Page 1

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

SN8P1800 Series

USER’S MANUAL

General Release Specification

SN8P1808

S

O

Nii

S

O

SONIX reserves the right to make change without further notice to any products herein to improve reliability, function or design. SONIX does not

assume any liability arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent

rights nor the rights of others. SONIX products are not designed, intended, or authorized for us as components in systems intended, for surgical

implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the SONIX product

could create a situation where personal injury or death may occur. Should Buyer purchase or use SONIX products for any such unintended or

unauthorized application. Buyer shall indemnify and hold SONIX and its officers, employees, subsidiaries, affiliates and distributors harmless against

all claims, cost, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use even if such claim alleges that SONIX was negligent regarding the design or manufacture of

the part.

N

X 88--

X

Biitt

B

Miiccrroo--

M

Coonnttrroolllleerr

C

SONiX TECHNOLOGY CO., LTD Revision 1.94

Page 2

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

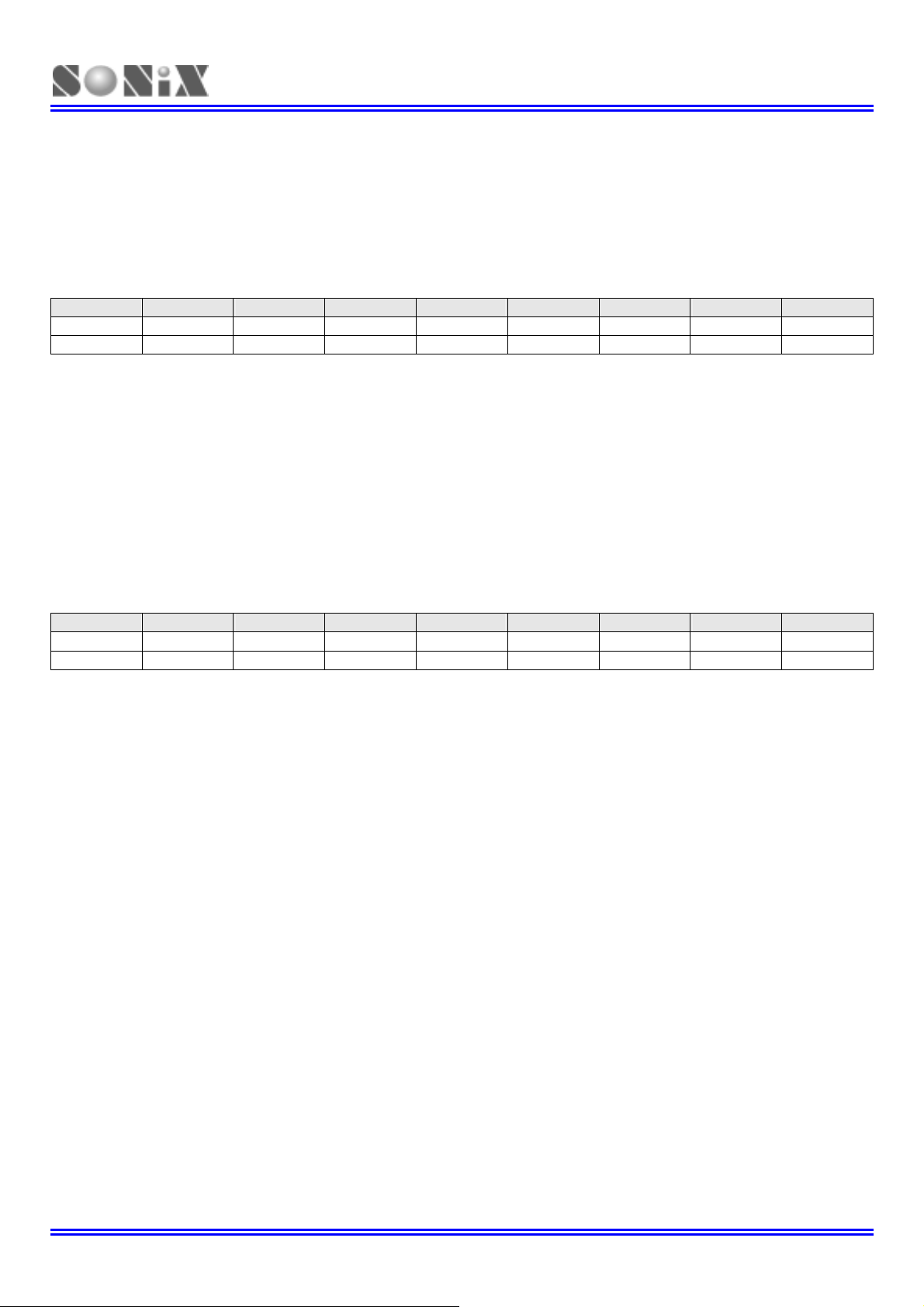

AMENDMENT HISTORY

Version Date Description

VER 1.90 Sep. 2002 V1.90 first issue

VER 1.93 Feb. 2003 1. Extend chip operating temperature from “0°C ~ +70°C” to “-20°C ~ +70°C”.

2. Change the description of ADD M,A instruction from “M M+A” to “M A+M”

3. Add ADC grade.

4. Change bit name and initial value of RBANK register.

5. Change “ACC can’t be access by “B0MOV” instruction” to “ACC can’t be access by

“B0MOV” instruction during the instant addressing mode”.

6. Correct the description of STKnH.

7. Correct the bit definition of INTEN register.

8. Change “The low-speed clock frequency is supplied through on-chip RC oscillator

circuit” to “The low-speed clock frequency is supplied through external low clock

oscillator (32.768K) by crystal or RC mode”.

9. Change all “internal low-speed clock” to “external low-speed clock”.

10. Correct the description of “TC0 CLOCK FREQUENCY OUTPUT” section.

11. Correct the description of “TC1 CLOCK FREQUENCY OUTPUT” section.

12. SCKMD = 1 means SIO is in SLAVE mode. SCKMD = 0 means SIO is in MASTER

mode.

13. Remove “SIO clock and SPI clock are compatible”.

14. Remove this line: “B0MOV A, P2”. P2 of SN8P1808 is output only.

15. Note: The clock source of LCD driver is external low clock.

16. Modify the description ADR register.

17. Modify ADB’s output data table.

18. Correct an error of template code: “b0bclr FWDRST” “b0bset FWDRST”.

19. Add a notice about OSCM register access cycle.

20. Add slow mode (high clock stop and LVD OFF) operating current.

VER 1.94 Sep. 2003 1. Correct RAM Bank value.

2. Correct EOC description.

3. Correct watchdog timer overflow time.

4. Correct POP operand.

5. Correct ADCKS table.

6. Modify figure 11-1 (adjust circuit of LCD contrast) and related description.

7. Add new section about checksum calculate must avoid 04H~07H

8. Correct description of Port6 as I/O port in Chapter 10.

9. Add WTCKS bit in OSCM register

10. Add TC0CKS/TC1CKS in TC0M/TC1M

11. Reserved Last 16 word ROM addresses

SONiX TECHNOLOGY CO., LTD Revision 1.94

Page 3

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

12. Add SIOM Table and Note for SIO Rate

13. Remove register bit description

14. Modify TC0M description

15. Modify TC1M description

16. Modify PWM description

17. Modify ADC Frequency description.

18. Change watchdog over flow table.

19. Change Code option table Chapter 2

20. Add ADC current consumption

21. Add LVD detect voltage

22. Modify electrical characteristic table

23. Remove approval sheet.

24. Remove PCB layout notice section.

25. Modify the description of INTRQ register.

26. Modify the calculation formula of SIOR and SIO clock.

SONiX TECHNOLOGY CO., LTD Page 3 Revision 1.94

Page 4

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

Table of Contents

AMENDMENT HISTORY.............................................................................................................. 2

1

1

1

PRODUCT OVERVIEW ................................................................................................... 10

GENERAL DESCRIPTION ......................................................................................................... 10

FEATURES SELECTION TABLE ............................................................................................... 10

ADC GRADE TABLE................................................................................................................... 10

FEATURES................................................................................................................................. 11

SYSTEM BLOCK DIAGRAM ...................................................................................................... 12

PIN ASSIGNMENT..................................................................................................................... 13

PIN DESCRIPTIONS.................................................................................................................. 14

PIN CIRCUIT DIAGRAMS .......................................................................................................... 15

2

2

2

3

3

3

CODE OPTION TABLE................................................................................................... 17

ADDRESS SPACES........................................................................................................ 18

PROGRAM MEMORY (ROM)..................................................................................................... 18

OVERVIEW............................................................................................................................. 18

USER RESET VECTOR ADDRESS (0000H).......................................................................... 19

INTERRUPT VECTOR ADDRESS (0008H)............................................................................ 19

CHECKSUM CALCULATION.................................................................................................. 21

GENERAL PURPOSE PROGRAM MEMORY AREA.............................................................. 22

LOOKUP TABLE DESCRIPTION............................................................................................ 22

JUMP TABLE DESCRIPTION................................................................................................. 24

DATA MEMORY (RAM).............................................................................................................. 26

OVERVIEW............................................................................................................................. 26

RAM BANK SELECTION ........................................................................................................ 27

WORKING REGISTERS............................................................................................................. 28

H, L REGISTERS.................................................................................................................... 28

SONiX TECHNOLOGY CO., LTD Page 4 Revision 1.94

Page 5

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

Y, Z REGISTERS.................................................................................................................... 29

X REGISTERS........................................................................................................................ 30

R REGISTERS........................................................................................................................ 30

PROGRAM FLAG....................................................................................................................... 31

CARRY FLAG ......................................................................................................................... 31

DECIMAL CARRY FLAG......................................................................................................... 31

ZERO FLAG............................................................................................................................ 31

ACCUMULATOR ........................................................................................................................ 32

STACK OPERATIONS................................................................................................................33

OVERVIEW............................................................................................................................. 33

STACK REGISTERS............................................................................................................... 34

STACK OPERATION EXAMPLE............................................................................................. 35

PROGRAM COUNTER............................................................................................................... 36

ONE ADDRESS SKIPPING .................................................................................................... 37

MULTI-ADDRESS JUMPING.................................................................................................. 38

4

4

4

5

5

5

ADDRESSING MODE...................................................................................................... 39

OVERVIEW................................................................................................................................. 39

IMMEDIATE ADDRESSING MODE........................................................................................ 39

DIRECTLY ADDRESSING MODE .......................................................................................... 39

INDIRECTLY ADDRESSING MODE....................................................................................... 39

TO ACCESS DATA in RAM BANK 0 ....................................................................................... 40

TO ACCESS DATA in RAM BANK 1 ....................................................................................... 40

TO ACCESS DATA in RAM BANK 15 (LCD RAM) ................................................................. 40

SYSTEM REGISTER....................................................................................................... 41

OVERVIEW................................................................................................................................. 41

SYSTEM REGISTER ARRANGEMENT (BANK 0)..................................................................... 41

BYTES of SYSTEM REGISTER.............................................................................................. 41

BITS of SYSTEM REGISTER ................................................................................................. 42

6

6

6

SONiX TECHNOLOGY CO., LTD Page 5 Revision 1.94

POWER ON RESET ........................................................................................................ 44

Page 6

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

OVERVIEW................................................................................................................................. 44

EXTERNAL RESET DESCRIPTION........................................................................................... 45

LOW VOLTAGE DETECTOR (LVD) DESCRIPTION.................................................................. 46

7

7

7

OSCILLATORS................................................................................................................ 47

OVERVIEW................................................................................................................................. 47

CLOCK BLOCK DIAGRAM..................................................................................................... 47

OSCM REGISTER DESCRIPTION......................................................................................... 48

OPTION REGISTER DESCRIPTION...................................................................................... 48

EXTERNAL HIGH-SPEED OSCILLATOR............................................................................... 49

OSCILLATOR MODE CODE OPTION.................................................................................... 49

OSCILLATOR DEVIDE BY 2 CODE OPTION......................................................................... 49

OSCILLATOR SAFE GUARD CODE OPTION ....................................................................... 49

SYSTEM OSCILLATOR CIRCUITS........................................................................................ 50

External RC Oscillator Frequency Measurement .................................................................... 51

SYSTEM MODE DESCRIPTION................................................................................................ 52

OVERVIEW............................................................................................................................. 52

NORMAL MODE.....................................................................................................................52

SLOW MODE.......................................................................................................................... 52

GREEN MODE........................................................................................................................ 52

POWER DOWN MODE........................................................................................................... 52

SYSTEM MODE CONTROL....................................................................................................... 53

SN8P1800 SYSTEM MODE BLOCK DIAGRAM..................................................................... 53

SYSTEM MODE SWITCHING ................................................................................................ 54

WAKEUP TIME........................................................................................................................... 55

OVERVIEW............................................................................................................................. 55

HARDWARE WAKEUP........................................................................................................... 55

8

8

8

SONiX TECHNOLOGY CO., LTD Page 6 Revision 1.94

TIMERS COUNTERS....................................................................................................... 56

WATCHDOG TIMER (WDT)....................................................................................................... 56

BASIC TIMER 0 ( T0 ) ................................................................................................................ 57

OVERVIEW............................................................................................................................. 57

T0M REGISTER DESCRIPTION ............................................................................................ 57

T0C COUNTING REGISTER.................................................................................................. 58

