Page 1

ICs for Consumer Electronics

VPS-Decoder

SDA 5642-6/X

Data Sheet 02.97

Page 2

SDA 5642-6/X

Revision History: Current Version: 02.97

Previous Version:

Page

(in previous

Version)

Page

(in current

Version)

Subjects (major changes since last revision)

Edition 02.97

This edition was realized using the software system FrameMaker

Published by Siemens AG,

Bereich Halbleiter, MarketingKommunikation, Balanstraße 73,

81541 München

.

© Siemens AG 1997.

All Rights Reserved.

Attention please!

As far as patents or other rights of third parties are concerned, liability is only assumed for components, not for applications, processes

and circuits implemented within components or assemblies.

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved.

For questions on technology, delivery and prices please contact the Semiconductor Group Offices in Germany or the Siemens Companies

and Representatives worldwide (see address list).

Due to technical requirements components may contain dangerous substances. For information on the types in question please contact

your nearest Siemens Office, Semiconductor Group.

Siemens AG is an approved CECC manufacturer.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest sales office. By agreement we

will take packing material back, if it is sorted. You must bear the costs of transport.

For packing material that is returned to us unsorted or which we are not obliged to accept, we shall have to invoice you for any costs incurred.

Components used in life-support devices or systems must be expressly authorized for such purpose!

Critical components1 of the Semiconductor Group of Siemens AG, may only be used in life-support devices or systems

written approval of the Semiconductor Group of Siemens AG.

1 A critical component is a component used in a life-support device or system whose failure can reasonably be expected to cause the

failure of that life-support device or system, or to affect its safety or effectiveness of that device or system.

2 Life support devices or systems are intended (a) to be implanted in the human body, or (b) to support and/or maintain and sustain hu-

man life. If they fail, it is reasonable to assume that the health of the user may be endangered.

2

with the express

Page 3

SDA 5642-6/X

Table of Contents Page

1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 I

2.2.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Chip Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.3 Write Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.4 Read Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Order of Data Output on the I

2.4 Description of DAVN and EHB Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2

C Bus and Bit Allocation . . . . . . . . . . . . . . . 12

3 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 VPS-Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Control Register Write (I

5.2 Data Register Read (I

2

C-Bus Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2

C-Bus Read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 DAVN and EHB Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Position of VPS Data Lines within the Vertical Blanking Interval . . . . . . . . . 23

5.5 Definition of Voltage Levels for VPS Data Line . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Data Format of Programme Delivery Data in the Dedicated TV Line (VPS) 24

6 Package Outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Purchase of Siemens I2C components conveys the license under the Philips I2C patent to use the components

2

in the I

Semiconductor Group 3 02.97

C system provided the system conforms to the I2C specifications defined by Philips.

Page 4

VPS-Decoder SDA 5642-6/X

MOS

1 General Description

The SDA 5642-6 VPS decoder chip receives all VPS

data.

1.1 Features

• On chip data slicer

• Low external component count

2

C-Bus interface

• I

communication with external microcontroller

• 5 V supply voltage

• Video input signal level: 0.7 Vpp to 2.0 Vpp

• Technology: CMOS

• P-DIP-14-1 and P-DSO-20-1 package

P-DIP-14-1

P-DSO-20-1

Type Ordering Code Package

SDA 5642-6 Q67100-H5182 P-DIP-14-1

SDA 5642-6X Q67106-H5183 P-DSO-20-1 (SMD)

