Page 1

Preliminary Rev. 0.31 8/ 01 Copyright © 2001 by Silicon Labora tor ies Si5530-DS031

This information applies to a product under development. Its char acteristics and spe c ifications are subject to change without notice.

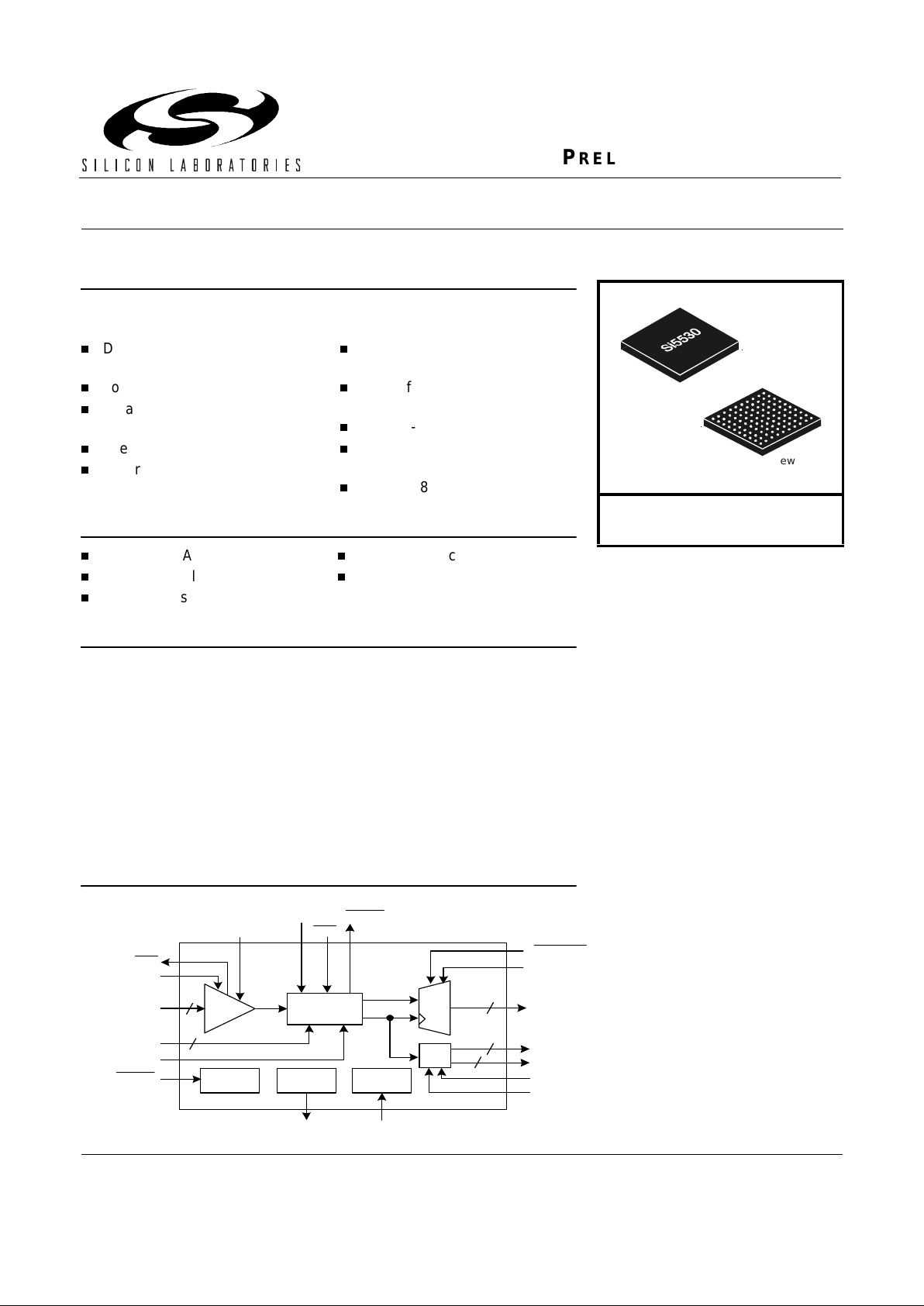

Si5530

SiPHY™ OC-192/STM-64 SONET/SDH RECEIVER

Features

Complete low power, high speed, receiver with integrated limiting amplifier,

clock and data recovery (CDR), and 1:16 demultiplexer:

Applications

Description

The Si5530 is a fully integrated low-power receiver for high-speed serial

communication systems. It combines post amplification, clock and data

recovery, and a 1:16 deserialization as required in OC-192/STM-64

applications. Support for data streams up to 10.7 Gbps is also provided for

applications that employ forward error correction (FEC). A fully integrated

clock and data recovery unit with integrated loop filter ensures optimal jitter

performance while reducing design complexity.

The Si5530 represents a new standard in low power and small size for

high-speed serial receivers. It operates from a single 1.8 V supply over the

industrial temperature range (–40°C to 85°C).

Functional Block Diagram

Data Rates Supported: OC-192/

STM-64, 10GbE, 10.7 Gbps FEC

Low Power Operation 0.6 W (typ)

Small Footprint 99-Pin BGA

Package (11 x 11 mm)

Integrated Limiting Amplifier

Programmable Slicing Level and

Sampling Phase

SFI-4 Compliant LVDS Low

Speed Interface

Loss-of-Signal and Loss-of-Lock

Detection

Lock-to-Reference Control

Optional 3.3 V Supply Pin for

LVTTL Compatible Outputs

Single 1.8 V Supply Operation

Sonet/SDH/ATM Routers

Add/Drop Multiplexers

Digital Cross Connects

Optical Transceiver Modules

Sonet/SDH Test Equipment

RXDOUT[15:0]

RXCLK1

RXCLK2

RXCLK2DIV

1:16

DEMUX

RXSQLCH

RXMSBSE L

32

2

2

RXCLK2DSBL

RXDIN

REFCLK

Limiting

AMP

LOSLVL

LOS

LTR

CDR

2

2

SLICE_LVL

PHASE_ADJ RXLOL

REFRATE

RESET

Reset

Control

Voltage

Ref

VREF

Bias

REXT

÷

Ordering Information:

See pa ge16.

