Page 1

SPT774

FAST, COMPLETE 12-BIT µP COMPATIBLE

A/D CONVERTER WITH SAMPLE/HOLD

FEATURES

• Improved Higher Performance Version of the HADC574Z

• Complete 12-Bit A/D Converter with Sample/Hold,

Reference and Clock

• Low Power Dissipation (120 mW Max)

• 12-Bit Linearity (Over Temp)

•8 µs Max Conversion Time

• Single +5 V Supply

• Full Bipolar and Unipolar Input Range

GENERAL DESCRIPTION

The SPT774 is a complete, 12-bit successive approximation

A/D converter manufactured in CMOS technology. The device is an improved version of the HADC574Z. Included on

chip are an internal reference, clock, and a sample-and-hold.

The S/H is an additional feature not available on similar

devices.

The SPT774 features 8 µs (max) conversion time of 10 or

20 V input signals. Also, a three-state output buffer is added

for direct interface to an 8-, 12- or 16-bit µP bus.

APPLICATIONS

• Data Acquisition Systems

• 8 or 12-Bit µP Input Functions

• Process Control Systems

• Test and Scientific Instruments

• Personal Computer Interface

The SPT774 has standard bipolar and unipolar input ranges

of 10 V and 20 V that are controlled by a bipolar offset pin and

laser trimmed for specified linearity, gain and offset accuracy.

The power supply is +5 V. The device also has an optional

mode control voltage which may be used depending on the

application. With a maximum dissipation of 120 mW at the

specified voltages, power consumption is about five times

lower than that of currently available devices.

The SPT774 is available in 28-lead ceramic sidebrazed DIP,

PDIP and SOIC packages in the commercial temperature

range.

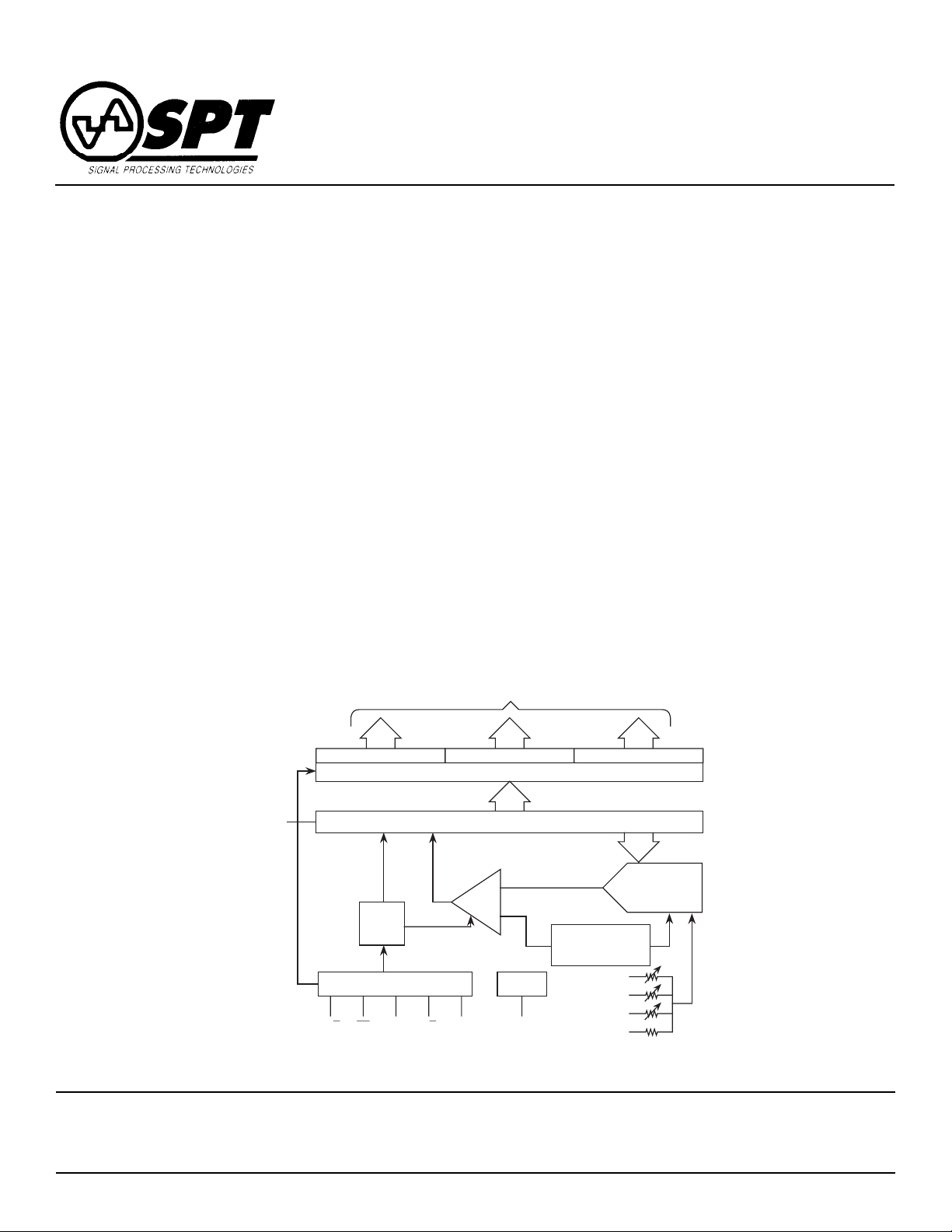

BLOCK DIAGRAM

Signal Processing Technologies, Inc.

