Page 1

SPT7830

A

A

10-BIT, 2.5 MSPS, SERIAL OUTPUT A/D CONVERTER

FEATURES

• 10-Bit, 1 kHz to 2.5 MSPS Analog-to-Digital Converter

• Monolithic CMOS

• Serial Output

• Internal Sample-and-Hold

• Analog Input Range: 0 to 2 V Nominal; 3.3 V Max

• Power Dissipation (Excluding Reference Ladder)

45 mW at +5 V

16 mW at +3.0 V

• Single Power Supply: +3 V to +5 V Range

• High ESD Protection: 3,000 V Minimum

GENERAL DESCRIPTION

The SPT 10-bit, 2.5 MSPS, serial analog-to-digital converter

delivers excellent high speed conversion performance with

low cost and low power. The serial port protocol is compatible

with the serial peripheral interface (SPI) or MICROWIRE™

industry standard, high-speed synchronous MPU interfaces.

The large input bandwidth and fast transient response time

allow for CCD applications operating up to 2.5 MSPS.

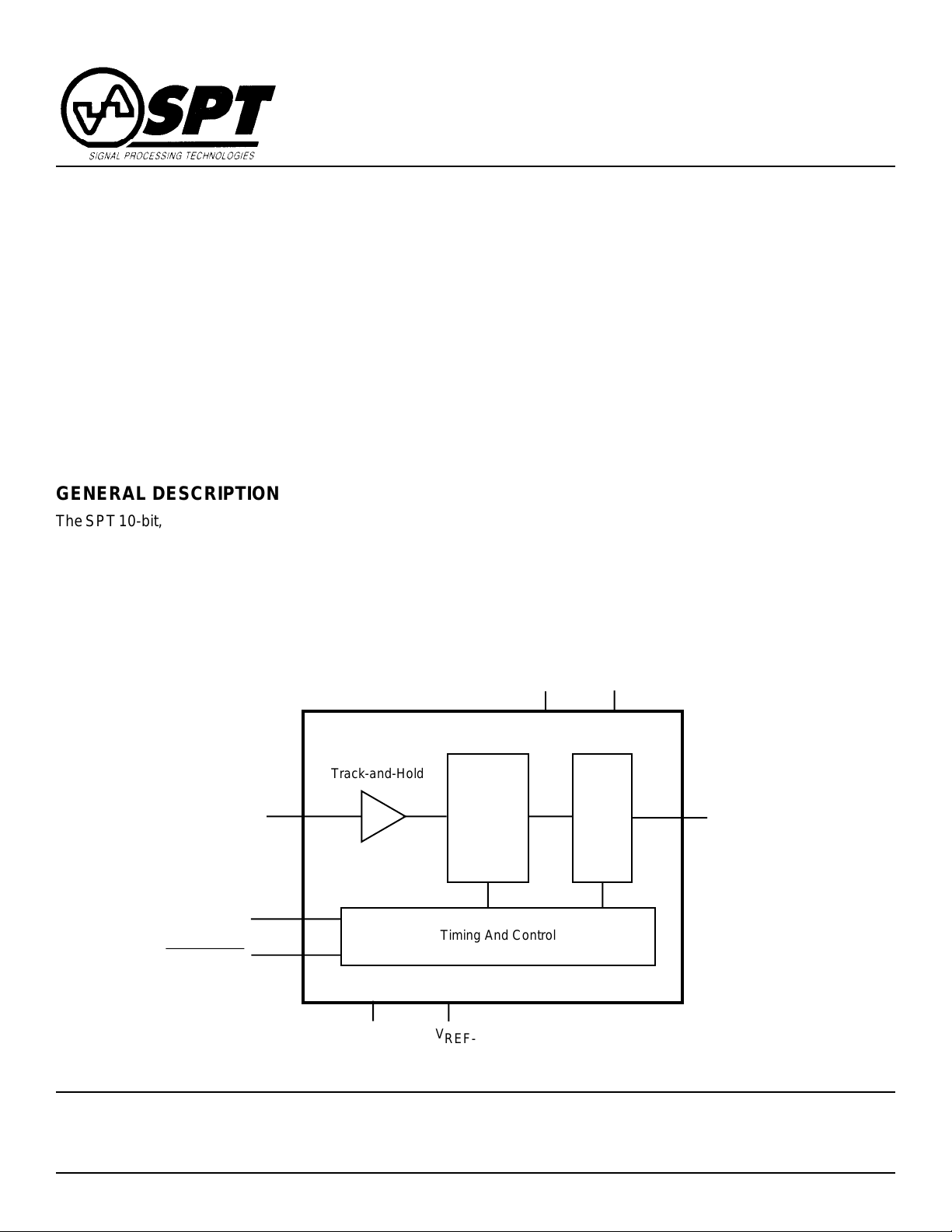

BLOCK DIAGRAM

APPLICATIONS

• Handheld and Desktop Scanners

• DSP Interface Applications

• Portable Digital Radios

• Portable and Handheld Applications

• Automotive Applications

• Remote Sensing

The device can operate with a power supply range from

+3 V to +5 V with very low power dissipation. The small

package size makes this part excellent for hand-held applications where board space is a premium. The SPT7830 is

available in an 8-lead SOIC package over the commercial

temperature range. Contact the factory for availability of die

and industrial temperature range versions.

Ground

V

DD

Track-and-Hold

Analog Input

Clock

Start Convert

SAR

10-Bit

A/D

AAAAAAAAAAAAAAAA

Timing And Control

AAAAAAAAAAAAAAAA

V

REF+

V

REF-

Serial

Output

Logic

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370

Data Out

Page 2

ABSOLUTE MAXIMUM RATING (Beyond which damage may occur)

1

Supply Voltages

VDD...........................................................................+6 V

Input Voltages

Analog Input.................................................. -0.7 to +6 V

V

+ ........................................................... -0.7 to +6 V

REF

V

- ............................................................ -0.7 to +6 V

REF

Clock and SC............................................... -0.7 to +6 V

Output

Data Out.................................................................10 mA

Temperature

Operating, ambient ................................... 0 to +70 °C

junction.........................................+175 °C

Lead, Soldering (10 seconds).............................+300 °C

Storage .....................................................-65 to +150 °C

Note: 1. Operation at any Absolute Maximum Ratings is not implied. See Electrical Specifications for proper nominal applied

conditions in typical applications.

