Page 1

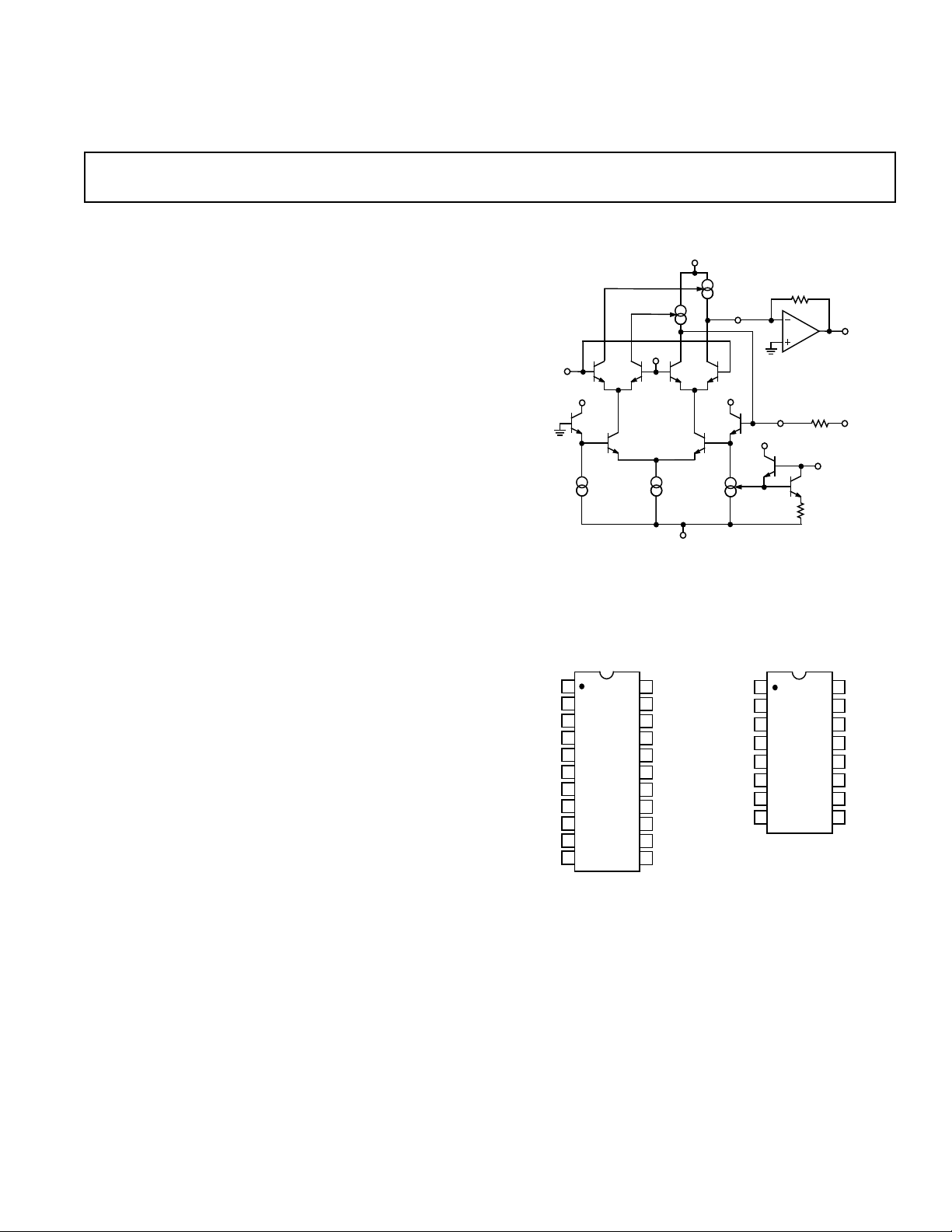

SIGNAL

OUT

CURRENT

MIRRORS

–V

C

+V

C

V+

V+

V+

SIGNAL

INPUT

36kΩ

36kΩ

V+

V–

I

REF

Dynamic Range

13

16

15

14

22

21

20

19

18

17

12

TOP VIEW

(Not to Scale)

11

10

9

8

1

2

3

4

7

6

5

SSM2120

THRESH 1

+V

C2

SIG

OUT 2

V+

GND

LOG AV 1

CON

OUT 1

SIG

OUT 1

SIG

IN 2

–V

C2

CFT 2

+V

C1

CFT 1

–V

C1

SIG

IN 1

REC

IN 1

I

REF

LOG AV 2

CON

OUT 2

REC

IN 2

V– THRESH 2

14

13

12

11

16

15

10

9

8

1

2

3

4

7

6

5

TOP VIEW

(Not to Scale)

SSM2122

GND

+V

C2

SIG

OUT 2

V+

GND

SIG

OUT 1

+V

C1

CFT 1

SIG

IN 2

–V

C2

CFT 2

–V

C1

SIG

IN 1

I

REF

V–

GND

a

FEATURES

0.01% THD at +10 dBV In/Out

100 dB VCA Dynamic Range

Low VCA Control Feedthrough

100 dB Level Detection Range

Log/Antilog Control Paths

Low External Component Count

APPLICATIONS

Compressors

Expanders

Limiters

AGC Circuits

Voltage-Controlled Filters

Noise Reduction Systems

Stereo Noise Gates

GENERAL DESCRIPTION

The SSM2120 is a monolithic integrated circuit designed for the

purpose of processing dynamic signals in various analog systems

including audio. This “dynamic range processor” consists of two

VCAs and two level detectors (the SSM2122 consists of two

VCAs only). These circuit blocks allow the user to logarithmically

control the gain or attenuation of the signals presented to the

level detectors depending on their magnitudes. This allows the

compression, expansion or limiting of ac signals, some of the

primary applications for the SSM2120.