Phone: (719) 528-2300 FAX: (719) 528-2370 Website: http://www.spt.com E-Mail: sales@spt.com

Output

Nibble A Nibble B Nibble C

Three-State Buffers And Control

STS

Clock

Control Logic

A

12/8 CS R/C

oCE

12-Bit SAR

Comp

+

-

Ref Out

Ref

Capacitance

Offset/Gain

Trim

20 V In

10 V In

BIP Off

AGND

4755 Forge Road, Colorado Springs, Colorado 80907, USA

12-Bit

DAC

Page 2

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur) 1 25 °C

Supply Voltages

Mode Control Voltage (VEE to DGND) ....................0 to +7 V

Logic Supply Voltage (VDD to DGND) ...................0 to +7 V

Analog to Digital Ground (AGND to DGND) .................±1 V

Input Voltages

Control Input Voltages (to DGND)

(CE, CS, Ao, 12/8, R/C)......................... -0.5 to VDD +0.5 V

Analog Input Voltage (to AGND)

(REF IN, BIP OFF, 10 VIN) ......................................±16.5 V

20 V VIN Input Voltage (to AGND) ..............................±24 V

Note: Operation at any Absolute Maximum Rating is not implied. See Operating Conditions for proper nominal applied

conditions in typical applications.

Output

Reference Output Voltage ..............Indefinite Short to GND

Momentary Short to V

Temperature

Operating Temperature, Ambient .................... 0 to +70 °C

Junction.........................+165 °C

Lead Temperature, (Soldering 10 Seconds)...........+300 °C

Storage Temperature....................................-65 to +150 °C

ELECTRICAL SPECIFICATIONS

DD

TA = T

PARAMETER CONDITIONS LEVEL MIN TYP MAX MIN TYP MAX UNITS

MIN

to T

MAX

, V

EE

= 0 to +5 V, V

TEST TEST SPT774C SPT774B

= +5 V, fS = 117 kHz, fIN = 10 kHz, unless otherwise specified..

DD

DC ELECTRICAL CHARACTERISTICS

Resolution VI 12 12 Bits

Linearity Error TA= 0 to +70 °CVI ±1 ±0.5 LSB

Differential Linearity No Missing Codes VI 12 12 Bits

Unipolar Offset; 10 V, 20 V +25 °C Adjustable to Zero VI ±2 ±2 LSB

Bipolar Offset; ±5 V, ±10 V +25 °C Adjustable to Zero VI ±10 ±4 LSB

Full Scale Calibration Error

Full Scale Calibration Error1No Adjustment to Zero

Temperature Coefficients Using Internal Reference

Unipolar Offset V ±1.0 ±1.0 ppm/°C

Bipolar Offset V ±2.0 ±2.0 ppm/°C

Full Scale Calibration V ±12 ±12 ppm/°C

Power Supply Rejection Max change in full VI ±0.5 ±0.5 LSB

+4.75 V<VDD<+5.25 V scale calibration

Analog Input Ranges

Bipolar VI -5 +5 -5 +5 Volts

Unipolar VI 0 +10 0 +10 Volts

Input Impedance

10 Volt Span VI 8.5 12 8.5 12 kΩ

20 Volt Span VI 35 50 35 50 kΩ

1

+25 °C Adjustable to Zero VI 0.30 0.30 % of FS

TA = 0 to +70 °C V 0.47 0.37 % of FS

VI -10 +10 -10 +10 Volts

VI 0 +20 0 +20 Volts

SPT

SPT774

2 8/1/00

Page 3

ELECTRICAL SPECIFICATIONS

TA = T

MIN

to T

MAX

, V

EE

= 0 to +5 V, V

= +5 V, fS = 117 kHz, fIN = 10 kHz, unless otherwise specified.

DD

TEST TEST SPT774C SPT774B

PARAMETER CONDITIONS LEVEL MIN TYP MAX MIN TYP MAX UNITS

DC ELECTRICAL CHARACTERISTICS

Power Supplies Operating

Voltage Range

V

DD

2

V

EE

Operating Current

I

DD

IEE2V

= +5 V IV 167 167 µA

EE

Power Dissipation VI 75 120 75 120 mW

Internal Reference

Voltage VI 2.4 2.5 2.6 2.4 2.5 2.6 Volts

Output Current

3

DIGITAL CHARACTERISTICS

Logic Inputs

(CE,

, R/C, Ao, 12/8)

CS

Logic 0 VI -0.5 +0.8 -0.5 +0.8 Volts

Logic1 VI 2.0 5.5 2.0 5.5 Volts

Current VI -5.0 0. 1 5.0 -5.0 0. 1 5.0 µA

Capacitance V 5 5 pF

Logic Outputs

(DB11-DB0, STS)

Logic 0 (I

Logic 1 (I

= 1.6 mA) VI +0.4 +0.4 Volts

Sink

SOURCE

= 500 µA) VI +2.4 +2.4 Volts

Leakage (High Z State, VI -5 0.1 +5 -5 0.1 +5 µA

DB11-DB0 Only)

Capacitance V 5 5 pF

AC Accuracy fS=117 kHz, fIN=10 kHz

Spurious Free Dyn. Range V 73 78 76 78 dB

Total Harmonic Distortion V -77 -72 -77 -75 dB

Signal-to-Noise Ratio V 69 72 71 72 dB

Signal-to-Noise & Distortion V 68 71 70 71 dB

(SINAD)

Intermodulation Distortion fIN=20 kHz; V -75 -75 dB

f

=23 kHz

IN2

Note 1: Fixed 50 Ω resistor from REF OUT to REF IN and REF OUT to BIP OFF.

Note 2: VEE is optional and is only used to set the mode for the internal sample/hold. When not using VEE, the pin should be treated

as a no connect. If V

is connected to 0 to -15 V, aperture delay (tAP) will increase from 20 ns (typ) to 4000 ns (typ).

EE

Note 3: Available for external loads; external load should not change during conversion.

IV +4.5 +5.5 +4.5 +5.5 Volts

IV V

DD

V

DD

Volts

IV 15 24 15 24 mA

VI 0.5 0.5 mA

SPT

SPT774

3 8/1/00

Page 4

ELECTRICAL SPECIFICATIONS

TA = T

MIN

to T

MAX

, V

EE

= 0 to +5 V, V

= +5 V, fS = 117 kHz, fIN = 10 kHz, unless otherwise specified.

