Page 1

SUMMIT

MICROELECTRONICS, Inc.

Quad Power Supply Controller

FEATURES DESCRIPTION

SMT4004

l Programmable Voltage and Current Monitoring

w Monitors 4 independent supplies

w Programmable Host-side Under- and Over-

Voltage Thresholds

w Programmable Card-side Under-Voltage

Monitors

w Programmable Card-side Circuit Breaker

Delay and QuickTrip™ Threshold Levels

l Programmable Card-side Trakker Function

w Programmable Slew Rate Control

w Guarantees and Enforces Supply Differential

Tracking

l Programmable Watchdog and Longdog Timers

(0 to 6.4 seconds)

l Operates From Any One of Four Supply Voltages

l Nonvolatile Fault Register

w Records Source of Any Interrupt

w Readable in “Dead Board” Environment

l All Communications to Configuration Registers

and Memory Array are via I2C Interface

The SMT4004 is a fully integrated programmable voltage

manager IC, providing supervisory functions and tracking

control for up to four independent power supplies. The

four internal managers perform the following functions:

Monitor source (bus-side) voltages for under- and overvoltage conditions, monitor each supply for over-current

conditions, monitor back end (card-side) voltages for two

staged levels of under-voltage conditions, insure power to

the card-side logic tracks within the specified parametric

limits, and provide supply status information to a host

processor.

The SMT4004 incorporates nonvolatile programmable

circuits for setting all of the monitored thresholds for each

manager. Individual functions are also programmable

allowing interrupts or reset conditions to be generated by

any combination of events. Because of a proprietary

EEPROM technology that it employs it is also able to store

fault conditions as they occur. In the case of a catastrophic

failure the fault is recorded in the registers and then can be

read for analysis.

Programming of configuration, control and calibration

values by the user can be simplified with the interface

adapter and Windows GUI software obtainable from Summit Microelectronics.

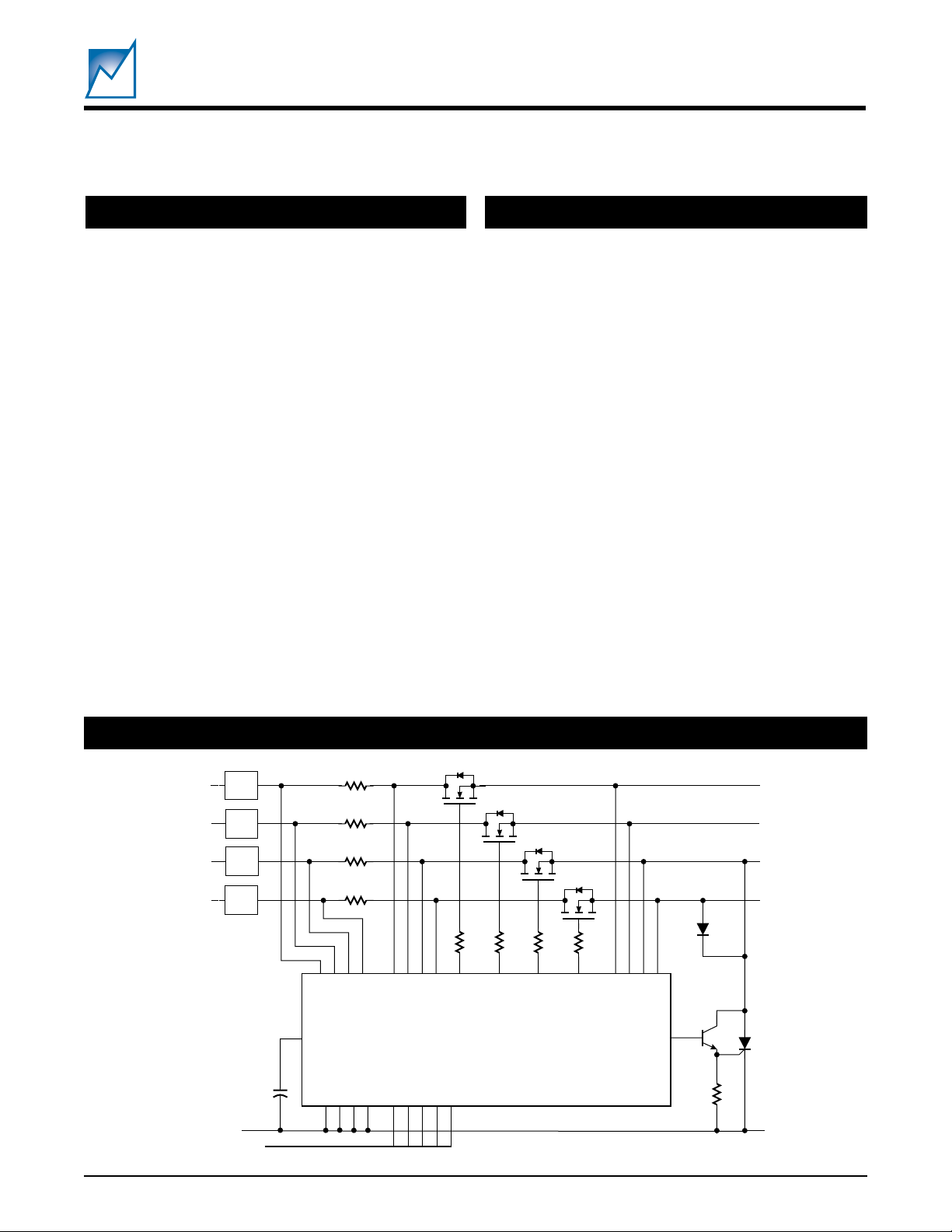

SIMPLIFIED APPLICATION DIAGRAM

5V

3.3V

2.5V

1.8V

OPTIONAL

VI1

VI2

VI3

VI4

CB1

CB2

VDD_CAP

SDA

GND4

SCLA0A1

GND1

GND2

GND3

I2C

©SUMMIT MICROELECTRONICS, Inc., 2001 • 300 Orchard City Dr., Suite 131 • Campbell, CA 95008 • Phone 408-378-6461 • FAX 408-378-6586 • www.summitmicro.com

