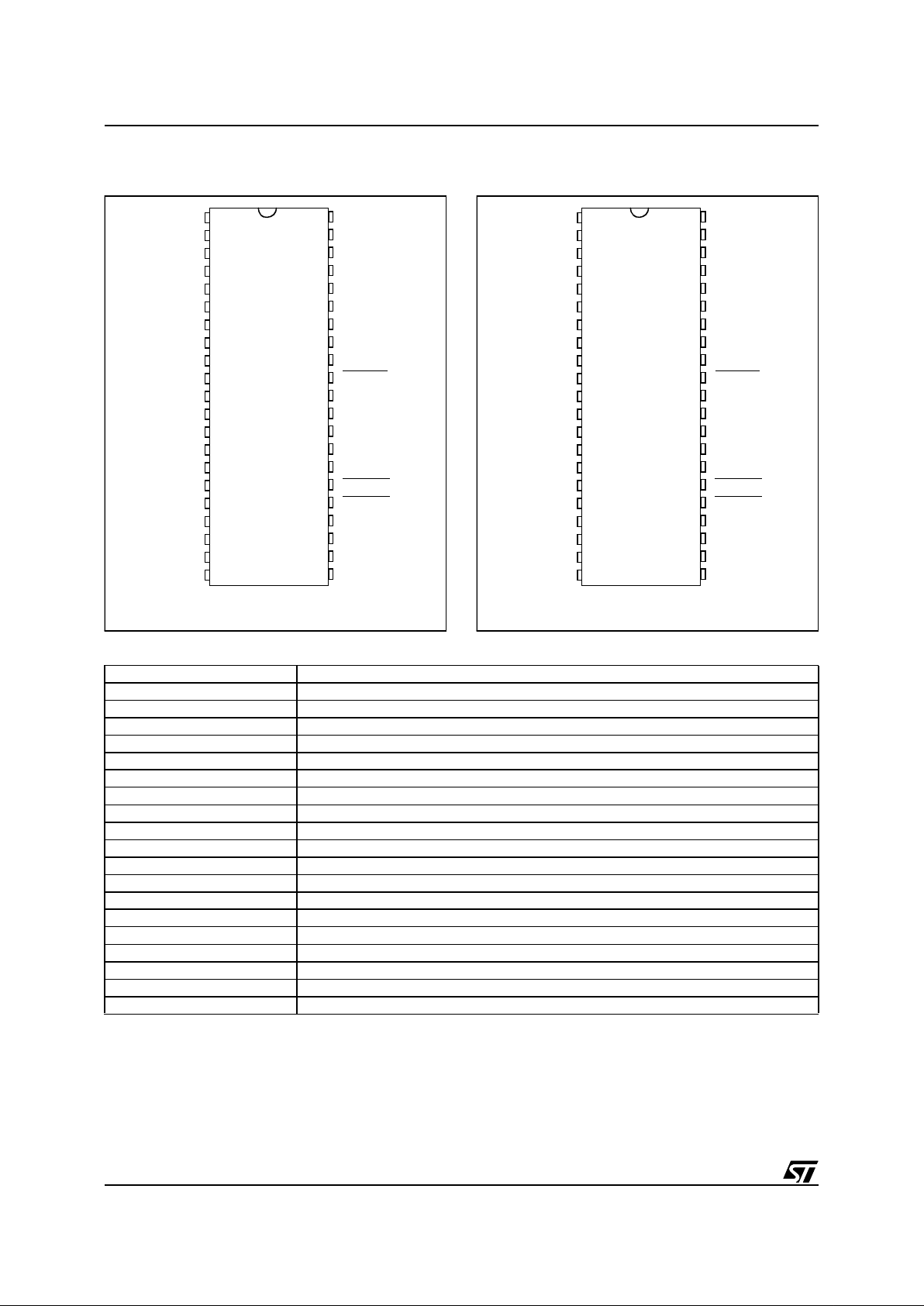

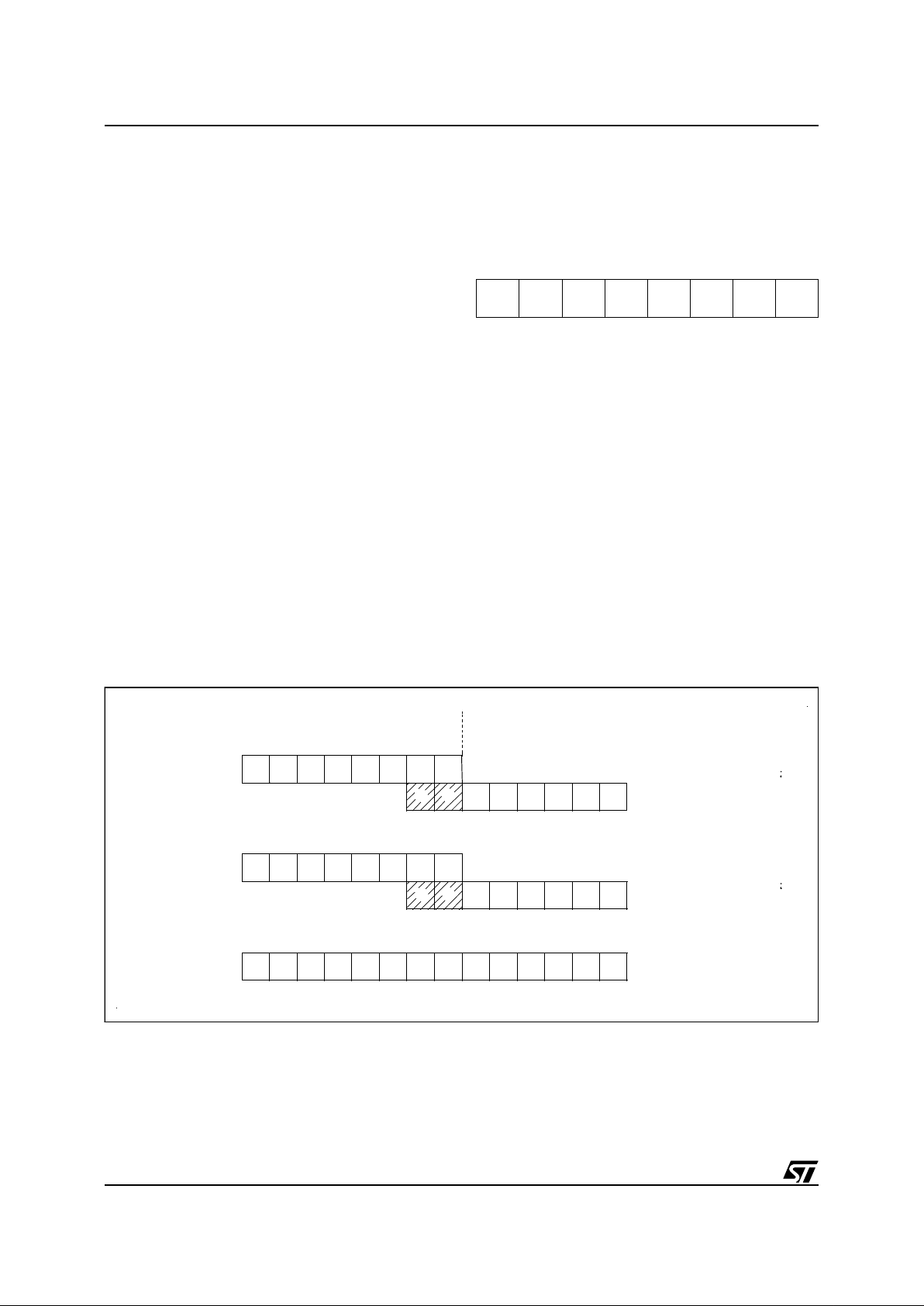

Figure 4. 20K-Byte Program Space Addressing

Figure 5. Me m ory A ddressin g D iag ram

Program

counter

space

0FFFh

0800h

07FFh

0000h

0000h

Static

Page

Page 1

Page 0

4FFFh

Page 1

Page 9

Static Page

...

PROGRAM SPACE

ROM

INTERR UPT &

RESET VECTORS

ACCUMULATOR

DATA RAM

BANK SELECT

DATA ROM

WINDOW SELECT

RAM

X REGISTER

Y REGISTER

V REGISTER

W REGISTER

DATA ROM

WINDOW

RAM / EEPROM

BANKING AREA

000h

03Fh

040h

07Fh

080h

081h

082h

083h

084h

0C0h

0FFh

0-63

DATA SPACE

0000h

0FF0h

0FFFh

PROGRA M COUNTER

STACK LEVEL 1

STACK LEVEL 2

STACK LEVEL 3

STACK LEVEL 4

STACK LEVEL 5

STACK LEVEL 6

vr01568

STACK SPACE

ROM

07FFh

0800h

Page 10

10/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

MEMORY SPACES

(Cont’d)

Program ROM Page Register (PRPR)

Address: CAh - Write only

Reset Value: XXh

D7-D4

. These bits are not used but have to be

written to “0”.

PRPR3-PRPR0.

These are the program ROM

banking bits and the valu e load ed select s th e corresponding page to be addressed in the lower part

of 4K program address space as specified in Table

3. This register is undefined on reset.

Caution

:

This register contains at least one write

only bit. Single bit instructions (SET, RES, INC

and DEC) should not be used.

Note.

Only the lower pa rt of address space has

been bankswitched because int errupt v ectors and

common subroutines should be available all the

time. The reason of this structure is due to the fact

that it is not possible to jump from a dynamic page

to another, unless jumping back to the static page,

changing contents of PRPR and then jumping to a

different dynamic page.

