Page 1

DATA SH EET

Product specification

Supersedes data of 1999 Aug 17

File under Integrated Circuits, IC18

2000 Jan 04

INTEGRATED CIRCUITS

SJA1000

Stand-alone CAN controller

Page 2

2000 Jan 04 2

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 BLOCK DIAGRAM

5 PINNING

6 FUNCTIONAL DESCRIPTION

6.1 Description of the CAN controller blocks

6.1.1 Interface Management Logic (IML)

6.1.2 Transmit Buffer (TXB)

6.1.3 Receive Buffer (RXB, RXFIFO)

6.1.4 Acceptance Filter (ACF)

6.1.5 Bit Stream Processor (BSP)

6.1.6 Bit Timing Logic (BTL)

6.1.7 Error Management Logic (EML)

6.2 Detailed description of the CAN controller

6.2.1 PCA82C200 compatibility

6.2.2 Differences between BasicCAN and PeliCAN

mode

6.3 BasicCAN mode

6.3.1 BasicCAN address layout

6.3.2 Reset values

6.3.3 Control Register (CR)

6.3.4 Command Register (CMR)

6.3.5 Status Register (SR)

6.3.6 Interrupt Register (IR)

6.3.7 Transmit buffer layout

6.3.8 Receive buffer

6.3.9 Acceptance filter

6.4 PeliCAN mode

6.4.1 PeliCAN address layout

6.4.2 Reset values

6.4.3 Mode Register (MOD)

6.4.4 Command Register (CMR)

6.4.5 Status Register (SR)

6.4.6 Interrupt Register (IR)

6.4.7 Interrupt Enable Register (IER)

6.4.8 Arbitration Lost Capture register (ALC)

6.4.9 Error Code Capture register (ECC)

6.4.10 Error Warning Limit Register (EWLR)

6.4.11 RX Error Counter Register (RXERR)

6.4.12 TX Error Counter Register (TXERR)

6.4.13 Transmit buffer

6.4.14 Receive buffer

6.4.15 Acceptance filter

6.4.16 RX Message Counter (RMC)

6.4.17 RX Buffer Start Address register (RBSA)

6.5 Common registers

6.5.1 Bus Timing Register 0 (BTR0)

6.5.2 Bus Timing Register 1 (BTR1)

6.5.3 Output Control Register (OCR)

6.5.4 Clock Divider Register (CDR)

7 LIMITING VALUES

8 THERMAL CHARACTERISTICS

9 DC CHARACTERISTICS

10 AC CHARACTERISTICS

10.1 AC timing diagrams

10.2 Additional AC information

11 PACKAGE OUTLINES

12 SOLDERING

12.1 Introduction

12.2 DIP

12.2.1 Soldering by dipping or by wave

12.2.2 Repairing soldered joints

12.3 SO

12.3.1 Reflow soldering

12.3.2 Wave soldering

12.3.3 Repairing soldered joints

13 DEFINITIONS

14 LIFE SUPPORT APPLICATIONS

Page 3

2000 Jan 04 3

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

1 FEATURES

• Pin compatibility to the PCA82C200 stand-alone CAN

controller

• Electrical compatibility to the PCA82C200 stand-alone

CAN controller

• PCA82C200 mode (BasicCAN mode is default)

• Extended receive buffer (64-byte FIFO)

• CAN 2.0B protocol compatibility (extended frame

passive in PCA82C200 compatibility mode)

• Supports 11-bit identifier as well as 29-bit identifier

• Bit rates up to 1 Mbits/s

• PeliCAN mode extensions:

– Error counters with read/write access

– Programmable error warning limit

– Last error code register

– Error interrupt for each CAN-bus error

– Arbitration lost interrupt with detailed bit position

– Single-shot transmission (no re-transmission)

– Listen only mode (no acknowledge, no active error

flags)

– Hot plugging support (software driven bit rate

detection)

– Acceptance filter extension (4-byte code, 4-byte

mask)

– Reception of‘own’ messages (self reception request)

• 24 MHz clock frequency

• Interfaces to a variety of microprocessors

• Programmable CAN output driver configuration

• Extended ambient temperature range (−40 to +125 °C).

2 GENERAL DESCRIPTION

The SJA1000 is a stand-alone controller for the Controller

Area Network (CAN) used within automotive and general

industrial environments. It is the successor of the

PCA82C200 CAN controller (BasicCAN) from Philips

Semiconductors. Additionally, a new mode of operation is

implemented (PeliCAN) which supports the CAN 2.0B

protocol specification with several new features.

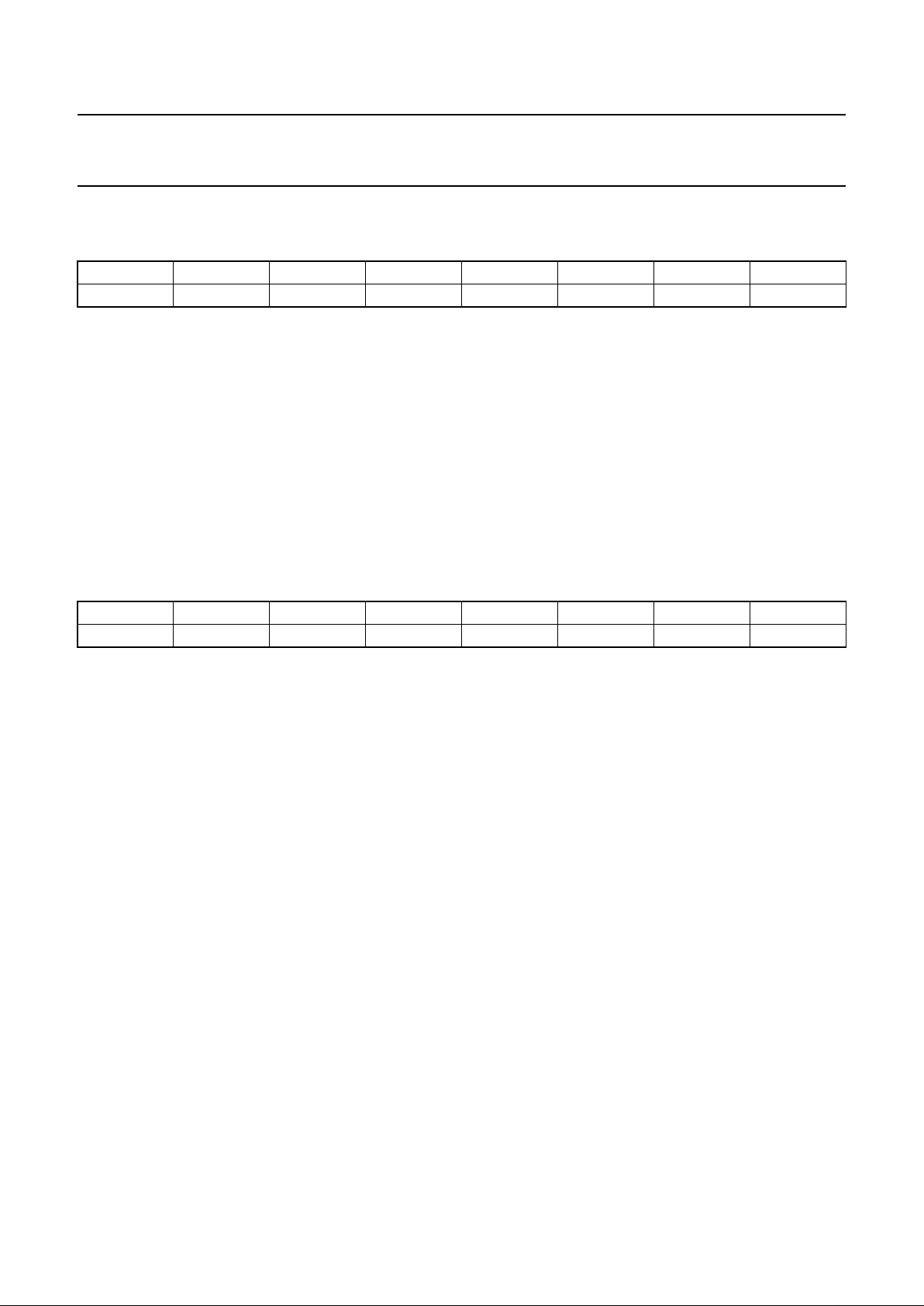

3 ORDERING INFORMATION

TYPE NUMBER

PACKAGE

NAME DESCRIPTION VERSION

SJA1000 DIP28 plastic dual in-line package; 28 leads (600 mil) SOT117-1

SJA1000T SO28 plastic small outline package; 28 leads; body width 7.5 mm SOT136-1

