Datasheet ST62T80BQ6, ST62E80BG1, ST6280BQ6, ST6280BQ1, ST6280B Datasheet (SGS Thomson Microelectronics)

Page 1

8-BIT OTP/EPROM MCU WITH LCD DRIVER,

■ 3.0 to 6.0V Supply Operating Range

■ 8 MHz Maximum Clock Frequency

■ -40 to +85°C Operating Temperature Range

■ Run, Wait and Stop Modes

■ 5 Interrupt Vectors

■ Look-up Table capability in Program Memory

■ Data Storage in Program Memory:

User selectable size

■ Data RAM: 192 bytes

■ Data EEPROM: 128 bytes

■ User Programmable Options

■ 22 I/O pins, fully programmable as:

– Input with pull-up resistor

– Input without pull-up resistor

– Input with interrupt generation

– Open-drain or push-pull output

– Analog Input

■ 10 I/O lines can sink up to 20mA to drive LEDs

or TRIACs directly

■ One 8-bit Timer/Counter with 7-bit

programmable prescaler

■ One 8-bit Auto-Reload Timer with 7-bit

programmable prescaler (ARTimer)

■ Digital Watchdog

■ 8-bit A/D Converter with 12 analog inputs

■ 8-bit Synchronous Peripheral Interface (SPI)

■ 8-bit AsynchronousPeripheralInterface (UART)

■ LCD driver with 48 segment outputs, 8

backplane outputs, 8 software selectable

segment/backplane outputs and selectable

multiplexing ratio.

■ 32kHz oscillator for stand-by LCD operation

■ On-chip Clockoscillator canbe driven by Quartz

Crystal or Ceramic resonator

■ One external Non-Maskable Interrupt

■ ST6280-EMU2 Emulation and Development

System (connects to an MS-DOS PC via a

parallel port).

ST62T80B/E80B

EEPROM AND A/D CONVERTER

PQFP100

CQFP100W

(See end of Datasheet for Ordering Information)

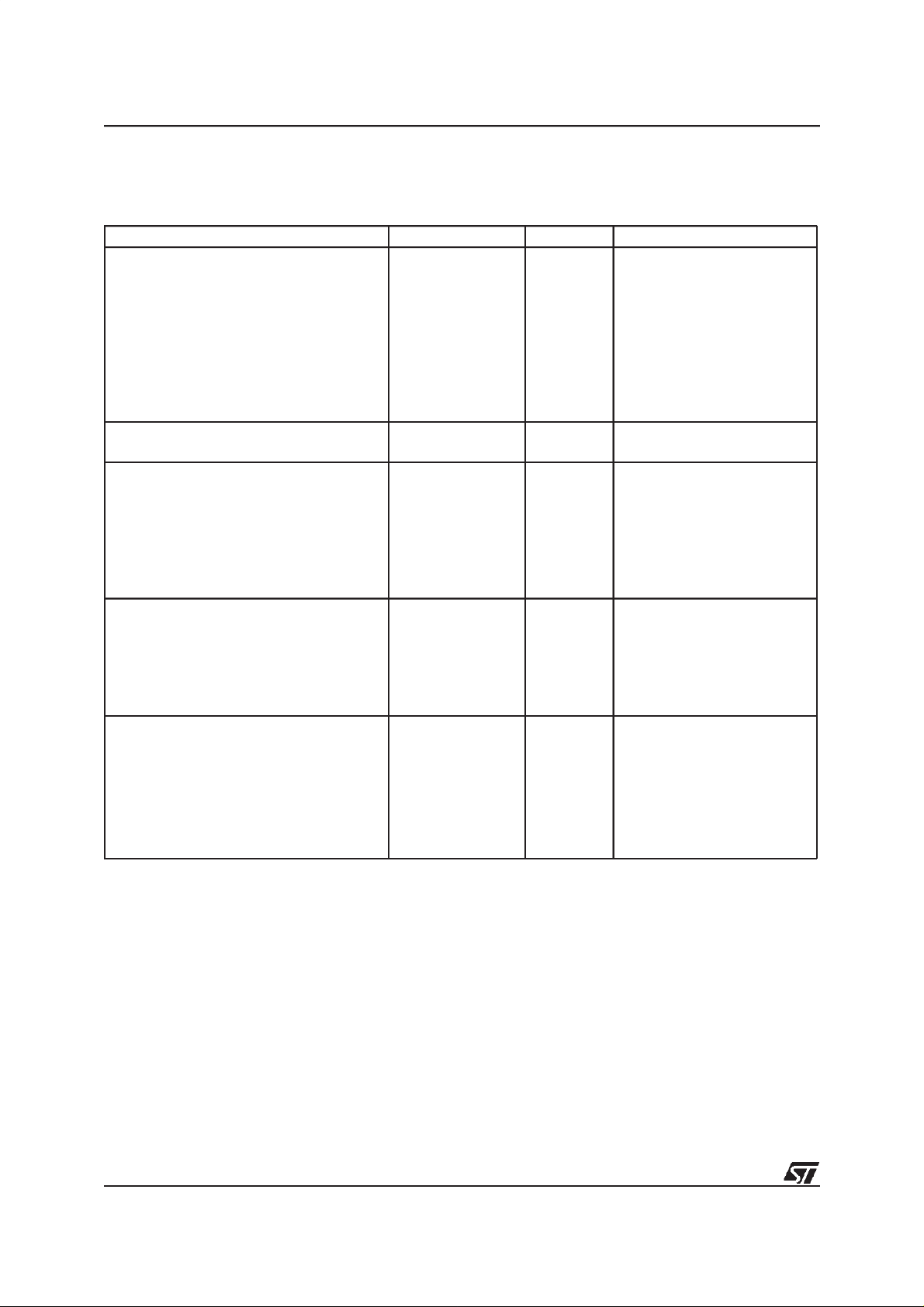

DEVICE SUMMARY

DEVICE

ST62T80B 7948 - 4 x 56 or 16 x 48

ST62E80B 7948 4 x 56 or 16 x 48

OTP

(Bytes)

EPROM

(Bytes)

LCD display

Rev. 2.5

August 1999 1/78

1

Page 2

Table of Contents

Document

Page

ST62T80B/E80B . ....................................1

1 GENERAL DESCRIPTION . . . . . . ................................................ 5

1.1 INTRODUCTION . . . . . . . . . . . . . ............................................5

1.2 PIN DESCRIPTIONS . . . . . . ................................................7

1.3 MEMORY MAP . . . . . . . . . . ................................................8

1.3.1 Introduction . . . ..................................................... 8

1.3.2 Program Space . . . . . . . . . . . . . . . . . . . . ................................. 8

1.3.3 Data Space . . . . . . . . . . . . . . . . . . . . . . . . . .............................. 10

1.3.4 Stack Space . . . . . . . . . . . . ...........................................10

1.3.5 Data Window Register (DWR) . ........................................11

1.3.6 Data RAM/EEPROM and LCD RAM Bank Register (DRBR) . . . . . . . . . . . . . . . . . . 12

1.3.7 EEPROM Description . . . . . . . . . . . . . . . . . . . . ........................... 13

1.4 PROGRAMMING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.1 Option Byte . . . .................................................... 15

1.4.2 Program Memory . . . ................................................ 15

1.4.3 EEPROM Data Memory . . . . . . . . . . . . . . . . . . . ........................... 15

1.4.4 EPROM Erasing .................................................... 15

2 CENTRAL PROCESSING UNIT . . ............................................... 16

2.1 INTRODUCTION . . . . . . . . . . . . . ........................................... 16

2.2 CPU REGISTERS . . . .................................................... 16

3 CLOCKS, RESET, INTERRUPTS AND POWER SAVING MODES . . ................... 18

3.1 CLOCK SYSTEM . . . . . . . . . . . . . ...........................................18

3.1.1 Main Oscillator . . . . . . . . . . . . . . . . . . . . ................................. 18

3.1.2 32 KHz STAND-BY OSCILLATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 RESETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 RESET Input . . .................................................... 20

3.2.2 Power-on Reset .................................................... 20

3.2.3 Watchdog Reset . . . . . . . . . . . . . . . . . . ................................. 21

3.2.4 Application Notes . . . ................................................ 21

3.2.5 MCU Initialization Sequence . . . . . . . . .................................. 21

3.3 DIGITAL WATCHDOG . . . . . . . . . . . . . . . . . . .................................. 23

3.3.1 Digital Watchdog Register (DWDR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.2 Application Notes . . . ................................................ 25

3.4 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . 27

3.4.1 Interrupt request . ...................................................27

3.4.2 Interrupt Procedure . . . . . . . . . . . . . . . . ................................. 28

3.4.3 Interrupt Option Register (IOR) . . . .. . . . . . . . . . . . . . . . . . . . . ............... 29

3.4.4 Interrupt sources . . . . . . . . . . . ........................................29

3.5 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 31

3.5.1 WAIT Mode ....................................................... 31

3.5.2 STOP Mode . . . . . . . . ...............................................31

3.5.3 Exit from WAIT and STOP Modes . . . . ..................................32

2/78

2

78

Page 3

Table of Contents

4 ON-CHIP PERIPHERALS . . . . . . . . . . . ...........................................33

4.1 I/O PORTS . . . . . . . . . . . . . . . . . . ...........................................33

4.1.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . ........................... 34

4.1.2 Safe I/O State Switching Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1.3 ARTimer alternate functions . . . . . . . . . . . . . . . ........................... 37

4.1.4 SPI alternate functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 37

4.1.5 UART alternate functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1.6 I/O Port Option Registers . . . . . . . . . . . .................................. 39

4.1.7 I/O Port Data Direction Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.8 I/O Port Data Registers . . . . . . ........................................ 39

4.2 TIMER . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . ................................. 40

4.2.1 Timer Operating Modes . . . . . . . . . . . . ..................................41

4.2.2 Timer Interrupt . . . . . . . . . . . . . . . . . . . . . ................................41

4.2.3 Application Notes . . . ................................................ 42

4.3 AUTO-RELOAD TIMER . . . . . . . . . . . . . . . . . . . . . .............................. 43

4.3.1 AR Timer Description . . . . . . . . ........................................43

4.3.2 Timer Operating Modes . . . . . . . . . . . . ..................................43

4.3.3 AR Timer Registers . . . . . . . . . . . . . . . . ................................. 47

4.4 U. A. R. T. (UNIVERSAL ASYNCHRONOUS RECEIVER/TRANSMITTER) . . . . . . . . . . . 49

4.4.1 PORTS INTERFACING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.4.2 CLOCK GENERATION . . . . . . . . . . ....................................50

4.4.3 DATA TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.4.4 DATA RECEPTION . . . . . . ...........................................51

4.4.5 INTERRUPT CAPABILITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.4.6 REGISTERS . . . . . . . . . . . . . . . . . . . . .................................. 51

4.5 A/D CONVERTER (ADC) . . ............................................... 53

4.5.1 Application Notes . . . ................................................ 53

4.6 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . ........... 55

4.7 LCD CONTROLLER-DRIVER . . . . . . ........................................57

4.7.1 Multiplexing ratio and frame frequency setting . . . . . . . . . ...................58

4.7.2 Segment and common plates driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.3 Stand by or STOP operation mode . . . . . . . . . . . . . . . . . . . . . . ............... 61

4.7.4 LCD Mode Control Register (LCDCR) ................................. 61

5 SOFTWARE . . . . . . . . . . . . . . . . . ............................................... 62

5.1 ST6 ARCHITECTURE . ...................................................62

5.2 ADDRESSING MODES . . . . . . . . . . . . . . . . . .................................. 62

5.3 INSTRUCTION SET . . . . . . . ............................................... 63

Document

Page

3/78

3

Page 4

Table of Contents

6 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . .............................. 68

