Page 1

Preliminary Rev. 0.8 3/06 Copyright © 2006 by Silicon Laboratories Si8250/1/2

This information applies to a product under development. Its characteristics and specifications are subject to change without notice.

Si8250/1/2

DIGITAL POWER CONTROLLER

Features

Description

Si8250/1/2 provides all control and protection functions necessary to implement

highly intelligent, fast response power delivery and management control systems

for isolated and non-isolated power supplies. On-board processing capability

enables intelligent control optimization for improved system performance and new

capabilities such as serial connectivity via the PMBus or on-board UART. The

Si8250/1/2 family is in-system Flash programmable enabling control and

protection parameters such as system regulation and protection settings, start-up

and shutdown modes, loop response, and modulation timing to be readily

modified. The built-in high-speed control path provides loop updates every 100nS

and provides pulse-by-pulse current limiting and over-current protection even

while the internal CPU is disabled.

The Si825x family is supported by the Si8250DK development kit, which contains

everything required to develop and program power supply applications with the

Si825x family of digital controllers.

Single-Chip, Flash-based digital

power controller

Supports isolated and non-isolated

applications

Enables new system capabilities

such as:

- Adaptive dead-time control for

higher efficiency

- Nonlinear control for faster

transient response

- Self diagnostics for higher

reliability

- Full PMBus command set

implementation for system

connectivity

Highly integrated control solution:

High-speed digital hardware

control loop

In-system programmable

supervisory processor

Programmable system protection

functions

Hardware cycle-by-cycle current

limiting and OCP

External clock and frame

synchronization inputs

Performs system management

functions such as external power

supply sequencing and fan

control/monitoring

In-system Flash programmable

Flash can also be used as NV

memory for data storage

Low cost, comprehensive

development tool kit includes:

Graphical, easy-to-use system

design tools

Integrated development

environment

In-system, on-line debugger

Turnkey isolated 35 W digital

half-bridge target board

Typical Applications

Isolated and non-isolated DC/DC

converters

AC/DC converters

Fully Pb-free and ROHS compliant

packages

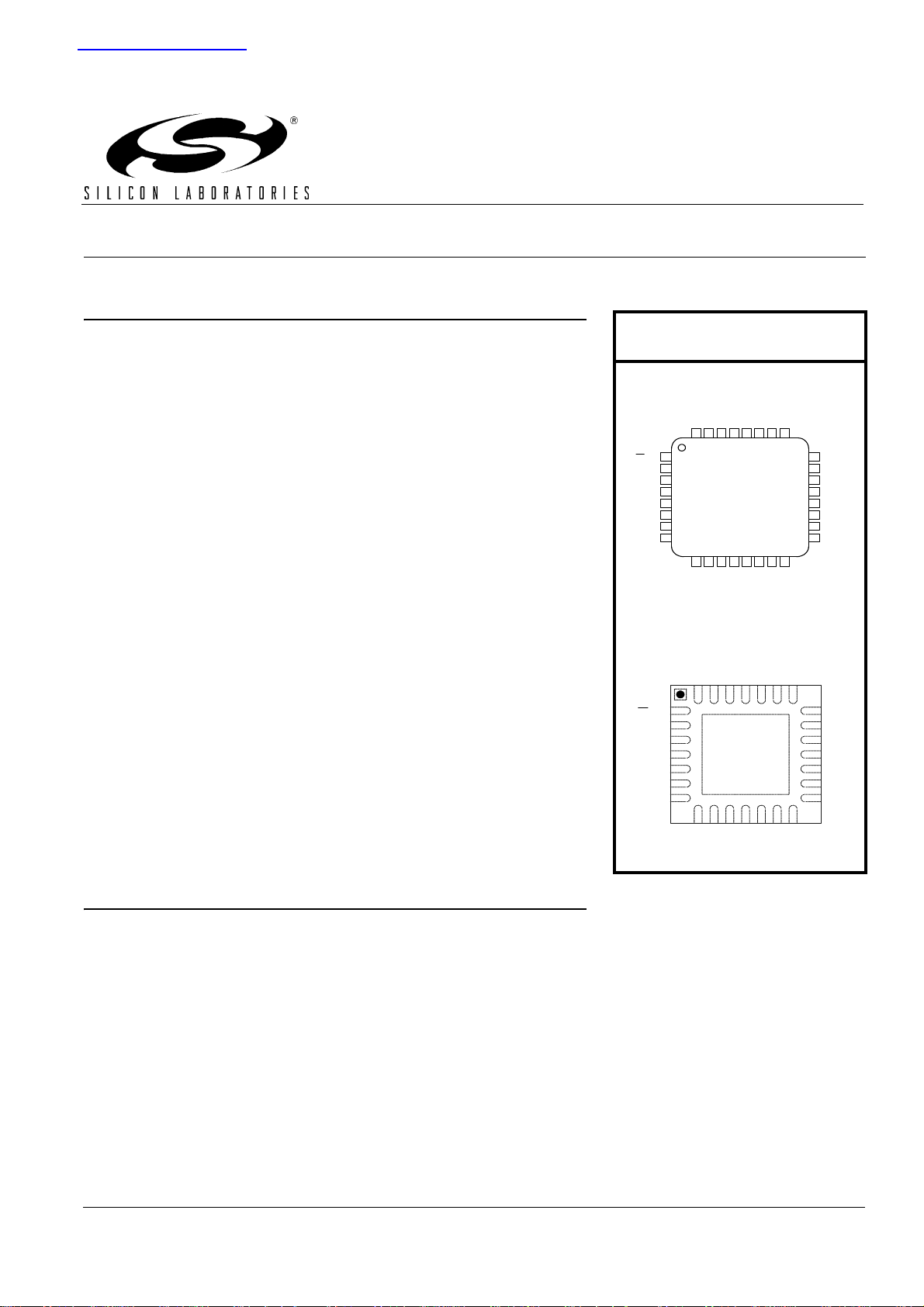

32-pin LQFP

28-pin 5 x 5 mm QFN

Temp Range: –40 to +125 ºC

Patents pending

Pin Assignments:

See page 23

4

5

6

7

2

1

3

111213

14

9

8

10

18

17

16

15

20

21

19

25

26

27

28

232224

Si8250/1/2

Top View

RST / C2CK

IPK

VSENSE

GND

VDD

VREF

P1.0/VIN/AIN0

P1.1/AIN1

P1.2/AIN2

P1.3/AIN3

P1.4/AIN4

P1.5/AIN5

P1.6/AIN6

P1.7/AIN7/C2D

P0.7

P0.6

P0.5

P0.4

P0.3/XCLK

P0.2

P0.1

P0.0

PH6

PH5

PH4

PH3

PH2

PH1

GND

GND

1

VSENSE

P0.0

P0.5

P0.2

P0.1

P0.3 / XCLK

P1.0/VIN/AIN 0

IPK

P0.6

P0.7

2

3

4

5

6

7

8

24

23

22

21

20

19

18

17

9

10111213141516

32313029282726

25

P0.4

Si8250/1/2

Top View

P1.1/AIN1

GNDA

VDDA

RST/C2CK

GND

VDD

P1.5/AIN5

P1.6/AIN6

P1.7/AIN7/C2D

PH6

PH5

P1.4/AIN4

VDD

GND

PH3

P1.3/AIN3

P1.2/AIN2

VREF

PH4

PH2

PH1

28-pin QFN

32-pin LQFP

查询SI8250-IQ供应商

Page 2

Si8250/1/2

2 Preliminary Rev. 0.8

Page 3

Si8250/1/2

Preliminary Rev. 0.8 3

TABLE OF CONTENTS

Section Page

1. Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. Benefits of Digital Power Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1. System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.2. Control Processor Functional Block Descriptions (Figure 1) . . . . . . . . . . . . . . . . . . . 16

3.3. System Management Processor Functional Block Descriptions . . . . . . . . . . . . . . . . 17

4. Design Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5. Example Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. Layout Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7. Pin Descriptions—Si8250/1/2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

8. Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9. Package Outline—32LQFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

10. Package Outline—28QFN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Document Change List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Page 4

