Page 1

SPT7824

10-BIT, 40 MSPS, TTL OUTPUT A/D CONVERTER

FEATURES

• Monolithic 40 MSPS Converter

• On-Chip Track/Hold

• Bipolar ±2.0 V Analog Input

• 57 dB SNR @ 3.58 MHz Input

• Low Power (1.0 W Typical)

• 5 pF Input Capacitance

• TTL Outputs

GENERAL DESCRIPTION

The SPT7824 A/D converter is a 10-bit monolithic converter

capable of word rates a minimum of 40 MSPS. On board

track/hold function assures excellent dynamic performance

without the need for external components. Drive requirement problems are minimized with an input capacitance of

only 5 pF.

Inputs and outputs are TTL compatible to interface with TTL

logic systems. An overrange output signal is provided to

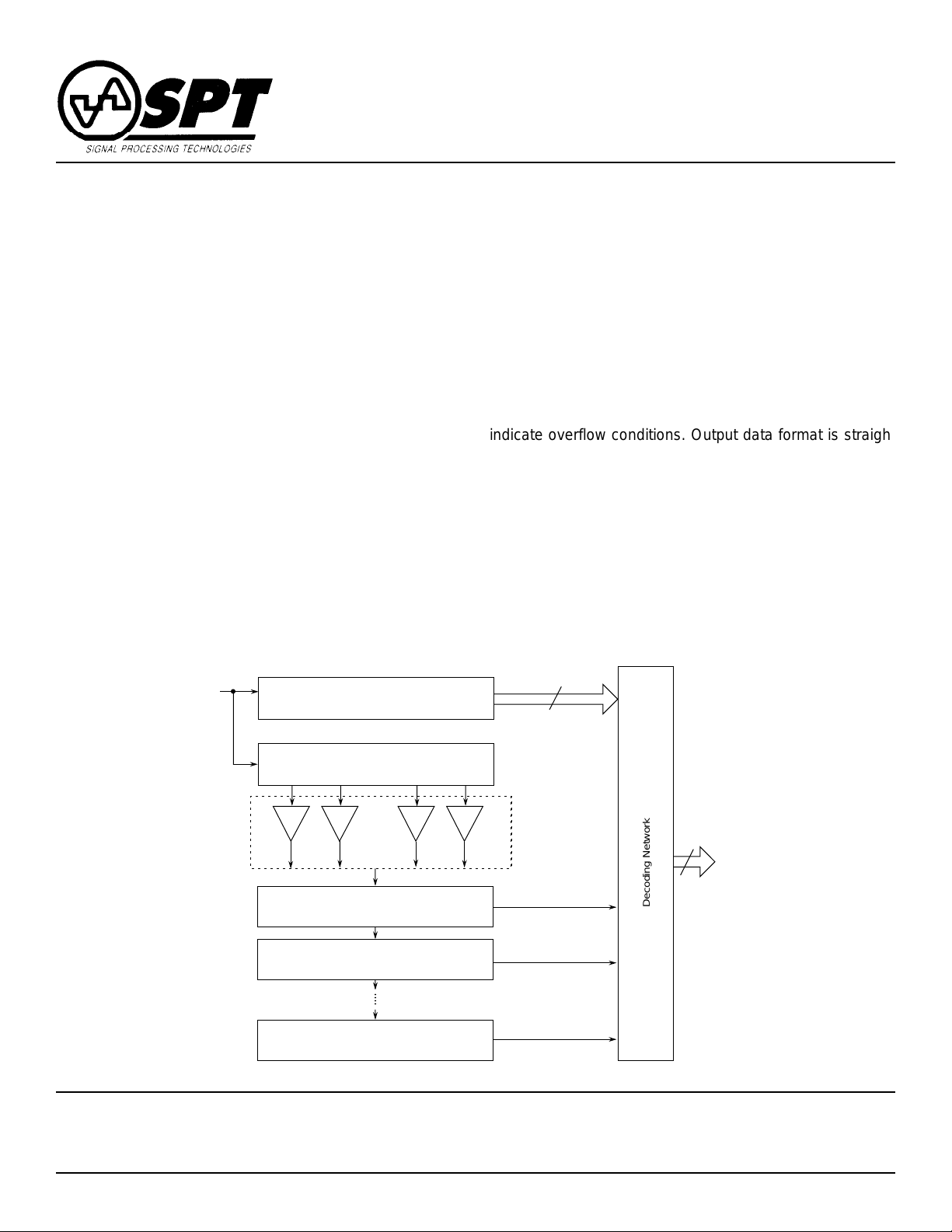

BLOCK DIAGRAM

APPLICATIONS

• Medical Imaging

• Professional Video

• Radar Receivers

• Instrumentation

• Electronic Warfare

• Digital Communications

indicate overflow conditions. Output data format is straight

binary. Power dissipation is very low at only 1.0 watt with

power supply voltages of +5.0 and -5.2 volts. The SPT7824

also provides a wide input voltage swing of ±2.0 volts.

The SPT7824 is available in 28-lead ceramic sidebrazed DIP,

PDIP and SOIC packages over the commercial, industrial and

military temperature ranges. Consult the factory for availability of die and /833 versions.

