Page 1

SUMMIT

MICROELECTRONICS, Inc.

SMS44

Highly Programmable V olta ge Supply Controller

and Supervisory Circuit

FEATURES INTRODUCTION

l Operational from any of four Voltage Monitoring

Inputs

l Programmable Closed Loop Power-up Cascad-

ing

l Programmability allows monitoring any voltage

between 0.9V and 6.0V with no external

components

l Programmable Watchdog Timer

l Programmable Longdog™ Timer

l Programmable Reset Pulse Width

l Programmable Nonvolatile Combinatorial Logic

for generation of Reset and Interrupt outputs

l Fault Status Register

l 4k-Bit Nonvolatile Memory

The SMS44 is a highly programmable voltage supply

controller and supervisory circuit designed specifically

for advanced systems that need to monitor multiple

voltages. The SMS44 can monitor four separate voltages

without the need of any external voltage divider circuitry.

The SMS44 can also be used to enable DC/DC converters

or LDOs to provide a closed loop cascading of the

supplies during power -up.

The SMS44 watchdog timer has a user programmable

time-out period and it can be placed in an idle mode for

system initialization or system debug. All of the functions

are user accessible through an industry standard 2-wire

serial interface.

Programming of configuration, control and calibration

values by the user can be simplified with the interface

adapter and Windows GUI software obtainable from Summit Microelectronics.

Preliminary

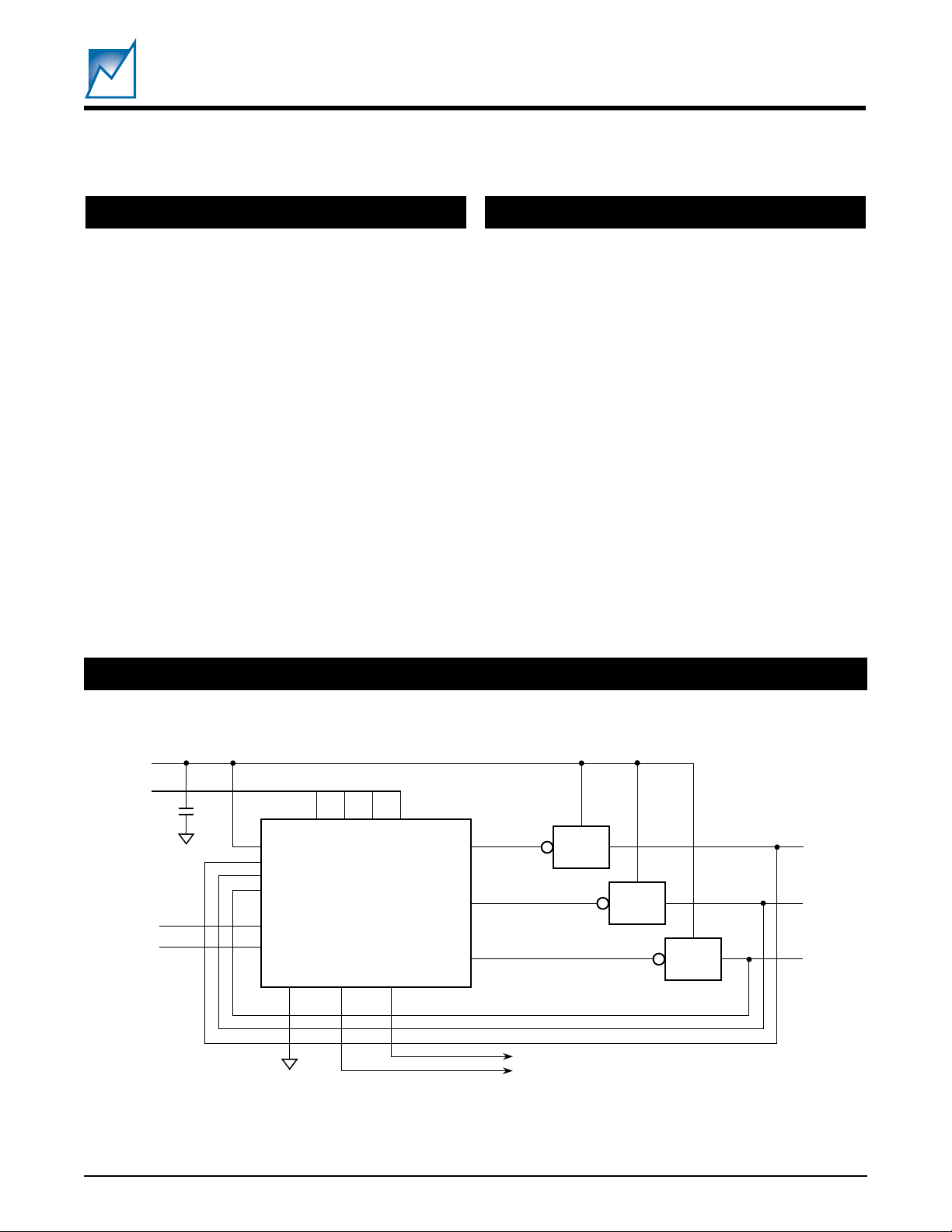

SIMPLIFIED APPLICATION DRAWING

5V

2

I

C

0.01µF

Reset#

16

14

15

7

A2

V

0

2

V

1

3

V

2

V

3

1

MR#

WLDI

GND

RESET#

8

9

6

SDA

A1

SMS44

IRQ#

11

10

SCL

PUP#1

PUP#2

PUP#3

12

4

5

13

LDO

LDO

LDO

3.3V

2.5V

1.8V

2047 SAD 2.0

Closed Loop Power-up Supply Cascading

©SUMMIT MICROELECTRONICS, Inc., 2001 • 300 Orchard City Dr., Suite 131 • Campbell, CA 95008 • Phone 408-378-6461 • FAX 408-378-6586 • www.summitmicro.com

Characteristics subject to change without notice 2047 4.0 6/7/01

1

Page 2

FUNCTIONAL BLOCK DIAGRAM

MR#

1

70kΩ

V

16

0

NV DAC

+

–

REF

V

2

1

NV DAC

+

–

REF

V

3

2

NV DAC

+

–

REF

V

14

3

NV DAC

+

–

REF

RESET

IRQ

RESET

IRQ

RESET

IRQ

RESET

IRQ

CONFIGURATION

REGISTER

CONFIGURATION

REGISTER

PROGRAMMABLE

RESET PULSE

GENERATOR

PROGRAMMABLE

LONGDOG

TIMER

PROGRAMMABLE

WATCHDOG

TIMER

V

CC

70kΩ

PROGRAMMABLE

POWER

CASCADING

SERIAL

BUS

CONTROL

LOGIC

4K-BIT NV

MEMORY

SMS44

Preliminary

V

CC

70kΩ

11

70kΩ

70kΩ

4

5

13

9

10

7

6

70kΩ70kΩ

V

CC

70kΩ

12

15

70kΩ

RESET#

PUP#1

PUP#2

PUP#3

SDA

SCL

A2

A1

IRQ#

WLDI

8

GND

CASCADING

If a specific order in which the supplies are turned on and

brought up to their valid voltage levels is needed, time

based sequencing will not suffice. In this case supply

cascading should be utilized, where the supplies are

enabled a certain period of time after the previous voltage

has reached its minimum valid level. Figure 1 shows that

each succeeding voltage must reach its minimum valid

level before the timer is started to time the interval, t, for

the next voltage. The duration of each t is programmable.

