Page 1

SPT5510

16-BIT, 200 MWPS ECL D/A CONVERTER

FEATURES

• 16-Bit, 200 MWPS digital-to-analog converter

• Differential linearity of ±0.6 LSB (typical)

• Integral linearity of ±0.75 LSB (typical)

• Fast settling time: 35 ns to 0.0008%; 25 ns to 0.01%

• Low glitch energy

• On-chip voltage reference

• ECL compatibility

GENERAL DESCRIPTION

The SPT5510 is a 16-bit, 200 MWPS digital-to-analog

converter designed for high-resolution waveform synthesis

for test and measurement instrumentation applications. It

features true 16-bit linearity, with differential non-linearity of

typically ±0.6 LSB and integral non-linearity of ±0.75 LSB. It

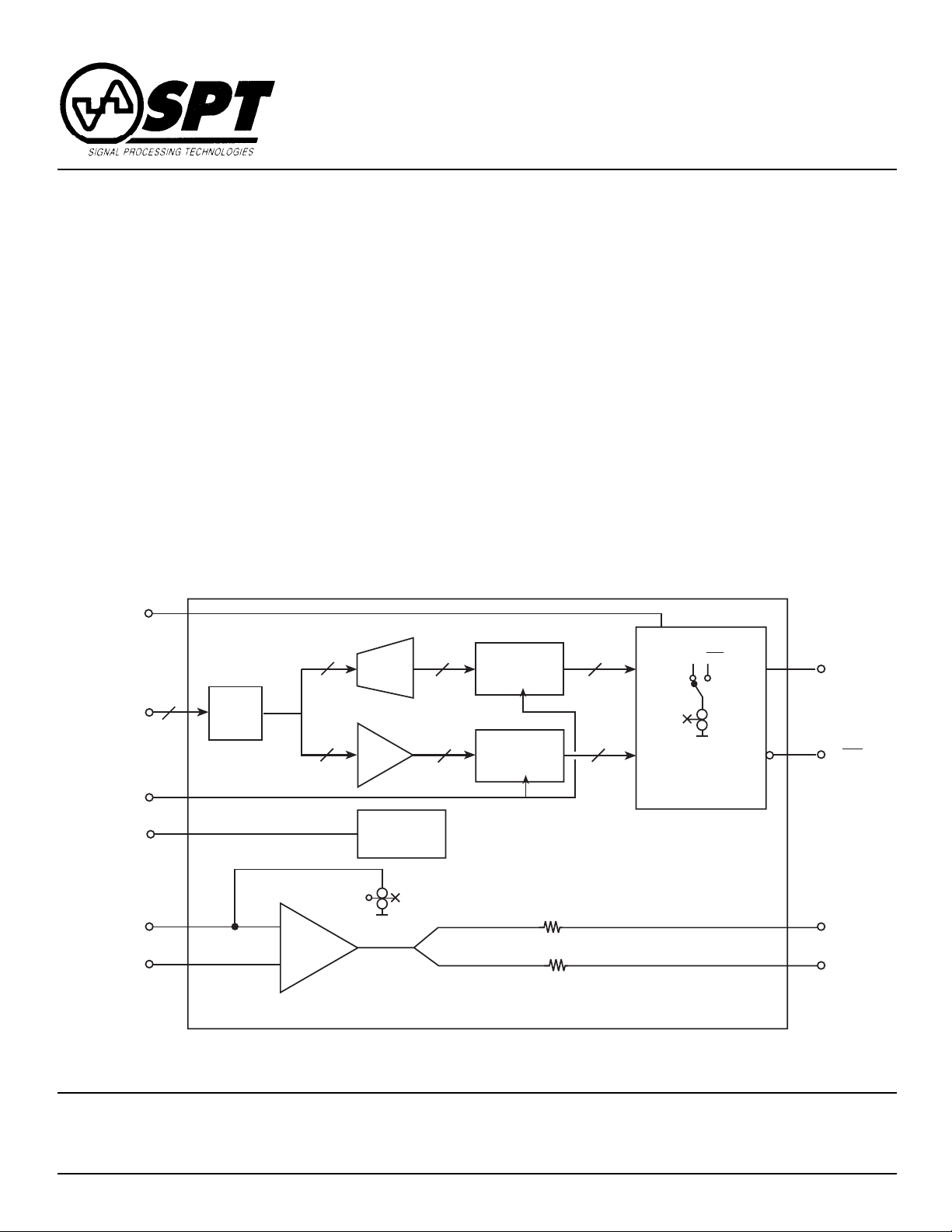

BLOCK DIAGRAM

REF

IN

D15–D12

MSB

Decoder

16 16

APPLICATIONS

• High-precision arbitrary waveform generation

• Test and measurement instrumentation

• Digital waveform synthesis

• Microwave and satellite modems

• Disk drive test equipment

• Industrial process control

• Military applications

has a very high-speed update rate of up to 200 MHz and is

ECL compatible. It has an ultrafast settling time of 25 ns to

0.01% and 35 ns to 0.0008%.

The SPT5510 operates over an industrial temperature

range of –40 °C to +85 °C and is available in a 10 x 10 mm,

44-lead metric quad flat pack (MQFP) plastic package.

I

I

OUT

MSB Latch

OUT

I

OUT

Digital Inputs

D15–D0

CLK

BG

OUT

R

SET

AMP

INB

Phone: (719) 528-2300 FAX: (719) 528-2370 Website: http://www.spt.com E-Mail: sales@spt.com

16

Input

Latch

D11–D0

+

Ref

Amp

–

LSB

Buffer

Bandgap

Reference

Reference

Cell

Bias

12

LSB Latch

Bias

12

Current

Cells

20

10

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

I

OUT

AMP

AMP

OUT

CC

Page 2

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)

1

Supply Voltages

Negative supply voltage (VEE) .................................–7 V

A/D ground voltage differential................................0.5 V

Input Voltages

Digital input voltage (D15–D0, Clock)... ...........–2.5 to 0 V

Ref amp input voltage range..........................–2.5 to 0 V

