Page 1

SPT7850

10-BIT, 20 MSPS, 140 mW A/D CONVERTER

TECHNICAL DATA

JUNE 15, 2001

FEATURES

• Monolithic 20 MSPS converter

• 140 mW power dissipation

• On-chip track-and-hold

• Single +5 V power supply

• TTL/CMOS outputs

• 5 pF input capacitance

• Low cost

• Tr i-state output buffers

• High ESD protection: 3,500 V minimum

• Selectable +3 V or +5 V logic I/O

GENERAL DESCRIPTION

The SPT7850 is a 10-bit monolithic, low-cost, ultralowpower analog-to-digital converter capable of minimum

word rates of 20 MSPS. The on-chip track-and-hold function assures very good dynamic performance without the

need for external components. The input drive requirements are minimized due to the SPT7850’s low input

capacitance of only 5 pF.

Po wer dissipation is e xtremely lo w at only 140 mW typical

(165 mW maximum) at 20 MSPS with a power supply of

+5.0 V. The digital outputs are +3 V or +5 V, and are user

selectable. The SPT7850 is pin-compatible with the entire

APPLICATIONS

• All high-speed applications where low power

dissipation is required

• Video imaging

• Medical imaging

• IR imaging

• Scanners

• Digital communications

family of SPT 10-bit, CMOS conver ters (SPT7835/40/50/

55/60/61), which simplifies upgrades. The SPT7850 has

incorporated proprietar y circuit design* and CMOS processing technologies to achieve its advanced performance. Inputs and outputs are TTL/CMOS-compatible to

interface with TTL/CMOS logic systems. Output data format is straight binary.

The SPT7850 is available in 28-lead 300 mil PDIP and

32-lead small (7 mm square) TQFP packages over the

commercial temperature range, and in a 28-lead SOIC

package over the industrial temperature range.

