®

SHC605

High-Speed Operational

TRACK-AND-HOLD AMPLIFIER

SHC605

DEMO BOARD

AVAILABLE

FEA TURES

● VERY GOOD SPURIOUS FREE DYNAMIC

RANGE:

90dB at 1MHz FIN and 20MSPS

86dB at 2MHz F

77dB at 5MHz F

and 20MSPS

IN

and 20MSPS

IN

● LOW ACQUISITION TIME: 30ns to 0.01%

● LOW DROOP RATE: 8mV/

T

MAX

µs max T

MIN

to

● LOW POWER CONSUMPTION: 335mW

● EXTREMELY VERSATILE ARCHITECTURE:

Noninverting, Inverting, and

Differential Gains

● LOGIC FLEXIBILITY: TTL and ECL

Compatible

● SMALL PACKAGE: SO-16

● EXTENDED TEMPERATURE SPECS:

°C to +85°C

–40

APPLICATIONS

● A/D CONVERTER FRONT ENDS

● MULTIPLE CHANNEL SIMULTANEOUS

SAMPLING

● IMPROVING FLASH ADC PERFORMANCE

● PEAK DETECTORS

● DAC DEGLITCHING

DESCRIPTION

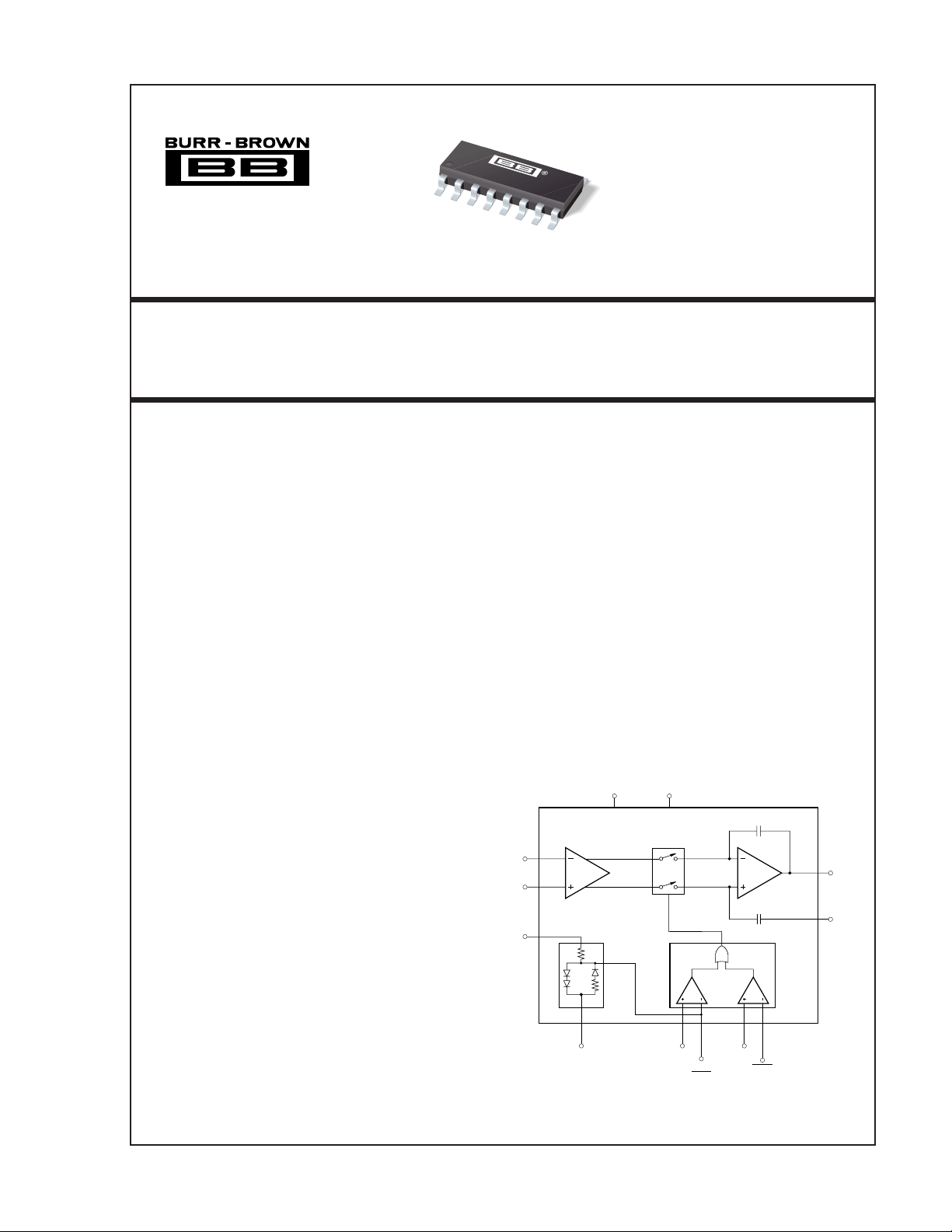

The SHC605 is a monolithic high-speed, high accuracy track-and-hold amplifier. It combines fast acquisition and low distortion to provide a complete solution for a wide range of sampling applications. Its new

proprietary closed-loop architecture provides a singlechip solution to many data acquisition problems formerly requiring more than one device. Noninverting,

inverting, and differential gain configurations are easy

to apply with the SHC605. An on-board logic reference circuit makes the SHC605 compatible with both

single-ended and differential ECL or TTL clock inputs. An internal track-mode lockout circuit allows

edge-triggered operation in data acquisition systems.

The SHC605 is available in a SO-16 surface-mount

package specified for the –40C to +85C industrial

temperature range.

–IN

+IN

Select

+V

2, 3 15, 16

8

1

10

–V

S

S

C

1

C

2

9

5, 6, 7

V

out

AGND

412111413

DGND

International Airport Industrial Park • Mailing Address: PO Box 11400 • Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd. • Tucson, AZ 85706

Tel: (520) 746-1111 • Twx: 910-952-1111 • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