Si5364

Bottom View

PRELIMINARY DATA SHEET

Page 2

Si5530

2 Preliminary Rev. 0.31

Page 3

Si5530

Preliminary Rev. 0.31 3

TABLE OF CONTENTS

Section Page

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Limiting Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Loss-of-Signal Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Slicing Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Clock and Data Recovery (CDR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sample Phase Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lock Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lock-to-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reference Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Deserialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Serial Input to Parallel Output Relationship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auxiliary Clock Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Data Squelch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Bias Generation Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Voltage Reference Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Si5530 Pinout: 99-Pin BGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pin Descriptions: Si5530 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 4

Si5530

4 Preliminary Rev. 0.31

Electrical Specifications

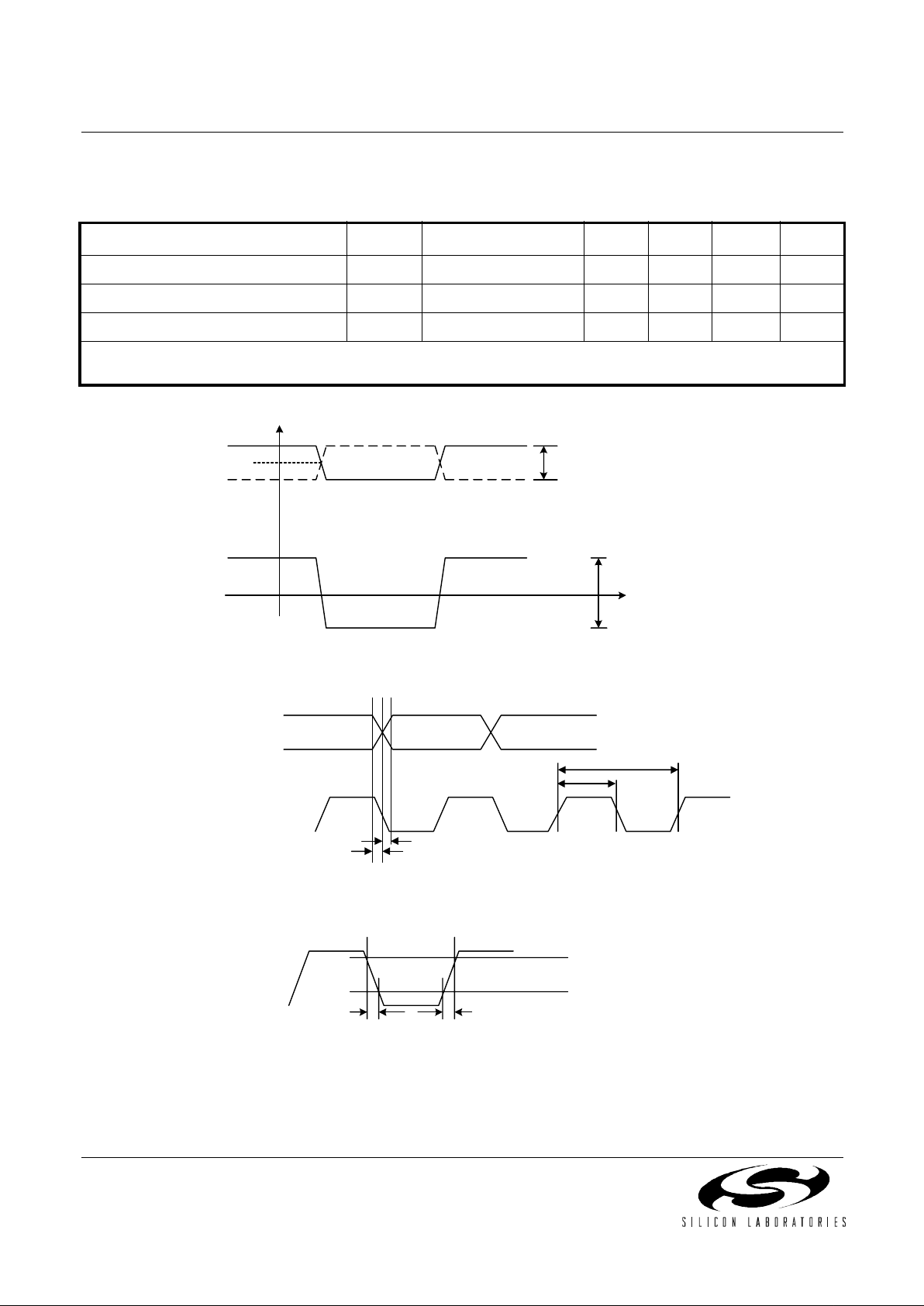

Figure 1. Differential Volta ge Measurement (RXDIN, RXDOUT, RXCLK1, RXCLK2)

Figure 2. Data to Clock Delay

Figure 3. Rise/Fall Time Measurement

Table 1. Recommended Operating Conditions

Parameter Symbol Test Condition

Min

*

Typ

Max

*

Unit

Ambient Temperature T

A

–40 25 85 °C

LVTTL Output Supply Voltage V

DD33

1.71 — 3.47 V

Si5530 Supply Voltage V

DD

1.71 1.8 1.89 V

*Note: All minimum and maximum specifications are guaranteed and apply across the recommended operating conditions.

T ypical values apply at nominal supply voltages and an oper ating temperature of 25°C unless otherwise stated.

