Page 1

INTEGRATED CIRCUITS

DATA SH EET

SAA7348GP

All Compact Disc Engine (ACE)

Preliminary specification

File under Integrated Circuits, IC22

1997 Jul 11

Page 2

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 QUICK REFERENCE DATA

5 BLOCK DIAGRAM

6 PINNING

7 FUNCTIONAL DESCRIPTION

7.1 Analog front-end

7.1.1 Decoder front-end

7.1.2 Servo front end

7.2 Decoder functions

7.3 Servo functions

7.3.1 Signal conditioning

7.3.2 Focus control

7.3.3 Radial control

7.3.4 Off-track counting

7.3.5 Off-track detection

7.3.6 Shock detection

7.3.7 Defect detection

7.3.8 Driver interface

7.3.9 Laser interface

7.4 Subcode interface

7.5 Digital output

7.5.1 Format

7.6 S2B interface

7.7 Audio support

7.7.1 Serial audio data interface

7.8 CD-ROM support

7.8.1 Serial CD-ROM data interface

7.9 Reset

7.10 External ROM support

8 MICROCONTROLLER INTERFACE

8.1 Microcontroller applications registers

8.1.1 CLK generate register (CLKgen)

8.1.2 Port Servo Register (PSR)

8.1.3 Servo Control Register (SCR)

8.1.4 Servo Status Register (STR)

8.1.5 Motor Output QCLV Register (MOQ; address

0XF2H and 0XF3H)

8.1.6 P3 Register

8.1.7 Decoder Status Register (DSR)

8.1.8 Motor Setpoint Register (MSR; address

0XF9H)

8.1.9 Motor Gain QCLV Register (address 0XFAH)

8.1.10 Data Direction Registers (DDR0, DDR2 and

DDR3)

8.1.11 Configuration Control Register (CCR)

8.1.12 A second serial interface

8.1.13 Memory map access to the servo

8.1.14 PLL Registers

8.1.15 DIV17 Register (address 0X9FH)

8.2 Memory map

8.3 Summary of the functions controlled by

decoder registers 0 to F

8.4 Summary of servo commands

8.4.1 Summary of servo command parameters

9 LIMITING VALUES

10 CHARACTERISTICS

10.1 General characteristics

10.2 Subcode interface timing characteristics

10.3 I2S timing characteristics

11 PACKAGE OUTLINE

12 SOLDERING

12.1 Introduction

12.2 Reflow soldering

12.3 Wave soldering

12.4 Repairing soldered joints

13 DEFINITIONS

14 LIFE SUPPORT APPLICATIONS

1997 Jul 11 2

Page 3

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

1 FEATURES

• Focus servo loop

• Radial servo loop

• Built-in access procedure with fast track count

possibilities

• Sledge motor servo loop with pulsed sledge support

• High speed error correction, up to sixteen times

over-speed

• Supports three different over-speed ranges with only

one external crystal

• Lock-to-disc mode

• Full turntable motor control

• Full error correction strategy, t = 2 ande=4

• All standard decoder functions implemented digitally

• Adaptive digital HF equalizer

• FIFO overflow concealment for rotational shock

resistance

• Digital audio interface (EBU), audio and data

• 2 and 4 times oversampling integrated digital filter,

including fs mode

• Audio data peak level detection

• Kill interface for DAC deactivation during digital silence

• All TDA1301 (DSIC2) digital servo functions

• Low focus noise

• Improved playability on ABEX TCD-721R, TCD-725 and

TCD-714 discs

• Automatic closed loop gain control available for focus

and radial loops

• On chip clock multiplier allows the use of 8.4672 MHz

crystal

• S2B serial interface with host controller

• Double speed servo

• Integrated engine controller (high speed embedded

80C51)

• External program support.

2 GENERAL DESCRIPTION

The SAA7348 All Compact Disc Engine (ACE) combines

the functionality of a CD decoder (LO9585), a digital servo

(OQ8868) and a microcontroller core (80C51 based) on a

single chip. It was developed for high speed CD-ROM

applications but, due to the large scale integration, can

also be used in other CD applications. The internal

microcontroller makes it possible to develop other

applications quickly. The microcontroller can operate with

internal or external ROM.

Additional features include:

• High level integration

• Improved communication speed.

3 ORDERING INFORMATION

TYPE NUMBER

NAME DESCRIPTION VERSION

SAA7348GP LQFP100 plastic low profile quad flat package; 100 leads; body 14 × 14 × 1.4 mm SOT407-1

1997 Jul 11 3

PACKAG0E

Page 4

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

4 QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DDD(pads)

V

DDD(core)

V

DDA

I

DD

f

xtal

T

amb

T

stg

Note

1. The analog and digital core supply pins (V

The core and pads can operate at different voltages and should never be connected together directly.

digital supply voltage for pad cells 4.5 5.0 5.5 V

digital supply voltage for the core note 1 3.0 3.3 3.6 V

analog supply voltage note 1 3.0 3.3 3.6 V

supply current n = 8 mode − 90 − mA

crystal frequency 8 8.4672 35 MHz

operating ambient temperature 0 − 70 °C

storage temperature −55 − +125 °C

DDA

and V

DDD(core)

) must be connected to the same external supply.

