Page 1

Typical Distortion Performance

Output 20MHz 50MHz 100MHz

Power 2nd 3rd 2nd 3rd 2nd 3rd

10dBm -59 -62 -52 -60 -35 -49

18dBm -52 -48 -45 -46 -30 -36

24dBm -50 -41 -36 -32 -40 -30

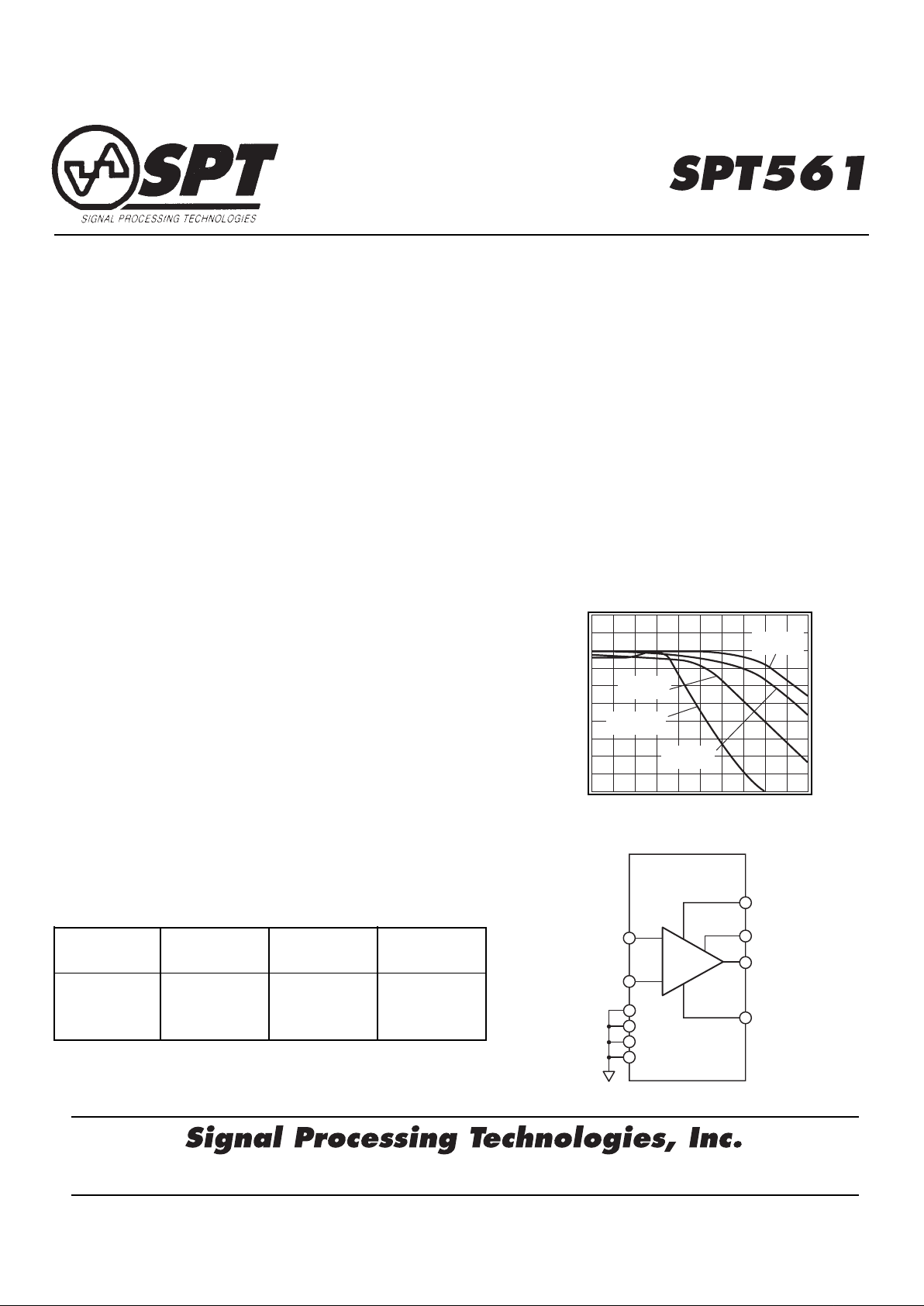

Frequency Response vs. Output Power

Gain (dB)

Frequency (MHz)

16

12

6

0 40 80 120 160 200

10

8

14

Po = 10dBm

V

o

= 2V

pp

Po = 24dBm

V

o

= 10V

pp

Po = 27.5dBm

V

o

= 15V

pp

Po = 18dBm

V

o

= 5V

pp

Features

■

150MHz bandwidth at +24dBm output

■

Low distortion (2nd/3rd:

-59/-62dBc @ 20MHz and 10dBm)

■

Output short circuit protection

■

User-definable output impedance, gain,

and compensation

■

Internal current limiting

■

Direct replacement for CLC561

Applications

■

Output amplification

■

Arbitrary waveform generation

■

ATE systems

■

Cable/line driving

■

Function generators

■

SAW drivers

■

Flash A/D driving and testing

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370 Website: http://www.spt.com E-Mail: sales@spt.com

WIDEBAND, LOW DISTORTION DRIVER AMPLIFIER

General Description

The SPT561 is a wideband DC coupled, amplifier that combines high

output drive and low distortion. At an output of +24dBm (10Vpp into

50Ω), the -3dB bandwidth is 150MHz. As illustrated in the table

below, distortion performance remains excellent even when amplifying high-frequency signals to high output power levels.

With the output current internally limited to 250mA, the SPT561 is

fully protected against shorts to ground and can, with the addition of a

series limiting resistor at the output, withstand shorts to the ±15V

supplies.

The SPT561 has been designed for maximum flexibility in a wide

variety of demanding applications. The two resistors comprising the

feedback network set both the gain and the output impedance,

without requiring the series backmatch resistor needed by most op

amps. This allows driving into a matched load without dropping half

the voltage swing through a series matching resistor. External

compensation allows user adjustment of the frequency response.

The SPT561 is specified for both maximally flat frequency response

and 0% pulse overshoot compensations.

The combination of wide bandwidth, high output power, and low

distortion, coupled with gain, output impedance and frequency

response flexibility, makes the SPT561 ideal for waveform generator

applications. Excellent stability driving capacitive loads yields superior performance driving ADC’s, long transmission lines, and SAW

devices.