Page 4

2000 Jan 04 4

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

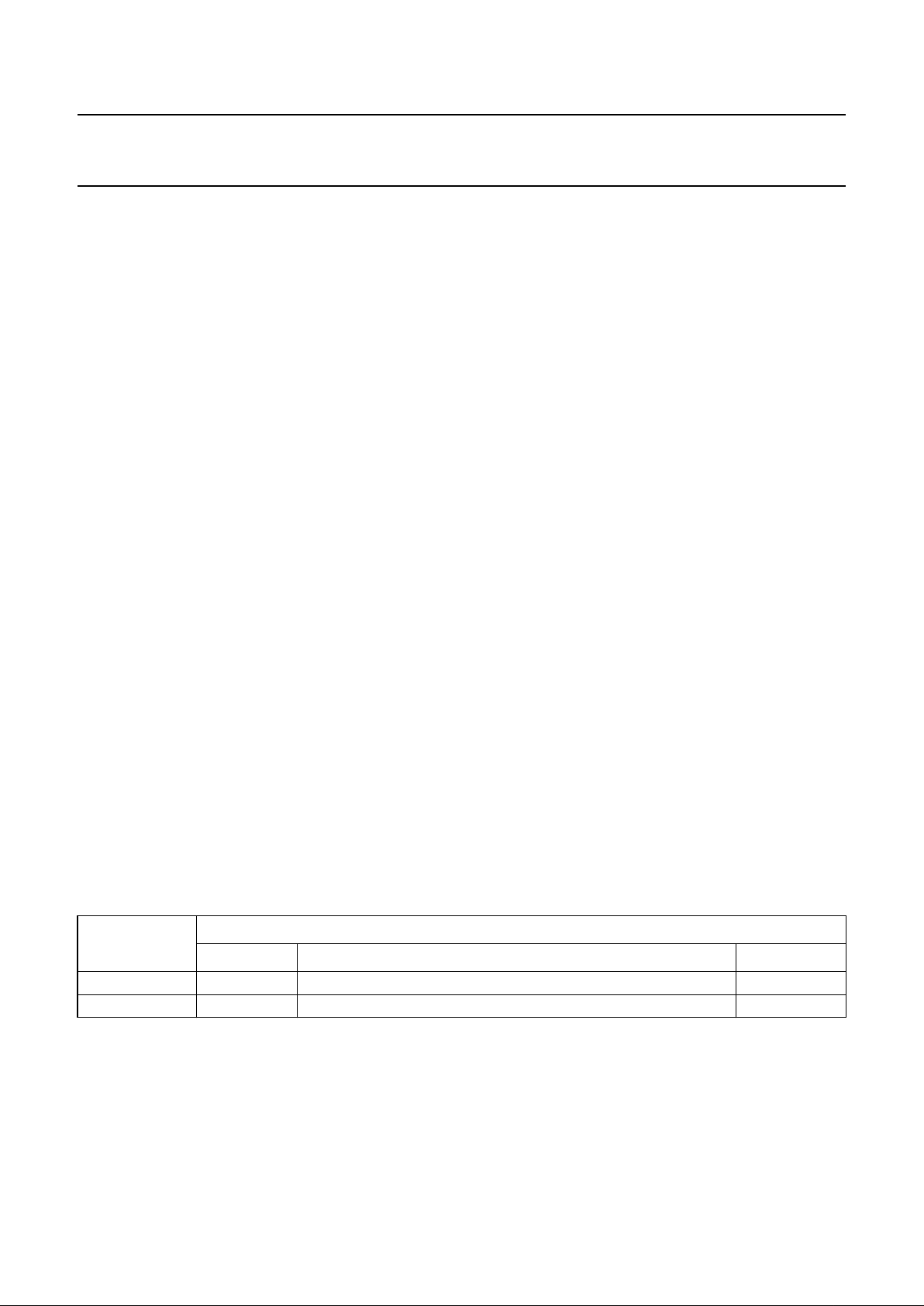

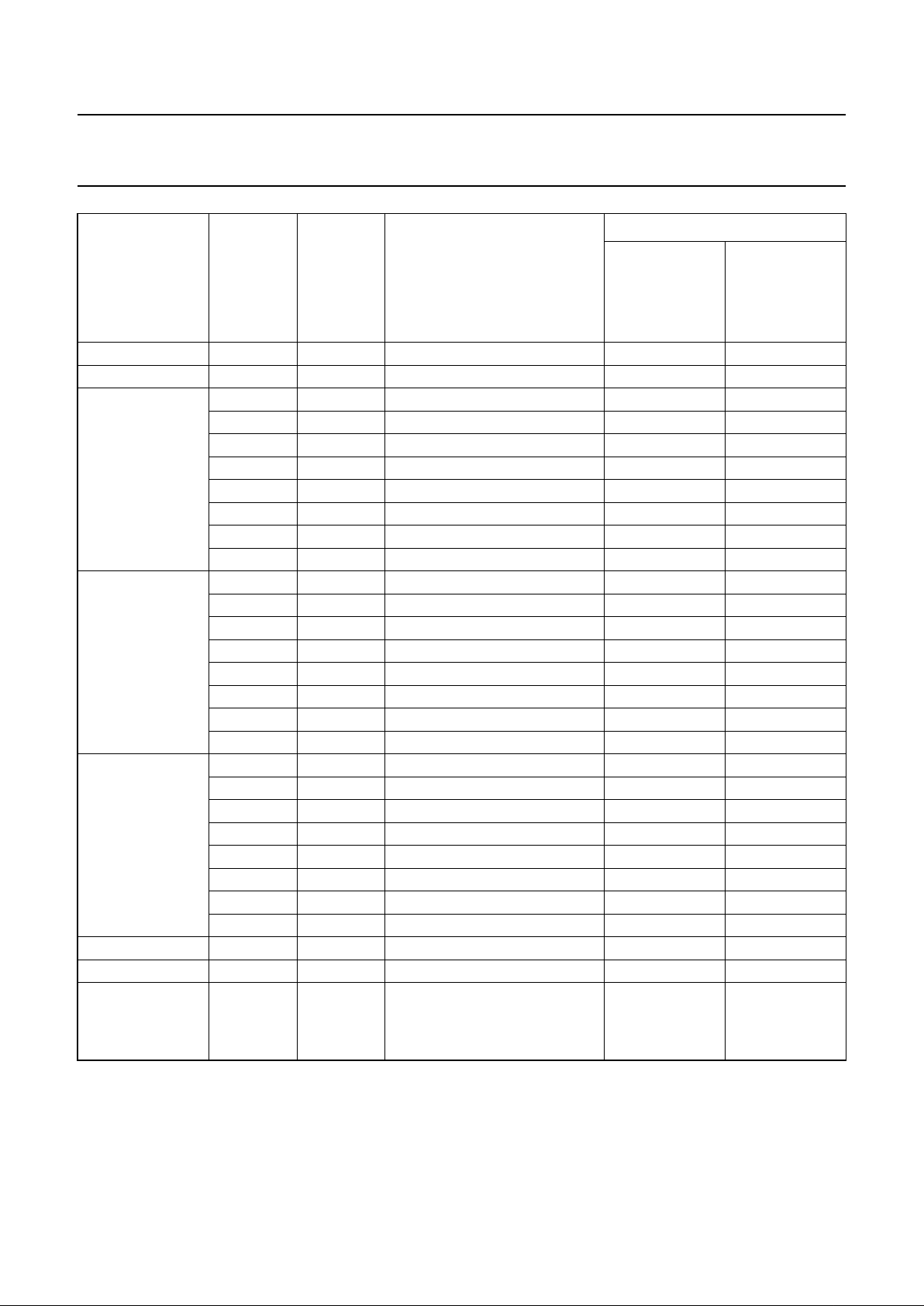

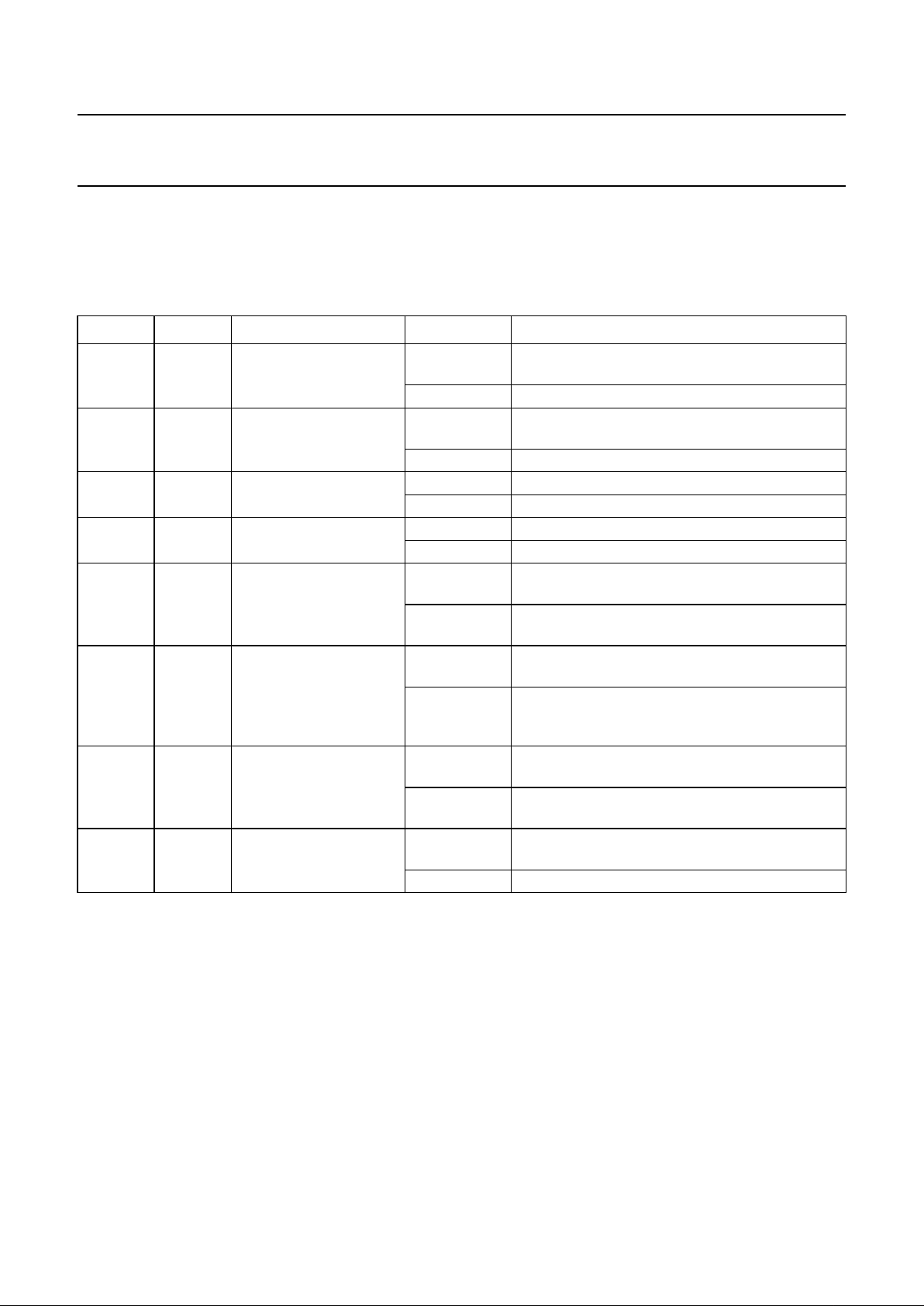

4 BLOCK DIAGRAM

Fig.1 Block diagram.

handbook, full pagewidth

MGK623

INTERFACE MANAGEMENT LOGIC

7

8

address/data

control

MESSAGE BUFFER

TRANSMIT

BUFFER

RECEIVE

BUFFER

RECEIVE

FIFO

BIT

STREAM

PROCESSOR

ACCEPTANCE

FILTER

BIT TIMING

LOGIC

ERROR

MANAGEMENT

LOGIC

RESETOSCILLATOR

XTAL1

9

XTAL2

10

TX0

TX1

RX0

RX1

17

18

21

20

19

14

13

15

12

8

22

internal bus

V

DD3

V

SS3

V

DD1

V

SS1

V

SS2

V

DD2

AD7 to AD0

2, 1,

28 to 23

3 to 7,

11, 16

ALE/AS, CS,

RD/E, WR,

CLKOUT,

MODE, INT

RST

SJA1000

Page 5

2000 Jan 04 5

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

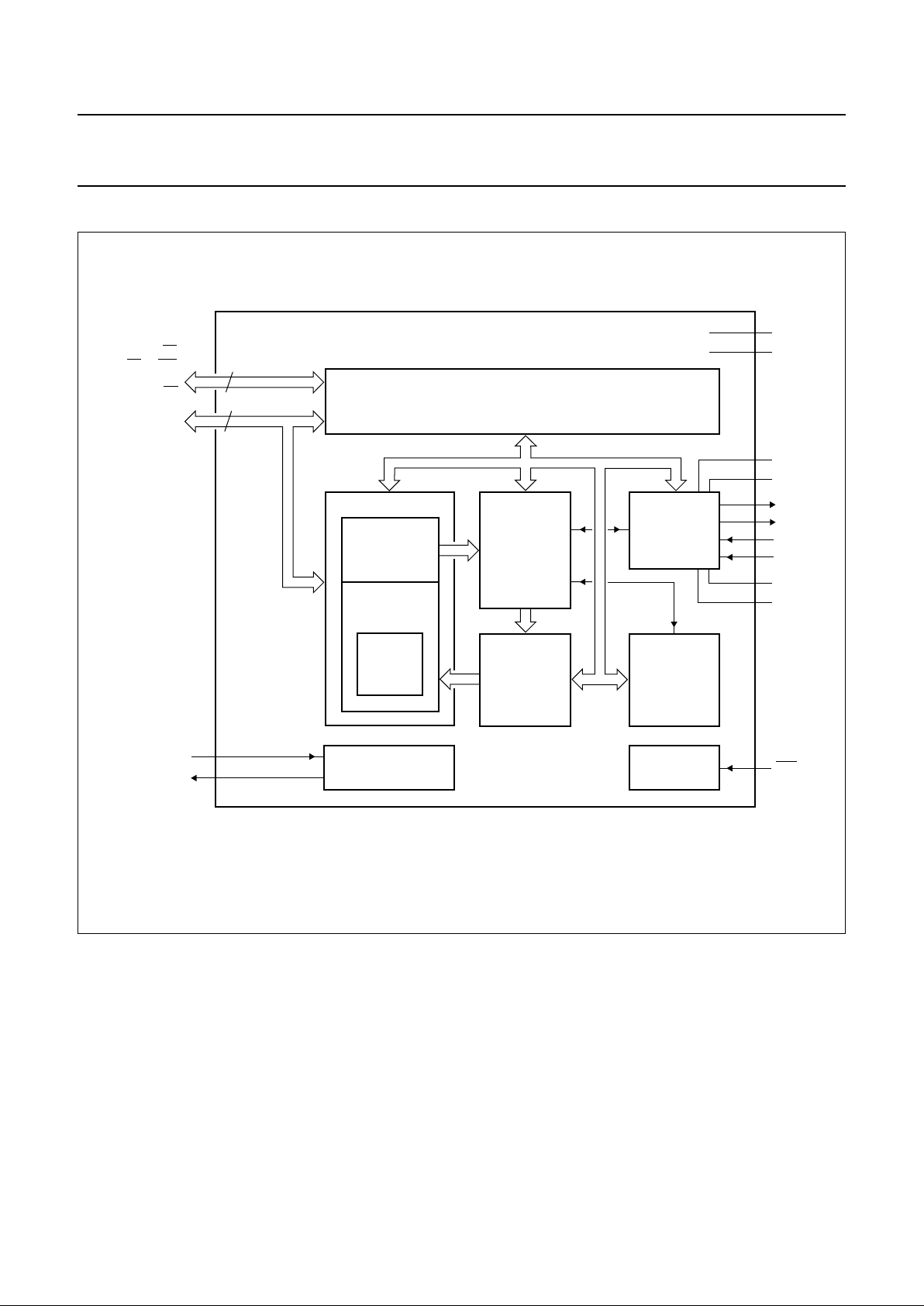

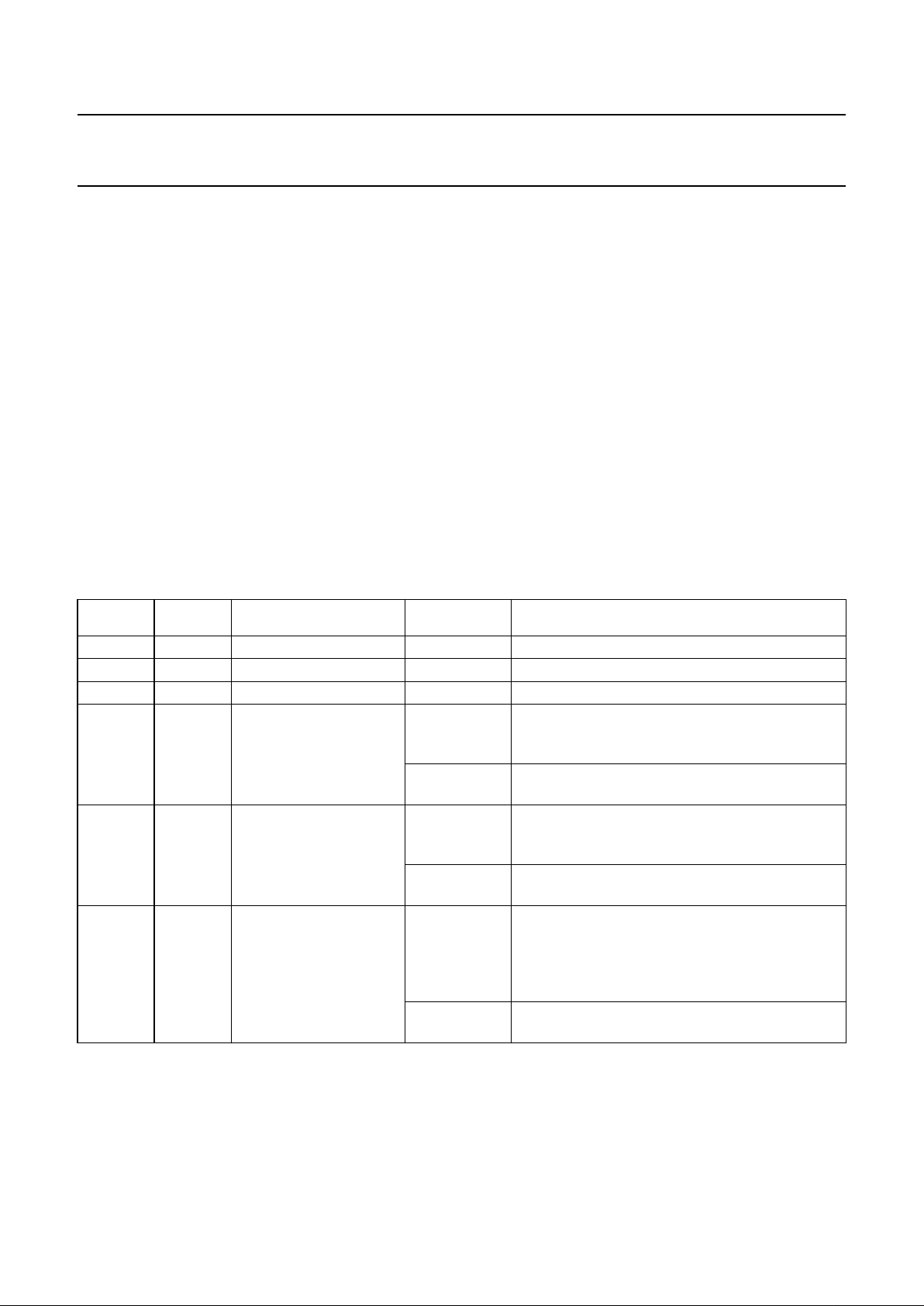

5 PINNING

Note

1. XTAL1 and XTAL2 pins should be connected to V

SS1

via 15 pF capacitors.

SYMBOL PIN DESCRIPTION

AD7 to AD0 2, 1, 28 to 23 multiplexed address/data bus

ALE/AS 3 ALE input signal (Intel mode), AS input signal (Motorola mode)

CS 4 chip select input, LOW level allows access to the SJA1000

RD/E 5 RD signal (Intel mode) or E enable signal (Motorola mode) from the microcontroller

WR 6 WR signal (Intel mode) or RD/WR signal (Motorola mode) from the microcontroller

CLKOUT 7 clock output signal produced by the SJA1000 for the microcontroller; the clock

signal is derived from the built-in oscillator via the programmable divider; the clock

off bit within the clock divider register allows this pin to disable

V

SS1

8 ground for logic circuits

XTAL1 9 input to the oscillator amplifier; external oscillator signal is input via this pin; note 1

XTAL2 10 output from the oscillator amplifier; the output must be left open-circuit when an

external oscillator signal is used; note 1

MODE 11 mode select input

1 = selects Intel mode

0 = selects Motorola mode

V

DD3

12 5 V supply for output driver

TX0 13 output from the CAN output driver 0 to the physical bus line

TX1 14 output from the CAN output driver 1 to the physical bus line

V

SS3

15 ground for output driver

INT 16 interrupt output, used to interrupt the microcontroller; INT is active LOW if any bit of

the internal interrupt register is set; INT is an open-drain output and is designed to

be a wired-OR with other INT outputs within the system; a LOW level on this pin will

reactivate the IC from sleep mode

RST 17 reset input, used to reset the CAN interface (active LOW);automatic power-on reset

can be obtained by connecting RST via a capacitor to VSS and a resistor to V

DD

(e.g. C = 1 µF; R = 50 kΩ)

V

DD2

18 5 V supply for input comparator

RX0, RX1 19, 20 input from the physical CAN-bus line to the input comparator of the SJA1000;

a dominant level will wake up the SJA1000 if sleeping; a dominant level is read, if

RX1 is higher than RX0 and vice versa for the recessive level; if the CBP bit (see

Table 49) is set in the clock divider register, the CAN input comparator is bypassed

to achieve lower internal delays if an external transceiver circuitry is connected to

the SJA1000; in this case only RX0 is active; HIGH is interpreted as recessive level

and LOW is interpreted as dominant level

V

SS2

21 ground for input comparator

V

DD1

22 5 V supply for logic circuits

Page 6

2000 Jan 04 6

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

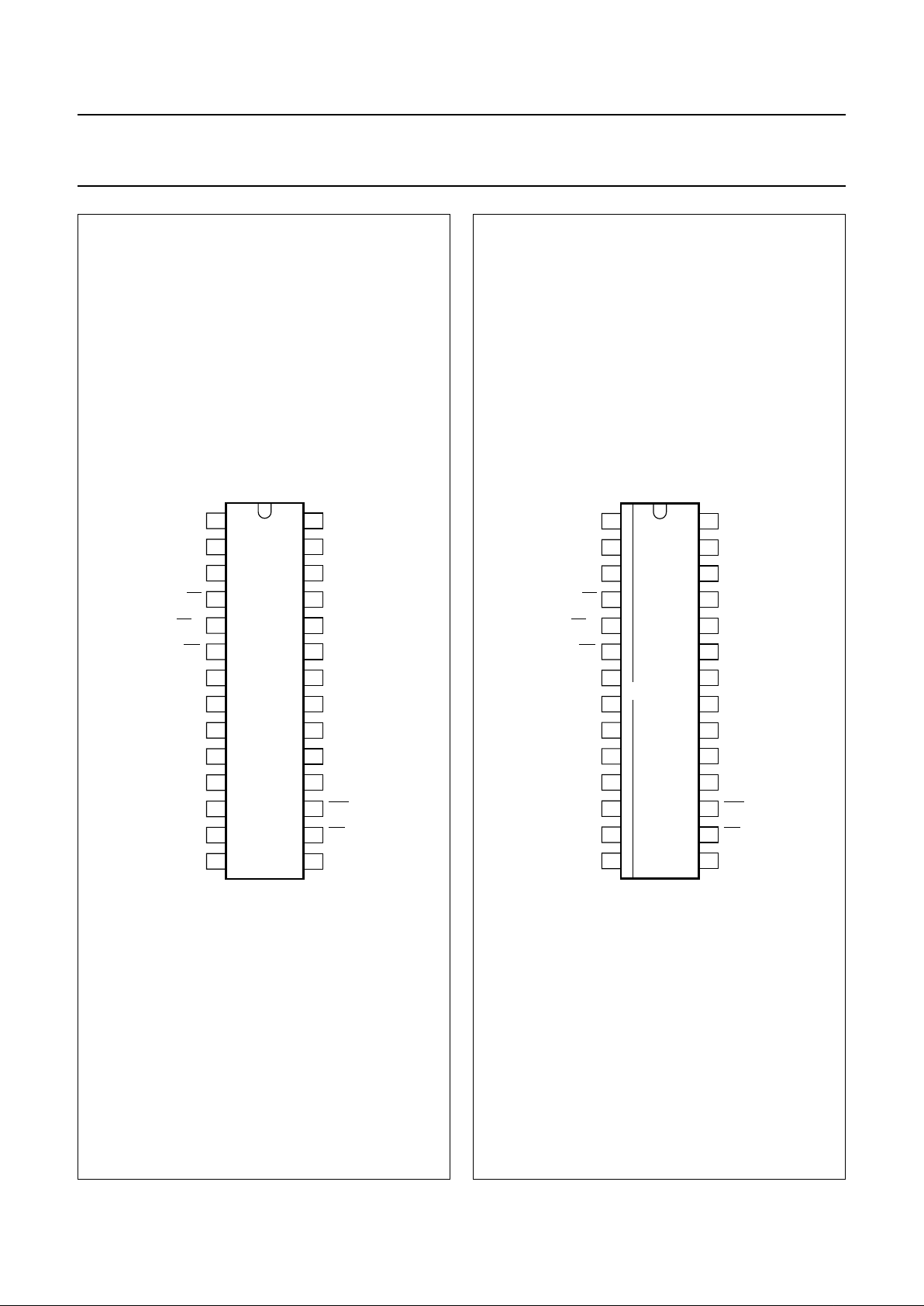

Fig.2 Pin configuration (DIP28).