1997 Jul 11 4

Page 5

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

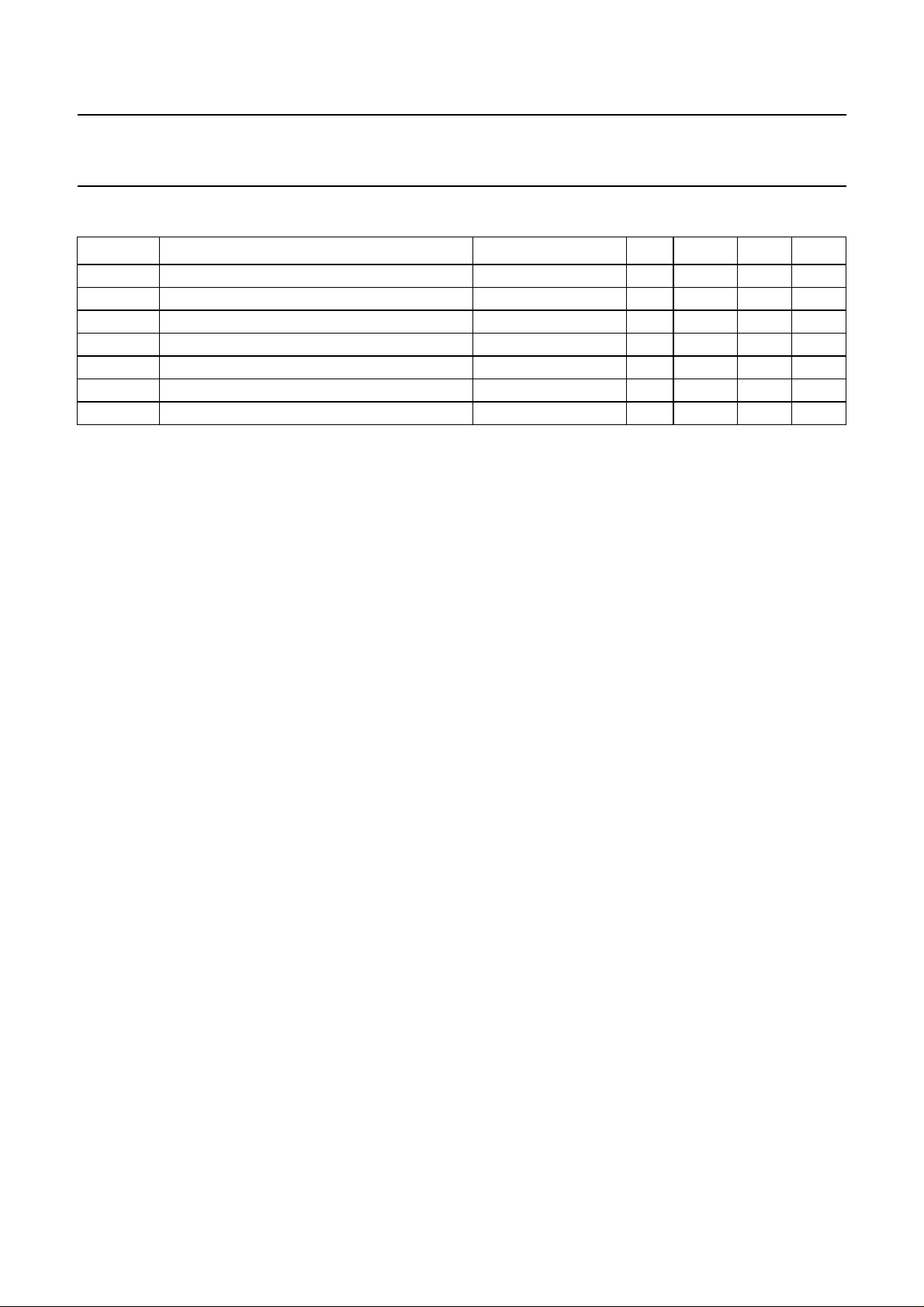

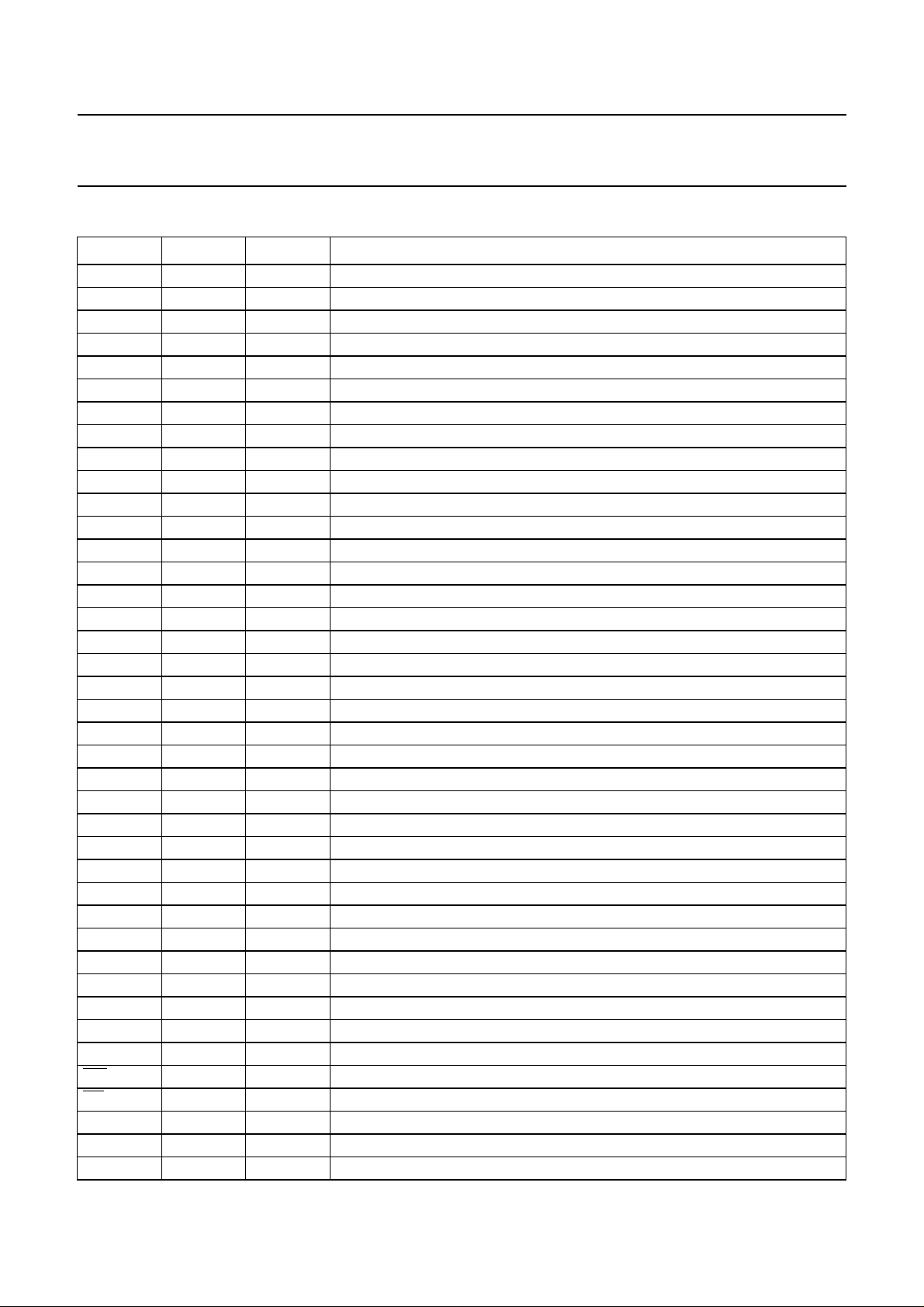

5 BLOCK DIAGRAM

handbook, full pagewidth

MIDLAD

REFLCA

HFIN

REFHCA

I

ref

V

RH

D1

D2

D3

D4

S1

S2

I

refT

FTC

H

FTC

L

V

DDD(core)

HF

V

V

SSA

V

DDA

2 2 2 9 3

(1) (2) (3) (4)

7

8

9

FRONT-END

10

11

SAA7348GP

14

15

16

17

20

21

22

23

24

25

LF

FRONT-END

SSD

V

DDD(pads)

(5)

SBSY RCK VALID

SFSY SUB DAC WCLK DACCLK

92

93

94 95 65 66 67 68 69 62 97 96

DECODER

DIGITAL SERVO

DATA SCLK KILL

DEEM

100

89

71

73

72

91

86

85

84

83

82

74

75

78

79

80

90

98

99

DOBM

SUBQW

MOTOV

MOTOS

FB

C2FAIL

CFLG

FOK

TL

RP

DSDEN

CLO

RA

FO

SL

OTD

DEFI

DEFO

LDON

XTALI

XTALO

SELPLL

(1) Pins 13 and 19.

(2) Pins 12 and 18.

(3) Pins 39 and 88.

(4) Pins 29, 38, 51, 61,

63, 70, 76, 81 and

87.

(5) Pins 52, 64 and 77.

28

27

26

CLOCK

PLL

TEST

1 2 3 30 31 32 33 34 35 36 37 48

TS1 TS3

TS2

R

XD0

T

XD0

INT0

INT1

R

XD1

T

Fig.1 Block diagram.

1997 Jul 11 5

XD1

80C51

8

40 to4753 to

A8 to

A15

AD0 to

AD7

5

TPWM

6

TEN

8

60

49 50

ALE

PSENWREARD

MGK498

Page 6

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

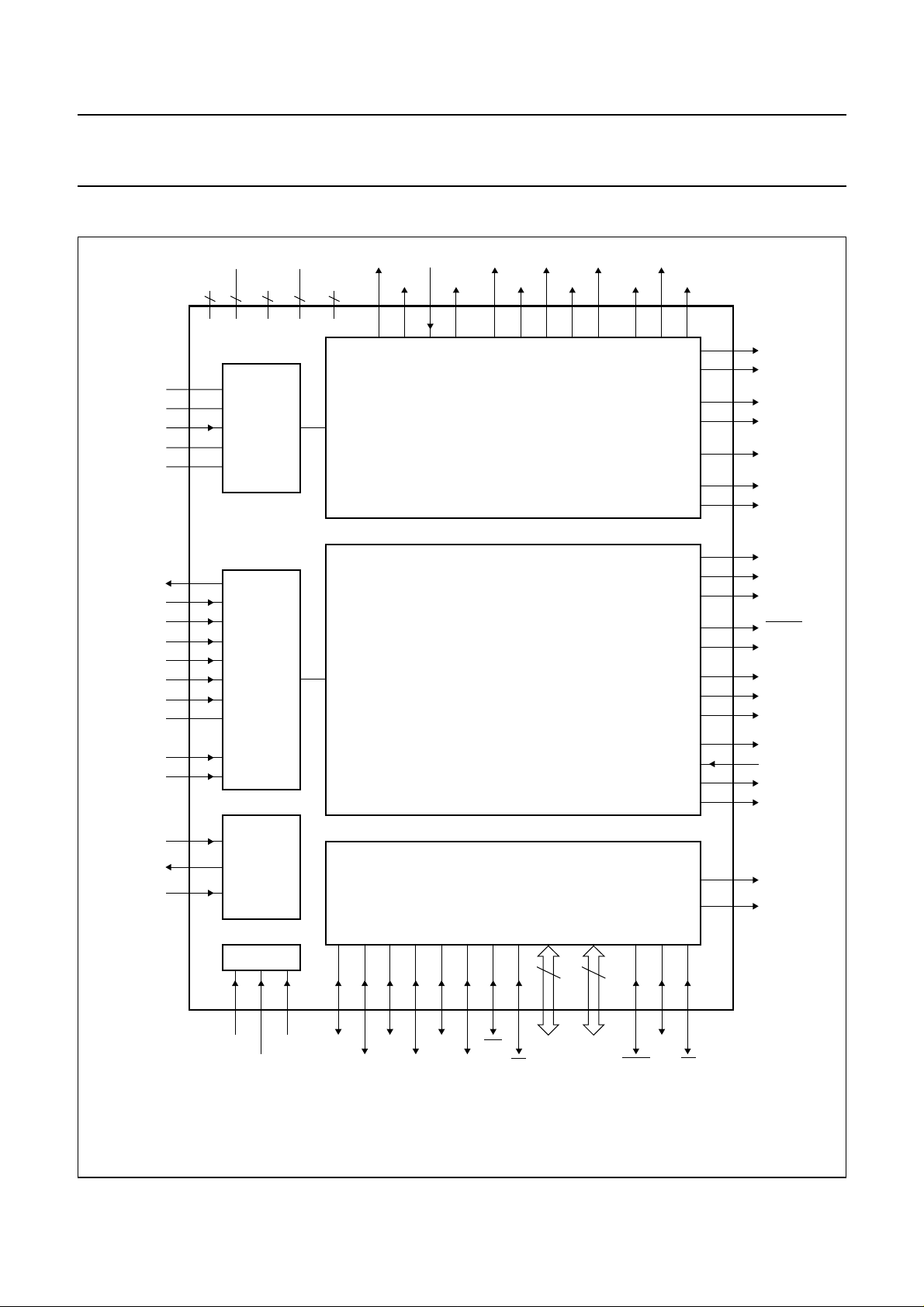

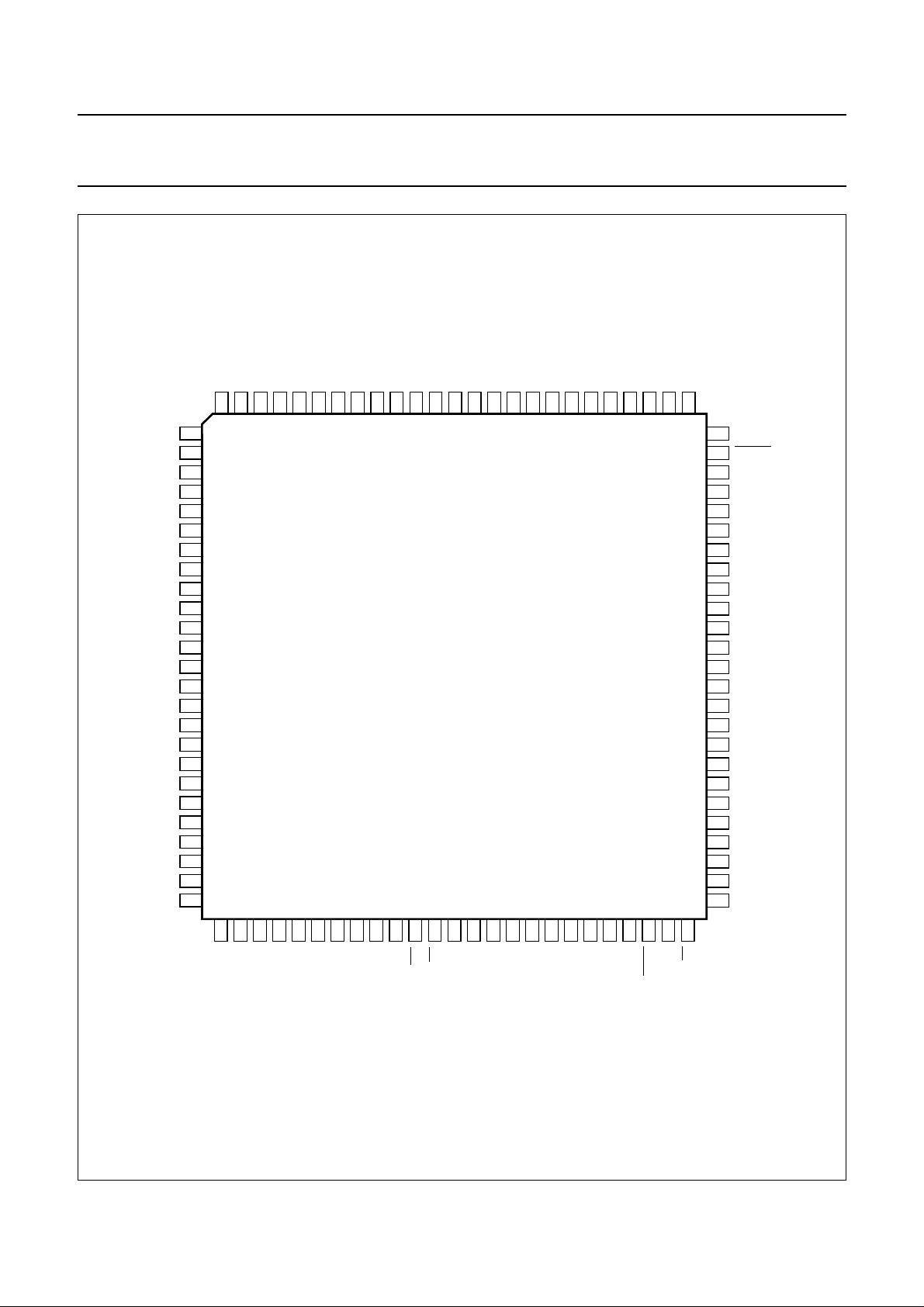

6 PINNING

SYMBOL PIN TYPE

(1)

