Page 1

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: 719-528-2300 Fax: 719-528-2370 Web Site: http://www .spt.com e-mail: sales@spt.com

SPT7610

6-BIT, 1 GSPS FLASH A/D CONVERTER

FEATURES

• 1:2 demuxed ECL-compatible outputs

• 1.0 GSPS conversion rate

• Wide input bandwidth: 1.4 GHz

• Low input capacitance: 8 pF

• Metastable errors reduced to 1 LSB

• Monolithic construction

• Binary/Two’s complement output

APPLICATIONS

• Radar, EW, ECM

• Direct RF down-conversion

• Microwave modems

• Industrial ultrasound

• Transient capture

• Test and measurement

GENERAL DESCRIPTION

The SPT7610 is a full parallel (flash) analog-to-digital converter capable of digitizing full-scale (0 to –1 V) inputs into

six-bit digital words at an update rate of 1 GSPS. The

ECL-compatible outputs are demultiplexed into two separate output banks, each with differential data-ready outputs to ease the task of data capture. The SPT7610’ s wide

input bandwidth and low capacitance eliminate the need

for external track-and-hold amplifiers for most applications. A proprietary decoding scheme reduces metastable

errors to the 1 LSB level. The SPT7610 operates from a

single –5.2 V supply, with a nominal power dissipation of

2.75 W .

The SPT7610 is available in a 44L hermetic cerquad

surface-mount package in the industrial temperature

range (–40 °C to +85 °C).