handbook, halfpage

AD6

AD7

ALE/AS

CLKOUT

V

SS1

XTAL1

XTAL2

MODE

V

DD3

TX0

TX1

AD5

AD4

AD3

AD2

AD0

V

DD1

AD1

V

SS2

RX1

RX0

V

DD2

RST

INT

V

SS3

1

2

3

4

5

6

7

8

9

10

11

12

13

28

27

26

25

24

23

22

21

20

19

18

17

16

1514

SJA1000

MGK616

CS

RD/E

WR

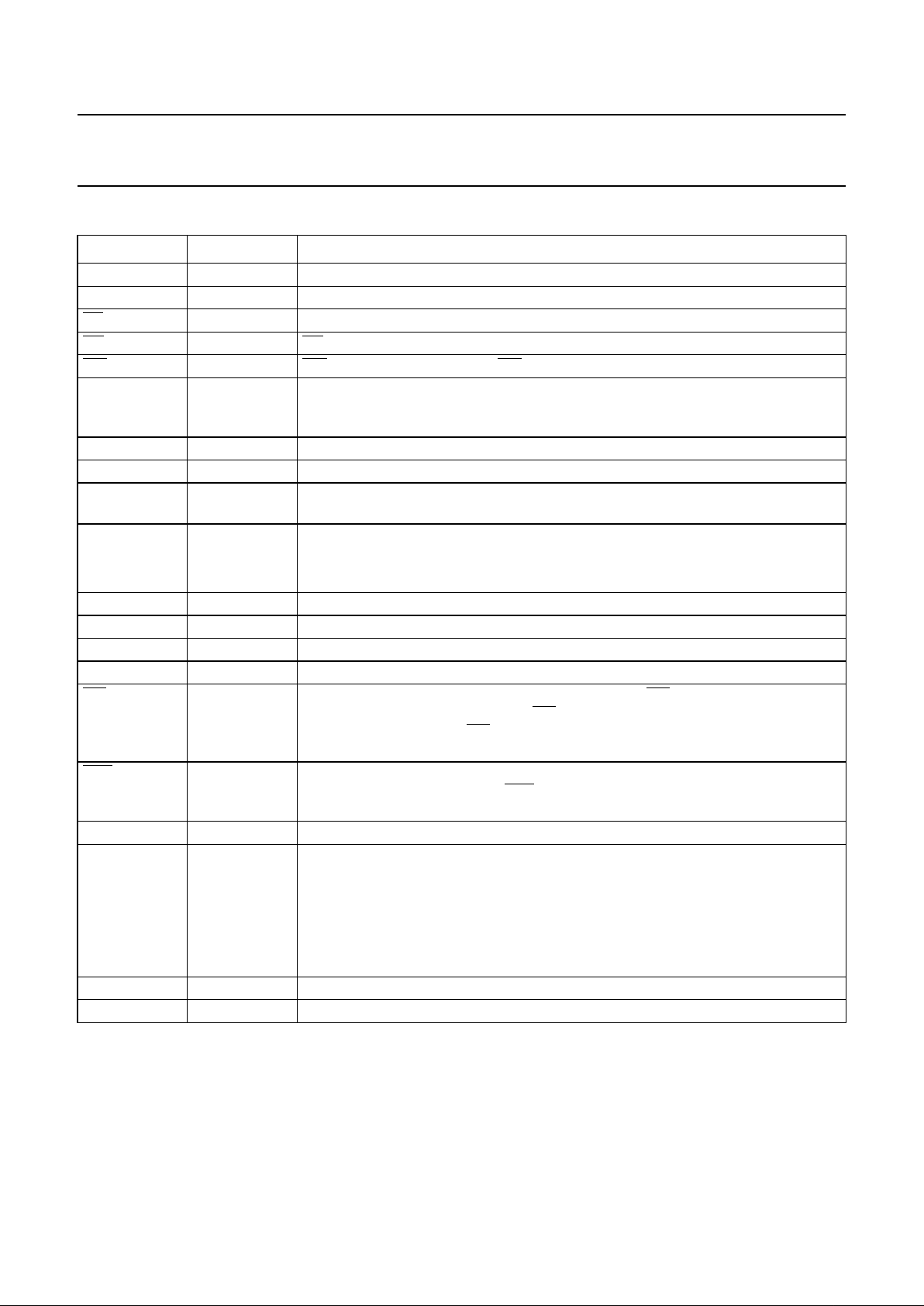

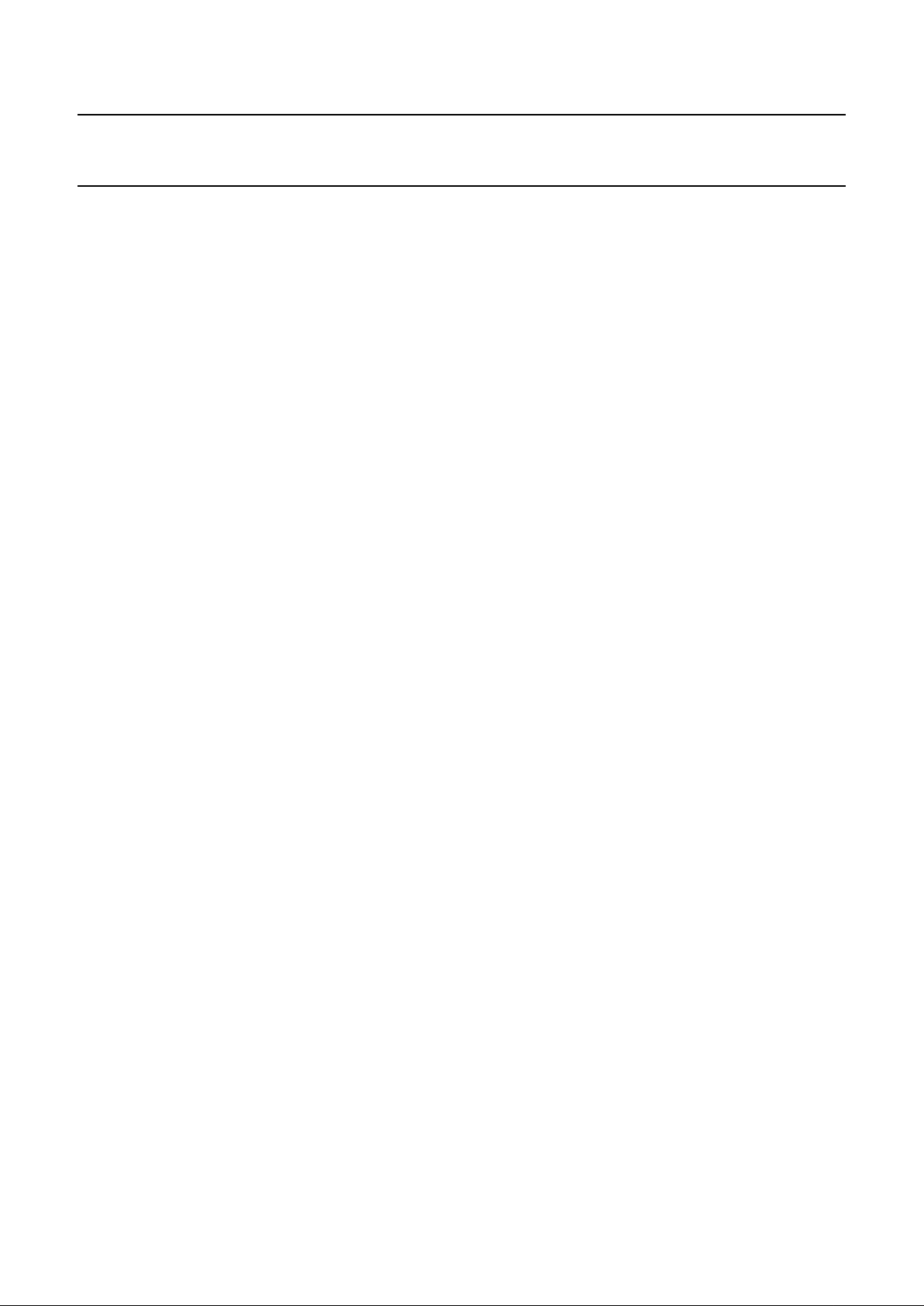

Fig.3 Pin configuration (SO28).

handbook, halfpage

AD6

AD7

ALE/AS

CLKOUT

V

SS1

XTAL1

XTAL2

MODE

V

DD3

TX0

TX1

AD5

AD4

AD3

AD2

AD0

V

DD1

AD1

V

SS2

RX1

RX0

V

DD2

RST

INT

V

SS3

1

2

3

4

5

6

7

8

9

10

11

12

13

28

27

26

25

24

23

22

21

20

19

18

17

16

1514

SJA1000T

MGK617

CS

RD/E

WR

Page 7

2000 Jan 04 7

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6 FUNCTIONAL DESCRIPTION

6.1 Description of the CAN controller blocks

6.1.1 INTERFACE MANAGEMENT LOGIC (IML)

The interface management logic interprets commands

from the CPU, controls addressing of the CAN registers

and provides interrupts and status information to the host

microcontroller.

6.1.2 TRANSMIT BUFFER (TXB)

The transmit buffer is an interface between the CPU and

the Bit Stream Processor (BSP) that is able to store a

complete message for transmission over the CAN

network. The buffer is 13 bytes long, written to by the CPU

and read out by the BSP.

6.1.3 RECEIVE BUFFER (RXB, RXFIFO)

The receive buffer is an interface between the acceptance

filter and the CPU that stores the received and accepted

messages from the CAN-bus line. The Receive Buffer

(RXB)representsaCPU-accessible13-bytewindowof the

Receive FIFO (RXFIFO), which has a total length of

64 bytes.

With the help of this FIFO the CPU is able to process one

message while other messages are being received.

6.1.4 ACCEPTANCE FILTER (ACF)

Theacceptance filter compares the receivedidentifierwith

the acceptance filter register contents and decides

whether this message should be accepted or not. In the

eventofapositiveacceptancetest, the complete message

is stored in the RXFIFO.

6.1.5 BIT STREAM PROCESSOR (BSP)

Thebitstreamprocessorisasequencerwhichcontrols the

data stream between the transmit buffer, RXFIFO and the

CAN-bus. It also performs the error detection, arbitration,

stuffing and error handling on the CAN-bus.

6.1.6 BIT TIMING LOGIC (BTL)

The bit timing logic monitors the serial CAN-bus line and

handlesthe bus line-related bit timing. It issynchronized to

the bit stream on the CAN-bus on a

‘recessive-to-dominant’bus line transition at the beginning

of a message (hard synchronization) and re-synchronized

on further transitions during the reception of a message

(soft synchronization). The BTL also provides

programmable time segments to compensate for the

propagation delay times and phase shifts (e.g. due to

oscillator drifts) and to define the sample point and the

number of samples to be taken within a bit time.

6.1.7 ERROR MANAGEMENT LOGIC (EML)

The EML is responsible for the error confinement of the

transfer-layer modules. It receives error announcements

from the BSP and then informs the BSP and IML about

error statistics.

6.2 Detailed description of the CAN controller

The SJA1000 is designed to be software and

pin-compatible to its predecessor, the PCA82C200

stand-alone CAN controller. Additionally, a lot of new

functions are implemented. To achieve the software

compatibility, two different modes of operation are

implemented:

• BasicCAN mode; PCA82C200 compatible

• PeliCAN mode; extended features.

The mode of operation is selected with the CAN-mode bit

located within the clock divider register. Default mode

upon reset is the BasicCAN mode.

6.2.1 PCA82C200 COMPATIBILITY

In BasicCAN mode the SJA1000 emulates all known

registers from the PCA82C200 stand-alone CAN

controller. The characteristics, as described in Sections

6.2.1.1 to 6.2.1.4 are different from the PCA82C200

design with respect to software compatibility.

6.2.1.1 Synchronization mode

The SYNC bit in the control register is removed (CR.6 in

the PCA82C200). Synchronization is only possible by a

recessive-to-dominant transition on the CAN-bus. Writing

tothis bit has no effect. Toachieve compatibility to existing

application software, a read access to this bit will reflect

the previously written value (flip-flop without effect).

6.2.1.2 Clock divider register

The clock divider register is used to select the CAN mode

of operation (BasicCAN/PeliCAN). Therefore one of the

reserved bits within the PCA82C200 is used. Writing a

value between 0 and 7, as allowed for the PCA82C200,

will enter the BasicCAN mode. The default state is divide

by 12 for Motorola mode and divide by 2 for Intel mode.

An additionalfunctionis implemented within another of the

reserved bits. Setting of bit CBP (see Table 49) enables

the internal RX input comparator to be bypassed thereby

reducing the internal delays if an external transceiver

circuit is used.

Page 8

2000 Jan 04 8

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.2.1.3 Receive buffer

The dual receive buffer concept of the PCA82C200 is

replaced by the receive FIFO from the PeliCAN controller.

Thishasnoeffecttotheapplication software except for the

data overrun probability. Now more than two messages

may be received (up to 64 bytes) until a data overrun

occurs.

6.2.1.4 CAN 2.0B

The SJA1000 is designed to support the full CAN 2.0B

protocol specification, which means that the extended

oscillator tolerance is implemented as well as the

processing of extended frame messages. In BasicCAN

mode it is possible to transmit and receive standard frame

messages only (11-bit identifier). If extended frame

messages (29-bit identifier) are detected on the CAN-bus,

they are tolerated and an acknowledge is given if the

message was correct, but there is no receive interrupt

generated.

6.2.2 DIFFERENCES BETWEEN BASICCAN AND PELICAN

MODE

In the PeliCAN mode the SJA1000 appears with a

re-organized register mapping with a lot of new features.

All known bits from the PCA82C200 design are available

as well as several new ones. In the PeliCAN mode the

complete CAN 2.0B functionality is supported (29-bit

identifier).

Main new features of the SJA1000 are:

• Reception and transmission of standard and extended

frame format messages

• Receive FIFO (64-byte)

• Single/dual acceptance filter with mask and code

register for standard and extended frame

• Error counters with read/write access

• Programmable error warning limit

• Last error code register

• Error interrupt for each CAN-bus error

• Arbitration lost interrupt with detailed bit position

• Single-shot transmission (no re-transmission on error or

arbitration lost)

• Listen only mode (monitoring of the CAN-bus, no

acknowledge, no error flags)

• Hot plugging supported (disturbance-free software

driven bit rate detection)

• Disable CLKOUT by hardware.

6.3 BasicCAN mode

6.3.1 BASICCAN ADDRESS LAYOUT

The SJA1000 appears to a microcontroller as a

memory-mapped I/O device. An independent operation of

both devices is guaranteed by a RAM-like implementation

of the on-chip registers.

The address area of the SJA1000 consists of the control

segment and the message buffers. The control segmentis

programmed during an initialization download in order to

configure communication parameters (e.g. bit timing).

Communication over the CAN-bus is also controlled via

this segment by the microcontroller. During initialization

the CLKOUT signal may be programmed to a value

determined by the microcontroller.