Care is required when handling the PRPR as it is

write only. For this reason, it is not allowed to

change the PRPR contents while ex ecuting interrupts drivers, as the driver cannot save and than

restore its previous c ontent. Anyway, this operation may be necess ary i f the sum of com mon routines and interrupt drivers will take more than 2K

bytes; in this case it could be necessary to divide

the interrupt driver in a (minor) part in the static

page (start and end), and in the second (major)

part in one dynamic page. If it is impossible to

avoid the writing of this register in interrupts drivers, an image of this register must be saved in a

RAM location. Each time the program writes the

PRPR register, the image register s hould also be

written. The image register must be written first, so

if an interrupt occurs between the t wo i ns tructions

the PRPR is not affected.

Table 3. Prog ram Memor y Page Re gister coding

Table 4. Program Memory Map

70

- - - - PRPR3 PRPR2 PRPR1 PRPR0

PRPR3 PRPR2 PRPR1 PRPR0 PC11 Memory Page

XXXX1

Static Page

(Page 1)

0 0 0 0 0 Page 0

00010

Page 1 (Static

Page)

0 0 1 0 0 Page 2

0 0 1 1 0 Page 3

0 1 0 0 0 Page 4

0 1 0 1 0 Page 5

0 1 1 0 0 Page 6

0 1 1 1 0 Page 7

1 0 0 0 0 Page 8

1 0 0 1 0 Page 9

Program Memory Page Device Address Description

PAGE 0

0000h-007Fh

0080h-07FFh

Reserved

User ROM

PAGE 1

“STATIC”

0800h-0F9Fh

0FA0h-0FEFh

0FF0h-0FF7h

0FF8h-0FFBh

0FFCh-0FFDh

0FFEh-0FFFh

User ROM

Reserved

Interrupt Vectors

Reserved

NMI Vector

Reset Vector

PAGE 2

0000h-000Fh

0010h-07FFh

Reserved

User ROM

PAGE 3

0000h-000Fh

0010h-07FFh

Reserved

User ROM (End of 8K ST6365, 67)

PAGE 4

0000h-000Fh

0010h-07FFh

Reserved

User ROM

PAGE 5

0000h-000Fh

0010h-07FFh

Reserved

User ROM

PAGE 6

0000h-000Fh

0010h-07FFh

Reserved

User ROM (End of 14K ST6375, 77)

PAGE 7

0000h-000Fh

0010h-07FFh

Reserved

User ROM

PAGE 8

0000h-000Fh

0010h-07FFh

Reserved

User ROM

PAGE 9

0000h-000Fh

0010h-07FFh

Reserved

User ROM (End of 20K ST6385, 87)

Page 11

11/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

MEMORY SPACES

(Cont’d)

1.3.3 Data Space

The ST6 Core instruction set operates on a specific space, referred to as the Data Space, which

contains all the data necessary for the program.

Figure 6. Dat a Sp a ce

The Data Space allows the addressing of RAM

(256 bytes), EEPROM (384 byt es) , ST6 Core and

peripheral registers, as well as read-only data

such as constants and look-up tables.

DATA RAM/EEPROM/OSD

BANK AREA

000h

03Fh

DATA ROM

WINDOW A REA

040h

07Fh

X REGISTER 080h

Y REGISTER 081h

V REGISTER 082h

W REGISTER 083h

DATA RAM

084h

0BFh

PORT A DA T A REGIS T ER 0C0h

PORT B DA T A REGIS T ER 0C1h

PORT C DATA REG I ST E R 0C2h

RESERVED 0C3h

PORT A DIRECTION REGISTER 0C4h

PORT B DIRECTION REGISTER 0C5h

PORT C DIRECTION REGISTER 0C6h

RESERVED 0C7h

INTERRUPT OPTION REGISTER 0C8h

DATA ROM WINDOW REGISTER 0C9h

PROGRAM ROM PAGE REGISTER 0CAh

RESERVED 0CBh

SPI DATA REGISTER 0CCh

RESERVED

0CDh

0D1h

TIMER 1 PRESCALER REGISTER 0D2h

TIMER 1 COUNTER RE G I ST E R 0D3h

TIMER 1 STATUS/CONTROL REGISTER 0D4h

RESERVED

0D5h

0D7h

WATCHDOG REGISTER 0D 8h

RESERVED 0D9h

TIMER 2 P RE SCALER REGISTE R 0DAh

TIMER 2 COUNTER REGISTER 0DB h

TIMER 2 STATUS/CONTROL REGISTER 0DCh

RESERVED

0DDh

0DFh

DA 0 DATA/CONTROL R E GISTER 0E0h

DA 1 DATA/CONTROL R E GISTER 0E1h

DA 2 DATA/CONTROL R E GISTER 0E2h

DA 3 DATA/CONTROL R E GISTER 0E3h

AFC, IR & OSD RESULT REGISTER 0 E5 h

OUTPUT CONTROL REGIS T ER 1 0E6h

DA 4 DATA/CONTROL R E GISTER 0E7h

DA 5 DATA/CONTROL R E GISTER 0E8h

DEDICA T E D LATCHES CONTR OL REGISTE R 0E9h

EEPROM CONTROL REGISTER 0EAh

SPI CONTROL REGISTER 1 0EBh

SPI CONTROL REGISTER 2 0ECh

OSD CHARACTER BANK SELECT REGISTER 0EDh

VS DATA REGISTER 1 0EEh

VS DATA REGISTER 2 0EFh

0F0h

RESERVED

0F5h

0FEh

ACCUMULATOR 0FFh

OSD CONTROL REGISTERS LOCATED IN

PAGE 6 OF BANKED DATA RAM

VERTICAL START ADDRESS REGISTER 010h

HORIZONTAL START ADDRESS REGISTER 011h

VERTICAL SPACE REGISTER 012h

HORIZONTAL SPACE REGISTER 013h

BACKGROUND COLOUR REGISTER 014h

GLOBAL ENABLE REGISTE R 017h

Page 12

12/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

MEMORY SPACES

(Cont’d)

Data ROM Addressing.

All the read-only data are

physically implemented in the ROM in which the

Program Space is also implemented. The ROM

therefore contains the program to be executed and

also the constants and the look-up table s needed

for the program. The locations of Data Space in

which the different constants and look-up tables

are addressed by the ST6 Core can be considered

as being a 64-byte window through which it is possible to access to the read-only data stored in the

ROM. This window is located from the 40h address to the 7Fh address in the Data space and allows the direct reading of t he byt es fr om the 000h

address to the 03Fh address in the ROM. All the

bytes of the ROM can be used to store either instructions or read-only data. Indeed, the window

can be moved by step of 64 by tes along the R OM

in writing the appropriate code in the Write-only

Data ROM Window register (DRWR, location

C9h). The effective address of the byte to be read

as a data in the ROM i s obtained by the concat enation of the 6 less significant bits of the address in

the Data Space (as less significant bits) and the

content of the DRWR (as most significant bits). So

when addressing location 40h of data space, and

0 is loaded in the DRWR, the phy sical addressed

location in ROM is 00h.

Note:

The data ROM Window can not address

window above the 16K byte range.

Data ROM Window Register (DRWR)

Address: C9h - Write only

Reset Value: XXh

DRWR7-DRWR0

. These are the Data Rom Window bits that correspond to the upper bits of data

ROM program space. This register is undefined after reset.

Caution

:

This register contains at least o ne write

only bit. Single bit instructions (SET, RES, INC

and DEC) should not be used.

Note:

Care is required when handling the DRWR

as it is write only. For this reason, it is not allowed

to change the DRWR contents while exec uting interrupts drivers, as the driver cannot save and

than restore its previous content. If it is impossible

to avoid the writing of this register in interrupts

drivers, an image of this register must be saved in

a RAM location, and each time the program writes

the DRWR it writes also the image register. The

image register must be written first, so if an interrupt occurs between the two instructions the

DRWR register is not affected.

