Page 1

CMOS Quad

a

FEATURES

Four Independent Sample-and-Holds

Internal Hold Capacitors

High Accuracy: 12 Bit

Very Low Droop Rate: 2 mV/s typ

Output Buffers Stable for C

TTL/CMOS Compatible Logic Inputs

Single or Dual Supply Applications

Monolithic Low Power CMOS Design

APPLICATIONS

Signal Processing Systems

Multichannel Data Acquisition Systems

Automatic Test Equipment

Medical and Analytical Instrumentation

Event Analysis

DAC Deglitching

≤ 500 pF

L

Sample-and-Hold Amplifier

SMP04*

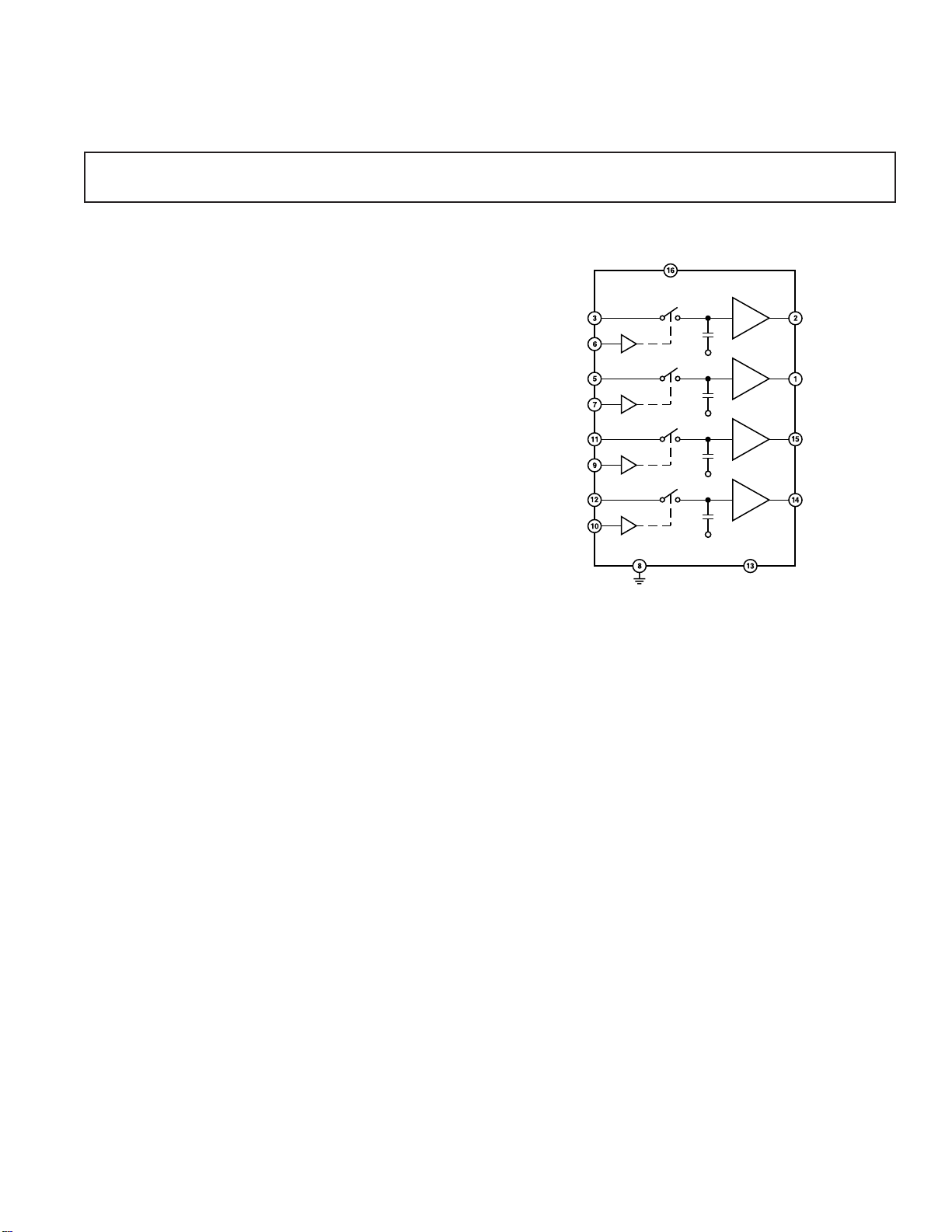

FUNCTIONAL BLOCK DIAGRAM

V

DD

SMP04

V

S/H

V

S/H

V

S/H

V

S/H

IN1

1

V

SS

IN2

2

V

SS

IN3

3

IN4

4

V

SS

V

SS

V

V

V

V

OUT1

OUT2

OUT3

OUT4

GENERAL DESCRIPTION

The SMP04 is a monolithic quad sample-and-hold; it has four

internal precision buffer amplifiers and internal hold capacitors.

It is manufactured in ADI’s advanced oxide isolated CMOS

technology to obtain the high accuracy, low droop rate and fast

acquisition time required by data acquisition and signal processing systems. The device can acquire an 8-bit input signal to

±1/2 LSB in less than four microseconds. The SMP04 can

operate from single or dual power supplies with TTL/CMOS

logic compatibility. Its output swing includes the negative supply.

The SMP04 is ideally suited for a wide variety of sample-andhold applications, including amplifier offset or VCA gain adjustments. One or more can be used with single or multiple DACs

to provide multiple setpoints within a system.

V

DGND

SS

The SMP04 offers significant cost and size reduction over

equivalent module or discrete designs. It is available in a

16-lead hermetic or plastic DIP and surface mount SOIC

packages. It is specified over the extended industrial tem-

perature range of –40°C to +85°C.

*Protected by U.S. Patent No. 4,739,281.

