Page 1

Si5022/Si5023

L

P

RELIMINARY DATA SHEET

ULTI-RATE

M

SONET/SDH CDR IC

WITH LIMITING AMP

Features

igh Speed Clock and Data Recovery device with Integrated Limiting Amp:

H

! Supports OC-48/12/3, STM-16/4/1,

Gigabit Ethernet, and 2.7 Gbps FEC

! DSPLL™ Technology

Low Power—370 mW (TYP)

!

! Small Footprint: 5 mm x 5 mm

! Bit-Error-Rate Alarm

! External Reference Not Required

!

Jitter Generation 3.0 mUI

RMS

(TYP)

! Loss-of-signal Level Alarm

! Data Slicing Level Control

! 10 mV

Differential Sensitivity

PP

! 2.5 V (Si5022) or 3.3 V (Si5023) Supply

Applications

! SONET/SDH/ATM Routers

! Add/Drop Multiplexers

! Digital Cross Connects

! Gigabit Ethernet Interfaces

! SONET/SDH Test Equipment

! Optical Transceiver Modules

! SONET/SDH Regenerators

! Board Level Serial Links

Description

The Si5022/23 is a fully integrated, high performance limiting amp and clock and

data recovery (CDR) IC for high-speed serial communication systems. It extracts

timing information and data from a serial input at OC-48/12/3, STM-16/4/1, or

Gigabit Ethernet (GbE) rates. Support for 2.7 Gbps data streams is also provided

for OC-48/STM-16 applications that employ forward error correction (FEC). An

external reference clock is not required; applications with or without an external

reference clock are supported. Silicon Laboratories’ DSPLL

™

technology

eliminates sensitive noise entry points thus making the PLL less susceptible to

board-level interaction and helping to ensure optimal jitter performance.

The Si5022/23 represents a new standard in low jitter, low power, small size, and

integration for high speed LA/CDRs. It operates from either a 3.3 V (Si5023) or

2.5 V (Si5022) supply over the industrial temperature range (–40°C to 85°C).

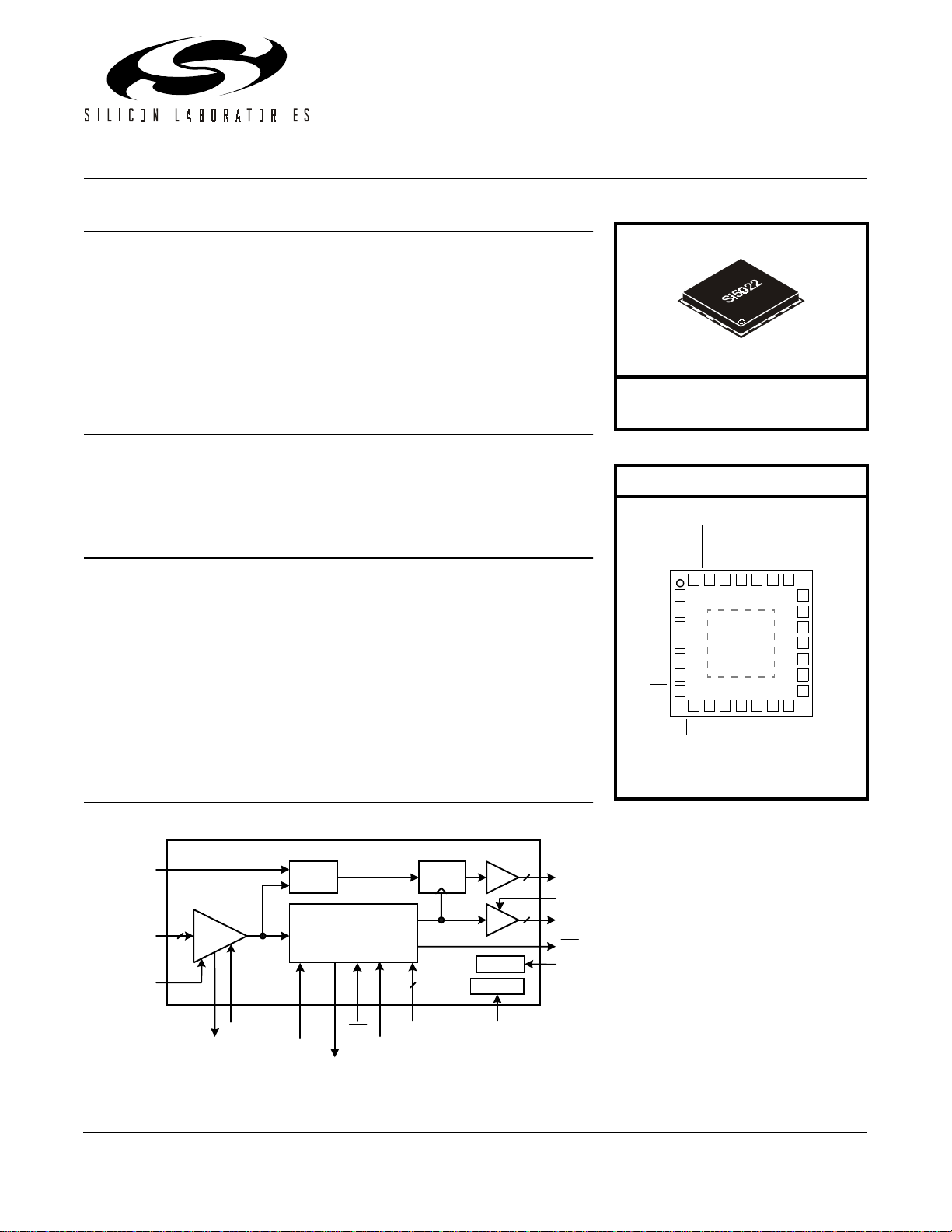

Functional Block Diagram

Ordering Information:

See page 14.

Pin Assignments

Si5022/23

NC

BER_ALM

RATESEL0

RATESEL1

LOS_LVL

SLICE_LVL

REFCLK+

REFCLK–

LOL

1

2

3

4

5

6

7

LTR

LOS

Top View

BER_LVL

GND

Pad

DSQLCH

VDD

VDD

CLKDSBL

DIN+

CLKOUT+

DIN–

22232425262728

141312111098

CLKOUT–

21

20

19

18

17

16

15

VDD

VDD

REXT

RESET/CA

VDD

DOUT+

DOUT–

TDI

DSQLCH

DIN+

DIN–

LOS_LVL

2

Limiting

AMP

LOS

SLICE_LVL

Squelch

Control

BER_LVL

DSPLL

Phase-Locked

Loop

BER_ALM

TM

LTR

REFCLK+

REFCLK–

(Optional)

Retimer

2

RATSEL[1:0]

BUF

BUF

Control

Bias Gen

REXT

2

2

DOUT+

DOUT–

CLKDSBL

CLKOUT+

CLKOUT–

LOL

RESET/CAL

Preliminary Rev. 0.46 5/01 Copyright © 2001 by Silicon Laboratories Si5022/23-DS046

This information applies to a product under development. Its characteristics and specifications are subject to change without notice.

Silicon Laboratories Confidential. Information contained herein is covered under non-disclosure agreement (NDA).