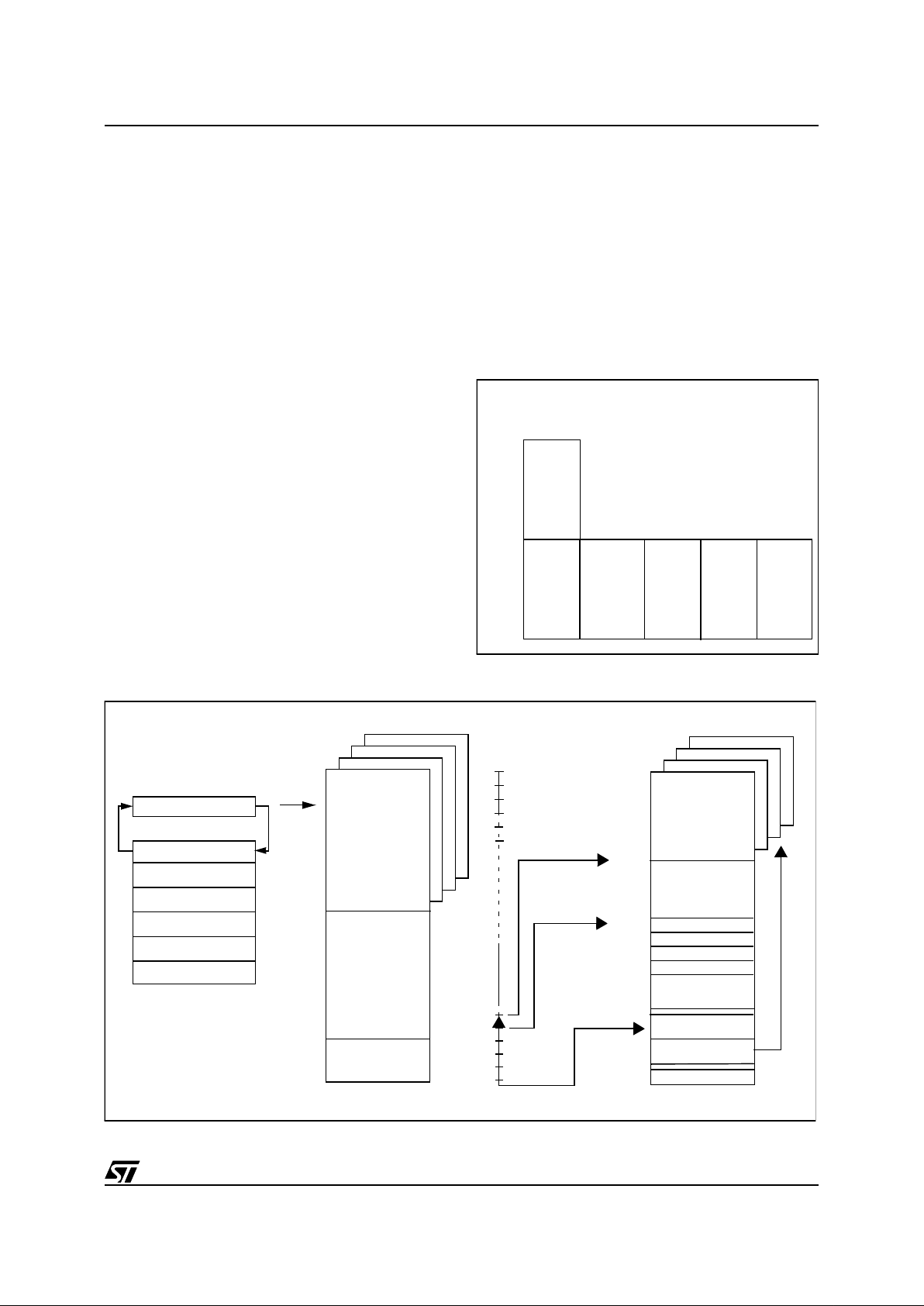

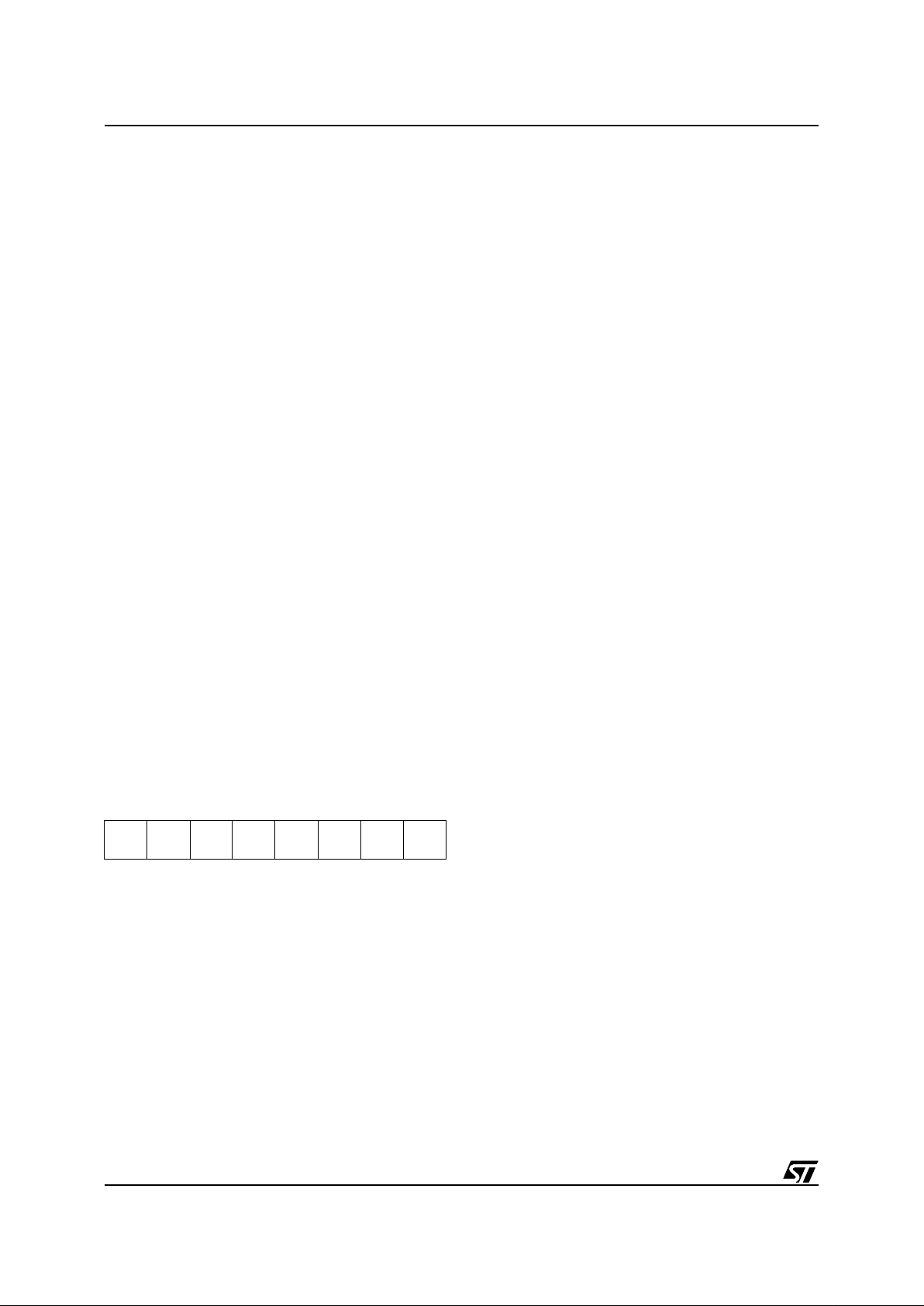

Figure 7. Data ROM Window Memory Addressing

70

DRWR7DRWR6DRWR5DRWR4DRWR3DRWR2DRWR1DRWR

0

DATA ROM

WINDOW REGISTER

CONTENTS

DATA SPACE ADDRESS

40h-7Fh

IN INSTRUCTION

PROGRAM SPACE ADDRESS

765432 0

543210

543210

READ

1

67891011

0

1

VR01573B

12

1

0

DATA SPACE ADDRESS

59h

0000

0

1

00

1

11

Example:

(DWR)

DWR=28h

11

0000

0 000

1

ROM

ADDRESS:A19h

11

13

0

1

0

0

Page 13

13/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

MEMORY SPACES

(Cont’d)

1.3.4 Data RAM/EEPROM/OSD RAM

Addressing

In all members of the ST638x family 64 b ytes of

data RAM are directly addressable in the data

space from 80h to BFh addresses. The a dditional

192 bytes of RAM, the 384 bytes of EEPROM, an d

the OSD RAM can be addressed using the banks

of 64 bytes located between addresses 00h and

3Fh. The selection of the bank is done by programming the Data R AM Bank Register (DRBR)

located at the E8h address of the Data Space. In

this way each bank of RAM, EEPROM or OSD

RAM can select 64 bytes at a time. No more than

one bank should be set at a time.

Data RAM Bank Register (DRBR)

Address: E8h - Write only

Reset Value: XXh

DRBR7,DRBR1,DRBR0

. These bits select the

EEPROM pages.

DRBR6, DRBR5

. Each of these bits, when set, will

select one OSD RAM register page.

DRBR4,DRBR3,DRBR2

. Each of these bits, when

set, will select oneRAM page.

This register is undefined after reset.

Table 5 summarizes how to set the Data RAM

Bank Register in order to select the various banks

or pages.

Caution

:

This register contains at least o ne write

only bit. Single bit instructions (SET, RES, INC

and DEC) should not be used.

Note

: Care is required when handling the DRBR

as it is write only. For this reason, it is not allowed

to change the DRBR con tents while ex ecuting interrupts drivers, as the driver cannot save and

than restore its previous content. If it is impossible

to avoid the writing of this register in interrupts

drivers, an image of this register must be saved in

a RAM location, and each time the program writes

the DRBR it writes also the image register. The image register must be written first, so if an interrupt

occurs between the two instructions the DRBR is

not affected.

Table 5. Data RAM Bank Register Set-up

70

DRBR7DRBR6DRBR5DRBR4DRBR3DRBR2DRBR1DRBR

0

DRBR Value

Selection

Hex. Binary

01h 0000 0001 EEPROM Page 0

02h 0000 0010 EEPROM Page 1

03h 0000 0011 EEPROM Page 2

81h 1000 0001 EEPROM Page 3

82h 1000 0010 EEPROM Page 4

83h 1000 0011 EEPROM Page 5

04h 0000 0100 RAM Page 2

08h 0000 1000 RAM Page 3

10h 0001 0000 RAM Page 4

20h 0010 0000 OSD Page 5

40h 0100 0000 OSD Page 6

Page 14

14/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

MEMORY SPACES

(Cont’d)

EEPROM Description

The data space of ST638x f am ily from 0 0h t o 3Fh

is paged as described in Table 5. 384 bytes of

EEPROM located in s ix p ages o f 64 by tes (pa ges

0,1,2,3,4 and 5, see Table 5).

