Page 1

SPT

SIGNAL PROCESSING TECHNOLOGIES

SPT2210

Y/C VIDEO ENCODER

FEA TURES

• Supports NTSC (M) and PAL (B, D, G, H, I)

• CCIR 601, square pixel and 4Fsc operation

• 4:2:2 YCrCb and 4:1:1 YCrCb digital input formats

• Two on-chip 8-bit video DACs

• Internally generates SYNC and color burst signals

• Internal vertical interpolation filter

• Analog composite or Y/C output

• High-resolution mode supports Video CD, V2.0

• 16 CLUT RAM (programmable)

• Four modes of video/graphics operation:

graphics, video, chroma key and external key

• Color bar generation test function

• Suspend function

• 64-lead PQFP package

• Single +3.3 V power supply

GENERAL DESCRIPTION

The SPT2210 is a single-chip video encoder that is capable of converting digital video data (YCrCb) into analog

NTSC or P AL video signals. Two digital input formats are

supported: 4:2:2 (YCrCb) and 4:1:1 (YCrCb). It internally

generates the proper SYNC and color burst signals for

NTSC (525 lines/60 Hz) and P AL (625/50 Hz) video standards operating in any one of three sample rate modes:

CCIR 601, square pixel and 4Fsc.

Composite or Y/C S-Video analog video output is generated via two 8-bit internal video DACs. In addition, the

APPLICATIONS

• Video cameras

• Digital video tape recorders

• Video conference equipment

• Video frame grabbers

• Set-top boxes

• Video projection and displays

• Video printers

• Video game machines

• Multimedia PCs

SPT2210 supports external or chroma key functions for

color graphics pixel-by-pixel overlay. It has a 16-color

lookup-table overlay palette which is fully programmable.

It also has an on-chip vertical interpolation filter that can

be activated to reduce jaggy noise and flicker. The chip

also features an internal test color bar pattern generator.

The SPT2210 operates from a single +3.3 V supply and

is built in a 0.5 µm CMOS process. It is available in a 64lead PQFP package and operates over the commercial

temperature range.

DTO

CBF

Suspend

V

CS

DAC

DAC

V

REF

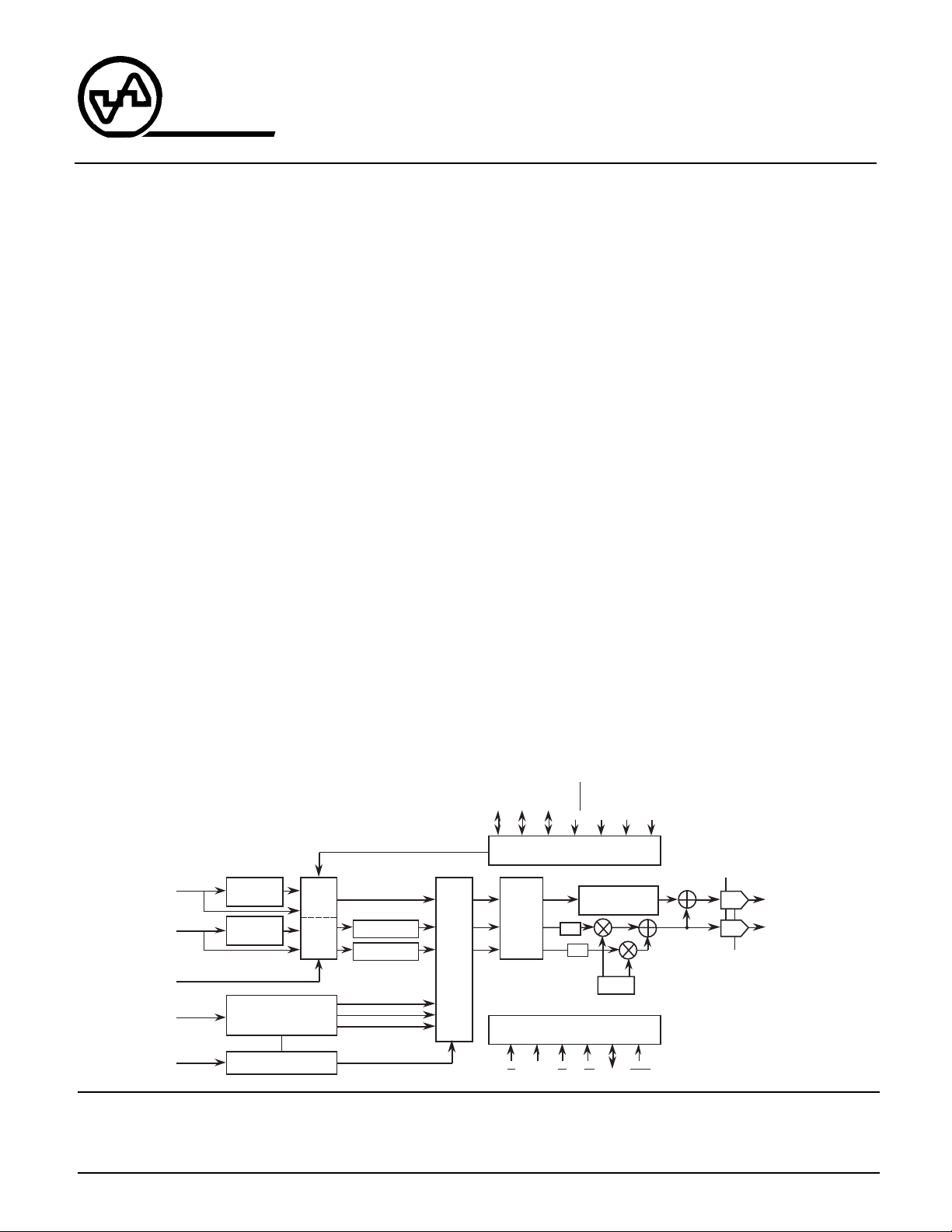

BLOCK DIAGRAM

YD7…0

CD7…0

VRTENB

GD3…0

KEY

Vertical

Interpolation

Vertical

Interpolation

KEY Logic

CLUT

16 x 16

MUX

MUX

Interpolation

Interpolation

Y

Cr

Cb

Y

Cr

Cb

MUX

Field

H

Y

Level

Converter

Cr

Cb

CS RS RD WR D7…0 Reset

BLANK

V

SYNC Generator

Y

SYNC/BLANK

Cr

LPF

Cb

LPF

MPU Interface

CLK

Pedestal

Signal Processing Technologies, Inc.

4755 Forge Road, Colorado Springs, Colorado 80907, USA

Phone: (719) 528-2300 FAX: (719) 528-2370 Website: http://www.spt.com E-Mail: sales@spt.com

Y/CVBS

C

Page 2

GENERAL DESCRIPTION OF FUNCTIONS

VIDEO MODES

The SPT2210 supports NTSC and PAL video standards

in Y/C (4:2:2) and Y/C (4:1:1) input formats. Table I shows

the video modes supported.

Table I – Supported Video Modes

Active Number Input Clock

Video Mode of Pixels Frequency

NTSC Square Pixel 640 x 483 12.2727 MHz

Y/C (4:2:2/4:1:1)

NTSC CCIR 601 720 x 483 13.5000 MHz

Y/C (4:2:2/4:1:1)

NTSC 4Fsc 768 x 483 14.3182 MHz

Y/C (4:2:2/4:1:1)

PAL Square Pixel 640 x 573 12.1875 MHz

Y/C (4:2:2/4:1:1)

PAL Square Pixel 768 x 573 14.7500 MHz

Y/C (4:2:2/4:1:1)

PAL CCIR 601 720 x 573 13.5000 MHz

Y/C (4:2:2/4:1:1)

PAL 4Fsc 948 x 573 17.7345 MHz

Y/C (4:2:2/4:1:1)

VERTICAL INTERPOLATION

The SPT2210 has a vertical interpolation filter that is

used to reduce jaggy noise and flicker. It also supports

the high-resolution mode for Video CD, version 2.0.

TWO-CHANNEL D/A CONVERTER OUTPUT

Digital video signals are output on two 8-bit D/A converters. Y/C (S-Video) output or composite video output can

be selected. The Y/C video outputs are current sources,

capable of driving a 75 Ω load to 1 V

ground. If both composite and S-Video are required simultaneously, a simple circuit (using the SPT9400 video

driver) may be added.