Page 7

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

T0 BASIC TIMER OPERATION SEQUENCE......................................................................... 59

TIMER COUNTER 0 (TC0)......................................................................................................... 60

OVERVIEW............................................................................................................................. 60

TC0M MODE REGISTER........................................................................................................ 61

TC0C COUNTING REGISTER................................................................................................ 62

TC0R AUTO-LOAD REGISTER.............................................................................................. 63

TC0 TIMER COUNTER OPERATION SEQUENCE................................................................ 64

TC0 CLOCK FREQUENCY OUTPUT (BUZZER).................................................................... 66

TC0OUT FREQUENCY TABLE.................................................................................................. 67

TIMER COUNTER 1 (TC1)......................................................................................................... 69

OVERVIEW............................................................................................................................. 69

TC1M MODE REGISTER........................................................................................................ 70

TC1C COUNTING REGISTER................................................................................................ 71

TC1R AUTO-LOAD REGISTER.............................................................................................. 72

TC1 TIMER COUNTER OPERATION SEQUENCE................................................................ 73

TC1 CLOCK FREQUENCY OUTPUT (BUZZER).................................................................... 75

PWM FUNCTION DESCRIPTION.............................................................................................. 76

OVERVIEW............................................................................................................................. 76

PWM PROGRAM DESCRIPTION........................................................................................... 77

9

9

9

INTERRUPT..................................................................................................................... 78

OVERVIEW................................................................................................................................. 78

INTEN INTERRUPT ENABLE REGISTER ................................................................................. 79

INTRQ INTERRUPT REQUEST REGISTER.............................................................................. 79

INTERRUPT OPERATION DESCRIPTION................................................................................ 80

GIE GLOBAL INTERRUPT OPERATION ............................................................................... 80

INT0 (P0.0) INTERRUPT OPERATION .................................................................................. 81

INT1 (P0.1) INTERRUPT OPERATION .................................................................................. 81

INT2 (P0.2) INTERRUPT OPERATION .................................................................................. 82

T0 INTERRUPT OPERATION................................................................................................. 83

TC0 INTERRUPT OPERATION.............................................................................................. 84

TC1 INTERRUPT OPERATION.............................................................................................. 85

SIO INTERRUPT OPERATION............................................................................................... 86

MULTI-INTERRUPT OPERATION.......................................................................................... 87

SONiX TECHNOLOGY CO., LTD Page 7 Revision 1.94

Page 8

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

1

1

1

0

0

0

OVERVIEW................................................................................................................................. 89

SIOM MODE REGISTER............................................................................................................ 90

SIOB DATA BUFFER.................................................................................................................. 91

SIOR REGISTER DESCRIPTION .............................................................................................. 91

SIO MASTER OPERATING DESCRIPTION .............................................................................. 92

RISING EDGE TRANSMITTER/RECEIVER MODE................................................................ 92

FALLING EDGE TRANSMITTER/RECEIVER MODE............................................................. 93

RISING EDGE RECEIVER MODE.......................................................................................... 94

FALLING EDGE RECEIVER MODE ....................................................................................... 95

SIO SLAVE OPERATING DESCRIPTION.................................................................................. 96

RISING EDGE TRANSMITTER/RECEIVER MODE................................................................ 97

FALLING EDGE TRANSMITTER/RECEIVER MODE............................................................. 98

RISING EDGE RECEIVER MODE.......................................................................................... 99

FALLING EDGE RECEIVER MODE ..................................................................................... 100

SIO INTERRUPT OPERATION DESCRIPTION....................................................................... 101

SERIAL INPUT/OUTPUT TRANSCEIVER (SIO).................................................. 89

1

1

1

1

1

1

1

1

1

OVERVIEW............................................................................................................................... 102

I/O PORT FUNCTION TABLE .................................................................................................. 103

PULL-UP RESISTOR (P

I/O PORT MODE ...................................................................................................................... 104

THE P0.3~P0.5 DISCRIPTION................................................................................................. 105

THE PORT2 DISCRIPTION...................................................................................................... 106

THE PORT3 DISCRIPTION...................................................................................................... 107

OPTION Register.................................................................................................................. 107

THE PORT6 DISCRIPTION...................................................................................................... 108

LCDM Register...................................................................................................................... 108

I/O PORT DATA REGISTER .................................................................................................... 110

2

2

2

I/O PORT............................................................................................................. 102

NUR) REGISTER ............................................................................... 103

LCD DRIVER....................................................................................................... 112

SONiX TECHNOLOGY CO., LTD Page 8 Revision 1.94

Page 9

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

LCDM REGISTER .................................................................................................................... 112

LCD TIMING............................................................................................................................. 113

LCD RAM LOCATION............................................................................................................... 114

1

1

1

1

1

1

3

3

3

OVERVIEW............................................................................................................................... 115

ADM REGISTER....................................................................................................................... 116

ADR REGISTERS..................................................................................................................... 116

ADB REGISTERS..................................................................................................................... 116

ADC CONVERTING TIME........................................................................................................ 118

ADC CIRCUIT........................................................................................................................... 119

4

4

4

TEMPLATE CODE.................................................................................................................... 120

CHIP DECLARATION IN ASSEMBLER.................................................................................... 124

PROGRAM CHECK LIST ......................................................................................................... 124

8-CHANNEL ANALOG TO DIGITAL CONVERTER........................................... 115

CODING ISSUE .................................................................................................. 120

1

1

1

1

1

1

1

1

1

SONiX TECHNOLOGY CO., LTD Page 9 Revision 1.94

5

5

5

6

6

6

ABSOLUTE MAXIMUM RATING.............................................................................................. 126

STANDARD ELECTRICAL CHARACTERISTIC....................................................................... 126

7

7

7

INSTRUCTION SET TABLE ............................................................................... 125

ELECTRICAL CHARACTERISTIC ..................................................................... 126

PACKAGE INFORMATION ................................................................................ 127

Page 10

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

1

1

1

PRODUCT OVERVIEW

GENERAL DESCRIPTION

The SN8P1800 is an series of 8-bit micro-controller including SN8P1808. This series is utilized with CMOS technology

fabrication and featured with low power consumption and high performance by its unique electronic structure.

These chips are designed with the excellent IC structure including the large program memory OTP ROM, the massive

data memory RAM, one 8-bit basic timer (T0), two 8-bit timer counters (TC0, TC1), high performance of real time clock

timer (RTC) , a watchdog timer, up to seven interrupt sources (T0, TC0, TC1, SIO, INT0, INT1, INT2), an 8-channel

ADC converter with 8-bit/12-bit resolution, two channel PWM output (PWM0, PWM1), tw0 channel buzzer output (BZ0,

BZ1) and 8-level stack buffers.

Besides, the user can choose desired oscillator configurations for the controller. There are four oscillator configurations

to select for generating system clock, including High/Low speed crystal, ceramic resonator or cost-saving RC.

SN8P1800 series is a dual clock system using a hi-speed crystal for normal mode operation and an external low speed

crystal for slow mode, real time clock and LCD function.

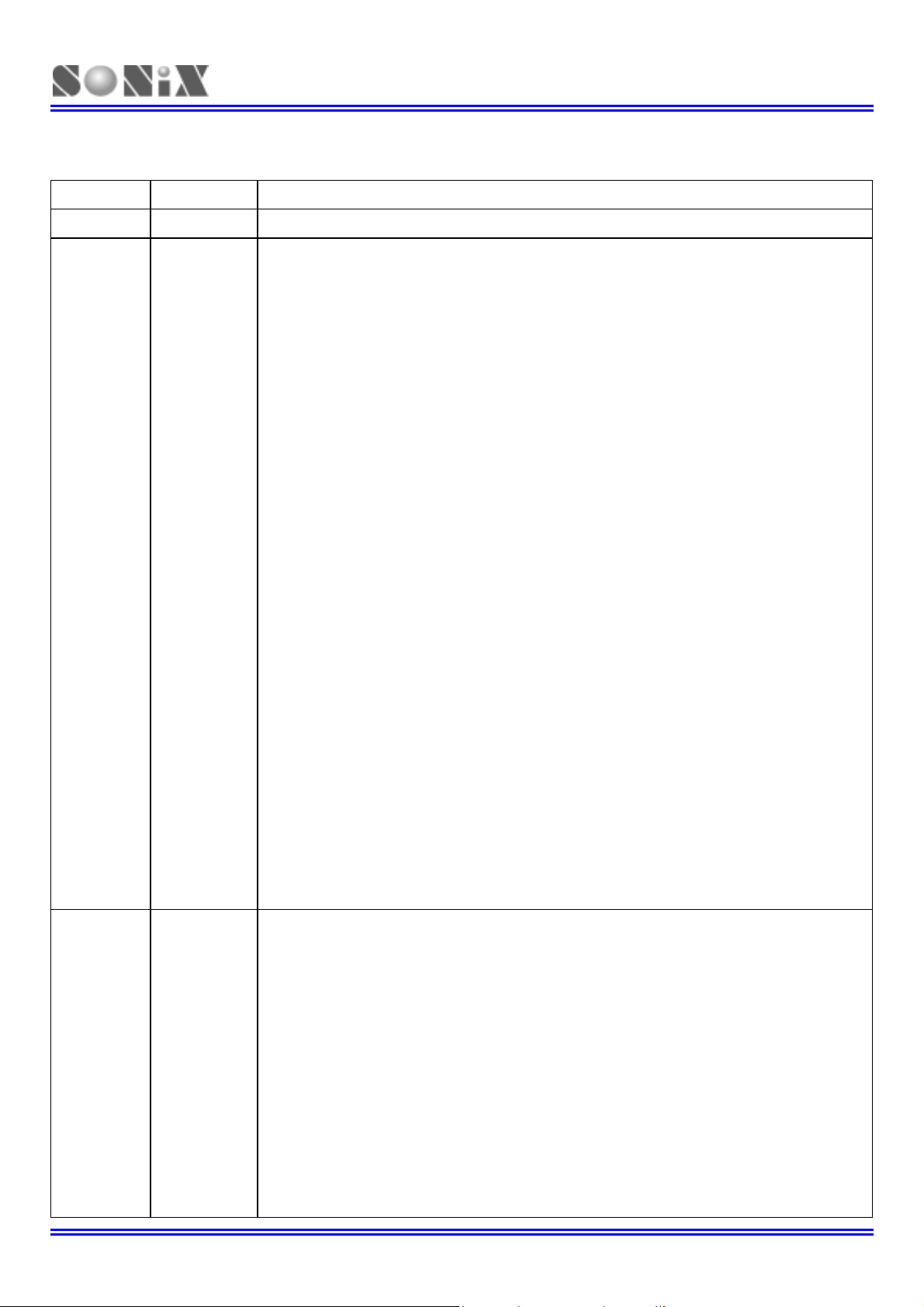

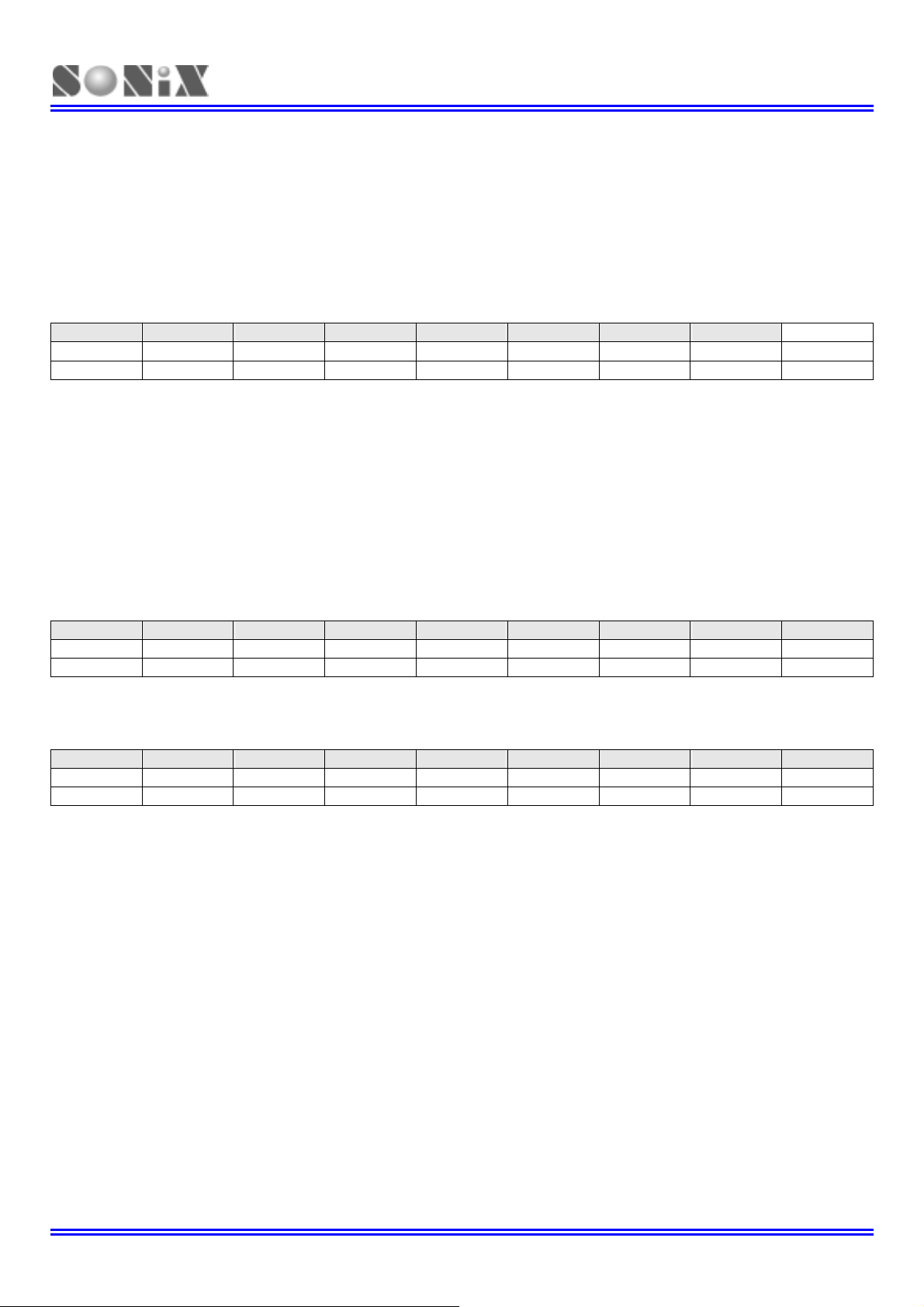

FEATURES SELECTION TABLE

CHIP ROM RAM Stack

SN8P1808 4K*16 256 8 V V V 47 8ch 2 1 10 LQPF64

Timer PWM Wakeup

T0 TC0 TC1

Table 1-1. Selection Table of SN8P1800

I/O ADC DAC

SIO

Buzzer

Pin no.

