Page 1

Data Sheet 05.94

Microcomputer Components

SAB 88C1 66/88C166W

16-Bit CMOS Single-Chip Microcontrollers

with/without oscillator prescaler

with 32 KByte Flash EPROM

Page 2

C16x-Family of

SAB 88C166(W)

High-Performance CMOS 16-Bit Microcontrollers

Preliminary

SAB 88C166(W) 16-Bit Microcontrollers with 32 KByte Flash EPROM

High Performance 16-bit CPU with 4-Stage Pipeline

●

●

100 ns Instruction Cycle Time at 20 MHz CPU Clock

500 ns Multiplication (16 × 16 bit), 1 µs Division (32 / 16 bit)

●

●

Enhanced Boolean Bit Manipulation Facilities

● Register-Based Design with Multiple Variable Register Banks

●

Single-Cycle Context Switching Support

●

Up to 256 KBytes Linear Address Space for Code and Data

1 KByte On-Chip RAM

●

●

32 KBytes On-Chip Flash EPROM with Bank Erase Feature

Read-Protectable Flash Memory

●

●

Dedicated Flash Control Register with Operation Lock Mechanism

● 12 V External Flash Programming Voltage

●

Flash Program Verify and Erase Verify Modes

●

100 Flash Program/Erase Cycles guaranteed

●

Programmable External Bus Characteristics for Different Address Ranges

●

8-Bit or 16-Bit External Data Bus

Multiplexed or Demultiplexed External Address/Data Buses

●

●

Hold and Hold-Acknowledge Bus Arbitration Support

● 512 Bytes On-Chip Special Function Register Area

●

Idle and Power Down Modes

●

8-Channel Interrupt-Driven Single-Cycle Data Transfer Facilities via Peripheral Event

Controller (PEC)

●

16-Priority-Level Interrupt System

10-Channel 10-bit A/D Converter with 9.7 µs Conversion Time

●

●

16-Channel Capture/Compare Unit

● Two Multi-Functional General Purpose Timer Units with 5 Timers

●

Two Serial Channels (USARTs)

●

Programmable Watchdog Timer

●

Up to 76 General Purpose I/O Lines

●

Direct clock input without prescaler in the SAB 88C166W (SAB 88C166 with prescaler)

Supported by a Wealth of Development Tools like C-Compilers, Macro-Assembler Packages,

●

Emulators, Evaluation Boards, HLL-Debuggers, Simulators, Logic Analyzer Disassemblers,

Programming Boards

●

On-Chip Bootstrap Loader

●

100-Pin Plastic MQFP Package (EIAJ)

Semiconductor Group 1 05.94

Page 3

SAB 88C166(W)

Introduction

The SAB 88C166 and the SAB 88C166W are members of the Siemens SAB 80C166 family of full

featured single-chip CMOS microcontrollers. They combine high CPU performance (up to 10 million

instructions per second) with high peripheral functionality, enhanced IO-capabilities and an on-chip

reprogrammable 32 KByte Flash EPROM.

The SAB 88C166W derives its CPU clock signal (operating clock) directly from the on-chip oscillator

without using a prescaler, as known from the SAB 80C166W/83C166W. This reduces the device’s

EME.

The SAB 88C166 operates at half the oscillator clock frequency (using a 2:1 oscillator prescaler), as

known from the SAB 80C166/83C166.