DD

TEST TEST SPT774C SPT774B

PARAMETER CONDITIONS LEVEL MIN TYP MAX MIN TYP MAX UNITS

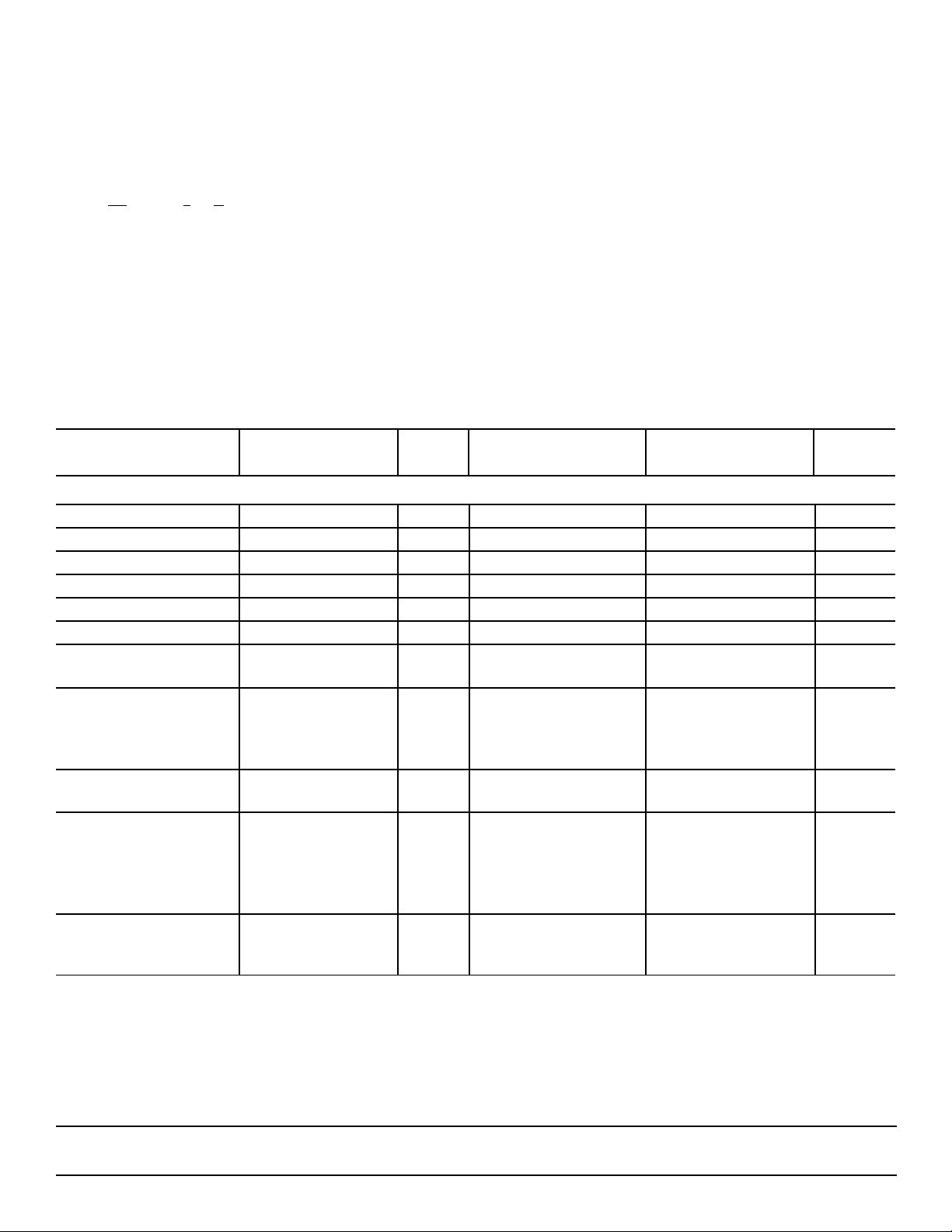

AC ELECTRICAL CHARACTERISTICS

4

Convert Mode Timing

t

STS Delay from CE VI 60 200 60 200 ns

DSC

t

CE Pulse Width VI 50 30 50 30 ns

HEC

t

CS to CE Setup VI 50 20 50 20 ns

SSC

CS Low during CE High VI 50 20 50 20 ns

t

HSC

R/C to CE Setup VI 50 0 50 0 ns

t

SRC

R/C Low During CE High VI 50 20 50 20 ns

t

HRC

t

Ao to CE Setup VI 0 0 ns

SAC

Ao Valid During CE High VI 50 20 50 20 ns

t

HAC

t

Conversion Time

C

5

12-Bit Cycle VI 7.5 8 7.5 8 µs

8-Bit Cycle VI 5.5 5.9 5.5 5.9 µs

Read Mode Timing

Access Time from CE VI 75 150 75 150 ns

t

DD

t

Data Valid After CE Low VI 25 35 25 35 ns

HD

t

Output Float Delay VI 100 150 100 150 ns

HL

CS to CE Setup VI 50 0 50 0 ns

t

SSR

R/C to CE Setup VI 0 0 ns

t

SRR

t

Ao to CE Setup VI 50 25 50 25 ns

SAR

CS Valid After CE Low VI 0 0 ns

t

HSR

R/C High After CE Low VI 0 0 ns

t

HRR

t

STS Delay After Data Valid VI 75 150 375 75 150 375 ns

HS

t

Ao Valid after CE Low VI 50 50 ns

HAR

Note 4: Time is measured from 50% level of digital transitions.

Note 5: Includes acquisition time.

