Page 1

V

OUT

B

IN –

IN +

SHUTDOWN

BYPASS

V

OUT

A

V– (GND)

BIAS

Low Distortion 1.5 Watt

a

FEATURES

1.5 W Output

Differential (BTL2) Output

Single-Supply Operation: 2.7 V to 5.5 V

Functions Down to 1.75 V

Wide Bandwidth: 4 MHz

Highly Stable, Phase Margin: >80 Degrees

Low Distortion: 0.2% THD @ 1 W Output

Excellent Power Supply Rejection

APPLICATIONS

Portable Computers

Personal Wireless Communicators

Hands-Free Telephones

Speakerphones

Intercoms

Musical Toys and Speaking Games

GENERAL DESCRIPTION

The SSM2211 is a high-performance audio amplifier that delivers

1 W RMS of low distortion audio power into a bridge-connected

8 Ω speaker load, (or 1.5 W RMS into 4 Ω load). It operates

over a wide temperature range and is specified for single-supply

voltages between 2.7 V and 5.5 V. When operating from batteries,

it will continue to operate down to 1.75 V. This makes the

SSM2211 the best choice for unregulated applications such as toys

and games. Featuring a 4 MHz bandwidth and distortion below

0.2 % THD @ 1 W, superior performance is delivered at higher

power or lower speaker load impedance than competitive units.

The low differential dc output voltage results in negligible losses

in the speaker winding, and makes high value dc blocking capacitors unnecessary. Battery life is extended by using the

Shutdown mode, which reduces quiescent current drain to

typically 100 nA.

1

Audio Power Amplifier

SSM2211

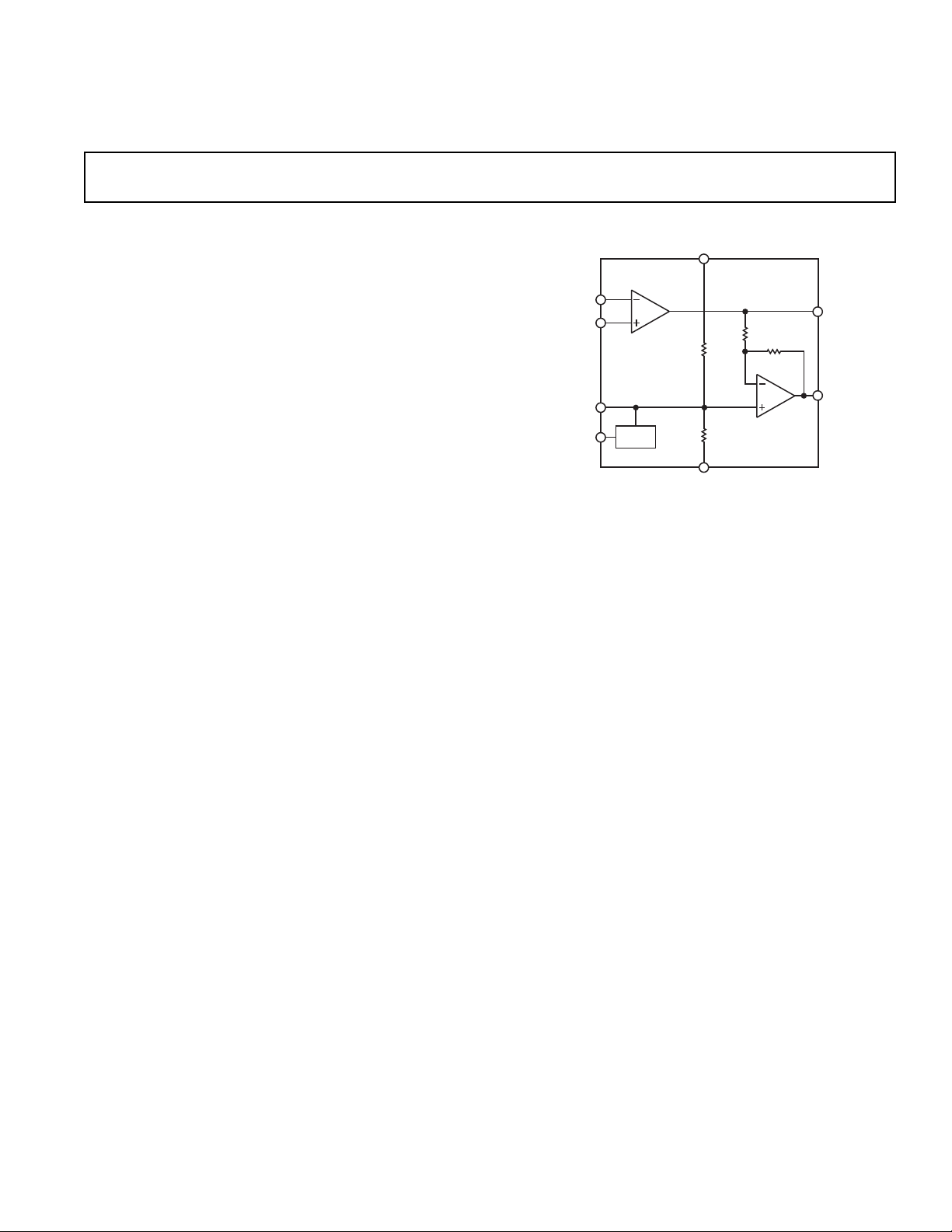

FUNCTIONAL BLOCK DIAGRAM

The SSM2211 is designed to operate over the –20°C to +85°C

temperature range. The SSM2211 is available in SO-8 and

LFCSP (Lead Frame Chip Scale Package) surface mount packages. The SO-8 features the patented Thermal Coastline lead

frame (see Figure 12). The advanced mechanical packaging of the

SSM2211 ensures lower chip temperature and enhanced performance relative to standard packaging options. DIP samples

are available; you should request a special quotation on production quantities. An evaluation board is available upon request of

your local Analog Device sales office.

Applications include personal portable computers, hands-free

telephones and transceivers, talking toys, intercom systems and

other low voltage audio systems requiring 1 W output power.

*

*Protected by U.S. Patent No. 5,519,576

NOTES

1

1.5 W @ 4 Ω, 25°C ambient, <1% THD, 5 V supply, 4 layer PCB.

2

Bridge Tied Load

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

SSM2211–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(V

= 5.0 V, TA = 25C, RL = 8 , CB = 0.1 F, VCM = VD/2, unless otherwise noted.)

S

Parameter Symbol Conditions Min Typ Max Unit

GENERAL CHARACTERISTICS

Differential Output Offset Voltage V

Output Impedance Z

OOS

OUT

AVD = 2 4 50 mV

0.1 Ω

SHUTDOWN CONTROL

Input Voltage High V

Input Voltage Low V

IH

IL

ISY = < 100 µA 3.0 V

ISY = Normal 1.3 V

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current I

Supply Current, Shutdown Mode I

SY

SD

= 4.75 V to 5.25 V 66 dB

S

VO1 = VO2 = 2.5 V 9.5 mA

Pin 1 = VDD, See TPC 29 100 nA

DYNAMIC PERFORMANCE

Gain Bandwidth GBP 4 MHz

Phase Margin Ø

0

86 Degrees

AUDIO PERFORMANCE

Total Harmonic Distortion THD + N P = 0.5 W into 8 Ω, f = 1 kHz 0.15 %

Total Harmonic Distortion THD + N P = 1.0 W into 8 Ω, f = 1 kHz 0.2 %

Voltage Noise Density e

n

ELECTRICAL CHARACTERISTICS

(V

= 3.3 V, TA = 25C, RL = 8 , CB = 0.1F, VCM = VD/2, unless otherwise noted.)

