Page 1

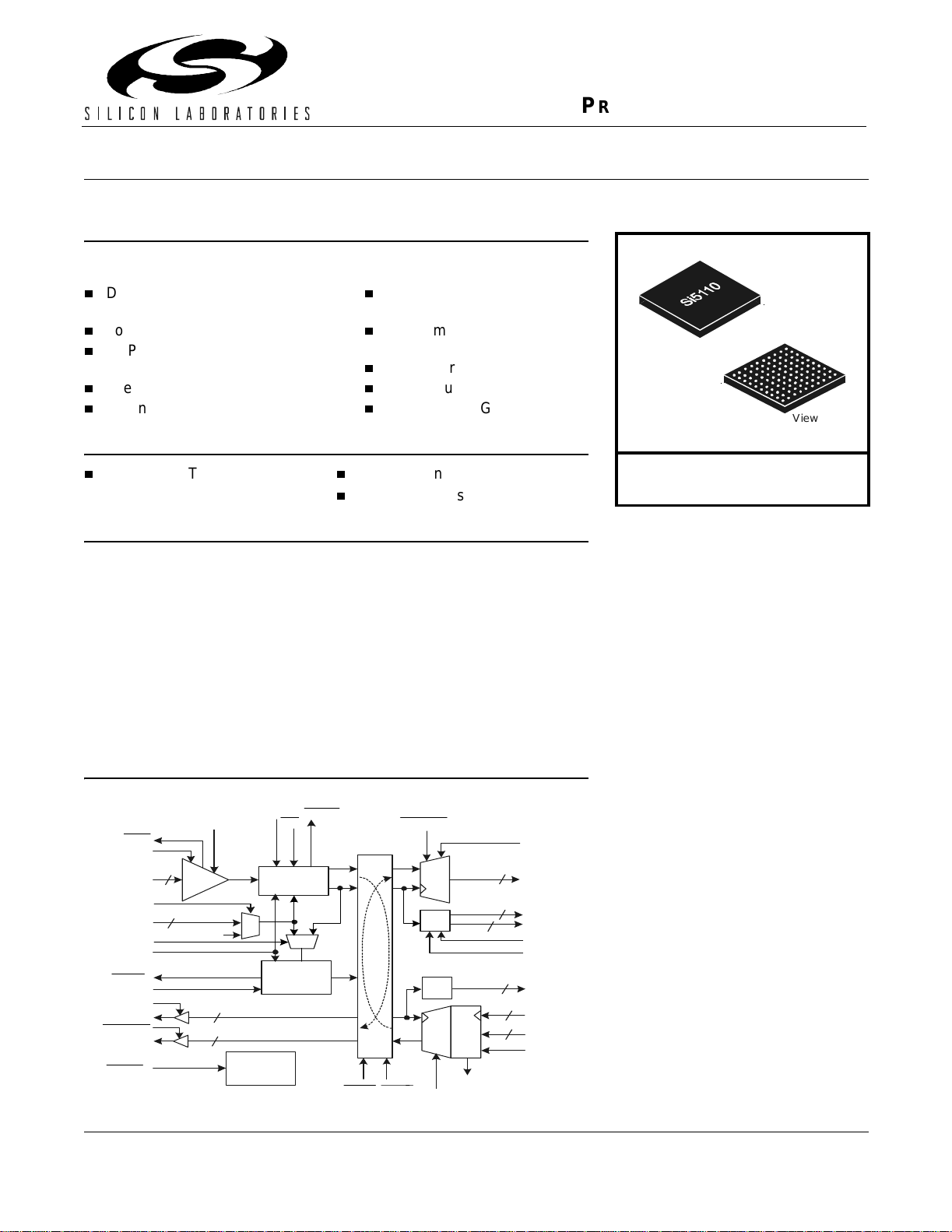

Si5110

:0

T

B

Bottom View

PRELIMINA RY DATA SHEET

SiPHY™ OC-48/STM-16 SONET/SDH TRANSCEIVER

Features

Complete low power, high speed, SONET/SDH transceiver with

integrated limiting amp, CDR, CMU, and MUX/DEMUX

Data Rates Supported:

OC-48/STM-16 and 2.7 Gbps FEC

Low Power Operation 1.0 W (typ)

DSPLL™ Based Clock Multiplier Unit

w/ Selectable Loop Filter Bandwidths

Integrated Limiting Amplifier

Diagnostic and Line Loopbacks

SONET Compliant Loop Timed

Operation

Programmable Slicing Level and

Sample Phase Adjustment

LVDS Parallel Interfa ce

Single Supply 1.8 V Ope ratio n

11 x 11 mm B GA Package

Applications

Sonet/SDH Transmission

Systems

Optical Transc eiv e r Mo dules

Sonet/SDH Test Equipment

Si5110

Ordering Information:

See pa ge2 3.

Description

The Si5110 is a complete low-power transceiver for high-speed serial

communication systems operating between 2.5 Gbps and 2.7 Gbps. The receive

path consists of a fully integrated lim iting amplifier, clock and data recover y unit

(CDR), and 1:4 deserializer. The transmit path combines a low jitter clock

multiplier unit (CMU) with a 4:1 serializer. The CMU uses Silicon Laboratories’

™

DSPLL

technology to provide superior jitter performance while reducing design

complexity by eliminating external loop filter components. To simplify BER

optimization in long haul applications, programmable slicing, and sample phase

adjustment are supported.

The Si5110 operates from a single 1.8 V supply over the industrial temperature

range (–40°C to 85°C).

Functional Block Diagram

LOS

LOSLVL

RXDIN

REFSEL

REFCLK

LPTM

REFRATE

TXLO L

BWSEL

TXCLKDSBL

TXCLKOUT

TXSQLCH

TXDOUT

RESET

SLICELVL

2

Limiting

AMP

2

TXCLK4IN

2

2

PHASEADJ

RESET

Control

LTR

CDR

DSPLL

TX CMU

RXLOL

tm

Loopback Control

DLBKLLBK

RXSQLCH

1:4

÷

÷

4:1

TXMSBSEL

DEMUX

MUX

8

2

2

FIFO

FIFOERR

2

2

8

RXMSBSEL

RXDOUT[3

RXCLK1

RXCLK2

RXCLK2DIV

RXCLK2DS

TXCLK4OU

TXCLK4IN

TXD IN[3:0]

FIFORST

Preliminary Rev. 0.41 8/ 01 Copyright © 2001 by Silicon Labora tories Si5110-DS041

This in formation applies to a product under devel opment. I ts characteristics and specifications are subject to change without notice.

Page 2

Si5110

2 Preliminary Rev. 0.41

Page 3

Si5110

TABLE OF CONTENTS

Section Page

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Limiting Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Clock and Data Recovery (CDR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Deserialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Auxiliary Clock Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Data Squelch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DSPLL™ Clock Multiplier Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Serialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loop Timed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Diagnostic Loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Bias Generation Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Voltage Reference Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transmit Differential Output Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Si5110 Pinout: 99-Pin BGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pin Descriptions: Si5110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preliminary Rev. 0.41 3

Page 4

Si5110

t

t

Electrical Specifications

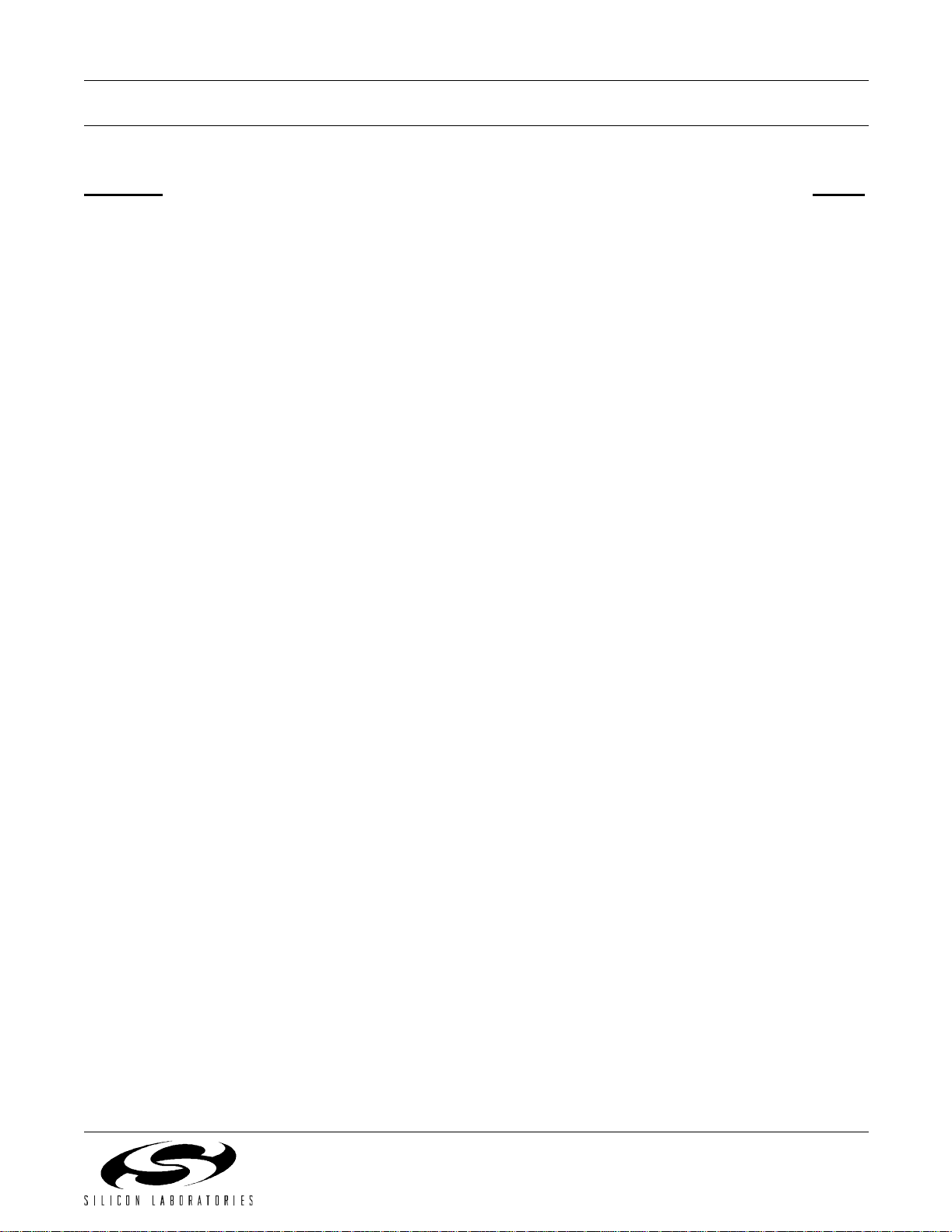

Table 1. Recommended Operating Condit ions

Parameter Symbol Test Condition

Ambient Temperatur e T

LVTTL Output Supply Voltage V

Si5110 Supply Voltage V

*Note: All minimum and maximum specifications are guaranteed and apply across the rec om me nded operating conditions.