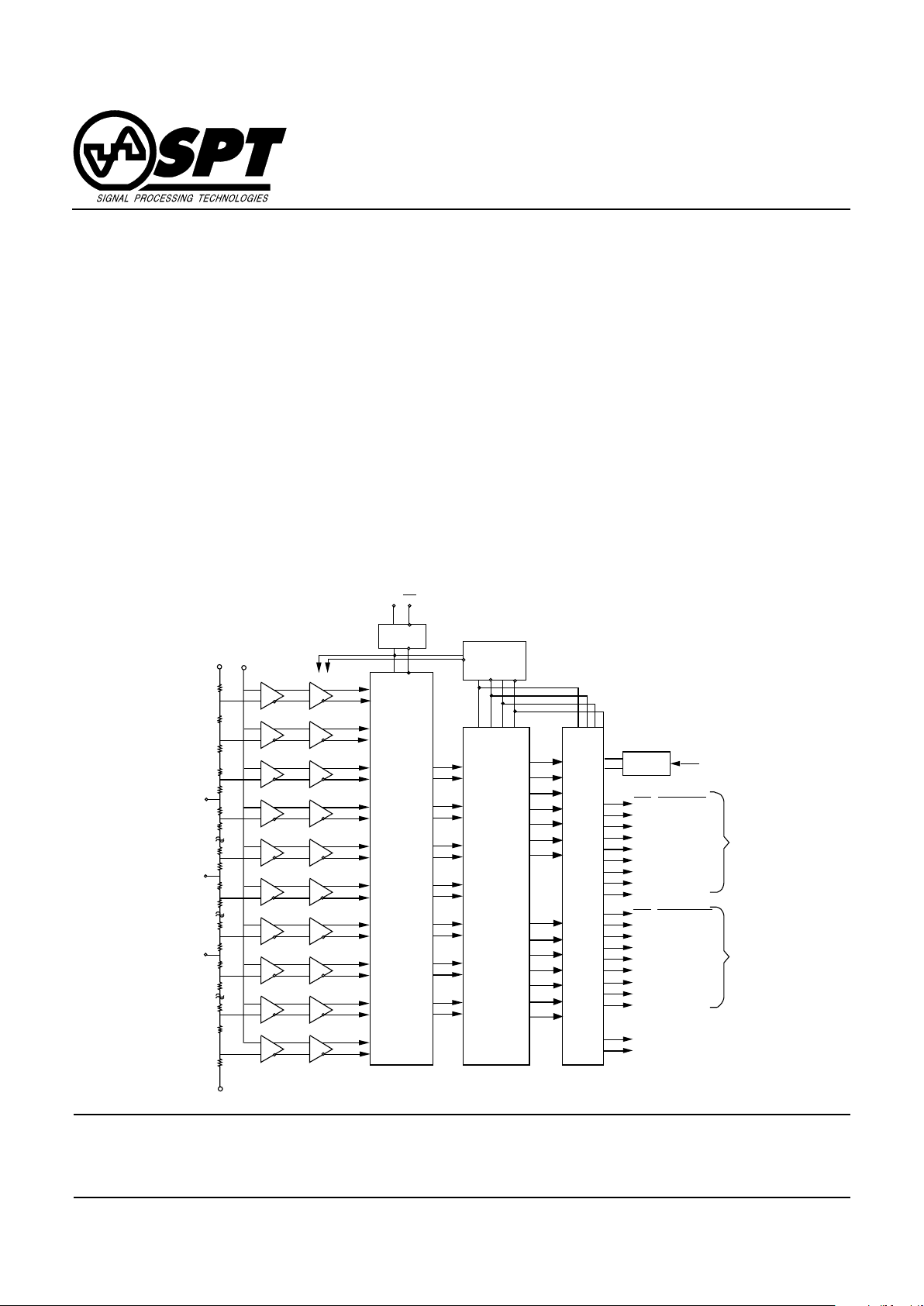

64

63

49

48

33

32

17

16

2

1

CLOCK

BUFFER

64 TO 6 BIT DECODER

WITH METASTABLE ERROR CORRECTION

DO

(LSB)

D1

D2

D3

D4

D5

(MSB)

D6

(OVR)

V

RT

Analog

Input

Preamp Comparator

V

RM

V

RB

CLKCLK

DEMUX

CLOCK

BUFFER

1:2 DEMULTIPLEXER

ECL OUTPUT BUFFERS AND LATCHES

DRB (DATA READY)

DRB (DATA READY)

D6B (OVR)

D5B (MSB)

D4B

D3B

D2B

D1B

D0B (LSB)

DRA (DATA READY)

DRA (DATA READY)

D6A (OVR)

D5A (MSB)

D4A

D3A

D2A

D1A

D0A (LSB)

D6B

D5B

D4B

D3B

D2B

D1B

D0B

D6A

D5A

D4A

D3A

D2A

D1A

D0A

BANK B

BANK A

V

R1

V

R3

MINV

LINV

TESTABILITY

TEST

BLOCK DIAGRAM

Page 2

SPT

2 1/30/01

SPT7610

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)1 25 °C

Supply Voltages

Negative Supply Voltage (AVEE TO GND) .–7.0 to +0.5 V

Ground V oltage Differential........................–0.5 to +0.5 V

Input Voltage

Analog Input Voltage ................................+0.5 V to AV

EE

Reference Input Voltage ...........................+0.5 V to AV

EE

Digital Input Voltage.................................. +0.5 V to AV

EE

Reference Current VRT to VRB............................+20 mA

Note: 1. Operation at any Absolute Maximum Rating is not implied. See

Electrical Specifications for proper nominal applied conditions

in typical applications.

Output

Digital Output Current...................................0 to –25 mA

Temperature

Operating Temperature, Ambient............... –40 to +85 °C

Lead Temperature, (soldering 10 seconds) ........ +300 °C

Storage Temperature ............................... –65 to +150 °C

ELECTRICAL SPECIFICATIONS

TA = T

MIN

to T

MAX

, AV

EE

= –5.2 V , V

RB

= –1.00 V , V

RM

= –0.5 V , V

RT

= 0.00 V, ƒ

CLK

= 1000 MSPS, Duty Cycle = 50%, unless otherwise specified.