Analog

Input

Coarse

A/D

Analog

Prescaler

T/H Amplifier

Bank

Successive Interpolation

Stage i

Successive Interpolation

Stage i+1

Successive Interpolation

Stage N

4

Digital

10

Decoding Network

Output

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370

Page 2

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)1 25 °C

Supply Voltages

VCC...........................................................................+6 V

Output

Digital Outputs .......................................... +30 to -30 mA

VEE........................................................................... -6 V

Temperature

Input Voltages

Analog Input............................................... VFB≤VIN≤V

VFT, V

..............................................................

FB

+3.0 V, -3.0 V

Reference Ladder Current .....................................12 mA

CLK Input.................................................................. V

FT

CC

Operating Temperature ............................-55 to +125 °C

1

Junction Temperature

..............................................

+175 °C

Lead Temperature, (soldering 10 seconds)........ +300 °C

Storage Temperature................................-65 to +150 °C

Note: 1. Operation at any Absolute Maximum Rating is not implied. See Electrical Specifications for proper nominal

applied conditions in typical applications.

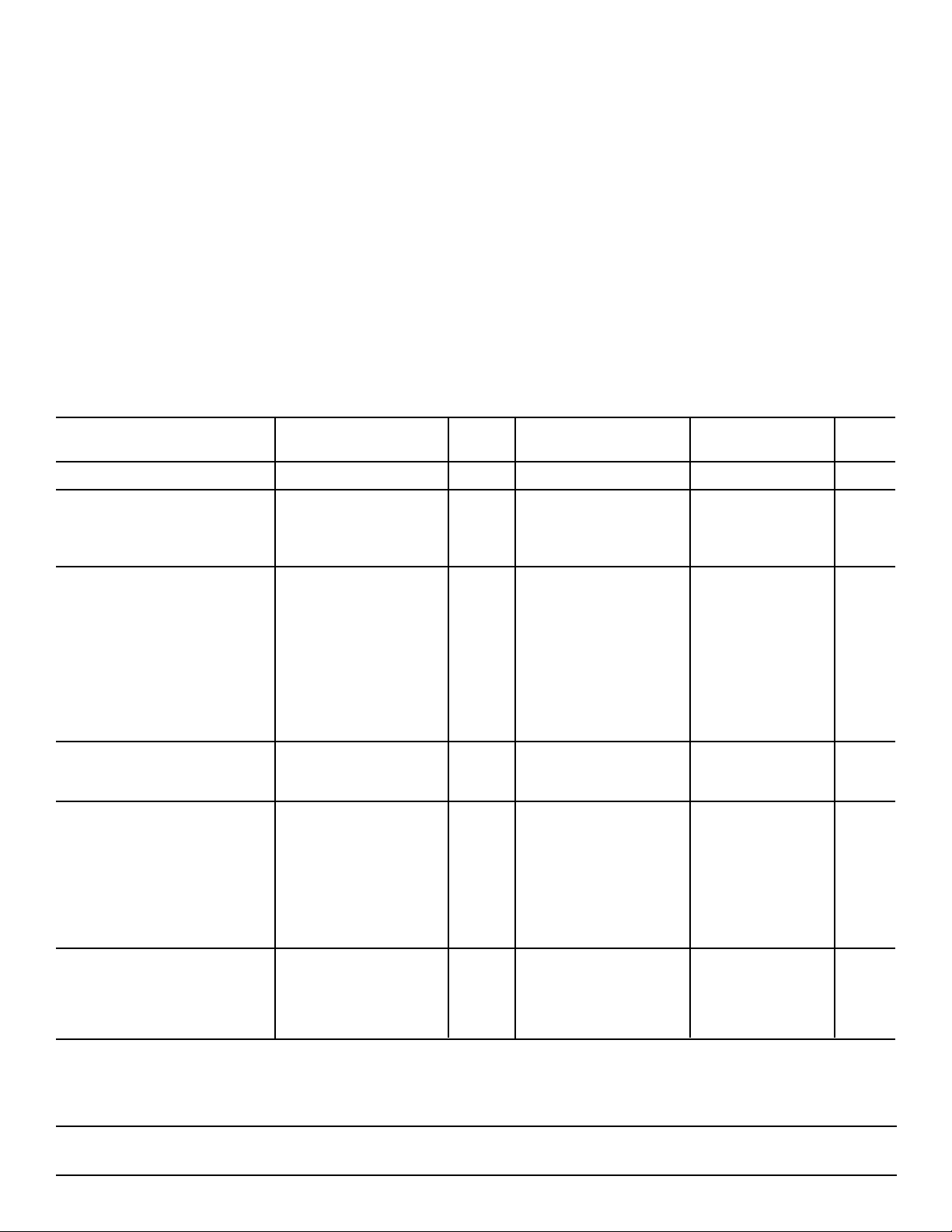

ELECTRICAL SPECIFICATIONS

TA=T

specified.