©

1992 Burr-Brown Corporation PDS-1165D Printed in U.S.A. July, 1993

Hold

Thresh/

Hold

Lock

Lock

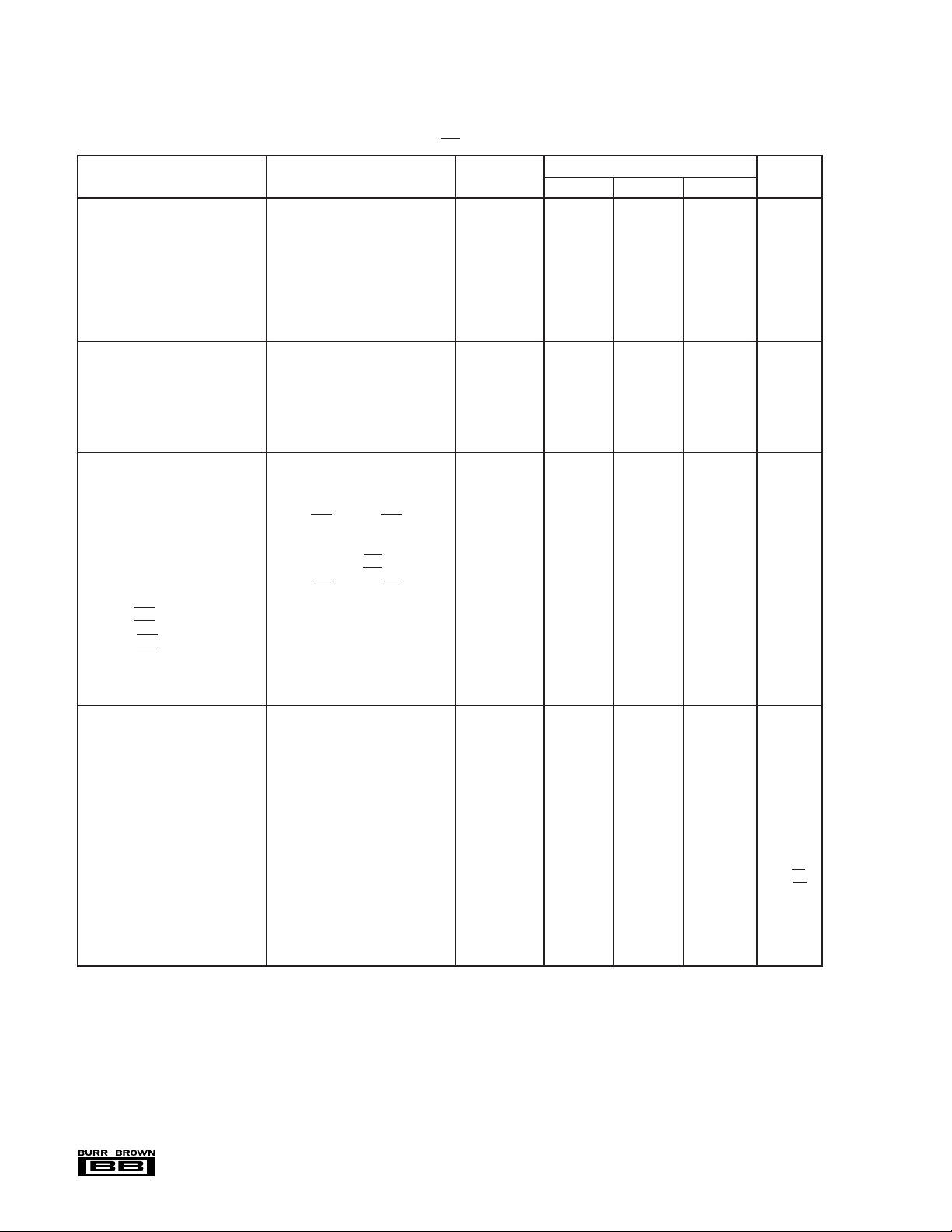

SPECIFICATIONS

ELECTRICAL

At TA = +25°C, ±VS = ±5V, G = +1V/V, RL = 100Ω, CL = 5pF, and ECL Hold/Hold Inputs, unless otherwise noted.

SHC605AU

PARAMETER CONDITION TEMP RANGE MIN TYP MAX UNITS

DC INPUT PARAMETERS

Offset Voltage Full ±1 ±7.5 mV

Power Supply Rejection V

Input Bias Current V

Input Offset Current V

Common-Mode Input Range Full ±2.0 ±2.5 V

Common-Mode Rejection V

Differential Input Impedance Full 13||1 kΩ||pF

Common-Mode Input Impedance Full 2||1 MΩ||pF

Open-Loop Voltage Gain V

OUTPUT

Voltage Output R

Current Output +25°C ±40 ±80 mA

Short Circuit Current Full ±140 mA

Output Resistance,

Closed-Loop: Track-Mode DC Full 0.0001 Ω

Hold-Mode DC Full 0.01 Ω

DIGITAL INPUTS/OUTPUTS

TTL Input Levels

V

IL

V

IH

Single-Ended ECL Input Levels

V

IL

V

IH

Common-Mode Input Voltages Hold/Hold Full –3 +5 V

(1)

(2)

Differential Input Voltages Hold/Hold and Lock/Lock Inputs Full 0.2 5.0 V

Digital Input Currents

I

, Lock/Lock Inputs Only ECL Logic “LO”, VIL = –1.60V Full 5 µA

IL

I

, Hold/Hold Inputs Only ECL or TTL Logic “LO” Full –100 µA

IL

I

, Lock/Lock Inputs Only Logic “HI”, VIH = –1.0V Full 50 µA

IH

I

, Hold/Hold Inputs Only Full –10 µA

IH

Threshold Voltage Output

(4)

TTL

(5)

ECL

(3)

TRACK-MODE RESPONSE

Closed-Loop Bandwidth Gain = +1V/V +25°C 100 200 MHz

Full Power Response ±1V Input, –3dB Output Full 32 MHz

Slew Rate

Acquisition Time to 1%

(6)

(7)

0.1% 2V Step Full 23 35 ns

0.012% 2V Step Full 30 45 ns

0.012% 4V Step Full 40 60 ns

Input Voltage Noise 1MHz to 100MHz 2.5 nV√Hz

Input Bias Current Noise 1MHz to 100MHz 2.5 pA/√Hz

Differential Gain 3.58MHz, V

Differential Phase 3.58MHz, V

Spurious Free Dynamic Range

(5MHz) V

(10MHz) V

NOTE: (1) Select (Pin 10) connected to +VS for TTL threshold voltage on Pin 11. (2) Select (Pin 10) connected to –VS for ECL threshold voltage on Pin 11. (3) Output

voltage on pin 11. (4) Pin 10 (Select) connected to +V

(7) Acquisition time includes hold-to-track delay switch time. (8) Hold noise is proportional to the time in the hold mode. For example, if the hold time is 25ns, the

accumulated noise is 10µVrms. (9) This is the maximum length of time the SHC605 can remain in the hold mode and still maintain a linear droop rate. (10) Select

(Pin 10) connected to +V

.