Si8250/1/2

4 Preliminary Rev. 0.8

1. Electrical Specifications

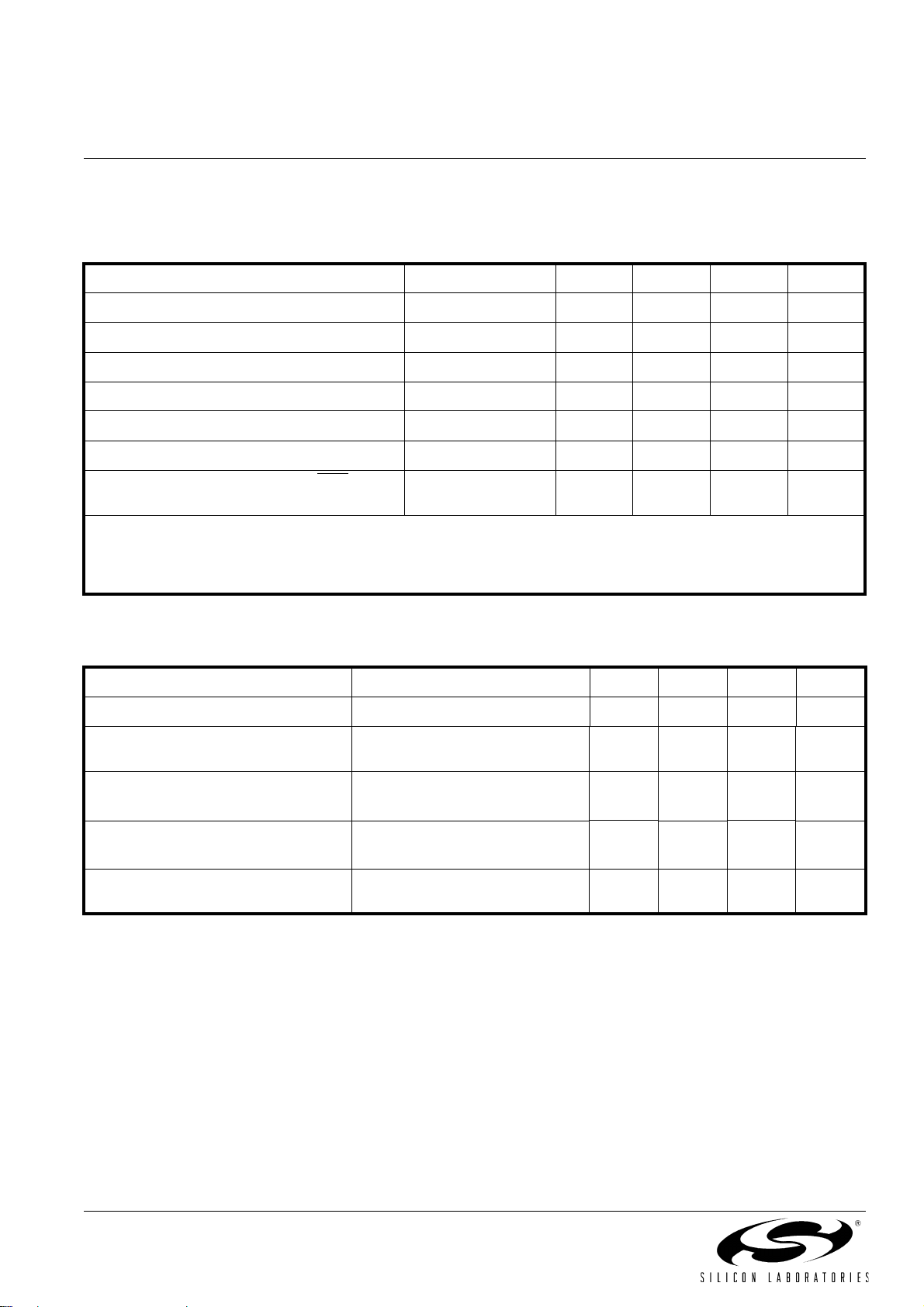

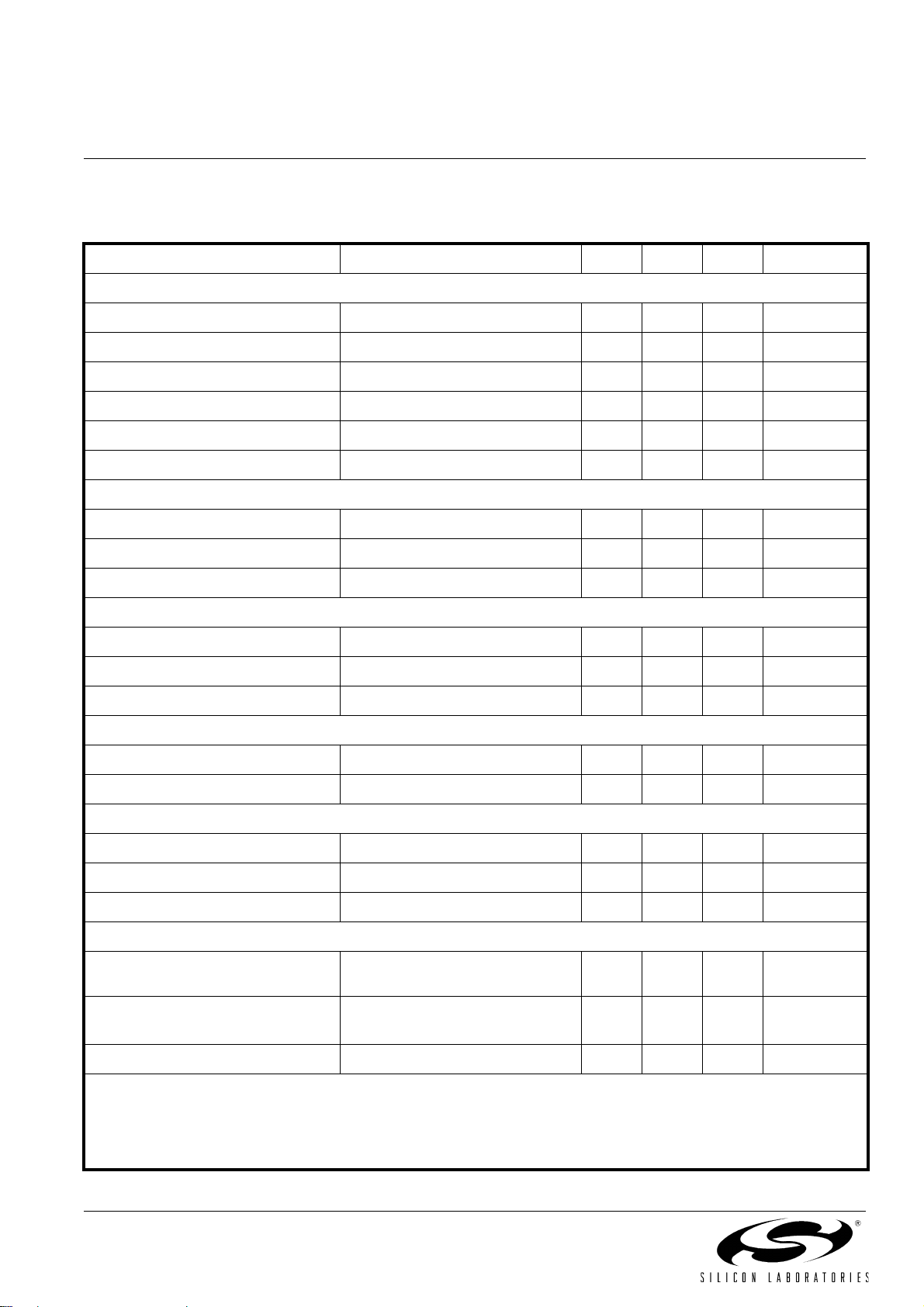

Table 1. Absolute Maximum Ratings*

Parameter Conditions Min. Typ. Max. Units

Ambient Temperature under Bias –55 — +135 °C

Storage Temperature –65 — +150 °C

Voltage on any Port0 Pin with respect to GND –0.3 — 5.5 V

Voltage on all other pins with respect to GND –0.3 — 4.0 V

Voltage on VDD with respect to GND –0.3 — 4.0 V

Maximum total current through VDD or GND — — 400 mA

Maximum output current sunk by RST

or any

Port pin

——80mA

*Note: Stresses above those listed under "2.1 Absolute Maximum Ratings" may cause permanent damage to the device. This

is a stress rating only, and functional operation of the devices at those or any other conditions above those indicated in

the operation listings of this specification is not implied. Exposure to maximum rating conditions for extended periods

may affect device reliability.

Table 2. DC Electrical Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Supply Voltage 2.25 — 2.75 V

Supply Current, all Peripherals

Enabled

Analog + digital supply current. — 26 — mA

Lockout mode supply current Analog + digital supply current.

(See Table 1 on page 4)

