Page 1

New Product

N-Channel 20-V (D-S) MOSFET

SiR404DP

Vishay Siliconix

PRODUCT SUMMARY

VDS (V) R

0.00160 at V

20

0.00175 at V

0.00225 at V

(Ω)

DS(on)

= 10 V

GS

= 4.5 V

GS

= 2.5 V

GS

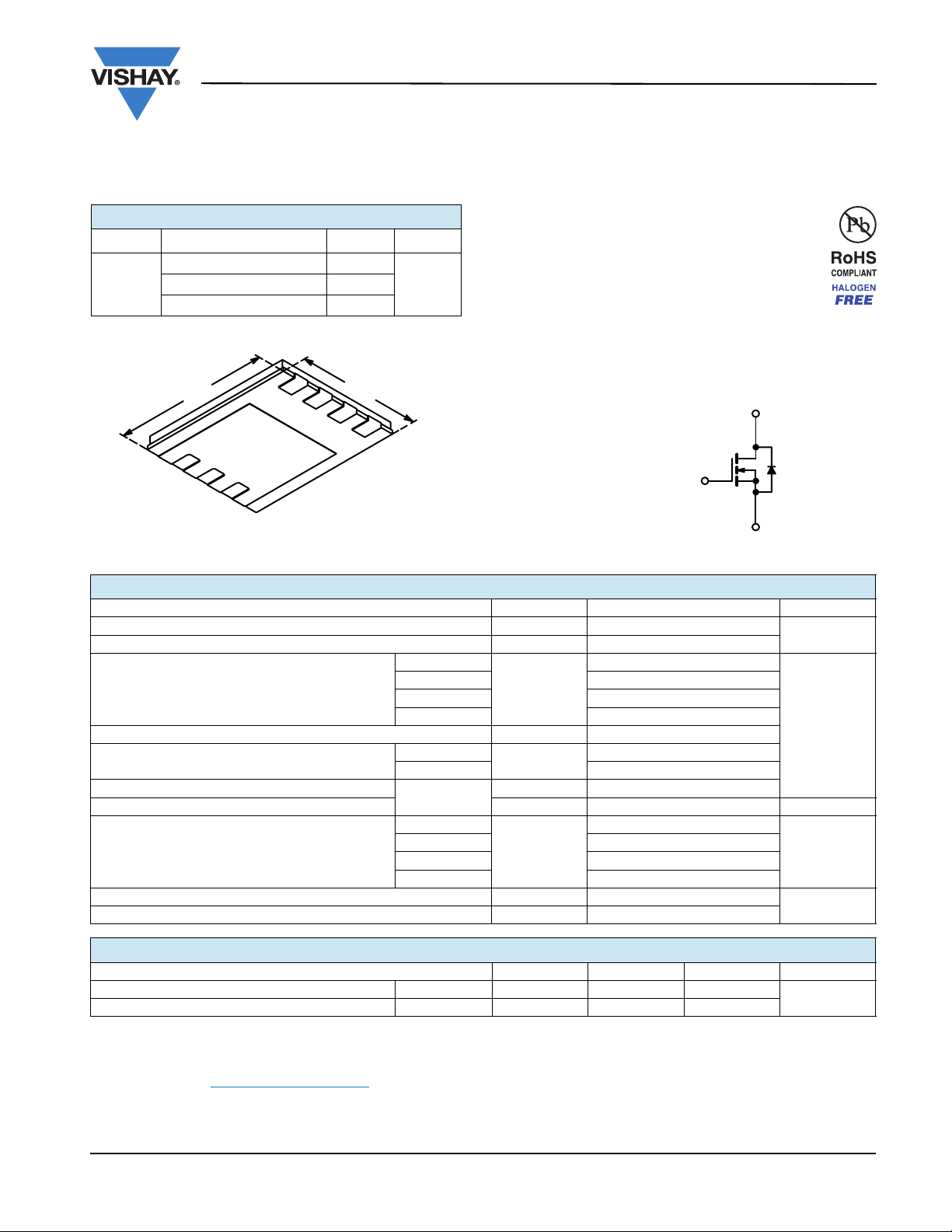

PowerPAK® SO-8

a

I

(A)

D

Qg (Typ.)

60

60

64.5 nC

60

FEATURES

• Halogen-free According to IEC 61249-2-21

Definition

• TrenchFET

• 100 % R

• 100 % UIS Tested

• 2.5 V and 3.3 V Gate Drive MOSFET for dc-to-dc

Applications

®

Gen III Power MOSFET

Tested

g

• Compliant to RoHS Directive 2002/95/EC

6.15 mm

D

8

D

7

D

6

5

Bottom View

Ordering Information: SiR404DP-T1-GE3 (Lead (Pb)-free and Halogen-free)

S

1

D

5.15 mm

S

2

S

3

G

4

APPLICATIONS

• Fixed Telecom

• OR-ing

• POL

D

G

S

N-Channel MOSFET

ABSOLUTE MAXIMUM RATINGS TA = 25 °C, unless otherwise noted

Parameter Symbol Limit Unit

Drain-Source Voltage

Gate-Source Voltage

Continuous Drain Current (T

= 150 °C)

J

Pulsed Drain Current

Continuous Source-Drain Diode Current

Single Pulse Avalanche Current

Single Pulse Avalanche Energy

Maximum Power Dissipation

Operating Junction and Storage Temperature Range

Soldering Recommendations (Peak Temperature)

d, e

= 25 °C

T

C

= 70 °C

T

C

TA = 25 °C

TA = 70 °C

T

= 25 °C

C

TA = 25 °C

L = 0.1 mH

= 25 °C

T

C

T

= 70 °C

C

= 25 °C

T

A

TA = 70 °C

V

DS

V

GS

I

D

I

DM

I

S

I

AS

E

AS

± 12

60

60

45.6

36.6

100

60

5.6

125

20

50

b, c

a

a

b, c

b, c

a

V

A

mJ

104

P

D

, T

T

J

stg

66.6

b, c

6.25

b, c

4.0

- 55 to 150

260

W

°C

THERMAL RESISTANCE RATINGS

Parameter Symbol Typical Maximum Unit

Maximum Junction-to-Ambient

Maximum Junction-to-Case (Drain)