PARAMETERS CONDITIONS LEVEL MIN TYP MAX MIN TYP MAX UNITS

Resolution 10 10 Bits

DC Accuracy (+25 °C)

- T

MIN

Integral Nonlinearity 100 kHz Sample Rate V ±1.0 ±1.5 LSB

Differential Nonlinearity V ±0.5 ±0.75 LSB

No Missing Codes VI Guaranteed Guaranteed

, VCC=+5.0 V, VEE=-5.2 V, DVCC=+5.0 V, VIN=±2.0 V, VSB=-2.0 V, VST=+2.0 V, f

MAX

TEST TEST SPT7824A SPT7824B

±

Full Scale

=40 MHz, 50% clock duty cycle, unless otherwise

CLK

Analog Input f

Input Voltage Range V ±2.0 ±2.0 V

Input Bias Current V

Input Bias Current T

Input Resistance VI 100 300 100 300 kΩ

Input Resistance T

Input Capacitance V 5 5 pF

Input Bandwidth 3 dB Small Signal V 120 120 MHz

+FS Error V ±2.0 ±2.0 LSB

-FS Error V ±2.0 ±2.0 LSB

Reference Input f

Reference Ladder Resistance VI 500 800 500 800 Ω

Reference Ladder Tempco V 0.8 0.8 Ω/°C

Timing Characteristics

Maximum Conversion Rate VI 40 40 MHz

Overvoltage Recovery Time V 20 20 ns

Pipeline Delay (Latency) IV 1 1

Output Delay TA=+25 °C V 14 18 14 18 ns

Aperture Delay Time T

Aperture Jitter Time T

Acquisition Time TA=+25 °C V 12 12 ns

Dynamic Performance

Effective Number of Bits

=1 MHz 8.7 8.2 Bits

f

IN

=3.58 MHz 8.7 8.2 Bits

f

IN

fIN=10.0 MHz 7.3 6.9 Bits

=1 MHz

CLK

=0 V VI 30 60 30 60 µA

IN

=-55 to +125 °CIV 75 75µA

A

=-55 to +125 °C IV 75 300 75 300 kΩ

A

=1 MHz

CLK

=+25 °CV1 1ns

A

=+25 °C V 5 5 ps-RMS

A

Clock Cycle

Typical thermal impedances (unsoldered, in free air): 28L sidebrazed DIP: θja = 50 °C/W, 28L plastic DIP: θja = 50°C/W,

28L SOIC: θ

SPT

= 100 °C/W.

