Page 1

1 SHC5320

®

SHC5320

FEATURES

● ACQUISITION TIME TO 0.01%: 1.5µs max

● HOLD MODE SETTLING TIME: 350ns max

● DROOP RATE AT +25°C: 0.5µV/µs max

● TTL COMPATIBLE

● FULL DIFFERENTIAL INPUTS

● INTERNAL HOLDING CAPACITOR

● TWO TEMPERATURE RANGES:

–40°C to +85°C (KH, KP, KU)

–55°C to +125°C (SH)

● PACKAGE OPTIONS: Ceramic and Plastic

DIP-14, SO-16

DESCRIPTION

The SHC5320 is a bipolar, monolithic, sample/hold

circuit designed for use in precision, high-speed, dataacquisition applications.

The circuit employs an input transconductance amplifier capable of providing large amounts of charging

current to the holding capacitor, thus enabling fast

acquisition times. It also incorporates a low leakage

analog switch and an output integrating amplifier with

input bias current optimized to assure low droop rates.

Since the analog switch always drives into a load at

virtual ground, charge injection into the holding capacitor is constant over the entire input voltage range.

As a result, the charge offset (pedestal voltage) resulting from this charge injection can be adjusted to zero

by use of the offset adjustment capability. The device

includes an internal holding capacitor to simplify ease

of application; however, provision is also made to add

additional external capacitance to improve the output

voltage droop rate.

The SHC5320 is manufactured using a dielectric isolation process which minimizes stray capacitance (enabling higher-speed operation), and eliminates latchup associated with substrate SCRs. The SHC5320KH,

KP, and KU feature fully specified operation over the

extended industrial temperature range of –40°C to

+85°C, while the SHC5320SH operates over the temperature range of –55°C to +125°C. The device requires ±15V supplies for operation, and is packaged in

a reliable 14-pin ceramic or plastic dual-in-line package, as well as a 16-pin surface mount plastic package.

FPO

APPLICA TIONS

● PRECISION DATA ACQUISITION

SYSTEMS

● DIGITAL-TO-ANALOG CONVERTER

DEGLITCHER

● AUTO ZERO CIRCUITS

● PEAK DETECTORS

100pF

Output

Bandwidth

Control

Reference

Common

+

–

External

Hold

Capacitor

Offset

Adjust

–Input

+Input

Mode

Control

High-Speed, Bipolar, Monolithic

SAMPLE/HOLD AMPLIFIER

© 1985 Burr-Brown Corporation PDS-585G Printed in U.S.A. April, 2000

®

For most current data sheet and other product

information, visit www.burr-brown.com

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

Page 2

2SHC5320

®

SPECIFICATIONS

At +25°C, rated power supplies, gain = +1, and with internal holding capacitor, unless otherwise noted.

SHC5320KH, KP, KU SHC5320SH

PARAMETERS MIN TYP MAX MIN TYP MAX UNITS

INPUT CHARACTERISTICS

ANALOG

Voltage Range ±10 ✻ V

Common-Mode Range ±10 ✻ V

Input Resistance 1 5 ✻✻ MΩ

Input Capacitance 3 ✻ pF

Bias Current ±100 ±300 ±70 ±200 nA

Bias Current Over Temperature Range ±300 ±200 nA

Offset Current ±30 ±300 ✻ ±100 nA

Offset Current Over Temperature Range ±300 ±100 nA

DIGITAL (Over Temperature Range)

V

IH

(Logic “1”) 2.0 ✻ V

V

IL

(Logic “0”) 0.8 ✻ V

I

IH

(VI = +5V) 0.1 ✻ µA

I

IL

(VI = 0V) 4 ✻ µA

Logic “0” = SAMPLE

Logic “1” = HOLD

OUTPUT CHARACTERISTICS

Voltage Range ±10 ✻ V

Current ±10 ✻ mA

Output Impedance (Hold Mode) 1 ✻ Ω

Noise, DC to 10MHz: Sample Hold 125 200 ✻✻µVrms

Hold Mode 125 200 ✻✻µVrms

DC ACCURACY/STABILITY

Gain, Open Loop, DC 3 x 10

5

2 x 10

6

10

6

✻ V/V

Input Offset Voltage ±0.5 ±0.2 mV

Input Offset Voltage Over Temperature Range ±1.5 ±2mV

Input Offset Voltage Drift ±5 ±20 ✻ ±15 µV/°C

CMRR

(1)