*Patent pending

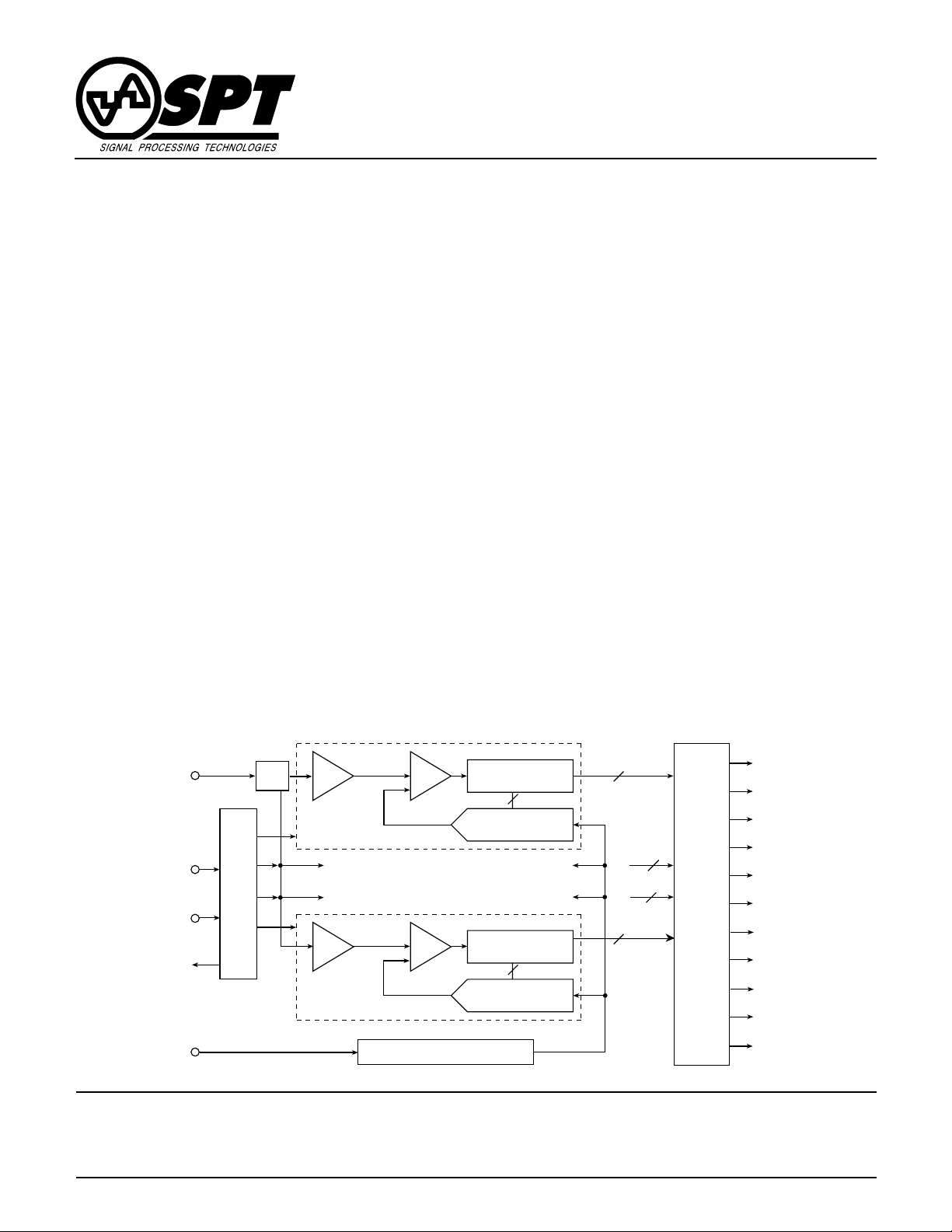

BLOCK DIAGRAM

A

CLK In

Enable

Data

Valid

Ref

ADC Section 1

Timing

and

Control

Mux

P1

P2

P7

P8

1:8

.

.

.

IN

In

T/H

ADC Section 2

ADC Section 7

ADC Section 8

T/H

.

.

.

Auto-

Zero

CMP

Auto-

Zero

CMP

Reference Ladder

11-Bit

SAR

DAC

11-Bit

SAR

DAC

11

11

11

.

.

.

11

V

REF

.

.

.

11

11

11-Bit

8:1

Mux/

Error

Correction

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: 719-528-2300 Fax: 719-528-2370 Web Site: http://www .spt.com e-mail: sales@spt.com

D10 Overrange

D9 (MSB)

D8

D7

D6

D5

D4

D3

D2

D1

D0 (LSB)

Page 2

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)1 25 °C

Supply Voltages

AVDD......................................................................+6 V

Output

Digital Outputs ...................................................10 mA

DVDD.....................................................................+6 V

Temperature

Input Voltages

Analog Input .............................. –0.5 V to AVDD +0.5 V

..............................................................0 to AV

V

REF

CLK Input ............................................................... V

AVDD – DVDD..................................................±100 mV

AGND – DGND ..............................................±100 mV

DD

DD

Operating T emper ature ............................ –40 to 85 °C

Junction Temperature ........................................ 175 °C

Lead Temperature, (soldering 10 seconds) ....... 300 °C

Storage Temperature............................ –65 to +150 °C

Note: 1. Operation at any Absolute Maximum Rating is not implied. See

Electrical Specifications for proper nominal applied conditions

in typical applications.