Notes:

a. Package limited.

b. Surface Mounted on 1" x 1" FR4 board.

c. t = 10 s.

d. See Solder Profile (www.vishay.com/ppg?73257

(not plated) as a result of the singulation process in manufacturing. A solder fillet at the exposed copper tip cannot be guaranteed and is not

required to ensure adequate bottom side solder interconnection.

e. Rework Conditions: manual soldering with a soldering iron is not recommended for leadless components.

f. Maximum under Steady State conditions is 54 °C/W.

Document Number: 64815

S09-0873-Rev. A, 18-May-09

b, f

t ≤ 10 s

Steady State

R

thJA

R

thJC

15 20

0.9 1.2

°C/W

). The PowerPAK SO-8 is a leadless package. The end of the lead terminal is exposed copper

www.vishay.com

1

Page 2

New Product

SiR404DP

Vishay Siliconix

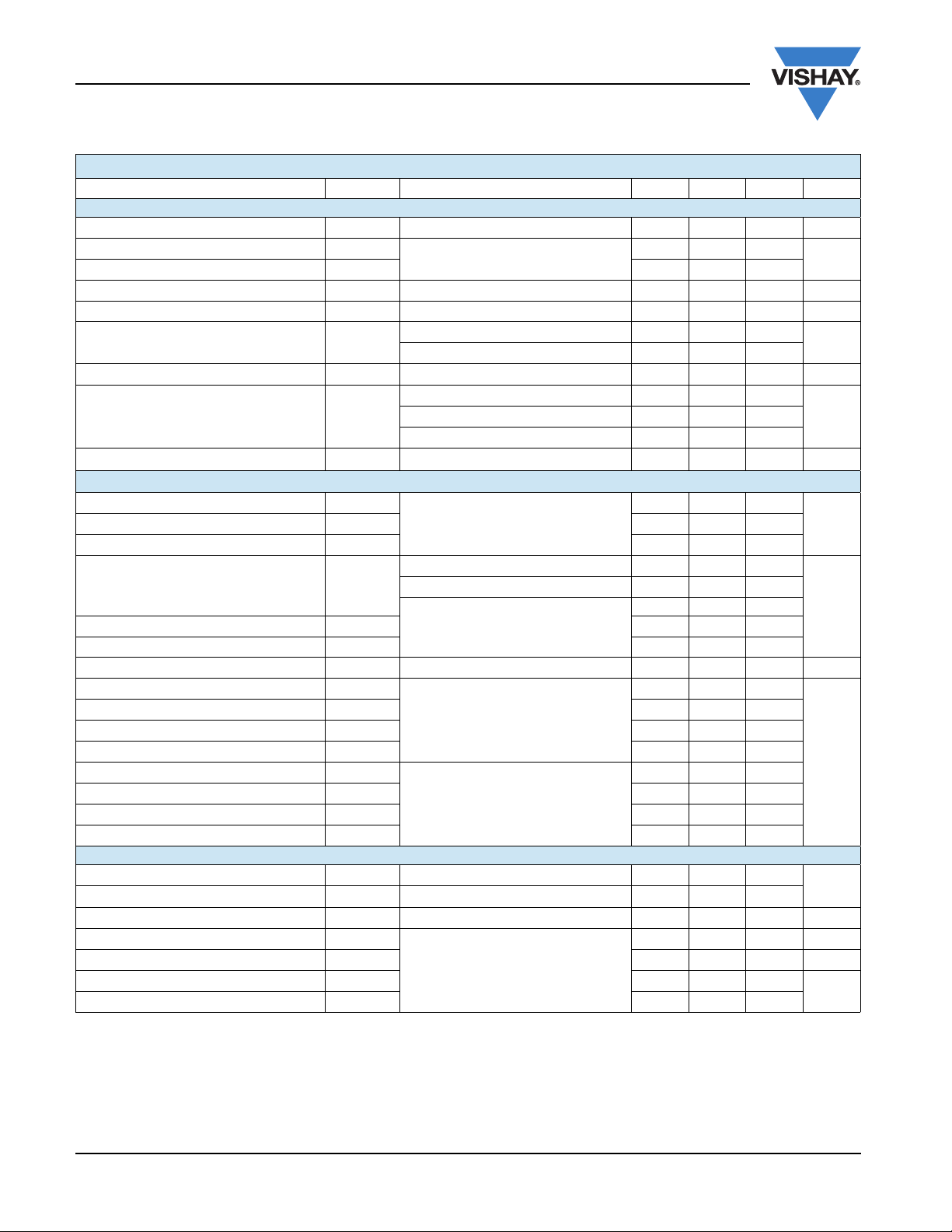

SPECIFICATIONS TJ = 25 °C, unless otherwise noted

Parameter Symbol Test Conditions Min. Typ. Max. Unit

Static

Drain-Source Breakdown Voltage

V

Temperature Coefficient ΔVDS/T

DS

V

Temperature Coefficient ΔV

GS(th)