DESCRIPTION

TS1 1 I test control input; this pin should be tied LOW

TS2 2 I test control input; this pin should be tied LOW

TS3 3 I test control input; this pin should be tied LOW

RST 4 I power-on reset input

TPWM 5 O tray PWM output

TEN 6 O tray enable output

MIDLAD 7 A ladder middle decoupling of High Frequency (HF) ADC

REFLCA 8 A ladder low decoupling of HF ADC

HFIN 9 A HF input

REFHCA 10 A ladder high decoupling of HF ADC

I

ref

V

V

V

SSA1

DDA1

RH

11 A reference current input

12 S analog ground 1 for HF front-end

13 S analog supply voltage 1 for HF front-end (3.3 V)

14 A calibrated reference voltage output from ADC

D1 15 A unipolar current input (central diode signal input)

D2 16 A unipolar current input (central diode signal input)

D3 17 A unipolar current input (central diode signal input)

V

V

SSA2

DDA2

18 S analog ground 2 for LF front-end

19 S analog supply voltage 2 for LF front-end (3.3 V)

D4 20 A unipolar current input (central diode signal input)

S1 21 A unipolar current input (satellite diode signal input)

S2 22 A unipolar current input (satellite diode signal input)

I

refT

FTC

FTC

H

L

23 A current reference, for input range of LF front-end ADCs

24 A fast track counter comparator (+) input

25 A fast track counter comparator (−) input

SELPLL 26 I enables internal clock multiplier PLL

XTALO 27 A crystal output

XTALI 28 A crystal input

V

R

T

SSD1

XD0

XD0

29 S digital ground 1

30 B P3.0

31 B P3.1

INT0 32 B P3.2 (interrupt 0)

INT1 33 B P3.3 (interrupt 1)

R

XD1

T

XD1

34 B P3.4

35 B P3.5

WR 36 B P3.6; active LOW

RD 37 B P3.7; active LOW

V

SSD2

V

DDD1(core)

38 S digital ground 2

39 S digital supply voltage 1 for the core (3.3 V)

A8 40 B P2.0 (address or I/O)

1997 Jul 11 6

Page 7

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

SYMBOL PIN TYPE

(1)

DESCRIPTION

A9 41 B P2.1 (address or I/O)

A10 42 B P2.2 (address or I/O)

A11 43 B P2.3 (address or I/O)

A12 44 B P2.4 (address or I/O)

A13 45 B P2.5 (address or I/O)

A14 46 B P2.6 (address or I/O)

A15 47 B P2.7 (address or I/O)

PSEN 48 B program store enable (pull-up; active LOW)

ALE 49 B address latch enable (pull-up)

EA 50 B external ROM select (active LOW); enhanced hooks

V

SSD3

V

DDD1(pads)

51 S digital ground 3

52 S digital supply voltage 1 for the pads (5 V); pins 26 to 60

AD0 53 B P0.0 (data, address or I/O)

AD1 54 B P0.1 (data, address or I/O)

AD2 55 B P0.2 (data, address or I/O)

AD3 56 B P0.3 (data, address or I/O)

AD4 57 B P0.4 (data, address or I/O)

AD5 58 B P0.5 (data, address or I/O)

AD6 59 B P0.6 (data, address or I/O)

AD7 60 B P0.7 (data, address or I/O)

V

SSD4

61 S digital ground 4

DACCLK 62 T BCC-DAC clock output

V

SSD5

V

DDD2(pads)

63 S digital ground 5

64 S digital supply voltage 2 (level shifter) for the pads (5 V)

VALID 65 T data validity flag; C2 error flag; (3-state)

DAC 66 T serial audio data output to DAC (3-state)

DATA 67 T serial data output to block decoder (3-state)

WCLK 68 T word clock output (3-state)

SCLK 69 T serial bit clock output (3-state)

V

SSD6

70 S digital ground 6

SUBQW 71 O subcode output; Q to W subcode bits

MOTOS 72 T motor output, sign

MOTOV 73 T motor output, value

DSDEN 74 O DSD enable output (active LOW)

CLO 75 O clock output

V

SSD7

V

DDD3(pads)

76 S digital ground 7

77 S digital supply voltage 3 for the pads (5 V); pins 1 to 6 and 65 to 100

RA 78 T radial actuator output

FO 79 T focus actuator output

SL 80 T sledge control output

V

SSD8

81 S digital ground 8

1997 Jul 11 7

Page 8

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

SYMBOL PIN TYPE

(1)

DESCRIPTION

RP 82 OD radial polarity signal (open drain)

TL 83 OD track loss signal (open drain)

FOK 84 OD focus OK signal or decoder measurement signal (open drain)

CFLG 85 OD correction flag output (open drain)

C2FAIL 86 OD indication of correction failure (open drain)

V

SSD9

V

DDD2(core)

87 S digital ground 9

88 S digital supply voltage 2 for the core (3.3 V)

DOBM 89 T EBU bi-phase mark output (externally buffered) (3-state)

OTD 90 O off-track detect

FB 91 OD FIFO boundary, motor overflow (open drain)

SBSY 92 T subcode block sync (3-state)

SFSY 93 T subcode frame sync (3-state)

RCK 94 I subcode clock input

SUB 95 T P to W subcode bits (3-state)

DEEM 96 O deemphasis active output

KILL 97 OD kill output (open drain)

DEFI 98 I defect detector input

DEFO 99 O defect detector output

LDON 100 OD laser drive on output (open drain)

Note

1. Pin type abbreviations: O = Output, I = Input, S = power Supply, A = Analog function, OD = Open Drain,

B = Bidirectional, T = 3-state output. All supply pins must be connected directly to their respective external power

supply voltages.