V

IS

VID,VOD (V

ID

= 2VIS)

Differential

I/Os

Differential

Voltage Swing

Single Ended Voltage

Differential Peak-to-Peak Voltage

SIGNAL +

SIGNAL –

(SIGNAL +) – (SIGNAL –)

V

ICM

, V

OCM

V

t

RXDOUT

RXCLK1

t

CP

t

CH

t

cq1

t

cq2

All Differential

IOs

t

F

t

R

80%

20%

Page 5

Si5530

Preliminary Rev. 0.31 5

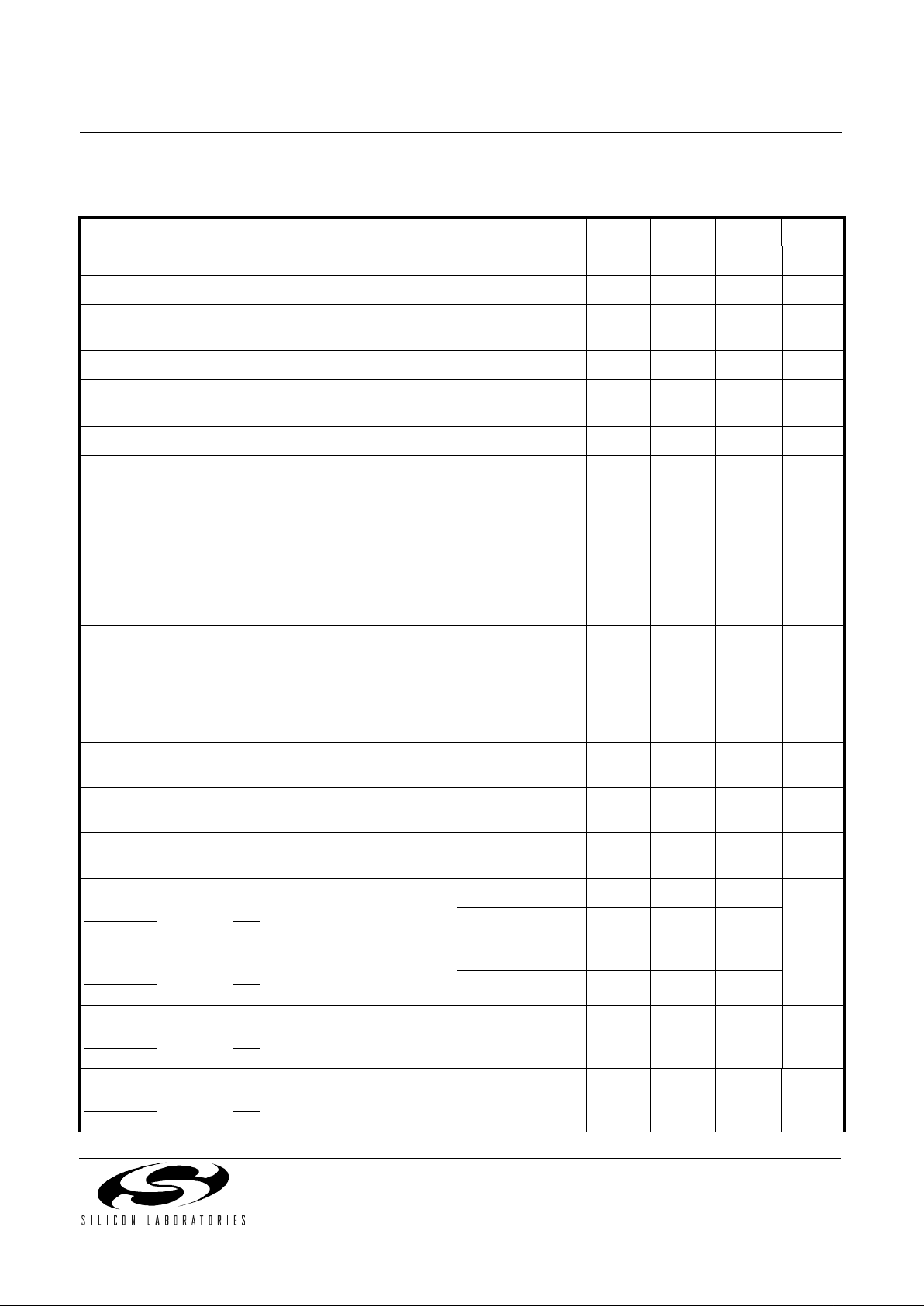

Table 2. D C Characteri sti cs

(VDD = 1.8 V ±5%, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Supply Current I

DD

— 278 TBD mA

Power Dissipation P

D

—0.5 TBDW

Voltage Reference (VREF) V

REF

VREF driving

10 k

Ω load

1.21 1.25 1.29 V

Common Mode Input Voltage (RXDIN) V

ICM

TBD 0.1 TBD V

Differential Input Voltage Swing (RXDIN) V

ID

See Figure 1 20 — 1.0 mV

(pk-pk)

L VPECL Input Voltage HIGH (REFCLK) V

IH

1.975 2.3 2.59 V

L VPECL Input Voltage LOW (REFCLK) V

IL

1.32 1.6 1.99 V

L VPECL Input Voltage Swing,

Differential pk-pk (REFCLK)

V

ID

Figure 1 250 — 2400 mV

(pk-pk)

L VPECL Internally Generated Input Bias

(REFCLK)

V

IB

1.65 1.95 2.3 V

L VDS Output High Voltage

(RXDOUT, RXCLK1, RXCLK2)

V

OH1

100 Ω Load

Line-to-Line

TBD — 1.475 mV

LVDS Output Low Voltage

(RXDOUT, RXCLK1, RXCLK2)

V

OL1

100 Ω Load

Line-to-Line

0.925 — TBD V

LVDS Output Voltage, Differential pk-pk

(RXDOUT, RXCLK1, RXCLK2)

V

OSE

100 Ω Load

Line-to-Line,

Figure 1

500 — 800 mV

(pk-pk)

LVDS Common Mode Voltage

(RXDOUT, RXCLK1, RXCLK2)

V

CM

1.125 — 1.275 V

Output Short to GND

(RXDOUT, RXCLK1, RXCLK2)

I

SC(–)

—25TBDmA

Output Short to V

DD

(RXDOUT, RXCLK1, RXCLK2)

I

SC(+)

TBD –100 — µA

LVTTL Input Voltage Low

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

, REFSE L , LTR, RESET)

V

IL2

VDD33 = 3.3 V — — 0.8 V

VDD33 = 1.8 V — — 0.7

LVTTL Input Voltage High

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

, REFSE L , LTR, RESET)

V

IH2

VDD33 = 3.3 V 2.0 — — V

VDD33 = 1.8 V 1.7 — —

LVTTL Input Low Current

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

, REFSE L , LTR, RESET)

I

IL

——10µA

LVTTL Input High Current

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

, REFSE L , LTR, RESET)