Gate-Source Threshold Voltage

Gate-Source Leakage

Zero Gate Voltage Drain Current

On-State Drain Current

Drain-Source On-State Resistance

Forward Transconductance

Dynamic

b

a

a

a

Input Capacitance

Reverse Transfer Capacitance

Total Gate Charge

Gate-Source Charge

Gate-Drain Charge

Gate Resistance

Tur n -O n De l a y T i m e

Rise Time

Turn-Off Delay Time

Fall Time

Tur n -O n De l a y T i m e

Rise Time

Turn-Off Delay Time

Fall Time

V

DS

J

GS(th)/TJ

V

GS(th)

I

GSS

I

DSS

I

V

D(on)

R

DS(on)

g

fs

C

iss

C

oss

C

rss

Q

g

Q

gs

Q

gd

R

g

t

d(on)

t

r

t

d(off)

t

f

t

d(on)

t

r

t

d(off)

t

f

Drain-Source Body Diode Characteristics

Continuous Source-Drain Diode Current

Pulse Diode Forward Current

a

Body Diode Voltage

Body Diode Reverse Recovery Time

Body Diode Reverse Recovery Charge

Reverse Recovery Fall Time

Reverse Recovery Rise Time

I

S

I

SM

V

SD

t

rr

Q

rr

t

a

t

b

Notes:

a. Pulse test; pulse width ≤ 300 µs, duty cycle ≤ 2 %.

b. Guaranteed by design, not subject to production testing.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation

of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

VGS = 0 V, ID = 250 µA

ID = 250 µA

V

= VGS, ID = 250 µA

DS

VDS = 0 V, VGS = ± 12 V

V

V

DS

= 20 V, V

DS

= 20 V, V

GS

≥ 5 V, V

DS

V

= 10 V, ID = 20 A

GS

V

= 4.5 V, ID = 20 A

GS

V

= 2.5 V, ID = 15 A

GS

= 0 V

GS

= 0 V, TJ = 55 °C

= 10 V

GS

VDS = 10 V, ID = 20 A

VDS = 10 V, V

VDS = 10 V, V

V

= 10 V, V

DS

= 10 V, V

V

DS

= 0 V, f = 1 MHz

GS

= 2.5 V, ID = 20 A

GS

= 3.3 V, ID = 20 A

GS

= 4.5 V, ID = 20 A

GS

f = 1 MHz 0.2 1.0 2 Ω

V

= 10 V, RL = 1.0 Ω

DD

≅ 10 A, V

I

D

V

I

≅ 10 A, V

D

DD

= 10 V, Rg = 1 Ω

GEN

= 10 V, RL = 1.0 Ω

= 4.5 V, Rg = 1 Ω

GEN

TC = 25 °C

IS = 5 A

IF = 10 A, dI/dt = 100 A/µs, TJ = 25 °C

20 V

17

- 4.4

mV/°C

0.6 1.5 V

± 100 nA

1

10

30 A

0.0013 0.00160

0.0014 0.00175

0.0018 0.00225

150 S

8130

1570

735

36.5

47.5

64.5 97

11.4

12.1

14 28

918

68 120

918

35 60

20 40

123 210

26 50

60

100

0.65 1.1 V

38 75 ns

36 72 nC

21

17

µA

Ω

pFOutput Capacitance

nC

ns

A

ns

www.vishay.com

2

Document Number: 64815

S09-0873-Rev. A, 18-May-09

Page 3

New Product

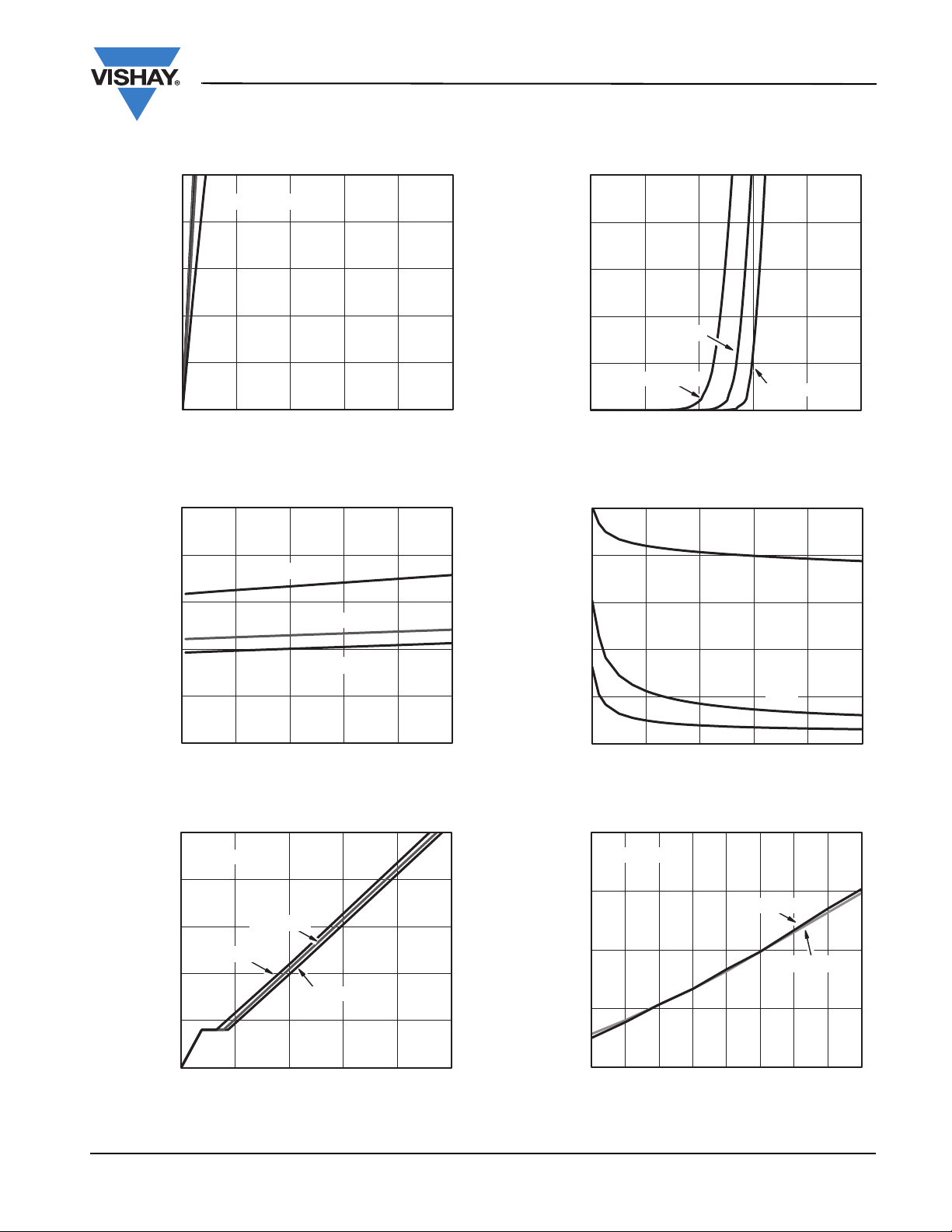

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

SiR404DP

Vishay Siliconix

80

VGS=10V thru 3 V

64

48

32

- Drain Current (A)I

D

16

0

0.0 0.5 1.0 1.5 2.0 2.5

V

- Drain-to-Source Voltage (V)

DS

Output Characteristics

0.0025

0.0021

VGS=2.5V

0.0017

VGS=4.5V

10

8

6

4

- Drain Current (A)I

D

2

0

0.0 0.5 1.0 1.5 2.0 2.5

TC= 25 °C

TC= 125 °C

V

- Gate-to-Source Voltage (V)

GS

TC= - 55 °C

Transfer Characteristics

10 000

C

iss

8000

6000

0.0013

- On-Resistance (Ω)R

DS(on)

0.0009

0.0005

0163248 64 80

ID- Drain Current (A)

VGS=10V

On-Resistance vs. Drain Current and Gate Voltage

10

ID=20A

8

6

4

- Gate-to-Source Voltage (V)

GS

2

V

0

0 306090120150

VDS=10V

VDS=5V

VDS=15V

Qg- Total Gate Charge (nC)

Gate Charge

4000

C - Capacitance (pF)

2000

C

rss

0

048 12 16 20

VDS- Drain-to-Source Voltage (V)

C

Capacitance

1.8

ID=20A

1.5

1.2

- On-ResistanceR

(Normalized)

DS(on)

0.9

0.6

- 50 - 25 0 25 50 75 100 125 150

-Junction Temperature (°C)

