Page 1

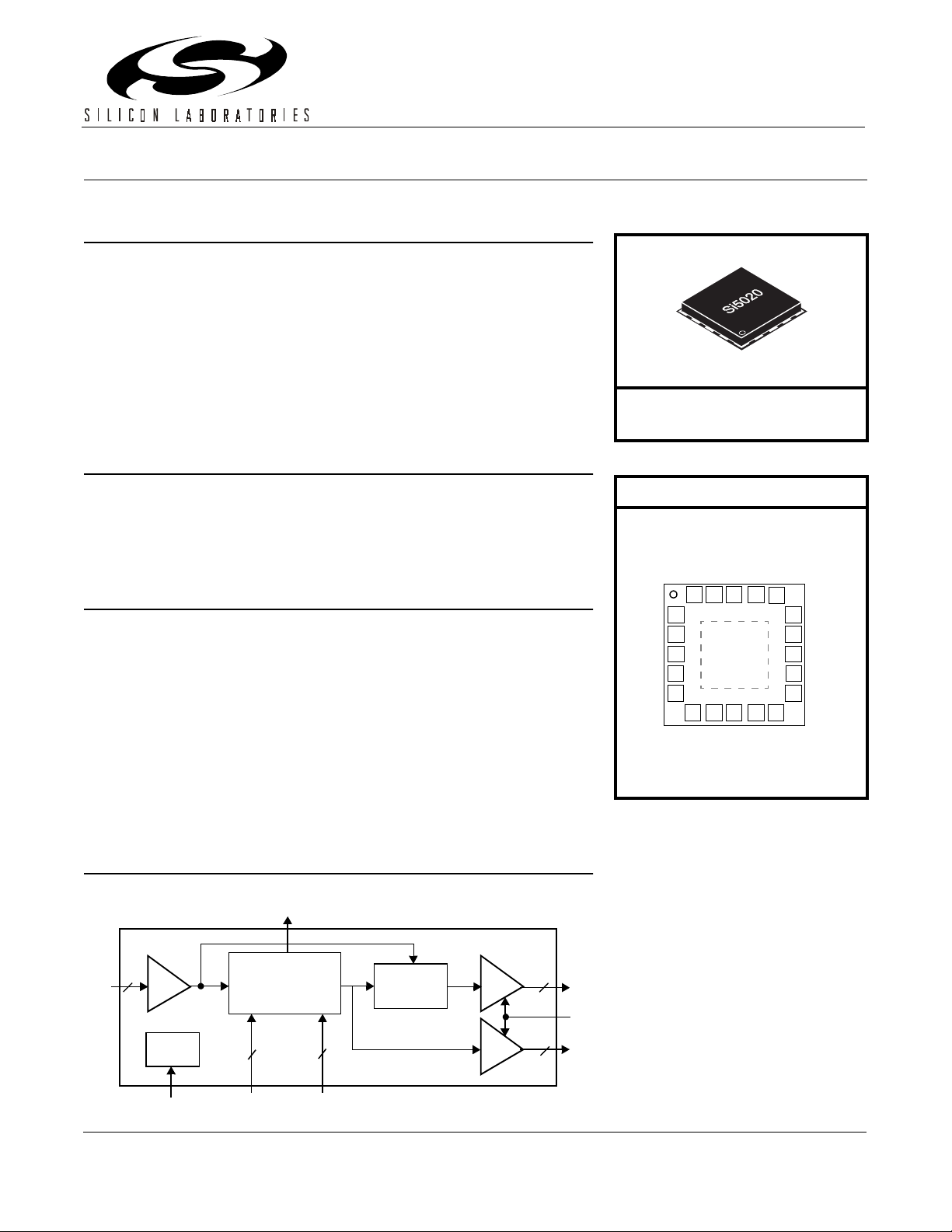

Si5020

SiPHY™ M

ULTI-RATE

SONET/SDH C

LOCK AND DATA RECOVERY

Features

Complete high speed, low power, CDR solution includes the following:

!

Supports OC-48/12/3, STM-16/4/1,

Gigabit Ethernet, and 2.7 Gbps FEC

!

Low Power—270 mW (TYP OC-48)

!

Small Footprint: 4 mm x 4 mm

!

DSPLL™ Eliminates External Loop

Filter Components

!

3.3 V T olerant Control Inputs

!

Exceeds All SONET/SDH

Jitter Specifications

!

Jitter Generation

3.0 mUI

!

Device Power Down

!

Loss-of-Lock Indicator

!

Single 2.5 V Supply

RMS

(TYP)

Applications

!

SONET/SDH/ATM Routers

!

Add/Drop Multiplexers

!

Digital Cross Connects

!

Gigabit Ethernet Interfaces

!

SONET/SDH Test Equipment

!

Optical Transceiver Modules

!

SONET/SDH Regenerators

!

Board Level Serial Links

Description

The Si5020 is a fully integrated low-p ower clock and d ata recovery (CDR)

IC designed for high-speed serial communication systems. It extracts

timing information and data from a serial input at OC-48/12/3, STM-16/4/1,

or Gigabit Ethernet (GbE) rates. Support for 2.7 Gbps data streams is also

provided for OC-48/STM-16 applications that employ forward error

correction (FEC). DSPLL™ technology eliminates sensitive noise entry

points thus making the P LL les s susce ptible to board- level inter actio n and

helping to ensure optimal jitter performance.

The Si5020 repres ents a new stan dard in low ji tter, low power, and small

size for high spe ed CDRs. It o perates fr om a singl e 2.5 V supply over the

industrial temperature range (–40°C to 85°C).

Ordering Information:

See page 14.