VG1

CB3

CB4

SMT4004

A2

VG2

VG3

GND

VG4

CROWBAR

VO1

CROWBAR

VO2

VO3

VO4

100Ω

Characteristics subject to change without notice 2049 3.1 3/19/01

1

Page 2

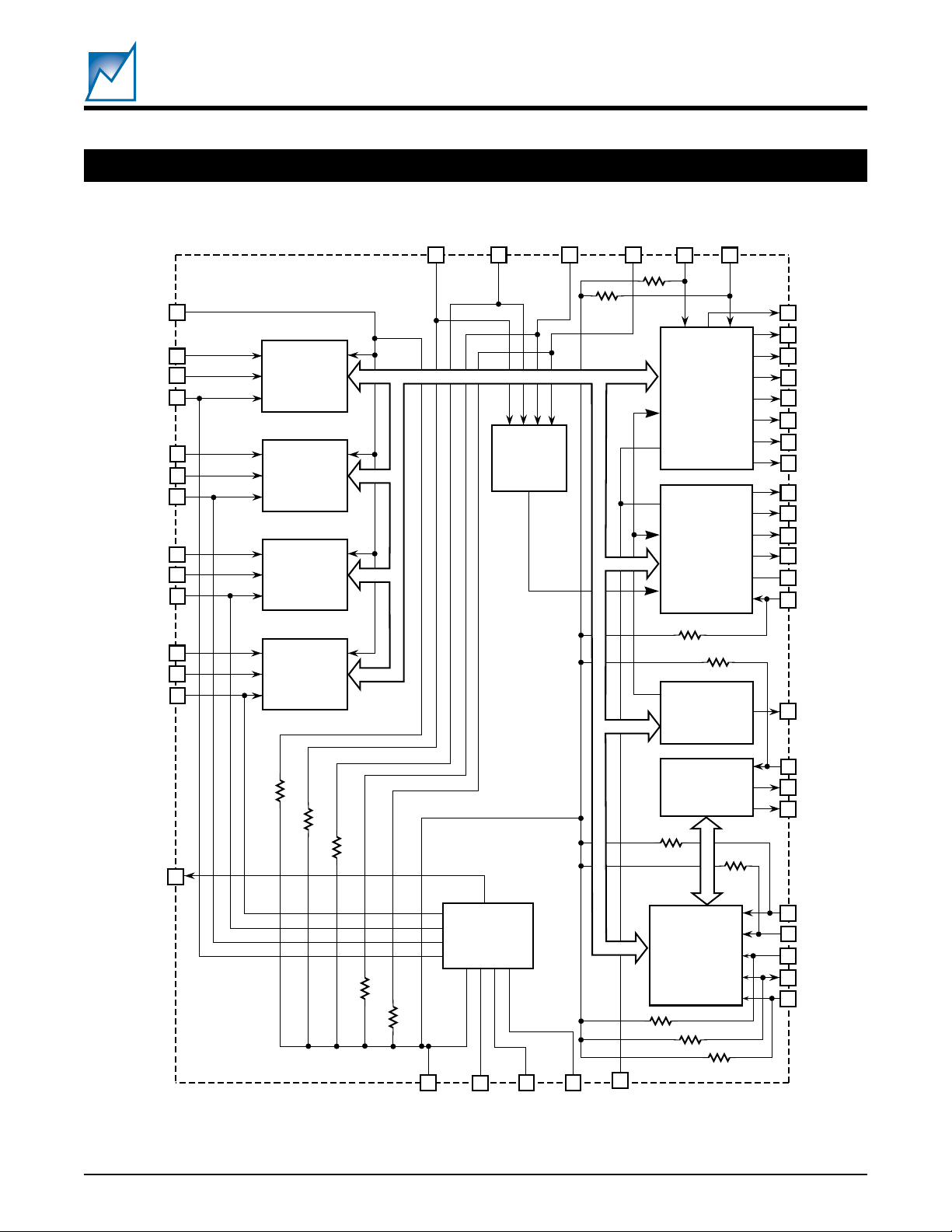

FUNCTIONAL BLOCK DIAGRAM

SMT4004

UV_OVERRIDE

VO1

CB1

VI1

VO2

CB2

VI2

VO3

CB3

VI3

VO4

CB4

VI4

PWR_ON

12

20

37

41

21

36

40

22

35

39

23

34

38

SUPPLY

MANAGER

#1

SUPPLY

MANAGER

#2

SUPPLY

MANAGER

#3

SUPPLY

MANAGER

#4

33

FORCE_SD

27

SEQUENCE

ENABLE

LOGIC

All Resistors

are 100kΩ

SEATED1#

SEATED2#

10

11

MR#

IRQ_CLR#

5

RESET &

STATUS

OUTPUT

CONTROL

LOGIC

CHARGE

PUMP &

VGATE

CONTROL

TRAKKER

LOGIC

TIMER

LOGIC

6

IRQ#

7

RST1#

13

14

RST2#

RST3#

15

16

RST4#

CROWBAR

3

CBFAULT

25

HEALTHY#

26

VGATE1

32

VGATE2

31

VGATE3

30

VGATE4

29

VGG_CAP

28

ENABLE

24

TRKR_IRQ#

9

48

WLDI

1

LDO#

2

WDO#

REF

4

A0

43

A1

44

A2

45

SDA

46

SCL

47

2049 BD 2.2

42

VDD_CAP

2049 3.1 3/19/01

POWER

SUPPLY

ARBITRATION

8

PGND

18

DGND

19

AGND

MEMORY

& 2-WIRE

BUS

INTERFACE

17

PGND

SUMMIT MICROELECTRONICS, Inc.

1.25V

2

Page 3

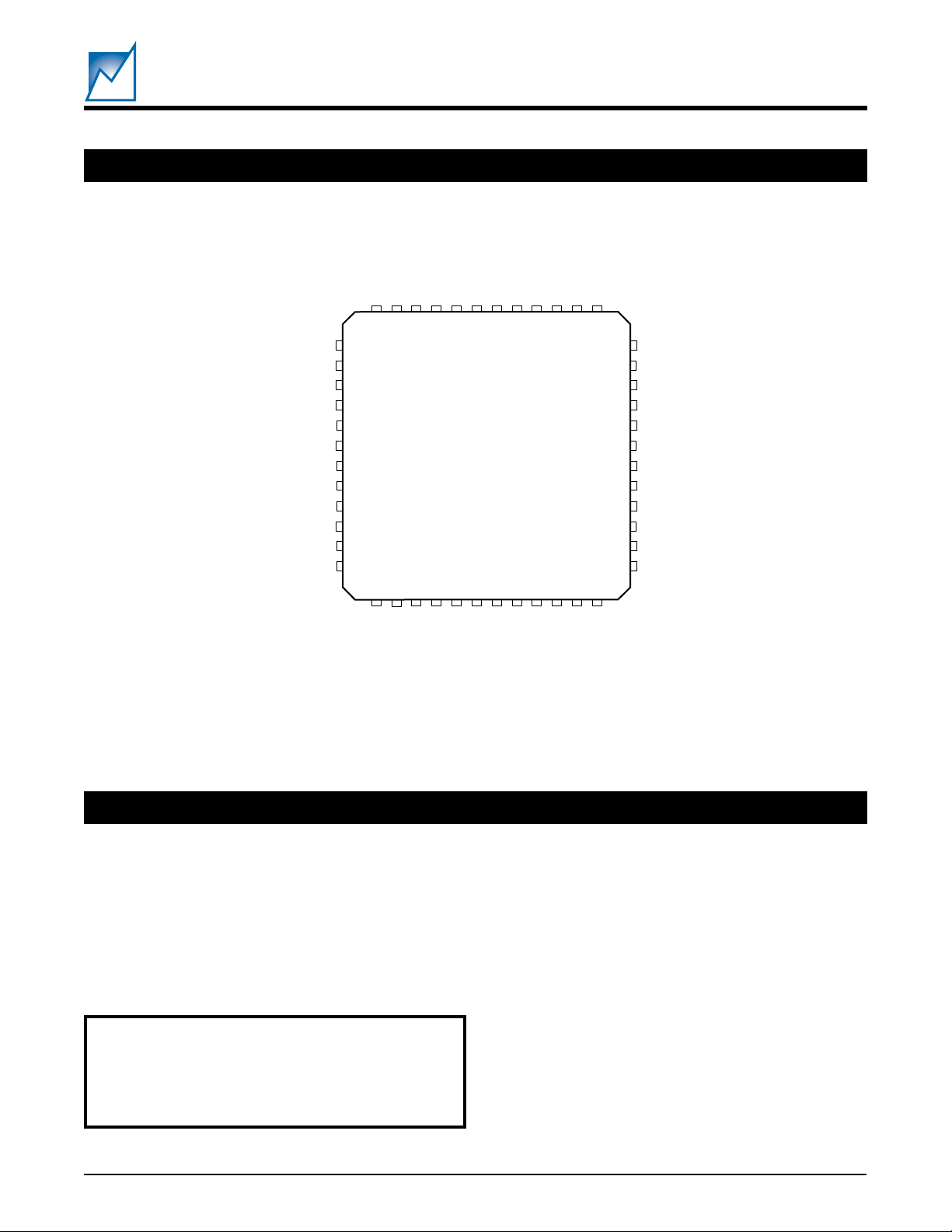

PIN CONFIGURATION

WLDI

SCL

48-Pin TQFP

SDAA2A1A0V

_CAP

DD

VI1

VI2

VI3

VI4

SMT4004

CB1

LDO#

WDO#

CROWBAR

1.25V

REF

MR#

IRQ_CLR#

IRQ#

PGND

TRKR_IRQ#

SEATED1#

SEATED2#

UV_OVERRIDE

4847464544434241403938

1

2

3

4

5

6

7

8

9

10

11

12

1314151617181920212223

VO1

PGND

DGND

RST1#

RST2#

RST3#

RST4#

AGND

VO2

VO3

37

36

35

34

33

32

31

30

29

28

27

26

25

24

VO4

ENABLE

CB2

CB3

CB4

PWR_ON

VGATE1

VGATE2

VGATE3

VGATE4

VGG_CAP

FORCE_SD

HEALTHY#

CBFAULT

2049 PCon 2.1

ABSOLUTE MAXIMUM RATINGS*

Temperature Under Bias .......................-55°C to 125°C

Storage Temperature ............................-65°C to 150°C

Lead Solder Temperature (10 secs) ...................300 °C

Terminal Voltage with Respect to GND:

V0, V1, V2, and V3........... -0.3V to 6.0V

All Others........................ -0.3V to 6.0V

RECOMMENDED OPERATING CONDITIONS

Temperature –40ºC to 85ºC.

Voltage 2.7V to 5.5V

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

*COMMENT

Stresses listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions

outside those listed in the operational sections of this specification is not

implied. Exposure to any absolute maximum rating for extended

periods may affect device performance and reliability.