Processors/Dual VCA

SSM2120/SSM2122

FUNCTIONAL BLOCK DIAGRAM

PIN CONNECTIONS

22-Pin Plastic DIP

(P Suffix)

16-Pin Plastic DIP

(P Suffix)

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

© Analog Devices, Inc., 1995

Page 2

SSM2120/SSM2122–SPECIFICATIONS

(@VS = 615 V, TA = +258C, I

ELECTRICAL CHARACTERISTICS

unless otherwise noted)

Parameter Conditions Min Typ Max Units

POWER SUPPLY

Supply Voltage Range ±5 ±18 V

Positive Supply Current 810mA

Negative Supply Current –6 –8 mA

VCAs

Max I

(In/Out) ±300 ±325 ±350 µA

SIGNAL

Output Offset ±1 ±8 µA

Control Feedthrough (Trimmed) R

IN

= R

= 36 kΩ, –30 dB ≤ AV ≤ 0 dB ±750 µV

OUT

Gain Control Range Unity-Gain –85 +40 dB

Control Sensitivity 6 mV/dB

Gain Scale Factor Drift –3300 ppm/°C

Frequency Response Unity Gain or Less 250 kHz

Off Isolation At 1 kHz 100 dB

Current Gain +V

= –VC = 0 V –0.5 +0.5 dB

C

THD (Unity-Gain) +10 dBV IN/OUT 0.005 0.04 %

Noise (20 kHz Bandwidth) RE: 0 dBV –80 dB

LEVEL DETECTORS (SSM2120 ONLY)

Detection Range 90 95 dB

Input Current Range 0.085 2800 µA p-p

Rectifier Input Bias Current 4nA

Output Sensitivity (At LOG AV Pin) 3 mV/dB

Output Offset Voltage ±0.5 ±3.4 mV

Frequency Response

I

= 1 mA p-p 1000

IN

I

= 10 µA p-p 50 kHz

IN

I

= 1 µA p-p 7.5

IN

CONTROL AMPLIFIERS (SSM2120 ONLY)

Input Bias Current ±85 ±175 nA

Output Drive (Max Sink Current) 5.0 7.5 mA

Input Offset Voltage ±0.5 ±4.2 mV

Specifications are subject to change without notice.

= 200 mA, +VC = –VC = GND (AV = 0 dB). 0 dB = 1 V rms

REF

SSM2120/SSM2122

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Operating Temperature Range . . . . . . . . . . . . –10°C to +55°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Maximum Current into Any Pin . . . . . . . . . . . . . . . . . . 10 mA

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300°C

Package Type θ

1

JA

θ

JC

Units

Model Range Description Option

SSM2120 –10°C to +50°C 22-Pin Plastic DIP (N-22)

SSM2122 –10°C to +50°C 16-Pin Plastic DIP (N-16)

ORDERING GUIDE

Temperature Package Package

16-Pin Plastic DIP (P) 86 10 °C/W

22-Pin Plastic DIP (P) 70 7 °C/W

NOTE

1

θJA is specified for worst case mounting conditions, i.e., θJA is specified for

device in socket for P-DIP.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the SSM2120/SSM2122 features proprietary ESD protection circuitry, permanent damage

may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–2–

WARNING!