Page 2

Si5022/Si5023

2 Preliminary Rev. 0.46

Page 3

Si5022/Si5023

T

ABLE OF

C

ONTENTS

Section Page

Detailed Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Limiting Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DSPLL™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Multi-Rate Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Without an External Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation With an External Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lock Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lock-to-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Loss-of-Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bit-Error-Rate (BER) Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Slicing Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PLL Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

RESET/DSPLL Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clock Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data Squelch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Device Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Bias Generation Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Voltage Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Differential Input Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Differential Output Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pin Descriptions: Si5022/23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Preliminary Rev. 0.46 3

Page 4

Si5022/Si5023

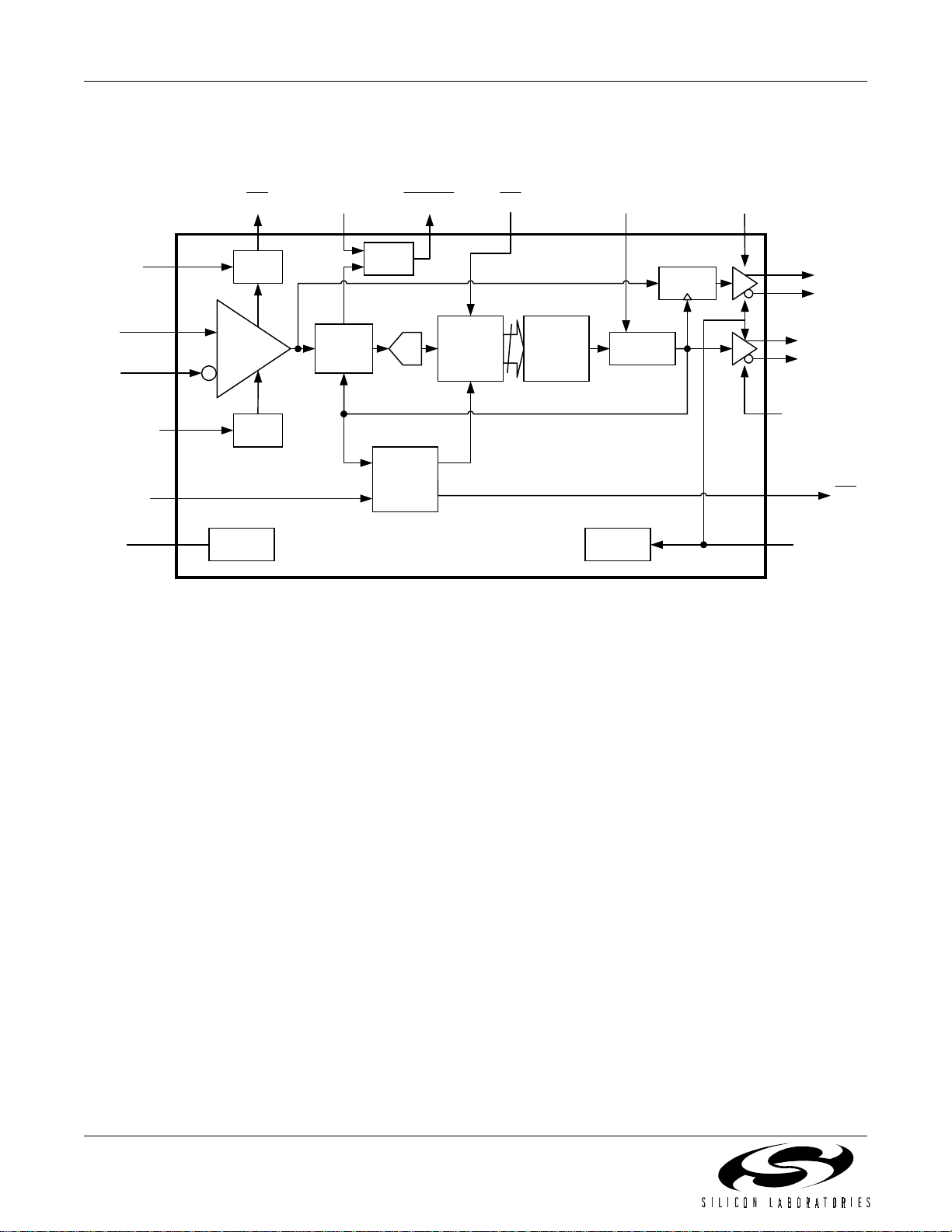

Detailed Block Diagram

LOS_LVL

DIN+

DIN+

SLICE_LVL

REFCLK±

(optional)

REXT

Signal

Detect

Limiting

Amp

Slicing

Control

Bias

Generation

LTR

DSP VCO

n

Phase

Detector

BER_ALMBER_LVLLOS

BER

Monitor

A/D

Lock

Detection

Figure 1. Detailed Block Diagram

RATESEL[0:1]

Retime

CLK

Dividers

Calibration RESET/CAL

DSQLCH

DOUT+

DOUT–

CLKOUT+

CLKOUT–

CLK_DSBL

LOL

4 Preliminary Rev. 0.46

Page 5

Electrical Specifications

Table 1. Recommended Operating Conditions

Si5022/Si5023

Parameter

Symbol Test Condition

Ambient Temperature T

Si5022 Supply Voltage

Si5023 Supply Voltage

2

2

V

V

A

DD

DD

1

Min

Typ

–40 25 85 °C

2.375 2.5 2.625 V

3.135 3.3 3.465 V

Max

1

Notes:

1. All minimum and maximum specifications are guaranteed and apply across the recommended operating

conditions. Typical values apply at nominal supply voltages and an operating temperature of 25°C unless

otherwise stated.

2. The Si5022/23 specifications are guaranteed when using the recommended application circuit (including

component tolerance) of Figure 5 on page 10.

V

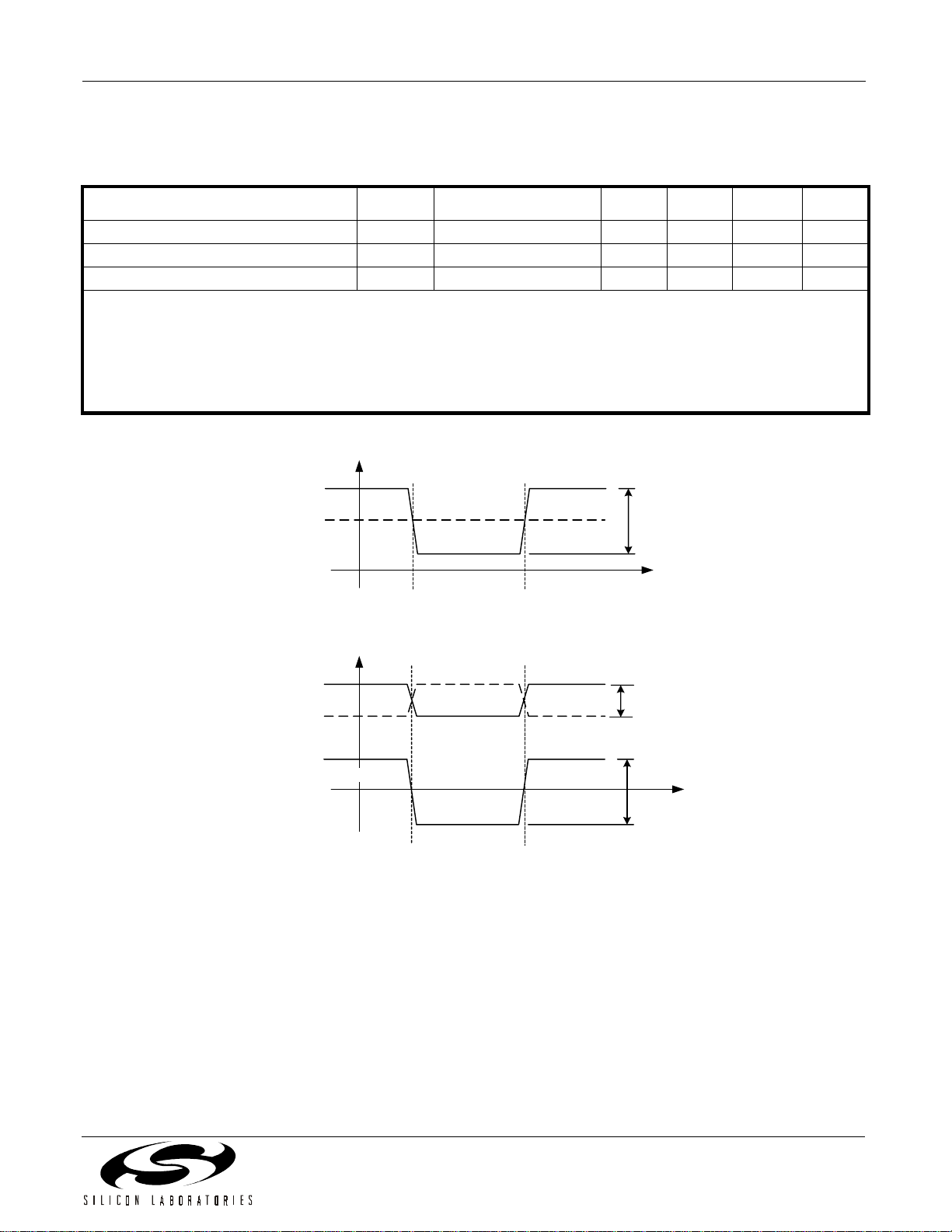

SIGNAL+

SIGNAL–

A. Operation with Single-Ended Inputs

V

IS

t

Unit

V

SIGNAL+

0.5 V

SIGNAL–

(SIGN A L +) – (SIG N A L –)