3

Page 4

DC OPERATING CHARACTERISTICS

(Over Recommended Operating Conditions; Voltages are relative to GND)

lobmySretemaraPsetoN.niM.pyT.xaMstinU

IV4IVhguorht1IVsegatlovylppuS

I

nO

DD

ffOevitcaniELBANE1.0Am

I

DD

P

TIV

IV

SYH

V

BC

BC

YALED

V

BCQ

V

FER

nO

V

GV

ffOGV

V

GV

I

GV

RS

GV

RS

ATLED

P

TVO

VO

SYH

V

HI

V

LI

V

LO

t

WORC

egnar

V52.1

FER

tnerrucylppusrewoP

dlohserhttupniIVelbammargorP

siseretsyhpirtVU/VO 01Vm

egatlovpirtrekaerbtiucriC515204Vm

retliftnerruc-revO

egatlovpirt-kciuQ

.g.e

(

egatlovtuptuoR

egatlovtuptuoevirdETAGV

tnerructuptuoevirdETAGVnOsehctiwsTEFSOM08Aµ

etarwelsegatlovtuptuoETAGV

laitnereffidwelsREKKART

egatlovedis-dracelbammargorP

egnardlohserht

siseretsyhtupniVO 01Vm

egatlovhgihtupnI

egatlovwoltupnI

stuptuoniardnepOI

KNIS

htdiwesluptuptuorabworCk1otni.nimV5.2 Ω 6182sµ

(IVtsehgiH ≥ ehtsrewop)V7.2

4004TMS

evitcaELBANEdnaNO_RWP13Am

tib/Vm02,noitulosertib-89.00.6V

.elbammargorP

,0D&1Dstibatad

ylevitcepser

.elbammargorP

6D&7Dstibatad

ylevitcepser,)

k2= Ω 32.152.172.1V

DAOL

00 52sµ

01 05sµ

,B1RretsigeRybteS

10 001sµ

11 002sµ

00 ffO

01 57Vm

,A1RretsigeRybteS

10 001Vm

11 051Vm

nOsehctiwsTEFSOM4161V

Am1=04.0V

KNIS

.elbammargorP

00 04001041s/V

01 001052053s/V

,01RretsigeRybteS

ro2D&3Dstibatad

10 002005007s/V

ylevitcepser,0D&1D

11 00400010041s/V

laitnereffidatled,snipOV

dewolla

tib/Vm02,noitulosertib-89.00.6V

V7.2=IV9.0 × IVIVV

V5=IV7.0 × IVIVV

V7.2=IV1.0– 1.0 × IVV

V5=IV1.0– 3.0 × IVV

Am2=04.0V

SMT4004

7.25.5V

001Vm

2049 Elect Table 1.1

4

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Page 5

PIN DESCRIPTIONS AND DEVICE OPERATION

THE

TRAKKER

SUPPLY VOLTAGES

SMT4004

SUPPLY MANAGERS

The VI inputs of all four supply managers are diode ORed

and tied to the device's internal VDD node. The

will use the highest VI input for its supply voltage. At least

one VI input must be at or above 2.7V for proper device

operation.

VDD_CAP — Charge storage connection for the chip's

internal power supply. For most applications a 10µF

capacitor should be connected to his pin.

VGG_CAP — This pin should be tied to a capacitor to be

charged by the charge pump. The capacitor should be of

sufficient size so as to provide current to the VGATE

outputs under varying load conditions.

PGND — Power ground

DGND — Digital Ground

AGND — Analog Ground

TRAKKER

TIMERS

LDO# — The longdog timer output is an active-low open-

drain output that can be wire-ORed with other open-drain

signals. The longdog timer is generally programmed to

generate an output at a time interval longer than the

watchdog timer. The time interval is programmed in

Register

WDO# — The watchdog timer output is an active-low

open-drain output that can be wire-ORed with other opendrain signals. The watchdog timer is generally programmed to generate an output at a time interval shorter

than the longdog timer. The time interval is programmed

in Register

R1C

R1C

.

.

The electrical placement of the SMT4004 on a printed

circuit card is such that it separates the host power supply

and any on-board DC-to-DC converters (or LDOs) from

the backend circuitry such as multiple DSPs, microprocessors and associated glue logic. The host supplies, and

any other regulated voltages that will be “switched” by the

device, are referred to as bus-side voltages. The voltages

that are on the backend circuitry side of the switches are

referred to as card-side voltages.

The four supply manager blocks are identical. Each

contains three primary functional blocks: the first monitors

the bus-side voltages, the second monitors the card-side

voltages, and the third monitors over-current conditions

for that particular supply.

BUS-SIDE MANAGEMENT

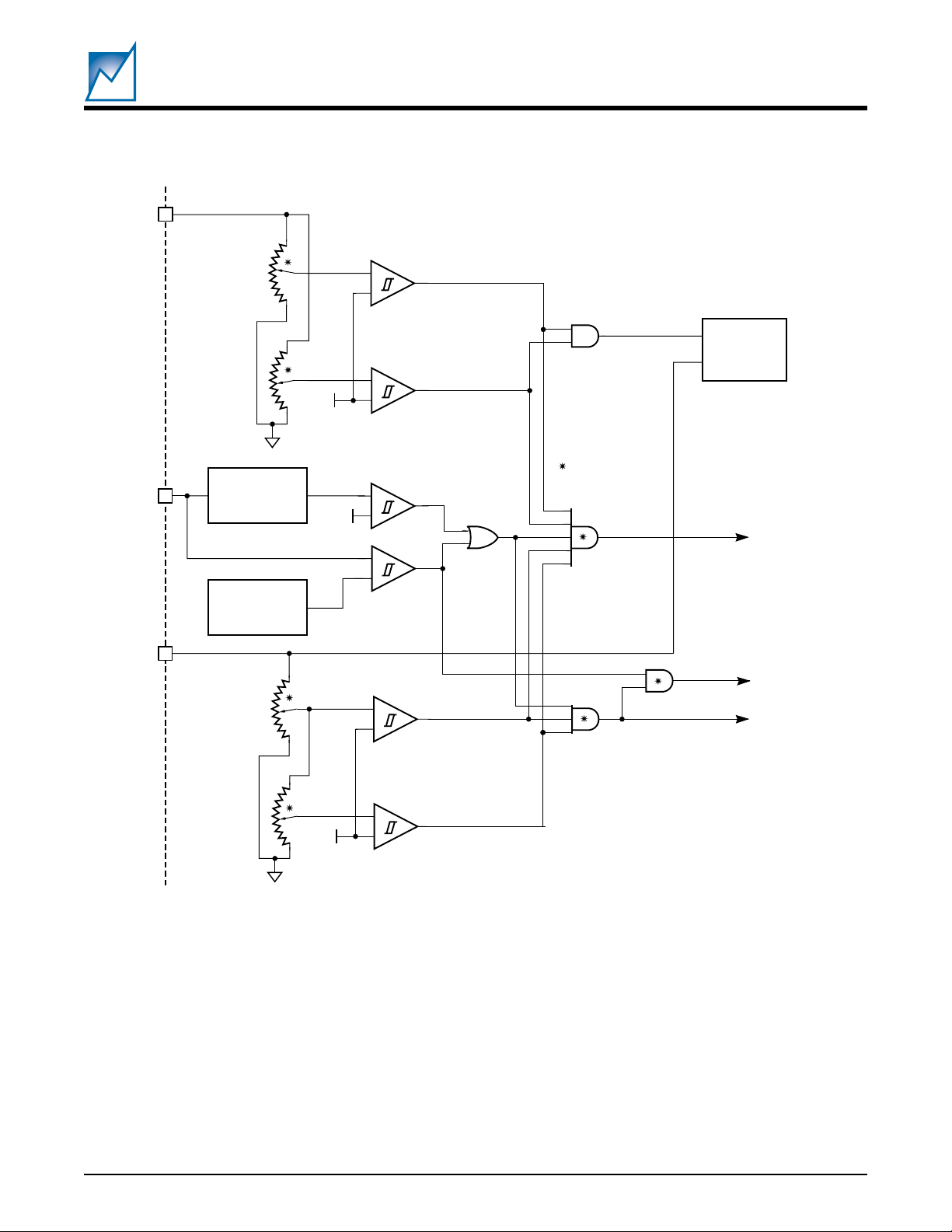

Figure 1 illustrates the functional blocks of the four supply

managers. Each manager block can be independently

enabled or electrically removed from the device.

The VI input monitors the bus-side voltage for both undervoltage and over-voltage conditions. The thresholds for

the under-voltage detection for VI inputs are programmed

in Registers

the V

designed so that the threshold can be determined by

multiplying the binary value of the Register times 20mV

and adding that to 0.9V in the formula P

× n), where n is the register value (0 - 255 decimal). This

allows very precise monitoring of voltages in the range of

0.9V to 6V without the use of external resistor divider

networks.

R00

through

of a nonvolatile DAC. The DAC has been

REF

R03

. The VI input is effectively

= 0.9V + (0.2mV

VIT

WLDI — Watchdog and longdog timer reset input. A low-

to-high transition on this pin will reset both the watchdog

timer and the longdog timer.