72 90 80 ✻ dB

Power Supply Rejection

(2)

:+V

CC

80 ✻ dB

–V

CC

65 ✻ dB

HOLD-TO-SAMPLE MODE

DYNAMIC CHARACTERISTICS

Acquisition Time, A = –1, 10V Step

(3)

:

to ±0.01% 1 1.5 ✻✻µs

to ±0.1% 0.8 1.2 ✻✻µs

SAMPLE MODE

Gain-Bandwidth Product (Gain = +1)

(4)

:

C

H

= 100pF 2 ✻ MHz

C

H

= 1000pF 180 ✻ kHz

Full Power Bandwidth

(5)

600 ✻ kHz

Slew Rate

(6)

45 ✻ V/µs

Rise Time

(4)

100 ✻ ns

Overshoot

(4)

15 ✻ %

SAMPLE-TO-HOLD MODE

DYNAMIC CHARACTERISTICS

Aperture Time

(7)

25 ✻ ns

Effective Aperture Time –50 –25 0 ✻✻✻ns

Aperture Uncertainty (Aperture Jitter) 0.3 ✻ ns

Charge Offset (Pedestal)

(8)

(Adjustable to Zero) 1 5 ✻✻mV

Charge Transfer

(8)

0.1 0.5 ✻✻pC

Sample-to-Hold Transient Settling Time

to ±0.01% of FSR 165 350 ✻✻ns

HOLD MODE

Droop

(9)

0.08 0.5 ✻✻µV/µs

Droop at Maximum Temperature

(9)

1.2 100 17 ✻ µV/µs

Drift Current

(9)

850 ✻✻pA

Drift Current at Maximum Temperature

(9)