—300— µA

Digital Supply Current (shutdown) Oscillator not running, VDD mon-

itor disabled

——TBDµA

Digital Supply RAM Data Retention

Voltage

—1.5— V

Page 5

Si8250/1/2

Preliminary Rev. 0.8 5

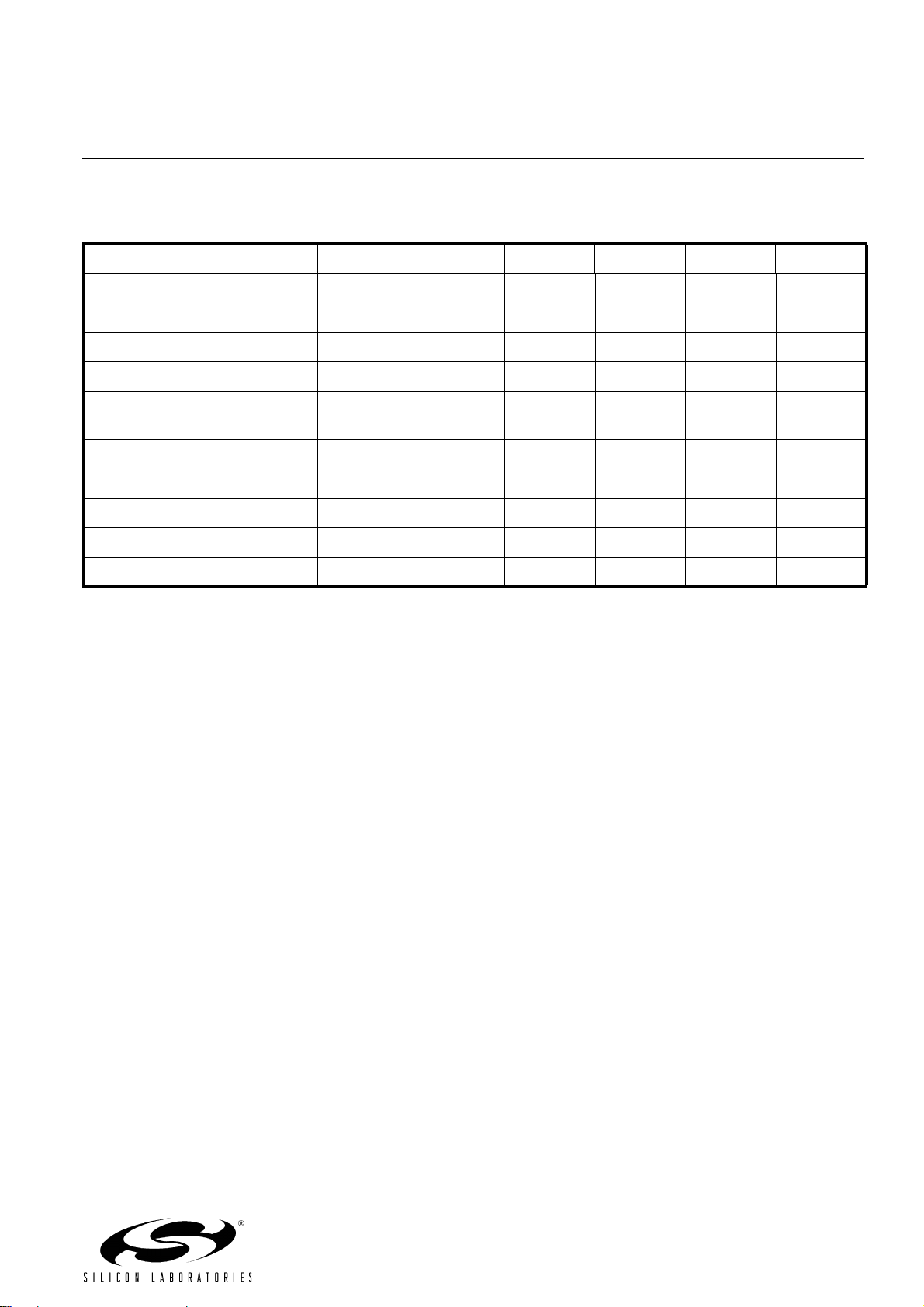

Table 3. Reference DAC Electrical Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Resolution — — 9 Bits

LSB Size — 2.44 — mV

Integral Nonlinearity (INL) –2 — +2 LSB

Differential Nonlinearity (DNL) –1.0 — +1.0 LSB

Settling Time 1/2 LSB change from 0 to

full scale

—2—µs

Turn-on Time — 20 — µs

Noise 2 MHz BW — 1 — mV

PP

Power Supply Rejection — 70 — db

Supply Current — 220 — µA

Shutdown Supply Current — 0.1 — µA

Page 6

Si8250/1/2

6 Preliminary Rev. 0.8

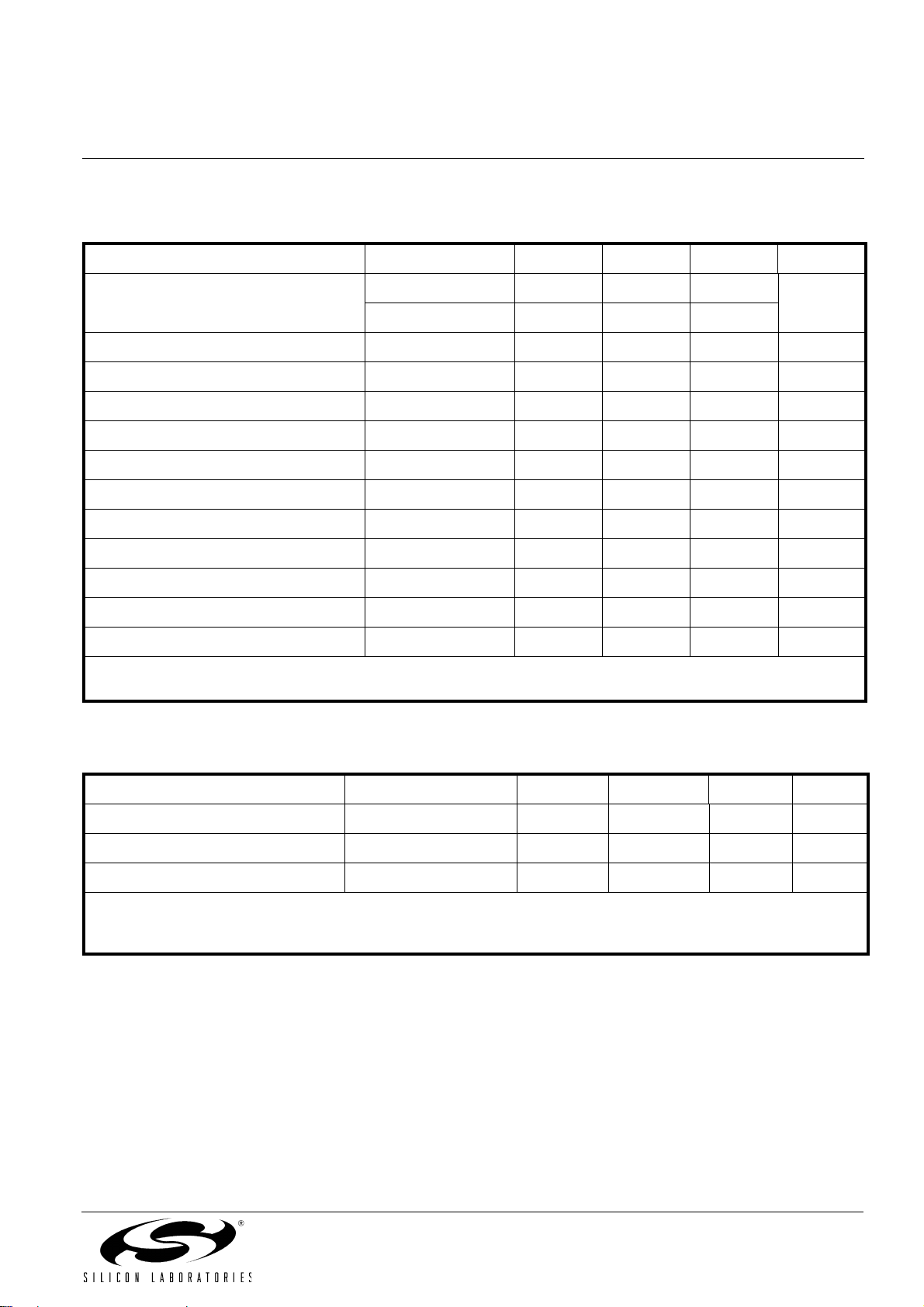

Table 4. ADC0 (12-Bit ADC) Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

DC Accuracy

Resolution — 12 — bits

Integral Nonlinearity — — ±2 LSB

Differential Nonlinearity Guaranteed Monotonic — — ±1 LSB

Offset Error — ±3 — LSB

Full Scale Error Differential mode — 3 — LSB

Offset Temperature Coefficient — TBD — ppm/°C

Dynamic Performance (10 kHz sine-wave Single-ended input, 0 to 1 dB below Full Scale, 200 ksps)

Signal-to-Noise Plus Distortion — 64 — dB

Total Harmonic Distortion Up to the 5

th

harmonic — 83 — dB

Spurious-Free Dynamic Range — –73 — dB

Conversion Rate

Conversion Time in SAR Clocks Note 1 — 13 — clocks

Track/Hold Acquisition Time Note 2 1 — — µs

Throughput Rate — — 200 ksps

Analog Inputs

Input Voltage Range 0 — V

REF

V

Input Capacitance — 15 — pF

Temperature Sensor

Linearity Notes 3, 4 — ±TBD — °C

Gain Notes 3, 4 — 1353 — µV/°C

Offset Notes 3, 4 (Temp = 0 °C) — 488 — mV

Power Specifications

Power Supply Current (V

DD

sup-

plied to ADC0)

Operating Mode, 200 ksps — 780 — µA

Power-On Time After V

REF

settle, before tracking

begins

—5— µs

Power Supply Rejection — TBD — mV/V

Notes:

1. An additional 2

F

CLK

cycles are required to start and complete a conversion.