B. Operation with Differential Inputs and Outputs

ID

V

ID

t

Figure 2. Differential Voltage Measurement (DI N , REFCLK, DOUT, CLKOUT)

Preliminary Rev. 0.46 5

Page 6

Si5022/Si5023

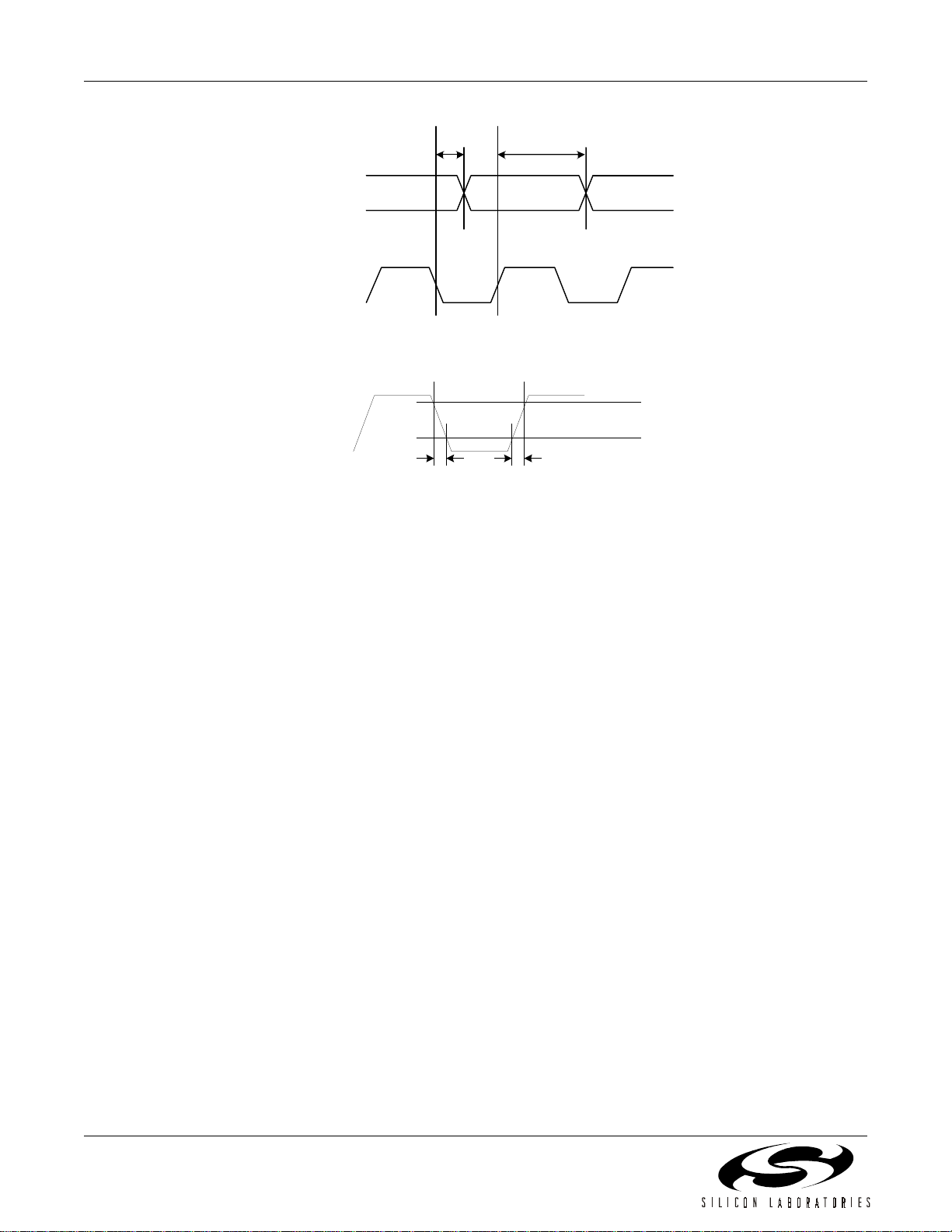

t

Cr-D

DOUT

CLKO UT

t

Cf-D

Figure 3. Clock to Data Timing

DOUT,

CLKOUT

t

F

t

R

Figure 4. DOUT and CLKOUT Rise/Fall Times

80%

20%

6 Preliminary Rev. 0.46

Page 7

Si5022/Si5023

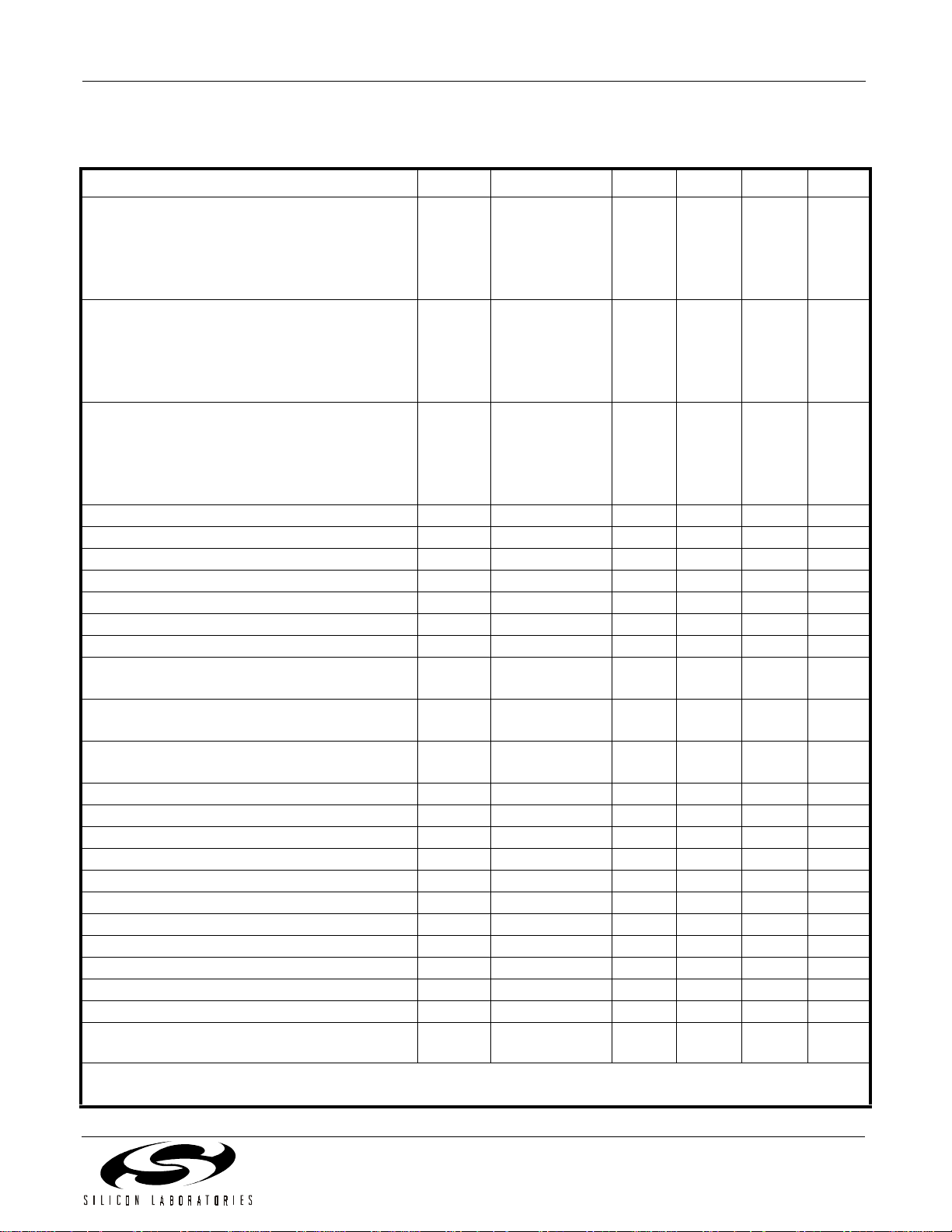

Table 2. DC Characteristics

(VDD=2.5 V ± 5% for Si5022 or 3.3V ± 5% for Si5023, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Supply Current