Semiconductor Group 4 02.97

Page 5

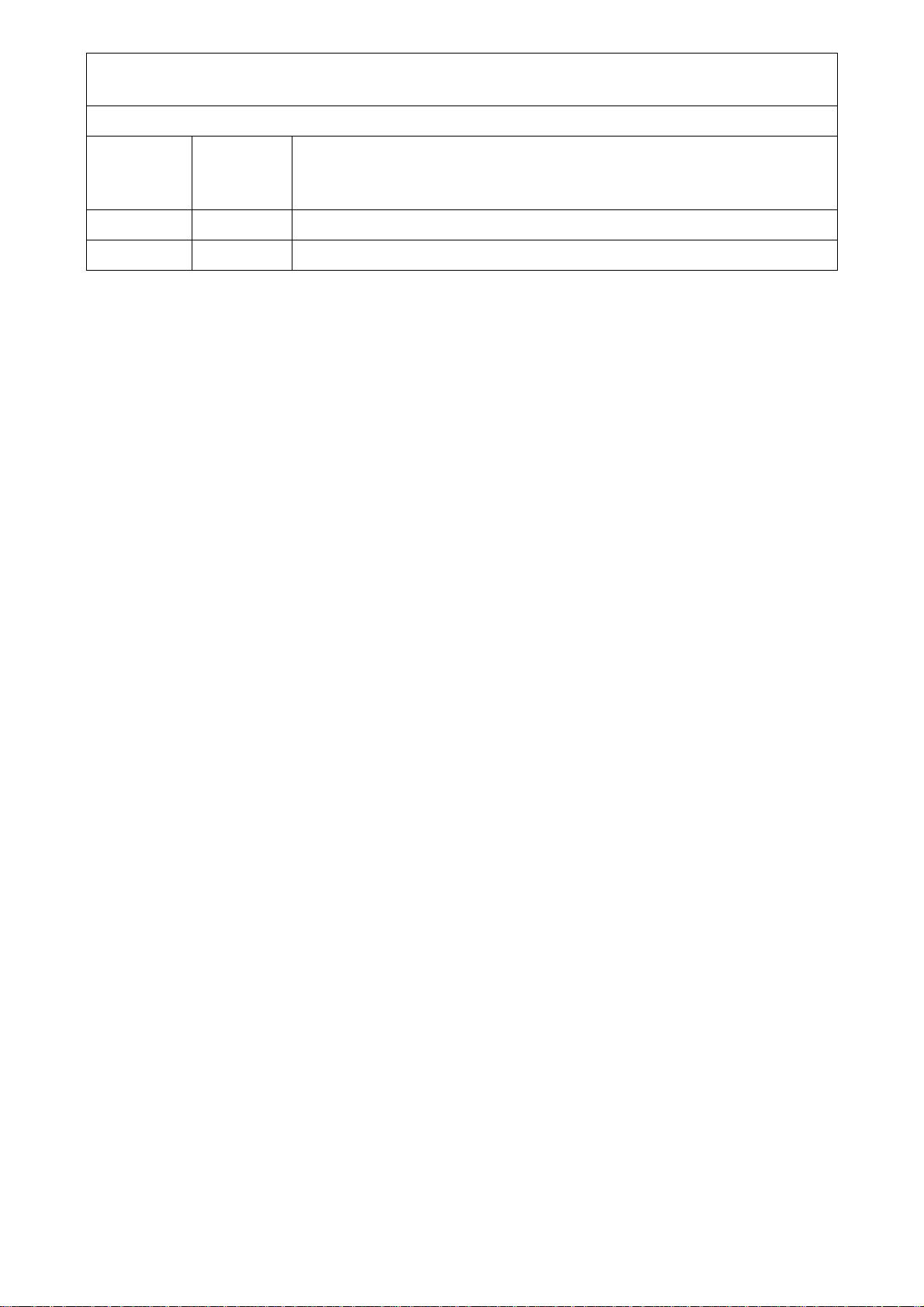

1.2 Pin Configurations

P-DIP-14-1 P-DSO-20-1

SDA 5642-6/X

Figure 1

Semiconductor Group 5 02.97

Page 6

1.3 Pin Description

Pin No. Symbol Function

P-DIP-14-1 P-DSO-20-1

SDA 5642-6/X

1 V

1

2

V

V

SS

SSA

SSD

Ground (0 V)

Analog ground (0 V)

Digital ground (0 V)

3, 8, 13, 18 N.C. Not connected

2 4 SCL Serial clock input of I

3 5 SDA Serial data input of I

4 6 CS0 Chip select input determining the I

20

/ 21H, when pulled low

H

22

/ 23H, when pulled high.

