Page 1

SP8853A/B

1·3GHz Professional Synthesiser

The SP8853 is a low power single chip synthesiser

intended for professional radio applications, containing all the

elements (apart from the loop amplifier) required to build a PLL

frequency synthesis loop

The device is serially programmable by a three-wire data

highway and contains three independent buffers to store one

reference divider word and two local oscillator divider words.

A digital phase detector with two charge pumps,

programmable in phase and gain, are provided to improve

lock-up performance. The preset operation of the charge

pumps can be overwritten or the comparison frequencies

switched to output ports under control of the divider word. The

dual modulus ratio and so operating range is also

programmable through the same word.

A power down mode is incorporated as a battery economy

feature.

The SP8853 is specified at 1·3GHz at 255°C to1125°C (A

grade) and 240°C to185°C (B grade).

Supersedes March 1997 version, DS2352 - 3.0 DS2352 - 4.0 March 1998

FEATURES

■ Improved Digital Phase Detector Eliminates

‘Dead Band’ Effects

■ Low Operating Power, Typically 175mW

■ 1·3GHz Operating Frequency

■ Complete Phase Locked Loop

■ High Input Sensitivity

■ Programmed throughThree-Wire Bus

■ Wide Range of Reference Division Ratios

■ Local Storage for Two Frequency Words, giving

Rapid Frequency Toggling

■ Programmable Phase Detector Gain

■ Power Down Mode

ABSOLUTE MAXIMUM RATINGS

Supply voltage

Storage temperature

Prescaler input voltage

20·3V to 17V

255°C to 1150°C

2·5V p-p

Fig. 1 Pin identification diagram (top view)

ORDERING INFORMATION

SP8853/A/HC Military temperature range

SP8853/B/HC Industrial temperature range

4321282726

12 13 14 15 16 17 18

5

6

7

8

9

10

11

25

24

23

22

21

20

19

PD2 OUTPUT

RPD

V

CC

3

GROUND

XTAL 1

XTAL2

V

EE

2

F

REF

*

POWER DOWN

V

EE

4

V

CC

4

V

CC

1

RF INPUT

RF INPUT

F

PD

*

PD1 OUTPUT

V

EE

3

ICCdLOCK DETECT

NC

V

EE

1

F1/F2

DATA

CLOCK

ENABLE

NC

V

CC

2

SP8853

HC28

*FPD and F

REF

outputs are reversed by the phase

detector sense bit in the F1/F2 programming word. The

above diagram is correct when the sense bit is low. See

Table 2 and Fig. 7.