S

f = 1 kHz 85 nV√Hz

Parameter Symbol Conditions Min Typ Max Unit

GENERAL CHARACTERISTICS

Differential Output Offset Voltage V

Output Impedance Z

OOS

OUT

AVD = 2 5 50 mV

0.1 Ω

SHUTDOWN INPUT

Input Voltage High V

Input Voltage Low V

IH

IL

ISY = < 100 µA 1.7 V

1V

POWER SUPPLY

Supply Current I

Supply Current, Shutdown Mode I

SY

SD

VO1 = VO2 = 1.65 V 5.2 mA

Pin 1 = VDD, See TPC 29 100 nA

AUDIO PERFORMANCE

Total Harmonic Distortion THD + N P = 0.35 W into 8 Ω, f = 1 kHz 0.1 %

(V

ELECTRICAL CHARACTERISTICS

= 2.7 V, TA = 25C, RL = 8 , CB = 0.1 F, VCM = VS/2, unless otherwise noted.)

S

Parameter Symbol Conditions Min Typ Max Unit

GENERAL CHARACTERISTICS

Differential Output Offset Voltage V

Output Impedance Z

OOS

OUT

AVD = 2 5 50 mV

0.1 Ω

SHUTDOWN CONTROL

Input Voltage High V

Input Voltage Low V

IH

IL

ISY = < 100 µA 1.5 V

ISY = Normal 0.8 V

POWER SUPPLY

Supply Current I

Supply Current, Shutdown Mode I

SY

SD

VO1 = VO2 = 1.35 V 4.2 mA

Pin 1 = VDD, See TPC 29 100 nA

AUDIO PERFORMANCE

Total Harmonic Distortion THD + N P = 0.25 W into 8 Ω, f = 1 kHz 0.1 %

Specifications subject to change without notice

–2–

REV. A

Page 3

SSM2211

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1, 2

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Common Mode Input Voltage . . . . . . . . . . . . . . . . . . . . . . V

DD

DD

ESD Susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 V

Storage Temperature Range . . . . . . . . . . . . 65°C to +150°C

Operating Temperature Range . . . . . . . . . . . 20°C to +85°C

Junction Temperature Range . . . . . . . . . . . . 65°C to +165°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . . 300°C

NOTES

1

Absolute maximum ratings apply at 25°C, unless otherwise noted.

2

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; the functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Package Type

8-Lead LFCSP (CP)

8-Lead SOIC (S) 98 43 °C/W

8-Lead PDIP (P)

NOTES

1

For the SOIC package, θJA is measured with the device soldered to a 4-layer

printed circuit board.

2

For the LFCSP package, θJA is measured with exposed lead frame soldered to

the printed circuit board.

3

Special order only.

2

3

1

JA

JC

Units

50 °C/W

103 43 °C/W

PIN CONFIGURATIONS

8-Lead SOIC

(SO-8)

+IN

–IN

1

2

TOP VIEW

(Not to Scale)

3

4

SHUTDOWN

BYPASS

8-Lead LFCSP

(CP-8)

+IN

–IN

1

2

TOP VIEW

(Not to Scale)

3

4

SHUTDOWN

BYPASS

8-Lead Plastic DIP

(N-8)

+IN

–IN

1

2

TOP VIEW

(Not to Scale)

3

4

SHUTDOWN

BYPASS

8

B

V

OUT

7

–V

6

+V

5

V

A

OUT

8

B

V

OUT

7

–V

6

+V

5

V

A

OUT

8

V

B

OUT

7

–V

6

+V

5

V

A

OUT

ORDERING GUIDE

Temperature Package Package

Model Range Description Options Brand

SSM2211CP-Reel –20°C to +85°C 8-Lead LFCSP CP-8 B5A

SSM2211S –20°C to +85°C 8-Lead SOIC SO-8

SSM2211S-Reel –20°C to +85°C 8-Lead SOIC SO-8

SSM2211S-Reel7 –20°C to +85°C 8-Lead SOIC SO-8

SSM2211P –20°C to +85°C 8-Lead PDIP N-8

*Special order only.

*

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the SSM2211 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. A