T ypical values apply at nominal supply voltages and an operating temper ature of 25°C unless otherwise st ated.

A

DD33

DD

*

Min

Typ

–40 25 85 °C

1.71 — 3.47 V

1.71 1.8 1.89 V

Max

*

Unit

V

SIGNAL +

Differential

I/Os

V

ICM

SIGNAL –

, V

OCM

V

IS

Single Ended Voltage

(SIGNAL +) – (SIGNAL –)

Differential

Voltage Swing

VID,VOD (V

= 2VIS)

ID

Differential Peak-to-Peak Voltage

t

Figure 1. Differential Voltage Measurement

(RXDIN, RXDOUT, RXCLK1, RXCLK2, TXDIN, TXDOUT, TXCLKOUT, TXCLK4OUT, TXCLK4IN)

TXDOUT,

TXDIN

TXCLKOUT,

TXCLK4IN

RXDOUT

RXCLK1

su

hd

t

t

CH

CP

t

t

cq1

cq2

Figure 2. Data to Clock Delay

4 Preliminary Rev. 0.41

Page 5

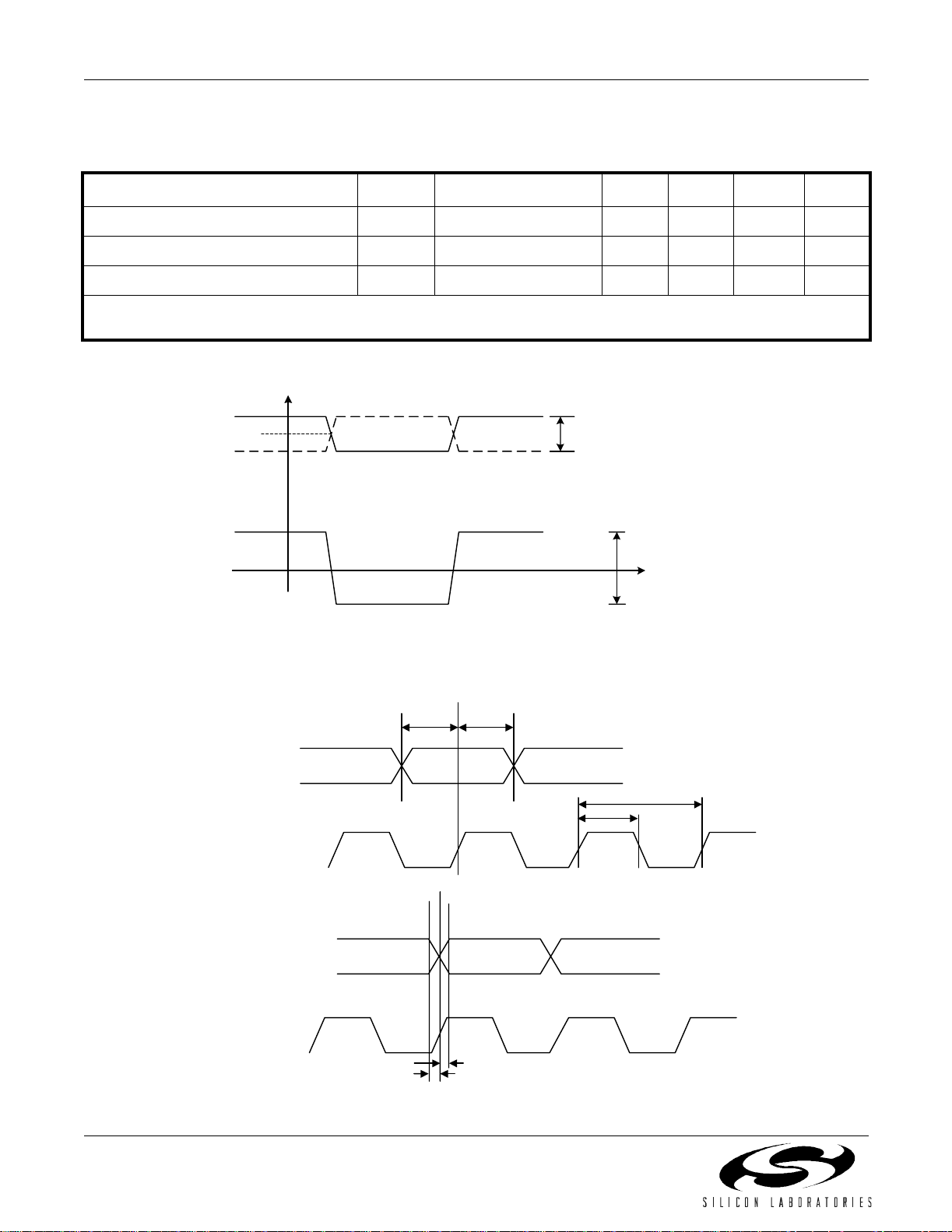

Si5110

All

80%

Differential

IOs

t

F

t

R

20%

Figure 3. I/O Rise/Fall Times

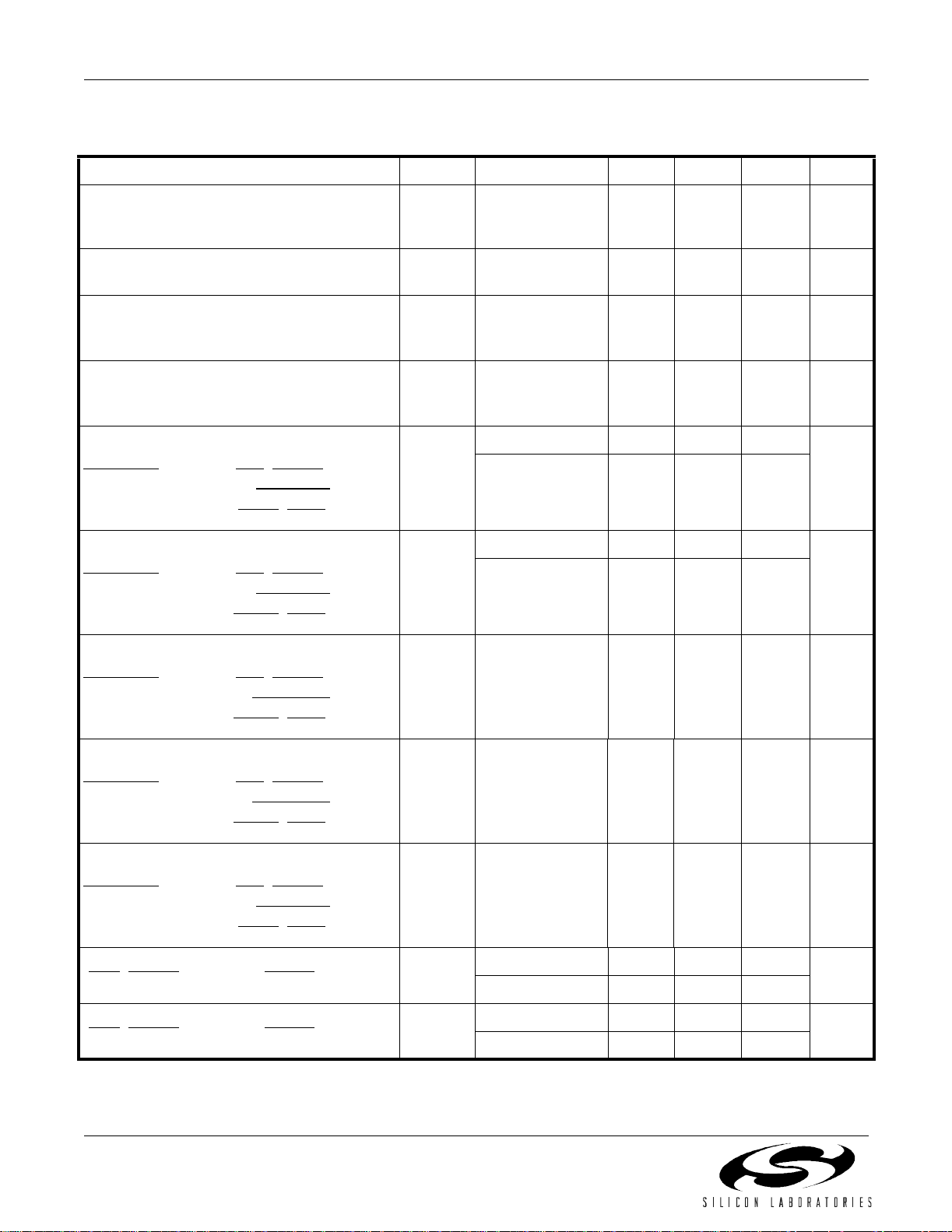

Table 2. DC Characteristic s

(VDD = 1.8 V ±5% , TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Supply Current I