S

= ±4.5 to ±5.5V +25°C60 85 dB

S

= 0V Full 15 50 µA

CM

= 0V Full ±0.2 ±5 µA

CM

= ±2VDC Full 80 dB

CM

= ±2V, RL = 100Ω +25°C 100 dB

O

= 50Ω Full ±2.0 ±2.5 V

L

Full ±40 ±60 mA

Hold Input Only

Logic “LO” Full 0 +1.0 V

Logic “HI” Full +2.0 +5.0 V

Hold/Hold and Lock/Lock Inputs

Logic “LO” Full –1.80 –1.45 V

Logic “HI” Full –1.05 –0.80 V

Lock/Lock Full –V

S

+3 V

Full 1.1 1.5 1.9 V

–VS = –5.2V Full –1.40 –1.10 V

Gain = +2V/V +25°C 75 MHz

Gain = +5V/V +25°C 20 MHz

Gain = +10V/V +25°C 10 MHz

G = +1, 2V Step +25°C 140 200 V/µs

Full 120 200 V/µs

2V Step Full 15 25 ns

= 0 to 0.7Vp–p 0.005 %

O

= 0 to 0.7Vp–p 0.005 Degrees

O

= ±1V 83 dBc

O

= ±1V 73 dBc

O

. (5) Pin 10 (Select) connected to –VS. (6) Slew rate is rate of change from 10% to 90% of a 2V output step.

S

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN

assumes no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject

to change without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize

or warrant any BURR-BROWN product for use in life support devices and/or systems.

®

SHC605

2

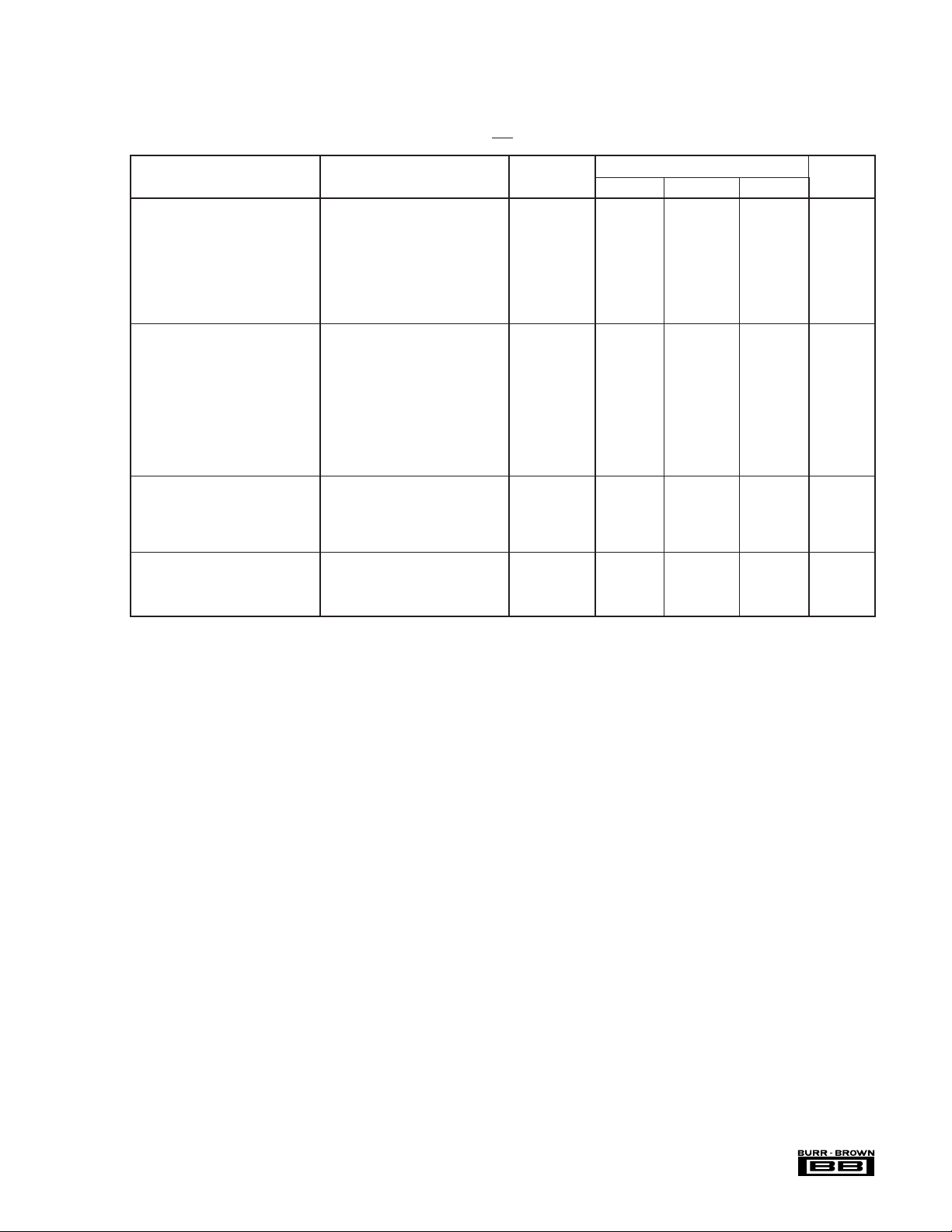

SPECIFICATIONS (CONT)

ELECTRICAL

At TA = +25°C, ±VS = ±5V, G = +1V/V, RL = 100Ω, CL = 5pF, and ECL Hold/Hold Inputs, unless otherwise noted.

SHC605AU

PARAMETER CONDITION TEMP RANGE MIN TYP MAX UNITS

TRACK-TO-HOLD SWITCHING

V

IN

= 0V

Aperture Delay Full 1.7 ns

Aperture Jitter Full 2.4 ps rms

Pedestal Offset +25°C ±5 ±20 mV

over Temperature Full ±5 ±25 mV

Transient Amplitude Full ±5mV

Settling Time to 1mV Full 8 15 ns

100µV Full 15 ns

HOLD-MODE RESPONSE

Spurious Free Dynamic Range

(1MHz, 20MSPS) V

(2MHz, 20MSPS) V

(5MHz, 20MSPS) V

(10MHz, 20MSPS) V

(10MHz, 20MSPS) V

Hold Noise

Droop Rate Full ±1 ±8 mV/µs

Hold Time

(8)

(9)

= ±1V Full 78 90 dBc

O

= ±1V Full 74 86 dBc

O

= ±1V Full 65 77 dBc

O

= ±1V +25°C 60 dBc

O

= ±0.5 +25°C 72 dBc

O

400xt

H

V/s rms

Full 2 µs

Feedthrough Rejection (20MHz) +25°C85dB

POWER SUPPLY

Specified Operating Voltage Full ±4.50 ± 5 ±5.50 V

Positive Supply Current

Negative Supply Current

(10)

(10)

Full 34 39 mA

Full 33 39 mA

Total Power Dissipation Full 335 390 mW

TEMPERATURE RANGE

Specification Ambient Full –40 +85 °C

Storage –55 +150 °C

Thermal Resistance,

NOTE: (1) Select (Pin 10) connected to +V

Output voltage on pin 11. (4) Pin 10 (Select) connected to +V

output step. (7) Acquisition time includes hold-to-track delay switch time. (8) Hold noise is proportional to the time in the hold mode. For example, if the hold time

θ

JA

for TTL threshold voltage on Pin 11. (2) Select (Pin 10) connected to –VS for ECL threshold voltage on Pin 11. (3)

S

. (5) Pin 10 (Select) connected to –VS. (6) Slew rate is rate of change from 10% to 90% of a 2V

S

Full 100 °C/W

is 25ns, the accumulated noise is 10µVrms. (9) This is the maximum length of time the SHC605 can remain in the hold mode and still maintain a linear droop rate.