, referenced to

P-P

HOST INTERFACE

The operational modes and parameters of the SPT2210

can be changed via a MPU host parallel interface. The

following parameters can be changed:

• Low-pass filter

• Switching between Y/C output and composite output

• Switching between two’s complement or offset binary

data format

• Selecting between seven video modes

• 50%, Y, Y/C and color enable/disable

• Color bar test pattern

• Color kill (monochrome only out)

• Graphics mode control

• Software reset

• Select Y/C 4:2:2 or 4:1:1 input format

• Change of the Cr/Cb sampling order

• Interpolation field changeover

• Vertical interpolation filter bypass

• Free run or reset of subcarrier phase

• Turn off/on NTSC setup

• Suspend mode

• Input logic polarity set

• V Blank_ timing adjust

• H Blank_ timing adjust

EXTERNAL SETTING PINS

In addition to host interface control, the SPT2210 can be

operated independent of host interface using external pin

control. The external pin controls available are listed

below:

• Select between seven video modes

• Sync/Blank I/O mode

• Output of the built-in color bars

• Free run or reset of subcarrier phase

• Switching between Y/C output and composite output

• Turn off/on NTSC setup

See the External Setting Pin Descriptions section for

operation.

FOUR-BIT TITLE/GRAPHICS

MULTIPLEXING FUNCTION

Graphics from a 16-entry color lookup table can be arbitrarily displayed. In chroma mode it is possible to superimpose graphics and video input by specifying transparent colors. In the external key mode it is possible to

display graphics in the areas specified pixel by pixel.

SPT

SPT2210

2 8/22/00

Page 3

Table II – Y/C Video Encoder Pin Functions

DESCRIPTION OF PIN FUNCTIONS

Signal Pin

Name Numbers I/O Function

Digital Video Inputs and Controls

YD7...0 1-8 I Luminance Digital Input

CD7...0 57-64 I Color Difference Digital Input

CBF 11 I Cr/Cb Sampling Order Control

BLANK_ 12 I External Blanking Control Signal

FIELD 16 I Field Indicator Signal (TTL Level)

V 13 I/O Vertical Synchronization Signal

H 14 I/O Horizontal Synchronization Signal

KEY 17 I Keying Signal Input (TTL Level)

GD3...0 18-21 I CLUT Ram Address (GD0 = LSB)

VRTENB 15 I Vertical Interpolation Enable

SUSPEND 43 I Suspend Mode Enable/Disable

Video Outputs

Y 53 O Luminance or Composite Video

C 49 O Chrominance Video Analog Signal

V

REF

V

CS

MPU Interface and Clock

D7...0 29-32,36-39 I/O Address/Data Bus (TTL Level)

CS_ 22 I Chip Select (TTL Level)

RS 23 I Register Select (TTL Level)

RD_ 24 I Read from Data Bus (TTL Level)

WR_ 25 I Write to Data Bus (TTL Level)

RESET_ 26 I Reset Signal Input (TTL Level)

CLK 34 I System Clock Input (Pixel Clock)

TEST 42 I Test Mode Enable/Disable

Power Supply Connections

VDD10,28,35,41,56 - +3.3 V Power Supply for Digital

AV

DD

GND 9,27,33,40,55 - Ground for Digital Circuitry

AGND 45,48,54 - Ground for Analog Circuitry

46 I Internal D/A Reference Voltage

47 I Internal D/A Output Signal

44,52 - +3.3 V Power Supply for Analog

(YD0 = LSB) (TTL Level)

(CD0 = LSB) (TTL Level)

(TTL Level)

Input (TTL Level)

Input (TTL Level)

Input (TTL Level)

(TTL Level)

(TTL Level)

Analog Signal Output (1 V

Output (1 V

Input

Amplitude Control Voltage

Circuitry

Circuitry

) (Includes burst)

P-P

P-P

)

DIGITAL VIDEO INPUTS AND CONTROLS

YD7...0 Pins

The luminance signal digital data is input on YD7...0 (TTL

level). The input can be in either offset binary or two’s

complement format. The range of the input data is

bounded from 16 to 235. Any data less than 16 is converted to 16 and data greater than 235 is converted to

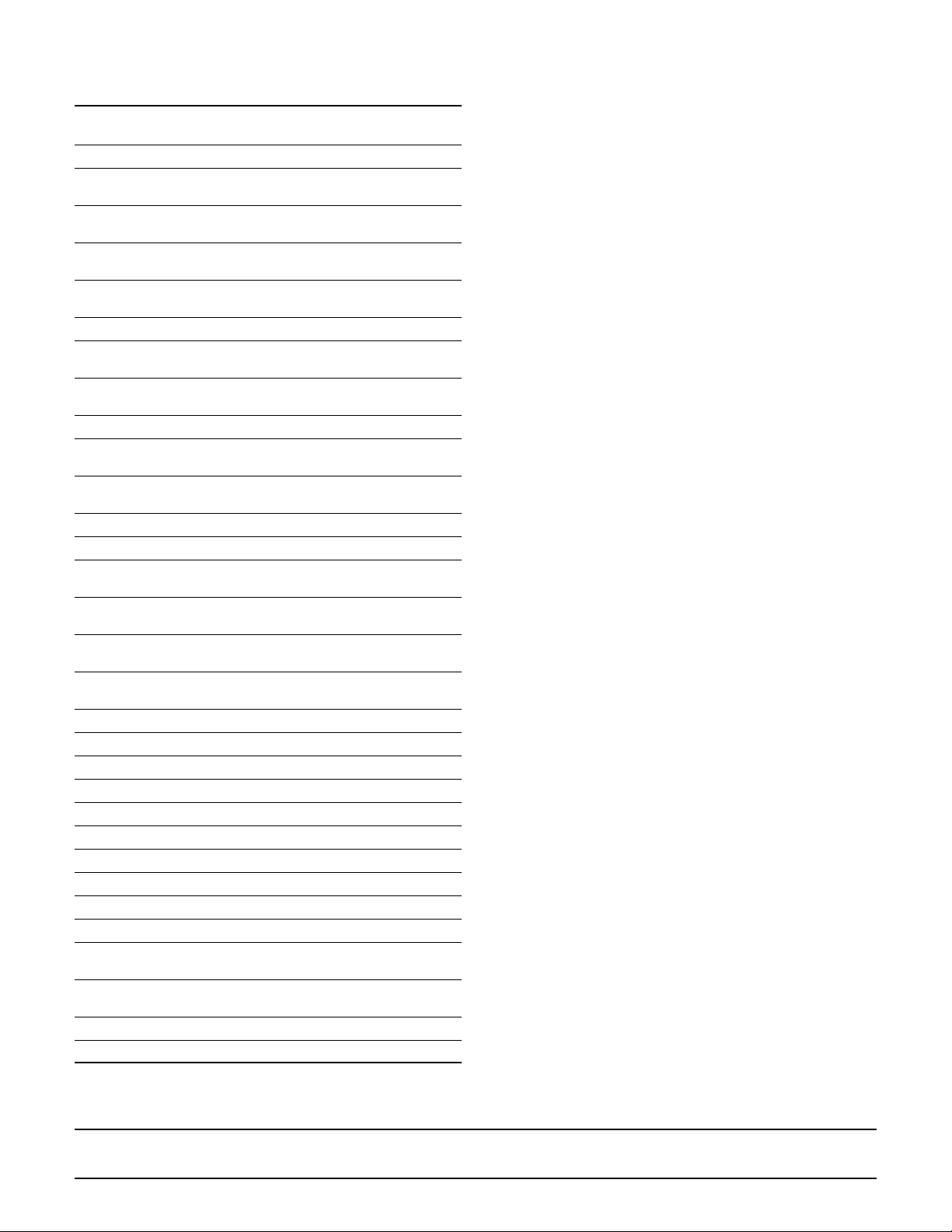

235. The active pixels will be output after completion of

the back porch as shown in figure 2. YD7 is the MSB and

YD0 is the LSB.

CD7...0 Pins

The color difference digital data is input on CD7...0 (TTL

level). The input can be in either offset binary or two’s

complement format. The input range of the offset binary

mode is from 16 to 240, and the input range of the two’s

complement mode is from –112 to +112. Signal data is

bounded to these minimum and maximum limits.

As a means of dealing with abnormal data, color kill is

carried out when 00(H) of FF(H) is detected for two successive clocks or more at CD7...0 (automatic color kill

mode). Color kill is immediately cancelled when data

other than 00(H) or FF(H) are entered.