Reference input voltage range (Ref In)...... V

to –2.5 V

EE

Output Currents

Bandgap reference output current .....................±500 µA

Ref amplifier output current................................ ±2.5 mA

Temperature

Operating temperature............................... –40 to +85 °C

Junction temperature .......................................... +150 °C

Lead, soldering (10 seconds) ............................. +250 °C

Storage ....................................................–65 to +150 °C

Note: 1. Operation at any Absolute Maximum Rating is not implied. See Electrical Specifications for nominal operating

conditions.

ELECTRICAL SPECIFICATIONS

TA= 25 °C, VEE=–5.2 V ±5%, 50% duty cycle clock, unless otherwise specified.

TEST TEST SPT5510

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

DC Performance

Resolution 16 Bits

Differential Linearity VI –1.95 ±0.6 1.95 LSB

Differential Linearity T

Integral Linearity VI –1.95 ±0.75 1.95 LSB

Integral Linearity T

Integral Linearity Drift IV –0.2 0.2 LSB/°C

Offset Drift T

Monotonicity V 15 Bits

Output Capacitance V 10 pF

Gain Error I –2 0.4 2 % FS

Gain Error Tempco With Ext Reference V 50 ppm FS/°C

Gain Error Tempco With Internal Bandgap Ref V 50 ppm FS/°C

Offset Error I –4 4 µA

Compliance Voltage IV –1.2 2 V

Output Resistance IV 0.88 1.1 1.32 kΩ

Dynamic Performance

Conversion Rate IV 200 MHz

Settling Time t

Delay Time t

Glitch Energy V 30 pV-s

Full Scale Output Current With On-Chip References V 19 mA

Rise Time/Fall Time R

Spurious Free Dynamic Range

ƒ

=5 MHz; ƒ

OUT

ƒ

=10 MHz; ƒ

OUT

1

Measured at 0 V output using I-V.

2

Measured as voltage settling for mid-scale transition; RL = 50 Ω.

1

MIN–TMAX

MIN–TMAX

MIN–TMAX

2

ST

Settling to ±0.01% V 25 ns

Settling to ±0.0008% V 35 ns

D

= 50 Ω V2ns

L

=30 MHz 10 MHz Span V 84 dB

CLOCK

=100 MHz 10 MHz Span V 76 dB

CLOCK

IV –4.0 ±1.0 4.0 LSB

IV –4.0 ±1.5 4.0 LSB

IV –2.5 2.5 ppm FS/°C

V2ns

SPT

SPT5510

2 9/27/00

Page 3

ELECTRICAL SPECIFICATIONS

TA= 25 °C, VEE=–5.2 V ±5%, 50% duty cycle clock, unless otherwise specified.