The next supply is not enabled until the timer has elapsed.

See also Figure 5.

2047 BD 4.0

6V

5V

5V Valid

4V

V

2V

0V

t

3.3V Valid

t

3.3V

2.5V

1.8V

2.5V Valid

t

T

2047 Fig01

Figure 1. Cascading Power Supplies

2

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 3

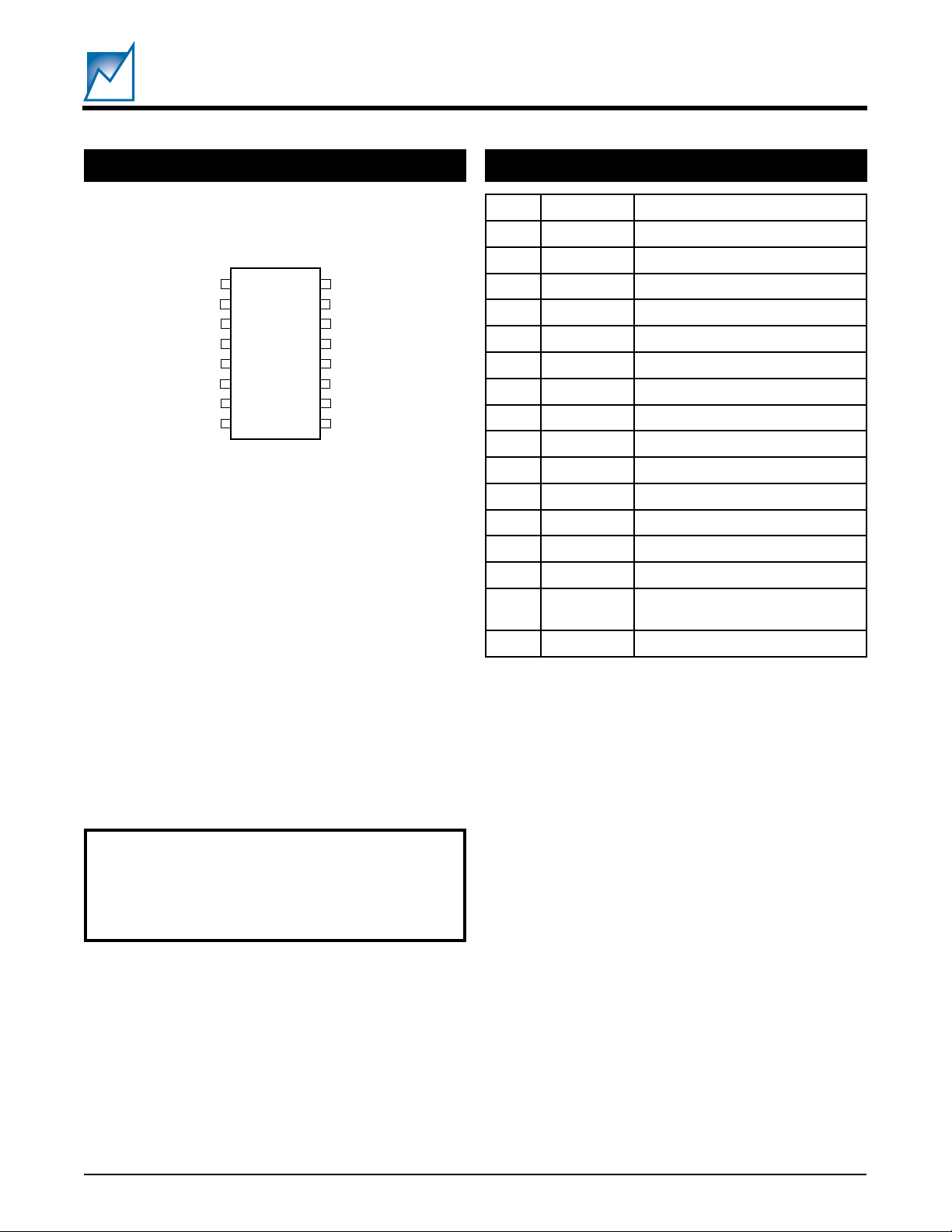

PIN CONFIGURATION PIN NAMES

SMS44

Preliminary

MR#

V

V

PUP#1

PUP#2

A1

A2

GND

16-Pin SOIC or

16-Pin SSOP

1

2

1

3

2

4

5

6

7

8

16

15

14

13

12

11

10

9

2047 PCon 2.0

V

0

WLDI

V

3

PUP#3

IRQ#

RESET#

SCL

SDA

niPemaNnoitcnuF

1#RMtupniteserlaunaM

2V

3V

1

2

41#PUPtuptuodettimreppurewoP

52#PUPtuptuodettimreppurewoP

61AtupnisserddA

72AtupnisserddA

8DNGnruterylppusrewoP

9ADSO/IatadlaireS

01LCSkcolcatadlaireS

11#TESERtuoteseR

21#QRItuotpurretnI

313#PUPtuptuodettimreppurewoP

41V

51IDLW

61V

3

tpurretni

0

tupnirotinomdnaylppusegatloV

tupnirotinomdnaylppusegatloV

tupnirotinomdnaylppusegatloV

remitgodgnol/godhctaW

tupnirotinomdnaylppusegatloV

2047 Pins Table 2.0

RECOMMENDED OPERATING CONDITIONS

Temperature –40ºC to 85ºC.

Voltage 2.7V to 5.5V

SUMMIT MICROELECTRONICS, Inc.

2047 4.0 6/7/01

3

Page 4

ABSOLUTE MAXIMUM RATINGS*

SMS44

Preliminary

Temperature Under Bias ......................–55°C to 125°C

Storage Temperature ...........................–65°C to 150°C

Lead Solder Temperature (10s) .........................300 °C

Terminal Voltage with Respect to GND:

V0, V1, V2, and V3.......... –0.3V to 6.0V

All Others ...................... –0.3V to 6.0V

*COMMENT

Stresses beyond the listed Absolute Maximum Ratings may cause

permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions

outside those listed in the operational sections of this specification is not

implied. Exposure to any absolute maximum rating for extended

periods may affect device performance and reliability.