Pin Assignments

Si5020

RATESEL1

REXT

1

VDD

2

GND

3

REFCLK+

REFCLK–

4

5

6 7 8 9

LOL

Top View

VDD

RATESEL0

GND

Pad

GND

GND

IC

CLKOUT+

CLKOUT–

17181920

16

PWRDN/CAL

15

VDD

14

DOUT+

13

DOUT–

12

11

VDD

10

DIN–

DIN+

Functional Block Diagram

LOL

DIN+

DIN–

BUF

2

Bias

REXT

Preliminary Rev. 0.8 12/00 Copyright © 2000 by Silicon Laboratories Si5020-DS08

This information applies to a product under development. Its characteristics and specifications are subject to change without notice.

DSPLL™

Phase-Locked

Loop

2

RATESEL1–0

2

REFCLK+

REFCLK–

Retimer

BUF

BUF

2

2

DOUT+

DOUT–

PWRDN/CAL

CLKOUT+

CLKOUT–

Page 2

Si5020

2 Preliminary Rev. 0.8

Page 3

Si5020

T

ABLE OF

C

ONTENTS

Section Page

Detailed Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DSPLL™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PLL Self-Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Multi-Rate Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reference Clock Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Forward Error Correction (FEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lock Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PLL Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Device Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bias Generation Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Differential Input Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Differential Output Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pin Descriptions: Si5020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Preliminary Rev. 0.8 3

Page 4

Si5020

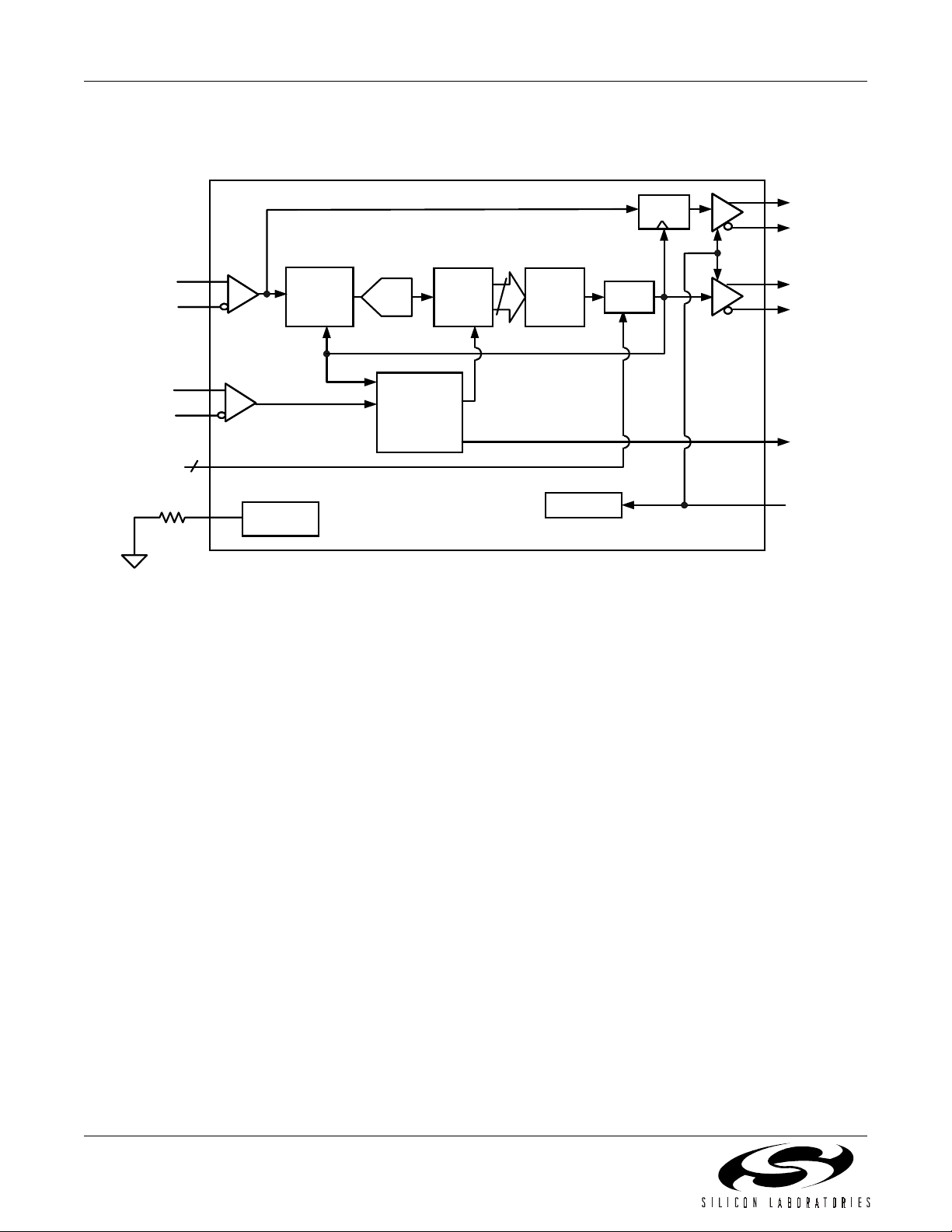

Detailed Block Diagram

DIN+

DIN+

DIN–

REFCLK+

REFCLK+

REFCLK–

RATESEL1-0

RATESEL1-0

REXT

Retime

RetimeRetime

DOUT+

DOUT–

c

Phase

Phase

Phase

Detector

Detector

Detector

A/D

DSP

VCO

CLK

Divider

c

CLKOUT+

CLKOUT–

n

Lock

Detector

LOL

2

Bias

Bias

Bias

Generation

Generation

Generation

Ca libra t io n

PWRDN/CAL

Figure 1. Detailed Block Diagram

4 Preliminary Rev. 0.8

Page 5

Electrical Specifications

Table 1. Recommended Operating Conditions

Si5020

Parameter

Symbol Test Condition

Ambient Temperature T

Si5020 Supply Voltage

2

V

A

DD

1

Min

Typ

–40 25 85 °C

2.375 2.5 2.625 V

Max

1

Notes:

1. All minimum and maximum specifications are guaranteed and apply across the recommended operating

conditions. Typical values apply at nominal supply voltages and an operating temperature of 25°C unless

otherwise stated.