I

IH

——10µA

Page 6

Si5530

6 Preliminary Rev. 0.31

LVTTL Input Impedanc e

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

, REFSE L , LTR, RESET)

R

IN

10 — — kΩ

L VTTL Output Voltage Low

(LOS

, RXLOL)

V

OL2

VDD33 = 1.8 V — — 0.4 V

VDD33 = 3.3 V — — 0.4

L VTTL Output Voltage High

(LOS

, RXLOL)

V

OH2

VDD33 = 1.8 V 1.4 — — V

VDD33 = 3.3 V 2.4 — —

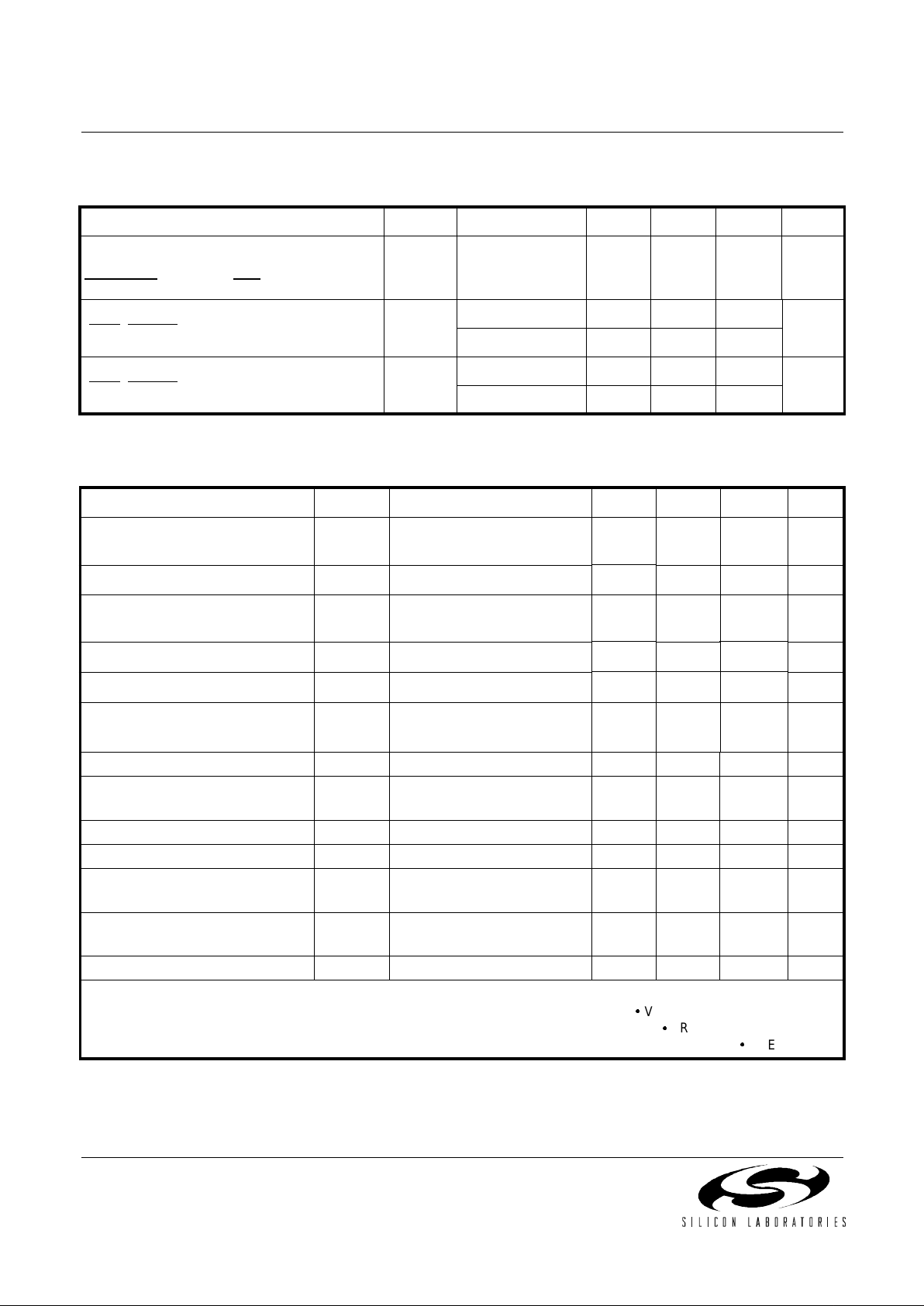

Table 3. AC Characteristics (RXDIN, RXDOUT, RXCLK1, RXCLK2)

(VDD = 1.8 V ±5%, TA = –40°C to 85°C)

Parameter Symbol T est Condition Min Typ Max Unit

Output Clock Frequency

(RXCLK1)

f

clkout

See Figure 2 — 622.08 667 MHz

Duty Cycle (RXCLK1, RXCLK2) tch/tcp, Figure 2 45 — 55 %

Output Rise and Fall Times

(RXCLK1, RXCLK2,RXD O U T)

t

R,tF

Figure 3 — 50 — ps

Data Invalid Prior to RXCLK1 t

cq1

Figure 2 — — 200 ps

Data In v a l i d After RXC L K1 t

cq2

Figure 2 — — 200 ps

Input Return Loss (RXIN) 400 kHz–10.0 GHz

10.0 GHz–16.0 GHz

18.7

TBD

—

—

—

—

dB

dB

Slicing Adjust Dynam ic Ran ge SLICELVL = 200–800 mV –20 — 20 m V

Slicing Level Offset

1

(referred to RXDIN)

SLICELVL = 200–800 mV –500 — 500

µV

Slicing Level Accuracy VSLICE –5 — 5 %

Sampling Phase Adjustment

2

PHASEADJ = 200–800 mV -45

o

—45

o

LOS Threshold Dynamic Range LOSLVL = 200–800 mV 10 — 50 mV

pk-pk

LOS Threshold Offset

3

(referred to RXDIN)

LOSLVL = 200–800 mV –500 — 500

µV

LOS Threshold Accuracy VLOS –5 — 5 %

Note:

1. Slice level (referred to RXDIN) is calculated as follows: VSLICE = (SLICE_LVL – 0.4

VREF)/15.