–3–

Page 4

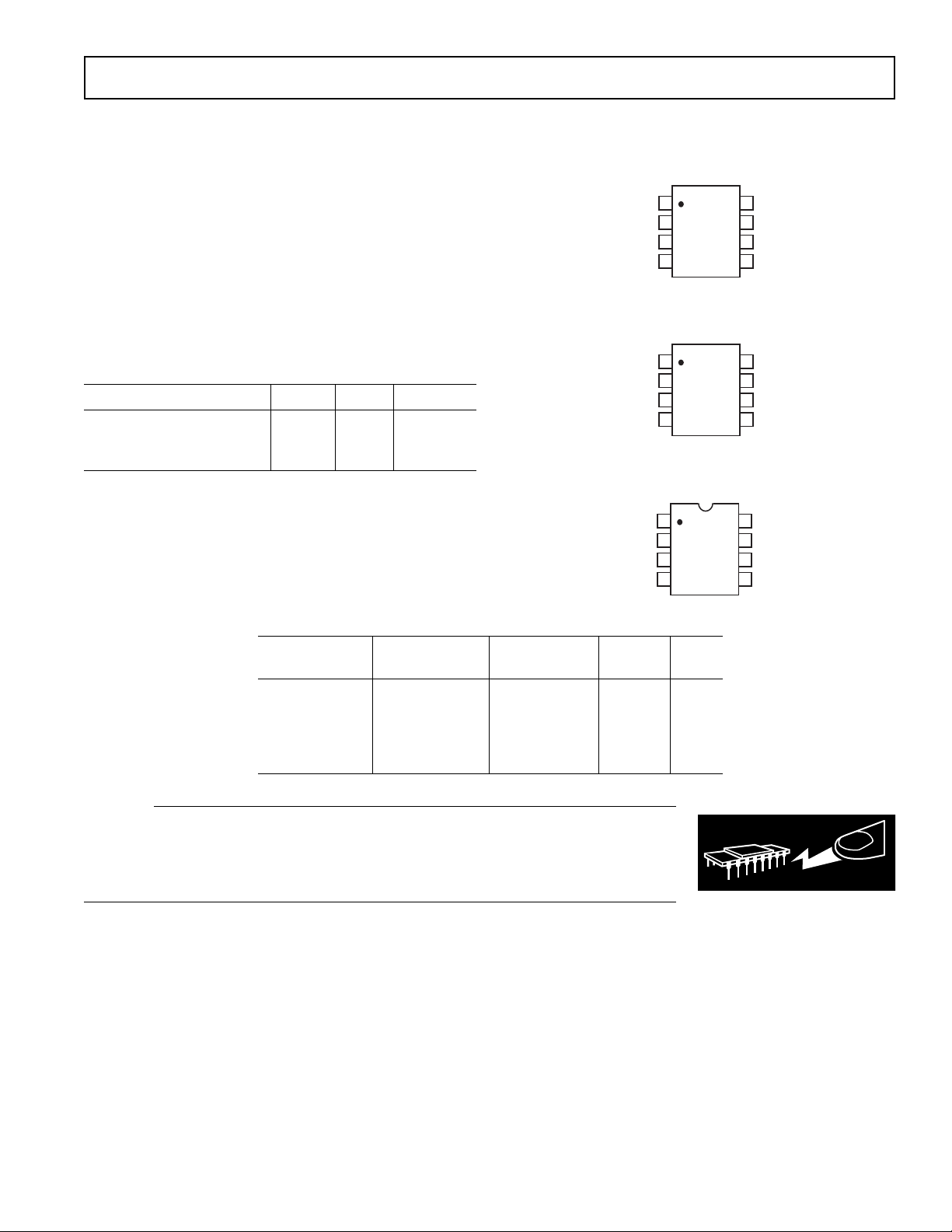

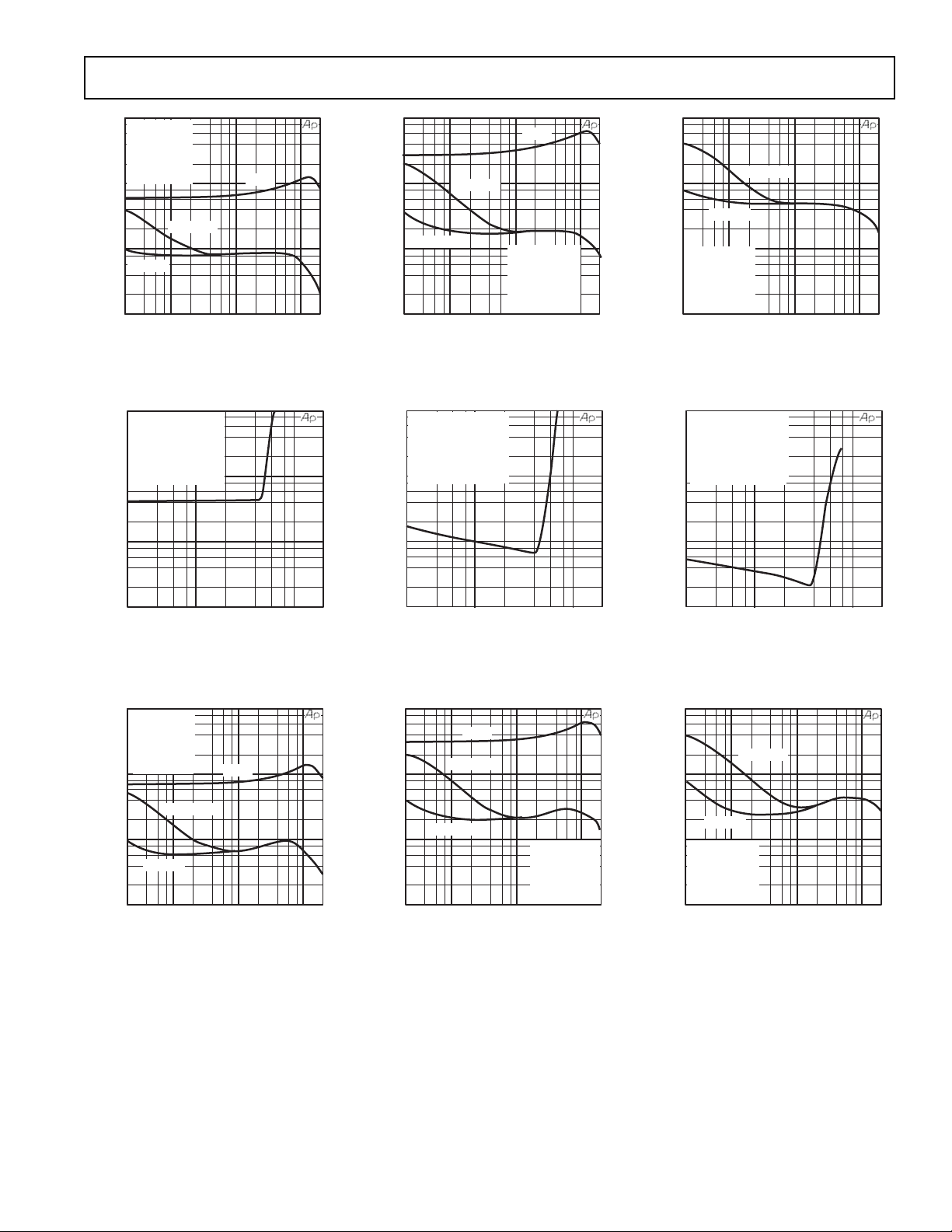

SSM2211–Typical Performance Characteristics

10

TA = 25C

= 5V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

= 500mW

P

L

1

CB = 0.1F

CB = 1F

THD + N – %

0.1

0.01

20 100 20k

C

= 0

B

FREQUENCY – Hz

1k 10k

TPC 1. THD+N vs. Frequency

10

TA = 25C

= 5V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

= 1W

P

L

1

CB = 0.1F

THD + N – %

0.1

CB = 1F

0.01

20 100 20k

CB = 0

1k 10k

FREQUENCY – Hz

TPC 4. THD+N vs. Frequency

10

CB = 0

= 5V

DD

= 10 (BTL)

VD

= 8

L

= 500mW

L

CB = 0.1F

1k 10k

FREQUENCY – Hz

1

CB = 1F

THD + N – %

0.1

TA = 25C

V

A

R

P

0.01

20 100 20k

TPC 2. THD+N vs. Frequency

10

1

CB = 1F

THD + N – %

0.1

TA = 25C

V

DD

A

VD

= 8

R

L

= 1W

P

L

0.01

20 100 20k

CB = 0.1F

= 5V

= 10 (BTL)

FREQUENCY – Hz

CB = 0

1k 10k

TPC 5.THD+N vs. Frequency

10

CB = 0.1F

1

CB = 1F

THD + N – %

0.1

TA = 25C

= 5V

V

DD

= 20 (BTL)

A

VD

= 8

R

L

= 500mW

P

L

0.01

20 100 20k

FREQUENCY – Hz

1k 10k

TPC 3. THD+N vs. Frequency

10

CB = 0.1F

1

CB = 1F

THD + N – %

0.1

TA = 25C

= 5V

V

DD

= 20 (BTL)