(10) Select (Pin 10) connected to +V

.

S

®

3

SHC605

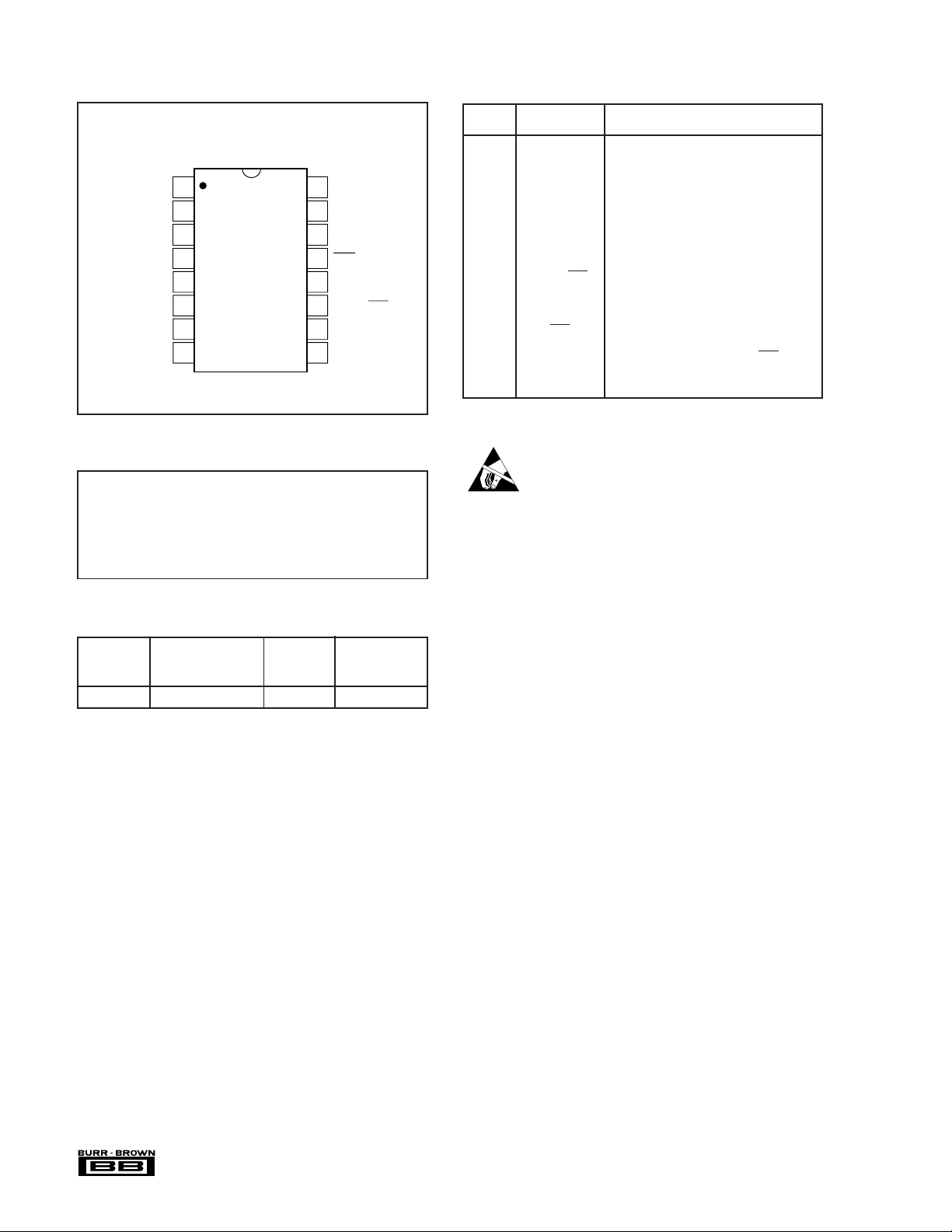

PIN CONFIGURATION PIN DESCRIPTION

PIN # SYMBOL DESCRIPTION

U Package SO-16

1

+In

2

+V

S

3

+V

S

4

DGND

5

AGND

6

AGND

7

AGND

8

–In

16

–V

15

–V

14

Lock

13

Lock

12

Hold

11

Thresh/Hold

10

Select

9

V

S

S

OUT

1 +In Non-Inverting Input

2+V

3+V

4 DGND Digital Ground

5 AGND Analog Ground

6 AGND Analog Ground

7 AGND Analog Ground

8 –In Inverting Input

9V

10 Select +5V Selects TTL; –5V Selects ECL

11 Thresh/Hold Logic threshold for single-ended

12 Hold True Hold input

13 Lock Complement Lock Input

14 Lock True Lock input; Locks SHC605 in

15 –V

16 –V

S

S

OUT

S

S

+5V Supply

+5V Supply

Output Voltage

operation or complement Hold input for

differential operation

Hold-mode regardless of Hold/Hold Inputs

–5V Supply

–5V Supply

ABSOLUTE MAXIMUM RATINGS

Supply ............................................................................................. ±7VDC

Input Voltage Range ............................................................................ ± 5V

Differential Input Voltage .................... ±5.5V (

Storage Temperature Range ..........................................–40°C to +125°C

Lead Temperature (soldering, SOIC 3s) ....................................... +260°C

Output Short Circuit to Ground (+25°C) ................. Continuous to Ground

Junction Temperture (T

) ............................................................... +175°C

j

between +In and –In inputs

PACKAGE/ORDERING INFORMATION

PACKAGE

DRAWING TEMPERATURE

PRODUCT PACKAGE NUMBER

SHC605AU SO-16 Surface-Mount 265 –40°C to +85°C

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix D of Burr-Brown IC Data Book.