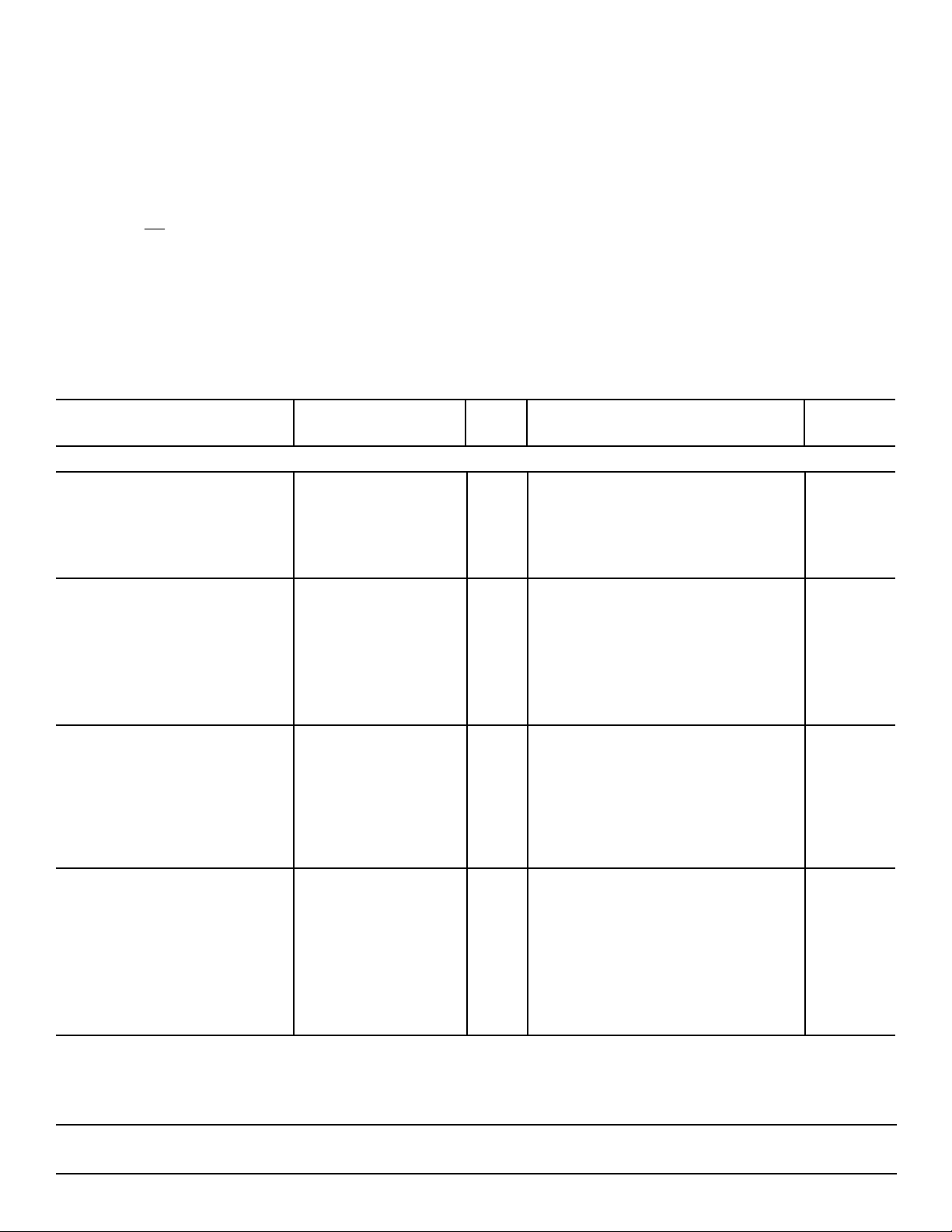

ELECTRICAL SPECIFICATIONS

TA = +25 °C, VDD = +5.0 V, VIN = 0 to +3 V, f

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

DC ELECTRICAL CHARACTERISTICS

DC Performance

Resolution 10 Bits

Differential Linearity I ±0.5 ±1.0 LSB

Integral Linearity I ±1.0 ±1.5 LSB

No Missing Codes I Guaranteed

Analog Input

Input Voltage Range

Input Resistance I 5 MΩ

Input Capacitance IV 5 pF

Input Bandwidth (Small Signal) IV 30 MHz

Offset IV -2 +2 % of FSR

Gain Error IV -2 +2 % of FSR

Reference Input

Resistance IV 250 280 350 Ω

Voltage Range

2

V

REF-

2

V

REF+

V

REF+ -VREF-

Reference Settling Time IV 90 ns

Timing Characteristics

Maximum Conversion Rate I 2.5 1.0 MSPS

Minimum Conversion Rate IV 1 kSPS

Maximum External Clock Rate I 35 14 MHz

Minimum External Clock Rate IV 14 kHz

Aperture Delay Time IV 5 ns

Aperture Jitter Time IV 5 ps

Data Output LSB Hold Time T

1

Percentages refer to percent of [(V

2

∆ = Minimum (V

1

1

(∆) IV 1/10 V

REF+

REF+ -VREF-

)

= 35 MHz, fS = 2.5 MSPS, V

CLK

TEST TEST

to T

MIN

) -(V

REF-

MAX

)]

REF

+ = +3.0 V, V

IV V

REF-

IV -4% 0 V

IV V

IV68 ns

- = 0.0 V, unless otherwise specified.