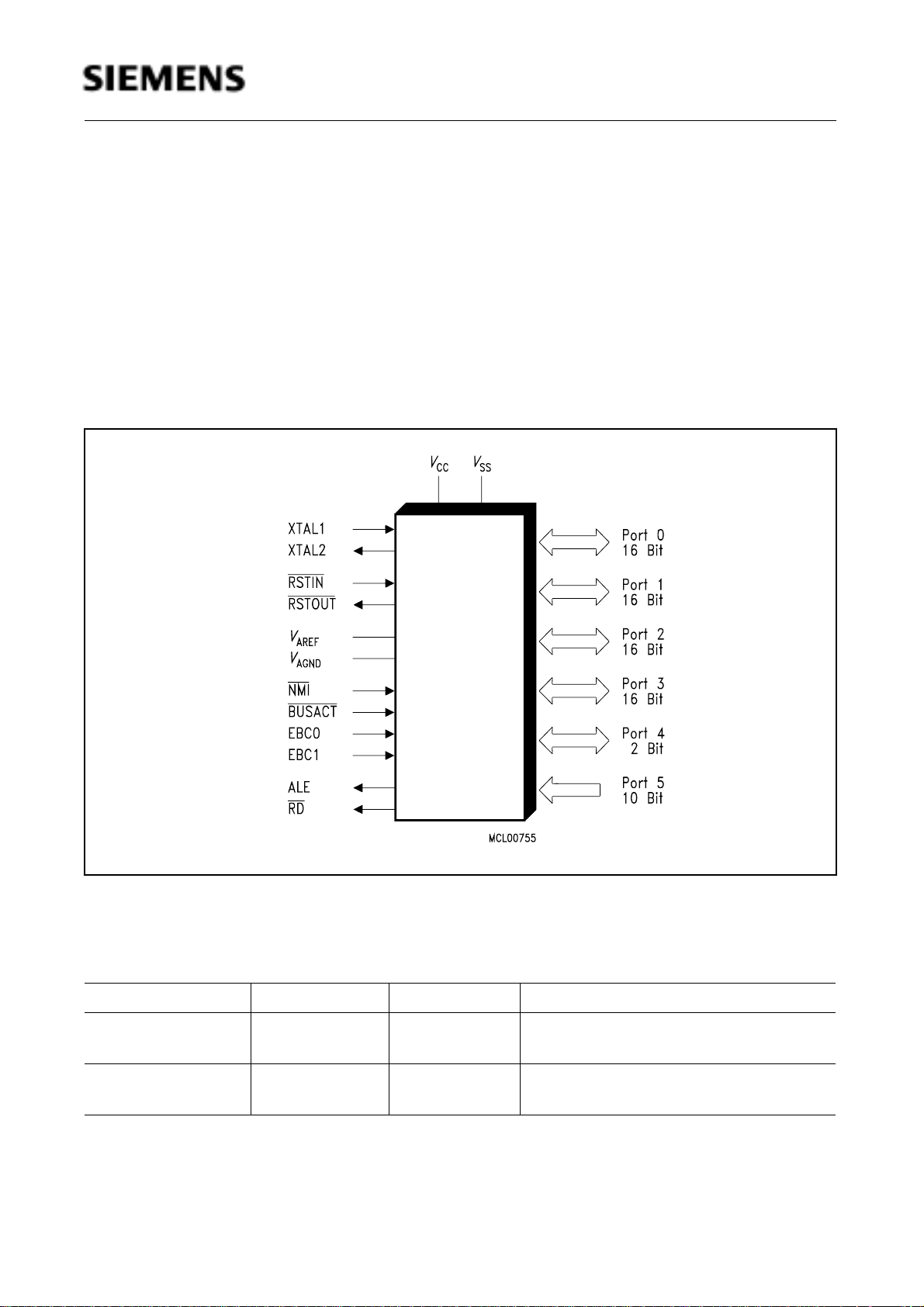

SAB

88C166

SAB

88C166W

V

/

PP

Figure 1

Logic Symbol

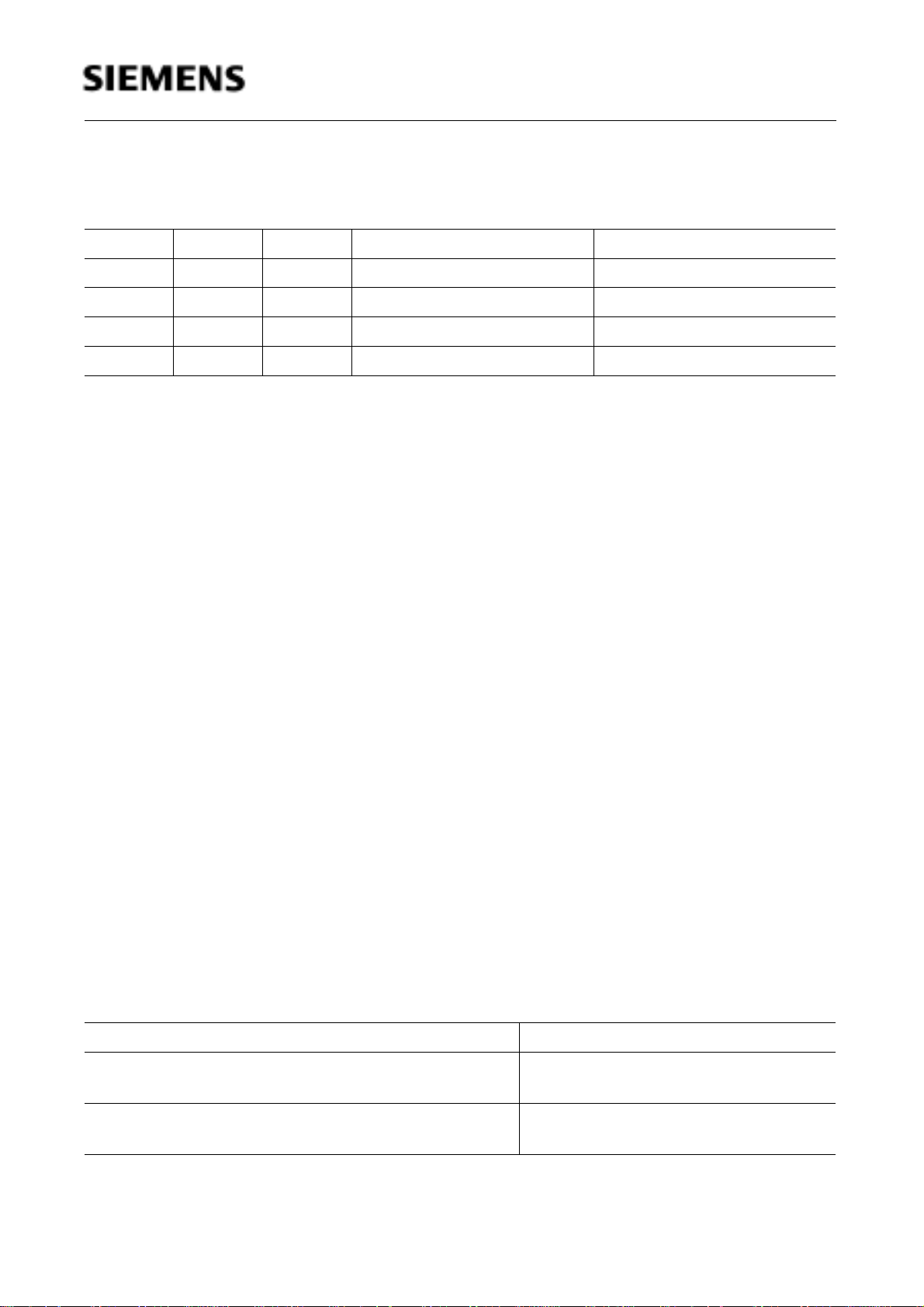

Ordering Information

Type Ordering Code Package Function

SAB 88C166-5M Q67120-C850 P-MQFP-100 16-bit microcontroller, 0 ˚C to + 70 ˚C,

1 KByte RAM, 32 KByte Flash EPROM

SAB 88C166W-5M Q67120-C934 P-MQFP-100 16-bit microcontroller, 0 ˚C to + 70 ˚C,

1 KByte RAM, 32 KByte Flash EPROM

Semiconductor Group 2

Page 4

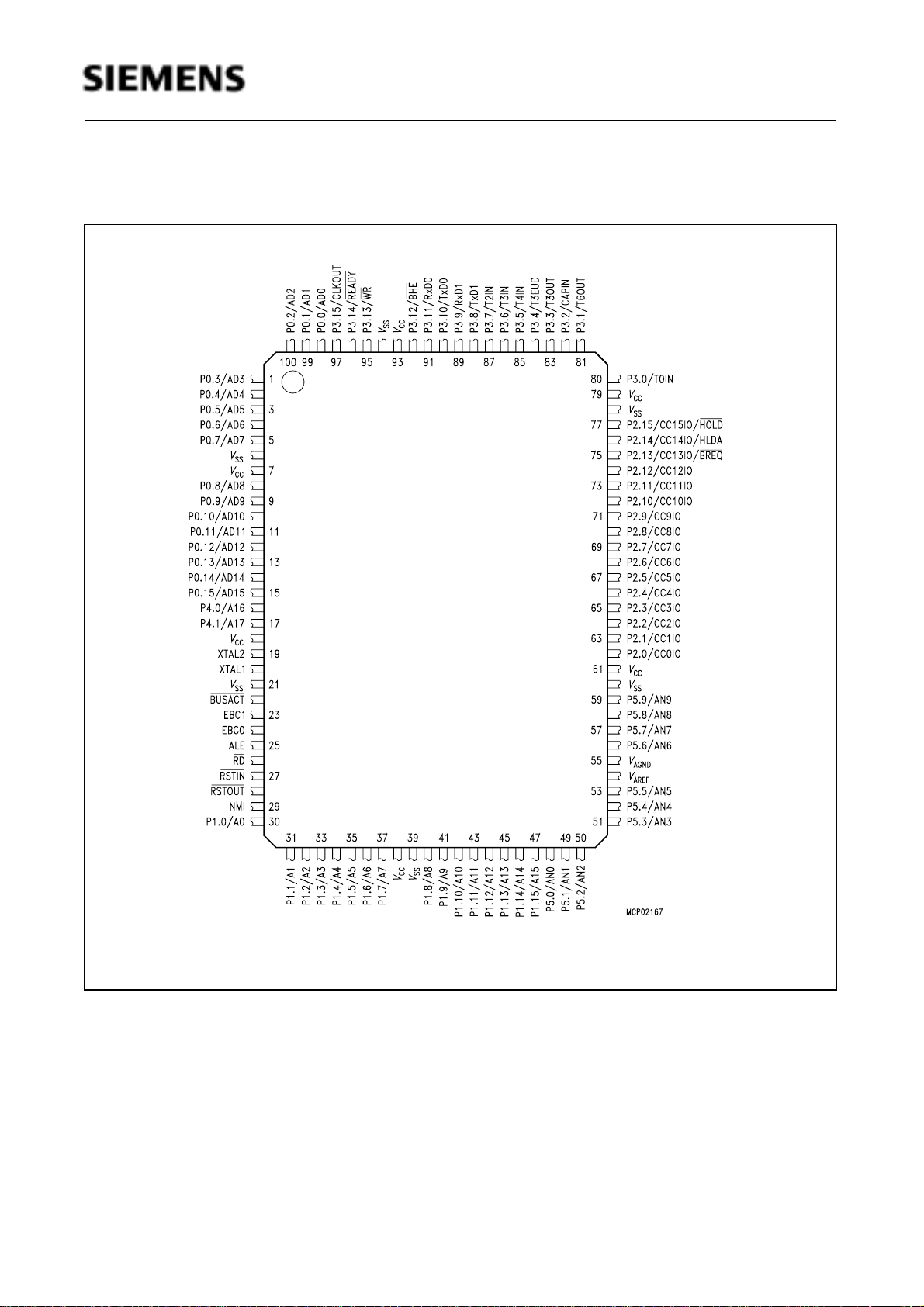

Pin Configuration Rectangular P-MQFP-100 (top view)

SAB 88C166(W)

Figure 2

SAB 88C166(W)

VPP /

Semiconductor Group 3

Page 5

Pin Definitions and Functions

SAB 88C166(W)

Symbol Pin

Number

P4.0 –

16 - 17

P4.1

16

17

XTAL1

XTAL2

BUSACT

EBC1,

EBC0

V

PP

RSTIN

RSTOUT

20

19

22

,

23

24

23

27 I Reset Input with Schmitt-Trigger characteristics. A low level at

28 O Internal Reset Indication Output. This pin is set to a low level

Input (I)

Output (O)

I/O

O

O

I

O

I

I

I

Function

Port 4 is a 2-bit bidirectional I/O port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state.

In case of an external bus configuration, Port 4 can be used to

output the segment address lines:

P4.0 A16 Least Significant Segment Addr. Line

P4.1 A17 Most Significant Segment Addr. Line

XTAL1: Input to the oscillator amplifier and input to the

internal clock generator

XTAL2: Output of the oscillator amplifier circuit.

To clock the device from an external source, drive XTAL1,

while leaving XTAL2 unconnected. Minimum and maximum

high/low and rise/fall times specified in the AC Characteristics

must be observed.

External Bus Configuration selection inputs. These pins are

sampled during reset and select either the single chip mode

or one of the four external bus configurations:

BUSACT

EBC1 EBC0 Mode/Bus Configuration

0 0 0 8-bit demultiplexed bus

0 0 1 8-bit multiplexed bus

0 1 0 16-bit muliplexed bus

0 1 1 16-bit demultiplexed bus

1 0 0 Single chip mode

1 0 1 Reserved.

1 1 0 Reserved.

1 1 1 Reserved.

After reset pin EBC1 accepts the programming voltage for the

Flash EPROM as an “alternate function”:

Flash EPROM Programming Voltage V

= 12 V.

PP

this pin for a specified duration while the oscillator is running

resets the SAB 88C166(W). An internal pullup resistor permits

power-on reset using only a capacitor connected to V

SS

.

when the part is executing either a hardware-, a software- or a

watchdog timer reset. RSTOUT remains low until the EINIT

(end of initialization) instruction is executed.

Semiconductor Group 4

Page 6

Pin Definitions and Functions (cont’d)

SAB 88C166(W)

Symbol Pin

Number

NMI 29 I Non-Maskable Interrupt Input. A high to low transition at this

ALE 25 O Address Latch Enable Output. Can be used for latching the

RD

P1.0 –

P1.15

26 O External Memory Read Strobe. RD is activated for every

30 - 37

40 - 47

Input (I)

Output (O)

I/O Port 1 is a 16-bit bidirectional I/O port. It is bit-wise

Function

pin causes the CPU to vector to the NMI trap routine. When

the PWRDN (power down) instruction is executed, the NMI

pin must be low in order to force the SAB 88C166(W) to go

into power down mode. If NMI is high, when PWRDN is

executed, the part will continue to run in normal mode.

If not used, pull NMI high externally.

address into external memory or an address latch in the

multiplexed bus modes.

external instruction or data read access.

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state. Port 1 is used as the 16-bit address bus (A)

in demultiplexed bus modes and also after switching from a

demultiplexed bus mode to a multiplexed bus mode..

P5.0 –

P5.9

P2.0 –

P2.15

48 – 53

56 – 59II

62 – 77

62

...

75

76

77

I/O

I/O

I/O

O

I/O

O

I/O

I

Port 5 is a 10-bit input-only port with Schmitt-Trigger

characteristics. The pins of Port 5 also serve as the (up to 10)

analog input channels for the A/D converter, where P5.x

equals ANx (Analog input channel x).

Port 2 is a 16-bit bidirectional I/O port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state.

The following Port 2 pins also serve for alternate functions:

P2.0 CC0IO CAPCOM: CC0 Cap.-In/Comp.Out

... ... ...

P2.13 CC13IO CAPCOM: CC13 Cap.-In/Comp.Out,

BREQ

P2.14 CC14IO CAPCOM: CC14 Cap.-In/Comp.Out,

HLDA External Bus Hold Acknowl. Output

P2.15 CC15IO CAPCOM: CC15 Cap.-In/Comp.Out,

HOLD External Bus Hold Request Input

External Bus Request Output

Semiconductor Group 5

Page 7

Pin Definitions and Functions (cont’d)

SAB 88C166(W)

Symbol Pin

Number

P3.0 –

P3.15

80 – 92,

95 – 97

80

81

82

83

84

85

86

87

88

89

90

91

92

95

96

97

Input (I)

Output (O)

I/O

I/O

I

O

I

O

I

I

I

I

O

I/O

O

I/O

O

O

I

O

Function

Port 3 is a 16-bit bidirectional I/O port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state.

The following Port 3 pins also serve for alternate functions:

P3.0 T0IN CAPCOM Timer T0 Count Input

P3.1 T6OUT GPT2 Timer T6 Toggle Latch Output

P3.2 CAPIN GPT2 Register CAPREL Capture Input

P3.3 T3OUT GPT1 Timer T3 Toggle Latch Output

P3.4 T3EUD GPT1 Timer T3 Ext.Up/Down Ctrl.Input

P3.5 T4IN GPT1 Timer T4 Input for

Count/Gate/Reload/Capture

P3.6 T3IN GPT1 Timer T3 Count/Gate Input

P3.7 T2IN GPT1 Timer T2 Input for

Count/Gate/Reload/Capture

P3.8 TxD1 ASC1 Clock/Data Output (Asyn./Syn.)

P3.9 RxD1 ASC1 Data Input (Asyn.) or I/O (Syn.)

P3.10 T×D0 ASC0 Clock/Data Output (Asyn./Syn.)

P3.11 R×D0 ASC0 Data Input (Asyn.) or I/O (Syn.)

P3.12 BHE

Ext. Memory High Byte Enable Signal,

P3.13 WR External Memory Write Strobe

P3.14 READY Ready Signal Input

P3.15 CLKOUT System Clock Output (=CPU Clock)

P0.0 –

P0.15

V

AREF

V

AGND

98 – 5

8 – 15

I/O Port 0 is a 16-bit bidirectional IO port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state.

In case of an external bus configuration, Port 0 serves as the

address (A) and address/data (AD) bus in multiplexed bus

modes and as the data (D) bus in demultiplexed bus modes.

Demultiplexed bus modes:

Data Path Width: 8-bit 16-bit

P0.0 – P0.7: D0 – D7 D0 - D7

P0.8 – P0.15: output! D8 - D15

Multiplexed bus modes:

Data Path Width: 8-bit 16-bit

P0.0 – P0.7: AD0 – AD7 AD0 - AD7

P0.8 – P0.15: A8 - A15 AD8 - AD15

54 - Reference voltage for the A/D converter.

55 - Reference ground for the A/D converter.

Semiconductor Group 6

Page 8

Pin Definitions and Functions (cont’d)

SAB 88C166(W)

Symbol Pin

Number

V

CC

7, 18,

38, 61,

79, 93

V

SS

6, 21,

39, 60,

78, 94

Input (I)

Function

Output (O)

- Digital Supply Voltage:

+ 5 V during normal operation and idle mode.

≥ 2.5 V during power down mode

- Digital Ground.

Functional Description

This document only describes specific properties of the SAB 88C166(W), e.g. Flash memory

functionality or specific DC and AC Characteristics, while for all other descriptions common for the

SAB 88C166(W) and the SAB 80C166(W)/83C166(W), e.g. functional description, it refers to the

respective Data Sheet for the Non-Flash device.

A detailled description of the SAB 88C166(W)’s instruction set can be found in the “C16x Family

Instruction Set Manual”.

Semiconductor Group 7

Page 9

SAB 88C166(W)

Memory Organization

The memory space of the SAB 88C166(W) is configured in a Von Neumann architecture which

means that code memory, data memory, registers and I/O ports are organized within the same

linear address space which includes 256 KBytes. Address space expansion to 16 MBytes is

provided for future versions. The entire memory space can be accessed bytewise or wordwise.

Particular portions of the on-chip memory have additionally been made directly bit addressable.

1 KByte of on-chip RAM is provided as a storage for user defined variables, for the system stack,

general purpose register banks and even for code. A register bank can consist of up to 16 wordwide

(R0 to R15) and/or bytewide (RL0, RH0, …, RL7, RH7) so-called General Purpose Registers

(GPRs).

512 bytes of the address space are reserved for the Special Function Register area. SFRs are

wordwide registers which are used for controlling and monitoring functions of the different on-chip

units. 98 SFRs are currently implemented. Unused SFR addresses are reserved for future

members of the SAB 80C166 family.

In order to meet the needs of designs where more memory is required than is provided on chip, up

to 256 KBytes of external RAM and/or ROM can be connected to the microcontroller.