0.12 10 1.7 ✻ nA

Feedthrough, 10Vp-p, 100kHz Sinewave 2 ✻ mV

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

Page 3

3 SHC5320

®

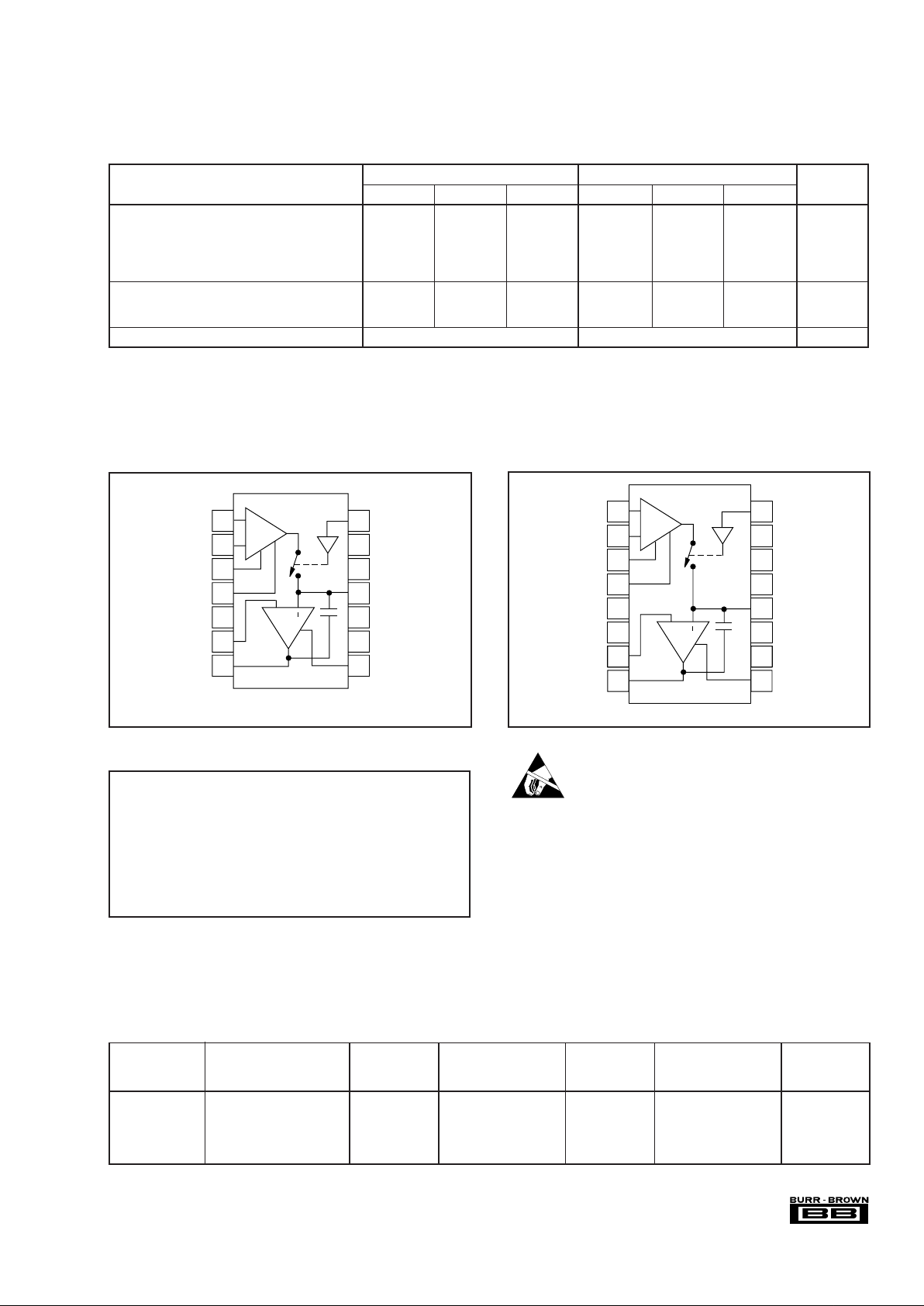

Hermetic Ceramic

Top View DIP

+

1

2

3

4

5

6

7

14

13

12

11

10

9

8

–Input

+Input

Offset Adjustment

Offset Adjustment

–V

CC

Reference

Common

Output

Mode Control

Supply Common

NC

External Hold

Capacitor

NC

+V

CC

Bandwidth Control

SHC5320KH, KP

SHC5320KU

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

–Input

+Input

Offset Adjustment

Offset Adjustment

NC

–V

CC

Reference

Common

Output

Mode Control

Supply Common

NC

NC

External Hold

Capacitor

NC

+V

CC

Bandwidth Control

+

PIN CONNECTIONS

Voltage Between +VCC and –VCC Terminals ......................................... 40V

Input Voltage........................................................... Actual Supply Voltage

Differential Input Voltage ................................................................... ±24V

Digital Input Voltage.................................................................. +15V, –1V

Output Current, continuous

(2)

......................................................... ±20mA

Internal Power Dissipation ............................................................. 450mW

Storage Temperature Range .................................... –65°C < T

A

< +150°C

Output Short-Circuit Duration

(3)

.........................................................None

Lead Temperature (soldering, 10s) ................................................. 300°C

CAUTION: These devices are sensitive to electrostatic discharge.

Appropriate I.C. handling procedures should be followed.

NOTES: (1) Absolute maximum ratings are limiting values, applied individually,

beyond which the serviceability of the circuit may be impaired. Functional

operation under any of these conditions is not necessarily implied. Absolute

maximum ratings apply to both dice and package parts, unless otherwise noted.

(2) Internal power dissipation may limit output current to less than +20mA. (3)

WARNING: This device cannot withstand even a momentary short circuit

to either supply.

ABSOLUTE MAXIMUM RATINGS

(1)

Top View SO

SPECIFICATIONS (Cont.)

At +25°C, rated power supplies, gain = +1, and with internal holding capacitor, unless otherwise noted.

SHC5320KH, KP, KU SHC5320SH

PARAMETERS MIN TYP MAX MIN TYP MAX UNITS

POWER SUPPLIES

+V

CC

+12 +15 +18 ✻✻✻V

–V

CC

–12 –15 –18 ✻✻✻V

+I

CC

(+VCC = 15V)

(9)

11 13 ✻✻mA

–I

CC

(–VCC = 15V)

(9)

–11 –13 ✻✻mA

TEMPERATURE

Specification –40 +85 –55 +125 °C

Storage –65 +150 ✻✻°C

PACKAGE Hermetic Ceramic, Plastic DIP, SO

✻ Specification the same as SCH5320KH, KP, KU.