REF

+4% V

+∆ 2/3 V

REF-

DD

REF+

REF+

-6% V

-∆ V

DD

V

V

SPT

SPT7830

2 12/19/97

Page 3

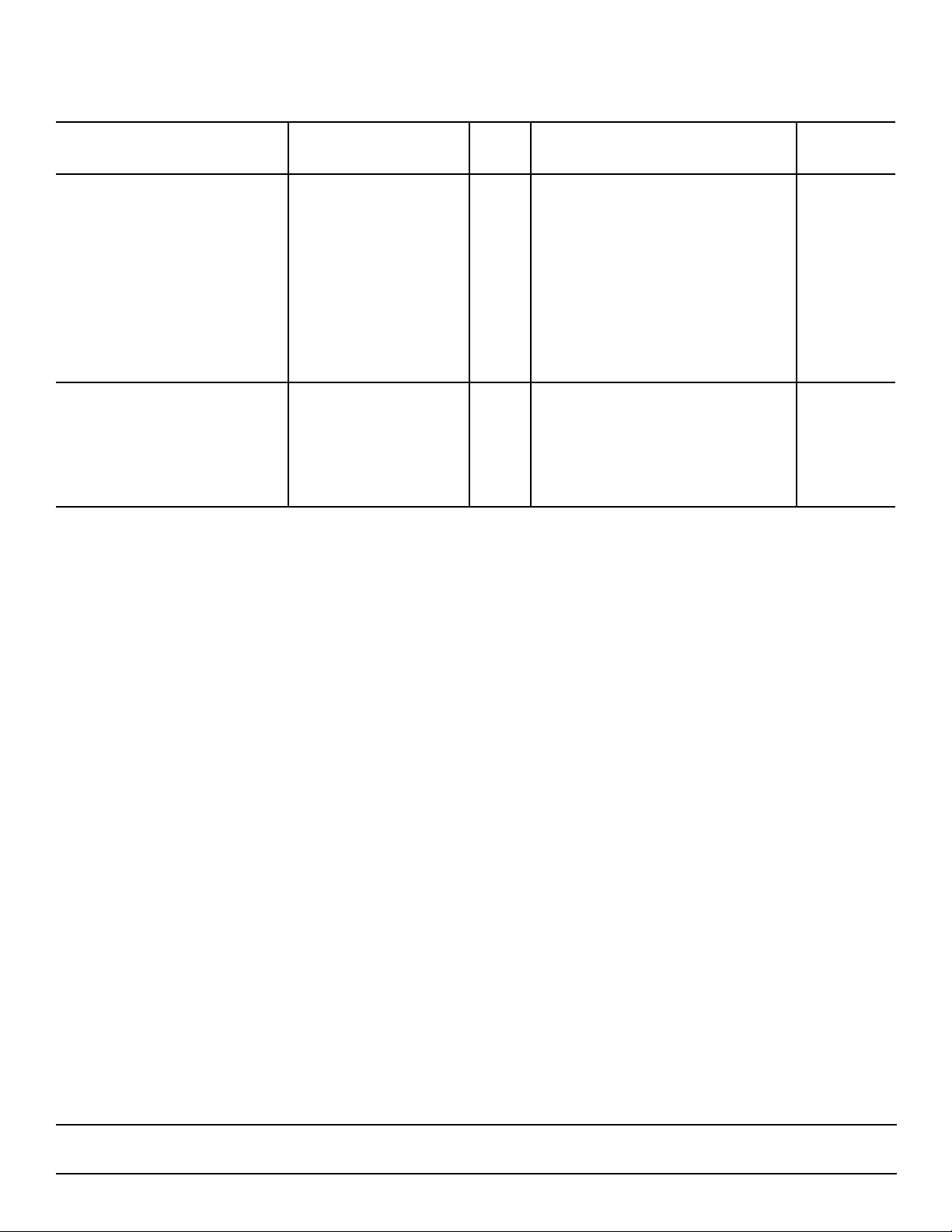

ELECTRICAL SPECIFICATIONS

TA = +25 °C, VDD = +5.0 V, VIN = 0 to +3 V, f

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Dynamic Performance

Effective Number of Bits

f

= 500 kHz IV 8.9 Bits

IN

f

= 1 MHz IV 8.5 Bits

IN

Signal-to-Noise Ratio

f

= 500 kHz IV 56 dB

IN

f

= 1 MHz IV 55 dB

IN

Harmonic Distortion

f

= 500 kHz IV 63 dB

IN

fIN = 1 MHz IV 58 dB

Power Supply Requirements

+V

Supply Voltage IV 3 5.5 V

DD

+V

Supply Current VDD = 3.0 V IV 5.4 7 mA

DD

Power Dissipation

3

Excluding reference ladder.

3

= 35 MHz, fS = 2.5 MSPS, V

CLK

TEST TEST

V

= 5.0 V I 9 10 mA

DD

VDD = 3.0 V IV 16 22 mW

VDD = 5.0 V I 45 50 mW

+ = +3.0 V, V

REF

- = 0.0 V, unless otherwise specified.

REF

TEST LEVEL CODES

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification is not

tested at the specified condition.

TEST LEVEL

I

II

III

IV

V

VI

TEST PROCEDURE

100% production tested at the specified temperature.

100% production tested at TA=25 °C, and sample

tested at the specified temperatures.

QA sample tested only at the specified temperatures.