6.1 ABSOLUTE MAXIMUM RATINGS . . . ........................................68

6.2 RECOMMENDED OPERATING CONDITIONS . . . .............................. 69

6.3 DC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . ...........70

6.4 AC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.5 A/D CONVERTERCHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.6 TIMER CHARACTERISTICS . . . . ...........................................72

6.7 SPI CHARACTERISTICS . . ...............................................72

6.8 LCD ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . ............... 72

7 GENERAL INFORMATION . . . . . . . . . . ........................................... 73

7.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . ........................... 73

7.2 PACKAGE THERMAL CHARACTERISTIC . . . . . . . . ........................... 74

7.3 .ORDERING INFORMATION . . . . ...........................................74

Document

Page

ST6280B ...........................................75

1 GENERAL DESCRIPTION . . . . . . ............................................... 76

1.1 INTRODUCTION . . . . . . . . . . . . . ........................................... 76

1.2 ROM READOUT PROTECTION . . . . . . . . . . . . ................................76

1.3 ORDERING INFORMATION . . . . . . . . . . . . . .................................. 78

1.3.1 Transfer of Customer Code . . . . . . . . . . ................................. 78

1.3.2 Listing Generation and Verification . . . . ................................. 78

4/78

4

78

Page 5

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

ST62T80B/E80B

The ST62T80B and ST62E80B devices are low

cost members of the ST62xx 8-bit HCMOS family

of microcontrollers, which is targetedat low to medium complexity applications. All ST62xx devices

are based on a building block approach: a com-

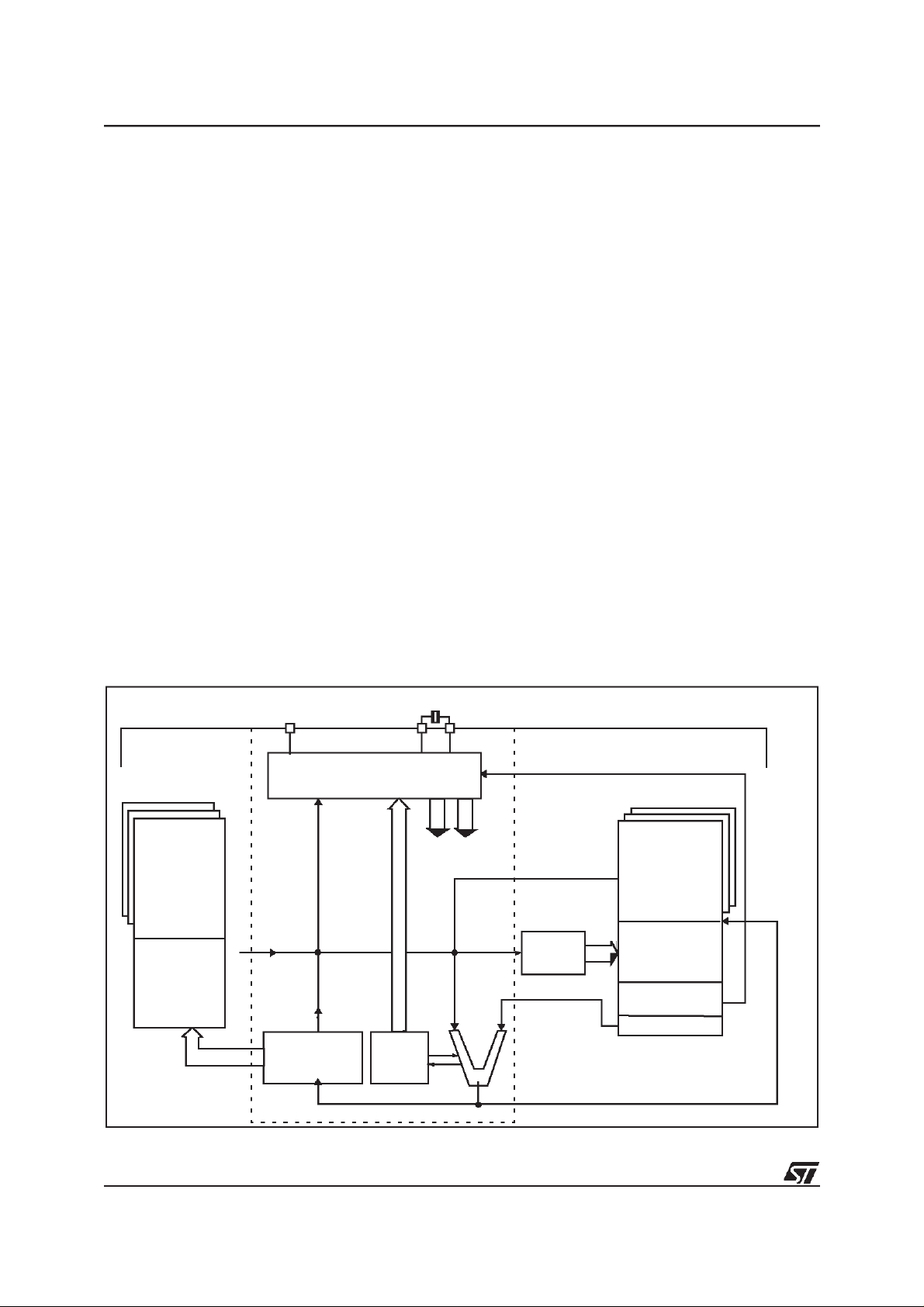

Figure 1. Block Diagram

8-BIT

TEST/V

NMI

PP

TEST

INTERRUPT

PROGRAM

Memory

7948 bytes

PC

STACK LEVEL 1

STACK LEVEL 2

STACK LEVEL 3

STACK LEVEL 4

STACK LEVEL 5

STACK LEVEL 6

POWER

SUPPLY

OSCILLATOR

A/D CONVERTER

DATA ROM

USER

SELECTABLE

DATA RAM

192 Bytes

DATA EEPROM

128 Bytes

8 BIT CORE

RESET

mon core is surrounded by a number of on-chip

peripherals.

The ST62E80B is the erasable EPROM version of

the ST62T80B device, which may be used to emulate the ST62T80B device, as well as the respective ST6280B ROM devices.

PA2..PA3 / 20mA Sink

PORT A

PORT B

ARTIMER

UART

PORT C

LCD DRIVER

OSC 32kHz

TIMER

DIGITAL

WATCHDOG

SPI (SERIAL

PERIPHERAL

INTERFACE)

PA4 / TIMER / 20mA Sink

PA5 / Scl / 20mA Sink

PA6 / Sin / 20mA Sink

PA7 / Sout / 20mA Sink

PB0 / RXD / Ain

PB1 / TXD / Ain

PB2..PB5 / Ain

PB6 / ARTIMin/ Ain

PB7 / ARTIMout / Ain

PC0..PC3/ 20mA Sink

PC4..PC7/ Ain

COM1..COM8

S9..S56

COM9..COM16 / S1..S8

VLCD

VLCD1/5

VLCD2/5

VLCD3/5

VLCD4/5

OSC32in

OSC32out

V

DDVSS

(V

on EPROM/OTP versions only)

PP

OSCin OSCout RESET

VA0479

5/78

5

Page 6

ST62T80B/E80B

INTRODUCTION (Cont’d)

OTP and EPROM devices are functionally identical. The ROM based versions offer the same functionality selecting as ROM options the options defined in the programmable option byte of the

OTP/EPROM versions.OTP devices offer all the

advantages of user programmability at low cost,

which make them the ideal choice in a wide range

of applications where frequent code changes, multiple code versions or last minute programmability

are required.

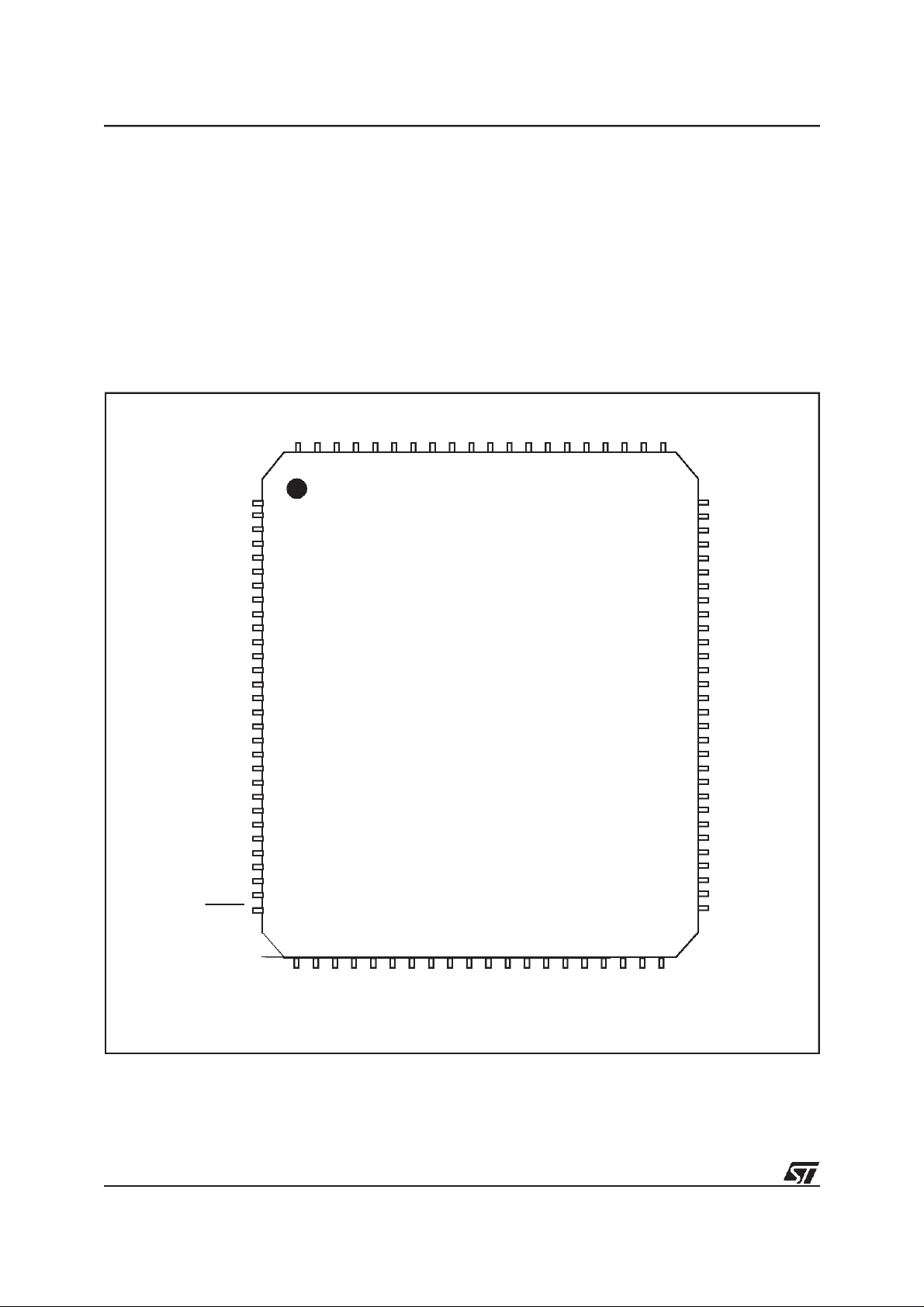

Figure 2. ST6280B Pin Description

S38

S37

S36

S35

S34

S33

S32

100 99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81

1

S39

2

S40

3

S41

4

S42

5

S43

6

S44

7

S45

S46

8

S47

9

S48

10

11

S49

12

S50

S51

13

14

S52

15

S53

16

S54

17

S55

18

S56

PB7/ARTIMout/Ain

PB6/ARTIMin/Ain

PB5/Ain

PB4/Ain

PB3/Ain

PB2/Ain

PB1/Ain

PB0/Ain

TEST

OSCout

OSCin

RESET

19

20

21

22

23

24

25

26

27

28

29

30

These compact low-cost devices feature one Timer comprising an 8-bit counter and a 7-bit programmable prescaler, one 8-bit autoreload timer

with 7-bit programmable prescaler (ARTimer),

EEPROM data capability, a serial synchronous

port interface (SPI), an 8-bit A/D Converterwith 12

analog inputs, a Digital Watchdog timer, and a

complete LCD controller driver, making them well

suited for a wide range of automotive, appliance

and industrial applications.