ESD SENSITIVE DEVICE

REV. C

Page 3

+V

GAIN – dB

0.03

THD – %

0.01

–20 20–10 0 10

0.003

C1

INPUT 1 OUTPUT 1

–V

C1

+V

C2

INPUT 2 OUTPUT 2

–V

C2

SSM2122

CFT 1

CFT 2

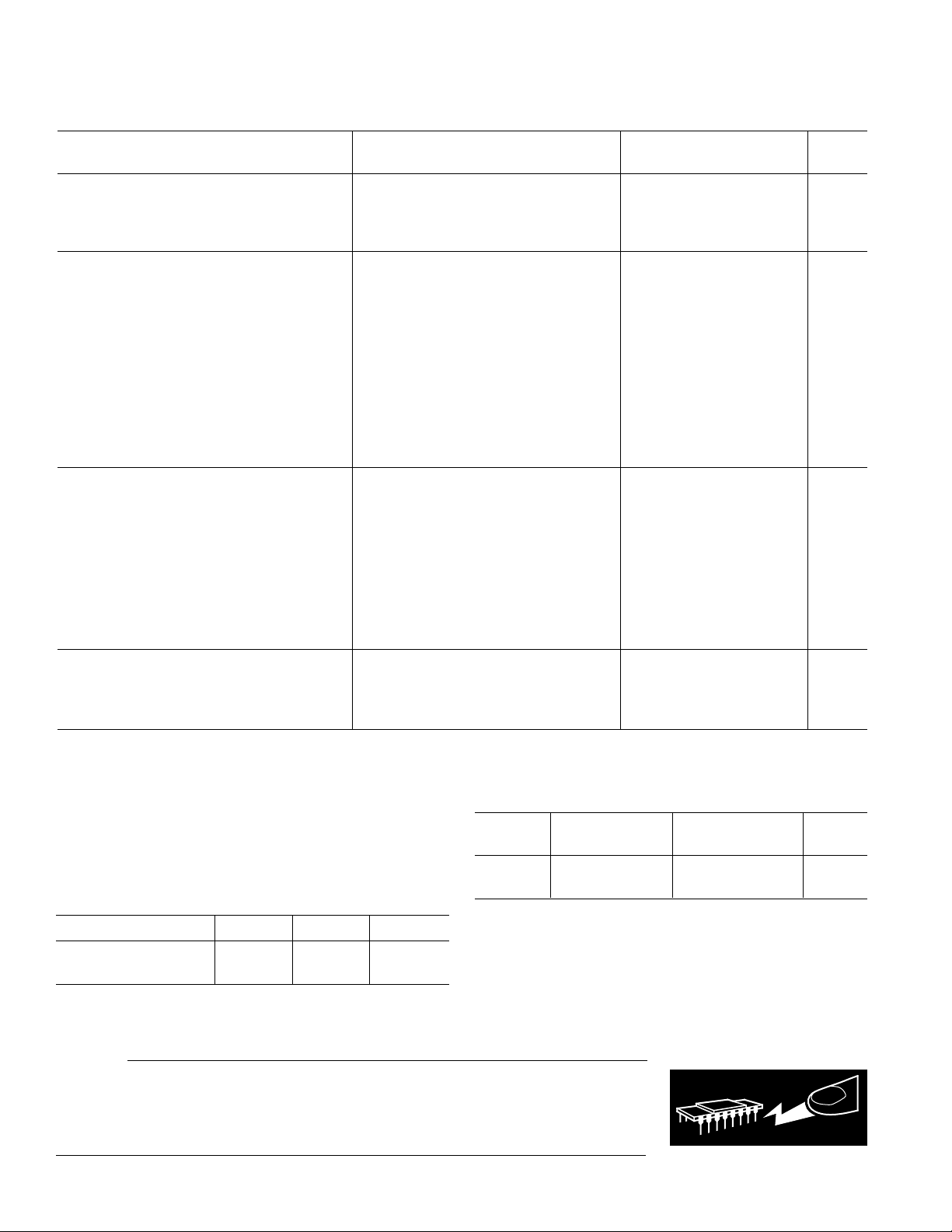

Figure 1. SSM2120 Block Diagram

REC

REC

IN 1

IN 2

SSM2120/SSM2122

V+ THRESH 1

|IIN|

FULL

WAVE

RECTIFIER

2V

LOG AV 1

V+ THRESH 2

|IIN|

FULL

WAVE

RECTIFIER

2V

LOG AV 2

CON

CON

OUT 1

V–

OUT 2

V–

VOLTAGE-CONTROLLED AMPLIFIERS

The two voltage-controlled amplifiers are full Class A current

in/current out devices with complementary dB/V gain control

ports. The control sensitivities are +6 mV/dB and –6 mV/dB. A

resistor divider (attenuator) is used to adapt the sensitivity of an

external control voltage to the range of the control port. It is

best to use 200 Ω or less for the attenuator resistor to ground.

VCA INPUTS

The signal inputs behave as virtual grounds. The input current

compliance range is determined by the current into the reference

current pin.

REFERENCE PIN

The reference current determines the input and output current

compliance range of the VCAs. The current into the reference

pin is set by connecting a resistor to V+. The voltage at the

reference pin is about two volts above V– and the current will be

[(V +)–((V–)+2V )]

=

I

REF

R

REF

The current consumption of the VCAs will be directly proportional to I

which is nominally 200 µA. The device will

REF

operate at lower current levels which will reduce the effective

dynamic range of the VCAs. With a 200 µA reference current,

the input and output clip points will be ± 400 µA. In general:

I

= ±2 I

CLIP

REF

VCA OUTPUTS

The VCA outputs are designed to interface directly with the virtual

ground inputs of external operational amplifiers configured as

current-to-voltage converters. The outputs must operate at virtual

ground because of the output stage’s finite output impedance.

The power supplies and selected compliance range determines

the values of input and output resistors needed. As an example,

with ±15 V supplies and ±400 µA maximum input and output

current, choose R

IN

= R

= 36 kΩ for an output compliance

OUT

range of ±14.4 V. Note that the signal path through the VCA

including the output current-to-voltage converter is noninverting.

VCA PERFORMANCE

Figures 2a and 2b show the typical THD and noise performance

of the VCAs over ±20 dB gain/attenuation. Full Class A operation

provides very low THD.

a. VCA THD Performance vs. Gain

(+10 dBV In/Out @ 1 kHz)

–70

–80

NOISE – dBV

–90

–20 20–10 0 10

GAIN – dB

b. VCA Noise vs. Gain (20 kHz Bandwidth)

Figure 2. Typical THD and Noise Performance

REV. C

–3–

Page 4

SSM2120/SSM2122

TRIMMING THE VCAs

The control feedthrough (CFT) pins are optional control feedthrough null points. CFT nulling is usually required in applications

such as noise gating and downward expansion. If trimming is

not used, leave the CFT pins open.

Trim Procedure

1. Apply a 100 Hz sine wave to the control point attenuator.

The signal peaks should correspond to the control voltages

which induce the VCAs maximum intended gain and at least

30 dB of attenuation.

2. Adjust the 50 kΩ potentiometer for the minimum

feedthrough.

(Trimmed control feedthrough is typically well under 1 mV rms

when the maximum gain is unity using 36 kΩ input and output

resistors.)

Applications such as compressor/limiters typically do not require

control feedthrough trimming because the VCA operates at

unity-gain unless the signal is large enough to initiate gain

reduction. In this case the signal masks control feedthrough.

This trim is ineffective for voltage-controlled filter applications.