The SPT561 is constructed using thin film resistor/bipolar transistor

technology, and is available in the following versions:

SPT561AIJ -25°C to +85°C 24-pin Ceramic DIP

SPT561AMJ -55°C to +125°C 24-pin Ceramic DIP, features

burn-in and hermetic testing

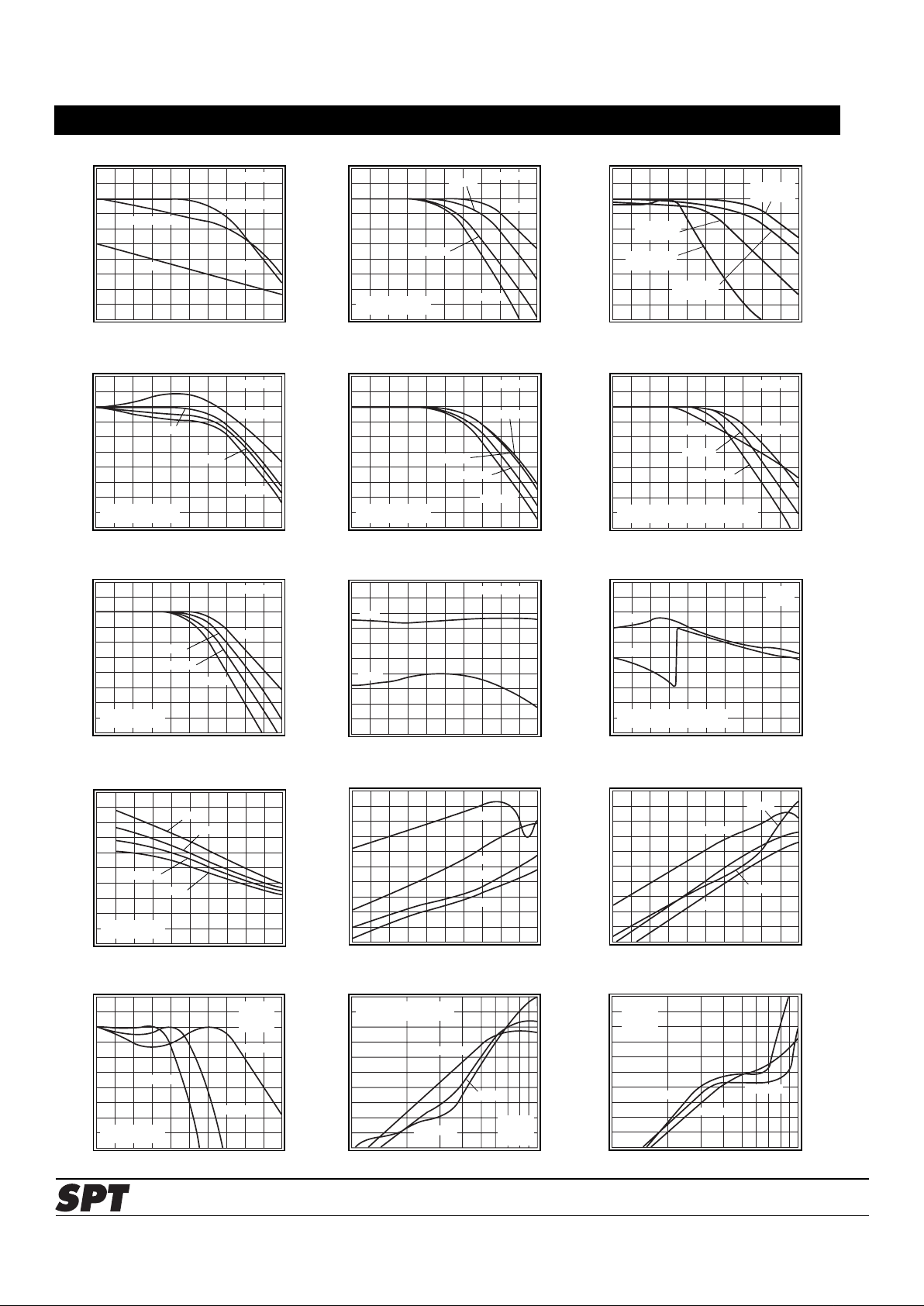

4

19

23

21

20

15

10

5

18

8

+

-

Compensation

V

o

-V

CC

All undesignated

pins are internally

unconnected. May

be grounded if

desired.

+V

CC

V+

V-

Block Diagram

Page 2

2 10/9/98

SPT561

PARAMETERS CONDITIONS TYP MIN & MAX RATINGS UNITS SYM

Case Temperature SPT561AIJ +25°C -25°C +25°C +85°C

Case Temperature SPT561AMJ +25°C -55°C +25°C +125°C

FREQUENCY DOMAIN RESPONSE (Max. Flat Compensation)

✝ -3dB bandwidth

✝ maximally flat compensation V

o

<2Vpp (+10dBm) 215 >175 >185 >175 MHz SSBW

0% overshoot compensation V

o

<2Vpp (+10dBm) 210 >170 >180 >170 MHz

large signal bandwidth Vo <10Vpp (+24dBm) 150 >145 >135 >120 MHz FPBW

(see Frequency Response vs. Output Power plot)

gain flatness Vo <2Vpp (+10dBm)

✝ peaking 0.1 -50MHz 0 <0.50 <0.40 <0.50 dB GFPL

✝ peaking >50MHz 0 <1.75 <0.75 <1.00 dB GFPH

✝ rolloff at 100MHz 0.1 <1.00 <0.75 <1.00 dB GFR

group delay to 100MHz 2.9 – – – ns GD

linear phase deviation to 100MHz 0.6 <1.7 <1.2 <1.7 ° LPD

return loss (

see discussion of R

x

) to 100MHz -15 <-11 <-11 <-11 dB RL

DISTORTION (Max. Flat Compensation)

2nd harmonic distortion

✝ 24dBm (10V

pp

): 20MHz -50 <-38 <-40 <-38 dBc HD2HL

✝ 50MHz -36 <-29 <-29 <-22 dBc HD2HM

100MHz -40 <-25 <-25 <-25 dBc HD2HH

✝ 18dBm (5V

pp

): 20MHz -52 <-42 <-44 <-42 dBc HD2ML

✝ 50MHz -45 <-30 <-35 <-30 dBc HD2MM

✝ 100MHz -30 <-22 <-25 <-25 dBc HD2MH

✝ 10dBm (2V

pp

): 20MHz -59 <-48 <-52 <-48 dBc HD2LL

✝ 50MHz -52 <-36 <-40 <-40 dBc HD2LM

100MHz -35 <-27 <-28 <-28 dBc HD2LH

3rd harmonic distortion

✝ 24dBm (10V

pp

): 20MHz -41 <-34 <-34 <-30 dBc HD3HL

✝ 50MHz -32 <-26 <-26 <-21 dBc HD3HM

✝ 100MHz -30 <-24 <-24 <-24 dBc HD3HH

✝ 18dBm (5V

pp

): 20MHz -48 <-40 <-44 <-44 dBc HD3ML

✝ 50MHz -46 <-37 <-37 <-35 dBc HD3MM

100MHz -36 <-30 <-30 <-30 dBc HD3MH

✝ 10dBm (2V

pp

): 20MHz -62 <-54 <-57 <-57 dBc HD3LL

✝ 50MHz -60 <-49 <-52 <-49 dBc HD3LM

100MHz -49 <-45 <-45 <-45 dBc HD3LH

2-tone 3rd order

intermod intercept

2

20MHz 38 >36 >36 >36 dBm IM3L

50MHz 35 >32 >32 >32 dBm IM3M

100MHZ 29 >27 >27 >23 dBm IM3H

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

SPT561 Electrical Characteristics

(Av = +10V, VCC = ±15V, RL = 50Ω, Rf = 410Ω, Rg = 40Ω, Ro = 50Ω; unless specified)