2. Additional tracking time may be required depending on the output impedance connected to the ADC input.

3. Represents one standard deviation from the mean.

4. Includes ADC offset, gain, and linearity variations.

Page 7

Si8250/1/2

Preliminary Rev. 0.8 7

Table 5. ADC1 Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Sampling Frequency ADCSP = 0 — 10 — Msps

ADCSP = 1 — 5 —

Resolution — — 6 Bits

LSB Size 4 — 20 mV

Differential Input Voltage Range Note 1 –32 — +31 LSB

Common-mode input voltage range 0.8 — 1.3 V

Integral Nonlinearity –2 — +2 LSB

Differential Nonlinearity –1 — +1 LSB

Gain Error — 5 — %

Offset Error — 3 — mV

Input Bias Current — 5 — µA

Standby Mode Supply Current disabled — 0.1 — µA

Operating Mode Supply Current — — 3 mA

Notes:

1. LSB size (mV) is programmable using the RES[3:0] bits in the ADC1CN register.

Table 6. DSP Filter Engine Electrical Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Resolution

1

——9Bits

Dithering

2

——6Bits

Standby Mode Supply Current disabled — 0.1 — µA

Notes:

1. Internal word length = 22 bits.

2. Up to a total 15 bits of resolution when dithering is enabled.

Page 8

Si8250/1/2

8 Preliminary Rev. 0.8

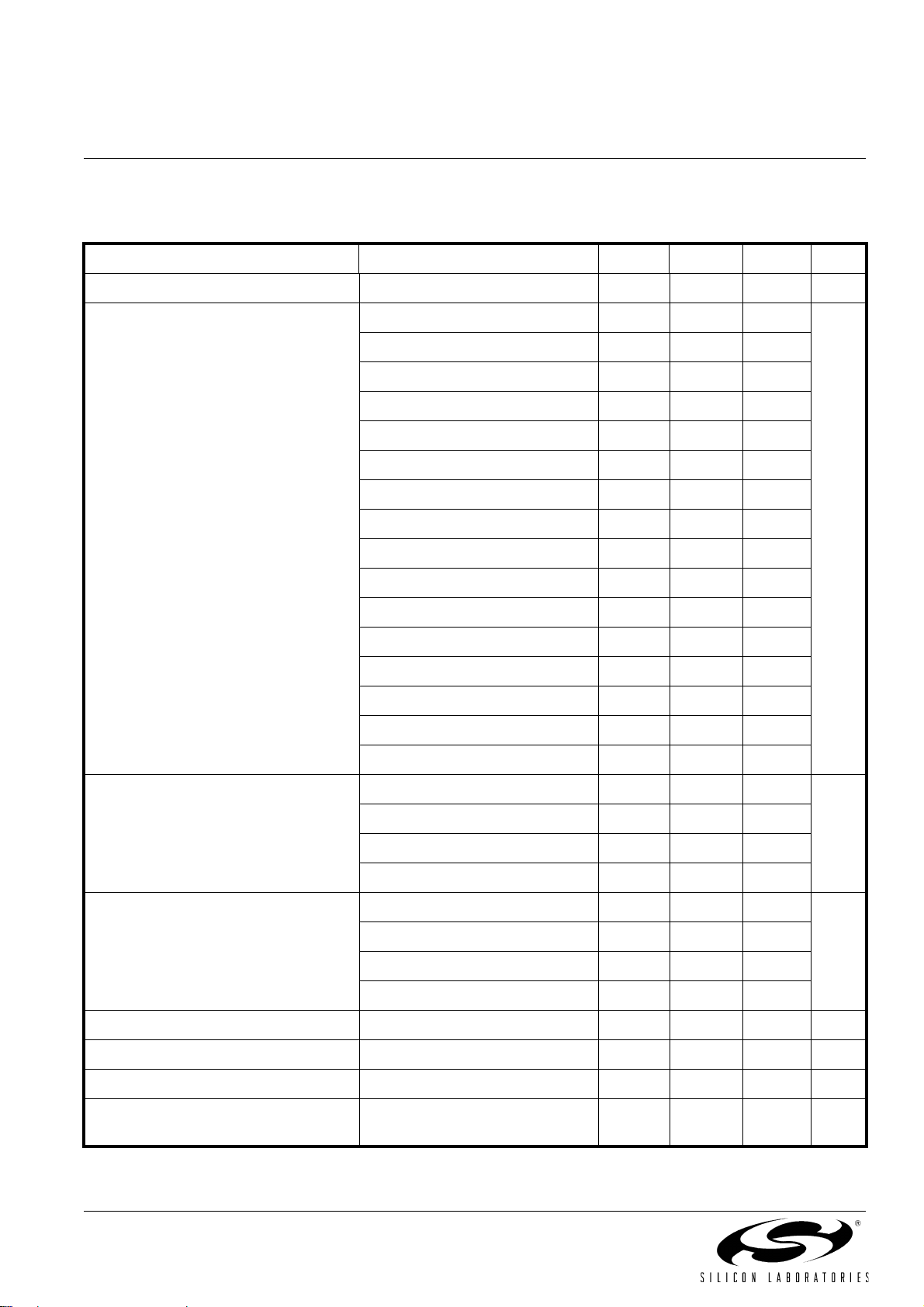

Table 7. Peak Current Limit Detector Electrical Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

IPK Input to DPWM Output Latency 10 mV Overdrive — 45 — ns

Threshold Detector Voltage VT[3:0] = 0000 35 50 65 mV

VT[3:0] = 0001 85 100 115

VT[3:0] = 0010 135 150 165

VT[3:0] = 0011 185 200 215

VT[3:0] = 0100 235 250 265

VT[3:0] = 0101 285 300 315

VT[3:0] = 0110 335 350 365

VT[3:0] = 0111 485 400 415

VT[3:0] = 1000 435 450 465

VT[3:0] = 1001 485 500 515

VT[3:0] = 1010 535 550 565

VT[3:0] = 1011 585 600 615

VT[3:0] = 1100 635 650 665

VT[3:0] = 1101 685 700 715

VT[3:0] = 1110 735 750 765

VT[3:0] = 1111 785 8 00 815

Hysteresis HYST[1:0] = 00 — 0 — mV

HYST[1:0] = 01 — 5 —

HYST[1:0] = 10 — 10 —

HYST[1:0] = 11 — 20 —

Blanking Time LEB[1:0] = 00, f

PLL

= 200 MHz — 0 — ns

LEB[1:0] = 01, f

PLL

=200MHz — 20 —

LEB[1:0] = 10, f

PLL

=200MHz — 40 —

LEB[1:0] = 11, f

PLL

= 200 MHz — 80 —

Input Capacitance — 4.5 — pF

Input Bias Current — 0.1 — µA

Shutdown Supply Current Enable bit = 0 — 0.1 — µA

Active Supply Current IIN = (Vt + 100 mVpp),

1.5 MHz sq. wave

—100—µA

Page 9

Si8250/1/2

Preliminary Rev. 0.8 9

Table 8. DPWM Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Clock Frequency DPWMSP[4:3] = 00 — — 200 MHz

DPWMSP[4:3] = 01 — — 50

DPWMSP[4:3] = 1x — — 25

Resolution No dithering — — 9 Bits

Dithering enabled — — 15

Time Resolution DPWMSP[4:3] = 00 5 — — ns

DPWMSP[4:3] = 01 20 — —

DPWMSP[4:3] = 1x 40 — —

SYNC Pulse set-up time SYNC signal minimum LOW time

before positive transition

3——DPWM

clock cycles

PH Rise, Fall Time 50pF on pin — — 5 ns

Output Resistance High I

OUT

=–5mA — 75 — Ω

Output Resistance Low I

OUT

=8mA — 40 — Ω

Shutdown Supply Current — — 0.1 µA

Table 9. Bandgap Voltage Reference Specs

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Output Voltage — 1.20 — V

Temperature Stability –1 — +1 %

Turn-on Response (0.01%, 4.7 µF) — 6.5 — ms

no load — 2 — µs

Noise 4.7 µF — 2 — µV (RMS)