Figure 1 - Convert Mode Timing Diagram Figure 2 - Read Mode Timing Diagram

CE

CE

CS

R/C

Ao

STS

DB11-DB0

SPT

t

t

t

SSC

SRC

SAC

t

t

t

t

DSC

High Impedance

HSC

HRC

HAC

t

HEC

t

C

4 8/1/00

R/C

STS

DB11-DB0

CS

Ao

t

SSR

t

SRR

t

SAR

HIGH

IMPEDANCE

t

DD

t

HSR

t

HRR

t

HAR

t

HS

DATA

VALID

t

HL

t

HD

SPT774

Page 5

ELECTRICAL SPECIFICATIONS

TA = T

MIN

to T

MAX

, V

EE

= 0 to +5 V, V

= +5 V, fS = 117 kHz, fIN = 10 kHz, unless otherwise specified.

DD

TEST TEST SPT774C SPT774B

PARAMETER CONDITIONS LEVEL MIN TYP MAX MIN TYP MAX UNITS

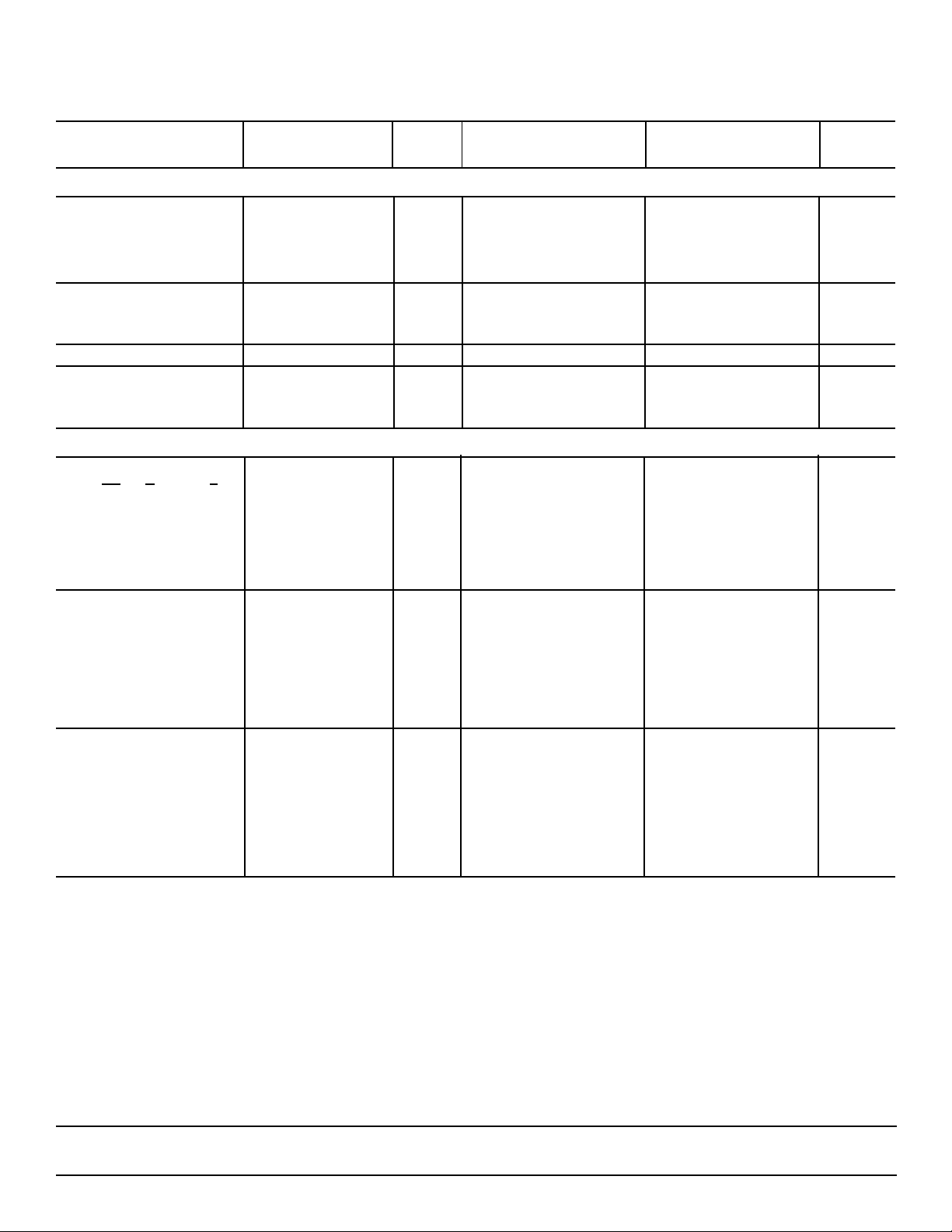

AC ELECTRICAL CHARACTERISTICS

4

Stand-Alone Mode Timing

Low R/C Pulse Width VI 25 25 ns

t

HRL

STS Delay from R/

t

DS

Data Valid After R/C Low VI 25 25 ns

t

HDR

t

STS Delay After Data Valid VI 75 150 375 75 150 375 ns

HS

t

High R/C Pulse Width VI 100 100 ns

HRH

t

Data Access Time VI 150 150 ns

DDR

C

VI 200 200 ns

Sample-and-Hold

Aperture Delay VEE = +5 V IV 20 20 ns

Aperture Uncertainty Time VEE = +5 V V 300 300 ps, RMS

TEST LEVEL CODES

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification is not

tested at the specified condition.

TEST LEVEL

I

II

III

IV

V

VI

TEST PROCEDURE

100% production tested at the specified temperature.

100% production tested at TA=25 °C, and sample

tested at the specified temperatures.

QA sample tested only at the specified temperatures.

Parameter is guaranteed (but not tested) by design

and characterization data.

Parameter is a typical value for information purposes

only.

100% production tested at TA = 25 °C. Parameter is

guaranteed over specified temperature range.