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

80

S18

79

S17

78

S16

77

S15

76

S14

75

S13

74

S12

73

S11

72

S10

71

S9

70

COM16/S8

69

COM15/S7

68

COM14/S6

67

COM13/S5

66

COM12/S4

65

COM11/S3

64

COM10/S2

63

COM9/S1

62

COM8

61

COM7

60

COM6

59

COM5

58

COM4

57

COM3

56

COM2

55

COM1

54

OSC32in

53

OSC32out

52

PA2*

51

PA3*

*Note: 20mA Sink

6/78

6

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

SS

DD

V

NMI

PC7/Ain

PC6/Ain

PC5/Ain

PC4/Ain

PC3*

PC2*

PC1*

PC0*

V

VLCD

VLCD4/5

VLCD3/5

VLCD2/5

VLCD1/5

PA6/Sin*

PA5/SCL*

PA7/Sout*

PA4/TIM1

Page 7

1.2 PIN DESCRIPTIONS

ST62T80B/E80B

VDDand VSS. Power is supplied to the MCU via

these two pins. VDDis the power connection and

VSSis the ground connection.

OSCin and OSCout. These pins are internally

connected tothe on-chip oscillator circuit. A quartz

crystal, a ceramic resonator or an external clock

signal can be connected between these two pins.

The OSCin pin is the input pin, the OSCout pin is

the output pin.

RESET. The active-low RESET pin is used to restart the microcontroller.

TEST/VPP. The TEST must be held at VSSfor nor-

mal operation. If TEST pin is connected to a

+12.5V level during the reset phase, the

EPROM/OTP programming Mode is entered.

NMI. TheNMI pin provides the capability for asynchronous interruption, byapplying an external non

maskable interrupt to the MCU. The NMI input is

falling edge sensitive with Schmitt trigger characteristics. The user can select as option the availability of an on-chip pull-up at this pin.

PA2-PA7. These 6 lines are organised as one I/O

port (A). Each line may be configured under software controlas inputs with or without internal pullup resistors, interrupt generating inputs with pullup resistors, open-drain or push-pull outputs,

PA5/SCL, PA6/Sin and PA7/Sout can be used respectively as data clock, data in and clock pins for

the on-chip SPI, while PA4/TIMER can be used as

Timer I/O. In addition, PA2-PA7 can sink20mA for

direct LED or TRIAC drive.

PB0...PB7. These 8 lines are organised asone I/O

port (B). Each line may be configured under software controlas inputs with or without internal pullup resistors, interrupt generating inputs with pullup resistors, open-drain or push-pull outputs, analog inputs for the A/D converter. PB6/ARTIMin

and PB7/ARTIMout are either Port B I/O bitsor the

input and output of the ARTimer. PB0 (resp. PB1)

can also be usedas reception (resp. transmission)

line for the embedded UART.

PC0-PC7. These 8 lines are organised as one I/O

port (C). Each line may be configured under software control as input with or without internal pullup resistor, interrupt generating input with pull-up

resistor, open-drain or push-pull output, or analog

imputs for the A/D Converter. PC0-PC3 can sink

20mA for direct LED or TRIAC drive, while PC4PC7 can be used as analog inputs for the A/D

Converter.

COM1-COM8. These eight pins are the LCD peripheral common outputs. They are the outputs of

the on-chip backplane voltage generator which is

used for multiplexing the LCD lines.

COM9/S1-COM16/S8. These pins are the 8 multiplexed common/segment lines. Under software

selected control, they can act as LCD common

outputs allowing a 48x 16 dot matrix operation, or

they can act as segment outputs alowwing 56 x 8

dot matrix operation.

S9-S56. These pins are the 48 LCD peripheral

segment outputs.

VLCD1/5, VLCD5/5. Display supplyvoltage inputs

for determining the display voltage levels on

common and segment pins during multiplex operation.

OSC32in and OSC32out. These pins are internally connected with the on-chip 32kHz oscillator

circuit. A 32.768kHz quartz crystal can be connected between these two pins if it is necessary to

provide the LCD stand-by clockand real time interrupt. OSC32in is the input pin, OSC32out is the

output pin.

7/78

7

Page 8

ST62T80B/E80B

1.3 MEMORY MAP

1.3.1 Introduction

The MCU operates in three separate memory

spaces: Program space, Data space, and Stack

space. Operationin these three memory spaces is

described in the following paragraphs.

Briefly, Program space contains user program

code in Program memory and user vectors; Data

space contains user data in RAM and in Program

memory, and Stack space accommodates six levels of stack for subroutine and interrupt service

routine nesting.

1.3.2 Program Space

Program Space comprises the instructions to be

executed, the data required for immediate addressing mode instructions, the reserved factory

test area and the user vectors. Program Space is

addressed via the 12-bit Program Counter register

(PC register).

Program Space is organised in four 2K pages.

Three of them are addressedin the 000h-7FFh locations of the Program Space by the Program

Counter and by writing the appropriate code in the

Program ROM Page Register (PRPR register). A

Figure 4. Memory Addressing Diagram

common (STATIC) 2K page is available all the

time for interrupt vectors and common subroutines, independently of the PRPR register content.

This “STATIC” page is directly addressed in the

0800h-0FFFh by the MSB of the ProgramCounter

register PC 11. Note this page can also be addressed in the 000-7FFh range. It is two different

ways of addressing the same physical memory.

Jump from a dynamic page to another dynamic

page is achieved by jumping back to the static

page, changing contents of PRPR and then jumping to the new dynamic page.

Figure 3. 8Kbytes Program Space Addressing

PC

SPACE

000h

7FFh

800h

FFFh

0000h

Page 0

Page 1

Static

Page

ROM SPACE

Page 1

Static

Page

1FFFh

Page 2 Page 3

0000h

0FF0h

0FFFh

PROGRAM SPACE

PROGRAM

MEMORY

INTERRUPT &

RESET VECTORS

0-63

000h

03Fh

040h

07Fh

080h

081h

082h

083h

084h

0C0h

0FFh

DATA SPACE

RAM / EEPROM

BANKING AREA

DATA READ-ONLY

MEMORY

X REGISTER

Y REGISTER

V REGISTER

W REGISTER

DATA READ-ONLY

WINDOW SELECT

BANK SELECT

ACCUMULATOR

WINDOW

RAM

MEMORY

DATA RAM

VR01568

8/78

8

Page 9

MEMORY MAP (Cont’d)

ST62T80B/E80B

Table 1. ST62E80B/T80B Program MemoryMap

ROM Page Device Address Description

Page 0

Page 1

“STATIC”

Page 2

Page 3

0000h-007Fh

0080h-07FFh

0800h-0F9Fh

0FA0h-0FEFh

0FF0h-0FF7h

0FF8h-0FFBh

0FFCh-0FFDh

0FFEh-0FFFh

0000h-000Fh

0010h-07FFh

0000h-000Fh

0010h-07FFh

Reserved

User ROM

User ROM

Reserved

Interrupt Vectors

Reserved

NMI Vector

Reset Vector

Reserved

User ROM

Reserved

User ROM

Note: OTP/EPROM devices can be programmed

with thedevelopment toolsavailable fromSTMicroelectronics (ST62E8X-EPB).

1.3.2.1 Program ROM Page Register (PRPR)

The PRPR register can be addressed like a RAM

location in the Data Space at the address CAh ;

nevertheless it is a write only register that cannot

be accessed with single-bit operations. This register is used to select the 2-Kbyte ROM bank of the

Program Space that will be addressed. The

number of the page has to be loaded in the PRPR

register. Refer to the Program Space description

for additional information concerning the use of

this register. The PRPR register is not modified

when an interrupt or a subroutine occurs.

Care is required when handling the PRPR register

as it is write only. For this reason, it is not allowed

to change the PRPR contents while executing interrupt service routine, as the service routine

cannot save and then restore its previous content.

This operation may be necessary if common routines and interrupt service routines take more than

2K bytes ; in this case it could be necessary to divide the interruptservice routineinto a (minor) part

in the static page (start and end) and to a second

(major) part in one ofthe dynamic pages. If it is impossible to avoid the writing ofthis register in interrupt service routines, an image of this register

must be saved in a RAM location, and each time

the program writes to the PRPR it must write also

to the image register. The image register must be

written before PRPR, so if an interrpt occurs between the two instructions the PRPR is not affected.

Program ROM Page Register (PRPR)

Address: CAh — Write Only

70

- - - - - - PRPR1 PRPR0

Bits 2-7= Not used.

Bit 5-0 = PRPR1-PRPR0:

Program ROM Select.

These two bits select the corresponding page to

be addressed in the lower part of the 4K program

address space as specified in Table 2.

This register is undefined on Reset. Neither read

nor single bit instructions may be used to address

this register.

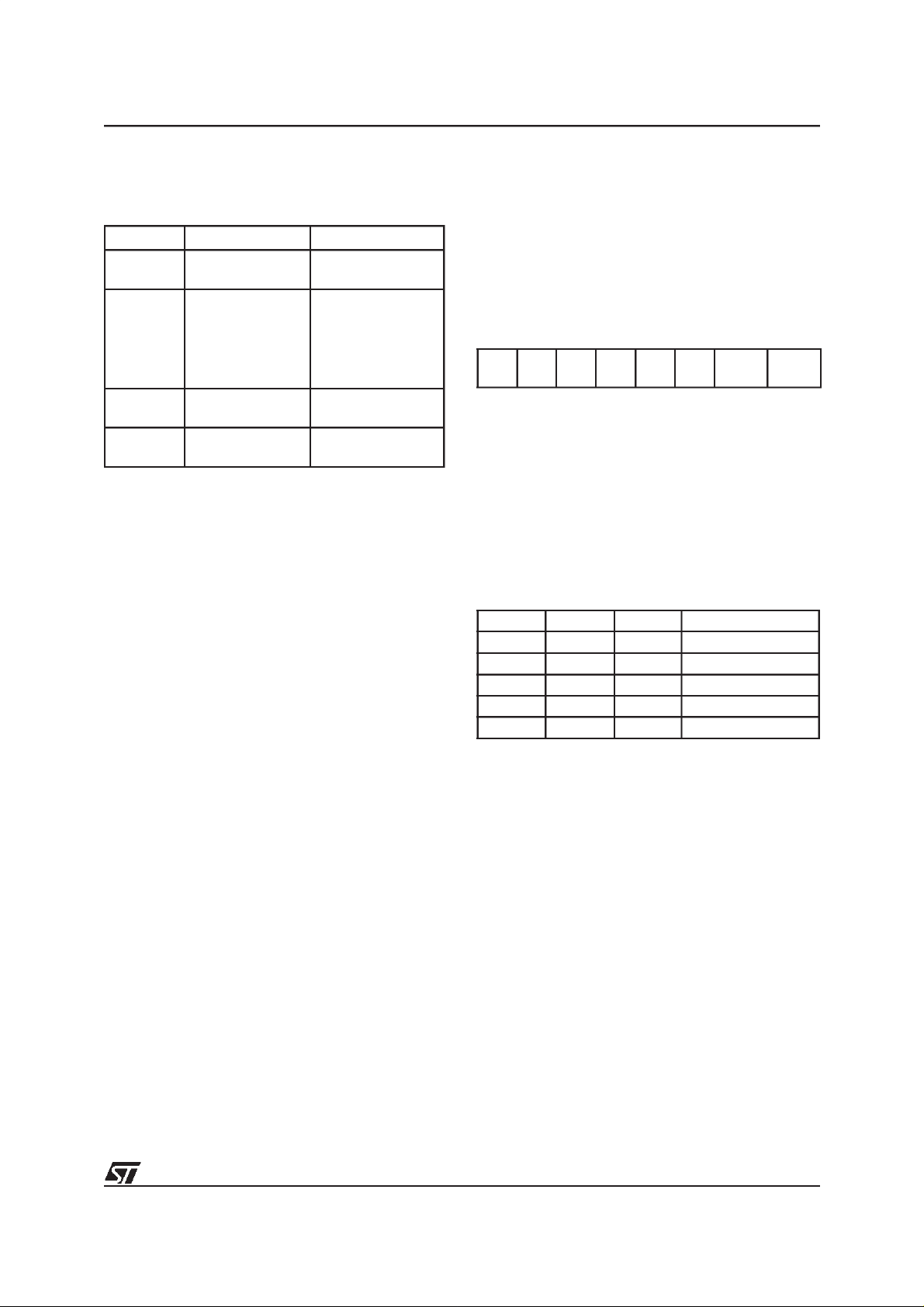

Table 2. 8Kbytes Program ROM Page Register

Coding

PRPR1 PRPR0 PC bit 11 Memory Page

X X 1 Static Page (Page 1)

0 0 0 Page 0

0 1 0 Page 1 (Static Page

1 0 0 Page 2

1 1 0 Page 3

1.3.2.2 Program Memory Protection

The Program Memory in OTP or EPROM devices

can be protected againstexternal readoutof memory by selecting the READOUT PROTECTION option in the option byte.