V

CC

1, VEE1 – preamplifier and prescaler supplies

VCC2, VEE2 – oscillator supplies

V

CC

3, VEE3 – charge pump 2 supplies

VCC4, VEE4 – ECL supplies

Page 2

2

SP8853A/B

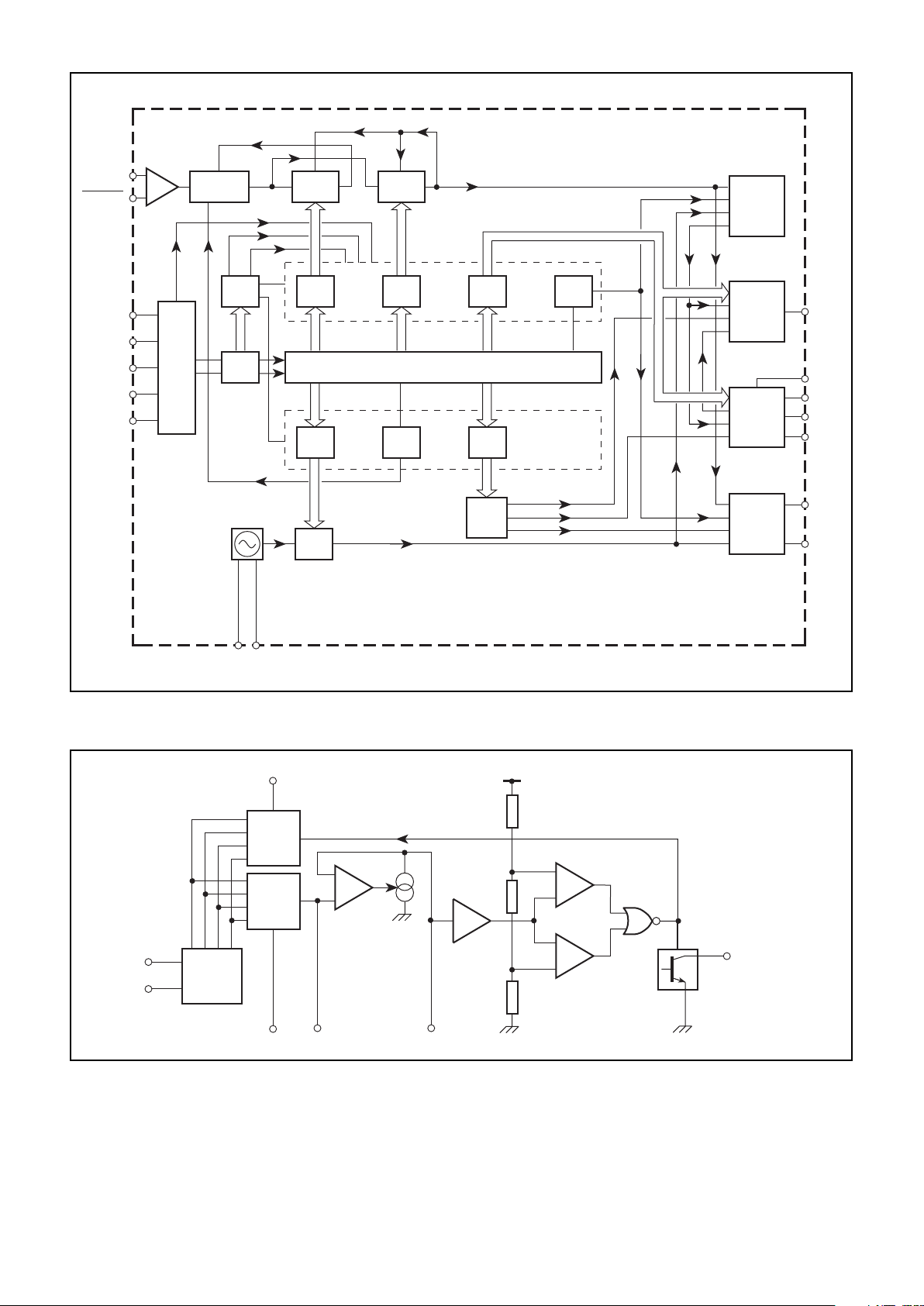

Fig. 2 SP8853 block diagram

Fig. 3 Detailed block diagram of lock detect circuit

f

PD

11

15 BIT

M COUNT

1LOGIC

4 BIT

A COUNT

1LOGIC

2 BIT 1 BIT

DUAL

F1/F2

DATA

BUFFER

N0 N3 N4 N18 N19 N20 N21

22 BIT SHIFT REGISTER

1 BIT13 BIT 2 BIT

N0 N12 N14 N15N13

SINGLE

REFERENCE

BUFFER

LOGIC

2-BIT

SR

DATA

INPUT

16/17 OR 8/9

CONTROL

f

REF

PHASE

DETECTOR

LOGIC

R

COUNT

OUTPUT

INTERFACE

CHARGE

PUMP 1

CHARGE

PUMP 2

PD1

3

LOCK

DETECT

RF INPUT

10

F1/F2

DATA

CLOCK

ENABLE

POWER

DOWN

13

14

15

16

6

PD2

25

27

Cd

28

RPD

24

20

21

CRYSTAL

F

REF

*

5

4

FPD*

*

F

REF

and FPD outputs are reversed by the phase detector

sense bit in the F1/F2 programming word. The pin allocations

shown are correct when the sense bit is low (see Table 2 and Fig. 7).

RF INPUT

REFERENCE

DIVIDER

−

+

V

CC

PHASE

DETECTOR

f

PD

f

REF

CHARGE

PUMP 2

TRANSCONDUCTANCE

AMPLIFIER

31

CHARGE

PUMP 1

−

+

−

+

31

31 BUFFER

10k

45k

45k

DUAL VOLTAGE

COMPARATOR

PD1

3

CHARGE PUMP 1 DISABLE

(SEE TABLE 4)