Figure 3 - Low Pulse for R/C - Outputs Enabled

After Conversion

t

HRL

R/C

t

DS

STS

t

HDR

t

C

t

HS

DATA VALIDDATA VALIDDB11-DB0

SPT

Figure 4 - High Pulse for R/C - Outputs Enabled While

R/C is High, Otherwise High Impedance

R/C

STS

DB11-DB0

HIGH-Z

t

t

DDR

HRH

t

HDR

DATA VALID

t

DS

t

C

HIGH-Z

SPT774

5 8/1/00

Page 6

CIRCUIT OPERATION

The SPT774 is a complete 12-bit analog-to-digital converter

that consists of a single chip version of the industry standard

774. This single chip contains a precision 12-bit capacitor

digital-to-analog converter (CDAC) with voltage reference,

comparator, successive approximation register (SAR), sampleand-hold, clock, output buffers and control circuitry to make it

possible to use the SPT774 with few external components.

other 774 circuits will cause a transient load current on the

sample-and-hold which will upset the buffer output and may

add error to the conversion itself.

Furthermore, the isolation of the input after the acquisition

time in the SPT774 allows the user an opportunity to release

the hold on an external sample-and-hold and start it tracking

the next sample. This increases system throughput with the

user’s existing components.

When the control section of the SPT774 initiates a conversion

command, the clock is enabled and the successive-approximation register is reset to all zeros. Once the conversion

cycle begins, it cannot be stopped or restarted and data is not

available from the output buffers.

The SAR, timed by the clock, sequences through the conversion cycle and returns an end-of-convert flag to the control

section of the ADC. The clock is then disabled by the control

section, the output status goes low, and the control section is

enabled to allow the data to be read by external command.

The internal SPT774 12-bit CDAC is sequenced by the SAR

starting from the MSB to the LSB at the beginning of the

conversion cycle to provide an output voltage from the CDAC

that is equal to the input signal voltage (which is divided by the

input voltage divider network). The comparator determines

whether the addition of each successively-weighted bit voltage causes the CDAC output voltage summation to be

greater or less than the input voltage; if the sum is less, the

bit is left on; if more, the bit is turned off. After testing all the

bits, the SAR contains a 12-bit binary code which accurately

represents the input signal to within ±1/2 LSB.

The internal reference provides the voltage reference to the

CDAC with excellent stability over temperature and time. The

reference is trimmed to 2.5 volts and can supply at least

0.5 mA to an external load. Any external load on the SPT774

reference must remain constant during conversion.

The sample-and-hold feature is a bonus of the CDAC architecture. Therefore the majority of the S/H specifications are

included within the A/D specifications.

Although the sample-and-hold circuit is not implemented in

the classical sense, the sampling nature of the capacitive

DAC makes the SPT774 appear to have a built-in sampleand-hold. This sample-and-hold action substantially increases the signal bandwidth of the SPT774 over that of

similar competing devices.

Note that even though the user may use an external sampleand-hold for very high frequency inputs, the internal sampleand-hold still provides a very useful isolation function. Once

the internal sample is taken by the CDAC capacitance, the

input of the SPT774 is disconnected from the user’s sampleand-hold. This prevents transients occurring during conversion from affecting the attached sample-and-hold buffer. All

TYPICAL INTERFACE CIRCUIT

The SPT774 is a complete A/D converter that is fully operational when powered up and issued a Start Convert Signal.

Only a few external components are necessary as shown in

figures 5 and 6. The two typical interface circuits are for

operating the SPT774 in either an unipolar or bipolar input

mode. Information on these connections and on conditions

concerning board layout to achieve the best operation are

discussed below.

For each application of this device, strict attention must be

given to power supply decoupling, board layout (to reduce

pickup between analog and digital sections), and grounding.

Digital timing, calibration and the analog signal source must

be considered for correct operation.

POWER SUPPLIES

The supply voltage for the SPT774 must be kept as quiet as

possible from noise pickup and also regulated from transients

or drops. Because the part has 12-bit accuracy, voltage

spikes on the supply lines can cause several LSB deviations

on the output. Switching power supply noise can be a

problem. Careful filtering and shielding should be employed

to prevent the noise from being picked up by the converter.

VDD should be bypassed with a 10 µF tantalum capacitor

located close to the converter to filter noise and counter the

problems caused by the variations in supply current. VEE is

only used as a logic input and is immune to typical supply

variation.

GROUNDING CONSIDERATIONS

Resistance of any path between the analog and digital

grounds should be as low as possible to accommodate the

ground currents present with this device.

To achieve specified accuracy, a double-sided printed circuit

board with a copper ground plane on the component side is

recommended. Keep analog signal traces away from digital

lines. It is best to lay the PC board out such that there is an

analog section and a digital section with a single point ground

connection between the two through an RF bead located as

close to the device as possible. If possible, run analog signals

between ground traces and cross digital lines at right angles

only.

SPT

SPT774

6 8/1/00

Page 7

The analog and digital common pins should be tied together

as close to the package as possible to guarantee best

performance. The code dependent currents flow through the

VDD terminal and not through the analog and digital common

pins.

RANGE CONSIDERATIONS

The SPT774 may be operated by a microprocessor or in the

stand-alone mode. The part has four standard input ranges:

0 V to +10 V, 0 V to +20 V, ±5 V and ±10 V. The maximum

errors that are listed in the specifications for gain and offset

may be adjusted externally to zero as explained in the next

two sections.

CALIBRATION & CONNECTION PROCEDURES

UNIPOLAR

The calibration procedure consists of adjusting the

converter’s most negative output to its ideal value for offset

adjustment and then adjusting the most positive output to its

ideal value for gain adjustment.

Starting with offset adjustment and referring to figure 5, the

midpoint of the first LSB increment should be positioned at

the origin to get an output code of all 0s. To do this, an input

of +1/2 LSB or +1.22 mV for the 10 V range and +2.44 mV for

the 20 V range should be applied to the SPT774. Adjust the

offset potentiometer R1 for code transition flickers between

0000 0000 0000 and 0000 0000 0001.

The gain adjustment should be done at positive full scale. The

ideal input corresponding to the last code change is applied.