REV. D

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

Page 2

SMP04–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ VDD = +12.0 V, VSS = DGND = 0 V, RL = No Load, TA = Operating Temperature Range

specified in Absolute Maximum Ratings, unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Units

Linearity Error 0.01 %

V

Buffer Offset Voltage V

Hold Step V

Droop Rate ∆V/∆tV

Output Source Current

Output Sink Current

1

1

OS

HS

I

SOURCE

I

SINK

Output Voltage Range OVR R

LOGIC CHARACTERISTICS

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

DYNAMIC PERFORMANCE

Acquisition Time

Acquisition Time

Hold Mode Settling Time t

Slew Rate

3

3

4

2

Capacitive Load Stability C

INH

INL

IN

t

AQ

t

AQ

H

SR R

L

Analog Crosstalk 0 V to 10 V Step –80 dB

SUPPLY CHARACTERISTICS

Power Supply Rejection Ratio PSRR 10.8 V ≤ V

Supply Current I

Power Dissipation P

DD

DIS

= 6 V –10 ±2.5 +10 mV

IN

VIN = 6 V, T

= 6 V, T

V

IN

= 6 V, T

IN

= +25°C to +85°C2.54mV

A

= –40°C5mV

A

= +25°C 2 25 mV/s

A

VIN = 6 V 1.2 mA

VIN = 6 V 0.5 mA

= 20 kΩ 0.06 10.0 V

L

R

= 10 kΩ 0.06 9.5 V

L

2.4 V

0.8 V

0.5 1 µA

T

= +25°C, 0 V to 10 V Step to 0.1% 3.5 4.25 µs

A

–40°C ≤ T

T

= +25°C, 0 V to 10 V Step to 0.01% 9 µs

A

≤ +85°C 3.75 5.25 µs

A

To 1 mV 1 µs

= 20 kΩ 34 V/µs

L

<30% Overshoot 500 pF

≤ 13.2 V 60 75 dB

DD

47 mA

84 mW

ELECTRICAL CHARACTERISTICS

(@ VDD = +5.0 V, VSS = –5.0 V, DGND = 0.0 V, RL = No Load, TA = Operating Temperature

Range specified in Absolute Maximum Ratings, unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Units

Linearity Error 0.01 %

V

Buffer Offset Voltage V

Hold Step V

OS

HS

Droop Rate ∆V/∆tV

Output Resistance R

Output Source Current

Output Sink Current

1

1

OUT

I

SOURCE

I

SINK

Output Voltage Range OVR R

LOGIC CHARACTERISTICS

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

DYNAMIC PERFORMANCE

Acquisition Time

Acquisition Time

Hold Mode Settling Time t

Slew Rate

3

3

5

2

Capacitive Load Stability C

INH

INL

IN

t

AQ

t

AQ

H

SR R

L

SUPPLY CHARACTERISTICS

Power Supply Rejection Ratio PSRR ±5 V ≤ V

Supply Current I

Power Dissipation P

NOTES

1

Outputs are capable of sinking and sourcing over 20 mA, but linearity and offset are guaranteed at specified load levels.

2

All input control signals are specified with tR = tF = 5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

3

This parameter is guaranteed without test.

4

Slew rate is measured in the sample mode with a 0 V to 10 V step from 20% to 80%.

5

Slew rate is measured in the sample mode with a –3 V to +3 V step from 20% to 80%.

Specifications are subject to change without notice.

DD

DIS

= 0 V –10 ±2.5 +10 mV

IN

VIN = 0 V, T

= 0 V, T

V

IN

= 0 V, T

IN

= +25°C to +85°C2.54mV

A

= –40°C5mV

A

= +25°C 2 25 mV/s

A

1 Ω

VIN = 0 V 1.2 mA

VIN = 0 V 0.5 mA

= 20 kΩ –3.0 +3.0 V

L

2.4 V

0.8 V

0.5 1 µA

–3 V to +3 V Step to 0.1% 3.6 11 µs

–3 V to +3 V Step to 0.01% 9 µs

To 1 mV 1 µs

= 20 kΩ 3V/µs

L

<30% Overshoot 500 pF

≤ ±6 V 60 75 dB

DD

3.5 5.5 mA

55 mW

–2–

REV. D

Page 3

SMP04

ABSOLUTE MAXIMUM RATINGS

(T

= +25°C unless otherwise noted)

A

VDD to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, 17 V

V

to VSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.7 V, 17 V

DD

to DGND . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

V

LOGIC

VIN to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VSS, V

V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VSS, V

OUT

DD

DD

DD

Analog Output Current . . . . . . . . . . . . . . . . . . . . . . . ±20 mA

(Not Short-Circuit Protected)

Digital Input Voltage to DGND . . . . . . . –0.3 V, V

+ 0.3 V

DD

Operating Temperature Range

EQ, EP, ES . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . .+150°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . .+300°C