NOTES TO THE ELECTRICAL SPECIFICATIONS

The electrical characteristics shown here apply to the specific test conditions shown above (see also Figure 1 in

description of the operation). The SPT561 provides an equivalent, non-zero, output impedance determined by the

external resistors. The signal gain to the load is therefore load dependent. The signal gain shown above (Av = +10)

is the no load gain. The actual gain to the matching 50Ω load used in these specifications is half of this (+5).

The SPT561 requires an external compensation capacitor. Unless otherwise noted, this has been set to 10.5pF for

the frequency domain specifications (yielding a maximally flat frequency response) and 12.5pF for the time domain

specifications (yielding a 0% small signal pulse overshoot response).

Page 3

3 10/9/98

SPT561

PARAMETERS CONDITIONS TYP MIN & MAX RATINGS UNITS SYM

Case Temperature SPT561AIJ +25°C -25°C +25°C +85°C

Case Temperature SPT561AMJ +25°C -55°C +25°C +125°C

TIME DOMAIN RESPONSE (0% Overshoot Compensation)

rise and fall time

2V step 1.5 <2.0 <1.9 <2.0 ns TRS

10V step 2.4 <2.8 <2.8 <3.4 ns TRL

settling time to 0.5% (time <1µs) 5V step 7 <12 <12 <15 ns TS

long term thermal tail (time >1µs) 5V step 1.5 <2.0 <2.0 <2.0 % SE

slew rate 10V

pp

, 175MHz 3300 >3000 >2900 >2500 V/µsSR

overshoot 2V step

maximally flat compensation 5 <13 <10 <13 % OSMF

0% overshoot compensation 0 <5 <3 <5 % OSZO

EQUIVALENT INPUT NOISE

voltage >100KHz 2.1 <2.5 <2.5 <2.5 nV/√Hz VN

inverting current >100KHz 34 <40 <40 <45 pA/√Hz ICN

non-inverting current >100KHz 2.8 <4.5 <4.5 <5.0 pA/√Hz NCN

noise floor >100KHz -159 <-157 <-157 <-157

dBm/(1Hz) SNF

integrated noise 1kHz to 200MHz 35 <45 <45 <45 µV INV

noise figure >100KHz 15 <17 <17 <17 dB NF

STATIC, DC PERFORMANCE

* input offset voltage 2.0 <14.0 <5.0 <15.0 mV VIO

average temperature coefficient 35 <100 – <100 µV/°C DVIO

* non-inverting bias current 5.0 <35 <20 <20 µA IBN

average temperature coefficient 20 <175 – <100 nA/°C DIBN

* inverting bias current 10.0 <50 <30 <50 µA IBI

average temperature coefficient 100 <200 – <200 nA/°C DIBI

* power supply rejection ratio (DC) 57 >54 >54 >52 dB PSRR

* supply current no load 50 <60 <60 <65 mA ICC

MISCELLANEOUS PERFORMANCE

open loop current gain (±2% tolerance) 10.0 – – – mA/mA G

average temperature coefficient +0.02 <+.03 – <+.02 %/°CDG

inverting input resistance (±5% tolerance) 14.0 – – – Ω RIN

average temperature coefficient +.02 <+.025 – <+.025 Ω/°C DRIN

non-inverting input resistance 700 >200 >400 >400 KΩ RNI

non-inverting input capacitance to 100MHz 2.7 <3.5 <3.5 <3.5 pF CNI

output voltage range 150mA load current ±10.5 – >±10.0 – V VO

output current limit 210 <250 <250 <250 mA OCL

Min/max ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are

determined from tested parameters.

Absolute Maximum Ratings Recommended Operating Conditions

V

CC

(reversed supplies will destroy part) ±20V V

CC

±10V to ±15V

differential input voltage ±3V I

o

≤ ±200mA

common mode input voltage ±V

CC

common mode input voltage < ±(|VCC| -6)V

junction temperature (see thermal model) +175°C output impedance 25Ω to 200Ω

storage temperature -65°C to +150°C gain range (no-load voltage gain) +5 to +80

lead temperature (soldering 10s) +300°C case temperature: AIJ -25°C to +85°C

output current (internally limited) ±250mA AMJ -55°C to +125°C

Notes

1) * AIJ, AMJ 100% tested at +25°C

✝ AMJ 100% tested at at +25°C and sample tested

at -55°C and +125°C

✝ AIJ sample tested at +25°C

2) Test Tones are set ±100kHz of indicated frequency.

SPT561 Electrical Characteristics

(Av = +10V, VCC = ±15V, RL = 50Ω, Rf = 410Ω, Rg = 40Ω, Ro = 50Ω; unless specified)

Page 4

4 10/9/98

SPT561

Small Signal Gain and Phase

Gain (dB)

Frequency (MHz)

6

8

10

12

14

16

0 50 100 150 200 250

Maximally Flat

Phase (degrees)

0

-90

-360

-180

-270

0% Overshoot

Gain

Phase

Po = 10dBm

Frequency Response vs. Gain

Normalized Magnitude (1dB/div)

Frequency (MHz)

0 50 100 150 200 250

Po = 10dBm

Av = 10

Av = 5

Av = 15

Av = 20

Re-compensated at

each gain (see text)

Frequency Response vs. Output Power

Gain (dB)

Frequency (MHz)

16

12

6

0 40 80 120 160 200

10

8

14

Po = 10dBm

V

o

= 2V

pp

Po = 24dBm

V

o

= 10V

pp

Po = 27.5dBm

V

o

= 15V

pp

Po = 18dBm

V

o

= 5V

pp

Frequency Response vs. R

L

Normalized Magnitude (1dB/div)

Frequency (MHz)

0 50 100 150 200 250

Pi = -4dBm

RL = 50Ω

RL = 25Ω

RL = 75Ω

RL = 100Ω

Fixed gain and

compensated vs. load

Frequency Response vs. Power Supply

Frequency (MHz)