The watchdog and longdog work in tandem: resetting one

resets the other. Generally, the longdog will be programmed to time out sometime after the watchdog. As an

example, the WDO# output could be used to generate a

warning interrupt and the LDO# output could be tied to a

system reset line.

Both timers can be turned off, facilitating system debug

and also allowing operating systems to ‘boot up’ and

configure themselves without interrupts or resets.

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

The over-voltage level is determined by the value in

registers

SMT4004 GUI. All enabled manager blocks must ensure

their respective VI inputs are within the programmed limits

before the VGATE outputs can be turned on and the

TRAKKER

also be used to generate a general interrupt.

It should be noted that either one or both of the bus-side

monitors could be disabled via Registers

R07

R04

through

logic enabled. The VI comparator outputs can

.

R07

, and is selected by the

R04

through

5

Page 6

SMT4004

VI

X

CB

VO

–

+

+

V

REF

X

X

Programmable

Delay

Programmable

Quick Trip

Threshold

25mV

–

+

–

+

–

Comparator

–

+

OV

Comparator

UV

Comparator

Circuit

Breaker

Comparator

Quick

Trip

UV1

Comparator

Quick Trip

OC

VGATE Enable

( = Programmable)

To IRQ

VGATE and

TRAKKER

Logic

To Crowbar

To RST

+

V

REF

–

UV2

Comparator

Figure 1. Supply Manager Circuit

CARD-SIDE MANAGEMENT

On the card-side the

mable under-voltage thresholds on the VO inputs: UV1

and UV2. UV1 can be used to generate a warning interrupt

that the supply is decaying, and UV2 can be used to

generate a reset condition or a crowbar output. The cardside under-voltage (UV1) threshold value is programmed

in Registers R08 through R0B. Like the bus-side thresholds the levels can be programmed in 20mV increments

(on top of 0.9V). The second level (UV2) is determined by

6

TRAKKER

monitors two program-

2049 3.1 3/19/01

2049 Fig01 1.0

the value in Registers R0C through R0F, and is selected

by the SMT4004 GUI.

It should be noted that either one or both of the card-side

monitors can be disabled via Registers

R0C

through

R0F

OVER-CURRENT PROTECTION

The CB inputs are the circuit breaker inputs for the supply

voltages. With a series resistor placed in the supply path

between VI and CB the circuit breaker will trip whenever

the voltage across the resistor exceeds 25mV.

SUMMIT MICROELECTRONICS, Inc.

.

Page 7

SMT4004

The on-board electronic circuit breaker can be programmed to application specific levels. The circuit

breaker delay defines the period of time the voltage drop

across RS is greater than 25mV but less than V

QCB

before

the VGATE output will be shut down. This is effectively a

filter to prevent spurious shutdowns of VGATE. The

delays that can be programmed are 25µs, 50µs, 100µs

and 200µs. The programmable delay bits are located in

Register

The Quick-Trip circuit breaker threshold (V

to 150mV, 100mV, 75mV or off (Register

R1B

.

) can be set

QCB

R1A

). This is the

threshold voltage drop across RS that is placed between

V

and CBSENSE. If the voltage drop exceeds the

SS

programmed threshold, the electronic circuit breaker will

immediately trigger with no delay.

The outputs of these comparators can be used to generate

interrupts and reset conditions and toggle the crowbar

output.

POWER-ON SEQUENCING

In order to begin sequencing of the card-side supplies

(ramping the VGATE outputs) a number of conditions

must be met. All enabled bus-side voltages must be above

their respective under-voltage thresholds, the card-side

voltages (

be near zero volts, and the following inputs must be

properly set.

ENABLE — When active the ENABLE input brings

the IC out of a standby mode where the charge pump

supplying the VGATE outputs is turned on (and

begins charging the VGG_CAP) and the bandgap

reference is turned on. The ENABLE input can be

programmed to be either active low (default from the

factory) or active high (Register

SEATED1# and SEATED2# — the SEATED inputs

are effectively two additional enable inputs that must

be low to enable the sequencing of the card-side

voltages. In a staggered pin environment these

inputs can be tied to the “short” pins, insuring the card

is fully seated before any power is applied to the cardside logic. These inputs can also be tied to card

insertion switches to indicate proper seating.

PWR_ON — the PWR_ON input is the last input that

will typically be driven to enable power sequencing to

the card-side. The PWR_ON input can be programmed to be either active low (default from the

factory) or active high (Register

e.g.

, residual capacitor stored potentials) must

R1B

).

R1B

).

TRAKKING

AND SOFTSTART CONTROL

VGATE — The VGATE outputs are used to control the

“turning-on” of the card-side voltages. The ramp rate (for

both turn-on and turn-off) of the outputs is programmable

from 100V/s to 1000V/s (Register

R10

). The four outputs

ramp at the same slew-rate, so normally there will be no

differential voltage between any of the supplies until each

reaches its maximum level.

The ramp rates are inherently adaptive. That is, if the

difference between any VO input is greater than 100mV in

the linear region, the slew rate will be increased or decreased to minimize the differential. The comparisons are

made between VO1 and VO2, VO2 and VO3, VO3 and

VO4, and VO4 and VO1. If at any time a differential of

greater than 300mV is detected a pre-programmed (Register

R10

) action can be taken. The

TRAKKER

can shut

down the offending supply, generate an interrupt output, or

ignore the situation.

If SoftStart is enabled (Registers

R0C

through

R0F

) the

supply or supplies designated will be ramped as soon as

the input conditions are met and no Trakking will be

performed. Any supply not designated as a softstart

supply will not be ramped until the designated supply has

reached its VO threshold. This type of operation would

commonly be used where a bus voltage (

e.g.

, 5V) is first

switched to a DC-to-DC converter or group of LDOs; and

then their outputs would be switched in a Trakking mode

to the card-side logic.

Supply managers designated for Trakking will not begin

start-up until the soft start channels are fully turned on.

The delay is approximated by the formula tD =16,000 ÷ SR,

where tD is the time delay in milliseconds between the

PWR_ON signal going high and the start of the tracking

ramp-up, and SR is the programmed start-up slew rate in

V/s. For example, the time delay for a programmed slew

rate of 500V/s is: tD = 16,000 ÷ 500 = 32ms.

POWER MANAGEMENT STATUS OUTPUTS

The

TRAKKER

provides to the host system or host processor resident on

its board. One type of output is “hardwired” internally and

the other is programmable.

HEALTHY# — The HEALTHY output is an active-low

open-drain output that can be wire-ORed with other opendrain signals. It is driven low when all of the enabled

managers’ card-side voltages are valid and there are no

over-current conditions. The signal is used to indicate the

power supplies are within their programmed operating

limits.

has two types of status outputs that it

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

7

Page 8

SMT4004

CBFAULT — CBFAULT is driven active whenever an

over-current condition is detected. It is a programmable

output that can be either an active high or active low

(factory default) output.

RESETS

RST1# to RST4# — Associated with each manager is a

reset output. They are active-low open-drain outputs that

can be wire-ORed with other open-drain signals. The user

can select UV1, UV2 and/or an over-current condition as

the trigger for the reset pulse by programming Registers

R11

and

R12

(the default condition from the factory is all

conditions generate a reset). The reset pulse width is

adjustable by writing to Register

from the factory is pulse of 200ms).

MR# — When driven low the manual reset input will

automatically drive all four reset outputs low. During

programming the MR# input must be pulled low.

R1C

(default condition

INTERRUPTS

IRQ# — the IRQ# output is an active low open-drain output

that is driven low whenever one or more of its programmed

triggers is active. There are twenty programmable

sources for generating the interrupt: bus-side over- and

under-voltage, card-side under-voltage 1 and 2, and an

over-current condition. Each source is individually enabled by writing to Registers

default from the factory is to enable all sources. The IRQ#

output can only be cleared by bringing IRQ_CLR# low, or

after a power-down/power-up sequence.

TRKR_IRQ# — the

was a skew of greater than 300mV during the power on

cycle. The source of the TRKR_IRQ# is programmable

and can be initiated by any one of the managers. The

configuration Registers

interrupt. Configuration Register

TRKR_IRQ# output (or one of three other options). The

default from the factory is to enable all sources. The

TRKR_IRQ# output can only be cleared by bringing

IRQ_CLR# low or after a power-down/power-up sequence.

In order to avoid false interrupts during a power-on sequence there is a programmable “power-on interrupt holdoff” register. The delay can be programmed from 200ms

to 1600ms. The interrupt hold-off is in Register

its default value from the factory will be 1600ms.