2. Sample Phase Offset is calcul ated as follows: PHASE OFFSET = 45° (PHASEADJ – 0.4

VREF)/0.3

3. LOS Threshold voltage (r eferred to RXDIN) is calculated as follows: VLOS = 30mV + (LOS_LVL – 0.4

VREF)/15.

Table 2. DC Characteristics (Continued)

(VDD = 1.8 V ±5%, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Page 7

Si5530

Preliminary Rev. 0.31 7

Table 4. A C Characteri sti cs (PLL Cha r acteristics)

(VDD = 1.8 V ± 5%, TA = –40°C to 85°C)

Parameter Symbol T est Condition Min Typ Max Unit

Jitter Tolerance J

TOL(PP)

f = 2.4 kHz 15 30 — UI

PP

f = 24 kHz 1.5 3.0 — UI

PP

f = 400 kHz 1.5 3.0 — UI

PP

f = 4 MHz 0.15 0.3 — UI

PP

Acquisition Time T

AQ

——20 µs

Input Reference Clock Frequency RC

FREQ

REFRATE= 1 — 622 667 MHz

REFRATE= 0 — 155 167 MHz

Reference Clock Duty Cycle RC

DUTY

40 50 60 %

Reference Clock Frequency

Tolerance

RC

TOL

–100 — 100 ppm

Frequency Difference at which

Receive PLL goes out of Lock

(REFCLK compared to the

divided down VCO clock)

LOL TBD 600 1000 ppm

Frequency Difference at which

Receive PLL goes into Lock

(REFCLK compared to the

divided down VCO clock)

LOCK TBD 300 TBD ppm

Note: Bellcore specifications: GR-1377-CORE, Issue 5, December 1998.

Table 5. A b so l u te M aximum R atings

Parameter Symbol Value Unit

DC Supply Voltage V

DD

–0.5 to TBD V

LVTTL Input Voltage V

DD33

–0.5 to 3.6 V

Differential Input Voltages V

DIF

–0.3 to (VDD+ 0.3) V

Maximum Current any output PIN ±50 mA

Operating Junction Temperature T

JCT

–55 to 150 °C

Storage Temperature Range T

STG

–55 to 150 °C

Package Temperature

(soldering 10 seconds)

275

°C

ESD HBM Tolerance (100 pf, 1.5 k

Ω)TBDV

Note: Permanent device damage m ay occur if the above Absolute Maximum Ratings are exceeded. Func ti onal operation

should be restricted to the conditions as specified in the operational sections of this data sheet. Exposure to absolute

maximum rating condit ions for extended periods may affect device re li ability.

Table 6. Thermal Ch ar acteristics

Parameter Symbol Test Condition Value Unit

Thermal Resistance Junction to Ambient ϕ

JA

Still Air 38 °C/W

Page 8

Si5530

Preliminary Rev. 0.31 8

Functional Description

The Si5530 is a high performance, low power, fully

integrated receiver for SONET/SDH applications

operating at OC-192/ST M-64 data rate s. It saves board

space by integrating a limiting amplifier, clock and data

recovery unit, and a demultiplexer into a small 99-pin

BGA package. Further space savings are realized

because no external loop filter components are required

to support CDR operation. The Si5530 also provides a

low-speed LVDS interface that is compliant to the

Optical Interface Forums SFI-4 standard.

To support long haul transmission applications,

operation at data rates up to 10.7 Gbps is support ed to

accommodate forward error correction (FEC). In

addition, programmable data slicing and sampling

phase adjustment a re provided to support bit- error-rate

(BER) optimization.

Limiting Amplifier

The Si5530 incorporates a high sensitivity limiting

amplifier with sufficient gain to directly accept the output

of transimpedance amplifiers. High sensitivity is

achieved by using a digital calibration algorithm to

cancel out amplifier offsets. This algorithm achieves

superior offset cancellation by using statistical

averaging to remove noise that can degrade more

traditional calibra tion routines.

The limiting amplifier provides sufficient gain to fully

saturate with input signals that are less than 20 mV

peak-to-peak differentia l. In addition, input signals that

exceed 1 V peak-to-peak differen tial will not cause any

performance degradation.

Loss-of-Signal Detection

The limiting am plifie r incl udes circ uitry t hat g enerates a

loss-of-signal (LOS

) alarm when the input signal

amplitude on RXDIN falls below an externally control led

threshold. The Si5530 can be configured to drive the

LOS

output low when the differential input amplitude

drops below a threshold set between ~10 mV and

50 mV pk-pk differential. Approximately 3 dB of

hysteresis prevents unnecessa ry switc hing on LOS

.

The LOS threshold is set by applying a voltage between

0.20 V and 0.80 V to the LOSLVL input. The voltage

present on LOSLVL maps to an input signal threshold

as follows:

V

LOS

is the differential pk-pk LOS threshold referred to

the RXDIN input, V

LOSLVL

is the voltage applied to the

LOSLVL pin, and VREF is reference voltage output on

the VREF pin.

The LOS detection circuitry is disabled by tieing the

LOSLVL input to the supply (VDD). T his forces the LOS

output high.

Slicing Level Adjustment

To support applications that require BER optimization,

the limiting amplifier provides circuitry that supports

adjustment of t he 0/1 decision threshold (slicing l evel)

over a range of ±20 mV when referred to the RXDIN

input. The slicing level is set by applying a voltage

between 0.20 V and 0.80 V to the SLICELVL input. The

voltage present o n SLICELV L sets the slicing level as

follows:

V

LEVEL

is the slicing l evel referred to the RXDI N input,

V

SLICE

is the voltage applied to the SLICE_LVL pin, and

VREF is reference voltage output on the VREF pin.

The slicing lev el adjustment may be disabled by tiei ng

the SLCLVL input to the supply (VDD). When slicing is

disabled, the slicing offset is set to 0.0 V relative to

internally biased input common mode voltage for

RXDIN.