Power Dissipation P

Voltage Reference (VREF) V

Common Mode Input Voltage (RXDIN) V

Differential Input Voltage Swing (RXDIN) V

Common Mode Output Voltage

V

(TXDOUT, TXCLKOUT)

Differential Output Voltage Swing

V

(TXDOUT, TXCLKOUT), Differential pk-pk

DD

D

REF

ICM

ID

OCM

OD

VREF driving

Ω load

10 k

See Figure 1 10 — 1.0 mV

See Figure 1 800 1000 1200 mV

—611TBDmA

—1.0TBDW

1.21 1.25 1.29 V

TBD 0.1 TBD V

(pk-pk)

.8 0.9 1.0 V

(pk-pk)

L VPECL Input Voltage HIGH (REFCLK) V

L VPECL Input Voltage LOW (REFCLK) V

L VPECL Input Voltage Swing,

Differential pk-pk (REFCLK)

LVPECL Internally Gene rated Input Bias

(REFCLK)

L VDS Input High Voltage (TXDIN,

TXCLK4IN)

L VDS Input Low Voltage (TXDIN, TXCLK4IN) V

L VDS Input Voltage, Single Ended pk-pk

V

(TXDIN, TXCLK4IN)

LVDS Output High Voltage

V

(RXDOUT, RXCLK1, RXCLK2,

TXCLK4OUT)

LVDS Output Low Voltage

V

(RXDOUT, RXCLK1, RXCLK2,

TXCLK4OUT)

L VDS Output Voltage, Differential pk-pk

V

(RXDOUT, RXCLK1, RXCLK2,

TXCLK4OUT)

V

V

V

ISE

OH1

OL1

OSE

IH

IL

ID

IB

IH

IL

1.975 2.3 2.59 V

1.32 1.6 1.99 V

Figure 1 250 — 2400 mV

1.6 1.95 2.3 V

——2.4V

0.0 — — V

100 — 600 mV

100 Ω Load

TBD — 1.475 mV

Line-to-Line

100 Ω Load

0.925 — TBD V

Line-to-Line

100 Ω Load

500 — 800 mV

Line-to-Line,

Figure 1

(pk-pk)

(pk-pk)

(pk-pk)

Preliminary Rev. 0.41 5

Page 6

Si5110

Table 2. DC Characteristic s (Con tinued)

(VDD = 1.8 V ±5% , TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

L VDS Common Mode Voltage

(RXDOUT, RXCLK1, RXCLK2,

TXCLK4OUT)

Input Impedance (TXDIN, TXCLK4I N,

REFCLK, RXDIN)

Output Short to GND

(RXDOUT, RXCLK1, RXCLK2,

TXCLK4OUT, TXDOUT, TXCLKOUT)

Output Short to V

DD

(RXDOUT, RXCLK1, RXCLK2,

TXCLK4OUT, TXDOUT, TXCLKOUT)

LVTTL Input Voltage Low

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

TXCLKDSBL, FI FOR ST, TXSQL CH

BWSEL, TXMSBSEL, DLBK

, REFSEL, LTR, RESET, MODE16

,

, LLBK, LPTM)

LVTTL Input Voltage High

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

TXCLKDSBL, FI FOR ST, TXSQL CH

BWSEL, TXMSBSEL, DLBK

, REFSEL, LTR, RESET, MODE16

,

, LLBK, LPTM)

LVTTL Input Low Current

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

TXCLKDSBL, FI FOR ST, TXSQL CH

BWSEL, TXMSBSEL, DLBK

, REFSEL, LTR, RESET, MODE16

,

, LLBK, LPTM)

LVTTL Input High Current

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

TXCLKDSBL, FI FOR ST, TXSQL CH

BWSEL, TXMSBSEL, DLBK

, REFSEL, LTR, RESET, MODE16

,

, LLBK, LPTM)

L VTTL Input Impedance

(RXMSBSEL, RXCLK2DIV, RXCLK2DSBL,

RXSQLCH

TXCLKDSBL, FI FOR ST, TXSQL CH

BWSEL, TXMSBSEL, DLBK

, REFSEL, LTR, RESET, MODE16

,

, LLBK, LPTM)

LVTTL Output Voltage Low

(LOS

, RXLOL, FIFOERR, TXL OL)

V

CM

R

I

SC(–)

I

SC(+)

V

IL2

V

IH2

I

IL

I

IH

R

V

OL2

1.125 — 1.275 V

IN

Each input to

42 50 58 Ω

common mode

—25TBDmA

TBD –100 — µA

VDD33 = 3.3 V — — 0.8 V

VDD33 = 1.8 V — — 0.7

VDD33 = 3.3 V 2.0 — — V

VDD33 = 1.8 V 1.7

——10µA

——10µA

IN

10 — — kΩ

VDD33 = 1.8 V — — 0.4 V

VDD33 = 3.3 V — — 0.4

LVTTL Output Voltage High

(LOS

, RXLOL, FIFOERR, TXL OL)

6 Preliminary Rev. 0.41

V

OH2

VDD33 = 1.8 V 1.4 — — V

VDD33 = 3.3 V 2.4 — —

Page 7

Si5110

Table 3. AC Characteristics (RXDIN, RXDOUT, RXCLK1, RXCLK2)

(VDD = 1.8 V ±5% , TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Output Clock Frequency

f

clkout

See Figure 2 — 622 667 MHz

(RXCLK1)

Duty Cycle (RXCLK1, RXCLK2) tch/tcp, Figure 2 45 — 5 5 %

Output Rise and Fall Times

t

R,tF

Figure 3 — 50 — ps

(RXCLK1, RXCLK2, RXDOUT)

Data Invalid Prior to RXCLK1 t

Data In valid A fter RXCL K1 t

cq1

cq2

Input Return Loss (RXIN) 100 kHz–2.5 GHz

Figure 2 — — 200 ps

Figure 2 — — 200 ps

2.5 GHz–4.0 GHz

18.7

TBD

—

—

—

—

dB

dB

Slicing Adjust Dynam ic Range SLICELVL = 200–800 mV –20 — 20 mV

Slicing Level Offset

1

SLICELVL = 200–800 mV –500 — 500

µV

(referred to RXDIN)

Slicing Level Accuracy VSLICE –5 — 5 %

Sampling Phase Adjustment

2

PHASEADJ = 200–800 mV –22.5° — 22.5°

LOS Threshold Dynamic Range LOSLVL = 200–800 m V 10 — 50 mV

pk-pk

LOS Threshold Offset

3

LOSLVL = 200–800 mV –500 — 500

µV

(referred to RXDIN)

LOS Threshold Accuracy VLOS –5 — 5 %

Note:

1. Slice level (referred to RXDIN) is calculated as follows: VSLICE = (SLICE_LVL – 0.4

2. Sample Phase Offset is calcul ated as follows: PHASE OFFSET = 22.5

3. LOS Threshold voltage (referred to RXDIN) is calculated as follows: VLOS = 30 mV + (LOS_LVL – 0.4

°(PHASEADJ – 0.4

VREF)/15.

VREF)/0.3

VREF)/15.

Preliminary Rev. 0.41 7

Page 8

Si5110

Table 4. AC Characteristics (TXCLK4OUT, TXCLK4IN, TXCLKOUT, TXDIN, TXDOUT)

(V

1.8 V ±5%, TA = –40°C to 85°C)

DD =

Parameter Symbol Test Condition Min Typ Max Unit

TXCLKOUT Frequency f

clkout

Figure 2 — 2.5 2.7 GHz

TXCLKOUT Duty Cycle tch/tcp, Figure 2 45 — 55 %

Output Rise Time

t

R

Figure 3 — 25 — ps

(TXCLKOUT, TXDOUT)

Output Fall Time

t

F

Figure 3 — 25 — ps

(TXCLKOUT, TXDOUT)