2. The Si5020 specifications are guaranteed when using the recommended application circuit (including

component tolerance) of Figure 5 on page 9.

V

SIGNAL+

Differential

I/Os

V

ICM,VOCM

SIGNAL–

V

IS

Single-Ended Voltage

(SIGNAL+) – (SIGNAL–)

Differential

Voltage Swing

VID,VOD (V

= 2VIS)

ID

Differential Peak-to-Peak Voltage

t

Unit

DOUT

CLKOUT

DOUT,

CLKOUT

Figure 2. Differential Voltage Measurement (DI N, REFCLK, DOUT, CLKOUT)

t

Cf-D

t

Cr-D

Figure 3. Clock to Data Timing

80%

20%

t

F

t

R

Figure 4. DOUT and CLKOUT Rise/Fall Times

Preliminary Rev. 0.8 5

Page 6

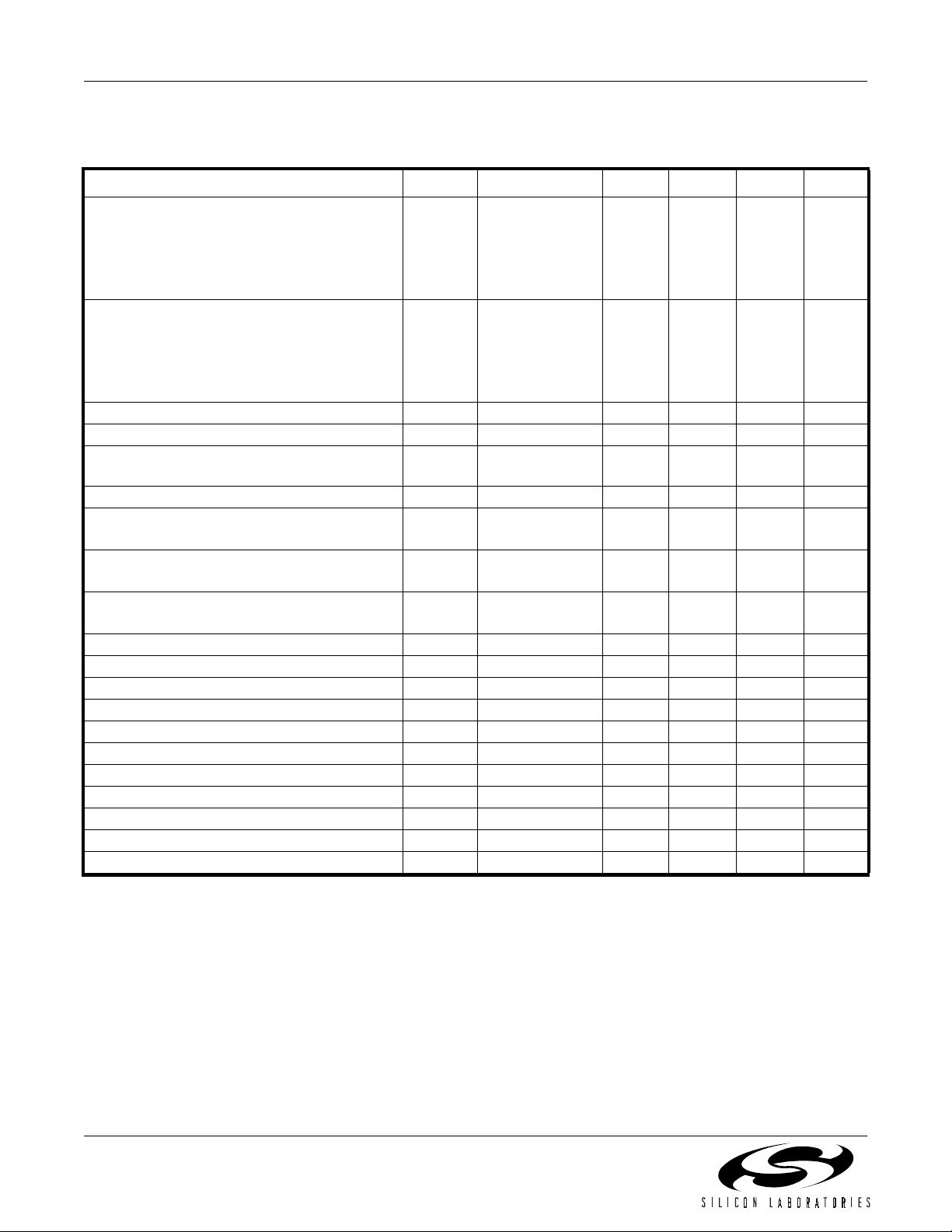

Si5020

Table 2. DC Characteristics

(VDD = 2.5 V ± 5%, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Supply Current

OC-48 and FEC (2.7 GHz)

GigE

OC-12

OC-3

Power Dissipation

OC-48 and FEC (2.7 GHz)

GigE

OC-12

OC-3

Common Mode Input Voltage (DIN, REFCLK) V

Single Ended Input Voltage (DIN, REFCLK) V

Differential Input Voltage Swing

(DIN, REFCLK)

Input Impedance (DIN, REFCLK) R

Differential Output Voltage Swing

(DOUT)

Differential Output Voltage Swing

(CLKOUT)

Output Common Mode Voltage

(DOUT,CLKOUT)