1997 Jul 11 8

Page 9

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

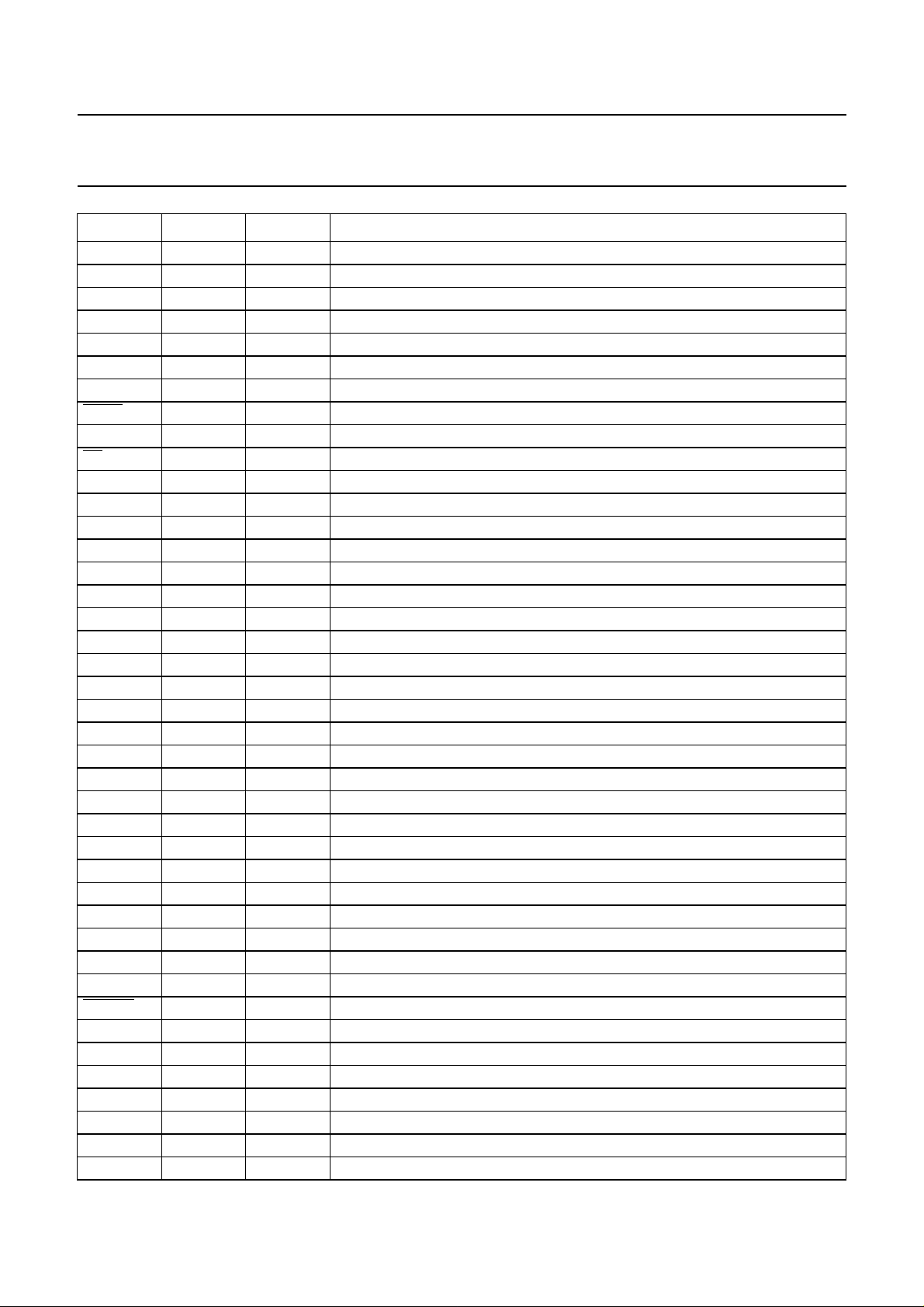

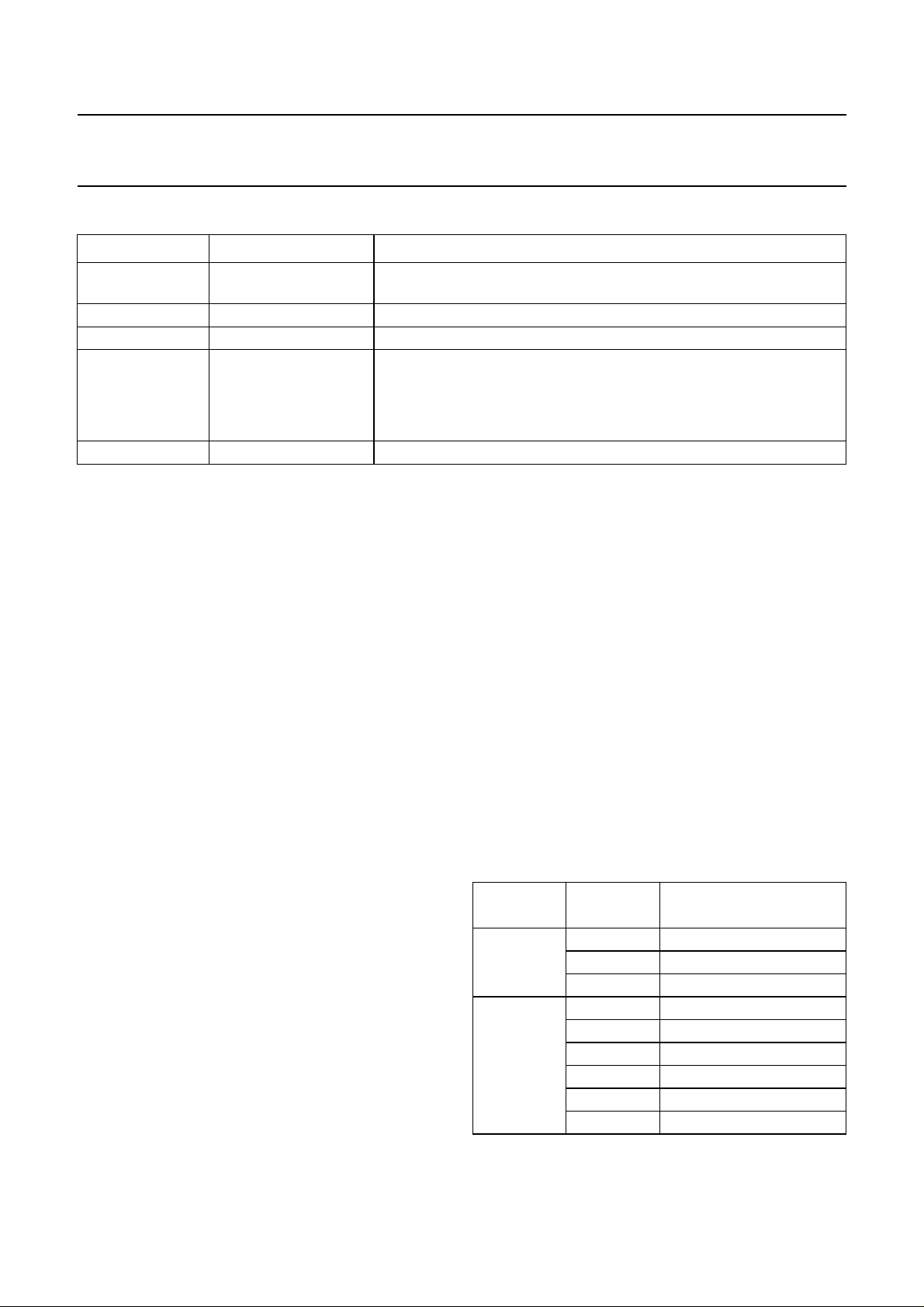

handbook, full pagewidth

DDD3(pads)

SSD7

V

V

75

CLO

74

DSDEN

MOTOV

73

MOTOS

72

71

SUBQW

V

70

SSD6

SCLK

69

68

WCLK

67

DATA

DAC

66

VALID

65

V

64

DDD2(pads)

V

63

SSD5

DACCLK

62

V

61

SSD4

AD7

60

59

AD6

AD5

58

AD4

57

AD3

56

AD2

55

AD1

54

AD0

53

V

52

DDD1(pads)

V

51

SSD3

TS1

TS2

TS3

RST

TPWM

TEN

MIDLAD

REFLCA

HFIN

REFHCA

I

ref

V

SSA1

V

DDA1

V

RH

D1

D2

D3

V

SSA2

V

DDA2

D4

S1

S2

I

refT

FTC

FTC

DDD2(core)

LDON

DEFO

DEFI

KILL

DEEM

SUB

RCK

SFSY

SBSYFBOTD

99989796959493929190898887868584838281

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

H

25

L

SAA7348GP

DOBM

V

SSD9

V

C2FAIL

CFLG

FOKTLRP

SSD8

SLFORA

V

8079787776

26

XTALO

SELPLL

XTALI

31323334353637383940414243444546474849

RD

SSD1

V

XD0

R

XD0

T

INT0

INT1

XD1TXD1

R

WR

30

29

28

27

Fig.2 Pin configuration.

1997 Jul 11 9

SSD2

V

DDD1(core)

V

A8

A9

A10

A11

A12

A13

A14

A15

PSEN

ALE

50

EA

MGK497

Page 10

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

7 FUNCTIONAL DESCRIPTION

The ACE combines the functionality of a DSICS

(OQ8868), a CD65 (LO9585) and an 80C51-based

microcontroller (83C654). In addition, a large part of the

glue logic has been integrated to help minimize the

number of external components required in CD-ROM

applications.

7.1 Analog front-end

The front-end circuit can be split into two parts:

1. The decoder input (HF front-end)

2. The servo input (LF front-end).

Each is powered by a separate power supply pin pair.

7.1.1 D

ECODER FRONT-END

The EFM signal is fed to the decoder through an ADC,

which is preceded by an AGC stage. In order to make full

use of the digital front-end resolution, the gain control

amplifier should deliver a constant 1.4 V p-p output signal.

The gain range of the AGC is 16 dB and is controlled in

steps of 1.0 dB. The gain of the variable gain amplifier is

controlled by an on-chip digital gain control block. This

block allows for both automatic and microcontroller gain

control.

The internal HF detector is sensitive to any disturbance on

the HF signal; a clean (good signal-to-noise ratio) EFM

signal is necessary since high frequency components can

disturb the HF detector. The input range of the HF

front-end varies from 2.3 V p-p down to 0.35 V p-p. If in the

lower range the signal level is between 25% and 75% of

the ADC range, the HF detector will signal NO HF (In this

range an ADC LSB translates into 5.5 mV, so half the

range equals 175 mV. If the total offset was equal to

6 LSBs, the signal range would be reduced by 2 × 33 mV.

In this case a signal of less than 109 mV would signal NO

HF). To ensure the AGC offset is minimized when the AGC

gain is high, it is necessary to connect a resistor divider to

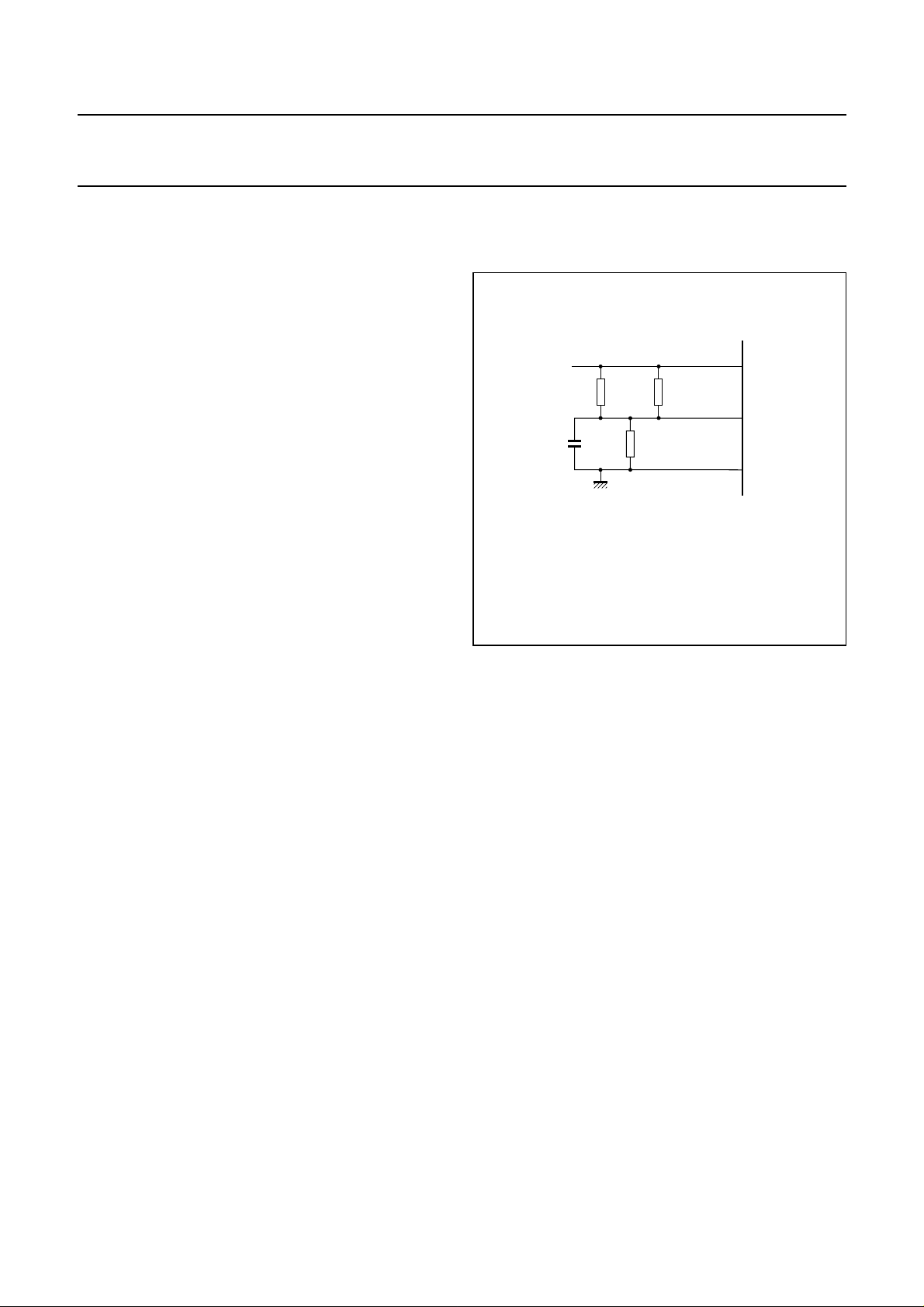

MIDLAD, as shown in Fig.3.

