Page 1

FEATURES

SPT8100

16-BIT, 5 MSPS CMOS A/D CONVERTER

TECHNICAL DATA

JANUARY 9, 2002

APPLICATIONS

• 16-bit, 5 MSPS CMOS analog-to-digital converter

• On-chip PGA: gain range from 0 to 19.5 dB in se v e n

selectable settings:

0 dB, +2.9 dB, +5.8 dB, +11.8 dB , +14.8 dB , +17.5 dB ,

+19.5 dB

• DLE: ±0.5 LSB , ILE: ±1.25 LSB

• SFDR: 94 dB @ ƒIN = 900 kHz, –8.1 dBFS

• Internal sample-and-hold and voltage reference

• Po wer dissipation: 465 mW at 5 MSPS

• +5 V analog supply and +3.3 to +5.25 V digital output

supply

• 44-lead LQFP plastic package

DESCRIPTION

The SPT8100 is a high-performance, 16-bit analog-todigital converter that operates at a sample rate of up to

5 MSPS. Excellent dynamic performance and high linearity is achieved by a digitally calibrated pipelined architecture fabricated in CMOS process technology.

A low-noise programmable gain amplifier (PGA) is also incorporated on chip. The PGA is digitally programmable in

seven selected settings over a 0 to +19.5 dB range. The

• Data acquisition systems

• IR imaging

• Scanners and digital copiers

• High-end CCD cameras

• Medical imaging

• Wireless communications

• Lab and test equipment

• Automatic test equipment

SPT8100 also features an on-chip internal sample-andhold and internal reference for minimal e xternal circuitry .

It operates from a single +5 V supply. Total power dissipation, including internal reference, is 465 mW. A separate

digital output supply pin is provided for +3.3 V or 5 V logic

output levels. The SPT8100 is available in a 44-lead LQFP

package over the industrial temperature range of –40 °C to

+85 °C.