Output Impedance (DOUT,CLKOUT) R

Output Short to GND (DOUT,CLKOUT) I

Output Short to V

(DOUT,CLKOUT) I

DD

Input Voltage Low (LVTTL Inputs) V

Input Voltage High (LVTTL Inputs) V

Input Low Current (LVTTL Inputs) I

Input High Current (LVTTL Inputs) I

Output Voltage Low (LVTTL Outputs) V

Output Voltage High (LVTTL Outputs) V

Input Impedance (LVTTL Inputs) R

PWRDN/CAL Leakage Current I

I

DD

P

D

varies with V

See Figure 2 100 — 750 mV

See Figure 2 200 — 1500 mV

Line-to-Line 84 100 116 Ω

100 Ω Load

V

ICM

V

IS

ID

IN

OD

Line-to-Line

V

OD

100 Ω Load

Line-to-Line

V

OCM

100 Ω Load

Line-to-Line

OUT

SC(–)

SC(+)

IL

IH

IL

IH

OL

OH

IN

PWRDNVPWRDN

Single-ended 84 100 116 Ω

IO = 2 mA — — 0.4 V

IO = 2 mA 2.0 — — V

DD

—

—

—

—

—

—

—

—

—.80*VDD—V

108

113

117

124

270

283

293

310

118

123

127

134

310

323

333

352

mA

mW

(pk-pk)

TBD 940 TBD mV

(pk-pk)

TBD 900 TBD mV

(pk-pk)

—VDD –

—V

0.20

—25TBDmA

TBD –15 — mA

——.8V

2.0 — — V

——10µA

——10µA

10 — — kΩ

≥ 0.8 V TBD 25 TBD µA

6 Preliminary Rev. 0.8

Page 7

Si5020

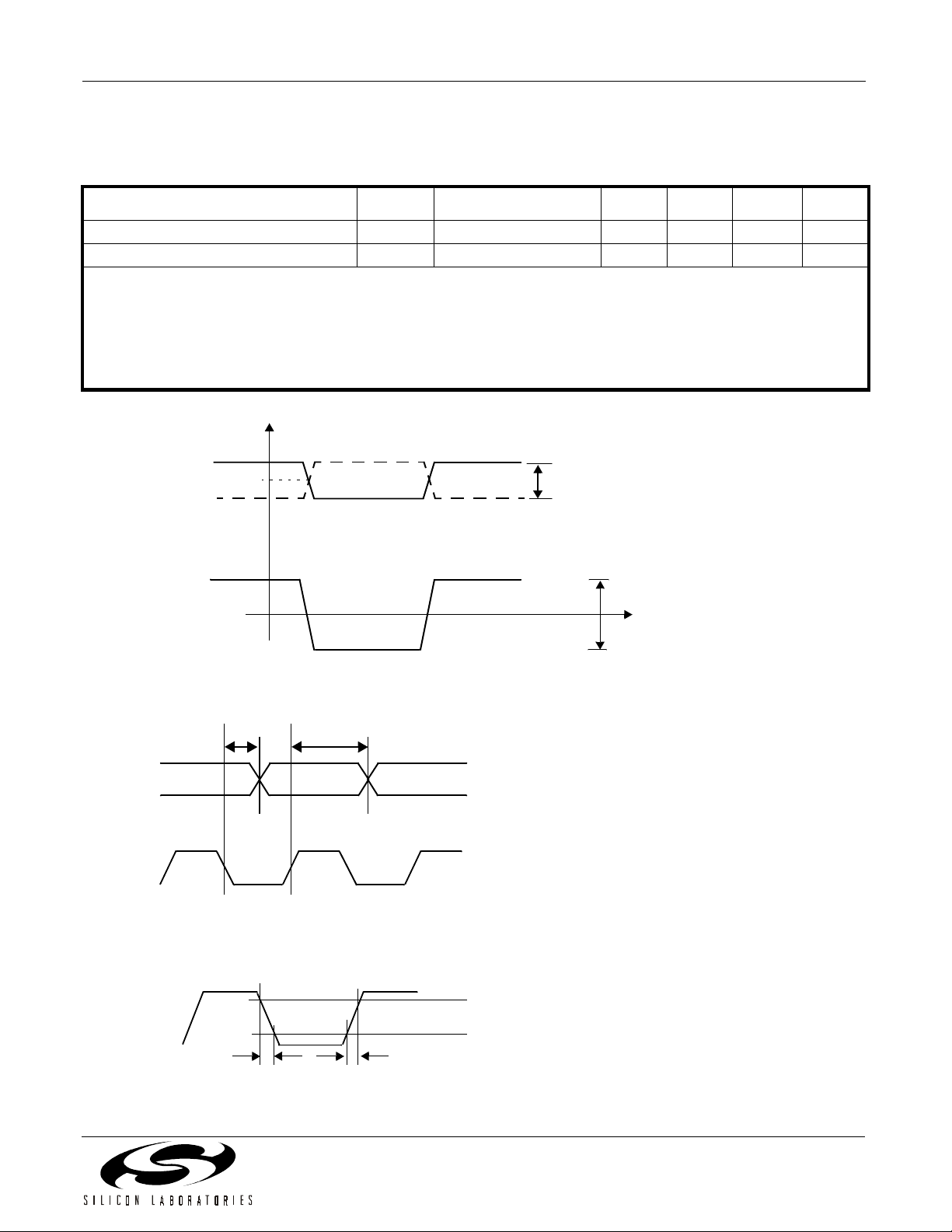

Table 3. AC Characteristics (Clock & Data)

(VA 2.5 V ± 5%, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Output Clock Rate f

Output Rise Time t

Output Fall Time t

Clock to Data Delay

CLK

t

Cr-D

R

F

Figure 4 — 100 TBD ps

Figure 4 — 100 TBD ps

Figure 3

FEC (2.7 GHz)

OC-48

GigE

OC-12

OC-3

Clock to Data Delay

t

Cf-D

Figure 3

FEC (2.7 GHz)