Clock and Data Recovery (CDR)

The Si5530 uses an integrated CDR to recover clock

and data from a non-return to zero (NRZ) signal input on

RXDIN. The recovered data clock is used to regenerate

the incoming data by sam pling the output of the limi ting

amplifier at the center of the NRZ bit period. The

recovered clock and data is then deserial ized by a 1: 16

demultiplexer and output via a LVDS compatible low

speed interface (RXDOUT[15:0], RXCLK1, and

RXCLK2).

Sample Phase Adjustment

In applications where it is not desirable t o recover d ata

by sampling in the center of the data eye, the Si5530

supports adjustment of the CDR sampling phase across

the NRZ data period. When sample phase adjustment is

enabled, the sampling instant used for data recovery

can be moved over a range of ±45

° relative to the center

of the incoming NRZ bit period. Adjustment of the

sampling phase is de sirable when data eye distortions

are introduced by the transmission medium.

The sample phas e is s et by applying a voltage betwe en

0.20 V and 0.80 V t o the PHASEADJ input. The voltage

present on PHASEADJ maps to sam ple phase off set as

follows:

V

LOS

V

LOSLVL

0.4xVR EF–

()

15

--------------------------------------------------------------- 30 mV+=

V

LEVEL

V

SLICE

0.4xVREF–

()

15

---------------------------------------------------------- -

=

Page 9

Si5530

9 Preliminary Rev. 0.31

Phase Offset is the sa mpling off set in deg rees from the

center of the data eye, V

PHASE

is the voltage applie d to

the PHASEADJ pin, and VREF is reference voltage

output on the VREF pin. A positive phase offset will

adjust the sampli ng point to lead the de fault samp ling

point at the center of the data eye, and a negative

phase offset will adjust the sampling point to lag the

default sampling point.

Data recovery using a sampling phase offset is disabled

by tieing t he PHASEADJ input to the suppl y (VDD). Thi s

forces a default phase offset of 0

° to be used for data

recovery.

Lock Detect

The Si5530 provides lock-detect circuitr y that indicates

whether the PLL has achieved frequency lock with the

incoming data. This circuit compares the frequen cy of a

divided down version of the recovered clock with the

frequency of the s upplied reference c lock (REFCLK). If

the recovered clo ck freque ncy deviat es from that o f the

reference clock by the amount specified in Table 4 on

page 7, the PLL is declared out of lock, and the loss-oflock (RXLOL

) pin is assert ed. In this s tate, the PLL will

try to reacquire lock with the incoming data stream.

During reacquisition, the recovered clock frequency

(RXCLK1 and RXCLK2) will drift over a 1% range

relative to the supplied reference clock. The RXLOL

output will remain asserted until the recovered clock

frequency is within the REFCLK frequency by the

amount specified in T able 4 on page 7.

Lock-to-Reference

In applications where it is desirable to main tain a stable

output clock during an alarm condition like loss-ofsignal, the lock-t o-referen ce input (LTR

) can be used to

force a stable output clock . When LTR

is asserted, the

CDR is prevented from acquiring the data signal and the

CDR will lock the RXCLKOUT1 and RXCLKOUT2

outputs to the provided REFCLK. In typical applications,

the LOS

output would be tied to the LTR input to force a

stable output clock.

Reference Clock

The CDR within the S i5530 uses a reference clock to

center the PLL fre quency so that it is close e nough to

the data frequency to achieve lock. The device is

designed to oper ate with reference clock so urces that

are either 1/16th or 1/64th the input data rate. The

Si5530 will operate with data streams between

9.9 Gbps and 10.7 Gbps and the reference clock should

be scaled accordingly. For example, to support

10.66 Gbps operation the REFCLK frequencies would

be approximately 166 MHz or 666 MH z. The REFRATE

input pin is us ed to configure the device for op eration

with one of the two supported reference clock

submultiples of the data rate.

Deserialization

The Si5530 uses a 1:16 dem ult ipl ex er to deserialize the

high-speed input . The deserialized data is out put on a

16-bit parallel data bus RXDOUT[15:0] synchronous

with the rising edge of RXCLK1. This clock output is

derived by dividing down the recovered clock by a factor

of 16.

Serial Input to Parallel Output Relationship

The Si5530 provides the capabi lit y to se lect the order in

which the receiv ed s erial data is m apped t o the paralle l

output bus RXDOUT[15:0]. The mapping of the receive

bits to the output data word is controlled by the

RXMSBSEL input. If RXMSBSEL is tied low, the first bit

received is output on RXDOUT0 and the followi ng bits

are output in order on RXDOUT1 through RXDOUT15.

If RXMSBSEL is tied high, the first bit received is output

on RXDOUT15, and the following bits are output in

order on RXDOUT14 through RXDOUT0.

Auxiliary Clock Output

To support the widest range of system timing

configurations, a second clock output is provided on

RXCLK2. This output can be configured to provide a

clock that is a 1/1 6th or 1/64th submultiple of the high

speed recovered clock. The divide factor used to

generate RXCLK2 is controlled via the RXCLKDIV2

input as described in "Pin Descriptions: Si5530" on

page 13. In application s whic h do not us e RXC LK2 , this

output can be powered down by forcing the

RSCLK2DSBL input high.

Data Squelch

During some system error conditions, such as LOS, it

may be desirable to force the receive data output to

zero in order to avoid propagation of erroneous data

into the downstream electronics. In these applications ,

the Si5530 provides a data squelching control input,

RXSQLCH

. When this input is active low, the data on

RXDOUT will be forced to 0.

PhaseOffset

45°xV

PHASE

0.4xVREF–

()

0.30

--------------------------------------------------------------------------

=

Page 10

Si5530

Preliminary Rev. 0.31 10

Bias Generation Circuitry

The Si5530 makes use of an external resistor to set

internal bias currents. The external resistor allows

precise generation of bias currents which significantly

reduces power consumption versus traditional

implementations that us e an internal resistor. The bias

generation circuitry requires a 3.09 k

Ω (1%) resistor

connected between REXT and GND.

Vo ltage Ref er en ce Outp ut

The Si5530 provides an output voltage reference that

can be used by an external circuit to set the LOS

threshold, slicing level, or sampling pha se adjust. One

possible implementation would use a resistor divider to

set the control voltage for LOSLVL, SLICELVL, or

PHASEADJ. A second alternative would use a DAC to

set the control voltage. Using this approach, VREF

would be used to establish the range of a DAC output.