TEST TEST SPT7610

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Resolution 6 Bits

DC Accuracy

Integral Linearity VI –0.5 +0.5 LSB

Differential Linearity VI –0.5 +0.5 LSB

No missing codes VI Guaranteed

Analog Input

Offset Error V

RT

VI –30 +30 mV

Offset Error V

RB

VI –30 +30 mV

Input Voltage Range VI –1 0.0 Volts

Input Capacitance Over Full Input Range V 8 pF

Input Resistance V 50 kΩ

Input Bias Current VI 200 400 µA

Bandwidth Small Signal V 1.4 GHz

Input Slew Rate V 5 V/ns

Clock Synchronous Input Currents V 2 µA

Power Supply Requirements

Supply Current VI 550 770 mA

Power Dissipation VI 2.85 4.0 W

Reference Inputs

Ladder Resistance VI 60 80 120 Ω

Reference Bandwidth V 100 MHz

Digital Outputs

Digital Output High Voltage R

1

= 50 Ω to –2 V VI –1.2 –0.9 Volts

Digital Output Low Voltage R1 = 50 Ω to –2 V VI –1.8 –1.5 Volts

Digital Inputs

Digital Input High Voltage

(CLK, NCLK) VI –1.1 –0.7 Volts

Digital Input Low Voltage

(CLK, NCLK) VI –2.0 –1.5 Volts

Clock Input Swing

(CLK, NCLK) IV 100 700 mV

Maximum Sample Rate VI 1000 1200 MSPS

Clock Low Width, TPW0 VI 0.5 0.4 ns

Clock High Width, TPW1 VI 0.5 0.4 ns

Page 3

SPT

3 1/30/01

SPT7610

ELECTRICAL SPECIFICATIONS

TA = T

MIN

to T

MAX

, AV

EE

= –5.2 V , V

RB

= –1.00 V , V

RM

= –0.5 V , V

RT

= 0.00 V, ƒ

CLK

= 1000 MSPS, Duty Cycle = 50%, unless otherwise specified.

TEST TEST SPT7610

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Timing Characteristics

Clock to Data Ready delay (t

dr

) +25 °C case V 950 ps

Clock to Output Data (t

od

) +25 °C case V 1.25 ns

Output Data to Data Ready (t

odr

) –40 to 85 °C case IV 550 750 950 ps

Output Data Skew (t

osk

) –40 to 85 °C case IV –150 150 ps

Aperture Jitter V 2 ps

Acquisition Time V 250 ps

Dynamic Performance

Spurious Free Dynamic Range (SFDR)

ƒ

IN

= 250 MHz V 45 dB

ƒ

IN

= 400 MHz V 34 dB

Signal-to-Noise and Distortion (SINAD)

ƒ

IN

= 250 MHz VI 31 34 dB

ƒ

IN

= 400 MHz VI 28 32 dB

Signal to Noise Ratio (SNR)

ƒ

IN

= 250 MHz VI 33 36 dB

ƒ

IN

= 400 MHz VI 32 36 dB

Total Harmonic Distortion (THD)

ƒ

IN

= 250 MHz VI –40 –37 dB

ƒ

IN

= 400 MHz VI –34 –30 dB

TEST LEVEL CODES

All electrical characteristics are subject to the

following conditions:

All parameters having min/max specifications

are guaranteed. The Test Level column indicates the specific device testing actually performed during production and Quality Assurance inspection. Any b lank section in the data

column indicates that the specification is not

tested at the specified condition.

Unless otherwise noted, all test are pulsed

tests; therefore, T

J

= TC = TA.

LEVEL TEST PROCEDURE

I 100% production tested at the specified temperature.

II 100% production tested at TA = +25 °C, and sample tested at the

specified temperatures.

III QA sample tested only at the specified temperatures.

IV Parameter is guaranteed (but not tested) by design and characteri-

zation data.

V Parameter is a typical value for information pur poses only.