OC-48 and FEC (2.7 G Hz)

GigE

OC-12

OC-3

Power Dissipation

OC-48 and FEC (2.7 G Hz)

GigE

OC-12

OC-3

Power Dissipation

OC-48 and FEC (2.7 G Hz)

GigE

OC-12

OC-3

Common Mode Input Voltage (DIN)* V

Common Mode Input Voltage (REFCLK)* V

DIN Single-ended Input Voltage Swing* V

DIN Differential Input Voltage Swing* V

REFCLK Single-ended Input Voltage Swing* V

REFCLK Differential Input Voltage Swing* V

Input Impedance (DIN, REFCLK) R

Differential Output Voltage Swing

(DOUT)

Differential Output Voltage Swing

(CLKOUT)

Output Common Mode Voltage

(DOUT,CLKOUT)

Output Impedance (DOUT,CLKOUT) R

Output Current Short to GND (DOUT,CLKOUT) I

Output Current Short to V

(DOUT,CLKOUT) I

DD

Input Voltage Low (LVTTL Inputs) V

Input Voltage High (LVTTL Inputs) V

Input Low Current (LVTTL Inputs) I

Input High Current (LVTTL Inputs) I

Output Voltage Low (LVTTL Outputs) V

Output Voltage High (LVTTL Outputs) V

Input Impedance (LVTTL Inputs) R

PWRDN/CAL Leakage Current I

LOS_LVL, BER_LVL, SLICE_LVL Input Imped-

ance

*Note: These inputs may be driven differentially or single-endedly. When driven single-endedly, the unused input must be ac

coupled to ground.

I

DD

P

D

VDD =

2.5 V (

P

D

VDD =

3.3 V (

See Figure 11 1.42 1.50 1.58 V

See Figure10 1.90 2.00 2.10 V

See Figure 2A 10 — 500 mV

See Figure 2B 10 — 1000 mV

See Figure 2A 200 — 750 mV

See Figure 2B 200 — 1500 mV

Line-to-Line 84 100 116 Ω

100 Ω Load

V

ICM

ICM

IS

ID

IS

ID

IN

OD

Line-to-Line

V

OD

100 Ω Load

Line-to-Line

V

OCM

100 Ω Load

Line-to-Line

OUT

SC(–)

SC(+)

IL

IH

IL

IH

OL

OH

IN

PWRDNVPWRDN

R

IN

Single-ended 84 100 116 Ω

IO = 2 mA — — 0.4 V

IO = 2 mA 2.0 — — V

± 5%)

± 5%)

—

—

—

—

—

—

—

—

—

—

—

—

148

150

152

154

370

375

380

385

488

495

502

508

160

162

164

165

400

405

410

414

554

561

568

572

mA

mW

mW

TBD 940 TBD mV

(pk-pk)

TBD 900 TBD mV

(pk-pk)

TBD 1.825 TBD V

—25TBDmA

TBD –15 — mA

——.8V

2.0 — — V

——10µA

——10µA

10 — — kΩ

≥ 0.8 V TBD 25 TBD µA

TBD 100 TBD kΩ

Preliminary Rev. 0.46 7

Page 8

Si5022/Si5023

Table 3. AC Characteristics (Clock and Data)

(VDD=2.5 V ± 5% for Si5022 or 3.3V ± 5% for Si5023, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Output Clock Rate f

Output Rise Time t

Output Fall Time t

Clock to Data Delay

CLK

t

Cr-D

R

F

Figure 4 — 100 TBD ps

Figure 4 — 100 TBD ps

Figure 3

FEC (2.7 GHz)

OC-48

GigE

OC-12

OC-3

Clock to Data Delay

t

Cf-D

Figure 3

FEC (2.7 GHz)

OC-48

Input Return Loss 100 kHz–2.5 GHz

2.5 GHz–4.0 GHz

Slicing Level Offset*

(relative to the internally set input

common mode voltage)

V

SLICE

SLICE_LVL = 750 mV to

2.25 V

Slicing Level Accuracy SLICE_LVL = 750 mV to

.15 — 2.7 GHz

TBD

TBD

TBD

TBD

TBD

TBD

TBD

TBD

TBD

250

255

500

890

4100

TBD

TBD

—

—

–15 — 15 mV

–500 — 500 µV

2.25 V

*Note: Adjustment voltage (relative to the internally set input common mode voltage) is calculated as follows:

(SLICE_LVL – 1.50 V)/50.

TBD

TBD

TBD

TBD

TBD

TBD

TBD

—

—

V

SLICE

ps

ps

dB

dB

=

8 Preliminary Rev. 0.46

Page 9

Si5022/Si5023

Table 4. AC Characteristics (PLL Characteristics)

(VDD=2.5 V ± 5% for Si5022 or 3.3V ± 5% for Si5023, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Jitter Tolerance

J

TOL(PP)

(OC-48)*

Jitter Tolerance

(OC-12 Mode)

*

Jitter Tolerance

(OC-3 Mode)

*

Jitter Tolerance (Gigabit Ethernet)

J

TOL(PP)

J

TOL(PP)

T

JT(PP)

IEEE 802.3z Clause 38.68 600 TBD — ps

Receive Data Total Jitter

Tolerance

Jitter Tolerance (Gigabit Ethernet)

D

JT(PP)

IEEE 802.3z Clause 38.69 370 TBD — ps

Receive Data Deterministic Jitter

Tolerance

RMS Jitter Generation

*

Peak-to-Peak Jitter Generation

Jitter Transfer Bandwidth

Jitter Transfer Peaking

*

*

Acquisition Time

*

J

GEN(RMS)

J

GEN(PP)

J

BW

J

P

T

AQ

with no jitter on serial data — 3.0 5.0 mUI

with no jitter on serial data — 25 55 mUI

(Reference clock applied)

Acquisition Time

T

AQ

(Reference-less operation)

Reference Clock Range 19.44 — 168.75 MHz

Input Reference Clock Frequency

C

TOL

Tolerance

Frequency Difference at which

Receive PLL goes out of Lock

(REFCLK compared to the divided

down VCO clock)

Frequency Difference at which

Receive PLL goes into Lock (REFCLK compared to the divided

down VCO clock)

*Note: As defined in Bellcore specifications: GR-253-CORE, Issue 2, December 1995. Using PRBS 223– 1 data pattern.

f = 600 Hz 40 TBD — UI

f = 6000 Hz 4 TBD — UI

f = 100 kHz 4 TBD — UI

f = 1 MHz 0.4 TBD — UI

f = 30 Hz 40 TBD — UI

f = 300 Hz 4 TBD — UI

f = 25 kHz 4 TBD — UI

f = 250 kHz 0.4 TBD — UI

f = 30 Hz 60 TBD — UI

f = 300 Hz 6 TBD — UI

f = 6.5 kHz 6 TBD — UI

f = 65 kHz 0.6 TBD — UI

OC-48 Mode — — 2.0 MHz

OC-12 Mode — — 500 kHz

OC-3 Mode — — 130 kHz

— 0.03 0.1 dB

After falling edge of

1.45 1.5 1.7 ms

PWRDN/CAL

From the return of valid

40 60 150 µs

data

After falling edge of

TBD TBD TBD ms

PWRDN/CAL

From the return of valid

TBD TBD TBD ms

data

–100 — 100 ppm

TBD 600 TBD ppm

TBD 300 TBD ppm

PP

PP

PP

PP

PP

PP

PP

PP

PP

PP

PP

PP

Preliminary Rev. 0.46 9

Page 10

Si5022/Si5023

Table 5. Absolute Maximum Ratings

Parameter Symbol Value Unit

DC Supply Voltage V

DD

–0.5 to 2.8 (Si5022)