TEST TEST SPT5510

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNITS

Power Supply Requirements

Negative Supply Current (–5.2 V) T

Nominal Power Dissipation V 600 800 mW

Power Supply Rejection Ratio ∆V Supply = ±5 % I –0.6 ±0.002 0.6 % FS

Voltage Input and Control

Bandgap Reference Voltage V –1.2 V

Bandgap Output Current T

Ref Amp Bandwidth

3

Ref Amp Input Current V 16 µA

Ref Amp Output Current V 200 µA

Ref In Operating Voltage V –3.4 V

Digital Inputs

Logic 1 Voltage T

Logic 0 Voltage T

Logic 1 Current –0.8 V V 2.5 µA

Logic 0 Current –1.8 V V 0 µA

Input Capacitance V 3 pF

Input Setup Time (tS) IV 3.0 ns

Input Hold Time (t

Clock Pulse Width (t

3

Ref Amp Bandwidth is limited by its compensation network

) IV 0.5 ns

H

) IV 1.5 ns

PWH

–T

MIN

MAX

=25 °C ±10 °C IV –110 16 220 µA

A

VI 115 150 mA

V 40 MHz

MIN

MIN

–T

–T

MAX

MAX

VI –1.0 –0.8 V

VI –1.7 –1.5 V

TEST LEVEL CODES

All electrical characteristics are subject

to the following conditions:

All parameters having min/max specifications are guaranteed. The Test Level

column indicates the specific device

testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification

is not tested at the specified condition.

TEST LEVEL TEST PROCEDURE

I 100% production tested at the specified temperature.

II 100% production tested at TA = +25 °C, and sample tested at the specified

temperatures.

III QA sample tested only at the specified temperatures.

IV Parameter is guaranteed (but not tested) by design and characterization

data.

V Parameter is a typical value for information purposes only.

VI 100% production tested at T

specified temperature range.

= +25 °C. Parameter is guaranteed over

A

SPT

SPT5510

3 9/27/00

Page 4

THEORY OF OPERATION

The SPT5510 is a segmented 16-bit current-output DAC.

The four MSBs, D15–D12, are decoded to fifteen unit cells

(current sinks). The remaining bits (D11–D0) are binary;

bits D9–D0 are derived from an R-2R ladder. All cells are

laser trimmed for maximum accuracy. The block diagram

shows the basic architecture.

All output cells are always on, with the data determining

whether a given cell’s current is routed from I

This provides nearly constant power dissipation independent of data and clock rate. It also reduces noise transients

on power and ground lines.

The reference loop utilizes an MSB-weighted cell and provides a gain of about 16 to the output. The on-chip reference amplifier has very high open-loop gain and is offset

trimmed to provide a very low temperature drift (typically

<10 ppm/°C gain drift).

OUT

or I

OUT

POWER SUPPLY AND GROUNDING

The SPT5510 requires a single –5.2V power supply. All

supply pins attach to a common on-chip power bus and

should be treated as analog supplies. For best settling performance, each supply pin should be decoupled as shown

in figure 1 – typical interface circuit.

There are three separate on-chip ground busses. DGND

pins should be tied together and connected to system

ground through a ferrite bead. REFGND and OGND pins

.

should be tied directly to the SPT5510’s ground plane and

connected to system ground through a ferrite bead. It is

critical that REFGND and OGND are very tightly coupled,

as any differential signal (dc offset, noise, etc.) will be

transmitted to the output. Two of the OGND pins can be

disconnected from the ground plane and used as sense

lines for a current-to-voltage converter, as shown in the

OUTPUTS section.

Figure 1 – Typical Interface Circuit

Input

Data

C1–C13 — SURFACE MOUNT CERAMIC CHIP

C14–C17 — TANTALUM

R1–R6 — CARBON FILM 1/4 W

R7–R10 — SURFACE MOUNT CERAMIC CHIP

FB — FERRITE BEAD is to be located as closely

to the device as possible.