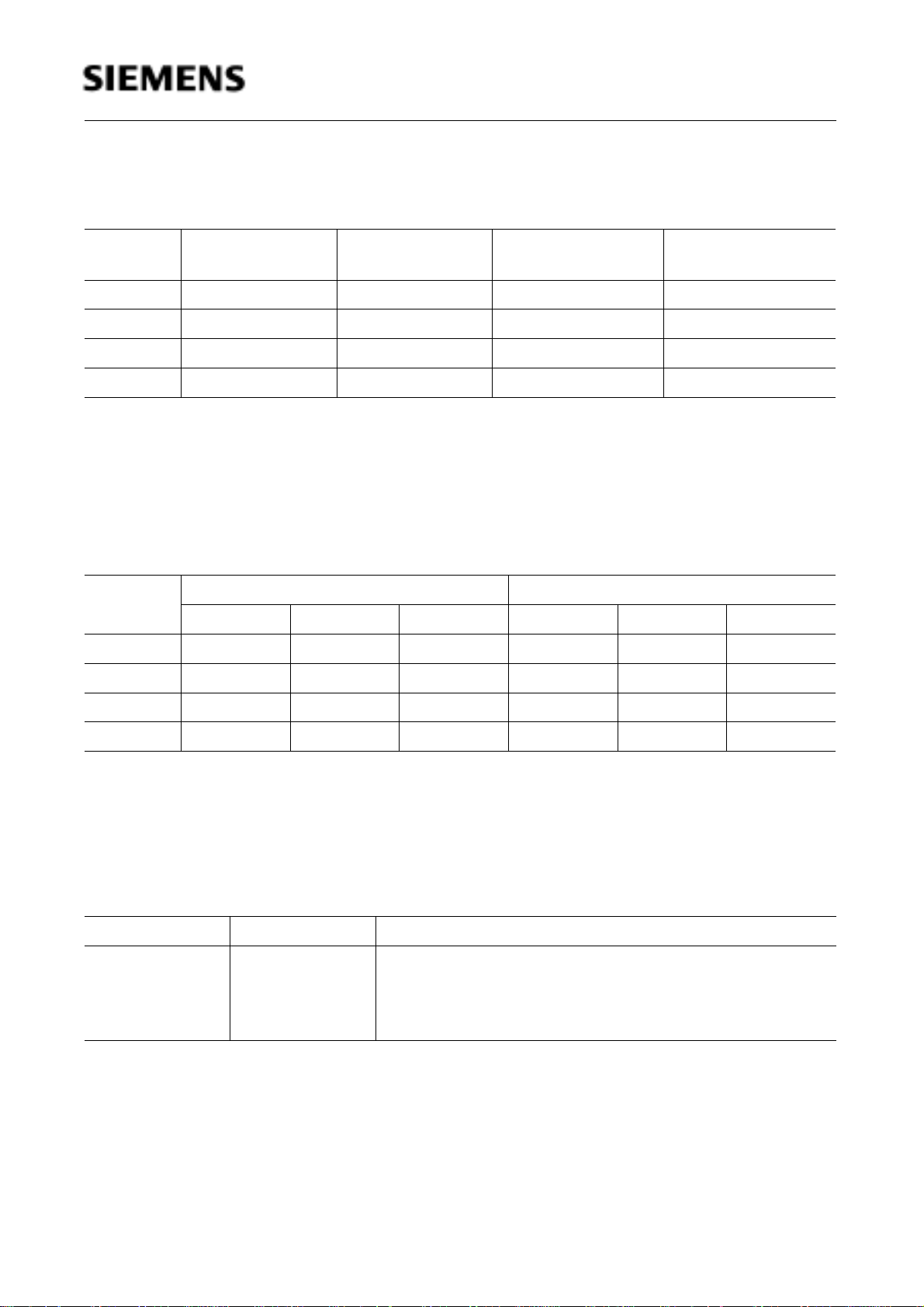

Flash Memory Overview

The SAB 88C166(W) provides 32 KBytes of electrically erasable and reprogrammable non-volatile

Flash EPROM on-chip for code or constant data, which can be mapped to either segment 0

(0’0000H to 0’7FFFH) or segment 1 (1’0000H to 1’7FFFH) during the initialization phase.

A separate Flash Control Register (FCR) has been implemented to control Flash operations like

programming or erasure. For programming or erasing an external 12 V programming voltage must

be applied to the VPP/EBC1 pin.

The Flash memory is organized in 8 K x 32 bits, which allows even double-word instructions to be

fetched in just one machine cycle. The entire Flash memory is divided into four blocks with different

sizes (12/12/6/2 KByte). This allows to erase each block separately, when only parts of the Flash

memory need to be reprogrammed. Word or double word programming typically takes 100 µs, block

erasing typically takes 1 s (@ 20 MHz CPU clock). The Flash memory features a typical endurance

of 100 erasing/programming cycles. Erased Flash memory cells contain all ‘1’s, as known from

standard EPROMs.

The Flash memory can be programmed both in an appropriate programming board and in the target

system, which provides a lot of flexibility. The SAB 88C166(W)’s on-chip bootstrap loader may be

used to load and start the programming code.

To save the customer’s know-how, a Flash memory protection option is provided in the SAB

88C166(W). If this was activated once, Flash memory contents cannot be read from any location

outside the Flash memory itself.

Semiconductor Group 8

Page 10

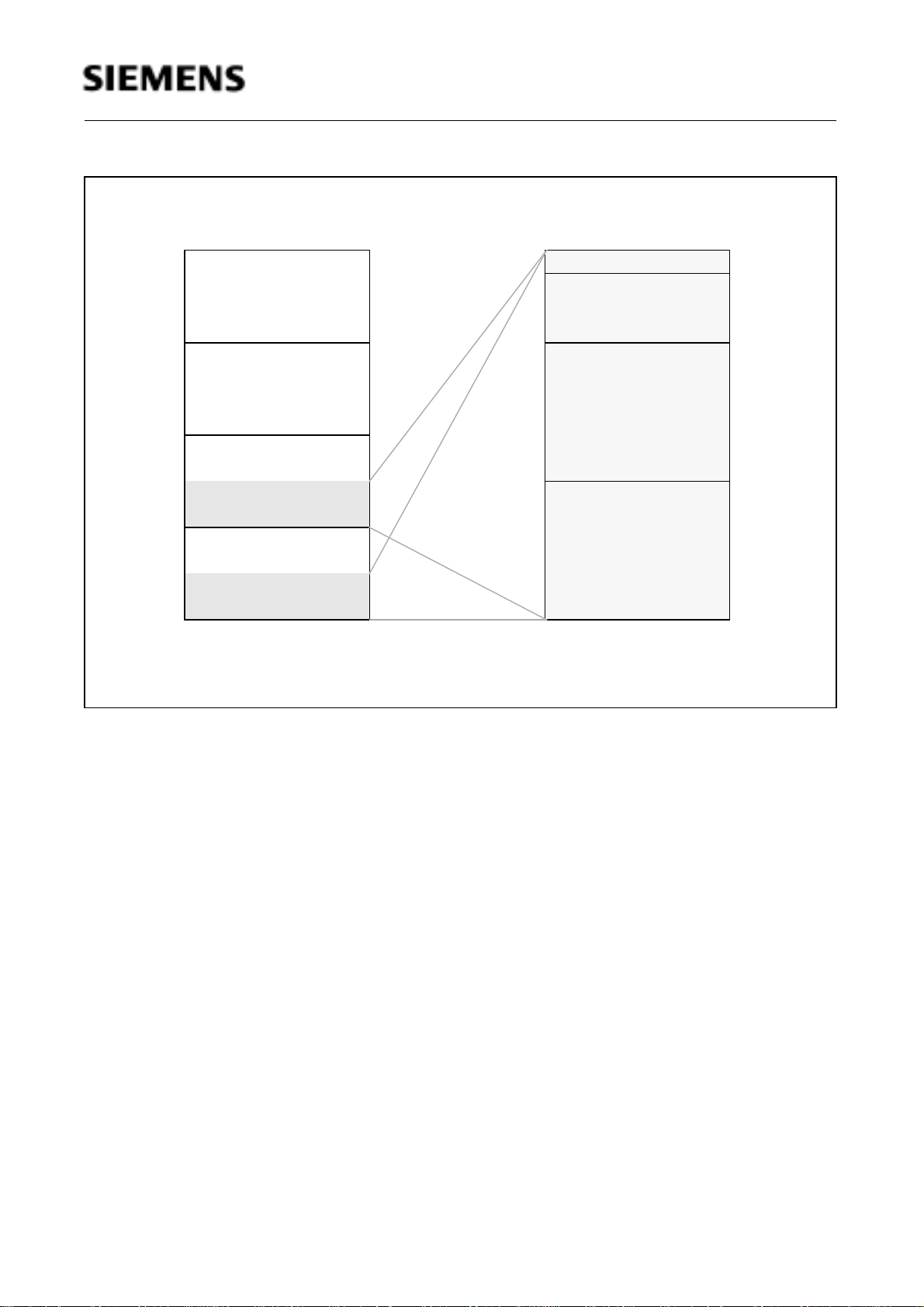

SAB 88C166(W)

3’FFFF

3’0000

2’0000

1’0000

0’0000

H

3

H

Bank 3

Bank 2

2

Bank 1

H

1

H

Bank 0

0

H

Memory Segments Flash Banks

x’7800

x’6000

x’3000

x’0000

H

H

H

H

Figure 3

Flash Memory Overview

The Flash Control Register (FCR)

In standard operation mode the Flash memory can be accessed like the normal maskprogrammable on-chip ROM of the SAB 83C166. So all appropriate direct and indirect addressing

modes can be used for reading the Flash memory.

All programming or erase operations of the Flash memory are controlled via the 16-bit Flash control

register FCR. To prevent unintentional writing to the Flash memory the FCR is locked and inactive

during standard operation mode. Before a valid access to the FCR is enabled, the Flash memory

writing mode must be entered. This is done via a special key code instruction sequence.

Semiconductor Group 9

Page 11

SAB 88C166(W)

FCR (FFA0H / D0H) SFR Reset Value: 00X0

5 4 3 2 1 011 10 9 8 7 615 14 13 12

FWM

SET

rw

rw-rw-rw-rw-rw

- FWE

BE

WDW

W

CKCTL

VPP

REVFCVPP

FBUSY

RPROT

FEE

rw

*)

H

rwrw rrw rw r/wrw

Bit Function

FWE Flash Write Enable Bit (see description below)

0 : Flash write operations (program / erase) disabled

1 : Flash write operations (program / erase) enabled

FEE Flash Erase Enable Bit (Significant only, when FWE = ’1’, see description below)

0 : Flash programming mode selected

1 : Flash erase mode selected

FBUSY

Flash Busy Bit (On read accesses)

0 : No Flash write operation in progress

1 : Flash write operation in progress

RPROT

Flash Read Protection Activation Bit (On write accesses)

0 : Deactivates Flash read protection

1 : Activates Flash read protection, if this is enabled

FCVPP Flash Control V

PP

Bit

0 : No VPP failure occurred during a Flash write operation

1 : VPP failure occurred during a Flash write operation

VPPREV Flash V

0 : No valid VPP applied to pin V

Revelation Bit

PP

PP

1 : VPP applied to pin VPP is valid

CKCTL Internal Flash Timer Clock Control

Determines the width of an internal Flash write or erase pulse

WDWW Word / Double Word Writing Bit (significant only in programming mode)

0 : 16-bit programming operation

1 : 32-bit programming operation

BE Bank Erase Select (significant only in erasing mode)

Selects the Flash Bank to be erased

FWMSET Flash Writing Mode Set Bit (see description below)

0 : Exit Flash writing mode, return to standard mode

1 : Stay in Flash writing mode

*)

The reset value of bit VPPREV depends on the voltage on pin VPP.

Note: The FCR is no real register but is rather virtually mapped into the active address space of the

Flash memory while the Flash writing mode is active. In writing mode all direct (mem)

accesses refer to the FCR, while all indirect ([Rwn]) accesses refer to the Flash memory

array itself.