V

–0.5 to 3.5 (Si5023)

LVTTL Input Voltage V

Differential Input Voltages V

DIG

DIF

–0.3 to 3.6 V

–0.3 to (VDD+ 0.3) V

Maximum Current any output PIN ±50 mA

Operating Junction Temperature T

Storage Temperature Range T

JCT

STG

–55 to 150 °C

–55 to 150 °C

Lead Temperature (soldering 10 seconds) 300 °C

ESD HBM Tolerance (100pf, 1.5 kΩ)1kV

Note: Permanent device damage may occur if the above Absolute Maximum Ratings are exceeded. Functional operation

should be restricted to the conditions as specified in the operational sections of this data sheet. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Table 6. Thermal Characteristics

Parameter Symbol Test Condition Value Unit

Thermal Resistance Junction to Ambient ϕ

LVTTL

Control Inputs

JA

BER Alarm

Indicator

Loss-of-Lock

Still Air 38 °C/W

Loss-of-Signal

Indicator

Indicator

High Speed

Serial Input

System

Reference

Clock

(Optional)

2

LOL

DOUT+

DOUT–

DIN+

DIN–

LTR

CLKDSBL

DSQLCH

RESET/CAL

RATESEL1-0

BER_ALM

Si5022/23

REFCLK+

REFCLK–

LOS_LVL

Loss-of-Signal

Level Set

Bit Error Rate

Level Set

BER_LVL

SLICE_LVL

Data Slice

Level Set

10 k

REXT

VDD

ΩΩΩΩ

CLKOUT+

CLKOUT–

VDD

µµµµ

0.1

F

2200 pF

20 pF

GND

Figure 5. Si5022/23 Typical Application Circuit

LOS

Recovered

Data

Recovered

Clock

10 Preliminary Rev. 0.46

Page 11

Functional Description

Si5022/Si5023

The Si5022/23 integrates a high-speed limiting amplifier

(LA) with a multi-rate clock and data recovery unit

(CDR) that operates up to 2.7 Gbps. No external

reference clock is required for clock and data recovery.

The limiting amplifier magnifies very low-level input data

signals so that accurate clock and data recovery can be

performed. The CDR uses Silicon Labo ratories’ DSPLL

technology to reco ver a clock synch ronous to the input

data stream. The rec overed clock is used to retime th e

incoming data, and both are output synchronously via

current-mode logic (CML) drivers. Silicon Laboratories’

DSPLL technology ensures superior jitter p erformance

while eliminating the need for external loop filter

components found in traditional phase-lock loop

implementations.

The limiting amplifier includes a control input for

adjusting the 0/1 data sl icing leve l and provides a loss of-signal level alarm output. The CDR includes a biterror-rate performa nc e m oni tor w hic h si gn als a h igh biterror-rate condition (associated with excessive

incoming jitter) relative to an externally adjustable biterror-rate threshold.

The optional reference clock minimizes the CDR

acquisition time and provides a stable reference for

maintaining the output clock when locking to reference

is desired.

Limiting Amplifier

The limiting amplifier accepts the low-level signal output

from a transimpedance amplifier (TIA). The low-level

signal is amplified to a usable level for the clock and

data recovery unit. The minimum input swing

requirement is specified in Table 2. Larger input

amplitudes (up to the max imum i nput sw ing spe cifi ed in

Table 2) are accommodated without degradation of

performance. The limiting amplifier ensures optimal

data slicing by using a digital dc offset cancellation

technique to remove any dc bias introduced by the

amplification stage.

DSPLL

The Si5022/23 PLL structure (shown in Figure 1 on

page 4) utilizes Si lico n Labor atories ' DSPL L te chnol ogy

to maintain superior jitter performance while eliminating

the need for external loop filter components found in

traditional PLL implementations. This is achieved by

using a digital signal processing (DSP) algorithm to

replace the loop filter commonly found in analog PLL

designs. This algorithm processes the phase detector

error term and generates a digital control value to adjust

the frequency of th e v ol tage c ont roll ed os ci ll ato r (V CO) .

™

This technology enables clock and data recovery with

far less ji tt er t ha n is ge nerated usin g traditiona l m e tho d s

and it eliminates performance degradation caused by

external component aging. In addition, because

external loop filter components are not required,

sensitive noise en try poin ts ar e elim inated , thus m aking

the DSPLL less susceptible to board-level noise

sources and making SONET/SDH jitter compliance

easier to attain in the application.

Multi-Rate Operation

The Si5022/23 supports clock and data recovery for

OC-48 and STM-16 data stre ams. In addition, the PLL

was designed to operate at data rates up to 2.7 Gbps to

support OC-48/STM-16 applications that employ

forward error correction (FEC).

Multi-rate operation is achieved by configuring the

device to divide down the output of the VCO to the

desired data rate. The divi de factor is confi gured by th e

RATESEL[0:1] pins. The RATESEL[0:1] configuration

and associated data rates are given in Table 7.

Table 7. Multi-Rate Configuration

OC-48

RATESEL

[0:1]

11 2.488 Gbps — 2.67 Gbps 1

10 1.244 Gbps 1.25 Gbps — 2

01 622.08 Mbps — — 4

00 155.52 Mbps — — 16

SONET/

SDH

Gigabit

Ethernet

with

15/14

FEC

CLK

Divider

Operation Without an External Reference

The Si5022/23 can perform clock and data recovery

without an external referen ce clock. Tying the REFCLK

inputs to GND configures the device to operate without

an external reference c lock. Clock recove ry is achie ved

by monitoring the timing quality of the incoming data

relative to the VCO frequency. Lock is maintained by

continuously monitoring the incoming data timing quality

and adjusting the VCO accordingly. Details of the lo ck

detection and the lock-to-reference functions while in

this mode are described in their respective sections

below.

Note: Without an ex t er na l r e fe re nc e t h e a cq u is it i on o f da ta is

dependent solely on the data itself and will typically

require more time to acquire lock than when a reference is applied.

Preliminary Rev. 0.46 11

Page 12

Si5022/Si5023

)

Operation With an External Reference

The Si5022/23 device’s optional external reference

clock centers the DSPLL, minimizes the acquisition

time, and maintains a stable output clock (CLKOUT)

when lock-to-reference (LTR

) is asserted.

When the reference clock is present, the Si502 2/23 will

use the reference clock to center the VCO output

frequency so that clock and data can be recovered from

the input data stream. The de vice will self con figure for

operation with one of thr ee refe re nc e cl ock fr eq uen ci es .

This eliminates the need to externally configure the

device to operate with a particular reference clock.

The reference clock centers the VCO for a nominal

output between 2.5 and 2.7 GHz. The VCO frequency is

centered at 16, 32, or 128 times the reference clock

frequency. Detection circuitry continuously mon itors the

reference clock input to determine whether the devic e

should be configur ed for a reference clock tha t is 1/16,

1/32, or 1/128 the nominal VCO output. Approximate

reference clock frequencies for some target applications

are given in Table 8.

Table 8. Typical REFCLK Frequencies

SONET/

SDH with

15/14 FEC

SONET/SDH

Gigabit

Ethernet

19.44 MHz 19.53 MHz 20.83 MHz 128

77.76 MHz 78.125 MHz 83.31 MHz 32

155.52 MHz 156.25 MHz 166.63 MHz 16

Ratio of

VCO to

REFCLK

Lock Detect

The Si5022/23 provides lock-detect circuitry that

indicates whether the PL L has achieved freque ncy lock

with the incoming data. The operation of the lockdetector depends on the reference clock option used.