T

J

VGS=10V

On-Resistance vs. Junction Temperature

oss

VGS=2.5V

Document Number: 64815

S09-0873-Rev. A, 18-May-09

www.vishay.com

3

Page 4

New Product

SiR404DP

Vishay Siliconix

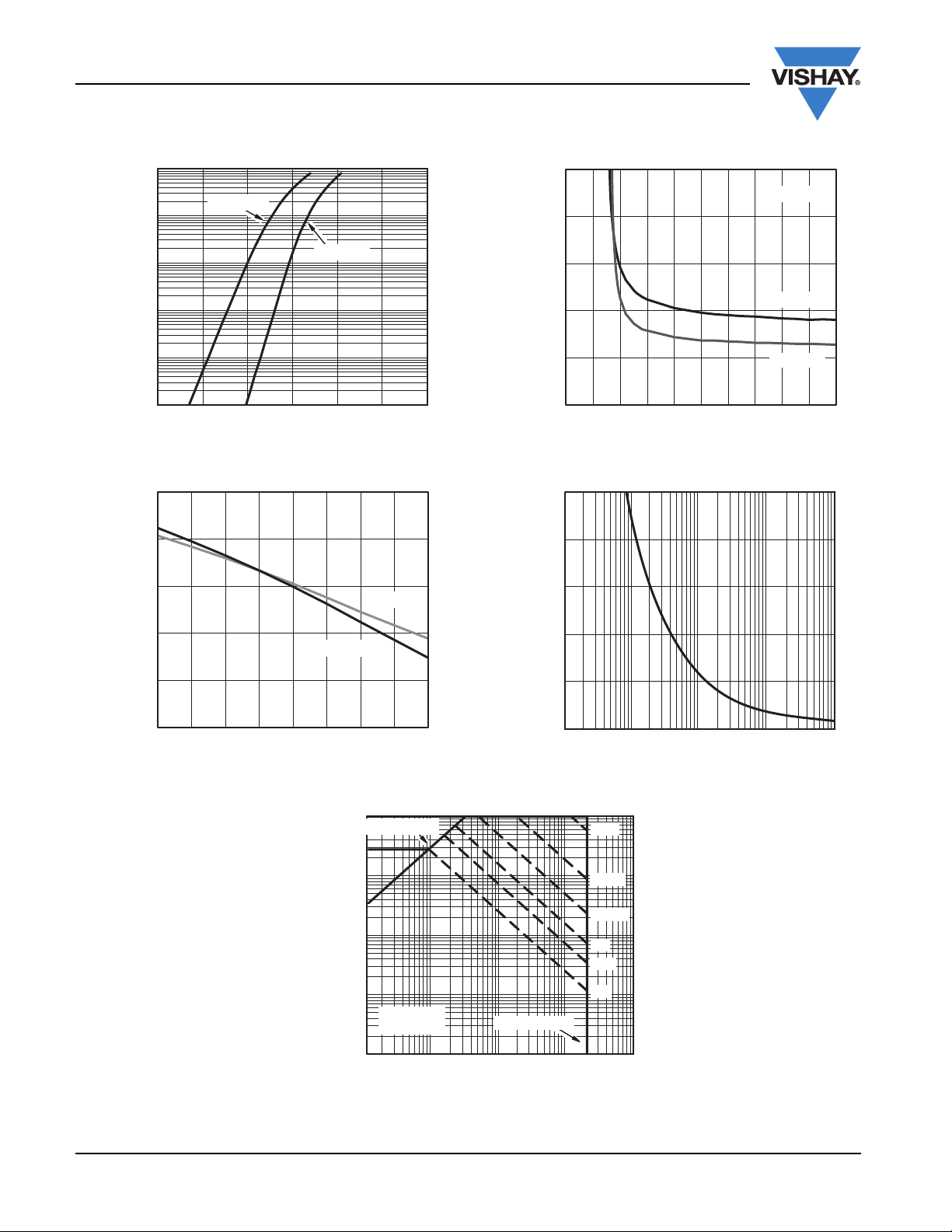

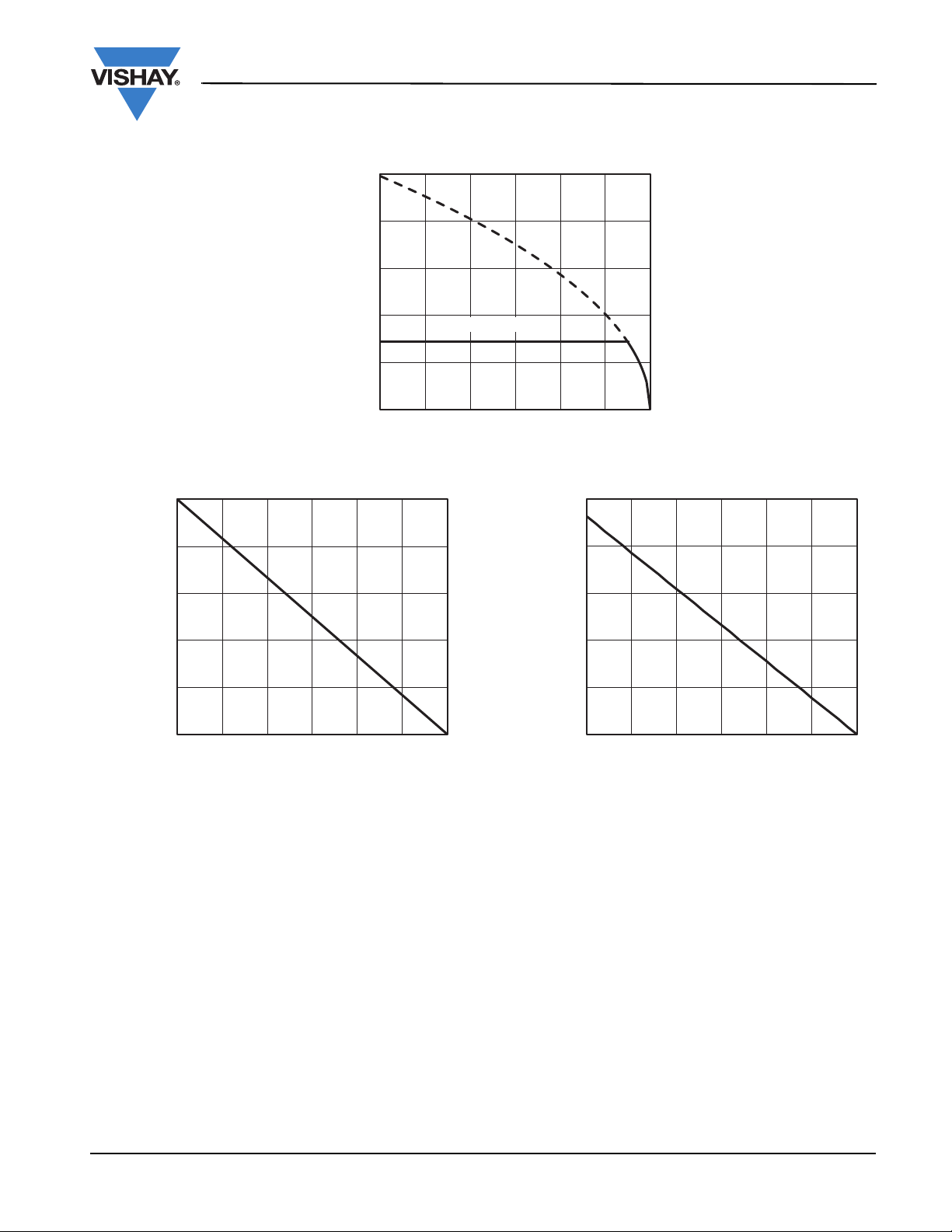

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

100

TJ= 150 °C

10

0.005

ID=20A

0.004

1

0.1

- Source Current (A)I

S

0.01

0.001

0.0 0.2 0.4 0.6 0.8 1.0 1.2

-Source-to-Drain Voltage (V)

V

SD

Source-Drain Diode Forward Voltage

0.5

0.2

- 0.1

Variance (V)V

- 0.4

GS(th)

- 0.7

TJ= 25 °C

ID= 250 µA

ID=5mA

0.003

0.002

- On-Resistance (Ω)

DS(on)

R

0.001

0.000

012345678 910

VGS- Gate-to-Source Voltage (V)

On-Resistance vs. Gate-to-Source Voltage

200

160

120

Power (W)

80

40

TJ= 125 °C

TJ=25 °C

- 1.0

- 50 - 25 0 25 50 75 100 125 150

www.vishay.com

4

TJ- Temperature (°C)

Threshold Voltage

- Drain Current (A)

D

I

100

Limited byR

10

1

0.1

Single Pulse

0.01

0.01

* V

*

DS(on)