Semiconductor Group 10

Page 12

SAB 88C166(W)

The selection of Flash Operation and Read Mode is done via the three bits FWE, FEE and

FWMSET. The table below shows the combinations for these bits to select a specific function:

FWMSET FEE FWE Flash Operation Mode Flash Read Mode

1 1 1 Erasing mode Erase-Verify-Read via [Rn]

1 0 1 Programming mode Program-Verify-Read via [Rn]

1 X 0 Non-Verify mode Normal Read via [Rn]

0 X X Standard mode Normal Read via [Rn] or mem

FWE enables/disables write operations, FEE selects erasing or programming, FWMSET controls

the writing mode. Bits FWE and FEE select an operation, but do not execute it directly.

Note: Watch the FWMSET bit, when writing to register FCR (word access only), in order not to exit

Flash writing mode unintentionally by clearing bit FWMSET.

FBUSY: This read-only flag is set to ‘1’ while a Flash programming or erasing operation is in

progress. FBUSY is set via hardware, when the respective command is issued.

RPROT: This write-only Flash Read Protection bit determines whether Flash protection is active

or inactive. RPROT is the only FCR bit which can be modified even in the Flash standard mode but

only by an instruction executed from the on-chip Flash memory itself. Per reset, RPROT is set to ‘1’.

Note: RPROT is only significant, if the general Flash memory protection is enabled.

V

FCVPP and VPPREV: These read-only bits allow to monitor the

Revelation bit VPPREV reflects the state of the

‘0’ indicates that

V

is below the threshold value necessary for reliable programming or erasure,

PP

otherwise VPPREV = ‘1’). The Flash Control

V

voltage in the Flash writing mode (VPPREV =

PP

V

bit FCVPP indicates, if

PP

voltage. The Flash Vpp

PP

V

fell below the valid

PP

threshold value during a Flash programming or erase operation (FCVPP = ‘1’). FCVPP = ‘0’ after

such an operation indicates that no critical discontinuity on

V

has occurred.

PP

CKCTL: This Flash Timer Clock Control bitfield controls the width of the programming or erase

pulses (TPRG) applied to Flash memory cells during the corresponding operation. The width of a

single programming or erase pulse and the cumulated programming or erase time must not exceed

certain values to avoid putting the Flash memory under critical stress (see table below).

Time Specification Limit Value

Maximum Programming Pulse Width

Maximum Cumulated Programming Time

Maximum Erase Pulse Width

Maximum Cumulated Erase Time

128 µs

2.5 ms

10 ms

30 s

Semiconductor Group 11

Page 13

SAB 88C166(W)

In order not to exceed the limit values listed above, a specific CKCTL setting requires a minimum

CPU clock frequency, as listed below.

Setting of

CKCTL

0 0 2

0 1 2

1 0 2

1 1 2

Length of

TPRG

7

* 1/f

CPU

11

* 1/f

CPU

15

* 1/f

CPU

18

* 1/f

CPU

TPRG

@ f

CPU

= 20 MHz

f

CPUmin

for programming

f

CPUmin

for erasing

6.4 µs 1 MHz ---

102.4 µs 16 MHz 1 MHz

1.64 ms --- 3.28 MHz

13.11 ms --- 13.11 MHz

The maximum number of allowed programming or erase attempts depends on the CPU clock

frequency and on the CKCTL setting chosen in turn. This number results from the actual pulse width

compared to the maximum pulse width (see above tables).

The table below lists some sample frequencies, the respective recommended CKCTL setting and

the resulting maximum number of program / erase pulses:

f

CPU

CKCTL TPROG N

Programming Erasing

PROGmax

CKCTL TPROG N

ERASEmax

1 MHz 0 0 128 µs 19 0 1 2.05 ms 14648

10 MHz 0 0 12.8 µs 195 1 0 3.28 ms 9155

16 MHz 0 0 8 µs 312 1 0 2.05 ms 14648

20 MHz 0 0 6.4 µs 390 1 0 1.64 ms 18310

BE: The Flash Bank Erasing bit field determines the Flash memory bank to be erased (see table

below). The physical addresses of the selected bank depend on the Flash memory mapping

chosen.

BE setting Bank Addresses Selected for Erasure (x = 0 or 1)

0 0

0 1

1 0

1 1

0

1

2

3

x’0000

to x’2FFF

H

x’3000H to x’5FFF

x’6000H to x’77FF

x’7800H to x’7FFF

H

H

H

H

Semiconductor Group 12

Page 14

SAB 88C166(W)

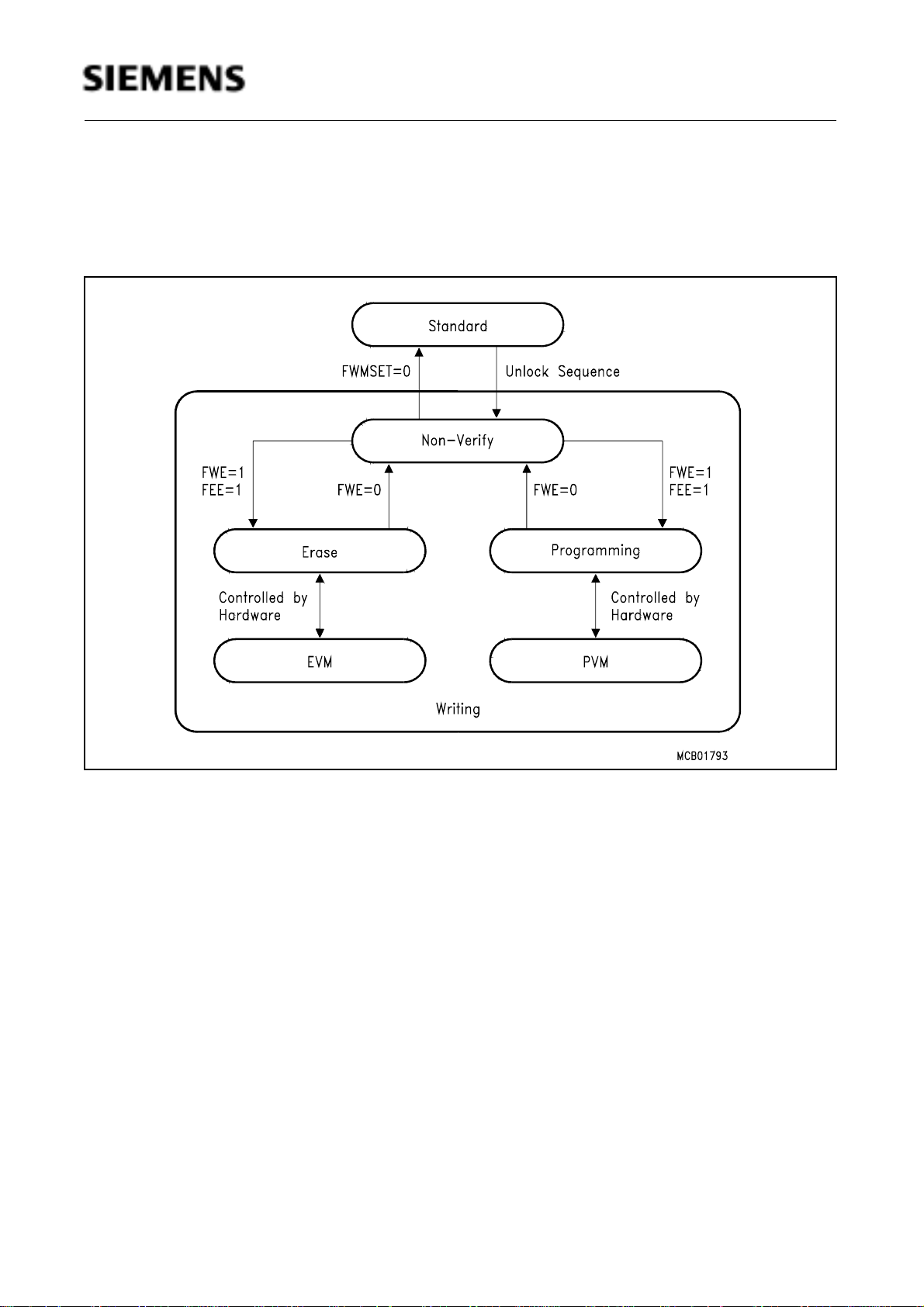

Operation Modes of the Flash Memory

There are two basic operation modes for Flash accesses: The standard and the writing mode. Submodes of the writing mode are the programming, the erase and the non-verify mode.

Figure 4

Flash Operating Mode Transitions

In Standard Mode the Flash memory can be accessed from any memory location (external

memory, on-chip RAM or Flash memory) for instruction fetches and data operand reads. Data

operand reads may use both direct 16-bit (mnemonic: mem) and indirect (mnemonic: [Rw])

addressing modes. Standard mode does not allow accesses to the FCR or Flash write operations.

Note: When Flash protection is active, data operands can be accessed only by instructions that are

executed out of the internal Flash memory.

The Flash Writing Modes must be entered for programming or erasing the Flash memory. The

SAB 88C166 enters these modes by a specific key code sequence, called UNLOCK sequence.

In writing mode the used addressing mode decides whether the FCR or a Flash memory location is

accessed. The FCR can be accessed with any direct access to an even address in the active

address space of the Flash memory. Only word operand instructions are allowed for FCR accesses.

Accesses to Flash memory locations must use indirect addressing to even addresses.

direct 16-bit addressing mode: mem --> Access to FCR

indirect addressing mode: [Rw

] --> Access to Flash location

n

Semiconductor Group 13

Page 15

SAB 88C166(W)

After entering writing mode the first erase or programming operation must not be started for at least

10 µs. This absolute (!) delay time is required to set up the internal high voltage. In general, Flash

write operations need a 12 V external

It is not possible to erase or to program the Flash memory via code executed from the Flash memory

itself. The respective code must reside within the on-chip RAM or within external memory.

When programming or erasing ‘on-line’ in the target system, some considerations have to be taken:

While these operations are in progress, the Flash memory cannot be accessed as usual. Therefore

care must be taken that no branch is taken into the Flash memory and that no data reads are

attempted from the Flash memory during programming or erasure. If the Flash memory is mapped

to segment 0, it must especially be ensured that no interrupt or hardware trap can occur, because

this would implicitly mean such a ‘forbidden’ branch to the Flash memory in this case.

The UNLOCK sequence is a specific key code sequence, which is required to enable the writing

modes of the SAB 88C166(W). The UNLOCK sequence must use identical values (see example

below) and must not be interrupted:

V

voltage to be applied to the

PP

V

PP

/EBC1 pin.

MOV FCR, Rw

MOV [Rw

], Rw

n

n

n

; Dummy write to the FCR

; Both operands use the same GPR

CALL cc_UC, WAIT_10 ; Delay for 10 µs (may be realized also by

; instructions other than a delay loop

where Rw

can be any word GPR (R0…R15). [Rwn] and FCR must point to even addresses within

n

the active address space of the Flash memory.

Note: Data paging and Flash segment mapping, if active, must be considered in this context.

In Flash Erase Mode (FEE=’1’, FWE=’1’) the SAB 88C166(W) is prepared to erase the bank

selected by the Bank Erase (BE) bit field in the FCR. The width of the erase pulses generated

internally is defined by the Internal Flash Timer Clock Control (CKCTL) bit field of the FCR. The

maximum number of erase pulses (EN

in the Flash erase algorithm. The chosen values for CKCTL and EN

) applied to the Flash memory is determined by software

max

must guarantee a maximum

max

cumulated erase time of 30 s per bank and a maximum erase pulse width of 20 ms.

The Flash bank erase operation will not start before the erase command is given. This provides

additional security for the erase operation. The erase command can be any write operation to a

Flash location, where the data and the even address written to must be identical:

MOV [Rwn], Rw

n

; Both operands use the same GPR

Upon the execution of this instruction, the Flash Busy (FBUSY) flag is automatically set to ‘1’

indicating the start of the operation. End of erasure can be detected by polling the FBUSY flag.

V

PP

must stay within the valid margins during the entire erase process.

At the end of erasure the Erase-Verify-Mode (EVM) is entered automatically. This mode allows to

check the effect of the erase operation (see description below).