A message, which should be transmitted, has tobe written

to the transmit buffer. After a successful reception the

microcontroller may read the received message from the

receive buffer and then release it for further use.

The exchange of status, control and command signals

between the microcontroller and the SJA1000 is

performed in the control segment. The layout of this

segment is shown in Table 3. After an initial download, the

contents of the registers acceptance code, acceptance

mask, bus timing registers 0 and 1 and output control

should not be changed. Therefore these registers may

only be accessed when the reset request bit in the control

register is set HIGH.

For register access, two different modes have to be

distinguished:

• Reset mode

• Operating mode.

The reset mode (see Table 3, control register, bit Reset

Request) is entered automatically after a hardware reset

or when the controller enters the bus-off state (see

Table 5, status register, bit Bus Status). The operating

modeisactivatedby resetting of the reset request bit in the

control register.

Page 9

2000 Jan 04 9

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

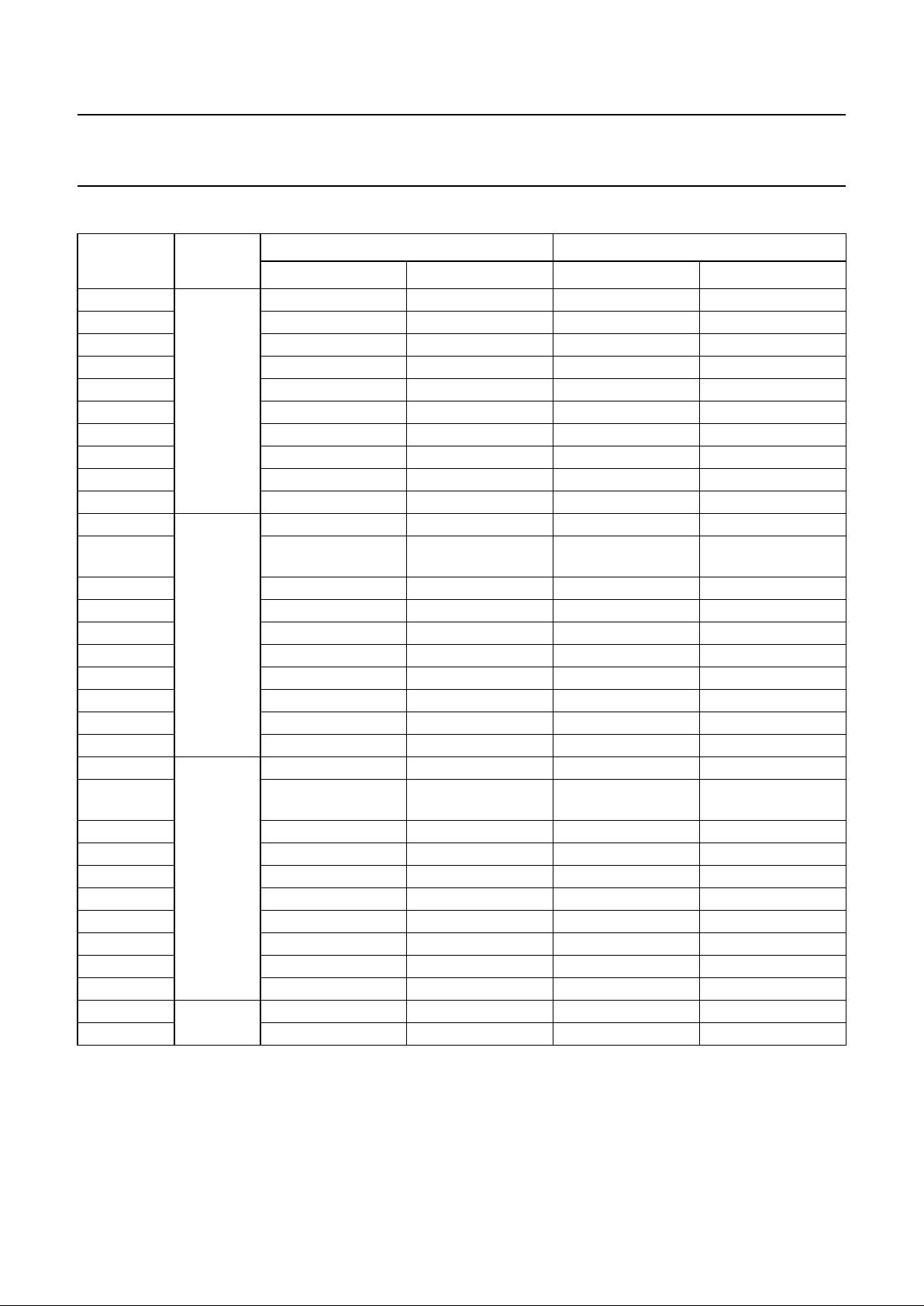

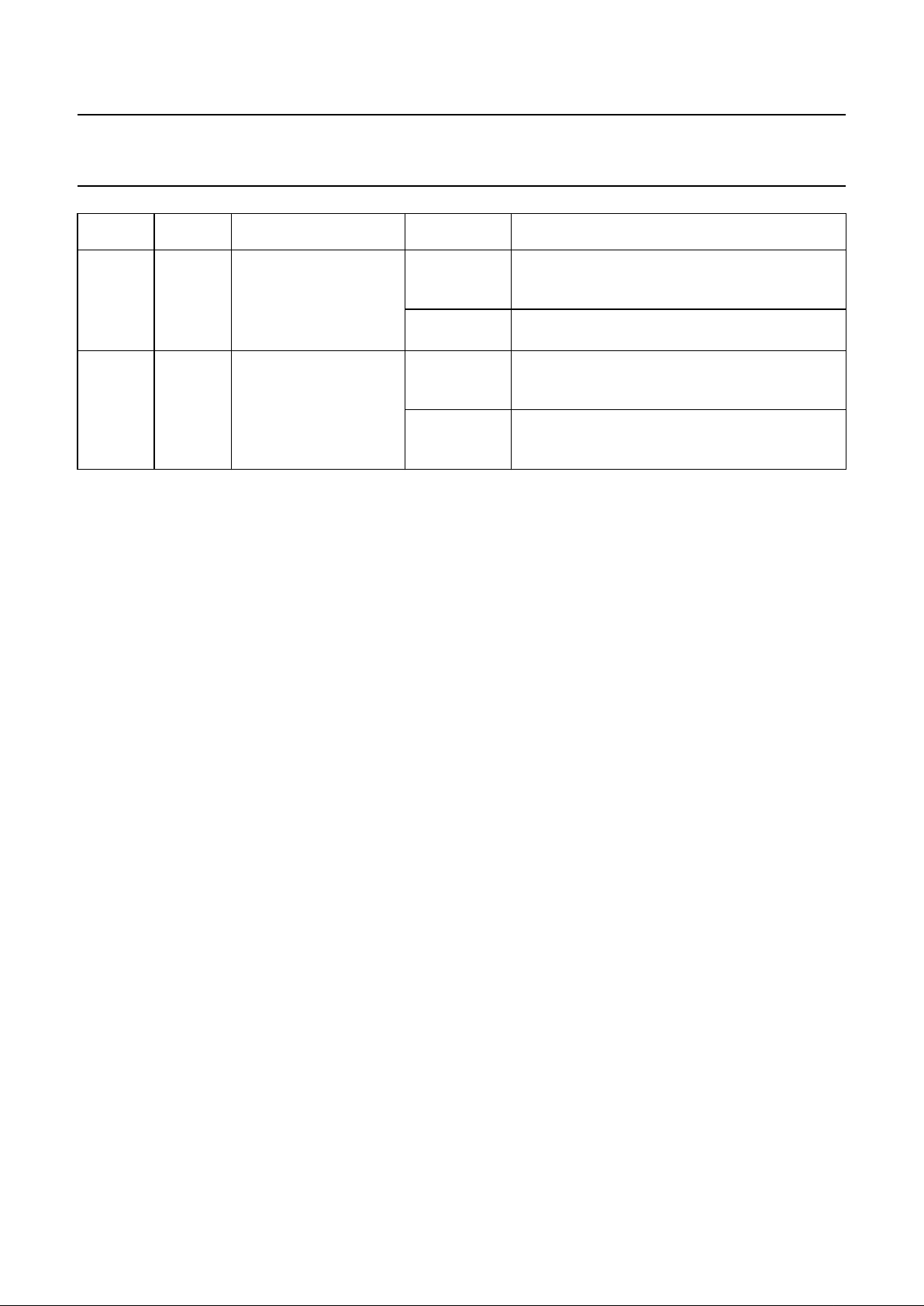

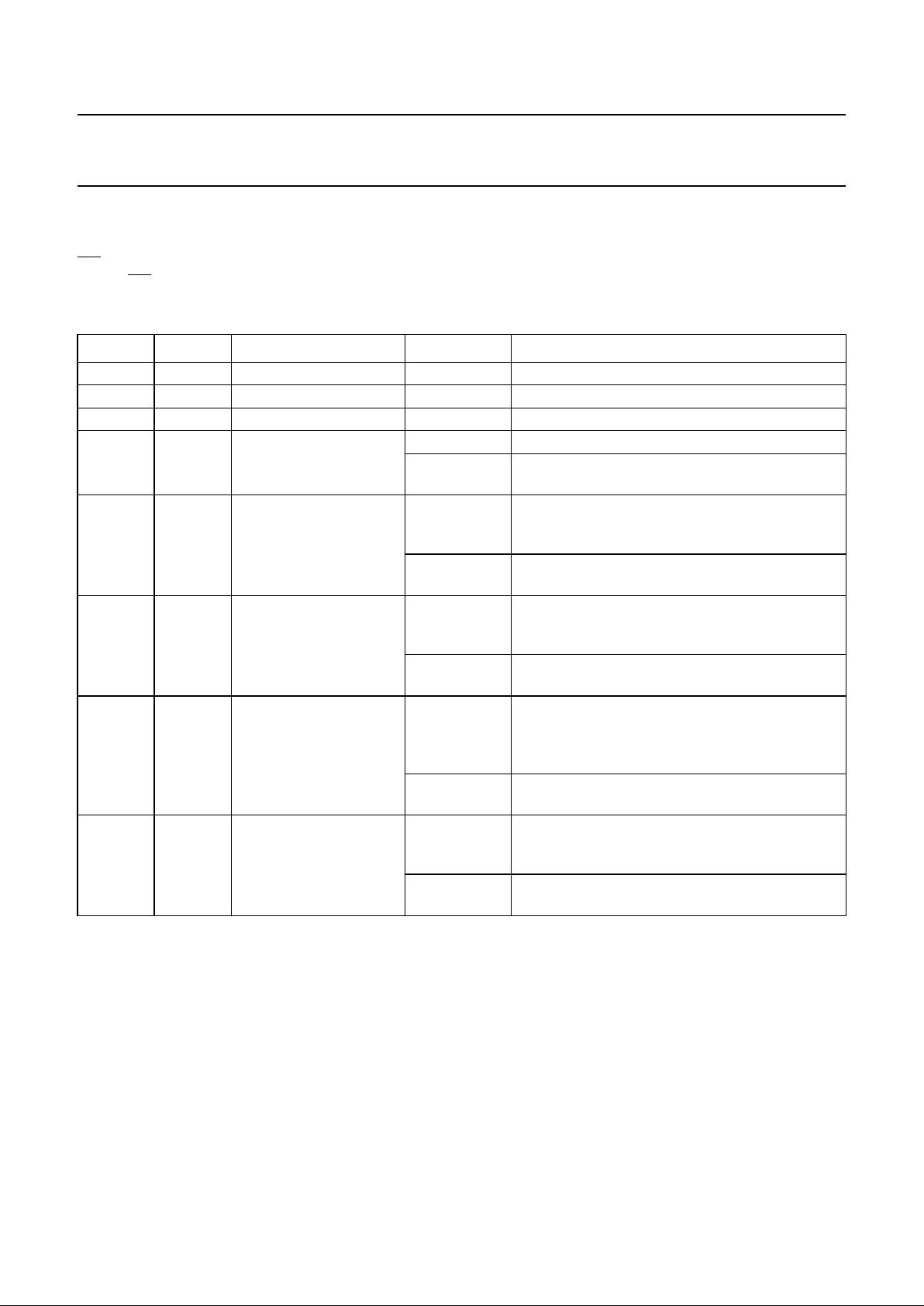

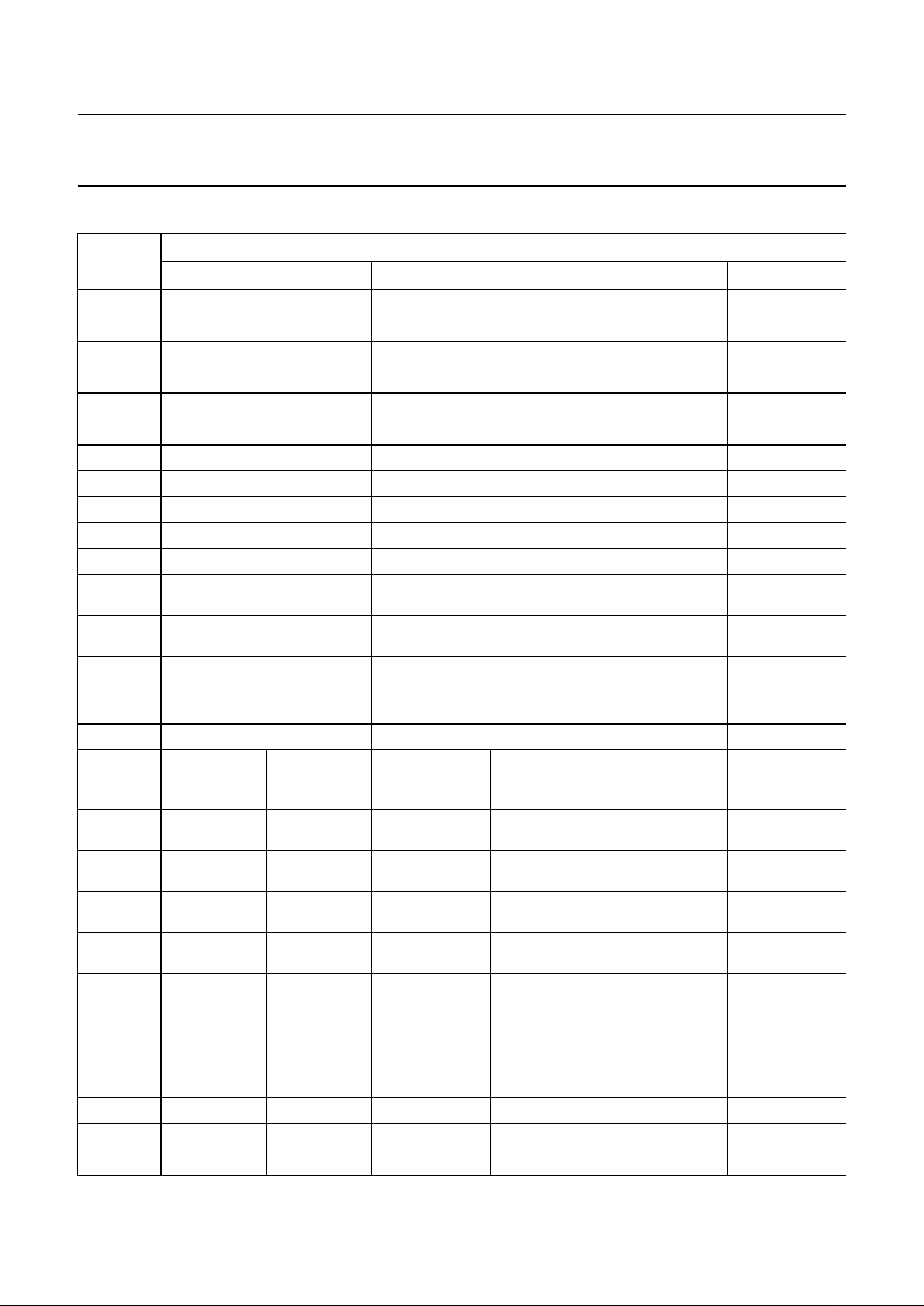

Table 1 BasicCAN address allocation; note 1

Notes

1. It should be noted that the registers are repeated within higher CAN address areas (the most significant bits of the

8-bit CPU address are not decoded: CAN address 32 continues with CAN address 0 and so on).

2. Test register is used for production testing only. Using this register during normal operation may result in undesired

behaviour of the device.