Parameter is guaranteed (but not tested) by design

and characterization data.

Parameter is a typical value for information purposes

only.

100% production tested at TA = +25 °C. Parameter is

guaranteed over specified temperature range.

SPT

SPT7830

3 12/19/97

Page 4

GENERAL DESCRIPTION AND OPERATION

The SPT7830 is a 10-bit analog-to-digital converter that uses

a successive approximation architecture to perform data

conversion. Each conversion cycle is 14 clocks in length.

When the Not Start Convert (SC) line is held low, conversion

begins on the next rising edge of the input clock. When the

conversion cycle begins, the data output pin is forced low until

valid data output begins.

The first two clock cycles are used to perform internal offset

calibrations and tracking of the analog input. The analog input

is then sampled using an internal track-and-hold amplifier on

the falling edge of the third clock cycle. On clock cycles 4

through 14, a 10-bit successive approximation conversion is

performed, and the data is output starting with the MSB.

Serial data output begins with output of the MSB. See the

Data Output Timing section for details. Each bit of the data

conversion is sequentially determined and placed on the data

output pin at the clock rate. This process continues until the

LSB has been determined and output. At this point, if the

SC

line is high, the data output pin will be forced into a high

impedance state, and the converter will go into an idle state

waiting for the SC line to go low. This is referred to as Single

Shot Mode. See Modes of Operation for details.

If the SC is either held low through the entire 14 clock

conversion cycle (free run mode) or is brought low prior to the

trailing edge of the fourteenth clock cycle (synchronous

mode), the data output pin goes low and stays low until valid

data output begins. Because the chip has either remained

selected in the free run mode or has been immediately

selected again in the synchronous mode, the next conversion

cycle begins immediately after the fourteenth clock cycle of the

previous conversion. See Modes of Operation for details.

TYPICAL INTERFACE CIRCUIT

CLOCK INPUT

The SPT7830 requires a 50% ±10% duty cycle clock running

at 14 times the desired sample rate. The clock may be

stopped in between conversion cycles without degradation of

operation (single shot type of operation), however, the clock

should remain running during a conversion cycle.

POWER SUPPLY

The SPT7830 requires only a single supply and operates

from 3.0 V to 5.0 V. SPT recommends that a 0.01 µF chip

capacitor be placed as close as possible to the supply pin.

DATA OUTPUT SET UP AND HOLD TIMING

As figure 8 shows, all of the data output bits (except the LSB)

remain valid for a duration equivalent to one clock period and

delayed by 8 ns after the falling edge of clock. Because the

data converter enters into a next conversion ready state at the

leading edge of clock 14, the LSB bit is valid for a duration

equivalent to only the clock pulse width low and delayed

by 8 ns after the falling edge of clock. Care should be taken

to ensure that the LSB is latched into an external latch with the

proper amount of set and hold time.

DATA OUTPUT CODING

The coding of the output is straight binary. (See table I.)

Table I - Data Output Coding

ANALOG INPUT OUTPUT CODE D9 - DO

+FS -1/2 LSB 1 1 1111 111Ø

+1/2 FS ØX XXXX XXXX

+1/2 LSB OO OOOO OOOØ

V

REF-

OO OOOO OOOO

Ø indicates the flickering bit between logic O and 1.

X indicates the flickering bit between logic 1 and O.

ANALOG INPUT AND REFERENCE SETTLING TRACK

AND HOLD TIMING

Figure 9 shows the timing relationship between the input

clock and SC versus the analog input tracking and reference

settling. The analog input is tracked from the fourteenth clock

cycle of the previous conversion to the third clock cycle of the

current conversion. On the falling edge of the third clock

cycle, the analog input is held by the internal sample-andhold. After this sample, the analog input may vary without

affecting data conversion.

The reference ladder inputs (V

REF

+ and V

-) may be

REF

changed starting on the falling edge of the thirteenth clock

cycle of the previous conversion and must be settled by the

falling edge of the third clock cycle of the current conversion.

VOLTAGE REFERENCE AND ANALOG INPUT

The SPT7830 requires the use of a single external voltage

reference for driving the high side of the reference ladder. The

V

+ can be a maximum of 2/3 VDD. For example, if VDD =

REF

+5 V, then V

+ max = (2/3) * 5 V = +3.3 V. The lower side

REF

of the ladder is typically tied to AGND (0.0 V), but can be run

up to a voltage that is 1/10th of VDD below V

V

- max. = V

REF

+ - (1/10) * VDD.