Note: Before the erase algorithm can be properly executed, the respective bank of the Flash

memory must be programmed to all zeros (‘0000H’).

Semiconductor Group 14

Page 16

SAB 88C166(W)

In Flash Programming Mode (FEE=’0’, FWE=’1’) the SAB 88C166(W) is prepared to program

Flash locations in the way specified by the Word or Double Word Write (WDWW) bit in the FCR. The

width of the programming pulses generated internally is defined by the Internal Flash Timer Clock

Control (CKCTL) bit field of the FCR. The maximum number of programming pulses (PN

applied to the Flash memory is determined by software in the Flash programming algorithm. The

chosen values for CKCTL and PN

must guarantee a maximum cumulated programming time of

max

2.5 ms per cell and a maximum programming pulse width of 200 µs.

If 16-bit programming was selected, the operation will start automatically when an instruction is

executed, where the first operand specifies the address and the second operand the value to be

programmed:

max

)

MOV [Rwn], Rw

m

; Program one word

If 32-bit programming was selected, the operation will start automatically when the second of two

subsequent instructions is executed, which define the doubleword to be programmed. Note that the

destination pointers of both instructions refer to the same even double word address. The two

instructions must be executed without any interruption.

MOV [Rw

MOV [Rw

], Rw

n

], Rw

n

x

y

; Prepare programming of first word

; Start programming of both words

Upon the execution of the second instruction (the one and only in 16-bit programming mode), the

Flash Busy (FBUSY) bit is automatically set to ‘1’. End of programming can be detected by polling

the FBUSY bit.

V

must stay within the valid margins during the entire programming process.

PP

At the end of programming the Program-Verify-Mode (PVM) is entered automatically. This mode

allows to check the effect of the erase operation (see description below).

The Flash Verify-Modes Erase-Verify-Mode (EVM) and Program-Verify-Mode (PVM) allow to

verify the effect of an erase or programming operation. In these modes an internally generated

margin voltage is applied to a Flash cell, which makes reading more critical than for standard read

accesses. This ensures safe standard accesses after correct verification.

To get the contents of a Flash word in this mode, it has to be read in a particular way:

MOV Rw

, [Rwn] ; First (invalid) read of dedicated cell

m

… ; 4 µs delay to stabilize internal margin voltage

MOV Rw

, [Rwn] ; Second (valid) read of dedicated cell

m

Such a Flash verify read operation is different from the reading in the standard or in the non-verify

mode. Correct verify reading needs a read operation performed twice on the same cell with an

absolute time delay of 4 µs which is needed to stabilize the internal margin voltage applied to the

cell. To verify that a Flash cell was erased or programmed properly, the value of the second verify

read operation has to be compared against FFFFH or the target value, respectively. Clearing bit

FWE to ‘0’ exits the Flash programming mode and returns to the Flash non-verify mode.

In Flash non-verify mode all Flash locations can be read as usual (via indirect addressing modes),

which is not possible in Flash programming or Flash erase mode (see EVM and PVM).

Semiconductor Group 15

Page 17

SAB 88C166(W)

Flash Protection

If active, Flash protection prevents data operand accesses and program branches into the on-chip

Flash area from any location outside the Flash memory itself. Data operand accesses and branches

to Flash locations are exclusively allowed for instructions executed from the Flash memory itself.

Erasing and programming of the Flash memory is not possible while Flash protection is active.

Note: A program running within the Flash memory may of course access any location outside the

Flash memory and even branch to a location outside.

However, there is no way back, if Flash protection is active.

Flash protection is controlled by two different bits:

• The user-accessible write-only Protection Activation bit (RPROT) in register FCR and

• The one-time-programmable Protection Enable bit (UPROG).

Bit UPROG is a ‘hidden’ one-time-programmable bit only accessible in a special mode, which can

be entered eg. via a Flash EPROM programming board. Once programmed to ‘1’, this bit is

unerasable, ie. it is not affected by the Flash Erase mechanism.

To activate Flash Protection bit UPROG must have been programmed to ‘1’, and bit RPROT in

register FCR must be set to ‘1’. Both bits must be ‘1’ to activate Flash protection.

To deactivate Flash Protection bit RPROT in register FCR must be cleared to ‘0’. If any of the two

bits (UPROG or RPROT) is ‘0’, Flash protection is deactivated.

Generally Flash protection will remain active all the time. If it has to be deactivated intermittently, eg.

to call an external routine or to reprogram the Flash memory, bit RPROT must be cleared to ‘0’.

To access bit RPROT in register FCR, an instruction with a ‘mem, reg’ addressing mode must be

used, where the first operand has to represent the FCR address (any even address within the active

address space of the Flash memory) and the second operand must refer to a value which sets the

RPROT bit to ‘0’, eg.:

MOV FCR, ZEROS ; Deactivate Flash Protection

RPROT is the only bit in the FCR which can be accessed in Flash standard mode without having to

enter the Flash writing mode. Other bits in the FCR are not affected by such a write operation.

However, this access requires an instruction executed out of the internal Flash memory itself.

After reset bit RPROT is set to ’1’. For devices with protection disabled (UPROG=’0’) this has no

effect. For devices with protection enabled this ensures that program execution starts with Flash

protection active from the beginning.

Note: In order to maintain uninterrupted Flash protection, be sure not to clear bit RPROT

unintentionally by FCR write operations. Otherwise the Flash protection is deactivated.

Semiconductor Group 16

Page 18

SAB 88C166(W)

Flash Programming Algorithm

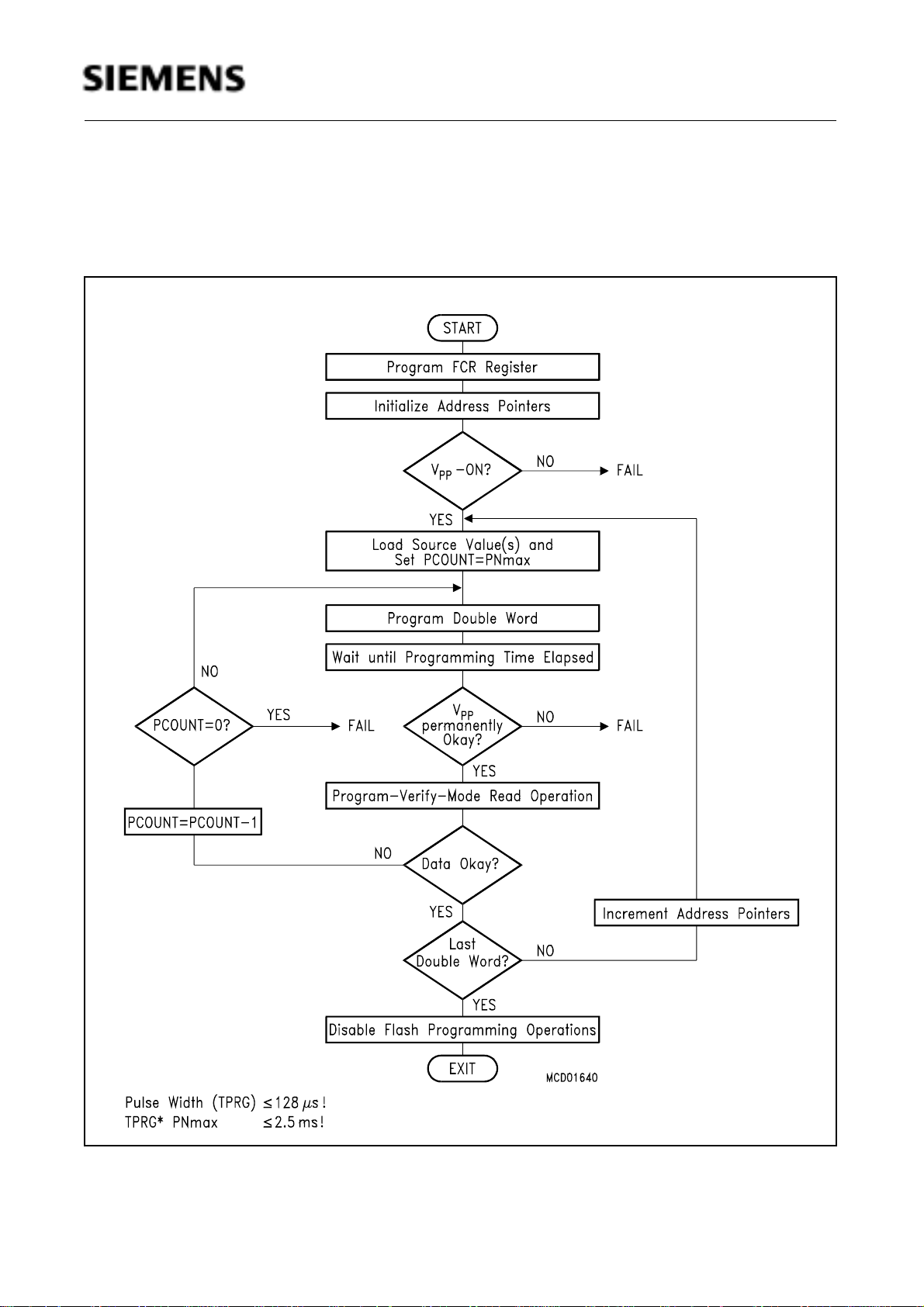

The figure below shows the recommended Flash programming algorithm. The following example

describes this algorithm in detail.

Figure 5

Flash Programming Algorithm

Semiconductor Group 17

Page 19

SAB 88C166(W)

Flash Programming Example

This example describes the Flash programming algorithm. A source block of code and/or data

within the first 32 Kbytes of segment 0 is copied (programmed) to a target block within the Flash

memory, which is mapped to segment 1 in this case. The start and the end address of the source

block to be copied are specified by the parameters SRC_START or SRC_END respectively. The

target Flash memory block begins at location FLASH_START. This example uses 32-bit Flash

programming.

Figure 6

Memory Allocation for Flash Programming Example

Note: This example represents one possibility how to program the Flash memory. Other solutions

may differ in the way they provide the source data (eg. without external memory), but use the

same Flash programming algorithm.

The FCR has been defined with an EQU assembler directive. Accesses to bits of the FCR are made

via an auxiliary GPR, as the FCR itself is not bit-addressable.

The shown example uses the following assumptions:

● Pin

● The SAB 88C166(W) runs at 20 MHz CPU clock (absolute time delays refer to it).

● The Flash memory is mapped to segment 1. All DPPs are set correctly.

V

/EBC1 receives a proper

PP

V

supply voltage.

PP

Semiconductor Group 18

Page 20

SAB 88C166(W)

● Enter writing mode via unlock sequence (prerequisite for any programming or erase

operation).

MOV FCR, Rw

MOV [Rw

], Rw

n

n

n

; Dummy write to the FCR

; Both operands use the same GPR

CALL cc_UC, WAIT_10 ; Delay for 10 µs

● Program the FCR register with a value that selects the desired operating mode. Note that this

does not yet start the programming operation itself.

MOV R15, #1000 0000 1010 0001B

; #xxxx xxxx xxxx xxx1: FWE=’1’: Enable Flash write operations

; #xxxx xxxx xxxx xx0x: FEE=’0’: Select programming mode

; #xxxx xxxx x01x xxxx: CKCTL=’01’: 100 µs programming pulse (fCPU = 20 MHz)

; #xxxx xxxx 1xxx xxxx: WDWW=’1’: Select 32-bit programming mode

; #1xxx xxxx xxxx xxxx: FWMSET=’1’: Stay in writing mode

MOV DPP1:pof FCR, R15 ; Write Value to the FCR using 16-bit access

● Initialize pointers and counter for the first transfer of the programming algorithm.

The source data block is accessed via the pointer SRC_PTR, initialized with SRC_START. All

read operations via SRC_PTR use DPP2, which selects data page 1 in this example.

The Flash memory must be accessed indirectly and uses the pointer FLASH_PTR, initialized

with FLASH_START.

The counter DWCOUNT defines the number of doublewords to be programmed.