3. Some bits are writeable in reset mode only (CAN mode and CBP).

CAN

ADDRESS

SEGMENT

OPERATING MODE RESET MODE

READ WRITE READ WRITE

0 control control control control control

1 (FFH) command (FFH) command

2 status − status −

3 interrupt − interrupt −

4 (FFH) − acceptance code acceptance code

5 (FFH) − acceptance mask acceptance mask

6 (FFH) − bus timing 0 bus timing 0

7 (FFH) − bus timing 1 bus timing 1

8 (FFH) − output control output control

9 test test; note 2 test test; note 2

10 transmit

buffer

identifier (10 to 3) identifier (10 to 3) (FFH) −

11 identifier (2 to 0),

RTR and DLC

identifier (2 to 0),

RTR and DLC

(FFH) −

12 data byte 1 data byte 1 (FFH) −

13 data byte 2 data byte 2 (FFH) −

14 data byte 3 data byte 3 (FFH) −

15 data byte 4 data byte 4 (FFH) −

16 data byte 5 data byte 5 (FFH) −

17 data byte 6 data byte 6 (FFH) −

18 data byte 7 data byte 7 (FFH) −

19 data byte 8 data byte 8 (FFH) −

20 receive

buffer

identifier (10 to 3) identifier (10 to 3) identifier (10 to 3) identifier (10 to 3)

21 identifier (2 to 0),

RTR and DLC

identifier (2 to 0),

RTR and DLC

identifier (2 to 0),

RTR and DLC

identifier (2 to 0),

RTR and DLC

22 data byte 1 data byte 1 data byte 1 data byte 1

23 data byte 2 data byte 2 data byte 2 data byte 2

24 data byte 3 data byte 3 data byte 3 data byte 3

25 data byte 4 data byte 4 data byte 4 data byte 4

26 data byte 5 data byte 5 data byte 5 data byte 5

27 data byte 6 data byte 6 data byte 6 data byte 6

28 data byte 7 data byte 7 data byte 7 data byte 7

29 data byte 8 data byte 8 data byte 8 data byte 8

30 (FFH) − (FFH) −

31 clock divider clock divider; note 3 clock divider clock divider

Page 10

2000 Jan 04 10

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.3.2 RESET VALUES

Detection of a ‘reset request’ results in aborting the current transmission/reception of a message and entering the reset

mode. On the ‘1-to-0’ transition of the reset request bit, the CAN controller returns to the operating mode.

Table 2 Reset mode configuration; notes 1 and 2

REGISTER BIT SYMBOL NAME

VALUE

RESET BY

HARDWARE

SETTING

BIT CR.0 BY

SOFTWAREOR

DUE TO

BUS-OFF

Control CR.7 − reserved 0 0

CR.6 − reserved X X

CR.5 − reserved 1 1

CR.4 OIE Overrun Interrupt Enable X X

CR.3 EIE Error Interrupt Enable X X

CR.2 TIE Transmit Interrupt Enable X X

CR.1 RIE Receive Interrupt Enable X X

CR.0 RR Reset Request 1 (reset mode) 1 (reset mode)

Command CMR.7 − reserved note 3 note 3

CMR.6 − reserved

CMR.5 − reserved

CMR.4 GTS Go To Sleep

CMR.3 CDO Clear Data Overrun

CMR.2 RRB Release Receive Buffer

CMR.1 AT Abort Transmission

CMR.0 TR Transmission Request

Status SR.7 BS Bus Status 0 (bus-on) X

SR.6 ES Error Status 0 (ok) X

SR.5 TS Transmit Status 0 (idle) 0 (idle)

SR.4 RS Receive Status 0 (idle) 0 (idle)

SR.3 TCS Transmission Complete Status 1 (complete) X

SR.2 TBS Transmit Buffer Status 1 (released) 1 (released)

SR.1 DOS Data Overrun Status 0 (absent) 0 (absent)

SR.0 RBS Receive Buffer Status 0 (empty) 0 (empty)

Interrupt IR.7 − reserved 1 1

IR.6 − reserved 1 1

IR.5 − reserved 1 1

IR.4 WUI Wake-Up Interrupt 0 (reset) 0 (reset)

IR.3 DOI Data Overrun Interrupt 0 (reset) 0 (reset)

IR.2 EI Error Interrupt 0 (reset) X; note 4

IR.1 TI Transmit Interrupt 0 (reset) 0 (reset)

IR.0 RI Receive Interrupt 0 (reset) 0 (reset)

Page 11

2000 Jan 04 11

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Acceptance code AC.7 to 0 AC Acceptance Code X X

Acceptance mask AM.7 to 0 AM Acceptance Mask X X

Bus timing 0 BTR0.7 SJW.1 Synchronization Jump Width 1 X X

BTR0.6 SJW.0 Synchronization Jump Width 0 X X

BTR0.5 BRP.5 Baud Rate Prescaler 5 X X

BTR0.4 BRP.4 Baud Rate Prescaler 4 X X

BTR0.3 BRP.3 Baud Rate Prescaler 3 X X

BTR0.2 BRP.2 Baud Rate Prescaler 2 X X

BTR0.1 BRP.1 Baud Rate Prescaler 1 X X

BTR0.0 BRP.0 Baud Rate Prescaler 0 X X

Bus timing 1 BTR1.7 SAM Sampling X X

BTR1.6 TSEG2.2 Time Segment 2.2 X X

BTR1.5 TSEG2.1 Time Segment 2.1 X X

BTR1.4 TSEG2.0 Time Segment 2.0 X X

BTR1.3 TSEG1.3 Time Segment 1.3 X X

BTR1.2 TSEG1.2 Time Segment 1.2 X X

BTR1.1 TSEG1.1 Time Segment 1.1 X X

BTR1.0 TSEG1.0 Time Segment 1.0 X X

Output control OC.7 OCTP1 Output Control Transistor P1 X X

OC.6 OCTN1 Output Control Transistor N1 X X

OC.5 OCPOL1 Output Control Polarity 1 X X

OC.4 OCTP0 Output Control Transistor P0 X X

OC.3 OCTN0 Output Control Transistor N0 X X

OC.2 OCPOL0 Output Control Polarity 0 X X

OC.1 OCMODE1 Output Control Mode 1 X X

OC.0 OCMODE0 Output Control Mode 0 X X

Transmit buffer − TXB Transmit Buffer X X

Receive buffer − RXB Receive Buffer X; note 5 X; note 5

Clock divider − CDR Clock Divider Register 00000000

(Intel);

00000101

(Motorola)

X

REGISTER BIT SYMBOL NAME

VALUE

RESET BY

HARDWARE

SETTING

BIT CR.0 BY

SOFTWAREOR

DUE TO

BUS-OFF

Page 12

2000 Jan 04 12

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. X means that the value of these registers or bits is not influenced.

2. Remarks in brackets explain functional meaning.

3. Reading the command register will always reflect a binary ‘11111111’.

4. On bus-off the error interrupt is set, if enabled.

5. Internal read/write pointers of the RXFIFO are reset to their initial values. A subsequent read access to the RXB

would show undefined data values (parts of old messages). If a message is transmitted, this message is written in

parallel to the receive buffer but no receive interrupt is generated and the receive buffer area is not locked. So, even

if the receive buffer is empty, the last transmitted message may be read from the receive buffer until it is overridden

by the next received or transmitted message.

Upon a hardware reset, the RXFIFO pointers are reset to the physical RAM address ‘0’. Setting CR.0 by software or

due to the bus-off event will reset the RXFIFO pointers to the currently valid FIFO start address which is different

from the RAM address ‘0’ after the first release receive buffer command.

6.3.3 CONTROL REGISTER (CR)

The contents of the control register are used to change the behaviour of the CAN controller. Bits may be set or reset by

the attached microcontroller which uses the control register as a read/write memory.

Table 3 Bit interpretation of the control register (CR); CAN address 0

BIT SYMBOL NAME VALUE FUNCTION

CR.7 −− −reserved; note 1

CR.6 −− −reserved; note 2

CR.5 −− −reserved; note 3

CR.4 OIE Overrun Interrupt Enable 1 enabled; if the data overrun bit is set, the

microcontroller receives an overrun interrupt

signal (see also status register; Table 5)

0 disabled; the microcontroller receives no overrun

interrupt signal from the SJA1000

CR.3 EIE Error Interrupt Enable 1 enabled; if the error or bus status change, the

microcontroller receives an error interrupt signal

(see also status register; Table 5)

0 disabled; the microcontroller receives no error

interrupt signal from the SJA1000

CR.2 TIE Transmit Interrupt Enable 1 enabled; when a message has been successfully

transmitted or the transmit buffer is accessible

again, (e.g. after an abort transmission command)

the SJA1000 transmits a transmit interrupt signal

to the microcontroller

0 disabled; the microcontroller receives no transmit

interrupt signal from the SJA1000

Page 13

2000 Jan 04 13

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. Any write access to the control register has to set this bit to logic 0 (reset value is logic 0).

2. In the PCA82C200 this bit was used to select the synchronization mode. Because this mode is not longer

implemented, setting this bit has no influence on the microcontroller. Due to software compatibility setting this bit is

allowed. This bit will not change after hardware or software reset. In addition the value written by users software is

reflected.

3. Reading this bit will always reflect a logic 1.

4. During a hardware reset or when the bus status bit is set to logic 1 (bus-off), the reset request bit is set to logic 1

(present). If this bit is accessed by software, a value change will become visible and takes effect first with the next

positiveedge of the internal clock whichoperateswith1⁄2ofthe external oscillator frequency. During anexternalreset

the microcontroller cannot set the reset request bit to logic 0 (absent). Therefore, after having set the reset request

bit to logic 0, the microcontroller must check this bit to ensure that the external reset pin is not being held LOW.

Changes of the reset request bit are synchronized with the internal divided clock. Reading the reset request bit

reflects the synchronized status.

After the reset request bit is set to logic 0 the SJA1000 will wait for:

a) One occurrence of bus-free signal (11 recessive bits), if the preceding reset request has been caused by a

hardware reset or a CPU-initiated reset

b) 128 occurrencesof bus-free, if the preceding resetrequesthas been caused by a CAN controllerinitiated bus-off,

before re-entering the bus-on mode; it should be noted that several registers are modified if the reset request bit

was set (see also Table 2).

6.3.4 COMMAND REGISTER (CMR)

A command bit initiates an action within the transfer layer of the SJA1000. The command register appears to the

microcontroller as a write only memory. If a read access is performed to this address the byte ‘11111111’ is returned.

Between two commands at least one internal clock cycle is needed to process. The internal clock is divided by two from

the external oscillator frequency.

CR.1 RIE Receive Interrupt Enable 1 enabled; when a message has been received

without errors, the SJA1000 transmits a receive

interrupt signal to the microcontroller

0 disabled; the microcontroller receives no transmit

interrupt signal from the SJA1000

CR.0 RR Reset Request; note 4 1 present; detection of a reset request results in

aborting the current transmission/reception of a

message and entering the reset mode

0 absent; on the ‘1-to-0’ transition of the reset

request bit, the SJA1000 returns to the operating

mode

BIT SYMBOL NAME VALUE FUNCTION

Page 14

2000 Jan 04 14

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Table 4 Bit interpretation of the command register (CMR); CAN address 1

Notes

1. The SJA1000 will enter sleep mode if the sleep bit is set to logic 1 (sleep); there is no bus activity and no interrupt is

pending. Setting of GTS with at least one of the previously mentioned exceptions valid will result in a wake-up

interrupt. After sleep mode is set, the CLKOUT signal continues until at least 15 bit times have passed, to allow a

host microcontroller clocked via this signal to enter its own standby mode before the CLKOUT goes LOW.

The SJA1000 will wake up when one of the three previously mentioned conditions is negated: after ‘Go To Sleep’ is

set LOW (wake-up), there is bus activity or

INT is driven LOW (active). On wake-up, the oscillator is started and a

wake-up interrupt is generated. A sleeping SJA1000 which wakes up due to bus activity will not be able to receive

thismessageuntilit detects 11 consecutive recessive bits (bus-free sequence). It should be noted thatsettingofGTS

isnotpossiblein reset mode. After clearing of reset request, setting ofGTSispossiblefirst, when bus-free is detected

again.

2. This command bit is used to clear the data overrun condition indicated by the data overrun status bit. As long as the

data overrun status bit is set no further data overrun interrupt is generated. It is allowed to give the clear data overrun

command at the same time as a release receive buffer command.

3. After reading the contents of the receive buffer, the microcontroller can release this memory space of the RXFIFO

by setting the release receive buffer bit to logic 1. This may result in another message becoming immediately

available within the receive buffer. This event will force another receive interrupt, if enabled. If there is no other

message available no further receive interrupt is generated and the receive buffer status bit is cleared.

4. The abort transmission bit is used when the CPU requires the suspension of the previously requested transmission,

e.g. to transmit a more urgent message before. A transmission already in progress is not stopped. In order to see if

the original message had been either transmitted successfully or aborted, the transmission complete status bit

should be checked. This should be done after the transmit buffer status bit has been set to logic 1 (released) or a

transmit interrupt has been generated.

5. If the transmission request was set to logic 1 in a previous command, it cannot be cancelled by setting the

transmission request bit to logic 0. The requested transmission may be cancelled by setting the abort transmission

bit to logic 1.

BIT SYMBOL NAME VALUE FUNCTION

CMR.7 −− −reserved

CMR.6 −− −reserved

CMR.5 −− −reserved

CMR.4 GTS Go To Sleep; note 1 1 sleep; the SJA1000 enters sleep mode if no CAN

interrupt is pending and there is no bus activity

0 wake up; SJA1000 operates normal

CMR.3 CDO Clear Data Overrun;

note 2

1 clear; data overrun status bit is cleared

0 no action

CMR.2 RRB Release Receive Buffer;

note 3

1 released; the receive buffer, representing the

message memory space in the RXFIFO is

released

0 no action

CMR.1 AT Abort Transmission;

note 4

1 present; if not already in progress, a pending

transmission request is cancelled

0 absent; no action

CMR.0 TR Transmission Request;

note 5

1 present; a message will be transmitted

0 absent; no action

Page 15

2000 Jan 04 15

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.3.5 STATUS REGISTER (SR)

The content of the status register reflects the status of the SJA1000. The status register appears to the microcontroller

as a read only memory.

Table 5 Bit interpretation of the status register (SR); CAN address 2

BIT SYMBOL NAME VALUE FUNCTION

SR.7 BS Bus Status; note 1 1 bus-off; the SJA1000 is not involved in bus

activities

0 bus-on; the SJA1000 is involved in bus activities

SR.6 ES Error Status; note 2 1 error; at least one of the error counters has

reached or exceeded the CPU warning limit

0 ok; both error counters are below the warning limit

SR.5 TS Transmit Status; note 3 1 transmit; the SJA1000 is transmitting a message

0 idle; no transmit message is in progress

SR.4 RS Receive Status; note 3 1 receive; the SJA1000 is receiving a message

0 idle; no receive message is in progress

SR.3 TCS Transmission Complete

Status; note 4

1 complete; the last requested transmission has

been successfully completed

0 incomplete; the previouslyrequestedtransmission

is not yet completed

SR.2 TBS Transmit Buffer Status;

note 5

1 released; the CPU may write a message into the

transmit buffer

0 locked; the CPU cannot access the transmit

buffer; a message is waiting for transmission or is

already in process

SR.1 DOS Data Overrun Status;

note 6

1 overrun; a message was lost because there was

not enough space for that message in the RXFIFO

0 absent; no data overrun has occurred since the

last clear data overrun command was given

SR.0 RBS Receive Buffer Status;

note 7

1 full; one or more messages are available in the

RXFIFO

0 empty; no message is available

Page 16

2000 Jan 04 16

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. When the transmit error counter exceeds the limit of 255 [the bus status bit is set to logic 1 (bus-off)] the

CAN controller will set the reset request bit to logic 1 (present) and an error interrupt is generated, if enabled. It will

stay in this mode until the CPU clears the reset request bit. Once this is completed the CAN controller will wait the

minimum protocol-defined time (128 occurrences of the bus-free signal). After that the bus status bit is cleared

(bus-on), the error status bit is set to logic 0 (ok), the error counters are reset and an error interrupt is generated, if

enabled.

2. Errors detected during reception or transmission will affect the error counters according to the CAN 2.0B protocol

specification. The error status bit is set when at least one of the error counters has reached or exceeded the CPU

warning limit of 96. An error interrupt is generated, if enabled.

3. If both the receive status and the transmit status bits are logic 0 (idle) the CAN-bus is idle.

4. The transmission complete status bit is set to logic 0 (incomplete) whenever the transmission request bit is set to

logic 1. The transmission complete status bit will remain at logic 0 (incomplete) until a message is transmitted

successfully.

5. If the CPU tries to write to the transmit buffer when the transmit buffer status bit is at logic 0 (locked), the written byte

will not be accepted and will be lost without being indicated.