Bandgap Current — 60 — µA

Reference Buffer Current — 30 — µA

Power supply rejection — 50 — dB

Page 10

Si8250/1/2

10 Preliminary Rev. 0.8

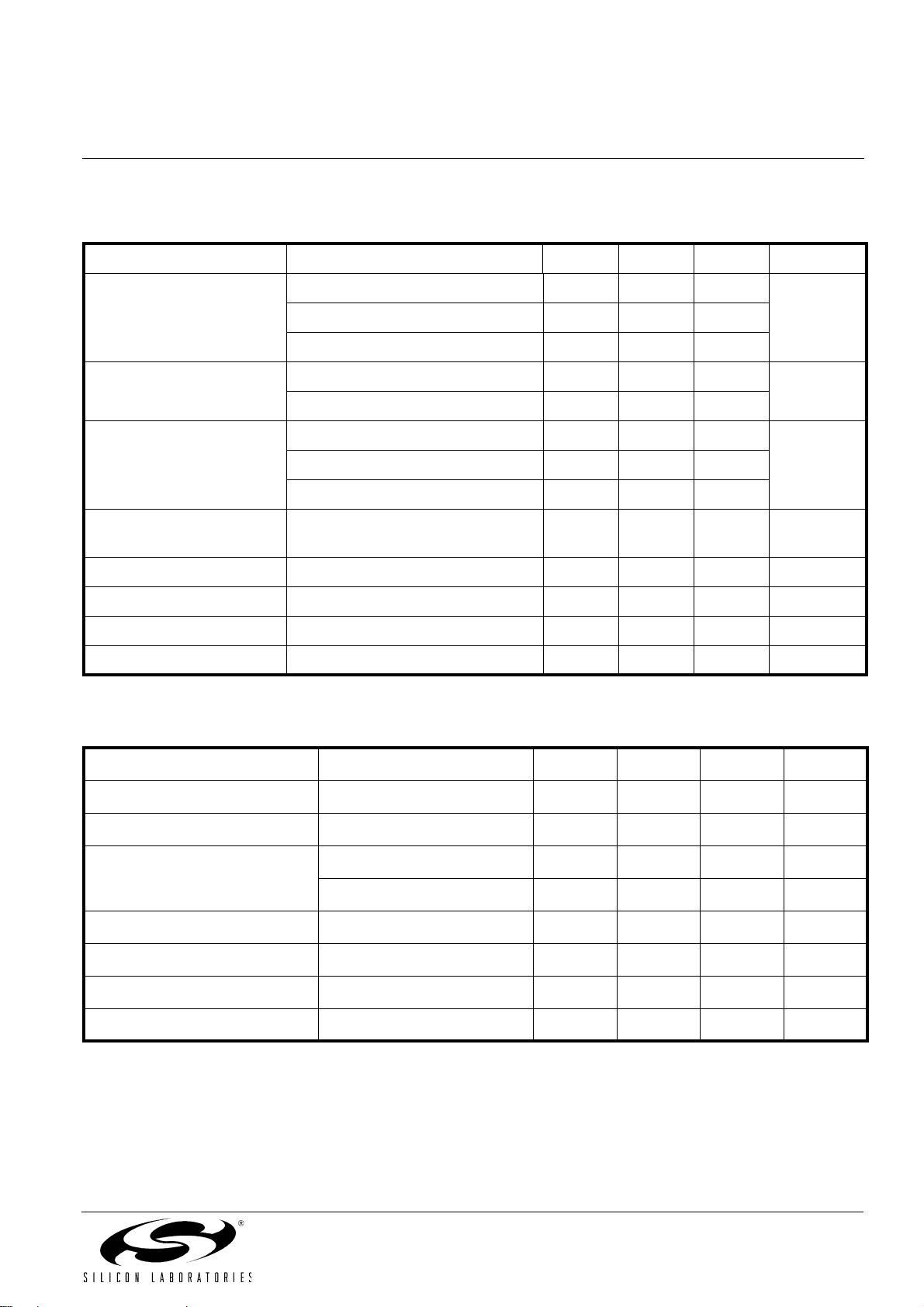

Table 10. Comparator0 Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Vin 0 — V

DD

V

Low-Speed Supply Current — 8 — µA

Full-speed Supply Current — 225 — µA

Hysteresis CP0HYP[1:0] = 00 — 0 — mV

CP0HYP[1:0] = 01 — 7 —

CP0HYP[1:0] = 10 — 14 —

CP0HYP[1:0] = 11 — 28 —

CP0HYN[1:0] = 00 — 0 —

CP0HYN[1:0] = 01 — –7 —

CP0HYN[1:0] = 10 — –14 —

CP0HYN[1:0] = 11 — –28 —

Response Time Low Power Mode, 25 mV Overdrive — 180 — ns

High-Speed Mode, 25 mV Overdrive — 25 —

Input Capacitance — 5 — pF

CMRR — 50 — db

Input offset — 5 — mV

Page 11

Si8250/1/2

Preliminary Rev. 0.8 11

Table 11. Reset Electrical Characteristics

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

RST

Output Low Voltage IOL= 8.5mA, VDD = 2.5V — — 0.7 V

RST

Input High Voltage 0.7 x V

DD

—— V

RST

Input Low Voltage — — 0.3 x V

DD

V

RST

Input Pull-up Current RST =0.0 — 25 TBD µA

VDD POR Threshold 2.0 2.1 2.2 V

Missing clock detector timeout Time from last system clock ris-

ing edge to start of reset

— 250 650 µs

Reset time delay Delay between release of any

reset source and code execu-

tion at location 0x0000

5.0 — — µs

Minimum RST

Low time to gen-

erate a System Reset

6.5 — — µs

VDD monitor turn-on time 100 — — µs

VDD monitor supply current — 40 — µA

Table 12. Flash Electrical Characteristics

TA = –40 to +125 °C, VDD = 2.25 V – 2.75 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Flash Size Si8250 32768

(1)

—— bytes

Si8251, Si8252 16383

(1)

——

Endurance 10 K 100 K — Erase/Write

Read Cycle Time TBD — — ns

Erase Cycle Time 50 MHz System Clock 32 — 48 ms

Write Cycle Time 50 MHz System Clock 76 — 114 µs

Notes:

1. The last 512 bytes of memory are reserved.

Page 12

Si8250/1/2

12 Preliminary Rev. 0.8

Table 13. Port I/O DC Electrical Characteristics

TA = –40 to +125 °C, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameters Conditions Min Typ Max Units

Port0 Input Voltage Tolerance push-pull — — V

DD

+ 0.7 V

open-drain — — 5.5

Port1 Input Voltage Tolerance — — V

DD

+ 0.7

Output High Voltage I

OH

=–3mA,

Port I/O push-pull

VDD – 0.4 — — V

I

OH

=–10µA,

Port I/O push-pull

VDD – 0.1 — —

I

OH

= –10 mA,

Port I/O push-pull

—VDD – 0.8 —

Output Low Voltage I

OL

=8.5mA — — 0.6 V

I

OL

=10µA — — 0.1

I

OL

= 25 mA — 1.25 —

Input High Voltage (0.7) V

DD

——V

Input Low Voltage — — (0.3) V

DD

V

Input Leakage Current Weak Pullup Off — — ±10 µA

Weak Pullup On, V

IN

=0V — 20 50

Table 14. PLL Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Stabilization Time — 30 — µs

Input Frequency Range 15 — 25 MHz

PLL Frequency — 200 — MHz

Cycle-to-cycle jitter — 250 — ps

Supply current — 15 — mA

Shutdown current — 0.1 — µA

Page 13

Si8250/1/2

Preliminary Rev. 0.8 13

Table 15. 25MHz Oscillator Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Frequency — 24.5 — MHz

Start-up time — 100 — µs

Power supply sensitivity — 0.3 — %/V

Temperature coefficient — 50 — PPM/°C

Supply current — 450 — µA

Shutdown current — 0.1 — µA

Table 16. Low Frequency Oscillator (LFO) Specifications

TA = –40 to +125 °C, VDD = 2.5 V, SYSCLK = 25 MHz, PLLCLK = 200 MHz unless otherwise specified.

Parameter Conditions Min Typ Max Units

Frequency — 80 — kHz

Start-up time — 100 — µs

Power supply sensitivity — 1.7 — %/V

Temperature coefficient — 1000 — PPM/°C

Supply current — 4 — µA

Shutdown current — 0.1 — µA

Page 14

Si8250/1/2

14 Preliminary Rev. 0.8

2. Benefits of Digital Power Control

Digitally controlled power systems have the following

key advantages over analog implementations:

In-system programmability: Virtually all aspects of

digital controller behavior can be changed in

software locally or remotely, and without hardware

modification. This benefits the system in several

ways:

Hardware designs can be segregated into base

platforms (for example, by form factor or output power),

and optimized to the end application in software. This

lowers development costs by reducing the total number

of hardware designs required to address a given

application segment.

The controller's ability to readily accept change makes

possible low-cost, custom power supply versions with

relatively short lead-time.

The cost and risk of field configuration and/or updating

is greatly reduced, lowering the overhead associated

with customer support.

More advanced control algorithms: Power supply

design with fixed-function analog components leads

to many performance trade-offs. For example,

analog compensator design routinely trades stability

for higher loop bandwidth, and places the required

poles and zeros using passive components. The "ifthen-else" decision-making capability of digital

control can change loop bandwidth as needed for

optimum control response. For example the

controller can operate the compensator at a

relatively low bandwidth during steady-state

operation, but significantly extend bandwidth during

a transient. This adaptive response concept can be

applied to improve other operating parameters such

as efficiency.

Power Efficiency Optimization: In a switched mode

power supply, it is desirable to maintain high power

efficiency over a wide range of loads. Software

algorithms can optimize efficiency at every point of

line and load. For example, the software can adjust

dead time with changes load, disable synchronous

rectification at low loads, or take other measures to

maximize efficiency.

Higher operating precision: Switch timing, control

response and protection setting thresholds in analog

systems are typically determined by the values of

external passive components. These components

typically have a wide tolerance and vary with

temperature and time. Designers must allow for

these tolerances when considering worst case

operating conditions. Digital control offers tighter

parameter tolerances with greatly reduced

temperature/time variations resulting in improved

worst-case operating specifications.

Power management and power delivery functions in

a single package: Power management functions,

such as external supply sequencing, PMBus

communication support and fan control can be

performed by the digital controller, eliminating

dedicated external components.

System connectivity: PMBus and other emerging

communication protocols enable system processors

to communicate with the power supply to obtain data

and command action. For example, the system

processor may request the power supply operating

history, perform self-diagnostics or change system

settings without taking the supply off-line.

Communications with the system controller enables

notification of a pending power supply failure,

enhancing system reliability. This attribute also

reduces the cost and complexity of field

configurations and upgrades.

Higher integration/smaller size/lower cost: Many

discrete circuits can be transformed to lines of

software code, eliminating components and saving

cost. The digital controller can be used to execute

self-diagnostic routines during production test

thereby reducing test time and saving cost. The

small physical size of the Si8250 in particular

(5 x 5 mm) saves board space.