NOTES: (1) V

CM

= ±5VDC. (2) Based on a ±0.5V swing for each supply with all other supplies held constant. (3) VO = 10V step, RL = 2kΩ, CL = 50pF. (4) VO = 200mVp-p,

R

L

= 2kΩ, CL = 50pF. (5) VIN = 20Vp-p, RL = 2kΩ, CL = 50pF, unattenuated output. (6) VO = 20V step, RL = 2kΩ, CL = 50pF. (7) Simulated only, not tested. (8) VIN =

0V, V

IH

= +3.5V, tR < 20ns (VIL to VIH). (9) Specified for zero differential input voltage between pins 1 and 2. Supply current will increase with differential input (as may

occur in the Hold mode) to approximately ±28mA average at 20V differential.

PACKAGE SPECIFIED

DRAWING TEMPERATURE PACKAGE ORDERING TRANSPORT

PRODUCT PACKAGE NUMBER RANGE MARKING NUMBER

(1)

MEDIA

SHC5320KH CERDIP-14 163 –40°C to +85°C SHC5320KH SHC5320KH Rail

SHC5320KP DIP-14 010 –40°C to +85°C SHC5320KP SHC5320KP Rail

SHC5320KU SO-16 211 –40°C to +85°C SHC5320KU SHC5320KU Rail

""""SHC5320KU SHC5320KU/1K Tape and Reel

SHC5320SH CERDIP-14 163 –55°C to +125°C SHC5320SH SHC5320SH Rail

NOTE: (1) Models with a slash (/) are available only in Tape and Reel in the quantities indicated (e.g., /1K indicates 1000 devices per reel). Ordering 1000 pieces

of “SHC5320KU/1K” will get a single 1000-piece Tape and Reel.

PACKAGE/ORDERING INFORMATION

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

Page 4

4SHC5320

®

TYPICAL PERFORMANCE CURVES

±VCC = 15V.

TYPICAL SAMPLE/HOLD PERFORMANCE

AS FUNCTION OF HOLDING CAPACITOR

10

5

100 1000 10 100 1M

1.0

0.5

0.1

0.05

0.01

Charge Offset

Error (mV)

Voltage Droop (mV/100ms)

during Hold Mode

Acquisition Time (µs)

for 10V Step to ±0.01%

C Value (pF)

H

CHARGE OFFSET

vs MODE CONTROL (V ) VOLTAGE

IH

2.0

1.5

1.0

0.5

0

Hold Step Voltage (mV)

12345

+25°C

+75°C

C = 100pF

H

Logic Level High (V)

OPEN-LOOP GAIN

AND PHASE RESPONSE

120

100

80

60

40

20

0

Gain (dB)

1

Fre

q

uency (Hz

)

10 100 1k 10k 100k 1M 10M

CH = 1100pF

CH = 100pF

G

G

θ

–45

0

45

90

135

180

225

Phase (degrees)

DRIFT CURRENT

vs TEMPERATURE

10k

1k

100

10

1

0

–50

Temperature (°C)

–25 0 25 50

75

100 125

C = 100pF

H

I (pA)

DRIFT

Page 5

5 SHC5320

®

Input

Feed-

though

Output

Slew Rate

Limited

Settling

Time

SampleMode ControlSample

Offset

Aperture Time

Hold

Acquisition

Time

Aperture

Uncertainty

Droop

Settling

Time

Sample-to-Hold

Transient and

Charge Offset

DISCUSSION OF

SPECIFICATIONS

WHAT IS A SAMPLE/HOLD AMPLIFIER?

A sample/hold amplifier (also sometimes called a track-andhold amplifier) is a circuit that captures and holds an analog

voltage at a specific point in time under control of an

external circuit, such as a microprocessor. This type of

circuit has many applications; however, its primary use is in

data acquisition systems which require that the voltage be

captured and held during the analog-to-digital conversion

process. Use of a sample/hold effectively increases the

bandwidth of a data acquisition system by a significant

amount. For further discussion of this capability, refer to

“Signal Digitization” in the Applications section of this data

sheet.