(1)

RANGE

ELECTROSTATIC

DISCHARGE SENSITIVITY

)

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

®

SHC605

4

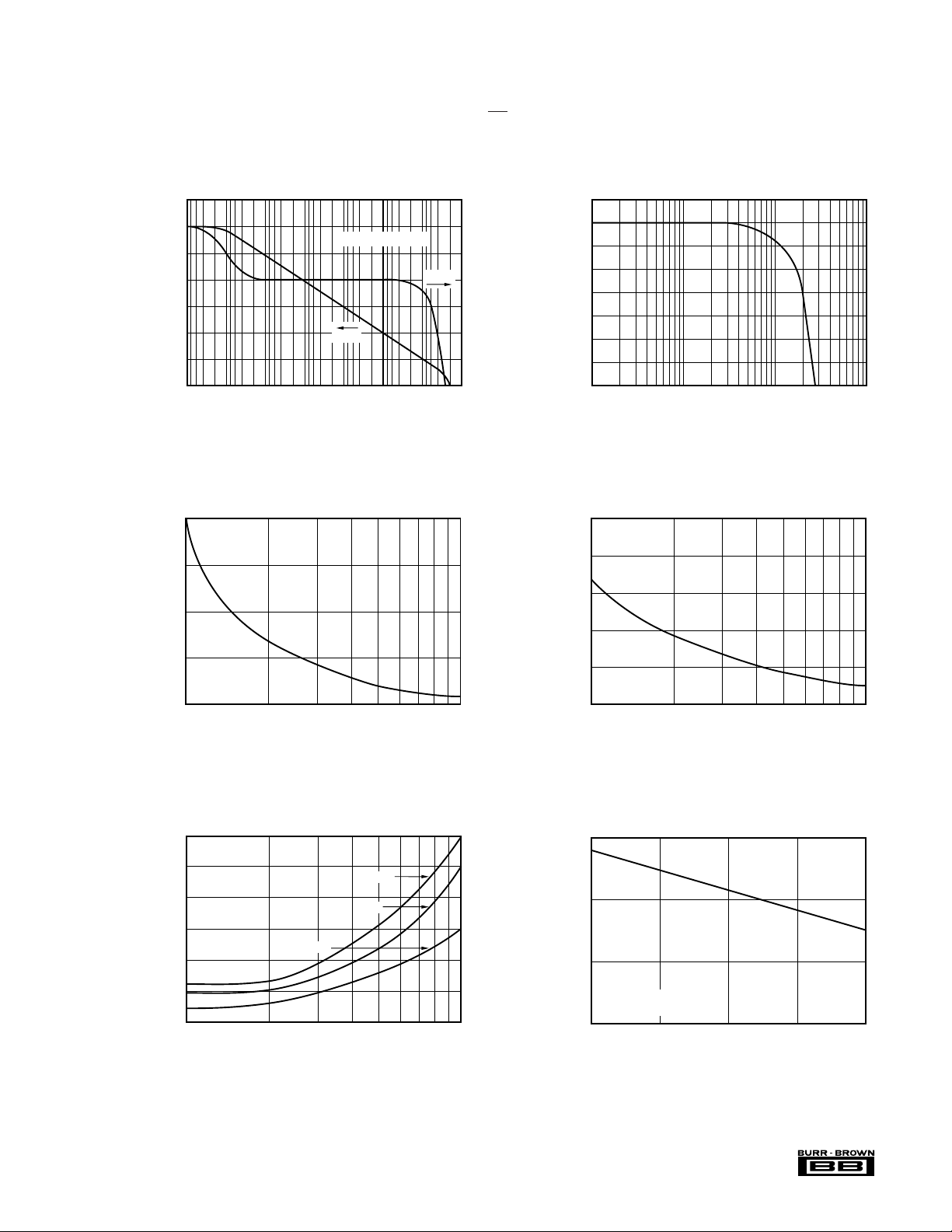

TYPICAL PERFORMANCE CURVES

INVERTING CLOSED-LOOP GAIN

vs SMALL SIGNAL BANDWIDTH

Small Signal Bandwidth (MHz)

Inverting Closed-Loop Gain (V/V)

–1 –2 –5 –10

100

80

60

40

20

0

At TA = +25°C, ±VS = ±5V, G = +1V/V, RL = 100Ω, CL = 5pF, and ECL Hold/Hold Inputs, unless otherwise noted.

OPEN-LOOP FREQUENCY RESPONSE (Track Mode)

120

100

80

60

40

20

Open-Loop Voltage Gain (dB)

0

–20

100 1k 10k 100k 1M 10M 100M 1G

Frequency (Hz)

NON-INVERTING CLOSED-LOOP GAIN

200

150

100

vs SMALL SIGNAL BANDWIDTH

Phase Margin ≈ 65°

Gain

Phase

0

–45

–90

–135

–180

–225

Phase Shift (°)

Gain (dB)

CLOSED-LOOP GAIN = +1V/V

vs FREQUENCY (Track Mode)

0

–1

–2

–3

–4

–5

–6

–7

1 10 100 1000

Frequency (MHz)

50

Small Signal Bandwidth (MHz)

0

+1 +2 +5 +10

Non-Inverting Closed-Loop Gain (V/V)

150

125

100

75

50

Acquisition Time (ns)

25

0

vs NON-INVERTING CLOSED-LOOP GAIN

+1 +2 +5 +10

ACQUISITION TIME

0.01%

0.1%

1%

Inverting Closed-Loop Gain (V/V)

75

70

SNR (dB)

65

V

OUT

60

DC 2.5 5 7.5 10

SNR vs INPUT FREQUENCY

= 2.0Vpp

20MSPS

Input Frequency (MHz)

®

5

SHC605

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, ±VS = ±5V, G = +1V/V, RL = 100Ω, CL = 5pF, and ECL Hold/Hold Inputs, unless otherwise noted.