TRAKKER

R11

R13, R14

interrupt indicates there

and

R12

and

R15

select the source of

R10

enables the

. The

R15

and

FAULT REGISTER

Whenever an interrupt is generated the cause of the fault

will be recorded in the nonvolatile status Register. In order

to avoid false recordings during power-down situations,

no faults will be recorded if the PWR_ON input has been

deactivated. The fault Registers are located at

through

assigned bit location. Overwriting the fault Register with

“0’s” is the only way to clear a recorded fault condition.

CROWBAR — The CROWBAR output is another form of

status output. The conditions to generate a crowbar

output are programmable in Register

of the conditions occurs the CROWBAR output will strobe.

Rapid shutdown of the card-side supplies may be required

to prevent damage to the DSP’s or microprocessors. The

VGATE outputs will be shut down when CROWBAR

occurs. SCRs with a fast turn-on time make excellent

crowbar devices and only need a pulse of gate current to

‘trigger.’

R1F

. The fault source is indicated by a “1” in the

R19

. Whenever one

R1D

MEMORY AND REGISTER ACCESS

A0, A1 & A2 — The address pins are biased either to the

highest VI pin or GND, and provide a mechanism for

assigning a unique address to the SMT4004.

SDA — SDA is a bidirectional serial data pin. It is

configured as an open drain output and will require a pullup to the highest VI pin.

SCL — SCL is the serial clock input.

MISCELLANEOUS MANAGER SIGNALS

1.25V

be used in conjunction with external circuitry.

UV_OVERRIDE — The Under-Voltage Override input will

disable the under-voltage comparators. This can be used

for board test and also during system margining.

FORCE_SD — When asserted the Force Shut Down input

will immediately clamp the VGATE outputs to ground. This

can be used in conjunction with the CROWBAR. The

active level for FORCE_SD is programmable and accessible in Register

— This pin is a 1.25V Reference output that can

REF

R1B

.

8

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Page 9

REGISTER FORMATS AND FUNCTIONS

There are four basic register types. The first are those that

set a monitoring threshold where the binary value written

to the register is multiplied times the base incremental

voltage. The second type enables or disables a specific

function: unless otherwise indicated a “1” will always

enable the function and a “0” will disable or deselect that

function. Note: only the enabled condition will be depicted

in the following tables. The third Register type allows

selection of various timer values. These are not incremen-

Bus-side Under-voltage Threshold

Registers 00, 01, 02 and 03 are identical. Their contents

select the under-voltage threshold for the VI1, VI2, VI3 and

VI4 inputs, respectively.

7D6D5D4D3D2D1D0DnoitcA

11111111 V0.6=tnemtsujdadlohserhttsehgiH

00000000 V9.0=tnemtsujdadlohserhttsewoL

00000010 2(+V9.0=dlohserhT × ,V49.0=)V20.

Bus-side Under-voltage Threshold Enable and

Over-voltage Offset

tal, like the thresholds, but specific bit patterns select

specific timer values. The fourth register type is the

nonvolatile fault register that records fault conditions. A “0”

in any bit location indicates its corresponding monitor

function was within specified limits when the fault occurred. A “1” in any bit location indicates its corresponding

monitor function was outside its specified limits when the

fault occurred.

30R,20R,10R,00RretsigeR

SMT4004

.g.e

2049 Table01 1.0

Registers 04*, 05, 06 and 07 are identical. Their contents

determine whetheror not the under- or over-voltage capabilities are enabled, and establish the over-voltage offset

* Note: In Register 4 (only) Bit 7 can be set to

allow tracking to begin even when the card side

voltages haven't bled down to zero.

value for the VI1, VI2, VI3 and VI4 inputs, respectively.

70R,60R,50R,40RretsigeR

7D6D5D4D3D2D1D0DnoitcA

x

*

1

xx

xxx

xxxxxx noitcetedegatlovrednuselbanE

1

xxxxx noitcetedegatlovrevoselbanE

00010

IUG

Card-side Under-voltage Threshold

Registers 08, 09, 0A and 0B are identical. Their contents

select the under-voltage threshold for the VO1, VO2, VO3

and VO4 inputs, respectively.

B0R,A0R,90R,80RretsigeR

7D6D5D4D3D2D1D0DnoitcA

11111111 V0.6=tnemtsujdadlohserhttsehgiH

00000000 V9.0=tnemtsujdadlohserhttsewoL

00000010 2(+V9.0=dlohserhT × ,V49.0=)V20.

4004TMSybdetcelesnoitarugifnocdlohserhT

2049 Table02 1.1

.g.e

2049 Table03 1.0

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

9

Page 10

SMT4004

Card- side Under-voltage Threshold Enable

and Over-voltage Offset

agement functions and soft start capability. Their contents

also determine whether the under- or over-voltage capabilities are enabled and the contents establish the over-

Registers 0C, 0D, 0E and 0F are identical These registers

will either enable or disable their associated power man-

voltage offset value for the VO1, VO2, VO3 and VO4

inputs, respectively.

F0R,E0R,D0R,C0RretsigeR

7D6D5D4D3D2D1D0DnoitcA

1

x

xx

xxx

Addressing and Slew Rate Control

Configuration Register 10 is used to configure the addressing protocol for the TRAKKER. Bit 7 determines

whether the device will respond with an acknowledge to

xxxxxxx delbanelennahctnemeganamrewoP

1

xxxxxx gnikkarTelbanE=0;tratstfoselbanE=1

1

xxxxx 2egatlovrednuselbanE

00010

any bus request addressing its device type identifier, or

whether it will be selective and only respond if the A2, A1

and A0 bits match the biasing of the external pins. Bit 6

selects the device type identifier to be used for the memory

array.

IUG

01RretsigeR

7D6D5D4D3D2D1D0DnoitcA

0

1

x

x

x

x sesserddasubllaotsdnopseR

x

0

1

noitcalaitnereffidVm003rednu/revoREKKART

00

01

x

x

10

11

)nootffo(hgihotwoletarwelsREKKART

00

x

01

10

x

11

)ffootno(wolothgihetarwelsREKKART

00

x

01

10

11

4004TMSybdetcelesnoitarugifnocdlohserhT

2049 Table04 1.1

subdesaibniPotylnosdnopseR

sesserdda

0101reifitnediepyt-ecivedyromeM

1101reifitnediepyt-ecivedyromeM

erongI

dnaylppusytluafehtnwodtuhS

#QRI_RKRT

dnaseilppusllanwodtuhS

#QRI_RKRT

#QRI_RKRTetareneG

s/V001

s/V052

s/V005

s/V0001

s/V001

s/V052

s/V005

s/V0001

2049 Table05 1.0

10

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Page 11

SMT4004

Reset Source Select and

TRAKKER

IRQ Select (for Supply Managers 1 and 2)

7D6D5D4D3D2D1D0D

1-1OV2-1OVO1IV1RKRT1-2OV2-2OVO2IV2RKRT

1

x

xx

xxx

xxxx

xxxxx

xxxxxxx

1

xxxxxx

1

xxxxx reggirt1#TSRsa1IBCstceleS

1

xxxx

1

xxx

1

xxxxxx

xxxxxxx

11RretsigeR

xx

1

xreggirt2#TSRsa2IBCstceleS

1

noitcA

1#TSRsa1VU1edis-dracstceleS

reggirt

1#TSRsa2VU1edis-dracstceleS

reggirt

tpurretninasarorre1KRTstceleS

ecruos

2#TSRsa1VU2edis-dracstceleS

reggirt

2#TSRsa2VU2edis-dracstceleS

reggirt

tpurretninasarorre2KRTstceleS

ecruos

2049 Table06 1.0

Reset Source Select and

TRAKKER

IRQ Select (for Supply Managers 3 and 4)

7D6D5D4D3D2D1D0D

1-3OV2-3OVO3IV3RKRT1-4OV2-4OVO4IV4RKRT

1

x

xx

xxx

xxxx

xxxxx

xxxxxxx

1

xxxxxx

1

xxxxx reggirt3#TSRsa3IBCstceleS

1

xxxx

1

xxx

1

xxxxxx

xxxxxxx

21RretsigeR

xx

1

xreggirt4#TSRsa4IBCstceleS

1

noitcA

3#TSRsa1VU3edis-dracstceleS

reggirt

3#TSRsa2VU3edis-dracstceleS

reggirt

tpurretninasarorre3KRTstceleS

ecruos

4#TSRsa1VU4edis-dracstceleS

reggirt

4#TSRsa2VU4edis-dracstceleS

reggirt

tpurretninasarorre4KRTstceleS

ecruos

2049 Table07 1.0

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

11

Page 12

IRQ Source Select (for Supply Managers 1 and 2)