RPD

24

PD2

25

Cd

28

LOCK DETECT

27

Output current at pin 27 is proportional to

voltage difference between pins 25 and 28,

I

MAX

= 625µA

Page 3

3

SP8853A/B

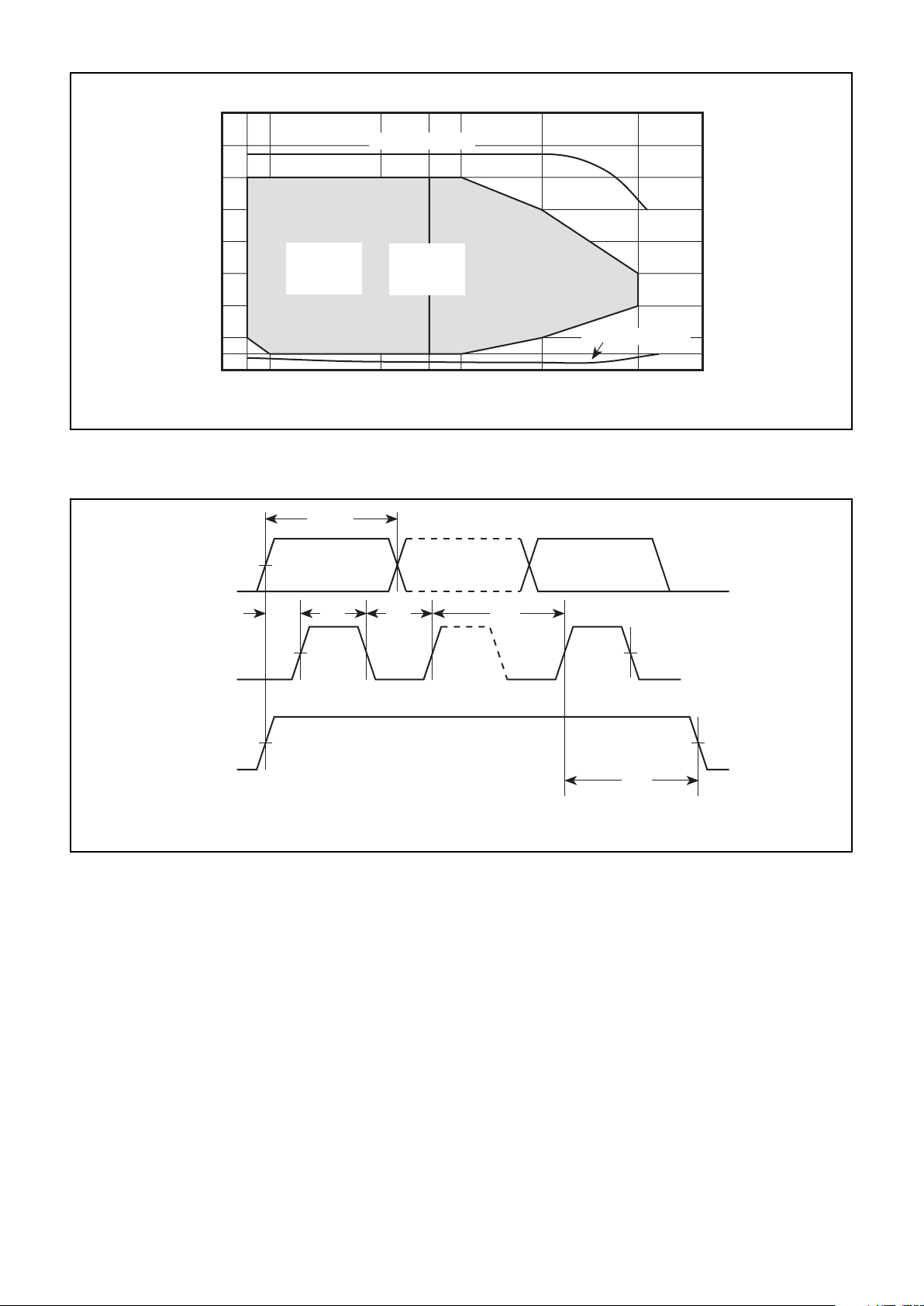

tS1t

CH

2V

t

S

t

CH

t

CL

t

REP

2V

2V

t

E

LAST DATA BITFIRST DATA BIT

DATA

CLOCK

ENABLE

t

REP

= 1µs min., t

S

= 50ns min., tCH = 50ns min., tCL = 100ns min., tE = 50ns min.

FREQUENCY (MHz)

400

350

300

250

200

150

100

50

0

0

INPUT VOLTAGE (mV RMS)

25

500

650 750

1000 1300 150015080

GUARANTEED

OPERATING

WINDOW

4

16/17 MODE

GUARANTEED

OPERATING

WINDOW

4

8/9 MODE

TYPICAL OVERLOAD

TYPICAL SENSITIVITY

Fig. 4 Typical input characteristics and input drive requirements for SP8853 A and B

Fig. 5 Data and clock timing requirements

Page 4

4

SP8853A/B

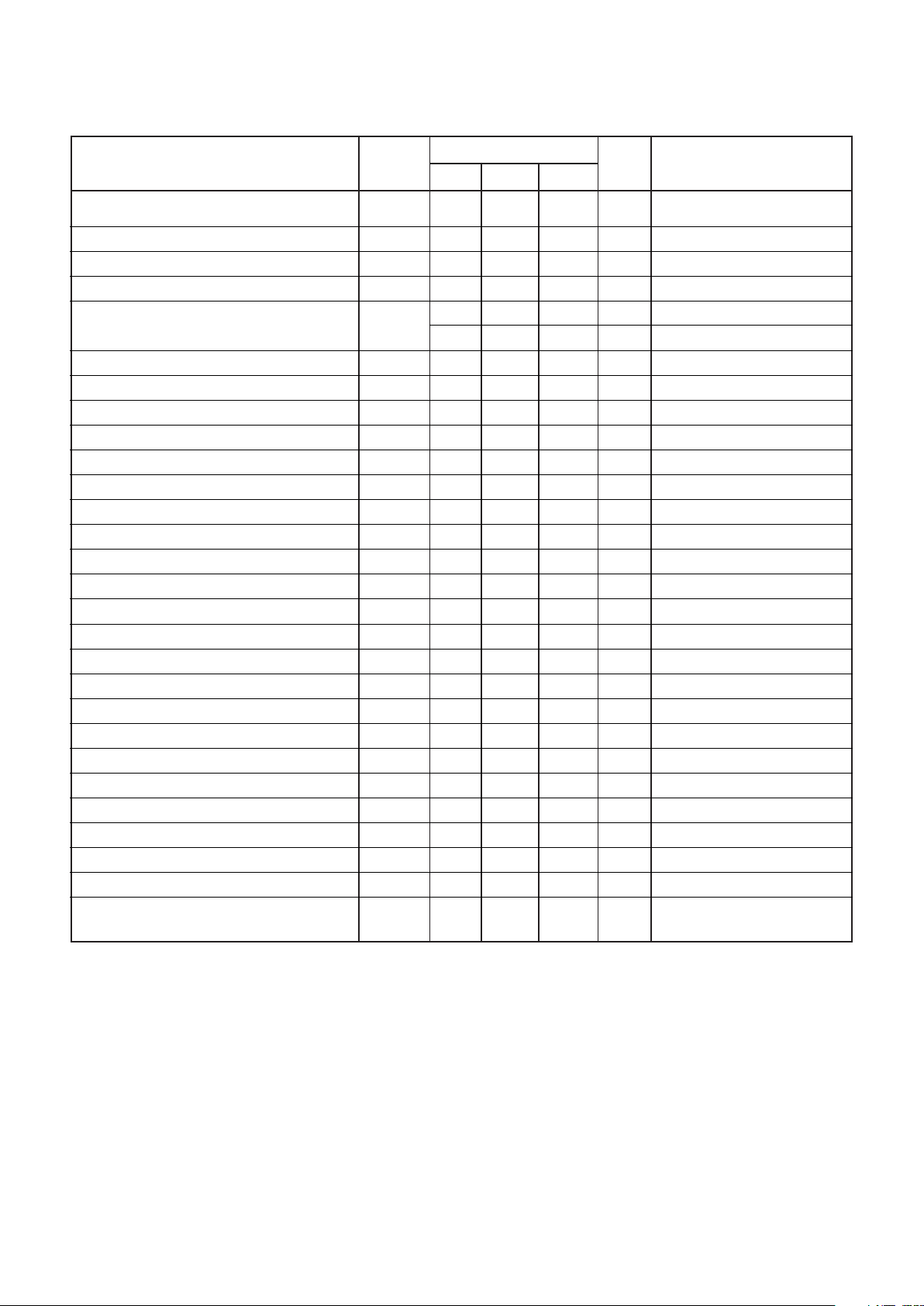

ELECTRICAL CHARACTERISTICS

These characteristics are guaranteed over the following range of operating conditions unless otherwise stated:

Supply voltage VCC = 14·75V to 15·25V. T

AMB

= 255°C to 1125°C (A Grade), 240°C to 185°C (B Grade)