This is 1 and 1/2 LSB below the nominal full scale which is

+9.9963 V for the 10 V range and +19.9927 V for the 20 V

range. Adjust the gain potentiometer R2 for flicker between

codes 1111 1111 1110 and 1111 1111 1111. If calibration is

not necessary for the intended application, replace R2 with a

50 Ω, 1% metal film resistor and remove the network from the

BIP OFF pin. Connect the BIP OFF pin to AGND. Connect the

analog input to the 10 V IN pin for the 0 to 10 V range or to the

20 V IN pin for the 0 to 20 V range.

BIPOLAR

The gain and offset errors listed in the specification may be

adjusted to zero using the potentiometers R1 and R2. (See

figure 6.) If adjustment is not needed, either or both pots may

be replaced by a 50 Ω, 1% metal film resistor.

To calibrate, connect the analog input signal to the 10 V IN pin

for a ±5 V range or to the 20 V IN pin for a ±10 V range. First

apply a DC input voltage 1/2 LSB above negative full scale

which is -4.9988 V for the ±5 V range or -9.9976 V for the ±10

V range. Adjust the offset potentiometer R1 for flicker between output codes 0000 0000 0000 and 0000 0000 0001.

Next, apply a DC input voltage 1 and 1/2 LSB below positive

full scale which is +4.9963 V for the ±5 V range or +9.9927 V

for the ±10 V range. Adjust the gain potentiometer R2 for

flicker between codes 1111 1111 1110 and 1111 1111 1111.

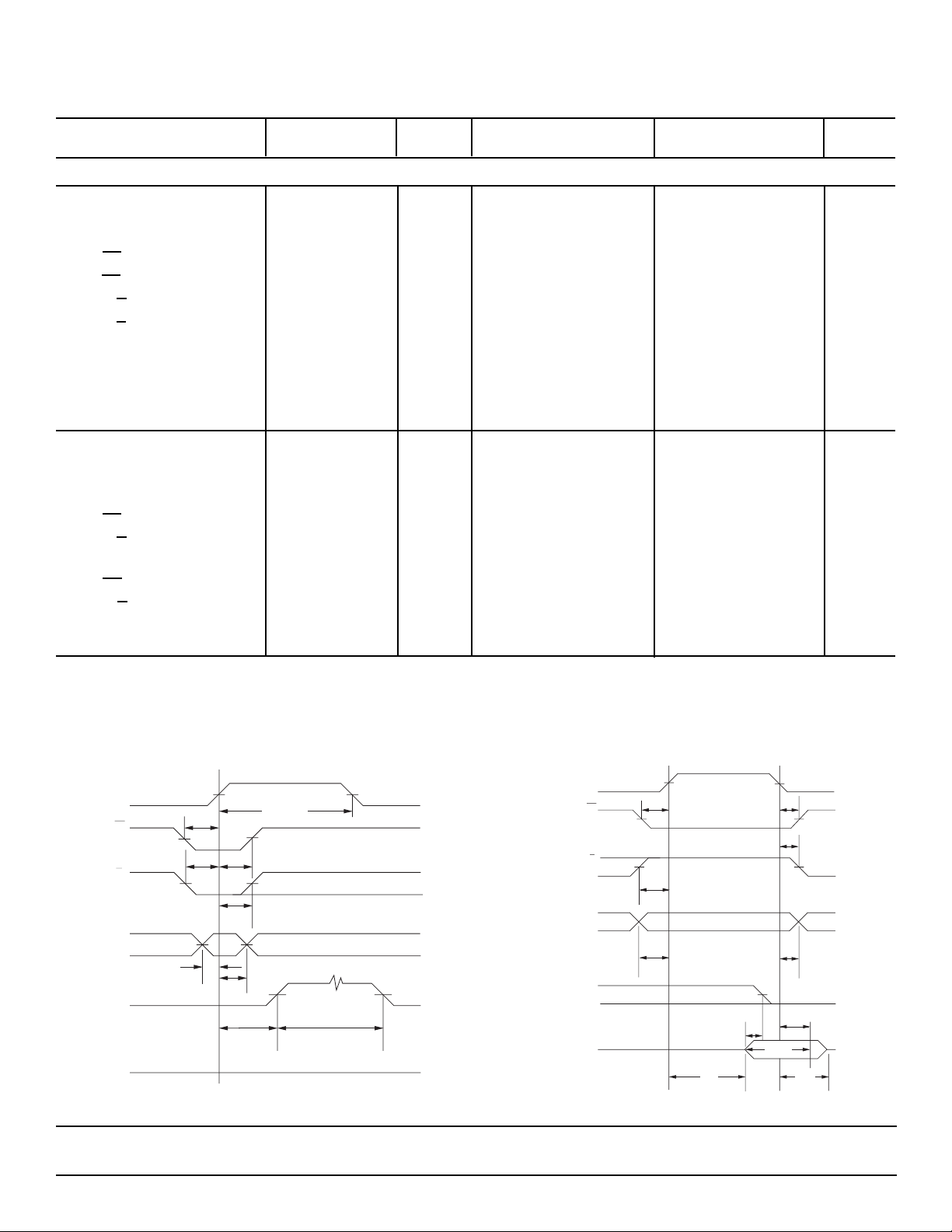

Figure 5 - Unipolar Input Connections

Output Bits

R/C

R1

100 kΩ

-15 V +15 V

0 to 10 V

Analog

100 kΩ

Inputs

0 to 20 V

100 Ω

R2

100 Ω

(Calibration)

V

12/8

10 V In

20 V In

BIP Off

Ref

V

CS

Ao

CE

Out

In

Ref

Control

Oscillator

Logic

Sample/Hold

MSB

Ref

Amp

V

EE

Nibble A Nibble B

Three-State Buffers And Control

12-Bits

12-Bit SAR

12-Bits

CDAC

Ref

Offset/Gain

Trim Network

Strobe

LSB

Nibble C

Comp

STS

V

DD

DGND

.1 µF

Figure 6 - Bipolar Input Connections

R/C

CS

Ao

12/8

CE

+5 V

Analog

Inputs

±5 V

±10 V

100 Ω

100 Ω

10 V In

20 V In

BIP Off

R1

V

Out

Ref

R1

V

Ref

Control

Logic

Oscillator

Sample/Hold

MSB

Ref

Amp

In

V

EE

Output Bits

Nibble A Nibble B

Three-State Buffers And Control

12-Bits

12-Bit SAR

CDAC

Strobe

LSB

Offset/Gain

Trim Network

12-Bits

Ref

Nibble C

Comp

STS

V

DD

.1 µF

DGND

+5 V

SPT

SPT774

7 8/1/00

Page 8

ALTERNATIVE

In some applications, a full scale of 10.24 V (for an LSB of

2.5 mV) or 20.48 V (for an LSB of 5.0 mV) is more convenient.