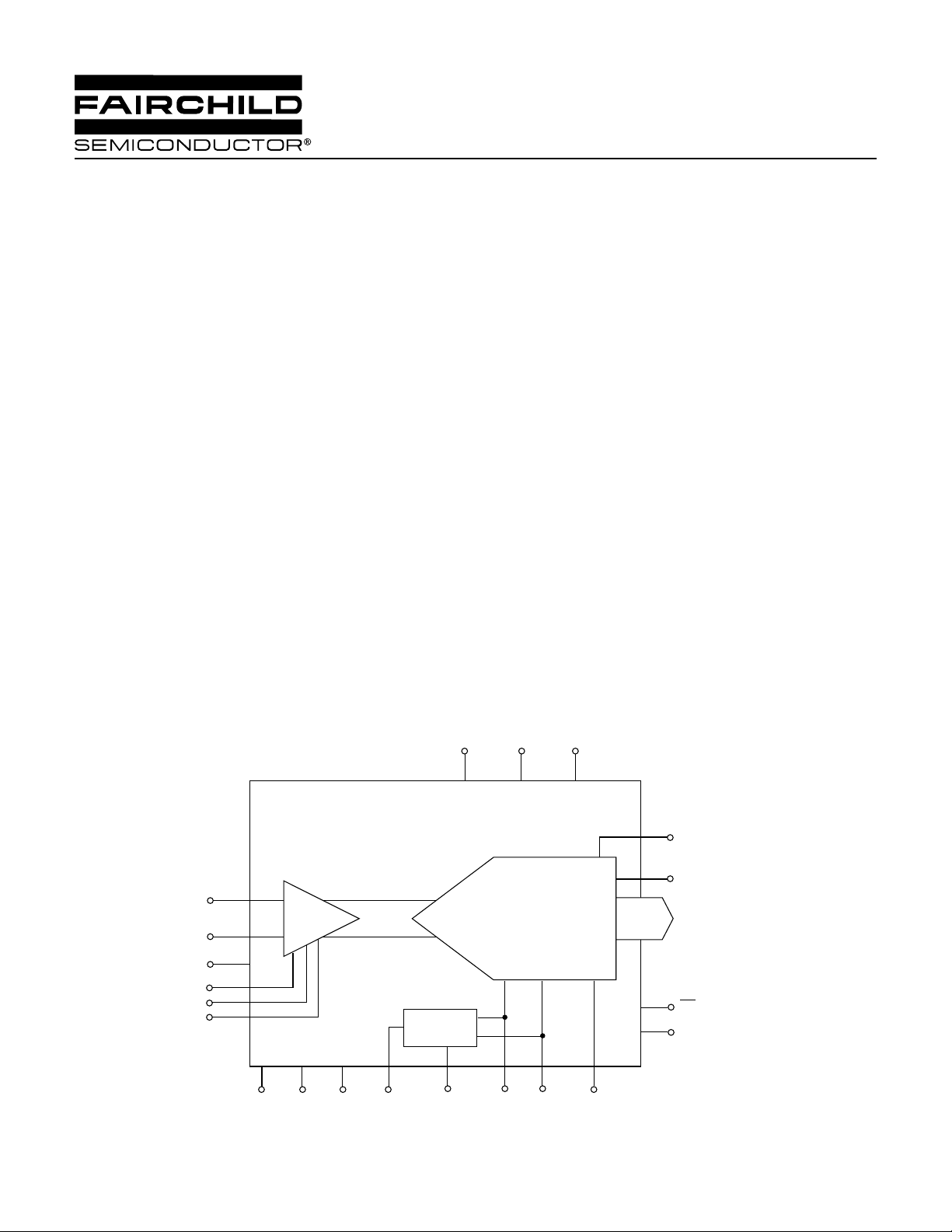

BLOCK DIAGRAM

V

+

IN

V

–

IN

V

CM

GS2 – GS0

(Gain Set)

Low-Noise

AGND

PGA

DD

DV

+5V

AV

+5V

16-bit, 5 MSPS ADC

VREF

OGNDDGND

BIAS

C

(Ext Bias

Capacitor)

BIAS

(Ext Bias

Resistor)

V

R

RTVRB

DD

OV

DD

+3/5 V

CLK

16-bits

OE (Output Enable)

OVR (Over-Range)

D15 – D0

(Data Outputs)

RS (Reset)

RDY (Ready)

Page 2

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)1 25 °C

Supply V oltages

AVDD...................................................................... +6 V

DVDD..................................................................... +6 V

OVDD..................................................................... +6 V

Input V oltages

Analog Input ................................. –0.5 V to VDD +0.5 V

CLK Input ............................................................... V

AVDD – DVDD.................................................. ±100 mV

Delta between AGND, DGND , and OGND...... ±100 mV

Output

Digital Outputs.................................................... 10 mA

T emperature

Operating T emperature........................... –40 to +85 °C

Junction T emperature ...................................... +175 °C

Lead Temperature (soldering 10 seconds) ...... +300 °C

DD

Storage T emperature............................ –65 to +150 °C

Note 1: Operation at any Absolute Maximum Rating is not implied. See

Electrical Specifications for proper nominal applied conditions in

typical applications.