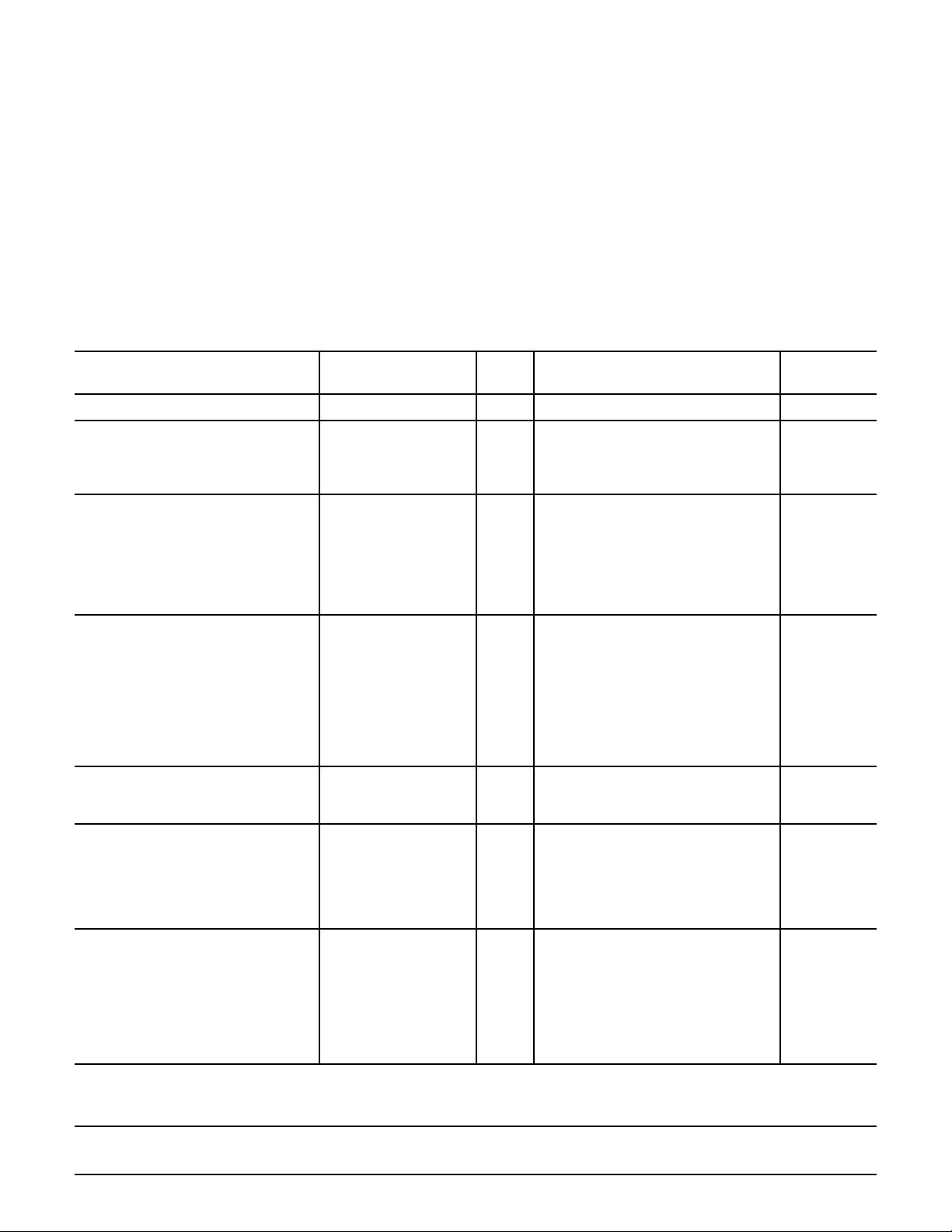

ELECTRICAL SPECIFICATIONS

TA=T

to T

MIN

, AVDD=DVDD=OVDD=+5.0 V , VIN=0 to 4 V, ƒ

MAX

TEST TEST SPT7850

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Resolution 10 Bits

DC Accuracy 100 kHz clock rate

Integral Linearity Error (ILE) V ±1.0 LSB

Differential Linearity Error (DLE) V ±0.5 LSB

No Missing Codes VI Guaranteed

Analog Input

Input Voltage Range VI V

Input Resistance IV 50 kΩ

Input Capacitance V 5.0 pF

Input Bandwidth (Small Signal) V 100 MHz

Offset V ±2.0 LSB

Gain Error V ±2.0 LSB

=40 MHz, ƒS=20 MSPS, V

CLK

1

RHS

RLS

=4.0 V , V

=0.0 V, unless otherwise specified.

RLS

V

RHS

V

Reference Input

Resistance VI 400 500 600 Ω

Bandwidth V 100 150 MHz

Voltage Range

IV 0 2.0 V

IV 3.0 AV

DD

V 1.0 4.0 5.0 V

V

∆(V

∆(V

V

V

V

RLS

RHS

RHS

RHF

RLS

– V

RLS

– V

)V90mV

RHS

– V

)V75mV

RLF

Reference Settling Time

V

RHS

V

RLS

V 15 Clock Cycles

V 20 Clock Cycles

Conversion Characteristics

Maximum Conversion Rate VI 20 MHz

Minimum Conversion Rate V 50 kHz

Pipeline Delay (Latency) IV 12 Clock Cycles

Aperture Delay Time V 5 ns

Aperture Jitter Time V 30 ps (p-p)

Dynamic Performance

Effective Number of Bits (ENOB)

= 3.58 MHz VI 8.8 Bits

ƒ

IN

= 10.3 MHz VI 8.5 Bits

ƒ

IN

Signal-to-Noise Ratio (SNR)

(without Harmonics)

= 3.58 MHz VI 53 56 dB

ƒ

IN

ƒIN = 10.3 MHz VI 52 55 dB

1

SPT7850SCN is screened for DC accuracy tests at 100 kHz. SPT7850SIS and SPT7850SCT are screened f or DC accuracy tests at 35 MHz.