In the unipolar mode of operation, replace R2 with a 200 Ω

potentiometer and add 150 Ω in series with the 10 V IN pin for

10.24 V input range or 500 Ω in series with the 20 V IN pin for

20.48 V input range. In bipolar mode of operation, replace R1

with a 500 Ω potentiometer (in addition to the previous

changes). The calibration will remain similar to the standard

calibration procedure.

CONTROLLING THE SPT774

The SPT774 can be operated by most microprocessor systems due to the control input pins and on-chip logic. It may

also be operated in the stand-alone mode and enabled by the

R/C input pin. Full µP control consists of selecting an 8 or

12-bit conversion cycle, initiating the conversion, and reading

the output data when ready. The output read has the options

of choosing either 12-bits at once or 8 bits followed by

4-bits in a left-justified format. All five control inputs are TTL/

CMOS compatible and include 12/8, CS, Ao, R/C and CE.

The use of these inputs in controlling the converter’s operations is shown in table I, and the internal control logic is shown

in a simplified schematic in figure 10.

STAND-ALONE OPERATION

The simplest interface is a control line connected to R/C. The

output controls must be tied to known states as follows: CE

and 12/8 are wired high, Ao and CS are wired low. The output

data arrives in words of 12-bits each. The limits on R/C duty

cycle are shown in figures 3 and 4. It may have a duty cycle

within and including the extremes shown in the specifica-

tions. In general, data may be read when R/C is high unless

STS is also high, indicating a conversion is in progress.

Table I - Truth Table for the SPT774 Control Inputs

CE Ao

CS R/C 12/8

0XXXXNone

X 1 X X X None

0 0 X 0 Initiate 12 bit conversion

0 0 X 1 Initiate 8 bit conversion

1 0 X 0 Initiate 12 bit conversion

1 0 X 1 Initiate 8 bit conversion

1 0 X 0 Initiate 12 bit conversion

1 0 X 1 Initiate 8 bit conversion

10 1X1 Enable 12 bit Output

10 001 Enable 8 MSB's Only

10 011 Enable 4 LSB's Plus 4

Operation

Trailing Zeroes

Figure 7 - Interfacing the SPT774 to an 8-Bit Data Bus

Address Bus

Ao

~

STS

12/8

Ao

MSB

LSB

DIG

COM

Data

Bus

CONTROLLED OPERATION

CONVERSION LENGTH

A conversion start transition latches the state of Ao as shown

in figure 7 and table I. The latched state determines if the

conversion stops with 8 bits (Ao high) or continues for 12 bits

(Ao low). If all 12 bits are read following an 8-bit conversion, the

three LSBs will be a logic 0 and DB3 will be a logic 1. Ao is latched

because it is also involved in enabling the output buffers as

will be explained later. No other control inputs are latched.

CONVERSION START

A conversion may be initiated by a logic transition on any of

the three inputs: CE, CS, R/C, as shown in table I. The last

of the three to reach the correct state starts the conversions,

so one, two or all three may be dynamically controlled. The

nominal delay from each is the same and all three may

change state simultaneously. In order to assure that a particular input controls the start of conversion, the other two

should be set up at least 50 ns earlier. Refer to the convert

mode timing specifications. The Convert Start timing diagram

is illustrated in figure 1.

The output signal STS is the status flag and goes high only

when a conversion is in progress. While STS is high, the

output buffers remain in a high impedance state so that data

can not be read. Also, when STS is high, an additional Start

Convert will not reset the converter or reinitiate a conversion.

Note, if Ao changes state after a conversion begins, an

additional Start Convert command will latch the new start of

Ao and possibly cause a wrong cycle length for that conversion (8 versus 12 bits).

SPT

SPT774

8 8/1/00

Page 9

READING THE OUTPUT DATA

SAMPLE-AND-HOLD (S/H) CONTROL MODE

The output data buffers remain in a high impedance state until

the following four conditions are met: R/C is high, STS is low,

CE is high, and CS is low. The data lines become active in

response to the four conditions and output data according to

the conditions of 12/8 and Ao. The timing diagram for this

process is shown in figure 2. When 12/8 is high, all 12 data

outputs become active simultaneously and the Ao input is

ignored. This is for easy interface to a 12 or 16-bit data bus.

The 12/8 input is usually tied high or low, although it is

TTL/CMOS compatible. When 12/8 is low, the output is

separated into two 8-bit bytes as shown below.

Figure 8 - Output When 12/8 Is Low

BYTE 1

X X X XX X X X

MSB

This configuration makes it easy to connect to an 8-bit data

bus as shown in figure 7. The Ao control can be connected to

the least significant bit of the address bus in order to store the

output data into two consecutive memory locations. When Ao

is pulled low, the 8 MSBs are enabled only. When Ao is high,

the 4 MSBs are disabled, bits 4 through 7 are forced to a zero

and the four LSBs are enabled. The two byte format is left

justified data as shown above and can be considered to have

a decimal point or binary to the left of byte 1.

Ao may be toggled without damage to the converter at any

time. Break-before-make action is guaranteed between the

two data bytes. This assures that the outputs in figure 7 will

never be enabled at the same time.