VI 100% production tested at TA = +25 °C. Parameter is guaranteed

over specified temperature range.

Page 4

SPT

4 1/30/01

SPT7610

GENERAL OVER VIEW

The SPT7610 is an ultra high-speed monolithic 6-bit

parallel flash A/D converter. The nominal conversion rate

is 1 GSPS, and the analog bandwidth is typically 1.4 GHz.

A major advance over previous flash converters is the

inclusion of 64 input preamplifiers between the reference

ladder and input comparators. (See the block diagram.)

This not only reduces clock transient kickback to the input

and reference ladder due to a low AC beta but also

reduces the effect of the dynamic state of the input signal

on the latching characteristics of the input comparators.

The preamplifiers act as buffers and stabilize the input

capacitance so that it remains constant over different

input voltage and frequency ranges. This makes the part

easier to drive than previous flash converters. The preamplifiers also add a gain of two to the input signal so that

each comparator has a wider overdrive or threshold range

to “trip” into or out of the active state. This gain reduces

metastable states that can cause errors at the output.

The SPT7610 has true differential analog and digital data

paths from the preamplifiers to the output buffers (Current

Mode Logic) for reducing potential missing codes while

rejecting common mode noise. Signature errors are also

reduced by careful layout of the analog circuitry. The output drive capability of the device can provide full ECL

swings into 50 Ω loads.

Only one –5.2 V power supply is required. Two external

references are applied across the internal reference ladder that has a resistance of 80 Ω typical (60 Ω minimum).

The top reference is typically 0 V or connected to AGND

(analog ground). The device has top force and sense pins

(V

RFT

and V

RST

) that are internally connected together.

These voltage force and sense pins can be used to minimize the voltage drop across the parasitic line resistance.

The bottom reference is typically –1 V . The device also has

bottom force and sense pins (V

RFB

and V

RSB

) that are

internally connected together. These can also be used to

minimize the voltage drop across the parasitic line resistance. Three additional reference taps (V

R3

= –0.25 V typ,

VRM = –0.5 V typ, and VR1 = –0.75 V typ) are brought out.

These taps can be used to control the linearity error.

All logic levels are compatib le with both 10K ECL or 100K

ECL. It is recommended that the clock input be driven

differentially (CLK and NCLK) to improve noise immunity

and reduce aperture jitter.

The digital outputs are split into two banks of 6-bit words

and an overrange bit. Each bank is updated at 1/2 of the

clock rate and is 180° out of phase from the other . The differential data ready signals for each bank are provided to

accurately latch each data bank into the register. The output data is in a straight binary, inverted binary, two’s

complement or inverted two’s complement format. Figure

1 shows a timing diagram of the device and shows the input-to-output relationship, clock-to-output delay and output latency. The SPT7610 has a built-in offset in the ÷2

clock divider (D Flip-Flop) to assure that output bank A will

come up first after power turn on.

Page 5

SPT

5 1/30/01

SPT7610

Figure 1 – Timing Diagram

CLK (1 GHz)

DRA

DRA

Data Bank A

DRB

DRB

Data Bank B

V

IN

N

N+1

N+2

N+3

N+4

1 nsec

t

odB

t

drB

OutputA Skew

(t

oskA

)

DOB-DRB Delay

(t

odrB

)

t

drA

N-4 N

N-2

t

odA

N-1N-3

N-5

OutputB Skew

(t

oskB

)

DOADRA Delay

(t

odrA

)

2

FIRST

RISING EDGE

POWER

ON

8

OUTPUT

BANK A

(DA0-6)

OUTPUT

BANK B

(DB0-6)

DRA

CLK IN

DRB

V

IN

NDRA

NDRB

TEST

3

5

4

2

1

6

INVALID DATA

1

ADC (Normal Operation)

9

10

11

8

TEST MODE

7

t

su

t

dr

t

od

t

dr

t

od

ADC (Normal Operation)