Package

ADC GRADE TABLE

CHIP PARAMETER MIN MAX UNITS REMARK

Resolution 12 Bits

SN8P1808

SN8P1808-12

No Mission Code 8 12 Bits

Differential Nonlinearity (DNL) 16 LSB

Resolution 12 Bits

No Mission Code 10 12 Bits

Differential Nonlinearity (DNL) 4 LSB

Table 1-2. ADC Grade Table

SONiX TECHNOLOGY CO., LTD Page 10 Revision 1.94

Page 11

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

FEATURES

SN8P1808

Memory configuration

OTP ROM size: 4K * 16 bits

RAM size: 256 * 8 bits (bank 0 and bank 1)

LCD RAM size: 24 * 3 bits

I/O pin configuration

Input only: P0, P3

Output only: P2 shared with LCD segment

Bi-directional: P1, P4, P5, P6

Wakeup: P0, P1

Pull-up resisters: P0, P1, P3, P4, P5, P6

External interrupt: P0

Port 3 shared with LCD segment

All LCD pins shared with the I/O pins

59 powerful instructions

Four clocks per instruction cycle

All of instructions are one word length.

Most of instructions are one cycle only.

Maximum instruction cycle is two.

All ROM area JMP instruction.

All ROM area lookup table function (MOVC)

Support hardware multiplier (MUL).

Seven interrupt sources

Four internal interrupts: T0, TC0, TC1, SIO

Three external interrupts: INT0, INT1, INT2

A real time clock timer

An 8-bit basic timer with green mode wakeup

function

Two 8-bit timer counters with PWM or buzzer

On chip watchdog timer

Eight levels stack buffer

An 8-channel ADC with 8-bit/12-bit resolution

SIO function

LCD driver: 1/3 duty, 1/2 bias. 3 common * 24

segment

Dual clock system offers four operating modes

External high clock: RC type up to 10 MHz

External high clock: Crystal type up to 16 MHz

External Low clock: Crystal 32768Hz

Normal mode: Both high and low clock active.

Slow mode: Low clock only.

Sleep mode: Both high and low clock stop.

Green mode: Periodical wakeup by timer.

Package

Chip form: LQFP 64 pins

SONiX TECHNOLOGY CO., LTD Page 11 Revision 1.94

Page 12

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

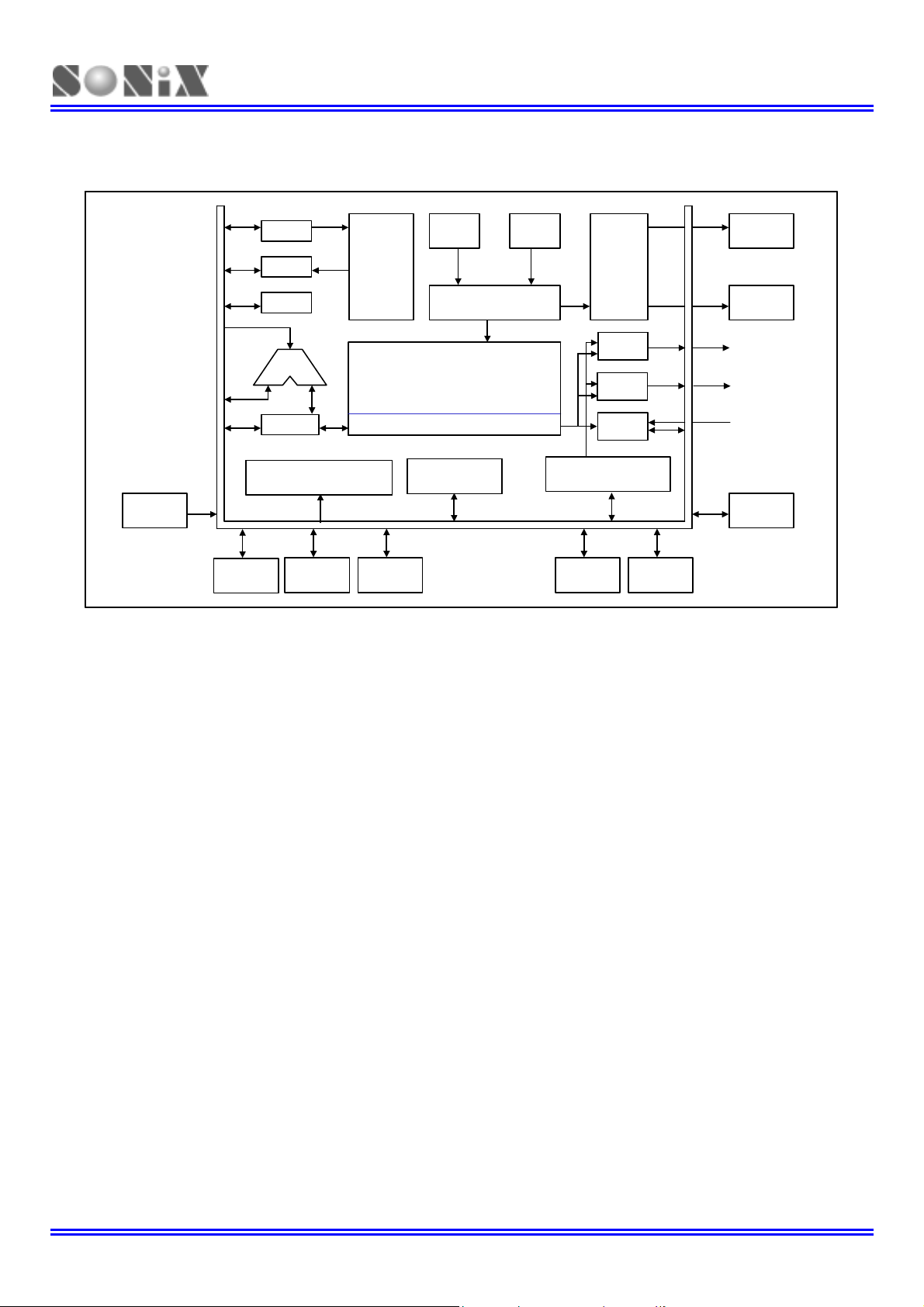

SYSTEM BLOCK DIAGRAM

H-OSC

PC

PC

OTP

OTP

ROM

IR

IR

FLAGS

FLAGS

ALU

ALU

ACC

ACC

INTERRUPT CONTROL

INTERRUPT CONTROLINTERRUPT CONTROL

ROM

H-OSC

TIMING GENERATOR

TIMING GENERATOR

RAM

RAM

SYSTEM REGISTE R

SYSTEM REGISTE R

SIO TX/RX

SIO TX/RXSIO TX/RX

L-OSC

L-OSC

TIMER & COUNTER

TIMER & COUNTER

LCD

LCD

DRIVER

DRIVER

PWM1

PWM1PWM1

PWM0

PWM0PWM0

ADC

ADC

COM.

COM.

SEG.

SEG.

PWM1/Buzzer1

PWM1/Buzzer1

PWM0/Buzzer0

PWM0/Buzzer0

AIN0~AIN7

AIN0~AIN7

PORT 0

PORT 0

PORT 1

PORT 1

PORT 2 PORT 3 PORT 4 PORT 5

PORT 2 PORT 3 PORT 4 PORT 5

Figure 1-1.Simplified System Block Diagram

PORT 6

PORT 6

SONiX TECHNOLOGY CO., LTD Page 12 Revision 1.94

Page 13

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

PIN ASSIGNMENT

SN8P1808 (LQFP64)

P0.0/INT0 2 O 47SEG15/P3.7

P0.1/INT1 3 46SEG16/P2.0

P0.2/INT24 45SEG17/P2.1

P1.05 44SEG18/P2.2

P1.16 43SEG19/P2.3

P1.27 42SEG20/P2.4

P1.3 8 SN8P1808Q 41 SEG21/P2.5

VDD9 40SEG22/P2.6

AVREFH 10 39 SEG23/P2.7

P4.0/AIN011 38COM0/P0.3

P4.1/AIN112 37COM1/P0.4

P4.2/AIN213 36COM2/P0.5

P4.3/AIN314 35V1

P4.4/AIN415 34V2

P4.5/AIN516 33VLCD

VSS

SEG0/P6.0

SEG1/P6.1

SEG2/P6.2

SEG3/P6.3

SEG4/P6.4

SEG5/P6.5

SEG6/P6.6

SEG7/P6.7

SEG8/P3.0

VDD

SEG9/P3.1

SEG10/P3.2

SEG11/P3.3

SEG12/P3.4

SEG13/P3.5

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

RST1 48SEG14/P3.6

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

LXIN

LXOUT

XIN

XOUT

AVREFL

P4.6/AIN6

P4.7/AIN7

VSS

AVSS

P5.1/SI

P5.2/SO

P5.0/SCK

P5.3/BZ1/PWM1

P5.4/BZ0/PWM0

VDD

VPP/VDD

SONiX TECHNOLOGY CO., LTD Page 13 Revision 1.94

Page 14

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

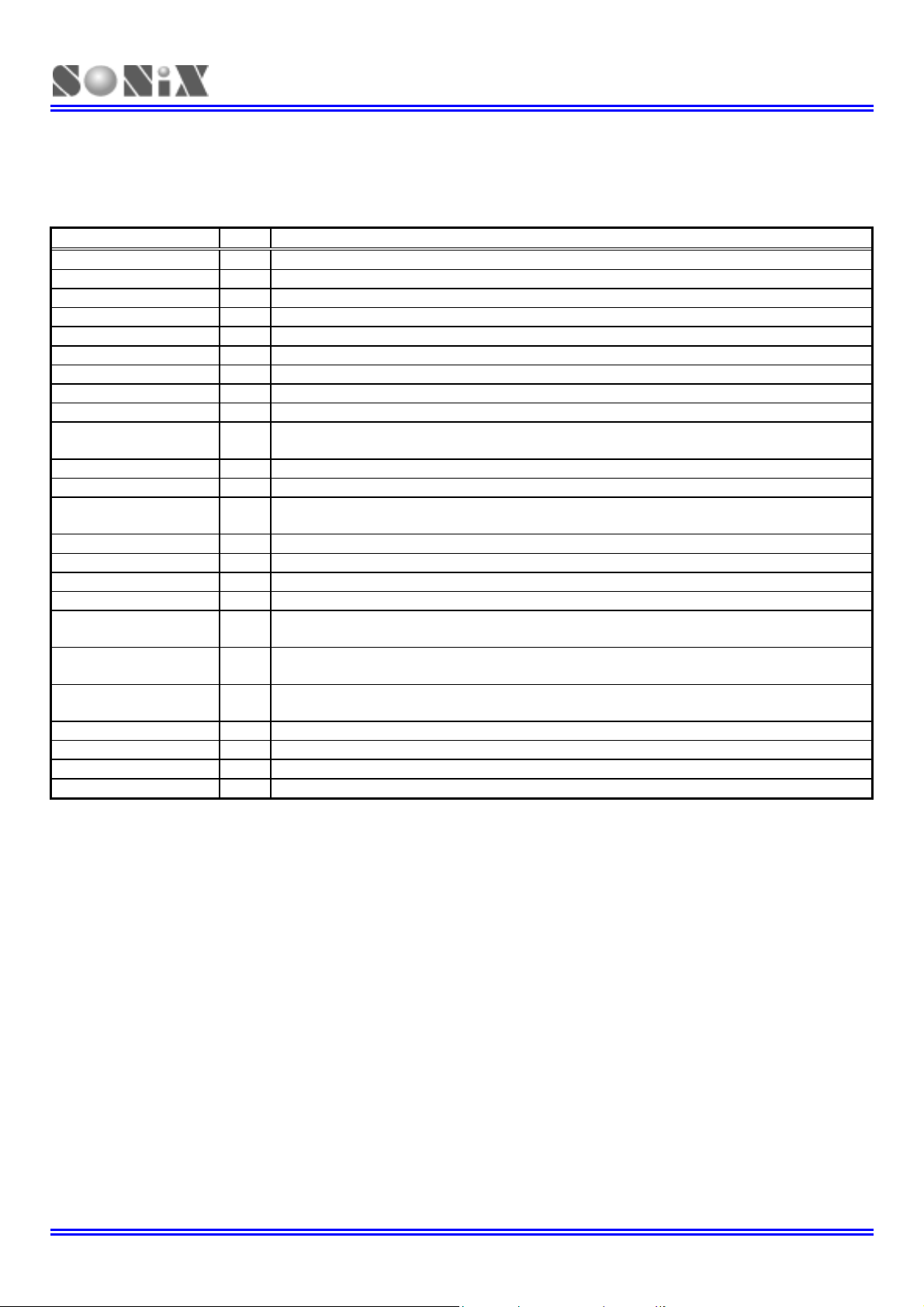

PIN DESCRIPTIONS

PIN NAME TYPE DESCRIPTION

VDD, VSS P Power supply input pins for digital circuit.