0 50 100 150 200 250

Po = 10dBm

±VCC = 18

±VCC = 12

±VCC = 15

±VCC = 10

Gain (dB)

16

12

6

10

8

14

Re-compensated at

each supply voltage

Frequency Response vs. R

o

Frequency (MHz)

0 50 100 150 200 250

Pi = -4dBm

Normalized Magnitude (1dB/div)

Ro = 50Ω

Ro = 25Ω

Ro = 75Ω

Ro = 100Ω

Response measured with matched load

Re-compensated at each R

o

Frequency Response vs. Gain (R

o, RL

= 75Ω)

Frequency (MHz)

0 50 100 150 200 250

Vo = 2V

pp

Normalized Magnitude (1dB/div)

Av = 5

Av = 10

Av = 15

Av = 20

Re-compensated

at each gain

Gain Flatness/Deviation from Linear Phase

Gain (0.1dB/div)

Frequency (MHz)

0 20406080100

Phase (0.5°/div)

Gain

Phase

Po = 10dBm

Internal Current Gain and Phase

Gain (10dB/div)

Frequency (MHz)

-30

-20

0

20

30

10

0 100 200 300 400 500

Phase (90°/div)

180

90

-180

0

-90

Gain

Phase

-10

Cx = 0

R

L

= 0

Phase consistant with current

polarity connection of Figure 3

Two Tone, 3rd-Order Intermodulation

Intercept (2.5dB/div)

Frequency (MHz)

45

35

20

0 20406080100

30

25

40

Av = 15

Av = 5

Av = 10

Av = 20

Re-compensated

at each gain

2nd Harmonic Distortion vs. Frequency

Distortion (dBc)

Output Power (dB)

-25

-45

-75

4 8 12 16 20 24

-55

-65

-35

50MHz

10MHz

20MHz

100MHz

3rd Harmonic Distortion vs. Frequency

Distortion (dBc)

Output Power (dB)

-25

-45

-75

4 8 12 16 20 24

-55

-65

-35

50MHz

10MHz

20MHz

100MHz

Frequency Response Driving C

L

Frequency (MHz)

0 50 100 150 200 250

Gain (1dB/div)

Av = +5

R

o

= 25

V

o

= 2V

pp

CL = 100pF

CL = 20pF

CL = 50pF

Re-compensated

at each C

L

2nd Harmonic Distortion Driving C

L

Frequency (MHz)

10 20 30 40 50 100

Distortion (5dBc/div)

Av = +5

R

o

= 25

V

o

= 2V

pp

CL = 100pF

CL = 20pF

CL = 50pF

70

-80

-70

-60

-50

-40

-30

Compensation as shown in

Frequency Response plot

3rd Harmonic Distortion Driving C

L

Frequency (MHz)

10 20 30 40 50 100

Distortion (5dBc/div)

Av = +5

R

o

= 25

V

o

= 2V

pp

CL = 100pF

CL = 20pF

CL = 50pF

70

-80

-70

-60

-50

-40

-30

SPT561 Typical Performance Characteristics

(TA = +25°C, Circuit in Figure 1; unless specified)

Page 5

5 10/9/98

SPT561

Small Signal Pulse Response

Time (2ns/div)

Output Voltage (V)

Maximally Flat

Compensation

0

-1.2

-0.8

-0.4

0.4

1.2

0% Overshoot

Compensation

0.8

Large Signal Pulse Response

Time (5ns/div)

Output Voltage (V)

Maximally Flat

Compensation

0

-6

-4

-2

2

6

0% Overshoot

Compensation

4

Uni-Polar Pulse Response

Time (5ns/div)

Output Voltage (V)

Maximally Flat

Compensation

0

-6

-4

-2

2

6

4

Settling Time into 50Ω Load

Time (sec)

Settling Error (%)

0

-1.5

-1.0

-0.5

0.5

1.5

1.0

2.0

-2.0

10

-9

10-710-510-310-110

1

5V Output Step

Settling Time into 500Ω Load

Time (sec)

Settling Error (%)

5V Output Step

0

-1.5

-1.0

-0.5

0.5

1.5

1.0

2.0

-2.0

10

-9

10-710-510-310-110

1

Reverse Transmission Gain & Phase (S12)

Reverse Gain (dB)

Frequency (MHz)

-100

-80

-60

-40

-20

0

0 50 100 150 200 250

Reverse Phase (degrees)

0

-45

-180

-90

-135

Gain

Phase

Settling Time into 50pF Load

Time (sec)

Settling Error (%)

5V Output Step

0

-1.5

-1.0

-0.5

0.5

1.5

1.0

2.0

-2.0

10

-9

10-710-510-310-110

1

Output Return Loss (S22)

Magnitude (dB)

Frequency (MHz)

-25

-20

-15

-10

-5

0

0 50 100 150 200 250

Ro = 50Ω

R

x

= 0Ω

-50

-45

-40

-35

-30

Ro = 40Ω

R

x

= 10Ω

Re-compensated

at each R

x

Input Return Loss (S11)

Magnitude (dB)

Frequency (MHz)

-50

-40

-30

-20

-10

0

0 50 100 150 200 250

Phase (degrees)

0

-45

-180

-90

-135

Magnitude

Phase

Re-compensated

at each R

x

-1dB Compensation Point

-1dB Compensation (dBm)

Frequency (MHz)

29

30

31

32

33

34

0 20406080100

Ro = 50Ω

24

25

26

27

28

Ro = 75Ω

Match Load

Re-compensated at each load

Noise Figure

Noise Figure (dBm)

No Load Gain

17

18

19

20

21

22

5 1015202530

Ro = 50Ω

12

13

14

15

16

Ro = 25Ω

Ro = 75Ω

Ro = 100Ω

Non-inverting input impedance

matched to source impedance

Equivalent Input Noise

Noise Voltage (nV/√Hz)

Frequency (Hz)

1

6

20

40

60

100

100 1k 10k 100k 10M 100M

Inverting Current 34pA/√Hz

Noise Current (pA/√Hz)

10

4

2

1

6

20

40

60

100

10

4

2

Non-Inverting Voltage 2.1nV/√Hz

Non-Inverting Current 2.8pA/√Hz

1M

Group Delay

Group Delay (ns)

Frequency (MHz)

3.0

3.2

3.4

3.6

3.8

4.0

0 50 100 150 200 250

2.0

2.2

2.4

2.6

2.8

Aperture set to 5%

of span (12.8MHz)

Gain Error Band (Worst Case, DC)

Gain Error at Load (%)