Characteristic Conditions

Supply current

Supply current in power down mode

Input sensitivity

Input overload

RF input division ratio

Comparison frequency

Reference oscillator input frequency

External reference input voltage

Reference division ratio

Data clock repetition rate, t

REP

Minimum setup time, t

S

DATA input high

DATA input low

CLOCK input high

CLOCK input low

Data ENABLE high

Data ENABLE low

F1/F2 input high

F1/F2 input low

POWER DOWN input high

POWER DOWN input low

F1/F2 input current

POWER DOWN input current

RDP external resistance

LOCK DETECT output voltage when in lock

LOCKDETECT switching voltage high

LOCK DETECT switching voltage low

F

PD

and F

REF

output voltage swing

256

56

4

10

1

50

0·6V

CC

V

EE

0·6V

CC

V

EE

0·6V

CC

V

EE

0·6V

CC

V

EE

0·6V

CC

V

EE

68

2·7

40

7·5

524287

262143

5

20

500

8191

1

V

CC

0·3V

CC

V

CC

0·3V

CC

V

CC

0·3V

CC

V

CC

0·3V

CC

0·9V

CC

0·3V

CC

5

5

330

1

2·3

33

4·5

0·9

Pin

8,9,18,23

8

10,11

10,11

10,11,4

4,5

20,21

20

20,5

15

14,15

14

14

15

15

16

16

13

13

6

6

13

6

24

27

25

25

Typ. Max.

Min.

mA

mA

MHz

MHz

mVrms

µs

ns

V

V

V

V

V

V

V

V

V

V

µA

µA

kΩ

V

V

V

V

Units

Value

See Fig. 4

See Fig. 4

With 416/17 selected

With 48/9 selected

See Fig. 5

See Fig. 5

F1 buffer selected

F2 buffer selected

V pin 13 = 5·0V

V pin 6 = 4·5V

I pin 27 = 1mA

V

CC

= 5V

V

CC

= 5V

V

CC

= 5V, external pulldown

may be required

Page 5

5

SP8853A/B

DESCRIPTION

Prescaler and AM Counter

The programmable divider chain is of AM counter design

and therefore contains a dual modulus front end prescaler, an

A

counter which controls the dual modulus ratio and an

M

counter which controls the bulk multi-modulus division.

A programmable divider of this type has a division ratio of

MN1A

and a minimum integer steppable division ratio

of N(N21).

In the SP8853, the dual modulus front end prescaler is a

dual

N

ratio device, capable of being statically switched

between 416/17 and 48/9 ratios. The controlling A counter is

of four-bit design, allowing a maximum count sequence of 15

(2

4

21), which begins with the start of the M counter sequence

and stops when it has counted by the pre-loaded number of

cycles. While the A counter is counting, the dual modulus

prescaler is held in the

N

11 mode then reverts to the N mode

at the completion of the sequence.

The

M

counter is a 15-bit asynchronous divider which

counts with a ratio set by a control word. In both A and

M

counters the controlling data from the F1/F2 buffer is loaded

in sequence with every

M

count cycle. The N ratio of the dual

modulus prescaler is selected by a one-bit word in the

reference divider buffer and, when when a ratio of 48/9 is

selected, the A counter requires only three programming bits,

having an impact on the frequency bit allocation as described

in the data entry section.

Reference Source and Divider

The reference source in the SP8853 is obtained from an

on-chip oscillator which is frequency controlled by an external

crystal. The oscillator can also function as a buffer amplifier to

allow the use of an external reference source. In this mode, the

source is simply AC-coupled into the oscillator transistor base

on pin 20.

The oscillator output is coupled to a programmable reference

counter (

R

) whose output is the reference for the phase

detector. The reference divider is a fully programmable 13-bit

asynchronous design and can be set to any division ratio

between 1 and 8191. The actual division ratio is controlled by

a data word stored in the internal reference buffer.