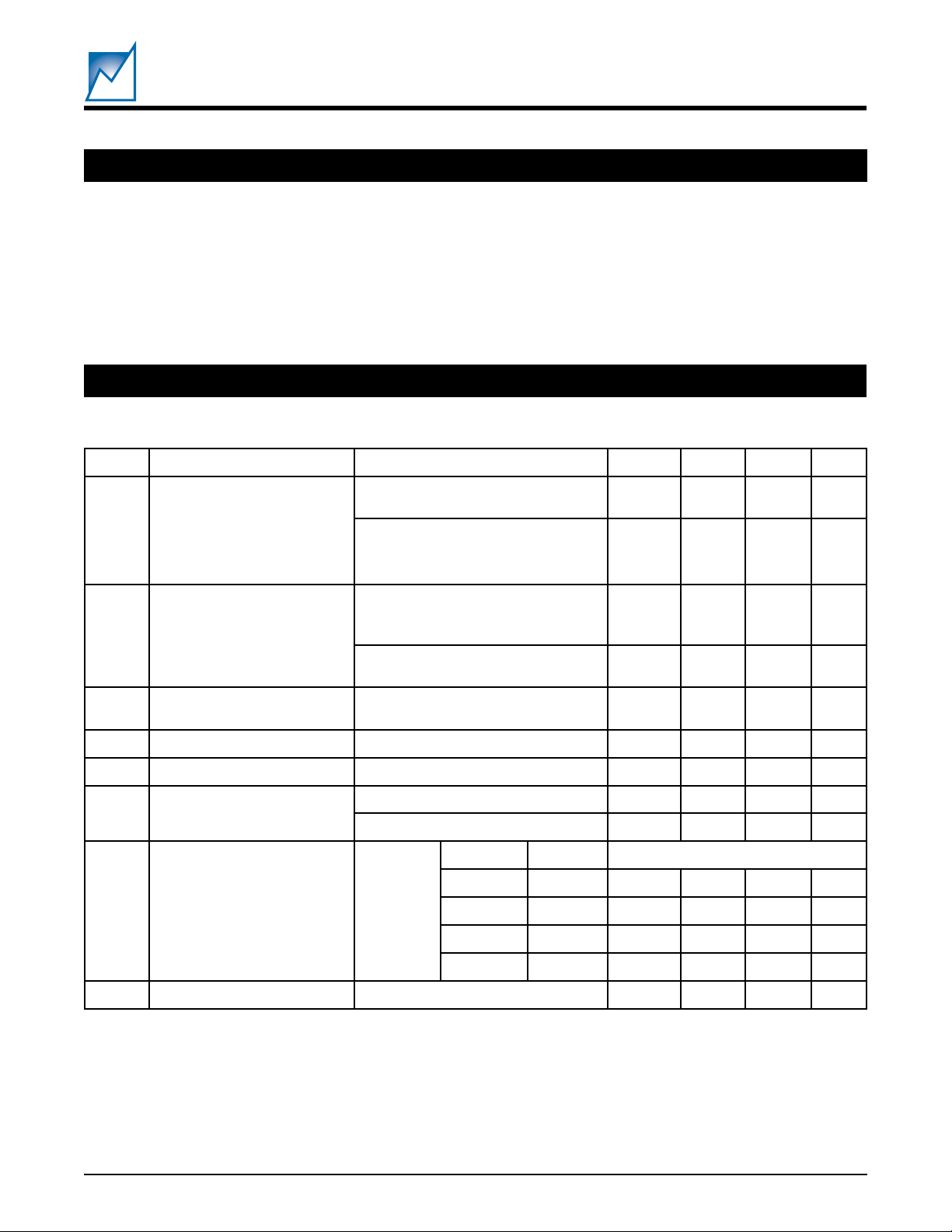

DC OPERATING CHARACTERISTICS

(Over Recommended Operating Conditions; Voltages are relative to GND)

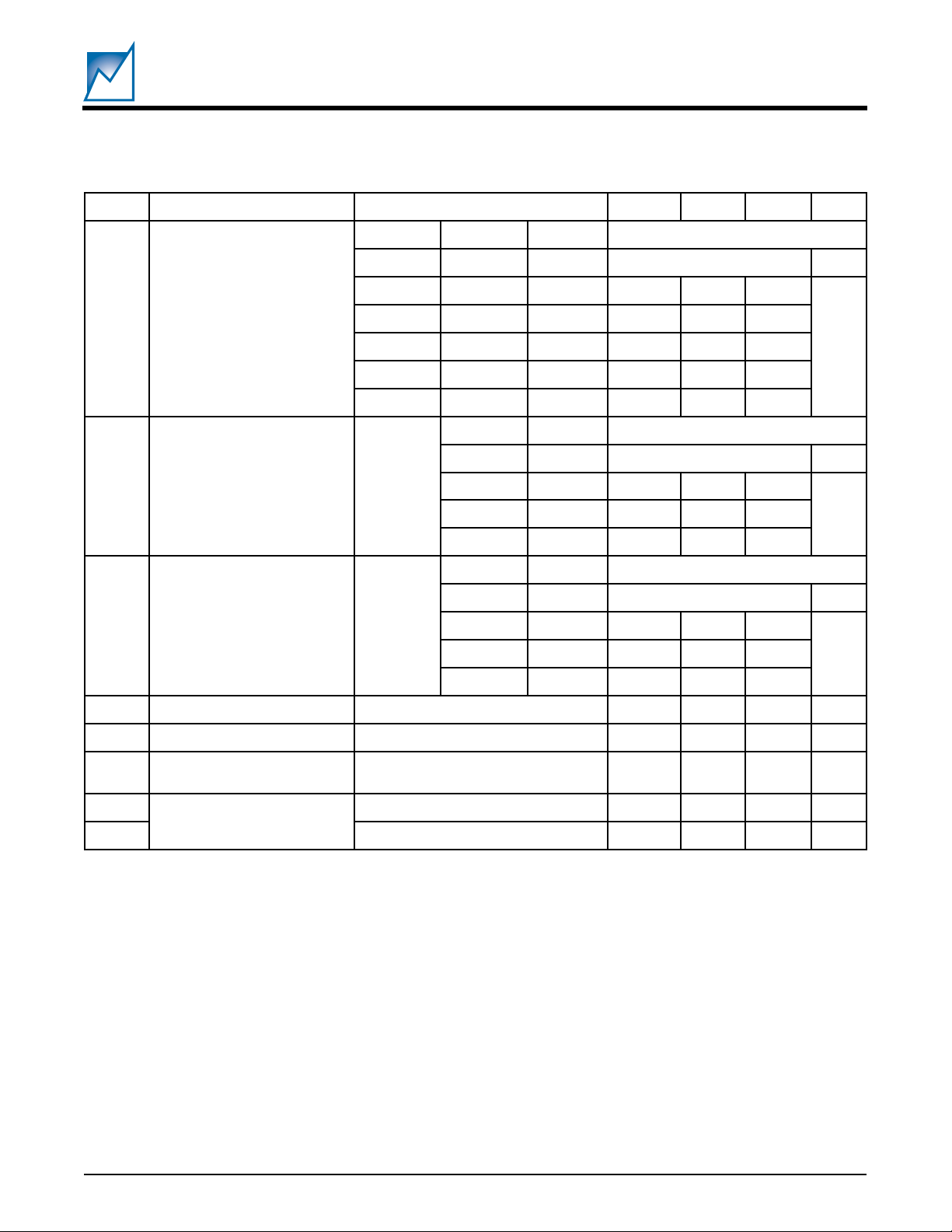

lobmySretemaraPsetoN.niM.pyT.xaMtinU

-tuoteserdilavaotsrefer.nimV1

detareneggniebtup

V

CC

I

CC

V

HTP

egnaR

V

HTP

V

TSYH

V

LO

egnar

V

TSR

tnerrucylppuS

siseretsyh 03Vm

egatlovylppusgnitarepO

ta:snoitarepoetirw/daeryromeM

taebtsumstupniVehtfoenotsael

Vevobaro

≤ V;V5.5

V

CC

V

3

.nim

CC

V;V7.4tnioppirt

0

V=#RM;DNG=

CC

1V,2

stuptuolla;