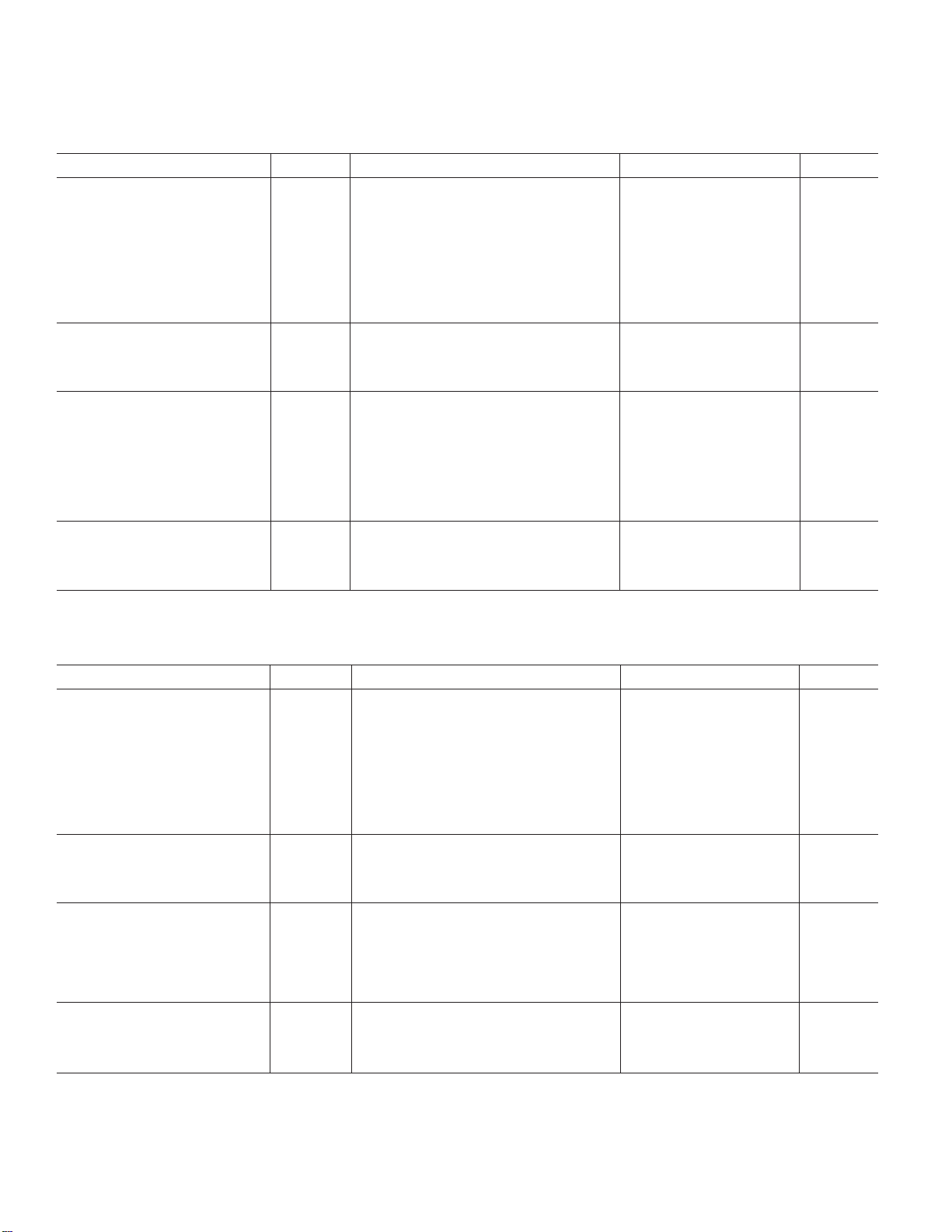

PIN CONNECTIONS

16-Lead Cerdip

16-Lead Plastic DIP

16-Lead SO

V

1

OUT2

2

V

OUT1

3

V

IN1

NC

4

V

5

IN2

S/H

6

1

S/H

7

2

DGND

8

NC = NO CONNECT

SMP04

TOP VIEW

(Not to Scale)

V

16

DD

V

15

OUT3

V

14

OUT4

V

13

SS

V

12

IN4

V

11

IN3

10

S/H

4

9

S/H

3

Package Type JA*

JC

Units

16-Lead Cerdip 94 12 °C/W

16-Lead Plastic DIP 76 33 °C/W

16-Lead SO 92 27 °C/W

*JA is specified for worst case mounting conditions, i.e., JA is specified for device

in socket for cerdip and plastic DIP packages;

to printed circuit board for SO package.

is specified for device soldered

JA

CAUTION

1. Stresses above those listed under Absolute Maximum Ratings may cause

permanent damage to the device. This is a stress rating only; function operation

at or above this specification is not implied. Exposure to the above maximum

rating conditions for extended periods may affect device reliability.

2. Digital inputs and outputs are protected; however, permanent damage may

occur on unprotected units from high energy electrostatic fields. Keep units in

conductive foam or packaging at all times until ready to use. Use proper antistatic

handling procedures.

3. Remove power before inserting or removing units from their sockets.

ORDERING GUIDE

Temperature Package Package

Model Range Description Options*

SMP04EQ –40°C to +85°C Cerdip-16 Q-16

SMP04EP –40°C to +85°C PDIP-16 N-16

SMP04ES –40°C to +85°C SO-16 R-16A

*Q = Cerdip; N = Plastic DIP; R = Small Outline.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the SMP04 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

REV. D

–3–

Page 4

SMP04

OUT2

DGND

2

V

V

OUT3

DD

V

OUT4

S/H3S/H

V

SS

V

IN4

V

IN3

4

V

V

S/H

V

IN1

IN2

1

OUT1

V

S/H

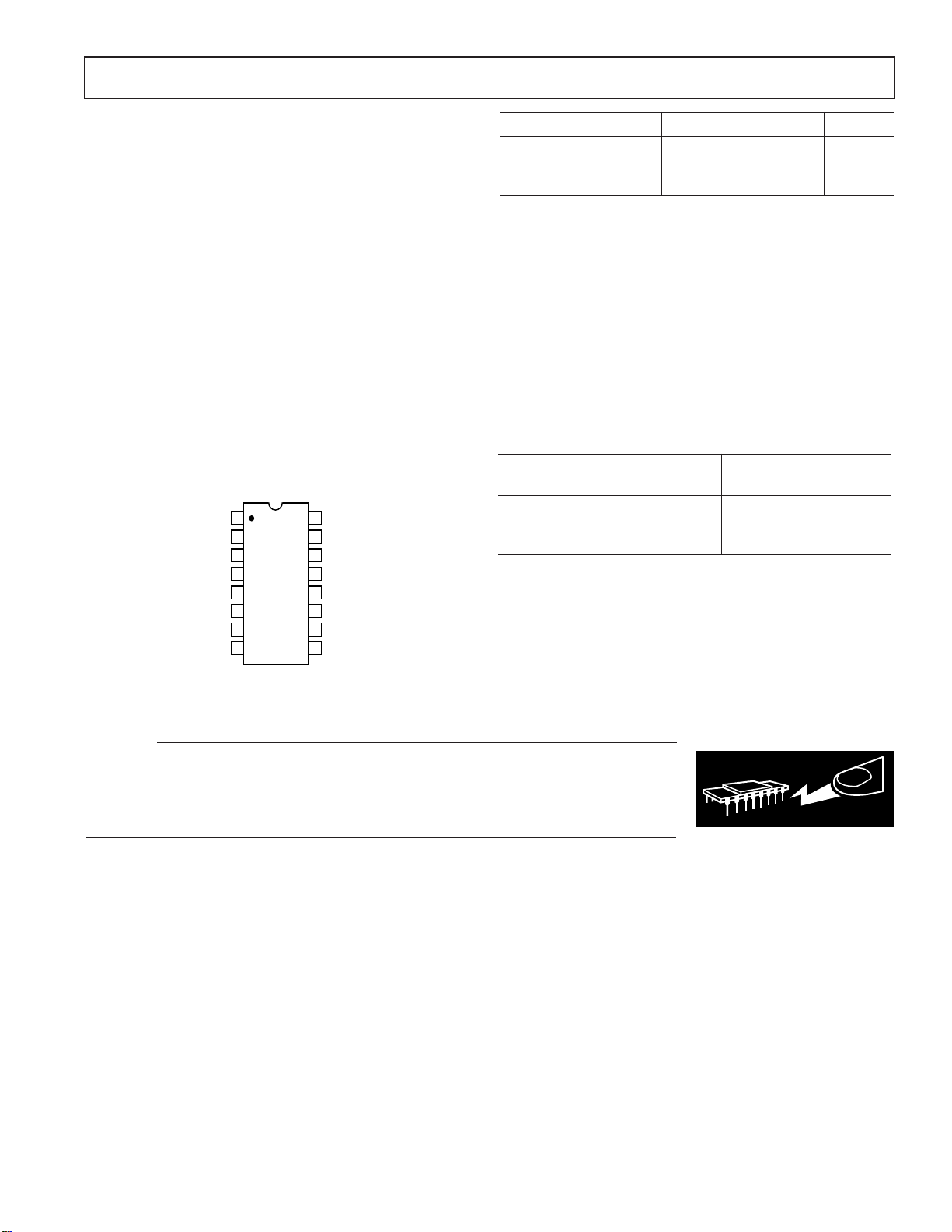

Dice Characteristics

Die Size: 0.80 x 0.120 mil = 9,600 sq. mil

(2.032 x 3.048mm = 6.193 sq. mm)