Page 15

Si8250/1/2

Preliminary Rev. 0.8 15

3. Product Description

Figure 1. Functional Block Diagram

Figure 2. Si8250 Top-Level Block Diagram

Si8250/1/2

System Management Processor

I/O (8)

I/O (8)

50MIPS 8051 CPU

1280 Byte

RAM

16/32 kB

Flash

PORT 0

8

MUX

TEMP

SENSOR

PORT 1

HARDWARE

DEBUG

RESET

CONTROL

2% 25 Mhz OSC,

and LFO

INTERRUPT

CONTROL

4x 16-BIT

TIMERS

SMBus

3 CH PCA

I/O PORT

LATCHES

ADC

REGISTERS

& LIMIT

DETECTORS

12-BIT

200 Ksps

ADC

UART

AUTO

SCAN

LOGIC

VSENSE

DEBUG

PORT

VDD

SYSCLKIN

Control Processor

IPK

VSENSE

VREF

GATE CONTROL

(6)

MULTIPHASE

DPWM

Pulse-by-Pulse

Current Limiter

and OCP

ICYC

u(n)

10 MHz

ADC

REFDAC

VREF

DSP

FILTER ENGINE

VSENSE

OCP

POWER STAGES

Si8250

System Management Processor

PORT 0

I/O CROSSBAR

TEMP

SENSOR

PORT 1

50MIPS 8051 CPU

and Memory

Digital Peripherals:

- UART

- SMBus Port

- 4 x 16-Bit Timers

- 3 Ch PCA (PWM)

- I/O Port La tches

VSENSE

DEBUG

PORT

VDD

SYSCLKIN

Control Processor

IPK

VSENSE

VREF

MULTIPHASE

DPWM

Pulse-by-Pulse

Current Limiter

and OCP

ICYC

u(n)

ADC1

10Msps

REFDAC

VREF

DSP

FILTER ENGINE

VSENSE

OCP

ADC 0

12-Bit, 200Ksps

10-Channel

Up to 6 Gate

Control Outputs

GATE

DRIVERS

16 General-Purpose

Analog/Digital I/O Lines

SUPPLY INPUT

VOLTAGE

OUTPUT

FILTER

SWITCHES

AND

MAGNETICS

Analog Input (e.g. average current)

Digital Ouput (e.g. fan speed control)

VOUT

Peak Current Signal (e.g. CT)

Page 16

Si8250/1/2

16 Preliminary Rev. 0.8

3.1. System Operation

Figure 2 shows the Si8250/1/2 controlling a nonisolated DC/DC converter operating in digital voltage

mode control. The output voltage signal connects to the

VSENSE input through a resistive divider, limiting the

common mode voltage range applied to ADC1 to a

maximum of VREF. The equivalent resistance of the

divider and the capacitor form an anti-aliasing filter with

a cutoff frequency equal to ADC1 sampling frequency of

divided by 2 (the amplitudes of frequencies above fS/2

must be minimized to prevent aliasing).

Differential ADC1 and the DSP Filter Engine together

perform the same function as an analog error amplifier

and associated RC compensation network. ADC1

digitizes the difference between the scaled output

voltage and a programmable reference voltage provided

by the REFDAC. The ADC1 output signal is frequency

compensated (in digital domain) by the DSP Filter

Engine. The resulting output from the DSP Filter Engine

is a digital code that represents the compensated duty

cycle ratio, u(n). The digital PWM generator (DPWM)

directly varies output timing to the external gate drivers

based on the value of u(n) until the difference between

VSENSE and ADC1 reference level is driven to zero.

Sensing circuitry within the power stages (current

transformer, sense amp, etc.) provides a signal

representative of inductor or transformer current. This

signal connects to the pulse-by-pulse current limiting

hardware in the Si8250/1/2 via the IPK input pin. This

current limiting circuitry is similar to that found in a

voltage mode analog PWM. It contains a fast analog

comparator and a programmable leading-edge blanking

circuit to prevent unwanted tripping of the current

sensing circuitry on the leading edge of the current

pulse. Current limiting occurs when the sensed current

exceeds the programmed threshold. When this occurs,

the on-going active portions of the PWM outputs are

terminated. A programmable OCP counter keeps track

of the number of consecutive current limit cycles, and

automatically shuts the supply down when the

accumulated number of limit cycles exceeds the

programmed maximum.

The System Management Processor is based on a 50

million instruction per second (MIPS) 8051 CPU and

dedicated A/D converter (ADC0). ADC0 digitizes key

analog parameters that are used by the MCU to provide

protection, as well as manage and control other aspects

of the power system. On-board digital peripherals

include: timers, an SMBus interface port (for PMBus or

other protocols); and a universal asynchronous

receiver/transmitter (UART) for serial communications,

useful for communicating across an isolation boundary.

The System Management Processor serves several

purposes, among these are:

1. Continuously optimizes Control Processor operation

(e.g. efficiently optimization)

2. Executes user-specific algorithms (e.g. support for

proprietary system interfaces)

3. Provides regulation for low-bandwidth system

variables (e.g. VIN feed-forward)

4. Performs system fault detection and recovery

5. Provides system housekeeping functions such as

PMBus communication support

6. Manages external device functions (e.g. external

supply sequencing, fan control/monitoring)

The Si8250/1/2 system development requires using the

Si8250DK, a comprehensive development kit providing

all required hardware and software for control system

design. It comes complete with pre-written and verified

application software, and a set of tools that enable the

user to adapt this software to the end application. It also

includes a turnkey isolated half-bridge DC/DC converter

based on the Si8250/1/2 for evaluation and

experimentation.

3.2. Control Processor Functional Block

Descriptions (Figure 1)

ADC 1: Differential input, 10 Msps control loop analogto-digital converter. ADC1 digitizes the difference

between the Vsense input and the programmable

voltage reference level from the REFDAC. ADC1 can be

operated at either 5 Msps or 10 Msps and has a

programmable LSB size to prevent limit cycle oscillation

(Limit cycle oscillation can also be avoided using

dithering to increase DPWM resolution). ADC1 has

programmable conversion rates of 10 Msps and 5 Msps

to accommodate a wide loop gain range. ADC1 also

contains a hardware transient detector that interrupts

the CPU at the onset of an output load or unload

transient. The CPU responds by executing specific

algorithms to accelerate output recovery. These

algorithms may include increasing loop bandwidth or

other measures.

REFDAC

: 9-bit digital-to-analog converter provides the

output voltage reference setting. The REFDAC uses the

on-board band gap as its voltage reference, or can be

referenced to an external voltage reference source.

REFDAC is used for output voltage calibration,

margining and positioning. The CPU continuously

manages the REFDAC during soft-start and soft-stop.

DSP Filter Engine

: This two-stage loop compensation

filter is the functional equivalent of an active RC

compensation in an analog control scheme. The first

filter stage is a PID filter providing one pole and two

Page 17

Si8250/1/2

Preliminary Rev. 0.8 17

zeros. The second stage is selectable: a two-pole lowpass filter (LPF) for the fastest possible response, or

SINC (multiple zero) decimation filter for relatively

quieter operation. The PID plus the LPF result in a three

pole, two zero composite filter, while the PID plus the

SINC results in a single pole, multiple zero composite

filter. The SINC filter provides zeros at intervals equal to

f

S

/(2*DEC) where DEC is the decimation ratio (i.e. ratio

of input to output sampling rate). DEC is a softwareprogrammable parameter, and can be programmed

such that zero placement occurs that the PWM

frequency and its harmonics. This creates more than

100 db attenuation at these frequencies providing lower

system noise levels.

The end-to-end response of the filter is defined using

only six software parameters, and can be reprogrammed during converter operation to implement

nonlinear control response for improved transient

resolution.

As described in the ADC1 section above, limit cycle

oscillation can be avoided by increasing ADC1 LSB size

to allow the DPWM LSB to fit within a single ADC1

output code (i.e. zero-error bin). However in some

applications, it may not be desirable to lower ADC1

sensitivity. For such applications, limit cycle oscillation

can be avoided by dithering the DPWM output. The

DSP Filter Engine contains a pseudo-random,

broadband noise generator - mixing this noise into the

filter output randomly moves the gate control output(s)

over a range of 1 LSB, such that the time-averaged

resolution of the DPWM is increased.

The filter response is programmed using S-domain

design tools included in the Si8250DK development kit,

greatly minimizing software writing tasks.

Pulse-by-pulse Current Limiter/OCP

: High-speed

comparator with 4-bit DAC threshold generator and 2-bit

programmable leading-edge blanking delay generator.

The comparator output causes the DPWM to terminate

the on-going portions of the active outputs when the

peak current signal applied to the IPK input exceeds the

threshold setting. Hardware performs an OCP supply

shutdown when the number of consecutive current limit

events equals a programmed maximum.

DPWM

: Output generator may be programmed for

pulse width (PWM) or phase-shift modulation using

design tools contained in the Si8250DK design kit. The

DPWM may be modulated by the front-end of the

Control Processor (ADC1 and DSP Filter Engine); or by

the CPU. The DPWM has individually programmable

stop states for supply off (disable) and OCP. Software

bypass mode allows the CPU to force selected outputs

high or low while the remaining outputs continue normal

operation. The DPWM includes an external SYNC input

and ENABLE input, both of which can be connected to

the I/O pins. The Enable is a logic input used to turn the

power supply on and off. It can be configured to be

active high or active low. The SYNC input allows the

start of each switching cycle to be synchronized to an

external clock source, including another Si8250/1/2.

3.3. System Management Processor Functional Block Descriptions

ADC0: Self-sequencing, 10-input, 200 Ksps analog-todigital converter. This general-purpose ADC acquires

other analog system parameters for supplemental

control by the CPU (e.g. dead time control using

average input current as the control variable). ADC0

also converts the output of the on-board temperature

sensor. Eight of the ten analog inputs may be

connected to the I/O pins for external interface. The

remaining two analog inputs (Vsense and Temp Sensor)

are internally connected. When placed in Auto

Sequencing mode, ADC0 automatically converts, stores

and limit-checks each analog input, and interrupts the

CPU when a converted result is outside of its

programmed range. This feature greatly facilitates

protection functions because all measurement and

comparison operations are automated.