TXCLKOUT Setup to TXDOUT t

TXCLKOUT Hold From TXDOUT t

su

hd

Output Return Loss 100 kHz–2. 5 GHz

TXCLK4OUT Frequency f

CLKIN

Figure 2 25 — — ps

Figure 2 25 — — ps

2.5 GHz–4.0 GHz

TBD

TBD

—

—

—

—

— 622 667 MHz

dB

dB

TXCLK4OUT Duty Cycle tch/tcp, Figure 2 40 — 60 %

TXCLK4OUT Rise & Fall Times t

TXDIN Setup to TXCLK4IN t

TXDIN Hold from TXCLK4IN t

TXCLK4IN Frequency f

R,tF

DSIN

DHIN

CLKIN

100 — 300 ps

— — 300 ps

— — 300 ps

— 622 667 MHz

TXCLK4IN Duty Cycle tch/tcp, Figure 2 40 — 60 %

TXCLK4IN Rise & Fall Times t

R,tF

100 — 300 ps

8 Preliminary Rev. 0.41

Page 9

Si5110

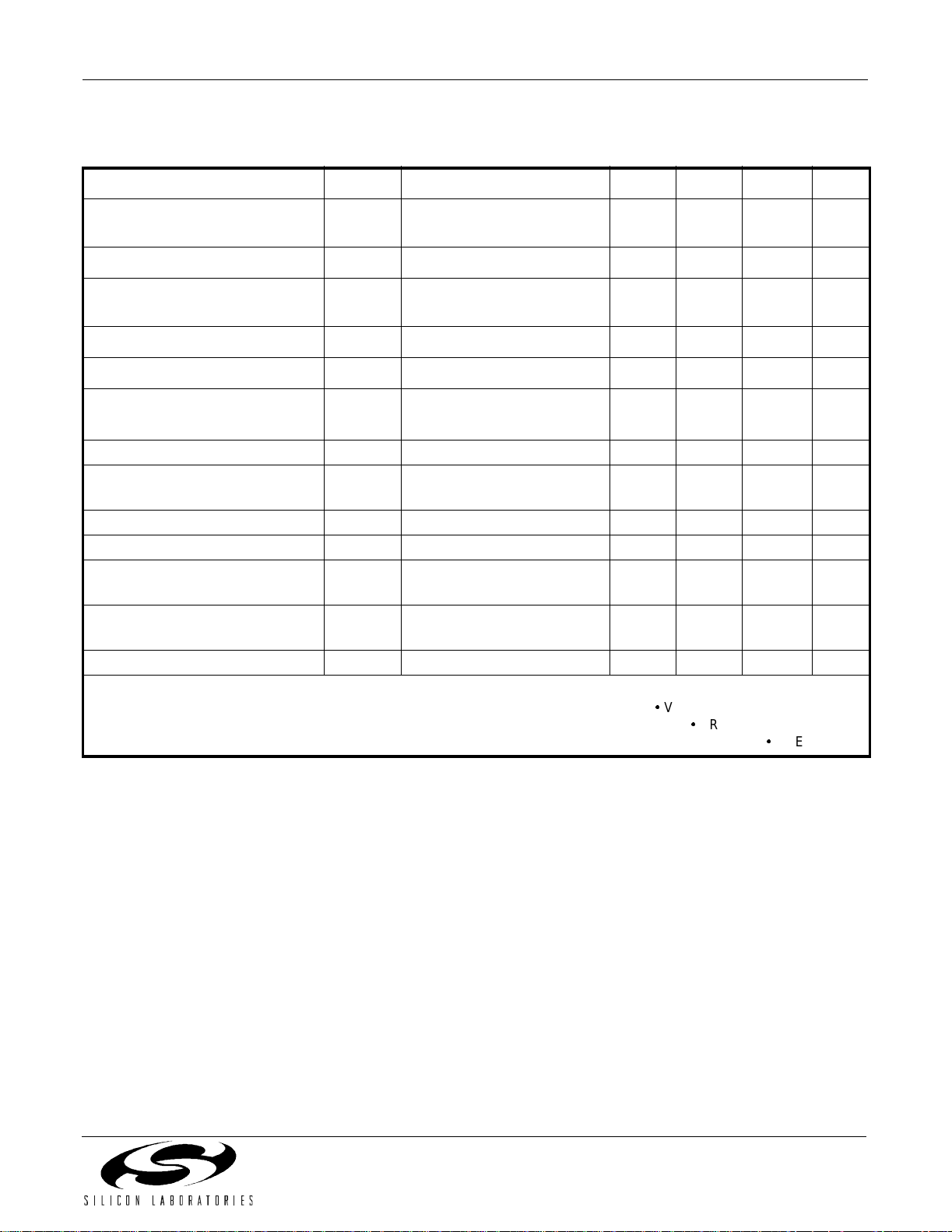

Table 5. AC Character i sti cs (Receiver PLL)

(VDD = 1.8 V ±5% , TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Jitter Tolerance J

TOL(PP)

f = 600 Hz 15 30 — UIpp

f = 6000 kHz 1.5 3.0 — UIpp

f = 100 kHz 1.5 3.0 — UIpp

f = 1 MHz 0.15 0.3 — UIpp

Acquisition Time T

Input Reference Clock Frequency RC

AQ

FREQ

REFRAT E= 1 — 155 167 MHz

REFRATE = 0 — 78 83 MHz

Reference Clock Duty Cycle RC

Reference Clock Frequency

RC

DUTY

TOL

Tolerance

Frequency Difference at which

LOL TBD 600 1000 ppm

Receive PLL goes out of Lock

(REFCLK compared to the

divided down VCO clock)

Frequency Difference at which

LOCK TBD 300 TBD ppm

Receive PLL goes into Lock

(REFCLK compared to the

divided down VCO clock)

Note: Bellcore specifications: GR-1377-CORE, Issue 5, December 1998.

——20 µs

40 50 60 %

–100 — 100 ppm

Table 6. AC Characteristics (Transmitter Clock Multiplier)

(VDD = 1.8 V ±5% , TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Jitter Generation J

Jitter Transfer Bandwidth J

GEN(rms)

BW

Jitter Transfer Peaking — 0.05 0.1 dB

Acquisition Time T

Input Reference Clock Frequency RC

Input Reference Clock Duty

RC

AQ

FREQ

DUTY

Cycle

Input Reference Clock Frequency

RC

TOL

Tolerance

Note: Bellcore specifications: GR-1377-CORE, Issue 5, December 1998.

PRBS 23 0.005 TBD UI

BWSEL = 0 — — 6 kHz

BWSEL = 1 — — 2 5 kHz

Valid REFCLK — — 20 µs

REFRAT E= 1 — 155 167 MHz

REFRATE = 0 — 78 84 MHz

40 — 60 %

–100 — 100 ppm

RMS

Preliminary Rev. 0.41 9

Page 10

Si5110

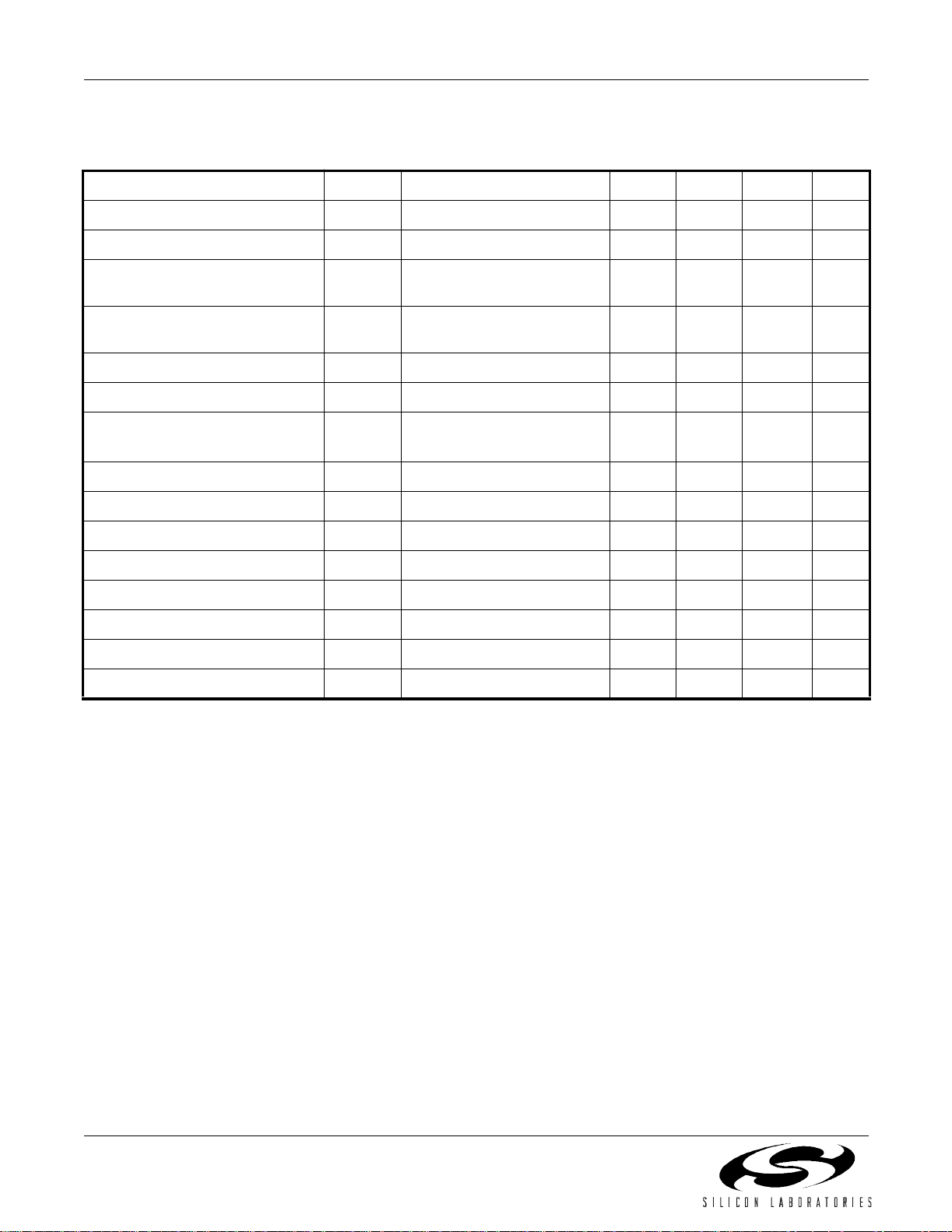

Table 7. Ab so l u te M aximu m R atings

Parameter Symbol Value Unit

DC Supply Voltage V

LVTTL Input Voltage V

Differential Input Voltages V

DD

DD33

DIF

–0.5 to TBD V

–0.5 to 3.6 V

–0.3 to (VDD+ 0.3) V

Maximum Current any output PIN ±50 mA

Operating Junction Temperature T

Storage Temperature Range T

Package Temperature

JCT

STG

–55 to 150 °C

–55 to 150 °C

275

°C

(soldering 10 seconds )

ESD HBM Toler anc e (100 pf, 1.5 k

Note: Permanent device damage m ay occur if the above Absolute Ma ximum Ratings are exceeded. Functional operation

should be restricted to the conditions as specified in the operational sections of this data sheet. Exposur e to absolute

maximum rating conditions for extende d periods may affect device reliability.