SPT

SPT7850

2 6/15/01

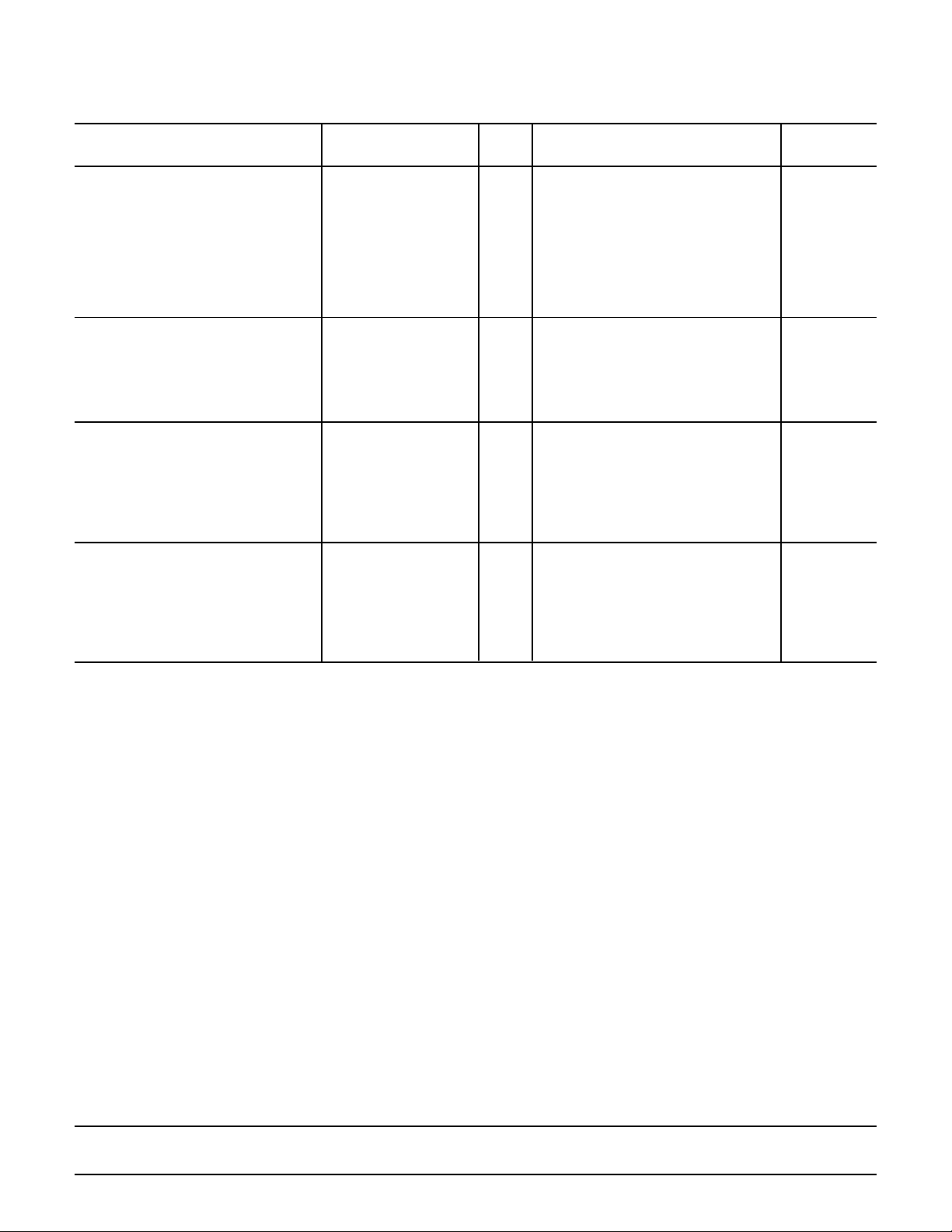

Page 3

ELECTRICAL SPECIFICATIONS

TA=T

to T

MIN

, AVDD=DVDD=OVDD=+5.0 V , VIN=0 to 4 V, ƒ

MAX

TEST TEST SPT7850

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Dynamic Performance

Total Harmonic Distortion (THD)

= 3.58 MHz VI 56 59 dB

ƒ

IN

= 10.3 MHz VI 53 56 dB

ƒ

IN

Signal-to-Noise and Distortion

(SINAD)

= 3.58 MHz VI 52 55 dB

ƒ

IN

ƒ

= 10.3 MHz VI 50 53 dB

IN

Spurious Free Dynamic Range ƒ

= 1 MHz V 63 dB

IN

Digital Inputs

Logic 1 Voltage VI 2. 0 V

Logic 0 Voltage VI 0.8 V

Maximum Input Current Low VI –10 +10 µA

Maximum Input Current High VI –10 +10 µA

Input Capacitance V 5 pF

=40 MHz, ƒS=20 MSPS, V

CLK

RHS

=4.0 V , V

=0.0 V, unless otherwise specified.

RLS

Digital Outputs

Logic 1 Voltage I

Logic 0 Voltage I

t

RISE

t

FALL

Output Enable to Data Output Delay 20 pF load, T

= 0.5 mA VI 3. 5 V

OH

= 1.6 mA VI 0.4 V

OL

15 pF load V 10 ns

15 pF load V 10 ns

= +25 °CV 10 ns

A

50 pF load over temp. V 22 ns

Power Supply Requirements

Voltages OV

DV

AV

Currents AI

DI

DD

DD

DD

DD

DD

IV 3.0 5.25 V

IV 4.75 5.0 5.25 V

IV 4.75 5.0 5.25 V

VI 10 12 mA

VI 18 21 mA

Power Dissipation VI 140 165 m W

TEST LEVEL CODES

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification is not

tested at the specified condition.