LARGEST HARMONIC

100

95

90

85

SFDR (dB)

80

75

70

DC246810

100

90

80

vs INPUT FREQUENCY (Track Mode)

Gain = +1

Gain = +2

Input Frequency (MHz)

FEEDTHROUGH REJECTION

vs INPUT FREQUENCY

V

OUT

= 2.0Vpp

LARGEST HARMONIC

90

85

80

75

SFDR (dB)

70

65

60

DC246810

120

100

80

vs INPUT FREQUENCY (Hold Mode)

V

= 2.0Vpp

O

20MSPS

Input Frequency (MHz)

POWER SUPPLY REJECTION

vs SUPPLY RIPPLE FREQUENCY (Track Mode)

70

60

Feedthrough Rejection (dB)

50

10 20 40 60 100 200

Input Frequency (MHz)

2.5

2.0

|

1.5

1.0

Droop Rate (mV/µs)

|

0.5

0

–50 –25 0 25 50 75 100

DROOP RATE vs TEMPERATURE

Temperature (°C)

60

40

Power Supply Rejection (dB)

20

100 1000 10k 100k 1M 10M 100M

Frequency (Hz)

0

2

4

6

Pedestal (mV)

8

10

–50 –25 0 25 50 75 100

PEDESTAL vs TEMPERATURE

Temperature (°C)

®

SHC605

6

TYPICAL PERFORMANCE CURVES (CONT)

HOLD-MODE DISTORTION

AT 20MSPS, V

IN

= 5MHz

Amplitude (dB)

Frequency (MHz)

0

0

–20

–40

–60

–80

–100

–120

16 32 48 64

V

OUT

= 2Vpp

R

L

= 100Ω

V

IN

= 5MHz

f

T/H

= 20MHz

t

TRACK

= 35ns

HOLD-MODE DISTORTION

AT 20MSPS, V

IN

= 10MHz

Amplitude (dB)

Frequency (MHz)

0

0

–20

–40

–60

–80

–100

–120

16 32 48 64

V

OUT

= 2Vpp

R

L

= 100Ω

V

IN

= 10MHz

f

T/H

= 20MHz

t

TRACK

= 35ns

At TA = +25°C, ±VS = ±5V, G = +1V/V, RL = 100Ω, CL = 5pF, and ECL Hold/Hold Inputs, unless otherwise noted.

0

–20

–40

–60

Amplitude (dB)

–80

–100

–120

0

0

–20

–40

–60

Amplitude (dB)

–80

HOLD-MODE DISTORTION

AT 20MSPS, V

= 2MHz

IN

V

= 2Vpp

OUT

= 100Ω

R

L

= 2MHz

V

IN

= 20MHz

f

T/H

= 35ns

t

TRACK

2nd

51015

Frequency (MHz)

HOLD-MODE DISTORTION

3rd

= 10MHz

IN

V

OUT

= 100Ω

R

L

= 10MHz

V

IN

= 20MHz

f

T/H

t

TRACK

= 1Vpp

= 35ns

AT 20MSPS, V

2nd

2nd

3rd

2nd 3rd

–100

–120

0

16 32 48 64

Frequency (MHz)

®

7

SHC605

TIMING DEFINITIONS

Acquisition Time is the time it takes to reacquire the input

signal when switching from the hold to track mode. This

time interval starts at 50% of the clock transition and ends

when the input signal is reacquired to within a specified

accuracy at the output. This specification does not include

the track-to-hold settling time.

Aperture Delay is a measure of the track-to-hold switch

delay time. It is the difference between the analog input

amplifier’s signal path delay and the digital track-to-hold

switch delay. A positive delay indicates the digital switch

delay is larger than the analog amplifier delay.

Aperture Jitter is random variation in the aperture delay.

This specification is measured in ps-rms and results in phase

noise on the held signal. A large aperture jitter value can

manifest itself by degrading the SNR of a sampling ADC.

Droop Rate is the change of the held output voltage as a

function of time. The measurement starts immediately after

the device switches from the track to hold mode.

Feedthrough Rejection is a measure of the amount of the

input signal that “feeds through” to the output while the

device is in the hold mode. This specification is usually a

function of frequency, with degradation at higher frequencies.

Hold-to-Track Delay is the time from the track command

to the point when the output begins changing to acquire a

new signal. This delay is included in the SHC605’s specified

acquisition time.

Pedestal Offset is the error voltage step incurred at the

output when the device is switched from the track to hold

mode.

Track-to-Hold Settling Time is the time for the track to

hold transient to settle to within a specified accuracy.

Analog

Input

Analog

Output

Hold

Command

+2V

–2V

+2V

–2V

0V

0V

“1”

Aperture

Delay

Voltage

Level Held

Acquisition Time

Hold to

Track

Switch

Delay

Time

“Hold” “Track” “Hold”

Track to

Hold Settling

“0”

FIGURE 1. SHC605 Timing Diagram.

®

SHC605

8

THEORY OF OPERATION

The SHC605 is a monolithic track-and-hold circuit fabricated on an extremely fast complementary bipolar process.

Figure 2 provides a simplified circuit diagram of the SHC605.

A conventional two-stage operational amplifier is shown

with a standard differential phase compensation scheme

sometimes referred to as “doublet compensation.” Capacitors C1 and C2 compensate the amplifier in the track-mode

and hold the analog output signal in the hold-mode. Switching from track to hold is achieved by turning off the

amplifier’s input stage and isolating C

and C2 from the

1

input signal.

The differential two-stage amplifier architecture of the

SHC605 provides many performance advantages over traditional open-loop designs. The use of differential hold capacitors provides a first-order correction for many errors

including distortion, pedestal, and droop. A dominant cause

of distortion in high-speed amplifiers is the nonlinear transistor junction capacitance connected to the hold capacitor(s).

This parasitic capacitance varies as the voltage across it

changes. Most open-loop track-and-hold circuits have a

fixed gain of +1V/V, which means the hold capacitor(s) and

parasitic junction capacitance sees the full output signal

swing. In the SHC605 the second gain stage attenuates the

signal across the capacitors and greatly reduces the nonlinear capacitance. The SHC605’s second stage has a unitygain bandwidth of approximately 250MHz and its open-loop

gain rolls off at –20dB/decade. With a 2.5MHz signal, the

voltage across the hold capacitors is 100 times less than the

output signal, and therefore, the nonlinear capacitance is

greatly reduced.

The SHC605’s patented architecture provides users with an

extremely accurate high-speed operational track-and-hold

amplifier. All common operational amplifier transfer functions can be realized with the SHC605; i.e. unity-gain, noninverting gain, inverting gain, and differential gain. These

configurations are shown in Figures 3 through 6. In many

instances, the SHC605 provides a superior single-chip solution to applications previously requiring two or more devices. As with any conventional voltage feedback op amp, it

is important to consider tradeoffs between noise, bandwidth,

and settling time for these applications. Refer to Discussion

of Performance and Typical Performance Curves for more

details.

+V

S

C

2

C

Track/Hold

+In

–In

FIGURE 2. SHC605 Simplified Circuit Diagram.

C

Comp

1

G = 1 V

OUT

C

1

2

C

3

–V

S

®

9

SHC605

DISCUSSION OF

PERFORMANCE

DISTORTION

Hold-mode distortion is an important specification for a

track-and-hold amplifier. This is a measure of the accuracy

of the amplifier’s held output while sampling a sinusoidal

input signal. It includes errors from both the switching

network and the amplifier’s signal path. Hold-mode distortion depends on the input signal’s amplitude and frequency

as well as the sampling rate. The biggest cause of distortion

in the SHC605 is slew-induced nonlinearity; the higher the

amplitude of a high frequency input, the higher the distortion. Hold-mode distortion can also result from sampling too

fast or not allowing enough acquisition time or track-to-hold

settling time. The SHC605 has a typical 0.01% acquisition

time of 30ns for a 2V step, and a typical 100µV track-tohold settling time of 15ns. Thus, for 12-bit accuracy the

clock rate should not exceed 22MHz (refer to Typical

Performance Curves for details).