WAFER TEST LIMITS

(@ VDD = +12 V, VSS = DGND = 0 V, RL = No Load, TA = +25ⴗC, unless otherwise noted.)

SMP04G

Parameter Symbol Conditions Limits Units

V

Buffer Offset Voltage V

Hold Step V

OS

HS

Droop Rate ∆V/∆tV

Output Source Current I

Output Sink Current I

SOURCE

SINK

Output Voltage Range OVR R

= +6 V ±10 mV max

IN

V

= +6 V ±4 mV max

IN

= +6 V 25 mV/s max

IN

VIN = +6 V 1.2 mA min

VIN = +6 V 0.5 mA min

= 20 kΩ 0.06/10.0 V min/max

L

R

= 10 kΩ 0.06/9.5 V min/max

L

LOGIC CHARACTERISTICS

Logic Input High Voltage V

Logic Input Low Voltage V

Logic Input Current I

INH

INL

IN

2.4 V min

0.8 V max

1 µA max

SUPPLY CHARACTERISTICS

Power Supply Rejection Ratio PSRR 10.8 V ≤ V

Supply Current I

Power Dissipation P

NOTE

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

DD

DIS

≤ 13.2 V 60 dB min

DD

7 mA max

84 mW max

–4–

REV. D

Page 5

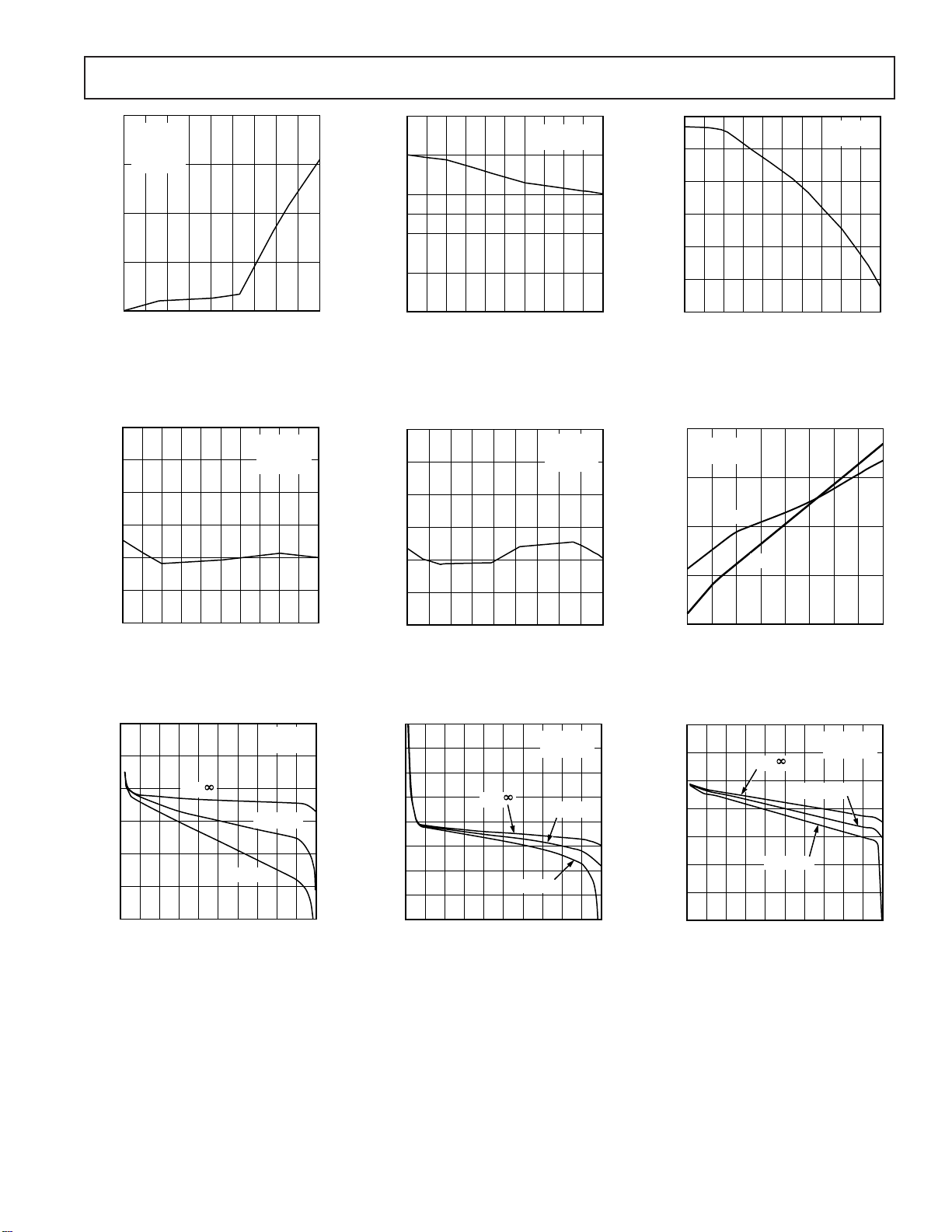

Typical Performance Characteristics–SMP04

INPUT VOLTAGE – Volts

DROOP RATE – mV/s

1800

1200

600

01 10

23456789

1600

1400

1000

800

VDD = +12V

V

SS

= 0V

10000

VDD = +12V

V

= 0V

SS

VIN = +5V

1000

= 10kV

R

L

100

DROOP RATE – mV/s

10

0

–55 –35 125

–15 5 25 65 85 10545

TEMPERATURE – 8C

Figure 1. Droop Rate vs. Temperature

3

2

1

0

–1

HOLD STEP – mV

–2

TA = +258C

V

= +12V

DD

V

= 0V

SS

5

3

1

0

–1

DROOP RATE – mV/s

–3

–5

01 10

23456789

INPUT VOLTAGE – Volts

VDD = +12V

V

= 0V

SS

Figure 2. Droop Rate vs. Input

Voltage (T

3

2

1

0

–1

HOLD STEP – mV

–2

= +25°C)