● Test for correct

V

margin at pin

PP

V

/EBC1 before a programming operation is started. If bit

PP

VPPREV reads ‘1’, the programming voltage is correct and the algorithm can be continued.

V

Otherwise, the programming routine could wait in Flash writing mode until

reaches its correct

PP

value and resume programming then, or it could exit writing mode.

MOV R15, DPP1:pof FCR ; Read FCR contents using 16-bit access

JB R15.4, Vpp_OK1 ; Test

V

via bit VPPREV (= FCR.4)

PP

… ; VPPREV=’0’: Exit programming procedure

Vpp_OK1: ; VPPREV=’1’: Test Okay! Continue

Semiconductor Group 19

Page 21

SAB 88C166(W)

● Load source values and initialize loop counter (PCOUNT) with the maximum number of

programming trials (PNmax) to be performed before exiting the routine with a failure. Each trial

means applying a pulse of 100 µs to the selected words in the Flash memory. According to the

maximum cumulated programming time of 2.5 ms allowed per cell, PNmax must be ‘25’ here.

The doubleword at memory location [SRC_PTR] is loaded into two auxiliary registers DATAWR1

and DATAWR2.

● Program one doubleword stored in the auxiliary data registers to the Flash memory location

[FLASH_PTR]. FLASH_PTR is not incremented here, since in 32-bit programming mode the

hardware automatically arranges the two data words correctly. The execution of the second write

instruction automatically starts the programming of the entire double word.

This instruction sequence must not be interrupted.

MOV [FLASH_PTR], DATAWR1 ; Write low word to Flash

MOV [FLASH_PTR], DATAWR2 ; Write high word to Flash, starts programming

● Wait until programming time elapsed (100 µs in this example), which depends on bit field

CKCTL in the FCR register and on the CPU clock frequency. End of programming is detected by

polling the FBUSY flag in the FCR register. The Flash memory switches to PVM mode

automatically.

WAIT_PROG: ; Polling Loop to check bit FBUSY

MOV R15, DPP1: pof FCR ; Read FCR contents using 16-bit access

JB R15.2, WAIT_PROG ; Loop while bit FBUSY (FCR.2) is ‘1’

… ; Continue in PVM mode, when FBUSY is ‘0’

● Verify

V

validity during programming to make sure

PP

V

did not exceed its valid margins

PP

during the programming operation. Otherwise programming may have not been performed

properly. The FCVPP flag is set to ‘1’ in case of this error condition. If FCVPP reads ‘1’, the

programming routine can abort, when

V

proves to be stable now.

PP

V

still fails, or repeat the programming operation, when

PP

Semiconductor Group 20

Page 22

SAB 88C166(W)

● Perform Program-Verify operation and compare with source data in order to check whether

a programming operation was performed correctly. PVM reading consists of two identical Flash

read instructions with 4 µs delay in between. This example uses CMP instructions to access the

Flash memory. In case of a mismatch the programming routine repeats the programming cycle

provided that the maximum number of attempts was not yet reached. PVM reading and data

comparison must be performed on both words of the double word to be tested.

CMP DATAWR1, [FLASH_PTR] ; 1st step of PVM read (low word)

CALL cc_UC, WAIT_4 ; Delay for 4 µs

CMP DATAWR1, [FLASH_PTR] ; 2nd step of PVM read (low word)

JMP cc_NZ, PROG_FAILED ; Reprogram on mismatch, if (PCOUNT) > 0

MOV R15, FLASH_PTR

ADD R15, #0002H ; Auxiliary pointer to upper word of doubleword

CMP DATAWR2, [R15] ; 1st step of PVM read (high word)

CALL cc_UC, WAIT_4 ; Delay for 4 µs

CMP DATAWR2, [R15] ; 2nd step of PVM read (high word)

JMP cc_NZ, PROG_FAILED ; Reprogram on mismatch, if (PCOUNT) > 0

. . . ; Programming was OK. Go on with next step.

● Check number of programming attempts to decide, if another programming attempt is

allowed. PCOUNT is decremented by ‘1’ upon each unsuccessful programming attempt. If it

expires, the failing Flash cells are classified as unprogrammable and should be left out. This

failure is very unlikely to occur. However, it should be checked for safe programming.

Note: This step is taken only in case of a program verify mismatch.

● Check for last doubleword and increment pointers to decide, if another programming cycle is

required. The auxiliary counter DWCOUNT is decremented by ‘1’ after each successful double

word programming. If it expires, the complete data block is programmed and the programming

routine is exited successfully. Otherwise source and target pointers (SRC_PTR and

FLASH_PTR) are incremented to the next doubleword to be programmed.

● Disable Flash programming operations and exit routine, when the Flash memory block was

programmed successfully or when a failure occurred. In either case bit FWE of the FCR is reset

to ‘0’ and the programming routine is exited. This means that the Flash non-verify mode is

entered again, where the FCR stays accessible but Flash memory locations can be read

normally again using indirect addressing. For returning to the Flash standard mode, bit FWMSET

of the FCR must be reset to ‘0’ by the calling routine. The programming routine may return an exit

code that indicates correct programming or identifies the type of error.

Semiconductor Group 21

Page 23

SAB 88C166(W)

Flash Erase Algorithm

The figure below shows the recommended Flash erase algorithm. The following example describes

this algorithm in detail.

Figure 7

Flash Erase Algorithm

Semiconductor Group 22

Page 24

SAB 88C166(W)

Flash Erase Example

This example describes the Flash erase algorithm. The four banks of the Flash memory can be

erased separately. The algorithm erases the Flash memory bank, which is selected by bitfield BE in

the FCR. Start address and size of the selected Flash bank have to be considered.

Note: Before a bank can be erased, all its contents must be programmed to ‘0000H’. This is

required by the physics of the Flash memory cells and is done with the Flash programming

algorithm already described.

Figure 8

Memory Banking for Flash Erasure

The FCR has been defined with an EQU assembler directive. Accesses to bits of the FCR are made

via an auxiliary GPR, as the FCR itself is not bit-addressable.

The shown example uses the following assumptions:

● Pin

● The SAB 88C166(W) runs at 20 MHz CPU clock (absolute time delays refer to it).

● The Flash memory is mapped to segment 1. All DPPs are set correctly.

V

/EBC1 receives a proper

PP

V

supply voltage.

PP

Semiconductor Group 23

Page 25

SAB 88C166(W)

● Enter writing mode via unlock sequence (prerequisite for any programming or erase

operation).

MOV FCR, Rw

MOV [Rw

], Rw

n

n

n

; Dummy write to the FCR

; Both operands use the same GPR

CALL cc_UC, WAIT_10 ; Delay for 10 µs

● Program the FCR register with a value that selects erase mode. Note that this does not yet start

the erase operation itself.

MOV R15, #1000 00XX 0110 0011B

; #xxxx xxxx xxxx xxx1: FWE=’1’: Enable Flash write operations

; #xxxx xxxx xxxx xx1x: FEE=’1’: Select erase mode

; #xxxx xxxx x11x xxxx: CKCTL=’11’: 10 ms erase pulse (fCPU = 20 MHz)

; #xxxx xxXX xxxx xxxx: BE=’xx’: Select the desired bank (3...0)

; #1xxx xxxx xxxx xxxx: FWMSET=’1’: Stay in writing mode

MOV DPP1:pof FCR, R15 ; Write Value to the FCR using 16-bit access

● Initialize target pointer with the start address of the selected Flash memory bank. The Flash

memory must be accessed indirectly and uses the pointer FLASH_PTR. This pointer will apply

to DPP0 or DPP1, which are expected to select data pages 4 or 5, respectively.

● Test for correct

V

margin at pin

PP

V

/EBC1 before an erase operation is started. If bit

PP

VPPREV reads ‘1’, the erase voltage is correct and the algorithm can be continued. Otherwise,

the erase routine could wait in Flash writing mode until

V

reaches its correct value and resume

PP

erasing then, or it could exit writing mode.

MOV R15, DPP1:pof FCR ; Read FCR contents using 16-bit access

JB R15.4, Vpp_OK2 ; Test

V

via bit VPPREV (= FCR.4)

PP

… ; VPPREV=’0’: Exit erase procedure

Vpp_OK2: ; VPPREV=’1’: Test Okay! Continue

● Initialize loop counter (PCOUNT) with the maximum number of erase trials (ENmax) to be

performed before exiting the routine with a failure. Each trial means applying a pulse of 10 ms to

the selected Flash memory bank. According to the maximum cumulated erase time of 30 s

allowed per cell, ENmax must be ‘3000’ here.

● Erase selected Flash memory bank by writing to a Flash memory location using the target

address as write data.

MOV [FLASH_PTR], FLASH_PTR ; Write address to Flash, starts erasing

● Wait until erase time elapsed, which depends on bit field CKCTL in the FCR register and on the

CPU clock frequency (10 ms in this example). End of erasing is detected by polling the FBUSY

flag in the FCR register. The Flash memory switches to EVM mode automatically.

Semiconductor Group 24

Page 26

SAB 88C166(W)

WAIT_ERASE: ; Polling Loop to check bit FBUSY

MOV R15, DPP1: pof FCR ; Read FCR contents using 16-bit access

JB R15.2, WAIT_ERASE ; Loop while bit FBUSY (FCR.2) is ‘1’

… ; Continue in EVM mode, when FBUSY is ‘0’

● Verify

V

validity during erasing to make sure

PP

V

did not exceed its valid margins during the

PP

erase operation. Otherwise erasing may have not been performed properly. The FCVPP flag is

set to ‘1’ in case of this error condition. If FCVPP reads ‘1’, the erase routine can abort, when

still fails, or repeat the erase operation, when

● Perform Erase-Verify operation and compare with ‘FFFF

V

proves to be stable now.

PP

’ in order to check whether an

H

V

PP

erase operation was performed correctly. EVM reading consists of two identical Flash read

instructions with 4 µs delay in between. This example uses CMP instructions to access the Flash

memory. In case of a mismatch the erase routine repeats the erase cycle provided that the

maximum number of attempts was not yet reached.

MOV R15, ONES ; Load auxiliary GPR with anticipated value

CMP R15, [FLASH_PTR] ; 1st step of EVM read

CALL cc_UC, WAIT_4 ; Delay for 4 µs

CMP R15, [FLASH_PTR] ; 2nd step of EVM read

JMP cc_NZ, ERASE_FAILED ; Re-erase on mismatch, if (PCOUNT) > 0

. . . ; Erasing was OK. Go on with next step.

● Check number of erase attempts to decide, if another erase attempt is allowed. PCOUNT is

decremented by ‘1’ upon each unsuccessful erase attempt. If it expires, the failing Flash memory

bank is classified as unerasable. This failure is very unlikely to occur. However, it should be

checked for safe erasing.

Note: This step is taken only in case of a erase verify mismatch.

● Check for last word and increment pointers to decide, if another cell must be verified. The

target pointer (FLASH_PTR) is incremented to the next word to be verified and checked against

the upper limit of the respective bank. If the target pointer exceeds the bank limit, the erase

routine is exited successfully.

● Disable erase operations and exit routine, when the Flash memory bank was erased

successfully or when a failure occurred. In either case bit FWE of the FCR is reset to ‘0’ and the

erase routine is exited. This means that the Flash non-verify mode is entered again, where the

FCR stays accessible but Flash memory locations can be read normally again using indirect

addressing. For returning to the Flash standard mode, bit FWMSET of the FCR must be reset to

‘0’ by the calling routine. The erase routine may return an exit code that indicates correct erasing

or identifies the type of error.

Semiconductor Group 25

Page 27

SAB 88C166(W)

Fundamentals of Flash Technology

The Flash memory included in the SAB 88C166(W) combines the EPROM programming

mechanism with electrical erasability (like an EEPROM) to create a highly reliable and cost effective

memory. A Flash memory cell consists of a single transistor with a floating gate for charge storage

like an EPROM, uses a thinner gate oxide, however.

The programming mechanism of a Flash cell is based on ‘hot’ electron injection which works as

follows: The high voltage between drain and source forces ‘hot’ electrons supplied from the source

to enter the channel. Attracted by the high voltage on the cell’s control gate there, free electrons are

trapped into the floating gate. The amount of negative charge on the floating gate is basically

determined by the length and the number of programming pulses applied to the cell. A special read

operation, Program-Verify, is provided for verifying that the charge put onto the floating gate

represents a proper ‘0’.