6. When a message that shall be received has passed the acceptance filter successfully (i.e. earliest after arbitration

field), the CAN controller needs space in the RXFIFO to store the message descriptor. Accordingly there must be

enough space for each data byte which has been received. If there is not enough space to store the message, that

message will be dropped and the data overrun condition will be indicated to the CPU only, if this received message

has no errors until the last but one bit of end of frame (message becomes valid).

7. After reading a message stored in the RXFIFO and releasing this memory space with the command release receive

buffer, this bit is cleared. If there is another message available within the FIFO this bit is set again with the next bit

quantum (t

scl

).

Page 17

2000 Jan 04 17

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.3.6 INTERRUPT REGISTER (IR)

The interrupt register allows the identification of an interrupt source. When one or more bits of this register are set, the

INT pin is activated (LOW). After this register is read by the microcontroller, all bits are reset what results in a floating

level at INT. The interrupt register appears to the microcontroller as a read only memory.

Table 6 Bit interpretation of the interrupt register (IR); CAN address 3

Notes

1. Reading this bit will always reflect a logic 1.

2. A wake-up interrupt is also generated if the CPU tries to set go to sleep while the CAN controller is involved in bus

activities or a CAN interrupt is pending.

3. The overrun interrupt bit (if enabled) and the data overrun status bit are set at the same time.

4. The receive interrupt bit (if enabled) and the receive buffer status bit are set at the same time.

It should be noted that the receive interrupt bit is cleared upon a read access, even if there is another message

available within the FIFO. The moment the release receive buffer command is given and there is another message

valid within the receive buffer, the receive interrupt is set again (if enabled) with the next t

scl

.

BIT SYMBOL NAME VALUE FUNCTION

IR.7 −− − reserved; note 1

IR.6 −− − reserved; note 1

IR.5 −− − reserved; note 1

IR.4 WUI Wake-Up Interrupt;

note 2

1 set; this bit is set when the sleep mode is left

0 reset; this bit is cleared by any read access of the

microcontroller

IR.3 DOI Data Overrun Interrupt;

note 3

1 set; this bit is set on a ‘0-to-1’ transition of the data

overrun status bit, when the data overrun interrupt

enable is set to logic 1 (enabled)

0 reset; this bit is cleared by any read access of the

microcontroller

IR.2 EI Error Interrupt 1 set; this bit is set on a change of either the error

status or bus status bits if the error interrupt

enable is set to logic 1 (enabled)

0 reset; this bit is cleared by any read access of the

microcontroller

IR.1 TI Transmit Interrupt 1 set; this bit is set whenever the transmit buffer

status changes from logic 0 to logic 1 (released)

and transmit interrupt enable is set to logic 1

(enabled)

0 reset; this bit is cleared by any read access of the

microcontroller

IR.0 RI Receive Interrupt; note 4 1 set; this bit is set while the receive FIFO is not

empty and the receive interrupt enable bit is set

to logic 1 (enabled)

0 reset; this bit is cleared by any read access of the

microcontroller

Page 18

2000 Jan 04 18

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.3.7 TRANSMIT BUFFER LAYOUT

Theglobal layout of the transmit buffer is showninTable 7. The buffer serves to store amessagefrom the microcontroller

to be transmitted by the SJA1000. It is subdivided into a descriptor and data field. The transmit buffer can be written to

and read out by the microcontroller in operating mode only. In reset mode a ‘FFH’ is reflected for all bytes.

Table 7 Layout of transmit buffer

CAN

ADDRESS

FIELD NAME

BITS

76543210

10 descriptor identifier byte 1 ID.10 ID.9 ID.8 ID.7 ID.6 ID.5 ID.4 ID.3

11 identifier byte 2 ID.2 ID.1 ID.0 RTR DLC.3 DLC.2 DLC.1 DLC.0

12 data TX data 1 transmit data byte 1

13 TX data 2 transmit data byte 2

14 TX data 3 transmit data byte 3

15 TX data 4 transmit data byte 4

16 TX data 5 transmit data byte 5

17 TX data 6 transmit data byte 6

18 TX data 7 transmit data byte 7

19 TX data 8 transmit data byte 8

6.3.7.1 Identifier (ID)

The identifier consists of 11 bits (ID.10 to ID.0). ID.10 is

themostsignificant bit, which is transmitted first on thebus

during the arbitration process. The identifier acts as the

message’s name. It is used in a receiver for acceptance

filtering and also determining the bus access priority

during the arbitration process. The lower the binary value

of the identifier the higher the priority. This is due to a

larger number of leading dominant bits during arbitration.

6.3.7.2 Remote Transmission Request (RTR)

If this bit is set, a remote frame will be transmitted via the

bus.This means that nodata bytes are included withinthis

frame. Nevertheless, it is necessary to specify the correct

data length code which depends on the corresponding

data frame with the same identifier coding.

If the RTR bit is not set, a data frame will be sent including

the number of data bytes as specified by the data length

code.

6.3.7.3 Data Length Code (DLC)

The number of bytes in the data field of a message is

coded by the data length code. At the start of a remote

frame transmission the data length code is not considered

due to the RTR bit being at logic 1 (remote). This forces

the number of transmitted/received data bytes to be

logic 0. Nevertheless, the data length code must be

specified correctly to avoid bus errors if two

CAN controllersstartaremoteframetransmissionwiththe

same identifier simultaneously.

The range of the data byte count is 0 to 8 bytes and is

coded as follows:

DataByteCount = 8 × DLC.3 + 4 × DLC.2 + 2 × DLC.1 +

DLC.0

Forreasons of compatibility no datalengthcode >8 should

be used. If a value >8 is selected, 8 bytes are transmitted

in the data frame with the data length code specified in

DLC.

6.3.7.4 Data field

The number of transferred data bytes is determined by the

data length code. The first bit transmitted is the most

significant bit of data byte 1 at address 12.

6.3.8 RECEIVE BUFFER

The global layout of the receive buffer is very similar to the

transmit buffer described in Section 6.3.7. The receive

buffer is the accessible part of the RXFIFO and is located

in the range between CAN address 20 and 29.

Page 19

2000 Jan 04 19

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

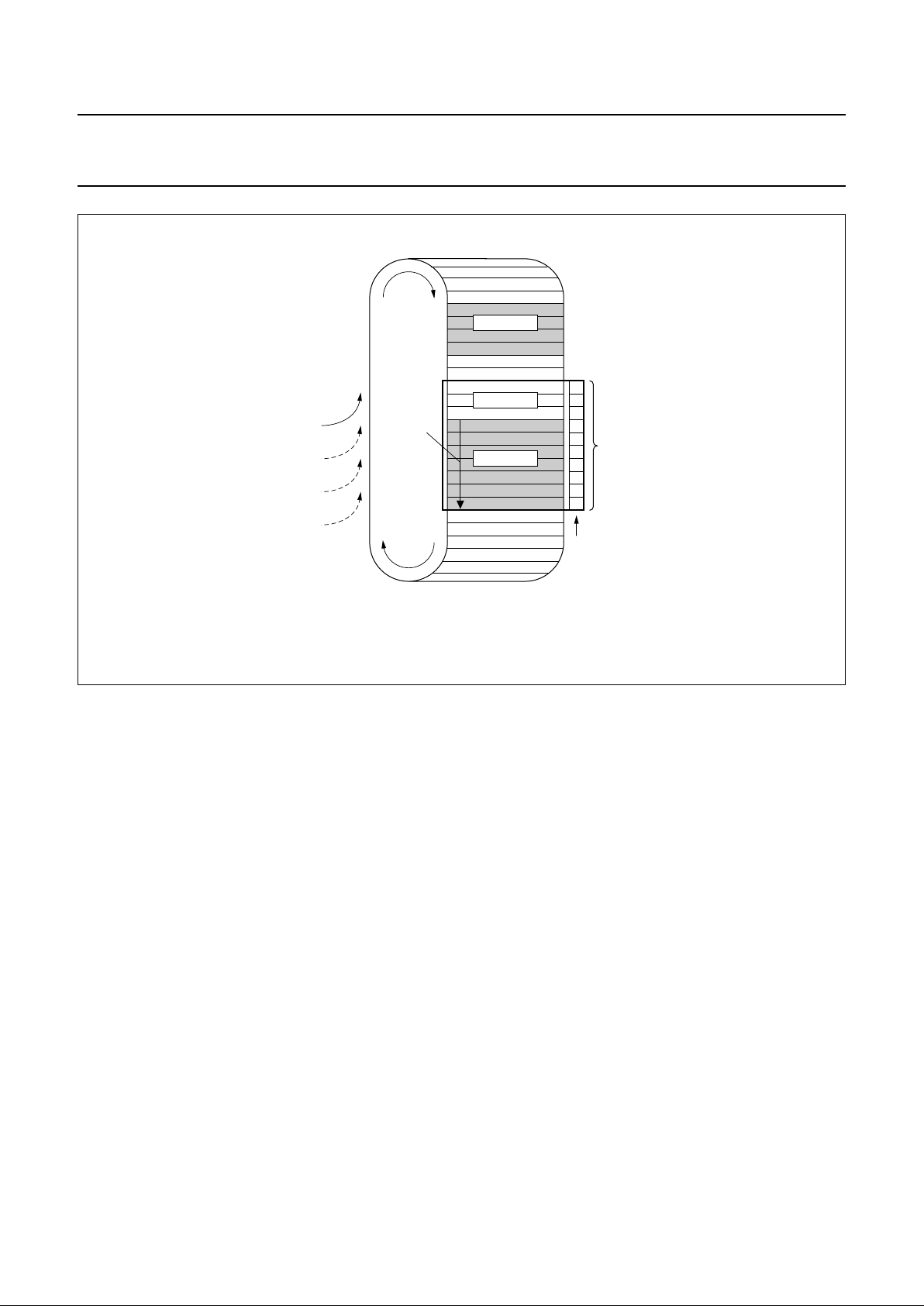

Fig.4 Example of the message storage within the RXFIFO.

Message 1 is now available in the receive buffer.

handbook, full pagewidth

MGK618

release

receive

buffer

command

64-byte

FIFO

incoming

messages

message 3

message 2

message 1

29

28

27

26

25

24

23

22

21

20

receive

buffer

window

CAN address

Identifier, remote transmission request bit and data length

code have the same meaning and location as described in

the transmit buffer but within the address range 20 to 29.

As illustrated in Fig.4 the RXFIFO has space for

64 message bytes in total. The number of messages that

can be stored in the FIFO at any particular moment

depends on the length of the individual messages. If there

is not enough space for a new message within the

RXFIFO, the CAN controller generates a data overrun

condition. A message which is partly written into the

RXFIFO, when the data overrun condition occurs, is

deleted. This situation is indicated to the microcontroller

via the status register and the data overrun interrupt, if

enabled and the frame was received without any errors

until the last but one bit of end of frame (RX message

becomes valid).

6.3.9 ACCEPTANCE FILTER

With the help of the acceptance filter the CAN controller is

abletoallow passing of received messages to the RXFIFO

only when the identifier bits of the received message are

equal to the predefined ones within the acceptance filter

registers. The acceptance filter is defined by the

acceptance code register (ACR; see Section 6.3.9.1) and

the acceptance mask register (AMR; see Section 6.3.9.2).

Page 20

2000 Jan 04 20

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.3.9.1 Acceptance Code Register (ACR)

Table 8 ACR bit allocation; can address 4

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

AC.7 AC.6 AC.5 AC.4 AC.3 AC.2 AC.1 AC.0

This register can be accessed (read/write), if the reset

request bit is set HIGH (present). When a message is

received which passes the acceptance test and there is

receive buffer space left, then the respective descriptor

and data field are sequentially stored in the RXFIFO.

When the complete message has been correctly received

the following occurs:

• The receive status bit is set HIGH (full)

• If the receive interrupt enable bit is set HIGH (enabled),

the receive interrupt is set HIGH (set).

The acceptance code bits (AC.7 to AC.0) and the eight

most significant bits of the message’s identifier

(ID.10 to ID.3) must be equal to those bit positions which

are marked relevant by the acceptance mask bits

(AM.7 to AM.0). If the conditions as described in the

following equation are fulfilled, acceptance is given:

(ID.10 to ID.3) ≡ (AC.7 to AC.0)] ∨ (AM.7 to AM.0)

≡ 11111111

6.3.9.2 Acceptance Mask Register (AMR)

Table 9 AMR bit allocation; CAN address 5

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

AM.7 AM.6 AM.5 AM.4 AM.3 AM.2 AM.1 AM.0

This register can be accessed (read/write), if the reset

request bit is set HIGH (present). The acceptance mask

register qualifies which of the corresponding bits of the

acceptance code are ‘relevant’ (AM.X = 0) or ‘don’t care’

(AM.X = 1) for acceptance filtering.

6.3.9.3 Other registers

The other registers are described in Section 6.5.

6.4 PeliCAN mode

6.4.1 PELICAN ADDRESS LAYOUT

The CAN controller’s internal registers appear to the CPU

as on-chip memory mapped peripheralregisters. Because

the CAN controller can operate in different modes

(operating/reset; see also Section 6.4.3), one has to

distinguish between different internal address definitions.

Starting from CAN address 32 the complete internal RAM

(80-byte) is mapped to the CPU interface.