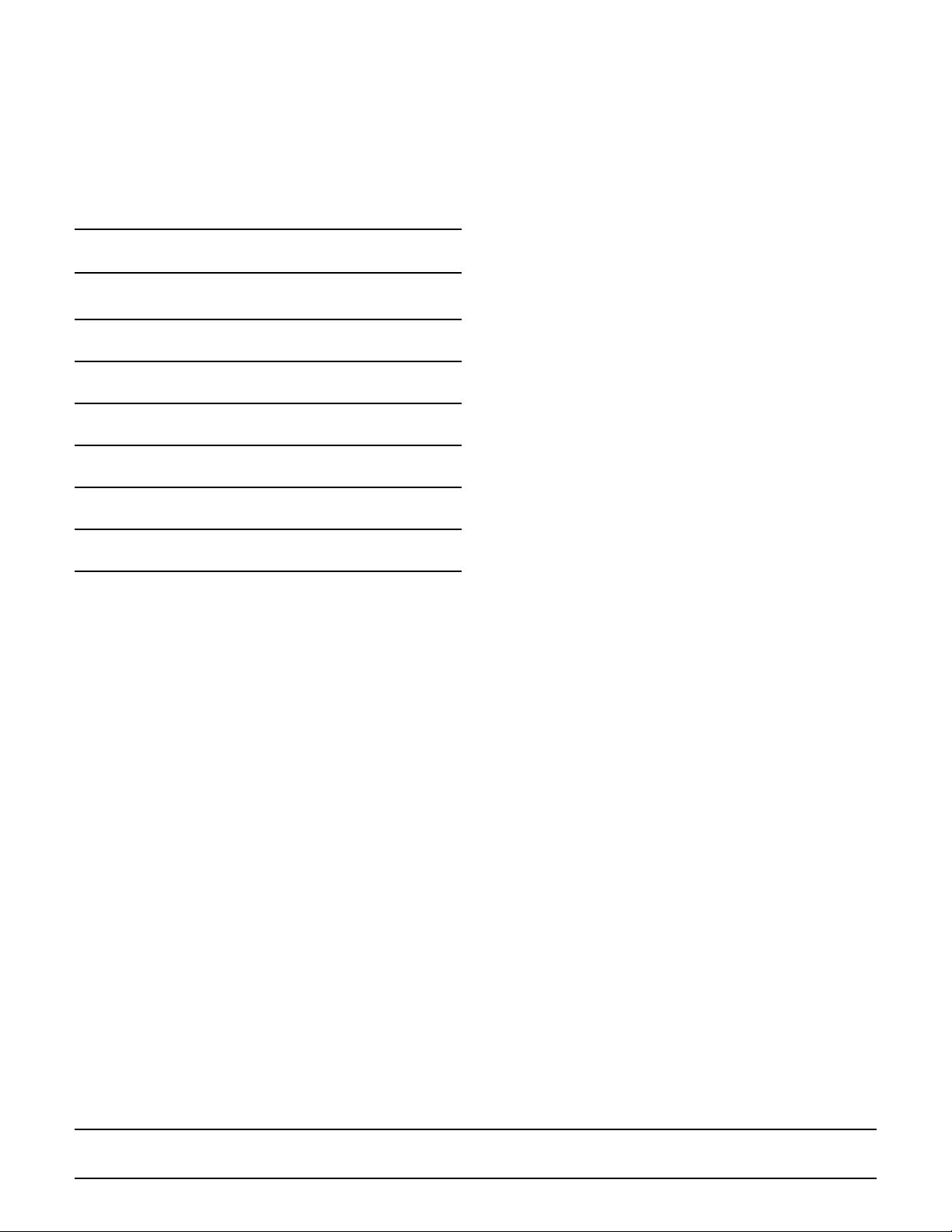

The order of Cr and Cb is determined by the combination

of the CBF pin (described below) and the Cr/Cb inversion

bit, D2 (data bit 2), of the command register CR1. In normal setup mode (Cr/Cb inversion bit = 0 and CBF pin = 1)

and 4:2:2 format, the input is started with the Cb data

and, after that, Cr and Cb are repeated alternately . (Refer

to figure 1.)

In the 4:1:1 format only (with normal CBF setup) the first

and the second data positions in time are used, and the

third and fourth data are ignored (or not present). (Refer

to figure 1.) The first data is repeated again after the

fourth data. The active pixels are output after the back

porch as shown in figure 2. CD7 is the MSB and CD0 is

the LSB.

CBF Pin

This is the Cr/Cb control pin. It determines the sampling

order of Cr/Cb. When the command register CR1, data

bit 2, (Cr/Cb inversion) is low (clear), the CBF pin is input

as positive true logic. (See the Command Register Descriptions.) When CBF is high, the SPT2210 samples the

data as Cb after the leading edge of HSYNC_ and the

back porch has occurred. When CBF is low, the SPT2210

samples the data as Cr after the leading edge of

HSYNC_ and the back porch has occurred.

When the command register CR1, data bit 2, (Cr/Cb Inversion) is high (set), the CBF pin is input as negative

logic. (See the Command Register Descriptions.) In this

mode the CBF pin is read as inverted.

SPT

SPT2210

3 8/22/00

Page 4

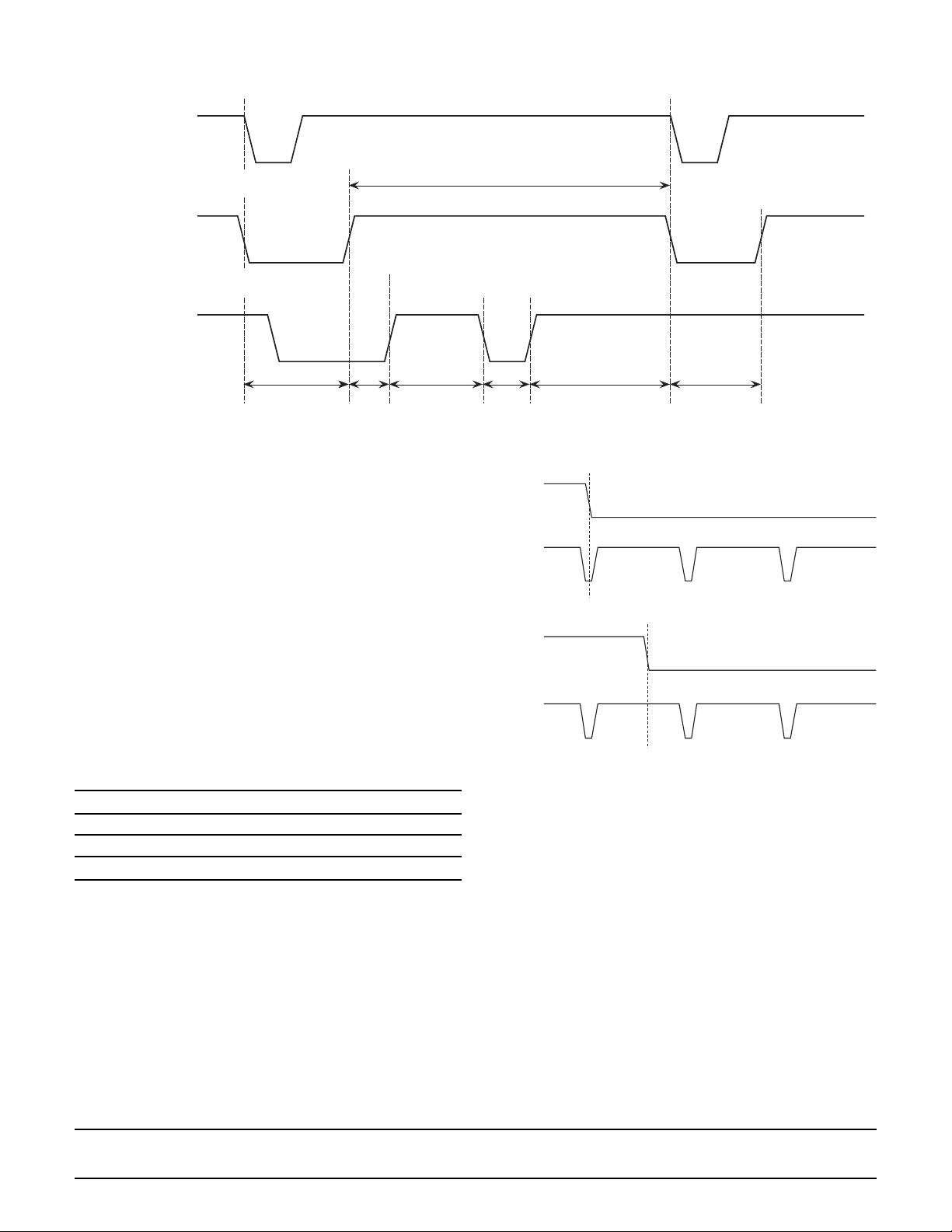

Figure 1 – Y/C Data Input Format (CBF=High, CR1:D2=0)