The reference voltage is nominall y 1.25 V.

Page 11

Si5530

Preliminary Rev. 0.31 11

Si5530 Pinout: 99 BGA

Figure 4. Si5530 Pin Configuration (Bottom View)

Bottom View

RXDOUT[4]+ RXDOUT[2]– RXDOUT[2]+ RXDOUT[0]– RXDOUT[0]+ RXCLK[1]– RXCLK[1]+

RXCLK2

DSBL

REXT

RXDOUT[4]– RXDOUT[3]– RXDOUT[3]+ RXDOUT[1]– RXDOUT[1]+ RXCLK[2]– RXCLK[2]+ NC VREF SLICELVL

RXDOUT[6]+ RXDOUT[5]+ GND GND GND GND GND

RSVD_

GND

LOSLVL PHASEADJ

RXDOUT[6]– RXDOUT[5]– GND VDD VDD VDD VDD RXSQLCH GND GND

RXDOUT[8]+ RXDOUT[7]+ GND VDD VDD VDD VDD

RSVD_

GND

GND RXDIN+

RXDOUT[8]– RXDOUT[7]– GND VDD VDD VDD VDD

RSVD_

GND

GND RXDIN–

RXDOUT[10]+ RXDOUT[9]+ GND VDD VDD VDD VDD

RSVD_

VDD33

GND GND

RXDOUT[10]– RXDOUT[9]– GND GND GND GND GND VDD33

RSVD_

GND

LTR

RXDOUT[12]+ RXDOUT[11]+ RXDOUT[11]– RXDOUT[13]+ RXDOUT[13]– RXDOUT[15]+ RXDOUT[15]– REFRATE

RSVD_

VDD33

RXLOL

RXDOUT[14]+ RXDOUT[14]– REFCLK+ REFCLK–

RSVD_

GND

RXMSBSEL RXCLK2DIV RESET LOS

RXDOUT[12]–

10 123456789

A

K

J

G

H

F

E

D

C

B

Page 12

Si5530

12 Preliminary Rev. 0.31

Figure 5. Si5530 Pin Configuration (Transparent Top View)

G

VDD

E

Top View

RXDOUT[4]+RXDOUT[2]–RXDOUT[2]+RXDOUT[0]–RXDOUT[0]+RXCLK[1]–RXCLK[1]+

RXCLK2

DSBL

REXT

RXDOUT[4]–RXDOUT[3]–RXDOUT[3]+RXDOUT[1]–RXDOUT[1]+RXCLK[2]–RXCLK[2]+NCVREFSLICELVL

RXDOUT[6]–

RXDOUT[8]+RXDOUT[7]+

RXDOUT[8]–RXDOUT[7]–GND

RXDOUT[10]+RXDOUT[9]+GND

RXDOUT[10]–RXDOUT[9]–GNDGNDGND

RXDOUT[12]+RXDOUT[11]+RXDOUT[11]–RXDOUT[13]+RXDOUT[13]–

RXDOUT[14]+RXDOUT[14]–REFCLK+REFCLK–

RSVD_

GND

RXMSBSELRXCLK2DIV

RXDOUT[12]–

10123456789

A

H

B

RXDOUT[15]+RXDOUT[15]–REFRATE

RSVD_

VDD33

RXLOL

J

GNDGNDVDD33

RSVD_

GND

LTR

VDDVDDVDD

RSVD_

VDD33

GNDGND

VDDVDDVDDVDD

RSVD_

GND

GNDRXDIN–

F

VDDVDDVDDVDD

RSVD_

GND

GNDRXDIN+ GND

RXDOUT[5]–GNDVDDVDDVDDVDDRXSQLCHGNDGND

D

RXDOUT[5]+GNDGNDGNDGNDGND

RSVD_

GND

LOSLVLPHASEADJ

C

RXDOUT[6]+

K

RESETLOS

Page 13

Si5530

Preliminary Rev. 0.31 13

Pin Descr ip t io ns : Si 553 0

Pin Number(s) Name I/O Signal Level Description

C4–8, D8, D1–

2, E8 , E2, F8,

F2, G8, G1–2,

H4–8

GND GND

GND.

K1 LOS OLVTTL

Loss-of-Signal.

This output is driven low when the peak-to-pea k

signal amplitude is below thres hold s et via

LOSLVL.

C2 LOSLVL I —

LOS Thresh ol d Lev el.

Applying an analog voltage to this pin allows

adjustment of the Threshold used to declare

LOS. Tieing this input high disables LOS detection and forces the LOS

output high.

H1 LTR

ILVTTL

Lock-to-Reference.

This input forces a stable output clock by locking

RXCLK1 and RXCLK2 to the provided reference. Driving LTR low activates this feature.

B3 NC

No Connect.

Reserved for device testing leave elec t r ic ally

unconnected.

C1 PHASEADJ I —

Sampling Phase Adjust.

Applying an analog voltage to this pin allows

adjustment of the sampling phase across the

data eye. Tieing this input high nominally centers

the sampling phase.

K6–7 REFCLK–,

REFCLK+

I LVPECL

Differential Reference Clock.

The reference clock sets the initial operating frequency used by the onboard PLL for clock and

data recovery. The device will operate with reference frequencies that are 1/16th or 1/64th the

input data rate (nominally 155 MHz or 622 MHz).

J3 REFRATE I LVTTL

Reference Clock Select.

This input configures the Si5530 to operate with

one of two reference clock frequencies. If REFSEL is held high, the device requires a reference

clock that is 1/16 the input data rate. If REFSEL

is low, a reference clock at 1/64 the input data

rate is required.

K2 RESET

ILVTTL

Device Reset.

Forcing this input low for a at least 1µs will cause

a device reset. For normal operation, thi s pin

should be held high.

Page 14

Si5530

14 Preliminary Rev. 0.31

A2 REXT

External Bias Resistor.

This resistor is used by onboard circuitr y to

establish bias currents within the device. This pin

must be connected to GND through a 3.09 k

Ω

(

1%) resistor.