When an external reference clock is provided, the circuit

compares the frequency of a divided down version of

the recovered clock wi th the frequency of the supplied

reference clock (REFCLK). If the recovered clock

frequency deviates from that of the re ference clock by

the amount specified in Table 4 on page 9, the PLL is

declared out of lock, and the loss-of-lock (LOL

asserted. In this s tate, the DSPLL will periodica lly tr y to

reacquire lock with the incoming data stream. During

reacquisition, the recov ered clock frequ ency (CLKO UT)

will drift over a 1% range relative to the supplied

reference clock. The LOL

output will remain asserted

until the recovered clock frequency is within the

REFCLK frequency by the amount specified in Table 4

on page 9. In applications requiring a more stable

) pin is

output clock during out-of-lock conditions, the lock-toreference (LTR

) input can be used to force t he PLL to

lock to the externally supplied reference.

In the absence of an external refere nce, the lock detec t

circuitry uses a data quality measure to determine when

frequency lock has been lost with the incoming data

stream. Once LOL

has been asserted, it will remain

active until data is reacquired. During thi s reacquisition

period, CLKOUT may vary by approximately ±10% from

the nominal data rate. For applications req uir i ng a m or e

stable output clock during out-of-lock conditions, LTR

can be used to stabilize the output clock.

Lock-to-Reference

The lock-to-reference input (L TR) can be used to force a

stable output clock when an alarm conditio n, like LOS,

exists. In typica l applications, the LOS

tied to the LTR

input to force a stable output clock when

the input data signal is los t. When LTR

output would be

is asserted, the

DSPLL is prevented from acquiring the data signal

present on DIN. The operati on of the LTR

control inpu t

depends on which reference clocking mode is used.

When an external referenc e clock is present, assertio n

of LTR

will force the DSPLL to lock CLKOUT to the

provided reference. If no external reference clock is

used, LTR

will force the DSPLL to hold the digital

frequency control input to the VCO at the last value.

This produces an outpu t clock that is stable as long as

supply and temperature are constant.

Loss-of-Signal

The Si5022/23 indicates a loss-of-signal condition on

the LOS

level on DIN falls below an externally controlled

threshold. The LOS threshold range is specified in

Table 3 and is set by applying a voltage on the

LOS_LVL pin. The graph in Figure 6 illustrates the

LOS_LVL mapping to the LOS threshold. The LOS

output is asserted when the input signal drops below the

programmed peak-to-peak value.

output pin w hen the input peak-to-peak signal

)

PP

30 mV

15 mV

LOS Disabled

LOS Threshold (mV

0 mV

0 V

LOS

Undefined

LOS_LVL (V

1.875 V

40mV/V

2.25 V1.50 V1.00 V

Figure 6. LOS_LVL Mapping

12 Preliminary Rev. 0.46

Page 13

Si5022/Si5023

Approximately 6 dB of level detection hysteresis

prevents unnecess ary s witching on LOS

when marginal

input data swing peak-to-peak levels are present.

Hysteresis is defined as the difference between the LOS

deassert level (LOSD) and the LOS assert level

(LOSA). The hysteresis in decibels is calculated as

20log((LOSD – LOSA)/LOSA). The relationship

between the LOS

level is shown in Figure 7. When the LOS

assert level and the LOS deassert

assert level is

set below 10 mV, the amount of hysteresis is fixed at

5 mV. When the LOS assert level is set above 10 mV,

the amount of hysteresis is approximately 6 dB.

45 mV

)

PP

(m V

LOS D eassert Level

15 mV

11 mV

common mode voltage) are su pported. The 0/1 slicing

level is set by apply ing a voltage between 0.75 V and

2.25 V to the S LICE_LVL input. The voltage present on

SLICE_LVL maps to the 0/1 slicing level as follows:

where V

V

SLICE_LVL

V

SLICE

is the slicing l evel and V

SLICE

-------------------------------------------------------=

1.5 V–()

50

SLICE_LVL

is the

voltage applied to the SLICE_LVL pin.

When SLICE_LVL is driven below 500 mV, the 0/1

slicing level ad jus tm ent is di sabl ed, and the s li cing lev el

is set to the cross-point of the differential input signal.

PLL Performance

The PLL implementatio n used in the Si5022/23 is fully

compliant with the jitter specifications proposed for

SONET/SDH equipment by Bellcore GR-253-CORE,

Issue 2, December 1995 and ITU-T G.958.

Jitter Tolerance

The Si5022/23’s tolera nce to in put jitter ex ceeds t hat of

the Bellcore/ITU mask shown in Figure 8. This mask

defines the level of peak-to-peak sinusoid jitter that

must be tolerated when applied to the differential data

input of the device.

Note: There are no entries in the mask table for the data rate

corresponding to OC-24 as that rate is not specified by

either GR-253 or G.958.

6 mV

10 mV

30 mV

LOS As sert Level (mVPP)

Figure 7. Hysteresis Dependency

Bit-Error-Rate (BER) Detection

The Si5022/23 uses a proprietary Silicon Laborato ries

algorithm to generate a bit-error-rate (BER) alarm on

the BER_ALM

pin if the observed BER is greater tha n a

user programmable thr eshold. Bit error detec tion relies

on the input data edge timing; edges o ccurring outside

of the expected event wi nd ow ar e co unte d as bit errors.

The BER alarm threshold can be set to one of 64

discrete values between 10

–3

and 10–4. The BER

threshold is programmed by applying a voltage to the

BER_LVL pin between 500 mV and 2.25 V

corresponding to 10

-3

and 10-4 respectively.

Data Slicing Level

The Si5022/23 provides th e ability to externally adjust

the 0/1 slicing level for applications that require biterror-rate (BER) optimization. Adjustments in slicing

level of ±15 mV (relative to the internally set input

Sinusoidal

Input

Jitter (U I

)

PP

15

1.5

0.15

SONET

Data Rate

OC-48

OC-12

OC-3

Slope = 20 dB/Decade

f0 f1 f2 f3 ft

F0

(Hz )F1(Hz )F2(kHz )

10

10

10

Frequency

600

30

30

6000

300

300

F3

(kHz )Ft(kHz )

100 1000

25

6.5

250

65

Figure 8. Jitter Tolerance Specification

Jitter Transfer

The Si5022/23 exceeds all relevant Bellcore/ITU

specifications related to SONET/SDH jitter transfer.

Jitter transfer is defined as the ratio of output signal jitter

to input signal jitter as a function of jitter frequency . (See

Figure 9. ) The se meas ur em ents ar e ma de wi th an input

Preliminary Rev. 0.46 13

Page 14

Si5022/Si5023

test signal that is degraded wi th sinusoidal jitter whose

magnitude is defined by the mask in Figure 9.

Jitter

Transfer

0.1 dB

Acceptable

Range

Fc

Frequency

SONET

Data Rate

OC-48

OC-12

OC-3

20 dB/Decade

Slope

Fc

(kHz )

2000

500

130

Figure 9. Jitter Transfer Specification

Jitter Generation

The Si5022/23 exceeds all relevant specifications for

jitter generation p roposed for SONET/SDH equip ment.

The jitter generation specification defines the amount of

jitter that may be present on the recovered clock and

data outputs when a jitter free input signal is provided.

The Si5022/23 typically generates less than

3.0 mUI

of jitter when presented with jitter-free input

RMS

data.

RESET/DSPLL Calibration

The Si5022/23 achieves optimal jitter performance by

using self-calibration circuitry to set the loop gain

parameters within the DSPLL. For the self-calibration

circuitry to operate correctly, the power supply voltage

must exceed TBD V when calibration occurs. Selfcalibration is initi ated by a high-to-low trans ition on the

RESET/CAL pin. The RESET/CAL pin must be held

high for at least 1 µS after the suppl y has stabilized on

power-up for optimum d evice operation. W hen RESET/

CAL is released (set to low) the digital logic resets to a

known initial conditio n, recali brates the DSP LL, and will

begin to lock to the incoming data stream.

Clock Disable

The Si5022/23 provides a clock disable pin,

CLK_DSBL, that is used to disable the recovered clock

output, CLKOUT. When the CLK_DSBL pin i s asserted ,

the positive and negativ e terminals of CLK OUT are tied

to VDD through 100 Ω on-chip r esistors. Thi s feature is

used to reduce power consum ption in applications that

do not use the recovered clock.