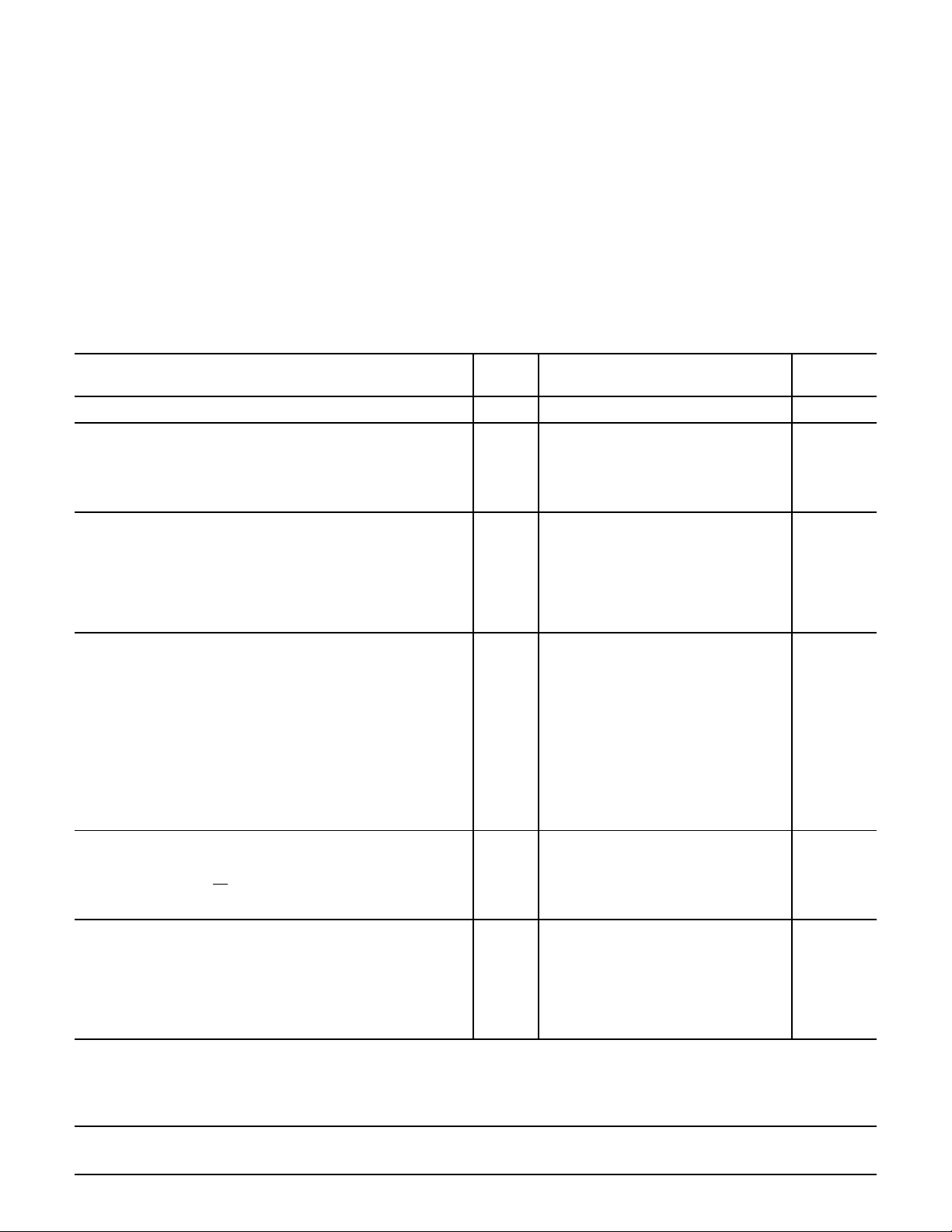

ELECTRICAL SPECIFICATIONS

TA=T

otherwise specified.

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Resolution 15.9 16 Bits

DC Accuracy

Analog Input (into PGA)

MIN

to T

, AVDD=DVDD=+5.0 V, OVDD= 3.3 V, ƒS=5 MSPS, 2.5 VPP input span, Gain=0 dB, R

MAX

=1.43 kΩ, unless

EXT

TEST TEST SPT8100

Integral Linearity Error (ILE) V ±1.25 LSB

Differential Linearity Error (DLE) V ±0.5 LSB

Gain Error

Offset Error

1

2

IV –7.5 +7.5 %FSR

IV –5+5%FSR

Differential Input Voltage Range

+, VIN– V5V

V

IN

PPD

Input Capacitance IV 15 pF

Input Resistance

Input Bandwidth

3

4

PGA Gain = 0 dB IV 5.5 kΩ

PGA Gain = 0 dB V 12 MHz

Input Common Mode Voltage Range V 1.15 2.40 3.65 V

Programmable Gain Amp

Composite Input-Referred ƒ

> 300 kHz

IN

Noise Floor PGA Gain = 0 dB V 1.4 LSB

PGA Gain = 2.9 dB V 1.5 LSB

PGA Gain = 5.8 dB V 1.6 LSB

PGA Gain = 11.8 dB V 2.0 LSB

PGA Gain = 14.8 dB V 2.3 LSB

PGA Gain = 17.5 dB V 2.6 LSB

PGA Gain = 19.5 dB V 2.8 LSB

PGA Range V 19.5 dB

PGA Gain Steps

3

VI 0,2.9,5.8,11.8,14.8,17.5,19.5 dB

PGA Gain Accuracy VI ±0.3 dB

Conversion Characteristics

Maximum Conversion Rate VI 5 MSPS

Pipeline Delay (Latency)

Reset Pulse Time (

RS) IV 3 Clocks

5

IV 5.5 Clocks

Reset Calibration Time FS = 5 MSPS V 150 ms

References and External Bias

– VRB (Internal Ref) VI 2.375 2.5 2.625 V

V

RT

Bias Resistor Range (External) V 800 1430 2500 Ω

Output Voltage IV 2.275 2.40 2.525 V

V

CM

Output Current IV 47 µA

V

CM

V

RT

V

RB

1

Total gain error of PGA and ADC using inter nal references.

2

Total offset error of PGA and ADC relative to mid-scale.

3

See table I for input resistance as a function of PGA gain.

4

Input bandwidth is a frequency to which the fundamental energy drops by 3 dB

5

The input is sampled on the falling edge of the clock and is available on the

output after the rising edge of the clock, 5.5 clock cycles later.