AVDD, AVSS P Power supply input pins for analog circuit.

VPP P OTP ROM programming pin. Connect to VDD in normal operation.

RST I System reset input pin. Schmitt trigger structure, active “low”, normal stay to “high”.

XIN, XOUT I, O External oscillator pins. RC mode from XIN.

LXIN, LXOUT I, O Low speed (32768 Hz) oscillator pins. RC mode from LXIN.

P0.0 / INT0 I Port 0.0 and shared with INT0 trigger pin. (Schmitt trigger) / Built-in pull-up resisters.

P0.1 / INT1 I Port 0.1 and shared with INT1 trigger pin. (Schmitt trigger) / Built-in pull-up resisters.

P0.2 / INT2 I Port 0.2 and shared with INT2 trigger pin. (Schmitt trigger) / Built-in pull-up resisters.

P0.3~ P0.5 I

P1.0 ~ P1.3 I/O Port 1.0~Port 1.3 bi-direction pins / Built-in pull-up resisters.

P2.0 ~ P2.7 O Port 2.0~Port 2.7 output only port and shared with LCD’s SEG16~SEG23.

P3.0 ~ P3.7 I

P4.0 ~ P4.7 I/O Port 4.0~Port 4.7 bi-direction pins / Built-in pull-up resisters.

P5.0 / SCK I/O Port 5.0 bi-direction pin and SIO’s clock input/output / Built-in pull-up resisters.

P5.1 / SI I/O Port 5.1 bi-direction pin and SIO’s data input / Built-in pull-up resisters.

P5.2 / SO I/O Port 5.2 bi-direction pin and SIO’s data output / Built-in pull-up resisters.

P5.3 / BZ1 / PWM1 I/O

P5.4 / BZ0 / PWM0 I/O

P6.0 ~ P6.7 I/O

AIN0 ~ AIN7 I Analog signal input pins for ADC converter.

COM0 ~ COM2 O LCD driver common pins.

SEG0 ~ SEG23 O LCD driver segment pins.

AvrefH,AverfL I ADC’s reference high / low voltage input pins.

Port 0.3~Port 0.5 input pins and shared with LCD’s COM0~COM2. (Schmitt trigger).

Built-in pull-up resisters.

Port 3.0~Port 3.7 input port with pull-up resister and shared with LCD’s SEG8~SEG15.

Built-in pull-up resisters.

Port 5.3 bi-direction pin, TC1 ÷ 2 signal output pin or PWM1 output pin.

Built-in pull-up resisters.

Port 5.4 bi-direction pin, TC0 ÷ 2 signal output pin or PWM0 output pin.

Built-in pull-up resisters.

Port 6.0 ~ Port 6.7 bi-direction pins and shared with LCD’s SEG0~SEG7.

Enable pull-up resisters in input mode automatically.