Ω)TBDV

Table 8. Thermal Ch ar acteristi cs

Parameter Symbol Test Condition Value Unit

Thermal Resistance Junction to Ambient ϕ

JA

Still Air 38 ° C/W

10 Preliminary Rev. 0.41

Page 11

Functional Description

V

0.4xVREF–

V

0.4xVREF–

Si5110

The Si5110 transceiver is a low power, fully integrated

serializer/deserializer that prov i des s ignificant mar gin to

all SONET/SDH jitter specifications. The device

operates from 2.5–2.7 Gbps making it suitable for OC48/STM-16, and OC-48/STM-16 applications that use

15/14 forward error correction (FEC) coding. The low

speed receive/transmit interface uses a low power

parallel LVDS interface.

Receiver

The receiver within the Si5110 includes a precision

limiting amplifier, jitter tolerant cloc k and data recovery

unit (CDR), and 1:4 demultiplexer. In addition,

programmable data slicing and sampling phase

adjustment are prov ided to suppo rt bit-error-rat e (BER)

optimization for long haul ap plications.

Limiting Amplifier

The Si5110 incorporates a high sensitivity limiting

amplifier with sufficient gain to directly accept the output

of transimpedance amplifiers. High sensitivity is

achieved by using a digital calibration algorithm to

cancel out amplifier offsets. This algorithm achieves

superior offset cancellation by using statistical

averaging to remove noise that may degrade more

traditional calibra tion routines.

The limiting amplifier provides sufficient gain to fully

saturate with input signals that are less than 10 mV

peak-to-peak differentia l. In addition, input signals that

exceed 1 V peak- to-peak differential will not cau se any

performance degradation.

Loss-of-Signal (LOS) Detection

The limiting am plifie r incl udes circ uitry t hat g enerates a

loss-of-signal (LOS) alarm when the input signal

amplitude on RXDIN falls below an externally controlled

threshold. The Si5110 can be configured to drive the

LOS

output low when the differential input amplitude

drops below a threshold s et b etween ~8 m V a nd 50 mV

pk-pk differential. Approximately 3 dB of hysteresis

prevents unnecessary switching on LOS

The LOS threshold is set by applying a voltage between

0.20 V and 0.80 V to the LOSLVL input. The voltage

present on LOSLVL maps to an input signal threshold

as follows:

()

LOSLVL

V

V

is the differential pk-pk LOS threshold referred to

LOS

the RXDIN input, V

---------------------------------------------------------------

LOS

LOSLVL

15

is the voltage applied to the

LOSLVL pin, and VREF is reference voltage output on

.

30 mV+=

the VREF pin.

The LOS detection circuitry is disabled by tieing the

LOSLVL input to the supply (VDD). T his fo rces t he LOS

output high.

Slicing Level Adjustment

To support applications that require BER optimization,

the limiting amplifier provides circuitry that supports

adjustment of t he 0/1 decision threshold (slicing l evel)

over a range of ±20 m V when referred to the interna lly

biased RXDIN input . The slicing le vel is set by applying

a voltage between 0.20 V and 0.80 V t o the SLICELVL

input. The voltage present on S LICELVL sets the slicing

level as follow s:

()

SLICE

-----------------------------------------------------------

LEVEL

=

15

V

LEVEL

V

SLICE

V

is the slicing l evel referred to the RX DIN input,

is the voltage applied to the SLICE_LVL pin, and

VREF is reference voltage outpu t on the VREF pin.

The slicing lev el adjustment may be disabled by tiei ng

the SLCLVL input to the supply (VDD). When slicing is

disabled, the slicing offset is set to 0.0 V relative to

internally biased input common mode voltage for

RXDIN.

Clock and Data Recovery (CDR)

The Si5110 uses an integrated CDR to recover clock

and data from a non-return to zero (NRZ) signal input on

RXDIN. The recovered data clock is used to regenerate

the incoming data by sam pling the output of the l imiting

amplifier at the center of the NRZ bit period. The

recovered cloc k and data is then deserialized by a 1:4

demultiplexer and output via a LVDS compatible low

speed interface (RXDOUT[3:0], RXCLK1, and

RXCLK2).

Sample Phase Adjustment

In applications where it is not desirable t o recover d ata

by sampling in the center of the data eye, the Si5110

supports adjustment of the CDR sampling phase across

the NRZ data period. When sample phase adjustment is

enabled, the sampling instant used for data recovery

can be moved over a range of ±22.5

center of the incoming NRZ bit period. Adjustment of the

sampling phase is de sirable when data eye distortions

are introduced by the transmission medium.

The sample phas e is s et by applying a voltage b etween

0.20 V and 0.80 V t o t he P H A SEADJ input. The voltage

present on PHASEADJ maps to sam ple phas e offset as

follows:

° relative to the

Preliminary Rev. 0.41 11

Page 12

Si5110

22.5°xV

PhaseOffset

Phase Offset is the s ampli ng offset in deg rees from the

center of the data eye, V

the PHASEADJ pin, and VREF is reference voltage

output on the VREF pin. A positive phase offset will

adjust the sampli ng point to lead the de fault sampling

point in the center of the data eye, and a negative phase

offset will adjust the sampling point to lag the default

sampling point.

Data recovery using a sampling phase offset is disabled

by tieing t he PHASEADJ input to the supply (VDD). This

forces a phase offset of 0

Receiver Lock Detect

The Si5110 provides lock-detec t circuitry that indicates

whether the PLL has achieved frequenc y lock with the

incoming data. This circuit compares the frequen cy of a

divided down version of the recovered clock with the

frequency of the s upplied reference c lock (REFC LK). If

the recovered clo ck freque ncy deviat es from that o f the

reference clock by the amount specified in Table 5 on

page 9, the PLL is de cl ared out of lo ck, and the loss- oflock (RXLOL

attempt to reacquire lock with the incoming data stream.

During reacquisition, the recovered clock frequency

(RXCLK1 and RXCLK2) will drift over a ±1000 ppm

range relative to the supplied reference clock. The

RXLOL

clock frequency is w ithin t he REF CLK fre quency by t he

amount specified in Table 5 on page 9.

Lock-to-Reference

In applications where it is desirable t o maintain a stable

output clock during an alarm condition like loss-ofsignal, the lock-t o-referen ce input (LTR

force a stable output clock . When LTR

CDR is prevented from acquiring the data signal and the

CDR will lock the RXCLKOUT1 and RXCLKOUT2

outputs to the provided REFCLK. In typical applications,

the LOS

stable output clock.

) pin is assert ed. In this state, the PLL will

output will remain asserted until the recovered

output would be tied to the LTR input to force a

-------------------------------------------------------------------------------

=

PHASE

is the voltage applie d to

PHASE

o

to be used for data recovery.

0.4xVREF–()

0.30

) can be used to

is asserted, the

Deserialization

The Si5110 uses a 1:4 demultiplexer to de serialize the

high speed input. The deserialized data is output on a 4bit parallel data bus, RXDOUT[3:0], synchronous with

the rising edge of RXCLK1. This clock output is deriv ed

by dividing down the recovered clock by a factor of 4.

Serial In put to Parallel Output Relatio nship

The Si5110 provides the capability to select the order in

which the receiv ed serial data is m apped to the parallel

output bus RXDOUT[3:0]. The mappi ng of the receive

bits to the output data word is controlled by the

RXMSBSEL input. If RXMSBSEL is tied low, the first bit

received is output on RXDOUT0 and the followi ng bits

are output in order on RXDOUT1 throug h RXDOUT3. If

RXMSBSEL is tied high, the fir st bit received is output

on RXDOUT3, and the following bits are output in order

on RXDOUT2 through RXDOUT0.

Auxiliary Clock Output

To support the widest range of system timing

configurations, a second clock output is provided on

RXCLK2. This output can be configured to provide a

clock equal to either the parallel output word rate or

1/4th the output word rate. The divide factor used to

generate RXCLK2 is controlled via the RXCLKDIV2

input as described in the Pin Description table. In

applications which do not use RXCLK2, this output can

be powered down by forcing the RSCLK2DSBL input

high.

Data Squelch

During some system error conditions, such as LOS, it

may be desirable to force the receive data output to

zero in order to avoid propagation of erroneous data

into the downstream processing circuitry. In these

applications, the Si5110 provides a data squelching

control input, RXSQLCH

the data on RXDOUT will be forced to 0. Data squelch is

disabled if the device is operating in diagnostic

loopback mode (DLBK

. When this input is active low,

= 0).

Transmitter

The transmitter consists of a low jitter, clock multiplier

unit (CMU) with a 4:1 serializer. The CMU uses a

phase-locked loop (PLL) architect ure based on Silic on

Laboratories’ proprietary DSPLL

technology is u sed t o generate ultra-low j itter cloc k a nd

data outputs that provide significant margin to the

SONET/SDH specifications. The DSPLL architecture

also utilizes a digitally implemented loop filter that

eliminates the need for external loop f ilter components.

As a result, sensit iv e nois e c oupling nodes that typi ca lly

cause degraded jitter performance in crowded PCB

environments are removed.

The DSPLL also reduces the complexity and

performance requirements of reference clock

distribution strategies for OC-48/STM-16 optical port

cards. This is possible because the DSPLL provides

selectable wideband and narr owband loop filter setti ngs

that allow the user to set the jitter attenuation

characteristics o f the CMU to accommodat e reference

clock sources that have a high jitter content. Unlike

traditional analog PLL implementations, the loop filter

™

technology. This

12 Preliminary Rev. 0.41

Page 13

Si5110

bandwidth is controlled by a digital filter inside the

DSPLL and can be changed without any modification to

external components.