Temperature Sensor

: This sensor measures the die

temperature of the Si8250/1/2. It can achieve 3 C

accuracy with a single-point calibration and 1 C with a

two-point calibration. The temperature output signal is

digitized by ADC0.

8051 CPU

: 50MIPS CPU core with 1K of SRAM and up

to 32 kB of Flash memory. This processor has its own

on-board oscillator and PLL, reset sources and realtime in-system hardware debug interface eliminating the

need for external processor supervisors, timebases,

and "emulators". The CPU has an external interrupt

(INT0/) that can be connected to an external device via

the I/O pins. When interrupted, the CPU suspends

execution of the current task, and immediately vectors

to an interrupt service routine specifically designed to

handle the interrupting device.

Digital peripherals

: Peripherals include: four 16-bit

timers, a three-channel programmable counter array

(PCA), each channel useful as a PWM, an SMBus port

useful as a PMBus interface, a UART (useful as a serial

data port for isolated applications, and two 8-bit I/O port

latches for logic control outputs.

Page 18

Si8250/1/2

18 Preliminary Rev. 0.8

4. Design Tools

The Si8250DK development kit (Figure 3) contains

everything required to develop applications with the

Si825x family of digital power controllers. This kit

supports all phases of power supply development from

controller design through real-time system debugging. It

also includes a turnkey, 35 W isolated DC/DC target

board for evaluation and experimentation.

Figure 3. Si8250DK Development Kit

Figure 4. Software Download to Si8250

Mounted in Power Supply

Figure 5. Timing Design Tool (Top) and Buck

Regulator Compensation Tool (Bottom)

The tool set enables the user to configure pre-written

application software included in the kit to his application

using a set of PC-based graphical user interface (GUIs).

These GUIs (Figure 5) allow the user to quickly and

easily specify and verify system timing, loop

compensation and protection settings, and compile and

download the resulting code into the Si8250/1/2

(Figure 4).

Page 19

Si8250/1/2

Preliminary Rev. 0.8 19

5. Example Applications

Isolated DC/DC Converter: A 35 W, 400 kHz Si8250-based half bridge converter is shown in Figure 6. This circuit

is the same as that of the target (evaluation) board shipped in the Si8250DK development kit.

Figure 6. Isolated Half-Bridge DC/DC Converter

The Si8250/1/2 is located on the secondary-side of the power supply for optimum transient response. DPWM

outputs PH3 and PH4 control gates of the synchronous rectifiers via a dual driver I.C. DPWM outputs PH1 and

PH2 control the gates of the primary-side switching transistors with isolation provided by a Silicon Laboratories

isolator. A current transformer circuit provides peak current sensing. Primary side analog parameters (input voltage

and current and the filter node voltage) are digitized by a Silicon Laboratories C8051F300 microcontroller and

passed to the Si8250/1/2 using the on-board UART through additional channels of the isolator I.C. to the

Si8250/1/2. The Si8250/1/2 is uses the application software included with the Si8250DK development kit after

being configured for the half-bridge application using the tools supplied in the kit.

When power is applied, the CPU executes an internal reset followed by initialization of all parameters. The

Si8250/1/2 remains in a low-power state, monitoring digitized VIN data from the primary-side MCU until VIN is

within specified limits. At this time, the controller is fully enabled and executes soft-start by monitoring Vout while

sequentially incrementing the loop voltage reference (REFDAC) until the supply output voltage is within specified

range, at which time steady-state operation begins.

During steady-state operation, the MCU operates in interrupt mode where hardware events divert program

execution to specific routines in priority order.

2.2uF

180nH

6 x 100 uF

Cerami c

DRIVER

P2

IRLR8113

IRLR8113

180nH

.0.001

6:1

Si8250

Digi tal Contr oller

VOUT

P3

P4

PH4

PH3

P2

P1

10K

3.9K

0.01uF

IPK

Vsens eIOUT

C8051F300

Micr ocontrol ler

33K

1K

AIN

RX

Isol ator

PH2

PH1

0.010

AIN

1uH

33K

1K

VIN+

1.2nF

120uF

VI N-

GND

VDD

3V3P

IIN

DC BAL

AIN

VIN

2.2uF

TX

4.7

DRIVER

P1

4.7

0.01uF

4.7

4.7

7.5

~ +

~ -

FDS3572

FDS3 572

DRIVER

P3

DRIVER

P4

200

200

3V3P

VDDA

GNDA

3V3P

VDDB

GNDB

GND

VDD

Page 20

Si8250/1/2

20 Preliminary Rev. 0.8

Single Phase POL (point of load) converter: A 65 W, 400 KHz Si8252 based single phase POL converter block

diagram is shown in Figure 7. DPWM outputs PH1 and PH2 control the gates of the buck and synchronous

switching transistors. A lossless current sensing method that relies on the resistor and inductance of the inductor is

used to measure the current for over current protection. The input voltage is measured using resistor divider

network and analog input port AIN0 of 12bit, 200 kHz ADC0.

Figure 7. Single-phase POL Block Diagram

When power is applied, the CPU executes an internal reset followed by initialization of all parameters. The Si8252

remains in a low-power state, monitoring digitized VIN data until VIN is within specified limits. At this time, the

controller is fully enabled and executes soft-start by monitoring output voltage while sequentially incrementing the

loop voltage reference (REFDAC) until the supply output voltage is within specified range, at which time steadystate operation begins.

As in the previous half-bridge example, transient response is improved by adjusting loop gain at the onset of a

transient (i.e. nonlinear control). The efficiency of the POL converter can be optimized over the complete load

range by dynamically adjusting the dead-times. Typical efficiency simulation results for the POL are shown in

Figure 8. In this case, the single-phase POL operates at a PWM frequency of 400 kHz with an output voltage of

3.3 V and an input voltage range of 10 to 15 V. The curve shows the efficiency with an input voltage of 12.0 V.

Figure 8. POL Efficiency

PH1

PH2

Vsense

Ipk

DRIVER

DRIVER

VIN

+2.5 V

CIN

GND

Si8252

AIN0

VIN

Vout

LOAD

Ipk

DIFFERENTIAL

AMPLIFIER

L

C

VDD

Ipk

0 5 10 15 20 25

80

85

90

95

Eff I o()

Io

Page 21

Si8250/1/2

Preliminary Rev. 0.8 21

6. Layout Considerations

The mixed-signal nature of the Si8250/1/2 mandates clean bias supplies and ground returns. It is best to provide

separate ground planes for analog, digital and power switch returns. These planes should tie together at only one

point to eliminate the possibility of circulating ground currents.

For best performance, the VDD supply should be decoupled from the main supply. The LQFP-32 package provides

the best noise performance because it has separate analog and digital VDD and ground inputs (AVDD, AGND). As

shown in Figure 9, the AVDD is decoupled by a filter consisting of a 1 Ω resistor in series with a 500 mA, 40 Ω

ferrite bead and a parallel combination of a 10 uF with a 0.1 uF high-frequency bypass capacitor. All connections

should be kept as short as possible. The VDDA and GNDA should be connected into their respective ground

planes. The QFN-28 package shares analog and digital power with ground on the same pins. Power supply

decoupling is shown in Figure 10. Again, all connections should be kept as short as possible.

Figure 9. Power Supply Connections for LQFP-32 Package

Figure 10. Power Supply Connections for QFN-28 Package

AVDD DVDD

Ferrite bead

500 mA, 40 Ω

0.1 uF10 uF

Si8250/1/2

AGND DGND

AGND

10 uF 0.1 uF

2.5 V

1 Ω

Keep trace

lengths as short

as possible

VDD

Ferrite bead

500 mA, 40 Ω

0.1 uF10 uF

Si8250/1/2

GND

2.5 V

1 Ω

Keep trace

lengths as short

as possible

Page 22

Si8250/1/2

22 Preliminary Rev. 0.8

In both cases, the bias supplies must be filtered using low ESR/ESL capacitors placed close to the IC pins.

Thick copper traces should be connected to the bias pins (VDD, VDDA) and the ground pins (GND, GNDA) to

reduce resistance and inductance. The copper routings from the drivers to the FETs should be kept short and wide,

especially in very high frequency applications, to reduce inductance of the traces so that the drive signals can be

kept clean.

Connections between VSENSE and the output voltage must be kept absolutely as short as possible to minimize

inductance and parasitic ringing effects. It is best to locate the Si8250/1/2 as close to the output voltage terminal as

possible and use a Kelvin connection to ensure to difference in ground potential between the Si8250/1/2 and the

output voltage ground return.

Most applications will require access to the debug pins. These pins are susceptible to damage from electrostatic

discharge (ESD). It is therefore recommended the debug circuit interface use the input protection circuitry shown in

Figure 11.