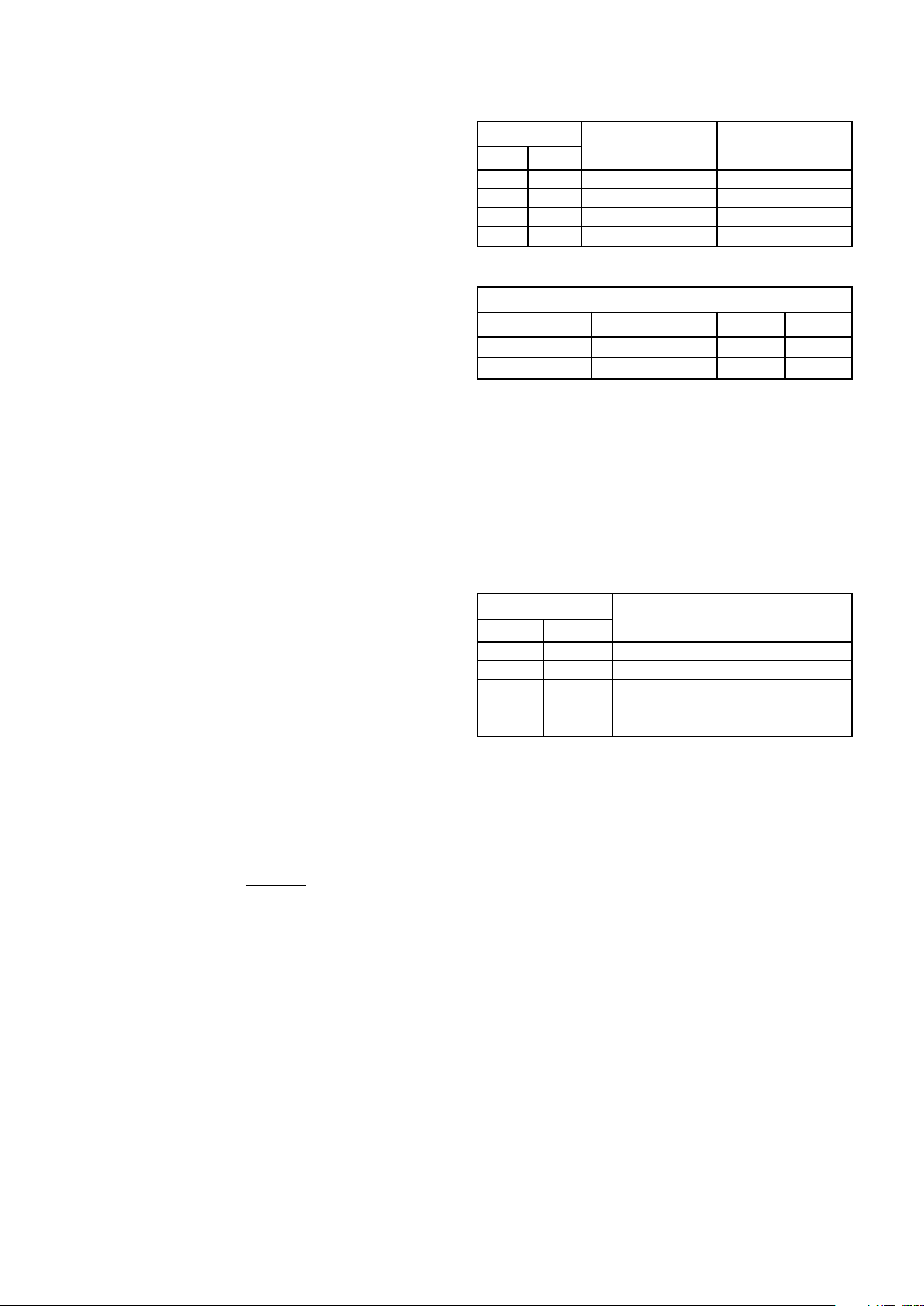

Phase Detector

The SP8853 contains a digital phase detector which feeds

two charge pump circuits. Charge pump 1 has preset currents

which are programmble as shown in Table 1. Charge pump 2

has a current level set by an external resistor RPD; the current

is multiplied by a factor which is determined by bits G1 and G2

of the F1 or F2 word (see Table 1). Note that charge pump 2

current is pin 24 current 3 muliplication factor, where

I pin 24 =

A lock detect circuit is connected to the output of charge

pump 2. when the voltage level at pin 25 is between

approximately 2·25V and 2·75V, LOCK DETECT (pin 27) will

be low and charge pump 1 disabled, depending on the PD1

and PD2 programming bits as shown in Table 4.

The output signals from the

R

and M counters are available

on pins 4 and 5 (FPD and F

REF

) when programmed by the

reference programming word; the various options are shown

in Table 4. An external phase detector may be connected to

pins 4 and 5 and may be used independently or in conjunction

with the on-chip phase detector.

To allow for control direction changes introduced by the

design of the control loop, a control bit in the F1/F2 programming

word interchanges the inputs to the on-chip phase detector

and reverses the functions on pins 4 and 5 (see Table 2).

V

CC

21·5V

RPD

F1 or F2 word

G2 G1

Charge pump 1

current (

µA)

Charge pump 2

multiplier

0

1

Current source

Current sink

F

PD

F

REF

F1/F2 sense bit Pins 3 and 25 Pin 4

Output for RF phase lag

F

REF

F

PD

Pin 5

0

1

0

1

0

0

1

1

50

75

125

200

1

1·5

2·5

4

Table 1 Charge pump currents

Table 2

Data Entry and Storage

The data section of the SP8853 consists of a data input

interface, a data shift register and three data buffers.

Data is entered to the data input interface via a three-wire

highway, with DATA (pin 24), CLOCK (pin 15) and ENABLE

(pin16) inputs. The input interface routes the data into a 24bit shift register with bus connections to three data buffers.

Data entered via the serial bus is transferred to the appropriate

data buffer on the negative transition of the data enable input

according to the two final data bits C1 and C2 as shown in

Table 3. The MSB of the data is entered first.

2-bit SR contents

C2 C1

0

1

0

1

F1

F2

Transfer A counter bits (N0:N3)

into 4-bit buffer (see Figs. 2 and 7)

Reference

0

0

1

1

Buffer loaded

Table 3

The dual F1/F2 buffer can receive two 22-bit words and

controls the programmable divider A and M counters using 19

bits, the phase detector gain with two bits and the phase

detector sense with one bit. A fourth input from the synthesiser

control system selects the active buffer.

The third buffer contains only 16 bits, 13 being used to set

the reference divider division ratio and 2 to control the phase

detector enable logic. The remaining bit sets the dual modulus

prescaler

N

ratio.

The data words may be entered in any individual multiple

sequence and the shift register can be updated whils the data

buffers retain control of the synthesiser with the previously

loaded data. This enables four unique data words to be stored

in the device, with three in the data buffers and a fourth in the

shift register, while the chip is enabled. The F1 word may also

be updated while F2 is controlling the programmable divider

and vice-versa.

The dual F1/F2 buffer enables allows the device to be

toggled between two frequencies using the F1/F2 select input

at a rate determined by the comparison frequency and also

permits random frequency hopping at a rate determined by a

btye load period; this is possible because the loop can be

locked to F1 while F2 is updated by entering new data via the

shift register. The F1/F2 input is high to select F1.

Page 6

6

SP8853A/B

An F1 or F2 update cycle will consist of a byte containing

24 bits whereas the reference byte will contain 18 bits. The

device requires 3 bytes, each with a chip select sequence,

totalling 66 bits to fully program.

When the dual modulus

A

counter is set to 48/9, the data

required to set the counter is reduced by one bit, leaving an

unused bit in the 22-bit F1/F2 buffer. This bit must always be

set to zero when the 48/9 mode is required. Various

programming sequences are shown in Fig. 7.