H

2

C Bus.

2

C Bus.

2

C-Bus addresses:

5 7 VCS Video Composite Sync output from sync slicer used

for PLL based clock generation.

6 9 DAVN Data available output active low, when VPS data is

received.

7 10 EHB Output signaling the presence of the first field active

high.

8 11 TI Test input; activates test mode when pulled high.

Connect to ground for operating mode.

9 12 PD1 Phase detector/charge pump output of data PLL

(DAPLL).

10 14 PD2/

Connector of the loop filter for the SYSPLL.

VCO2

11 15 VCO1 Input to the voltage controlled oscillator #1 of the

DAPLL.

12 16

I

REF

Reference current input for the on-chip analog circuit.

13 17 CVBS Composite video signal input.

14

19

V

V

DD

DDD

Positive supply voltage (+ 5 V nom.).

Positive supply voltage for the digital circuits

(+ 5 V nom.).

20

V

DDA

Positive supply voltage for the analog circuits

(+ 5 V nom.).

Semiconductor Group 6 02.97

Page 7

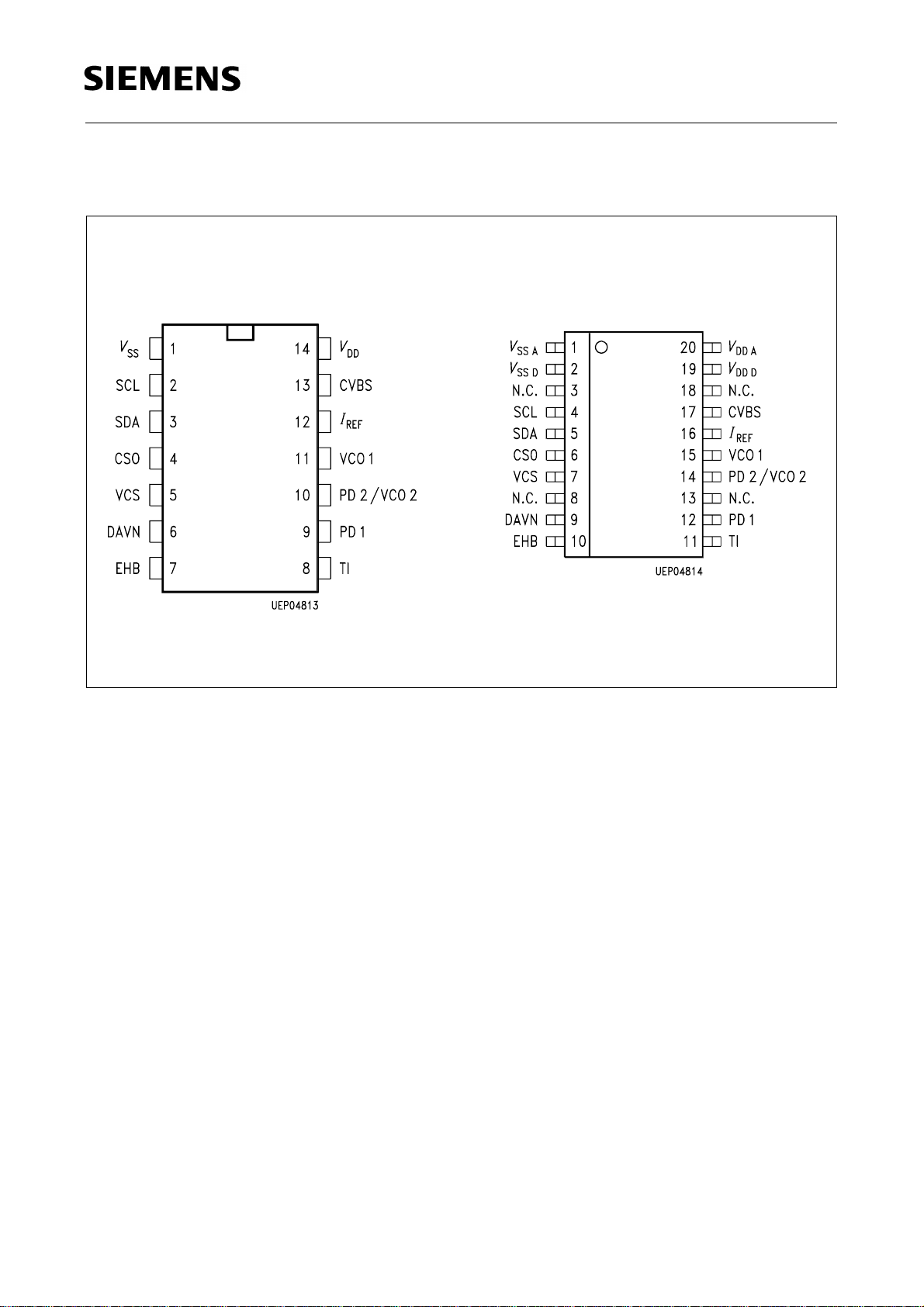

1.4 Block Diagram

SDA 5642-6/X

Figure 2

Semiconductor Group 7 02.97

Page 8

SDA 5642-6/X

2 System Description

2.1 Functions

Referring to the functional block diagram of the VPS decoder, the composite video signal

with negative going sync pulses is coupled to the pin CVBS through a capacitor which is

used for clamping the bottom of the sync pulses to an internally fixed level. The signal is

passed on to the slicer, an analogue circuitry separating the sync and the data parts of

the CVBS signal, thus yielding the digital composite sync signal VCS and a digital data

signal for further processing by comparing those signals to internally generated slicing

levels.

The output of the sync separator is forwarded, on one hand, to the output pin VCS, and

on the other hand, to the clock generator and the timing block. The VCS signal

represents a key signal that is used for deriving a system clock signal by means of a PLL

and all other timing signal.

The data slicer separates the data signal from the CVBS signal by comparing the video

voltage to an internally generated slicing level which is found by averaging the data

signal during TV line no. 16.

The clock generator delivers the system clock needed for the basic timing as well as for