,

gnitaolf

yromemroretsigernoitarugifnoC

ssecca

dlohserhtelbammargorP

V

3

)stnemercniVm02(

VegnaregatlovdlohserhtteseR

ot

0

dlohserhtelbammargorP5.2– V

V,Am2.1=

I

tuptuoegatlovwoL

KNIS

I

KNIS

≥ V7.23.0V

CC

V,Aµ002=

CC

V2.1=3.0V

1OTR0OTR

0.15.5V

7.25.5V

002004Aµ

3Am

9.00.6V

HTP

5.2%

00025203sm

t

OTRP

htdiw

eslupteserelbammargorP

01530556sm

1056001531sm

11031002072sm

t

TSRD

4

yaled#TESERotniVevirdrevoVm00102sµ

2047 Elect TableA 4.2

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 5

lobmySretemaraPsetoN.niM.pyT.xaMtinU

2DW1DW0DW

000 FFO —

011 004

t

OTDWP

doirepremit

godhctaWelbammargorP

100 008

101 0061

110 0023

111 0046

1DL0DL

00 FFO —

t

OTDLP

doirepremit

godgnoLelbammargorP

01 0061

11 0046

SMS44

Preliminary

sm

sm10 0023

1-X#PUP0-X#PUP

00 FFO —

t

X

YLDP

V

HTP

tuo#PUPot

morfyaledelbammargorP

01 52

sm10 05

11 001

I

RM

T

RM

T

TSRRMD

V

LI

V

HI

wol#TESER

tnerrucpullup#RM 001Aµ

htdiwesluptupni#RM 003sn

otwol#RMmorfyaleD

002sn

dlohserhttupnI

7.0 × V

CC

6.0V

V

2047 Elect TableB 4.2

SUMMIT MICROELECTRONICS, Inc.

2047 4.0 6/7/01

5

Page 6

PIN DESCRIPTIONS

SMS44

Preliminary

V0, V1, V2, V3 (16, 2, 3, 14)

These inputs are used as the voltage monitor inputs and

as the voltage supply for the SMS44. Internally they are

diode ORed and the input with the highest voltage

potential will be the default supply voltage.

The RESET# output will be true if any one of the four inputs

is above 1V. However, for full device operation at least

one of the inputs must be at 2.7V or higher.

The sensing threshold for each input is independently

programmable in 20mV increments from 0.9V to 6.0V.

Also, the occurrence of an under- or over-voltage condition that is detected as a result of the threshold setting can

be used to generate subsequent action(s), such as

RESET# or IRQ#. The programmable nature of the

threshold voltage eliminates the need for external voltage

divider networks.

GND

Power supply return.

MR# (1)

The manual reset input always generates a RESET#

output whenever it is driven low. The duration of the

RESET# output pulse will be initiated when MR# goes low

and it will stay low for the duration of MR# low plus the

programmed reset time-out period (t

). If MR# is

PRTO

brought low during a power-on cascade of the PUP#s the

cascade will be halted for the reset duration, and will then

resume from the point at which it was interrupted. MR#

must be held low during a configuration register Write or

Read. This signal is pulled down internally through a 70kΩ

resistor, consequently the part is normally in reset mode

when powered down.

RESET# (11)

The reset output is an active low open drain output. It will

be driven low whenever the MR# input is low or whenever

an enabled under-voltage or over-voltage condition ex-

MR#

t

DMRRST

RESET#

t

PRTO

t

PRTO

V

RST

2047 Fig03 2.0

V0 — V

RESET#

IRQ#

V

3

PTH

t

PRTO

t

D

Figure 3. RESET# Timing with IRQ#

ists, or when a longdog timer expiration exists. The four

voltage monitor inputs are always functioning, but their

ability to generate a reset is programmable (configura-

tion register 4). Refer to Figures 2 and 3 for a detailed

illustration of the relationship between MR#, IRQ#, RESET# and the VIN levels. This signal is pulled up internally

through a 70kΩ resistor.

IRQ# (12)

The interrupt output is an active low open-drain output. It

will be driven low whenever the watchdog timer times out

or whenever an enabled under-voltage or over-voltage

condition on a V input exists (configuration register 6).

This signal is pulled up internally through a 70kΩ resistor.

WLDI (15)

Watchdog and longdog timer interrupt input. A low to high

transition on the WLDI input will clear both the watchdog

and longdog timers, effectively starting a new time-out

period. This signal is pulled down internally through a

70kΩ resistor.

If WLDI is stuck low and no low-to-high transition is

received within the programmed t

PWDTO

period (programmed watch dog time-out) IRQ# will be driven low. If

a transition is still not received within the programmed

t

period (programmed longdog time-out) RESET#

PLDTO

will be driven low. Refer to Figure 4 for a detailed

illustration.

Holding WLDI high will block interrupts from occurring but

will not block the longdog from timing out and generating

a reset. Refer to Figure 4 for a detailed illustration of the

relationship between IRQ#, RESET#, and WLDI.

2047 Fig02 2.0

Figure 2. RESET# Timing with MR#

6

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 7

SMS44

Preliminary

A1, A2 (6, 7)

A1 and A2 are the address inputs. When addressing the

SMS44 memory or configuration registers the address

inputs distinguish which one of four possible devices

sharing the common bus is being addressed. These

signals are pulled down internally through 70kΩ resistors.

SDA (9)

SDA is the serial data input/output pin. It should be tied

to V

through a pull-up resistor.

CC

SCL (10)

SCL is the serial clock input. It should be tied to V

CC

through a pull-up resistor.

t

PWDTO

t

t

0

IRQ#

RESET#

t

PLDTO

WLDI

t

0

t

PRTO

t

0

t

0

0

t

PRTO

t

PLDTO

2047 Fig04 3.0

PUP#1, PUP#2, PUP#3 (4, 5, 13)

These are the power-up permitted outputs when the

SMS44 is programmed to provide the cascading of LDOs

or DC/DC converters (

tions of cascading

see Figures 1 and 5 for illustra-

). Each delay is independently

enabled and programmable for its duration (configura-

tion register 7). If all PUP# outputs are enabled the order

of events would be as follows: V0 above threshold then

delay to PUP#1 turning on; V

above threshold then delay

1

to PUP#2 turning on; V2 above threshold then delay to

PUP#3 turning on. The delays are programmable. These

signals are pulled up internally through 70kΩ resistors.

Figure 4. Watchdog, Longdog and WLDI Timing

SUMMIT MICROELECTRONICS, Inc.

2047 4.0 6/7/01

7

Page 8

DEVICE OPERATION

SMS44

Preliminary

SUPPLY AND MONITOR FUNCTIONS

The V0, V1, V2, and V3 inputs are internally diode-ORed so

that any one of the four can act as the device supply. The

RESET# output will be guaranteed true so long as one of

the four pins is at or above 1V.

Note

: for performing a memory operation (Read

or Write) and to have the ability to change

configuration register contents at least one supply input must be above 2.7V.