Page 21

2000 Jan 04 21

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

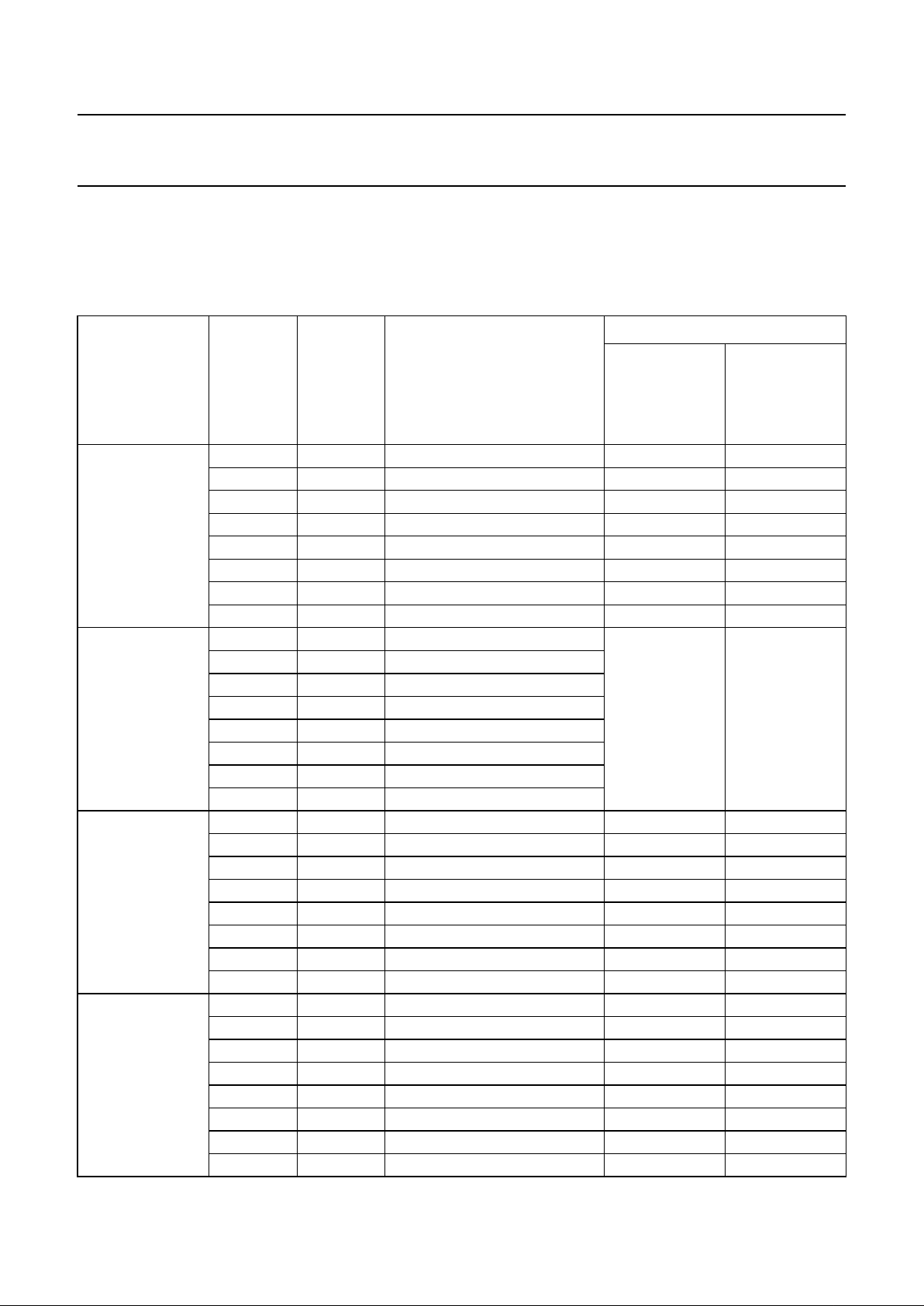

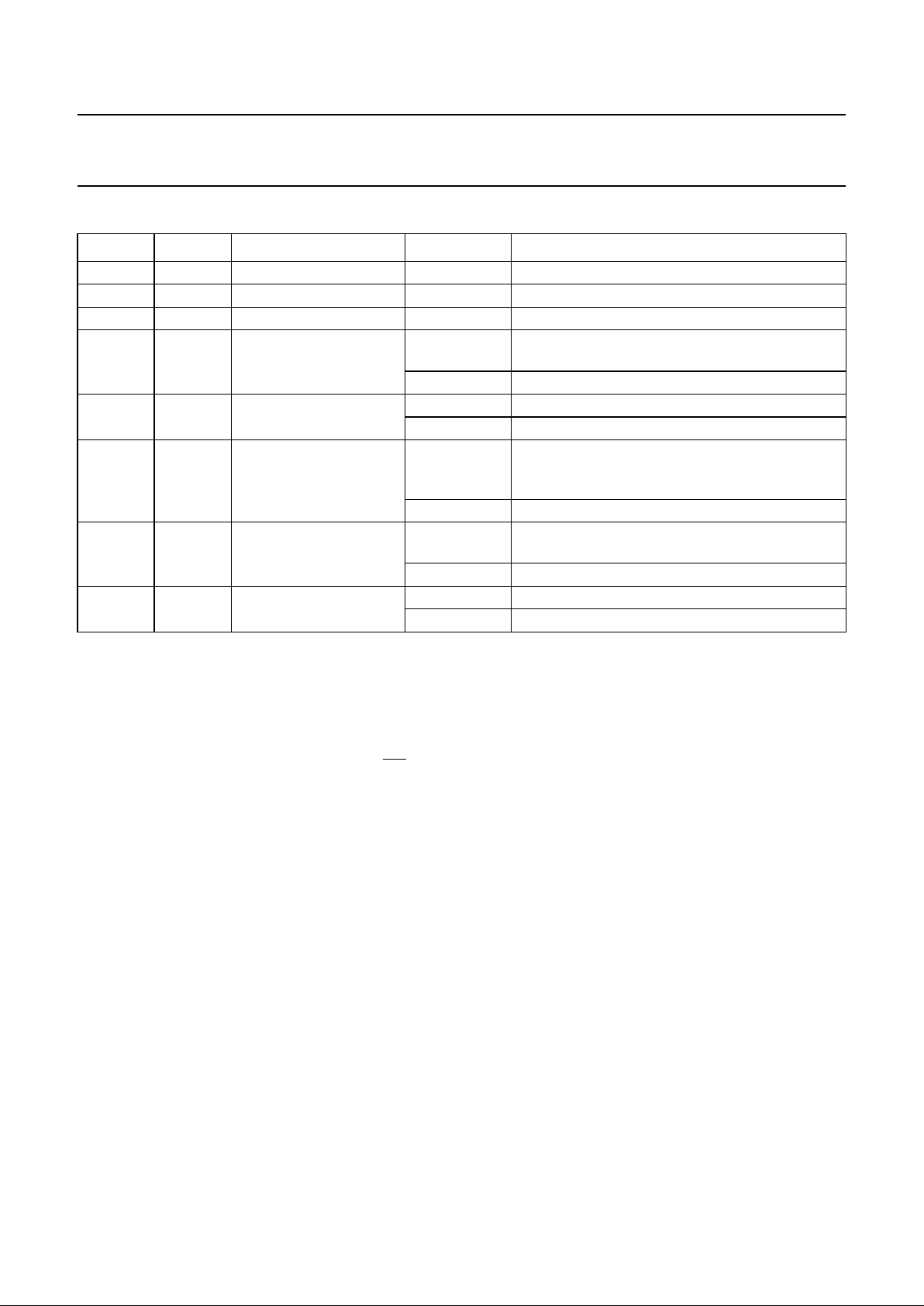

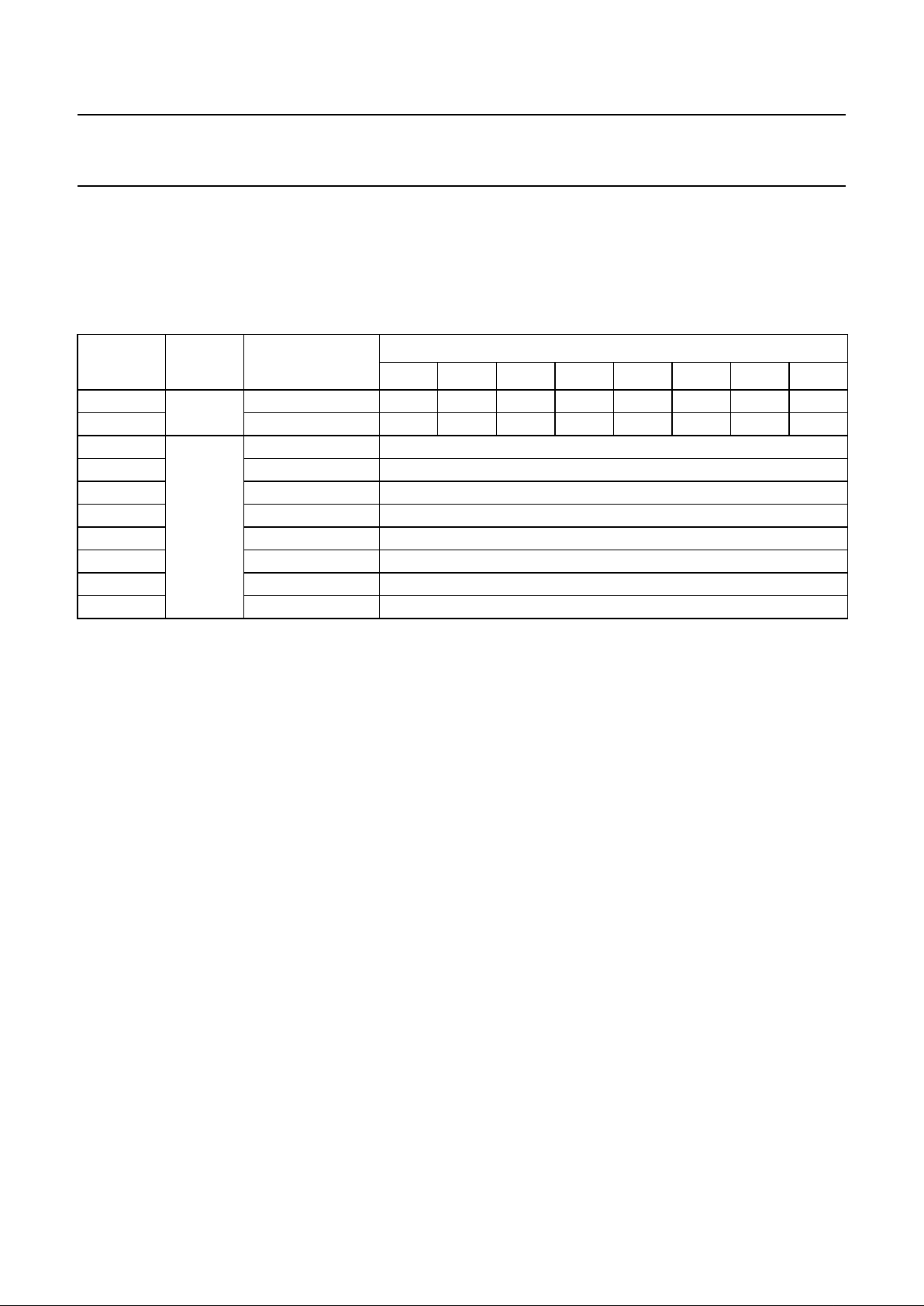

Table 10 PeliCAN address allocation; note 1

CAN

ADDRESS

OPERATING MODE RESET MODE

READ WRITE READ WRITE

0 mode mode mode mode

1 (00H) command (00H) command

2 status − status −

3 interrupt − interrupt −

4 interrupt enable interrupt enable interrupt enable interrupt enable

5 reserved (00H) − reserved (00H) −

6 bus timing 0 − bus timing 0 bus timing 0

7 bus timing 1 − bus timing 1 bus timing 1

8 output control − output control output control

9 test test; note 2 test test; note 2

10 reserved (00H) − reserved (00H) −

11 arbitration lost capture − arbitration lost

capture

−

12 error code capture − error code

capture

−

13 error warning limit − error warning

limit

error warning

limit

14 RX error counter − RX error counter RX error counter

15 TX error counter − TX error counter TX error counter

16 RX frame

information

SFF; note 3

RX frame

information

EFF; note 4

TX frame

information

SFF; note 3

TX frame

information

EFF; note 4

acceptance

code 0

acceptance

code 0

17 RX identifier 1 RX identifier 1 TX identifier 1 TX identifier 1 acceptance

code 1

acceptance

code 1

18 RX identifier 2 RX identifier 2 TX identifier 2 TX identifier 2 acceptance

code 2

acceptance

code 2

19 RX data 1 RX identifier 3 TX data 1 TX identifier 3 acceptance

code 3

acceptance

code 3

20 RX data 2 RX identifier 4 TX data 2 TX identifier 4 acceptance

mask 0

acceptance

mask 0

21 RX data 3 RX data 1 TX data 3 TX data 1 acceptance

mask 1

acceptance

mask 1

22 RX data 4 RX data 2 TX data 4 TX data 2 acceptance

mask 2

acceptance

mask 2

23 RX data 5 RX data 3 TX data 5 TX data 3 acceptance

mask 3

acceptance

mask 3

24 RX data 6 RX data 4 TX data 6 TX data 4 reserved (00H) −

25 RX data 7 RX data 5 TX data 7 TX data 5 reserved (00H) −

26 RX data 8 RX data 6 TX data 8 TX data 6 reserved (00H) −

Page 22

2000 Jan 04 22

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. It should be noted that the registers are repeated within higher CAN address areas (the most significant bit of the

8-bit CPU address is not decoded: CAN address 128 continues with CAN address 0 and so on).

2. Test register is used for production testing only. Using this register during normal operation may result in undesired

behaviour of the device.

3. SFF = Standard Frame Format.

4. EFF = Extended Frame Format.

5. These address allocations reflect the FIFO RAM space behind the current message. The contents are random after

power-up and contain the beginning of the next message which is received after the current one. If no further

message is received, parts of old messages may occur here.

6. Some bits are writeable in reset mode only (CAN mode, CBP, RXINTEN and clock off).

27 (FIFO RAM);

note 5

RX data 7 − TX data 7 reserved (00H) −

28 (FIFO RAM);

note 5

RX data 8 − TX data 8 reserved (00H) −

29 RX message counter − RX message

counter

−

30 RX buffer start address − RX buffer start

address

RX buffer start

address

31 clock divider clock divider; note 6 clock divider clock divider

32 internal RAM address 0 (FIFO) − internal RAM

address 0

internal RAM

address 0

33 internal RAM address 1 (FIFO) − internal RAM

address 1

internal RAM

address 1

↓↓ ↓ ↓ ↓

95 internal RAM address 63

(FIFO)

− internal RAM

address 63

internal RAM

address 63

96 internal RAM address 64

(TX buffer)

− internal RAM

address 64

internal RAM

address 64

↓↓ ↓ ↓ ↓

108 internal RAM address 76

(TX buffer)

− internal RAM

address 76

internal RAM

address 76

109 internal RAM address 77 (free) − internal RAM

address 77

internal RAM

address 77

110 internal RAM address 78 (free) − internal RAM

address 78

internal RAM

address 78

111 internal RAM address 79 (free) − internal RAM

address 79

internal RAM

address 79

112 (00H) − (00H) −

↓↓ ↓ ↓ ↓

127 (00H) − (00H) −

CAN

ADDRESS

OPERATING MODE RESET MODE

READ WRITE READ WRITE

Page 23

2000 Jan 04 23

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.4.2 RESET VALUES

Detection of a set reset mode bit results in aborting the current transmission/reception of a message and entering the

reset mode. On the ‘1-to-0’ transition of the reset mode bit, the CAN controller returns to the mode defined within the

mode register.

Table 11 Reset mode configuration; notes 1 and 2

REGISTER BIT SYMBOL NAME

VALUE

RESET BY

HARDWARE

SETTING MOD.0

BY SOFTWARE

OR DUE TO

BUS-OFF

Mode MOD.7 to 5 − reserved 0 (reserved) 0 (reserved)

MOD.4 SM Sleep Mode 0 (wake-up) 0 (wake-up)

MOD.3 AFM Acceptance Filter Mode 0 (dual) X

MOD.2 STM Self Test Mode 0 (normal) X

MOD.1 LOM Listen Only Mode 0 (normal) X

MOD.0 RM Reset Mode 1 (present) 1 (present)

Command CMR.7 to 5 − reserved 0 (reserved) 0 (reserved)

CMR.4 SRR Self Reception Request 0 (absent) 0 (absent)

CMR.3 CDO Clear Data Overrun 0 (no action) 0 (no action)

CMR.2 RRB Release Receive Buffer 0 (no action) 0 (no action)

CMR.1 AT Abort Transmission 0 (absent) 0 (absent)

CMR.0 TR Transmission Request 0 (absent) 0 (absent)

Status SR.7 BS Bus Status 0 (bus-on) X

SR.6 ES Error Status 0 (ok) X

SR.5 TS Transmit Status 1 (wait idle) 1 (wait idle)

SR.4 RS Receive Status 1 (wait idle) 1 (wait idle)

SR.3 TCS Transmission Complete

Status

1 (complete) X

SR.2 TBS Transmit Buffer Status 1 (released) 1 (released)

SR.1 DOS Data Overrun Status 0 (absent) 0 (absent)

SR.0 RBS Receive Buffer Status 0 (empty) 0 (empty)

Interrupt IR.7 BEI Bus Error Interrupt 0 (reset) 0 (reset)

IR.6 ALI Arbitration Lost Interrupt 0 (reset) 0 (reset)

IR.5 EPI Error Passive Interrupt 0 (reset) 0 (reset)

IR.4 WUI Wake-Up Interrupt 0 (reset) 0 (reset)

IR.3 DOI Data Overrun Interrupt 0 (reset) 0 (reset)

IR.2 EI Error Warning Interrupt 0 (reset) X; note 3

IR.1 TI Transmit Interrupt 0 (reset) 0 (reset)

IR.0 RI Receive Interrupt 0 (reset) 0 (reset)

Page 24

2000 Jan 04 24

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Interrupt

enable

IER.7 BEIE Bus Error Interrupt

Enable

XX

IER.6 ALIE Arbitration Lost Interrupt

Enable

XX

IER.5 EPIE Error Passive Interrupt

Enable

XX

IER.4 WUIE Wake-Up Interrupt

Enable

XX

IER.3 DOIE Data Overrun Interrupt

Enable

XX

IER.2 EIE Error Warning Interrupt

Enable

XX

IER.1 TIE Transmit Interrupt

Enable

XX

IER.0 RIE Receive Interrupt Enable X X

Bus timing 0 BTR0.7 SJW.1 Synchronization Jump

Width 1

XX

BTR0.6 SJW.0 Synchronization Jump

Width 0

XX

BTR0.5 BRP.5 Baud Rate Prescaler 5 X X

BTR0.4 BRP.4 Baud Rate Prescaler 4 X X

BTR0.3 BRP.3 Baud Rate Prescaler 3 X X

BTR0.2 BRP.2 Baud Rate Prescaler 2 X X

BTR0.1 BRP.1 Baud Rate Prescaler 1 X X

BTR0.0 BRP.0 Baud Rate Prescaler 0 X X

Bus timing 1 BTR1.7 SAM Sampling X X

BTR1.6 TSEG2.2 Time Segment 2.2 X X

BTR1.5 TSEG2.1 Time Segment 2.1 X X

BTR1.4 TSEG2.0 Time Segment 2.0 X X

BTR1.3 TSEG1.3 Time Segment 1.3 X X

BTR1.2 TSEG1.2 Time Segment 1.2 X X

BTR1.1 TSEG1.1 Time Segment 1.1 X X

BTR1.0 TSEG1.0 Time Segment 1.0 X X

REGISTER BIT SYMBOL NAME

VALUE

RESET BY

HARDWARE

SETTING MOD.0

BY SOFTWARE

OR DUE TO

BUS-OFF

Page 25

2000 Jan 04 25

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Output control OCR.7 OCTP1 Output Control

Transistor P1

XX

OCR.6 OCTN1 Output Control

Transistor N1

XX

OCR.5 OCPOL1 Output Control Polarity 1 X X

OCR.4 OCTP0 Output Control

Transistor P0

XX

OCR.3 OCTN0 Output Control

Transistor N0

XX

OCR.2 OCPOL0 Output Control Polarity 0 X X

OCR.1 OCMODE1 Output Control Mode 1 X X

OCR.0 OCMODE0 Output Control Mode 0 X X

Arbitration lost

capture

− ALC Arbitration Lost Capture 0 X

Error code

capture

− ECC Error Code Capture 0 X

Error warning

limit

− EWLR Error Warning Limit

Register

96 X

RX error

counter

− RXERR Receive Error Counter 0 (reset) X; note 4

TX error

counter

− TXERR Transmit Error Counter 0 (reset) X; note 4

TX buffer − TXB Transmit Buffer X X

RX buffer − RXB Receive Buffer X; note 5 X; note 5

ACR 0 to 3 − ACR0 to ACR3 Acceptance Code

Registers

XX

AMR 0 to 3 − AMR0 to AMR3 Acceptance Mask

Registers

XX

RX message

counter

− RMC RX Message Counter 0 0

RX buffer start

address

− RBSA RX Buffer Start Address 00000000 X

Clock divider − CDR Clock Divider Register 00000000 Intel;

00000101

Motorola

X

REGISTER BIT SYMBOL NAME

VALUE

RESET BY

HARDWARE

SETTING MOD.0

BY SOFTWARE

OR DUE TO

BUS-OFF

Page 26

2000 Jan 04 26

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. X means that the value of these registers or bits is not influenced.