No Load Gain

0

1

2

3

4

5

5 9 13 17 21 25

-5

-4

-3

-2

-1

Ro (nominal) = 50Ω

R

L

= 50Ω ± 0%

Rf and R

g

tolerance = ±0.1%

Rf and R

g

tolerance = ±1%

PSRR

PSRR (dB)

Frequency (Hz)

50

60

70

80

90

100

100 1k 10k 100k 1M 100M

0

10

20

30

40

10M

SPT561 Typical Performance Characteristics

(TA = +25°C, Circuit in Figure 1; unless specified)

Page 6

6 10/9/98

SPT561

Rf – Feedback resistor

from output to inverting

input

Rg – Gain setting

resistor from inverting

input to ground

Cx – External

compensation capacitor

from output to

pin 19 (in pF)

Where:

Ro – Desired equivalent output impedance

Av– Non-inverting input to output voltage

gain with no load

G – Internal current gain from inverting input

to output = 10 ±1%

Ri– Internal inverting input impedance = 14Ω ±%5

Rs– Non-inverting input termination resistor

RL– Load resistor

AL– Voltage gain from non-inverting input to

load resistor

RG1RAR

R

RR

A1

C

1

R

300 1

2

R

0.08

f

ovi

g

f

o

v

x

o

g

=+

()

−

=

−

−

=

−

−

SUMMARY DESIGN EQUATIONS AND DEFINITIONS

SPT561 Description of Operation

Looking at the circuit of Figure 1 (the topology and

resistor values used in setting the data sheet specifications), the SPT561 appears to bear a strong external

resemblance to a classical op amp. As shown in the

simplified block diagram of Figure 2, however, it differs in

several key areas. Principally, the error signal is a

current into the inverting input (current feedback) and the

forward gain from this current to the output is relatively

low, but very well controlled, current gain. The SPT561

has been intentionally designed to have a low internal

gain and a current mode output in order that an equivalent

output impedance can be achieved without the series

matching resistor more commonly required of low output

impedance op amps. Many of the benefits of a high loop

gain have, however, been retained through a very careful

control of the SPT561’s internal characteristics.

The feedback and gain setting resistors determine both

the output impedance and the gain. Rf predominately

sets the output impedance (Ro), while Rg predominately

determines the no load gain (Av). solving for the required

Rf and Rg, given a desired Ro and Av, yields the design

equations shown below. Conversely, given an Rf and Rg,

the performance equations show that both Rf and Rg play

a part in setting Ro and Av. Independent Ro and A

v

adjustment would be possible if the inverting input impedance (Ri) were 0 but, with Ri = 14Ω as shown in the

specification listing, independent gain and output impedance setting is not directly possible.

Figure 1: Test Circuit

Design Equations

RG1RAR

R

RR

A1

f

ovi

g

f

o

v

=+

()

−

=

−

−

R

RR1

R

R

G1

R

R

A1

R

R

G

R

R

G1

R

R

o

f

i

f

g

i

g

v

f

g

i

f

i

g

=

++

++

=+

−

++

Simplified Circuit Description

Looking at the SPT561’s simplified schematic in Figure 2, the

amplifier’s operation may be described. Going from the noninverting input at pin 8 to the inverting input at pin 18,

transistors Q1 – Q4 act as an open loop unity gain buffer

forcing the inverting node voltage to follow the non-inverting

voltage input.

Transistors Q3 and Q4 also act as a low impedance (14Ω

looking into pin 18) path for the feedback error current. This

current, (i

err

), flows through those transistors into a very well

defined current mirror having a gain of 10 from this error

current to the output. The current mirror outputs act as the

amplifier output.

The input stage bias currents are supply voltage independent.

Since these set the bias level for the whole part, relatively

constant performance over supply voltage is achieved. A

current sense in the error current leg of the 10X current mirror

Where:

G ≡ forward current gain

(=10)

Ri≡ inverting node input

resistance (=14Ω)

Ro ≡ desired output

impedance

Av≡ desired non-

inverting voltage

gain with no load

Performance Equations

6.8µF.1µF

-V

CC

(-15)

410Ω

R

g

40Ω

5,10,15,

20

R

f

21

SPT561

+

-

18

R

s

50Ω

8

V

i

(Pi)

R

L

50Ω

V

o

(Po)

R

o

4

19

+V

CC

(+15)

.1µF

6.8µF

+

+

C

x

23

10.5pF

Resistor Values

shown result in:

Ro = 50Ω

Av = +10

(no-load gain)

A

L

= +5 [14dB]

(gain to 50Ω load)

Page 7

7 10/9/98

SPT561

R

g

R

o

i

err

V

o

R

f

C

x

19

I

o

I

o

I

bias

10X Current Mirror

Current Limit

5pF

Q3

Q1

-V

CC

+V

CC

4

I

bias

10X Current Mirror

Current Limit

5pF

Q4

Q2

+V

CC

-V

CC

21

23

8

V

i

i

err

R

g

R

f

i

f

Gi

err

R

o

V

o

X1

R

i

l

o

V

-

+

-

V i R and

ii

V

R

i1

R

R

VViRi RR1

R

R

ViRR1

R

R

and

IGi iiG1

err i

f

err

g

err

i

g

o

ff

err i

f

i

g

o err

f

i

f

g

o err

f

err

−

−

−

=

=+ = +

=+ = + +

=++

=+= +

++

≡=

++

++

=

+

=

R

R

then

R

V

I

RR1

R

R

G1

R

R

note that R

R

G1

R0

i

g

o

o

o

f

i

f

g

i

g

o

f

i

i

err

R

g

R

f

Gi

err

V

o

X1

R

i

V

-

+

-

V

i

Noload gain

A

V

V

v

o

i

≡

feeds back to the bias current setup providing a current

shutdown feature when the output current approaches

250mA.

Figure 2: Simplified Circuit Diagram

Developing the Performance Equations

The SPT561 is intended to provide both a controllable

voltage gain from input to output as well as a controllable

output impedance. It is best to treat these two operations

separately with no load in place. Then, with the no-load

gain and output impedance determined, the gain to the

load will simply be the no-load gain attenuated by the

voltage divider formed by the load and the equivalent

output impedance.

Figure 3 steps through the output impedance development using an equivalent model of Figure 2. Offering an

equivalent, non-zero, output impedance into a matched

load allows the SPT561 to operate at lower internal

voltage swings for a given desired swing at the load. This

allows higher voltage swings to be delivered at the load

for a given power supply voltage at lower distortion levels

than an equivalent op amp needing to generate twice the

voltage swing actually desired at the matched load. This

improved distortion is specified and tested over a wide

range as shown in the specification listing.