In the EPROM parts, READOUT PROTECTION

option can be disactivated only by U.V. erasure

that also results into the whole EPROM context

erasure.

Note: Once the Readout Protection is activated, it

is no longer possible, even for STMicroelectronics,

to gain access to the Program memory contents.

Returned parts with a protection set can therefore

not be accepted.

9/78

9

Page 10

ST62T80B/E80B

MEMORY MAP (Cont’d)

1.3.3 Data Space

Data Space accommodates all the data necessary

for processing the user program. This space comprises the RAM resource, the processor core and

peripheral registers, as well as read-only data

such as constants and look-up tables in Program

memory.

1.3.3.1 Data ROM

All read-only data is physically stored in program

memory, which also accommodates the Program

Space. The program memory consequently contains the program code to be executed, as well as

the constants and look-up tables required by the

application.

The Data Space locations in which the different

constants and look-up tables are addressedby the

processor core may be thought of as a 64-byte

window through which it is possible to access the

read-only data stored in Program memory.

1.3.3.2 Data RAM/EEPROM

In ST62T80B and ST62E80B devices, the data

space includes 60 bytes of RAM, the accumulator

(A), the indirect registers (X), (Y), the short direct

registers (V), (W), the I/O port registers, the peripheral data and control registers, the interrupt

option register and the Data ROM Window register

(DRW register).

Additional RAM and EEPROM pages can also be

addressed using banks of 64 bytes located between addresses 00h and 3Fh.

1.3.4 Stack Space

Stack space consists of six 12-bit registers which

are used to stack subroutine and interrupt return

addresses, as well as the current program counter

contents.

Table 3. Additional RAM/EEPROM Banks.

Device RAM EEPROM LCD RAM

ST62T80B/E80B 2 x 64 bytes 2 x 64 bytes 2 x 64 bytes

Table 4. ST62T80B/E80B Data Memory Space

DATA RAM/EEPROM, LCD RAM

DATA ROM WINDOW AREA

X REGISTER 080h

Y REGISTER 081h

V REGISTER 082h

W REGISTER 083h

DATARAM

PORT A DATAREGISTER 0C0h

PORT B DATAREGISTER 0C1h

SPI INTERRUPT DISABLE REGISTER 0C2h

PORT C DATAREGISTER 0C3h

PORT A DIRECTION REGISTER 0C4h

PORT B DIRECTION REGISTER 0C5h

PORT C DIRECTION REGISTER 0C6h

RESERVED 0C7h

INTERRUPTOPTION REGISTER 0C8h*

DATAROM WINDOW REGISTER 0C9h*

ROM BANK SELECTREGISTER 0CAh*

DATARAM/EEPROM, LCD BANK SELECT REGISTER 0CBh*

PORT A OPTION REGISTE R 0CCh

RESERVED 0CDh

PORT B OPTION REGISTE R 0CEh

PORT C OPTION REGISTER 0CFh

A/D DATAREGISTER 0D0h

A/D CONTROL REGISTER 0D1h

TIMER 1 PRESCALER REGISTER 0D2h

TIMER 1 COUNTERREGISTER 0D3h

TIMER 1 STATUS/CONTROLREGISTER 0D4h

RESERVED 0D5h

UARTDATA REGISTER 0D6h

UARTCONTROL REGISTER 0D7h

WATCHDOGREGISTER 0D8h

RESERVED

32kHz OSCILLATORCONTROL REGISTER 0DBh

LCD MODE CONTROL REGISTE R 0DCh

SPI DATAREGISTER 0DDh

RESERVED 0DEh

EEPROM CONTROL REGISTER 0DFh

RESERVED

ARTIMER MODE/CONTROL REGISTER 0E5h

ARTIMER STATUS/CONTROL REGISTER 0 0E6h

ARTIMER STATUS/CONTROL REGISTER 1 0E7h

RESERVED

ARTIMER RELOAD/CAPTUREREGISTER 0E9h

ARTIMER COMPARE REGISTER 0EAh

ARTIMER LOAD REGISTER 0EBh

RESERVED

ACCUMULATOR OFFh

* WRITE ONLYREGISTER

000h

03Fh

040h

07Fh

084h

0BFh

0D9h

0DAh

0E0h

0E4h

0ECh

0FEh

10/78

10

Page 11

MEMORY MAP (Cont’d)

1.3.5 Data Window Register (DWR)

ST62T80B/E80B

Data Window Register (DWR)

TheData read-only memorywindowislocatedfrom

address 0040h to address 007Fh in Data space. It

allows directreading of 64 consecutive bytes located anywhere in program memory, between address 0000h and 1FFFh (top memory address depends on the specific device). All the program

memory can therefore be used to store either instructions or read-only data. Indeed, the window

can be moved in steps of 64 bytes along the program memoryby writingtheappropriate code inthe

Data Window Register (DWR).

The DWR can beaddressed like anyRAM location

in the Data Space, it is however a write-only register and therefore cannotbe accessed using singlebit operations. This register is used to position the

64-byte read-only data window (from address 40h

to address 7Fh of the Data space) in program

memory in 64-byte steps. The effective address of

the byte to be read as data in program memory is

obtained by concatenating the 6 least significant

bits of the register address given in the instruction

(as least significant bits) and the content of the

DWR register(as most significant bits), as illustrated in Figure 5 below. For instance, when addressing location 0040h of the Data Space, with 0 loaded in the DWR register, the physical location addressed inprogram memory is 00h. The DWRregister is not cleared on reset, therefore it must be

written to prior tothe first access to the Data readonly memory window area.

Address: 0C9h — Write Only

70

- DWR6 DWR5 DWR4 DWR3 DWR2 DWR1 DWR0

Bits 7 = Not used.

Bit 6-0 = DWR6-DWR0:

Window Register Bits.

Data read-only memory

These are the Data readonly memory Window bits that correspond to the

upper bits of the data read-only memory space.

Caution:

This register is undefined on reset. Neither read nor single bit instructions may be used to

address this register.

Note: Care is required when handling the DWR

register as it is write only. For this reason, the

DWR contents should not be changed while executing an interrupt service routine, as the service

routine cannot saveand then restore the register’s

previous contents. If it is impossible to avoid writing to the DWR during the interrupt service routine,

an image of the register must be saved in a RAM

location, and each time the program writes to the

DWR, it must also write to the image register. The

image register must be written first so that, if an interrupt occurs between the two instructions, the

DWR is not affected.

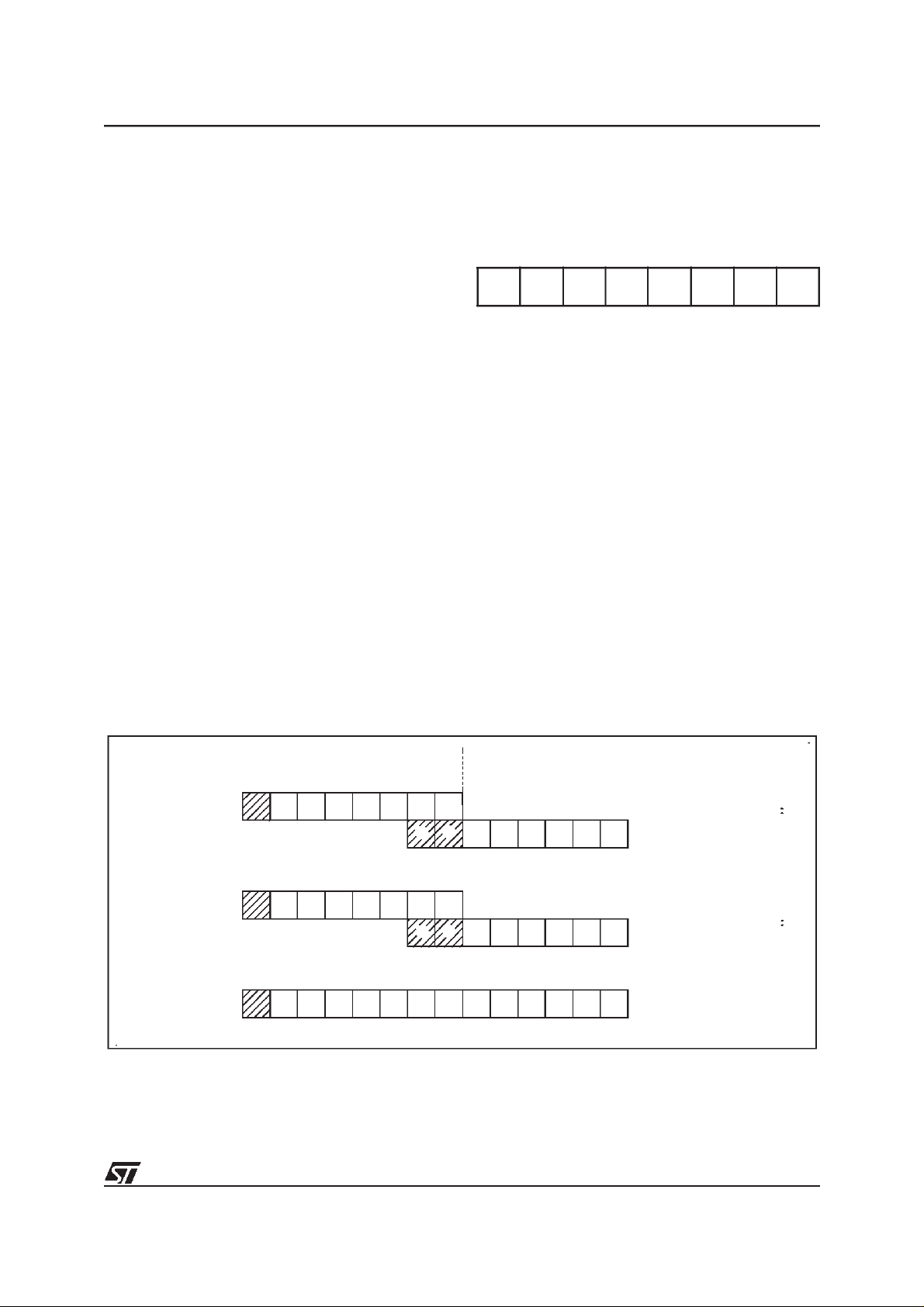

Figure 5. Data read-only memory Window Memory Addressing

543210

DATA ROM

WINDOW REGISTER

CONTENTS

(DWR)

12

13

765432 0

67891011

1

543210

01

Example:

DWR=28h

ROM

ADDRESS:A19h

11

00000000

11

0

0000

0

1

1

01001

1

11

PROGRAM SPACE ADDRESS

READ

DATA SPACE ADDRESS

40h-7Fh

IN INSTRUCTION

DATA SPACE ADDRESS

59h

VR0A1573

11/78

11

Page 12

ST62T80B/E80B

MEMORY MAP (Cont’d)

1.3.6 Data RAM/EEPROM and LCD RAM Bank

Register (DRBR)

Address: CBh — Write only

70

- DRBR6 DRBR5 DRBR4 DRBR3 - DRBR1 DRBR0

Bit 7 = This bit is not used

Bit 6 - DRBR6. This bit, when set, selects LCD

RAM Page 2.