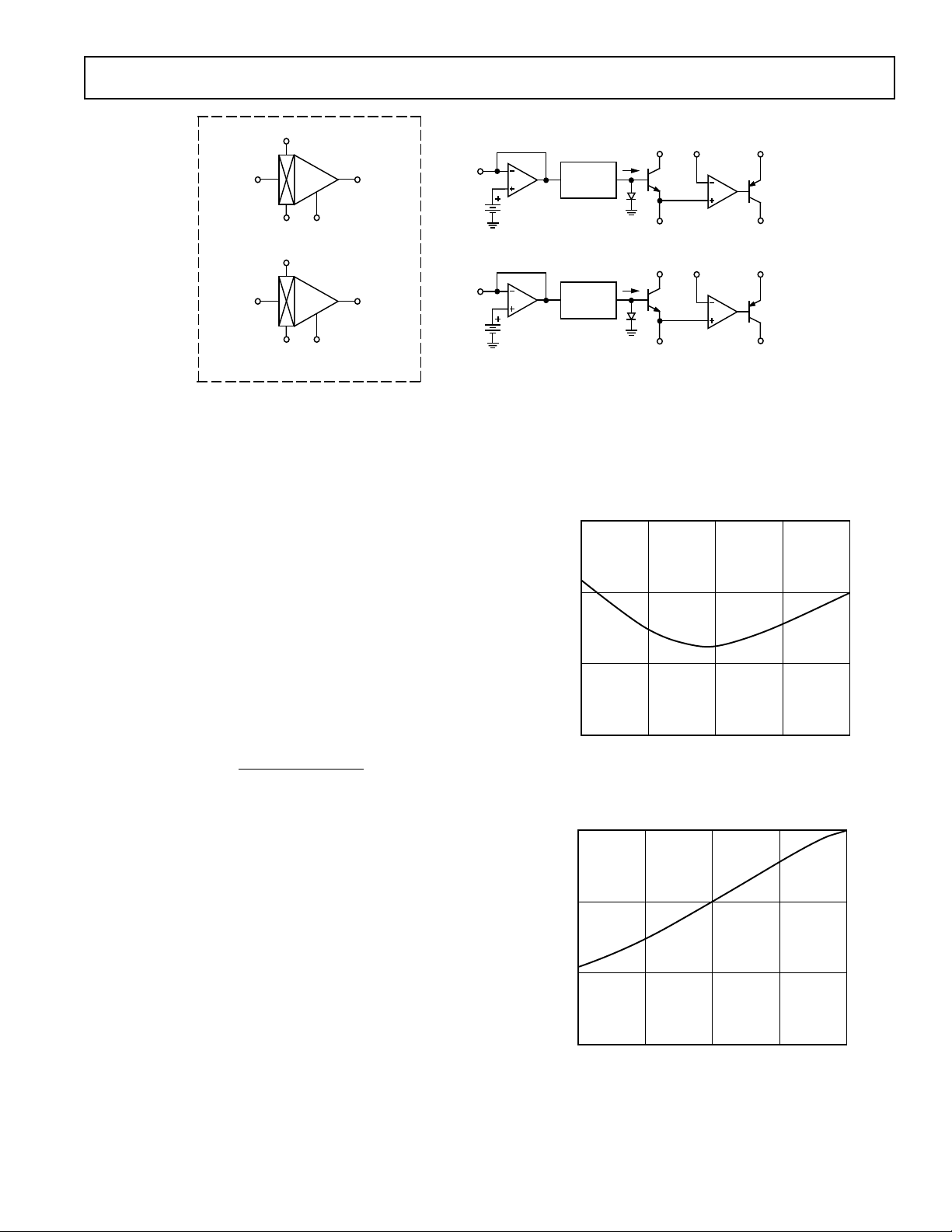

LEVEL DETECTION CIRCUITS

The SSM2120 contains two independent level detection

circuits. Each circuit contains a wide dynamic range full-wave

rectifier, logging circuit and a unipolar drive amplifier. These

circuits will accurately detect the input signal level over a

100 dB range from 30 nA to 3 mA peak-to-peak.

LEVEL DETECTOR THEORY OF OPERATION

Referring to the level detector block diagram of Figure 3, the

REC

input is an AC virtual ground. The next block imple-

IN

ments the full-wave rectification of the input current. This

current is then fed into a logging transistor (Q

transistor (Q

) has a fixed collector current of I

2

) whose pair

1

. The LOG

REF

AV output is then:

AV =

kT

q

V

LOG

ln

|

|I

IN

I

REF

With the use of the LOG AV capacitor the output is then the log

of the average of the absolute value of I

.

IN

(The unfiltered LOG AV output has broad flat plateaus with

sharp negative spikes at the zero crossing. This reduces the

“work” that the averaging capacitor must do, particularly at low

frequencies.)

Note: It is natural to assume that with the addition of the

averaging capacitor, the LOG AV output would become the

average of the log of the absolute value of I

. However, since the

IN

capacitor forces an ac ground at the emitter of the output

transistor, the capacitor charging currents are proportional to

the antilog of the voltage at the base of the output transistor.

Since the base voltage of the output transistor is the log of the

absolute value of I

, the log and antilog terms cancel, so the

IN

capacitor becomes a linear integrator with a charging current

directly proportional to the absolute value of the input current.

This effectively inverts the order of the averaging and logging

functions. The signal at the output therefore is the log of the

average of the absolute value of I

.

IN

USING DETECTOR PINS RECIN, LOGAV, THRESH AND

CON

OUT

When applying signals to RECIN (rectifier input) an input series

resistor should be followed by a low leakage blocking capacitor

since REC

ground. Choose R

has a dc voltage of approximately 2.1 V above

IN

for a ±1.5 mA peak signal. For ± 15 V

IN

operation this corresponds to a value of 10 kΩ.

A 1.5 MΩ value of R

a 10 µA reference current in the logging transistor (Q

from log average to –15 V will establish

REF

). This

1

will bias the transistor in the middle of the detector’s dynamic

current range in dB to optimize dynamic range and accuracy.

The LOG AV outputs are buffered and amplified by unipolar

drive op amps. The 39 kΩ, 1 kΩ resistor network at the

THRESH pin provides a gain of 40.

An attenuator from the CON

(control output) to the

OUT

appropriate VCA control port establishes the control sensitivity.

Use 200 Ω for the attenuator resistor to ground and choose

R

for the desired sensitivity. Care should be taken to minimize

CON

capacitive loads on the control outputs CON

. If long lines

OUT

or capacitive loads are present, it is best to connect the series

resistor R

as closely to the CON

CON

pin as possible.

OUT

DYNAMIC LEVEL DETECTOR CHARACTERISTICS

Figures 4 and 5 show the dynamic performance of the level

detector to a change in signal level. The input to the detector (not

shown) is a series of 500 ms tone bursts at 1 kHz in successive

10 dBV steps. The tone bursts start at a level of –60 dBV (with

R

= 10 k) and return to –60 dBV after each successive 10 dB

IN

step. Tone bursts range from –60 dBV to +10 dBV. Figure 4

shows the logarithmic level detector output. The output of the

detector is 3 mV/dB at LOG AV and the amplifier gain is 40

which yields 120 mV/dB. Thus, the output at CON

OUT

is seen

to increase by 1.2 V for each 10 dBV increase in input level.