A

VDD = +12V

V

= 0V

SS

V

= +5V

IN

Figure 3. Droop Rate vs. Input

Voltage (T

7

TA = +258C

VSS = 0V

6

5

SLEW RATE – V/ms

4

= +125°C)

A

–SR

+SR

–3

01 10

23456789

INPUT VOLTAGE – Volts

Figure 4. Hold Step vs. Input Voltage

2

1

0

–1

–2

OFFSET VOLTAGE – mV

–3

–4

01 10

RL =

23456789

INPUT VOLTAGE – Volts

RL = 20kV

RL = 10kV

VDD = +12V

V

= 0V

SS

Figure 7. Offset Voltage vs. Input

Voltage (T

= +25°C)

A

–3

–55 –35 125

–15 5 25 65 85 10545

TEMPERATURE – 8C

Figure 5. Hold Step vs. Temperature

20

15

10

5

0

–5

–10

OFFSET VOLTAGE – mV

–15

–20

01 10

RL =

23456789

INPUT VOLTAGE – Volts

VDD = +12V

V

RL = 10kV

= 0V

SS

RL = 20kV

Figure 8. Offset Voltage vs. Input

Voltage (T

= +125°C)

A

3

10 11 18

Figure 6. Slew Rate vs. V

4

2

0

–2

–4

–6

OFFSET VOLTAGE – mV

–8

–10

12 13 14 15 16 17

V

– Volts

DD

DD

VDD = +12V

V

= 0V

RL =

RL = 10kV

01 10

23456789

INPUT VOLTAGE – Volts

SS

RL = 20kV

Figure 9. Offset Voltage vs. Input

Voltage (T

= –55°C)

A

REV. D

–5–

Page 6

SMP04

FREQUENCY – Hz

REJECTION RATIO – dB

90

80

0

10 100 1M1k 10k 100k

40

30

20

10

70

50

60

+PSSR

–PSSR

VDD = +12V

V

SS

= 0V

VIN = +6V

0

–1

–2

–3

OFFSET VOLTAGE – mV

–4

–5

–55 –33 125

–15 5 25 65 85 10545

TEMPERATURE – 8C

VDD = +12V

V

= 0V

SS

V

= +5V

IN

R

= 10kV

L

Figure 10. Offset Voltage vs.

Temperature

2

1

0

–1

–2

GAIN – dB

–3

–4

–5

100 1k 10M

10k 100k 1M

FREQUENCY – Hz

PHASE

GAIN

Figure 13. Gain, Phase Shift vs.

Frequency

SUPPLY CURRENT – mA

Figure 11. Supply Current vs. V

90

45

0

–45

–90

–135

PHASE SHIFT – Degrees

–180

–225

OUTPUT IMPEDANCE – V

Figure 14. Output Impedance vs.

Frequency

7

VSS = 0V

RL =

6

5

4

3

2

1

46 18

35

30

25

20

15

10

5

0

10 100 1M

+1258C

+258C

–558C

8 10121416

VDD – Volts

1k 10k 100k

FREQUENCY – Hz

DD

Figure 12. Sample Mode

Power Supply Rejection

15

12

9

6

3

PEAK-TO-PEAK OUTPUT – Volts

0

10k 100k 10M

FREQUENCY – Hz

TA = +258C

V

DD

V

SS

1M

= +6V

= –6V

Figure 15. Maximum Output Voltage

vs. Frequency

–6–

REV. D

Page 7

SMP04

GENERAL INFORMATION

The SMP04 is a quad sample-and-hold with each track-andhold having its own input, output, control, and on-chip hold

capacitor. The combination of four high performance track-andhold capacitors on a single chip greatly reduces board space and

design time while increasing reliability.

After the device selection, the primary considerations in using

track-and-holds are the hold capacitor and layout. The SMP04

eliminates most of these problems by having the hold capacitors

internal, eliminating the problems of leakage, feedthrough,

guard ring layout and dielectric absorption.

POWER SUPPLIES

The SMP04 is capable of operating with either single or dual

supplies over a voltage range of 7 to 15 volts. Based on the

supply voltages chosen, V

and VSS establish the output volt-

DD

age range, which is:

V

+ 0.05 V ≤ V

SS

OUT

≤ V

DD

–2 V

Note that several specifications, including acquisition time,

offset and output voltage compliance will degrade for a total

supply voltage of less than 7 V. Positive supply current is typically 4 mA with the outputs unloaded. The SMP04 has an internally regulated TTL supply so that TTL/CMOS compatibility

will be maintained over the full supply range.

Single Supply Operation Grounding Considerations

In single supply applications, it is extremely important that the

V

(negative supply) pin be connected to a clean ground. This

SS

is because the hold capacitor is internally tied to V

. Any noise

SS

or disturbance in the ground will directly couple to the output of

the sample-and-hold, degrading the signal-to-noise performance.

It is advisable that the analog and digital ground traces on the

circuit board be physically separated to reduce digital switching

noise from entering the analog circuitry.

Power Supply Bypassing

For optimum performance, the VDD supply pin must also be

bypassed with a good quality, high frequency ceramic capacitor.

The recommended value is 0.1 µF. In the case where dual sup-

plies are used, V

(negative supply) bypassing is particularly

SS

important. Again this is because the internal hold capacitor is

tied to V

. Good bypassing prevents high frequency noise from

SS

entering the sample-and-hold amplifier. A 0.1 µF ceramic bypass

capacitor is generally sufficient. For high noise environments,

adding a 10 µF tantalum capacitor in parallel with the 0.1 µF

provides additional protection.

Power Supply Sequencing

It may be advisable to have the VDD turn on prior to having logic

levels on the inputs. The SMP04 has been designed to be resistant to latch-up, but standard precautions should still be taken.

OUTPUT BUFFERS (Pins 1, 2, 14 and 15)

The buffer offset specification is ±10 mV; this is less than 1/2 LSB

of an 8-bit DAC with 10 V full scale. Change in offset over the

output range is typically 3 mV. The hold step is the magnitude

of the voltage step caused when switching from sample-to-hold

mode. This error is sometimes referred to as the pedestal

error or sample-to-hold offset, and is about 2 mV with little

variation. The droop rate of a held channel is 2 µV/ms typical

and ±25 µV/ ms maximum.