Data Squelch

The Si5022/23 provides a data squelching pin,

DSQLCH, that is us ed to s et th e re co ve re d data o utpu t,

DOUT, to binary zero. When the DSQLCH pin is

asserted, the DOUT logic signal is held at a binary zero.

This pin can be is used to s quelch corrupt data during

LOS and LOL situa tions. Care must be tak en when ac

coupling these out puts; a long string of zeros wil l not be

held through ac coupling capacitors.

Device Grounding

The Si5022/23 uses th e GND pad on the bottom of th e

28-pin micro leaded pack age (MLP) for device ground .

This pad should be connected directly to the analog

supply ground. See Figures 13 and 14 for the ground

(GND) pad location.

Bias Generation Circuitry

The Si5022/23 make s use of an e xternal res istor to se t

internal bias currents. The external resistor allows

precise generation of bias currents which significantly

reduces power consumption versus traditional

implementations tha t use an internal resistor. The bias

generation circuitry requires a 10 kΩ (1%) resistor

connected between REXT and GND.

Voltage Regulator

The Si5022 and Si5023 oper ate from different external

supply voltages. Inter nally the dev ices are id entical and

operate from a 2.5 V supply. The Si5022 takes the 2.5 V

supply directly from the external supply connections.

The Si5023 regulates 2.5 V internally down from the

external 3.3 V supply. Both devices consume 148 mA

typically.

In addition to supporting 3.3 V systems, the on-chip

linear regulator offers better power supply noise

rejection versus the direct 2.5 V supply.

Differential Input Circuitry

The Si5022/23 provides differential inputs for both the

high speed data (DIN) and the reference clock

(REFCLK) inputs. An example termination for these

inputs is shown in Figur e 10 and Figure 11 respectively.

In applications where dir ect dc coupling is possible, the

0.1 µF capacitors may be omitted. (LOS operation is

only guaranteed when ac coupled.) The data input

limiting amplifier requires an input signal with a

differential peak-to-peak voltage as specif ied in Table 2

to ensure a BER of at le ast 10

differential peak-to-peak voltage requirement is

specified in Table 2.

–12

. The REFCLK input

14 Preliminary Rev. 0.46

Page 15

Clock source

0.1 µF

Zo = 50

Si5022/Si5023

Si5022/23

2.5 V (±5%)

Ω

2.5 k

Ω

RFCLK +

0.1

2.5 kΩ10 kΩ

µ

F

Zo = 50 Ω

RFCLK –

10 kΩ

102Ω

GND

Figure 10. Input Termination for REFCLK (AC Coupled)

DIN +,

DIN –,

Si5022/23

Ω

50

Ω

50

2.5 V (±5%)

Ω

5 k

7.5 k

GND

TIA

0.1 µF

0.1

Ω

Zo = 50

µ

F

Zo = 50

Ω

Figure 1 1. Input Termination for DIN (AC Coupled)

Ω

Preliminary Rev. 0.46 15

Page 16

Si5022/Si5023

Differential Output Circuitry

The Si5022/23 utili zes a cu rrent- mode lo gic ( CML) archite ctur e to outp ut both t he rec overed cloc k (CL KOUT) and

data (DOUT). An example of outp ut termination with ac coupling is shown in Figure 12. In applications in whi ch

direct dc coupling is possible, the 0.1 µF capacitors may be omitted. The differential peak-to-peak voltage swing of

the CML architecture is specified in Table 2.

Si5022/23 VDD

2.5 V (±5%)

100 Ω

DOUT+,

CLKOUT+

0.1 µF

Zo = 50

50 Ω

Ω

Ω

100

2.5 V (±5%)

DOUT–,

CLKOUT–

0.1

µF

Zo = 50

Ω

50 Ω

VDD

Figure 12. Output Termination for DOUT and CLKOUT (AC Coupled)

16 Preliminary Rev. 0.46

Page 17

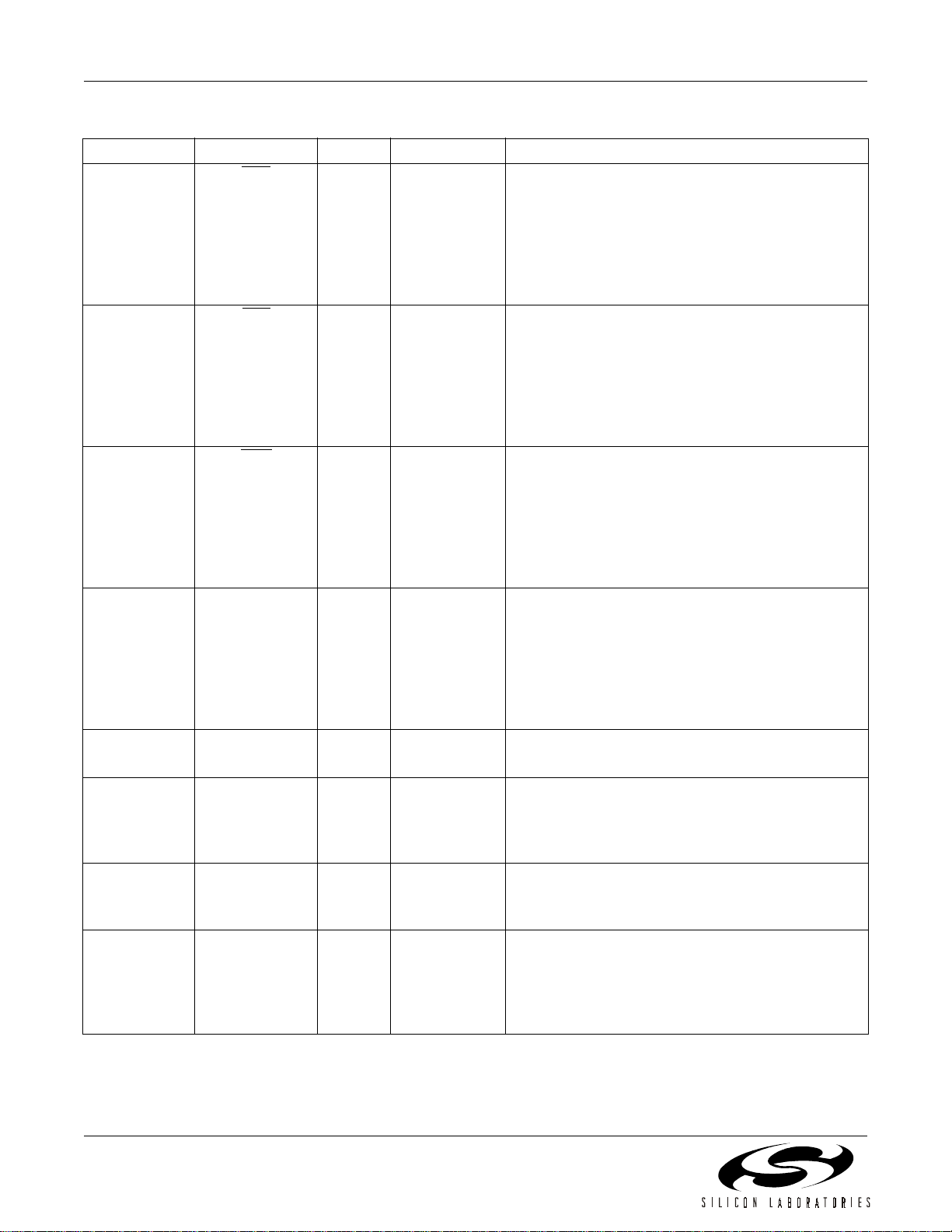

Pin Descriptions: Si5022/23

RATESEL0

RATESEL1

SLICE_LVL

Figure 13. Si5022/23 Pin Configuration

Table 9. Si5022/23 Pin Descriptions

LOS_LVL

REFCLK+

REFCLK-

LOL

NC

1

2

3

4

5

6

7

BER_ALM

BER_LVL

GND

LTR

LOS

DSQLCH

Top View

Pad

VDD

VDD

CLKDSBL

DIN+

CLKOUT+

DIN-

CLKOUT-

22232425262728

141312111098

VDD

VDD

21

REXT

20

RESET/CAL

19

VDD

18

DOUT+

17

DOUT-

16

TDI

15

Si5022/Si5023

Pin # Pin Name I/O Signal Level Description

1,2 RATESEL0,

RATESEL1

ILVTTLData Rate Select.