2. Remarks in brackets explain functional meaning.

3. On bus-off the error warning interrupt is set, if enabled.

4. If the reset mode was entered due to a bus-off condition, the receive error counter is cleared and the transmit error

counter is initialized to 127 to count-down the CAN-defined bus-off recovery time consisting of 128 occurrences of

11 consecutive recessive bits.

5. Internal read/write pointers of the RXFIFO are reset to their initial values. A subsequent read access to the RXB

would show undefined data values (parts of old messages).

If a message is transmitted, this message is written in parallel to the receive buffer. A receive interrupt is generated

only if this transmission was forced by the self reception request. So, even if the receive buffer is empty, the last

transmitted message may be read from the receive buffer until it is overwritten by the next received or transmitted

message.

Upon a hardware reset, the RXFIFO pointers are reset to the physical RAM address ‘0’. Setting CR.0 by software or

due to the bus-off event will reset the RXFIFO pointers to the currently valid FIFO start address (RBSA register)

which is different from the RAM address ‘0’ after the first release receive buffer command.

6.4.3 MODE REGISTER (MOD)

The contents of the mode register are used to change the behaviour of the CAN controller. Bits may be set or reset by

the CPU which uses the control register as a read/write memory. Reserved bits are read as logic 0.

Table 12 Bit interpretation of the mode register (MOD); CAN address ‘0’

BIT SYMBOL NAME VALUE FUNCTION

MOD.7 −− −reserved

MOD.6 −− −reserved

MOD.5 −− −reserved

MOD.4 SM Sleep Mode; note 1 1 sleep; the CAN controller enters sleep mode if no

CAN interrupt is pending and if there is no bus

activity

0 wake-up; the CAN controller wakes up if sleeping

MOD.3 AFM Acceptance Filter Mode;

note 2

1 single; the single acceptance filter option is

enabled (one filter with the length of 32 bit is

active)

0 dual; the dual acceptance filter option is enabled

(two filters, each with the length of 16 bit are

active)

MOD.2 STM Self Test Mode; note 2 1 self test; in this mode a full node test is possible

without any other active node on the bus using the

self reception request command; the

CAN controller will perform a successful

transmission, even if there is no acknowledge

received

0 normal; an acknowledgeis required for successful

transmission

Page 27

2000 Jan 04 27

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. The SJA1000 will enter sleep mode if the sleep mode bit is set to logic 1 (sleep); then there is no bus activity and no

interrupt is pending. Setting of SM with at least one of the previously mentioned exceptions valid will result in a

wake-up interrupt. After sleep mode is set, the CLKOUT signal continues until at least 15 bit times have passed, to

allow a host microcontroller clocked via this signal to enter its own standby mode before the CLKOUT goes LOW.

The SJA1000 will wake up when one of the three previously mentioned conditions is negated: after SM is set LOW

(wake-up), there is bus activity or INT is driven LOW (active). On wake-up, the oscillator is started and a wake-up

interrupt is generated. A sleeping SJA1000 which wakes up due to bus activity will not be able to receive this

message until it detects 11 consecutive recessive bits (bus-free sequence). It should be noted that setting of SM is

not possible in reset mode. After clearing of reset mode, setting of SM is possible first, when bus-free is detected

again.

2. A write access to the bits MOD.1 to MOD.3 is only possible, if the reset mode is entered previously.

3. This mode of operation forces the CAN controller to be error passive. Message transmission is not possible.

The listen only mode can be used e.g. for software driven bit rate detection and ‘hot plugging’. All other functions can

be used like in normal mode.

4. During a hardware reset or when the bus status bit is set to logic 1 (bus-off), the reset mode bit is also set to logic 1

(present). If this bit is accessed by software, a value change will become visible and takes effect first with the next

positive edge of the internal clock which operates at half of the external oscillator frequency. During an external reset

the microcontroller cannot set the reset mode bit to logic 0 (absent). Therefore, after having set the reset mode bit to

logic 1, the microcontroller must check this bit to ensure that the external reset pin is not being held HIGH. Changes

of the reset request bit are synchronized with the internal divided clock. Reading the reset request bit reflects the

synchronized status. After the reset mode bit is set to logic 0 the CAN controller will wait for:

a) Oneoccurrenceof bus-free signal (11 recessive bits), if the precedingresethasbeen caused by a hardware reset

or a CPU-initiated reset.

b) 128 occurrences of bus-free, if the preceding reset has been caused by a CAN controller initiated bus-off, before

re-entering the bus-on mode.

MOD.1 LOM Listen Only Mode;

notes 2 and 3

1 listen only; in this mode the CAN controller would

give no acknowledge to the CAN-bus, even if a

message is received successfully; the error

counters are stopped at the current value

0 normal

MOD.0 RM Reset Mode; note 4 1 reset; detection of a set reset mode bit results in

aborting the current transmission/reception of a

message and entering the reset mode

0 normal; on the ‘1-to-0’ transition of the reset mode

bit, the CAN controller returns to the operating

mode

BIT SYMBOL NAME VALUE FUNCTION

Page 28

2000 Jan 04 28

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.4.4 COMMAND REGISTER (CMR)

A command bit initiates an action within the transfer layer of the CAN controller. This register is write only, all bits will

return a logic 0 when being read. Between two commands at least one internal clock cycle is needed in order to proceed.

The internal clock is half of the external oscillator frequency.

Table 13 Bit interpretation of the command register (CMR); CAN address 1

Notes

1. Upon self reception request a message is transmitted and simultaneously received if the acceptance filter is set to

the corresponding identifier. A receive and a transmit interrupt will indicate correct self reception (see also self test

mode in mode register).

2. Setting the command bits CMR.0 and CMR.1 simultaneously results in sending the transmit message once.

No re-transmission will be performed in the event of an error or arbitration lost (single-shot transmission).

Setting the command bits CMR.4and CMR.1 simultaneously resultsin sending the transmitmessage once using the

self reception feature. No re-transmission will be performed in the event of an error or arbitration lost.

Setting the command bits CMR.0, CMR.1 and CMR.4 simultaneously results in sending the transmit message once

as described for CMR.0 and CMR.1.

The moment the transmit status bit is set within the status register, the internal transmission request bit is cleared

automatically.

Setting CMR.0 and CMR.4 simultaneously will ignore the set CMR.4 bit.

3. This command bit is used to clear the data overrun condition indicated by the data overrun status bit. As long as the

data overrun status bit is set no further data overrun interrupt is generated.

4. After reading the contents of the receive buffer, the CPU can release this memory space in the RXFIFO by setting

the release receive buffer bit to logic 1. This may result in another message becoming immediately available within

the receive buffer. If there is no other message available, the receive interrupt bit is reset.

BIT SYMBOL NAME VALUE FUNCTION

CMR.7 − reserved −−

CMR.6 − reserved −−

CMR.5 − reserved −−

CMR.4 SRR Self Reception Request;

notes 1 and 2

1 present; a message shall be transmitted and

received simultaneously

0 − (absent)

CMR.3 CDO Clear Data Overrun;

note 3

1 clear; the data overrun status bit is cleared

0 − (no action)

CMR.2 RRB Release Receive Buffer;

note 4

1 released; the receive buffer, representing the

message memory space in the RXFIFO is

released

0 − (no action)

CMR.1 AT Abort Transmission;

notes 5 and 2

1 present; if not already in progress, a pending

transmission request is cancelled

0 − (absent)

CMR.0 TR Transmission Request;

notes 6 and 2

1 present; a message shall be transmitted

0 − (absent)

Page 29

2000 Jan 04 29

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

5. The abort transmission bit is used when the CPU requires the suspension of the previously requested transmission,

e.g. to transmit a more urgent message before. A transmission already in progress is not stopped. In order to see if

the original message has been either transmitted successfully or aborted, the transmission complete status bit

should be checked. This should be done after the transmit buffer status bit has been set to logic 1 or a transmit

interrupt has been generated.

It should be noted that a transmit interrupt is generatedeven if the message was aborted because the transmit buffer

status bit changes to ‘released’.

6. If the transmission request was set to logic 1 in a previous command, it cannot be cancelled by setting the

transmission request bit to logic 0. The requested transmission may be cancelled by setting the abort transmission

bit to logic 1.

6.4.5 STATUS REGISTER (SR)

The content of the status register reflects the status of the CAN controller. The status register appears to the CPU as a

read only memory.

Table 14 Bit interpretation of the status register (SR); CAN address 2

BIT SYMBOL NAME VALUE FUNCTION

SR.7 BS Bus Status; note 1 1 bus-off; the CAN controller is not involved in bus

activities

0 bus-on; the CAN controller is involved in bus

activities

SR.6 ES Error Status; note 2 1 error; at least one of the error counters has

reached or exceeded the CPU warning limit

defined by the Error Warning Limit Register

(EWLR)

0 ok; both error counters are below the warning limit

SR.5 TS Transmit Status; note 3 1 transmit; the CAN controller is transmitting a

message

0 idle

SR.4 RS Receive Status; note 3 1 receive; the CAN controller is receiving a

message

0 idle

SR.3 TCS Transmission Complete

Status; note 4

1 complete; last requested transmission has been

successfully completed

0 incomplete; previously requested transmission is

not yet completed

SR.2 TBS Transmit Buffer Status;

note 5

1 released; the CPU may write a message into the

transmit buffer

0 locked; the CPU cannot access the transmit

buffer; a message is either waiting for

transmission or is in the process of being

transmitted

Page 30

2000 Jan 04 30

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. When the transmit error counter exceeds the limit of 255, the bus status bit is set to logic 1 (bus-off), the

CAN controller will set the reset mode bit to logic 1 (present) and an error warning interrupt is generated, if enabled.

The transmit error counter is set to 127 and the receive error counter is cleared. It will stay in this mode until the CPU

clears the reset mode bit. Once this is completed the CAN controller will wait the minimum protocol-defined time

(128 occurrences of the bus-free signal) counting down the transmit error counter. After that the bus status bit is

cleared (bus-on), the error status bit is set to logic 0 (ok), the error counters are reset and an error warning interrupt

is generated, if enabled. Reading the TX error counter during this time gives information about the status of the

bus-off recovery.

2. Errors detected during reception or transmission will effect the error counters according to the CAN 2.0B protocol

specification. The error status bit is set when at least one of the error counters has reached or exceeded the CPU

warning limit (EWLR). An error warning interrupt is generated, if enabled. The default value of EWLR after hardware

reset is 96.

3. If both the receive status and the transmit status bits are logic 0 (idle) the CAN-bus is idle. If both bits are set the

controller is waiting to become idle again. After a hardware reset 11 consecutive recessive bits have to be detected

until the idle status is reached. After bus-off this will take 128 of 11 consecutive recessive bits.

4. The transmission complete status bit is set to logic 0 (incomplete) whenever the transmission request bit or the self

reception request bit is set to logic 1. The transmission complete status bit will remain at logic 0 until a message is

transmitted successfully.

5. If the CPU tries to write to the transmit buffer when the transmit buffer status bit is logic 0 (locked), the written byte

will not be accepted and will be lost without this being indicated.

6. When a message that is to be received has passed the acceptance filter successfully, the CAN controller needs

space in the RXFIFO to store the message descriptor and for each data byte which has been received. If there is not

enough space to store the message, that message is droppedand the data overrun condition is indicated to the CPU

at the moment this message becomes valid. If this message is not completed successfully (e.g. due to an error), no

overrun condition is indicated.

7. After reading all messages within the RXFIFO and releasing their memory space with the command release receive

buffer this bit is cleared.

SR.1 DOS Data Overrun Status;

note 6

1 overrun; a message was lost because there was

not enough space for that message in the RXFIFO

0 absent; no data overrun has occurred since the

last clear data overrun command was given

SR.0 RBS Receive Buffer Status;

note 7

1 full; one or more complete messages are available

in the RXFIFO

0 empty; no message is available

BIT SYMBOL NAME VALUE FUNCTION

Page 31

2000 Jan 04 31

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

6.4.6 INTERRUPT REGISTER (IR)

The interrupt register allows the identification of an interrupt source. When one or more bits of this register are set, a CAN

interruptwillbe indicated to the CPU. After this register isreadbythe CPU all bits are reset except forthereceiveinterrupt

bit.

The interrupt register appears to the CPU as a read only memory.

Table 15 Bit interpretation of the interrupt register (IR); CAN address 3

BIT SYMBOL NAME VALUE FUNCTION

IR.7 BEI Bus Error Interrupt 1 set; this bit is set when the CAN controller detects

an error on the CAN-bus and the BEIE bit is set

within the interrupt enable register

0 reset

IR.6 ALI Arbitration Lost Interrupt 1 set; this bit is set when the CAN controller lost the

arbitration and becomes a receiver and the ALIE

bit is set within the interrupt enable register

0 reset

IR.5 EPI Error Passive Interrupt 1 set; this bit is set whenever the CAN controller has

reached the error passive status (at least one

error counter exceeds the protocol-defined level of

127) or if the CAN controller is in the error passive

status and enters the error active status again and

the EPIE bit is set within the interrupt enable

register

0 reset

IR.4 WUI Wake-Up Interrupt;

note 1

1 set; this bit is set when the CAN controller is

sleeping and bus activity is detected and the

WUIE bit is set within the interrupt enable register

0 reset

IR.3 DOI Data Overrun Interrupt 1 set; this bit is set on a ‘0-to-1’ transition of the data

overrun status bit and the DOIE bit is set within

the interrupt enable register

0 reset

IR.2 EI Error Warning Interrupt 1 set; this bit is set on every change (set and clear)

of either the error status or bus status bits and the

EIE bit is set within the interrupt enable register

0 reset

IR.1 TI Transmit Interrupt 1 set; this bit is set whenever the transmit buffer

status changes from ‘0-to-1’ (released) and the

TIE bit is set within the interrupt enable register

0 reset

IR.0 RI Receive Interrupt; note 2 1 set; this bit is set while the receive FIFO is not

empty and the RIE bit is set within the interrupt

enable register

0 reset; no more message is available within the

RXFIFO

Page 32

2000 Jan 04 32

Philips Semiconductors Product specification

Stand-alone CAN controller SJA1000

Notes

1. A wake-up interrupt is also generated, if the CPU tries to set the sleep bit while the CAN controller is involved in bus

activities or a CAN interrupt is pending.

2. The behaviour of this bit is equivalent to that of the receive buffer status bit with the exception, that RI depends on

the corresponding interrupt enable bit (RIE). So the receive interrupt bit is not cleared upon a read access to the

interrupt register. Giving the command ‘release receive buffer’ will clear RI temporarily. If there is another message

available within the FIFO after the release command, RI is set again. Otherwise RI remains cleared.

6.4.7 INTERRUPT ENABLE REGISTER (IER)

The register allows to enable different types of interrupt sources which are indicated to the CPU.

The interrupt enable register appears to the CPU as a read/write memory.