R10

C13 20 pF

C12 10 pF

C7 .01 µF

50

1

D15

2

D14

3

D13

4

D12

5

D11

6

D10

7

D9

8

D8

25

D7

26

D6

27

D5

28

D4

29

D3

30

D2

31

D1

32

D0

22

9

12

CLK

REFGND

REFGND

DGND

DGND

DGND

DGND

10442433404235

FB

AV

EE

16

OUT

BG

OGND

OGND

R7 1K

17

18

INB

SET

R

AMP

SPT5510

OGND

OGND

37

R1

10

AV

EE

R8 1K

19

15

B

CC

AMP

AMP

EE

AV

AVEEAVEEAVEEAVEEAVEEAVEEAV

39431113142334

R2

10

R9 50

C8 .01 µF

20

21

IN

OUT

REF

AMP

EE

38

R3

R4

10

10

C9 47 pF

C10 47 pF

C11 47 pF

41

I

I

OUT

OUT

36

R5

10

Output

Output

Complementary

R6

10

SPT

2.2 µF

C14

2.2 µF

C15

2.2 µF

C16

2.2 µF

C17

.01 µF

C1

.01 µF

C2

.01 µF

C3

.01 µF

C4

.01 µF

C5

C6 .01 µF

SPT5510

4 9/27/00

Page 5

Wideband decoupling is required for optimum settling performance. This may require several capacitors in parallel,

and series resistors when appropriate, to reduce resonance

effects. Some applications may need only a single capacitor; however, decoupling influences both long- and shortterm settling, so caution is urged. Your application may

require some research to determine the optimum power

supply decoupling network.

DIGITAL INPUTS AND TIMING

Each digital input is buffered, decoded, and then latched

into D flip-flops which drive the output switches. Masterslave flip-flops are not used; thus, there is only a 1/2 clock

period delay (max) from data change to output change. In

this architecture, clock and data edge speeds (i.e., rise/fall

times) may affect data feedthrough. Using a data edge of

approximately 0.8 ns will cause data feedthrough of about

10 pV-s, while a 5 ns data edge will reduce the feedthrough

to about 4 pV-s. Data lines may include series resistors or

RC filters for edge control if desired.

The clock signal controls when the data is latched into the

flip-flops. When the CLK is high, the DAC is in track mode. A

negative going CLK latches the data. If CLK is held low, the

DAC is in hold mode. See figure 2.

Figure 2 – Timing Diagram

t

H

t

D

CLK

DATA

t

S

OUTPUTS

The output is comprised of current sinks, R-2R ladder, and

associated parasitics. See figure 3 for an equivalent output

circuit.

The DAC’s full-scale output current when using the internal

reference amplifier is determined by the voltage at pin

AMP

and the R

INB

resistance. It can be found (to within

SET

an LSB) by using the following formula:

I

FS = (AMP

OUT

INB/RSET

) x 16

The inputs determine whether the current from each sink

comes from I

Code (D15 is MSB) I

0 (zero scale) No current All current

32768 (mid-scale) I

65535 (full-scale) All current No current

OUT

or I

as follows:

OUT

OUT

= I

OUT

I

OUT

OUTIOUT

= I

OUT

Differential outputs facilitate maximum noise rejection and

signal swing. The DAC is trimmed using a current to voltage

(I-V) converter which provides a virtual ground at the outputs and includes sense lines to mitigate the impact of bus

drops. Operating into a load other than a virtual ground will

introduce a slight bow at the output. This bow is related to

the current sinks’ finite output impedance and ladder

impedance.

An example circuit using an I-V converter is shown in figure

4. Note that resistor and op-amp self heating over the DAC’s

full-scale range will introduce additional temperature dependence. The op-amp and feedback resistor must both have

very low tempcos if the DAC’s intrinsic gain drift is to be

maintained. A sense line helps reduce wire effects – both IR

loss and temperature drift.