Get both Vo and Io into terms of just the error current, i

err

,

using:

Figure 3: Output Impedance Derivation

Note that the Ro expression simplifies considerably if

Ri = 0. Also note that if the forward current gain were to go

to infinity , the output impedance would go to 0. This would

be the normal op amp topology with a very high internal

gain. The SPT561 achieves a non-zero Ro by

setting the internal forward gain to be a low, well

controlled, value .

Developing the No-Load Gain Expression

Taking the output impedance expression as one constraint setting the external resistor values, we now need

to develop the no-load voltage gain expression from the

non-inverting input to the output as the other constraint.

Figure 4 shows the derivation of the no load gain.

Page 8

8 10/9/98

SPT561

recognize that [takingV positive]

V V Gi R

solvingfor V from two directions

V ViR G1iR

solvingfor i fromthis

i

V

G1R R

then

VV

VR

G1R R

and,substitutingfor V and i in the original V expression

VV1

GR R

i

o err

f

i err i err g

err

err

i

gi

i

ii

gi

err o

oi

f

=+

=− = +

()

=

+

()

+

=−

+

()

+

=+

−

−

−

−

−

−

ii

gi

f

g

v

o

i

f

g

i

f

i

g

v

f

g

i

G1R R

pullingan

R

R

out of the fraction

A

V

V

1

R

R

G

R

R

G1

R

R

note that A 1

R

RGG1

R0

+

()

+

≡=+

−

++

=+

+

=

R

RR

R

R

G

R

R

A

R

R

G

R

R

G

R

R

o

f

i

f

g

i

g

v

f

g

i

f

i

g

=

++

++

=+

−

++

1

1

1

1

RGRAR

R

RR

A

f

ovi

g

f

o

v

=+

()

−

=

−

−11

Figure 4: Voltage Gain Derivation

Note again that if Ri = 0 this expression would simplify

considerably. Also, if G were very large the voltage gain

expression would reduce to the familiar non-inverting op

amp gain equation. These two performance equations,

shown below, provide a means to derive the design

equations for Rf and Rg given a desired no load gain and

output impedance. The details of that derivation may be

found in Application Note SPT-01.

Performance Equations Design Equations

Equivalent Model

Given that the physical feedback and gain setting

resistors have been determined in accordance with the

design equations shown above, an equivalent model may

be created for the gain to the load where the amplifier block

is taken as a standard op amp. Figure 5 shows this analysis

model and the resulting gain equation to the load.

R

g

V

i

R

L

V

o

R

o

Rf - R

o

Classical

op-amp

+

-

V

V

1

RR

R

R

RR

substitutinginfor R andR withtheir design

equationyields

V

V

A

R

RR

A (gain to load)

o

i

f

o

g

L

Lo

f

g

o

i

v

L

Lo

L

=+

−

+

=

+

=

Figure 5: Equivalent Model

This model is used to generate the DC error and noise

performance equations. As with any equivalent model, the

primary intent is to match the external terminal characteristics recognizing that the model distorts the internal currents

and voltages. In this case, the model would incorrectly

predict the output pin voltage swing for a given swing at the

load. But it does provide a simplified means of getting to the

external terminal characteristics.

External Compensation Capacitor (Cx)

As shown in the test circuit of Figure 1, the SPT561 requires

an external compensation capacitor from the output to pin

19. The recommended values described here assume that a

maximally flat frequency response into a matched load is

desired. The required Cx varies widely with the desired value

of output impedance and to a lesser degree on the desired

gain. Note from Figure 2, the simplified internal schematic,

that the actual total compensation (Ct) is the series combination of Cx and the internal 10pF from pin 19 to the

compensation nodes. With this total value derived, the

required external Cx is developed by backing out the effect

of the internal 10pF. The total compensation (Ct) is developed in two steps as shown below.

C

300

R

1

2.0

R

pFintermediate equation

C

C

1 0.02 C

pF totalcompensation

1

og

t

1

1

=−

=

+

()

Page 9

9 10/9/98

SPT561

This, and an expression for the external Cx without the

intermediate steps are shown below.

C

10C

10 C

or

C

1

R

300 1

2

R

0.08

pF

x

t

t

x

o

g

=

−

=

−

−

The plot in Figure 6 shows the required Cx vs. gain for

several desired output impedances using the equations

shown above. Note that for lower Ro’s, Cx can get very

large. But, since the total compensation is actually the

series combination of Cx and 10pF, going to very high

Cx’s is increasingly ineffective as the total compensation

is only slightly changed. This, in part, sets the lower limits

on allowable Ro.

C

x

(pF)

No Load Voltage Gain

0

2

4

6

8

10

12

14

16

18

20

5

10 15 20 25

30

35 40 45 50 55

Maximally Flat Response

into a Matched Load

Ro = 50Ω

Ro = 75Ω

Ro = 100Ω

Figure 6: External Compensation Capacitance (Cx)

A 0% small signal overshoot response can be achieved

by increasing Cx slightly from the maximally flat value.

Note that this applies only for small signals due to slew

rate effects coming into play for large, fast edge rates.

Beyond the nominal compensation values developed

thus far, this external Cx provides a very flexible means

for tailoring the frequency response under a wide variety

of gain and loading conditions. It is oftentimes useful to

use a small adjustable cap in development to determine

a Cx suitable to the application, then fixing that value for

production. An excellent 5pF to 20pF trimmer cap for this

is a Sprague-Goodman part #GKX20000.

When the SPT561 is used to drive a capacitive load,

such as an ADC or SAW device, the load will act to

compensate the response along with Cx. Generally,

considerably lower Cx values are required than the

earlier development would indicate. This is advantageous in that a low Ro would be desired to drive a

capacitive load which, without the compensating effect of

load itself, would otherwise require very large Cx values.

No Load Gain

Output Impedance (Ω)

0

10

20

30

40

50

60

70

80

90

100

0

20 40 60 80

100

120 140 160 180 200

Low Rf or Rg Region

Recommended

Region

High Noise Region

Gain and Output Impedance Range

Figure 7 shows a plot of the recommended gain and

output impedances for the SPT561. Operation outside of

this region is certainly possible with some degradation in

performance. Several factors contribute to set this range.

At very low output impedances, the required value of

feedback resistor becomes so low as to excessively load

the output causing a rapid degradation in distortion.

The maximum Ro was set somewhat arbitrarily at 200Ω.

This allows the SPT561 to drive into a 2:1 step down

transformer matching to a 50Ω load. (This offers

some advantages from a distortion standpoint. See Application Note SPT-01.

Figure 7: Recommended Gain and

Output Impedance Range

For a given Ro, the minimum gain shown in Figure 7 has

been set to keep the equivalent input noise voltage less

than 4nV/√Hz. Generally, the equivalent input noise

voltage decreases with higher signal gains. The high gain

limit has been set by targeting a minimum Rg of 10Ω or a

minimum Rf of 100Ω.