The ideal sample/hold amplifier in its simplest form contains

four primary components as illustrated in Figure 1, although

in actual practice they may not be internally connected

exactly as shown. Amplifier A1, the input buffer, provides a

high impedance load to the source circuit and supplies

charging current to the holding capacitor CH. Switch S

1

opens and closes under external control to gate the buffered

input signal to the holding circuit or to remove it so that the

most recently sampled signal will be held. Amplifier A

2

serves to present a high impedance load to the holding

capacitor and to provide a low impedance voltage source for

external loads. A minimum of three terminals are provided

for the user: input, output, and mode control (or sample/hold

control). When S1, is closed, the output signal follows the

input signal, subject to errors imposed by amplifier bandwidth and other errors as discussed below. When S1, is

opened, the voltage stored on the holding capacitor will be

held indefinitely (in the ideal case), and will appear at the

output of the circuit until S1, is again closed under command

of the mode control signal.

FIGURE 2. Illustration of Sample/Hold Specifications.

actual acquisition time to be highly dependent on the amplitude of the voltage to be acquired, relative to the value

already held by the capacitor. Therefore, proper specification of sample/hold amplifier performance includes definition of both output value step size and required error band

accuracy.

Aperture Time (or aperture delay time) is the time required

for switch S1, to open and remove the charging signal from

the capacitor after the mode control signal has changed from

“sample” to “hold.” This time is measured from the 50%

point of the Hold mode transition to the time at which the

output stops tracking the input. This parameter is very

important in applications for which the input signal is

changing very rapidly when the Hold mode is initiated.

Effective Aperture Time is the difference in propagation

delay times of the analog signal and the mode control signal

from their respective input pins to switch S1. This time may

be negative, zero, or positive. A negative value indicates that

the mode control propagation delay is shorter than the

analog propagation delay, with the result that the analog

value present on the capacitor at the time the switch opens

occurred earlier than the application of the mode control

signal by the amount of the effective aperture delay time.

Aperture Uncertainty (or aperture jitter) is the variation

observed in the aperture time over a large number of observations. This parameter is important when the analog input

is a rapidly changing signal, as aperture uncertainty contributes to lack of knowledge (at the output) about the true value

of the input at the precise time the Hold mode is initiated.

The maximum input frequency for a given acceptable error

contribution due to aperture uncertainty is

f

MAX

= Maximum Fractional Error/2πt

U

where Maximum Fractional Error (MFE) is the ratio of the

maximum allowable error voltage to peak voltage, and tU is

the aperture uncertainty time. For a bipolar ±10V signal and

a maximum uncertainty error of 1/2LSB in a 12-bit system,

the MFE is equal to 1/2LSB ÷ V

PEAK

= 2.44mV ÷ 10V =

0.000244V/V, since 1/2LSB = 2.44mV for a 20V full-scale

range.

For the same system operating with a unipolar 0V to 10V

signal, MFE would be 0.000122V/V.

The following discussion of specifications covers the critical

types of errors which may be experienced in applications of

a sample/hold amplifier. These errors are depicted graphically in Figure 2, and in the Typical Performance Curves.

Acquisition Time is the time required for the sample/hold

output to settle within a given error band of its final value

after the sample mode is initiated. Included in this time are

effects of switch delay time, slew rate of the buffer amplifier, and settling time for a specified change in held voltage

value. Slew rate limitations of the buffer amplifier will cause

FIGURE 1. Ideal Sample/Hold Amplifier.

+

–

+

–

Input

Mode

Control

Output

C

H

S

1

A

1

A

2

Page 6

6SHC5320

®

Charge Offset (pedestal) is the output voltage change that

results from charge transfer into the hold capacitor through

stray capacitance when the Hold mode command is given.

This charge appears as an offset voltage at the output, and in

some sample/hold amplifiers may be a function of the input

voltage.

Charge offset is specified for the SHC5320 using only the

internal holding capacitor. When an external capacitor is

added, charge offset is calculated as Charge Transfer (pC)

divided by total hold capacitance. Charge Transfer is also

specified for the SHC5320, and total hold capacitance is the

sum of the internal hold capacitor value (100pF) and the

external hold capacitor. Since charge transfer is not a function of analog input voltage for the SHC5320, this error may

be removed by means of the offset adjustment capability of

the amplifier.

Droop Rate is the change in output voltage over time during

the Hold mode as a result of hold capacitor leakage, switch

leakage, and bias current of the output amplifier. Droop rate

varies with temperature and the quality of the external

holding capacitor, if used. Careful circuit layout is also

required to minimize droop.