The data entry and storage registers are always powered

up, making it possible to enter data when the device is in the

powered down state.

PD2 PD2 Result

0

1

0

1

0

0

1

1

F

REF

and FPD outputs off, charge pumps 1 and 2 on

F

REF

and FPD outputs on, charge pump 1 off, charge pump 2 on

F

REF

and FPD outputs off, charge pump 1 disabled by lock detect, charge pump 2 on

F

REF

and FPD outputs on, charge pump 1 disabled by lock detect, charge pump 2 on

Table 4

Fig. 6 Application diagrams

15V

CONTROL

MICRO

4321282726

12 13 14 15 16 17 18

5

6

7

8

9

10

11

25

24

23

22

21

20

19

SP8853

1n

33p

39p

F

REF

F

PD

15V

1n0·1µ

15V

SL562

−

+

C1

C2

R2

Rx

Rx

LOOP FILTER

VOLTAGE

CONTROLLED

OSCILLATOR

1n

V

CC

2

15V

Rb RPD

15V

2·2k

Rb

>

0·25

PD2 current

Fig. 6a Typical application

1282726

25

24

SP8853

Cd

V

CC

Ra

Ra

23

TO LOOP

AMPLIFIER

Fig. 6c Use of lock detect circuit with PD1

Fig. 6b Connection

of external reference

EXTERNAL

REFERENCE

SOURCE

NC

21

20

19

15V

22k

470

TO VCO

VARICAP

SUPPLY

10k

LOOP

FILTER

FROM

CHARGE

PUMP

Fig. 6d Simple discrete amplifier

Ra

> 23

0·25

PD2 current

V

CC

Page 7

7

SP8853A/B

Fig. 7 Data format diagrams

G2 G1 21821721621521421321221121029282726252423222120C2 C1

MSB LSB

PHASE

DETECTOR GAIN

CONTROL

(SEE TABLE 1)

PHASE

DETECTOR

SENSE BIT

(SEE TABLE 2)

15-BIT PROGRAMMABLE COUNTER (M COUNTER) 4-BIT

PROGRAMMABLE

COUNTER

(A COUNTER)

CONTROL

LOGIC

(SEE

TABLE 3)

Fig. 7a F1 or F2 word, bit allocation with 416/17 selected

G2 G1 2172162152142132122112102928272625242

3

222120C2 C1

MSB LSB

PHASE

DETECTOR GAIN

CONTROL

(SEE TABLE 1)

15-BIT PROGRAMMABLE COUNTER (M COUNTER) 3-BIT

PROGRAMMABLE

COUNTER

(A COUNTER)

CONTROL

LOGIC

(SEE

TABLE 3)

Fig. 7b F1 or F2 word, bit allocation with 48/9 selected

0

MUST BE ZERO

PD1 PD2 21221121029282726252423222120C2C

1

MSB LSB

PHASE

DETECTOR

BISTABLE

CONTROL

(SEE TABLE 4)

13-BIT PROGRAMMABLE COUNTER (R COUNTER)

CONTROL

LOGIC

(SEE

TABLE 3)

Fig. 7c Reference word bit allocation

DUAL MODULUS

N RATIO SELECT

0 = 416/17

1 = 48/9

22 BITS 0 0 22 BITS 1 0 22 BITS 1 1

22 CLOCKS

22 CLOCKS 22 CLOCKS

F1 WORD F2 WORD REF WORD

DATA LOADS ON FALLING EDGES

DATA

DATA CLOCK

CHIP SELECT

Fig. 7d Data load sequence

PHASE

DETECTOR

SENSE BIT

(SEE TABLE 2)

Page 8

8

SP8853A/B

6k

50µA

3, 14, 6

6k

VCC4

VEE4

62·5k

37·5k

500500

13·25k

1250 1250

0·8mA

10

11

RF INPUT

RF INPUT

VCC1

VEE1

10k

12k

50µA

15, 16

12k

VCC4

VEE4

77·5k

27·5µA

24k

176k

Fig. 8a RF preamplifer inputs Fig. 8b F1/F2 data and

power down inputs

Fig. 8c Hysteresis inputs, data clock

and enable

20

VCC2

V

EE

2

24k

100µA

50µA

21

Fig. 8d Oscillator pins

VCC3

VEE3

27

80k

35k

Fig. 8e Lock detect output

VCC4 (CP1) / VCC3 (CP2)

VEE4 (CP1) / VEE3 (CP2)

Fig. 8f Phase detector charge pumps

V

CC

3, 25

V

EE

f

UP

f

DOWN

f

UP

f

DOWN

FROM M OR R

COUNTERS

OUTPUT

ENABLE

10k

VEE4

V

CC

4

4, 5

50µA100µA

Fig. 8h FPD and F

REF

outputs

Fig. 8g Charge pump 2 current

programming

VEE3

V

CC

3

RPD

(See Table 1)

EXTERNAL

RESISTOR

24

Fig. 8 Input and output interface diagrams

Page 9

9

SP8853A/B

DESCRIPTION

A basic application using a single phase detector is shown

in Fig. 6a. The SP8853 is a 1·3GHz part so good RF design

techniques should be employed, including the use of a ground

plane and suitable high frequency capacitors at the RF input

and for power supply decoupling.

The RF input should be coupled to either pin 10 or pin 11,

with the other pin decoupled to ground. The reference oscillator

is of conventional Colpitts type, with two capacitors required to

provide a low impedance tap for the feedback signal to the

transistor emitter. Typical values are shown in Fig. 6a, although

these may be varied to suit the loading requirements of

particular crystals. Where a suitable reference signal already

exists or where a very stable source is required, it is possible

to apply an external reference as shown in Fig. 6b. The

amplitude should be kept below 0·5Vrms to avoid forward

biasing the transistor’s collector-base junction.