NOISE

The SHC605’s noise performance is almost completely

determined by track-mode noise. This is the noise sampled

by the differential hold capacitors during track-mode, which

is greater than the noise measured directly at the output. The

input referred noise of the SHC605 is 2.5nV/√Hz. For unitygain this corresponds to an output noise of approximately

35µVrms; which is much lower than the typical 150µVrms

noise sampled by the hold capacitors. The track-mode noise

sampled by the hold capacitors is independent of closedloop gain, and therefore, the SHC605 can be used with

higher closed-loop gain without degrading the overall noise

performance.

The SHC605’s noise performance is also affected by hold-

mode noise and aperture jitter. Hold-mode noise is the result

of current noise reacting with the hold capacitors. This noise

accumulates on the capacitors at a rate which is proportional

to the square root of the hold time. For sample rates above

1MHz this noise is usually insignificant. Aperture jitter

describes the random variation in track-to-hold aperture

delay, and causes increased hold-mode noise when high

slew rate signals are sampled. A differential ECL clock input

will provide lower aperture jitter than a single-ended ECL or

TTL clock.

CHOOSING THE BEST ARCHITECTURE

The SHC605 is basically a high-speed operational amplifier

which can hold its output on command. Unlike traditional

high-speed track-and-hold amplifiers, which have fixed gains

of +1V/V, the SHC605 can be used with non-inverting,

inverting, or differential gains. In many applications, a

single SHC605 can be used to solve a problem that previously required two or more devices.

Figures 3 through 6 show the SHC605 connected for noninverting, inverting, and differential gains. As with any op

amp, it is important to consider performance tradeoffs for all

of these configurations. For gains less than ±10, the SHC605’s

track-to-hold settling, pedestal offset, droop, and total holdmode noise remains constant. However, small-signal bandwidth and acquisition time will be compromised as the

closed-loop gain is increased (refer to the Typical Performance Curves for details).

+5V

1µF

V

IN

V

IN

.01µF

1

2

3

4

5

6

7

8

+In

+V

S

+V

S

DGND

AGND

AGND

AGND

–In

50Ω

–V

–V

Lock

Lock

Hold

Hold

Select

V

OUT

16

S

15

S

14

13

12

11

10

9

.01µF 1µF

NC

Hold

+5V = TTL

–5V = ECL

V

OUT

–5V

+5V

1µF

.01µF

R

1

+In

2

+V

S

3

+V

S

4

DGND

5

AGND

6

AGND

7

AGND

8

–In

249Ω

2

249Ω

V

OUT

V

IN

R

1

= 1 +

–V

–V

Lock

Lock

Hold

Hold

Select

V

OUT

16

S

15

S

14

13

12

11

10

9

R

1

R

2

.01µF

NC

FIGURE 3. Gain of +1 Track-and-Hold Amplifier. FIGURE 4. Gain of +2 Track-and-Hold Amplifier.

®

SHC605

10

–5V

1µF

Hold

+5V = TTL

–5V = ECL

V

OUT

+5V

+In

+V

S

+V

S

DGND

AGND

AGND

AGND

–In

–V

S

–V

S

Lock

Lock

Hold

Hold

Select

V

OUT

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

1µF

.01µF

.01µF 1µF

–5V

+5V

V

+IN

NC

Hold

+5V = TTL

–5V = ECL

V

OUT

249Ω

249Ω

V

–IN

249Ω

249Ω

V

OUT

R

1

R

2

= (V

+IN

– V

–IN

)

R

1

R

2

R

2

R

1

1µF

125Ω

1

+In

2

+V

S

.01µF

R

V

IN

249Ω

3

+V

S

4

DGND

5

AGND

6

AGND

7

2

AGND

8

–In

R

249Ω

Lock

Lock

Hold

Hold

Select

V

1

–V

–V

OUT

16

S

15

S

14

13

12

11

10

9

.01µF

NC

–5V

1µF

Hold

+5V = TTL

–5V = ECL

V

OUT

V

OUT

V

R

1

= –

R

IN

2

FIGURE 5. Gain of –1 Track-and-Hold Amplifier. FIGURE 6. Differential Gain of 1 Track-and-Hold Amplifier.

APPLICATIONS INFORMATION

LOGIC COMPATIBILITY/TRACK-TO-HOLD

SWITCHING

The SHC605 contains an internal reference circuit which

produces either an ECL or TTL logic threshold voltage for

single-ended track-to-hold switching. Differential ECL

switching is also possible with the SHC605. Table I provides

the proper pin connections for all of the possible switching

options and the Performance Specifications Table gives the

logic levels and input bias currents.

LOCKOUT CIRCUITRY

The SHC605 includes additional logic circuitry which allows edge-triggered operation for sampling ADCs. The

lockout comparator and Track/Hold comparator form a wiredor mode control circuit as shown in the block diagram on

page one. When the Lock input, pin 14, is high with respect

to the Lock input, pin 13, the SHC605 is in the Hold-mode

regardless of the Hold/Hold inputs. This feature provides

more flexibility in the convert command duty cycle and

reduces noise resulting from aperture jitter.

Figure 7 shows how the SHC605 lockout circuit can be used

with an ECL one-shot to provide an edge-triggered sampling

LOGIC TYPE (Pin 4) (Pin 10) (Pin 11) (Pin 12)

Single-ended TTL GND +5V NC Clock

Single-ended ECL GND –5V NC Clock

Differential ECL NC NC Clock Clock

DGND SELECT THRESH/HOLD HOLD

TABLE I. Track-to-Hold Switching Options.

V

IN

+5V

1µF

FIGURE 7. Edge-Triggered ADC.

.01µF

1

+In

2

+V

S

3

+V

S

4

DGND

5

AGND

6

AGND

7

AGND

8

–In

50Ω

Select

–V

–V

Lock

Lock

Hold

Hold

V

OUT

16

S

15

S

14

13

12

11

10

9

.01µF

V

OUT

ADC. An ECL threshold voltage is generated on Thresh/

Hold (Pin 11), which is connected to Lock (Pin 13), to allow

a single-ended lockout input on Lock (Pin 14). The ECL

convert command is applied directly to the SHC605. The

10ns delay on the ADCs convert signal is to allow for

SHC605 track-to-hold settling. The one-shot’s duty cycle

ECL Convert Command

1µF

–5V

(10ns minimum pulsewidth)

ECL

One-Shot

11

10ns

Delay

Line

Convert

ADC

HOLD LOCK MODE

0 0 Track

0 1 Hold

1 0 Hold

1 1 Hold

Digital

Output

SHC605

®

will depend on the ADC conversion time. In this application

the one-shot is used to set the critical ADC timing which

means the user has more freedom in selecting the convert

command duty cycle. Since the convert command is applied

directly to the SHC605—instead of after additional logic

and clock conditioning—aperture jitter noise is minimized.