Drift Current is the net leakage current affecting the hold

capacitor during the Hold mode. With knowledge of the drift

current, droop can be calculated as:

Droop (V/s) = ID(pA)/CH(pF)

Hold Mode Feedthrough is the fraction of the input signal

which appears at the output while in the Hold mode. It is

primarily a function of switch capacitance, but may also be

increased by poor layout practices.

Hold Mode Settling Time is the time required for the sampleto-hold transient to settle within a specified error band.

OPERATING INSTRUCTIONS

(Developed Around 14-Pin Package)

OFFSET ADJUSTMENT

The offset should be adjusted with the input grounded.

During the adjustment, the sample/hold should be switching

continuously between the Sample and the Hold modes. The

offset should then be adjusted to zero output for the periods

when the amplifier is in the Hold mode. In this way, the

effects of both amplifier offset and charge offset will be

accounted for.

SAMPLE/HOLD CONTROL

A TTL logic “0” applied to pin 14 switches the SHC5320

into the Sample (track) mode. In this mode, the device acts

as an amplifier which exhibits normal operational amplifier

behavior, with the relationship of output to input signal

depending upon the circuit configuration selected (see the

Installation section below). Application of a logic “1” to pin

14 switches the SHC5320 into the Hold mode, with the

output voltage held constant at the value present when the

hold command is given. Pin 14 presents less than one

LSTTL load to the driving circuit throughout the full operating temperature range.

ADDITION OF AN EXTERNAL CAPACITOR

The SHC5320 contains an internal 100pF MOS holding

capacitor, sufficient for most high-speed applications. If

improved droop performance is desired (with increased

acquisition time), additional capacitance may be added between pins 7 and 11. If an external holding capacitor CH is

used, then a noise-bandwidth capacitor with a value 0.1C

H

should be connected from pin 8 to ground. The exact value

and type of this bandwidth capacitor are not critical.

Capacitors with high insulation resistance and low dielectric

absorption, such as Teflon® or polystyrene units, should be

used as storage elements (polystyrene should not be used

above +85°C). Care should be taken in the printed circuit

layout to minimize leakage currents from the capacitor to

minimize droop errors.

The value of the external capacitor determines the droop,

charge offset, and acquisition time of the sample/hold. Both

droop and charge offset will vary linearly with total hold

capacitance from the values given in the specification table

for the internal 100pF capacitor. The behavior of acquisition

time versus total hold capacitance is shown in the Typical

Performance Curves.

OUTPUT PROTECTION

In order to optimize high-frequency performance of this

device, output protection is not included. This high frequency performance is mandatory for a good sample/hold,

which must absorb high-frequency changes in load current

when driving a successive-approximation A/D converter.

Due to the lack of output protection, the output circuit will

not tolerate an indefinite short to common, but a momentary

short is permissible. The output should never be shorted to

a supply.

INSTALLATION

(Developed Around 14-Pin Package)

LAYOUT PRECAUTIONS

Since the holding capacitor is connected to virtual ground at

one end (pin 11) and to a low-impedance voltage source at

the other (pin 7), the SHC5320 does not require the use of

guard rings and other careful layout techniques which are

required by many sample/hold circuits. However, normal

good layout practice should be observed, minimizing the

possibility of leakage paths across the holding capacitor. As

in all digital-analog circuits, analog signal lines on the

circuit board should cross digital signal paths at right angles

whenever possible.

GROUNDING AND BYPASSING

Pin 6 (Reference Common) should be connected to the

system analog signal common as close to the unit as possible. Likewise, pin 13 (Supply Common) should be connected to the system supply common. If the system design

prevents running these two common lines separately, they

should be connected together close to the unit, preferably to

Teflon® Du Pont Corporation

Page 7

7 SHC5320

®

a large ground plane surrounding the sample/hold. Bypass

capacitors (0.01µF to 0.1µF ceramic in parallel with 1µF to

10µF tantalum) should be connected from each power supply terminal of the device to pin 13 (Supply Common).

OFFSET ADJUSTMENT

Offset adjustment capability may be achieved by connecting

a 10kΩ, 10-turn potentiometer as illustrated in Figure 3.

FIGURE 5. Noninverting Configuration with Gain = 1 + R

2/R1

.