Figure 9

Flash Memory Cell Programming Mechanism

The cell erase mechanism is based on ‘Fowler-Nordheim’ tunnelling which works as follows:

A high voltage is applied to the cell’s source whilst the control gate grounded. The cell’s drain is

disconnected in this case. Attracted by the high voltage on the cell’s source, electrons migrate from

the floating gate to the source. The amount of negative charge removed from the floating gate is

basically determined by the length and the number of erasing pulse applied to the cell. A special

read operation, Erase-Verify, is provided for verifying that the charge remaining on the floating gate

represents a proper ‘1’.

Unlike a standard EEPROM, where individual bytes can be erased, the Flash memory of the SAB

88C166(W) is erased block-wise which means that the high voltage is applied to all cells belonging

to one block simultaneously.

One requirement for performing proper Flash programming and erase operations is to have all cells

of a block set to a minimum threshold level before the operation is started. A cell erasing faster than

others could have a threshold voltage too low or negative. In this case the corresponding transistor

could become conductive and affect other cells placed in the same column of the transistor array.

Thus, all cells of that column could erroneously be read as ‘1’ instead of ‘0’.

Semiconductor Group 26

Page 28

SAB 88C166(W)

To avoid this possible malfunction, the user must equalize the amount of charge on each cell by

programming all cells of one block to ‘0’ before performing a block erasure.

Figure 10

Flash Memory Cell Erase Mechanism

The introduced erase algorithm meets this requirement. In combination with the Flash technology

used, it provides a tight threshold voltage distribution, generating a sufficient margin even to cells

erasing faster than others.

Figure 11

Flash Erasure

Note that the following terminology is used in this document: Flash WRITING means changing the

state of the floating gate. Flash PROGRAMMING means loading electrons onto the floating gate.

Flash ERASING means removing electrons from the floating gate.

Semiconductor Group 27

Page 29

SAB 88C166(W)

Absolute Maximum Ratings

Ambient temperature under bias (TA):

SAB 88C166(W)-5M.......................................................................................................0 to + 70 ˚C

Storage temperature (TST) ....................................................................................... – 65 to + 125 ˚C

Voltage on VCC pins with respect to ground (VSS) ..................................................... – 0.5 to + 6.5 V

Voltage on any pin with respect to ground (VSS).................................................– 0.5 to VCC + 0.5 V

Input current on any pin during overload condition.................................................. – 10 to + 10 mA

Absolute sum of all input currents during overload condition ..............................................|100 mA|

Power dissipation........................................................................................................................ 1 W

Flash programming voltage (VPP)............................................................................ – 0.3 to + 13.5 V

Note: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent

damage to the device. This is a stress rating only and functional operation of the device at

these or any other conditions above those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended

periods may affect device reliability. During overload conditions (VIN > VCC or VIN < VSS) the

voltage on pins with respect to ground (VSS) must not exceed the values defined by the

Absolute Maximum Ratings.

Parameter Interpretation

The parameters listed in the following partly represent the characteristics of the SAB 88C166(W)

and partly its demands on the system. To aid in interpreting the parameters right, when evaluating

them for a design, they are marked in column “Symbol”:

CC (Controller Characteristics):

The logic of the SAB 88C166(W) will provide signals with the respective timing characteristics.

SR (System Requirement):

The external system must provide signals with the respective timing characteristics to the SAB

88C166(W).

Semiconductor Group 28

Page 30

SAB 88C166(W)

DC Characteristics

V

= 5 V ± 10 %; VSS = 0 V; f

CC

T

= 0 to + 70 ˚C for SAB 88C166(W)-5M

A

Parameter Symbol Limit Values Unit Test Condition

= 20 MHz

CPU

min. max.

Input low voltage EBC1/V

PP

V

SR – 0.3 0.2 V

IL1

CC

V–

– 0.1

Input low voltage

(all except EBC1/V

PP

)

Input high voltage

(all except RSTIN

and XTAL1)

Input high voltage RSTIN

Input high voltage XTAL1

Output low voltage

(Port 0, Port 1, Port 4, ALE, RD

SR – 0.5 0.2 V

IL2

CC

– 0.1

V

SR 0.2 V

IH

CC

V

+ 0.5 V –

CC

+ 0.9

V

SR 0.6 V

IH1

V

SR 0.7 V

IH2

V

CC – 0.45 V IOL = 2.4 mA

OL

CC

CC

V

+ 0.5 V –

CC

V

+ 0.5 V –

CC

,

V–

V

WR, BHE, CLKOUT, RSTOUT)

Output low voltage

V

CC – 0.45 V I

OL1

= 1.6 mA

OL1

(all other outputs)

Output high voltage

(Port 0, Port 1, Port 4, ALE, RD

CC 0.9 V

OH

,

CC

2.4

–VI

= – 500 µA

OH

I

= – 2.4 mA

OH

V

WR, BHE, CLKOUT, RSTOUT)

Output high voltage

(all other outputs)

Input leakage current (Port 5)

1)

Input leakage current (all other) I

VPP leakage current EBC1/V

PP

RSTIN pullup resistor R

Read inactive current

Read active current

ALE inactive current

ALE active current

4)

4)

4)

4)

CC 0.9 V

OH1

CC

2.4

I

CC – ± 200 nA 0 V < VIN < V

OZ1

CC – ± 500 nA 0 V < VIN < V

OZ2

I

CC – ± 100 µA VPP ≤ V

PPS

CC 50 150 kΩ –

RST

2)

I

RH

I

RL

I

ALEL

I

ALEH

3)

– – 40 µA V

-500 – µA V

2)

– 150 µA V

3)

2100 – µA V

–V

V

I

= – 250 µA

OH

I

= – 1.6 mA

OH

OUT

OUT

OUT

OUT

= V

= V

= V

= V

CC

OHmin

OLmax

OLmax

OHmin

V

XTAL1 input current IILCC – ± 20 µA 0 V < VIN < V

Pin capacitance

(digital inputs/outputs)

Power supply current

Idle mode supply current I

5)

C

CC – 10 pF f = 1 MHz

IO

T

A

I

CC

ID

– 50 +

5 x f

– 30 +

1.5 x f

CPU

CPU

mA RSTIN = V

f

CPU

mA RSTIN = V

f

CPU

= 25 ˚C

IL2

in [MHz]

IH1

in [MHz]

CC

CC

CC

6)

6)

Semiconductor Group 29

Page 31

SAB 88C166(W)

Parameter Symbol Limit Values Unit Test Condition

min. max.

Power-down mode supply current I

V

read current I

PP

V

writing current I

PP

PD

PPR

PPW

–50µAV

= 5.5 V

CC

– 200 µA VPP > V

– 50 mA 1/TCL = 40 MHz

32-bit

programming

V

= 12 V

PP

V

during write/read V

PP

PP

Notes

1)

This specification does not apply to the analog input (Port 5.x) which is currently converted.

2)

The maximum current may be drawn while the respective signal line remains inactive.

3)

The minimum current must be drawn in order to drive the respective signal line active.

4)

This specification is only valid during Reset, or during Hold-mode.

5)

Not 100% tested, guaranteed by design characterization.

6)

The supply current is a function of the operating frequency. This dependency is illustrated in the figure below.

These parameters are tested at V

or VIH.

V

IL

7)

All inputs (including pins configured as inputs) at 0 V to 0.1 V or at VCC – 0.1 V to VCC, V

and 20 MHz CPU clock with all outputs disconnected and all inputs at

CCmax

(including pins configured as outputs) disconnected.

A voltage of V

≥ 2.5 V is sufficient to retain the content of the internal RAM during power down mode.

CC

11.4 12.6 V

= 0 V, all outputs

REF

7)

CC

Semiconductor Group 30

Page 32

150

100

I [mA]

SAB 88C166(W)

I

CCmax

50

10

5 10

15 20

Figure 12

Supply/Idle Current as a Function of Operating Frequency

I

IDmax

f

CPU

[MHz]

Semiconductor Group 31

Page 33

SAB 88C166(W)

A/D Converter Characteristics

V

= 5 V ± 10 %; VSS = 0 V

CC

T

= 0 to + 70 ˚C for SAB 88C166(W)-5M

A

4.0 V ≤ V

Parameter Symbol Limit Values Unit Test Condition

Analog input voltage range

Sample time tSCC – 2 t

Conversion time tCCC – 10 tCC +

Total unadjusted error TUECC – ± 2 LSB

Internal resistance of reference

voltage source

Internal resistance of analog

source

ADC input capacitance C

≤ VCC + 0.1 V; VSS – 0.1 V ≤ V

AREF

≤ VSS + 0.2 V

AGND

min. max.

V

SR V

AIN

R

CC – tCC / 250

AREF

AGND

V

AREF

SC

t

+ 4TCL

S

- 0.25

R

CC – tS / 500

ASRC

– 0.25

CC – 50 pF

AIN

V

kΩ

kΩ

1)

2) 4)

3) 4)

5)

t

in [ns]

CC

t

in [ns]

S

7)

6) 7)

2) 7)

Notes

1)

V

may exceed V

AIN

cases will be X000

2)

During the sample time the input capacitance CI can be charged/discharged by the external source. The

or V

AGND

or X3FFH, respectively.

H

up to the absolute maximum ratings. However, the conversion result in these

AREF

internal resistance of the analog source must allow the capacitors to reach their final voltage level within t

After the end of the sample time t

The value for the sample clock is t

3)

This parameter includes the sample time tS, the time for determining the digital result and the time to load the

, changes of the analog input voltage have no effect on the conversion result.

S

= TCL x 32.

SC

result register with the conversion result.

The value for the conversion clock is t

4)

This parameter depends on the ADC control logic. It is not a real maximum value, but rather a fixum.

5)

TUE is tested at V

AREF

= 5.0 V, V

= TCL x 32.

CC

= 0 V, VCC = 4.8 V. It is guaranteed by design characterization for all

AGND

other voltages within the defined voltage range.

6)

During the conversion the ADC’s capacitance must be repeatedly charged or discharged. The internal

resistance of the reference voltage source must allow the capacitors to reach their respective voltage level

within t

7)

Not 100% tested, guaranteed by design characterization.

. The maximum internal resistance results from the CPU clock period.

CC

.

S

Semiconductor Group 32

Page 34

SAB 88C166(W)

Testing Waveforms

AC inputs during testing are driven at 2.4 V for a logic ‘1’ and 0.4 V for a logic ‘0’.

Timing measurements are made at V

Figure 13

Input Output Waveforms

min for a logic ‘1’ and VIL max for a logic ‘0’.

IH

For timing purposes a port pin is no longer floating when a 100 mV change from load

voltage occurs, but begins to float when a 100 mV change from the loaded VOH/VOL level occurs

(IOH/IOL = 20 mA).

Figure 14

Float Waveforms

Memory Cycle Variables

The timing tables below use three variables which are derived from registers SYSCON and

BUSCON1 and represent the special characteristics of the programmed memory cycle. The

following table describes, how these variables are to be computed.

Description Symbol Values

ALE Extension

Memory Cycle Time Waitstates

Memory Tristate Time

t

A

t

C

t

F

TCL x <ALECTL>

2TCL x (15 – <MCTC>)

2TCL x (1 – <MTTC>)

Semiconductor Group 33

Page 35

SAB 88C166(W)

AC Characteristics

The specification of the timings depends on the CPU clock signal that is used in the respective

device. In this regard the specification for the SAB 88C166 and the SAB 88C166W are different.

While the SAB 88C166W directly uses the clock signal fed to XTAL1 and therefore has to take into

account the duty cycle variation of this signal, the SAB 88C166 derives its CPU clock from the

XTAL1 signal via a 2:1 prescaler and therefore is independant from these variations.

For these reasons the following pages provide the timing specifications for SAB 88C166 and for

SAB 88C166W separately (where applicable).