Through the programming of the Data RAM Bank

Register (DRBR=E8h) the user can select the

bank or page leaving unaffected the way to address the static registers. The way to address the

“dynamic” page is to set the DRBR as described in

Table 5 (e.g. to select EEPROM page 0, the

DRBR has to be loaded with content 01h, see

Data RAM/EEPROM/OSD RAM addressing for

additional information). Bits 0, 1 and 7 of the

DRBR are dedicated to the EEPROM.

The EEPROM pages do not require dedicated instructions to be accessed in reading or writing.

The EEPROM is controlled by the EEPROM Control R e g ister (EEC R=EAh). Any EEPROM location

can be read just like any other data location, also

in terms of access time.

To write an EEPROM location takes an average

time of 5 ms (10ms max ) and during this time the

EEPROM is not accessibl e by the Core. A busy

flag can be read by the Core to know the EEPROM

status before trying any access. In writing the

EEPROM can work in two modes: Byte Mode

(BMODE) and Parallel Mode (PMODE). The

BMODE is the normal way t o use the EEPROM

and consists in accessing one byte at a time. The

PMODE consists in accessing 8 bytes per time.

EEPROM Control Register (EECR)

Address: EAh - Read only/Write only

Reset Value:

D7

. Not used

Caution

:

This register contains at least one write

only bit. Single bit instructions (SET, RES, INC

and DEC) should not be used.

SB

. WRITE ONLY. If this bit is set th e EEPROM is

disabled (any access will be meaningless) and the

power consumption of the EEPROM is reduced to

the leakage values.

D5, D4

. Reserved for testing purposes, they must

be set to zero.

PS

. WRITE ONLY. Once in Parallel Mode, as

soon as the user software sets the PS bit the parallel writing of the 8 adjacent registers will start. PS

is internally reset at the end of the programming

procedure. Note that less than 8 bytes can be written; after parallel programming the remaining undefined bytes will have no particular content.

PE

. WRITE ONLY. This bit must be set by the user

program in order to perform parallel programming

(more bytes per time). If PE is set and the “parallel

start bit” (PS) is low, up to 8 adjacent bytes can be

written at the maximum speed, the content being

stored in volatile registers. These 8 adjacent bytes

can be considered as row, who se A7 , A6, A 5, A4,

A3 are fixed while A2, A1 and A0 are the changing

bytes. PE is automatically reset at the end of any

parallel programming procedure. PE can be reset

by the user software before starting the programming procedure, leaving unchanged the EEPROM

registers.

BS

. READ ONLY. This bit will be automatically set

by the CORE when the user program modifies an

EEPROM register. The user program has to test it

before any read or w rite EEPROM o peration; any

attempt to access the EEPROM while “busy bit” is

set will be aborted and the writing procedure in

progress completed.

EN

. WRITE ONLY. This bit MUST be set to one in

order to write any EEPROM register. If the user

program will attempt to write the EEPROM when

EN= “0” the involved registers will be unaffected

and the “busy bit” will not be set.

After RESET the content of EECR register will be

00h.

Notes

: When the EEPROM is busy (BS=”1”) the

EECR can not be accessed in write mode, it is only

possible to read BS status. This implies that as

long as the EEP ROM is busy it i s not possible t o

change the status of the EEPROM control register.

EECR bits 4 and 5 are reserved for test purposes,

and must never be set to “1”.

70

- SB - - PSPEBSEN

Page 15

15/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

MEMORY SPACES

(Cont’d)

Additiona l Notes on Parall el Mode

. If the user

wants to perform a parallel programming the first

action should be the setting of the PE bit; from this

moment, the first time the EEPROM will be addressed in writing, the ROW address will be

latched and it w ill be pos sible to change it only at

the end of the programming procedure or by resetting PE without prog r amming the EEPROM.

After the ROW address latching the Core can

“see” just one EEPROM row (the selected one)

and any attempt to write or read other rows will

produce errors. Do not read the EEPROM while

PE is set.

As soon as PE bit is set, the 8 volatile ROW latches are cleared. From this moment the user can

load data in the whole ROW or just in a subset. PS

setting will modify the EEPROM registers corresponding to the ROW latches access ed after PE.

For example, if the software sets PE and accesses

EEPROM in writing at addresses 18h,1Ah,1Bh

and then sets PS, these three registers will be

modified at the same time; the remaining bytes will

have no particular content. Note that PE is internally reset at the end of the programming procedure. This implies that the user must set PE bit between two parallel programming procedures. Anyway the user can set and then reset PE without

performing any EEPROM programming. PS is a

set only bit and is internally reset at the end of the

programming procedure. Note that if the user tries

to set PS while PE is not set there will not be any

programming procedure and th e PS bit will be unaffected. Consequently PS bit can not be set if EN

is low. PS can be affected by the user s et if, and

only if, EN and PE bits are also set to one.

Page 16

16/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

2 CENTRAL PR OCESSING UNI T

2.1 INTRODUCTION

The CPU Core of ST6 devices is independent of the

I/O or Memory conf iguration. As such, it may be

thought of as an independent central processor

communicating with on-chip I/O, Memory and P eripherals via internal address, data, and control

buses. In-core communication is arranged as

shown in Figure 8; the controller being externally

linked to both the Reset and Oscillator circuits,

while the core is linked to the dedicated on-chip peripherals via the serial data bus and indirectly, for

interrupt purposes, through the control registers.

2.2 CPU REGISTERS

The ST6 Family CPU core features six registers

and three pairs of flags available to the programmer. These are described in the following paragraphs.

Accumulator (A)

. The accumulator is an 8-bit

general purpose register used in all arithmetic calculations, logical operations, and data manipulations. The accumulator can be ad dressed in Data

space as a RAM location at address FFh. Thus the

ST6 can manipulate the accumulator just like any

other register in Data space.

Indirect Registers (X, Y).

These two indirect registers are used as pointers to memory locations in

Data space. They are used in the register-indirect

addressing mode. These registers can be addressed in the data space as RAM locations at addresses 80h (X) and 81h (Y). They can also be accessed with the direct, short direct, or bit direct addressing modes. Accordingly, the ST6 in struction

set can use the indirect registers as any other register of the data space.

Short Direct Registers (V, W).

These two registers are used to save a byte in short direct addressing mode. They can be addressed in Data

space as RAM locations at addresses 82h (V) and

83h (W). They can also be acc ess ed using the direct and bit direct addressing modes. Thus, the

ST6 instruction set can use the short direct registers as any other register of the data space.

Program Counter (PC). The program counter is a

12-bit register which contains the address of the

next ROM location to be processed by the core.

This ROM location may be an opcode, an operand, or the address of an operand. The 12-bit

length allows the direct addressing of 4096 bytes

in Program space.

Figure 8. ST6 Core Block Diagram

PROGRAM

RESET

OPCODE

FLAG

VALUES

2

CONTROLLER

FLAGS

ALU

A-DATA

B-DATA

ADDRESS/READ LINE

DATA SPACE

INTERRUPTS

DATA

RAM/EEPROM

DATA

ROM/EPROM

RESULTS TO DATA SPACE (WRITE LINE)

ROM/EPROM

DEDICATIONS

ACCUMULATOR

CONTROL

SIGNALS

OSCin

OSCout

ADDRESS

DECODER

256

12

Program C ounter

and

6 LAYER STACK

0,01 TO 8MHz

VR01811

Page 17

17/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

CPU REGISTERS

(Cont’d)

However, if the program space contains more than

4096 bytes, the additional memory in program

space can be addressed by using the Program

Bank Switch register.

The PC value is incremented after reading the address of the current instruction. To execute relative

jumps, the PC and the offset are shifted through

the ALU, where they are added; the resul t is then

shifted back into the PC. The program counter can

be changed in the following ways:

- JP (Jump) instruction. . . . . PC=Jump address

- CALL instruction . . . . . . . . . PC= Call address

- Relative Branch Instruction . PC= PC +/- offset

- Interrupt . . . . . . . . . . . . . .PC=Interrupt vector

- Reset . . . . . . . . . . . . . . . . . PC= Reset vector

- RET & RETI instructions . . . . PC= Pop (stack)

- Normal instruction . . . . . . . . . . . . .PC= PC + 1

Flags (C, Z)

. The ST6 CPU includes three pairs of

flags (Carry and Zero), each pair being associated

with one of the three normal modes of o peration:

Normal mode, Interrupt mod e and Non Maskable

Interrupt mode. Each pair consists of a CARRY

flag and a ZERO flag. One pa ir (CN, ZN) is used

during Normal operation, another pair is used during Interrupt mode (CI, ZI), and a third pair is used

in the Non Maskable Interrupt mode (CNM I, ZNMI).

The ST6 CPU uses the pair of flags associated

with the current mode: as soon as an interrupt (or

a Non Maskable I nterrupt) is generated, the ST6

CPU uses the Interrupt flags (resp. the NM I flags)

instead of the Normal flags. When the RETI instruction is executed, the previously used set of

flags is restored. It should be noted that each flag

set can only be addressed in its own context (Non

Maskable Interrupt, Normal Interrupt or Main routine). The flags are not cleared during context

switching and thus retain their status.

The Carry flag is set when a carry or a borrow occurs during arithmetic operations; otherwise it is

cleared. The Carry flag is also set to the valu e of

the bit tested in a bit test instruction; it also participates in the rotate left instruction.

The Zero flag is set if the result of the last arithmetic or logical operation was equal to zero; otherwise it is cleared.