the regeneraton of the dataclock. It is based on two phase locked loops (PLL’s) all parts

of which are integrated on chip with the exception of the loop filter components. Each of

the PLL’s is composed of a voltage controlled relaxation oscillator (VCO), a phase/

frequency detector (PFD), and a charge pump which converts the digital output signals

of the PFD to an analogue current. That current is transformed to a control voltage for

the VCO by the off-chip loop filter. The generated VCO frequency is 10 MHz.

All signals necessary for the control of sync and data slicing as well as for the data

acquisition are generated by the Timing block.

The extracted data bits of TV line no. 16 are checked for biphase errors. With no biphase

errors encountered, the acquired bytes are stored in the transfer register to the I

2

C Bus.

That transfer is signalled by a H/L transition of the DAVN output.

Data are updated when a new data line has been received, provided that the chip is not

accessed via the I2C Bus at the same time.

2

A micro controller can read the stored bytes via the I

C-Bus interface at any time.

However, one must be aware that the storage of new data from the acquisition interface

is inhibited as long as the VPS decoder is being accessed via the I

2

C Bus.

Semiconductor Group 8 02.97

Page 9

SDA 5642-6/X

2.2 I2C Bus

2.2.1 General Information

2

The I

i.e., both reading from and writing to the VPS decoder is possible. The clock line SCL is

controlled only by the bus master usually being a micro controller, whereas the SDA line

is controlled either by the master or by the slave. A data transfer can only be initiated by

the bus master when the bus is free, i.e., both SDA and SCL lines are in a high state. As

a general rule for the I

The only exception to that rule are the Start Condition and the Stop Condition. Further

Details are given below. The following abbreviations are used:

START: Start Condition generated by master

AS: Acknowledge by slave

AM: Acknowledge by master

NAM: No Acknowledge by master

STOP: Stop condition generated by master

C-Bus interface implemented on the VPS decoder is a slave transmitter/receiver,

2

C Bus, the SDA line changes state only when the SCL line is low.