ja

2 3/11/97

SPT7824

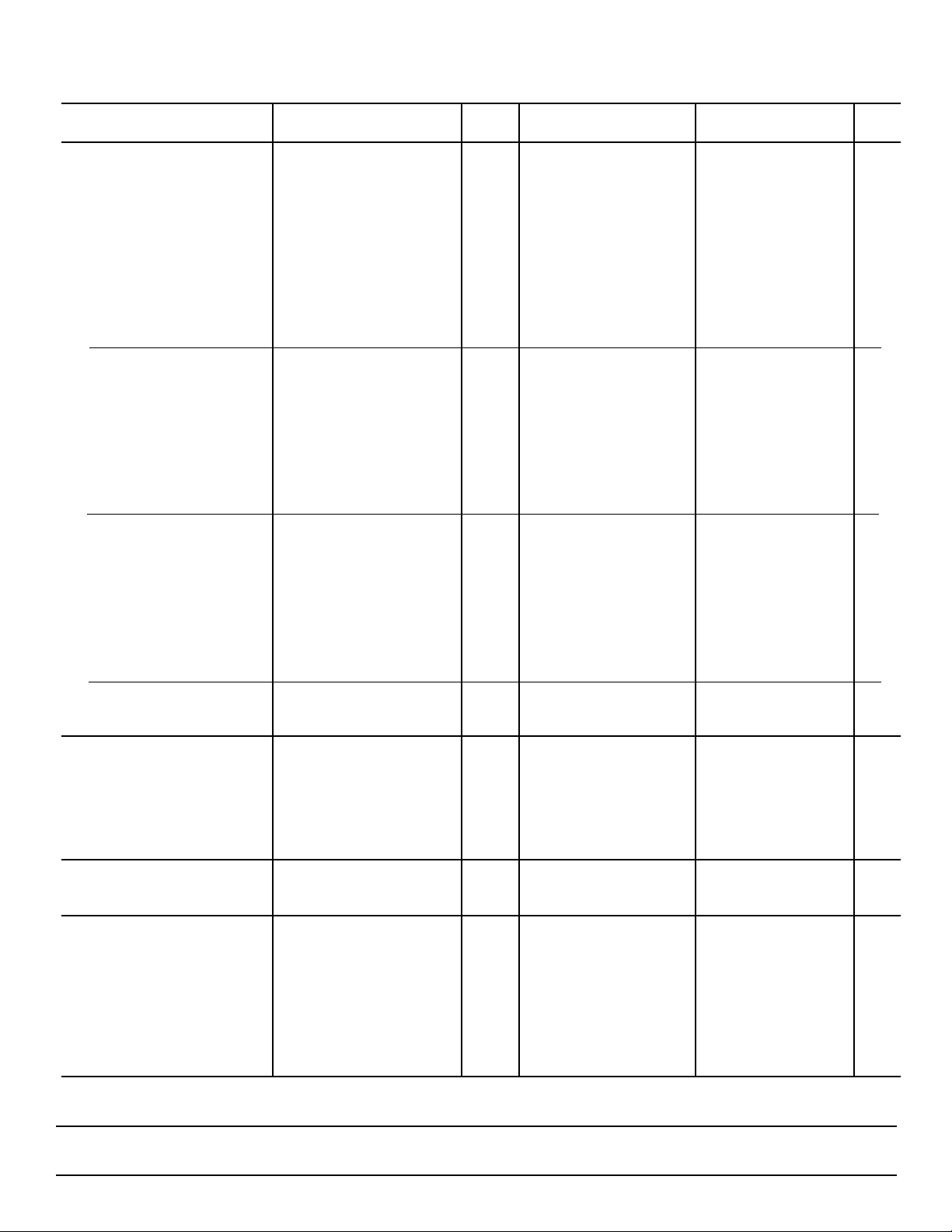

Page 3

ELECTRICAL SPECIFICATIONS

TA=T

MIN-TMAX

PARAMETERS CONDITIONS LEVEL MIN TYP MAX MIN TYP MAX UNITS

Dynamic Performance

Signal-To-Noise Ratio

(without Harmonics)

Harmonic Distortion

Signal-to-Noise and Distortion

Spurious Free Dynamic Range T

Differential Phase

Differential Gain T

Digital Inputs f

Logic 1 Voltage VI 2.4 4.5 2.4 4.5 V

Logic 0 Voltage VI 0.8 0.8 V

Maximum Input Current Low T

Maximum Input Current High T

Pulse Width Low (CLK) IV 10 10 ns

Pulse Width High (CLK) IV 10 300 10 300 ns

Digital Outputs f

Logic "1" Voltage VI 2.4 2.4 V

Logic "0" Voltage VI 0.6 0.6 V

Power Supply Requirements

VoltagesV

CurrentsI

Power Dissipation T

Power Supply Rejection +5 V ±0.25 V, -5.2 V ±0.25 V V 1.0 1.0 LSB

*Temperature tested /883 only.

, VCC=+5.0 V, VEE=-5.2 V, DVCC=+5.0 V, VIN=±2.0 V, VSB=-2.0 V, VST=+2.0 V, f

=40 MHz, 50% clock duty cycle unless otherwise specified.