Switching between the three sets of flags is performed automatically when an NMI, an interrupt or

a RETI instructions occurs. As the NMI mode is

automatically selected aft er the reset of the MCU,

the ST6 core uses at first the NMI flags.

Stack.

The ST6 CPU in cludes a true LIFO hardware stack which eliminates the need for a stack

pointer. The stack con sists of six sepa rate 12-bit

RAM locations that do not belong to the data

space RAM area. When a subroutine call (or interrupt request) occurs, the contents of each level are

shifted into the next higher level, while the content

of the PC is shifted into the first level (the original

contents of the sixth stack level are lost). When a

subroutine or interrupt return occurs (RET or RETI

instructions), the first level register is shifted back

into the PC and the value of each l evel is popped

back into the previous level. Since the acc umulator, in common with all other data space registers,

is not stored in this stack, management of these

registers should be performed within the subroutine. The stack will remain in its “deepest” position

if more than 6 nested calls or interrupts are executed, and consequent ly the last return address wi ll

be lost. It will al so remain in its highest position if

the stack is empty and a RET or RETI is executed.

In this case the next instruction will be executed.

Figure 9. ST6 CP U Pr ogrammin g M ode

l

SHORT

DIRECT

ADDRESSING

MODE

VREGISTER

WREGISTER

PROGRAMCOUNTER

SIX LEVELS

STACK REGISTER

CZNORMAL FLAGS

INTERRUPT FLAGS

NMI FLAGS

INDEX

REGISTER

VA 000 42 3

b7

b7

b7

b7

b7

b0

b0

b0

b0

b0

b0b11

ACCUMULATOR

YREG.POINTER

XREG.POINTER

CZ

CZ

Page 18

18/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

3 CLOCKS, RESET, INTERRUPTS AND POWE R SAVING MODES

3. 1 ON- CHIP CLO CK OS CILL ATOR

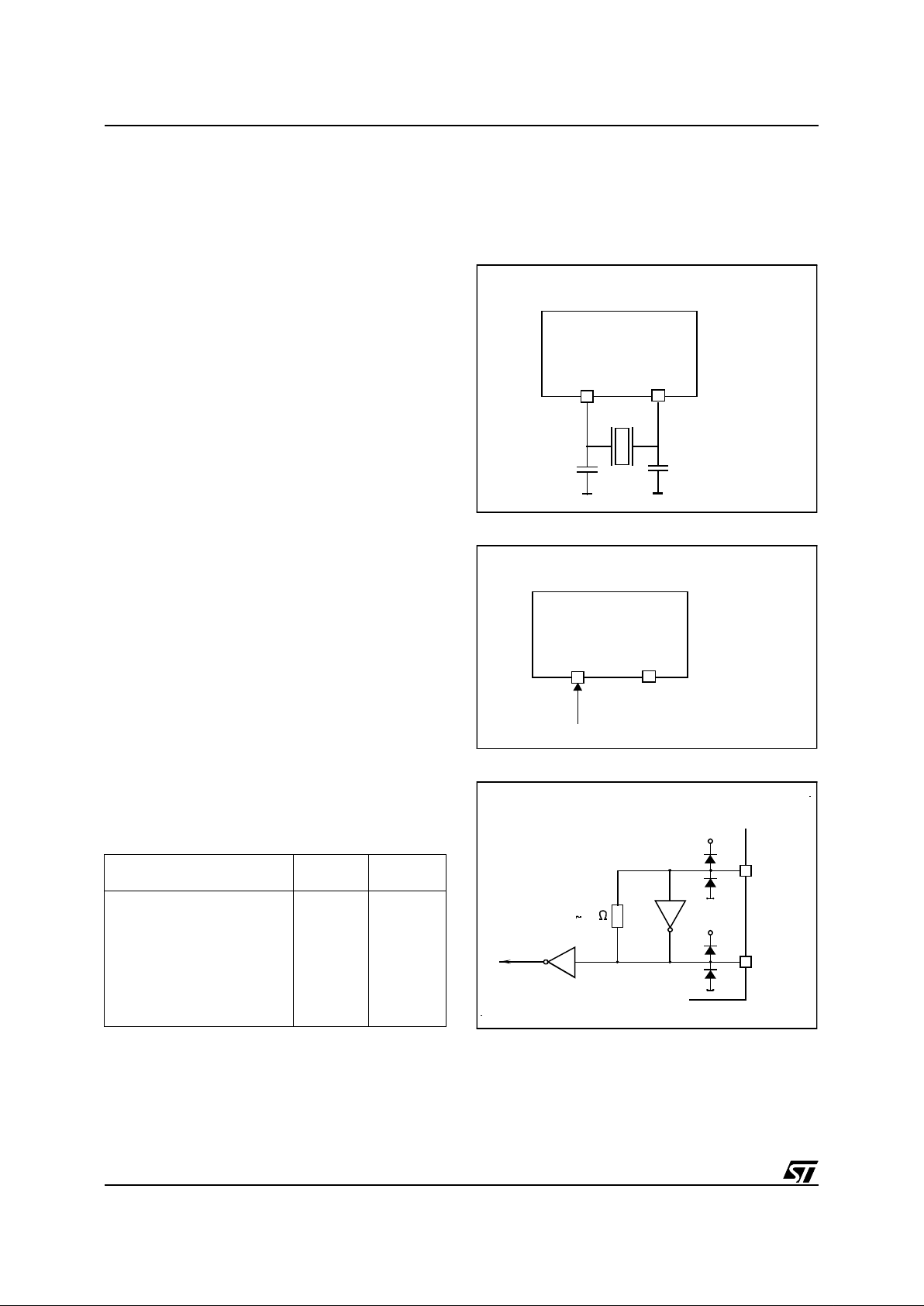

The internal oscillator circuit is designed to require

a minimum of external components. A crystal

quartz, a ceramic reso nator, or an external s ignal

(provided to the OSCin pin) may be used to generate a system clock with various stability/cost tradeoffs. The typical clock f requency is 8 MHz. Ple ase

note that different frequen cies wil l affect t he operation of those peripherals (D/As, SPI) whose reference frequencies are derived from the system

clock.

The different clock generator connection schemes

are shown in Figure 10 and 11. One machine cycle

takes 13 oscillator pulses; 12 clock pulses are

needed to increment the PC while and a dditional

13th pulse is needed to stabilize the internal latches during memory addressing. This means that

with a clock frequency of 8MHz the machine cycle

is 1.625µSec.

The crystal o scilla tor start-u p time is a func tion of

many variables: crystal parameters (especially

RS), oscillator load capacitanc e (CL), IC parameters, ambient temperature, and supply voltage.It

must be observed that the crystal or ceramic leads

and circuit connections must be as short as possible. Typical values for CL1 and CL2 are in the

range of 15pF to 22pF but these should be chosen

based on the crystal manufacturers specificat ion.

Typical input capacitance for OSCin and OSCout

pins is 5pF.

The oscillator output frequency is internally divided

by 13 to produce the machine cycle and by 12 to

produce the Timers and the Watchdog clock. A

byte cycle is the smallest unit needed to execute

any operation (i.e., increment the prog ram counter). An instruction may need two, four, or five byte

cycles to be executed (See Table 6).