Table 1-3. SN8P1800 Pin Description

SONiX TECHNOLOGY CO., LTD Page 14 Revision 1.94

Page 15

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

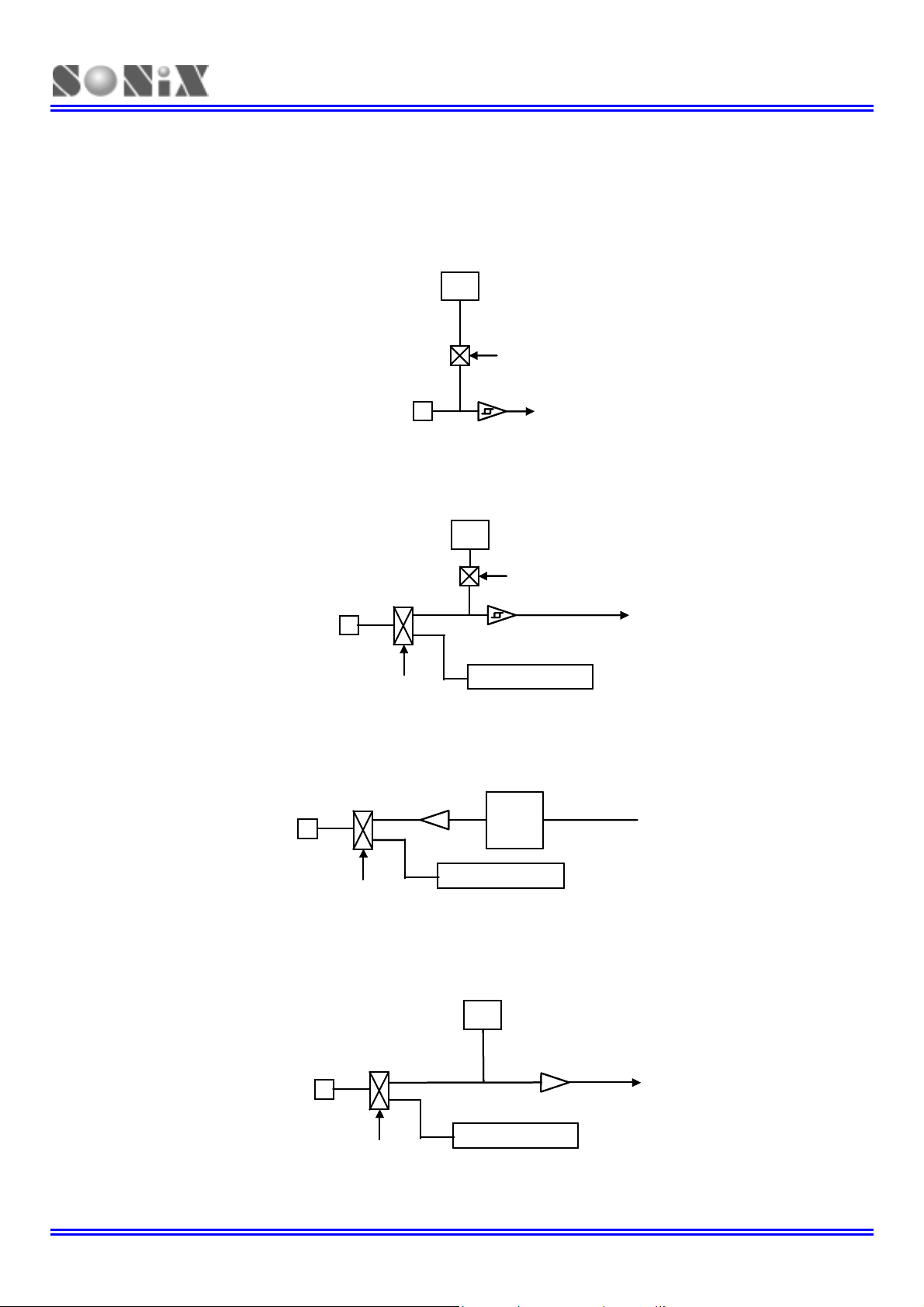

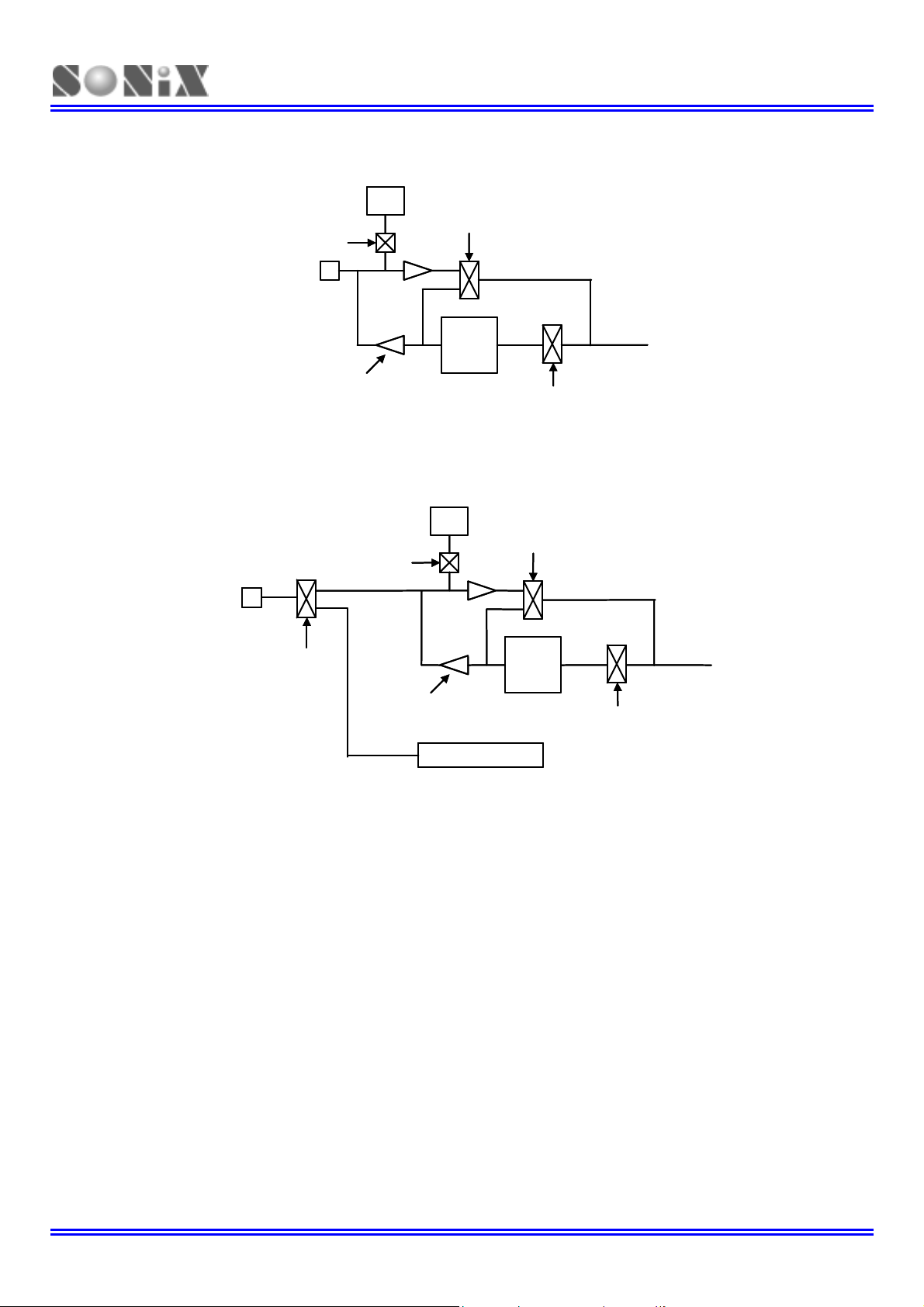

PIN CIRCUIT DIAGRAMS

Port0.0~P0.2 structure

Port0.0~P0.2 structure

PUR

PUR

P0UR

P0UR

Pin

Pin

Port0.3~P0.5 structure

Port0.3~P0.5 structure

Port0.3~P0.5 structure

Port0.3~P0.5 structure

Int. bus

Int. bus

PUR

PUR

PUR

PUR

P0UR

P0URP0UR

Int. bus

Int. bus

Pin

PinPin

LCD waveform

LCD Code Option

LCD Code Option

LCD waveformLCD waveform

Port2 structure

Port2 structure

Int. bus

Int. bus

Pin

PinPin

LCD Code Option

LCD Code Option

Latch

Latch

LCD waveform

LCD waveform

LCD waveform

Port3 structure

Port3 structure

Port3 structure

PUR

PUR

PUR

Int. bus

Int. bus

Pin

PinPin

LCD waveform

LCD waveformLCD waveform

P3LCD

P3LCD

SONiX TECHNOLOGY CO., LTD Page 15 Revision 1.94

Page 16

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

Port1,Port4,Port5 structure

Port1,Port4,Port5 structure

PUR

PUR

PnM

PnM

PnM, PnUR

PnM, PnUR

Pin

Pin

Int. bus

Latch

Latch

PnM

PnM

PnM

PnM

Port6 structure

Port6 structure

PUR

PUR

PnM

PnM

PnM

PnM

Int. bus

Pin

PinPin

Int. bus

P6HSEG, P6LSEG

P6HSEG, P6LSEG

PnM

PnM

LCD waveform

LCD waveformLCD wavef orm

Latch

Latch

PnM

PnM

Int. bus

Figure 1-2. Pin Circuit Diagram

SONiX TECHNOLOGY CO., LTD Page 16 Revision 1.94

Page 17

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

2

2

2

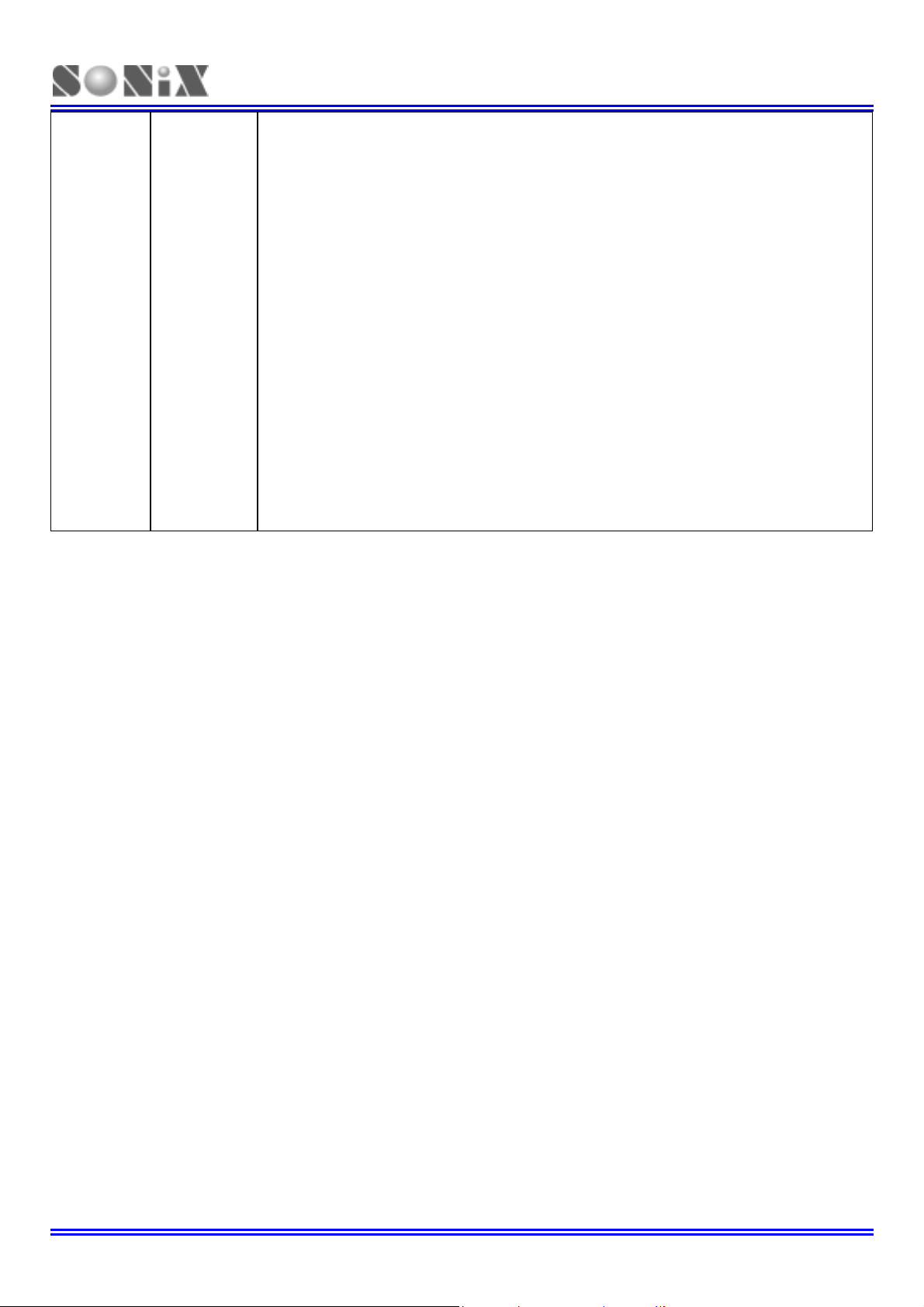

Code Option Content Function Description

High_Clk

High_Clk / 2

OSG

Watch_Dog

LVD

Security

LCD

CODE OPTION TABLE

RC Low cost RC for external high clock oscillator

32K X’tal

12M X’tal High speed crystal /resonator (e.g. 12M) for external high clock oscillator

4M X’tal Standard crystal /resonator (e.g. 3.58M) for external high clock oscillator

Enable External high clock divided by two, Fosc = high clock / 2

Disable Fosc = high clock

Enable Enable Oscillator Safe Guard function

Disable Disable Oscillator Safe Guard function

Enable Enable Watch Dog function

Disable Disable Watch Dog function

Enable Enable the low voltage detect

Disable Disable the low voltage detect

Enable Enable ROM code Security function

Disable Disable ROM code Security function

Enable Enable LCD function

Disable Disable LCD function

Low frequency, power saving crystal (e.g. 32.768K) for external high

clock oscillator

Table 2-1. Code Option Table of SN8P1800

SONiX TECHNOLOGY CO., LTD Page 17 Revision 1.94

Page 18

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

3

3

3

ADDRESS SPACES

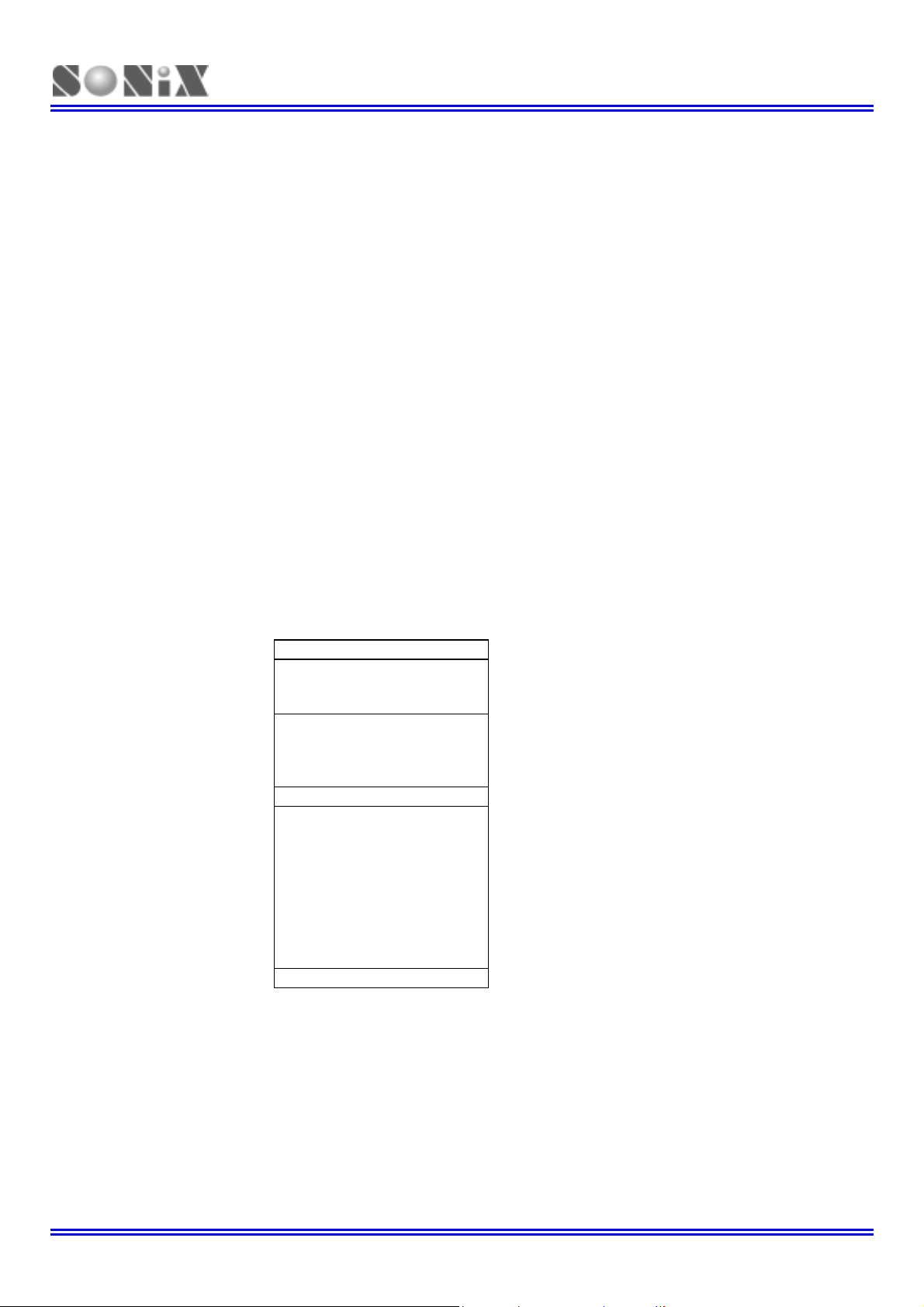

PROGRAM MEMORY (ROM)

OVERVIEW

ROM Maps for SN8P1800 devices provide 4K x 16 OTP memory that programmable by user. The SN8P1800 program

memory is able to fetch instructions through 12-bit wide PC (Program Counter) and can look up ROM data by using

ROM code registers (R, X, Y, Z). In standard configuration, the device’s 4,096 x 16-bit program memory has four

areas:

1-word reset vector addresses

1-word Interrupt vector addresses

5-words reserved area

4K words general purpose area

All of the program memory is partitioned into two coding areas, located from 0000H to 0008H and from 0009H to

0FFEH. The former area is assigned for executing reset vector and interrupt vector. The later area is for storing

instruction’s OP-code and lookup table’s data. User’s program is in the last area (0010H~0FFEH).

0000H

0001H Jump to user start address

0002H Jump to user start address

0003H

0004H

0005H

0006H

0007H

0008H

0009H User program

.

.

000FH

0010H

0011H

.

.

0FFEH

0FFFH

General purpose area

General purpose area

ROM

Reset vector

Reserved

Interrupt vector

Reserved

User reset vector

Jump to user start address

User interrupt vector

End of user program

Figure 3-1. ROM Address Structure

SONiX TECHNOLOGY CO., LTD Page 18 Revision 1.94

Page 19

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

USER RESET VECTOR ADDRESS (0000H)

A 1-word vector address area is used to execute system reset. After power on reset or watchdog timer overflow reset,

then the chip will restart the program from address 0000h and all system registers will be set as default values. The

following example shows the way to define the reset vector in the program memory.

Example: After power on reset, external reset active or reset by watchdog timer overflow.

CHIP SN8P1808

ORG 0 ; 0000H

JMP START ; Jump to user program address.

. ; 0001H ~ 0007H are reserved

ORG 10H

START: ; 0010H, The head of user program.

. ; User program

.

.

.

ENDP

; End of program

INTERRUPT VECTOR ADDRESS (0008H)

A 1-word vector address area is used to execute interrupt request. If any interrupt service is executed, the program

counter (PC) value is stored in stack buffer and points to 0008h of program memory to execute the vectored interrupt.

Users have to define the interrupt vector. The following example shows the way to define the interrupt vector in the

program memory.

Example 1: This demo program includes interrupt service routine and the user program is behind the

interrupt service routine.

CHIP SN8P1808

ORG 0 ; 0000H

JMP START ; Jump to user program address.

. ; 0001H ~ 0007H are reserved

ORG 8

START: ; The head of user program.

B0XCH A, ACCBUF

PUSH

.

.

.

POP

B0XCH A, ACCBUF

RETI

.

.

.

.

JMP START

ENDP

; Interrupt service routine

; B0XCH doesn’t change C, Z flag

; Push 80H ~ 87H system registers

; Pop 80H ~ 87H system registers

; End of interrupt service routine

; User program

; End of user program

; End of program

SONiX TECHNOLOGY CO., LTD Page 19 Revision 1.94

Page 20

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

Example 2: The demo program includes interrupt service routine and the address of interrupt service

routine is in a special address of general-purpose area.

CHIP SN8P1808

ORG 0 ; 0000H

JMP START ; Jump to user program address.

. ; 0001H ~ 0007H are reserved

ORG 08

JMP MY_IRQ ; 0008H, Jump to interrupt service routine address

ORG 10H

START: ; 0010H, The head of user program.

. ; User program

.

.

.

MY_IRQ: ;The head of interrupt service routine

Remark: It is easy to get the rules of SONIX program from demo programs given above. These points are

as following.

1. The address 0000H is a “JMP” instruction to make the program go to general-purpose ROM area. The

0004H~0007H are reserved. Users have to skip 0004H~0007H addresses. It is very important and

necessary.

2. The interrupt service starts from 0008H. Users can put the whole interrupt service routine from 0008H

(Example1) or to put a “JMP” instruction in 0008H then place the interrupt service routine in other

general-purpose ROM area (Example2) to get more modularized coding style.

JMP START

B0XCH A, ACCBUF

PUSH

.

.

.

POP

B0XCH A, ACCBUF

RETI

ENDP

; End of user program

; B0XCH doesn’t change C, Z flag

; Push 80H ~ 87H system registers

; Pop 80H ~ 87H system registers

; End of interrupt service routine

; End of program

SONiX TECHNOLOGY CO., LTD Page 20 Revision 1.94

Page 21

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

CHECKSUM CALCULATION

The ROM addresses 0004H~0007H and last address are reserved area. User should avoid these addresses

(0004H~0007H and last address) when calculate the Checksum value.