Lock Detect and Charge Pump Operation

In some systems, it is useful to have an indication of phase

lock. This function is provided on pin 27 (LOCK DETECT),

which goes low when the output of charge pump 2 (PD2) is

between 2·25V and 2·75V and can be used to drive an LED to

give visual indication of phase lock. Alternatively, a pullup

resistor may be connected from pin 27 to V

CC

and the output

used to signal to the control microprocessor that the loop is

locked, thus speeding up system operation. The output current

available from pin 27 is limited to 1·5mA; if this is exceeded,

the logic low level will be uncertain.

The circuit diagram of Fig. 6a is a basic application with

minimum component count but which is neverthless perfectly

adequate for many applications. Charge pump 1 output (pin3)

is used to drive the loop amplifier which provides the control

voltage for the VCO. When charge pump 1 is used in this

mode, the PD1 and PD2 bits in the reference programming

word must be set to enable charge pump 1 continuously (see

Table 4). This application could also use charge pump 2 output

(pin 25) or, if a higher phase detectot gain is required, pins 3

and 25 could be connected in parallel to use the combined

output current from both charge pumps.

The lock detect circuit can be programmed to automatically

disable charge pump 1 as shown in Table 4. This feature can

be used to reduce the system lock up time by connecting the

charge pump outputs in parallel to the loop amplifier with

resistor Rb connected in series with charge pump 2 output.

This connection allows a relatively high current to be used

from charge pump 1 to give a short lock up time, and a low

charge pump 2 current to be set to give low reference frequency

sidebands. The degree of lock up time improvement depends

on the ratio of charge pump 1 and charge pump 2 currents.

When the loop is out of lock, both charge pumps will be

enabled and will feed current to the loop amplifier to bring the

VCO to phase lock. The current from charge 2 will produce a

voltage drop across Rb, allowing operation of the lock detect

circuit and enabling charge pump 1. The value of Rb must be

chosen to give a voltage drop greater than 0·25V at the current

level programmed for charge pump 2. When phase lock is

achieved, there will be no charge pump current and therefore

the voltage at pin 25 will be equal to that on the virtual earth

point of the loop amplifier (2·5V), disabling charge pump 1.

Charge pump 1 should not be left open circuit when

enabled as this would prevent correct operation of the phase

detector. The output on pin 3 should be biased to half supply

with a pair of 4·7kΩ resistors connected across supplies.

When charge pump 2 is used to drive the loop amplifier, the

lock detect circuit will only give an out of lock indication when

large frequency changes are made or when a frequency

outside the range of the VCO is programmed. at other times

the loop amplifier is maintained at 2·5V by the action of the

loop filter components. Again, a resistor connected between

pin 25 and the loop amplifier, producing a voltage drop greater

than 0·25V at the charge current programmed will allow

sensitive out of lock detection.

When phase lock detection is required using charge

pump 1 only, charge pump 2 output should be biased to 2·5V,

using two equal value resistors, Ra, across the supply as

shown in Fig. 6c. A small capacitor, Cd, connected frompin 28

to ground may be used to reduce chatter at the lock detect

output. A detailed block diagram of the lock detect circuit is

shown in Fig. 3.

Choice of Loop Amplifier

The loop amplifier converts the charge pump current pulses

into a voltage of a magnitude suitable for driving the chosen

VCO. The choice of amplifier is determined by the voltage

swing required at the VCO to achieve the necessary range. In

most cases, an operational amplifier will be used to provide the

essential characteristcs of high input impedance, high gain

and low output impedance required in this application. A

simple discrete design could also be used as shown in Fig. 6d.

This arrangement can be particularly useful where the minimum

VCO control voltage must be close to ground and where

negative supplies are inconvenient. This form of amplifier is

not suitable for use with charge pump 2 when the lock detect

circuit is required.

When an operational amplifier is used in the inverting

configuration shown in Fig. 6a, the charge pump output is

connected directly to the virtual earth point and will therefore

operate a a voltage close to that set on the non-inverting input.

Normally, this operating point should be set at half supply

using a potential divider of two equal value resistors, Rx, but

if necessary the voltage can be set up to 1V higher or lower

without detrimental effect. When the lock detect function is

required on charge pump 2 however, the non-inverting input

must be at half supply.

The digital phase detector and charge pump in the

SP8853 produces bi-directional current pulses in order to

correct errors between the reference and the VCO divider

outputs. Once synchronisation is achieved, in theory no

further output from the charge pump should be required. In

practice, due to leakage currents and particularly the input

current of the amplifier, the capacitors in the loop filter will

gradually discharge, modifying the VCO control voltage and

requiring further outputs from the charge pump to restore

the charge. The effect of this continuous correction is to

frequency modulate the VCO frequency and thus produce

sidebands at the reference frequency. In order to reduce

this effect to a minimum, an amplifier with low input bias is

essential.

Page 10

10

SP8853A/B

Fig. 9 Standard form of second order loop filter Fig. 10 Modified form of second order loop filter

LOOP CALCULATIONS

Many frequency synthesiser designs use a second order

loop with a loop filter of the form shown in Fig. 9.

In practice, an additional RC time constant (shown dashed

in Fig. 9) is often added to reduce noise from the amplifier. In

addition, any feedthrough capacitor or local decoupling at the

VCO will be added to the value of

C

2

. These additional

components in fact form a third order loop and, if the values

are chosen correctly, the additional filtering provided can

considerably reduce the level of reference frequency sidebands

and noise without adversely affecting the loop settling time.

The calculations of values for both types of loop are shown

below.