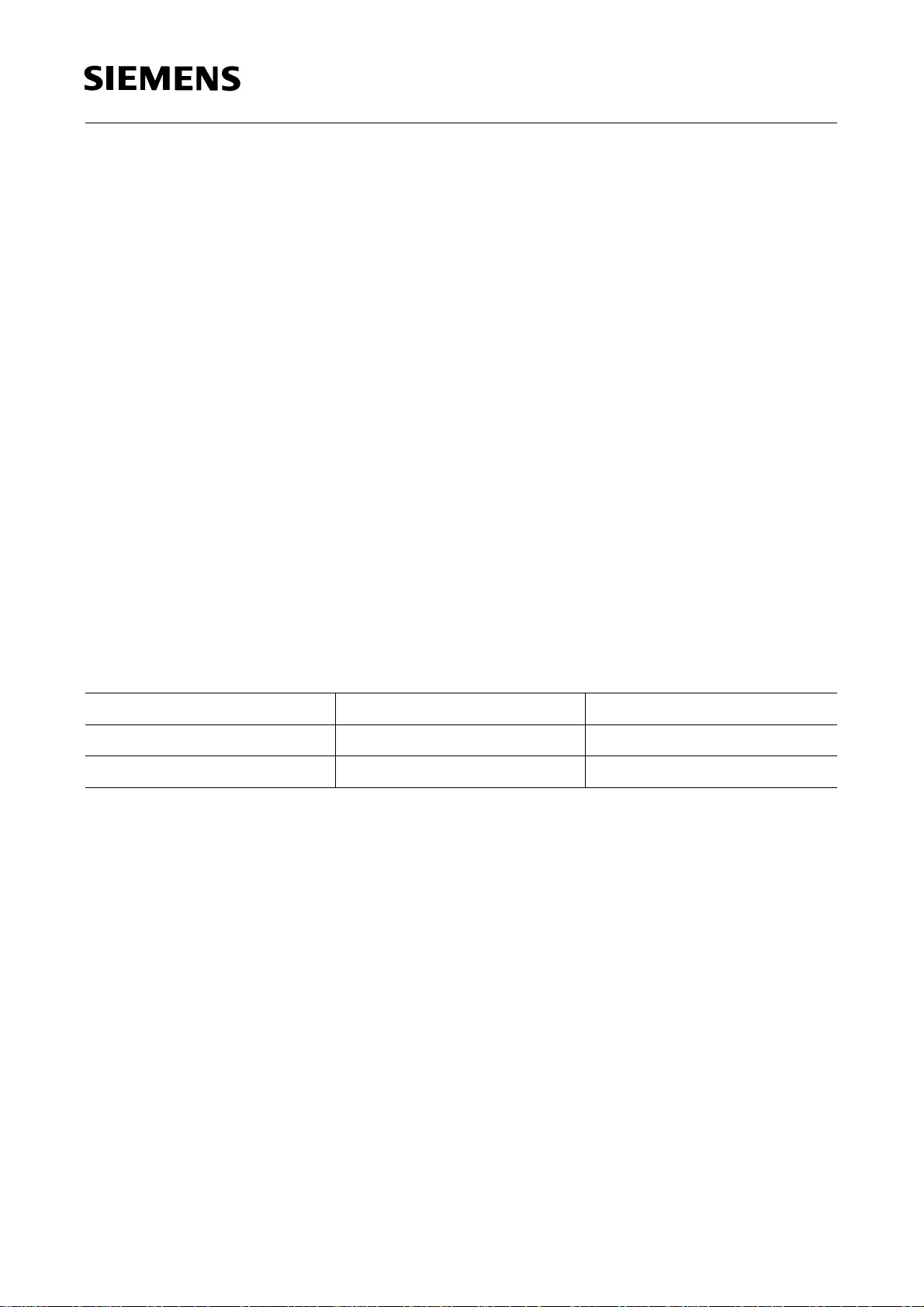

2.2.2 Chip Address

There are two pairs of chip addresses, which are selected by the CS0-input pin

according to the following table:

CS0 Input Write Mode Read Mode

Low 20 (hex) 21 (hex)

High 22 (hex) 23 (hex)

Semiconductor Group 9 02.97

Page 10

SDA 5642-6/X

2.2.3 Write Mode

For writing to the VPS decoder, the following format has to be used:

Start Chipaddress and Write Mode AS Byte to set Control Register AS Stop

Description of Data Transfer (Write Mode)

Step1: In order to start a data transfer the master generates a Start Condition on the

bus by pulling the SDA line low while the SCL line is held high.

Step 2: The bus master puts the chip address on the SDA line during the next eight

SCL pulses.

Step 3: The master releases the SDA line during the ninth clock pulse. Thus the slave

can generate an acknowledge (AS) by pulling the SDA line to a low level.

Step 4: The controller transmits the data byte to set the Control register

Step 5: The slave acknowledges the reception of the byte.

Step 6: The master concludes the data communication by generating a Stop

Condition.

2

The write mode is used to set the I

C-Bus control register which determines the

operating mode:

Control Register:

Bit Number: 76543210

T7 T6 T5 T4 T3 T2 T1 T0

Default: All bits are set to 0 on power-up.

The bits T4 through T7 are used for test purposes and must not be changed for normal

operation by user software! (0 = normal operation)

You may write 00H, 01H, 02H, 03H, 04H, 05H, 06H, 07H, 08H, 09H, 0AH, 0BH, 0CH,

0DH, 0EH, 0FH to the register without efect. This enables the SDA 5642-6 to be used

for VPS decoding instead of the SDA 5050 or SDA 5649 without software problems.

Semiconductor Group 10 02.97

Page 11

SDA 5642-6/X

2.2.4 Read Mode

For reading from the VPS decoder, the following format has to be used

Start Chipaddress Read Mode AS 1st Byte AM ..... Last Byte NAM Stop

:

The contents of up to 16 registers (bytes) can be read starting with byte 1 bit 7 (refer to

2

the table Order of Data Output on the I

operating mode.

Description of Data Transfer (Read Mode)

Step1: To start a data transfer the master generates a Start Condition on the bus by

pulling the SDA line low while the SCL line is held high. The byte address

counter in the decoder is reset and points to the first byte to be output.

Step 2: The bus master puts the chip address on the SDA line during the next eight

SCL pulses.

C Bus and...) depending on the selected

Step 3: The master releases the SDA line during the ninth clock pulse. Thus the slave

can generate an acknowledge (AS) by pulling the SDA line to a low level. At

this moment, the slave switches to transmitting mode.

Step 4: During the next eight clock pulses the slave puts the addressed data byte

onto the SDA line.

Step 5: The reception of the byte is acknowledged by the master device which, in

turn, pulls down the SDA line during the next SCL clock pulse. By

acknowledging a byte, the master prompts the slave to increment its internal

address counter and to provide the output of the next data byte.

Step 6: Steps no. 4 and no. 5 are repeated, until the desired amount of bytes have

been read.

Step 7: The last byte is output by the slave since it will not be acknowledged by the

master.

Step 8: To conclude the read operation, the master doesn’t acknowledge the last byte

to be received. A No Acknowledge by the master (NAM) causes the slave to

switch from transmitting to receiving mode. Note that the master can

prematurely cease any reading operation by not acknowledging a byte.

Step 9: The master gains control over the SDA line and concludes the data transfer

by generating a Stop Condition on the bus, i. e., by producing a low/high

transition on the SDA line while the SCL line is in a high state. With the SDA

2

and the SCL lines being both in a high state, the I

C Bus is free and ready for

another data transfer to be started.