Bit 5 - DRBR5. This bit, when set, selects LCD

RAM Page 1.

Bit 4 - DRBR4. This bit, when set, selects RAM

Page 2.

Bit 3 - DRBR3. This bit, when set, selects RAM

Page 1.

Bit2. These bits are not used.

Bit 1 - DRBR1. This bit, when set, selects

EEPROM Page 1.

Bit 0 - DRBR0. This bit, when set, selects

EEPROM Page 0.

The selection of the bank is made by programming

the Data RAM Bank Switch register (DRBR register) located at address CBh of the Data Space according to Table 1. No more than one bank should

be set at a time.

The DRBR register can be addressed like a RAM

Data Space at the address CBh; nevertheless it is

a write only register that cannot be accessed with

single-bit operations. This register isused to select

the desired 64-byte RAM/EEPROM bank of the

Data Space. Thenumber of banks has to be loaded in the DRBR register and the instruction has to

point to the selected location as if it was in bank 0

(from 00h address to 3Fh address).

This register is not cleared during the MCU initialization, therefore it must be written before the first

access to the Data Space bank region. Refer to

the Data Space description for additional information. The DRBR register is not modified when an

interrupt or a subroutine occurs.

Notes :

Care is required when handling the DRBR register

as it is write only. For this reason, it is not allowed

to change the DRBR contents while executing interrupt service routine, as the service routine cannot save and thenrestore its previous content. If it

is impossible to avoid the writing of this register in

interrupt service routine, an image of this register

must be saved in a RAM location, and each time

the program writes to DRBR it must write also to

the image register. The image register must be

written first, so if an interrupt occurs between the

two instructions the DRBR is not affected.

In DRBR Register, only 1 bit must be set. Otherwise two or more pages are enabled in parallel,

producing errors.

Table 5. Data RAM Bank Register Set-up

DRBR ST62T80B/E80B

00 None

01 EEPROM Page 0

02 EEPROM Page 1

08 RAM Page 1

10h RAM Page 2

20h LCD RAM Page 1

40h LCD RAM Page 2

other Reserved

12/78

12

Page 13

MEMORY MAP (Cont’d)

1.3.7 EEPROM Description

EEPROM memory is located in 64-byte pages in

data space. This memory maybe used by theuser

program for non-volatile data storage.

Data spacefrom 00h to3Fh is paged as described

in Table 6. EEPROM locations are accessed directly by addressing these paged sections of data

space.

The EEPROM does not require dedicated instructions forreadorwrite access.Onceselectedvia the

Data RAM Bank Register, the active EEPROM

page is controlled by the EEPROM Control Register (EECTL), which is described below.

Bit E20FFof the EECTL registermust bereset prior

to any write or read access to the EEPROM. If no

bank hasbeen selected, or if E2OFF is set, any access is meaningless.

Programming must be enabled by setting the

E2ENA bit of the EECTL register.

The E2BUSY bitof the EECTL register is setwhen

the EEPROM is performing a programming cycle.

Any access to the EEPROM when E2BUSY is set

is meaningless.

Provided E2OFF and E2BUSY are reset, an EEPROM location is read just like any other data location, also in terms of access time.

Writing to the EEPROM may be carried out in two

modes: Byte Mode (BMODE) and Parallel Mode

ST62T80B/E80B

(PMODE). In BMODE, one byte is accessed at a

time, while in PMODE up to 8 bytes in the same

row are programmed simultaneously (with consequent speed and power consumption advantages,

the latter being particularly important in battery

powered circuits).

General Notes:

Data should be written directly to the intended ad-

dress in EEPROM space. There is nobuffer memory between data RAM and the EEPROM space.

When the EEPROM is busy (E2BUSY = “1”)

EECTL cannot be accessed in write mode, it is

only possible to read the status of E2BUSY. This

implies that as long as the EEPROM is busy, it is

not possible to change the status of the EEPROM

Control Register. EECTL bits 4 and 5 are reserved

and must never be set.

Care is required whendealing withthe EECTL register, as some bits are write only. For this reason,

the EECTL contents must not be altered while executing an interrupt service routine.

If it is impossible to avoid writing to this register

within an interrupt service routine, an image of the

register must be saved in a RAM location, and

each time the program writes to EECTL it must

also write to the image register.The image register

must be written to first so that, if an interrupt occurs between the two instructions, the EECTL will

not be affected.

Table 6. Row Arrangement for Parallel Writing of EEPROM Locations

Dataspace

addresses.

Banks 0 and 1.

Byte 0 1234567

ROW7 38h-3Fh

ROW6 30h-37h

ROW5 28h-2Fh

ROW4 20h-27h

ROW3 18h-1Fh

ROW2 10h-17h

ROW1 08h-0Fh

ROW0 00h-07h

Up to 8 bytes in each row may be programmed simultaneously in Parallel Write mode.

The number of available 64-byte banks (1 or 2) is device dependent.

13/78

13

Page 14

ST62T80B/E80B

MEMORY MAP (Cont’d)

Additional Notes on Parallel Mode:

If the user wishes to perform parallel programming, the first step should be to set the E2PAR2

bit. From this time on, the EEPROM will be addressed in write mode, the ROW address will be

latched and it will be possible to change it only at

the end of the programming cycle, or by resetting

E2PAR2 without programming the EEPROM. After the ROW addressis latched,the MCU can only

“see” the selected EEPROM row and any attempt

to write or read other rows will produce errors.

The EEPROM should not be read while E2PAR2

is set.

As soon as the E2PAR2 bit is set, the 8 volatile

ROW latches are cleared. From this moment on,

the user can load data in allor in part ofthe ROW.

Setting E2PAR1 will modify the EEPROM registers corresponding to the ROW latches accessed

after E2PAR2. For example, if the software sets

E2PAR2 and accesses the EEPROM by writing to

addresses 18h, 1Ah and 1Bh, and then sets

E2PAR1, these three registers will be modified simultaneously; the remaining bytes in the row will

be unaffected.

Note that E2PAR2 is internally reset at the end of

the programming cycle. This implies that the user

must setthe E2PAR2 bit between two parallel programming cycles. Note that if the user tries to set

E2PAR1 while E2PAR2 is not set, there will be no

programming cycleand the E2PAR1 bit will be unaffected. Consequently, the E2PAR1bit cannot be

set if E2ENA is low. The E2PAR1 bit can be setby

the user, only if the E2ENA and E2PAR2 bits are

also set.

EEPROM Control Register (EECTL)

Address: DFh — Read/Write

Reset status: 00h

70

D7 E2OFF D5 D4 E2PAR1 E2PAR2 E2BUSY E2ENA

Bit 7 = D7:

Bit6= E2OFF:

Unused.

Stand-byEnable Bit.

WRITE ONLY.

IfthisbitissettheEEPROMisdisabled(anyaccess

will bemeaningless) and the power consumption of

the EEPROM is reduced to its lowest value.

Bit 5-4 = D5-D4:

Bit 3 = E2PAR1:

Reserved.

MUST be kept reset.

Parallel Start Bit.

WRITE ONLY.

OnceinParallelMode,as soonastheuser software

sets the E2PAR1 bit, parallel writing of the 8 adjacent registers will start. This bit is internally reset at

the end of the programming procedure. Note that

less than 8 bytescan bewritten if required, the undefined bytes being unaffected by the parallel programmingcycle;thisis explained ingreater detailin

the Additional Notes on Parallel Mode overleaf.

Bit 2 = E2PAR2:

Parallel Mode En. Bit.

WRITE

ONLY. This bit must be set by the user program in

order to perform parallel programming. If E2PAR2

is set and the parallel start bit (E2PAR1) is reset,

up to 8 adjacent bytes can be written simultaneously. These 8 adjacent bytes are considered as a

row, whose address lines A7, A6, A5, A4, A3 are

fixed while A2, A1 and A0 are the changingbits, as

illustrated in Table 6. E2PAR2 is automatically reset at the end of any parallel programming procedure. It can be reset by the user software before

starting the programming procedure, thus leaving

the EEPROM registers unchanged.

Bit 1 = E2BUSY:

EEPROM Busy Bit.

READ ONLY. This bit is automatically set by the EEPROM

control logic when the EEPROM is in programming mode. The userprogram should test it before

any EEPROM read or write operation; any attempt

to access the EEPROM while the busy bit is set

will be aborted and the writing procedure in

progress will be completed.

Bit 0 = E2ENA:

EEPROM Enable Bit.

WRITE ONLY. This bit enables programming of the EEPROM

cells. It must be set before any write to the EEPROM register. Any attempt to write to the EEPROM when E2ENA is low is meaningless and will

not trigger a write cycle.

14/78

14

Page 15

1.4 PROGRAMMING MODES

ST62T80B/E80B

1.4.1 Option Byte

The Option Byte allows configuration capability to

the MCUs. Option byte’s content is automatically

read, and the selected options enabled, when the

chip reset is activated.

It can only be accessed during the programming

mode. This access is made either automatically

(copy from a master device) or by selecting the

OPTION BYTE PROGRAMMING modeof the programmer.

The option byte is located in a non-user map. No

address has to be specified.

EPROM Code Option Byte

70

--

PRO-

TECT

NMI

PULL

- WDACT -

Bit 7-5. Reserved.

Bit 5= PROTECT. This bit allows the protection of

the software contents against piracy. When the bit

PROTECT is set high, readout of the OTP contents is prevented by hardware. No programming

equipment is able to gain access to the user program. When this bit is low, the user program can

be read.

Bit 4. Reserved.

Bit 3 = NMI PULL. . This bit must beset highto en-

able the internal pull-up resistor. When low, no

pull-up is provided.

Bit 2. Reserved.

Bit 1 = WDACT. This bit controls the watchdog ac-

tivation. When it is high, hardware activation is selected. The software activation is selected when

WDACT is low.

Bit 0 = Reserved.

The Option byte is written during programming ei-

ther by using the PC menu (PC driven Mode) or

1.4.2 Program Memory

EPROM/OTP programming mode is set by a

+12.5V voltage applied to the TEST/VPPpin. The

programming flow of the ST62T80B/E80B is described in the User Manual of the EPROM Programming Board.

The MCUs can be programmed with the

ST62E8xB EPROM programming tools available

from STMicroelectronics.

1.4.3 EEPROM Data Memory

EEPROM data pages are supplied in the virgin

state FFh. Partial or total programming of EEPROM data memory can be performed either

through the application software, or through anexternal programmer. Any STMicroelectronics tool

used for the program memory (OTP/EPROM) can

also be used to program the EEPROM data memory.

1.4.4 EPROM Erasing

The EPROM of the windowed package of the

MCUs may be erased by exposure to Ultra Violet

light. The erasure characteristic of the MCUs is

such that erasure begins when the memory is exposed to light with a wave lengths shorter than approximately 4000Å. It should be noted that sunlights and some types of fluorescent lamps have

wavelengths in the range 3000-4000Å.

It is thus recommended that the window of the

MCUs packages be covered by an opaque label to

prevent unintentional erasure problems when testing the application in such an environment.