NONINVERTING MODE

The most common application of the SHC5320 will utilize

the connection illustrated in Figure 4. In this mode of

operation, the sample/hold will operate as a unity-gain

noninverting amplifier when in the Sample mode, and the

output signal will track the input. The high bandwidth of the

SHC5320 and the large open-loop gain assure that gain error

will be minimized.

INVERTING MODE

Unlike most sample/holds, the SHC5320 may also be connected to act as an inverting amplifier, as shown in Figure 6.

For this configuration, the gain is equal to –R2/R1.

INPUT OVERLOAD PROTECTION

It is possible that the input transconductance amplifier of the

SHC5320 will saturate when the unit is in the Hold mode,

due to a non-zero differential signal appearing between pins

1 and 2. This differential signal may be the result of a rapidly

changing input signal or application of a new channel from

an input multiplexer. When the input buffer is saturated in

this fashion, acquisition time may be degraded because of

the time required for the buffer to recover from saturation. In

addition, the input buffer, which is designed to provide large

amounts of charging current to the output integrator, may

draw large amounts of supply current which may exceed

40mA peak in some applications. For these reasons, it is

desirable to limit the differential voltage which may appear

at the summing junction of the input buffer. Figures 7 and 8

illustrate possible methods of providing this voltage limitation for the inverting and noninverting configurations. The

FIGURE 6. Inverting Configuration with Gain = –(R2/R1).

–V

CC

10kΩ

SHC5320

3

4

5

FIGURE 3. Connection of Offset Adjustment Potentiometer.

FIGURE 4. Noninverting Unity-Gain Connections.

When sampling lower-amplitude signals, the SHC5320 may

also be connected as a noninverting amplifier with gain, as

illustrated in Figure 5. In this circuit the gain of the amplifier

is equal to –R2/R1 when sampling.

The Burr-Brown SHC5320 uses current sources to bias the

internal amplifiers. This means that the bias of the amplifiers

is not dependent on the common-mode voltage of the input

signal. This makes the spurious free dynamic range in the

non-inverting mode equal that of the inverting mode.

11

7

1

2

Input

14

Mode

Control

68

Signal

Common

0.1 C

H

Optional

External C

H

11

7

1

2

Input

14

Mode

Control

68

Signal

Common

0.1 C

H

Optional

External C

H

R

2

R

1

11

7

1

2

Input

14

Mode

Control

68

Signal

Common

0.1 C

H

Optional

External C

H

100pF

R

2

R

1

Page 8

8SHC5320

®

diodes may be Schottky diodes, which will provide the

fastest clamping action and lowest clamping voltage, but

fast signal diodes such as IN914 will also work in most

applications. In each configuration the value of R1 should be

large enough to avoid excessive loading of the input signal

source. Similarly, R2 should have a value of 2kΩ or greater

to insure sufficient load current capability from the sample/

hold. If the value of R2 becomes too large, however, the

added capacitance of the diodes may change the sample/hold

phase response enough to cause oscillation.

APPLICATIONS

(Developed Around 14-Pin Package)

SIGNAL DIGITIZATION

Sample/hold amplifiers are normally used to hold input

voltages to an A/D converter constant during conversion.

Digitizing errors result if the analog signal being digitized

varies excessively during conversion.

For example, the Burr-Brown ADC80MAH-12 is a 12-bit

successive-approximation converter with a 25µs conversion

time. To insure the accuracy of the output data, the analog

input signal to the A/D converter must not change more than

1/2LSB during conversion.

The maximum rate of change of a sine wave of frequency,

f, is dv/dt (max) = 2πAf(V/s). If one allows a 1/2LSB change

(2.44mV) for a ±10V input swing to the A/D converter, the

allowable input rate-of-change limit would be 2.44mV/25µs

= 0.0976mV/µs. Thus the sampled sinusoidal signal frequency limit is

f = (0.0976 x 103)/2πA = 15.5/A (Hz),

where A is the peak amplitude of the sine wave. For a ±10V

sine wave, this corresponds to a frequency of 1.6Hz, hardly

acceptable for the majority of sampled data systems.