V 3.45 3.65 3.85 V

V 0.95 1.15 1.35 V

RMS

RMS

RMS

RMS

RMS

RMS

RMS

SPT8100

2 1/9/02

Page 3

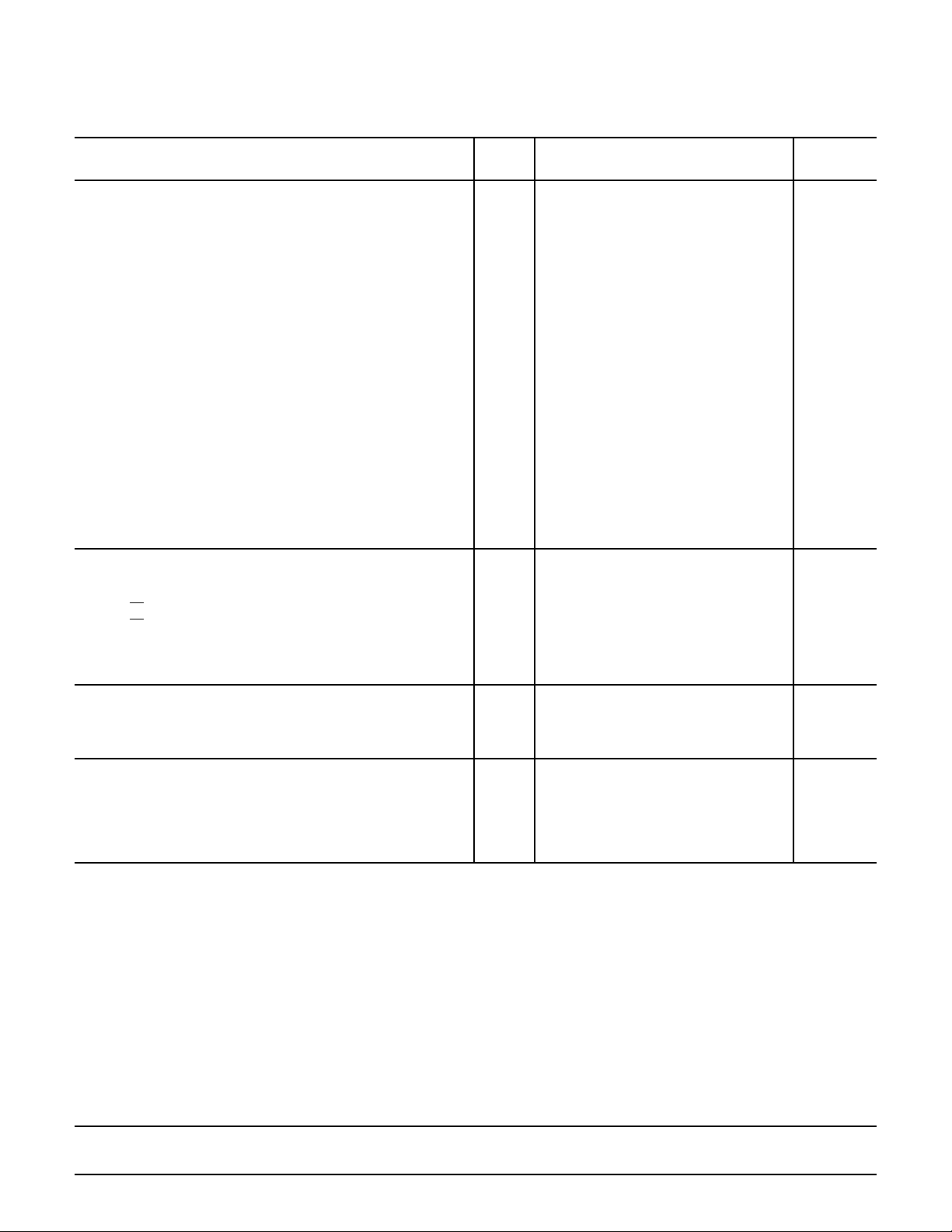

ELECTRICAL SPECIFICATIONS

TA=T

otherwise specified.

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Dynamic Performance

MIN

to T

, AVDD=DVDD=+5.0 V, OVDD= 3.3 V, ƒS=5 MSPS, 2.5 VPP input span, Gain=0 dB, R

MAX

=1.43 kΩ, unless

EXT

TEST TEST SPT8100

1

Effective Number of Bits ADC Input = –1 dBFS

2

ƒIN = 60 kHz IV 12.2 13.0 Bits

= 900 kHz V 12.7 Bits

ƒ

IN

Signal-to-Noise Ratio

(without Harmonics) ADC Input = –1 dBFS

2

ƒIN = 75 kHz IV 78 81 dB

ƒ

= 900 kHz V 80 dB

IN

Harmonic Distortion ADC Input = –0.5 dBFS

= 60 kHz IV –92 –84 dB

ƒ

IN

ƒ

= 900 kHz V –82 dB

IN

Signal-to-Noise and Distortion

(SINAD) ADC Input = –1 dBFS

= 60 kHz IV 75 80 dB

ƒ

IN

= 900 kHz V 78 dB

ƒ

IN

Spurious Free Dynamic Range

3

ƒIN = 60 kHz ADC Input = –0.5 dB IV 85 94 dBc

= 900 kHz V 94 dBc

ƒ

IN

= 2 MHz R

ƒ

IN

ƒIN = 3 MHz R

= 1 kΩ @ 10 MSPS V 83 dBc

EXT

= 1 kΩ @ 10 MSPS V 78 dBc

EXT

Two-Tone Intermodulation

3rd Order Distortion ƒ

=400 kHz, ƒ2=410 kHz

1

ƒ1=890 kHz, ƒ2=900 kHz

4

V –94 dB

5

V –89 dB

Inputs

GS0–GS2 Logic 1 Voltage VI 2.4 V

GS0–GS2 Logic 0 Voltage VI 0.8 V

RS Logic 1 Voltage VI 2.0 V

CLK,

RS Logic 0 Voltage VI 0.8 V

CLK,

Maximum Input Current Low VI –10 +10 µA

Maximum Input Current High VI –10 +10 µA

Input Capacitance V 5 pF

Digital Outputs

Logic 1 Voltage I

= –2 mA VI OVDD – 0.5 V

OH

Logic 0 Voltage IOL = 2 mA VI 0.4 V

CLK to Output Delay Time (t

)C

D

= 20 pF IV 30 ns

LOAD

Power Supply Requirements

Voltages OV

AV

DV

Currents I

DD

DD

DD

DD

IV 3.0 3.3 5.25 V

IV 4.75 5.0 5.25 V

IV 4.75 5.0 5.25 V

VI 93 103 mA

Power Dissipation VI 4 65 515 mW

1

Dynamic performance tested at ƒS=4.4 MSPS

2

0 dBFS is 5.0 V peak-to-peak differential

3

ADC Input = –8.1 dBFS, unless otherwise noted

TEST LEVEL CODES

All electrical characteristics are subject

to the following conditions:

All parameters having min/max specifications are guaranteed. The Test Level

column indicates the specific device

testing actually performed during

production and Quality Assurance

inspection. Any blank section in the data

column indicates that the specification is

not tested at the specified condition.

TEST LEVEL TEST PROCEDURE

I 100% production tested at the specified temperature.

II 100% production tested at TA = +25 °C, and sample tested at the

III QA sample tested only at the specified temperatures.

IV Parameter is guaranteed (but not tested) by design and characteriza-

V Parameter is a typical value for information pur poses only.

VI 100% production tested at TA = +25 °C. Parameter is guaranteed

4

Test Conditions: PGA setting of 5.8 dB; Analog Input at ADC = –0.7 dB

5

Test Conditions: PGA setting of 0 dB; Analog Input at ADC = –1.9 dB

specified temperatures.

tion data.

over specified temperature range.

SPT8100

3 1/9/02

Page 4

DEVICE OVERVIEW

ADC CLOCK

The SPT8100 combines a high-resolution 5 MSPS 16-bit

ADC, a built-in reference, and a programmable gain amplifier (PGA) with resistive input impedance in a 44-pin

package.

The device includes a digitally calibrated pipeline ADC,

which is calibrated on assertion of a simple reset signal.

The combination of low noise, high linearity, a high-input

impedance buffer (with programmable gain), wideband

S/H, on-board voltage references , and simple digital interface (16-bit parallel output word synchronous with the

master sampling clock) makes the SPT8100 extremely

easy to use in a wide variety of systems.

For optimum performance, the analog inputs should be

driven differentially, and may be AC-coupled or DCcoupled to a source. Typical applications include high-performance data acquisition systems, automatic test equipment, and wideband digital communications receivers

such as wireless basestations.

OPERATIONAL DESCRIPTION

The following sections describe in greater detail individual

blocks and functions of the SPT8100.

The incoming analog differential signal (maximum le vel 5 V

peak-to-peak differential) enters the device at the pins

VIN+/VIN–. The analog signal path is partitioned into a programmable gain amplifier (PGA) and an ADC. The PGA

has maximum gain of +19.5 dB; the gain is set b y the digital control signals GS0 to GS2.

The output of the PGA is fed directly to the ADC, which

samples at a rate equal to the CLK frequency and outputs

a 16-bit wide parallel word. The ADC uses a pipeline multistage architecture. Latency is 5.5 cloc k cycles .

The chip requires a single low-jitter clock to be applied at

the CLK pin, with nominal 40–60% duty cycle. All clock

generation is performed internally and all converter and

S/H clocks in the ADC path are directly derived from CLK.

If the sample rate is changed by more than a factor of 2,

the device must be recalibrated using the RS (reset) pin.

DEVICE ST ARTUP/INITIALIZATION SEQUENCE

Note: This initialization sequence is

required

. Without

it, the device will not work.

Allow sufficient time for the analog bloc ks on the SPT8100

to power on and come up to their quiescent DC states.

Allowance may also be needed f or thermal time constants

associated with the package/board.

On powerup, the SPT8100’s RS (reset) should be held low

for at least three clock cycles. The power supply voltages

applied to the device must be stable during this time. The

clock signal (CLK) must be running for at least three cloc k

cycles prior to the rising edge of RS, and must continue

running.

When the RS signal goes from low to high, calibration is initiated. RDY is driven low two clock cycles after the rising

edge of RS, and will stay low for 150 ms with a 5 MHz cloc k.

When the initialization is complete, RDY returns high and

the device is ready for normal operation. Note that the calibration of the ADC can be interrupted (before completion)

by changing the RS signal from high to low, which will

cause another reset to occur. When RS goes from low back

to high, another calibration cycle will begin.

RDY cannot be tri-stated: it is alwa ys driven either high or

low. The CLK must be constantly running throughout the

Figure 1 – Device Initialization Timing

PWR ON

A

IN

CLK

RS

RDY

D

OUT

Requires external reset on powerup

3 clock cycles min

N+8

N+7

N+4

2 clock cycles

Initialization period: 150 ms with 5 MHz clock

INVALID DATA

N+6

N+5

5 ns typ

24 ns typ

N N+1 N+2

SPT8100

4 1/9/02

Page 5

initialization phase until RDY is deasserted. Note that,

although typically the device is initialized when power is

first applied, the initialization is only started when the

RS is

asserted; there is no “power-on-reset” circuitry on chip. RS

may be held low f or an indefinite period of time. While RS is

low , RD Y will remain high. After RS is returned to high, RDY

will go low for the duration of the calibration.