HSYNC_

YD7…0

CD7…0

HSYNC_

YD7…0

CD7…0

Y1 Y2 Y3 Y4 Y5 Y6 Y7

Cb1 Cr1 – – Cb5 Cr5 –

Y1 Y2 Y3 Y4 Y5 Y6 Y7

Cb1 Cr1 Cb5 Cr5

Figure 2 – Y/C Data Input Timing

HSYNC_

4:1:1 Format

Cb7Cb3 Cr3

4:2:2 Format

SPT

YD7…0

CD7…0

Effective Pixels

Back Porch Front Porch

Number of

Operation Mode Effective Pixels Back Porch Front Porch

NTSC CCIR 601 720 Clocks 122 Clocks 16 Clocks

NTSC Square Pixel 640 Clocks 120 Clocks 20 Clocks

NTSC 4Fsc 768 Clocks 124 Clocks 18 Clocks

PAL CCIR 601 720 Clocks 132 Clocks 12 Clocks

PAL Square Pixel (14.75) 768 Clocks 152 Clocks 24 Clocks

PAL 4Fsc 948 Clocks 164 Clocks 23 Clocks

PAL Square Pixel (12.18) 640 Clocks 120 Clocks 20 Clocks

SPT2210

4 8/22/00

Page 5

Figure 3 – Set of BLANK_ Terminal and Display/Nondisplay

HSYNC_

Internal Blank

Blank_

Nondisplay Non-

display

Display Non-

Blank_ Pin

This is the input pin for the external blanking control signal (TTL level). The SPT2210 samples BLANK_ at the

rising edge of CLK. When BLANK_ is high, the output

proceeds with normal operation and when it is low the

output signal gets blanked (i.e., no display). The specification of the blank state can be performed on a pixel-bypixel basis.

The chip has an internal blanking function that operates

independent of the external blanking signal. Figure 3

shows operation of the internal blanking in conjunction

with external blanking. Table III delineates the internal

blanking that is generated regardless of the level of the

blank pin, upon detection of HSYNC_.

Table III – Internal Blanking Periods for NTSC and

PAL

NTSC PAL

Lines 1 to 20 1 to 23

Lines 263 to 283 310 to 335

Line(s) 525 623 to 625

V Pin

This input pin provides the timing to generate the vertical

signal out of the SPT2210. The mode of operation for this

pin is controlled by Command Register, CR5. The sampling of the sync signal occurs on the rising edge of clock.

When the Vsync input signal is asserted during an Hsync

signal the field is considered to be odd, else the field is

even. (Refer to figure 4.)

display

Display Nondisplay

Figure 4 – Sync Signal Input Timing

VSYNC_

HSYNC_

Odd Numbered Field

VSYNC_

HSYNC_

Even Numbered Field

H Pin

This input pin provides the timing to generate the horizontal signal out of the SPT2210. The mode of operation for

this pin is controlled by Command Register, CR5. The

sampling of the sync signal occurs on the rising edge of

clock. When the timing for Hsync/Hblank input is different

from the number of clock cycles shown in table IV, the

phase of the subcarrier will be put into free-run.

Since the horizontal blanking period in Figure 2 is determined internally, the width and the trailing edge of

HSYNC_ are not detected. The active pixels are output

after the completion of the back porch as shown in

figure 2.

When in the blank operational mode the field is determined by the field input signal.

SPT

SPT2210

5 8/22/00

Page 6

Table IV – Expected Line Clock Count for Various

Modes

Video Mode Clocks

NTSC 4Fsc 910

NTSC Square Pixel 780

NTSC CCIR 601 858

PAL 4Fsc 1135

PAL Square Pixel (ƒs = 14.75 MHz) 944

PAL Square Pixel (ƒs = 12.1875 MHz) 780

PAL CCIR 601 864

FIELD

This is an input signal controlled by CR5. It is sampled on

the leading edge of the clock cycle. It indicates the field

odd or even and is required in the Blank mode. High level

indicates ODD and low level indicates EVEN field.

TEST

This is an input signal. During normal operation it is set to

a logic low. Test functions of the device are enabled by

taking this pin to a logic high.

SUSPEND

This input pin is set to a logic low for normal operation.

When set to a logic high, the SPT2210 suspends operation and no output is active. This includes taking in data

from either the MPU data ports or video data.

KEY Pin

This is the external key input pin (TTL level). Input from

this pin is enabled when the external key mode is activated by setting the command register CR1 bits to D1 = 1

and D0 = 1. (See the Command Register Descriptions

section.) When KEY is high, the colors of the contents of

color lookup table (CLUT) that is specified by means of

GD3...0 are displayed. When KEY is low, the data of

YD7...0 and CD7...0 are output. This mode is called the

external key mode.

GD3...0 Pins

These are the graphic data input pins (TTL level). This

4-bit input port specifies which one of the 16 color entries

in the CLUT is to be output for the current pixel. If GD3...0

is all low when the SPT2210 is in chroma mode, the

CLUT output is transparent and the data of the YD7...0

and CD7...0 ports are output. (This assumes that the

transparent color was not changed in Address 0H of the

CLUT.) Refer to the Color Lookup Table (CLUT) Description section.

VRTENB Pin

This is the vertical interpolation enable signal input pin

(TTL level). When VRTENB is high, vertical interpolation

is enabled and when it is low, vertical interpolation is disabled.

N/C Pins

These are no connect pins.

VIDEO OUTPUTS

Y Pin

This is the luminance or composite analog output signal

pin. The Y output pin is a current source capable of driving a 75 Ω load terminated to ground to 1 V

. The en-

P-P

coded analog luminance or composite signal is output on

this pin.

C Pin

This is the chroma analog output signal pin. The C output

pin is a current source capable of driving a 75 Ω load

terminated to ground to 1 V

. The chroma signal is out-

P-P

put on this pin.

V

Pin

REF

This is the reference voltage input pin for the internal D/A

converters. A 0.1 µF capacitor and voltage divider of

6.8 kΩ and 5.1 kΩ resistors should be connected to this

pin from +3.3 V.

VCS Pin

This is the control voltage for the output amplitude of the

internal D/A converters. The D/A output amplitude can be

adjusted from 1.0 to 1.4 V

using this pin.

P-P

MPU INTERFACE AND CLOCK

D7...0 Pins

These are the address and data input/output bus pins

(TTL level). This is a bidirectional 8-bit bus. D7 is the

MSB and D0 is the LSB. When the CS_ (chip select) pin

is high, the D7...0 bus is in a high impedance state.

The SPT2210 features the ability to run without an external MPU host. In this mode, D7...0 and RS (Register

Select) pins can be used as external mode setting pins.

The D7...0 pins and RS pin become external setting pins

when CS_, RD_ (Read Enable) and WR_ (Write Enable)

are low for three clock cycles or more. Refer to the External Setting Pin Descriptions section for more details.

CS_ Pin

This is the chip select input pin (TTL level). The SPT2210

is selected for read/write operation when this pin is low.

The CS_ pin is also used in enabling the external pin

mode. Refer to the External Setting Pin Descriptions

section for more details.

SPT

SPT2210

6 8/22/00

Page 7

RS_ Pin

This is the register select input pin (TTL level). The D7...0

pins operate as either address or data registers (except

when operating as external setting pins). The RS_ pin

determines the mode in which D7...0 will operate. When

RS_ is low the D7...0 bus is switched to the address bus

mode, and when it is high the bus is switched to the data

bus mode. The RS_ pin is also used as an external pin in

the external pin mode. Refer to the External Setting Pin

Descriptions section for more details.

RD_ Pin

This is the read enable input pin (TTL level). The data on

D7...0 is read out of the SPT2210 on the leading edge of

a high-to-low transition of RD_. If RS_ is high, the data is

read from the internal register specified by the last address write. If RS_ is low, the current address value is

read from the address register. The RD_ pin is also used

in enabling the external pin mode. Refer to the External

Setting Pin Descriptions section for more details.

WR_ Pin

This is the write enable input pin (TTL level). The data on

D7...0 is written into the address or command register on

the leading edge of a high-to-low transition of RD_. If RS_

is high, the data is written into the internal command register specified by the last address write. If RS_ is low, the

data is written into the address register. The WR_ pin is

also used in enabling the external pin mode. Refer to the

External Setting Pin Descriptions section for more

details.

AVDD Pins

These are the +3.3 V power supply pins for the analog

circuitry. VDD and AVDD are completely independent

of each other. Be sure to keep the following operating

condition:

| VDD – AVDD | ≤ 0.5 V.

GND Pins

These are the ground pins for the digital circuitry.

AGND Pins

These are the ground pins for the analog circuitry. Since

GND and AGND are completely independent of each

other, it is necessary to keep them at the same electric

potential by externally tying them together through a

ferrite bead.

Internal Pullup and Pulldown Resistors

The following pins are either pulled up or down with an

internal resistor of approximately 100 kΩ:

Pins with internal pulldown: CD7...0, YD7...0, GD3...0,

KEY, VRTENB, TEST, SUSPEND.