Semiconductor Group 11 02.97

Page 12

2.3 Order of Data Output on the I2C Bus and Bit Allocation

2

I

C Bus VPS Mode

t

Byte 1 bit 7

byte 11 bit 0

6

5

4

3

2

1

0

1)

1

2

3

4

5

6

7

SDA 5642-6/X

Byte 2 bit 7

Byte 3 bit 7

Byte 4 bit 7

byte 12 bit 0

6

5

4

3

2

1

0

1

2

3

4

5

6

7

byte 13 bit 0

6

5

4

3

2

1

0

1

2

3

4

5

6

7

byte 14 bit 0

6

5

4

3

2

1

0

1

2

3

4

5

6

7

1)

Transmission bit number

Semiconductor Group 12 02.97

Page 13

SDA 5642-6/X

2.3 Order of Data Output on the I

2

I

C Bus VPS Mode

Byte 5 bit 7

byte 5 bit 0

6

5

4

3

2

1

0

Byte 6 bit 7

byte 15 bit 0

6

5

4

3

2

1

0

2

C Bus and Bit Allocation (cont’d)

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Byte 7 bit 7

1)

Transmission bit number

– set to “1”

6

5

4

3

2

1

0

– set to “1”

– set to “1”

– set to “1”

– set to “1”

– set to “1”

– set to “1”

– set to “1”

Semiconductor Group 13 02.97

Page 14

2.4 Description of DAVN and EHB Outputs

DAVN (Data Valid active low)

EHB (First Field active high)

Signal Output VPS Mode

DAVN

SDA 5642-6/X

H/L-transition

in line 16 when valid VPS data is received

(set low)

L/H-transition

at the start of line 16

(set high)

always set high on power-up or during I

2

C-Bus accesses when the

bus master doesn’t acknowledge in order to

generate the stop condition

EHB

L/H-transition at the beginning of the first field

H/L-transition at the beginning of the second field

In test mode (i.e. TI = high), both DAVN and EHB are controlled by the CS0 pin and

reproduce the state of the CS0 input.

Semiconductor Group 14 02.97

Page 15

SDA 5642-6/X

3 Electrical Characteristics

Absolute Maximum Ratings

T

= 25 °C

A

Parameter Symbol Limit Values Unit Test

min. typ. max.

Condition

Ambient temperature

Storage temperature

Total power dissipation

Power dissipation per

T

T

P

P

A

stg

tot

DQ

070°C in operation

– 40 125 °C by storage

300 mW

10 mW

output

Input voltage

Supply voltage

Thermal resistance

V

V

R

IM

DD

th SU

– 0.3 6 V

– 0.3 6 V

80 K/W

Note: Maximum ratings are absolute ratings; exceeding any one of these values may

cause irreversible damage to the integrated circuit.

Operating Range

Supply voltage

Supply current

V

I

DD

DD

4.5 5 5.5 V

515mA

Ambient temperature

T

A

070°C

range

Note: In the operating range the functions given in the circuit description are fulfilled.

Semiconductor Group 15 02.97

Page 16

SDA 5642-6/X

Electrical Characteristics

T

= 25 °C

A

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Input Signals SDA, SCL, CS0

H-input voltage

L-input voltage

Input capacitance

Input current

V

V

C

I

Input Signal TI

H-input voltage V

L-input voltage

Input capacitance

Input current

V

C

I

Input Signals CVBS

(pos. Video, neg. Sync)

Video input signal

V

level

IH

IL

I

IM

IH

IL

I

IM

CVBS

0.7 × V

DD

V

DD

V

0 0.3 × VDDV

10 pF

10 µA

0.9 × V

DD

V

DD

V

0 0.1 × VDDV

10 pF

10 µA

0.7 1.0 2.0 V 2 Vpp with

0.8 V

1.2 V

V

SYNC

V

DAT

and

Synchron signal

amplitude

V

SYNC

0.15 0.3 0.8 (1.0) V 1.0 V only related

to VCS signal

generation

Data amplitude

Coupling capacitor

H-input current

L-input current

Source impedance

Leakage resistance

V

C

I

I

R

R

DAT

IH

IL

S

C

0.25

1.5 ×

C

V

SYNC

0.5 1.2 V

33 nF

10 µA VI=5V

– 1000 – 400 – 100 µA VI=0V

250 Ω

0.91 1 1.2 MΩ

at coupling capacitor

Semiconductor Group 16 02.97

Page 17

SDA 5642-6/X

Electrical Characteristics (cont’d)