The SAA7348 contains an on-chip digital equalizer and

data slicer. The equalizer is adaptive; actual equalization

depends on the disc speed. The data slicer has a

microcontroller programmable bandwidth. A fully digital

internal PLL is used to regenerate the bit clock.

The bandwidth and equalization of the PLL can be

programmed by the microcontroller. An off-track input is

necessary for certain applications. If the off-track input flag

is HIGH, the SAA7348 will assume that the servo is

following on the wrong track, and will flag all incoming HF

data as incorrect. The off-track input is connected

internally to the servo section.

handbook, halfpage

+3.3 V

820 Ω 820 Ω

10 nF

820 Ω

V

DDA1

MIDLAD

V

SSA1

MGK500

13

7

12

Fig.3 Front-end offset compensation.

7.1.2 SERVO FRONT END

The servo front end contains six current-input ADCs (four

for focus and two for the radial signals). The ADCs do not

require external capacitors, unlike the OQ8868 or CD7

(SAA7370). For high performance radial access, a

comparator input is available for the FTC (Fast Track

Count) signal.

The dynamic range of the ADC input currents can be

adjusted over a range dependent on the value of an

external resistor connected to I

. The maximum input

refT

current for the central and satellite diodes, respectively, is

given below:

I

i(central) max()

I

i satellite()max()

V

is generated internally. The value of VRH is dependent

RH

2.4 106×

----------------------- R

1.2 106×

----------------------- R

µ A()=

IrefT

µ A()=

IrefT

upon the spread of internal capacitors and on the value of

the reference current generated by the external resistor on

I

. Typical input currents for a range of resistance values

refT

are given in Table 1.

1997 Jul 11 10

Page 11

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

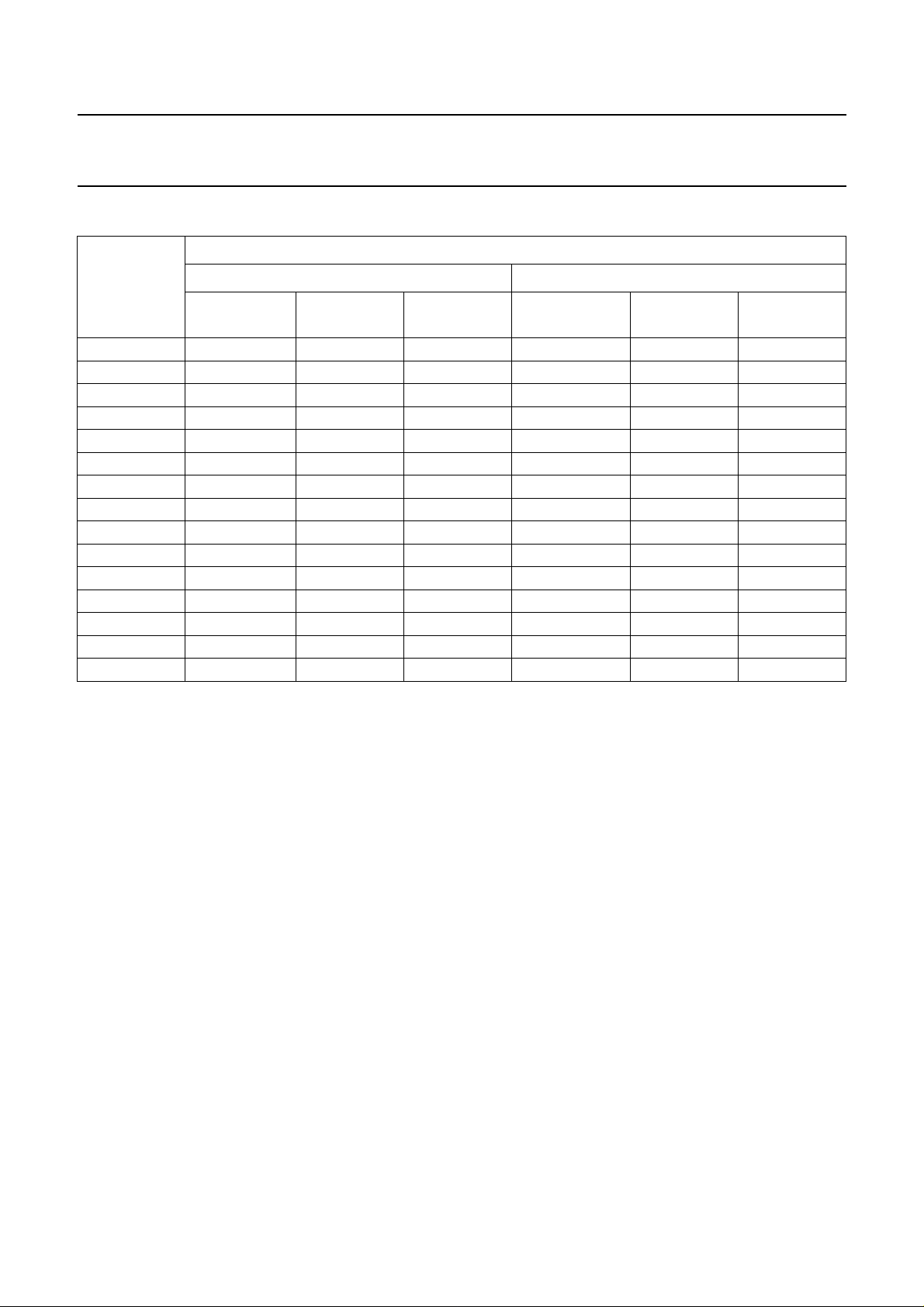

Table 1 Typical input currents for a range of values of R

IrefT

TYPICAL CURRENT INPUT RANGE

R

IrefT

(kΩ)

D1, D2, D3, D4

(µA)

(1)

f

= 4.2336 MHz f

sys

S1, S2

(µA)

V

(V)

RH

D1, D2, D3, D4

(µA)

(1)

= 8.4672 MHz

sys

S1, S2

(µA)

V

(V)

RH

200 12.000 6.000 1.891 12.000 6.000 0.946

220 10.909 5.455 1.719 10.909 5.455 0.860

240 10.000 5.000 1.576 10.000 5.000 0.788

270 8.889 4.444 1.396 8.889 4.444 0.698

300 8.000 4.000 1.261 8.000 4.000 0.631

330 7.273 3.636 1.146 7.273 3.636 0.573

360 6.667 3.333 1.051 6.667 3.333 0.526

390 6.154 3.077 0.970 6.350 3.175 0.500

430 5.581 2.791 0.880 −−−

470 5.106 2.553 0.805 −−−

510 4.706 2.353 0.742 −−−

560 4.286 2.143 0.675 −−−

620 3.871 1.935 0.610 −−−

680 3.529 1.765 0.556 −−−

750 3.200 1.600 0.504 −−−

Note

1. f

is always equal to ; see Table 9.

sys

servo clock

------------------------------2

The preset latch command can be used to select this

method of V

automatic adjustment.

RH

Alternatively, the dynamic range of the input currents can

be made dependent on the ADC reference voltage, V

RH

In this case, the maximum input current for the central and

satellite diodes, respectively, is:

I

i(central) max()

I

i(satellite) max()

where f

sys

f

× 1.10× 106–×µA()=

sysVRH

f

× 0.55× 106–×µA()=

sysVRH

= 4.2336 MHz.

VRH can be set to any one of 32 pre-defined levels,

selectable under software control. VRH is initially set to

2.5 V using the preset latch command, then incremented

or decremented one level at a time by repeatedly

resending the same commend.

7.2 Decoder functions

The SAA7348 is a multi-speed decoding device with an

internal phase locked loop clock multiplier. Several

playback speeds can be selected, depending on the

crystal frequency and the internal clock settings;

see Table 2.

The following functions are performed in the decoder

.

block:

• Demodulation (includes sync protection circuit);

converts the 14-bit EFM data and subcode words into

8-bit symbols.

• Subcode data processing.

• Error correction; a t = 2, e = 4 type is used on both C1

(32 symbol) and C2 (28 symbol) frames. The error

corrector can correct up to 2 errors on the C1 level and

up to 4 errors on the C2 level. The error corrector also

contains a flag processor. Flags are assigned to

symbols when the error corrector cannot ascertain if the

symbols are definitely good. C1 generates output flags

that are used by C2. The C2 output flags are used by the

interpolator to conceal uncorrectable errors for audio

output; they are also output via the EBU signal (DOBM)

and the VALID output with I

2

S for CD-ROM applications.

1997 Jul 11 11

Page 12

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

• Motor control; the spindle motor is controlled by a fully

integrated digital servo. Address information from the

internal 8 frame FIFO and disc speed information are

used to calculate the motor control output signals.

Several output modes are supported:

– Pulse density, 2-line (true complement output),

1 × n MHz sample frequency

– PWM-output, 2-line, 22.05 × n kHz modulation

frequency

– CDV motor mode

– Brushless motor control mode.