Example:

The demo program shows how to avoid 0004H~0007H when calculated Checksum from 00H to the end of

user’s code

MOV A,#END_USER_CODE$L

B0MOV END_ADDR1,A ;save low end address to end_addr1

MOV A,#END_USER_CODE$M

B0MOV END_ADDR2,A ;save middle end address to end_addr2

CLR Y ;set Y to ooH

CLR Z ;set Z to 00H

@@:

CALL YZ_CHECK ;call function of check yz value

MOVC ;

B0BSET FC ;clear C glag

ADD DATA1,A ;add A to Data1

MOV A,R

ADC DATA2,A ;add R to Data2

JMP END_CHECK ;check if the YZ address = the end of code

AAA:

INCMS Z ;Z=Z+1

JMP @B ;if Z!= 00H calculate to next address

JMP Y_ADD_1 ;if Z=00H increase Y

END_CHECK:

MOV A,END_ADDR1

CMPRS A,Z ;check if Z = low end address

JMP AAA ;if Not jump to checksum calculate

MOV A,END_ADDR2

CMPRS A,Y ;if Yes, check if Y = middle end address

JMP AAA ;if Not jump to checksum calculate

JMP CHECKSUM_END ;if Yes checksum calculated is done.

YZ_CHECK: ;check if YZ=0004H

MOV A,#04H

CMPRS A,Z ;check if Z=04H

RET ;if Not return to checksum calculate

MOV A,#00H

CMPRS A,Y ;if Yes, check if Y=00H

RET ;if Not return to checksum calculate

INCMS Z ;if Yes, increase 4 to Z

INCMS Z

INCMS Z

INCMS Z

RET ;set YZ=0008H then return

Y_ADD_1:

INCMS Y ;increase Y

NOP

JMP @B ;jump to checksum calculate

CHECKSUM_END:

……….

……….

END_USER_CODE: ;Label of program end

SONiX TECHNOLOGY CO., LTD Page 21 Revision 1.94

Page 22

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

GENERAL PURPOSE PROGRAM MEMORY AREA

The 4089-word at ROM locations 0010H~0FFEH are used as general-purpose memory. The area is stored

instruction’s op-code and look-up table data. The SN8P1800 includes jump table function by using program counter

(PC) and look-up table function by using ROM code registers (R, X, Y, Z).

The boundary of program memory is separated by the high-byte program counter (PCH) every 100H. In jump table

function and look-up table function, the program counter can’t leap over the boundary by program counter

automatically. Users need to modify the PCH value to “PCH+1” as the PCL overflow (from 0FFH to 000H).

LOOKUP TABLE DESCRIPTION

In the ROM’s data lookup function, the X register is pointed to the highest 8-bit, Y register to the middle 8-bit and Z

register to the lowest 8-bit data of ROM address. After MOVC instruction is executed, the low-byte data of ROM then

will be stored in ACC and high-byte data stored in R register.

Example: To look up the ROM data located “TABLE1”.

B0MOV Y, #TABLE1$M ; To set lookup table1’s middle address

B0MOV Z, #TABLE1$L ; To set lookup table1’s low address.

MOVC ; To lookup data, R = 00H, ACC = 35H

;

;

@@:

. . ;

TABLE1: DW 0035H ; To define a word (16 bits) data.

DW 5105H ; “

DW 2012H ; “

CAUSION: The Y register can't increase automatically if Z register cross boundary from 0xFF to 0x00.

Therefore, user must take care such situation to avoid loop-up table errors. If Z register overflow, Y

register must be added one. The following INC_YZ macro shows a simple method to process Y and Z

registers automatically.

Note: Because the program counter (PC) is only 12-bit, the X register is useless in the application. Users

can omit “B0MOV X, #TABLE1$H”. SONiX ICE support more larger program memory addressing

capability. So make sure X register is “0” to avoid unpredicted error in loop-up table operation.

INCMS Z ; Z+1

JMP @F ; Not overflow

INCMS Y ; Z overflow (FFH 00), Y=Y+1

NOP ; Not overflow

MOVC ; To lookup data, R = 51H, ACC = 05H.

; Increment the index address for next address

Example: INC_YZ Macro

INC_YZ MACRO

INCMS Z ; Z+1

JMP @F ; Not overflow

INCMS Y ; Y+1

NOP ; Not overflow

@@:

ENDM

SONiX TECHNOLOGY CO., LTD Page 22 Revision 1.94

Page 23

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

The other coding style of loop-up table is to add Y or Z index register by accumulator. Be careful if carry happen. Refer

following example for detailed information:

Example: Increase Y and Z register by B0ADD/ADD instruction

B0MOV Y, #TABLE1$M ; To set lookup table’s middle address.

B0MOV Z, #TABLE1$L ; To set lookup table’s low address.

GETDATA: ;

MOVC ; To lookup data. If BUF = 0, data is 0x0035

; If BUF = 1, data is 0x5105

; If BUF = 2, data is 0x2012

.

.

. . ;

TABLE1: DW 0035H ; To define a word (16 bits) data.

DW 5105H ; “

DW 2012H ; “

B0MOV A, BUF ; Z = Z + BUF.

B0ADD Z, A

B0BTS1 FC ; Check the carry flag.

JMP GETDATA ; FC = 0

INCMS Y ; FC = 1. Y+1.

NOP

SONiX TECHNOLOGY CO., LTD Page 23 Revision 1.94

Page 24

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

JUMP TABLE DESCRIPTION

The jump table operation is one of multi-address jumping function. Add low-byte program counter (PCL) and ACC

value to get one new PCL. The new program counter (PC) points to a series jump instructions as a listing table. The

way is easy to make a multi-stage program.

When carry flag occurs after executing of “ADD PCL, A”, it will not affect PCH register. Users have to check if the jump

table leaps over the ROM page boundary or the listing file gener ated by SONIX assembly software. If the jump table

leaps over the ROM page boundary (e.g. from xxFFH to xx00H), move the jump table to the top of next program

memory page (xx00H). Here one page mean 256 words.

Example : If PC = 0323H (PCH = 03H、PCL = 23H)

ORG 0X0100 ; The jump table is from the head of the ROM boundary

B0ADD PCL, A ; PCL = PCL + ACC, the PCH can’t be changed.

JMP A0POINT ; ACC = 0, jump to A0POINT

JMP A1POINT ; ACC = 1, jump to A1POINT

JMP A2POINT ; ACC = 2, jump to A2POINT

JMP A3POINT ; ACC = 3, jump to A3POINT

In following example, the jump table starts at 0x00FD. When execute B0ADD PCL, A. If ACC = 0 or 1, the jump

table points to the right address. If the ACC is larger then 1 will cause error because PCH doesn't increase one

automatically. We can see the PCL = 0 when ACC = 2 but the PCH still keep in 0. The program counter (PC) will

point to a wrong address 0x0000 and crash system operation. It is important to check whether the jump table

crosses over the boundary (xxFFH to xx00H). A good coding style is to put the jump table at the start of ROM

boundary (e.g. 0100H).

Example: If “jump table” crosses over ROM boundary will cause errors.

ROM Address

. .

. .

. .

0X00FD

0X00FE

0X00FF

0X0100

0X0101

. .

. .

SONIX provides a macro for safe jump table function. This macro will check the ROM boundary and move the jump

table to the right position automatically. The side effect of this macro is maybe wasting some ROM size. Notice the

maximum jmp table number for this macro is limited under 254.

@JMP_A MACRO VAL

IF (($+1) !& 0XFF00) !!= (($+(VAL)) !& 0XFF00)

JMP ($ | 0XFF)

ORG ($ | 0XFF)

ENDIF

ADD PCL, A

ENDM

Note: “VAL” is the number of the jump table listing number.

B0ADD PCL, A ; PCL = PCL + ACC, the PCH can’t be changed.

JMP A0POINT ; ACC = 0

JMP A1POINT ; ACC = 1

JMP A2POINT

JMP A3POINT ; ACC = 3

; ACC = 2 jump table cross boundary here

SONiX TECHNOLOGY CO., LTD Page 24 Revision 1.94

Page 25

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

Example: “@JMP_A” application in SONIX macro file called “MACRO3.H”.

B0MOV A, BUF0 ; “BUF0” is from 0 to 4.

@JMP_A 5 ; The number of the jump table listing is five.

JMP A0POINT ; If ACC = 0, jump to A0POINT

JMP A1POINT ; ACC = 1, jump to A1POINT

JMP A2POINT ; ACC = 2, jump to A2POINT

JMP A3POINT ; ACC = 3, jump to A3POINT

JMP A4POINT ; ACC = 4, jump to A4POINT

If the jump table position is from 00FDH to 0101H, the “@JMP_A” macro will make the jump table to start from 0100h.

SONiX TECHNOLOGY CO., LTD Page 25 Revision 1.94

Page 26

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

DATA MEMORY (RAM)

OVERVIEW

The SN8P1808 has internally built-in the huge data memory up to 256 bytes for storing general purpose data and

featured with LCD memory space up to 24 locations (24 * 3 bits) for displaying pattern.

256 * 8-bit general purpose area

128 * 8-bit system register area

24 * 3-bit LCD memory space

These memory are separated into bank 0, bank1 and bank 15. The user can program RBANK register of RAM bank

selection bit to access all data in any of the three RAM banks. The bank 0 and bank1, using the first 128-byte location

assigned as general-purpose area, and the remaining 128-byte in bank 0 as system register. The bank 15 is LCD RAM

area designed for storing LCD display data.

RAM location

000h General purpose area ; 000h~07Fh of Bank 0 = To store general

. ; purpose data (128 bytes).

BANK 0

BANK 1

200h “ ; reserved

“ ; “

280h “ ; “

“ ; “

300h “ ; “

“ ; “

380h “ ; “

“ ; “

BANK 15

07Fh .

080h System register ; 080h~0FFh of Bank 0 = To store system

. ; registers (128 bytes).

0FFh End of bank 0 area

100h General purpose area ; Bank 1 = To store general purpose data.

.

17Fh End of bank 1 area ; Bank 1 only has 128 bytes RAMs.

F00h LCD RAM area ; Bank 15 = To store LCD display data

. ; (24 bytes).

F17h End of LCD Ram ;

Figure 3-2 RAM Location of SN8P1808

Note:1. The undefined locations of system register area are logic “high” after executing read instruction

“MOV A, M”.

Note:2. The lower 24 locations of bank15 are used to store LCD display data and the other locations are

reserved. The RAMs of LCD data area only have lowest 3-bit to be used. The highest 5-bit are

undefined.

SONiX TECHNOLOGY CO., LTD Page 26 Revision 1.94

Page 27

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

RAM BANK SELECTION

The RBANK is a 1-bit register located at 87H in RAM bank 0. The user can access RAM data by using this register

pointing to working RAM bank for ACC to read/write RAM data.

RBANK initial value = xxxx 0000

087H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

RBANK

- - - - R/W R/W R/W R/W

RBNKn: RAM bank selecting control bit. 0 = bank 0, 1 = bank 1.

Example: RAM bank selecting.

; BANK 0

CLR RBANK

.

; BANK 1

MOV A, #1

B0MOV RBANK, A

.

Note: “B0MOV” instruction can access the RAM of bank 0 in other bank situation directly.

Example: Access RAM bank 0 in RAM bank 1.

; BANK 1

B0BSET RBNKS0 ; Get into RAM bank 1

B0MOV A, BUF0 ; Read BUF0 data. BUF0 is in RAM bank0.

MOV BUF1, A ; Write BUF0 data to BUF1. BUF1 is in RAM bank1.

.

. .

MOV A, BUF1 ; Read BUF1 data and store in ACC.

B0MOV BUF0, A ; Write ACC data to BUF0.

Under bank 1 situation, using “B0MOV” instruction is an easy way to access RAM bank 0 data. User can make a habit

to read/write system register (0087H~00FFH). Then user can access system registers without switching RAM bank.

Example: To Access the system registers in bank 1 situation.

; BANK 1

B0BSET RBNKS0 ; Get into RAM bank 1

. .

MOV A, #0FFH ; Set all pins of P1 to be logic high.

B0MOV P1, A

.

B0MOV A, P0 ; Read P0 data and store into BUF1 of RAM bank 1.

MOV BUF1, A

- - - - RBNKS3 RBNKS2 RBNKS1 RBNKS0

SONiX TECHNOLOGY CO., LTD Page 27 Revision 1.94

Page 28

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

WORKING REGISTERS

The locations 80H to 86H of RAM bank 0 in data memory stores the specially defined registers such as register H, L, R,

X, Y, Z and PFLAG, respectively shown in the following table. These registers can use as the general purpose of

working buffer and can also be used to access ROM’s and RAM’s data. For instance, all of the ROM’s table can be

looked-up with R, X, Y and Z registers. And the data of RAM memory can be indirectly accessed with H, L, Y and Z

registers.

80H 81H 82H 83H 84H 85H 86H

RAM

R/W R/W R/W R/W R/W R/W R/W

H, L REGISTERS

The H and L are 8-bit register with two major functions. One is to use the registers as working register. The other is to

use the registers as data pointer to access RAM’s data. The @HL that is data point_0 index buffer located at address

E6H in RAM bank_0. It employs H and L registers to addressing RAM location in order to read/write data through ACC.

The Lower 4-bit of H register is pointed to RAM bank number and L register is pointed to RAM address number,

respectively. The higher 4-bit data of H register is truncated in RAM indirectly access mode.