The recommended erasure procedure of the

MCUs EPROM is the exposure to short wave ultraviolet light which have a wave-length 2537A.

The integrated dose (i.e. U.V. intensity x exposure

time) for erasure should be a minimum of 15Wsec/cm2. The erasure time with this dosage is approximately 15 to 20 minutes using an ultraviolet

lamp with 12000µW/cm2power rating. The

ST62E80B should be placed within 2.5cm (1Inch)

of the lamp tubes during erasure.

automatically (stand-alone mode)

15/78

15

Page 16

ST62T80B/E80B

2 CENTRAL PROCESSING UNIT

2.1 INTRODUCTION

The CPU Coreof ST6devicesisindependent ofthe

I/O or Memory configuration. As such, it may be

thought of as an independent central processor

communicating with on-chip I/O, Memory and Peripherals via internal address, data, and control

buses. In-core communication is arranged as

shown in Figure 6; the controller being externally

linked to both the Reset and Oscillator circuits,

while thecore is linked to thededicated on-chip peripherals via the serial data bus and indirectly, for

interrupt purposes, through the control registers.

2.2 CPU REGISTERS

TheST6FamilyCPUcorefeaturessixregisters and

three pairs of flags available to the programmer.

These are described in the following paragraphs.

Accumulator (A). The accumulator is an 8-bit

general purpose register used in all arithmetic calculations, logical operations, and data manipulations. The accumulator can be addressed in Data

space as a RAM location at address FFh. Thus the

ST6 can manipulate the accumulator just like any

other register in Data space.

Figure 6. ST6 Core Block Diagram

Indirect Registers (X, Y). These two indirect reg-

isters are used as pointers to memory locations in

Data space. They are used in the register-indirect

addressing mode. These registers can be addressed in the dataspace as RAM locations at addresses 80h (X) and 81h (Y). They can also beaccessed with the direct, short direct, or bit direct addressing modes. Accordingly, the ST6 instruction

set can usethe indirect registers as any other register of the data space.

Short Direct Registers (V, W). These two registers are used to save a byte in short direct addressing mode. They can be addressed in Data

space as RAM locations at addresses 82h (V)and

83h (W). They can also be accessed using the direct and bit direct addressing modes. Thus, the

ST6 instruction set can use the short direct registers as any other register of the data space.

Program Counter (PC). The program counter is a

12-bit register which contains the address of the

next ROM location to be processed by the core.

This ROM location may be an opcode, an operand, or the address of an operand. The 12-bit

length allows the direct addressing of 4096 bytes

in Program space.

PROGRAM

ROM/EPROM

12

RESET

CONTROLLER

OPCODE

Program Counter

and

6 LAYER STACK

FLAG

VALUES

0,01 TO 8MHz

OSCin

CONTROL

SIGNALS

2

A-DATA

FLAGS

OSCout

ADDRESS/READ LINE

ADDRESS

DECODER

B-DATA

ALU

RESULTS TO DATA SPACE (WRITE LINE)

INTERRUPTS

256

DATA SPACE

DATA

RAM/EEPROM

DATA

ROM/EPROM

DEDICATIONS

ACCUMULATOR

VR01811

16/78

16

Page 17

CPU REGISTERS (Cont’d)

However, ifthe program space contains more than

4096 bytes, the additional memory in program

space can be addressed by using the Program

Bank Switch register.

The PC value is incremented after reading the address of the current instruction. Toexecute relative

jumps, the PC and the offset are shifted through

the ALU, where they are added; the result is then

shifted backinto the PC.The programcounter can

be changedin the following ways:

- JP (Jump) instructionPC=Jump address

- CALL instructionPC= Call address

- Relative Branch Instruction.PC= PC +/- offset

- Interrupt PC=Interrupt vector

- Reset PC= Reset vector

- RET & RETI instructionsPC= Pop (stack)

- Normal instructionPC=PC + 1

Flags (C, Z). The ST6 CPU includes three pairs of

flags (Carry and Zero), each pair being associated

with one of the three normal modes of operation:

Normal mode, Interrupt mode and Non Maskable

Interrupt mode. Each pair consists of a CARRY

flag and a ZERO flag. One pair (CN, ZN) is used

during Normal operation, another pair is used during Interrupt mode (CI, ZI), and a third pair is used

in the Non Maskable Interrupt mode (CNMI, ZNMI).

The ST6 CPU uses the pair of flags associated

with the current mode: as soon as an interrupt (or

a Non Maskable Interrupt) is generated, the ST6

CPU uses the Interrupt flags (resp. the NMI flags)

instead of the Normal flags. When the RETI instruction is executed, the previously used set of

flags is restored. It should be noted that each flag

set can only be addressed in its own context (Non

Maskable Interrupt, Normal Interrupt or Main routine). The flags are not cleared during context

switching and thus retain their status.

The Carry flag is set when a carry or a borrow occurs during arithmetic operations; otherwise it is

cleared. The Carry flag is also set to the value of

the bit tested in a bit test instruction; it also participates in the rotate left instruction.

The Zero flag is set if the result of the last arithmetic or logical operation was equal to zero; otherwise it is cleared.

Switching between the three sets of flags is performed automatically when an NMI, an interrupt or

a RETI instructions occurs. As the NMI mode is

ST62T80B/E80B

automatically selected after the reset of the MCU,

the ST6 core uses at first the NMI flags.

Stack. The ST6 CPU includes a true LIFO hardware stack which eliminates the need for a stack

pointer. The stack consists of six separate 12-bit

RAM locations that do not belong to the data

space RAM area. When a subroutine call (or interrupt request) occurs, the contents of each level are

shifted intothe next higher level, while the content

of the PC is shifted into the first level (the original

contents of the sixth stack level are lost). When a

subroutine or interruptreturn occurs (RET or RETI

instructions), the first level register is shifted back

into the PC and the value of each level is popped

back into the previous level. Since the accumulator, in common with all other data space registers,

is not stored in this stack, management of these

registers should be performed within the subroutine. The stack will remain in its “deepest” position

if morethan 6 nested calls orinterrupts are executed, and consequently the last return address will

be lost. It will also remain in its highest position if

the stack is emptyand aRET or RETI is executed.

In this case the next instruction will be executed.

Figure 7. ST6 CPU Programming Mode

l

INDEX

REGISTER

INTERRUPTFLAGS

NMI FLAGS

b7

b7

b7

b7

b7

PROGRAMCOUNTER

SIX LEVELS

STACKREGISTER

X REG. POINTER

Y REG. POINTER

VREGISTER

W REGISTER

ACCUM ULATOR

b0

b0

b0

b0

b0

b0b11

CZNORMAL FLAGS

CZ

CZ

SHORT

DIRECT

ADDRESSING

MODE

VA000 4 23

17/78

17

Page 18

ST62T80B/E80B

3 CLOCKS, RESET, INTERRUPTS AND POWER SAVING MODES

3.1 CLOCK SYSTEM

3.1.1 Main Oscillator

The MCU featuresa Main Oscillator which can be

driven by an external clock, or used in conjunction

with an AT-cut parallel resonant crystal or a suitable ceramic resonator.

Figure 8 illustrates various possible oscillator configurations using anexternal crystal or ceramic resonator, an external clock input. CL1an CL2should

have acapacitance in the range 12 to 22 pF for an

oscillator frequency in the 4-8 MHz range.

The internal MCU clock Frequency (F

) is divid-

INT

ed by 13 to drive the CPU core and by 12 to drive

the A/D converter and the watchdog timer, while

clock used to drive on-chip peripherals depends

on the peripheral as shown in the clock circuit

block diagram.

With an 8MHz oscillator frequency, the fastest machine cycle is therefore 1.625µs.

A machine cycle is the smallest unit of time needed

to executeany operation (for instance, toincrement

the Program Counter). An instruction may require

two, four, or five machine cycles for execution.

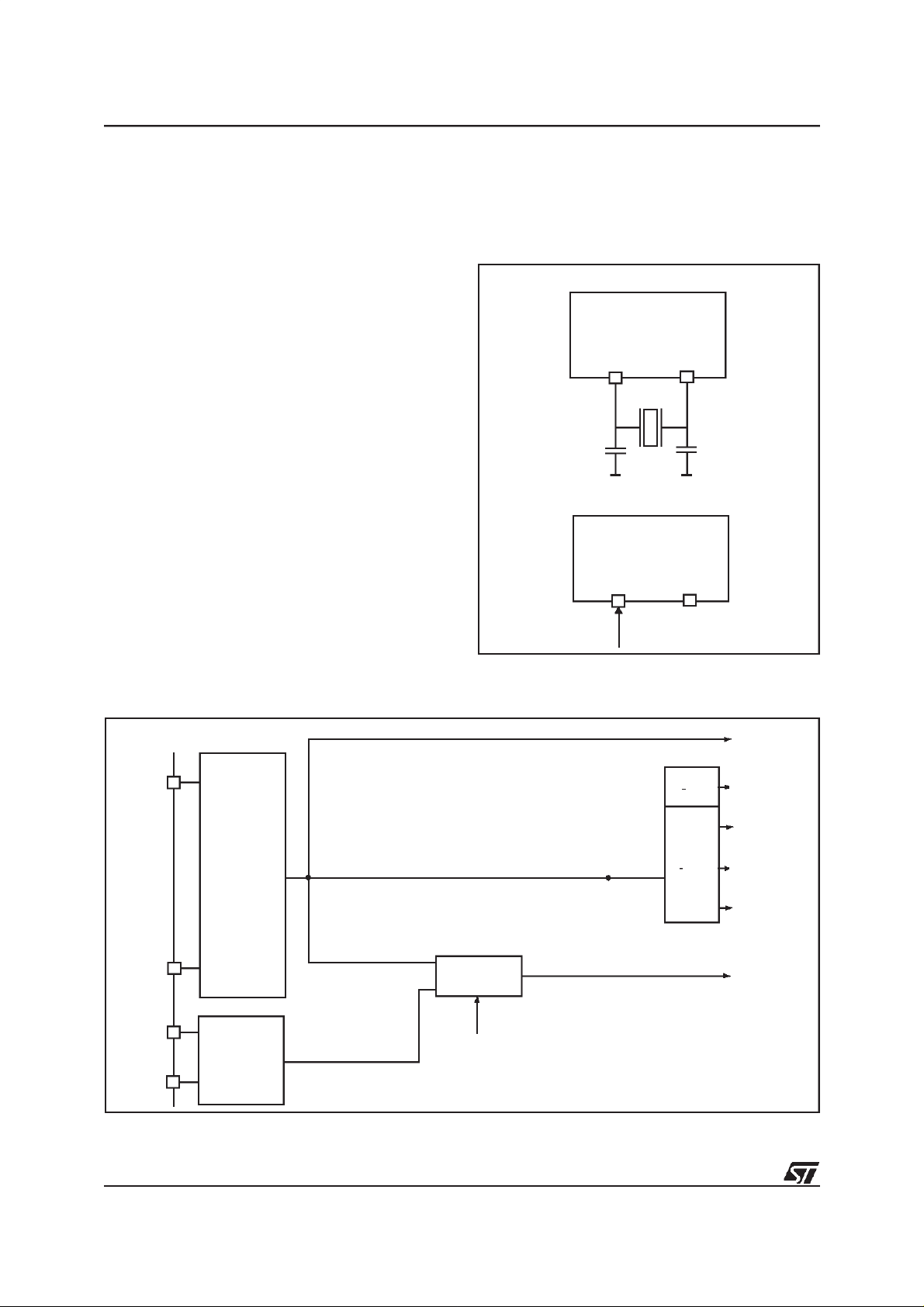

Figure 9. Clock Circuit Block Diagram

Figure 8. Oscillator Configurations

CRYSTAL/RESONATOR CLOCK

ST6xxx

OSC

C

L1n

EXTERNAL CLOCK

OSC

in

ST6xxx

in

OSC

OSC

NC

out

out

C

L2

VA0016

VA0015A

OSCin

OSCout

OSC32in

OSC32out

18/78

18

f

OSC

MAIN

OSCILLATOR

32kHz

OSCILLATOR

POR

f

INT

f

INT

MUX

EOCR bit 5

(START/STOP)

:13

:12

Core

Timer 1 & 2

Watchdog

ADC

LCD

CONTROLLER

DRIVER

Page 19

CLOCK SYSTEM (Cont’d)

3.1.2 32 KHz STAND-BY OSCILLATOR

An additional32KHz stand-by on chip oscillatorallows to generate real time interrupts and to supply

the clock to the LCD driver with the main oscillator

stopped. This enables the MCU to perform real

time functions with the LCD display running while

keeping advantages of low power consumption.