7D6D5D4D3D2D1D0D

VO-1IVVU-1IV1-1OV2-1OVVO-2IVVU-2IV1-2OV2-2OV

1

x

xx

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx

xxxxxxx

1

xxxxxx

1

xxxxx

1

xxxx

1

xxx

1

31RretsigeR

xx

1

x

1

SMT4004

noitcA

#QRInasaVO1edis-substceleS

reggirt

#QRInasaVU1edis-substceleS

reggirt

#QRInasa1VU1edis-dracstceleS

reggirt

#QRInasa2VU1edis-dracstceleS

reggirt

#QRInasaVO2edis-substceleS

reggirt

#QRInasaVU2edis-substceleS

reggirt

#QRInasa1VU2edis-dracstceleS

reggirt

#QRInasa2VU2edis-dracstceleS

reggirt

2049 Table08 1.0

IRQ Source Select (for Supply Managers 3 and 4)

7D6D5D4D3D2D1D0D

VO-3IVVU-3IV1-3OV2-3OVVO-4IVVU-4IV1-4OV2-4OV

1

x

xx

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx

xxxxxxx

1

xxxxxx

1

xxxxx

1

xxxx

1

xxx

1

41RretsigeR

xx

1

x

1

noitcA

#QRInasaVO3edis-substceleS

reggirt

#QRInasaVU3edis-substceleS

reggirt

#QRInasa1VU3edis-dracstceleS

reggirt

#QRInasa2VU3edis-dracstceleS

reggirt

#QRInasaVO4edis-substceleS

reggirt

#QRInasaVU4edis-substceleS

reggirt

#QRInasa1VU4edis-dracstceleS

reggirt

#QRInasa2VU4edis-dracstceleS

reggirt

2049 Table09 1.0

12

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Page 13

IRQ Power-on Delay and Source Select (for All Supply Managers)

51RretsigeR

7D6D5D4D3D2D1D0DnoitcA

x

x

x

x

x

000

100

101

110

111

xxxx

xxxxx

xxxxxx

xxxxxxx

xxxx )sm0(ffoyalednorewop#QRI

xxxx sm002yalednorewop#QRI

xxxx sm004yalednorewop#QRI

xxxx sm008yalednorewop#QRI

xxxx sm0061yalednorewop#QRI

1

xxx #QRIsreggirttnerruc-revo1ylppuS

1

xx #QRIsreggirttnerruc-revo2ylppuS

1

x#QRIsreggirttnerruc-revo3ylppuS

1

SMT4004

#QRIsreggirttnerruc-revo4ylppuS

2049 Table10 1.0

CROWBAR Source Enables

7D6D5D4D3D2D1D0D

ECROF

DS_

1

x

#QRI

xxxxxxx DS_ECROFelbanE

1

xx

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx

_KRT

#QRI

1TSR2TSR3TSR4TSR

xxxxxx tpurretnilareneG

1

xxxxx tpurretniREKKART

1

xxxx teser1ylppuS

1

xxx teser2ylppuS

1

91RretsigeR

KCIUQ

PIRT

xx teser3ylppuS

1

xteser4ylppuS

1

noitcA

noitidnocpirTkciuQ

2049 Table11 1.0

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

13

Page 14

Quick-trip Voltage Thresholds

7D6D5D4D3D2D1D0D

1REGANAM2REGANAM3REGANAM4REGANAM

00

01

10

11

x

x

00

01

10

11

x

x

x

00

01

10

11

A1RretsigeR

x

00

01

10

11

SMT4004

noitcA

ffO

Vm57

Vm001

Vm051

ffO

Vm57

Vm001

Vm051

ffO

Vm57

Vm001

Vm051

ffO

Vm57

Vm001

Vm051

2049 Table12 1.0

Over-current Delay and Active Pin Level Select

7D6D5D4D3D2D1D0D

ananBCNEOPDS-FYLD-CO

xxxxx )hgihevitca=1(tuptuoTLUAFBC

1

xxxx )hgihevitca=1(tupniELBANE

1

xxx )hgihevitca=1(tupniNO_RWP

1

2049 3.1 3/19/01

xx

xx

14

1

x

xx

xxx

xxxx

xxxx

xxxx

xxxx

B1RretsigeR

xx )hgihevitca=1(tupniDS_ECROF

yaledtnerruc-revO

00

01

10

11

noitcA

sµ52

sµ05

sµ001

sµ002

2049 Table13 1.0

SUMMIT MICROELECTRONICS, Inc.

Page 15

Timer Configuration Register

7D6D5D4D3D2D1D0D

DOIREPTESERREMITGODGNOLREMITGODHCTAW

00

01

10

11

0xx

100

x

101

110

111

xx

xx

0xx

100

101

110

111

SMT4004

C1RretsigeR

noitcA

sm52

sm05

sm001

sm002

ffO

sm008

x

sm0061

sm0023

sm0046

ffO

sm004

sm008

sm0061

sm0023

2049 Table14 1.0

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

15

Page 16

Status Registers

D1RS

7D6D5D4D3D2D1D0D

VU-1IVVU-2IVVU-3IVVU-4IVVO-1IVVO-2IVVO-3IVVO-4IV

1

x

xx

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx

xxxxxxx VU1edis-suB

1

xxxxxx VU2edis-suB

1

xxxxx VU3edis-suB

1

xxxx VU4edis-suB

1

xxx VO1edis-suB

1

xx VO2edis-suB

1

xVO3edis-suB

1

SMT4004

noitcA

VO4edis-suB

2049 Table15 1.0

E1RS

7D6D5D4D3D2D1D0D

-1OV

1VU

1

x

xx

xxx

xxxx

xxxxx

xxxxxx

-2OV

1VU

-3OV

1VU

-4OV

1VU

-1OV

2VU

-2OV

2VU

-3OV

2VU

xxxxxxx 1VU1edis-draC

1

xxxxxx 1VU2edis-draC

1

xxxxx 1VU3edis-draC

1

xxxx 1VU4edis-draC

1

xxx 2VU1edis-draC

1

xx 2VU2edis-draC

1

xxxxxxx

F1RS

7D6D5D4D3D2D1D0D

1KRT2KRT3KRT4KRT1CO2CO3CO4CO

1

x

xx

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx 1ylppusrorreREKKART

1

xxxxxx 2ylppusrorreREKKART

1

xxxxx 3ylppusrorreREKKART

1

xxxx 4ylppusrorreREKKART

1

xxx 1ylppustnerruc-revO

1

xx 2ylppustnerruc-revO

1

xxxxxxx

-4OV

2VU

x2VU3edis-draC

1

x3ylppustnerruc-revO

1

noitcA

2VU4edis-draC

2049 Table16 1.0

noitcA

4ylppustnerruc-revO

2049 Table17 1.0

16

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Page 17

AC OPERATING CHARACTERISTICS

Over recommended operating conditions

lobmySretemaraPsnoitidnoC.niM.xaMstinU

SMT4004

f

LCS

t

WOL

t

HGIH

t

FUB

t

ATS:US

t

ATS:DH

t

OTS:US

t

AA

t

HD

t

R

t

F

t

TAD:US

t

TAD:DH

emiteerfsuBnoissimsnartwenerofeB7.4sµ

ycneuqerfkcolcLCS 0001zHk

doirepwolkcolC 7.4sµ

doirephgihkcolC 0.4sµ

emitputesnoitidnoctratS 7.4sµ

emitdlohnoitidnoctratS 0.4sµ

emitputesnoitidnocpotS 7.4sµ

tuptuodilavotegdekcolC)nelcyc(ADSdilavotwolLCS3.05.3sµ

emitdlohtuOataDegnahcADSot)1+nelcyc(wolLCS3.0sµ

emitesirADSdnaLCS 0001sn

emitllafADSdnaLCS 003sn

emitputesnIataD 052sn

emitdlohnIataD 0sn

ITADSdnaLCSretlifesioNnoisserppusesioN001sn

t

RW

emitelcycetirW 5sm

2049 Table18 2.0

t

SCL

t

SDA In

SDA Out

R

SU:SDA

t

t

F

t

HD:SDA

t

AA

HIGH

t

HD:DAT

t

LOW

t

DH

Figure 2. Memory Operating Characteristics

t

SU:DAT

t

SU:STO

t

BUF

2049 Fig02 1.0

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

17

Page 18

SMT4004

Master

SDA

Slave

Master

SDA

Slave

Master

SDA

Slave

S

T

A

Device T ype

R

Address

T

S

T

A

R

T

1

S

T

A

R

T

10

Typical Write Operation

Bus

Address

B

A

0110

2

(Standard memory device type)

R

B

B

A

A

1

0

A7A6A5A4A3A2A

/

W

A

C

K

Current Address Read

(Alternate memory device type)

B

A

010

2

R

B

B

A

A

1

0

A7A6A5A4A3A2A1A

/

W

A

C

K

Writing Configuration Registers

R

B

X

A

1

C7C6C5C4C3C2C1C

/

W

A

C

K

01

B

A

2

D7D6D5D4D3D2D1D

A

0

1

A

C

K

A

C

K

D7D6D5D4D3D2D1D

0

D7D6D5D4D3D2D1D

0

A

C

K

S

T

O

P

0

A

C

K

A

C

K

0

S

T

O

P

0

A

C

K

Up to 15

additional bytes

can be written

before issuing

the stop.