A

VD

= 8

R

L

= 1W

P

L

0.01

20 100 20k

FREQUENCY – Hz

1k 10k

TPC 6. THD+N vs. Frequency

10

TA = 25C

= 5V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20Hz

1

= 0.1F

C

B

THD + N – %

0.1

0.01

20n 0.1 2

TPC 7. THD+N vs. P

P

OUTPUT

– W

OUTPUT

10

TA = 25C

= 5V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 1kHz

= 0.1F

C

1

B

THD + N – %

0.1

1

0.01

20n 0.1 2

TPC 8. THD+N vs. P

P

OUTPUT

– W

OUTPUT

1

10

TA = 25C

= 5V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20kHz

1

= 0.1F

C

B

THD + N –%

0.1

0.01

20n 0.1 2

TPC 9. THD+N vs. P

P

OUTPUT

– W

OUTPUT

1

–4–

REV. A

Page 5

SSM2211

10

TA = 25C

= 3.3V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

= 350mW

P

L

1

C

= 0.1F

THD + N – %

0.1

CB = 1F

0.01

20 100 20k

B

FREQUENCY – Hz

CB = 0

1k 10k

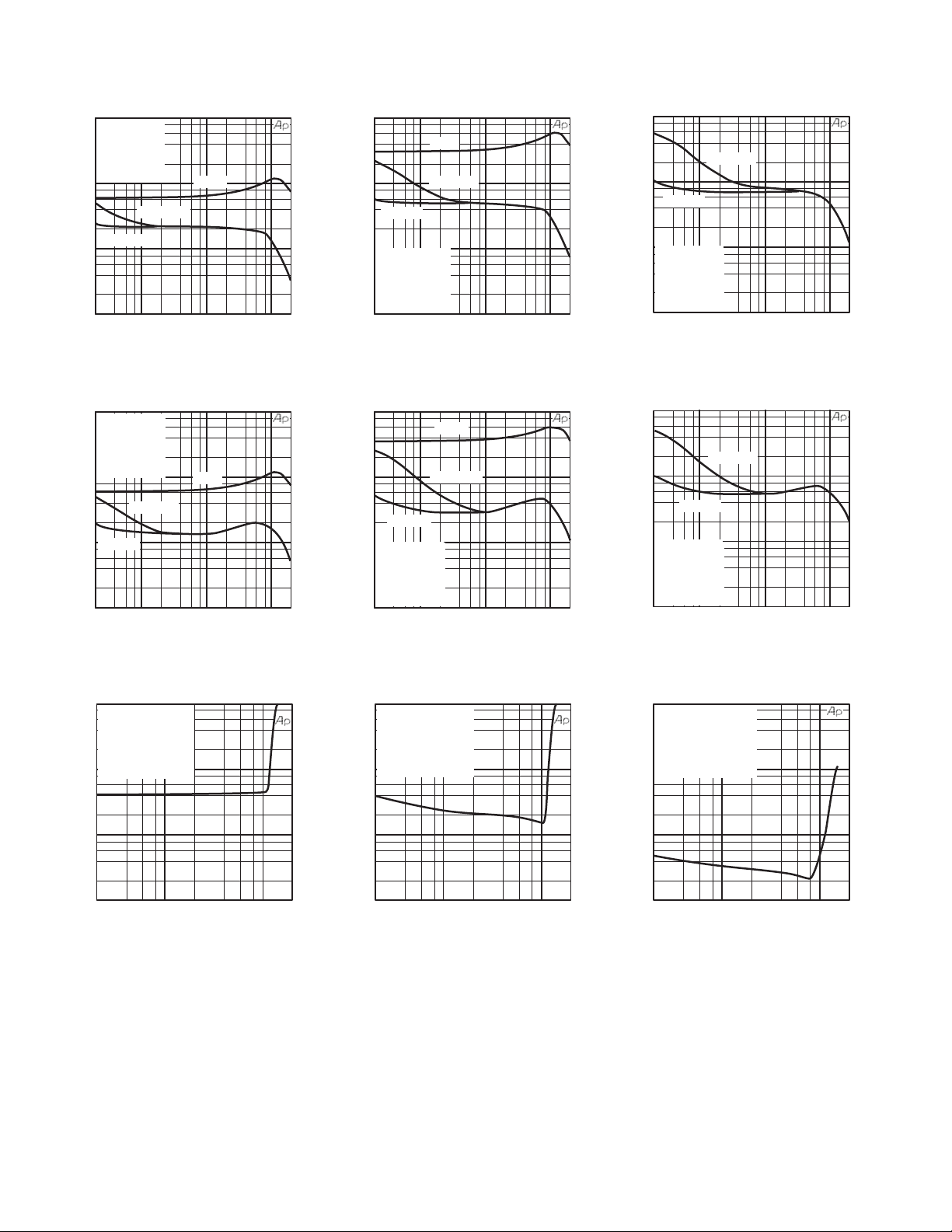

TPC 10. THD+N vs. Frequency

10

TA = 25C

= 3.3V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20Hz

1

= 0.1F

C

B

THD + N – %

0.1

10

1

THD + N – %

0.1

0.01

20 100 20k

CB = 0.1F

CB = 1F

FREQUENCY – Hz

CB = 0

TA = 25C

= 3.3V

V

DD

= 10 (BTL)

A

VD

= 8

R

L

= 350mW

P

L

1k 10k

TPC 11. THD+N vs. Frequency

10

TA = 25C

= 3.3V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 1kHz

= 0.1F

C

1

B

THD + N – %

0.1

10

CB = 1F

= 3.3V

= 20 (BTL)

= 8

= 350mW

CB = 0.1F

1k 10k

FREQUENCY – Hz

1

THD + N – %

0.1

TA = 25C

V

DD

A

VD

R

L

P

L

0.01

20 100 20k

TPC 12. THD+N vs. Frequency

10

TA = 25C

= 3.3V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20kHz

1

= 0.1F

C

B

THD + N – %

0.1

0.01

20n 0.1 2

TPC 13. THD+N vs. P

10

TA = 25C

= 2.7V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

= 250mW

P

L

1

THD + N – %

0.1

CB = 1F

0.01

20 100 20k

P

OUTPUT

CB = 0.1F

FREQUENCY – Hz

– W

OUTPUT

CB = 0

1k 10k

TPC 16. THD+N vs. Frequency

0.01

1

20n 0.1 2

P

OUTPUT

– W

TPC 14. THD+N vs. P

10

CB = 0

1

THD + N – %

0.1

0.01

20 100 20k

CB = 0.1F

CB = 1F

1k 10k

FREQUENCY – Hz

OUTPUT

TA = 25C

= 2.7V

V

DD

= 10 (BTL)

A

VD

= 8

R

L

= 250mW

P

L

1

TPC 17. THD+N vs. Frequency

0.01

20n 0.1 2

P

OUTPUT

– W

TPC 15. THD+N vs. Frequency

10

CB = 0.1F

1

CB = 1F

THD + N – %

0.1

TA = 25C

= 2.7V

V

DD

= 20 (BTL)

A

VD

= 8

R

L

= 250mW

P

L

0.01

20 100 20k

FREQUENCY – Hz

1k 10k

TPC 18. THD+N vs. Frequency

1

REV. A

–5–

Page 6

SSM2211–Typical Performance Characteristics

10

TA = 25C

= 2.7V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20Hz

1

THD + N – %

0.1

0.01

20n 0.1 2

TPC 19. THD+N vs. P

10

TA = 25C

= 5V

V

DD

= 10 SINGLE ENDED

A

VD

= 0.1F

C

B

= 1000F

C

C

1

THD + N – %

0.1

RL = 32

= 60mW

P

O

0.01

20 100 20k

P

– W

OUTPUT

RL = 8

= 250mW

P

O

FREQUENCY – Hz

1k 10k

OUTPUT

TPC 22. THD+N vs. Frequency

10

TA = 25C

= 2.7V

V

DD

= 2 (BTL)

A

VD

R

= 8

L

FREQUENCY = 1kHz

1

THD + N – %

0.1

1

0.01

20n 0.1 2

TPC 20. THD+N vs. P

10

TA = 25C

V

DD

A

VD

= 0.1F

C

B

= 1000F

C

C

1

THD + N – %

0.1

RL = 32

P

O

0.01

20 100 20k

P

OUTPUT

= 3.3V

= 10 SINGLE ENDED

RL = 8

= 85mW

P

O

= 20mW

FREQUENCY – Hz

– W

OUTPUT

1k 10k

1

TPC 23. THD+N vs. Frequency

10

TA = 25C

= 2.7V

V

DD

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20kHz

1

THD + N – %

0.1

0.01

20n 0.1 2

TPC 21. THD+N vs. P

10

TA = 25C

= 2.7V

V

DD

= 10 SINGLE ENDED

A

VD

= 0.1F

C

B

= 1000F

C

C

1

THD + N – %

0.1

RL = 32

= 15mW

P

O

0.01

20 100 20k

P

– W

OUTPUT

RL = 8

= 65mW

P

O

FREQUENCY – Hz

1k 10k

OUTPUT

TPC 24. THD+N vs. Frequency

1

10

TA = 25C

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20Hz

CB = 0.1F

1

THD + N – %

0.1

0.01

20n 0.1 2

TPC 25. THD+N vs. P

VDD = 2.7V

VDD = 3.3V

P

OUTPUT

– W

VDD = 5V

OUTPUT

10

TA = 25C

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 1kHz

CB = 0.1F

1

THD + N – %

0.1

1

0.01

20n 0.1 2

TPC 26. THD+N vs. P

VDD = 2.7V

VDD = 3.3V

P

OUTPUT

– W

VDD = 5V

1

OUTPUT

10

TA = 25C

= 2 (BTL)

A

VD

= 8

R

L

FREQUENCY = 20kHz

= 0.1F

C

B

1

THD + N – %

0.1

0.01

20n 0.1 2

P

TPC 27. THD+N vs. P

VDD = 2.7V

OUTPUT

VDD = 3.3V

– W

OUTPUT

VDD = 5V

1

–6–

REV. A

Page 7

SSM2211

1.5

SOIC JA = 98C/W

1

0.5

POWER DISSIPATION – W

0

–20 0 100

20 40 60 80

TEMPERATURE – C

T

= 150C

J,MAX

FREE AIR

NO HEAT SINK

TPC 28. Maximum Power Dissipation

vs. Ambient Temperature

1.6

1.4

1.2

1.0

0.8

0.6

OUTPUT POWER – W

0.4

0.2

0

48 4812 16 20 24 28 32 36 40 44

TPC 31. P

2.7V

LOAD RESISTANCE –

vs. Load

OUTPUT

5V

3.3V

Resistance

10,000

8,000

6,000

4,000

SUPPLY CURRENT – A

2,000

0

1234

05

SHUTDOWN VOLTAGE AT PIN 1 – V

TPC 29. Supply Current vs.