Amplifier Configurations

(Additional discussion in Application Note SPT-01.) The

SPT561 is intended for a fixed, non-inverting, gain configuration as shown in Figure 1. Due to its low internal

forward gain, the inverting node does not present a low

impedance, or virtual ground, node. Hence, in an inverting configuration, the signal’s source impedance will see

a finite load whose value depends on the output loading.

Inverting mode operation can be best achieved using a

wideband, unity gain buffer with low output impedance, to

isolate the source from this varying load. A DC level can,

however, be summed into the inverting node to offset the

output either for offset correction or signal conditioning.

SPT Application Note SPT-01 describes this and a

composite amplifier structure that enhances the DC and

gain accuracy characteristics of the SPT561.

Accuracy Calculations

Several factors contribute to limit the achievable SPT561

accuracy . These include the DC errors, noise ef fects, and

Page 10

10 10/9/98

SPT561

the impact internal amplifier characteristics have on the

signal gain. Both the output DC error and noise model

may be developed using the equivalent model of Figure

5. Generally, non-inverting input errors show up at the

output with the same gain as the input signal, while the

inverting current errors have a gain of simply (Rf - Ro) to

the output voltage (neglecting the Ro to RL attenuation).

Output DC Offset:

The DC error terms shown in the specification listing

along with the model of Figure 5 may be used to estimate

the output DC offset voltage and drift. Each term shown

in the specification listing can be of either polarity. While

the equations shown below are for output offset voltage,

the same equation may be used for the drift with each

term replaced by its temperature drift value shown in the

specification listing.

Recall that the source impedance, Rs, includes both the

terminating and signal source impedance and that the

actual DC level to the load includes the voltage divider

between Ro and RL. Also note that for the SPT561, as

well as for all current feedback amplifiers, the non-inverting

and inverting bias currents do not track each other in

either magnitude or polarity. Hence, there is no meaning

in an offset current specification, and source impedance

matching to cancel bias currents is ineffective.

Noise Analysis:

Although the DC error terms are in fact random, the

calculation shown above assumes they are all additive in

a worst case sense. The effect of all the various noise

sources are combined as a root sum of squared terms to

get an overall expression for the spot noise voltage. The

circuit of Figure 8 shows the equivalent circuit with all the

various noise voltages and currents included along with

their gains to the output.

R

g

i

i

e

R

o

Rf - R

o

Classical

op-amp

+

-

√4kTRV

o

√4kT(Rf - Ro)

**

√4kTR

s

√

4kT

R

g

*

*

R

s

i

ni

*

*

*

e

ni

where: Gain to e

o

eni – non-inverting input voltage noise A

v

ini – non-inverting input current noise AvR

s

ii – inverting input current noise Rf - R

o

A

v

Rf - R

o

1

1

Figure 8: Equivalent Noise Model

To get an expression for the equivalent output noise voltage,

each of these noise voltage and current terms must be

taken to the output through their appropriate gains and

combined as the root sum of squares.

e e i R kTR A i R R

kT R R A kTR

oninis svifo

f

ov o

=+

()

+

()

+−

()

+−

()

+

2

2

22

2

4

44

L

Where the 4kT(Rf - Ro) Av term is the combined noise power

of Rg and Rf - Ro.

It is often more useful to show the noise as an equivalent

input spot noise voltage where every term shown above is

reflected to the input. This allows a direct measure of the

input signal to noise ratio. This is done by dividing every

term inside the radical by the signal voltage gain squared.

This, and an example calculation for the circuit of Figure 1,

are shown below. Note that RL may be neglected in this

calculation.

e e i R kTR

iR R

A

kT R R

A

kTR

A

nninis s

i

f

o

v

f

o

v

o

v

=+

()

++

−

()

+

−

()

+

2

2

2

2

2

2

4

4

4

L

An example calculation for the circuit in Figure 1 using

typical 25°C DC error terms and Rs = 25Ω, RL = 50Ω

yields:

4

4

4

4

kTR sourceresis ce voltage

noise

kT R gainsettlingresistor

noise current

kT R R feedback resistor

voltagenoise

kTR outputresistor voltage noise

s

g

f

o

o

−

−

−

()

−

−

tan

/

VIRV1

RR

R

IRR

where: I non invertingbias current

I invertingbias current

V input offset voltage

V 5 A 25 2.0mV 10 10 A 360

12.4mV

attentuationbetweenR andR

os bn s io

f

o

g

bi

f

o

bn

bi

io

o

oL

1/2

=⋅±

()

⋅+

−

±−

()

≡−

≡

≡

=⋅±

()

±

()

[]

=±

↑

µµΩΩL

DC

Page 11

11 10/9/98

SPT561

For the circuit of Figure 1, the equivalent input noise

voltage may be calculated using the data sheet spot

noises and Rs = 25Ω, RL = ∞. Recall that 4kT = 16E-21J. All

terms cast as (nV/√Hz)

2

e 2.1 .07 .632 1.22 .759 .089

2.62nV/ Hz

n

222222

=

()+()+()+()+()+()

=

Gain Accuracy (DC):

A classical op amp’s gain accuracy is principally set by the

accuracy of the external resistors. The SPT561 also depends on the internal characteristics of the forward current

gain and inverting input impedance. The performance equations for Av and Ro along with the Thevinin model of Figure 5

are the most direct way of assessing the absolute gain

accuracy. Note that internal temperature drifts will decrease

the absolute gain slightly as the part warms up. Also note

that the parameter tolerances affect both the signal gain and

output impedance. The gain tolerance to the load must

include both of these effects as well as any variation in the

load. The impact of each parameter shown in the performance equations on the gain to the load (AL) is shown

below.

Increasing current gain G Increases A

L

Increasing inverting input R

i

Decreases A

L

Increasing R

f

lncreases A

L

Increasing R

g

Decreases A

L

Applications Suggestions

Driving a Capacitive Load:

The SPT561 is particularly suitable for driving a capacitive

load. Unlike a classical op amp (with an inductive output

impedance), the SPT561’s output impedance, while starting

out real at the programmed value, goes somewhat capacitive at higher frequencies. This yields a very stable performance driving a capacitive load. The overall response is

limited by the (1/RC) bandwidth set by the SPT561’s output

impedance and the load capacitance. It is therefore advantageous to set a low Ro with the constraint that extremely

low Rf values will degrade the distortion performance. Ro =

25Ω was selected for the data sheet plots. Note from

distortion plots into a capacitive load that the SPT561

achieves better than 60dBc THD (10-bits) driving 2Vpp into a

50pF load through 30MHz.