1kΩ

39kΩ

INPUT

I

REF

LOG AV

R

REF

THRESH

CON

OUT

V–

R

CON

200Ω

TO V

C

V+

R

REC

IN

IN

RECTIFIER

2V

FULL

WAVE

|IIN|

Q2

Q1

C

AV

V–

Figure 3. Level Detector

–4–

REV. C

Page 5

SSM2120/SSM2122

2V

100

90

10

0%

1s

Figure 4. Detector Output

2V

100

90

10

0%

50ms

Figure 5. Overlayed Detector Output

DYNAMIC ATTACK AND DECAY RATES

Figure 5 shows the output levels overlayed using a storage

scope. The attack rate is determined by the step size and the

value of C

. The attack time to final value is a function of the

AV

step size increase. Table I shows the values of total settling

times to within 5 dB, 3 dB, 2 dB and 1 dB of final value with

C

= 10 µF. When step sizes exceed 40 dB, the increase in

AV

settling time for larger steps is negligible. To calculate the attack

time to final value for any value of C

value in the chart by C

/10 µF.

AV

, simply multiply the

AV

The decay rates are linear ramps that are dependent on the

current out of the LOG AV pin (set by R

C

. The integration or decay time of the circuit is derived from

AV

) and the value of

REF

the formula:

I

×333

Decrementation Rate (in dB/s) =

REF

C

AV

Table I. Settling Time (tS) for CAV = 10 mF. tS = tS (CAV = 10 mF)

5 dB 3 dB 2 dB 1 dB

10 dB Step 11.28 ms 21.46 30.19 46.09

20 dB Step 16.65 26.83 35.56 51.46

30 dB Step 18.15 28.33 37.06 52.96

40 dB Step 18.61 27.79 37.52 53.42

50 dB Step (+144 µs)

60 dB Step (+46 µs)

APPLICATIONS

The following applications for the SSM2120 use both the VCAs

and level detectors in conjunction to assimilate a variety of

functions.

The first section describes the arrangement of the threshold

control in each control circuit configuration. These control

circuits form the foundation for the applications to follow which

include the downward expander, compressor/limiter and

compandor.

THRESHOLD CONTROL

Figure 6a shows the control circuit for a typical downward

expander while Figure 6b shows a typical control curve. Here,

the threshold potentiometer adjusts V

to provide a negative

T

unipolar control output. This is typically used in noise gate,

downward expander, and dynamic filter applications. This

potentiometer is used in all applications to control the signal

level versus control voltage characteristics.

CON

V

+

–

THRESHOLD

*

*LOWER LIMIT CAN BE FIXED

BY CONNECTING A RESISTOR

FROM RECIN TO GROUND

R

LL

VIN – dB

R

IN

L

R

MONO

OR R

IN

MONO – RIN = 10kΩ

STEREO – R

= 20kΩ

IN

REC

THRESHOLD

CONTROL

V

T

V–

R

T

39kΩ

CON

R

CON

OUT

V–

200Ω

TO +V

C

LOG AV

AV

V+

1kΩ

1.5MΩ

V–

IN

R

LL

|IIN|

2V

C

a. Control Circuit b. Typical Downward Expander

Control Curve

Figure 6. Noise Gate/Downward Expander Control Circuit and Typical Response

REV. C

–5–

Page 6

SSM2120/SSM2122

In the noise gate, downward expander and compressor/limiter

applications, this potentiometer will establish the onset of the

control action. The sensitivity of the control action depends on

the value of R

.

T

For a positive unipolar control output add two diodes as shown

in Figure 7a. This is useful in compressor/limiter applications.

Figure 7b shows a typical response.

Bipolar control outputs can be realized by adding a resistor from

the op amp output to V+. This is useful in compandor circuits

THRESHOLD

CONTROL

R

IN

L

R

MONO

OR R

IN

MONO – RIN = 10kΩ

STEREO – R

= 20kΩ

IN

REC IN

V+

|IIN|

2V

C

AV

LOG AV

1.5MΩ

V–

1kΩ

THRESH

V

T

R

T

39kΩ

as shown in Figure 8a, with its response in Figure 8b. The value

of the resistor R

will determine the maximum output from the

PV

control amplifier.

STEREO COMPRESSOR/LIMITER

The two control circuits of Figures 6 and 7 can be used in

conjunction to produce composite control voltages. Figures 9a

and 9b show this type of circuit and transfer function for a

stereo compressor/limiter which also acts as a downward

expander for noise gating. The output noise in the absence of a

V+

R

PV

R

CON

CON

OUT

V–

200Ω

TO –V

C

+

CON

V

–

*UPPER LIMIT CAN BE FIXED BY

VALUE OF PULL UP RESISTOR (R

CONNECTED TO POSITIVE SUPPLY

THRESHOLD

*

PV

VIN – dB

)

a. Control Circuit b. Typical Compressor/Limiter Control

Curve

Figure 7. Compressor/Limiter Control Circuit and Typical Response

R

IN

L

R

MONO

OR R

IN

MONO – RIN = 10kΩ

STEREO – R

= 20kΩ

IN

REC

GAIN

V+

IN

R

LL

2V

|IIN|

C

LOG AV

AV

V–

1kΩ

THRESH

1.5MΩ

V–

V+

V

T

R

T

39kΩ

R

CON

PV

TO +V

C

OR –V

OUT

200Ω

C

+

VT < 0V

CON

V

–

V–

*

VT = 0

LOWER LIMITS CAN

BE ESTABLISHED BY

VALUES OF R

*

, RESPECTIVELY

R

LL

VIN – dB

>

0

T

*UPPER AND

AND

PV

a. Control Circuit b. Typical Compandor Control Curves

Figure 8. Compandor Control Circuit and Typical Curves

MONO

OR R

EXPANSION

– dB

OUT

V

THRESHOLD

THRESHOLD EXP.