CLK

TEST TEST SPT7824A SPT7824B

f

=1 MHz TA=+25 °C I 55 57 52 54 dB

IN

f

=3.58 MHz TA=+25 °C I 55 57 52 54 dB

IN

=10.0 MHz TA=+25 °C I 48 50 46 48 dB

f

IN

=1 MHz TA=+25 °C I 54 56 52 54 dB

f

IN

f

=3.58 MHz TA=+25 °C I 54 56 52 54 dB

IN

=10.0 MHz TA=+25 °C I 46 48 43 45 dB

f

IN

=1 MHz TA=+25 °C I 52 54 49 51 dB

f

IN

f

=3.58 MHz TA=+25 °C I 52 54 49 51 dB

IN

f

=10.0 MHz TA=+25 °C I 44 46 41 43 dB

IN

CC

DV

CC

-V

EE

CC

DI

CC

-I

EE

=0 to +70, -25 to +85 °CIV 5355 5052 dB

T

A

T

=-55 to +125 °C* IV 49 51 46 48 dB

A

=0 to 70, -25 to +85 °CIV 5355 5052 dB

T

A

T

=-55 to +125 °C* IV 49 51 46 48 dB

A

T

=0 to 70, -25 to +85 °CIV 4547 4345 dB

A

T

=-55 to +125 °C* IV 41 43 39 41 dB

A

=0 to 70, -25 to +85 °CIV 5153 4951 dB

T

A

T

=-55 to +125 °C* IV 50 52 48 50 dB

A

=0 to 70, -25 to +85 °CIV 5153 4951 dB

T

A

T

=-55 to +125 °C* IV 50 52 48 50 dB

A

T

=0 to 70, -25 to +85 °CIV 4547 4144 dB

A

T

=-55 to +125 °C* IV 44 46 40 42 dB

A

=0 to 70, -25 to +85 °CIV 49 46 dB

T

A

T

=-55 to +125 °C* IV 48 45 dB

A

=0 to 70, -25 to +85 °CIV 49 46 dB

T

A

T

=-55 to +125 °C* IV 48 45 dB

A

=0 to 70, -25 to +85 °CIV 43 40 dB

T

A

T

=-55 to +125 °C* IV 40 37 dB

A

=+25 °C, fIN=1 MHz V 67 67 dB

A

TA=+25 °C, fIN = 3.58 & 4.35 MHz V 0.2 0.2 Degree

=+25 °C, fIN = 3.58 & 4.35 MHz V 0.5 0.7 %

A

=1 MHz

CLK

=+25 °C I 0 +5 +20 0 +5 +20 µA

A

=+25 °C I 0 +5 +20 0 +5 +20 µA

A

=1 MHz

CLK

IV 4.75 5.25 4.75 5.25 V

IV 4.75 5.0 5.25 4.75 5.0 5.25 V

IV -4.95 -5.2 -5.45 -4.95 -5.2 -5.45 V

TA=+25 °C I 118 145 118 145 mA

TA=+25 °C I 40 55 40 55 mA

TA=+25 °C I 40 57 40 57 mA

=+25 °C I 1.0 1.3 1.0 1.3 W

A

SPT

SPT7824

3 3/11/97

Page 4

TEST LEVEL CODES

TEST LEVEL

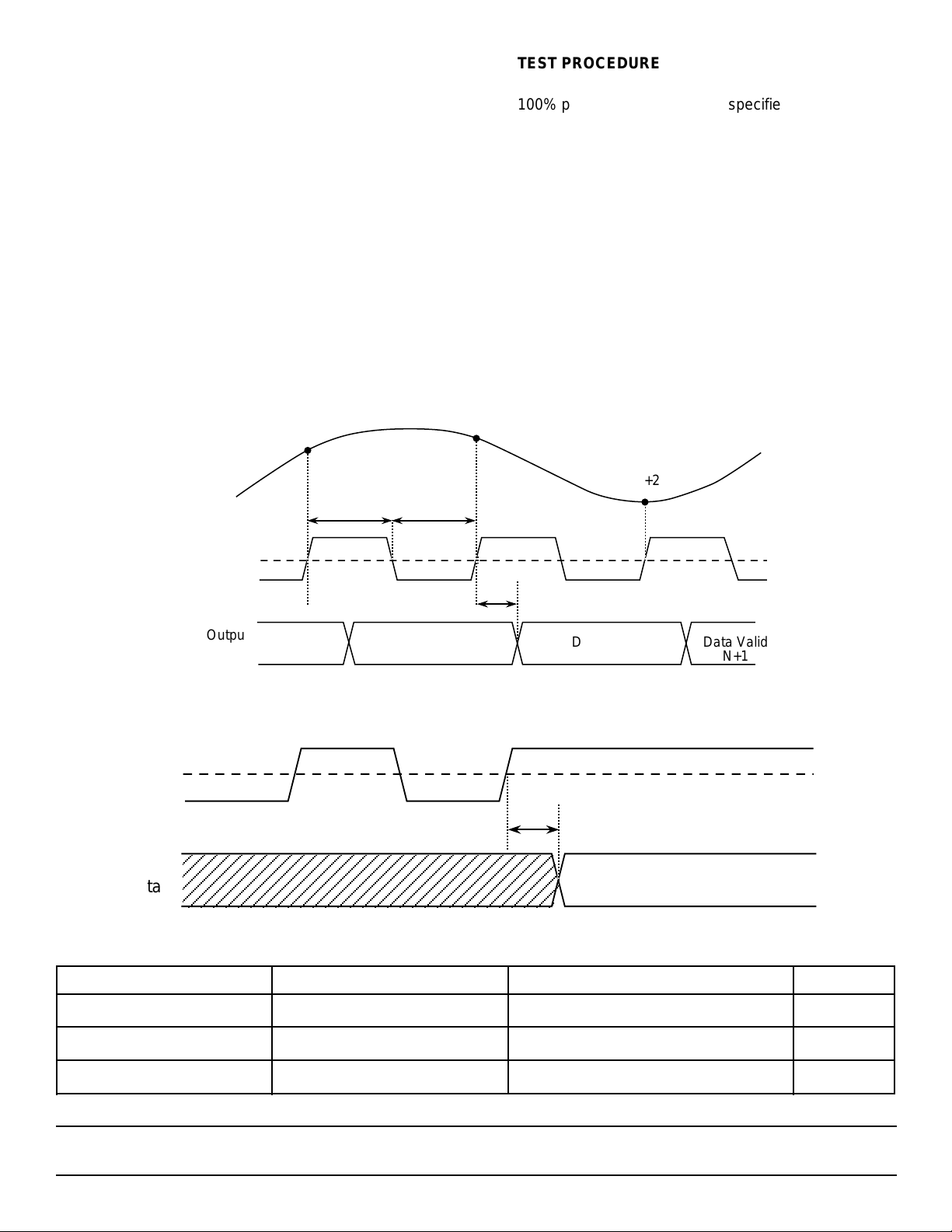

TEST PROCEDURE

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification is not

tested at the specified condition.

Figure 1A - Timing Diagram

N

t

pwH

II

III

IV

V

VI

t

pwL

I

100% production tested at the specified temperature.

100% production tested at TA = +25 °C, and sample

tested at the specified temperatures.

QA sample tested only at the specified temperatures.

Parameter is guaranteed (but not tested) by design

and characterization data.

Parameter is a typical value for information purposes

only.

100% production tested at TA = +25 °C. Parameter is

guaranteed over specified temperature range.