S

T

O

P

The host may continue

clocking out data so long as

it provides an ACK response

after each byte.

Master

SDA

Slave

18

S

T

A

Reading the Configuration Register

R

T

B

B

R

10

01

X

A

A

2

1

C7C6C5C4C3C2C1C

/

W

A

C

K

Figure 3. Read and Write Operations

S

T

A

A

C

R

K

T

0

2049 3.1 3/19/01

10

01

S

A

T

C

O

K

P

B

B

R

A

A

X

2

1

D7D6D5D4D3D2D1D

/

W

A

C

K

0

2049 Fig03 2.1

SUMMIT MICROELECTRONICS, Inc.

Page 19

MEMORY AND REGISTER OPERATION

The

TRAKKER

ured as a 256 x 8 array. Configuration Registers reside in

another ‘device type’ address space.

All read and write operations to both ‘device type’ spaces

are handled via an industry standard two-wire interface.

The bus was designed for two-way, two-line serial communication between different integrated circuits. The two

lines are a serial data line (SDA), and a serial clock line

(SCL). The SDA line must be connected to a positive

supply by a pull-up resistor, located somewhere on the

bus.

Note: The MR# input must be pulled low during

programming.

Data Protocol

The protocol defines any device that sends data onto the

bus as a “transmitter” and any device that receives data as

a “receiver.” The device controlling data transmission is

called the “master” and the controlled device is called the

“slave.” The

since it never initiates a data transfer.

One data bit is transferred during each clock pulse. The

data on the SDA line must remain stable during clock high

time, because changes on the data line while SCL is high

will be interpreted as start or stop condition.

START and STOP Conditions

When both the data and clock lines are high, the bus is said

to be not busy. A high-to-low transition on the data line,

while the clock is high, is defined as the “START” condition. A low-to- high transition on the data line while the

clock is high is defined as the “STOP” condition.

Acknowledge (ACK)

Acknowledge is a software convention used to indicate

successful data transfers. The transmitting device, either

the master or the slave, will release the bus after transmitting eight bits. During the ninth clock cycle the receiver will

pull the SDA line low to Acknowledge that it received the

eight bits of data.

has a nonvolatile memory that is config-

TRAKKER

will always be a “slave” device

SMT4004

TRAKKER

The

recognition of a START condition and its slave address

byte. If both the device and a write operation are selected

the

TRAKKER

receipt of each subsequent 8-Bit word. In the READ mode

the

TRAKKER

SDA line, and then monitors the line for an Acknowledge

signal. If an Acknowledge is detected, and no STOP

condition is generated by the master, the

continue to transmit data. If an Acknowledge is not

detected the

missions and await a STOP condition before returning to

the standby power mode.

Device Addressing

Following a start condition the master must output the

address of the slave it is accessing. The most significant four bits of the slave address are the device type

identifier (see the following Table). The next three bits

are the physical device address.

Read/Write Bit

The last bit of the data stream defines the operation to

be performed. When set to “1,” a read operation is

selected; when set to “0,” a write operation.

MEMORY WRITE OPERATIONS

The

TRAKKER

write and page write. A byte-write operation writes a single

byte during the nonvolatile write period (tWR). The page

write operation allows up to 16 bytes in the same page to

be written during tWR.

Byte Write

After the slave address is sent (to identify both the slave

device and a read or write operation), a second byte is

transmitted which contains the 8-Bit address of any one of

the 256 words in the array. Upon receipt of the word

address the

will respond with an Acknowledge after

will respond with an Acknowledge after the

transmits eight bits of data, releases the

TRAKKER

TRAKKER

allows two types of write operations: byte-

TRAKKER

will terminate further data trans-

responds with an Acknowledge.

will

Table 10. Register 84 V

epyTeciveDsserddAsuBW/R

7D6D5D4D3D2D1D0D

10 10

10 11 sserddaepyt-ecivedyromemetanretlA

100 1 sserddaepyt-ecivedsretsigernoitarugifnoC

SUMMIT MICROELECTRONICS, Inc.

2A1A0A0/1

2049 3.1 3/19/01

CC0

/CH4 OV Threshold

noitcA

sserddaepyt-ecivedyromeM

2049 Table19 1.0

19

Page 20

SMT4004

After receiving the next byte of data it again responds with

an Acknowledge. The master then terminates the transfer

by generating a STOP condition, at which time the

KER

begins the internal write cycle. While the internal

write cycle is in progress the

TRAKKER

inputs are dis-

TRAK-

abled, and the device will not respond to any requests from

the master.

Page Write

The

TRAKKER

tion. It is initiated in the same manner as the byte-write

operation, but instead of terminating the write cycle after

the first data word the master can transmit up to 15 more

bytes of data. After the receipt of each byte the

will respond with an Acknowledge.

The

TRAKKER

subsequent data words. After the receipt of each word, the

low order address bits are internally incremented by one.

The high order bits of the address byte remain constant.

Should the master transmit more than 16 bytes, prior to

generating the STOP condition, the address counter will

“roll over” and the previously written data will be overwritten. As with the byte-write operation, all inputs are

disabled during the internal write cycle. Refer to Figure 3

for the address, Acknowledge and data transfer sequence.

is capable of a 16-byte page-write opera-

TRAKKER

automatically increments the address for

Write Cycle

In Progress

Issue Start

Issue Slave

Address and

R/W = 0

ACK

Returned

Yes

Next

Operation

a Write?

Yes

Issue

Address

Issue Stop

No

No

Issue Stop

Acknowledge Polling

When the

operation it will ignore any new START conditions. Since

the device will only return an acknowledge after it accepts

the START, the part can be continuously queried until an

acknowledge is issued, indicating that the internal WRITE

cycle is complete. See the flow diagram for the proper

sequence of operations for polling.

TRAKKER

is performing an internal WRITE

READ OPERATIONS

Read operations are initiated with the R/W bit of the

identification field set to “1.” There are two different read

options:

1. Current Address Byte Read

2. Random Address Byte Read

Current Address Read

The

TRAKKER

which maintains the address of the last word accessed,

incremented by one. If the last address accessed (either

contains an internal address counter

Proceed

With

Write

Await

Next

Command

2049 Flow01 1.0

Flow Chart

a read or write) was to address location n, the next read

operation would access data from address location n+1

and increment the current address pointer. When the

TRAKKER

receives the slave address field with the R/W

bit set to “1” it issues an acknowledge and transmits the 8Bit word stored at address location n+1. The current

address byte read operation only accesses a single byte

of data. The master does not acknowledge the transfer,

but does generate a stop condition. At this point the

TRAKKER

discontinues data transmission.

Random Address Read

Random address read operations allow the master to

access any memory location in a random fashion. This

operation involves a two-step process. First, the master

issues a write command which includes the start condition

20

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Page 21

and the slave address field (with the R/W bit set to WRITE),

followed by the address of the word it is to read. This

procedure sets the internal address counter of the

KER

to the desired address. After the word address

acknowledge is received by the it the master immediately

reissues a start condition followed by another slave address field with the R/W bit set to READ. The

will respond with an acknowledge and then transmit the 8

data bits stored at the addressed location. At this point, the

master does not acknowledge the transmission but does

generate the stop condition. The

data transmission and reverts to its standby power mode.

TRAKKER

TRAK-

TRAKKER

discontinues

Sequential READ

Sequential reads can be initiated as either a current

address READ or random access READ. The first word

is transmitted as with the other byte read modes (current

address byte READ or random address byte READ).

However, the master now responds with an Acknowledge,

indicating that it requires additional data from the

KER

. The

TRAKKER

Acknowledge received. The master terminates the sequential READ operation by not responding with an Acknowledge, and issues a STOP condition. During a

sequential read operation the internal address counter is

automatically incremented with each Acknowledge signal.