H initial value = 0000 0000

081H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

H

R/W R/W R/W R/W R/W R/W R/W R/W

L initial value = 0000 0000

080H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

L

R/W R/W R/W R/W R/W R/W R/W R/W

Example: If want to read a data from RAM address 20H of bank_0, it can use indirectly addressing mode

to access data as following.

B0MOV H, #00H ; To set RAM bank 0 for H register

B0MOV L, #20H ; To set location 20H for L register

B0MOV A, @HL ; To read a data into ACC

Example: Clear general-purpose data memory area of bank 0 using @HL register.

CLR H ; H = 0, bank 0

MOV A, #07FH

B0MOV L, A ; L = 7FH, the last address of the data memory area

CLR_HL_BUF:

CLR @HL ; Clear @HL to be zero

DECMS L ; L – 1, if L = 0, finish the routine

JMP CLR_HL_BUF ; Not zero

CLR @HL

END_CLR: ; End of clear general purpose data memory area of bank 0

. .

. .

L H R Z Y X PFLAG

HBIT7 HBIT6 HBIT5 HBIT4 HBIT3 HBIT2 HBIT1 HBIT0

LBIT7 LBIT6 LBIT5 LBIT4 LBIT3 LBIT2 LBIT1 LBIT0

SONiX TECHNOLOGY CO., LTD Page 28 Revision 1.94

Page 29

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

Y, Z REGISTERS

The Y and Z registers are the 8-bit buffers. There are three major functions of these registers. First, Y and Z registers

can be used as working registers. Second, these two registers can be used as data pointers for @YZ register. Third,

the registers can be address ROM location in order to look-up ROM data.

Y initial value = 0000 0000

084H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Y

R/W R/W R/W R/W R/W R/W R/W R/W

Z initial value = 0000 0000

083H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Z

R/W R/W R/W R/W R/W R/W R/W R/W

The @YZ that is data point_1 index buffer located at address E7H in RAM bank 0. It employs Y and Z registers to

addressing RAM location in order to read/write data through ACC. The Lower 4-bit of Y register is pointed to RAM

bank number and Z register is pointed to RAM address number, respectively. The higher 4-bit data of Y register is

truncated in RAM indirectly access mode.

Example: If want to read a data from RAM address 25H of bank 1, it can use indirectly addressing mode

to access data as following.

B0MOV Y, #01H ; To set RAM bank 1 for Y register

B0MOV Z, #25H ; To set location 25H for Z register

B0MOV A, @YZ ; To read a data into ACC

Example: Clear general-purpose data memory area of bank 1 using @YZ register.

MOV A, #1

B0MOV Y, A ; Y = 1, bank 1

MOV A, #07FH

B0MOV Z, A ; Y = 7FH, the last address of the data memory area

CLR_YZ_BUF:

CLR @YZ ; Clear @YZ to be zero

DECMS Z ; Y – 1, if Y= 0, finish the routine

JMP CLR_YZ_BUF ; Not zero

CLR @YZ

END_CLR: ; End of clear general purpose data memory area of bank 0

.

Note: Please consult the “LOOK-UP TABLE DESCRIPTION” about Y, Z register look-up table application.

YBIT7 YBIT6 YBIT5 YBIT4 YBIT3 YBIT2 YBIT1 YBIT0

ZBIT7 ZBIT6 ZBIT5 ZBIT4 ZBIT3 ZBIT2 ZBIT1 ZBIT0

SONiX TECHNOLOGY CO., LTD Page 29 Revision 1.94

Page 30

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

X REGISTERS

The X register is the 8-bit buffer. There are two major functions of the register. First, X register can be used as working

registers. Second, the X registers can be address ROM location in order to look-up ROM data. The SN8P1800’s

program counter only has 12-bit. In look-up table function, users can omit X register.

X initial value = 0000 0000

085H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X

R/W R/W R/W R/W R/W R/W R/W R/W

Note: Please consult the “LOOK-UP TABLE DESCRIPTION” about X register look-up table application.

XBIT7 XBIT6 XBIT5 XBIT4 XBIT3 XBIT2 XBIT1 XBIT0

R REGISTERS

The R register is the 8-bit buffer. There are two major functions of the register. First, R register can be used as working

registers. Second, the R registers can be store high-byte data of look-up ROM data. After MOVC instruction executed,

the high-byte data of a ROM address will be stored in R register and the low-byte data stored in ACC.

R initial value = 0000 0000

082H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

R

R/W R/W R/W R/W R/W R/W R/W R/W

Note: Please consult the “LOOK-UP TABLE DESCRIPTION” about R register look-up table application.

RBIT7 RBIT6 RBIT5 RBIT4 RBIT3 RBIT2 RBIT1 RBIT0

SONiX TECHNOLOGY CO., LTD Page 30 Revision 1.94

Page 31

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

PROGRAM FLAG

The PFLAG includes carry flag (C), decimal carry flag (DC) and zero flag (Z). If the result of operating is zero or there

is carry, borrow occurrence, then these flags will be set to PFLAG register.

PFLAG initial value = xxxx x000

086H Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PFLAG

- - - - - R/W R/W R/W

- - - - - C DC Z

CARRY FLAG

C = 1: If executed arithmetic addition with occurring carry signal or executed arithmetic subtraction without borrowing

signal or executed rotation instruction with shifting out logic “1”.

C = 0: If executed arithmetic addition without occurring carry signal or executed arithmetic subtraction with borrowing

signal or executed rotation instruction with shifting out logic “0”.

DECIMAL CARRY FLAG

DC = 1: If executed arithmetic addition with occurring carry signal from low nibble or executed arithmetic subtraction

without borrow signal from high nibble.

DC = 0: If executed arithmetic addition without occurring carry signal from low nibble or executed arithmetic subtraction

with borrow signal from high nibble.

ZERO FLAG

Z = 1: After operation, the content of ACC is zero.

Z = 0: After operation, the content of ACC is not zero.

SONiX TECHNOLOGY CO., LTD Page 31 Revision 1.94

Page 32

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

ACCUMULATOR

The ACC is an 8-bits data register responsible for transferring or manipulating data between ALU and data memory. If

the result of operating is zero (Z) or there is carry (C or DC) occurrence, then these flags will be set to PFLAG register.

ACC is not in data memory (RAM), so ACC can’t be access by “B0MOV” instruction during the instant addressing

mode.

Example: Read and write ACC value.

; Read ACC data and store in BUF data memory

MOV BUF, A

. .

; Write a immediate data into ACC

MOV A, #0FH

. .

; Write ACC data from BUF data memory

MOV A, BUF

. .

The PUSH and POP instructions don’t store ACC value as any interrupt service executed. ACC must be exchanged to

another data memory defined by users. Thus, once interrupt occurs, these data must be stored in the data memory

based on the user’s program as follows.

Example: ACC and working registers protection.

ACCBUF EQU 00H ; ACCBUF is ACC data buffer in bank 0.

INT_SERVICE:

B0XCH A, ACCBUF ; Store ACC value

PUSH. . ; Push instruction

. .

.

.

POP ; Pop instruction

B0XCH A, ACCBUF ; Re-load ACC

RETI ; Exit interrupt service vector

Notice: To save and re-load ACC data must be used “B0XCH” instruction, or the PLAGE value maybe

modified by ACC.

SONiX TECHNOLOGY CO., LTD Page 32 Revision 1.94

Page 33

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

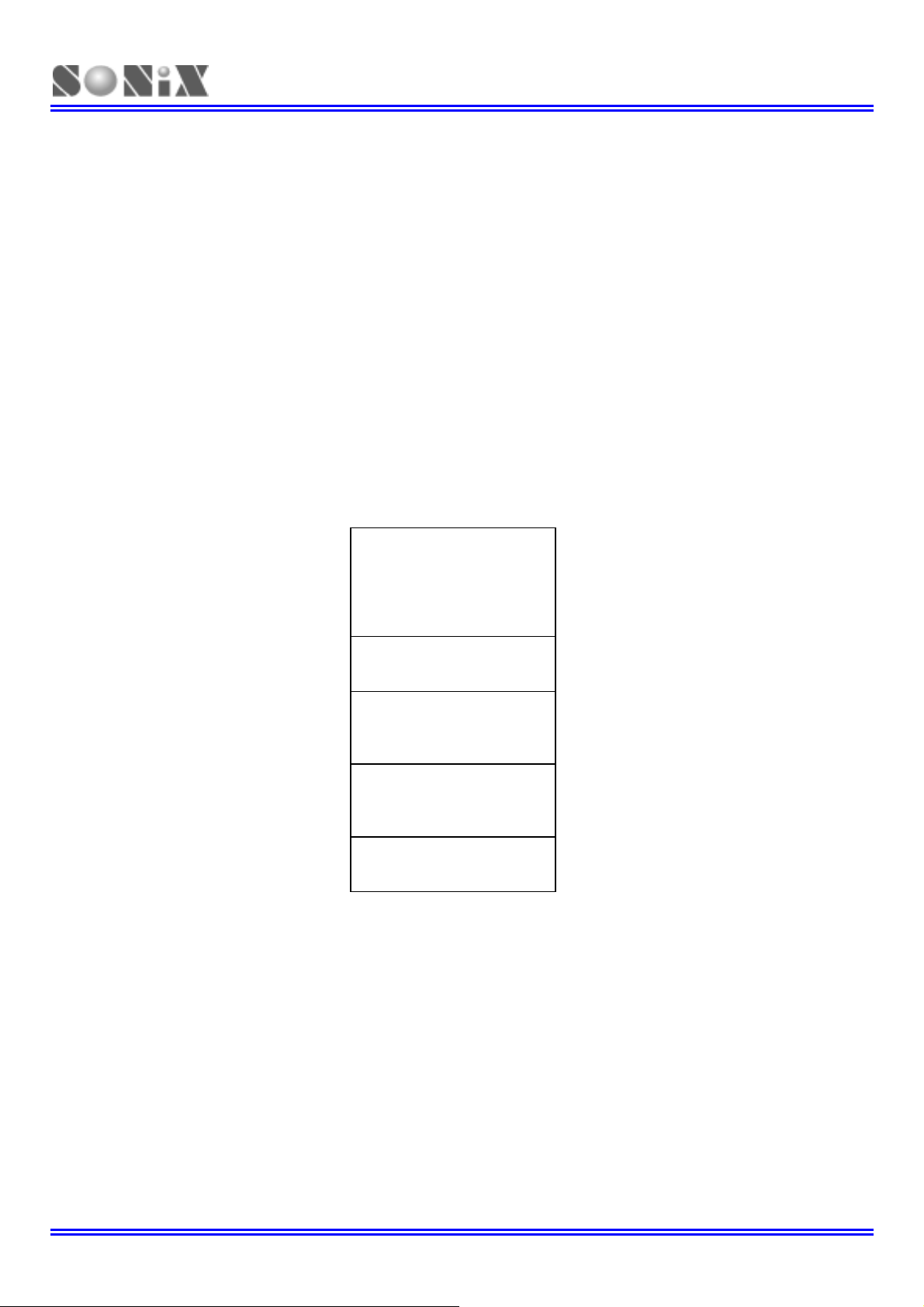

STACK OPERATIONS

OVERVIEW

The stack buffer of SN8P1800 has 8-level high area and each level is 12-bits length. This buffer is designed to save

and restore program counter’s (PC) data when interrupt service is executed. The STKP register is a pointer designed

to point active level in order to save or restore data from stack buffer for kernel circuit. The STKnH and STKnL are the

12-bit stack buffers to store program counter (PC) data.

STACK BUFFER

STACK BUFFER

PCL

PCL

PCLPCL

STK0L

STK0L

STK0L

RET /

RET /

RETI

RETI

CALL /

CALL /

interrupt

interrupt

STKP = 7

STKP = 7

STKP = 7

PCH

PCH

PCHPCH

STK0H

STK0H

STK0H

STKP + 1

STKP + 1

STKP + 1

STKP - 1

STKP - 1

STKP - 1STKP - 1

STKP = 6

STKP = 6

STKP = 6

STKP = 5

STKP = 5

STKP = 5

STKP = 4

STKP = 4

STKP = 4

STKP = 3

STKP = 3

STKP = 3

STKP = 2

STKP = 2

STKP = 2

STKP = 1

STKP = 1

STKP = 1

STKP = 0

STKP = 0

STKP = 0

STKP

STKPSTKP

STK1H

STK1H

STK1H

STK2H

STK2H

STK2H

STK3H

STK3H

STK3H

STK4H

STK4H

STK4H

STK5H

STK5H

STK5H

STK6H

STK6H

STK6H

STK7H

STK7H

STK7H

STKP

STKPSTKP

Figure 3-3 Stack-Save and Stack-Restore Operation

STK1L

STK1L

STK1L

STK2L

STK2L

STK2L

STK3L

STK3L

STK3L

STK4L

STK4L

STK4L

STK5L

STK5L

STK5L

STK6L

STK6L

STK6L

STK7L

STK7L

STK7L

SONiX TECHNOLOGY CO., LTD Page 33 Revision 1.94

Page 34

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

STACK REGISTERS

The stack pointer (STKP) is a 4-bit register to store the address used to access the stack buffer, 12-bits data memory

(STKnH and STKnL) set aside for temporary storage of stack addresses.

The two stack operations are writing to the top of the stack (Stack-Save) and reading (Stack-Restore) from the top of

stack. Stack-Save operation decrements the STKP and the Stack-Resotre operation increments one time. That makes

the STKP always points to the top address of stack buffer and writes the last program counter value (PC) into the stack

buffer.