OFFSET VOLTAGE ADJUSTMENT

The SHC605’s input offset voltage is laser-trimmed and will

require no further adjustment for most applications. However, if additional adjustment is needed, the circuit in Figure

8 can be used without degrading offset drift with temperature. Avoid external adjustment whenever possible since

extraneous noise, such as power supply noise, can be inadvertently coupled into the amplifier’s inverting input. Remember that additional offset errors can be created by the

amplifier’s input bias currents. Whenever possible, match

the impedance seen by both inputs as is shown with R

. This

3

will reduce input offset voltage errors due to the amplifier’s

input offset current, which is typically only 0.2µA.

20kΩ

+V

–V

CC

R

TRIM

47kΩ

CC

R

1

R3 = R1 || R

8

1

R

SHC605

2

2

9

(1)

damage can cause subtle changes in SHC605 input characteristics without necessarily destroying the device. In precision track-and-hold amplifiers, this may cause a noticeable

degradation in performance. Therefore, static protection is

recommended when handling the SHC605.

+V

CC

ESD Protection Diodes Internally

Connected to All Pins

External

Pin

–V

CC

Internal

Circuitry

FIGURE 9. Internal ESD Protection.

LAYOUT AND BYPASSING

For best performance, good high speed design techniques

must be applied. The component (top) side ground plane

should be as large as possible and continuous (not fragmented). Two ounce copper cladding is recommended.

All traces should be as short as possible, especially the

output. As much of the ground plane as possible should be

removed from around the +In, –In, and V

pins to reduce

OUT

parasitic capacitance and minimize coupling onto the analog

signal path.

Power supply decoupling capacitors must be used as shown

in Figures 3 through 6. The 0.01µF capacitors should be low

inductance surface mount devices and should be connected

as close to the SHC605 ±Vs leads as possible (within 30

mils). The 1µF low frequency bypass capacitors should be

tantalum capacitors (preferably surface mount) and should

be located within one inch of the SHC605. Surface mount

resistors are also recommended and should be placed as

close to the SHC605 as possible to minimize inductance.

VIN or Ground

R

Output Trim Range ≈ +VCC to –V

NOTE: (1) R3 is optional and can be used to cancel

offset errors due to input bias currents.

2

R

TRIM

R

2

CC

R

TRIM

FIGURE 8. Offset Voltage Trim.

INPUT PROTECTION

The SHC605 incorporates on-chip ESD protection diodes as

shown in Figure 9. All pins on the SHC605 are internally

protected from ESD by means of a pair of back-to-back

reverse-biased diodes to either power supply as shown.

These diodes will begin to conduct when the input voltage

exceeds either power supply by about 0.7V. This situation

can occur with loss of the amplifier’s power supplies while

a signal source is still present. The diodes can typically

withstand a continuous current of 30mA without destruction. To insure long term reliability diode current should be

externally limited to 10mA or so whenever possible. Static

®

SHC605

CAPACITIVE LOADS

The SHC605’s output stage has been optimized to drive

resistive loads as low as 50Ω. Capacitive loads will decrease

the amplifier’s phase margin which may cause high frequency peaking or oscillations. Capacitive loads greater than

10pF should be buffered by connecting a small resistance,

usually 20Ω to 50Ω, in series with the output as shown in

(R

is typically 20Ω to 50Ω)

8

SHC605

1

S

R

S

9

R

L

FIGURE 10. Driving Capacitance Load.

12

C

L

Figure 10. This is particularly important when driving high

capacitance loads such as flash A/D converters.

The series resistor, R

SHC605 as possible. If R

, should be connected as close to the

S

causes excessive output attenua-

S

tion, add closed-loop gain to the SHC605 as shown in

Figures 4 through 6.

In general, capacitive loads should be minimized for optimum high frequency performance. Coax lines can be driven

if the cable is properly terminated. The capacitance of

coaxial cable (29pF/foot for RG-58) will not load the amplifier when the coaxial cable or transmission line is terminated

in its characteristic impedance.

APPLICATIONS

The SHC605’s combination of high speed and accuracy,

small size, and low price makes it ideally suited for many

data acquisition applications. Its versatile operational amplifier architecture and switching flexibility provides users

with an extremely reliable single-chip solution to problems

that previously required several components. Figures 11

through 16 show many application circuits using the SHC605.

These include high-speed flash and sub-ranging ADC driving, multi-channel simultaneous sampling, DAC deglitching,

and peak detecting.

Analog

Sampling

FIGURE 11. Sampling ADC.

Analog Input

Ch 1

Ch 2

Ch 3

Ch 4

Input

Clock

Analog

MUX

SHC605

Channel

Select

Hold

Timing

Circuit

SHC605

High-speed Sub-ranging

Hold

or Flash

ADC

Convert

ADC

Digital

Output

Digital

Output

Convert

Sampling

Clock

FIGURE 12. Traditional Data Acquisition System.

Timing

Circuit

13

®

SHC605

Analog Inputs

Ch 1

SHC605

Hold

Ch 2

Ch 3

Ch 4

SHC605

SHC605

SHC605

Hold

Hold

Hold

Analog

MUX

Sampling

Clock

FIGURE 13. Multi-Channel Simultaneous Sampling System.

I Channel

Q Channel

SHC605

Hold

SHC605

Hold

Channel

Select

100Ω

100Ω

–

+

+

–

A

OPA678

B

SHC605

Timing

Circuit

Channel

Select

Hold

ADC

ADC

Convert

Digital

Output

Convert

Digital

Output

Sampling

Clock

FIGURE 14. I/Q Channel Simultaneous Sampling.

®

SHC605

Timing

Circuit

14

Analog

Input

Track

FIGURE 15. High-Speed Peak Detector.

SHC605

Hold

Hold

Input

2µs

max

Output

V

OUT

Comparator

with Hysteresis

Digital

Input

Sampling

Clock

DAC

Intput

DAC

Output

Hold

Track

SHC605

Output

DAC

Convert

011...1

Timing

Circuit

100...0

SHC605

Hold

V

OUT

FIGURE 16. DAC Deglitcher.

15

®

SHC605

Loading...

Loading...