INVALID DATA

INVALID DATA

INVALID DATA

7

9

Bank A Test Pattern 1:

- Even Bits = Hi

- Odd Bits = Low

Bank B Test Pattern 1:

- Even Bits = Hi

- Odd Bits = Low

Bank A Test Pattern 2:

- Even Bits = Low

- Odd Bits = Hi

Bank B Test Pattern 2:

- Even Bits = Low

- Odd Bits = Hi

LOGIC LOW

Figure 2 – Test Mode Timing Diagram

Page 6

SPT

6 1/30/01

SPT7610

TYPICAL INTERFACE CIRCUIT

The typical interface circuit is shown in figure 3. External

reference taps are provided for correcting integral

nonlinearity errors. These taps can be actively driven to

reduce these errors. (See the Reference Inputs discussion below.) The SPT7610 evaluation board application

note contains more details on interfacing the SPT7610.

The function of each pin and external connections to other

components is as follows:

POWER SUPPLY PINS: AVEE, AGND, DGND

AVEE is the supply pin with AGND as ground for the device. The AVEE power supply pin should be bypassed as

close to the device as possible with a 10 µF tantalum capacitor, in parallel with 100 pF and .01 µF chip capacitors.

Place the 100 pF chip capacitor closest to the SPT7610.

Digital ground (DGND) is the ground for the ECL outputs

and is to be referenced to the output pulldown voltage and

appropriately bypassed as shown in figure 3.

ANALOG INPUT: V

IN

There are two analog input pins that are tied to the same

point internally . Either one may be used as an analog input

sense and the other for input force. This is convenient for

testing the source signal to see if there is sufficient drive

capability . The pins can also be tied together and driven by

the same source. The SPT7610 is superior to similar devices due to a preamplifier stage before the comparators.

This makes the device easier to drive because it has constant capacitance and induces less slew rate distortion.

CLOCK INPUTS: CLK, NCLK

The clock inputs are designed to be driven differentially

with ECL levels. The duty cycle of the clock should be kept

at 50% to avoid causing larger second harmonics. If this is

not important to the intended application, then duty cycles

other than 50% may be used.

Figure 3 – Typical Interface Circuit

V

IN

V

IN

V

RTF

V

RTS

*

U1

+

*

U1

+

5.2 V

2N2907

V

RBS

V

RBF

50 W

V

IN

2.0 V

Reference

Convert

2 V

Pulldown

(Analog)

CLK

NCLK

V

RM

R

R

5.2 V

AV

EE

AGND

DGND

*

FB = Ferrite bead

U1 = TLV2464 or equivalent with low offset/noise.

R = 1 kW; 0.05% matched or better

= AGND

= DGND

U2 = Motorola ECLinPS Lite, MC10EL16, differential receiver.

* = 2.2 µF Tantalum Capacitor, 0.1 µF and 100 pF chip capacitors.

** = Care must be taken to avoid exceeding the maximum rating

for the input, especially during power up sequencing of the

analog input driver.

U2

DRB (DATA READY)

DRB (DATA READY)

DRA (DATA READY)

DRA (DATA READY)

DRB

DRA

DRB

DRA

**

FB

*

V

R3

*

V

R1

50 W

D6B (OVR)

D5B (MSB)

D4B

D3B

D2B

D1B

D0B (LSB)

2.0 V

Pulldown

(Digital)

50 W

.1 µF

D6A (OVR)

D5A (MSB)

D4A

D3A

D2A

D1A

D0A (LSB)

Test

LINV

MINV 5.2 V

5.2 V

5.2 V

SPT7610

50 W

5.2 V

22 W

22 W

50 W

Page 7

SPT

7 1/30/01

SPT7610

DIGITAL OUTPUTS: D0 TO D6, DR, NDR (A AND B)

The digital outputs can drive 50 Ω to ECL levels when

pulled down to –2 V. When pulled down to –5.2 V, the outputs can drive 130 Ω to 1 kΩ loads. SPT recommends

using differential receivers on the outputs of the data

ready lines to ensure the proper output rise and fall times.