However, a sample/hold in front of the A/D converter

“freezes” the converter’s input signal whenever it is necessary to make a conversion. The rate-of-change limitation

calculated above no longer exists. If a sample/hold has

acquired an input signal and is tracking it, the sample/hold

can be commanded to hold it at any instant in time. There is

a short delay (aperture delay) between the time the hold

command is asserted and the time the circuit actually holds.

The hold command signal can usually be advanced in time

(or delayed, in the case of negative effective aperture delay)

to cause the amplifier to hold the signal actually desired.

Aperture uncertainty (also called aperture jitter) is also a key

consideration. For the SHC5320 there is a 300ps period

during which the signal should not change more than the

amount allowed for aperture uncertainty in the system error

budget, perhaps 1/2LSB for a 12-bit system. For a ±10V

input range (1/2LSB = 2.44mV), the input signal rate of

change limitation is 2.44mV/0.3ns = 8.13mV/ns. The equivalent input sine wave frequency is

f = 8.13 X 106/2πA = 1.29/A (MHz),

a factor of almost 84,000 higher than using the A/D alone.

However, there are other considerations. The resampling

rate of an ADC80/SHC5320 combination is 26.5µs (25µs

A/D) conversion time plus 1.5µs S/H acquisition time).

Sampling a sine wave at the Nyquist rate, this permits a

maximum input signal frequency of 37.7kHz. The above

analysis assumes that the droop rate of the sample/hold is

negligible—less than 1/2LSB during the conversion time—

and that the large signal bandwidth response of the sample/

hold causes negligible waveform distortion. Both of these

assumptions are valid for the SHC5320 in this application.

DATA ACQUISITION

The SHC5320 may be used to hold data for analog-to-digital

conversion or may be used to provide pulse-amplitude

modulation (PAM) data output (see Figures 9 and 10).

FIGURE 9. Typical Data Acquisition Configuration.

Analog

Inputs

SHC5320

Analog

Multiplexer

(

Burr-Brown MPC Series

)

Mode

Control

Signal

Common

1

2

7

A/D

Converter

PAM Output

14 6

FIGURE 7. Input Overload Protection—Inverting Configu-

ration.

FIGURE 8. Input Overload Protection—Noninverting Con-

figuration.

R

2

1

2

R

1

Input

Output

7

R

2

1

2

Output

7

Input

R

1

Page 9

9 SHC5320

®

FIGURE 10. PAM Output.

Hold

Sample

Mode

Control

Analog Input

PAM Output

DATA DISTRIBUTION

The SHC5320 may be used to hold the output of a digitalto-analog converter and distribute several different analog

voltages to different loads (see Figure 11).

HIGH-SPEED DATA ACQUISITION

The minimum sample time for one channel in a data acquisition system is usually considered to be the acquisition time

of the sample/hold plus the conversion time of the A/D

converter. If two or more sample/holds are used with a

multiplexer (such as the Burr-Brown MPC800 or MPC801)

as shown in Figure 12, the acquisition time of the sample/

hold can be virtually eliminated. While the first channel is in

hold and switched into the A/ D converter, the multiplexer

may be addressed to the next channel. The second sample/

hold will have acquired this signal by the time the conversion is complete. Then, the sample/holds reverse roles and

another channel is addressed. In low level systems an instrumentation amplifier (such as the Burr-Brown INA101) and

a differential multiplexer (such as the Burr-Brown MPC509A

or MPC507A) may be required in front of the sample/hold.

The settling and acquisition times of the multiplexer, instrumentation amplifier, and sample/hold can be eliminated

from the total conversion time as before by operating in this

overlapped mode with the sample/holds.

Additional SHC5320 Units

D/A

Converter

Parallel

Inputs

Digital

Inputs

Mode

Control

Logic

SHC5320

1

2

14 6

Analog

Outputs

Channel 1

SHC5320

1

2

14 6

Channel 2

SHC5320

1

2

14 6

Channel N

Signal

Common

7

7

7

FIGURE 11. Typical Data Distribution Configuration.

Page 10

10SHC5320

®

FIGURE 12. Typical Overlapped Sample/Hold Configuration.

SHC5320

No. 1

1

2

14 6

SHC5320

No. 2

1

2

14 6

Signal

Common

Mode

Control

Signal

Common

“0”

“1”

Burr-Brown

A/D

Converter

Digital

Output

Burr-Brown

Analog

Multiplexer

Analog

Inputs

7

7

Loading...

Loading...