For read operations all address bits are incremented,

allowing the entire array to be read using a single read

command. After a count of the last memory address the

address counter will ‘roll-over’ and the memory will continue to output data.

continues to output data for each

TRAK-

SMT4004

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

21

Page 22

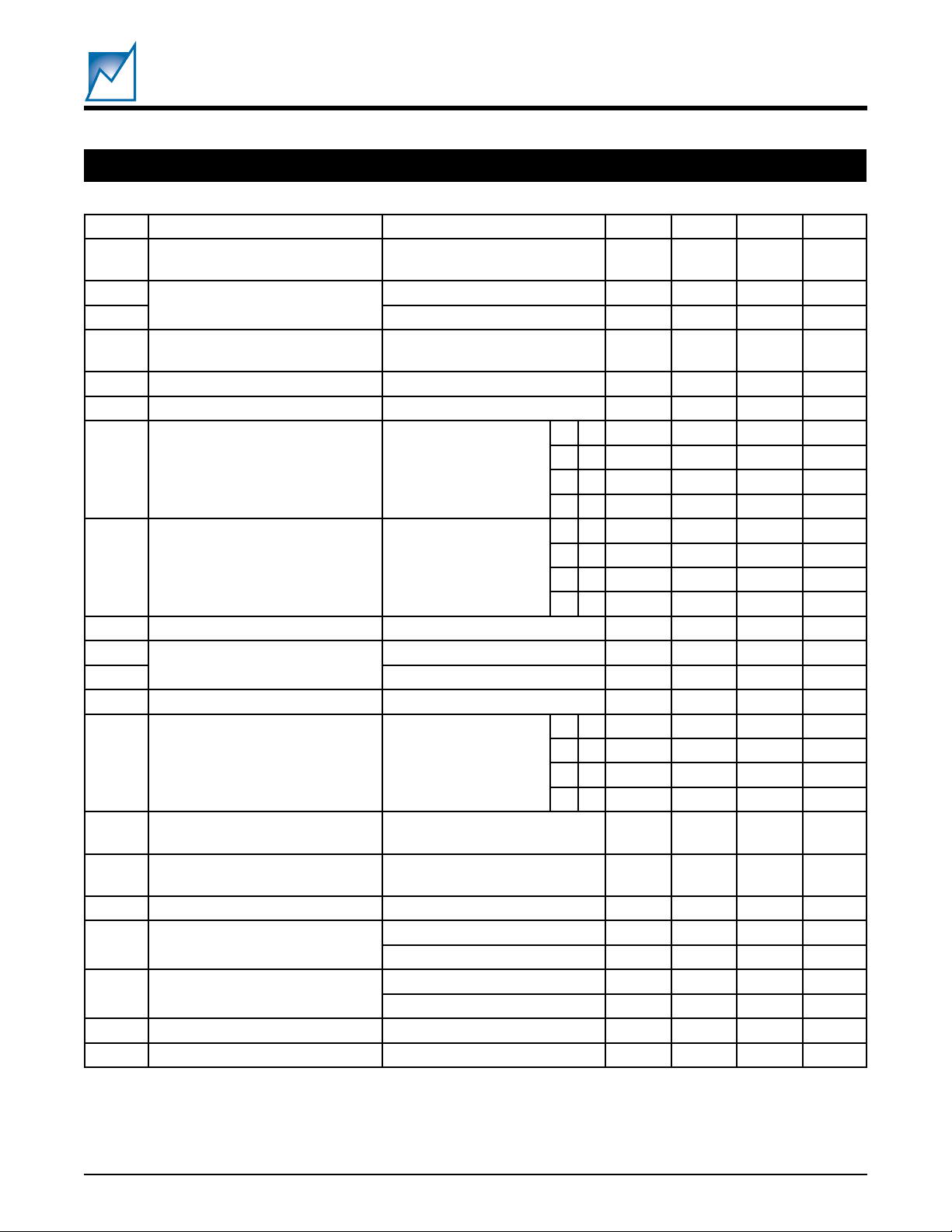

APPLICATION CIRCUIT

A typical circuit soft starting the 5V supply and TRAKKING the 3.3V, 2.5V and 1.8V supplies

1nF

1nF

VO4

VO3

VO2

VO1

VGATE4

VGATE3

VGATE2

VGATE1

1nF

1nF

RST1#

RST2#

RST3#

RST4#

VDD_CAP

CROWBAR

IRQ_CLR#

TRKR_IRQ#

VGG_CAP

HEALTHY#

1.25VREF

CBFAULT

5V

500µF

3.3V

5 × 220µF

2.5V

1.8V

4 × 330µF

2 × 330µF

10Ω

10Ω

10Ω

SMT4004

10Ω

2.5mΩ

2mΩ

5mΩ

2mΩ

CB4

CB3

CB2

CB1

VI4

VI3

VI2

VI1

ENABLE

UV_OVERRIDE

SEATED1#

PWR_ON

FORCE_SD

SEATED2#

SMT4004

GND

10µF

WLDI

WDO#

LDO#

MR#

100nF

IRQ#

A2

A1

A0

SCL

SDA

AGND

DGND

PGND

PGND

22

To

S

R

Pullup

RAW5V

4.7µF

RAW3.3V

4.7µF

2.5V

@4A

1.8V

@10A

Figure 4. Application Circuit

2049 3.1 3/19/01

10kΩ

10kΩ

10kΩ

GND

2049 Fig04 2.1

SUMMIT MICROELECTRONICS, Inc.

Page 23

ORDERING INFORMATION

SMT4004

SMT4004

Base Part Number

retsigeRstnetnoCxeH:saderugifnoC

0R4BV5.4fodlohserhTOV

1R96VO.3fodlohserhT1V

2R14V2.2fodlohserht2V

3R82V7.1fodlohserhT3V

4R06V5.5ottesVOdelbaneVOdnaVU0V

5R06V6.3tatesVOdelbaneVOdnaVU1V

6R26V8.2tatesVOdelbaneVOdnaVU2V

7R76V5.2tatesVOdelbaneVOdnaVU3V

8R9BV6.4fodlohserhTOVediSdraC

9RE6V1.3fodlohserhT1VediSdraC

AR64V3.2fodlohserht2VediSdraC

BRD2V8.1fodlohserhT3VediSdraC

F

Package

F = 48 Pin TQFP

CR2AV5.4fo2dlohserhTOVediSdraC

DR3AVO.3fo2dlohserhT1VediSdraC

ER4AV2.2fo2dlohserht2VediSdraC

FR6AV7.1fo2dlohserhT3VediSdraC

01R500101,sesserddadesaibnipotsdnopseR

11RFFsecruosTESERllaelbanE

21RFFsecruosQRIdnaTESERllaelbanE

31RFFsecruosQRIllaelbanE

41RFFsecruosQRIllaelbanE

51RFEsecruosllaelbane,yaledQRIotROPsm008

91R18ylnopirtkciuQdnatupnilaunamnorabworCelbanE

A1RAAstiucricreganamllapirtkciuQVm001elbanE

BIR20sµ001yaledtnerrucrevo,wolevitcastuptuollA

CIR6Fsm0061godhctaW,sm0023godgnoL,sm002teseR

NIB

ffodnanoetarwelss/V052,

2049 Reg Table 1.0

SUMMIT MICROELECTRONICS, Inc.

2049 3.1 3/19/01

23

Page 24

PACKAGE

48 PIN TQFP PACKAGE

SMT4004

Pin 1

0.354

(9.00)

A

BSC

0.276

(7.00)

[A]

BSC

[B]

B

[B]

Ref. JEDEC MS-026

Inches

(Millimeters)

[A]

0.007 - 0.011

(0.17 - 0.27)

0.037 - 0.041

(0.95 - 1.05)

0.047

MAX

(1.2)

0.004 - 0.008

(0.09 - 0.20)

DETAIL "A"

DETAIL "B"

0.02

(0.5)

BSC

0.039

(1.00)

0.018 - 0.030

(0.45 - 0.75)

48 Pin TQFP

NOTICE

SUMMIT Microelectronics, Inc. reserves the right to make changes to the products contained in this publication in order

to improve design, performance or reliability. SUMMIT Microelectronics, Inc. assumes no responsibility for the use of

any circuits described herein, conveys no license under any patent or other right, and makes no representation that

the circuits are free of patent infringement. Charts and schedules contained herein reflect representative operating

parameters, and may vary depending upon a user’s specific application. While the information in this publication has

been carefully checked, SUMMIT Microelectronics, Inc. shall not be liable for any damages arising as a result of any

error or omission.

SUMMIT Microelectronics, Inc. does not recommend the use of any of its products in life support or aviation applications

where the failure or malfunction of the product can reasonably be expected to cause any failure of either system or to

significantly affect their safety or effectiveness. Products are not authorized for use in such applications unless

SUMMIT Microelectronics, Inc. receives written assurances, to its satisfaction, that: (a) the risk of injury or damage has

been minimized; (b) the user assumes all such risks; and (c) potential liability of SUMMIT Microelectronics, Inc. is

adequately protected under the circumstances.

© Copyright 2001 SUMMIT Microelectronics, Inc.

This document supersedes all previous versions.

I2C is a trademark of Philips Corporation.

24

2049 3.1 3/19/01

SUMMIT MICROELECTRONICS, Inc.

Loading...

Loading...