N+1

N+2

CLK

Output

Data

Figure 1B - Single Event Clock

CLK

Output

Data

Table I - Timing Parameters

PARAMETERS DESCRIPTION MIN TYP MAX UNITS

t

d

t

pwH

t

d

N-2 N-1

t

d

Data Valid

N

Data Valid

N+1

Data Valid

CLK to Data Valid Prop Delay - 14 18 ns

CLK High Pulse Width 10 - 300 ns

SPT

t

pwL

CLK Low Pulse Width 10 - - ns

SPT7824

4 3/11/97

Page 5

TYPICAL PERFORMANCE CHARACTERISTICS

20

30

40

50

60

70

80

10

0

10

1

10

2

SNR, THD, SINAD vs Sample Rate

Sample Rate (MSPS)

SNR, THD, SINAD (dB)

THD

SINAD

f

IN

= 1 MHz

SNR

80

70

60

50

40

30

Total Harmonic Distortion (dB)

20

80

70

60

THD vs Input Frequency

80

70

fs = 40 MSPS

0

10

Input Frequency (MHz)

1

10

2

10

60

50

40

Signal-to-Noise Ratio (dB)

30

20

0

10

SNR vs Input Frequency

fs = 40 MSPS

1

10

Input Frequency (MHz)

2

10

SINAD vs Input Frequency

fs =40 MSPS

Signal-to-Noise and Distortion (dB)

Amplitude (dB)

-120

SPT

50

40

30

20

0

10

Input Frequency (MHz)

1

10

Spectral Response

0

-30

-60

-90

f

= 40 MSPS

S

fIN = 1 MHz

0 12345678910

Input Frequency (MHz)

2

10

SNR, THD, SINAD vs Temperature

65

60

SNR

55

THD

SINAD

50

= 40 MSPS

SNR, THD, SINAD (dB)

45

40

-25 0 +25 +50 +75

f

S

= 1 MHz

f

IN

Temperature (°C)

SPT7824

5 3/11/97

Page 6

TYPICAL INTERFACE CIRCUIT

The SPT7824 requires few external components to achieve

the stated operation and performance. Figure 2 shows the

typical interface requirements when using the SPT7824 in

normal circuit operation. The following section provides a

description of the pin functions and outlines critical performance criteria to consider for achieving the optimal device

performance.

POWER SUPPLIES AND GROUNDING

The SPT7824 requires -5.2 V and +5 V analog supply

voltages. The +5 V supply is common to analog VCC and

digital DVCC. A ferrite bead in series with each supply line is

intended to reduce the transient noise injected into the analog

VCC. These beads should be connected as closely as possible to the device. The connection between the beads and

the SPT7824 should not be shared with any other device.

Each power supply pin should be bypassed as closely as

possible to the device. Use 0.1 µF for VEE and VCC, and

0.01 µ F for DVCC (chip caps are preferred).

Figure 2 - Typical Interface Circuit

AGND and DGND are the two grounds available on the

SPT7824. These two internal grounds are isolated on the

device. The use of ground planes is recommended to achieve

optimum device performance. DGND is needed for the DV

CC

return path (40 mA typical) and for the return path for all digital

output logic interfaces. AGND and DGND should be separated from each other and connected together only at the

device through a ferrite bead.

A Schottky or hot carrier diode connected between AGND

and VEE is required. The use of separate power supplies

between VCC and DVCC is not recommended due to potential

power supply sequencing latch-up conditions. Using the

recommended interface circuit shown in figure 2 will provide

optimum device performance for the SPT7824.

V

OUT

Tri m

-

6

R1

100 Ω

± 2.5 V Max

6

5

- 5.2 V

4

.01 µF

10 kΩ

30 kΩ

1 µF

1 µF

30 kΩ

C1

+

.01 µF

+

CLK

(TTL)

V

(±2 V)

+ 5 V

+5 V

IN

2

V

IC1

IN

+

C19

1 µF

(REF-03)

4

GND

32

1

+

IC2

10 kΩ

OP-07

8

7

.01 µF

Notes to prevent latch-up due to power sequencing:

1) D1 = Schottky or hot carrier diode, P/N IN5817.

2) FB = Ferrite bead, Fair Rite P/N 2743001111

to be mounted as close to the device as possible. The f errite bead to the

ADC connection should not be shared with any other device.

3) C1-C11 = Chip cap (recommended) mounted as close to the device's pin

as possible.

4) Use of a separate supply for VCC and DVCC is not recommended.

5) R1 provides current limiting to 45 mA.

6) C6, C7, C8 and C9 should be ten times larger than C10 and C11.

7) C8 = C9 = a 0.1 µF cap in parallel with a 4.7 µF cap.

+2.5 V

-2.5 V

.01 µF

.01 µF

.01 µF

C5

.01 µF

CLK

V

IN

V

FT

C2

C3

C4

R

V

ST

2R

2R

V

RM

2R

2R

V

SB

R

V

FB

EE

EE

V

V

C6

.1 µF

C7

.1 µF

D1

10 µF

+

-5.2 V

(Analog)

AGND

10 µF

AGND

COARSE

A/D

ANALOG

PRESCALER

SUCCESSIVE

INTERPOLATION

STA GE # 1

SUCCESSIVE

INTERPOLATION

STA GE # N

CC

AGND

V

C8

C9

FB

+

(Analog)

V

+5 V

4

D E C O D I N G N E T W O R K

CC

CC

CC

.01 µF

.01 µF

DGND

DV

C10

C11

DGND

DV

FB

DGND

FB

D10 (Overrange)

D9 (MSB)

D8

D7

D6

D5

D4

D3

D2

D1

D0 (LSB)