Table 6. Instru c ti on Ti m i ng with 8MHz Clock

Figure 10. Cloc k Gene r a tor Option 1

Figure 11. Cloc k Gene r a tor Option 2

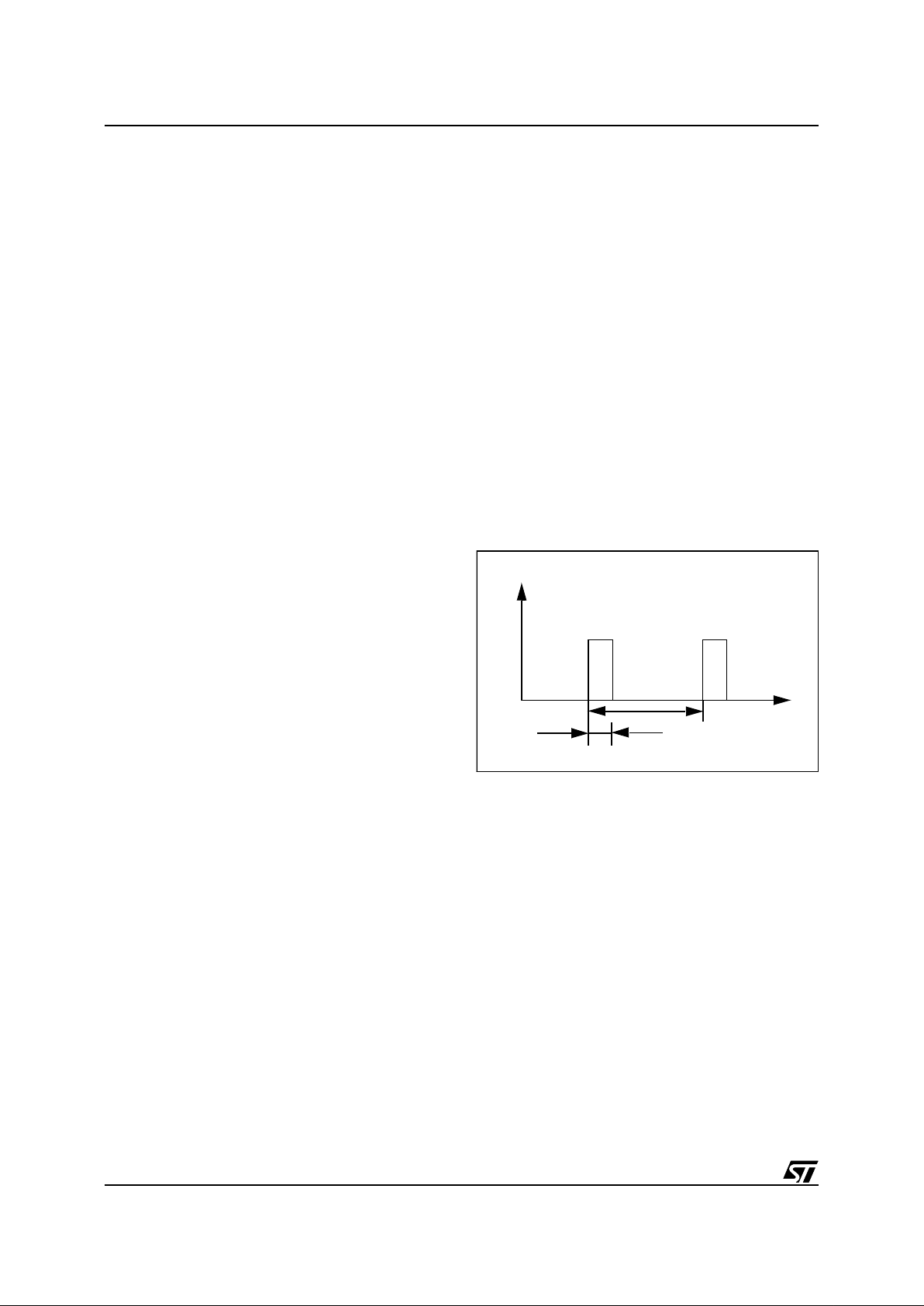

Figure 12. OSCin, OSCout Diagram

Instruction Type Cycle s

Execution

Time

Branch if set/reset 5 Cycles 8.125µs

Branch & Subroutine Branch 4 Cycles 6.50µs

Bit Manipulation 4 Cycles 6.50µs

Load Instruction 4 Cycles 6.50µs

Arithmetic & Logic 4 Cycles 6.50µs

Conditional Branch 2 Cycles 3.25µs

Program Control 2 Cycles 3.25µs

OSC

in

OSC

out

C

L1

C

L2

ST6xxx

CRYSTAL/RESONATOR CLOCK

VA0016B

OSC

in

OSC

out

ST6xxx

EXTERNAL CLOCK

NC

VA0015C

VA00462

OSCout

In

OSCin, OSCout (QUART Z PINS)

OSCin

1M

V

DD

DD

V

Page 19

19/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

3.2 RESETS

The MCU can be reset in three ways:

– by the external Reset input being pulled low;

– by Power-on Reset;

– by the digital Watchdog peripheral timing out.

3.2.1 RESET Input

The RESET

pin may be connected to a device of

the application board in order to reset the MCU if

required. The RESET

pin may be pulled low in

RUN, WAIT or STOP mode. This input can be

used to reset the MCU internal state and ensure a

correct start-up procedure. The pin is ac tive low

and features a Schmitt trigger input. The internal

Reset signal is generated by adding a delay to the

external signal. Therefore even short pulses on

the RESET

pin are acceptable, provide d VDD has

completed its rising phase and that the oscillator is

running correctly (normal RUN or WAIT modes).

The MCU is kept in the Reset state as long as the

RESET

pin is held low.

If RESET

activation occurs in RUN or WAIT

modes, processing of the user program is stopped

(RUN mode only), the Inputs and Outputs are configured as inputs with pull-up resistors if available.

When the level on the RESET pin then goes high,

the initialization sequence is executed following

expiry of the internal delay period.

If RESET

pin activation occurs in the STOP mode,

the oscillator starts up and all Inputs and Outputs

are configured as inputs with pull-up resistors if

available. When the le vel of the RESET

pin then

goes high, the initialization seq uence is executed

following expiry of the internal delay period.

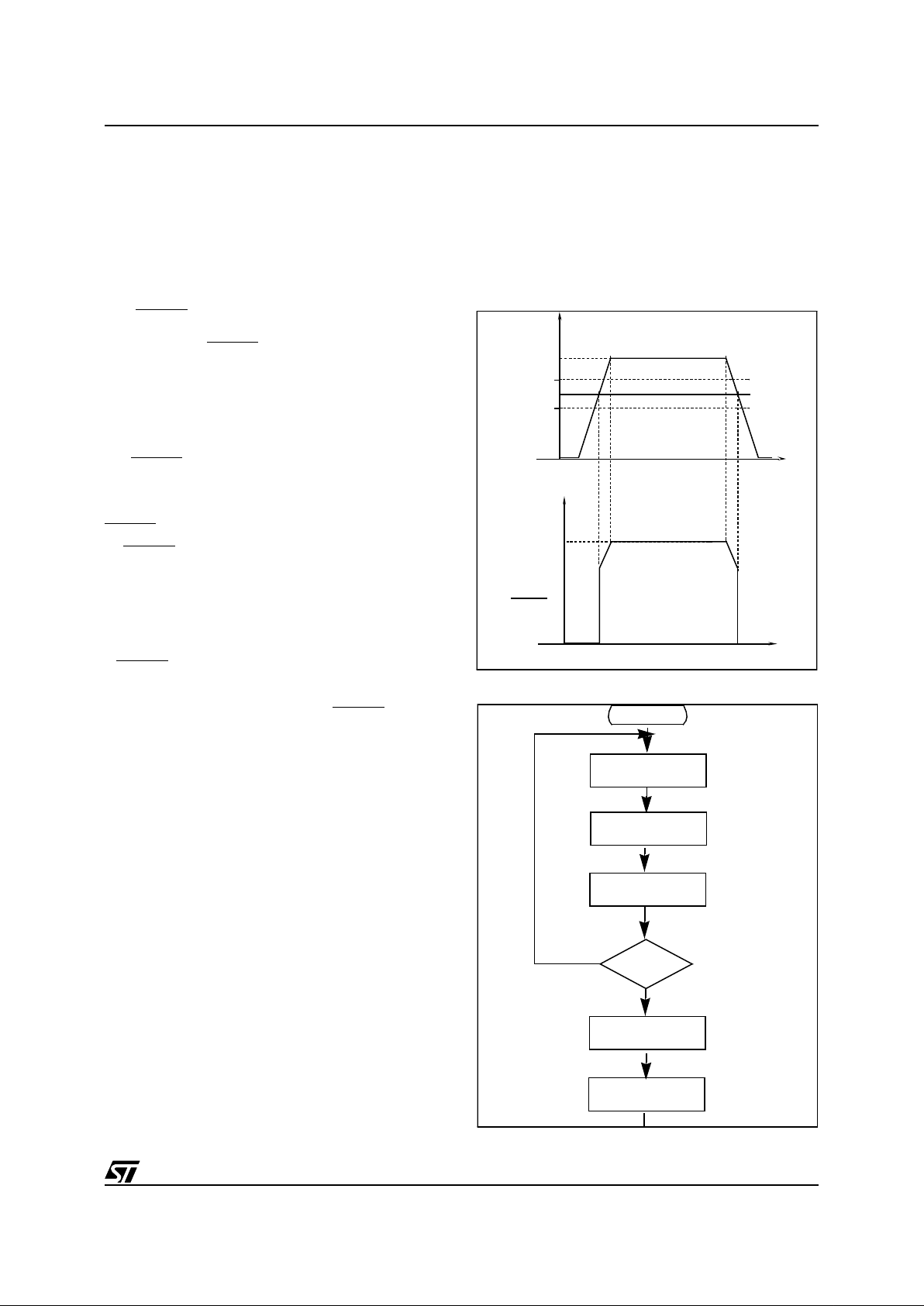

3.2.2 Power-on Reset

The function of the POR circuit cons ists in waking

up the MCU at an appropriate stage during the

power-on sequence. At the beginning of this sequence, the MCU is configured in the Reset state:

all I/O ports are configured as inputs with pull-up

resistors and no instruction is executed. When the

power supply voltage rises to a sufficient level, the

oscillator starts to operate, whereupon an internal

delay is initiated, in order to allow the oscillator to

fully stabilize before executing the first instruction.

The initialization sequence is executed immediately following the internal delay.

The internal delay is generated by an on-chip

counter. The internal reset line is released 2048 internal clock cycles after release of the external reset.

The internal POR device is a static mechanism

which forces the reset s tate when V

DD

is be low a

threshold voltage in the range 3.4 to 4. 2 Volts (see

Figure 1 3). The circuit guarantees that the MCU

will exit or enter the reset s tate correctly, without

spurious effects, ensuring, for exampl e, that E EPROM contents are not corrupted.

Note

: This feature is not available on OTP/EPROM

Devices.

Figure 13. Power ON/OFF Reset operati on

Figure 14. Reset and Interrupt Processing

VR02037

V

DD

4.2

3.4

t

V

t

POWER

ON/OFF

Threshold

DD

RESET

INT LATCH CLEARED

NMI MASK SET

RESET

( IF PRESENT )

SELECT

NMI MODE FLAGS

IS RESET STILL

PRESENT?

YES

PUT FFEH

ON ADDRESS BUS

FROM RESET LOCATIONS

FFE/FFF

NO

FETCH INSTRUCTION

LOAD PC

VA000427

Page 20

20/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

RESETS

(Cont’d)

3.2.3 Watchdog Reset

The MCU provides a Wat chdog timer function in

order to ensure graceful recovery from software

upsets. If the Watchdog regi ster is not refreshed

before an end-of-count condition is reached, the

internal reset will be activated. This, amongs t ot her things, resets the watchdog counter.