Figure 10 shows the 32KHz oscillator block diagram.

A 32.768KHz quartz crystalmust be connected to

the OSC32in and OSC32out pins to perform the

real time clock operation. Two external capacitors

of 15-22pF each must be connected between the

oscillator pinsand ground. The 32KHz oscillator is

managed by the dedicated status/control register

32OCR.

As long as the 32KHz stand-by oscillator is enabled, 32KHz internal clock is available to drive

LCD controller driver. This clock is divide by 214to

generate interrupt request every 500ms . The periodic interrupt request serves as reference timebase for real time functions.

Note: When the 32KHz stand-by oscillator is

stopped (bit 5 of the Status/Control register

cleared) the divider chain is supplied with a clock

signal synchronous with machine cycle (f

this produces an interrupt request every 13x2

INT

/13),

14

clock cycle (i.e. 26.624ms) with an 8MHz quartz

crystal.

ST62T80B/E80B

32KHz Oscillator Register (32OCR)

Address: DBh - Read/Write

70

EOSCI OSCEOC S/S D4 D3 D2 D1 D0

Bit 7= EOSCI.

when set, enables the 32KHz oscillator interrupt

request.

Bit 6 = OSCEOC.

indicates whenthe 32KHzoscillator has measured

a 500ms elapsed time (providing a

32.768KHzquartz crystal is connected to the

32KHz oscillator dedicated pins). An interrupt request can be generated in relation to the state of

EOSCI bit. This bit must be cleared by the user

program before leaving the interrupt service routine.

Bit 5 = START/STOP.O

This bit, when set, enables the 32KHz stand-by

oscillator and the free running divider chainis supplied by the 32KHz oscillator signal. When this bit

is cleared to zero the divider chain is supplied with

f

/13.

INT

This register is cleared during reset.

Note:

To achieve minimumpower consumption in STOP

mode (no system clock), the stand-by oscillator

must be switched off (real time function not available) by clearing the Start/Stop bit in the oscillator

status/control register.

Enable Oscillator Interrupt

Oscillator Interrupt Flag

scillator Start/Stop bit

. This bit,

. This bit

.

Figure 10. 32KHz Oscillator Block Diagram

2x15...22pF

OSC32IN

OSC32KHz MUX

32.768KHz

Crystal

OSC32OUT

EOSCI OSCEOC

START

STOP

OSC32KHz

f

INT

INT

1

0

/13

XXXXX

DIV2

14

19/78

19

Page 20

ST62T80B/E80B

3.2 RESETS

The MCU can be reset in three ways:

– by the external Reset input being pulled low;

– by Power-on Reset;

– by the digital Watchdog peripheral timing out.

3.2.1 RESET Input

The RESET pin may be connected to a device of

the application board in order to reset the MCU if

required. The RESET pin may be pulled low in

RUN, WAIT or STOP mode. This input can be

used to reset the MCU internal state and ensure a

correct start-up procedure. The pin is active low

and features a Schmitt trigger input. The internal

Reset signal is generated by adding a delay to the

external signal. Therefore even short pulses on

the RESET pin are acceptable, provided VDDhas

completed its risingphase andthat the oscillator is

running correctly (normal RUN or WAIT modes).

The MCU is kept in the Reset state as long as the

RESET pin is held low.

If RESET activation occurs in the RUN or WAIT

modes, processing of the user program is stopped

(RUN modeonly), the Inputs and Outputs are configured as inputs with pull-up resistors and the

main Oscillator is restarted. When the level on the

RESET pin then goes high, the initialization sequence is executed following expiry of the internal

delay period.

If RESET pin activation occurs in the STOP mode,

the oscillator starts up and all Inputs and Outputs

are configured as inputs with pull-up resistors.

When the level of the RESET pin then goes high,

the initialization sequence is executed following

expiry of the internal delay period.

3.2.2 Power-on Reset

The function of the POR circuit consists in waking

up the MCU at an appropriate stage during the

power-on sequence. At the beginning of this sequence, the MCU is configured in the Reset state:

all I/O ports are configured as inputs with pull-up

resistors and no instruction is executed. When the

power supplyvoltage rises to a sufficient level, the

oscillator starts to operate, whereupon an internal

delay is initiated, in order to allow the oscillator to

fully stabilize before executing the first instruction.

The initialization sequence isexecuted immediately following the internal delay.

The internaldelay isgenerated byan on-chipcounter. Theinternal reset lineis released 2048 internal

clock cycles after release of the external reset.

Notes:

To ensure correct start-up, the user should take

care that the reset signal is not released before the

VDDlevel is sufficient to allow MCU operation at

the chosen frequency (see Recommended Operating Conditions).

A proper reset signal for a slow rising VDDsupply

can generally be provided by an external RC network connected to the RESET pin.

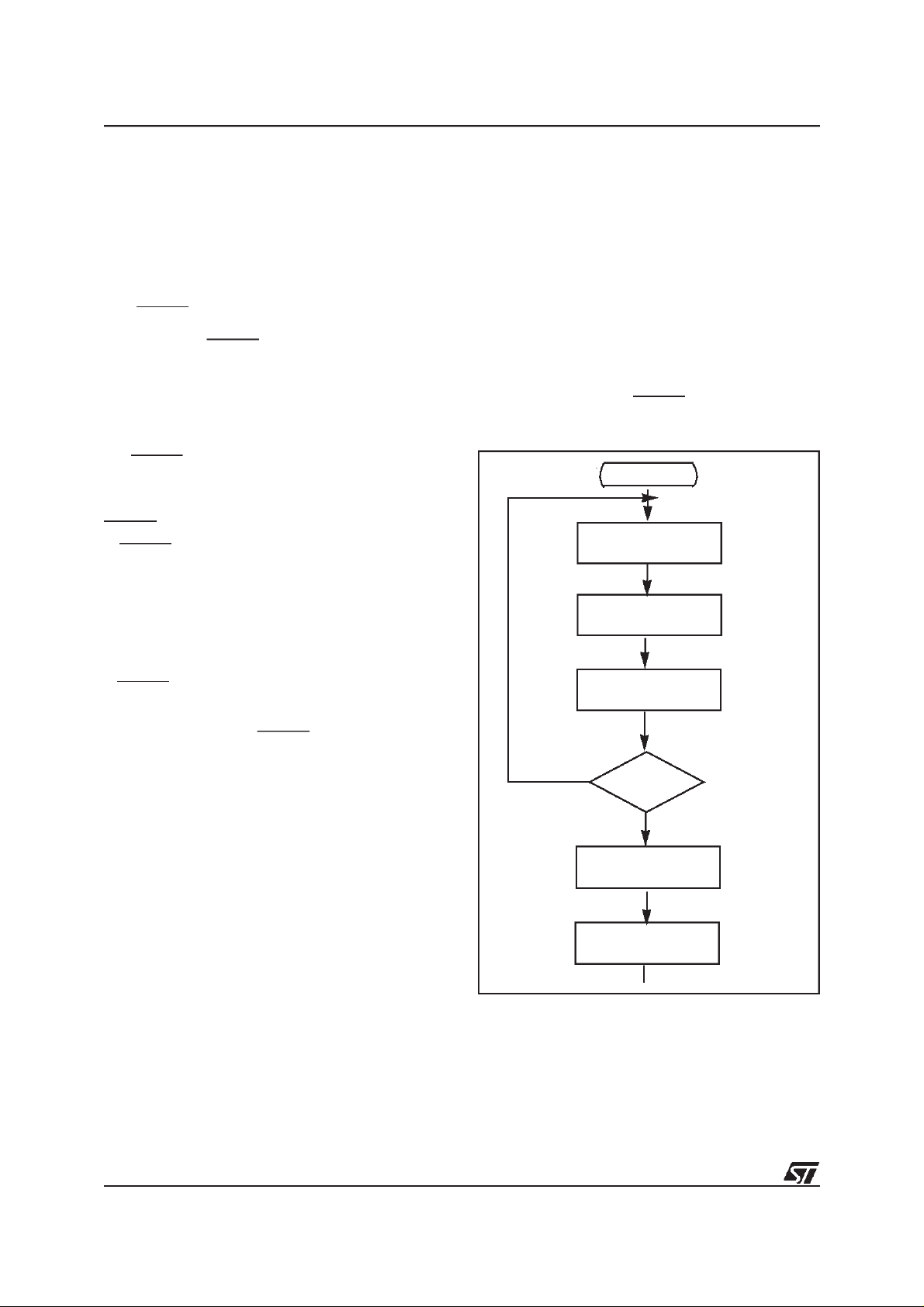

Figure 11. Reset and Interrupt Processing

RESET

NMI MASK SET

INT LATCH CLEARED

( IF PRESENT )

SELECT

NMI MODE FLAGS

PUT FFEH

ON ADDRESS BUS

YES

IS RESET STILL

PRESENT?

NO

LOAD PC

FROM RESET LOCATIONS

FFE/FFF

FETCH INSTRUCTION

VA000427

20/78

20

Page 21

RESETS (Cont’d)

3.2.3 Watchdog Reset

The MCU provides a Watchdog timer function in

order to ensure graceful recovery from software

upsets. If the Watchdog register is not refreshed

before an end-of-count condition is reached, the

internal reset will be activated. This, amongst other things, resets the watchdog counter.

The MCU restarts just as though the Reset had

been generated by the RESET pin, including the

built-in stabilisation delay period.

3.2.4 Application Notes

No external resistor is required between VDDand

the Reset pin, thanks to the built-in pull-up device.

The POR circuit operates dynamically, in that it

triggers MCU initialization on detecting the rising

edge of VDD. The typical threshold is in the region

of 2 volts, but the actual value of the detected

threshold depends on the way in which VDDrises.

The POR circuit is

NOT

designed to supervise

static, or slowly rising or falling VDD.

3.2.5 MCU Initialization Sequence

When a reset occurs the stack is reset, the PC is

loaded with the address of the Reset Vector (located in program ROM starting at address 0FFEh). A

jump tothe beginning of theuser program must be

coded at this address. Following a Reset, the Interrupt flag is automatically set, so that the CPU is

in Non Maskable Interrupt mode; this prevents the

ST62T80B/E80B

initialisation routine from being interrupted. The initialisation routine should therefore be terminated

by a RETI instruction, in order to revert to normal

mode and enable interrupts. Ifno pending interrupt

is presentat theend of the initialisation routine, the

MCU will continue by processing the instruction

immediately following the RETI instruction. If, however, a pending interrupt is present, it will be serviced.