TA= 25 °C

0.1 1 10

- Drain-to-Source Voltage (V)

V

DS

> minimum VGSat which R

GS

BVDSS Limited

Safe Operating Area, Junction-to-Ambient

0

DS(on)

0.1

Time (s)

Single Pulse Power, Junction-to-Ambient

1ms

10 ms

100 ms

1s

10 s

DC

100

is specified

Document Number: 64815

S09-0873-Rev. A, 18-May-09

011100.00.01

Page 5

New Product

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

210

168

126

SiR404DP

Vishay Siliconix

- Drain Current (A)

D

I

125

100

75

Power (W)

50

25

0

0 25 50 75 100 125 150

84

42

0

0 25 50 75 100 125 150

Package Limited

T

- Case Temperature (°C)

C

Current Derating*

3.0

2.4

1.8

Power (W)

1.2

0.6

0.0

0 25 50 75 100 125 150

T

- Case Temperature (°C)

C

Power, Junction-to-Case

* The power dissipation PD is based on T

dissipation limit for cases where additional heatsinking is used. It is used to determine the current rating, when this rating falls below the package

= 150 °C, using junction-to-case thermal resistance, and is more useful in settling the upper

J(max)

-Ambient Temperature (°C)

T

A

Power, Junction-to-Ambient

limit.

Document Number: 64815

www.vishay.com

S09-0873-Rev. A, 18-May-09

5

Page 6

New Product

SiR404DP

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

1

Duty Cycle = 0.5

0.2

Thermal Impedance

Normalized Effective Transient

Thermal Impedance

Normalized Effective Transient

0.1

0.1

0.05

0.01

-4

10

1

Duty Cycle = 0.5

0.1

0.02

0.2

0.1

0.02

Single Pulse

-3

10

Single Pulse

-2

10

-1

1

Square WavePulse Duration (s)

Normalized Thermal Transient Impedance, Junction-to-Ambient

0.05

Notes:

P

DM

1. Duty Cycle, D =

2. Per Unit Base = R

-T

3. T

JM

4. Surface Mounted

10

t

1

t

2

A=PDMZthJA

100

thJA

t

1

t

2

(t)

= 54 °C/W

100010

0.01

-4

10

-3

10

-2

10

-1

01110

Square WavePulse Duration (s)

Normalized Thermal Transient Impedance, Junction-to-Case

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package/tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?64815

www.vishay.com

6

.

Document Number: 64815

S09-0873-Rev. A, 18-May-09

Page 7

Package Information

Vishay Siliconix

PowerPAK® SO-8, (SINGLE/DUAL)

L

K

E4

D5

L

K

E4

D5

K1

W

1

2

3

4

θ

c

Notes

1.

2

3.

2

E1

E

Inch will govern.

Dimensions exclusive of mold gate burrs.

Dimensions exclusive of mold flash and cutting burrs.

M

e

L1

θ

A

H

θ

Z

2

D

D1

θ

A1

Detail Z

D4

D2

0.150 ± 0.008

Backside View of Single Pad

H

D4

D3(2x)

D2

Backside View of Dual Pad

E2

D

E3

E2

D1

D2

E3

MILLIMETERS INCHES

DIM. MIN. NOM. MAX. MIN. NOM. MAX.

A 0.97 1.04 1.12 0.038 0.041 0.044

A1 0.00 - 0.05 0.000 - 0.002

b 0.33 0.41 0.51 0.013 0.016 0.020

c 0.23 0.28 0.33 0.009 0.011 0.013

D 5.05 5.15 5.26 0.199 0.203 0.207

D1 4.80 4.90 5.00 0.189 0.193 0.197

D2 3.56 3.76 3.91 0.140 0.148 0.154

D3 1.32 1.50 1.68 0.052 0.059 0.066

D4

D5

0.57 TYP. 0.0225 TYP.

3.98 TYP. 0.157 TYP.

E 6.05 6.15 6.25 0.238 0.242 0.246

E1 5.79 5.89 5.99 0.228 0.232 0.236

E2 3.48 3.66 3.84 0.137 0.144 0.151

E3 3.68 3.78 3.91 0.145 0.149 0.154

E4

0.75 TYP. 0.030 TYP.

e 1.27 BSC 0.050 BSC

K

1.27 TYP. 0.050 TYP.

K1 0.56 - - 0.022 - -

H 0.51 0.61 0.71 0.020 0.024 0.028

L 0.51 0.61 0.71 0.020 0.024 0.028

L1 0.06 0.13 0.20 0.002 0.005 0.008

θ 0° - 12° 0° - 12°

W 0.15 0.25 0.36 0.006 0.010 0.014

M

0.125 TYP. 0.005 TYP.

ECN: T10-0055-Rev. J, 15-Feb-10

DWG: 5881

1

2

3

b

4

1

2

3

b

4

Document Number: 71655 www.vishay.com

Revison: 15-Feb-10 1

Page 8

PowerPAK® SO-8 Mounting and Thermal Considerations

Wharton McDaniel

AN821

Vishay Siliconix

MOSFETs for switching applications are now available

with die on resistances around 1 mΩ and with the

capability to handle 85 A. While these die capabilities

represent a major advance over what was available

just a few years ago, it is important for power MOSFET

packaging technology to keep pace. It should be obvious that degradation of a high performance die by the

package is undesirable. PowerPAK is a new package

technology that addresses these issues. In this application note, PowerPAK’s construction is described.

Following this mounting information is presented

including land patterns and soldering profiles for maximum reliability. Finally, thermal and electrical performance is discussed.