D I G I T A L O U T P U T S

SPT

SPT7824

6 3/11/97

Page 7

VOLTAGE REFERENCE

The SPT7824 requires the use of two voltage references:

VFT and VFB. VFT is the force for the top of the voltage

reference ladder (+2.5 V typ), VFB (-2.5 V typ) is the force for

the bottom of the voltage reference ladder. Both voltages are

applied across an internal reference ladder resistance of

800 ohms. The +2.5 V voltage source for reference VFT must

be current limited to 20 mA maximum if a different driving

circuit is used in place of the recommended reference circuit

shown in figures 2 and 3. In addition, there are three

reference ladder taps (VST, VRM and VSB). VST is the sense for

the top of the reference ladder (+2.0 V), VRM is the midpoint

of the ladder (0.0 V typ) and VSB is the sense for the bottom

of the reference ladder (-2.0 V). The voltages seen at VST and

VSB are the true full scale input voltages of the device when

VFT and VFB are driven to the recommended voltages (+2.5 V

and -2.5 V typical respectively). These points should be used

to monitor the actual full scale input voltage of the device and

should not be driven to the expected ideal values as is

commonly done with standard flash converters. When not

being used, a decoupling capacitor of .01 uF (chip carrier

preferred) connected to AGND from each tap is recommended

to minimize high frequency noise injection.

Figure 3 - Analog Equivalent Input Circuit

V

CC

V

IN

V

FT

ever, because the device is laser trimmed to optimize performance with ± 2.5 V references, the accuracy of the device will

degrade if operated beyond a ± 2% range.

The following errors are defined:

+FS error = top of ladder offset voltage = ∆(+FS -VST+1 LSB)

-FS error = bottom of ladder offset voltage = ∆(-FS -V

SB

-1 LSB)

where the +FS (full scale) input voltage is defined as the

output transition between 1-10 and 1-11 and the -FS input

voltage is defined as the output transition between 0-00 and

0-01.

ANALOG INPUT

VIN is the analog input. The full scale input range will be 80% of

the reference voltage or ±2 V with VFB=-2.5 V and VFT=+2.5 V.

The drive requirements for the analog inputs are minimal

when compared to conventional Flash converters due to the

SPT7824’s extremely low input capacitance of only 5 pF and

very high input resistance of 300 kΩ. For example, for an input

signal of ± 2 V p-p with an input frequency of 10 MHz, the peak

output current required for the driving circuit is only 628 µA.

CLOCK INPUT

The SPT7824 is driven from a single-ended TTL input (CLK).

The CLK pulse width (tpwH) must be kept between 10 ns and

300 ns to ensure proper operation of the internal track-andhold amplifier. (See timing diagram.) When operating the

SPT7824 at sampling rates above 3 MSPS, it is recommended that the clock input duty cycle be kept at 50% to

optimize performance. (See figure 4.) The analog input

signal is latched on the rising edge of the CLK.

Analog Prescaler

V

EE

An example of a reference driver circuit recommended is

shown in figure 2. IC1 is REF-03, the +2.5 V reference with a

tolerance of 0.6% or +/- 0.015 V. The potentiometer R1 is

10 kΩ and supports a minimum adjustable range of up to

150 mV. IC2 is recommended to be an OP-07 or equivalent

device. R2 and R3 must be matched to within 0.1% with good

TC tracking to maintain a 0.3 LSB matching between VFT and

VFB. If 0.1% matching is not met, then potentiometer R4 can

be used to adjust the VFB voltage to the desired level. VFT and

VFB should be adjusted such that VST and VSB are exactly

+2.0 V and -2.0 V respectively.

The analog input range will scale proportionally with respect

to the reference voltage if a different input range is required.

The maximum scaling factor for device operation is ± 20% of

the recommended reference voltages of VFT and VFB. How-

The clock input must be driven from fast TTL logic (VIH ≤4.5 V,

T

<6 ns). In the event the clock is driven from a high

RISE

current source, use a 100 Ω resistor in series to current limit

to approximately 45 mA.

Figure 4 - SNR vs Clock Duty Cycle

59

57

55

53

Duty

51

49

47

Signal-to-Noise Ratio (dB)

45

43

30 35 40 45 50 55 60 65 70 75

Duty Cycle of Positive Clock Pulse (%)

Cycle

=

tpwLtpwH

tpwH

tpwL

SPT

SPT7824

7 3/11/97

Page 8

DIGITAL OUTPUTS

OVERRANGE OUTPUT

The format of the output data (D0-D9) is straight binary. (See

table II.) The outputs are latched on the rising edge of CLK

with a propagation delay of 14 ns (typ). There is a one clock

cycle latency between CLK and the valid output data. (See

timing diagram.)

Table II - Output Data Information

ANALOG INPUT OVERRANGE OUTPUT CODE

D1O D9-DO

>+2.0 V + 1/2 LSB 1 11 1111 1111

+2.0 V -1 LSB O 11 1111 111Ø

0.0 V O ØØ ØØØØ ØØØØ

-2.0 V +1 LSB O OO OOOO OOOØ

<-2.0 V O OO OOOO OOOO

(Ø indicates the flickering bit between logic 0 and 1).