PROGRAMMABLE GAIN AMPLIFIER

The programmable gain amplifier (PGA) precedes the

ADC inputs. The diff erential inputs, which are resistive , are

at pins VIN+ and VIN–.The maximum input range is 5 V

peak-to-peak differential (2.5 V single-ended). To achieve

maximum overall system noise performance, the source

driving these inputs needs to be as low-noise and as lowjitter as possible, while maintaining the required distortion

performance. In addition, the driving source must be low

impedance to maintain the accuracy of the PGA gain.

TYPICAL INTERFACE CIRCUIT

ANALOG INPUT DRIVER

The differential analog inputs (VIN+, VIN–) have a resistiv e

input impedance of 1 kΩ minimum. F or best perf ormance,

the input source should be a differential input, as shown in

figure 2, typical interface circuit. The SPT8100 provides its

own common-mode voltage on the pin marked V

put drive capability of VCM is a maximum of 47 µA (50 kΩ to

ground).

The SPT8100 application note (AN8100) shows an example of two modes of driving the SPT8100. One mode is

through a transformer and the other is through a single-todifferential conver ter. In all cases, both inputs VIN+ and

VIN– must be kept within the input common-mode range

(1.15 V to 3.65 V).

BIASC CONNECTION

CM

. Out-

The internal 0 dB analog signal level and ADC full-scale

output level is 5 V peak-to-peak differential (2.5 V singleended). The PGA ma y be used to provide gain f or an input

less than 5 V peak-to-peak diff erential.

The gain of the PGA can be programmed using a three-bit

control, availab le at pins GS0 to GS2. See tab le I. Note that

the input resistance is a function of the gain setting.

Table I – PGA Gain Control

GS2 GS1 GS0 Gain Resistance Gain BW LSB

0 0 0 0 5.57 1 12 1.4

0 0 1 2.9 4.65 1.40 10 1.5

0 1 0 5.8 3.97 1.95 8 1.6

0 1 1 11.8 2.23 3.9 7 2.0

1 0 0 14.8 1.66 5.5 6 2.3

1 0 1 17.5 1.25 7.5 5.5 2.6

1 1 0 19.5 1.00 9.5 5 2.8

1 1 1 X Forbidden

PGA Input V/V 3 dB

(dB) (k

ΩΩ

Ω)

ΩΩ

RMS

An external capacitor, C

on the BIASC pin, is used only

EXT

for noise filtering of an internal voltage associated with the

references. Its value is not critical: 1 µF in parallel with

0.01 µF is recommended.

BIASR CONNECTION

As shown in the typical interface circuit, R

is needed to

EXT

connect between BIASR to ground. This resistor ranges

from 800 Ω to 2.5 kΩ. The proper selection of R

EXT

is a

function of the sample rate and input frequency . Nominally ,

at 5 MSPS, R

=1.43 kΩ is recommended. If linearity for

EXT

large signal levels at an analog bandwidth of 2 MHz is critical, the value should be decreased to R

for ev en higher-frequency analog inputs, R

=1.24 kΩ; and

EXT

=1.0 kΩ can

EXT

be used. At lower sample rates (for example 2 MSPS),

and lower analog input frequencies, the value may be increased to R

=2 kΩ. (Ref er to the typical interface circuit

EXT

table in figure 2b.)

POWER SUPPLIES AND GROUNDING

The SPT8100 requires three power supplies: analog A VDD,

digital DVDD and output supply OVDD. This device works

best if all three supplies are coming from the analog supply

side of the system as shown in the typical interface circuit

(figure 2a).

Note, in figure 2a, that the supplies to the logic interface

circuit and the OVDD are separate from each other. In a

case where the +A3.3/5 V supply is not available, try to

implement the design as close as possible to that shown

in figure 2b. Place the ferrite bead (FB1) as close to the

device as possible. To avoid latch-up, the delta between

all three grounds must stay with 100 mV; this includes

transients. (Refer to the absolute maximum ratings

specifications.)