Shutdown Voltage

80

60

40

20

0

GAIN – dB

–20

–40

–60

–80

100 1k 100M

10k 100k 1M 10M

FREQUENCY – Hz

TPC 32. Gain, Phase vs.

Frequency (Single Amplifier)

VDD = 5V

14

TA = 25C

12

= OPEN

R

L

10

8

6

4

SUPPLY CURRENT – mA

2

0

01 6

2345

SUPPLY VOLTAGE – V

TPC 30. Supply Current vs.

Supply Voltage

PHASE SHIFT – Degrees

25

VDD = 2.7V

SAMPLE SIZE = 300

20

15

10

FREQUENCY

5

0

–20 –15 25

–10 –5 0 10 15 205

OUTPUT OFFSET VOLTAGE – mV

180

135

90

45

0

–45

–90

–135

–180

TPC 33. Output Offset Voltage

Distribution

20

VDD = 3.3V

SAMPLE SIZE = 300

16

12

8

FREQUENCY

4

0

–30 –20 30

–10 0 10 20

OUTPUT OFFSET VOLTAGE – mV

TPC 34. Output Offset Voltage

Distribution

20

20

VDD = 3.3V

VDD = 5.0V

SAMPLE SIZE = 300

SAMPLE SIZE = 300

16

16

12

12

8

8

FREQUENCY

4

4

0

0

–30 –20 30

–30 –20 30

–10 0 10 20

–10 0 10 20

OUTPUT OFFSET VOLTAGE – mV

OUTPUT OFFSET VOLTAGE – mV

TPC 35. Output Offset Voltage

Distribution

600

500

400

300

FREQUENCY

200

100

0

6789101112131415

SUPPLY CURRENT – mA

VDD = 5.0V

SAMPLE SIZE = 1,700

TPC 36. Supply Current Distribution

REV. A

–7–

Page 8

SSM2211

–50

TA = 25C

= 5V 100mV

V

DD

= 15 mF

C

B

= 2

A

VD

–55

–60

PSRR – dB

–65

–70

20 100 30k1k 10k

FREQUENCY – Hz

TPC 37. PSRR vs. Frequency

PRODUCT OVERVIEW

The SSM2211 is a low distortion speaker amplifier that can run

from a 1.7 V to 5.5 V supply. It consists of a rail-to-rail input

and a differential output that can be driven within 400 mV of

either supply rail while supplying a sustained output current of

350 mA. The SSM2211 is unity-gain stable, requiring no external compensation capacitors, and can be configured for gains of

up to 40 dB. Figure 1 shows the simplified schematic.

20k

V

DD

6

20k

V

IN

0.1F

4

A1

3

50k

2

50k

SSM2211

5

50k

71

50k

A2

BIAS

CONTROL

SHUTDOWN

8

V

O1

V

O2

Figure 1. Simplified Schematic

Pin 4 and Pin 3 are the inverting and noninverting terminals to A1.

An offset voltage is provided at Pin 2, which should be connected

to Pin 3 for use in single supply applications. The output of A1

appears at Pin 5. A second op amp, A2, is configured with a fixed

gain of A

= –1 and produces an inverted replica of Pin 5 at Pin 8.

V

The SSM2211 outputs at Pins 5 and 8 produce a bridged configu-

ration output to which a speaker can be connected. This bridge

configuration offers the advantage of a more efficient power transfer from the input to the speaker. Because both outputs are symmetric, the dc bias at Pins 5 and 8 are exactly equal, resulting in

zero dc differential voltage across the outputs. This eliminates the

need for a coupling capacitor at the output.

Thermal Performance—SOIC

The SSM2211 can achieve 1 W continuous output into 8 Ω in

SOIC, even at ambient temperatures up to 85°C. This is due to a

proprietary SOIC package from Analog Devices that makes use of

an internal structure called a Thermal Coastline. The Thermal

Coastline provides a more efficient heat dissipation from the die

than in standard SOIC packages. This increase in heat dissipation

allows the device to operate in higher ambient temperatures or at

higher continuous output currents without overheating the die.

For a standard SOIC package, typical junction to ambient

temperature thermal resistance (

Coastline SOIC package,

JA

) is 158°C/W. In a Thermal

JA

is 98°C/W. Simply put, a die in a

Thermal Coastline package will not get as hot as a die in a standard SOIC package at the same current output.

Because of the large amounts of power dissipated in a speaker

amplifier, competitor’s parts operating from a 5 V supply can

only drive 1 W into 8 Ω in ambient temperatures less than

44°C, or 111°F. With the Thermal Coastline SOIC package, the

SSM2211 can drive an 8 Ω speaker with 1 W from a 5 V supply

with ambient temperatures as high as 85°C (185°F), without a

heat sink or forced air flow.

Thermal Performance—LFCSP

The addition of the LFCSP to the Analog Devices’ package

portfolio offers the SSM2211 user even greater choice when

considering thermal performance criteria. For the 8-lead 3 mm

3 mm LFCSP the

is 50°C/W. This is a significant perfor-

JA

mance improvement over most other packaging options and even

betters the thermal performance of the SOIC with Thermal

Coastline lead frame.

–8–

REV. A

Page 9

SSM2211

TYPICAL APPLICATION

R

F

5V

C

S

AUDIO

INPUT

C

C

R

I

4

–

SSM2211

3

+

2

C

B

6

5

8

1

7

–

+

SPEAKER

8V

Figure 2. Typical Configuration

Figure 2 shows how the SSM2211 would be connected in a

typical application. The SSM2211 can be configured for gain

much like a standard op amp. The gain from the audio input to

the speaker is:

R

=×2

F

R

I

(1)

A

V

The 2 factor comes from the fact that Pin 8 is opposite polarity from Pin 5, providing twice the voltage swing to the speaker

from the bridged output configuration.

is a supply bypass capacitor to provide power supply filter-

C

S

ing. Pin 2 is connected to Pin 3 to provide an offset voltage for

single supply use, with C

providing a low AC impedance to

B

ground to help power supply rejection. Because Pin 4 is a virtual

AC ground, the input impedance is equal to R

. CC is the input

I

coupling capacitor which also creates a high-pass filter with a

corner frequency of:

=

2

1

π

RC

×

IC

(2)

f

HP

Because the SSM2211 has an excellent phase margin, a feedback capacitor in parallel with R

to band-limit the amplifier is

F

not required, as it is in some competitor’s products.

Bridged Output vs. Single Ended Output Configurations

The power delivered to a load with a sinusoidal signal can be expressed in terms of the signal’s peak voltage and the resistance

of the load:

P

L

2

V

PK

=

R

2

L

(3)

By driving a load from a bridged output configuration, the voltage swing across the load doubles. An advantage in using a

bridged output configuration becomes apparent from Equation

3 as doubling the peak voltage results in four times the power

delivered to the load. In a typical application operating from a

5 V supply, the maximum power that can be delivered by the

SSM2211 to an 8 Ω speaker in a single ended configuration is

250 mW. By driving this speaker with a bridged output, 1 W of

power can be delivered. This translates to a 12 dB increase in

sound pressure level from the speaker.