L

FIGURE 6

THRESHOLD COM.

FIGURE 7

200Ω

200Ω

+V

C

–V

C

*

COMPRESSION

THRESHOLD

VIN – dB

a. Control Circuit b. Input/Output Curve

Figure 9. Control Circuit for Stereo Compressor/Limiter with Noise Gating and Input/Output Curve

–6–

REV. C

Page 7

SSM2120/SSM2122

1kΩ

10pF

36Ω

TRANSMISSION

OR

STORAGE

MEDIUM

V+

R

C

39kΩ

10kΩ

V–

SIGNAL

INPUT

36kΩ

1µF

10kΩ

47Ω

REC

2200pF

IN

200Ω

200Ω

|IIN|

1µF

+V

–V

C

C

V+

LOG AV

4.7MΩ

V–

Figure 10. Companding Noise Rejection System

signal will be dependent on the noise of the current-to-voltage

converter amplifier if the expansion ratio is high enough.

As discussed in the Threshold Control section, the use of the

control circuit of Figure 6, including the R

to V+ and two

PV

diodes, yields positive unipolar control outputs.

COMPANDING NOISE REDUCTION SYSTEM

A complete companding noise reduction system is shown in

Figure 10. Normally, to obtain an overall gain of unity, the

value of R

is equal to RE. The values of R

C

will determine the

C/E

compression/expansion ratio.

Table II shows compression/expansion ratios ranging from 1.5:1

to full limiting with the corresponding values of R

C/E

.

An example of a 2:1 compression/expansion ratio is plotted in

Figure 11. Note that signal compression increases gain for low

level signals and reduces gain for high levels while expansion

does the reverse. The net result for the system is the same as the

original input signal except that it has been compressed before

being sent to a given medium and expanded after recovery. The

compression/expansion ratio needed depends on the medium

1kΩ

10pF

36kΩ

SIGNAL

OUTPUT

V+

R

E

39kΩ

10kΩ

V–

36kΩ

1µF

10kΩ

47Ω

REC

2200pF

IN

200Ω

200Ω

|IIN|

1µF

–V

+V

C

C

V+

LOG AV

4.7MΩ

V–

being used. As an extreme example, a household tape player

would require a higher compression/expansion ratio than a

professional stereo system.

20

I

≈ 3µA

REF

= 4.7MΩ

R

REF

0

–20

–40

OUTPUT SIGNAL LEVEL – dB

–60

–80

–80 20–60

INPUT SIGNAL LEVEL – dB

OVERALL

RESPONSE

2:1

EXPANSION

2:1

COMPRESSION

–40 –20 0

25dB

Figure 11. Companding Noise Reduction with 2:1

Compression/Expansion Ratio

Table II.

Gain Compressor Expander

(Reduction Only Only

Input Signal or Increase) Output Signal Output Signal Compression/ DV

Increase (dB) (dB) Increase (dB) Increase (dB) Expansion Ratio R

V (mV/dB)

C/E

20 6.67 13.33 22.67 1.5:1 11,800 2.0

20 10.00 10.00 30.00 2:1 7,800 3.0

20 13.33 6.67 33.33 3:1 5,800 4.0

20 15.00 5.00 35.00 4:1 5,133 4.5

20 16.00 4.00 36.00 5:1 4,800 4.8

20 17.33 2.67 37.33 7.5:1 4,415 5.2

20 18.00 2.00 38.00 10:1 4,244 5.4

20 20.00 0 40.00 AGC*/Limiter 3,800 6.0

*AGC for Compression Only.

REV. C

–7–

CONTROL

–

Page 8

SSM2120/SSM2122

DYNAMIC FILTER

Figure 12 shows a control circuit for a dynamic filter capable of

single ended (nonencode/decode) noise reduction. Such circuits

usually suffer from a loss of high frequency content at low signal

levels because their control circuits detect the absolute amount

of highs present in the signal. This circuit, however, measures

wideband level as well as high frequency band level to produce

a composite control signal combined in a 1:2 ratio respectively.

The upper detector senses wideband signals with a cutoff of

20 Hz while the lower detector has a 5 kHz cutoff to sense only

high frequency band signals. This approach allows very good

noise masking with a minimum loss of “highs” when the signal

level goes below the threshold.

V+

THRESHOLD

AUDIO

INPUT

10kΩ

F

(WIDEBAND)

2.2µF

≤ 20Hz

C

REC

CONTROL

IN

|IIN|

9

LOG AV

3.3µF

2

1.5MΩ

160kΩ

V–

THRESH

1kΩ

39kΩ

CON

1

12kΩ

OUT

3

V–

3300pF

10kΩ

(HIGH FREQUENCY)