LEVEL TEST PROCEDURE

I 100% production tested at the specified temperature.

II 100% production tested at TA = +25 °C, and sample tested at the

specified temperatures.

III QA sample tested only at the specified temperatures.

IV Parameter is guaranteed (but not tested) by design and characteri-

zation data.

V Parameter is a typical value for information pur poses only.

VI 100% production tested at TA = +25 °C. Parameter is guaranteed

over specified temperature range.

SPT

SPT7850

3 6/15/01

Page 4

SPECIFICATION DEFINITIONS

APERTURE DELAY

Aperture delay represents the point in time, relative to the

rising edge of the CLOCK input, that the analog input is

sampled.

APERTURE JITTER

The variations in aperture delay for successive samples.

EFFECTIVE NUMBER OF BITS (ENOB)

SINAD = 6.02N + 1.76, where N is equal to the effective

number of bits.

SINAD – 1.76

N =

INPUT BANDWIDTH

Small signal (50 mV) bandwidth (3 dB) of analog input

stage.

DIFFERENTIAL LINEARITY ERROR (DLE)

Error in the width of each code from its theoretical value.

(Theoretical = VFS/2N)

INTEGRAL LINEARITY ERROR (ILE)

Linearity error refers to the deviation of each individual

code (normalized) from a straight line drawn from –FS

through +FS. The deviation is measured from the edge of

each particular code to the true straight line.

6.02

OUTPUT DELAY

Time between the clock’s triggering edge and output data

valid.

OVERVOLTAGE RECOVERY TIME

The time required for the ADC to recover to full accuracy

after an analog input signal 125% of full scale is reduced

to 50% of the full-scale value.

SIGNAL-TO-NOISE RATIO (SNR)

The ratio of the fundamental sinusoid power to the total

noise power. Harmonics are excluded.

SIGNAL-TO-NOISE AND DISTORTION (SINAD)

The ratio of the fundamental sinusoid power to the total

noise and distortion power.

TOTAL HARMONIC DISTORTION (THD)

The ratio of the total power of the first 9 harmonics to the

power of the measured sinusoidal signal.

SPURIOUS FREE DYNAMIC RANGE (SFDR)

The ratio of the fundamental sinusoidal amplitude to the

single largest harmonic or spurious signal.

SPT

SPT7850

4 6/15/01

Page 5

Figure 1A – Timing Diagram 1

1234567891011121314151617

ANALOG IN

CLOCK IN

SAMPLING CLOCK

(Internal)

DIGITAL OUT

DATA VALID

Figure 1B – Timing Diagram 2

VALIDINVALID

4

5 6 71 2 3 8 9 10 11

t

C

CLOCK

IN

t

OD

DATA

OUTPUT

Data 0

DATA

VALID

t

S

Table I – Timing Parameters

DESCRIPTION PARAMETERS MIN TYP MAX UNITS

Conversion Time t

Clock Period t

Clock High Duty Cycle t

Clock Low Duty Cycle t

Clock to Output Delay (15 pF Load) t

DAV Pulse Width t

Clock to DAV t

t

CH

t

CLK

t

CL

Data 1 Data 2

t

DAV

C

CLK

CH

CL

OD

DAV

S

2*t

t

DAV

CLK

ns

25 ns

40 50 60 %

40 50 60 %

15 20 25 ns

t

CLK

ns

16 21 26 ns

SPT

SPT7850

5 6/15/01

Page 6

TYPICAL PERFORMANCE CHARACTERISTICS

80

70

60

50

40

Signal-to-Noise Ratio (dB)

30

20

80

10

SNR vs Input Frequency

80

70

S = 20 MSPS

60

50

40

Total Harmonic Distortion (dB)

30

20

0

10

1

10

2

Input Frequency (MHz)

10

0

THD vs Input Frequency

s = 20 MSPS

1

Input Frequency (MHz)

10

10

2

Total Power Dissipation vs Sample Rate

SINAD vs Input Frequency

170

Reference is Excluded = 30 mW Typ

70

60

50

40

30

Signal-to-Noise and Distortion (dB)

20

10

S =20 MSPS

0

10

1

10

Input Frequency (MHz)

150

130

110

Power Dissipation (mW)

90

70

2

5 10 15 20

Sample Rate (CLK/2) MHz

SPT

SPT7850

6 6/15/01

Page 7

A

Figure 2 – Typical Interface Circuit

Ref In

(+4 V)

V

IN

CLK IN

+A5

AGND

V

RHF

V

RHS

V

RLS

V

RLF

SPT7850

V

IN

V

CAL

CLK

DAV

AVDDAGND DGND* DV

+A5

OGND

L1

D10

D9

D8

D7

D6

D5

OV

DD

D4

D3

D2

D1

D0

EN

DD

Enable/Tri-State

(Enable = Active Low)

3.3/5

Interfacing

Logics

DGND

3.3/5

3.3/5

+

10 µF

+5 V

nalog

+5 V

Analog

RTN

NOTES: 1) L1 is to be located as closely to the device as possible.