Pins with internal pullup: RESET_, BLANK_, V, H, CS_,

RD_, WR_, D7...0, CBF, RS, CLK.

Reset Pin

This is the reset input pin (TTL level). The reset input is

sampled on the leading edge of the system clock (CLK).

The SPT2210 is initialized by holding the RESET_ pin

low for a minimum of five clock cycles. The SPT2210 will

come out of reset five clock cycles after the RESET_ pin

has been brought back high.

CLK Pin

This is the system clock input pin (TTL level). The

YD7...0, CD7...0, GD3...0, BLANK_, V, H, Field and KEY

pins are all sampled on the rising edge of the CLK signal.

Additionally, when an asynchronous access from the

MPU is processed, the access is synchronized with this

clock and then the processing is carried out.

When the clock is switched over to another operating

frequency (i.e., changing video modes), the SPT2210

should be reset once to ensure proper operation. In this

case, the command registers will need to be set again.

VDD Pins

These are the +3.3 V power supply pins for the digital

circuitry.

SPT

SPT2210

7 8/22/00

Page 8

Figure 5 – Typical Interface Circuit

Video

Data

MPU

Interface

3.3 V

Buffer

3.3 V

Buffer

V

DD

Blank_

V

DD

0.1 4.7 µF

V

DD

V

H

8

YD7…0

8

CD7…0

CLK

CS_

CS_

WR_

WR_

RD_

RD_

RS

RS

8

D7…0

D7…0

Reset_

Reset_

SPT2210

GND

Suspend

Test

CBF

AV

DD

0.1 4.7 µF

AV

DD

GD3…0

Key

Y

C

V

REF

V

AGND

VRTENB

CS

900

75

900

75

1.4 V typ

0.1

2.7 kΩ

0.1

5

Graphics

Control

LPF

LPF

6.8 kΩ

5.1 kΩ

1 kΩ

4.7 µF

4.7 µF

SPT9400

AV

DD

33 µF75

33 µF

75

33 µF

75

Y

CVBS

C

SPT

SPT2210

8 8/22/00

Page 9

REGISTER FUNCTIONS

GENERAL DESCRIPTION

There are two general types of registers in the SPT2210.

One type is a command register and the other is a color

lookup table (CLUT). Table V shows the register mapping

for both types of registers. A third register is the address

register that enables access to command registers and

the CLUT.

Table V – Register Map

Address Register Name Default Value

00H Command Register 1 02H

01H Command Register 2 01H

02H Command Register 3 00H

03H Suspend 00H

04H HV I/O 00H

05H HV Timing 00H

06H Background Control 00H

07-0FH Reserved ---10H CLUT Entry 0 00,80,80 Transparent

1 1H CLUT Entry 1 28,70,F0 100% Blue

12H CLUT Entry 2 50,F0,58 100% Red

13H CLUT Entry 3 6C,E0,C8 100% Magenta

14H CLUT Entry 4 90,20,38 100% Green

15H CLUT Entry 5 A8,10,A8 100% Cyan

16H CLUT Entry 6 D0,90,10 100% Yellow

17H CLUT Entry 7 EC,80,80 100% White

18H CLUT Entry 8 Not Used

19H CLUT Entry 9 1C,78,B8 50% Blue

1AH CLUT Entry 10 30,B8,70 50% Red

1BH CLUT Entry 11 40,B0,A8 50% Magenta

1CH CLUT Entry 12 50,50,58 50% Green

1DH CLUT Entry 13 60,48,90 50% Cyan

1EH CLUT Entry 14 74,88,48 50% Yellow

1FH CLUT Entry 15 80,80,80 50% White

COMMAND REGISTER DESCRIPTIONS

Tables VI through XV give detailed descriptions for

programming the SPT2210 command registers.

SPT

SPT2210

9 8/22/00

Page 10

COMMAND REGISTER DESCRIPTIONS

COMMAND REGISTER CR1

CR1 (Address = 00H)

D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB

Table VI – Command Register CR1 Description Table

Address Bit # Function Bit Setting/Description Default

00H 7 Software reset 0 Normal operation 02H

1 Reset; all registers returned

to default

6 Test bar 0 Normal operation

1 Color test bar is generated

5 Not used 0 Use fixed at 0

1

4 Not used 0 Use fixed at 0

1

3 Color kill 0 Normal operation

1 Monochromatic (black and

white) image is output

2 Cr/Cb inversion 0 According to the order

1,0 Chroma key control. Set multiplex See table VII

mode of YD7...0 and CD7...0 video

input, and GD3...0 graphics input

specified by the CBF pin

1 According to the order

specified by the inverted

CBF pin

Table VII – Multiplexing Mode (Command Register 1)

D1 D0 Mode Operation

0 0 Graphics Mode GD3…0 is displayed irrespective of the KEY terminal pin state. The

transparent color cannot be specified in this mode.

0 1 Video Mode YD7…0 and CD7…0 are always selected irrespective of the state of the

1 0 Chroma Key Mode YD7…0 and CD7…0 are displayed only at the parts in which transpar-

1 1 External Key Mode YD7…0 and CD7…0 are displayed when the KEY terminal pin is set to

SPT

KEY terminal.

ent colors are specified by means of GD3…0. GD3…0 is displayed in all

other parts.

logic 0. GD3…0 is displayed when the KEY terminal is set to logic 1.

Transparent colors cannot be specified in this mode.

10 8/22/00

SPT2210

Page 11

COMMAND REGISTER DESCRIPTIONS

COMMAND REGISTER CR2

CR2 (Address = 01H)

D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB

Table VIII – Command Register CR2 Description Table

Address Bit # Function Bit Setting/Description Default

01H 7 Low pass filter bypass (U/V filters) 0 Enabled 01H

1 Disabled (bypassed)

6 Not used 0 Use fixed at 0

1

5 Not used 0 Use fixed at 0

1

4 Composite video enable 0 Component mode:

Luminance signal output

through the Y pin

1 Composite mode:

Composite signal output

through the Y pin

3 Color data format on CD7...0 0 Offset binary

1 Two’s complement

2,1,0 Video mode selection See table IX

Table IX – Video Mode (Command Register 2)

D2 D1 D0 Operation Mode

0 0 0 NTSC 4Fsc

0 0 1 NTSC square pixel

0 1 0 NTSC CCIR 601 525/60

0 1 1 Setting disabled

1 0 0 PAL 4Fsc

1 0 1 PAL square pixel, ƒS = 14.7500 MHz

1 1 0 PAL CCIR 601 625/50

1 1 1 PAL square pixel, ƒS = 12.1875 MHz

SPT

SPT2210

11 8/22/00

Page 12

COMMAND REGISTER DESCRIPTIONS

COMMAND REGISTER CR3

CR3 (Address = 02H)

D3 D2 D1 D0

MSB LSB

Table X – Command Register CR3 Description Table

Address Bit # Function Bit Setting/Description Default

02H 7-4 Not used Fix at 0 00H

3 Odd/even vertical interpolation field 0 Start at ODD field

1 Start at EVEN field

2 Vertical interpolation bypass 0 Normal operation

1 Vertical interpolation is

bypassed

1 Phase free run (NTSC only) 0 Subcarrier phase is reset

0 Setup enable (NTSC only) 0 Setup enabled

every odd frame

1 Subcarrier free run (i.e., not

reset)

1 No setup

SUSPEND REGISTER

(Address = 03H)

D0

MSB LSB

Table XI – Suspend Register Description Table

Address Bit # Function Bit Setting/Description Default

03H 7-1 Not used Fix at 0 00H

0 Suspend mode 0 Normal operation

1 Suspend

SPT

SPT2210

12 8/22/00

Page 13

COMMAND REGISTER DESCRIPTIONS

H/V I/O REGISTER

(Address = 04H)

D4 D3 D2 D1 D0

D1D2D3D4

MSB LSB

Table XII – H/V I/O Register Description Table

Address Bit # Function Bit Setting/Description Default

04H 7-5 Not used Fix at 0 00H

4 Field polarity 0 Positive logic.

3 V signal (VSYNC and VBLNK) polarity 0 Positive logic

2 H signal (HSYNC and HBLNK) polarity 0 Positive logic

1 Blank I/O 0 HBLNK/VBLNK/FIELD

0 Timing I/O 0 HSYNC/VSYNC input mode

High level = Odd field

1 Negative logic.

High level = Even field

1 Negative logic

1 Negative logic

output mode

1 HBLNK/VBLNK/FIELD

input mode

1 HBLNK/VBLNK/FIELD I/O

mode

H/V TIMING REGISTER

(Address = 05H)

D6 D5 D4 D3 D2 D1 D0

MSB LSB

Table XIII – H/V Timing Register Description Table

Address Bit # Function Bit Setting/Description Default

05H 7 Not used Fix at 0 00H

6-5 Vertical Blank timing 00 1V=240H

01 1V=241H

10 1V=242H

11 Not used

4-0 Horizontal Blank timing See table XIV

Table XIV – Horizontal Blank Timing Control (H/V Timing Register)

D4....D0 HBLNK Timing

01111 +15 clocks from the original point.