REF

REF

+:

For example,

if VDD = +5 V and V

V

- max = 3 V - (1/10)* 5 V = 2.5 V.

REF

+ = 3 V, then

REF

The +Full Scale (+FS) of the analog input is expected to be 6%

of [(V

of the analog input is expected to be 4% of [(V

above V

REF

+) - (V

REF

-. (See figure 1.)

REF

-)] below V

+ and the -Full Scale (-FS)

REF

+) - (V

REF

REF

-)]

Therefore,

Analog +FS = V

Analog -FS = V

+ - 0.06 * [(V

REF

- +0.04 * [(V

REF

REF

REF

+) - (V

+) - (V

REF

REF

-)], and

-)].

For example,

if V

+ = 3 V and V

REF

- = 0 V, then

REF

Analog +FS = 3 V - 0.06 * [3 V- 0 V ] = 2.82 V, and

Analog -FS = 0 V + 0.04 * [3 V - 0 V] = 0.12 V.

SPT

SPT7830

4 12/19/97

Page 5

Figure 1 - Analog Input Full-Scale Range

MODES OF OPERATION

V

+

REF

+FS

Full-Scale Range

-FS

V

-

REF

6% of [(V

REF

+) - (V

4% of [(V

REF

-)]

REF

+) - (V

REF

-)]

The drive requirements for the analog input are minimal when

compared to most other converters due to the SPT7830’s

extremely low input capacitance of only 5 pF and very high

input resistance of greater than 5 MΩ.

If the input buffer amplifier supply voltages are greater than

VDD + 0.7 V or less than Ground - 0.7 V, the analog input

should be protected through a series resistor and a diode

clamping circuit as shown in figure 2.

Figure 2 - Recommended Input Protection Circuit

+V

D1

47 Ω

D2

AV

ADCBuffer

DD

The SPT7830 has three modes of operation.The mode of

operation is based strictly on how the SC is used.

SINGLE SHOT MODE

When SC goes low, conversion starts on the next rising edge

of the clock (defined as the first conversion clock). The MSB

of data is valid 8 ns after the falling edge of the fourth

conversion clock. (See figure 8, Data Output Timing.)

The conversion is complete after 14 clock cycles. At the

falling edge of the fourteenth clock cycle, if SC is high (not

selected), the data output goes to a high impedance state,

and no more conversions will take place until the next SC low

event. (See the single shot mode timing diagram in figure 4.)

SYNCHRONIZED MODE

When SC goes low, conversion will start on the next rising

edge of the clock (defined as the first conversion clock). The

MSB is valid 8 ns after the falling edge of the fourth conversion

clock.

The first conversion is complete after 14 clock cycles. At any

time after the falling edge of the fourteenth clock cycle,

may go low again to initiate the next conversion. When the

SC

SC

goes low, the conversion starts on the rising edge of the next

clock. (See the synchronized mode timing diagram in figure 5.)

The data output will go to a high impedance state until the next

conversion is initiated.

-V

D1 = D2 = Hewlett Packard HP5712 or equivalent

INPUT PROTECTION

All I/O pads are protected with an on-chip protection circuit

shown in figure 3. This circuit provides ESD robustness to

>3.0 kV and prevents latch-up under severe discharge conditions without degrading analog transition times.

Figure 3 - On-Chip Protection Circuit

V

DD

120 Ω

120 Ω

Pad

Analog

FREE RUN MODE

When SC goes low, conversion starts on the next rising edge

of the clock (defined as the first conversion clock). The MSB

data is valid 8 ns after the falling edge of the fourth conversion

clock.

As long as SC is held low, the device operates in the free run

mode. New conversions start after every fourteenth cycle

with valid data available 8 ns after the falling edge of the fourth

clock within each new conversion cycle.

The data output remains low between conversion cycles.

(See the free run mode timing diagram in figure 6.)