SPT8100

5 1/9/02

Page 6

Figure 2a – Typical Interface Circuit

A

IN

Transformer

Mini-Circuit

T1-6T

0.1

+

4.7

R

T

(50)

+

10 0.1 1nF

1.43K

R

EXT

VIN+

V

GS0

Output

Enable

(active Hi)

OE

Clock

Input

CLK

RDY

D0–15

OVR

DD

16

Logic

Interfacing

Circuit

1.0

+

.01

BIAS

BIAS

R

V

CM

Reset

C

RS

Gain Control

GS1

GS2

SPT8100

–

IN

V

RT

V

RB

AV

DD

AGND DGND OGND OV

DV

DD

Figure 2b – Typical Interface Circuit

A

IN

ƒS (MSPS) R

–5 1.43 <2 MHz

–2 2.00 <2 MHz

–5 1.24 •2 MHz

–2 1.00 •2 MHz

800 Ω – R

Transformer

Mini-Circuit

EXT

– 2.5 kΩ

EXT

T1-6T

(k

0.1

ΩΩ

Ω) ƒ

ΩΩ

+

4.7

IN

R

T

(50)

+

10 0.1 1nF

1.43K

R

EXT

VIN+

V

IN

0.1

10

+

+A5V +A3.3/5V

1.0

+

.01

BIAS

C

BIAS

R

V

CM

–

V

RT

V

RB

AV

DD

Gain Control

Reset

GS0

GS2

GS1

RS

SPT8100

AGND DGND OGND OV

DV

DD

0.1

10

+

FB1

0.1

10

+

FB1

Output

Enable

(active Hi)

OE

0.1

10

Clock

Input

CLK

RDY

D0–15

OVR

DD

+

FB2

FB3

+D3.3/5V

16

Logic

Interfacing

Circuit

+A5V +D3.3/5V

Notes:

1. To avoid device latch-up, closely follow either figure 2a or 2b, depending on what is available in the system. The difference between figure 2a

and 2b is in the grounding.

2. FB = ferrite bead. FB1 must be placed as close to the device as possible.

3. R

= 1.43 kΩ, optimized for ƒS = 5 MSPS. Refer to the above table for recommended value of R

EXT

with respect to ƒS and ƒIN.

EXT

4. RT is AIN source termination resistor.

5. Power supplies and references pins must have adequate decoupling. Surface-mount capacitors are highly recommended. The smallest value

of capacitors are to be placed as close to the pin as possible.

SPT8100

6 1/9/02

Page 7

Figure 3 – Timing Diagram 1

n

Analog In

CLK

t

D

D0D15

OVR

n+1

n+2

n+3

n+4

n+5

n+6 n+7

n

n+1

n+8

n+2

INPUT/OUTPUT TIMING

The SPT8100 implements a simple interface: the 16 ADC

outputs appear on the pins D15–D0 as a parallel word synchronous with the ADC sampling clock. D0 is the LSB and

D15 is the MSB. The timing diagram for the ADC digital

outputs is shown in figure 3. The data is sampled at the f alling edge of the clock. The ADC sampling clock is at the

same frequency as CLK.

The output data is updated on the rising edge of CLK with

a clock latency of 5.5 clock cycles.

OUTPUT LOGIC LEVEL

The voltage levels on the D15–D0 lines and OVR are

CMOS levels: the HIGH level is determined by the power

supply voltage on the O VDD pin, which can be set independently of the other supply pins on the device over the range

from 3.0 V to 5.25 V (3.3 V typical). The RDY pin level is

determined by DVDD (+5 V).The external digital output

buffers should be placed as close as possible to the

SPT8100 digital outputs to minimize any line reflections

that would cause performance degradation.

ADC REFERENCES

The ADC full-scale range is set by ref erence voltages generated on chip. These two reference voltages appear on

pins VRT and VRB; nominally their difference is 2.5 V. The

references are not designed to be ov erdriven. The VRT and

VRB pins should be very carefully decoupled on the board

using as short a trace as possible. Some optimization of

the decoupling may be required, as shown in the typical

interface circuit diagram. The smallest capacitor should be

the closest one to the chip. (Refer to the typical interface

circuit diagram.)

OUTPUT ENABLE

The ADC digital outputs are enabled by the active high

output enable pin (OE).

OE = 1: ADC digital outputs are enabled

OE = 0:ADC digital outputs are high-impedance

(tri-stated)

DIGITAL CODE RANGE AND

OUT-OF-RANGE DETECTION

The output format of the ADC digital data is offset binary.

Due to the calibration algorithm used, there is a slight loss

in digital code range from the ADC. Instead of FFFFH and

0000H at the extremes of the range, the actual maximum

and minimum codes are less than that by 1.6% at both

ends of the scale, and vary from chip to chip. Effectively,

this is a loss in dynamic range of a few tenths of a dB , and

is negligible in many applications. The out-of-range function is defined accordingly , and sets the state of the activ e

high digital output OVR, as f ollo ws:

OVR is HIGH if the ADC digital code is greater

than or equal to FC00H or less than or equal to

03FFH. (See figure 4.)

If the output code exceeds FC00(max) or 03FF(min), this

implies that output is clipping. Therefore, once these limits

are crossed, the second harmonic becomes significant

and degrades performance.