OC-48

Input Return Loss 100 kHz – 2.5 GHz

2.5 GHz – 4.0 GHz

.15 — 2.7 GHz

TBD

TBD

TBD

TBD

TBD

TBD

TBD

18.7

TBD

250

255

500

890

4100

51

50

—

—

TBD

TBD

TBD

TBD

TBD

TBD

TBD

—

—

ps

ps

dB

dB

Preliminary Rev. 0.8 7

Page 8

Si5020

Table 4. AC Characteristics (PLL Characteristics)

(VA 2.5 V ± 5%, TA = –40°C to 85°C)

Parameter Symbol Test Condition Min Typ Max Unit

Jitter Tolerance

(OC-48)*

J

TOL(P–P)

f = 600 Hz 40 TBD — UIp-p

f = 6000 Hz 4 TBD — UIp-p

f = 100 kHz 4 TBD — UIp-p

f = 1 MHz 0.4 TBD — UIp-p

Jitter Tolerance (OC-12 Mode)

*

J

TOL(P–P)

f = 30 Hz 40 TBD — UIp-p

f = 300 Hz 4 TBD — UIp-p

f = 25 kHz 4 TBD — UIp-p

f = 250 kHz 0.4 TBD — UIp-p

Jitter Tolerance (OC-3 Mode)

*

J

TOL(P–P)

f = 30 Hz 60 TBD — UIp-p

f = 300 Hz 6 TBD — UIp-p

f = 6.5 kHz 6 TBD — UIp-p

f = 65 kHz 0.6 TBD — UIp-p

Jitter Tolerance (Gigabit Ethernet)

T

JT(P-P)

IEEE 802.3z Clause 38.68 600 TBD — ps

Receive Data Total Jitter

Tolerance

Jitter Tolerance (Gigabit Ethernet)

D

JT(P-P)

IEEE 802.3z Clause 38.69 370 TBD — ps

Receive Data Deterministic Jitter

Tolerance

RMS Jitter Generation

Peak-to-Peak Jitter Generation

Jitter Transfer Bandwidth

*

*

J

GEN(rms)

*

J

GEN(rms)

J

BW

with no jitter on serial data — 3.0 5.0 mUI

with no jitter on serial data — 25 55 mUI

OC-48 Mode — — 2.0 MHz

OC-12 Mode — — 500 kHz

OC-3 Mode — — 130 kHz

Jitter Transfer Peaking

Acquisition Time T

*

J

AQ

P

After falling edge of

— 0.03 0.1 dB

1.45 1.5 1.7 ms

PWRDN/CAL

From the return of valid

40 60 150 µs

data

Input Reference Clock Duty Cycle C

DUTY

40 50 60 %

Reference Clock Range 19.44 — 168.75 MHz

Input Reference Clock Frequency

C

TOL

–100 — 100 ppm

Tolerance

Frequency Difference at which

LOL TBD 600 TBD ppm

Receive PLL goes out of Lock

(REFCLK compared to the divided

down VCO clock)

Frequency Difference at which

LOCK TBD 300 TBD ppm

Receive PLL goes into Lock (REFCLK compared to the divided

down VCO clock)

*Note: Bellcore specifications: GR-253-CORE, Issue 2, December 1995. Using PRBS 223– 1 data pattern.

8 Preliminary Rev. 0.8

Page 9

Si5020

Table 5. Absolute Maximum Ratings

Parameter Symbol Value Unit

DC Supply Voltage V

LVTTL Input Voltage V

Differential Input Voltages V

DD

DIG

DIF

–0.5 to 2.8 V

–0.3 to 3.6 V

–0.3 to (VDD+ 0.3) V

Maximum Current any output PIN ±50 mA

Operating Junction Temperature T

Storage Temperature Range T

JCT

STG

–55 to 150 °C

–55 to 150 °C

Lead Temperature (soldering 10 seconds) 300 °C

ESD HBM Tolerance (100pf, 1.5 kΩ)1kV

Note: Permanent device damage may occur if the above Absolute Maximum Ratings are exceeded. Functional operation

should be restricted to the conditions as specified in the operational sections of this data sheet. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Table 6. Thermal Characteristics

Parameter Symbol Test Condition Value Unit

Thermal Resistance Junction to Ambient ϕ

LVTTL

Control Inputs

JA

Still Air 38 °C/W

Loss-of-Lock

Indicator

High Speed

Serial Input

System

Reference

Clock

2

LOL

RATESEL1-0

DIN+

DIN–

PWRDN/CAL

DOUT+

DOUT–

Si5020

VDD

0.1

2200pF

20pF

CLKOUT+

CLKOUT–

GND

µµµµ

F

REFCLK+

REFCLK–

ΩΩΩΩ

10k

(1%)

(1%)

(1%)(1%)

REXT

VDD

Figure 5. Si5020 Typical Application Circuit

Recovered

Data

Recovered

Clock

Preliminary Rev. 0.8 9

Page 10

Si5020

Functional Description

The Si5020 utilizes a phase-locked loop (PLL) to

recover a clock s ynchronous to the input data stream .

This clock is used to retime the data, and both the

recovered clock and data are output syn chronously via

current mode logic (CML) drivers. Optimal jitter

performance is obtained by using Silicon Laboratories'

DSPLL™ technology to eliminate the no ise entry poi nts

caused by external PLL loop filter components.

DSPLL

The phase-locked loop structure (shown in Figure 1 o n

page 4) utilizes Silicon Laboratories' DSPLL™

technology to elimin ate the need for external l oop filter

components found in traditional PLL implementations.