Read/Write operations require a 0.01µF capacitor from

the highest Vx input (normally V0) to GND. For optimum

performance connect capacitors from each of the Vx

If cascading is enabled, the designer must insure V

primary supply and is the first to become active.

Associated with each input is a comparator with a programmable threshold for detection of under-voltage conditions on any of the four supply inputs. The threshold can

be programmed in 20mV increments anywhere within the

range of 0.9V to 6.0V. Configuration registers 0, 1, 2, and

3 adjust the thresholds for V0, V1, V2, and V3 respectively.

If the value contained in any register is all zeroes, the

corresponding threshold will be 0.9V. If the contents were

05

the threshold would then be 1.0V [0.9V + (5 ×

HEX

0.02V)]. All four registers are configured as 8-Bit registers.

inputs to GND. Locate the capacitors as physically close

to the SMS44 as possible.

7D

BSM

6D5D4D3D2D1D

0D

BSL

11111111 V0.6=tnemtsujdadlohserhttsehgiH

00000000 V0.6=tnemtsujdadlohserhttsewoL

00000110 6(+V9.0=dlohserhT × V20.1=)V20.0

Table 1. Configuration Registers 0, 1, 2, and 3

is the

0

noitcA

).g.e(

2047 Table01

RESET AND IRQ FUNCTIONS

Both the reset and interrupt outputs have four programmable sources for activation. Configuration register 4 is

used for selecting the activation source, which can be any

combination of V0, V1, V2 and V3. A monitor input can only

be programmed to activate on either an under-voltage or

over-voltage condition, but not both conditions.

The RESET# output will become active when triggered by

a selected activation source such as an under-voltage

condition on V1. When this condition ceases, the RESET# output will remain active for t

reset time-out). This reset time-out interval takes priority

over the PUP outputs for use of the timer.

7D

V

3

6D5D4D3D2D1D

BSM

V

V

2

V

1

V

0

3

ecruoSreggirTTESERecruoSreggirTQRI

Table 2. Configuration Register 4

(programmable

PRTO

V

2

V

1

2047 Table02

0D

BSL

V

0

The RESET# output has two hardwired sources for

activation: the MR# input, and the expiration of the

Longdog timer. RESET# will remain active so long as

MR# is low, and will continue driving the RESET# output

for t

(programmable reset time out) after MR# returns

PRTO

high. The MR# input cannot be bypassed or disabled. The

Longdog timer can be bypassed by programming it to the

off or idle mode.

The sole hardwired source for driving the IRQ# output low

is the watchdog. The IRQ# circuitry is disabled during

initial power up until the reset condition has terminated

and the reset interval (t

) has timed out. The IRQ#

PRTO

output is cleared by a low-to-high transition of the WLDI

signal. It can effectively be bypassed by programming it

to the off or idle mode. Refer to Figures 2, 3 and 4 for a

detailed illustration of the relationships among the affected signals.

The SMS44 also provides the option of the monitors

triggering on either an under-voltage or over-voltage

condition. The low-order four bits of configuration register

5 program these options.

8

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 9

SMS44

Preliminary

3D

noitcA

V

3

2D1D

BSM

V

V

2

0D

BSL

V

1

0

selbane0agnitirW

rofnoitcetedegatlovrednu

0000

tupniVdetceleseht

selbane1agnitirW

rofnoitcetedegatlovrevo

1111

tupniVdetceleseht

2047 Table03

Table 3. Configuration Register 5 (D0 through D3)

The high order four bits of configuration register 5 are

Read only, and their state indicates the sources of

interrupts. Whenever an interrupt is generated the status

of the V inputs will be recorded in the status register. The

status will remain in the register until the device is

powered-down or another interrupt occurs that overwrites

the previous status.

If an interrupt occurs and no bits are set the default

assumption must be the watchdog generated the interrupt.

7D

V

3

6D5D

BSM

V

V

2

0000

1111

4D

BSL

V

1

0

noitcA

ehtsetacidni1agnidaeR

tpurretniehtfoecruos

2047 Table04

Table 4. Configuration Register 5 (D4 through D7)

WATCHDOG AND LONGDOG TIMERS

The SMS44 contains two timers that can be programmed

independently. The Watchdog is intended to be of shorter

duration and will generate an interrupt if it times out. The

Longdog timer will generally be programmed to be of

longer duration than the watchdog and it will generate a

reset if it times out. Both timers are cleared by a low to high

transition on WLDI and they both start simultaneously.

If the watchdog should time-out the device status will be

recorded in the status register. If the Longdog times out

RESET# will be driven low either until a WLDI clear is

received or until t

time it will return high. Refer to Figure 4 which illustrates

the action of RESET# and IRQ# with respect to the

Watchdog and Longdog timers and the WLDI input.

(whichever occurs first), at which

PRTO

7D

BSM

6D5D4D3D

SAC1OTR0OTR1DL0DLnoitcA

xxx

xxx

xxx

xxx

x

x

x

x

0

1

00

01

10

11

xxxx nOedacsaC

xxxx ffOedacsaC

00

01

10

11

xxt

xxt

xxt

xxt

OTRP

OTRP

OTRP

OTRP

2047 Table05

ffOgodgnoL

sm0061

sm0023

sm0046

sm52=

sm05=

sm001=

sm002=

Table 5. Configuration Register 6 (D3 through D7)

2D1D

0D

BSL

noitcA2DW1DW0DW

FFO 000

sm004011

sm008100

sm0061101

sm0023110

sm0046 111

2047 Table06 1.0

Table 6. Configuration Register 6 (D0, D1, D2)

If WLDI is held low the timers will free-run generating a

series of interrupts and resets. If WLDI is held high the

interrupt (watchdog) output will be disabled and only the

reset (Longdog) output will be active.

When the Longdog times out RESET# will be generated.

When RESET# returns high (after t

or after a WLDI

PRTO

strobe) both timers are reset to time zero. Therefore, if

the Longdog t

watchdog t

PWDTO

is equal to or shorter than the

PLDTO

, RESET# will effectively clear the

interrupt before it can drive the output low.

Register 6 is also used to set the programmable reset

time-out period (t

) and to select the cascade option.

PRTO

SUMMIT MICROELECTRONICS, Inc.

2047 4.0 6/7/01

9

Page 10

SMS44

Preliminary

Cascade Delay Programming

The cascade delays are programmed in register 7. Bit 7

of register 6 must be set to a 0 in order to enable the

cascading of the PUP# outputs. Cascading will not

commence until V0 is above its programmed threshold.

Each PUP# (-3, -2 and -1) is delayed according to the

states of its Bit 1 and Bit 0 as indicated in Table 9. Refer

to Figures 1 and 5 for the detailed timing relationship of

the programmable power-on cascading.

The delay from V

a similar t

PDLYX

until PUP#1 low is t

PTH0

PDLY1

. There is

delay for V1 to PUP#2 and V2 to PUP#3.

They are programmed in register 7. Cascading will

always occur as indicated in the flow chart (Figure 7).