The rise times and fall times of the digital outputs are not

symmetrical. The propagation delay of the rise time is typically 14 ns and the fall time is typically 6 ns. (See figure 5.)

The nonsymmetrical rise and fall times create approximately

8 ns of invalid data.

The OVERRANGE OUTPUT (D10) is an indication that the

analog input signal has exceeded the positive full scale input

voltage by 1 LSB. When this condition occurs, D10 will switch

to logic 1. All other data outputs (D0 to D9) will remain at

logic 1 as long as D10 remains at logic 1. This feature makes

it possible to include the SPT7824 into higher resolution

systems.

EVALUATION BOARD

The EB7824 Evaluation Board is available to aid designers in

demonstrating the full performance of the SPT7824. This

board includes a reference circuit, clock driver circuit, output

data latches and an on-board reconstruction of the digital

data. An application note describing the operation of this

board as well as information on the testing of the SPT7824 is

also available. Contact the factory for price and availability.

Figure 5 - Digital Output Characteristics

N

CLK In

Data Out

(Actual)

Data Out

2.4 V

3.5 V

2.4 V

0.8 V

0.5 V

6 ns

typ.

(N-2)

tpd1

(14 ns typ.)

(N-2)

Invalid

Invalid

(Equivalent)

Data

Data

(N-1)

(N-1)

N+1

Rise Time

≤ 6 nsec

Invalid

Data

Invalid

Data

(N)

(N-1)

SPT

SPT7824

8 3/11/97

Page 9

PACKAGE OUTLINES

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.200 5.08

B 0.120 0.135 3.05 3.43

C 0.020 0.51

D 0.100 2.54

E 0.067 1.70

F 0.013 0.33

G 0.170 0.180 4.32 4.57

H 0.622 15.80

I 0.555 14.10

J 1.460 37.08

K 0.085 2.16

28-Lead Sidebrazed

28

H

SYMBOL MIN MAX MIN MAX

I

1

J

G

A

INCHES MILLIMETERS

A 0.077 0.093 1.96 2.36

B 0.016 0.020 0.41 0.51

C 0.095 0.105 2.41 2.67

D .050 typ 0.00 1.27

E 0.040 0.060 1.02 1.52

F 0.215 0.235 5.46 5.97

G 1.388 1.412 35.26 35.86

H 0.585 0.605 14.86 15.37

I 0.009 0.012 0.23 0.30

J 0.600 0.620 15.24 15.75

E

F

C

B

D

28-Lead Plastic DIP

28

1

J

A

B

C

SPT

K

I

H

G

F

D

E

SPT7824

9 3/11/97

Page 10

B

28

1

CD

A

PACKAGE OUTLINES

28-Lead SOIC

SYMBOL MIN MAX MIN MAX

I H

F

E

INCHES MILLIMETERS

A 0.696 0.712 17.68 18.08

B 0.004 0.012 0.10 0.30

C .050 typ 0.00 1.27

D 0.014 0.019 0.36 0.48

E 0.009 0.012 0.23 0.30

F 0.080 0.100 2.03 2.54

G 0.016 0.050 0.41 1.27

H 0.394 0.419 10.01 10.64

I 0.291 0.299 7.39 7.59

G

SPT

SPT7824

10 3/11/97

Page 11

PIN ASSIGNMENTS

PIN FUNCTIONS

DGND

Name Function

1

D0

2

D1

3

D2

4

D3

5

D4

6

D5

7

DIP/PDIP/SOIC

D6

8

D7

9

D8

D9

D10

DGND

DV

CC

10

11

12

13

14

28

DV

CC

V

27

EE

AGND

26

V

25

CC

V

24

FB

V

23

SB

V

22

RM

V

21

IN

20

V

ST

19

V

FT

18

V

CC

17

AGND

V

16

EE

CLK

15

DGND Digital Ground

D0-D9 TTL Outputs (D0=LSB)

D10 TTL Output Overrange

CLK Clock

V

EE

-5.2 V Supply (Analog)

AGND Analog Ground

V

V

DV

V

V

V

V

V

CC

IN

CC

RM

FT

ST

FB

SB

+5.0 V Supply (Analog)

Analog Input

Digital +5.0 V Supply

Middle of Voltage Reference Ladder

Force for Top of Reference Ladder

Sense for Top of Reference Ladder

Force for Bottom of Reference Ladder

Sense for Bottom of Reference Ladder

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE TYPE

SPT7824AIJ -25 to +85 °C 28L Sidebrazed DIP

SPT7824BIJ -25 to +85 °C 28L Sidebrazed DIP

SPT7824ACN 0 to +70 °C 28L Plastic DIP

SPT7824BCN 0 to +70 °C 28L Plastic DIP

SPT7824ACS 0 to +70 °C 28L SOIC

SPT7824BCS 0 to +70 °C 28L SOIC

SPT7824AMJ -55 to +125 °C 28L Sidebrazed DIP

SPT7824BMJ -55 to +125 °C 28L Sidebrazed DIP

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby expressly

granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING - LIFE SUPPORT APPLICATIONS POLICY - SPT products should not be used within Life Support Systems without the specific

written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can be reasonably

expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

SPT

SPT7824

11 3/11/97

Loading...

Loading...