These pins configure the onboard PLL for clock and

data recovery at one of four user selectable data

rates. See Table 7 for configuration settings.

Note: These inputs have weak internal pull-ups.

3LOS_LVLI LOS Level Control.

The LOS threshold is set by the input voltage level

applied to this pin. Figure 6 on page 12 shows the

input setting to output threshold mapping.

LOS is disabled when the voltage applied is less

than 500 mV.

4SLICE_LVLI Slicing Level Control.

The slicing threshold level is set by applying a voltage to this pin as described in the Slicing Level section of the data sheet. If this pin is tied to GND,

slicing level adjustment is disabled, and the slicing

level is set to the midpoint of the differential input

signal on DIN. Slicing level becomes active when

the voltage applied to the pin is greater than

500 mV.

5,6 REFCLK+,

REFCLK–

I See Table2 Differential Reference Clock (Optional).

When present, the reference clock sets the center

operating frequency of the DSPLL for clock and

data recovery. Tie these pins to ground to configures the DSPLL to operate without an external reference clock.

See Table 8 for typical reference clock frequencies.

Preliminary Rev. 0.46 17

Page 18

Si5022/Si5023

Table 9. Si5022/23 Pin Descriptions (Continued)

Pin # Pin Name I/O Signal Level Description

7

8

9

10 DSQLCH LVTTL Data Squelch.

11,14,18,21,

25

12,13 DIN+,

15 TDI I LVTTL Production Test Input.

16,17 DOUT+,

LOL

LTR

LOS

VDD 2.5 V or

DIN–

DOUT–

OLVTTLLoss-of-Lock.

This output is driven low when the recovered clock

frequency deviates from the reference clock by the

amount specified in Table 4 on page 9. If no external reference is supplied, this signal will be active

when the internal PLL is no longer locked to the

incoming data.

ILVTTLLock-to-Reference.

When this pin is low, the DSPLL will disregard the

data inputs. If an external reference is supplied, the

output clock will be locked to the supplied reference. If no external reference is used, the DSPLL

will lock the control loop until LTR is r eleased.

Note: This input has a weak internal pull-up.

OLVTTLLoss-of-Signal.

This output pin is driven low when the input signal is

below the threshold set via LOS_LVL. The LOS

state will nominally have 3 dB of hysteresis relative

to the level set on LOS_LVL. (LOS operation is

guaranteed only when ac coupling is used on the

clock input.)

When driven high, this pin forces the data present

on DOUT to zero. For normal operation, this pin

should be low. DSQLCH can be used during LOS/

LOL conditions to prevent random data from being

presented to the system.

Note: This input has a weak internal pull-down.

Supply Voltage.

3.3 V

I See Table2 Differential Data Input.

OCMLDi ffer ent ial Data Out put.

Nominally 2.5 V for Si5022 and 3.3 V for Si5023.

Clock and data are recovered from the differential

signal present on these pins. ac coupling is recommended.

This pin is used during production testing and must

be tied to GND for normal operation.

The data output signal is a retimed version of the

data recovered from the signal present on DIN. It is

phase aligned with CLKOUT and is updated on the

rising edge of CLKOUT.

18 Preliminary Rev. 0.46

Page 19

Si5022/Si5023

Table 9. Si5022/23 Pin Descriptions (Continued)

Pin # Pin Name I/O Signal Level Description

19 RESET/CAL I LVTTL Reset/Calibrate.

Driving this input high for at least 1 µS will reset

internal device circuitry. A high to low transition on

this pin will force a DSPLL calibration. For normal

operation, drive this pin low. This pin should be

used to force a DSPLL calibration on power-up to

ensure optimal jitter performance.

Note: This input has a weak internal pull-down.

20 REXT External Bias Resistor.

This resistor is used to establish internal bias currents within the device. This pin must be connected

to GND through a 10 kΩ (1%) resistor.

22,23 CLKOUT–,

CLKOUT+

24 CLKDSBL I LVTTL Clock Disable.

26 BER_LVL I Bit Error Rate Level Control.

27

28 NC No Connect.

GND Pad GND GND Supply Ground.

BER_ALM

OCMLDi ffer en tial Clock Out pu t.

The output clock is recovered from the data signal

present on D IN e xce p t w he n LTR is asserted or t h e

LOL state has been entered.

When this input is high, the CLKOUT output drivers

are disabled. For normal operation, this pin should

be low.

Note: This input has a weak internal pull-down.

The BER threshold level is set by applying a voltage to this pin. The applied voltage is mapped to

one of 64 BER threshold levels. When the BER

exceeds the programmed threshold, BER_ALM is

driven low. If this pin is tied to GND, BER_ALM is

disabled. If it is tied to V

–3

10

BER

OLVTTLBit Error Rate Alarm.

This pin will be driven low to indicate that the BER

threshold set by BER_LVL has been exceeded. The

alarm will clear after the BER rate has improved by

approximately a factor of 2.

Leave this pin unconnected.

Nominally 0.0 V . The GND pad found on the bottom

of the 28-lead micro leaded package (see

Figure 14) must be connected directly to supply

ground. Minimize the ground path inductance for

optimal performance.

DD

, BER_LVL defaults to

Preliminary Rev. 0.46 19

Page 20

Si5022/Si5023

Ordering Guide

Part Number Package Voltage Temperature

Si5022-BM 28-lead MLP 2.5 –40°C to 85°C

Si5023-BM 28-lead MLP 3.3 –40°C to 85°C

Table 10. Ordering Guide

20 Preliminary Rev. 0.46

Page 21

Si5022/Si5023

Package Outline

Figure 14 illustrates the pack age details for the Si 5022 and Si5023. Table 11 lists the values for the dimen sions

shown in the illustration.

A

1

2

3

FOR ODD TERMINAL/SIDE

N

TOP VIEW

C

L

e

D

D/2

D1

D1/2

A

A1

E1/2 E/2

E1 E

L

θ

CC

C

L

e

FOR EV EN TERMINAL/SIDE

bA1

SECTION "C–C"

SCALE: NO NE

BOTTOM VIEW

Figure 14. 28-Lead Micro Leaded Package (MLP)

b

e

(N d–1) Xe

REF.

N

1

2

3

(N d–1) Xe

REF.

Table 11. Package Diagram Dimensions

Controlling Dimension: mm

Symbol Millimeters

Min Nom Max

A — 0.90 1.00

A1 0.00 0.01 0.05

b 0.18 0.23 0.30

D5.00 BSC

D1 4.75 BSC

E5.00 BSC

E1 4.75 BSC

N28

Nd 7

Ne 7

e0.50 BSC

L 0.50 0.60 0.75

θ

12

°

Preliminary Rev. 0.46 21

Page 22

Si5022/Si5023

Contact Information

Silicon Laborato ries Inc.

4635 Boston Lane

Austin, TX 78735

Tel: 1+(512) 416-8500

Fax: 1+(512) 416-9669

Toll Free: 1+(877) 444-3032

Email: productinfo@silabs.com

Internet: www.silabs.com

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change without notice.

Silicon Laboratories assumes no responsibility for errors and omissions, and disclaims responsibility for any consequences resulting from

the use of information included herein. Additionally, Silicon Laboratories assumes no responsibility for the functioning of undescribed features

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Silicon Laboratories assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life, or for any other application in which the failure of the Silicon Laboratories product could create a situation where personal injury or death may occur. Should Buyer purchase or use Silicon Laboratories products for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

Silicon Laboratories, Silicon Labs, and DSPLL are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

22 Preliminary Rev. 0.46

Loading...

Loading...