Driving a speaker differentially from a bridged output offers another advantage in that it eliminates the need for an output coupling capacitor to the load. In a single supply application, the

quiescent voltage at the output is half of the supply voltage. If a

speaker were connected in a single ended configuration, a coupling capacitor would be needed to prevent dc current from

flowing through the speaker. This capacitor would also need to

be large enough to prevent low frequency roll-off. The corner

frequency is given by:

f

dB

−=3

Where R

1

2

π

RC

LC

is the speaker resistance and CC is the coupling

L

(4)

capacitance

For an 8 Ω speaker and a corner frequency of 20 Hz, a 1000 µF

capacitor would be needed, which is quite physically large

and costly. By connecting a speaker in a bridged output configuration, the quiescent differential voltage across the speaker becomes

nearly zero, eliminating the need for the coupling capacitor.

Speaker Efficiency and Loudness

The effective loudness of 1 W of power delivered into an 8 Ω

speaker is a function of the efficiency of the speaker. The efficiency of a speaker is typically rated as the sound pressure level

(SPL) at 1 meter in front of the speaker with 1 W of power

applied to the speaker. Most speakers are between 85 dB and

95 dB SPL at 1 meter at 1 W. Table I shows a comparison of

the relative loudness of different sounds.

Table I. Typical Sound Pressure Levels

Source of Sound dB SPL

Threshold of Pain 120

Heavy Street Traffic 95

Cabin of Jet Aircraft 80

Average Conversation 65

Average Home at Night 50

Quiet Recording Studio 30

Threshold of Hearing 0

It can easily be seen that 1 W of power into a speaker can produce quite a bit of acoustic energy.

Power Dissipation

Another important advantage in using a bridged output configuration is the fact that bridged output amplifiers are more efficient than single ended amplifiers in delivering power to a load.

Efficiency is defined as the ratio of power from the power supply

to the power delivered to the load:

η

P

L

=

P

SY

An amplifier with a higher efficiency has less internal power dissipation, which results in a lower die-to-case junction tempera-

REV. A

–9–

Page 10

SSM2211

ture, as compared to an amplifier that is less efficient. This is

important when considering the amplifier device’s maximum

power dissipation rating versus ambient temperature. An internal power dissipation versus output power equation can be derived to fully understand this.

The internal power dissipation of the amplifier is the internal

voltage drop multiplied by the average value of the supply current. An easier way to find internal power dissipation is to take

the difference between the power delivered by the supply voltage

source and the power delivered into the load. The waveform of

the supply current for a bridged output amplifier is shown in

Figure 3.

V

OUT

V

PEAK

TIME

T

I

SY

I

DD, PEAK

I

DD, AVG

T

TIME

Figure 3. Bridged Amplifier Output Voltage and Supply

Current vs. Time

By integrating the supply current over a period T, then dividing

the result by T, I

can be found. Expressed in terms of

DD,AVG

peak output voltage and load resistance:

V

=2

I

DD AVG

,

therefore power delivered by the supply, neglecting the bias cur-

π

PEAK

R

L

(5)

rent for the device is:

VV

2

P

DD PEAK

=

SY

R

π

L

(6)

Now, the power dissipated by the amplifier internally is simply

the difference between Equation 6 and Equation 3. The equation for internal power dissipated, P

, expressed in terms of

DISS

power delivered to the load and load resistance is:

V

×

DISS

=

22

P

DD

PP

−

R

π

LL

L

(7)

The graph of this equation is shown in Figure 4.

1.5

VDD = 5V

RL = 4

1.0

0.5

POWER DISSIPATION – W

RL = 16

0

0 1.5

0.5 1.0

OUTPUT POWER – W

RL = 8

Figure 4. Power Dissipation vs. Output Power

with V

DD

=5V

Because the efficiency of a bridged output amplifier (Equation 3

divided by Equation 6) increases with the square root of P

, the

L

power dissipated internally by the device stays relatively flat, and

will actually decrease with higher output power. The maximum

power dissipation of the device can be found by differentiating

Equation 7 with respect to load power, and setting the derivative

equal to zero. This yields:

−

DD

1

2

P

−=

10

L

(8)

∂

P

DISS

∂π

P

L

×

V

2

=

R

L

And this occurs when:

2

V

=2

P

DISS MAX

,

DD

2

R

π

L

(9)

Using Equation 9 and the power derating curve in TPC 28, the

maximum ambient temperature can be easily found. This insures that the SSM2211 will not exceed its maximum junction

temperature of 150°C.

The power dissipation for a single ended output application

where the load is capacitively coupled is given by:

DISS

=

22

∂

P

DD

PP

−

π

R

LL

L

(10)

V

×

The graph of Equation 10 is shown in Figure 5.

–10–

REV. A

Page 11

SSM2211

0.35

0.30

0.25

0.20

0.15

0.10

POWER DISSIPATION – W

0.05

0

0 0.40.1

VDD = 5V

RL = 16

0.2 0.3

OUTPUT POWER – W

RL = 4

RL = 8

Figure 5. Power Dissipation vs. Single Ended Output

Power with (V

DD

= 5 V)

The maximum power dissipation for a single ended output is:

2

V

P

DISS MAX

,

DD

=

2

R

2

π

L

(11)

Output Voltage Headroom

The outputs of both amplifiers in the SSM2211 can come to

within 400 mV of either supply rail while driving an 8 Ω load.

As compared to other competitors’ equivalent products, the

SSM2211 has a higher output voltage headroom. This means

that the SSM2211 can deliver an equivalent maximum output

power while running from a lower supply voltage. By running at

a lower supply voltage, the internal power dissipation of the device is reduced, as can be seen from Equation 9. This extended

output headroom, along with the Thermal Coastline package,

allows the SSM2211 to operate in higher ambient temperatures

than other competitors’ devices.

The SSM2211 is also capable of providing amplification even at

supply voltages as low as 1.7 V. The maximum power available

at the output is a function of the supply voltage. Therefore, as

the supply voltage decreases, so does the maximum power output from the device. Figure 6 shows the maximum output power

versus supply voltage at various bridged-tied load resistances.

The maximum output power is defined as the point at which the

output has 1% THD.

1.6

1.4

1.2

1.0

0.8

@ 1% THD – W

OUT

0.6

MAX P

0.4

0.2

0

1.5 5.02.0

2.5 3.0 3.5 4.0 4.5

SUPPLY VOLTAGE – V

Figure 6. Maximum Output Power vs. V

RL = 4

R

= 8

L

RL = 16

SY

To find the minimum supply voltage needed to achieve a specified maximum undistorted output power, simply use Figure 6.

For example, an application requires only 500 mW to be output

for an 8 Ω speaker. With the speaker connected in a bridged output configuration, the minimum supply voltage required is 3.3 V.

Shutdown Feature

The SSM2211 can be put into a low power consumption shutdown mode by connecting Pin 1 to 5 V. In shutdown mode, the

SSM2211 has an extremely low supply current of less than 10 nA.

This makes the SSM2211 ideal for battery powered applications.

Pin 1 should be connected to ground for normal operation.

Connecting Pin 1 to V

will mute the outputs and put the

DD

SSM2211 into shutdown mode. A pull-up or pull-down resistor is

not required. Pin 1 should always be connected to a fixed potential, either V

or ground, and never be left floating. Leaving

DD

Pin 1 unconnected could produce unpredictable results.

Automatic Shutdown Sensing Circuit

Figure 7 shows a circuit that can be used to automatically take

the SSM2211 in and out of shutdown mode. This circuit can be

set to turn the SSM2211 on when an input signal of a certain

amplitude is detected. The circuit will also put the SSM2211

into its low-power shutdown mode once an input signal is not

sensed within a certain amount of time. This can be useful in a

variety of portable radio applications where power conservation

is critical.