AC Characteristics

External Clock Drive XTAL1 for the SAB 88C166

V

= 5 V ± 10 %; VSS = 0 V

CC

T

= 0 to +70 ˚C for SAB 88C166-5M

A

Parameter Symbol Max. CPU Clock

= 20 MHz

Variable CPU Clock

1/2TCL = 1 to 20 MHz

Unit

min. max. min. max.

Oscillator period TCLSR 25 25 25 500 ns

t

High time

Low time

Rise time

Fall time

SR6–6–ns

1

t

SR6–6–ns

2

t

SR–5–5ns

3

t

SR–5–5ns

4

Figure 15

External Clock Drive XTAL1

Semiconductor Group 34

Page 36

AC Characteristics (cont’d)

External Clock Drive XTAL1 for the SAB 88C166W

V

= 5 V ± 10 %; VSS = 0 V

CC

T

= 0 to + 70 ˚C for SAB 88C166W-M

A

SAB 88C166(W)

Parameter Symbol CPU Clock = 16 MHz

Duty cycle 0.4 to 0.6

Variable CPU Clock

1/CLP = 1 to 20 MHz

Unit

min. max. min. max.

Oscillator period CLPSR 62.5 62.5 50 1000 ns

High time TCL

Low time TCL

Rise time

Fall time

SR 25 – 25 CLP-TCL

H

SR 25 – 25 CLP-TCL

L

t

SR – 10 – 10 ns

R

t

SR – 10 – 10 ns

F

L

H

ns

ns

Oscillator duty cycle DCSR 0.4 0.6 25 / CLP 1 – 25 / CLP

Clock cycle TCLSR 25 37.5 CLP x DC

min

CLP x DC

max

ns

Note: In order to run the SAB 88C166W at a CPU clock of 20 MHz the duty cycle of the oscillator

clock must be 0.5, ie. the relation between the oscillator high and low phases must be 1:1. So

the variation of the duty cycle of the oscillator clock limits the maximum operating speed of

the device.

The 16 MHz values in the tables are given as an example for a typical duty cycle variation of

the oscillator clock from 0.4 to 0.6.

Figure 16

External Clock Drive XTAL1

Semiconductor Group 35

Page 37

SAB 88C166(W)

AC Characteristics (cont’d)

Multiplexed Bus for the SAB 88C166

V

= 5 V ± 10 %; VSS = 0 V

CC

T

= 0 to + 70 ˚C for SAB 88C166-5M

A

C

(for Port 0, Port 1, Port 4, ALE, RD, WR, BHE, CLKOUT) = 100 pF

L

ALE cycle time = 6 TCL + 2tA + tC + tF (150 ns at 20-MHz CPU clock without waitstates)

Parameter Symbol Max. CPU Clock

= 20 MHz

min. max. min. max.

ALE high time t5CC 15 + t

t

t

t

CC

6

CC

7

CC

8

10 +

15 +

15 +

Address setup to ALE

Address hold after ALE

ALE falling edge to RD

,

A

t

A

t

A

t

A

– TCL – 10 + tA–ns

– TCL – 15 + tA–ns

– TCL – 10 + tA–ns

– TCL – 10 + tA–ns

WR (with RW-delay)

t

ALE falling edge to RD

,

CC

9

– 10 +

t

– – 10 + t

A

WR (no RW-delay)

t

Address float after RD

,

10

CC

–5–5ns

WR (with RW-delay)

t

Address float after RD

,

11

CC

– 30 – TCL + 5 ns

WR (no RW-delay)

, WR low time

RD

t

CC 40 + t

12

C

– 2TCL – 10

(with RW-delay)

WR low time

RD

t

CC 65 + t

13

C

– 3TCL – 10

(no RW-delay)

to valid data in

RD

t

SR – 30 + t

14

C

(with RW-delay)

to valid data in

RD

t

SR – 55 + t

15

C

(no RW-delay)

ALE low to valid data in

t

SR – 55

16

+ tA + t

t

Address to valid data in

SR – 75

17

+ 2tA + t

t

Data hold after RD

SR0–0–ns

18

rising edge

Variable CPU Clock

1/2TCL = 1 to 20 MHz

A

+ t

C

+ t

C

– 2TCL – 20

– 3TCL – 20

– 3TCL – 20

C

– 4TCL – 25

C

Unit

–ns

–ns

–ns

ns

+ t

C

ns

t

+

C

ns

+ tA + t

C

ns

+ 2tA + t

C

t

Data float after RD

Data valid to WR

Data hold after WR

SR – 35 + t

19

t

CC 35 + t

22

t

CC 35 + t

23

C

F

Semiconductor Group 36

F

– 2TCL – 15

– 2TCL – 15

+ t

C

– 2TCL – 15

+ t

F

ns

+ t

F

–ns

–ns

Page 38

SAB 88C166(W)

Parameter Symbol Max. CPU Clock

= 20 MHz

min. max. min. max.

ALE rising edge after RD,

t

CC 35 + t

25

F

– 2TCL – 15

WR

Address hold after RD

,

t

CC 35 + t

27

F

– 2TCL – 15

WR

Variable CPU Clock

1/2TCL = 1 to 20 MHz

–ns

+ t

F

–ns

+ t

F

Unit

Semiconductor Group 37

Page 39

SAB 88C166(W)

AC Characteristics (cont’d)

Multiplexed Bus for the SAB 88C166W

V

= 5 V ± 10 %; VSS = 0 V

CC

T

= 0 to + 70 ˚C for SAB 88C166W-M

A

C

(for Port 0, Port 1, Port 4, ALE, RD, WR, BHE, CLKOUT) = 100 pF

L

ALE cycle time = 6 TCL + 2tA + tC + tF (150 ns at 20-MHz CPU clock without waitstates)

Parameter Symbol CPU Clock = 16 MHz

Duty cycle 0.4 to 0.6

min. max. min. max.

ALE high time t5CC 15 + t

t

Address setup to ALE

Address hold after ALE

ALE falling edge to RD

CC

6

t

CC

7

t

,

CC

8

10 +

15 +

15 +

A

t

A

t

A

t

A

– TCL

– TCL

– TCL

– TCL

WR (with RW-delay)

t

ALE falling edge to RD

,

CC

9

– 10 +

t

– – 10 + t

A

WR (no RW-delay)

t

Address float after RD

,

10

CC

–5–5ns

WR (with RW-delay)

t

Address float after RD

,

11

CC

– 42.5 – TCL

WR (no RW-delay)

, WR low time

RD

t

CC 52.5 + t

12

– CLP – 10

C

(with RW-delay)

WR low time

RD

t

CC 77.5 + t

13

– CLP+TCL

C

(no RW-delay)

RD

to valid data in

t

SR – 47.5 + t

14

C

(with RW-delay)

to valid data in

RD

t

SR – 72.5 + t

15

C

(no RW-delay)

t

ALE low to valid data in

Address to valid data in

Data hold after RD

SR – 72.5

16

+ tA + t

t

SR – 100

17

+ 2tA + t

t

SR0–0–ns

18

C

C

rising edge

Variable CPU Clock

1/CLP = 1 to 20 MHz

+ t

+ t

+ t

+ t

– 10

min

A

– 15

min

A

– 10

min

A

– 10

min

A

A

–ns

–ns

–ns

–ns

–ns

+ 5 ns

max

–ns

+ t

C

–ns

min

– 10 + t

C

– CLP – 20

+ t

C

– CLP+TCL

– 20 + t

C

– CLP+TCL

– 20 + t

C

– 2CLP – 25

+ 2tA + t

C

min

min

Unit

ns

ns

ns

ns

t

Data float after RD

SR – 47.5 + t

19

Semiconductor Group 38

– CLP – 15

F

+ t

ns

F

Page 40

SAB 88C166(W)

Parameter Symbol CPU Clock = 16 MHz

Duty cycle 0.4 to 0.6

min. max. min. max.

Data valid to WR t22CC 47.5 + t

t

Data hold after WR

ALE rising edge after RD

CC 47.5 + t

23

,

t

CC 47.5 + t

25

– CLP – 15

C

– CLP – 15

F

– CLP – 15

F

WR

Address hold after RD

,

t

CC 47.5 + t

27

– CLP – 15

F

WR

Variable CPU Clock

1/CLP = 1 to 20 MHz

–ns

+ t

C

–ns

+ t

F

–ns

+ t

F

–ns

+ t

F

Unit

Semiconductor Group 39

Page 41

SAB 88C166(W)

ALE

A17-A16

(A15-A8)

BHE

Read Cycle

BUS

RD

t

5

t

6

Address

t

8

t

16

t

17

t

25

t

27

Address

t

7

t

19

t

18

Data In

t

10

t

14

t

12

Write Cycle

BUS

Data OutAddress

t

t

8

10

t

22

t

23

WR

t

12

Figure 17

External Memory Cycle: Multiplexed Bus, With Read/Write Delay, Normal ALE

Semiconductor Group 40

Page 42

SAB 88C166(W)

ALE

A17-A16

(A15-A8)

BHE

Read Cycle

BUS

RD

t

5

t

16

t

17

t

25

t

27

Address

t

6

t

7

t

19

t

18

Data InAddress

t

t

8

10

t

14

t

12

Write Cycle

BUS

Data OutAddress

t

t

8

10

t

22

t

23

WR

t

12

Figure 18

External Memory Cycle: Multiplexed Bus, With Read/Write Delay, Extended ALE

Semiconductor Group 41

Page 43

SAB 88C166(W)

ALE

A17-A16

(A15-A8)

BHE

Read Cycle

BUS

RD

t

5

t

16

t

17

Address

t

6

t

7

Address Data In

t

9

t

11

t

15

t

13

t

25

t

27

t

19

t

18

Write Cycle

BUS

Data OutAddress

t

9

t

11

t

22

t

23

WR

t

13

Figure 19

External Memory Cycle: Multiplexed Bus, No Read/Write Delay, Normal ALE

Semiconductor Group 42

Page 44

SAB 88C166(W)

ALE

A17-A16

(A15-A8)

BHE

Read Cycle

BUS

RD

t

5

t

16

t

17

t

25

t

27

Address

t

6

t

7

t

19

t

18

Data InAddress

t

9

t

11

t

15

t

13

Write Cycle

BUS

Data OutAddress

t

9

t

11

t

22

t

23

WR

t

13

Figure 20

External Memory Cycle: Multiplexed Bus, No Read/Write Delay, Extended ALE

Semiconductor Group 43

Page 45

SAB 88C166(W)

AC Characteristics (cont’d)

Demultiplexed Bus for the SAB 88C166

V

= 5 V ± 10 %; VSS = 0 V

CC

T

= 0 to + 70 ˚C for SAB 88C166-5M

A

C

(for Port 0, Port 1, Port 4, ALE, RD, WR, BHE, CLKOUT) = 100 pF

L

ALE cycle time = 4 TCL + 2tA + tC + tF (100 ns at 20-MHz CPU clock without waitstates)

Parameter Symbol Max. CPU Clock

= 20 MHz

min. max. min. max.

ALE high time t5CC 15 + t

t

t

CC

6

CC

8

10 +

15 +

Address setup to ALE

ALE falling edge to RD

,

A

t

A

t

A

– TCL – 10 + tA–ns

– TCL – 15 + tA–ns

– TCL – 10

WR (with RW-delay)

t

ALE falling edge to RD

,

CC

9

– 10 +

t

– – 10

A

WR (no RW-delay)

, WR low time

RD

t

CC 40 + t

12

C

– 2TCL – 10

(with RW-delay)

, WR low time

RD

t

CC 65 + t

13

C

– 3TCL – 10

(no RW-delay)

to valid data in

RD

t

SR – 30 + t

14

C

(with RW-delay)

to valid data in

RD

t

SR – 55 + t

15

C

(no RW-delay)

t

ALE low to valid data in

SR – 55

16

+ tA + t

t

Address to valid data in

SR – 75

17

+ 2tA + t

Data hold after RD

t

SR0–0–ns

18

rising edge

Variable CPU Clock

1/2TCL = 1 to 20 MHz

+ t

A

+ t

A

+ t

C

+ t

C

– 2TCL – 20

– 3TCL – 20