Figure 4 – ADC Digital Code Range and Overrange

Bit Function

FFFFH

FC00H

ADC

Digital Code

Range

OVR = 1

OVR = Ø

65535

64512

1.6% FSR

03FFH

0000H

OVR = 1

1023

0

1.6% FSR

SPT8100

7 1/9/02

Page 8

Figure 5 – Timing Diagram 2

CLK

Digital

Outputs

OE

t

D1

FFT Plot Typical Differential Linearity Error (DLE)

T ab le II – Timing Parameters

Parameter Symbol Min Typ Max Units

CLK high to Data Valid t

OE inactive to HiZ t

OE active to Data Valid t

1

Conditions: load capacitance = 20 pF, VOH = 3.3 V

t

D2

t

D3

DLE (LSB)

D1

D2

D3

18 24 40

10 16 30 ns

10 16 30 ns

1

ns

Test Conditions:

= 2 MHz

ƒ

IN

= 4.4 MHz

ƒ

CLK

PGA Gain = 18 dB

T wo-Tone Intermodulation FFT Spurious-Free Dynamic Range

Test Conditions:

= 890 kHz

ƒ

1

ƒ2 = 900 kHz

= 4.4 MHz

ƒ

CLK

PGA Gain = 6 dB

R

= 1.08 kΩ

EXT

ADC Input (Post PGA) = –5.4 dBFS

= +25 °C

T

A

= 1.43 kΩ

R

EXT

ADC Input (Post PGA) = –8.0 dBFS

= +25 °C

T

A

Test Conditions:

ƒIN = 75 kHz

= 4.4 MHz

ƒ

CLK

100

0.9 MHz, low

95

0.9 MHz, med

0.9 MHz, high

90

85

80

75

70

SFDR (dBc)

65

60

55

50

45

–9

–10

Composite Level at ADC Input (dBFS)

Test Conditions:

10 MSPS, 5 V, 25 °C

Low: R

=1.43 kΩ @96 mA

EXT

–8

PGA Gain = 0 dB

Near Full-Scale Input

–5

–6

–7

Med: R

High: R

2 MHz, high

2 MHz, med

2 MHz, low

3 MHz, high

3 MHz, med

3 MHz, low

–4

–3

–2

=1.24 kΩ @109 mA

EXT

=1 kΩ @129 mA

EXT

–1

5 V

0

P-P

SPT8100

8 1/9/02

Page 9

PACKAGE OUTLINE

44-Lead LQFP

A

B

SYMBOL MIN MAX MIN MAX

INCHES MILLIMETERS

A 0.465 0.480 11.80 12.20

B 0.390 0.398 9.90 10.10

Pin 1

Index

C 0.390 0.398 9.90 10.10

D 0.465 0.480 11.80 12.20

E 0.0315 BSC 0.80 BSC

F 0.012 0.018 0.30 0.45

C

D

G 0.053 0.057 1.35 1.45

H 0.002 0.006 0.05 0.15

I 0.018 0.030 0.45 0.75

J 0.039 typ 1.0 typ

K0–7° 0–7°

E F

G

H

I

K

J

SPT8100

9 1/9/02

Page 10

PIN ASSIGNMENTS PIN FUNCTIONS

AGND

DGND

DV

DV

OGND

OV

CLK

D0 (LSB)

OE

AV

DD

44

1

2

DD

3

4

DD

5

6

DD

7

8

9

D1

10

D2

11

12

D3

GS0

43

13

D4

V

IN

42

14

D5

V

IN

+

41

15

D6D7D8

V

GS1

CM

40

39

161718

AGND

38

D9

RT

V

37

19

D10

V

RB

36

20

D11

BIASRBIAS

C

35

34

21

22

D12

D13

Pin Name Description

AGND Analog ground

DGND Digital ground

RDY

33

N/C

32

31

N/C

RS

30

AGND

29

AV

28

DD

GS2

27

N/C

26

OVR

25

24

D15 (MSB)

23

D14

DV

DD

Digital +5.0 V supply

OGND Ground for digital I/O

OV

DD

Digital outputs supply (+3.3/5 V)

CLK Master reference clock

OE Output enable (active high)

D0–D15 Data output bits; D0 is LSB; D15 is MSB

OVR Overrange indicator bit (active high)

N/C No connect

GS[2:0] 3-bit PGA gain setting control inputs

AV

DD

RS Resets internal state of chip (active low)

Analog +5.0 V supply

RDY Initialization in progress indicator; RDY goes low

during reset initialization. Chip is ready for normal

operation when RDY is high.

BIAS

BIAS

VRT, V

V

CM

External bias capacitor connection

C

External bias resistor connection

R

ADC reference voltage outputs

RB

Common mode reference voltage output

VIN+, VIN– Analog inputs to the PGA

ORDERING INFORMATION

PART NUMBER TEMPERA TURE RANGE PACKAGE

SPT8100SIT –40 to +85 °C 44L LQFP

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are

intended for surgical implant into the body, or (b) support or sustain life,

and whose failure to perform, when properly used in accordance with

instructions for use provided in the labeling, can be reasonably

expected to result in a significant injury to the user.

www.fairchildsemi.com © Copyright 2002 Fairchild Semiconductor Corporation

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to cause

the failure of the life support device or system, or to affect its safety or

effectiveness.

SPT8100

10 1/9/02

Loading...

Loading...