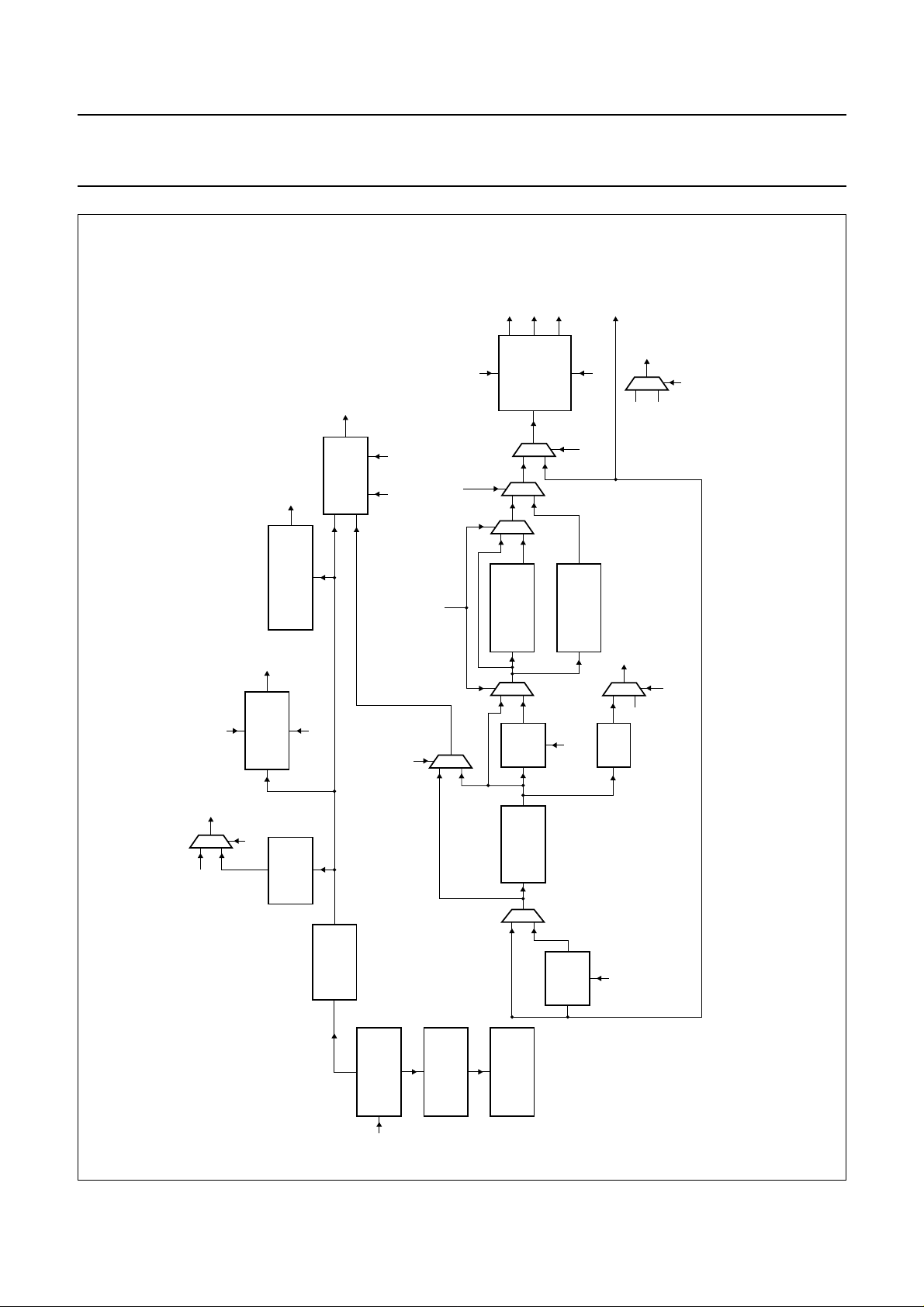

A simplified illustration of the data flow through the

decoder is shown in Fig.4.

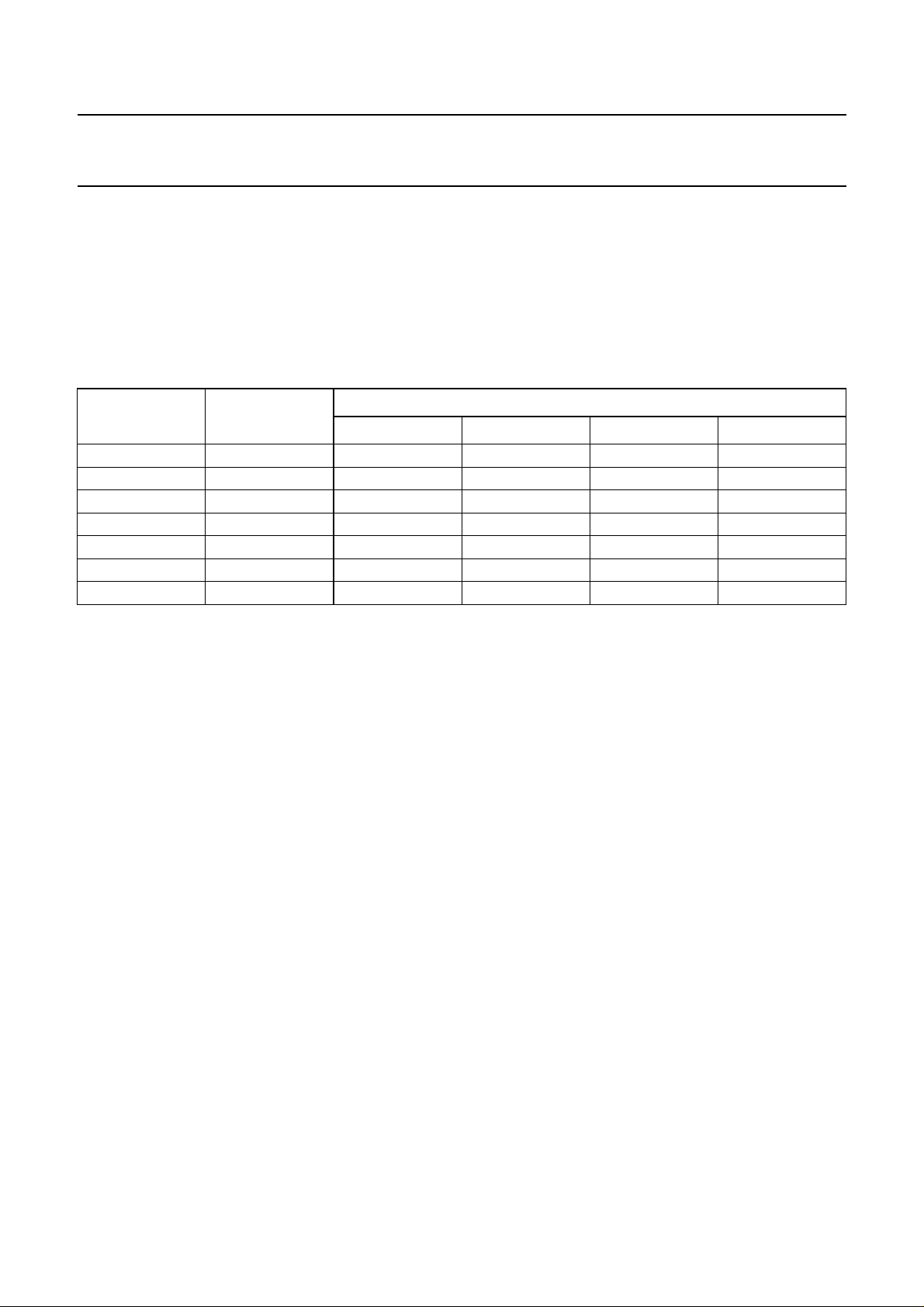

Table 2 Decoder playback speeds; note 1

INTERNAL FREQUENCY (MHz)

REGISTER B REGISTER E

67.7376

(2)

50.8032

(2)

33.8688

(2)(3)

16.9344

00XX 0XXX n = 2 n = 1.5 n = 1 −

00XX 1XXX n = 8 n = 6 n = 4 n = 2

01XX 0XXX −−−n=1

01XX 1XXX −−−n=4

10XX 0XXX n = 4 n = 3 n = 2 −

10XX 1XXX n= 16 n = 12 n = 8 −

11XX 0XXX −−−n=2

Notes

1. X = don’t care.

2. With an 8.4672 MHz crystal, and only if SELPLL = 1 (i.e. clock multiplier enabled; see also Section 8.1.1).

3. Can use external 33.8688 MHz crystal.

4. Can use external 16.9344 MHz crystal.

(4)