This is achieved by using a digital signal processing

(DSP) algorithm to replace the loop filter commonly

found in analog PLL designs . This algorithm pro cesses

the phase detector error term and generates a digital

control value to adjust the frequency of the voltage

controlled oscilla tor (VCO). Bec ause external loo p filter

components are not required, sensitive noise entry

points are eliminated thus making the DSPLL less

susceptible to board-level noise sources that make

SONET/SDH jitter compliance difficult to attain.

™

PLL Self-Calibration

The Si5020 achieves optimal jitter performance by

using self-calibration circuitry to set the loop gain

parameters within the DSPLL. For the self-calibration

circuitry to operate correctly, the power supply voltage

must exceed 2.25 V when calibration occurs. For best

performance, the user should force a self-calibration

once the supply has stabilized on power-up.

A self-calibration can be initiat ed by forcing a high-tolow transition on the power-down control input,

PWRDN/CAL, while a vali d reference clock is supplie d

to the REFCLK input. The PWRDN/CAL input should be

held high at least 1 µS before transitioning low to

guarantee a self-cal ibration. Sev eral applica tion circu its

that could be used to initiate a power- on self-cal ibration

are provided in Silico n Laboratories’ “ AN42: Controlling

the Si5018/20 Self-Calibration.”

Multi-Rate Operation

The Si5020 supports clock and data recovery for OC-48

and STM-16 data streams. In addition, the PLL was

designed to operate at data rates up to 2.7 Gbps to

support OC-48/STM-16 applications that employ

forward error correction (FEC ).

Multi-rate operation is achieved by configuring the

device to divide down the output of the VCO to the

desired data rate. The divide fa ctor is confi gured by the

RATESEL0-1 pins. Th e RATESEL0-1 configuration and

associated data rates are given in Table 7.

Table 7. Multi-Rate Configurati o n

OC-48

RATESEL

[0:1]

00 2.488 Gbps — 2.67 Gbps 1

10 1.244 Gbps 1.25 Gbps — 2

01 622.08 Mbps — — 4

11 155.52 Mbps — — 16

SONET/

SDH

Gigabit

Ethernet

with

15/14

FEC

CLK

Divider

Reference Clock Detect

The Si5020 uses the reference clock to cente r the VCO

output frequency so that clock and data can be

recovered from the input data stream. The device will

self configure for o peration with one of three refe rence

clock frequencies. This eliminates the need to externally

configure the device to operate with a particular

reference clock.

The reference clock centers the VCO for a nominal

output of between 2.5 GHz and 2.7 Ghz. The VCO

frequency is centered at 16, 32, or 128 times the

reference clock frequency. Detection circuitry

continuously monitors the reference clock input to

determine whether the dev ice should be configured for

a reference clock that is 1/16, 1/32, or 1/128 the

nominal VCO output. Approximate reference clock

frequencies for some target applications are given in

Table 8.

Table 8. Typical REFCLK Frequencies

SONET/SDH

19.44 MHz 19.53 MHz 20.83 MHz 128

77.76 MHz 78.125 MHz 83.31 MHz 32

155.52 MHz 156.25 MHz 166.63 MHz 16

Gigabit

Ethernet

SONET/

SDH with

15/14 FEC

Ratio of

VCO to

REFCLK

10 Preliminary Rev. 0.8

Page 11

Si5020

Forward Error Correction (FEC)

The Si5020 supports FEC in SONET OC-48 (SDH

STM-16) application s for data rates up to 2.7 Gbps. In

FEC applications, the appropriate reference clock

frequency is determined by dividing the input data rate

by 16, 32, or 128. For example, if an FEC code is use d

that produces a 2.70 Gbps data rate, the required

reference clock would be 168 .75 MHz, 84.375 MHz, or

21.09 MHz.

Lock Detect

The Si5020 provides lock-detect circuitry that i ndicates

whether the PLL has ac hieved frequency lock with th e

incoming data. The ci rcuit compare s the frequency of a

divided down version of the recovered clock with the

frequency of the supplied refer ence clock (REFCLK). If

the recovered clock frequen cy deviates from that of th e

reference clock by the amount specified in Table 4 on

page 8, the PLL i s decla red ou t of lock , and th e loss -oflock (LOL) pin is asserted “high.” In this state, the

DSPLL will periodically try to reacquire lock with the

incoming data stream. During reacquisition, the

recovered clock, CLKOUT, will drift over a ±600 ppm

range relative to the su pplied re ference clock. Th e LOL

output will remain asserted until the recovered clock

frequency is within the REFCLK frequency by the

amount specified in Table 4.

Note: LOL is not asserted during PWRDN/CAL.

PLL Performance

The PLL implementation used in the Si5020 is fully

compliant with the jitter specifications proposed for

SONET/SDH equipment by Bellcore GR-253-CORE,

Issue 2, December 1995 and ITU-T G.958.

Jitter Tolerance

The Si5020’s tolerance to input jitter exceeds that of the

Bellcore/ITU mask shown in Figure 6. This mask

defines the level of peak-to-peak sinusoid jitter that

must be tolerated when applied to the differential data

input of the device.

Note: There are no entries in the mask table for the data rate

corresponding to OC-24 as that rate is not specified by

either GR-253 or G.958.

Sinusoidal

Input

Jitter (UI p-p)

Slope = 20 dB/Decade

15

1.5

0.15

f0 f1 f2 f3 ft

Frequency

SONET

Data RateF0(Hz)F1(Hz)F2(Hz)F3(kHz)Ft(kHz)

OC-48 10 600 6000 100 1000

OC-12 10 30 300 25 250

OC-3 10 30 300 6.5 65

Figure 6. Jitter Tolerance Specification

Jitter Transfer

The Si5020 is fu lly compl iant w ith the rel evant Bell core /

ITU specifications related to SONET/SD H jitter transfer.