*To reduce the possibility of latch-up, avoid

connecting the DGND pins of the ADC to the

digital ground of the system.

2) All capacitors are 0.1 µF surface-mount unless otherwise specified.

3) L1 is a 10 µH inductor or a ferrite bead.

TYPICAL INTERFACE CIRCUIT

V ery few e xternal components are required to achiev e the

stated device performance. Figure 2 shows the typical interface requirements when using the SPT7850 in normal

circuit operation. The following sections provide descriptions of the major functions and outline critical performance criteria to consider for achieving the optimal device

performance.

POWER SUPPLIES AND GROUNDING

SPT suggests that both the digital and the analog supply

voltages on the SPT7850 be derived from a single analog

supply as shown in figure 2. A separate digital supply

should be used for all interface circuitry. SPT suggests

using this power supply configuration to prev ent a possible

latch-up condition on powerup.

+

10 µF

+5 V

Digital

RTN

+5 V

Digital

OPERATING DESCRIPTION

The general architecture for the CMOS ADC is shown in

the block diagram. The design contains eight identical

successive approximation ADC sections, all operating in

parallel, a 16-phase clock generator, an 11-bit 8:1 digital

output multiplexer, correction logic, and a voltage reference generator that provides common reference le vels f or

each ADC section.

The high sample rate is achieved by using multiple SAR

ADC sections in parallel, each of which samples the input

signal in sequence. Each ADC uses 16 clock cycles to

complete a conversion. The clock cycles are allocated as

shown in table II.

SPT

7 6/15/01

SPT7850

Page 8

Table II – Clock Cycles

Figure 3 – Ladder Force/Sense Circuit

Clock Operation

1 Reference zero sampling

2 Auto-zero comparison

3 Auto-calibrate comparison

4 Input sample

5-15 11-bit SAR conversion

16 Data transfer

The 16-phase clock, which is derived from the input clock,

synchronizes these ev ents. The timing signals f or adjacent

ADC sections are shifted by two clock cycles so that the

analog input is sampled on every other cycle of the input

clock by exactly one ADC section. After 16 clock periods,

the timing cycle repeats. The sample rate for the configuration is one-half of the clock rate; e.g., f or a 40 MHz cloc k

rate, the input sample rate is 20 MHz. The latency from

analog input sample to the corresponding digital output is

12 clock cycles.

• Since only eight comparators are used, a huge power

savings is realized.

• The auto-zero operation is done using a closed loop

system that uses multiple samples of the comparators’

response to a reference zero.

• The auto-calibrate operation, which calibrates the gain

of the MSB reference and the LSB reference, is also

done with a closed loop system. Multiple samples of the

gain error are integrated to produce a calibration voltage for each ADC section.

• Capacitive displacement currents, which can induce

sampling error, are minimiz ed since only one comparator samples the input during a clock cycle.

• The total input capacitance is very low since sections of

the converter that are not sampling the signal are isolated from the input by transmission gates.

VOLTAGE REFERENCE

The SPT7850 requires the use of a single external voltage

reference for driving the high side of the reference ladder.

It must be within the range of 3 V to 5 V. The lower side of

the ladder is typically tied to AGND (0.0 V), but can be run

up to 2.0 V with a second reference. The analog input v oltage range will track the total voltage difference measured

between the ladder sense lines, V

RHS

and V

RLS

.

Force and sense taps are provided to ensure accurate

and stable setting of the upper and lower ladder sense line

voltages across part-to-part and temperature variations.

By using the configuration shown in figure 3, offset and

gain errors of less than ±2 LSB can be obtained.

In cases where wider variations in offset and gain can be

tolerated, V

be tied directly to V

can be tied directly to V

REF

as shown in figure 4. Decouple

RLF

, and AGND can

RHF

AGND

+

+

V

RHF

V

RHS

V

RLS

V

RLF

V

IN

All capacitors are 0.01 µF

Figure 4 – Reference Ladder

+4.0 V

External

Reference

(+3.91 V)

(0.075 V)

V

RHS

V

RLS

V

RLF

(AGND)

0.0 V

90 mV

75 mV

R/2

R

R

R

R

R

R

R/2

R=30 W (typ)

All capacitors are 0.01 µF

force and sense lines to AGND with a .01 µF capacitor

(chip cap preferred) to minimize high-frequency noise injection. If this simplified configur ation is used, the following

considerations should be taken into account.