7D

6D

BSM

sserddA

tceleS

noitcA

kcoL0SA

x

x

0

1

0

1

xdelbaneetirW/daeR.geR.gifnoC

xtuodekcoletirW/daeR.geR.gifnoC

nehwylnosdnopser,0101=ITD

setatscigol1A&2A=stibsserdda

nehwylnosdnopser,1101=ITD

setatscigol1A&2A=stibsserdda

2047 Table07 3.0

Table 7. Configuration Register 7 (D7, D6)

5D4D3D2D1D

0D

BSL

3#PUP2#PUP1#PUP

1tiB0tiB1tiB0tiB1tiB0tiB

2047 Table08 3.0

Table 8. Configuration Register 7 (D5 through D0)

1tiB0tiBt

XYLDP

00 yaleD)on(sm0

01 yaleDsm52

10 yaleDsm05

11 yaleDsm001

2047 Table09 1.0

Table 9. PUP Delays, Configuration Register 7

10

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 11

V

0

RESET#

PUP1#

V

1

PUP2#

V

2

PUP3#

V

PTH0

t

PDLY1

V

PTH1

t

PDLY2

V

PTH2

t

PDLY3

t

PRTO

SMS44

Preliminary

V

3

Figure 5. VX Input and Resulting PUP# Cascade (RESET# set to trip on V3 Undervoltage)

V

V0

PUP1#

V1

PUP2#

V2

PTH0

50ms

V

50ms

2047 Fig05

PTH2

SUMMIT MICROELECTRONICS, Inc.

PUP3#

Figure 6. Timing with Register 7 Contents 22

2047 4.0 6/7/01

2047 Fig06

HEX

11

Page 12

HOOKUP

SMS44

Preliminary

Cascading

Enabled

V

0

>V

?

PTH

Yes

t

PDLY1

Turn On PUP#1

V1

?

>V

PTH

Yes

t

PDLY2

Turn On PUP#2

V2

?

>V

PTH

Yes

t

PDLY3

No

No

No

HARDWARE

The end user can use the summit SMX3200 programming

cable and software that have been developed to operate

with a standard personal computer. The programming

cable interfaces directly between a PC’s parallel port and

the target application. The application’s values are

entered via an intuitive graphical user interface employing

drop-down menus. See also Figure 13.

After the desired settings for the application are determined the software will generate a hex file that can be

transferred to the target device or downloaded to Summit.

If it is downloaded to Summit a customer part number will

be assigned and the file will be used to customize the

devices during the final electrical test operations.

Top view of straight 0.1" × 0.1" closed

side connector SMX3200 interface

Positive Supply

Negative Supply

Pin 10, Reserved

Pin 8, Reserved

Pin 6, MR#

Pin 4, SDA

Pin 2, SCL

V

SMS44

GND

0

A1

A2

MR#

SDA

SCL

10

9

8

7

6

5

4

3

2

1

Figure 8. Programming Hookup

Pin 9, 5V

Pin 7, 10V

Pin 5, Reserved

Pin 3, GND

Pin 1, GND

C1

0.01µF

2047 Fig08

12

Turn On PUP#3

2047 Fig07

Figure 7. Cascade Flow Chart

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 13

INTERFACE

SMS44

Preliminary

MEMORY OPERATION

Data for the configuration registers and the memory array

are read and written via an industry standard two-wire

interface. The bus was designed for two-way, two-line

serial communication between different integrated circuits. The two lines are a serial data line (SDA) and a

serial clock line (SCL). The SDA line must be connected

to a positive supply by a pull-up resistor, located somewhere on the bus. See Memory Operating Characteristics: Table 10 and Figure 9.

Input Data Protocol

The protocol defines any device that sends data onto the

bus as a transmitter and any device that receives data as

a receiver. The device controlling data transmission is

called the Master and the controlled device is called the

Slave. In all cases the SMS44 will be a Slave device,

since it never initiates any data transfers.

One data bit is transferred during each clock pulse. The

data on the SDA line must remain stable during clock high

time because changes on the data line while SCL is high

will be interpreted as start or stop condition.