I

OUT

I

OUT

tH = hold time

tD = time to output valid

tS = setup time

tST = settling time

Figure 3 – Equivalent Output Circuit

I

OUT

or

I

OUT

AV

1.1k

EE

SPT

t

10 pF

Figure 4 – I-V Converter

ST

OGND

I

OUT

OGND

OGND

I

OUT

OGND

BNC

”

"I

OUT

250

GND

–

+

+

–

GND

250

BNC

"I

"

OUT

SPT5510

5 9/27/00

Page 6

The feedback resistor should be matched to R

to reduce

SET

gain drift. Also, the op amp’s ground reference should be

the same as R

’s to reduce gain and offset errors. A com-

SET

posite amplifier may be required to obtain optimal dc performance. A differential circuit may be used; a common heat

sink covering both sides (op amps and resistors) will help

reduce temperature effects.

Achieving good settling performance requires careful board

layout with multiple decoupling circuits and very clean

power and ground routing. It is important that digital switching currents do not flow across analog input (REFIN) and

output signals. Terminations must be broadband and near

the device. Measuring settling performance is quite challenging and requires several test systems to ensure settling

errors from the instruments are not included.

Dynamic performance characteristics (e.g., settling, rise

and fall times, etc.) were measured with the outputs terminated to ground through 50 Ω resistors. SFDR was determined using a transformer to convert the output from differential to single-ended as shown in figure 5. The SPT5510 is

designed primarily for step and settle or narrowband RF

applications. The second harmonic generally dominates

wideband SFDR measurements, although close-in spurs

are very small.

Figure 5 – Transformer Output Circuit

I

OUT

BANDGAP VOLTAGE REFERENCE

The on-chip bandgap voltage reference is designed to bias

the non-inverting input of the reference amplifier (AMP

through a resistor equal to R

to help compensate the ref-

SET

INB

erence amplifier (see the following section). If the bandgap

voltage is required by another DAC, or elsewhere in the system, it must be buffered with a precision op amp configured

as a high impedance (e.g., unity gain follower) buffer. A

resistor, or RC filter, plus a ferrite bead will help isolate the

output from the reference amplifier’s compensation and

high-frequency charge pulses produced during operation.

The output should always be very carefully checked for

oscillations using a sensitive, wideband oscilloscope and

spectrum analyzer.

REFERENCE AMPLIFIER

The reference amplifier is a highly temperature-stable driver

to bias the precision current sinks. The reference amplifier

should only be used to drive REFIN. Additional loads will

change the amplifier’s compensation, which can lead to

instability and other settling issues.

There are two reference amplifier outputs: AMP

AMPCC. AMP

has a 20 ohm series resistor between the

OUT

output of the reference amplifier and the AMP

OUT

OUT

and

pin;

AMPCC has a 10 ohm resistor. These parallel outputs aide

compensation and decoupling. The open-loop output

impedance is approximately 1200 ohms.

)

25

25

I

OUT

Figure 6 – Reference Amplifier Circuit

R

SET

0.01 µF

1 kΩ

1 kΩ

16

17

18

BG

+

Ref Amp

–

OUT

15

AMP

B

V

EE

0.01 µF

Reference amplifier compensation is key to achieving high

performance. Without proper compensation, oscillations

that affect accuracy and settling time will occur. Figure 6

shows a typical reference amplifier compensation circuit.

Note that several small value capacitors are used from

REFIN to ground. This is to provide suitably low impedance

SPT5510 DAC

20 Ω

10 Ω

All components are ceramic chip-type.

20

19

AMP

AMP

OUT

CC

50Ω

10 pF

20 pF

C1 C2 C3

47 pF each

21

REF

IN

SPT

SPT5510

6 9/27/00

Page 7

around 300 MHz, the amplifier’s phase crossover point. The

unity-gain bandwidth is roughly 700 MHz. Larger value

capacitors exhibit lower self-resonance frequency and thus

may not adequately compensate the reference amplifier.

Large capacitors may also introduce low frequency tails

which increase settling time. The DAC itself exhibits very

broadband switching spikes (charge kickback) at the R

SET

node, which can contribute to amplifier instability if not suppressed. Note that the AMP

input must not be directly

INB

bypassed, as this will short all feedback to ground, leading

to severe oscillation.

Compensation must be optimized for each application. As

with any high-speed, high-resolution design, attention must

be paid to grounding, decoupling, and parasitic elements

that may cause instability. It may be wise to use a guard

ring, and/or clear the board ground, around the reference

amplifier’s inputs. All traces must be short, and capacitors

with high self-resonance must be used.