The buffers are designed primarily to drive loads connected to

ground. The outputs can source more than 1.2 mA each, over

the full voltage range and maintain specified accuracy. In split

supply operation, symmetrical output swings can be obtained by

restricting the output range to 2 V from either supply.

On-chip SMP04 buffers eliminate potential stability problems

associated with external buffers; outputs are stable with capacitive loads up to 500 pF. However, since the SMP04’s buffer

outputs are not short-circuit protected, care should be taken to

avoid shorting any output to the supplies or ground.

SIGNAL INPUT (Pins 3, 5, 11 and 12)

The signal inputs should be driven from a low impedance

voltage source such as the output of an op amp. The op amp

should have a high slew rate and fast settling time if the SMP04’s

fast acquisition time characteristics are to be maintained. As

with all CMOS devices, all input voltages should be kept within

range of the supply rails (V

≤ VIN ≤ V

SS

) to avoid the possibil-

DD

ity of setting up a latch-up condition.

The internal hold capacitance is typically 60 pF and the internal

switch ON resistance is 2 kΩ.

If single supply operation is desired, op amps such as the OP183

or AD820, that have input and output voltage compliances

including ground, can be used to drive the inputs. Split sup-

plies, such as ±7.5 V, can be used with the SMP04 and the

above mentioned op amps.

APPLICATION TIPS

All unused digital inputs should be connected to logic LOW

and the analog inputs connected to analog ground. For connectors or driven analog inputs that may become temporarily disconnected, a resistor to V

or analog ground should be used

SS

with a value ranging from 0.2 MΩ to 1 MΩ.

Do not apply signals to the SMP04 with power off unless the

input current’s value is limited to less than 10 mA.

Track-and-holds are sensitive to layout and physical connections.

For the best performance, the SMP04 should not be socketed.

REV. D

–7–

Page 8

SMP04

FREQUENCY DOMAIN PERFORMANCE

The SMP04 has been characterized in the frequency domain for

those applications that require capture of dynamic signals. See

Figure 16a for typical 86.1 kHz sample rate and an 8 kHz input

signal. Typically, the SMP04 can sample at rates up to 85 kHz.

In addition to the maximum sample rate, a minimum sample

pulsewidth will also be acceptable for a given design. Our testing

shows a drop in performance as the sample pulsewidth becomes

less than 4 µs.

10 dB/DIV RANGE 15.0 dBm 6.0 dBm

START 1 000.0 Hz STOP 100 000.0 Hz

a.

10 dB/DIV RANGE 15.0 dBm 6.3 dBm

START 1 000.0 Hz STOP 100 000.0 Hz

b.

Figure 16. Spectral Response at a Sampling Frequency of

86 kHz. Photo (a) Shows a 20 kHz Carrier Frequency and

Photo (b) Shows an 8 kHz Frequency.

Optimizing Dynamic Performance of the SMP04

Various operating parameters such as input voltage amplitude,

sampling pulsewidth and, as mentioned before, supply bypassing and grounding all have an effect on the signal-to-noise ratio.

Table I shows the SNR versus input level for the SMP04.

Distortion of the SMP04 is reduced by increasing the supply

voltage. This has the effect of increasing the positive slew rate.

Table II shows data taken at 12.3 kHz sample rate and 2 kHz

input frequency. Total harmonic distortion is dominated by the

second and third harmonics.

Table III shows the effect of sampling pulsewidth on the SNR of

the SMP04. The recommended operating pulsewidth should be

a minimum of 5 µs to achieve a good balance between acqui-

sition time and SNR for the 1.4 V p-p signal shown. For larger

swings the pulsewidth will need to be larger to account for

the time required for the signal to slew the additional voltage.

This could be used as a method of measuring acquisition

time indirectly.

Table I. SNR vs. V

IN

Input

Voltage SNR

(V p-p) (dB)

1 –61

2 –53

3 –50

4 –47

5 –45

6 –44

Conditions: V

fIN = 1.8 kHz, t

= ±6 V, f

S

= 10 µs.

PW

= 14.4 kHz,

S

Table II. SNR vs. Supply Voltage

Supply

Voltage 2nd 3rd

(V) (dB) (dB)

10 –49 –62

12 –55 –71

14 –60 –80

15 –62 <–80

16 –63 <–83

17 –65 <–85

Table III. SNR vs. Sample Pulsewidth

Sample

Pulsewidth SNR

(s) (dB)

1 –37

2 –44

3 –50

4 –54

5 –54.9

6 –55

7 –55.3

Conditions: V

fS = 14.4 kHz, fIN = 1.8 kHz.

= ±6 V, V

S

= 1.4 V p-p,

IN

–8–

REV. D

Page 9

SMP04

Sample-Mode Distortion Characteristics

Although designed as a sample-and-hold, the SMP04 may be

used as a straight buffer amplifier by configuring it in a continuous sample mode. This is done by connecting the S/H control

pin to a logic LOW. Its buffer bandwidth is primarily limited by

the distortion content as the signal frequency increases. Figure

17 shows the distortion characteristics of the SMP04 versus

frequency. It maintains less than 1% total harmonic distortion

over a voiceband of 8 kHz. Output spot noise voltage measures

4 nV/√Hz at f = 1 kHz.

10

VS = 66V

V

= 4Vp-p

IN

1

0.1

THD + NOISE – %

0.010

0.001

0.0005

20 100k

100 1k 10k

FREQUENCY – Hz

200k

Figure 17. THD+N vs. Frequency

Sampled Data Dynamic Performance

In continuous sampled data applications such as voice digitization or communication circuits, it is important to analyze the

spectral response of a sample-and-hold. Figures 16a and 16b

show the SMP04 sampling at a frequency of 86 kHz with a

1.4 V p-p pure sine wave input of 20 kHz and 8 kHz respectively. The photos include the sampling carrier frequency as

well as its multiplying frequencies. In the case of the 20 kHz

carrier frequency, the second harmonic measures 41 dB down

from the fundamental, because the second is dominant, the

signal-to-noise ratio is –40.9 dB. The 8 kHz case produces an

improved S/N performance of –48 dB.

In the V.32 and V.33 modem environment, where a 1.8 kHz

carrier signal frequency is applied to the SMP04, Figure 18

compares the spectral responses of the SMP04 under three

different sampling frequencies of 14.4 kHz, 9.6 kHz and

7.2 kHz. The signal-to-noise ratios measure 58.2 dB, 59.3 dB

and 60 dB respectively.