Jitter transfer is defined as the ratio of output signal jitter

to input signal jitter as a functi on of jitte r freq uency ( see

Figure 7). These meas urem ents are made with an input

test signal that is degraded with sinusoidal jitter whose

magnitude is defined by the mask in Figure 6.

Jitter Generation

The Si5020 exceeds all r elevant specifications for jitter

generation proposed for SONET/SDH equipment. The

jitter generation specification defines the amount of jitter

that may be present on the recovered clock and data

outputs when a ji tter free input signal is provi ded. The

Si5020 typically generates less than 3.0 mUI rms of

jitter when presented with jitter-free input data.

Preliminary Rev. 0.8 11

Page 12

Si5020

Jitter

Transfer

0.1 dB

Acceptable

Range

Fc

Frequency

20 dB / Decade

Slope

SONET

Data RateFc(kHz)

OC-48 2000

OC-12 500

OC-3 130

Figure 7. Jitter Transfer Specification

Power Down

The Si5020 provides a power do wn pin, PWRDN/CAL,

that disables the output drivers (DOUT, CLKOUT).

When the PWRDN/CAL pin is driven “high”, the positi ve

and negative terminals of CLKOUT and DOUT are each

tied to VDD through 100 Ω on-chip resistors. This

feature is useful in reducing power consumption in

applications that employ redundant serial channels.

When PWRDN/CAL is released (set to “low”) the d igital

logic resets to a kn own initia l conditi on, reca librate s the

DSPLL, and will begin to lock to the data stream.

Device Grounding

The Si5020 uses the GND pad on the bottom of the 20pin micro leaded package (MLP) for device ground. This

pad should be connected di rectly to the analog supply

ground. See Figures 10 and 11 for the ground (GND)

pad location.

Bias Generation Circuitry

The Si5020 makes use of an external resistor to set

internal bias currents. The external resistor allows

precise generation of bias currents which significantly

reduces power consumption versus traditional

implementations tha t use an internal resistor. The bias

generation circuitry requires a 10 kΩ (1%) resistor

connected between REXT and GND.

Differential Input Circuitry

The Si5020 provides d ifferentia l inputs f or both the hig h

speed data (DIN) and the reference clock (REFCLK)

inputs. An example termination for these inputs is

shown in Figure 8. In applications where direct DC

coupling is possible, the 0.1 µF capacitors may be

omitted. The DIN and REFCLK input amplifiers require

an input signal with a minimum differenti al peak- to -peak

voltage listed in Table 2 on page 6.

DIN+,

DIN–,

Si5020

2.5 kΩΩΩΩ

Differential Driver

0.1 µ

0.1 µ

µF

µ µ

µF

µ µ

Zo = 50 ΩΩΩΩ

Zo = 50 ΩΩΩΩ

REFCLK+

REFCLK–

Figure 8. Input Termination for DIN and REFCLK (AC Coupled)

12 Preliminary Rev. 0.8

VDD

2.5 kΩΩΩΩ10 kΩΩΩΩ

10 kΩΩΩΩ

GND

102 ΩΩΩΩ

Page 13

Si5020

Differential Output Circuitry

The Si5020 utilizes a current mode logic (CML) architecture to output both the recovered clock (CLKOUT) and data

(DOUT). An example of output termination with AC coupling is shown in Figure 9. In applications in which direct DC

coupling is possible, the 0.1 µF capacitors may be omitted. The differential peak-to-peak voltage swing of the CML

architecture is listed in Table 2 on page 6.

Si5020

100 ΩΩΩΩ

100 ΩΩΩΩ

VDD

VDD

DOUT+,

CLKOUT+

DOUT–,

CLKOUT–

0.1 µµµµF

0.1 µµµµF

Zo = 50 ΩΩΩΩ

Zo = 50 ΩΩΩΩ

VDD

50 ΩΩΩΩ

50 ΩΩΩΩ

VDD

Figure 9. Output Termination for DOUT and CLKOUT (AC Coupled)

Preliminary Rev. 0.8 13

Page 14

Si5020

Pin Descriptions: Si5020

RATESEL1

RATESEL0

GND

CLKOUT+

CLKOUT–

17181920

16

10

15

14

13

12

11

DIN–

PWRDN/CAL

VDD

DOUT+

DOUT–

VDD

REXT

VDD

GND

REFCLK+

REFCLK–

1

2

3

4

5

6 7 8 9

LOL

GND

VDD

Pad

GND

DIN+

Top View

Figure 10. Si5020 Pin Configuration

Table 9. Si5020 Pin Descriptions

Pin # Pin Name I/O Signal Level Description

1REXT External Bias Resistor.

This resistor is used by onboard circuitry to establish bias currents within the device. This pin must

be connected to GND through a 10 kΩ (1%) resis-

tor.

4, 5 REFCLK+,

REFCLK–

I See Table 2 Differential Reference Clock.

The reference clock sets the initial operating frequency used by the onboard PLL for clock and data

recovery. Additionally , the reference clock is used to

derive the clock output when no data is present.

6LOLOLVTTLLoss of Lock.

This output is driven high when the recovered clock

frequency deviates from the reference clock by the

amount specified in Table 4 on page 8.

9, 10 DIN+, DIN– I See Table 2 Differential Data Input.

Clock and data are recovered from the differential

signal present on these pins.

12, 13 DOUT–,

DOUT+

OCMLDifferential Data Output.

The data output signal is a retimed version of the

data recovered from the signal present on DIN. It is

phase aligned with CLKOUT and is updated on the

rising edge of CLKOUT.

14 Preliminary Rev. 0.8

Page 15

Table 9. Si5020 Pin Descriptions (Continued)

Pin # Pin Name I/O Signal Level Description

Si5020

15 PWRDN/CAL I LVTTL

16, 17 CLKOUT–,

CLKOUT+

19, 20 RATESEL1,

RATESEL0

2, 7, 11, 14 VDD 2.5 V Supply Voltage.