R8

V

DD

R5

C2

V

IN

R6

DD

V

R1 R3

NOTE

ADDITIONAL PINS OMITTED FOR CLARITY

–

OP181

+

R2

A2

R7

V

DD

R4

D1

C1

4

SSM2211

18

5

A1

Figure 7. Automatic Shutdown Circuit

The input signal to the SSM2211 is also connected to the

non-inverting terminal of A2. R1, R2, and R3 set the threshold

voltage of when the SSM2211 will be taken out of shutdown mode.

D1 half-wave rectifies the output of A2, discharging C1 to ground

when an input signal greater than the set threshold voltage is

detected. R4 controls the charge time of C1, which sets the time

until the SSM2211 is put back into shutdown mode after the

input signal is no longer detected.

R5 and R6 are used to establish a voltage reference point equal

to half of the supply voltage. R7 and R8 set the gain of the

SSM2211. D1 should be a 1N914 or equivalent diode and A2

should be a rail-to-rail output amplifier, such as an OP181 or

equivalent. This will ensure that C1 will discharge sufficiently to

bring the SSM2211 out of shutdown mode.

REV. A

–11–

Page 12

SSM2211

To find the appropriate component values, first the gain of A2

must be determined by:

V

A

VMIN

,

Where, V

V

is the threshold voltage.

THS

A

should be set to a minimum of 2 for the circuit to work prop-

V

SY

=

V

THS

is the single supply voltage and

SY

(12)

erly. Next choose R1 and set R2 to:

RR

211

=−

2

A

V

(13)

Find R3 as:

R

3

12

+

RR

12

−

A

1=

()

V

(14)

×

RR

C1 can be arbitrarily set but should be small enough to not cause

A2 to become capacitively overloaded. R4 and C1 will control the

shutdown rate. To prevent intermittent shutdown with low

frequency input signals, the minimum time constant should be:

RC

41

×≥

Where, f

Shutdown Circuit Design Example

10

f

LOW

is the lowest input frequency expected.

LOW

(15)

In this example a portable radio application requires the

SSM2211 to be turned on when an input signal greater than

50 mV is detected. The device should return to shutdown mode

within 500 ms after the input signal is no longer detected. The

lowest frequency of interest is 200 Hz, and a 5 V supply is

being used.

The minimum gain of the shutdown circuit from Equation 12 is

A

= 100. R1 is set to 100 kΩ, and using Equation 13 and

V

Equation 14, R2 = 98 kΩ and R3 = 4.9 MΩ. C1 is set to

0.01 µF, and based on Equation 15, R4 is set to 10 MΩ. To

minimize power supply current, R5 and R6 are set to 10 MΩ.

The above procedure will provide an adequate starting point for

the shutdown circuit. Some component values may need to be

adjusted empirically to optimize performance.

Turn On Popping Noise

During power-up or release from shutdown mode, the midrail

bypass capacitor, C

, determines the rate at which the

B

SSM2211 starts up. By adjusting the charging time constant of

, the start-up pop noise can be pushed into the sub-audible

C

B

range, greatly reducing startup popping noise. On power-up, the

midrail bypass capacitor is charged through an effective resistance of 25 kΩ. To minimize start-up popping, the charging

time constant for C

constant for the input coupling capacitor, C

CkCR

×Ω>25

BCI

For an application where R1 = 10 kΩ and C

midrail bypass capacitor, C

should be greater than the charging time

B

.

C

(16)

= 0.22 µF, the

, should be at least 0.1 µF to mini-

B

C

mize start-up popping noise.

SSM2211 Amplifier Design Example

Given:

Maximum Output Power 1 W

Input Impedance 20 kΩ

Load Impedance 8 Ω

Input Level 1 V rms

Bandwidth 20 Hz – 20 kHz ± 0.25 dB

The configuration shown in Figure 2 will be used. The first

thing to determine is the minimum supply rail necessary to obtain the specified maximum output power. From Figure 6, for

1 W of output power into an 8 Ω load, the supply voltage must

be at least 4.6 V. A supply rail of 5 V can be easily obtained

from a voltage reference. The extra supply voltage will also allow the SSM2211 to reproduce peaks in excess of 1 W without

clipping the signal. With V

= 5 V and RL=8Ω, Equation 9

DD

shows that the maximum power dissipation for the SSM2211 is

633 mW. From the power derating curve in TPC 28, the ambient temperature must be less than 85°C.

The required gain of the amplifier can be determined from

Equation 17:

PR

A

LL

==

V

V

,

IN rms

From Equation 1,

.28

RRA

FV

=

12

, or

RR

=×14 1.

F

. Since the

(17)

desired input impedance is 20 kΩ, R1=20kΩ and R2 = 28 kΩ.

The final design step is to select the input capacitor. Because

adding an input capacitor, C

, high pass filter, the corner frequency

C

needs to be far enough away for the design to meet the bandwidth

criteria. For a 1st order filter to achieve a passband response

within 0.25 dB, the corner frequency should be at least 4.14 times

away from the passband frequency. So, (4.14 f

) < 20 Hz.

HP

Using Equation 2, the minimum size of input capacitor can be found:

C

>

C

220

π

> 1.65 µF. Using a 2.2 µF is a practical choice for CC.

So C

C

1

20

414

.

Hz

()

k

Ω

(18)

The gain-bandwidth product for each internal amplifier in the

SSM2211 is 4 MHz. Because 4 MHz is much greater than

4.14 20 kHz, the design will meet the upper frequency bandwidth criteria. The SSM2211 could also be configured for higher

differential gains without running into bandwidth limitations.

Equation 16 shows an appropriate value for C

to reduce start-

B

up popping noise:

()

C

>

B

Selecting C

22 20

.

µ

25

to be 2.2 µF for a practical value of capacitor will

B

Ω

Fk

()

k

Ω

=µ

176

.

F

(19)

minimize start-up popping noise.

–12–

REV. A

Page 13

SSM2211

To summarize the final design:

V

DD

5V

R1 20 kΩ

R

F

C

C

C

B

Max. T

A

28 kΩ

2.2 µF

2.2 µF

85°C

Single Ended Applications

There are applications where driving a speaker differentially is

not practical. An example would be a pair of stereo speakers

where the minus terminal of both speakers is connected to

ground. Figure 8 shows how this can be accomplished.

10k

5V

AUDIO

INPUT

10k

0.47F

0.1F

4

–

SSM2211

3

+

2

6

5

8

1

7

470F

+

–

250mW

SPEAKER

(8)

Figure 8. A Single Ended Output Application

It is not necessary to connect a dummy load to the unused output

to help stabilize the output. The 470 µF coupling capacitor cre-

ates a high pass frequency cutoff as given in Equation 4 of 42 Hz,

which is acceptable for most computer speaker applications.

The overall gain for a single ended output configuration is

A

= RF/R1, which for this example is equal to 1.

V

Driving Two Speakers Single Endedly

It is possible to drive two speakers single endedly with both outputs of the SSM2211.

20k

5V

470F

–

AUDIO

INPUT

1F

20k

0.1F

4

–

SSM2211

3

+

2

6

5

8

1

7

470F

+

+

–

LEFT

SPEAKER

(8)

RIGHT

SPEAKER

(8)

Figure 9. SSM2211 Used as a Dual Speaker Amplifier

Each speaker is driven by a single ended output. The trade-off is

that only 250 mW sustained power can be put into each

speaker. Also, a coupling capacitor must be connected in series

with each of the speakers to prevent large DC currents from

flowing through the 8 Ω speakers. These coupling capacitors

will produce a high pass filter with a corner frequency given by

Equation 4. For a speaker load of 8 Ω and a coupling capacitor

of 470 µF, this results in a –3 dB frequency of 42 Hz.

Because the power of a single ended output is one quarter that of a

bridged output, both speakers together would still be half as loud

(–6 dB SPL) as a single speaker driven with a bridged output.

The polarity of the speakers is important, as each output is 180°

out of phase with the other. By connecting the minus terminal

of Speaker 1 to Pin 5, and the plus terminal of Speaker 2 to

Pin 8, proper speaker phase can be established.