SPT

SPT7830

5 12/19/97

Page 6

5

A

4

A

Clock

Data Out A9 A1

td=8 ns

1

3

A

1

4

A

td=8 ns td=8 ns td=8 ns

MSB

A0

LSB

Figure 4 - Single Shot Mode Timing Diagram

1

B

2

B3B

4

B

5

B

6

B

7

B

1

A

2

A

3

A

4

A

5

A

6

A

7

A8A

1

3

A

Start

Sample

Analog Input

A

Clock

Serial Data Out

Sample

Analog Input

B

B9 B8 B7A9 A8 A7 A6

MSB LSB

A0

A1

1

4

A

Latch

MSB

Start Convert

MSB

t

SC

Start Convert

Clock

Serial Data Out

1

2

A

3

A

A

Latch

MSB

4

A

A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

MSB LSB

Start

Conversion

Sample

Analog Input

Figure 5 - Synchronous Mode Timing Diagram

t

SC

Start Convert

1

2

3

Clock

Serial Data Out

Start

A

A

Analog Input

A

Sample

A

4

A

5

6

7

8

9

A

Latch

MSB

A

A

A

5

6

A

7

A

A8A

10A11A12A13

A

13

A

A9 A8 A7 A6

MSB LSB

14

A

A

High Z State

t

SC

Latch

MSB

15A16

14

A

High Z State

A0A1

1

2

3

4

A

B

B

B

5

B

B

B9

MSB

Sample

Analog Input

B

Figure 6 - Free Run Mode Timing Diagram

Figure 7 - Typical Interface Circuit

V

V

REF+

0 V

REF IN

V

IN

REF

Analog In

V

REF

Ground

+

-

V

DD

Data Out

Clock

SC

+V

.01 µF.01 µF

Figure 8 - Data Output Timing

DD

+V

DD

0 V

+V

DD

0 V

+V

DD

0 V

SPT

SPT7830

6 12/19/97

Page 7

Figure 9 - Analog Input Track-and-Hold Timing and Reference Settling-and-Hold Timing

SC

Clock

V

REF+

A

IN

Synchronous Mode

1

A

*

The rising edge of the SC line can occur any time between the

rising edge of clock 1A and the falling edge of clock 14A.

The reference settling window can be extended in the

**

synchronous mode by adding extra clocks between conversion

cycles. The example shown is the minimum number of clocks

required (14) per conversion cycle.

2

A

3

A

Sample

Input

*

4

A

Ref Hold

13

Single Shot Mode

(

SC

high, no B cycle)

14

A

A

Ref Settling Window

Free Run Mode (SC always Ø)

1

B

2

B

3

B

4

B

**

Sample

Input

G

B

A

C D E

PACKAGE OUTLINE

8-Lead SOIC

F

I J

K

INCHES MILLIMETERS

SYMBOL MI N MAX MIN MAX

A 0.187 0.194 4.80 4.98

B 0.228 0.242 5.84 6.20

C 0.050 typ 1.27 typ

D 0.014 0.019 0.35 0.49

E 0.005 0.010 0.13 0.25

F 0.060 0.067 1.55 1.73

G 0.055 0.060 1.40 1.55

H 0.149 0.156 3.81 3.99

I0°8°0°8°

J 0.007 0.010 0.19 0.25

K 0.016 0.035 0.41 0.89

H

SPT

SPT7830

7 12/19/97

Page 8

PIN ASSIGNMENTS

External V

Analog In

External V

REF

REF

Ground

+

1

2

-

3

4

8

7

6

5

V

DD

Data Out

Clock

Start Convert

PIN FUNCTIONS

Name Function

Analog In Analog Signal Input

Start Convert

Clock Clock that drives A/D conversion cycle and

Data Out Serial Data. Tri-state serial data output for

External V

External V

V

DD

GND Analog and Digital Ground

REF

REF

Start Convert. A high-to-low transition on

this input begins the conversion cycle and

enables serial data output.

the synchronous serial data output

the A/D result driven by the CLOCK input

+ External voltage reference for top of refer-

ence ladder

- External voltage reference for bottom of

reference ladder

Analog and Digital +3 V to +5 V

Power Supply Input

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

SPT7830SCS 0 to +70 °C 8L SOIC

SPT7830SCU +25 °C Die*

*Please see the die specification for guaranteed electrical performance.

Covered by Patent Numbers 5262779 and 5272481.

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby expressly

granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING - LIFE SUPPORT APPLICATIONS POLICY - SPT products should not be used within Life Support Systems without the specific

written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can be reasonably

expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

SPT

SPT7830

8 12/19/97

Loading...

Loading...