1997 Jul 11 12

Page 13

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

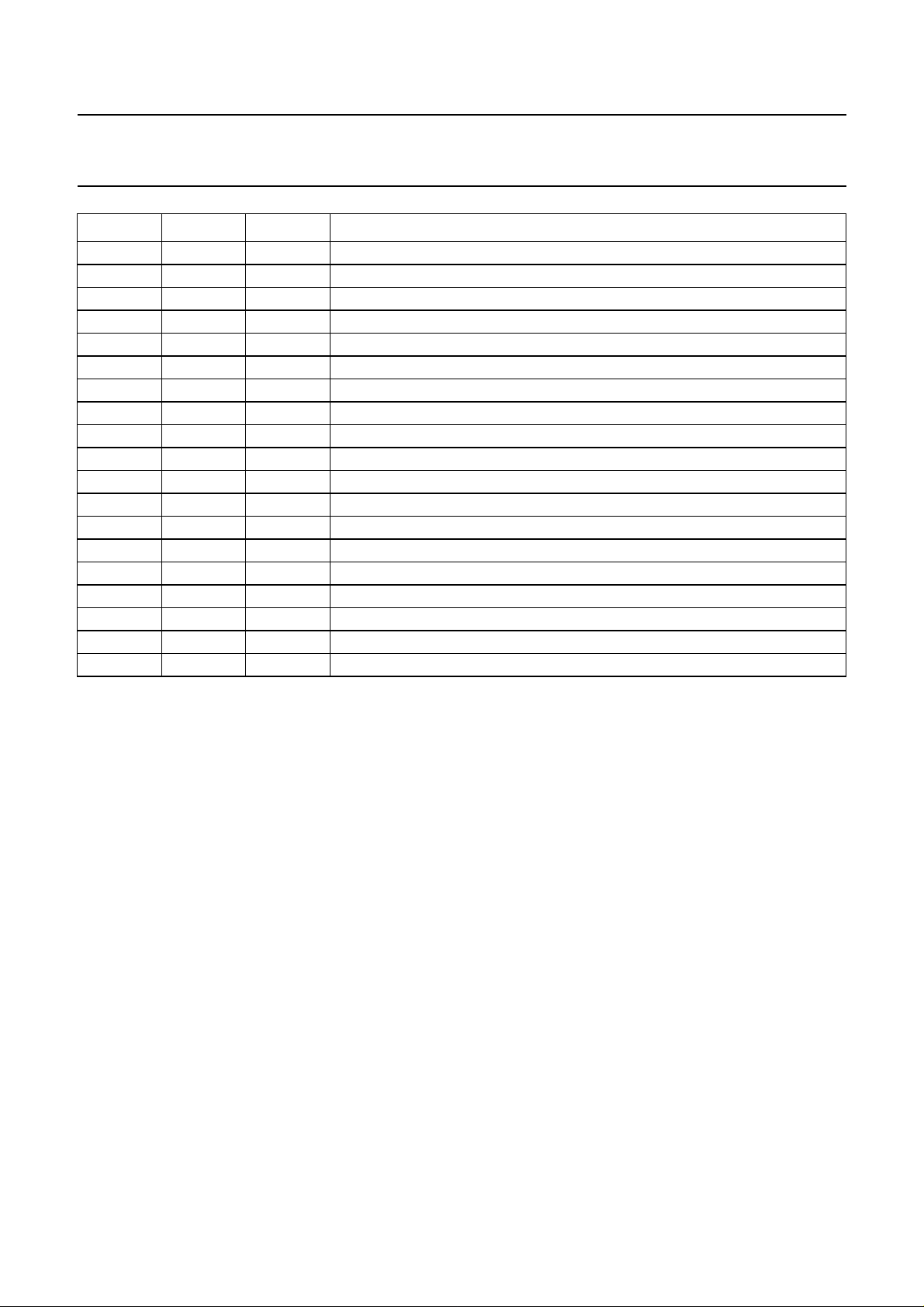

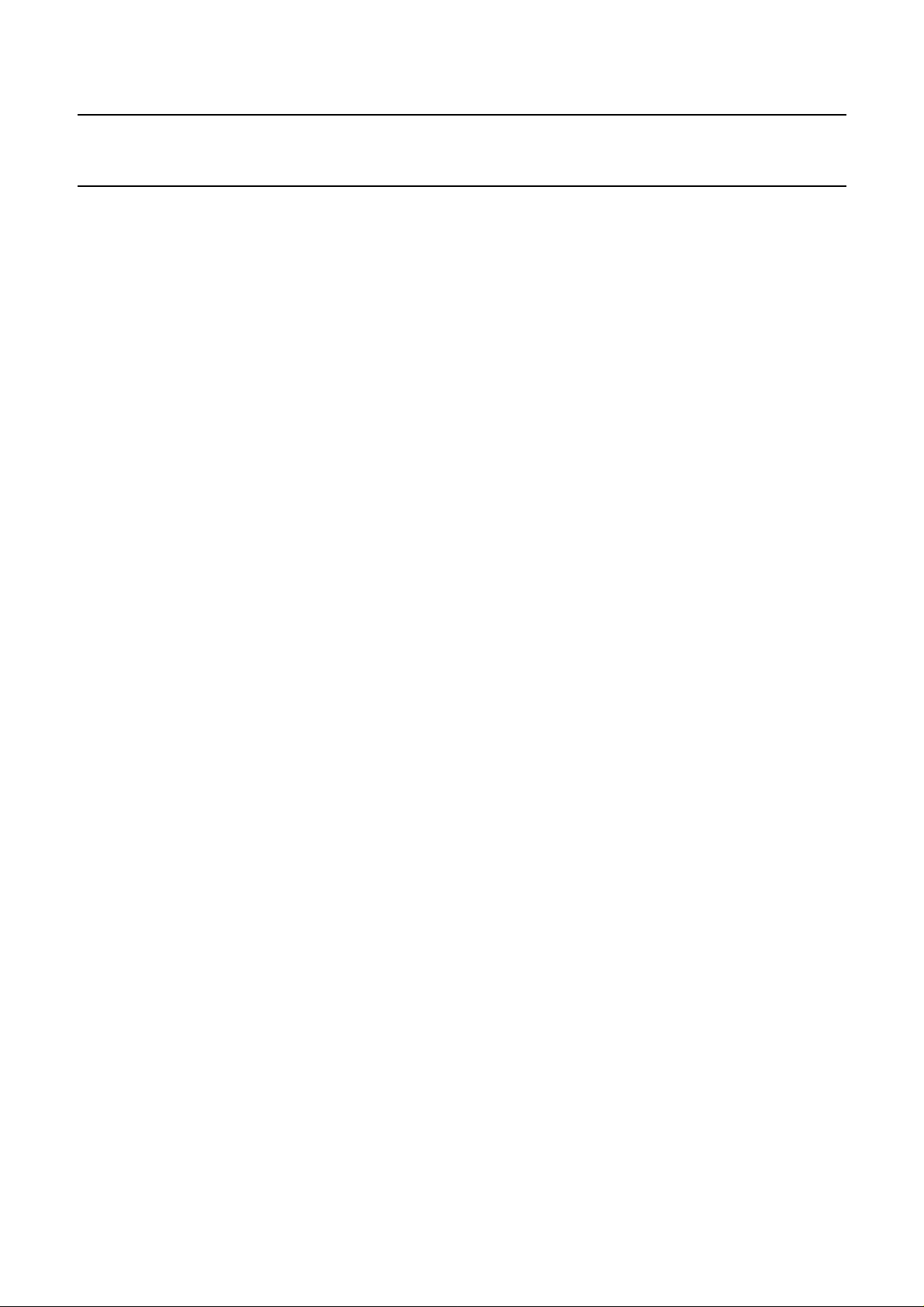

SCLK

WCLK

DAC

DATA

VALID

DEEM

handbook, full pagewidth

RCK

SUBQW

INTERFACE

MICROCONTROLLER

SBSY

SFSY

SUB

INTERFACE

CD GRAPHICS

reg F

DOBM

EBU

INTERFACE

registers 3, 7 and E

reg A reg E

0 : no pre-emphasis detected

OR reg D = 0xxx

1 : pre-emphasis detected

AND reg D = 1xxx

mode)

s

(1f

1 : reg 3 = xx10

0

1

0 : reg A = xx0x

1 : reg A = xx1x

S-BUS

2

I

INTERFACE

1

0

0

1

1

0

PHASE

COMPENSATION

1

0

FILTER

DIGITAL

reg 3

0 : reg 3 = 101x

(CD-ROM modes)

FILTER

DE-EMPHASIS

1

reg 3

KILL

1

0

1

0

1 : pre-emphasis detected AND reg D = 0xxx

OR reg D = 11xx

MGK499

KILL

0

0

0 : reg 0 = x000/reg 3 = 101x/reg 7 = 00xx/reg E = x0xx

1

0

0 : reg D = xx0x

SUBCODE

INTERFACE

0 : reg D = xx10

1 : reg D = xx11

SUBCODE

PROCESSOR

FIFO

DEMODULATOR

DIGITAL PLL AND

EFM

1997 Jul 11 13

FADE/MUTE/

INTERPOLATE

1

0

ERROR

CORRECTOR

1 : reg 7 = 11xx or 00xx

MONO

reg 7

FUNCTION

Fig.4 SAA7348 decoder function: simplified data flow.

Page 14

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

7.3 Servo functions

7.3.1 S

IGNAL CONDITIONING

The digital codes retrieved from the ADCs are applied to

logic circuitry to obtain various control signals. The signals

from the central aperture diodes are processed to obtain a

normalised focus error signal:

FE

n

D1 D2–

---------------------D1 D2+

D3 D4–

–=

---------------------D3 D4+

where the detector set-up illustrated in Fig.5 is assumed.

For single Foucault focusing, signal conditioning can be

switched under software control such that:

D1 D2–

FE

The error signal, FE

×=

2

n

---------------------D1 D2+

, is further processed by a

n

Proportional Integral and Differential (PID) filter section.

A Focus OK (FOK) flag is generated by means of the

central aperture signal and an adjustable reference level.

This signal is used to provide extra protection for

Track-Loss (TL) generation, drop out detection and the

focus start-up procedure.

The radial or tracking error signal is generated by the

satellite detector signals R1 and R2. The radial error signal

can be formulated as follows:

RE

= (R1 − R2) × re_gain + (R1 − R2) × re_offset

s

where the index ‘s’ indicates the automatic scaling

operation performed on the radial error signal. This scaling

is necessary to avoid non-optimal dynamic range usage in

the digital representation and to reduce the radial

bandwidth spread. Furthermore, the radial error signal will

be free of offset during disc start-up.

The four signals from the central aperture detectors,

together with the satellite detector signals, generate a

track position signal (TPI), which can be formulated as

follows:

TPI = sign [(D1 + D2 + D3 + D4) − (R1 + R2) × sum_gain]

where the weighting factor sum_gain is generated

internally by the SAA7348 during initialization.