In figure 2, it can be seen that a read operation usually begins

after the conversion is completed and STS is low. If earlier

access is needed, the read can begin no later than the

addition of time tDD and tHS before STS goes low.

BYTE 2

O O O OX X X X

LSB

This control mode is provided to allow full use of the internal

S/H, eliminating the need for an external S/H in most applications. The SPT774 in the control mode also eliminates the

need for one of the control signals, usually the convert

command. The command that puts the internal S/H in the

hold state also initiates a conversion, reducing time constraints in many systems. As soon as the conversion is

completed the internal S/H immediately begins slewing to

track the input signal. See figure 9.

In the control mode it is assumed that during the required 1.4

µs acquisition time the signal is not slewing faster than the

slew rate of the SPT774. No assumption is made about the

input level after the convert command arrives since the input

signal is sampled and conversion begins immediately after

the convert command. This means that the convert command can be used to switch an input multiplexer or change

gains on a programmable gain amplifier, allowing the input

signal to settle before the next acquisition at the end of the

conversion. Because aperture jitter is minimized by the

internal S/H, a high input frequency can be converted without

an external S/H. See table II.

Table II - Conversion Timing (VEE = +5 V)

S/H Control Mode

Parameter Min Typ Max Units

Throughput Time (tAQ+tC)

12-Bit Conversions 8 8.5 µs

8-Bit Conversions 6 6.3 µs

Conversion Time (tC)

12-Bit Conversions 6.4 µs

8-Bit Conversions 4.4 µs

Acquisition Time(tAC) 1.4 µs

Aperture Delay (tAP)20ns

Aperture Uncertainty (tJ) 0.3 ns

Figure 9 - S/H Control Mode Timing (VEE = +5 V)

R/C

t

AP

Signal Acquisition Conversion Signal Acquisition

t

AQ

SPT

t

C

SPT774

9 8/1/00

Page 10

Figure 10 - Control Logic

Input Buffers

12/8

Nibble B Zero

Override

Nibble A,B

Nibble C

CS

R/C

CE

Read Control

A

D

H

Q

CK

R

EOC8

CK

D

Q

AO Latch

Q

EOC12

Delay

STS

PACKAGE OUTLINES

28-Lead PDIP

28

1

A

B

C

SPT

J

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.250 6.35

B 0.115 0.200 2.92 5.08

C 0.014 0.022 0.36 0.56

K

D 0.100 2.54

E 0.030 0.070 0.76 1.78

F 0.008 0.015 0.20 0.38

G 0.125 0.195 3.18 4.95

I

H 0.600 0.625 15.24 15.88

I 0.485 0.580 12.32 14.73

J 1.380 1.565 35.05 39.75

K 0.005 0.040 0.13 1.02

H

G

F

D

E

SPT774

10 8/1/00

Page 11

PACKAGE OUTLINES

28-Lead Sidebrazed

28

1

G

A

E

B

C

D

H

SYMBOL MIN MAX MIN MAX

I

J

F

INCHES MILLIMETERS

A 0.077 0.093 1.96 2.36

B 0.016 0.020 0.41 0.51

C 0.095 0.105 2.41 2.67

D .050 typ 1.27 typ

E 0.040 0.060 1.02 1.52

F 0.215 0.235 5.46 5.97

G 1.388 1.412 35.26 35.86

H 0.585 0.605 14.86 15.37

I 0.009 0.012 0.23 0.30

J 0.600 0.620 15.24 15.75

28-Lead SOIC

B

28

1

CD

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.696 0.712 17.68 18.08

B 0.004 0.012 0.10 0.30

C .050 typ 1.27 typ

I H

A

F

E

H

D 0.014 0.019 0.36 0.48

E 0.009 0.012 0.23 0.30

F 0.080 0.104 2.03 2.64

G 0.016 0.050 0.41 1.27

H 0.394 0.419 10.01 10.64

I 0.291 0.299 7.39 7.59

G

SPT

SPT774

11 8/1/00

Page 12

PIN ASSIGNMENTS PIN FUNCTIONS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

V

DD

12/8

CS

Ao

R/C

CE

N/C

REF OUT

AGND

REF IN

V

EE

BIP OFF

10 V IN

20 V IN

28-LEAD DIP/SOIC

STS

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

DGND

28

27

26

25

24

23

22

21

20

19

18

17

16

15

V

DD

12/

8

CS

Ao Byte Address/Short Cycle

R/

C

CE Chip Enable

V

EE

REF OUT Reference Output, Nominally +2.5 V

AGND Analog Ground

REF IN Reference Input

N/C Pin Not Connected to Device

BIP OFF Bipolar Offset

10 V IN 10 Volt Analog Input

Logic Supply Voltage, Nominally +5 V

Data Mode Selection

Chip Selection

Read/Convert

Mode Control Voltage, Nominally +5 V

20 V IN 20 Volt Analog Input

DGND Digital Ground

NAME FUNCTION

DB0 - DB11 Digital Data Output

DB11 - MSB DB0 - LSB

STS Status

ORDERING INFORMATION

LINEARITY ERROR PACKAGE

PART NUMBER TEMPERATURE RANGE MAX TYPE

SPT774BCN 0 to +70 °C ±1/2 LSB 28L Plastic DIP

SPT774BCJ 0 to +70 °C ±1/2 LSB 28L Sidebrazed DIP

SPT774BCS 0 to +70 °C ±1/2 LSB 28L SOIC

SPT774CCN 0 to +70 °C ±1 LSB 28L Plastic DIP

SPT774CCJ 0 to +70 °C ±1 LSB 28L Sidebrazed DIP

SPT774CCS 0 to +70 °C ±1 LSB 28L SOIC

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby expressly

granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING - LIFE SUPPORT APPLICATIONS POLICY - SPT products should not be used within Life Support Systems without the specific

written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can be reasonably

expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

SPT774

SPT

12 8/1/00

Loading...

Loading...