The MCU restarts just as though the Reset had

been generated by the RESET

pin, including the

built-in stabilisation de lay period .

3.2.4 Application Note

No external resistor is requi red betw een V

DD

and

the Reset pin, thanks to the built-in pull-up device.

3.2.5 MCU Initialization Sequence

When a reset occurs the stack is reset, the PC is

loaded with the address of the Reset Vector (located in program ROM starting at address 0FFEh). A

jump to the beginning of the user program must be

coded at this address. Following a Reset, the I nterrupt flag is automatically set, so that the CPU is

in Non Maskable Interrupt mode; this prevents the

initialisation routine from being interrupted. The initialisation routine should therefore be terminated

by a RETI instruction, in order to revert to normal

mode and enable interrupts. If no pending interrupt

is present at the end of the initialisation routine, the

MCU will continue by processing the instruction

immediately following the RETI instruction. If, however, a pending interrupt is present, it will be serviced.

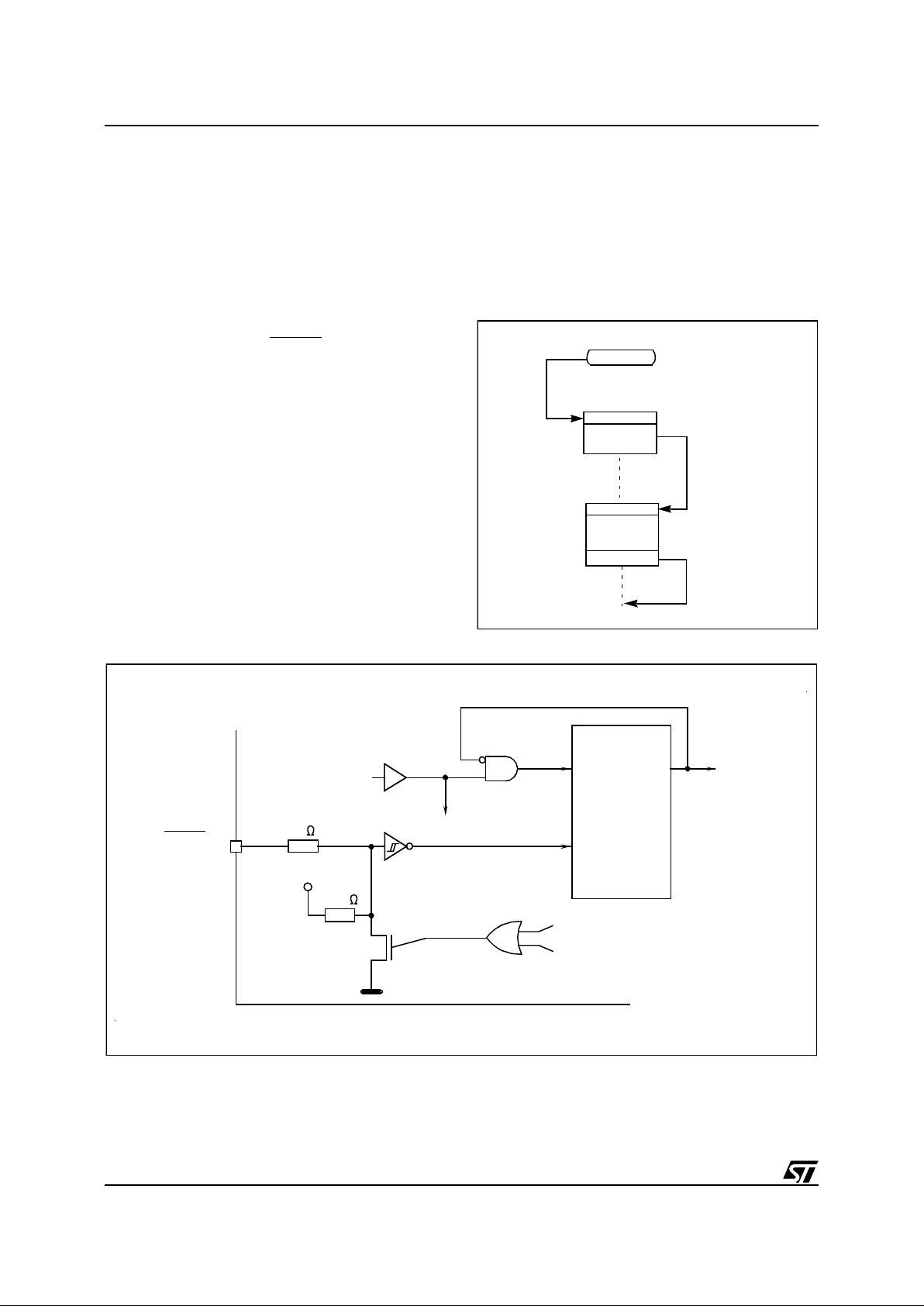

Figure 15. Reset and Interrupt Processing

Figure 16. Reset Circuit

RESET

RESET

VECTOR

JP

JP:2 BYTES/4 CYCLES

RETI

RETI: 1 BYTE/2 CYCLES

INITIALIZATION

ROUTINE

VA00181

VA0200E

TO ST6

RESET

ST6

INTERNAL

RESET

OSCILLATOR

SIGNAL

WATCHDOG RE SE T

V

DD

300k

RESET

(ACTIV E LO W )

COUNTER

1k

POWER ON/OFF RESET

Page 21

21/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

3.3 HARDWARE ACTIVATED DIGITAL WATCHDOG FUNCTION

The hardware activated digital watchdog func tion

consists of a down counter that is automatically initialized after reset so that this function does not

need to be activated by the user program. As the

watchdog function is always activated this down

counter can not be used as a timer. The watchdog

is using one data space register (HWDR location

D8h). The watchdog register is set to FEh on reset

and immediately starts to count down, requiring no

software start. Similarly the hardware activated

watchdog can not be stop ped or delayed by so ftware.

The watchdog time can be programmed us i ng the

6 MSBs in the watchdog register, this gives the

possibility to generate a reset in a time between

3072 to 196608 oscillator cycles in 64 possible

steps. (With a clock frequency of 8MHz this means

from 384ms to 24.576ms). The reset is prevented

if the register is reloaded with the desired value

before bits 2-7 decrement from all zeros to all

ones.

The presence of the hardware watchdog deactivates the STOP instruction and a WAIT instruction

is automatically executed instead of a STOP. Bit 1

of the watchdog register (set to one a t reset) can

be used to generate a soft ware reset if cleared t o

zero). Figure 17 shows the watchdog block dia-

gram while Figure 18 shows its working principle.

Figure 17. Hardware Activated Watchdog Block Diagram

RSFF

8

DATA BUS

VA00010

-2

-12

OSCILLATOR

RESET

WRITE

RESET

DB0

R

S

Q

DB1.7 SETLOAD

7

8

-2

SET

CLOCK

Page 22

22/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

HARDWARE ACTIVATED DIGITAL WATCHDOG FUNCTION (Cont’d)

Hardware Activated Watchdog Register

(HWDR)

Address: D8h - Read/Write

Reset Value: 0FEh

T1-T6

. These are the watchdog counter bits. It

should be noted that D7 (T1) is the LSB of the

counter and D2 (T6) is the MSB of the counter,

these bits are in the opposite order to normal.

SR

. This bit is set to one during the reset phase

and will generate a software res et if clear ed to zero.

C

. This is the watchdog activation bit that is hardware set. The watchdog function is always activated independently of changes of value of this bit.

The register reset value is FEh (Bit 1-7 set to one,

Bit 0 cleared).

Figure 18. Har dw a re A ct iva te d Wa tc h dog

Working Princ iple

70

T1 T2 T3 T4 T5 T6 SR C

BIT0

VA00190

BIT1

BIT2

BIT3

BIT4

BIT5

BIT6

BIT7

8-BIT

DOWN COUNTER

OSC-12

WATCHDOG CONTROL REGISTER

RESET

D0

D1

D2

D3

D4

D5

D6

D7

Page 23

23/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

3.4 INTERRUPT

The ST638x Core can m anag e 4 different maskable interrupt sources, pl us one non-maskable interrupt source (top priority level interrupt). Each

source is associated with a particular interrupt vector that contains a Jump instruction to the related

interrupt service routine. Each vector is located in

the Program Space at a particular address (see

Table 7). When a source provides an interrupt re-

quest, and the request processing is also enabled

by the ST638x Core, then the PC register is loaded with the address of the interrupt vector (i.e. of

the Jump instruction). Finally, the PC is loaded

with the address of the Jump instruction and the

interrupt routine is processed.

The relationship between vector and source and

the associated priority is hardware fixed for the different ST638x devices. For some interrupt sources it is also possible to select by software the kind

of event that will generate the interrupt.

All interrupts can be disabled by writing to the GEN

bit (global interrupt enable) of the interrupt op tion

register (address C8h). After a reset, ST638x is in

non maskable interrupt mode, so no interrupts will

be accepted and NMI flags will be used, until a

RETI instruction is executed. If an interrupt is executed, one special cycle is made by the core, during that the PC is set to the related interrupt vector

address. A jump instruction at this address has to

redirect program execution to the beginning of the

related interrupt routine. The interrupt detecting

cycle, also resets the related interrupt flag (not

available to the user), so that another interrupt c an

be stored for this current vector, while its driver is

under execution.