Figure 12. Reset and Interrupt Processing

RESET

JP:2 BYTES/4 CYCLES

RESET

VECTOR

INITIALIZATION

ROUTINE

JP

RETI: 1 BYTE/2 CYCLES

RETI

VA00181

Figure 13. Reset Block Diagram

V

DD

300kΩ

RESET

2.8kΩ

POWER

WATCHDOG RESET

ON RESET

f

OSC

RESET

CK

COUNTER

RESET

ST6

INTERNAL

RESET

VA0200B

21/78

21

Page 22

ST62T80B/E80B

RESETS (Cont’d)

Table 7. Register Reset Status

Register Address(es) Status Comment

EEPROM Control Register

Port Data Registers

Port A,B Direction Register

Port A,B Option Register

Interrupt Option Register

0DFh

0C0h, 0C1h, 0C3h

0C4h to 0C6h

0CCh, 0CEh, OCFh

0C8h

00h

EEPROM enabled

I/O are Input with pull-up

Interrupt disabled

SPI Registers

LCD Mode Control Register

32kHz Oscillator Register

UART Control

UART Data Register

X, Y,V, W, Register

Accumulator

Data RAM

Data RAM/EEPROM/LCDRAM Page Register

Data ROM Window Register

EEPROM

A/D Result Register

TIMER 1 Status/Control

TIMER 1 Counter Register

TIMER 1 Prescaler Register

Watchdog Counter Register

A/D Control Register

AR TIMER Mode Control Register

AR TIMER Status/Control 1 Register

AR TIMER Status/Control 2Register

AR TIMER Compare Register

0C2h, 0DDh

0DCh

0DBh

080H TO 083H

0FFh

084h to 0BFh

0CBh

0C9h

00h to 03Fh

0D0h

0D4h

0D3h

0D2h

0D8h

0D1h

0E5h

0E6h

0E7h

0EAh

SPI disabled

LCD display off

Interrupt disabled

00h UART disabled

Undefined As written if programmed

00h

FFh

7Fh

FEh

40h

00h

TIMER 1 disabled/Max count

loaded

A/D in Standby

AR TIMER stopped

AR TIMER Load Register

AR TIMER Reload/Capture Register

22/78

22

0EBh

0E9h

Undefined

As written if programmed

Page 23

3.3 DIGITAL WATCHDOG

ST62T80B/E80B

The digital Watchdog consists of a reloadable

downcounter timer which can be used to provide

controlled recovery from software upsets.

The Watchdog circuit generates a Reset when the

downcounter reaches zero. User software can

prevent this reset by reloading the counter, and

should therefore be written so that the counter is

regularly reloaded while the user program runs

correctly. Inthe event of a software mishap (usually caused by externally generated interference),

the userprogram will no longer behave in its usual

fashion and the timer register will thus not be reloaded periodically. Consequently the timer will

decrement down to 00h and reset the MCU. In order to maximise the effectiveness of the Watchdog

function, user software must be written with this

concept in mind.

Table 8. Recommended Option Choices

Functions Required Recommended Options

Stop Mode “SOFTWARE WATCHDOG”

Watchdog “HARDWARE WATCHDOG”

Watchdog behaviour is governed by one option,

known as “WATCHDOG ACTIVATION” (i.e.

HARDWARE or SOFTWARE) (See Table8).

In the SOFTWARE option, the Watchdog is disabled until bit C of the DWDR register has been set.

When the Watchdog is disabled, low power Stop

mode is available. Once activated, the Watchdog

cannot be disabled, except by resetting the MCU.

In the HARDWARE option, the Watchdog is permanently enabled. Sincethe oscillatorwill run continuously, low power mode is not available. The

STOP instruction is interpreted as a WAIT instruction, and the Watchdog continues to countdown.

When the MCU exits STOP mode (i.e. when aninterrupt is generated), the Watchdog resumes its

activity.

23/78

23

Page 24

ST62T80B/E80B

DIGITAL WATCHDOG (Cont’d)

The Watchdog is associated with a Data space

register (Digital WatchDog Register, DWDR, location 0D8h) which is described in greater detail in

Section 3.3.1 . This register is set to 0FEh on Reset: bit C is cleared to “0”, which disables the

Watchdog; the timer downcounter bits, T0 to T5,

and the SR bit are all set to “1”, thus selecting the

longest Watchdog timer period. This time period

can be set to the user’s requirements by setting

the appropriate value for bits T0 to T5 in the

DWDR register. The SR bit must be set to “1”,

since itis this bit which generates the Reset signal

when it changes to “0”; clearing this bit would generate an immediate Reset.

It should be noted that the order of the bits in the

DWDR register is inverted with respect to the associated bits in the down counter: bit 7 of the

DWDR register corresponds, in fact, to T0 and bit

2 to T5. The user should bear in mind the fact that

these bits are inverted and shifted with respect to

the physicalcounter bits when writing tothis register. The relationship between the DWDR register

bits and the physical implementation ofthe Watchdog timer downcounter is illustrated in Figure 14.

Only the 6 most significant bits may be used to define the time period, since it is bit 6 which triggers

the Reset when it changes to “0”. This offers the

user a choice of 64 timed periods ranging from

3,072 to 196,608 clock cycles (with an oscillator

frequency of8MHz, this is equivalent to timer periods ranging from 384µs to 24.576ms).

Figure 14. Watchdog Counter Control

D0

D1

C

SR

RESET

D2

D3

D4

D5

D6

WATCHDOG CONTROL REGISTER

D7

T5

T4

T3

WATCHDOG COUNTER

T2

T1

T0

8

÷2

OSC÷12

VR02068A

24/78

24

Page 25

DIGITAL WATCHDOG (Cont’d)

3.3.1 Digital Watchdog Register (DWDR)

Address: 0D8h — Read/Write

Reset status: 1111 1110b

70

It should be noted that the register bits are reversed and shifted with respect to the physical

counter: bit-7 (T0) is the LSB of the Watchdog

downcounter and bit-2 (T5) is the MSB.

These bits are set to “1” on Reset.

ST62T80B/E80B

T0 T1 T2 T3 T4 T5 SR C

Bit 0 = C:

Watchdog Control bit

If the hardware option is selected, this bitis forced

high and the user cannot change it (the Watchdog

is always active). When the software option is selected, the Watchdog function is activated by setting bit C to 1, and cannot then be disabled (save

by resetting the MCU).

When C is kept low the counter can be used as a

7-bit timer.

This bit is cleared to “0” on Reset.

Bit 1 = SR:

Software Reset bit

This bit triggers a Resetwhen cleared.

When C = “0” (Watchdog disabled) it is the MSB of

the 7-bit timer.

This bit is set to “1” on Reset.

Bits 2-7 = T5-T0:

Downcounter bits

3.3.2 Application Notes

The Watchdog plays an important supporting role

in the high noise immunity of ST62xx devices, and

should be used wherever possible. Watchdog related options should be selected on the basis of a

trade-off between application security and STOP

mode availability.

When STOP mode is not required, hardware activation should be preferred, as it provides maximum security, especially during power-on.

When software activation is selected and the

Watchdog is not activated, the downcounter may

be used as a simple 7-bit timer (remember that the

bits are in reverse order).

The software activation option should be chosen

only when the Watchdog counter is to be used as

a timer. To ensure the Watchdog has not been unexpectedly activated, the following instructions

should be executed within the first 27 instructions:

jrr 0, WD, #+3

25/78

25

Page 26

ST62T80B/E80B

DIGITAL WATCHDOG (Cont’d)

These instructions test the C bit and Reset the

MCU (i.e. disable the Watchdog) if the bit is set

(i.e. if the Watchdog is active), thus disabling the

Watchdog.

In all modes, a minimum of 28 instructions are executed after activation, before the Watchdog can

generate a Reset. Consequently, user software

Figure 15. Digital Watchdog Block Diagram

RESET

should load the watchdog counter within the first

27 instructions following Watchdog activation

(software mode), or within the first 27 instructions

executed following a Reset (hardware activation).

It should benoted that when the GEN bit is low(interrupts disabled), the NMI interrupt is active but

cannot cause a wake up from STOP/WAIT modes.

S

Q

RSFF

7

-2

R

DB0

DB1.7 SETLOAD

8

WRITE

RESET

DATA BUS

-2

SET

8

-12

OSCILLATOR

CLOCK

VA00010

26/78

26

Page 27

3.4 INTERRUPTS

ST62T80B/E80B

The CPU can manage four Maskable Interrupt

sources, in addition to a Non Maskable Interrupt

source (top priority interrupt). Each source is associated with a specific Interrupt Vector which contains aJump instruction to the associated interrupt

service routine. These vectors are located in Program space (see Table 9).

When an interrupt source generates an interrupt

request, and interrupt processing is enabled, the

PC registeris loaded with the address of the interrupt vector (i.e. of the Jump instruction), which

then causes a Jump to the relevant interrupt service routine, thus servicing the interrupt.

Interrupt sourcesare linked to events either on external pins, or on chip peripherals. Several events

can be ORed on the same interrupt source, and

relevant flags are available to determine which

event triggered the interrupt.

The Non Maskable Interrupt request has the highest priority and can interrupt any interrupt routine

at any time; the other four interrupts cannot interrupt each other. If more than one interrupt request

is pending, these are processed by the processor

core according to theirpriority level: source #1 has

the higher priority while source #4 the lower. The

priority of each interrupt source is fixed.

Table 9. Interrupt Vector Map

Interrupt Source Priority Vector Address

Interrupt source #0 1 (FFCh-FFDh)

Interrupt source #1 2 (FF6h-FF7h)

Interrupt source #2 3 (FF4h-FF5h)

Interrupt source #3 4 (FF2h-FF3h)

Interrupt source #4 5 (FF0h-FF1h)

3.4.1 Interrupt request

All interrupt sources but the Non Maskable Interrupt source can be disabled by setting accordingly

the GEN bit of the Interrupt Option Register (IOR).

This GEN bitalso defines if aninterrupt source,including the Non Maskable Interrupt source, can restart the MCU from STOP/WAIT modes.

Interrupt request from the Non Maskable Interrupt

source #0 is latched by a flip flop which is automat-

ically resetby the core at the beginning of the nonmaskable interrupt service routine.

Interrupt request from source #1 can be configured either as edge or level sensitive by setting accordingly the LES bit of the Interrupt Option Register (IOR).

Interrupt request from source #2 are always edge

sensitive. The edge polarity can be configured by

setting accordingly the ESB bit of the Interrupt Option Register (IOR).

Interrupt request from sources #3 & #4 are level

sensitive.

In edge sensitive mode, alatch is set when a edge

occurs on the interrupt source line and is cleared

when the associated interrupt routine is started.

So, the occurrence of an interrupt can be stored,

until completion of the running interrupt routine before being processed. If several interruptrequests

occurs before completion of the running interrupt

routine, only the first request is stored.

Storage of interrupt requests is notavailable in level sensitive mode. To be taken into account, the

low level must bepresent onthe interrupt pin when

the MCU samples the line after instruction execution.

At the end of every instruction, the MCU tests the

interrupt lines: if there is an interrupt request the

next instruction is not executed and the appropriate interrupt service routine is executed instead.

Table 10. Interrupt Option Register Description

GEN

ESB

LES

OTHERS NOT USED

SET Enable all interrupts

CLEARED Disable all interrupts

SET

CLEARED

SET

CLEARED

Rising edge mode on interrupt source #2

Falling edge mode on interrupt source #2

Level-sensitive mode on interrupt source #1

Falling edge mode on interrupt source #1

27/78

27

Page 28

ST62T80B/E80B

INTERRUPTS (Cont’d)

3.4.2 Interrupt Procedure

The interrupt procedure is very similarto a callprocedure, indeed the user can consider the interrupt

as an asynchronous call procedure. As this is an

asynchronous event, the user cannot know the

context and the time at which it occurred. As a result, the user should save all Data space registers

which may be used within the interrupt routines.

There are separate sets of processor flags for normal, interrupt and non-maskable interrupt modes,

which are automatically switched and so do not

need to be saved.

The following list summarizes the interrupt procedure:

MCU

– The interrupt is detected.

– The C and Z flags are replaced by the interrupt

flags (or by the NMI flags).

– The PC contents are stored in the first level of

the stack.

– The normal interrupt lines are inhibited (NMI still

active).

– The first internal latch is cleared.

– TheassociatedinterruptvectorisloadedinthePC.

WARNING: In some circumstances, when a