T

= 25 °C

A

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Output Signals DAVN, EHB, VCS

H-output voltage

L-output voltage

V

V

QH

QL

V

– 0.5 V IQ= – 100 µA

DD

0.4 V IQ= 1.6 mA

Output Signals SDA (Open-Drain-Stage)

L-output voltage V

Permissible output

QL

0.4 V IQ= 3.0 mA

5.5 V

voltage

PLL-Loop Filter Components (see application circuit)

Resistance at PD2/

R

1

6.8 kΩ

VCO2

Resistance at VCO1

Attenuation

R

R

2

3

1200 kΩ

6.8 kΩ

resistance

Resistance at PD2/

R

5

1200 kΩ

VCO2

Integration capacitor

Integration capacitor

C

C

1

3

2.2 nF

33 nF

VCO – Frequence Range Adjustment

Resistance at IREF

R

4

100 kΩ

(for bias current

adjustment)

Note: The listed characteristics are ensured over the operating range of the integrated

circuit. Typical characteristics specify mean values expected over the production

spread. If not otherwise specified, typical characteristics apply at

T

= 25°C and

A

the given supply voltage.

Semiconductor Group 17 02.97

Page 18

SDA 5642-6/X

Figure 3

2

I

C-Bus Timing

Parameter Symbol Limit Values Unit

min. max.

Clock frequency f

Inactive time prior to new transmission start-up

Hold time during start condition

Low-period of clock

High-period of clock

Set-up time for data

Rise time for SDA and SCL signal

Fall time for SDA and SCL signal

Set-up time for SCL clock during stop condition

V

All values referred to

and VIL levels.

IH

SCL

t

BUF

t

HD; STA

t

LOW

t

HIGH

t

SU;DAT

t

TLH

t

THL

t

SU; STO

0 100 kHz

4.7 µs

4.0 µs

4.7 µs

4.0 µs

250 ns

1 µs

300 ns

4.7 µs

Semiconductor Group 18 02.97

Page 19

4 VPS-Receiver

SDA 5642-6/X

Figure 4

Semiconductor Group 19 02.97

Page 20

5 Appendix

5.1 Control Register Write (I

2

C-Bus Write)

SDA 5642-6/X

Figure 5

Semiconductor Group 20 02.97

Page 21

5.2 Data Register Read (I2C-Bus Read)

SDA 5642-6/X

Figure 6

Semiconductor Group 21 02.97

Page 22

5.3 DAVN and EHB Timing

SDA 5642-6/X

Figure 7

Semiconductor Group 22 02.97

Page 23

SDA 5642-6/X

5.4 Position of VPS Data Lines within the Vertical Blanking Interval

Figure 8

1)

(shown for first field)

5.5 Definition of Voltage Levels for VPS Data Line

Figure 9

Semiconductor Group 23 02.97

Page 24

SDA 5642-6/X

5.6 Data Format of Programme Delivery Data in the Dedicated TV Line (VPS)

Figure 10

Semiconductor Group 24 02.97

Page 25

SDA 5642-6/X

Figure 11

Semiconductor Group 25 02.97

Page 26

6 Package Outlines

P-DIP-14-1

(Plastic Dual In-line Package)

SDA 5642-6/X

Sorts of Packing

Package outlines for tubes, trays etc. are contained in our

Data Book “Package Information”.

GPD05005

Dimensions in mm

Semiconductor Group 26 02.97

Page 27

P-DSO-20-1

(Plastic Dual Small Outline Package)

SDA 5642-6/X

Sorts of Packing

Package outlines for tubes, trays etc. are contained in our

Data Book “Package Information”.

SMD = Surface Mounted Device

GPS05094

Dimensions in mm

Semiconductor Group 27 02.97

Loading...

Loading...