Second Order Loop

For this filter, two equations are required to determine the

time constants

t

1

(=

C1R

1

) and t2 (=

C1R

2

); the equations are:

…(1)

…(2)

KuK

0

v

n

2

N

t

1

=

2

z

v

n

t

2

=

where

K

u

is the phase detector gain factor in V/radian

K

0

is the VCO gain factor = 2p310MHz/V

N

is the division ratio from VCO to reference frequency

v

n

is the natural loop frequency = 500Hz

z

is the damping factor = 0·7071

The SP8853 phase detector is a current source rather than

a conventional voltage source and has a gain factor specified

in µA/radian. Since the equations deal with a filter where

R

1

is feeding the virtual earth point of an operational amplifier

from a voltage source,

R

1

sets the input current to the filter –

similar to the circuit shown in Fig. 10 – where a current source

phase detector is connected directly to the virtual earth point

of the operational amplifier.

The equivalent voltage gain of the phase detector can be

calculated by assuming a value for

R

1

and calculating a gain

in V/radian which would produce the set current.

The digital phase detector used in the SP8853 is linear

over a range of 2

p radians and therefore the phase detector

gain is given by:

Phase detector current setting

2p

For

R

1

= 1kΩ and assuming a value of phase detector current

of 50µA, the phase detector gain is therefore:

µA/radian

−

+

R1

C1

R2

R3

C2

FROM PHASE

DETECTOR

TO VCO

−

+

C1

R2

PHASE

DETECTOR

K

u

=

50µA

2

p

K

u

=

310

3

This value can now be inserted in equation 1 to obtain a value

for

C

1

and equation 2 used to determine a value for

R

2

.

= 0·00796V/radian

Example

Calculate values for a second order loop with the following

parameters:

Frequency to be synthesised = 800MHz

Reference frequency =100kHz

= 8000

Division ration

N

=

From equation (1), t1 =

800MHz

100kHz

From equation (2), t2 =

Now, since t1 =

C1R

1

,

C

1

=

230·7071

2p3500

0·079632p310

6

(2p3500)238310

3

∴t1 = 6·334µs

∴

t

2

= 450µs

∴

C

1

= 6·33nF

6·334310

26

10

3

and, since t2 =

C1R

2

,

R

2

=

∴

R

2

= 71kΩ

4·5310

24

6·33310

29

Third Order Loop

The third order loop is normally as shown in Fig. 11. Fig. 12

shows the circuit redrawn to use an RC time constant after the

amplifier, allowing any feedthrough capacitance on the VCO

line to be included in the loop calculations. Where the modified

form in Fig. 12 is used, it is advantageous to connect a small

capacitor

C

X

of typically 100pF (shown dashed) across

R

2

to

reduce sidebands caused by the amplifier being forced into

non-linear operation by the phase comparator pulses

Three equations are required to determine the time

constants

t

1

, t2, and t3, where

for Fig. 11

and for Fig. 12

The equations are:

t

1

=

C1R

1

t

2

=

R

2

(

C

1

1

C

2

)

t

3

=

C2R

2

t

1

=

C1R

1

t

2

=

C1R

2

t

3

=

C2R

3

t

2

=

1

v

n

2

t

3

2

…(4)

2tan F

0

1

t

3

=

…(5)

v

n

…(3)

t

1

=

KuK

0

v

n

2

N

11

v

n

2

t

2

2

11

v

n

2

t

3

2

1

2

1

cos F

0

Page 11

11

SP8853A/B

Fig. 11 Standard form of third order loop filter Fig. 12 Modified form of third order loop filter

−

+

R1

C1

R2

C2

FROM

CHARGE

PUMP

TO VCO

−

+

R1

C1

R2

Cx

FROM

CHARGE

PUMP

TO VCO

R3

C3

where

K

u

,

K

0

,

N

and

v

n

are as defined for the second order

loop and F

0

is the phase margin, normally set to 45°. These

values can now be substituted in equation (3) to obtain a value

for

C

1

and in equations (4) and (5) to determine values for

C

2

and

R

2

.

Example

Calculate values for a third order loop with parameters as

for the second order loop and F

0

= 45°.

From equation (5):

2tan 45°1

t

3

=

500Hz32

p

1

cos 45°

∴t

3

= 131·8µs

=

3161·6

0·4142

From equation (4):

t

2

=

(500323p)231·318310

24

1

∴t

2

= 768·7µs

Using these values in equation (3):

t

1

=

80003(50032p)

2

7·963102332p310MHz/V

3[A]

11

v

n

2

t

2

2

11

v

n

2

t

3

2

where A =

=

1

2

11(50032p)23(7·68731024)

2

11(50032p)23(1·31831024)

2

t

1

=

7·896110

10

500141·6 6·832

1·1714

1

2

= 6·3343102632·415

∴t

1

= 15·3µs

Now, since

t

1

=

C1R

1

and

R

1

=1kΩ,

C

1

=

∴

C

1

= 0·0153µF

1·53310

25

10

3

For Fig. 11, t2 =

R

2

(

C

1

1

C

2

)

For Fig. 12,

t

3

=

C2R

2

Substituting for

C

2

:

t

3

=

C2R

2

=

t

2

=

R

2

C

1

1

t

3

R

2

=

R

2

C

11t3

t

22t3

C

1

or,

R

2

=

=

7·6873102421·318310

24

0·0153310

26

∴

R

2

= 41·627kΩ

t

3

R

2

=

1·318310

24

41627

∴

C

2

= 3·17nF

For Fig. 12,

t

1

=

C1R

1

1·53310

25

∴

C

1

= 0·0153nF

or,

C

1

=

∴

R

2

= 50·242kΩ

or,

R

2

=

t

2

=

C1R

2

7·687310

24

1·53310

28

t

3

=

C2R

3

Since the values of

C

2

and

R

3

are independent of the other

components, either can be chosen and the other determined.

Assuming that

R

3

= 1kΩ, then

10

3

1·318310

24

∴

C

2

= 0·01318µF

10

3

C

2

=

Page 12

Page 13

Page 14

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

http://www.mitelsemi.com

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or service or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form par t of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

Loading...

Loading...