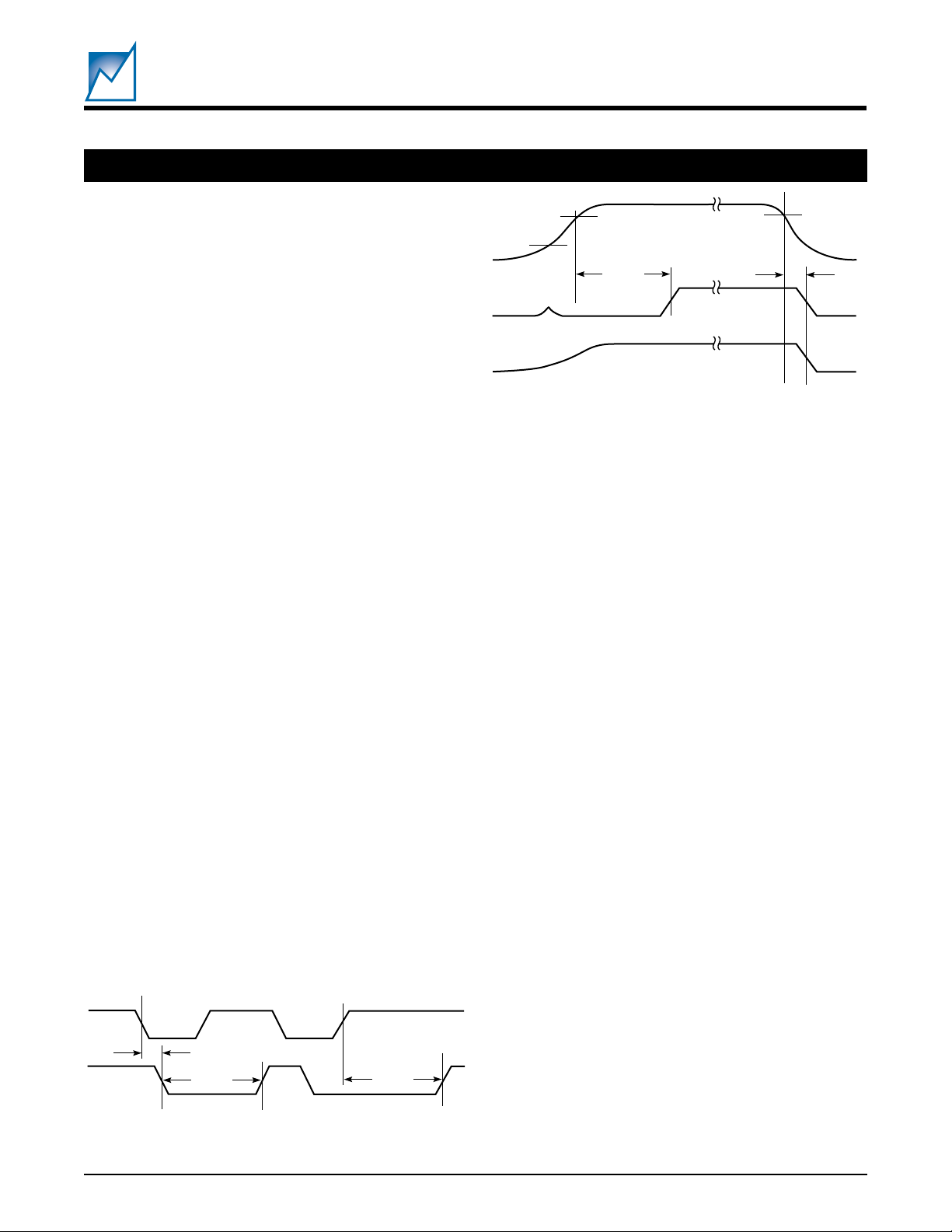

lobmySretemaraPsnoitidnoC.niM.xaMstinU

f

LCS

t

WOL

t

HGIH

t

FUB

t

ATS:US

t

ATS:DH

t

OTS:US

t

AA

t

HD

t

R

t

F

t

TAD:US

t

TAD:DH

ycneuqerfkcolcLCS 0001zHk

doirepwolkcolC 7.4sµ

doirephgihkcolC 0.4sµ

)1(emiteerfsuBnoissimsnartwenerofeB7.4sµ

emitputesnoitidnoctratS 7.4sµ

emitdlohnoitidnoctratS 0.4sµ

emitputesnoitidnocpotS 7.4sµ

)1(tuptuodilavotegdekcolC)nelcyc(ADSdilavotwolLCS3.05.3sµ

)1(emitdlohtuOataDegnahcADSot)1+nelcyc(wolLCS3.0sµ

)1(emitesirADSdnaLCS 0001sn

)1(emitllafADSdnaLCS 003sn

)1(emitputesnIataD 052sn

)1(emitdlohnIataD 0sn

IT)1(ADSdnaLCSretlifesioNnoisserppusesioN001sn

t

RW

Note (1): These values are guaranteed by design.

emitelcycetirW 5sm

Table 10. Memory Operating Characteristics

t

R

SCL

t

SU:STA

SDA In

t

SDA Out

Figure 9. Memory Operating Characteristics

SUMMIT MICROELECTRONICS, Inc.

2047 Table10 4.0

t

HIGH

t

F

t

HD:STA

AA

t

HD:DAT

t

LOW

t

DH

2047 4.0 6/7/01

t

SU:DAT

t

SU:STO

t

BUF

2047 Fig09

13

Page 14

SMS44

Preliminary

START and STOP Conditions

When both the data and clock lines are high the bus is said

to be not busy. A high-to-low transition on the data line,

while the clock is high, is defined as the Start condition.

A low-to-high transition on the data line, while the clock

is high, is defined as the Stop condition. See Figure 10.

START

Condition

SCL

SDA In

STOP

Condition

2047 Fig10

Figure 10. START and STOP Conditions

Acknowledge (ACK)

Acknowledge is a software convention used to indicate

successful data transfers. The transmitting device,

either the Master or the Slave, will release the bus after

transmitting eight bits. During the ninth clock cycle the

receiver will pull the SDA line low to Acknowledge that it

received the eight bits of data. The Master will leave the

SDA line high (NACK) when it terminates a read function.

The SMS44 will respond with an Acknowledge after

recognition of a Start condition and its slave address byte.

If both the device and a write operation are selected the

SMS44 will respond with an Acknowledge after the receipt

of each subsequent 8-Bit word. In the READ mode the

SMS44 transmits eight bits of data, then releases the SDA

line, and monitors the line for an Acknowledge signal. If

an Acknowledge is detected and no Stop condition is

generated by the Master, the SMS44 will continue to

transmit data. If a NACK is detected the SMS44 will

terminate further data transmissions and await a Stop

condition before returning to the standby power mode.

Device Addressing

Following a Start condition the Master must output the

address of the Slave it is accessing. The most significant

four bits of the Slave address are the device type

identifier/address. For the SMS44 the default is 1010

BIN

The next two bits are the Bus Address. The next bit (the

7th) is the MSB of the memory address.

7D

6D5D4D3D2D1D

BSM

stiBsserddA

epyTeciveDsuBBSMW/R

44SMSxxxx

1001

10 10

10 11

! retsigeRnoitarugifnoC

! )tluafed(yromeM

! yromeMetanretlA

2047 Table11 1.0

Table 11. Slave Addresses

Read/Write Bit

The last bit of the data stream defines the operation to be

performed. When set to 1 a Read operation is selected;

when set to 0 a Write operation is selected.

WRITE OPERATIONS

The SMS44 allows two types of Write operations: byte

Write and page Write. A byte Write operation writes a

single byte during the nonvolatile write period (tWR). The

page Write operation, limited to the memory array, allows

up to 16 bytes in the same page to be written during tWR.

Byte Write

After the Slave address is sent (to identify the Slave

device and select either a Read or Write operation), a

second byte is transmitted which contains the low order

8 bit address of any one of the 512 words in the array.

Upon receipt of the word address the SMS44 responds

with an Acknowledge. After receiving the next byte of data

it again responds with an Acknowledge. The Master then

terminates the transfer by generating a Stop condition, at

which time the SMS44 begins the internal Write cycle.

While the internal Write cycle is in progress the SMS44

inputs are disabled and the device will not respond to any

requests from the Master.

Page Write (memory only)

The SMS44 is capable of a 16-byte page Write operation.

It is initiated in the same manner as the byte Write

operation, but instead of terminating the Write cycle after

the first data word the Master can transmit up to 15 more

bytes of data. After the receipt of each byte the SMS44

will respond with an Acknowledge.

.

The SMS44 automatically increments the address for

subsequent data words. After the receipt of each word the

low order address bits are internally incremented by one.

0D

BSL

14

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 15

SMS44

Preliminary

The high order bits of the address byte remain constant.

Should the Master transmit more than 16 bytes, prior to

generating the Stop condition, the address counter will

rollover and the previously written data will be overwrit-

Master

SDA

Slave

Master

SDA

Slave

S

T

A

Device T ype

R

Address

T

S

T

Typical Reading Operation

A

(Alternate memory device type)

R

T

10

11

Bus

Address

B

A

0110

2

B

A

2

B

A

A

8

1

B

A

A

8

1

Typical Write Operation

(Standard memory device type)

R

A7A6A5A4A3A2A1A

/

W

A

C

K

R

A7A6A5A4A3A2A1A

/

W

A

C

K

0

ten. As with the byte Write operation, all inputs are

disabled during the internal Write cycle. Refer to Figure

11 for the address, Acknowledge, and data transfer

sequence.

S

T

O

P

D7D6D5D4D3D2D1D

0

A

C

K

S

T

A

A

C

R

K

T

10

11

0

A

C

K

B

B

R

A

A

A

8

2

1

D7D6D5D4D3D2D1D

/

W

A

C

K

Up to 15

additional bytes

can be written

before issuing

the stop.

N

A

C

K

0

S

T

O

P

S

T

Master

SDA

A

R

T

10

01

Slave

S

T

A

Master

SDA

Reading the Configuration Register

R

T

01

10

Slave

SUMMIT MICROELECTRONICS, Inc.