The program counter (PC) value is stored in the stack buffer before a CALL instruction executed or during interrupt

service routine. Stack operation is a LIFO type (Last in and first out). The stack pointer (STKP) and stack buffer

(STKnH and STKnL) are located in the system register area bank 0.

STKP (stack pointer) initial value = 0xxx 1111

0DFH Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

STKP

R/W - - - R/W R/W R/W R/W

STKPBn: Stack pointer. (n = 0 ~ 3)

GIE: Global interrupt control bit. 0 = disable, 1 = enable. More detail information is in interrupt chapter.

Example: Stack pointer (STKP) reset routine.

MOV A, #00001111B

B0MOV STKP, A

STKn (stack buffer) initial value = xxxx xxxx xxxx xxxx, STKn = STKnH + STKnL (n = 7 ~ 0)

0F0H~0FFH Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

STKnH

- - - - R/W R/W R/W R/W

0F0H~0FFH Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

STKnL

R/W R/W R/W R/W R/W R/W R/W R/W

STKnH: Store PCH data as interrupt or call executing. The n expressed 0 ~7.

STKnL: Store PCL data as interrupt or call executing. The n expressed 0 ~7.

GIE - - - STKPB3 STKPB2 STKPB1 STKPB0

- - - - SnPC11 SnPC10 SnPC9 SnPC8

SnPC7 SnPC6 SnPC5 SnPC4 SnPC3 SnPC2 SnPC1 SnPC0

SONiX TECHNOLOGY CO., LTD Page 34 Revision 1.94

Page 35

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

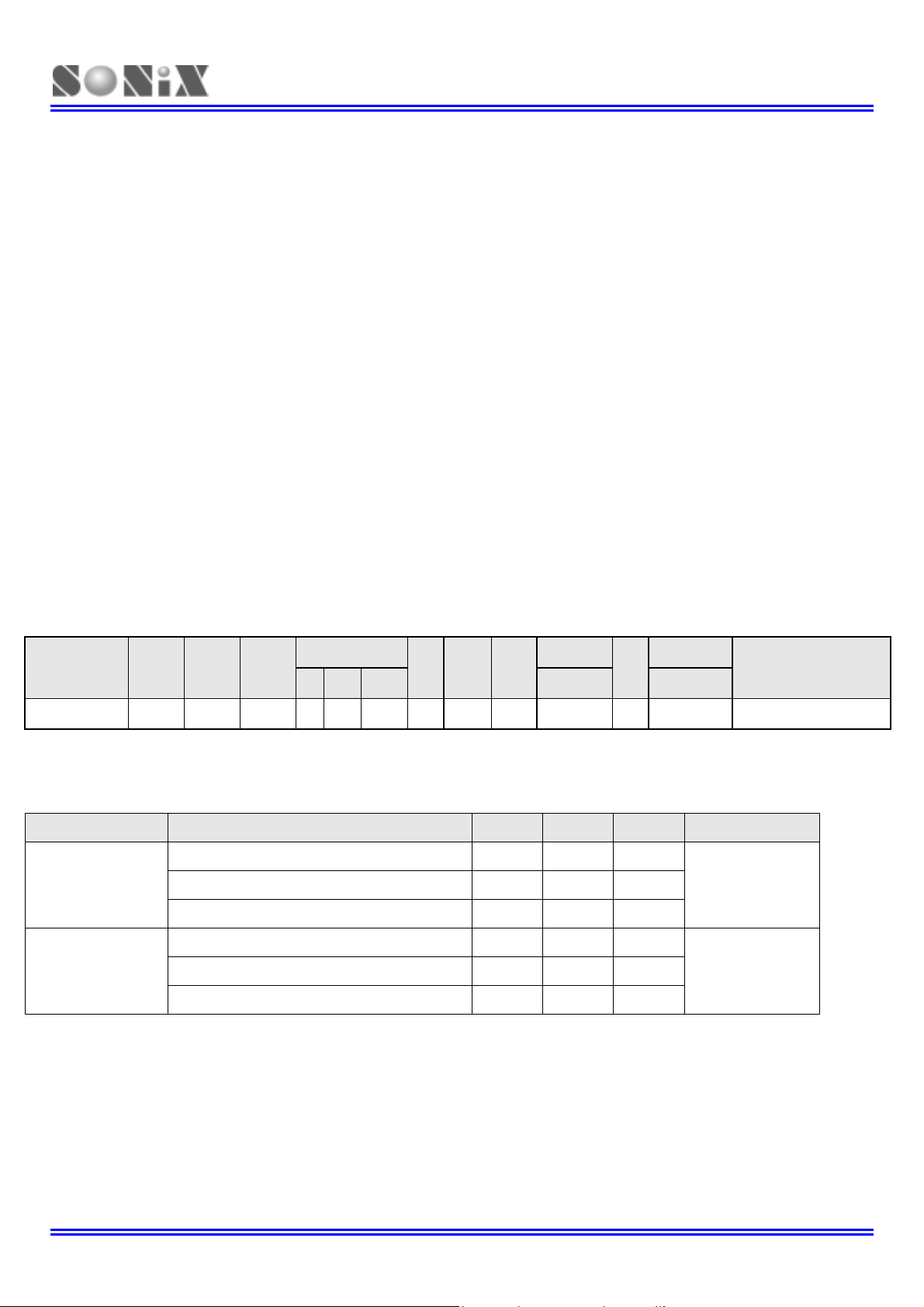

STACK OPERATION EXAMPLE

The two kinds of Stack-Save operations to reference the stack pointer (STKP) and write the program counter contents

(PC) into the stack buffer are CALL instruction and interrupt service. Under each condition, the STKP is decremented

and points to the next available stack location. The stack buffer stores the program counter about the op-code address.

The Stack-Save operation is as following table.

Stack Level

0

1

2

3

4

5

6

7

>8

STKPB3 STKPB2 STKPB1 STKPB0 High Byte Low Byte

1 1 1 1 STK0H STK0L

1 1 1 0 STK1H STK1L

1 1 0 1 STK2H STK2L

1 1 0 0 STK3H STK3L

1 0 1 1 STK4H STK4L

1 0 1 0 STK5H STK5L

1 0 0 1 STK6H STK6L

1 0 0 0 STK7H STK7L

- - - - - -

Table 3-1. STKP, STKnH and STKnL relative of Stack-Save Operation

STKP Register Stack Buffer

Description

-

-

-

-

-

-

-

-

Stack Overflow

There is a Stack-Restore operation corresponding each push operation to restore the program counter (PC). The RETI

instruction is for interrupt service routine. The RET instruction is for CALL instruction. When a Stack-Restore operation

occurs, the STKP is incremented and points to the next free stack location. The stack buffer restores the last program

counter (PC) to the program counter registers. The Stack-Restore operation is as following table.

Stack Level

7

6

5

4

3

2

1

0

STKPB3 STKPB2 STKPB1 STKPB0 High Byte Low Byte

1 0 0 0 STK7H STK7L

1 0 0 1 STK6H STK6L

1 0 1 0 STK5H STK5L

1 0 1 1 STK4H STK4L

1 1 0 0 STK3H STK3L

1 1 0 1 STK2H STK2L

1 1 1 0 STK1H STK1L

1 1 1 1 STK0H STK0L

Table 3-2. STKP, STKnH and STKnL relative of Stack-Restore Operation

STKP Register Stack Buffer

Description

-

-

-

-

-

-

-

-

SONiX TECHNOLOGY CO., LTD Page 35 Revision 1.94

Page 36

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

PROGRAM COUNTER

The program counter (PC) is a 12-bit binary counter separated into the high-byte 4 bits and the low-byte 8 bits. This

counter is responsible for pointing a location in order to fetch an instruction for kernel circuit. Normally, the program

counter is automatically incremented with each instruction during program execution.

Besides, it can be replaced with specific address by executing CALL or JMP instruction. When JMP or CALL

instruction is executed, the destination address will be inserted to bit 0 ~ bit 11.

PC Initial value = xxxx 0000 0000 0000

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PC

PCH Initial value = xxxx 0000

PCL Initial value = 0000 0000

- - - - 0 0 0 0 0 0 0 0 0 0 0 0

0CFH Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PCH

- - - - R/W R/W R/W R/W

0CEH Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PCL

R/W R/W R/W R/W R/W R/W R/W R/W

- - - - PC11 PC10 PC9 PC8

PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0

PCH PCL

SONiX TECHNOLOGY CO., LTD Page 36 Revision 1.94

Page 37

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

ONE ADDRESS SKIPPING

There are 9 instructions (CMPRS, INCS, INCMS, DECS, DECMS, BTS0, BTS1, B0BTS0, B0BTS1) with one address

skipping function. If the result of these instructions is matched, the PC will add 2 steps to skip next instruction.

If the condition of bit test instruction is matched, the PC will add 2 steps to skip next instruction.

JMP C0STEP ; Else jump to C0STEP.

.

C0STEP: NOP

B0MOV A, BUF0 ; Move BUF0 value to ACC.

JMP C1STEP ; Else jump to C1STEP.

.

C1STEP: NOP

If the ACC is equal to the immediate data or memory, the PC will add 2 steps to skip next instruction.

JMP C0STEP ; Else jump to C0STEP.

.

C0STEP: NOP

If the result after increasing or decreasing by 1 is 0xFF or 0x00, the PC will add 2 steps to skip next

instruction.

INCS instruction:

JMP C0STEP ; Jump to C0STEP if ACC is not zero.

…

C0STEP: NOP

INCMS instruction:

JMP C0STEP ; Jump to C0STEP if BUF0 is not zero.

…

C0STEP: NOP

DECS instruction:

JMP C0STEP ; Jump to C0STEP if ACC is not zero.

…

C0STEP: NOP

DECMS instruction:

JMP C0STEP ; Jump to C0STEP if BUF0 is not zero.

…

C0STEP: NOP

B0BTS1

B0BTS0

CMPRS

INCS

INCMS

DECS

DECMS

FC ; Skip next instruction, if Carry_flag = 1

FZ ; Skip next instruction, if Zero flag = 0.

A, #12H ; Skip next instruction, if ACC = 12H.

BUF0

BUF0

BUF0

BUF0

SONiX TECHNOLOGY CO., LTD Page 37 Revision 1.94

Page 38

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

MULTI-ADDRESS JUMPING

Users can jump round multi-address by either JMP instruction or ADD M, A instruction (M = PCL) to activate

multi-address jumping function. If carry signal occurs after execution of ADD PCL, A, the carry signal will not affect

PCH register.

Example: If PC = 0323H (PCH = 03H、PCL = 23H)

; PC = 0323H

MOV A, #28H

B0MOV PCL, A ; Jump to address 0328H

. .

. .

; PC = 0328H . .

MOV A, #00H

B0MOV PCL, A ; Jump to address 0300H

Example: If PC = 0323H (PCH = 03H、PCL = 23H)

; PC = 0323H

B0ADD PCL, A ; PCL = PCL + ACC, the PCH cannot be changed.

JMP A0POINT ; If ACC = 0, jump to A0POINT

JMP A1POINT ; ACC = 1, jump to A1POINT

JMP A2POINT ; ACC = 2, jump to A2POINT

JMP A3POINT ; ACC = 3, jump to A3POINT

. . ;

SONiX TECHNOLOGY CO., LTD Page 38 Revision 1.94

Page 39

SN8P1800

8-bit micro-controller build-in 12-bit ADC + 72 dots LCD driver

4

4

4

ADDRESSING MODE

OVERVIEW

The SN8P1800 provides three addressing modes to access RAM data, including immediate addressing mode, directly

addressing mode and indirectly address mode. The main purpose of the three different modes is described in the

following:

IMMEDIATE ADDRESSING MODE

The immediate addressing mode uses an immediate data to set up the location (MOV A, #I, B0MOV M,#I) in ACC or

specific RAM.

Immediate addressing mode

MOV A, #12H ; To set an immediate data 12H into ACC

DIRECTLY ADDRESSING MODE

The directly addressing mode uses address number to access memory location (MOV A,12H, MOV 12H,A).

Directly addressing mode

B0MOV A, 12H ; To get a content of location 12H of bank 0 and save in ACC

INDIRECTLY ADDRESSING MODE

The indirectly addressing mode is to set up an address in data pointer registers (Y/Z) and uses MOV instruction to

read/write data between ACC and @YZ register (MOV A,@YZ, MOV @YZ,A).

Example: Indirectly addressing mode with @YZ register

CLR Y ; To clear Y register to access RAM bank 0.

B0MOV Z, #12H ; To set an immediate data 12H into Z register.

B0MOV A, @YZ ; Use data pointer @YZ reads a data from RAM location

; 012H into ACC.

MOV A, #01H

B0MOV Y, A ; To set Y = 1 for accessing RAM bank 1.

B0MOV Z, #12H ; To set an immediate data 12H into Z register.

B0MOV A, @YZ ; Use data pointer @YZ reads a data from RAM location

; 012H into ACC.

MOV A, #0FH

B0MOV Y, A ; To set Y = 15 for accessing RAM bank 15.

B0MOV Z, #12H ; To set an immediate data 12H into Z register.

B0MOV A, @YZ ; Use data pointer @YZ reads a data from RAM location 012H

; Into ACC.

SONiX TECHNOLOGY CO., LTD Page 39 Revision 1.94

Page 40

SN8P1800