Figure 19 depicts SMP04’s spectral response operating with

voice frequency of 3 kHz sampling at a 15.7 kHz rate. Under

this condition, the signal-to-noise measures 53 dB.

10 dB/DIV RANGE 15.0 dBm 5.9 dBm

START 1 000.0 Hz STOP 20 000.0 Hz

Figure 19. SMP04 Spectral Response with an Input Carrier

Frequency of 3 kHz and the Sampling Frequency of 15.7 kHz

Sampled Data Dynamic Performance

In continuous sampled data applications such as voice digitization or communication circuits, it is important to analyze the

spectral response of a sample-and-hold. Figures 16a and 16b

show the SMP04 sampling at a frequency of 86 kHz with a

1.4 V p-p pure sine wave input of 20 kHz and 8 kHz respectively. The photos include the sampling carrier frequency as well

as its multiplying frequencies. In the case of the 20 kHz carrier

frequency, the second harmonic measures 41 dB down from the

fundamental, because the second is dominant, the signal-tonoise ratio is –40.9 dB. The 8 kHz case produces an improved

S/N performance of –48 dB.

In the V.32 and V.33 modem environment, where a 1.8 kHz

carrier signal frequency is applied to the SMP04, Figure 18

compares the spectral responses of the SMP04 under three

different sampling frequencies of 14.4 kHz, 9.6 kHz and

7.2 kHz. The signal-to-noise ratios measure 58.2 dB, 59.3 dB

and 60 dB respectively.

10 dB/DIV RANGE 15.0 dBm 5.9 dBm

CENTER 10 500.0 Hz SPAN 19 000.0 Hz

a.

10 dB/DIV RANGE 15.0 dBm 5.7 dBm

START 1 000.0 Hz STOP 12 000.0 Hz

b.

10 dB/DIV RANGE 15.0 dBm 5.2 dBm

START 1 000.0 Hz STOP 12 000.0 Hz

c.

Figure 18. SMP04 Spectral Response with a 1.8 kHz Carrier Frequency. (a) Shows the Sampling Frequency at 14.4 kHz;

it Exhibits a S/N Ratio of 58.2 dB. (b) Shows a 59.3 dB S/N at a Sampling Frequency of 8.6 kHz. (c) Shows a 60 dB S/N at

7.2 kHz.

REV. D

–9–

Page 10

SMP04

APPLICATIONS

MULTIPLEXED QUAD DAC (Figure 20)

The SMP04 can be used to demultiplex a single DAC converter’s

output into four separate analog outputs. The circuit is greatly

simplified by using a voltage output DAC such as the DAC8228.

To minimize output voltage perturbation, 5 µs should be allowed

to settle to its final voltage before a sample signal is asserted.

Each sample-and-hold amplifier must be refreshed every second

or less in order to assure the droop does not exceed 10 mV or

1/2 LSB.

+12V

0.1mF

WR

CS

DIGITAL

INPUTS

ADDRESS

INPUTS

REF02

+5V

V

Z

1/2 DAC8228

V

REF

+12V

V

DD

GND

5V TO 10V

V

O

CHANNEL

DECODE

S/H

S/H

S/H

S/H

1

2

3

4

Figure 20. Multiplexed Quad DAC

+12V

DGND

1mF

+

SMP04

V

SS

V

SS

V

SS

V

SS

V

V

V

V

OUT1

OUT2

OUT3

OUT4

–10–

REV. D

Page 11

SMP04

V

(63.5V)

RESET

PD/H

POSITIVE

PD/H

NEGATIVE

AMPLIFIER A

+5V

1/2 OP221

IN

–5V

AMPLIFIER B

1/2 OP221

R1

20kV

D

1

1N914

R3

20kV

D

3

1N914

D

SD214

D

SD214

V

DD

2

R2

100V

G

D

Q

1

S

1/2 SMP04

4

R4

100V

G

D

Q

2

S

DGND

–5V+5V

V

SS

V

OUT

POSITIVE

V

SS

V

OUT

NEGATIVE

V

SS

Figure 21. Positive and Negative Peak Detector with Hold Control

POSITIVE AND NEGATIVE PEAK DETECTOR WITH

HOLD CONTROL (Figure 21)

In this application the top amplifier (Amplifier A) is the positive

peak detector and the bottom amplifier (Amplifier B) is the

negative peak detector. Operation can be analyzed as follows:

Assume that the S/H switch is closed. As a positive increasing

voltage is applied to V

, D2 turns on, and D1 turns off, closing

IN

the feedback loop around Amplifier A and the SMP04, causing

the output to track the input. Conversely, in the negative peak

detector circuit at the bottom, D

turns off and D3 turns on,

4

holding the last most negative input voltage on the SMP04.

This voltage is buffered to the V

As V

falls in voltage the above conditions reverse, causing the

IN

most positive peak voltage to be held at V

O(NEG)

output.

O(POS)

output. This

voltage will be held until the input has a more positive voltage

than the previously held peak voltage, or a reset condition is

applied.

An optional HOLD control can be used by applying a logic HIGH

to the PD/H inputs. This HOLD mode further reduces leakage

current through the reverse-biased diodes (D

and D4) during

2

peak hold.

GAIN OF 10 SAMPLE-AND-HOLD (Figure 22)

This application places the SMP04 in a feedback loop of an

amplifier. Because the SMP04 has no sign inversion and the

amplifier has very high open-loop gain, the gain of the circuit is set

by the ratio of the sum of the source and feedback resistances

8.66kV 340V

+12V

V

V

OUT

0V TO

10V

SS

1kV

V

0V TO

1.0V

S/H

1N914

+12V

1/4 OP490

IN

100kV

1/4 SMP04

Figure 22. Gain of 10 Sample-and-Hold Amplifier

to the source resistance. When a logic LOW is applied to the

S/H control input, the loop is closed around the OP490,

yielding a gain of 10 (in the example shown) amplifier. When

the S/H control goes HIGH, the loop opens and the SMP04

holds the last sampled voltage. The loop remains open and the

output is unaffected by the input until a logic LOW is reapplied

to the S/H control. The pair of back-to-back diodes from the

output of the op amp to the output of the track-and-hold prevents the op amp from saturating when the track-and-hold is in

the hold mode and the loop is open.