Writing Configuration Registers

B

A

2

B

A

2

R

B

X

A

1

B

X

A

1

C7C6C5C4C3C2C1C

/

W

A

C

K

R

C7C6C5C4C3C2C1C

/

W

A

C

K

Figure 11. Read and Write Operations

2047 4.0 6/7/01

D7D6D5D4D3D2D1D

0

A

C

K

S

T

A

A

C

R

K

T

0

10

01

S

T

O

P

0

A

C

K

N

S

A

T

C

O

K

P

B

B

R

A

A

X

2

1

D7D6D5D4D3D2D1D

/

W

A

C

K

0

2047 Fig11

15

Page 16

SMS44

Preliminary

Acknowledge Polling

When the SMS44 is performing an internal Write operation it will ignore any new Start conditions. Since the

device will only return an acknowledge after it accepts the

Start the part can be continuously queried until an

acknowledge is issued, indicating that the internal Write

cycle is complete. See the flow chart for the proper

sequence of operations for polling.

Write Cycle

In Progress

Issue Start

Issue Stop

Issue Slave

Address and

R/W = 0

No

No

Issue Stop

Await

Next

Command

2047 Fig12

ACK

Returned

Yes

Next

Operation

a Write?

Yes

Issue

Address

Proceed

With

Write

Figure 12. Write Flow Chart

READ OPERATIONS

Read operations are initiated with the R/W bit of the

identification field set to 1. There are two different Read

options: 1. Current Address Byte Read, and 2. Random

Address Byte Read.

Current Address Read (memory only)

The SMS44 contains an internal address counter which

maintains the address of the last word accessed, incremented by one. If the last address accessed (either a

Read or Write) was to address location n, the next Read

operation would access data from address location n+1

and increment the current address pointer. When the

SMS44 receives the Slave address field with the R/W bit

set to 1 it issues an acknowledge and transmits the 8-Bit

word stored at address location n+1. The current address

byte Read operation only accesses a single byte of data.

The Master sets the SDA line to NACK and generates a

stop condition. At this point the SMS44 discontinues data

transmission.

Random Address Read (Register and Memory)

Random address Read operations allow the Master to

access any memory location in a random fashion. This

operation involves a two-step process. First, the Master

issues a write command which includes the start condition and the Slave address field (with the R/W bit set to

Write), followed by the address of the word it is to Read.

This procedure sets the internal address counter of the

SMS44 to the desired address. After the word address

acknowledge is received by the Master it immediately

reissues a Start condition, followed by another Slave

address field with the R/W bit set to READ. The SMS44

will respond with an Acknowledge and then transmit the

8 data bits stored at the addressed location. At this point

the Master sets the SDA line to NACK and generates a

Stop condition. The SMS44 discontinues data transmission and reverts to its standby power mode.

Sequential READ (Memory Only)

Sequential Reads can be initiated as either a current

address Read or random access Read. The first word is

transmitted as with the other byte Read modes (current

address byte Read or random address byte Read);

however, the Master now responds with an Acknowledge,

indicating that it requires additional data from the SMS44.

The SMS44 continues to output data for each Acknowledge received. The Master terminates the sequential

Read operation by responding with a NACK, and issues

a Stop condition. During a sequential Read operation the

internal address counter is automatically incremented

with each Acknowledge signal. For Read operations all

address bits are incremented, allowing the entire array to

be read using a single Read command. After a count of

the last memory address the address counter will rollover

and the memory will continue to output data.

16

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 17

V0

V1

V2

V3

C2

C3

NOTES:

1. C1, C2, C3 and C4 are all 0.01µF.

APPLICATIONS

R1

10kΩ

C4

2

1

4

3

6

5

J1

8

7

10

9

Figure 13. Application Schematic

C1

16

14

10

1

2

3

9

6

7

MR#

V0

V1

V2

V3

SMS44

SCL

SDA

A1

A2

RESET#

GND

PUP#1

PUP#2

PUP#3

IRQ#

WLDI

8

SMS44

Preliminary

4

5

13

11

12

15

2047 Fig13

2. C1 is required for Read/Write operations.

3. C2, C3, and C4 are recommended for noisy environments and whenever input voltages are near the OV

and/or UV reset level trip points.

4. Connector J1 is an SMX3200 (see Figure 8).

5. The signal MR# has an internal pull-down resistor.

Resistor R1 is required to provide pull-up.

SUMMIT MICROELECTRONICS, Inc.

2047 4.0 6/7/01

17

Page 18

ORDERING INFORMATION

SMS44

Preliminary

Base Part Number

PACKAGES

16 PIN SOIC PACKAGE

SMS44

G

Package

G = SSOP

S = SOIC

2047 Tree 1.0

0.386 - 0.394

(9.80 - 10.00)

0.0075 - 0.01

(0.19 - 0.25)

Ref. JEDEC MS-012

Inches

(Millimeters)

0.150 - 0.157

(3.80 - 4.00)

0.01 - 0.02

(0.25 - 0.50)

0.016 - 0.050

0.016 - 0.050

×45º

(0.40 - 1.27)

0 to 8

typ

0.053 - 0.069

(1.35 - 1.75)

0.05

(1.27)

0.228 - 0.244

(5.80 - 6.20)

1

0.004 - 0.01

0.013 - 0.020

(0.33 - 0.51)

(0.10 - 0.25)

16 Pin SOIC

18

2047 4.0 6/7/01

SUMMIT MICROELECTRONICS, Inc.

Page 19

Ref. JEDEC MO-137

SMS44

Preliminary

16 PIN SSOP PACKAGE

0.189 - 0.197

(4.80 - 5.00)

0.228 - 0.244

(5.79 - 6.20)

Inches

(Millimeters)

0.150 - 0.157

(3.81 - 3.99)

0.053 - 0.069

(1.35 - 1.75)

0.007 - 0.010

(0.18 - 0.25)

0º to 8º

0.016 - 0.050

(0.41 - 1.27)

Pin 1

0.025

(0.635)

0.008 - 0.012

(0.20 - 0.31)

0.059

MAX

(1.50)

0.004 - 0.010

(0.10 - 0.25)

16 Pin SSOP

NOTICE

SUMMIT Microelectronics, Inc. reserves the right to make changes to the products contained in this publication in

order to improve design, performance or reliability. SUMMIT Microelectronics, Inc. assumes no responsibility for

the use of any circuits described herein, conveys no license under any patent or other right, and makes no

representation that the circuits are free of patent infringement. Charts and schedules contained herein reflect

representative operating parameters, and may vary depending upon a user’s specific application. While the

information in this publication has been carefully checked, SUMMIT Microelectronics, Inc. shall not be liable for any

damages arising as a result of any error or omission.

SUMMIT Microelectronics, Inc. does not recommend the use of any of its products in life support or aviation applications

where the failure or malfunction of the product can reasonably be expected to cause any failure of either system or to

significantly affect their safety or effectiveness. Products are not authorized for use in such applications unless

SUMMIT Microelectronics, Inc. receives written assurances, to its satisfaction, that: (a) the risk of injury or damage has

been minimized; (b) the user assumes all such risks; and (c) potential liability of SUMMIT Microelectronics, Inc. is

adequately protected under the circumstances.

© Copyright 2001 SUMMIT Microelectronics, Inc.

This document supersedes all previous versions.

I2C is a trademark of Philips Corporation.

SUMMIT MICROELECTRONICS, Inc.

2047 4.0 6/7/01

19

Loading...

Loading...