LONG-TERM STABILITY

VERSUS TEMPERATURE

As with all high-speed, high-resolution digital-to-analog converters, the initial accuracy of the device will degrade with

both time and temperature. The graph shown in figure 7 can

be used to determine the expected change in linearity performance over time when the device is operated at various

ambient temperatures. This graph shows how long it will

take for the SPT5510 linearity to change by 8 ppm (or 1/2

LSB) at any operating temperature. The top curve shown

represents integral nonlinearity (ILE) changes; the bottom

curve shows differential nonlinearity (DLE) changes.

Figure 7 – Linearity Performance over Time

7

1000 years

10

6

100 years

10

Compensation is perhaps the most challenging aspect of

setting up the SPT5510. By slowly switching a full-scale

data input (generating a low-frequency square wave), with

appropriate clock timing, the DAC’s output can be observed

using a suitable oscilloscope and spectrum analyzer to

observe and suppress any oscillations caused by board and

decoupling parasitics. Consult SPT Applications for further

assistance if required.

PACKAGE OUTLINE

A

B

Pin 1

G

Index

C

E F

H

I

J

44-Lead MQFP

D

K

5

10

(Hours)

4

1 year

10

ILE

3

10

1 month

2

10

0 20 40 60 80 100 120

Expected time required to produce an 8 ppm (1/2 LSB) linearity

(ILE or DLE) shift as a function of temperature.

Temperature (°C)

DLE

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.5098 0.5295 12.95 13.45

B 0.3917 0.3957 9.95 10.05

C 0.3917 0.3957 9.95 10.05

D 0.5098 0.5295 12.95 13.45

E 0.0311 0.0319 0.79 0.81

F 0.0118 0.0177 0.30 0.45

G 0.0768 0.0827 1.95 2.10

H 0.0039 0.0098 0.10 0.25

I 0.0287 0.0406 0.73 1.03

J 0.0630 REF 1.60 REF

K0° 7° 0° 7°

SPT

SPT5510

7 9/27/00

Page 8

PIN ASSIGNMENTS

OGND

AV

EE

43

13

AV

EE

AV

EE

I

OUT

41

42

15

14

AMP

B

(MSB) D15

D14

D13

D12

D11

D10

D9

D8

CLK

DGND

AV

DGND

44

1

2

3

4

5

6

7

8

9

10

11

EE

12

REFGND

OGND

AV

EEAVEE

39

40

SPT5510

44-Pin

MQFP

17

16

R

BG

SET

OUT

INB

38

18

AMP

OGND

37

19

AMP

CC

I

OUT

36

20

AMP

OUT

OGND

35

21

REF

IN

AV

EE

34

33

32

31

30

29

28

27

26

25

24

23

22

REFGND

DGND

D0 (LSB)

D1

D2

D3

D4

D5

D6

D7

DGND

AV

EE

PIN FUNCTIONS

NAME FUNCTION

D15–D0 Digital Input Bits – all inputs high sends all

current to I

CLK Clock – latches D flip-flops

I

OUT

I

OUT

BG

AMP

R

SET

OUT

INB

Analog Current Output

Complementary Analog Current Output

Bandgap Voltage Reference

Ref Amp’s Inverting Input

Ref Amp’s Non-Inverting Input – connection for

reference-current-setting resistor, nominally

1kΩ to ground

AMP

OUT

Bias Voltage for Output Current Switches –

drives REF

compensation)

REF

IN

Bias Voltage Node for Output Current Switches

– driven by AMP

AMP

AMP

B

CC

Used to Decouple Ref Amp’s Circuits to AV

AMP

OUT

compensation

, none to I

OUT

(on-chip 20 Ω resistor for

IN

OUT

OUT

plus on-chip 10 Ω series resistor for

EE

AV

EE

Negative Supply – –5.2 V

DGND Digital Ground Return

OGND Output Ground Return

REFGND Reference Amplifier Ground Return

ORDERING INFORMATION

PART NUMBER TEMPERATURE RANGE PACKAGE

SPT5510SIM –40 to +85 °C 44L MQFP

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby expressly

granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING – LIFE SUPPORT APPLICATIONS POLICY – SPT products should not be used within Life Support Systems without the specific

written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can be reasonably

expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

SPT5510

SPT

8 9/27/00

Loading...

Loading...