DSPLL™ Clock Multiplier Unit

The Si5110’s clock multiplier unit (CMU) uses Silicon

Laboratories proprietary DSPLL techn ology to gene rate

a low jitter, high frequency clock source capable of

producing a high speed serial clock and data output with

significant margin to the SONET/SDH specifications.

This is achieved by using a digital signal processing

(DSP) algorithm to replace the loop filter commonly

found in analog PLL design s. This algorithm processes

the phase detector error term and generates a digital

control value to adjust the frequency of the voltage

controlled oscillator (VCO). Because exter nal loop filter

components are not required, sensitive noise entry

points are eliminated, thus making the DSPLL less

susceptible to board-level noise sources. Therefore,

SONET/SDH jitter compliance is easier to attain in the

application.

Programm able Loop Filt er B andwidth

The digitally implemented loop filter allows for two

bandwidth settings that provide either wideband or

narrowband jitter transfer characteristics. The filter

bandwidth is selected via the B WSEL control input. In

traditional PLL impleme ntations, changing the loop filter

bandwidth would require changing the values of

external loop filter components.

In narrowband mode, a loop filter cutoff of 6 kHz is

provided. This set ting makes the Si5110 more tolerant

to jitter on the reference c lock source. As a result, the

complexity of the clock distribution circuitry used to

generate the physical layer reference clocks can be

simplified without compromising jitter margin to the

SONET/SDH specification.

In wideband mode, the loop filter provides a cutoff of

25 kHz. T his setting is desirable in applications where

the reference clock is provided by a low jitter source like

the Si5364 Clock Synchronization IC or Si5320

Precision Clock Multiplier/Jitter Attenuator IC. This

allows the DSPLL to more closely track the precision

reference source resulting in the best possible jitter

performance.

Serialization

The Si5110 includes serialization circuitry that combines

a FIFO with a parallel t o serial shi ft register. Low speed

data on the parallel 4-bit input bus, TXDIN[3:0], is

latched into the FIFO on the rising edge of TXCLK4 IN.

The data in the FIFO is loaded int o the shift register by

TXCLK4OUT, an output clock that is produced by

dividing down the high speed transmit clock,

TXCLKOUT , by a factor of 4. The high-speed serial data

stream is clocked out of the shift register by

TXCLKOUT. The TXCLK4OUT clock output is provided

to support d ata wor d transf ers be tween t he S i5110 and

upstream devices using a counter cloc king s cheme.

Input FIFO

The Si5110 integrates a FIFO to decouple data

transferred into the FIFO via TXCLK4IN from data

transferred into the shift register via TXCLK4OUT. The

FIFO is e ight parallel words deep a nd accommodates

any static phase delay that m ay be intr oduced betwe en

TXCLK4OUT and TXCLK4IN in counter clocking

schemes. Further, the FIFO will accom modate a phase

drift or wander between TXCLK4IN and TXCLK4OUT of

up to three parallel data words.

The FIFO circuitry indicates an overflow or underflow

condition by asser ting FIFOERR high. This out put can

be used to recenter the FIFO read/write pointers by

tieing it di rectly to the FIFORST inp ut. The Si5110 will

also recenter the rea d/write pointers after the device’s

power on reset, external reset via RESET

time the DSPLL transitions from an out of lock state to a

locked state (TXLOL

Parallel Inp ut To Serial Output Relationship

The Si5110 provides the capability t o selec t the order in

which data on the parallel input bus is transmitted

serially. Data on this bus can be transmitted MSB first or

LSB first depending on the setting of TXMSBSEL. If

TXMSBSEL is tied low, TXDIN0 is transmitted first

followed in order by TXDIN1 through TXDIN3. If

TXMSBSEL is tied high, TXDIN3 is transmitted first

followed in order by TXDIN2 through TXDIN0. This

feature simpl ifies board routing when ICs are mounted

on both sides of the PCB.

Transmit Data Squelch

To pre vent the transmis sion of corrupted data into the

network, the Si5110 provides a control pin that can be

used to forc e TXDOUT to 0. By driving TXSQLCH

the high speed serial ou tput, TXDOUT will be forced to

0. Transmit data squelching is disabled when the device

is in line loopback mode (LLBK

Clock Disable

The Si5110 provides a clock disable pin, T XCLKDSBL,

that is used to disable the high -speed serial data clock

output, TXCLKOUT. When the TXCLKDSBL pin is

asserted, the positive and negative terminals of

CLKOUT are tied to 1.5 V through 50

resistors. This feature is used to reduce power

consumption in applications that do not use the high

speed transmit data clock.

transitions from low to high).

=0).

, and each

low,

Ω on-chip

Preliminary Rev. 0.41 13

Page 14

Si5110

Loop Timed Operation

The Si5110 can be configured to pr ovide SONET/SDH

compliant loop timed operation. When LPTM is asserted

high, the transmit c lock and data timing is der ived from

the recovered clock output by the CDR. This is achieved

by dividing down the reco vered clock and using it as a

reference source for the transmit CMU. This will

produce a transmit clock and data that ar e lock ed to the

timing recovered from the received data path. In this

mode, a narrow band loop filter setting is

recommended.

Diagnostic Loopback

The Si5110 supports diagnostic loopback which

establishes a loopback path from the serializer output to

the deserializer input. This provides a mechanism for

looping back data input via the low speed transmit

interface TXDIN to the low speed receive data interface

RXDOUT. This mode is enabled by forcing DLBK

low.

Line Loopback

The Si5110 supports line loopback which establis hes a

loopback path from the high speed receive input to the

high speed transmit output. This prov ides a mechan ism

for looping back the high-speed clock and data

recovered from RXDIN to the transmit data output

TXDOUT and clock TXCLKOUT. This mode is enabled

by forcing LLBK

low.

Bias Generation Circuitry

The Si5110 makes use of two external resistors,

RXREXT and TXREXT, to set internal bias currents for

the receive and transmit sections of the Si5110. The

external resistors allows precise generation of bias

currents that significantly reduce power consumption.

The bias generation circuitry requires 3.09 k

resistors connected between RXREXT/TXREXT and

GND.

Ω (1%)

reference cloc k sour c es. The first c onf igur at ion uses an

externally provided reference clock that is input via

REFCLK. The second configuration uses the parallel

data clock, TXCLK4I N, as the ref erence clock source.

When using TXCLK4IN as the reference source, the

narrowband loop filter setting in the CMU may be

preferable to remove jit ter that may be present on the

data clock. The selection of reference clock source is

controlled via the REFSEL input.

The CMU in the Si5110’s transmit section multiplies up

the provided ref erence to the serial transm it data rate.

When the CMU has achieved lock with the selected

reference, the TXLOL

CDR in the receive section of the Si5110 uses a

reference clock to cent er the PLL frequenc y so that it is

close enough to the data f requenc y t o ac hieve lock with

the incoming data. When the CDR has locked to the

data, R XLOL

is driven high.

output will be driven high.The

Reset

The Si5110 is reset by holding the RESET pin low for at

least 1

pointers reset an d the digital control circuitry initializ es.

When RESET

the CMU will be calibrated.

Voltage Reference Output

The Si5110 provides an output voltage reference that

can be used by an external circuit to set the LOS

threshold, slicing lev el, or sampling phase adjustment.

One possible implementation would use a resistor

divider to set the control voltage for LOSLVL,

SLICELVL, or PHASEADJ. A second altern ative would

use a DAC to set the control voltage. Using this

approach, VRE F would be used to establish the range

of a DAC output. The reference voltage is nominally

1.25 V.

µs. When RESET is asserted low, the input FIFO

transitions high to start n or mal operat ion,

Reference Clock

The Si5110 is designed to operate with refere nce cl ock

sources that are either 1/16th or 1/32nd the desired

transceiver data rate. T he device will support operation

with data rates between ~2.5 Gbps a nd ~2.7 Gbps and

the reference clock should be scaled accordingly. For

example, to suppo rt 2.67 Gbps operation the ref erence

clock source would be approximately 83 MHz or

167 MHz. T he REFRATE input pin is used t o configure

the device for operation with one of the two suppo rted

reference clock submultiples of the data rate.

The Si5110 supports operation with two selectable

14 Preliminary Rev. 0.41

Page 15

Si5110

Transmit Differential Output Circuitry

The Si5110 utilizes a current-mode logic (CML) architecture to drive the high speed serial output clock and data on

TXCLKOUT and TXDOUT. An example of output termination with ac cou pling is shown in Figure 4. In applications

where direct dc cou pling is possibl e, the 0.1

swing of the CML architecture is list ed in Table 2 on page 5.