3, 8, 18, and

GND Pad

GND GND Supply Ground.

OCMLDifferential Clock Output.

ILVTTLData Rate Select.

Power Down.

To shut down the high-speed outputs and reduce

power consumption, hold this pin high. For normal

operation, hold this pin low.

Calibration.

To initiate an internal self-calibration, force a highto-low transition on this pin. (See "PLL Self-Calibration‚" on page 10.)

Note: This input has a weak internal pulldown.

The output clock is recovered from the data signal

present on DIN. In the absence of data, the output

clock is derived from REFCLK.

These pins configure the onboard PLL for clock and

data recovery at one of four user selectable data

rates. See Table 7 for configuration settings.

Note: These inputs have weak internal pulldowns.

Nominally 2.5 V.

Nominally 0.0 V . The GND pad found on the bottom

of the 20-pin micro leaded package (see Figure 11)

must be connected directly to supply ground.

Preliminary Rev. 0.8 15

Page 16

Si5020

Ordering Guide

Table 10. Ordering Guide

Part Number Package Temperature

Si5020-BM 20-pin MLP –40°C to 85°C

16 Preliminary Rev. 0.8

Page 17

Si5020

Package Outline

Figure 11 illustrates the package detail s for the Si5020. Table 11 lists the values for the dimension s shown in the

illustration.

56

0.50 DIA.

TOP VIEW

A

1

2

3

D

D1

N

D1/2

2X

D/2

A

C0.25

E1/2 E/2

E1 E

0.252XB

C

BOTTOM VIEW

10

0.05

A

A2

C

A1

A3

4X P

R

4X P

4X Q

4

0.10 BAMC

b

D2

D2/2

8.

N

1

2

(Ne-1)X e

3

E2

REF.

0.20

C

2X

FOR ODD TERMINAL/SIDE FOR EVEN TERMINAL/SIDE

B

2X

e

AC0.20

C

L

TERMINAL TIP

CC

C

L

4

e

Figure 11. 20-pin Micro Leaded Package (MLP)

Table 11. Package Diagram Dimensions

B

b

SECTION "C-C"

SCALE: NONE

L

0

C

SEATING

11

A1

1.

2.

3.

4.

PLANE

NOTES:

DIE THICKNESS ALLOW ABLE IS 0.305mm MAXIMUM(.012 INCHES MAXIMUM)

DIMENSIONING & TOLERANCES C ON FOR M T O ASME Y14.5M. - 1994.

N IS THE NUMBER OF TERMINALS.

Nd IS THE NUMBER OF TERMINALS IN X-DIRECTION &

Ne IS THE NUMBER OF TERMINALS IN Y-DIRECTION.

DIMENSION b APPLIES TO PLATED TERMINAL AND IS MEASURED

BETWEEN 0.20 AND 0.25mm FROM T ERM INAL TIP.

5.

THE PIN #1 IDENTIFIER MUST BE EXISTED ON THE TOP SURF ACE O F TH E

PACKAGE BY USING INDENTATION MARK O R OT HER FEAT URE O F PAC KAG E BOD Y.

EXACT SHAPE AND SIZE OF THIS FEATURE IS OPTIONAL.

6.

7. ALL DIMENSIONS ARE IN MILLIMETERS.

THE SHAPE SHOWN ON FOU R CO RN ERS AR E NO T AC TUAL I/O.

8.

PACKAGE W AR PAG E MAX 0.05mm.9.

APPLIED FOR EXPOSED PAD AND T ERMINALS.

10.

EXCLUDE EMBEDDING PART O F EXPO SED

PAD FROM MEASURING.

APPLIED ONLY FOR TERM INALS.

11.

e

(Nd-1)Xe

REF.

E2/2

Symbol Millimeters Symbol Millimeters

Min Nom Max Min Nom Max

A — 0.85 1.00 E1 3.75 BSC

A1 0.00 0.01 0.05 E2 1.95 2.10 2.25

A2 — 0.65 0.80 N 20

A3 0.20 REF Nd 5

b 0.23 0.28 0.35 Ne 5

D 4.00 BSC L 0.50 0. 60 0.75

D1 3.75 BSC P 0.24 0.42 0.60

D2 1.95 2.10 2.25 Q 0.30 0.40 0.65

e 0.50 BSC R 0.13 0.17 0.23

E 4.00 BSC θ ——12°

Preliminary Rev. 0.8 17

Page 18

Si5020

Contact Information

Silicon Laborato ries Inc.

4635 Boston Lane

Austin, TX 78735

Tel: 1+(512) 416-8500

Fax: 1+(512) 416-9669

Toll Free: 1+(877) 444-30 32

Email: productinfo@silabs.com

Internet: www.silabs.com

The information in this document is believed to be accurate in all respects at the time of publication but is subject to change without notice.

Silicon Laboratories assumes no responsibility for errors and omissions, and disclaims responsibility for any consequences resulting from

the use of information included herein. Additionally, Silicon Laboratories assumes no responsibility for the functioning of undescribed features

or parameters. Silicon Laboratories reserves the right to make changes without further notice. Silicon Laboratories makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Silicon Laboratories assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. Silicon Laboratories products are not designed, intended, or authorized for use in applications intended to

support or sustain life, or for any other application in which the failure of the Silicon Laboratories product could create a situation where personal injury or death may occur. Should Buyer purchase or use Silicon Laboratories products for any such unintended or unauthorized application, Buyer shall indemnify and hold Silicon Laboratories harmless against all claims and damages.

Silicon Laboratories, Silicon Labs, and DSPLL are trademarks of Silicon Laboratories Inc.

Other products or brandnames mentioned herein are trademarks or registered trademarks of their respective holders.

18 Preliminary Rev. 0.8

Loading...

Loading...