F

C

REC

= 5kHz

V–

V+

IN

|IIN|

15

LOG AV

3.3µF

V–

13

1.5MΩ

160kΩ

THRESH

1kΩ

39kΩ

12

36kΩ

CON

V–

OUT

14

2200pF

5.6kΩ

47Ω

200Ω

SIG

8

+V

5

C

IN

7

–V

C

200Ω

SIG

36kΩ

OUT

5

36kΩ

36kΩ

100pF

AUDIO

OUTPUT

Figure 12. Dynamic Noise Filter Circuit

–8–

REV. C

Page 9

Figures 13a–c show the filter’s 3 dB frequency response with the

WIDEBAND SIGNAL LEVEL – dB

–50 –40 –30 –20 –10 0 10 20

20

HIGH-FREQUENCY SIGNAL LEVEL – dB

–20

–30

–40

–50

0

–10

10

1.5 2.2 3.1 4.2 4.2 4.2 4.2 4.2

4.9 7.1 10 10 10 10 10

15.1 22 22 22 22 22

48 49.2 49.2 49.2 49.2

50.6 50.6 50.6 50.6

50.6 50.6 50.6

50.6 50.6

50.6

WIDEBAND SIGNAL LEVEL – dB

–50 –40 –30 –20 –10 0 10 20

20

HIGH-FREQUENCY SIGNAL LEVEL – dB

–20

–30

–40

–50

0

–10

10

12.3 17.3 17.8 17.8 17.8 17.8 17.8 17.8

40 41 41 41 41 41 41

50.6 50.6 50.6 50.6 50.6 50.6

50.6 50.6 50.6 50.6 50.6

50.6 50.6 50.6 50.6

50.6 50.6 50.6

50.6 50.6

50.6

threshold potentiometer at V+, centered, and V–. Data was

taken by applying a 300 Hz signal to the wideband detector and

a 20 kHz signal to the high-frequency band detector simultaneously. These figures correspond to filter characteristics for

50 dB, 70 dB and 90 dB dynamic range program source

material, respectively. The system could thus treat signals from

anything ranging from 1/4" magnetic tape to high performance

compact disc players.

Note that in Figure 13a the control circuit is designed so that

the minimum cutoff frequency is about 1 kHz. This occurs as

the control circuit detects the noise floor of the source material.

Dynamic filtering limits the signal bandwidth to less than 1 kHz

unless enough highs are detected in the signal to cover the noise

floor in the mid- and high frequency range. In this case the filter

opens to pass more of the audio band as more highs are detected.

The filter’s bandwidth can extend to 50 kHz with a nominal

signal level at the input. At other signal levels with varying high

frequency content, the filter will close to the required bandwidth. Here, noise outside the band is removed while the

perceived noise is masked by other signals within the band.

Even in this system, however, a certain amount of mid- and high

frequency components will be lost, especially during transients

at very low signal levels. This circuit does not address low

frequency noise such as “hum” and “rumble.”

SSM2120/SSM2122

20

10

0

–10

–20

–30

–40

HIGH-FREQUENCY SIGNAL LEVEL – dB

–50

1.0 1.0 1.2 1.7 2.4 2.4 2.4

1.0 1.0 1.0 1.0 1.0 1.1 1.1 1.1

–50 –40 –30 –20 –10 0 10 20

6 8.3 11.7 11.7 11.7

1.9 2.75 3.9 5.5 5.5 5.5

WIDEBAND SIGNAL LEVEL – dB

a. V

THRESH

at V+

50.6

50.6 50.6

50.6 50.6 50.6

17.8 26 26 26

b. V

c. V

THRESH

THRESH

Centered

at V–

Figure 13. 3 dB Filter Response

REV. C

–9–

Page 10

SSM2120/SSM2122

+20

–30

–40

–50

–60

+20

–30

–45

–60

–75

INPUT – dB

OUTPUT – dB

V+

THRESHOLD

SIGNAL

INPUT

R

IN1

FC ≤ 20Hz

R

IN2

F

= 5Hz

C

REC

REC

IN

IN

IN |IIN|

C

AV1

IN |IIN|

C

AV2

V+

LOG AV

1.5MΩ

V–

V+

LOG AV

1.5MΩ

V–

160kΩ

1kΩ

160kΩ

1kΩ

36kΩ

Figure 14. Dynamic Filter with Downward Expander

DYNAMIC FILTER WITH DOWNWARD EXPANDER

A composite single-ended noise reduction system can be

realized by a combination of dynamic filtering and a downward

expander. As shown in Figure 14, the output from the wideband

detector can also be connected to the +V

control port of the

C

second VCA which is connected in series with the sliding filter.

This will act as a downward expander with a threshold that

tracks that of the filter. Although both of these techniques are

used for noise reduction, each alone will pass appreciable

amounts of noise under some conditions. When used together,

both contribute distinct advantages while compensating for each

other’s deficiencies.

Downward expansion uses a VCA controlled by the level

detector. This section maintains dynamic range integrity for all

levels above the user adjustable threshold level. As the input

level decreases below the threshold, gain reduction occurs at an

increasing rate (see Figure 15). This technique reduces audible

noise in fade outs or low level signal passages by keeping the

standing noise floor well below the program material.

This technique by itself is less effective for signals with

predominantly low frequency content such as a bass solo where

wideband frequency noise would be heard at full level. Also,

since the level detector has a time constant for signal averaging,

percussive material can modulate the noise floor causing a

“pumping” or “breathing” effect.

39kΩ

V–

39kΩ

200Ω

+V

C

–V

C

200Ω

DOWNWARD EXPANDER

36kΩ

36kΩ

100pF

36kΩ

36kΩ

SIGNAL

OUTPUT

CON

V–

V–

2200pF

OUT

CON

47Ω

OUT

12kΩ

5.6kΩ

200Ω

+V

–V

200Ω

2200pF

C

C

12kΩ

47Ω

36kΩ

The dynamic filter and downward expander techniques used

together can be employed more subtly to achieve a given level of

noise reduction than would be required if used individually. Up

to 30 dB of noise reduction can be realized while preserving the

crisp highs with a minimum of transient side effects.