THE PowerPAK PACKAGE

The PowerPAK package was developed around the

SO-8 package (Figure 1). The PowerPAK SO-8 utilizes the same footprint and the same pin-outs as the

standard SO-8. This allows PowerPAK to be substituted directly for a standard SO-8 package. Being a

leadless package, PowerPAK SO-8 utilizes the entire

SO-8 footprint, freeing space normally occupied by the

leads, and thus allowing it to hold a larger die than a

standard SO-8. In fact, this larger die is slightly larger

than a full sized DPAK die. The bottom of the die attach

pad is exposed for the purpose of providing a direct,

low resistance thermal path to the substrate the device

is mounted on. Finally, the package height is lower

than the standard SO-8, making it an excellent choice

for applications with space constraints.

PowerPAK SO-8 SINGLE MOUNTING

The PowerPAK single is simple to use. The pin

arrangement (drain, source, gate pins) and the pin

dimensions are the same as standard SO-8 devices

(see Figure 2). Therefore, the PowerPAK connection

pads match directly to those of the SO-8. The only difference is the extended drain connection area. To take

immediate advantage of the PowerPAK SO-8 single

devices, they can be mounted to existing SO-8 land

patterns.

Standard SO-8 PowerPAK SO-8

Figure 2.

The minimum land pattern recommended to take full

advantage of the PowerPAK thermal performance see

Application Note 826, Recommended Minimum Pad

Patterns With Outline Drawing Access for Vishay Siliconix MOSFETs. Click on the PowerPAK SO-8 single

in the index of this document.

In this figure, the drain land pattern is given to make full

contact to the drain pad on the PowerPAK package.

This land pattern can be extended to the left, right, and

top of the drawn pattern. This extension will serve to

increase the heat dissipation by decreasing the thermal resistance from the foot of the PowerPAK to the

PC board and therefore to the ambient. Note that

increasing the drain land area beyond a certain point

will yield little decrease in foot-to-board and foot-toambient thermal resistance. Under specific conditions

of board configuration, copper weight and layer stack,

experiments have found that more than about 0.25 to

2

0.5 in

of additional copper (in addition to the drain

land) will yield little improvement in thermal performance.

Figure 1. PowerPAK 1212 Devices

Document Number 71622

28-Feb-06

www.vishay.com

1

Page 9

AN821

Vishay Siliconix

PowerPAK SO-8 DUAL

The pin arrangement (drain, source, gate pins) and the

pin dimensions of the PowerPAK SO-8 dual are the

same as standard SO-8 dual devices. Therefore, the

PowerPAK device connection pads match directly to

those of the SO-8. As in the single-channel package,

the only exception is the extended drain connection

area. Manufacturers can likewise take immediate

advantage of the PowerPAK SO-8 dual devices by

mounting them to existing SO-8 dual land patterns.

To take the advantage of the dual PowerPAK SO-8’s

thermal performance, the minimum recommended

land pattern can be found in Application Note 826,

Recommended Minimum Pad Patterns With Outline

Drawing Access for Vishay Siliconix MOSFETs. Click

on the PowerPAK 1212-8 dual in the index of this document.

The gap between the two drain pads is 24 mils. This

matches the spacing of the two drain pads on the PowerPAK SO-8 dual package.

REFLOW SOLDERING

Vishay Siliconix surface-mount packages meet solder

reflow reliability requirements. Devices are subjected

to solder reflow as a test preconditioning and are then

reliability-tested using temperature cycle, bias humidity, HAST, or pressure pot. The solder reflow temperature profile used, and the temperatures and time

duration, are shown in Figures 3 and 4.

For the lead (Pb)-free solder profile, see http://

www.vishay.com/doc?73257.

Ramp-Up Rate + 6 °C /Second Maximum

Temperature at 155 ± 15 °C

Temperature Above 180 °C

Maximum Temperature

Time at Maximum Temperature

Ramp-Down Rate

Figure 3. Solder Reflow Temperature Profile

120 Seconds Maximum

70 - 180 Seconds

240 + 5/- 0 °C

20 - 40 Seconds

+ 6 °C/Second Maximum

www.vishay.com

2

140 - 170 °C

3 °C(max)

10 s (max)

210 - 220 °C

3 °C(max) 4 ° C/s (max)

183 °C

50 s (max)

60 s (min)

Pre-Heating Zone

Maximum peak temperature at 240 °C is allowed.

Figure 3. Solder Reflow Temperatures and Time Durations

Reflow Zone

Document Number 71622

28-Feb-06

Page 10

THERMAL PERFORMANCE

AN821

Vishay Siliconix

Introduction

A basic measure of a device’s thermal performance is

the junction-to-case thermal resistance, Rθ

junction-to-foot thermal resistance, Rθ

. This parameter

jf

, or the

jc

is measured for the device mounted to an infinite heat

sink and is therefore a characterization of the device

only, in other words, independent of the properties of the

object to which the device is mounted. Table 1 shows a

comparison of the DPAK, PowerPAK SO-8, and standard SO-8. The PowerPAK has thermal performance

equivalent to the DPAK, while having an order of magnitude better thermal performance over the SO-8.

TABLE 1.

DPAK and PowerPAK SO-8

Equivalent Steady State Performance

Thermal

Resistance Rθ

DPAK PowerPAK

SO-8

1.2 °C/W 1.0 °C/W 16 °C/W

jc

Standard

SO-8

Thermal Performance on Standard SO-8 Pad Pattern

Because of the common footprint, a PowerPAK SO-8

can be mounted on an existing standard SO-8 pad pattern. The question then arises as to the thermal performance of the PowerPAK device under these conditions.

A characterization was made comparing a standard SO-8

and a PowerPAK device on a board with a trough cut out

underneath the PowerPAK drain pad. This configuration

restricted the heat flow to the SO-8 land pads. The

results are shown in Figure 5.

Because of the presence of the trough, this result suggests a minimum performance improvement of 10 °C/W

by using a PowerPAK SO-8 in a standard SO-8 PC

board mount.