REV. D

–11–

Page 12

SMP04

+12V

V

1

V

2

VIN (0V TO 8V)

d

t

S/H

S/H (DELAYED)

2

0

0

t

t

1

V

1/2 SMP04

DD

V

SS

V

SS

DGND

Figure 23. Time Delta Sample-and-Difference Measurement

SAMPLE AND DIFFERENCE AMPLIFIER (Figure 23)

This circuit uses two sample-and-holds to measure the voltage

difference of a signal between two time points, t

and t2. The

1

sampled voltages are fed into the differential inputs of the AMP02

instrumentation amplifier. A single resistor R

sets the gain of

G

this instrumentation amplifier. Using two channels of the

SMP04 in this application has the advantage of matched

sample-and-hold performance, since they are both on the same

chip.

INSTRUMENTATION AMP

V

SS

V

1

R

G

V

2

+12V

AMP02

–5V OR –12V

= G(V1–V2)

V

OUT

50kV

G = +1

R

G

SINGLE SUPPLY, SAMPLING, INSTRUMENTATION

AMPLIFIER (Figure 24)

This application again uses two channels of the SMP04 and an

instrumentation amplifier to provide a sampled difference signal.

The sample-and-hold signals in this circuit are tied together to

sample at the same point in time. The other two parts of the

SMP04 are used as amplifiers by grounding their control lines

so they are always sampling. One section is used to drive a

guard to the common-mode voltage and the other to generate a

+6 V reference to serve as an offset for single supply operation.

+ INPUT

– INPUT

S/H

GUARD

GUARD

GUARD

DRIVE

1/4

SMP04

1/4

SMP04

SMP04

+12V

1/4

+12V

20kV

20kV

50kV

50kV

SMP04

0.01mF

1/4

+12V

AMP02

R

G

Figure 24. +12 V Single Supply Sampling Instrumentation Amplifier with Guard Drive

50kV

GAIN =

REFERENCE

+6V REFERENCE

R

0.1mF

+1

G

V

OUT

–12–

REV. D

Page 13

+15V

SMP04

0.1mF

V

OUT

WR

10-BIT

COUNTER

CLOCK

GENERATOR

+5V

DB2–DB

DB

DB

DB

9

9

DB

2

ANALOG

RETURN

DIGITAL

RETURN

0

1

A

A

1

0

MSB

LSB

V

SS

V

DD

1/4 DAC8426

AGND DGND

1/4 AD7432

DEGLITCH LOGIC

Figure 25. DAC Deglitcher

D/A CONVERTER DEGLITCHER

Most D/A converters output an appreciable amount of glitch

energy during a transition from one code to another. The glitch

amplitude can range from several millivolts to hundreds of millivolts. This may become unacceptable in many applications. By

selectively delaying the DAC’s output transition, the SMP04

can be used to smooth the output waveform. Figure 25 shows

the schematic diagram of such a deglitcher circuit. Two simple

logic gates (an OR and a NAND gate) provide the proper timing

sequence for the DAC WR strobe and the S/H control signal to

the SMP04. In this example a linear ramp signal is generated by

feeding the most significant eight bits of the 10-bit binary

counter to the DAC. The two least significant bits are used to

produce the delayed WR strobe and the S/H control signals.

Referring to Figure 26a, new data to the DAC input is set up at

the S/H’s falling edge, but the DAC output does not change

until a WR strobe goes active. During this period, the SMP04 is

in a sample mode whose output tracks the DAC output. When

S/H goes HIGH, the current DAC output voltage is held by the

SMP04. After 1.2 µs settling, the WR strobe goes LOW to allow

the DAC output to change. Any glitch that occurs at the DAC

output is effectively blocked by the SMP04. As soon as the WR

strobe goes HIGH, the digital data is latched; at the same time

the S/H goes LOW, allowing the SMP04 to track to the new

DAC output voltage.

Figure 26b shows the deglitching operation. The top trace

shows the DAC output during a transition, while the bottom

trace shows the deglitched output of the SMP04.

REF

DAC C

1/4 AD7400

OUT

0.1mF–1mF CERAMIC

V

IN

S/H

1/4 SMP04

DGND

V

5V

V

OUT

V

SS

DD

1mF

AGND

+15V

DB

0

DB

1

WR

1ms

S/H

a.

DLY

50m

627.4

1ms

m

s

b.

Figure 26. (a) Shows the Logic Timing of the Deglitcher.

The Top Two Traces Are the Two Least Significant Bits,

and DB1, Respectively. These Are Used to Generate

DB

0

WR

the

and S/H Signals Which Are Shown in the Bottom

Two Traces. (b) Shows the Typical Glitch Amplitude of a

DAC (Top Trace) and the Deglitched Output of the AMP04

(Bottom Trace).

REV. D

–13–

Page 14

SMP04

V

DD

V

V

IN

V

DD

N-CH

P-CH

C

H

OUT

LOAD

S/H

V

DGND

LOGIC

SS

V

SS

Figure 27. Simplified Schematic of One Channel

V

DD

16

15

14

13

12

11

10

+15V

R1

10V

C1

10mF

+

D

1

C2

1mF

R2

R2

10kV

10kV

R3

4kV

R2

10kV

R4

1kV

1

2

3

SMP04

5

R2

6

10kV

7

89

Figure 28. Burn-In Circuit

–14–

REV. D

Page 15

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Lead Cerdip

(Q-16)

SMP04

0.005 (0.13) MIN

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.080 (2.03) MAX

16

1

0.840 (21.34) MAX

0.023 (0.58)

0.014 (0.36)

PIN 1

0.100

(2.54)

BSC

9

0.310 (7.87)

0.220 (5.59)

8

0.070 (1.78)

0.030 (0.76)

0.060 (1.52)

0.015 (0.38)

16-Lead Plastic DIP

(N-16)

0.840 (21.34)

0.745 (18.92)

16

18

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

9

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.150

(3.81)

MIN

SEATING

PLANE

0.130

(3.30)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15°

0°

0.325 (8.26)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

C3131–0–4/98

0.015 (0.38)

0.008 (0.20)

0.195 (4.95)

0.115 (2.93)

REV. D

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

16-Lead SO

(R-16A)

0.3937 (10.00)

0.3859 (9.80)

16 9

PIN 1

0.0192 (0.49)

0.0500

(1.27)

0.0138 (0.35)

BSC

0.2440 (6.20)

81

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0099 (0.25)

0.0075 (0.19)

–15–

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

x 45°

PRINTED IN U.S.A.

Loading...

Loading...