Figure 15. Typical Downward Expander I/O Characteristics

at –30 dB Threshold Level (1:1.5 Ratio)

–10–

REV. C

Page 11

SSM2120/SSM2122

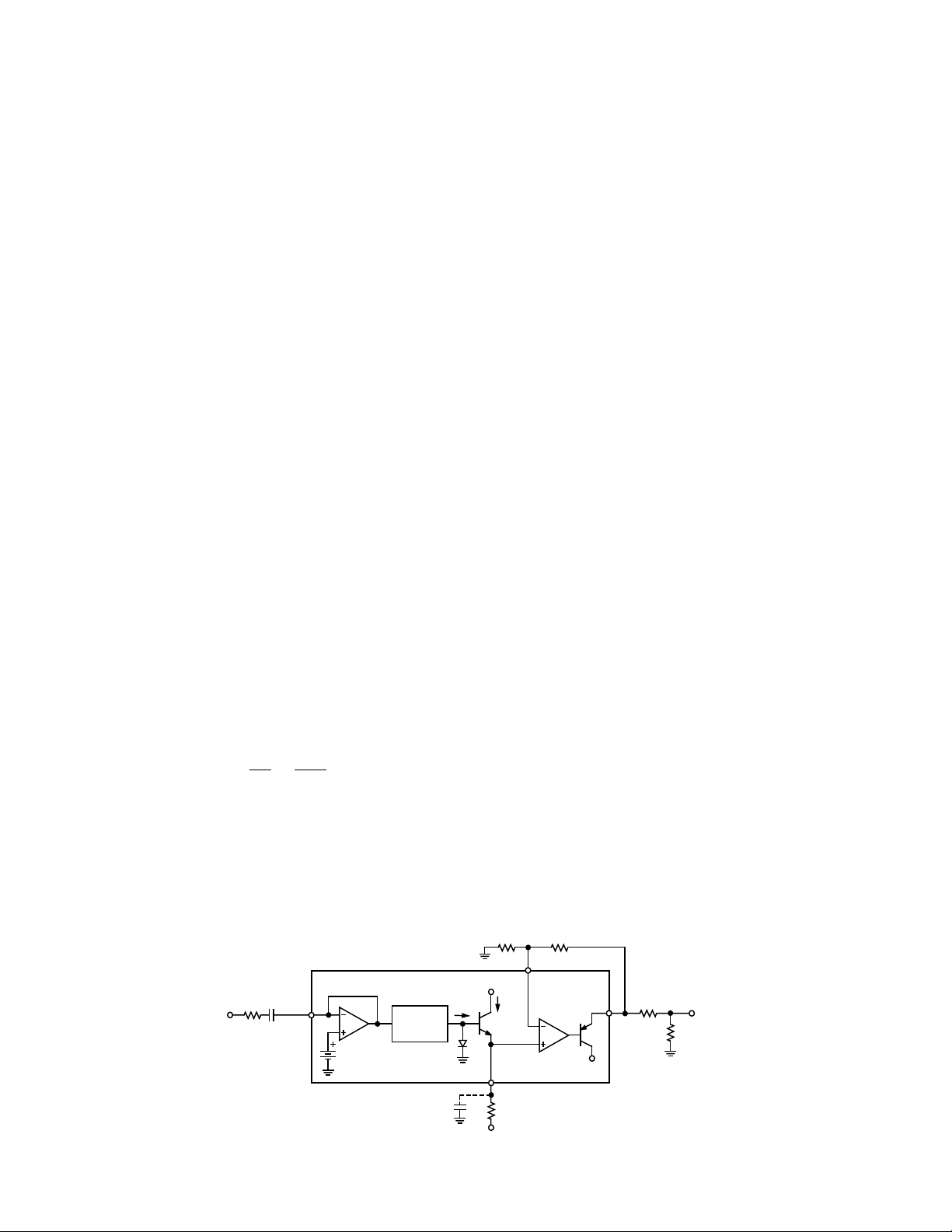

FADER AUTOMATION

The SSM2120 can be used in fader automation systems to serve

two channels. The inverting control port is connected through

an attenuator to the VCA control voltage source. The noninverting

control port is connected to a control circuit (such as Figure 6)

which senses the input signal level to the VCA. Above the

threshold voltage, which can be set quite low (for example

–60 dBV), the VCA operates at its programmed gain. Below

this threshold the VCA will downward expand at a rate determined by the +V

control port attenuator. By keeping the release

C

time constant in the 10 ms to 25 ms range, the modulation of

the VCA standing noise floor (–80 dB at unity-gain), can be

kept inaudibly low.

10pF

SIG

SIG

OUT 1

–V

IN 1

36kΩ

1/2

TL082

V+

50kΩ

*

V–

C1

36kΩ

2000pF

47Ω

220kΩ

V+

200Ω

200Ω

0.1µF

150kΩ

–15V

1

2

3

4

SSM2122

5

6

7

8

*

OPTIONAL CONTROL FEEDTHROUGH TRIM

The SSM2300 8-channel multiplexed sample-and-hold IC

makes an excellent controller for VCAs in automation systems.

Figure 16 shows the basic connection for the SSM2122 operating

as a unity-gain VCA with its noninverting control ports grounded

and access to the inverting control ports. This is typical for fader

automation applications. Since this device is a pinout option of

the SSM2120, the VCAs will behave exactly as described

earlier in the VCA section.

The SSM2122 can also be used with two or more op amps to

implement complex voltage-controlled filter functions. Biquad

and state-variable two-pole filters offering low pass, bandpass

and high pass outputs can be realized. Higher order filters can

also be formed by connecting two or more such stages in series.

+15V

0.1µF

16

15

14

200Ω

13

220kΩ

12

200Ω

11

10

9

10pF

36kΩ

1/2

TL082

2000pF

47Ω

36kΩ

SIG

50kΩ

OUT 2

*

–V

C2

SIG

IN 2

V+

V–

Figure 16. SSM2122 Basic Connection (Control Ports at 0 V)

REV. C

–11–

Page 12

SSM2120/SSM2122

0.210 (5.33)

0.160 (4.06)

0.115 (2.93)

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Pin Plastic DIP

(N-16)

0.840 (21.33)

0.745 (18.93)

16

18

PIN 1

MAX

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

9

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

22-Pin Plastic DIP

(N-22)

1.080 (27.43)

1.020 (25.91)

22

111

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

12

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

C2088–2–11/95

0.195 (4.95)

0.115 (2.93)

0.195 (4.95)

0.115 (2.93)

–12–

PRINTED IN U.S.A.

REV. C

Loading...

Loading...