The only concern when mounting a PowerPAK on a

standard SO-8 pad pattern is that there should be no

traces running between the body of the MOSFET.

Where the standard SO-8 body is spaced away from the

pc board, allowing traces to run underneath, the PowerPAK sits directly on the pc board.

Thermal Performance - Spreading Copper

Designers may add additional copper, spreading copper, to the drain pad to aid in conducting heat from a

device. It is helpful to have some information about the

thermal performance for a given area of spreading copper.

Figure 6 shows the thermal resistance of a PowerPAK

SO-8 device mounted on a 2-in. 2-in., four-layer FR-4

PC board. The two internal layers and the backside layer

are solid copper. The internal layers were chosen as

solid copper to model the large power and ground

planes common in many applications. The top layer was

cut back to a smaller area and at each step junction-toambient thermal resistance measurements were taken.

The results indicate that an area above 0.3 to 0.4 square

inches of spreading copper gives no additional thermal

performance improvement. A subsequent experiment

was run where the copper on the back-side was

reduced, first to 50 % in stripes to mimic circuit traces,

and then totally removed. No significant effect was

observed.

Si4874DY vs. Si7446DP PPAK on a 4-Layer Board

SO-8 Pattern, Trough Under Drain

60

50

)

s

ttaw/

40

C

( e

cn

30

adep

m

I

20

10

0

0.0001

Figure 5.

Document Number 71622

28-Feb-06

PowerPAK SO-8 and Standard SO-0 Land Pad Thermal Path

Si4874DY

1

Pulse Duration (sec)

Si7446DP

100

vs. Spreading Copper

R

th

(0 %, 50 %, 100 % Back Copper)

56

)sttaw/C(

51

ecn

46

adep

m

I

41

100000.01

36

0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00

0.00

Figure 6. Spreading Copper Junction-to-Ambient Performance

100 %

0 %

50 %

www.vishay.com

3

Page 11

AN821

Vishay Siliconix

SYSTEM AND ELECTRICAL IMPACT OF

PowerPAK SO-8

In any design, one must take into account the change in

MOSFET r

1.8

1.6

)

( ecnatsiseR-nO -r

1.4

)dezilamroN(

1.2

)no(SD

1.0

0.8

0.6

with temperature (Figure 7).

DS(on)

On-Resistance vs. Junction Temperature

VGS = 10 V

= 23 A

I

D

-50 -25 0 25 50 75 100 125 150

- Junction Temperature (°C)

T

J

Figure 7.

MOSFET

r

vs. Temperature

DS(on)

A MOSFET generates internal heat due to the current

passing through the channel. This self-heating raises

the junction temperature of the device above that of the

PC board to which it is mounted, causing increased

power dissipation in the device. A major source of this

problem lies in the large values of the junction-to-foot

thermal resistance of the SO-8 package.

PowerPAK SO-8 minimizes the junction-to-board thermal resistance to where the MOSFET die temperature is

very close to the temperature of the PC board. Consider

two devices mounted on a PC board heated to 105 °C

by other components on the board (Figure 8).

Suppose each device is dissipating 2.7 W. Using the

junction-to-foot thermal resistance characteristics of the

PowerPAK SO-8 and the standard SO-8, the die temperature is determined to be 107 °C for the PowerPAK

(and for DPAK) and 148 °C for the standard SO-8. This

is a 2 °C rise above the board temperature for the PowerPAK and a 43 °C rise for the standard SO-8. Referring

to Figure 7, a 2 °C difference has minimal effect on

r

whereas a 43C difference has a significant effect

DS(on)

on r

DS(on)

.

Minimizing the thermal rise above the board temperature by using PowerPAK has not only eased the thermal

design but it has allowed the device to run cooler, keep

r

low, and permits the device to handle more cur-

DS(on)

rent than the same MOSFET die in the standard SO-8

package.

CONCLUSIONS

PowerPAK SO-8 has been shown to have the same

thermal performance as the DPAK package while having the same footprint as the standard SO-8 package.

The PowerPAK SO-8 can hold larger die approximately

equal in size to the maximum that the DPAK can accommodate implying no sacrifice in performance because of

package limitations.

Recommended PowerPAK SO-8 land patterns are provided to aid in PC board layout for designs using this

new package.

Thermal considerations have indicated that significant

advantages can be gained by using PowerPAK SO-8

devices in designs where the PC board was laid out for

the standard SO-8. Applications experimental data gave

thermal performance data showing minimum and typical

thermal performance in a SO-8 environment, plus information on the optimum thermal performance obtainable

including spreading copper. This further emphasized the

DPAK equivalency.

PowerPAK SO-8

Figure 8.

www.vishay.com

4

Standard SO-8

107 °C

0.8 °C/W

PC Board at 105 °C

Temperature of Devices on a PC Board

16 C/W

148 °C

PowerPAK SO-8 therefore has the desired small size

characteristics of the SO-8 combined with the attractive

thermal characteristics of the DPAK package.

Document Number 71622

28-Feb-06

Page 12

RECOMMENDED MINIMUM PADS FOR PowerPAK® SO-8 Single

0.260

(6.61)

0.150

(3.81)

0.024

(0.61)

Application Note 826

Vishay Siliconix

Return to Index

Return to Index

0.026

(0.66)

0.050

(1.27)

0.050

(1.27)

0.032

(0.82)

Recommended Minimum Pads

Dimensions in Inches/(mm)

0.154

(3.91)

0.040

(1.02)

0.174

(4.42)

APPLICATION NOTE

Document Number: 72599 www.vishay.com

Revision: 21-Jan-08 15

Page 13

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12

1

Document Number: 91000

Page 14

Loading...

Loading...