BINARY AND TWO’S COMPLEMENT OUTPUT:

MINV, LINV

Control pins are provided that enable selection of one of

four digital output formats. (Table I shows selection of

these output formats as a function of the MINV and LINV

pins.) When the MINV pin is high, the MSB output is inverted and when it is low, the it is noninverted. Likewise,

when the LINV pin is high, the LSB output is inverted and

when it is low, the it is noninverted. The user can select

either binary, inverted binary, two’s complement or

inverted two’s complement digital output format.

REFERENCE INPUTS: V

RBF

, V

RBS

, VR1, VRM,

VR3, V

RTF

, V

RTS

There are two reference inputs and three external reference voltage taps. These are –1.0 V V

RBF

(bottom force)

and V

RBS

(bottom sense), –0.75 V VR1 (1/4 tap), –0.5 V

VRM (mid-point tap), –0.25 V VR3 (3/4 tap) and 0.0 V

(AGND) V

RTF

(top force) and V

RTS

(top sense). The top reference pin is normally tied to analog ground (AGND) and

the bottom reference pin can be driven by an op amp as

shown in figure 3.

The reference voltage taps can be used to control integr al

linearity over temperature. The mid-point reference tap

(VRM) is normally driven by an op amp to insure temperature stable operation or may be bypassed for limited temperature operation. The 1/4 (VR1) and 3/4 (VR3) reference

ladder taps are typically bypassed to add noise suppression as shown in figure 3 or may be driven with op amps to

adjust integral linearity .

SPT7610 TEST MODE FUNCTION: TEST PIN

The SPT7610 supports a special test mode function that

overrides the SPT7610’s internal data output latch stage

and exercises the digital outputs in an alternating test pattern. This enables the user to test digital interface logic

downstream from the SPT7610 with a known set of digital

test patterns.

Test mode pin 3 controls the SPT7610 mode of operation

such that when it is low, the SPT7610 operates in normal

mode. When test mode pin 3 is brought high, the

SPT7610 will begin to output test pattern 1 (table II) on the

next rising edge of the clock. (See figure 2.) It will output

the test patterns alternating between test pattern 1 and

test pattern 2 as long as test mode pin 3 is held high. The

minimum set-up time (tsu) can be as low as 0 nsec.

Only the digital output stage is involved in the test mode

operation. All ADC stages before the digital output stage

continue normal data conversion operation while the test

mode is active. When test mode pin 3 is brought bac k low,

the SPT7610 will resume output of valid data on the next

rising edge of the clock. The valid data output will correspond to a two-clock-cycle pipeline delay as shown in

figure 2.

Table II – SPT7610 Test Mode Output Bit Patterns

D6 D5 D4 D3 D2 D1 D0

Test Pattern 1 1010101

Test Pattern 2 0101010

BINARY TWOs COMPLEMENT

TRUE INVERTED TRUE INVERTED

MINV=LINV=0 MINV=LINV=1 MINV=1; LINV=0 MINV=0; LINV=1

ANALOG INPUT VOLTAGE D6 D5_______D

0

D5______D

0

D5______D

0

D5______D

0

–1 V + 1/2 LSB 0 000000 111111 1000000 0111111

0 000001 111110 1000001 0111110

–0.5 V 0 0111111 100000 111111 000000

100000 011111 000000 111111

0 V – 1/2 LSB 0 111111 000000 011111 100000

1 111111 000000 011111 100000

0 V 1 111111 000000 011111 100000

1

Tie MINV/LINV to GND for logic 1.

2

Float MINV/LINV for logic 0. (MINV/LINV are internally pulled down to –5.2 V.)