If additional interrupts arrive from the same

source, they will be lost. NMI can interrupt other interrupt routines at any time, while other interrupts

cannot interrupt each other. If more than one interrupt is waiting for service, they are executed according to their priority. The lower the number, the

higher the priority. Priority is, therefore, fixed. Interrupts are check ed dur i ng the last cycle of an instruction (RETI included). Level sensitive interrupts have to be valid during this period.

3.4.1 Interrupt Vectors/Sources

The ST638x Core includes 5 different interrupt

vectors in order to branch to 5 different interrupt

routines. The interrupt v ectors are located in the

fixed (or static) page of the Program Space.

The interrupt vector associated with the nonmaskab le interru p t so ur ce is named inter r up t v ec tor #0. It is located at the (FFCh,FFDh) addresses

in the Program Space. This vector is associated

with the PC6/IRIN pin.

The interrupt vectors located at addresses (F F6h,

FF7h), (FF4h, FF5h), (FF2h, FF3h), (FF0h, FF 1h)

are named interrupt vectors #1, #2, #3 and #4 respectively. These vectors are associated with TIMER 2 (#1), VSYNC (#2), TIMER 1 (#3) and

PC4(PWRIN) (#4).

Table 7. Interrupt Vectors/Sources

Relationships

Note 1

. This pin is associated with the NMI Inter-

rupt Vector

3.4.2 Interrupt Priority

The non-maskable interrupt request has the highest priority and can interrupt any other interrupt

routines at any time, nevertheless the other interrupts cannot interrupt each other. If more than one

interrupt request is pending, they are processed

by the ST638x Core according to their priority level: vector #1 has the higher priority while vector #4

the lower. The priority of each interrupt source is

hardware fixed.

Interrupt Source

Associated

Vector

Vector

Address

PC6/IRIN Pin

1

Interrupt

Vector # 0 (NMI)

0FFCh-0FFDh

Timer 2

Interrupt

Vector # 1

0FF6h-0FF7h

Vsync

Interrupt

Vector #2

0FF4h-0FF5h

Timer 1

Interrupt

Vector #3

0FF2h-0FF3h

PC4/PWRIN

Interrupt

Vector #4

0FF0h-0FF1h

Page 24

24/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

INTERRUPTS

(Cont’d)

3.4.3 Interrupt Option Register

Interrupt Option Register (IOR)

Address: (C8h) - Write only

Reset Value: X000XXXXb

The Interrupt Option Register (IOR register, location C8h) is used to enable/disable the individual interrupt sources and to select the operating mode of

the external interrupt inputs. This register can be addressed in the Data Space as RAM location at the

C8h address, nevertheless it is a write-only register

that can not be accessed with single-bit operations.

The operating modes of the external interrupt inputs

associated to interrupt vectors #1 and #2 are selected through bits 5 and 6 of the IOR register.

Caution

:

This register contains at least one write

only bit. Single bit instructions (SET, RES, INC

and DEC) should not be used.

D7

. Not used.

EL1

. This is the Edge/Level selection bit of interrupt #1. When set to one, the interrupt is generated on low level of the related signal; when cleared

to zero, the interrupt is generated on falling e dge.

The bit is cleared to zero after reset.

ES2

. This is the edge selection bit on interrupt #2.

This bit is used on the ST638x devices with onchip OSD generator for VSYNC detection. When

this bit is se to one, the interrupt #2 is positive

edge sensitive, when cleared to zero t he ne gative

edge sensitive interrupt is selected.

GEN

. This is the global enable bit. When set to

one all interrupts are globally enabled; when this

bit is cleared to zero all interrupts are disabled (excluding NMI).

D3 - D0.

These bits are not used.

3.4.4 Interrupt Procedure

The interrupt procedure is very similar to a call procedure; the user can consider the interrupt as an

asynchronous call procedure. A s this is an asynchronous event the us er d oes not know about the

context and the time at which it occurred. As a result

the user should save all the data space registers

which will be used inside the interrupt routines.

There are separate sets of processor flags for normal, interrupt and non-maskable interrupt modes

which are automatically switc hed an d s o t hese do

not need to be saved.

The following list summarizes the interrupt procedure (refer also to Figure 19*)

– Interrupt detection

– The flags C and Z of the main routine are ex-

changed with the flags C and Z of the interrupt

routine (resp. the NMI flags)

– The value of the PC is stored in the first level of

the stack - The normal interrupt lines are inhibit-

ed (NMI still active)

– The edge flip-flop is reset

– The related interrupt vector is loaded in the PC.

– User selected registers are saved inside the in-

terrupt service routine (normally on a software

stack)

– The source of the interrupt is found by polling (if

more than one source is associated to the same

vector)

– Interrupt servicing

– Return from interrupt (RETI)

– Automatically the ST638x core switches back to

the normal flags (resp the interrupt flags) and

pops the previous PC value from the stack

Figure 19. Interrupt Processing Flow-Cha rt

70

-

EL1 ES2 GEN

----

INSTRUCTION

FETCH

INSTRUCTION

EXECUTE

INSTRUCTION

WAS

THE INSTRUCTION

A RETI

?

?

CLEAR

INTERRUPT MASK

SELECT

PROGRAM FLAGS

“POP”

THE STACKED PC

?

CHECK IF THERE IS

AN INTERRUPT REQUEST

AND INTERRUPT MASK

SELECT

INTERNAL MODE FLAG

PUSH THE

PC INTO THE STACK

LOAD PC FROM

INTERRUPT VECTOR

(FFC/F FD )

SET

INTERRUPT MASK

NO

NO

YES

IS THE CORE

ALREADY IN

NORMAL MODE?

VA000014

YES

NO

YES

Page 25

25/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

INTERRUPTS

(Cont’d)

The interrupt routine begins usually by the identification of the device that has generated the interrupt request. The user should save the registers

which are used inside the interrupt routine (that

holds relevant data) into a software stack. After the

RETI instruction execution, the Core carries out

the previous actions and the main routine can continue.

3.4.5 ST638x Interrupt Details

IR Interrupt (#0) .

The IRIN/PC6 Interrupt is connected to the first interrupt #0 (NMI, 0FFCh). If the

IRINT

interrupt is disabled at the Latch circuitry,

then it will be high. The #0 interrupt input detects a

high to low level. Note that once #0 has been

latched, then the only way to remove the latched

#0 signal is to service the interrupt. #0 can interrupt the other interrupts. A simple latch is provided

from the PC6(IRIN) pin in order to generate the IRINT signal. This latch can be triggered by e ither

the positive or negative edge of IRINT

signal. IRINT is inverted with respect to the latch. The latch

can be read by software and reset by software.

TIMER 2 Interrupt (#1).

The TIMER 2 Interrupt is

connected to the interrupt #1 (0FF6h). The TIMER

2 interrupt generates a low level (which is latched

in the timer). Only the low level selection for #1 can

be used. Bit 6 of the interrupt option register C8h

has to be set.

VSYNC Interrupt (#2).

The VSYNC Interrupt is

connected to the interrupt #2. When disabled the

VSYNC INT signal is low. The VSYNC INT signal

is inverted with respect to the signal applied to the

VSYNC pin. Bit 5 of the interrupt option register

C8h is used to select the negat ive edge (ES2= 0)

or the positive edge (ES2=1); the edge will depend

on the application. Note that once an edge has

been latched, then the only way to remove the

latched signal is to service the interrupt. Care must

be taken not to generat e spurious interrupt s. This

interrupt may be used to s ynchronize the VSYNC

signal in order to change characters in the OSD

only when the screen is on vertical blanking (if desired). This method may also be used to blink

characters.

TIMER 1 Interru pt (#3).

The TIMER 1 I nt errupt is

connected to the fourth interrupt #3 (0FF2h) which

detects a low level (latched in the timer).

PWR Interrupt (#4).

The PWR Interrupt is connected to the fifth interrupt #4 (0FF0h). If the

PWRINT is disabled at the PWR circuitry, then it

will be high. The #4 interrupt input detects a low

level. A simple latch is provided from the PC4

(PWRIN)pin in order to generate the PWRINT signal. This latch can be triggered by either the positive or negative edge of the PWRIN signal.

PWRINT is inverted with respect to the latch. The

latch can be reset by software.

Notes:

Global disable does not reset edg e sensitive interrupt flags. These edge sensitive interrupts

become pending again when global disabling is released. Moreover, edge sensitive interrupts are

stored in the related flags also when interrupts are

globally disabled, unless each edge sensitive interrupt is also individually disabled before the interrupting event happens. Global disabl e is done

by clearing the GEN bit of Interrupt option r egister,

while any individual disab le is done in the control

register of the peripheral. The on-chip Timer peripherals have an interrupt request flag bit (TMZ),

this bit is set to one when the device wants to generate an interrupt request and a mask bit (ETI) that

must be set to one to al low the trans fer of the flag

bit to the Core.

Page 26

26/84

ST6365, ST6375, ST6385 ST6367, ST6377, ST6387

3.5 POWER SAVING MODES

STOP and WAIT m odes have be en implemented

in the ST638x in order to reduce the current consumption of the device d uring idle periods. These

two modes are described in the following paragraphs. Since the hardware activated digital

watchdog function is present, the STOP instruction is de-activated and any attempt to execute it

will cause th e automatic exe cution of a WAIT instruction.

3.5.1 WAIT Mode

The configuration of the MCU in the WAIT mode

occurs as soon as the WAIT instruction is executed. The microcontroller can also be considered as

being in a “software frozen” state where the Core

stops processing the instructions of the routine,

the contents of the RAM locations and peripheral

registers are saved as long as the power supply

voltage is higher than the RAM retention voltage

but where the peripherals are still working. The