µF capacitors may be omitted. The differential peak- to-peak voltag e

50 Ω

1.5 V

50 Ω

24 mA

0.1 µF

0.1 µF

Zo = 50 Ω

Zo = 50 Ω

VDD

50 Ω

50 Ω

VDD

Figure 4. CML Output Driver Termination (TXCLKOUT, TXDOUT)

Preliminary Rev. 0.41 15

Page 16

Si5110

Si5110 Pinout: 99 BGA

110 9 78 65432

PHASEADJSLICELVLRXREXTRXSQLCHRSVD_GNDRXCLK[2]RXCLK[2]RXDOUT[1]RXDOUT[0]

RXDINGNDLOSLVLVREFNCRSVD_GNDRXCLK[1]RXCLK[1]RXDOUT[1]RXDOUT[0]

RXDINGNDRXLOLLTRRSVD_GNDRSVD_GNDRXCLK2DSBLRXCLK2DIVRXDOUT[3]RXDOUT[2]

RSVD_GNDVDDVDDVDDVDDRXMSBSELRXDOUT[3]RXDOUT[2]

GNDLOS

TXCLKOUTGNDRESETVDDVDDVDDGNDGNDGNDREFCLK

TXCLKOUTGNDREFRATEVDDVDDVDDGNDGNDGNDREFCLK

GNDVDD33RSVD_GNDVDDVDDVDDVDDLPTMTXDIN[3]TXDIN[2]

A

B

C

D

E

F

G

TXDIN[2]

LLBKTXDIN[3]

Bottom View

Figure 5. Si5110 Pin Configuration (Bottom View)

16 Preliminary Rev. 0.41

TXDOUTGNDRSVD_GNDTXMSBSELFIFORSTBWSELDLBK

TXDOUTGNDRSVD_GNDRSVD_GNDFIFOERRTXSQLCHREFSELTXCLKDSBLTXDIN[1]TXDIN[0]

GNDNCTXREXTTXLOLTXCLK4OUTTXCLK4OUTTXCLK4INTXCLK4INTXDIN[1]TXDIN[0]

H

J

K

Page 17

1 1097865432

Si5110

A

B

C

D

E

F

G

RXDIN GND LOSLVL VREF NC RSVD_GND RXCLK[1] RXCLK[1] RXDOUT[1] RXDOUT[0]

RXDIN GND RXLOL LTR RSVD_GND RSVD_GND RXCLK2DSBL RXCLK2DIV RXDOUT[3] RXDOUT[2]

GND LOS RSVD_GND VDD VDD VDD VDD RXMSBSEL RXDOUT[3] RXDOUT[2]

TXCLKOUT GND RESET VDD VDD VDD GND GND GND REFCLK

TXCLKOUT GND REFRATE VDD VDD VDD GND GND GND REFCLK

GND VDD33 RSVD_GND VDD VDD VDD VDD LPTM TXDIN[3] TXDIN[2]

PHASEADJ SLICELVL RXREXT RXSQLCH RSVD_GND RXCLK[2] RXCLK[2] RXDOUT[1] RXDOUT[0]

H

K

TXDOUT GND RSVD_GND TXMSBSEL FIFORST BWSEL DLBK LLBK TXDIN[3] TXDIN[2]

TXDOUT

J

GND NC TXREXT TXLOL TXCLKOUT TXCLKOUT TXCLKIN TXCLKIN TXDIN[1] TXDIN[0]

GND RSVD_GND RSVD_GND FIFOERR TXSQLCH REFSEL TXCLKDSBL TXDIN[1] TXDIN[0]

Top View

Figure 6. Si5110 Pin Configuration (Transparent Top View)

Preliminary Rev. 0.41 17

Page 18

Si5110

Pin Descr i p tio ns : Si 5110

Pin

Number(s)

H6 BWSEL I LVTTL

H7 DLBK

J5 FIFOERR O LVTTL

H5 FIFORST I LVTTL

B2, C2, D1,

E2, E7–9,

F2, F7–9,

G1, H2, J2,

K1

Name I/O Signal Level

ILVTTL

GND GND

Description

Bandw idth Se lec t D S P LL.

This input selects loop bandwidth of the DSPLL.

BWSEL = 0: Loop bandwidth set to 6 kHz.

BWSEL = 1: Loop bandwidth set to 25 kHz.

Diagno s t ic Lo opback.

When this input is active low the transm it clock and

data are looped back for output on RXDOUT , RXCLK1

and RXCLK2. This pin should be held high for normal

operation.

FIFO Error.

This output is driven high when a FIFO overflow/underflow has occurred. This output will stick high

until reset by asserting FIFORST.

FIFO RESET.

This input when asserted high resets the read/write

FIFO pointers to their init ial s tate .

Supply Ground.

H8 LLBK ILVTTL

D2 LOS

B3 LOSLVL I

OLVTTL

Line Loopback.

When this input is active low the recovered clock and

data are looped back for output on TXDOUT, and

TXCLKOUT. This pin should be held high for normal

operation.

Loss-of-Signal.

This output is driven low when the peak-to-peak signal

amplitude is below threshold set via LOSLV L.

LOS Threshold Level.

Applying an analog voltage to this pin allows adjustment of the Threshold used to declar e LOS. Tieing

this input high disables LOS detect ion and fo rces the

LOS

output high.

18 Preliminary Rev. 0.41

Page 19

Si5110

Pin

Number(s)

G8 LPTM I LVTTL

C4 LTR

B5 NC

K2 NC

A2 PHASEADJ I

Name I/O Signal Level

ILVTTL

Description

Loop Timed Opera tion.

When this input is forced high , the recover ed c lock

from the receiver is divided down and us ed as the reference source for the transmit CMU. The narrowband

setting for the DSPLL CMU will be sufficient to provide

SONET compliant jitter generation and transfer on the

transmit data and clock outputs (TXDOUT , TXCLKOUT). This pin should be held low for normal operation.

Lock-to-Reference.

This input forces a stable output clock by locking

RXCLK1 and RXCLK2 to the provided reference.

Driv in g LTR

No Connect.

Reserved for device testing. Leave electrically

unconnected.

No Connect.

Reserved for device testing. Leave electrically unconnected.

Sampling Phase Adjust.

Applying an analog voltage to this pin allows adjustment of the sampling phase acro ss the data eye. Tieing this input high nomina lly cen ters the sampling

phase.

low activates this feature.

E10, F10 REFCLK,

REFCLK

F3 REFRATE I LVTTL

J7 REFSEL I LVTTL

I LVPECL

Differential Reference Clock.

The reference clock sets the operating frequency of

the PLL used to generate the high speed transm it

clock. In addition, REFCLK se ts the initial operat ing

frequency used by the onboard PLL for clock and data

recovery. The Si5110 will operate with reference clock

frequencies that are either 1/16 or 1/32 the serial data

rate (nominally 155 MHz or 78 MHz).

Reference Clock Select.

This input configures the Si5110 to operate with one of

two reference clock frequ enc ies. If REFRATE is held

high, the device requires a reference clock that is 1/16

the serial data rate. If REFRATE is low, a referenc e

clock at 1/32 the serial data rate is required.

Reference Clock Selection.

This inputs selects the reference clock source used by

the CMU. When REFSEL = 0, the low speed data

input clock, TXCLK4IN, is used as the CMU reference. When REFSEL = 0, the reference c lock provided on REFCLK is used.

Preliminary Rev. 0.41 19

Page 20

Si5110

Pin

Number(s)

E3 RESET ILVTTL

A6, B6, C5–

6, D3, G3,

H3, J3–4

B7–8 RXCLK1

C8 RXCLK2DIV I LVTTL

C7 RXCLK2DSBL I LVTTL

Name I/O Signal Level

RSVD_GND

,

RXCLK1

OLVDS

Description

Device Reset.

Forcing this input low for at least 1 µs will cause a

device reset. For normal operation, this pin should be

held high.

Reserved Tie To Ground.

Must tie directly to GND for proper operat ion.

Differential Clock Output 1.

The clock recovered from the sign al pres ent on

RXDIN is divided down to the parallel output word rate

and output on RXCLK1. In the absence of data, a stable clock on RXCLK1 can be maintained by asserting

LTR

.

Clock Divider Select.

This input selects the divide factor us ed to generat e

the RXCLK2 output. When this input is driv en low,

RXCLK2 is equal to the output word rate on RXDOUT.

When driven high, RXCLK2 is 1/4th the outp ut word

rate.

RXCLK2 Disable.

Driving this input high will disable the RXCLK2 output.

This would be used to save power in applications that

do not require an auxiliar y clock.

A7–8 RXCLK2

RXCLK2

B1, C1 RXDIN,

RXDIN

A9–10, B9,

B10, C9,

C10, D9,

D10

C3 RXLOL

RXDOUT[3:0],

RXDOUT

,

[3:0]

OLVDS

I High Speed

Differential

OLVDS

OLVTTL

Differential Clock Output 2.

An auxiliary output clock is provided on this pin that is

equivalent to, or a submultiple of, the output word rate.

The divide factor used in generating RX CLK 2 is set

via RXCLK2DIV.

Differential Data Input.

Clock and data are recovered from the high speed

data signal present on these pins.

Differential Parallel Data Output.

The data recovered from the signal present on RXDIN

is demultiplexed and output as a 4-bit parallel word on

RXDOUT[3:0]. These outputs are updated on the rising edge of RXCLK1.

Loss-of-Lock.

This output is driven low when the recovered clock frequency deviates from the referenc e cloc k by the

amount specified in Table 5.

20 Preliminary Rev. 0.41

Page 21

Si5110

Pin

Number(s)

D8 RXMSBSEL I LVTTL

A4 RXREXT

A5 RXSQLCH

A3 SLICELVL I

Name I/O Signal Level

ILVTTL

Description

Data Bus Receive Order.

This determines the order of the received data bits on

the output bus.

For RXMSBSEL = 0, the first data bit received is output on RXDOUT[0] and following data bits are output

on RDOUT[1] through RXDOUT[3].

For RXMSBSEL = 1, the first data bit is output on

RXDOUT[3] and following data bits are output on

RXDOUT[2] through RXDOUT[0].

External Bias Resistor.

This resistor is used by the receiver c irc uit r y to establish bias currents within the device . This pin must be

connected to GND through a 3.09 k

Data Squelch.

When this input is low the data on RXDOUT is forced

to 0. Set high for normal operation.

Slicing Level Adjustment.

Applying an analog voltage to this pin allows adjustment of the slicing level applied to t he input data eye.