Ta b le I – Output Coding Table

Page 8

SPT

8 1/30/01

SPT7610

SUBCIRCUIT SCHEMATICS

Figure 3A – Input Circuit Figure 3B – Output Circuit Figure 3C – Clock Input

Data Out

AGND DGND

AGND

AV

EE

V

IN

V

r

AGND

AV

EE

CLK CLK

THERMAL MANAGEMENT

Adequate heat sinking and air flow must be provided to

keep the die temperature below +150 °C. This device is

packaged with the cavity up (the die is on the bottom of

the package). Therefore, SPT recommends that the

device be heat sinked by contacting the bottom of the

package through a hole in the circuit board.

The thermal coefficients of the SPT7610 (44L cerquad)

are as follows:

θja = +78 °C/W (junction to ambient in

still air with no heat sink)

θjc = +4 °C/W (junction to case)

Page 9

SPT

9 1/30/01

SPT7610

PACKAGE OUTLINE

44-Lead Cerquad

INCHESINCHES

INCHESINCHES

INCHES

MILLIMETERSMILLIMETERS

MILLIMETERSMILLIMETERS

MILLIMETERS

SYMBOLSYMBOL

SYMBOLSYMBOL

SYMBOL

MINMIN

MINMIN

MIN

MAXMAX

MAXMAX

MAX

MINMIN

MINMIN

MIN

MAXMAX

MAXMAX

MAX

A 0.551 typ 14.0 typ

B 0.685 0.709 17.40 18.00

C 0.037 0.041 0.94 1.04

D 0.016 typ 0.41 typ

E 0.008 typ 0.20 typ

F 0.027 0.051 0.69 1.30

G 0.006 typ 0.15 typ

H 0.080 0.150 2.03 3.81

C

D

A

B

A

B

05°

E

F

G

H

Page 10

SPT

10 1/30/01

SPT7610

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

SPT7610SIQ –40 to +85 °C 44L Cerquad

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby

expressly granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING – LIFE SUPPORT APPLICATIONS POLICY – SPT products should not be used within Life Support Systems without

the specific written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails,

can be reasonably expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

PIN ASSIGNMENTS PIN FUNCTIONS

Name Function

AV

EE

Negative Supply; nominally –5.2 V

AGND Analog Ground

V

RTF

Reference Voltage Force Top; nominally 0 V

V

RTS

Reference Voltage Sense Top

V

RM

Reference Voltage Middle; nominally –0.5 V

V

RBF

Reference Voltage Force Bottom; nominally –1.0 V

V

RBS

Reference Voltage Sense Bottom

V

IN

Analog Input Voltage; can be either Voltage or

Sense

DGND Digital Ground

D0–D5A Data Output Bank A

D0–D5B Data Output Bank B

DRA Data Ready Bank A

NDRA Not Data Ready Bank A

DRB Data Ready Bank B

NDRB Not Data Ready Bank B

D6A Overrange Output Bank A

D6B Overrange Output Bank B

CLK Clock Input

NCLK Clock Input

MINV MSB Control Pin

LINV LSB Control Pin

TEST Test Control Pin

V

R1

Reference Voltage 1/4, nominally –0.75 V

V

R3

Reference Voltage 3/4, nominally –0.25 V

V

RTF

AV

EE

V

R3

AGND

V

INVIN

AGND

V

RM

V

R1

AV

EE

V

RBF

DGND

D2B

D3B

D4B

D5B

D6B

DGND

DRA

NDRA

D0A

D1A

SPT7610

Top View

44

1

V

RBS

MINV

Test

AGND

AV

EE

D6A

D5A

D4A

D3A

DGND

D2A

V

RTS

AGND

CLK

NCLK

AGND

LINV

AV

EE

DRB

NDRB

D0B

D1B

43

42

41

40

39

383736

35

34

33

32

31

30

29

28

27

26

25

24

23

12 13 14 15 161718 19 20 21 22

2

3

4

5

6

7

8

9

10

11

Loading...

Loading...