01110 +14 clocks from the original point.

••

••

••

00001 +1 clock from the original point.

00000 +0 (Default: original point)

D4....D0 HBLNK Timing

10001 –1 clock from the original point.

10010 –2 clocks from the original point.

••

••

••

11110 –14 clocks from the original point.

11111 –15 clocks from the original point.

SPT

SPT2210

13 8/22/00

Page 14

COMMAND REGISTER DESCRIPTIONS

BACKGROUND CONTROL

(Address = 06H)

D1 D0

MSB LSB

Table XV – Background Control Description Table

Address Bit # Function Bit Setting/Description Default

06H 7-2 Not used Fix at 0 00H

1 Half Y/C and 50% Color Enable. 0 Half Y/C and 50% Color

Input Y value is reduced by 50% and Disable

C is replaced with CLUT15 Cb/Cr data

1 Half Y/C and 50% Color

Enable

0 Half Y/C Enable. Input Y/C value is 0 Half Y/C Disable

reduced by half.

1 Half Y/C Enable

ACCESSING THE COMMAND REGISTERS

Access to the command registers for read or write purposes is performed in the following sequence. It requires

the correct setting of the control lines and setting the data

on the bidirectional 8-bit data bus.

Command Register Read and Write Operation

Address Setup:

Set CS_, RS low.

Set the data bus to the address required, then set

WR_ low.

Set WR_ high, then CS_ and RS high.

This completes the address write and points to the register that may be read from or written to.

Register Read:

After completing address setup, Set CS_ low, RS

high.

Set RD_ low, this enables the data from the pointed-to

register onto the data bus.

Set RD_, CS_ and RS high.

This completes the register read operation; subsequent

reads from the same register may be performed, if the

address has not been changed.

Register Write:

After completing address setup, set CS_ low, RS

high.

Set the data required onto the data bus, then set WR_

low.

Set WR_, CS_ and RS high, then release data bus

input data.

This completes the register write operation; subsequent

writes to the same register may be performed, if the

address has not been changed.

SPT

SPT2210

14 8/22/00

Page 15

COLOR LOOKUP TABLE (CLUT)

DESCRIPTION

values of Y, Cr and Cb are given by the following calculations:

CLUT FORMAT AND DATA LIMITS

The CLUT has 16 entries and is set up in YCrCb threebyte format. (See below.) The upper 6 bits in the Y data

are used (lower two are filled with zero) and the upper 5

bits in the Cr/Cb data are used (lower 3 bits are filled with

zero). Therefore the setting ranges are Y = 00H to FCH

(midpoint value = 80H) and Cr and Cb = 00H to F8H (midpoint value = 80H).

The numerical values of Cr and Cb are expressed in offset binary form, irrespective of the setting of bit D3 in

Command Register 2. Since no limit processing is carried

out in connection with the CLUT data entries, it is necessary to set Y within the limits of 16 to 236 (10H to ECH)

and Cr/Cb within the limits of 16 to 240 (10H to F0H).

Bit composition of Y (address=10H~1FH)

D7 D6 D5 D4 D3 D2 0 0

MSB LSB

Bit composition of Cr (offset binary, address=10H~1FH)

D7 D6 D5 D4 D3 000

MSB LSB

Bit composition of Cb (offset binary, address=10H~1FH)

D7 D6 D5 D4 D3

MSB LSB

000

1st Byte

2nd Byte

3rd Byte

TRANSPARENT COLOR

Transparent colors can be used in chroma key mode

(See Combining Video and Graphics Signals for more

details.) Transparent colors can be entered in the CLUT

with the following data values for Y, Cr and Cb:

Y = 00H, Cr = 80H, Cb = 80H

Y = 0.2990 x 120 + 0.5770 x 96 + 0.1140 x 96 = 102

Cr = 0.5000 x 120 – 0.4187 x 96 – 0.0813 x 96 +128

= 140

Cb = 0.1684 x 120 – 0.3316 x 96 + 0.5000 x 96 + 128

= 124

Since the SPT2210 CLUT only uses the upper 6 bits in

the Y data and the upper 5 bits in the Cr/Cb data, it is

necessary to round the results above. The second bit is

rounded in the Y calculation and the third bit is rounded in

the Cr and Cb calculation. The results are shown below:

Y = 102 = 01100110 (binary) results in 01101000

(binary) = 104

Cr = 140 = 10001100 (offset binary) results in

10010000 (offset binary) = 144

Cb = 124 = 01111100 (offset binary) results in

10000000 (offset binary) = 128

ACCESSING THE COLOR LOOKUP TABLE

The method for accessing the CLUT is different from the

method for accessing the command registers because

each entry of the CLUT has a length of 3 bytes at each

address. The CLUT is accessed by means of three successive bytes after writing the address. Note that Y, Cr

and Cb cannot be accessed individually in the CLUT.

They must be accessed in units of three bytes sequentially.

Color Lookup-table Register Read and Write

Operation

Address Setup:

Set CS_, RS low.

Set the data bus to the address required (10H – 1FH),

then set WR_ low.

Set WR_ high, then CS_ and RS high.

This completes the address write and points to the CLUT

registers that may be read from or written to.

When these data values are selected in the CLUT, the

graphics data becomes transparent and the SPT2210

displays the video YD7...0 and CD7...0 data instead.

COLOR SPACE CONVERSION FROM RGB TO

YCRCB FOR CLUT ENTRY

The SPT2210 CLUT stores data in YCrCb format only.

RGB graphics data must be converted in the host before

loading the CLUT. The conversion for RGB to YCrCb is

shown here:

Y = 0.2990 x R + 0.5770 x G + 0.1140 x B

Cr = 0.5000 x R – 0.4187 x G – 0.0813 x B +128

Cb = 0.1684 x R – 0.3316 x G + 0.5000 x B + 128

Example: Assume that each RGB data is 8 bits in length

and that their values are R = 120, G = 96, B = 96. The

SPT

Register Read:

After completing address setup, Set CS_ low, RS

high.

Set RD_ low; this enables the data from the pointed-

to register onto the data bus (first byte, Y data).

Set RD_ high, then set RD_ low; this enables the data

from the pointed-to register onto the data bus (second

byte, Cr data).

Set RD_ high, then set RD_ low; this enables the data

from the pointed-to register onto the data bus (third

byte, Cb data).

Set RD_, CS_ and RS high.

This completes the three-byte sequence of CLUT register

read operation at the specified address.

SPT2210

15 8/22/00

Page 16

Register Write:

After completing address setup, set CS_ low, RS

high.

Set the data required onto the data bus, then set WR_

low and then back high; this will write the Y data.

Set the data required onto the data bus, then set WR_

low and then back high; this will write the Cr data.

Set the data required onto the data bus, then set WR_

low and then back high; this will write the Cb data.

Set WR_, CS_ and RS high, then release data bus

input data.

This completes the three-byte sequence of the CLUT

register write operation at the specified address.

Figure 6 – Multiplex in Chroma Mode

GD3…0 (Except

transparent color)

YD7…0, CD7…0

+

GD3…0

YD7…0

CD7…0

GD3…0

(Transparent)

COMBINING VIDEO AND

GRAPHICS SIGNALS

VERTICAL INTERPOLATION

The SPT2210 has a vertical interpolation filter that is

used to reduce jaggy noise and flicker. It also supports

EXTERNAL KEY MODE

the high resolution mode for Video CD, version 2.0.

The external key mode is selected by setting the command register CR1, bits D1...0 = 1 1 (binary). In this mode

it is possible to combine the video signals (YD7...0,

CD7...0) with the graphics signals (GD3...0). When the

KEY pin is high, in conformity with the timing shown in

figure 8, the graphics signals (out of the CLUT and referenced by GD3...0) are output (i.e., displayed). This can

be done on a pixel-by-pixel basis.

CHROMA MODE

The chroma key mode is selected by setting the command register CR1, bits D1...0 = 10 (binary). In this mode

the graphics signal image becomes the front image, and

the Y/C image becomes the rear image. The Y/C image is

displayed in the portions of the display in which the transparent colors are specified in the graphics image data

stream. Figure 6 illustrates the combining of video and

graphics images in the chroma mode.