Improving the Output Impedance Match

vs. Frequency - Using Rx:

Using the loop gain to provide a non-zero output impedance

provides a very good impedance match at low frequencies.

As shown on the

Output Return Loss

plot, however, this

match degrades at higher frequencies. Adding a small

external resistor in series with the output, Rx, as part of the

output impedance (and adjusting the programmed Ro accordingly) provides a much better match over frequency.

Figure 9 shows this approach.

R

g

V

i

R

L

V

o

R

x

R

f

SPT561

+

-

R

s

R'

o

= R

x

+ R

o

C

x

R

o

= R'

o

- R

x

With:

R

o

= SPT561 output impedance

and R

o

+ Rx = RL generally

Figure 9: Improving Output Impedance

Match vs. Frequency

Increasing Rx will decrease the achievable voltage swing at

the load. A minimum Rx should be used consistent with the

desired output match. As discussed in the thermal analysis

discussion, Rx is also very useful in limiting the internal

power under an output shorted condition.

Interpreting the Slew Rate:

The slew rate shown in the data sheet applies to the voltage

swing at the load for the circuit of Figure 1. Twice this value

would be required of a low output impedance amplifier using

an external matching resistor to achieve the same slew rate

at the load.

Layout Suggestions:

The fastest fine scale pulse response settling requires

careful attention to the power supply decoupling. Generally,

the larger electrolytic capacitor ground connections should

be as near the load ground (or cable shield connection) as is

reasonable, while the higher frequency ceramic de-coupling

caps should be as near the SPT561’s supply pins as

possible to a low inductance ground plane.

Evaluation Boards:

An evaluation board (showing a good high frequency layout)

for the SPT561 is available. This board may be ordered as

part #730019.

Thermal Analysis and Protection

A thermal analysis of a chip and wire hybrid is directed at

determining the maximum junction temperature of all the

internal transistors. From the total internal power dissipation, a case temperature may be developed using the

ambient temperature and the case to ambient thermal

impedance. Then, each of the dominant power dissipating

paths are considered to determine which has the maximum

rise above case temperature.

The thermal model and analysis steps are shown below. As

is typical, the model is cast as an electrical model where the

temperatures are voltages, the power dissipators are current sources, and the thermal impedances are resistances.

Refer to the summary design equations and Figure 1 for a

description of terms.

Page 12

12 10/9/98

SPT561

Ambient

Temperature

θ

ca

200°C/W20°C/W

T

j(t)

T

A

P

t

T

j(q)

P

q

P

circuit

Case Temperature

T

c

Case to Ambient

Termal Impedance

Figure 10: Thermal Model

I V /R total output current

withR R

RA

A1

totalload

I I I .06

totalinternaloutput stage current

P I V 1.4 17.3 I output stage power

P .2 I V V 0.7 15.3 I

power inhottest internal junction

prior

ooeq

eq L

f

L

L

t

1

2

oo

2

2

tt

CC

t

qtCCot

=

=

−

=++

()

=⋅ − − ⋅

()

=⋅⋅ −−− ⋅

()

Ω

Ω0

toto output stage

P 1.3 V 2 I I 19.2mA P P

power inremainder of circuit [note V | V |]

circuit

CC

to t q

CC CC

=⋅ ⋅⋅−+

()

−−

=−

Note that the Pt and Pq equations are written for positive Vo.

Absolute values of -VCC, Vo, and Io, should be used for a

negative going Vo. since we are only interested in delta V’s.

For bipolar swings, the two powers for each output polarity

are developed as shown above then ratioed by the duty

cycle. Having the total internal power, as well as its component parts, the maximum junction temperature may be

computed as follows.

Tc = TA + (Pq + PT + P

circult

) • θca Case Temperature

θ

ca

= 35°C/W for the SPT561 with no heatsink in still air

T

j(t)

=Tc + Pt • 20°C/W

output transistor junction temperature

T

j(q)

= Tc + Pq • 200°C/W

hottest internal junction temperature

The Limiting Factor for Output Power is Maximum

Junction T emperature

Reducing θca through either heatsinking and/or airflow can

greatly reduce the junction temperatures. One effective

means of heatsinking the SPT561 is to use a thermally

conductive pad under the part from the package bottom to a

top surface ground plane on the component side. Tests

have shown a θca of 24°C in still air using a “Sil Pad”

available from Bergquist (800-347-4572).

As an example of calculating the maximum internal junction

temperatures, consider the circuit of Figure 1 driving ±2.5V,

50% duty cycle, square wave into a 50Ω load.

R50

410 5

51

45.6

I 2.5V / 45.6 54.9mA

I 54.9mA 54.9mA .06 68.1mA

P 68.1mA 15 2.5 0.7 15.3 68.1mA 733mW

totalpowerinbothsides of theoutput stage

P 2 68.1mA 15 1.4 17.3 68.1mA 169mW

totalpowerinbothsides of hottest

eq

o

T

1

2

22

T

q

=

⋅

−

=

=

()

=

=+

()

+

()

=

=−−−⋅

[]

=

=⋅ −− ⋅

[]

=

Ω

Ω

Ω

Ω

Ω

Ω0.

junctionsjunctions

prior to output stage

P 1.3 15 2 68.1mA 54.9mA 19.2mA

733mW 169mW 1.058W

powerin theremainder of circuit

With these powers and T 25 C and 35 C / W

T 25 C .733 .169 1.058 35 94 C

case temperature

Fromthis, the hottest internal junctions may be found as

T t 94 C .733 20 101

circuit

Aca

c

j

1

2

=⋅

()

⋅⋅ − +

[]

−−=

=° =°

=°+ + +

()

⋅=°

()

=°+

()

⋅= °θCC output stage

T q 94 C .169 200 111 C

hottestinternal junction

j

1

2

()

=°+

()

⋅=°

Note that 1/2 of the total PT and Pa powers were used here

since the 50% duty cycle output splits the power evenly

between the two halves of the circuit whereas the total

powers were used to get case temperature.

Even with the output current internally limited to 250mA, the

SPT561’s short circuiting capability is principally a thermal

issue. Generally, the SPT561 can survive short duration

shorts to ground without any special effort. For protection

against shorts to the ±15 volt supply voltages, it is very

useful to reduce some of the voltage across the output stage

transistors by using some external output resistance, Rx, as

shown in Figure 9. Application Note SPT-01 discusses this

in detail.

Evaluation Board

An evaluation board (part number 730019) for the SPT561

is available.

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby

expressly granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING - LIFE SUPPORT APPLICATIONS POLICY - SPT products should not be used within Life Support Systems without the

specific written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can be

reasonably expected to result in significant personal injury or death.

Loading...

Loading...