Figure 11. Debug Interface Pin Protection Circuit

DEBUG

CONNECTOR

10

10

Si8250/1/2

Debug Pins

(C2D, C2CK)

2.5 V

Page 23

Si8250/1/2

Preliminary Rev. 0.8 23

7. Pin Descriptions—Si8250/1/2

Figure 12. Example Pin Configurations

Table 17. Pin Descriptions

Name QFN-28

Pin #

LQFP-32

Pin#

Type D e s c r i p tion

RST

/C2CK

1 1 D I/O

Reset input or bidirect debug clock

IPK

22 AIN

Inductor current input

VSENSE

33 AIN

Output voltage feedback input

GND

4— AIN

Ground

GNDA

—4 AIN

Ground

VDD

5— AIN

Power supply input

VDDA

—5 AIN

Power supply input

VREF

66 AIN

External voltage reference input

P1.0/VIN or AIN0

7 7 D I/O or AIN

Port 1 I/O or scaled power supply input voltage or

ADC input 0

P1.1/AIN1

8 8 D I/O or AIN

Port 1 I/O or ADC input 1

P1.2/AIN2

9 9 D I/O or AIN

Port 1 I/O or ADC input 2

P1.3/AIN3

10 10 D I/O or AIN

Port 1 I/O or ADC input 3

P1.4/AIN4

11 11 D I/O or AIN

Port 1 I/O or ADC input 4

GND

—12 AIN

Ground

VDD

—13 AIN

Power supply input

P1.5/AIN5

12 14 D I/O or AIN

Port 1 I/O or ADC input 5

P1.6/AIN6

13 15 D I/O or AIN

Port 1 I/O or ADC input 6

P1.7/ AIN7/C2D

14 16 D I/O, DIN or

AIN

Port 1 I/O or ADC input 7 or C2 Data

32-pin LQFP 28-pin QFN

1

VSENSE

P0.0

P0.5

P0.2

P0.1

P0.3 / XCLK

P1.0/VIN/AIN0

IPK

P0.6

P0.7

2

3

4

5

6

7

8

24

23

22

21

20

19

18

17

9

101112

13

14

15

16

32

313029

28

27

26

25

P0.4

Si8250/1/2

Top View

P1.1/AIN1

GNDA

VDDA

RST/C2CK

GND

VDD

P1.5/AIN5

P1.6/AIN6

P1.7/AIN7/C2D

PH6

PH5

P1.4/AIN4

VDD

GND

PH3

P1.3/AIN3

P1.2/AIN2

VREF

PH4

PH2

PH1

4

5

6

7

2

1

3

11

12

13

14

9

8

10

18

17

16

15

20

21

19

25

26

27

28

23

22

24

Si8250/1/2

Top View

RST / C2CK

IPK

VSENSE

GND

VDD

VREF

P1.0/VIN /AIN0

P1.1/AIN1

P1.2/AIN2

P1.3/AIN3

P1.4/AIN4

P1.5/AIN5

P1.6/AIN6

P1.7/AIN7/C2D

P0.7

P0.6

P0.5

P0.4

P0.3/XC LK

P0.2

P0.1

P0.0

PH6

PH5

PH4

PH3

PH2

PH1

GND

GND

Page 24

Si8250/1/2

24 Preliminary Rev. 0.8

Pin Functions:

RST/C2CK: CPU reset or debug tool clock. Driving this pin low resets the CPU. This pin is also clocked by the USB

debug adaptor during debug.

IPK

: Input to the peak current detector for pulse-by-pulse current limiting and over-current protection shutdown

control.

VSENSE

: ADC1 inverting input. This is the voltage feedback input for the Si8250. The maximum allowable signal is

VREF.

GND

: Digital ground for the 32LQFP package, and the main ground for the 28MLP package.

GNDA

: Analog ground for 32LQFP only.

VDD

: Digital supply voltage for the 32LQFP package, and main supply voltage for the 28MLP package.

VDDA

: Analog supply for 32LQFP only.

P1.0/VIN or AIN0

: Programmable multifunction I/O pin. This pin can be software configured to be either a Port 1

digital input or output, or an ADC0 input at AMUX address 0. If used in a non-isolated application, positive input

supply voltage must be tied to this input through a resistor divider and anti-aliasing capacitor to minimize the

frequencies above fS/2 (100Khz) to prevent aliasing. Isolated applications may use this input as general-purpose

digital I/O or analog input.

P1.1 or AIN1–P1.7 or AIN7

: Programmable multifunction I/O pins. These pins can be software configured to be a

Port 1 digital input or output, or an ADC0 input. P1.7 also serves as the debug data input (C2D) and is used during

debug by the USB debug adaptor. P1.7 may be used as general-purpose digital I/O when not in debug mode. Any

of the digital peripherals may be programmed to connect to these pins.

P0.0–P0.7

: Programmable multifunction I/O pins. These pins can be software configured to be either a Port 1

digital input or output, or an ADC0 input. Any of the digital peripherals (including the ENABLE input) may be

programmed to connect to these pins. P0.3 may be programmed to serve as an external (25MHz nominal) clock

input.

PH1–PH6

: DPWM gate control (complementary drive) outputs. These signals connect to the MOSFET gates

through an external gate driver. The output levels swing between ground and Vdd.

P0.7

15 17 D I/O

Port 0 I/O

P0.6

16 18 D I/O

Port 0 I/O

P0.5

17 19 D I/O

Port 0 I/O

P0.4

18 20 D I/O

Port 0 I/O

P0.3/XCLK

19 21 D I/O

Port 0 I/O

P0.2

20 22 D I/O

Port 0 I/O

P0.1

21 23 D I/O

Port 0 I/O

P0.0

22 24 D I/O

Port 0 I/O or bidirectional debug data

PH6

23 25 DOUT

Phase 6 switch control output

PH5

24 26 DOUT

Phase 5 switch control output

PH4

25 27 DOUT

Phase 4 switch control output

VDD

—28 AIN

Power supply input

GND

—29 AIN

Ground

PH3

26 30 DOUT

Phase 3 switch control output

PH2

27 31 DOUT

Phase 2 switch control output

PH1

28 32 DOUT

Phase 1 switch control output

Table 17. Pin Descriptions (Continued)

Name QFN-28

Pin #

LQFP-32

Pin#

Type D e s c r i p tion

Page 25

Si8250/1/2

Preliminary Rev. 0.8 25

8. Ordering Guide

Ordering Number Flash Memory Number of

PWM

Outputs

UART Package

Si8250-IQ 32 kB 6 Yes LQFP-32

Si8250-IM 32 kB 6 Yes QFN-28

Si8251-IQ 16 kB 6 Yes LQFP-32

Si8251-IM 16 kB 6 Yes QFN-28

Si8252-IQ 16 kB 3 No LQFP-32

Si8252-IM 16 kB 3 No QFN-28

Page 26

Si8250/1/2

26 Preliminary Rev. 0.8

9. Package Outline—32LQFP

Figure 13 illustrates the package details for the 32-pin LQFP version of the Si8250/1/2. Table 18 lists the values for

the dimensions shown in the illustration.

Figure 13. 32-pin LQFP Package Diagram

Table 18. LQFP-32 Package Dimensions

MM

Min Typ Max

A——1.60

A1 0.05 — 0.15

A2 1.35 1.40 1.45

b 0.300.370.45

D — 9.00 —

D1 — 7.00 —

e — 0.80 —

E — 9.00 —

E1 — 7.00 —

PIN 1

IDENTIFIER

A1

eb

1

32

E1

D1

D

E

A2

A

L

Page 27

Si8250/1/2

Preliminary Rev. 0.8 27

10. Package Outline—28QFN

Figure 14 illustrates the package details for the 28-lead QFN version of the Si8250/1/2. Table 19 lists the values for

the dimensions shown in the illustration.

Figure 14. 28-lead Quad Flat No-lead (QFN) Package Diagram

Table 19. QFN-28 Package Dimensions

MM MM

Min Typ Max Min Typ Max

A 0.80 0.90 1.00 L 0.45 0.55 0.65

A1 0 0.02 0.05 N — 28 —

A2 0 0.65 1.00 ND — 7 —

A3 — 0.25 — NE — 7 —

b 0.180.230.30 R 0.09 — —

D — 5.00 — AA — 0.435 —

D2 2.90 3.15 3.35 BB — 0.435 —

E — 5.00 — CC — 0.18 —

E2 2.90 3.15 3.35 DD — 0.18 —

e—0.5—

1

E

D

A2

A

A1

e

A3

E2

R

e

L

Bottom View

Side View

2

3

4

5

6

7

8

9

10

12

13

14

21

20

19

17

16

15

28

27

26

24

23

22

E2

25

2

D2

11

18

D2

2

6 x e

6 x e

DETAIL 1

DETAIL 1

AA

BB

CC

DD

b

Page 28

Si8250/1/2

28 Preliminary Rev. 0.8

DOCUMENT CHANGE LIST

Revision 0.7 to Revision 0.8

Updated DPWM phase output drive-high and drive-

low resistance in Table 8, “DPWM Specifications,” on

page 9.

Page 29

Si8250/1/2

Preliminary Rev. 0.8 29

NOTES:

Page 30

Si8250/1/2

30 Preliminary Rev. 0.8

CONTACT INFORMATION

Silicon Laboratories Inc.

4635 Boston Lane

Austin, TX 78735

Tel: 1+(512) 416-8500

Fax: 1+(512) 416-9669

Toll Free: 1+(877) 444-3032

Email: productinfo@silabs.com

Internet: www.silabs.com

Silicon Laboratories and Silicon Labs are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change without notice.

Silicon Laboratories assumes no responsibility for errors and omissions, and disclaims responsibility for any consequences resulting from

the use of information included herein. Additionally, Silicon Laboratories assumes no responsibility for the functioning of undescribed features

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Silicon Laboratories assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life, or for any other application in which the failure of the Silicon Laboratories product could create a situation where personal injury or death may occur. Should Buyer purchase or use Silicon Laboratories products for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

Loading...

Loading...