The maximum power dissipation of the device can be found by

doubling Equation 11, assuming both loads are equal. If the

loads are different, use Equation 11 to find the power dissipation caused by each load, then take the sum to find the total

power dissipated by the SSM2211.

Evaluation Board

An evaluation board for the SSM2211 is available. Contact your

local sales representative or call 1-800-ANALOGD for more information.

1

2

SSM2211

3

4

20k

0.1F

V+

+

C

C

2

10F

6

8

5

7

R

F

C

1

1

0.1F

V

R

L

1W 8

02

V

01

J1

J2

AUDIO

INPUT

VOLUME

20k POT.

SHUTDOWN

ON

CW

C

1F

R1

51k

+

R

IN

IN

20k

Figure 10. Evaluation Board Schematic

The voltage gain of the SSM2211 is given by Equation 20 below:

R

A

=×2

V

F

R

IN

(20)

If desired, the input signal may be attenuated by turning the

10 kΩ potentiometer in the CW direction. C

isolates the input

IN

common mode voltage (V+/2) present at Pin 2 and 3. With

V+=5V, there is 2.5 V common-mode voltage present at both

output terminals V

and VO2 as well.

O1

CAUTION: The ground lead of the oscilloscope probe, or any

other instrument used to measure the output signal, must not be

connected to either output, as this would short out one of the

amplifier’s outputs and possibly damage the device.

A safe method of displaying the differential output signal using a

grounded scope is shown in Figure 11. Simply connect the Channel A probe to V

V

post, invert Channel B and add the two channels together.

O1

terminal post, connect the Channel B probe to

O2

Most multichannel oscilloscopes have this feature built in. If you

must connect the ground lead of the test instrument to either output signal pins, a power line isolation transformer must be used to

isolate the instrument ground from power supply ground.

REV. A

–13–

Page 14

SSM2211

Recall that

V = 2.8 V

VPR=×

rms, or 8 V p-p. If the available input signal is 1.4 V

rms or more, use the board as is, with R

gain is needed, increase the value of R

, so for PO= 1 W and RL=8Ω,

=20kΩ. If more

F=RI

to obtain the desired gain.

F

When you have determined the closed-loop gain required by

your source level, and can develop 1 W across the 8 Ω load resistor with the normal input signal level, replace the resistor

with your speaker. Your speaker may be connected across the

V

and VO2 posts for bridged mode operation only after the

O1

8 Ω load resistor is removed. For no phase inversion, V

O2

should be connected to the (+) terminal of the speaker.

V

SSM2211

5

2.5V

COMMON

MODE

8

8

1W

O2

GND

V

O1

PROBES

CH A

CH B

CH B

INV. ON

OSCILLOSCOPE

DISPLAY

A+B

Figure 11. Using an Oscilloscope to Display the Bridged

Output Voltage

To use the SSM2211 in a single ended output configuration,

replace J1 and J2 jumpers with electrolytic capacitors of a suitable value, with the NEGATIVE terminals to the output terminals V

and VO2. The single ended loads may then be returned

O1

to ground. Note that the maximum output power is reduced to

250 mW, one quarter of the rated maximum, due to the maximum swing in the non-bridged mode being one-half, and power

being proportional to the square of the voltage. For frequency

response down 3 dB at 100 Hz, a 200 µF capacitor is required

with 8 Ω speakers.

The SSM2211 evaluation board also comes with a SHUTDOWN switch which allows the user to switch between ON

(normal operation) and the power conserving shutdown mode.

Printed Circuit Board Layout Consideration—SOIC

All surface mount packages rely on the traces of the PC board

to conduct heat away from the package.

In standard packages, the dominant component of the heat resistance path is the plastic between the die attach pad and the

individual leads. In typical thermally enhanced packages, one or

more of the leads are fused to the die attach pad, significantly

decreasing this component. To make the improvement meaningful, however, a significant copper area on the PCB must be

attached to these fused pins.

The patented Thermal Coastline lead frame design used in the

SSM2211 (Figure 12) uniformly minimizes the value of the

dominant portion of the thermal resistance. It ensures that heat

is conducted away by all pins of the package. This yields a very

low, 98°C/W, thermal resistance for an SO-8 package, without

any special board layer requirements, relying on the normal

traces connected to the leads. The thermal resistance can be decreased by approximately an additional 10% by attaching a few

square cm of copper area to the ground pins. It is recommended

that the solder mask and/or silk screen on the PCB traces adjacent to the SSM2211 pins be deleted, thus reducing further the

junction to ambient thermal resistance of the package.

COPPER

LEAD-FRAME

1

2

COPPER PADDLE

3

4

8

7

6

5

Figure 12. Thermal Coastline

Printed Circuit Board Layout Consideration—LFCSP

The LFCSP is a plastic encapsulated package with a copper

leadframe substrate. This is a leadless package with solder lands

on the bottom surface of the package instead of conventional

formed perimeter leads. A key feature that allows the user to

reach the quoted

performance is the exposed die attach

JA

paddle (DAP) on the bottom surface of the package. When

soldered to the PCB, the DAP can provide efficient conduction

of heat from the die to the PCB. For the user to achieve optimum

package performance, consideration should be given to the PCB

pad design for both the solder lands and the DAP. For further

information the user is directed to the Amkor Technology document: “Application Notes for Surface Mount Assembly of

Amkor’s MicroLeadFrame (MLF) Packages.” This can be

downloaded from the Amkor Technology website,

www.amkor.com, as a product application note.

–14–

REV. A

Page 15

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

SSM2211

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

0.1968 (5.00)

0.1890 (4.80)

85

0.0500 (1.27)

BSC

PLANE

8-Lead SOIC

0.2440 (6.20)

0.2284 (5.80)

41

0.0192 (0.49)

0.0138 (0.35)

INDICATOR

(R-8)

0.0688 (1.75)

0.0532 (1.35)

PIN 1

0.0098 (0.25)

0.0075 (0.19)

0.118 (3.00)

BSC SQ

TOP

VIEW

8-Lead Plastic DIP

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.0196 (0.50)

0.0099 (0.25)

8

0.0500 (1.27)

0

0.0160 (0.41)

45

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

8-Lead Frame Chip Scale Package [LFCSP]

(CP-08)

0.108 (2.75)

BSC SQ

0.018 (0.45)

0.020 (0.50)

0.024 (0.60)

4

0.017 (0.42)

0.009 (0.24)

BSC

BOTTOM

VIEW

0.020 (0.50)

0.016 (0.40)

0.012 (0.30)

1

2

(N-8)*

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

*Special order only.

0.059 (1.50)

REF

SEATING

PLANE

PIN 1 INDICATOR

0.074 (1.89)

0.069 (1.74)

0.063 (1.59)

0.325 (8.25)

0.300 (7.62)

0.195 (4.95)

0.115 (2.93)

0.015 (0.381)

0.008 (0.204)

0.035 (0.90) MAX

0.033 (0.85) NOM

SEATING

PLANE

12 MAX

0.0118 (0.30)

0.0118 (0.23)

0.0071 (0.18)

0.028 (0.70) MAX

0.026 (0.65) NOM

0.0020 (0.05) MAX

0.0004 (0.01) NOM

0.008 (0.20) REF

0.010 (0.25)

MIN

0.063 (1.60)

0.057 (1.45)

0.051 (1.30)

REV. A

–15–

Page 16

SSM2211

Revision History

Location Page

5/02–Data Sheet changed from REV. 0 to REV. A

Edits to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to PACKAGE TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Edits to PRINTED CIRCUIT BOARD LAYOUT CONSIDERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Added section PRINTED CIRCUIT BOARD LAYOUT CONSIDERATION—LFCSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

C00358–0–5/02(A)

–16–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...