C3, E3, F3, H2, K5RSVD_GND

Reserved Tie to Ground.

Must tie directly to GND for proper operation.

G3, J2 RSVD_VDD33

Reserved Tie to VDD33.

Must tie directly to VDD33 for proper operation.

A4–5 RXCLK1+,

RXCLK1–

OLVDS

Differential Clock Output 1.

The clock recovered from the signal present on

RXDIN is divided down by 16 and output on

CLKOUT. In the absence of data, a stable clock

on RXCLK1 can be maintained by asserting

LTR

.

B4–5 RXCLK2+,

RXCLK2–

OLVDS

Differential Clock Output 2.

An auxiliary output clock is provided on this pin

that may be a divided down version of the high

speed clock recovered from the signal pre se nt

on RXDIN. The divide factor used in generating

RXCLK2 is set via RXCLK2DIV.

K3 RXCLK2DIV I LVTTL

Clock Divider Select.

This input selects the divide factor used to generate the RXCLK2 output. When this input is

driven low, RXCLK2 is 1/16th the recovered

high-speed clock. When driven high, RXCLK2 is

1/64th the recovered high speed clock rate.

A3 RXCLK2DSBL I LVTTL

RXCLK2 Disable.

Driving this input high will disable the RXCLK2

output. This would be used to save power in

applications that do not require an aux iliary

clock.

E1, F1 RXDIN+,

RXDIN–

I High Speed

Differential

Differential Data Input.

Clock and data are recovered from the high

speed data signal present on these pins.

A6–10, B6–10,

C9–10, D9–10,

E9–10, F9–10,

G9–10, H9–10,

J4–10, K8–10

RXDOUT[15:0]–,

RXDOUT[15:0]+

OLVDS

Differential Parallel Data Output.

The data recovered from the signal present on

RXDIN is demultiplexed and output as a 16-bit

parallel word via RXDOUT[15:0]. These outputs

are updated on the rising edge of RXCLK1.

J1 RXLOL

OLVTTL

Loss-of-Lock.

This output is driven low when the recovered

clock frequency deviates from the reference

clock by the amount specified in Table 4.

Pin Number(s) Name I/O Signal Level Description

Page 15

Si5530

Preliminary Rev. 0.31 15

K4 RXMSBSEL I LVT TL

Data Bus Receive Order.

This determines the order of the received data

bits on the output bus.

For RXMSBSEL = 0, the first data bit received is

output on RXDOUT[0] and following data bits are

output on RDOUT[1] through RXDOUT[15].

For RXMSBSEL = 1, the first data bit is output

on RXDOUT[15] and following data bits are output on RXDOUT[14] through RXDOUT[0].

D3 RXSQLCH

ILVTTL

Data Squelch.

When this input is low, the data on RXDOUT is

forced to 0. Set RXSQLCH

high for normal oper-

ation.

B1 SLICELVL I —

Slicing Level Adju s t ment .

Applying an analog voltage to this pin allows

adjustment of the slicing level applied to the

input data eye. Tieing this input high nominally

sets the slicing offset to 0.

D4–7, E4–7,

F4–7, G4–7,

VDD VDD 1.8 V

Supply Voltage.

Nominally 1.8 V.

H3 VDD33 VDD33 1.8 V or 3.3 V

Digital Output Su pply.

Must be tied to either 1.8 V or 3.3 V. When tied

to 3.3 V, LVTTL compatible output voltage

swings on RXLOL

and LOS are supported.

B2 VREF O Voltage Ref

Voltage Reference.

The Si5600 provides an output voltage reference

that can be used by an external circuit to set the

LOS threshold, slicing le vel, or sa mpl ing phas e

adjustment. The equivalent resistance between

this pin and GND should not be less than 10 k

Ω.

The reference voltage is nominally 1.2 5 V.

Pin Number(s) Name I/O Signal Level Description

Page 16

Si5530

16 Preliminary Rev. 0.31

Ordering Guide

Table 7. Ordering Guide

Part Number Package Temperature

Si5530-BC 99 BGA –40°C to 85°C

Page 17

Si5530

Preliminary Rev. 0.31 17

Package Ou tlin e

Figure 6 illustrat es the package details for the Si5530. Table 8 lists the v alues for the dimensions shown in the

illustration.

Figure 6. 99-Ba l l Gr id Array (BGA)

Table 8. Package Diagram Dim en sions

Symbol Millimeters

Min Nom Max

A 1.30 1.40 1.50

A1 0.31 0.36 0.41

A2 0.65 0.70 0.75

b — 0.46 —

D—11.00—

E—11.00—

e — 1.00 —

D

E

10987654321

A

B

C

D

E

F

G

H

J

K

A

1 Ball P ad

Corner

A1 Ball Pad

Corner

Seating

Plane

A

A1

A2

e

Bottom ViewTop View Side Vie w

1.00 Ref

1.00 Ref

b

e

Page 18

Si5530

18 Preliminary Rev. 0.31

Contact Informatio n

Silicon Laboratori es Inc.

4635 Boston Lane

Austin, TX 78735

Tel: 1+(512) 416-8500

Fax: 1+(512) 416-9669

Toll Free: 1+(877) 444-3032

Email: productinfo @ silabs.com

Internet : w ww.silabs .com

Silico n Laboratories, Silicon Labs, and S iPHY are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change without notice.

Silico n Laboratori es assumes no responsibility for err ors and omissions, and disclaims responsibil it y f or any consequences resulting from

the use of in format ion inclu ded her ein. Addit ionall y, Si licon Labor atories assu mes no respo nsib ility for the func tion ing of undes cribed fea tures

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty , represent ation or gu ara ntee rega rding the suit abilit y of its pro duct s for any particul ar purp ose, nor does Si licon Lab orat ories as sume an y liabili ty

arisin g out of the ap plic at ion or use of any prod uct or circ uit , and sp ecif ic ally dis clai ms an y and al l liab i lity , inclu di ng wi thout limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life, or for any other application in which the failure of the Sil icon Labo r atories p roduct coul d create a s ituation where personal injury or death may occur. Should Buyer purcha se or use Silicon Laborat ories prod ucts for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

Loading...

Loading...