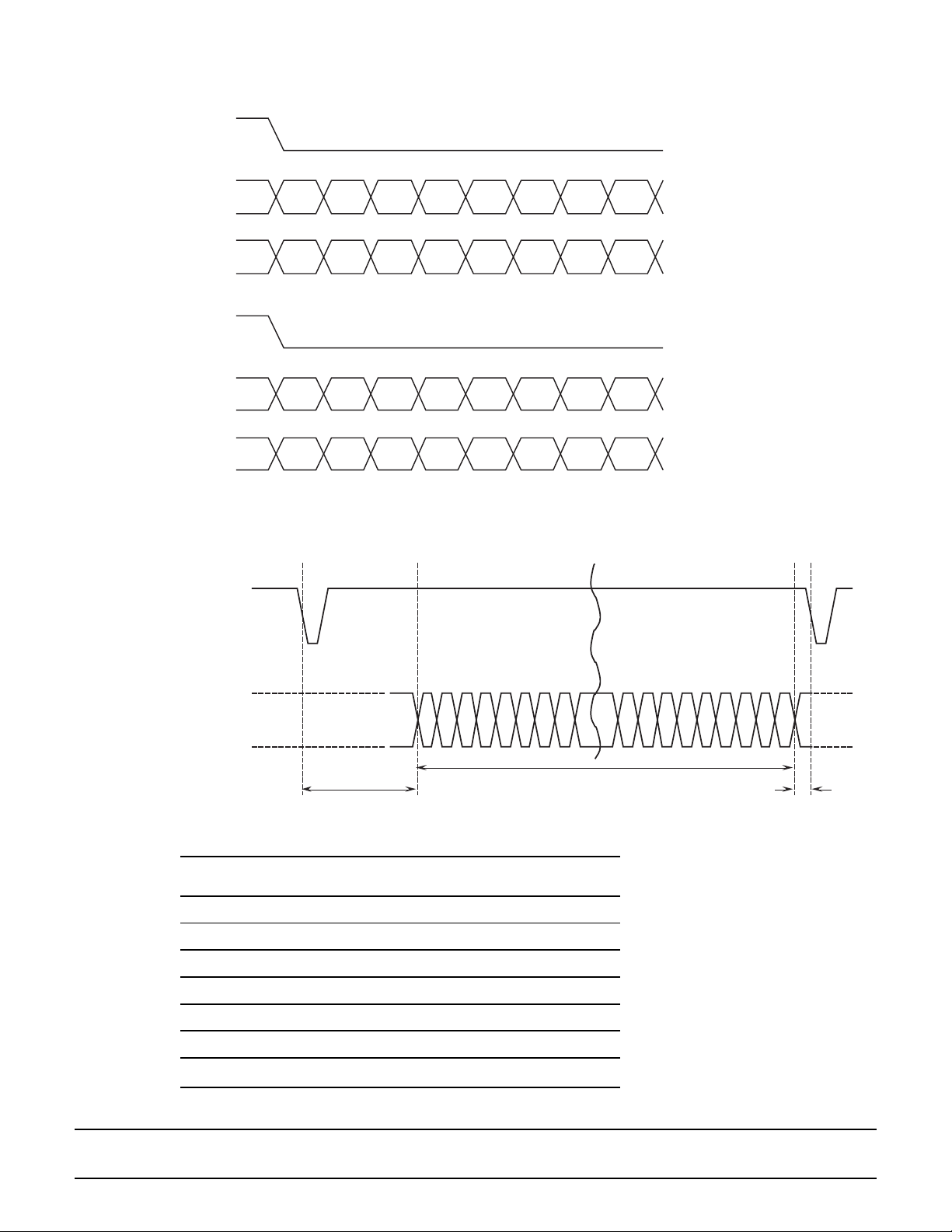

INTERPOLATION FIELD SELECTION

The vertical interpolation filter is active for each odd or

even field as specified in command register CR3, bit D3.

However, vertical interpolation is not active for NTSC line

21 and P AL line 25 when the ODD field is selected (CR3,

bit D3 = 0) and NTSC line 285 and P AL line 336 when the

EVEN field is selected (CR3, D3 = 1).

INTERPOLATION BYPASS

Vertical interpolation is automatically enabled and dis-

abled for the proper even/odd field depending on the field

selection specified in CR3, bit D3. The VRTENB pin en-

ables interpolation, in conjunction with the even/odd field

algorithm, as shown in figures 7 and 8. The interpolation

filter may be bypassed altogether by setting bit D2 in

command register CR3 or setting the VRTENB pin to

logic low.

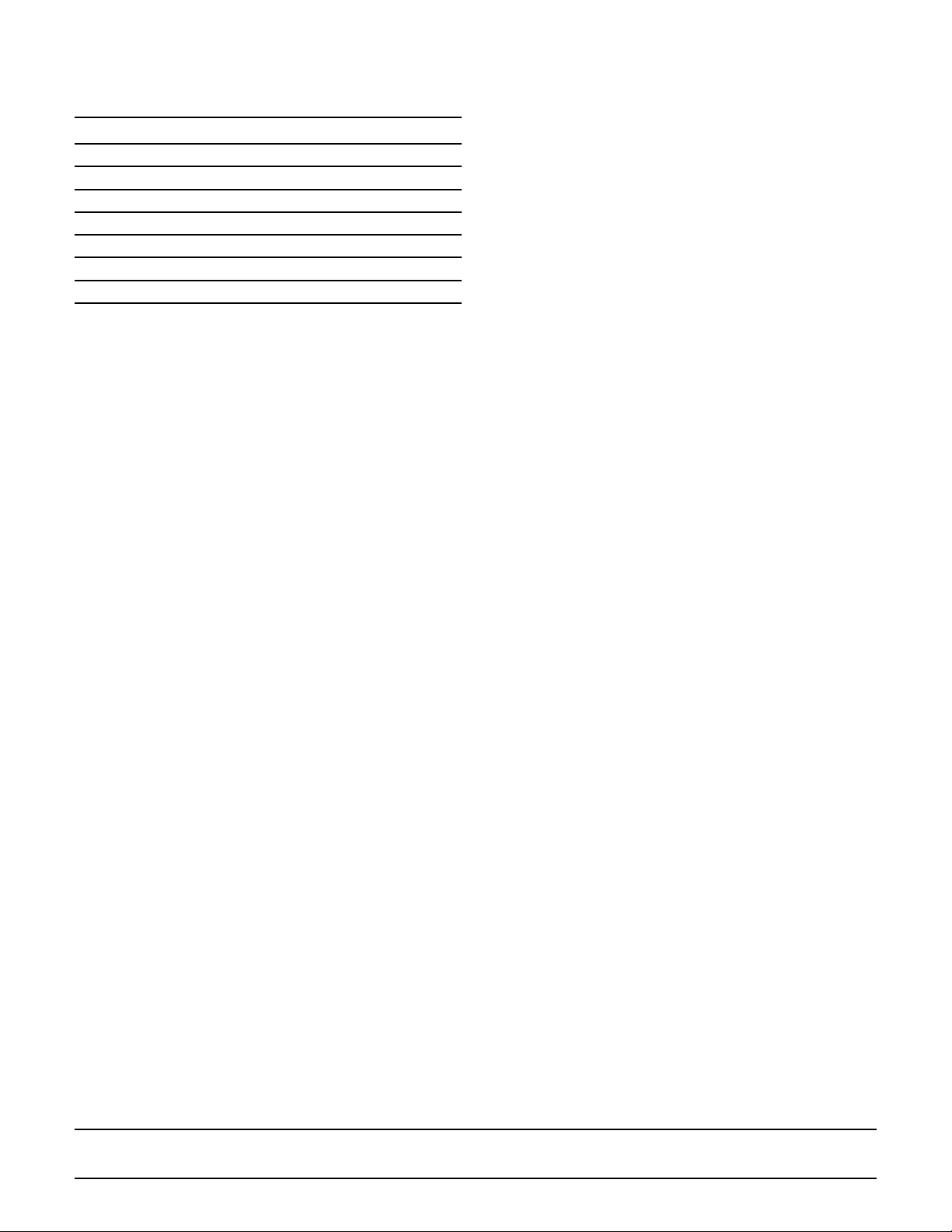

Figure 7 – Vertical Interpolation Timing CR3 D2=0, D3=1; Even Field

Even Odd Even Odd Even Odd

HSYNC_

VSYNC_

VRTENB

Vertical Interpolation

Bypass Bypass Active Bypass Bypass Bypass

Figure 8 – Vertical Interpolation Timing CR3 D2=0, D3=0; Odd Field

Even Odd Even Odd Even Odd

HSYNC_

VSYNC_

VRTENB

Vertical Interpolation

SPT

Bypass Active Bypass Active Bypass Bypass

16 8/22/00

SPT2210

Page 17

EXTERNAL SETTING PIN DESCRIPTIONS

The SPT2210 has the capability of operating without a

host interface and allowing certain programmable settings to be accessed via external pins. When the RD_,

WR_ and CS_ pins are all held (or tied) low for a minimum of three clock pulses, the D7...0 bus and the RS pin

can be used for external setting of various modes and

functions. (When these pins are not used as external setting pins, they are ordinary pins for host interface.)