The reference ladder circuit shown in figure 4 is a simplified representation of the actual reference ladder with

force and sense taps shown. Due to the actual inter nal

structure of the ladder, the voltage drop from V

is not equivalent to the voltage drop from V

RLF

RHF

to V

to V

RLS

RHS

.

SPT

SPT7850

8 6/15/01

Page 9

Typically, the top side voltage drop for V

RHF

to V

RHS

will

equal:

V

– V

RHF

and the bottom side voltage drop for V

= 2.25 % of (V

RHS

RHF

– V

) (typical),

RLF

RLS

to V

RLF

will

equal:

V

RLS

– V

= 1.9 % of (V

RLF

RHF

– V

) (typical).

RLF

Figure 4 shows an example of expected voltage drops for

a specific case. V

is tied to AGND. A 90 mV drop is seen at V

and a 75 mV increase is seen at V

of 4.0 V is applied to V

REF

RLS

, and V

RHF

(= 3.91 V),

RHS

(= 0.075 V).

RLF

ANALOG INPUT

VIN is the analog input. The input voltage range is from

V

RLS

to V

(typically 4.0 V) and will scale proportionally

RHS

with respect to the voltage reference. (See voltage reference section.)

The drive requirements for the analog inputs are very

minimal when compared to most other converters due to

the SPT7850’s extremely low input capacitance of only

5 pF and very high input resistance of 50 kΩ.

The analog input should be protected through a series

resistor and diode clamping circuit as shown in figure 5.

Upon powerup, the SPT7850 begins its calibration algorithm. In order to achieve the calibration accuracy required, the offset and gain adjustment step size is a fraction of a 10-bit LSB. Since the calibration algorithm is an

oversampling process, a minimum of 10,000 clock cycles

are required. This results in a minimum calibration time

upon powerup of 250 µsec for a 20 MHz sample rate.

Once calibrated, the SPT7850 remains calibrated over

time and temperature.

Since the calibration cycles are initiated on the rising edge

of the clock, the clock must be continuously applied f or the

SPT7850 to remain in calibration.

INPUT PROTECTION

All I/O pads are protected with an on-chip protection

circuit shown in figure 6. This circuit provides ESD robustness to 3.5 kV and prevents latch-up under severe discharge conditions without degrading analog transition

times.

Figure 6 – On-Chip Protection Circuit

V

DD

120 W

Analog

Figure 5 – Recommended Input Protection Circuit

+V

D1

Buffer

47 W

D2

V

D1 = D2 = Hewlett-Packard HP5712 or equivalent

AV

DD

ADC

CALIBRATION

The SPT7850 uses an auto-calibration scheme to ensure

10-bit accuracy over time and temperature. Gain and offset errors are continually adjusted to 10-bit accuracy

during device operation. This process is completely transparent to the user.

120 W

Pad

POWER SUPPLY SEQUENCING CONSIDERATIONS

All logic inputs should be held low until power to the de vice

has settled to the specific tolerances. Avoid power decoupling networks with large time constants that could delay

VDD power to the device.

CLOCK INPUT

The SPT7850 is driven from a single-ended TTL-input

clock. Because the pipelined architecture operates on the

rising edge of the clock input, the device can operate o ver

a wide range of input clock duty cycles without degrading

the dynamic performance. The device’s sample rate is

1/2 of the input clock frequency. (See figure 1A timing

diagram.)

SPT

SPT7850

9 6/15/01

Page 10

DIGITAL OUTPUTS

OVERRANGE OUTPUT

The digital outputs (D0–D10) are driven by a separate

supply (OV

makes it possible to drive the SPT7850’s TTL/CMOScompatible outputs with the user’s logic system supply.

The format of the output data (D0–D9) is straight binary.

(See table III.) The outputs are latched on the rising edge

of CLK. These outputs can be switched into a tri-state

mode by bringing EN high.

Table III – Output Data Information

ANALOG INPUT OVERRANGE OUTPUT CODE

+F.S. + 1/2 LSB 1 1 1 1 1 1 1 1 1 1 1

+F.S. –1/2 LSB 0 1 1 1 1 1 1 1 1 1Ø

+1/2 F.S. 0 ØØ ØØØØ ØØØØ

+1/2 LSB 0 0 0 0 0 0 0 0 0 0 Ø

0.0 V 0 0 0 0 0 0 0 0 0 0 0

(Ø indicates the flickering bit between logic 0 and 1.)

) ranging from +3 V to +5 V. This feature

DD

D10 D9–D0

The OVERRANGE OUTPUT (D10) is an indication that

the analog input signal has exceeded the positive fullscale input voltage by 1 LSB. When this condition occurs,

D10 will switch to logic 1. All other data outputs (D0 to D9)

will remain at logic 1 as long as D10 remains at logic 1.