Tieing this input high nominally s ets the slicing offset

to 0.

Ω (1%) resistor.

K7–8 TXCLK4IN

TXCLK4IN

K5–6 TXCLK4OUT

TXCLK4OUT

J8 TXCLKDSBL I LVTTL

E1, F1 TXCLKOUT

TXCLKOUT

,

,

,

ILVDS

OLVDS

Differential Data Clock Input.

The rising edge of this input clocks data present on

TXDIN into the device.

Divided Down Output Clock.

This clock output is generated by dividi ng down the

high speed output clock, TXCLKOUT, by a factor of 4.

It is intended for use in counter clocking schemes that

transfer data between the system ASIC and the

Si5110.

High Speed Clock Disable.

When this input is high, the output drive r for TXCLKOUT is disabled. In applications that do not require the

output data clock, the output clock driver s hould be

disabled to save power.

High Speed Clock Output.

The high speed clock output, TXCLK OUT, is generated by the PLL in the clock multiplier unit . I ts frequency is nominally 16 times or 32 times the selected

reference source.

Preliminary Rev. 0.41 21

Page 22

Si5110

Pin

Number(s)

G9–10, H9–

10, J9–10,

K9–10

H1, J1 TXDOUT,

K4 TXLOL

H4 TXMSBSEL I LVTTL

K3 TXREXT

Name I/O Signal Level

TXDIN[3:0],

TXDIN

[3:0]

TXDOUT

ILVDS

OCML

OLVTTL

Description

Differential Parallel Data Input.

The 4-bit data word present on these pins is multiplexed into a high speed serial stream and output on

TXDOUT. The data on these inputs is clocked into the

device by the rising edge of TXCLK4IN.

Differential High Speed Data Output.

The 4-bit word input on TXDIN[3:0] is multiplexed into

a high speed serial stream that is output on these

pins. Input data is multiplexed in s equence from

TXDIN0 to TXDIN3 with TXDIN0 transmitted first. This

output is updated by the rising edge of TXCLKOUT.

CMU Loss-of-Lock.

The output is asserted low when the CMU is not

phase locked to the selected reference source.

Data Bus Transmit Order.

For TXMSBSEL = 0, data on TXDIN[0] is transmitt ed

first followed by TXDIN[1] through TXDIN[3].

For TXMSBSEL = 1, TXDIN[3] is trans mi tted fi rst fo l lowed by TXDIN[2] through TXDIN[0].

External Bias Resistor.

This resistor is used by the trans m itter ci rcui try to

establish bias currents within the device. This pin must

be connected to GND through a 3.09 k

Ω (1%) resistor.

J6 TXSQLCH

D4–7, E4–6,

F4–6, G4–7

G2 VDD33 VDD33 1.8 V or 3.3 V

B4 VRE F O Voltage Ref

VDD VDD 1.8 V

ILVTTL

Transmit Data Squelch.

If TXSQLCH is asserted low, the output data stream

on TXDOUT will be forced to 0s. If TXSQLCH

squelching is turned off.

Supply Voltage.

Nominally 1.8 V.

Digi ta l O utpu t Su pply.

Must be tied to either 1.8 V or 3.3 V. When tied to

3.3 V, LVTTL compatible output voltage swings on

RXLOL

Voltage Reference.

The Si5110 provides an output voltage reference that

can be used by an external circuit to set the LOS

threshold, slicing level, or sampling phase adjustment.

The equivalent resistance between this pin and GND

should not be less than 10 k

is nominally 1.25 V.

, LOS, TXLOL, and FIFOERR are supported.

Ω. The reference voltage

=1, TX

22 Preliminary Rev. 0.41

Page 23

Ordering Guide

Si5110

Table 9. Ordering Guide

Part Number Package Temperature

Si5110-BC 99 BGA –40°C to 85°C

Preliminary Rev. 0.41 23

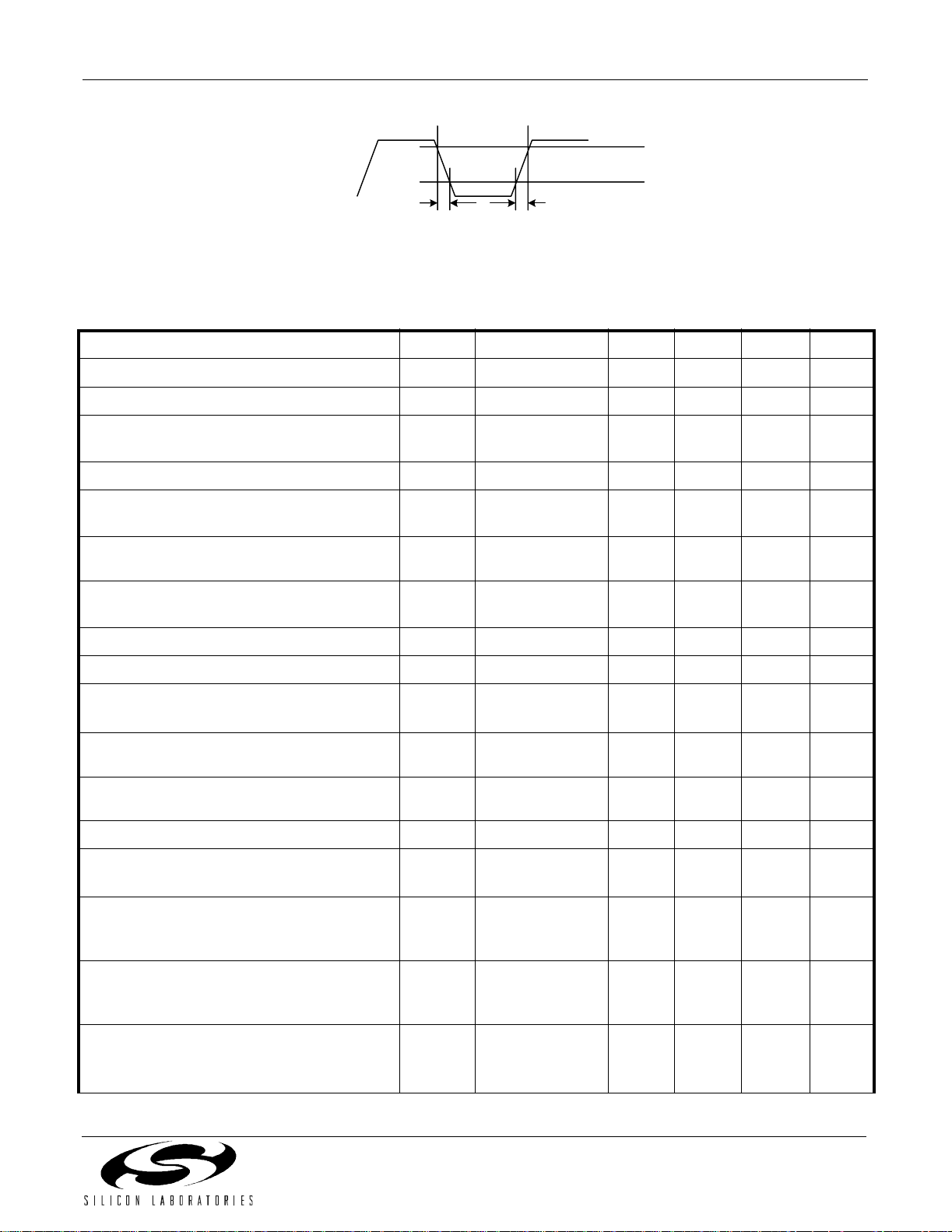

Page 24

Si5110

A

Package Ou tlin e

Figure 7 illustrates the package details for the Si5110. Table 10 lists the values for the dimensi ons shown in the

illustration.

1 Ball P ad

Corner

A1 Ball Pad

Corner

D

A

A1

E

b

A2

Seating

Plane

10987654321

e

1.00 Ref

1.00 Ref

A

B

C

D

E

F

G

H

J

K

e

Bottom ViewTop View Side Vi ew

Figure 7. 99-Ball Grid Array (B GA)

Table 10. Package Diagram Dimensions

Symbol Millimeters

Min Nom Max

A 1.30 1.40 1.50

A1 0.31 0.36 0.41

24 Preliminary Rev. 0.41

A2 0.65 0.70 0.75

b — 0.46 —

D—11.00—

E—11.00—

e — 1.00 —

Page 25

NOTES:

Si5110

Preliminary Rev. 0.41 25

Page 26

Si5110

Contact Information

Silicon Laboratori es Inc.

4635 Boston Lane

Austin, TX 78735

Tel: 1+(512) 416-8500

Fax: 1+(512) 416-9669

Toll Free: 1+(877) 444-3032

Email: productinfo @ silabs.com

Internet : w ww.silabs .com

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change withou t notice.

Silico n Laboratories assum es no responsibili ty for errors and omissions, and disclaim s r esponsibility for any conseq uences resulting from

the use of in form ation inclu ded her ein. Addit ionall y, Si licon Labor atories assu mes no re sponsib ility for the fu nction ing of undes cribed fea tures

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty, represent ation or gu ara ntee rega rding the suit abilit y of its pro duct s for any particul ar purp ose, nor does Silicon Lab orat ories as sume an y liabili ty

arisin g out of the ap plic at ion or use of any prod uct or circ uit , and sp eci fic ally dis clai ms an y and al l liab i lity , incl udi ng without limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life , or for any other application in w hich th e failure of the Silicon L aboratories product could creat e a situation where personal inj ury or death may occur . Should Buyer purchase or use Silicon Laboratories products for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

Silico n Laboratories, Silicon Labs, SiPHY, and DSPL L are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

26 Preliminary Rev. 0.41

Loading...

Loading...