Figure 9 – Multiplexing in the External Key Mode

VSYNC

HSYNC

Key

Key

Table XVI below shows the pin function assignments and

settings for the D7...0 and RS pins.

YD7…0

CD7…0

Table XVI – D7...0 and RS Pin External Setting Description Table

Pin # Function Bit Setting Description

D7 Composite video mode 0 Y/C (S-Video)

1 Composite video

D6 Color bars 0 Normal operation

1 Generate color bars

D5 Phase reset (NTSC only) 0 Subcarrier phase is reset at every

1 Free run; subcarrier phase is not reset

D4,3 SYNC/BLNK I/O D4 D3 SYNC, BLNK, I/O

0 0 BLNK Input

0 1 SYNC Input

1 0 BLNK Output

1 1 Reserved

D2...0 Video mode setting D2 D1 D0 Mode

0 0 0 NTSC 4Fsc

0 0 1 NTSC Square Pixel

0 1 0 NTSC CCIR 601 525/60

0 1 1 Setting disabled

1 0 0 PAL 4Fsc

1 0 1 PAL Square Pixel (ƒ

1 1 0 PAL CCIR 601 625/50

1 1 1 PAL Square Pixel (ƒS=12.1875 MHz)

RS Setup (NTSC only) 0 Setup enabled

1 No setup

odd frame

=14.7500 MHz)

S

GD3…0

SPT

SPT2210

17 8/22/00

Page 18

ABSOLUTE MAXIMUM RATINGS (Beyond which damage may occur)1 25 °C

Supply Voltages

VDD......................................... VSS –0.3 to V

AVDD...................................... VSS –0.3 to V

SS

SS

+4.6 V

+4.6 V

Input/Output Voltages

Digital Inputs ..........................V

Digital Outputs ....................... V

–0.3 to VDD +0.3 V

SS

–0.3 to VDD +0.3 V

SS

Note:1.Operation at any Absolute Maximum Rating is not implied. See Electrical Specifications for proper nominal

applied conditions in typical applications.

Temperature

Operating Temperature .............................. 0 to 70 °C

Junction Temperature ..................................... 150 °C

Lead Temperature (soldering 10 seconds) ..... 300 °C

Storage Temperature ......................... –40 to +125 °C

ELECTRICAL SPECIFICATIONS

TA = +25 °C, A VDD=VDD=+5.0 V , unless otherwise specified.

TEST TEST

PARAMETERS CONDITIONS LEVEL MIN TYP MAX UNIT

Analog Outputs

Differential Linearity ±0.5 LSB

Integral Linearity ±1.0 LSB

Output Full-Scale Current 13 mA

Digital Inputs

Reset Pin

V

IH

V

IL

I

IH

I

IL

VIH = V

VIL = V

DD

SS

0.7 x V

DD

0.3 x V

–10 10 µA

–10 10 µA

Digital Outputs

V

OH

V

OL

IOH = –4 mA 2.4 V

IOL = 4 mA 0.4 V

Power Supply

V

AV

V

I

DD

DD

DD

DD

–A V

DD

VDD=+3.3 V , ƒ=17.73 MHz 50 mA

3.0 3.6 V

3.0 3.6 V

–0.5 +0.5 V

Timing Characteristics

CS Setup (TCSS) 10 ns

CS Hold (TCSH) 10 ns

RS Setup (TRSS) 10 ns

RS Hold (TRSH) 10 ns

RDWR_ Pulse Low (TRWL) 1 X TCC

RDWR_ Pulse High (TRWH) 1 X TCC

Delay to Data Bus Valid (TDBV) C

=50 pF 25 ns

L

Output Data Delay Time (TDLY) CL=50 pF 3 20 ns

Data Output Disable (TDOD) 20 ns

Data Output Hold (TDOH) 3 ns

Write Data Setup (TWDS) 10 ns

Write Data Hold (TWDH) 10 ns

Clock Cycle (TCC) 56 ns

Clock Pulse High (TCH) 20 ns

Clock Pulse Low (TCL) 20 ns

Input Data/Cont Setup (TIS) 10 ns

Input Data/Cont Hold (TIH) 10 ns

Reset Pulse Width (TRSW) 5 X TCC ns

DD

V

V

SPT

SPT2210

18 8/22/00

Page 19

TEST LEVEL CODES

All electrical characteristics are subject

to the following conditions:

All parameters having min/max specifications are guaranteed. The Test Level

column indicates the specific device

testing actually performed during production and Quality Assurance inspection. Any blank section in the data

column indicates that the specification

is not tested at the specified condition.

TEST LEVEL TEST PROCEDURE

I 100% production tested at the specified temperature.

II 100% production tested at TA = +25 °C, and sample tested at the

specified temperatures.

III QA sample tested only at the specified temperatures.

IV Parameter is guaranteed (but not tested) by design and characteriza-

tion data.

V Parameter is a typical value for information purposes only.

VI 100% production tested at T

specified temperature range.

= +25 °C. Parameter is guaranteed over

A

SPT

SPT2210

19 8/22/00

Page 20

Figure 10 – MPU Interface Timing

CS_

RS_

TCSS TCSH

TRSS TRSH

TRWL TRWH

RD_, WR_

D7…0 (READ)

D7…0_

Figure 11 – AC Data Timing

CLK

TDOD

TDOHTDBV

TWDS TWDH

TCC

TCL TCH

INPUT DATA:

H, V, FIELD, BLANK,

YD7…0, CD7…0, GD7…0,

KEY, SUSPEND, VRTENB

OUTPUT DATA:

H, V, FIELD

SPT

TIS TIH

TDLY

SPT2210

20 8/22/00

Page 21

PACKAGE OUTLINE

64-LEAD PQFP

A

64 49

1 48

16

17

C D

B

Index

32

K

G

INCHES MILLIMETERS

SYMBOL MIN MAX MIN MAX

A 0.465 0.480 11.80 12.20

B 0.390 0.398 9.90 10.10

C 0.017 0.023 0.42 0.58

D 0.006 0.010 0.15 0.26

E 0.295 typ 7.5 typ

E F

F 0.465 0.480 11.80 12.20

G 0.055 0.067 1.40 1.70

H 0.0049 0.0052 0.125 0.132

33

I 0-10° 0-10°

J 0.012 0.028 0.30 0.70

K 0.000 0.008 0.00 0.20

H

J

I

SPT

SPT2210

21 8/22/00

Page 22

PIN ASSIGNMENTS

CD5

CD6

CD7

63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

64

YD0

YD1

YD2

YD3

YD4

YD5

YD6

YD7

GND

V

CBF

BLANK_

VRTENB

FIELD

DD

1

2

3

4

5

6

7

8

9

10

11

12

V

13

H

14

15

16

17

18 19 20 21

CD4

DD

V

AGND

GND

CD0

CD1

CD2

CD3

SPT2210

22 23 24 25 26 27 28 29 30 31

AV

N/C

N/C

DD

Y

32

C

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

AGND

V

CS

V

REF

AGND

AV

DD

SUSPEND

TEST

V

DD

GND

D0

D1

D2

D3

V

DD

CLOCK

GND

KEY

GD3

GD2

GD1

GD0

CS_

RS

RD_

WR_

RESET_

GND

DD

D7

V

D6

D5

D4

ORDERING INFORMATION

PART NUMBER DESCRIPTION TEMPERATURE RANGE PACKAGE TYPE

SPT2210SCT Y/C Video Encoder 0 to +70 °C 64L PQFP

Signal Processing Technologies, Inc. reserves the right to change products and specifications without notice. Permission is hereby

expressly granted to copy this literature for informational purposes only. Copying this material for any other use is strictly prohibited.

WARNING – LIFE SUPPORT APPLICATIONS POLICY – SPT products should not be used within Life Support Systems without the

specific written consent of SPT. A Life Support System is a product or system intended to support or sustain life which, if it fails, can

be reasonably expected to result in significant personal injury or death.

Signal Processing Technologies believes that ultrasonic cleaning of its products may damage the wire bonding, leading to device

failure. It is therefore not recommended, and exposure of a device to such a process will void the product warranty.

SPT

SPT2210

22 8/22/00

Loading...

Loading...