This feature makes it possible to include the SPT7850 in

higher resolution systems.

EVALUATION BOARD

The EB7850 evaluation board is av ailable to aid designers

in demonstrating the full performance of the SPT7850.

This board includes a reference circuit, clock driv er circuit,

output data latches, and an on-board reconstruction of the

digital data. An application note describing the operation

of this board, as well as information on the testing of the

SPT7850, is also available. Contact the factory for price

and availability.

SPT

SPT7850

10 6/15/01

Page 11

PACKAGE OUTLINES

28-Lead SOIC

B

28

1

CD

H

E

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.699 0.709 17.75 18.01

I

H

A

F

G

B 0.005 0.011 0.13 0.28

C 0.050 typ 1.27 typ

D 0.018 typ 0.46 typ

E 0.0077 0.0083 0.20 0.21

F 0.090 0.096 2.29 2.44

G 0.031 0.039 0.79 0.99

H 0.396 0.416 10.06 10.57

I 0.286 0.292 7.26 7.42

C D

32-Lead TQFP

A

B

E

F

K

GH

SYMBOL MIN MAX MIN MAX

A 0.346 0.362 8.80 9.20

B 0.272 0.280 6.90 7.10

C 0.346 0.362 8.80 9.20

D 0.272 0.280 6.90 7.10

E 0.031 typ 0.80 BSC

F 0.012 0.016 0.30 0.40

G 0.053 0.057 1.35 1.45

H 0.002 0.006 0.05 0.15

I 0.037 0.041 0.95 1.05

J 0.007 0.17

I

J

L

K0° 7° 0° 7°

L 0.020 0.030 0.50 0.75

INCHES MILLIMETERS

SPT

SPT7850

11 6/15/01

Page 12

PACKAGE OUTLINES

28-Lead Skinny PDIP

A

D

C

B

F

E

H

I

SYMBOL MIN NOM MAX MIN NO M MAX

A 0.280 0.288 0.295 7.112 7.315 7.493

B 1.360 1.365 1.370 34.544 34.671 34.798

C 0.130 3.302

D 0.055 0.060 0.065 1.397 1.524 1.651

E 0.100 BSC 2.540 BSC

F 0.020 0.508

G 0.120 0.130 0.135 3.048 3.302 3.429

G

H 0.300 BSC 7.620 BSC

I 0.430 10.922

INCHES MILLIMETERS

SPT

SPT7850

12 6/15/01

Page 13

PIN ASSIGNMENTS

A

A

A

1

AGND

2

V

RHF

V

3

RHS

4

N/C

5

V

RLS

V

6

RLF

V

7

IN

GND

8

V

CAL

9

AV

10

DD

DV

11

DD

DGND

12

CLK

13

14

DAV

V

V

RHS

RHF

RLS

32

30

31

V

PDIP

and

SOIC

AGND

AGND

29

28

D10

27

PIN FUNCTIONS

28

D10

27

D9

26

D8

25

D7

24

D6

23

D5

22

OV

DD

21

OGND

D4

20

D3

19

D2

18

D1

17

D0

16

15

EN

D9

D8

25

26

Name Function

AGND Analog Ground

V

V

V

V

V

V

AV

DV

RHF

RHS

RLS

RLF

CAL

IN

DD

DD

Reference High Force

Reference High Sense

Reference Low Sense

Reference Low Force

Calibration Reference

Analog Input

Analog V

Digital V

DD

DD

DGND Digital Ground

CLK Input Clock ƒ

= FS (TTL)

CLK

EN Output Enable

D0–9 Tri-State Data Output, (D0=LSB)

D10 Tri-State Output Overrange

DAV Data Valid Output

OV

DD

Digital Output Supply

OGND Digital Output Ground

N/C No Connect

V

GND

GND

V

AV

AV

DV

RLF

V

CAL

1

2

IN

3

4

5

6

DD

7

DD

8

DD

9

DV

DD

10

DGND

11

DGND

TQFP

12

CLK

16

15

14

13

D0

D1

EN

DAV

D7

24

D6

23

D5

22

OV

21

DD

OGND

20

D4

19

D3

18

D2

17

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE TYPE

SPT7850SCN 0 to +70 °C 28L Plastic DIP (300 mil)

SPT7850SIS –40 to +85 °C 28L SOIC

SPT7850SCT 0 to +70 °C 32L TQFP

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby

expressly granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING – LIFE SUPPORT APPLICATIONS POLICY – SPT products should not be used within Life Support Systems without

the specific written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails,

can be reasonably expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

SPT

SPT7850

13 6/15/01

Loading...

Loading...