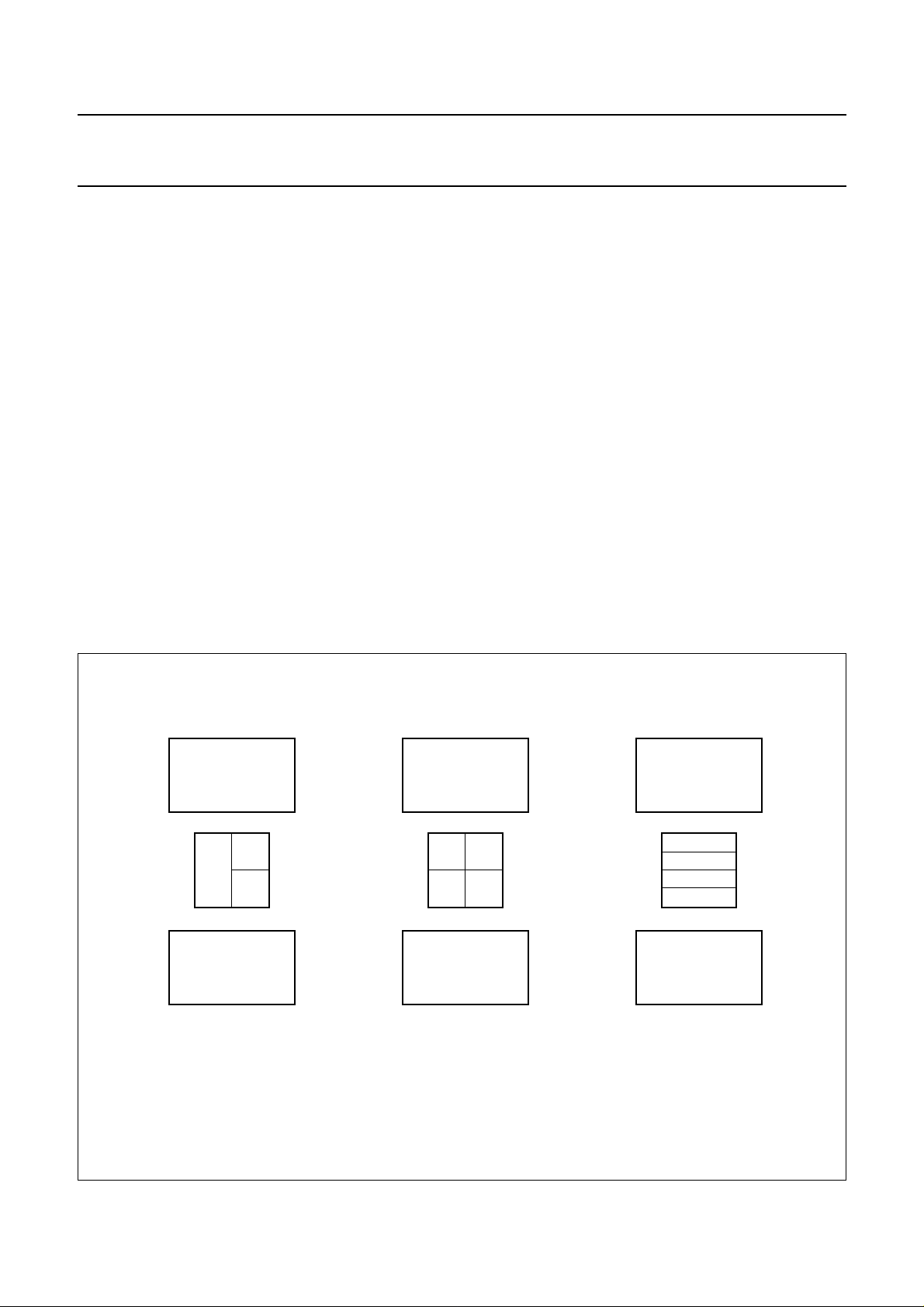

handbook, full pagewidth

SATELLITE

DIODE R1

D1

D3

D2

SATELLITE

DIODE R2

single Foucault astigmatic focus double Foucault

SATELLITE

DIODE R1

D1

D2

D3

D4

SATELLITE

DIODE R2

SATELLITE

DIODE R1

D1

D2

D3

D4

SATELLITE

DIODE R2

Fig.5 Detector arrangement.

MBG422

1997 Jul 11 14

Page 15

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

7.3.2 Focus control

The SAA7348 performs the following focus servo function:

• Focus start-up

• Focus position control loop

• Drop-out detection

• Focus loss detection and fast restart

• Focus loop gain switching

• Focus automatic gain control loop.

7.3.3 R

ADIAL CONTROL

The SAA7348 performs the following radial servo

functions:

• Level initialization

• Radial position control loop

• Sledge control

• Tracking control

• Access with or without track loss information

• Radial automatic gain control loop.

7.3.4 O

FF-TRACK COUNTING

The track position signal (TPI) is a flag used to indicate

whether the radial spot is positioned on the track with a

margin of ±0.25 of the track pitch. One of the following

three counting states is selected:

• Protected state

• Slow counting state

• Fast counting state.

7.3.5 O

FF-TRACK DETECTION

The Off-Track Detection (OTD) signal flags off-track

conditions; the polarity of this signal is programmable.

7.3.6 S

HOCK DETECTION

A shock detector can be switched on during normal track

following. Within an adjustable frequency range, it detects

whether disturbances in the radial spot relative to the track

exceed a programmable level. Every time the Radial

tracking Error (RE) exceeds this level, the radial control

bandwidth is switched to twice its original bandwidth and

the loop gain is increased by a factor of 4.

switched off, applied only to focus control, or applied to

both focus and radial controls under software control.

The actions of the circuit can be monitored on the DEFO

pin (active HIGH).

An external defect detector can be added by removing the

connection between DEFO and DEFI (normal operation)

and inserting the necessary circuitry.

7.3.8 D

RIVER INTERFACE

The control signals (pins RA, FO and SL) for the

mechanism actuators are pulse density modulated.

The modulating frequency can be set to either

servo clock

----------------------------- 8

servo clock

or MHz. An analog representation

----------------------------- 4

of the output signals can be generated by connecting a first

order low-pass filter to the outputs.

During reset (i.e. RST pin held HIGH) the RA, FO and SL

pins are high impedance.

7.3.9 L

ASER INTERFACE

The LDON pin (open-drain output) is used to turn the laser

on and off. When the laser is on, the output is high

impedance. The action of the LDON pin is controlled by the

xtra_preset parameter; the pin is automatically driven if the

focus control loop is active.

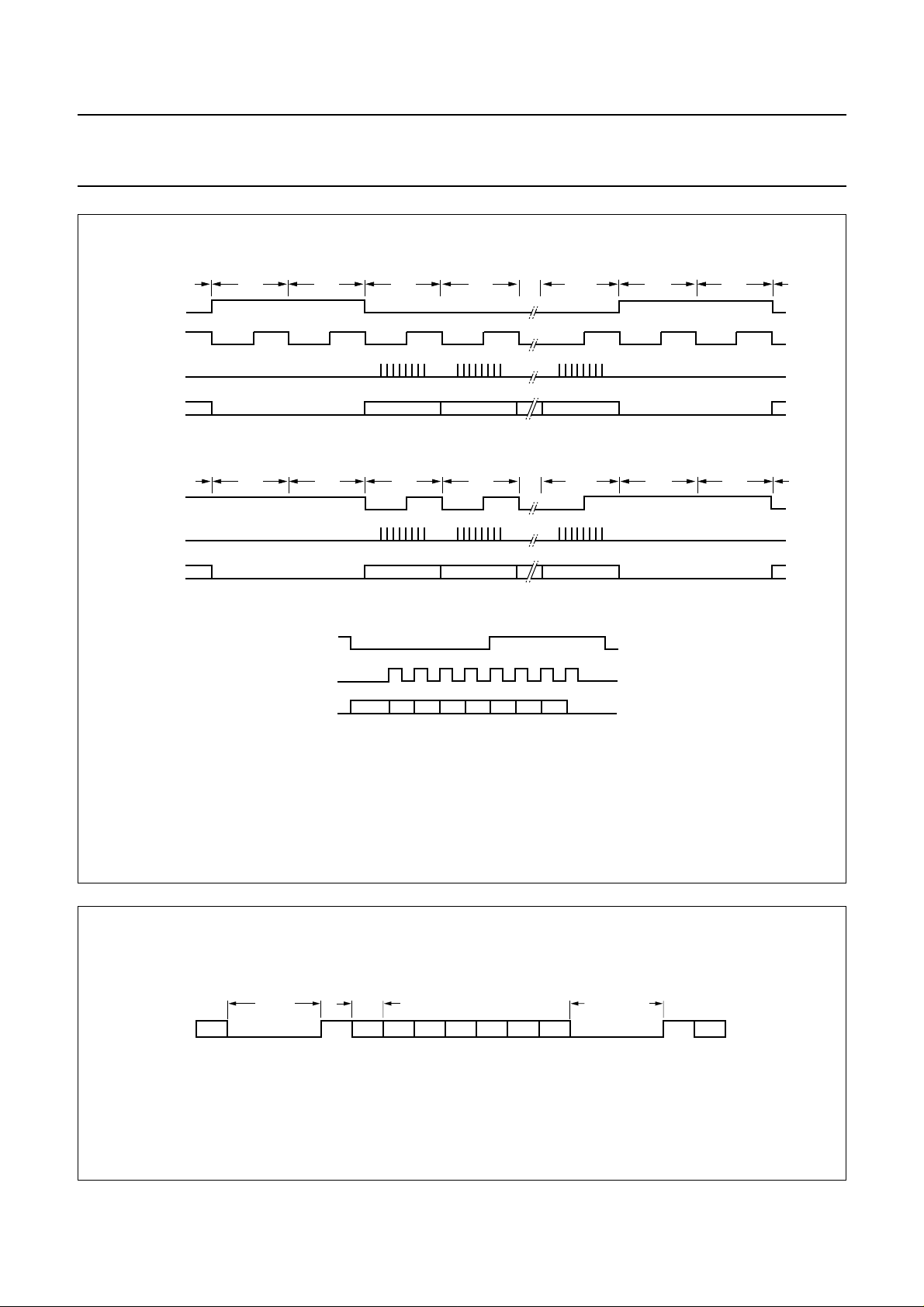

7.4 Subcode interface

There are two subcode interfaces:

• One which conforms to

“EIAJ CP-2401”

(using SBSY,

SFSY, RCK and SUB) and can be configured as either

a 3- or 4-wire interface. The interface formats are

illustrated in Fig.6.

• An RS232 like format on SUBQW as illustrated in Fig.7.

The subcode sync word is formed by a pause of µs

200

--------- n

minimum. Each subcode byte starts with a 1 followed by

7 bits (Q to W). The gap between bytes can vary

between and µs. Note that SUBQW is not

11.3

----------n

90

-----n

valid in lock-to-disc mode (includes QLLV).

The subcode data is also available at the EBU output

(DOBM).

7.3.7 D

EFECT DETECTION

A defect detection circuit is incorporated into the

SAA7348. If a defect is detected, the circuit can hold all

radial and focus controls. The defect detector can be

1997 Jul 11 15

Page 16

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

handbook, full pagewidth

SBSY

SFSY

RCK

SUB

SFSY

RCK

SUB

SF0 SF1

SF0 SF1 SF2 SF3 SF97 SF0 SF1

SFSY

RCK

SUB

SF2 SF3 SF97 SF0 SF1

P-W P-W P-W

EIAJ 4-wire subcode interface

P-W P-W P-W

EIAJ 3-wire subcode interface

PQRSTUVW

MBG410

Fig.6 EIAJ subcode (CD graphics) interface format.

11.3/n

µs

(1) n = disc speed.

200/n µs

min

W96 1 Q1 R1 S1 T U1 V W1 1 Q2

Fig.7 Subcode format and timing on SUBQW pin.

1997 Jul 11 16

11.3/n µs min

90/n µs max

MGK501

Page 17

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

7.5 Digital output

The AES/EBU signal on pin DOBM is in accordance with

the format defined in

“IEC 958”

. This signal is only

available in the decoder’s CLV modes if audio features are

enabled (not in QCLV modes). Three different modes can

be selected:

• DOBM pin held LOW

• Data taken before concealment, mute and fade (must

• Data taken after concealment, mute and fade (can only

be used for audio modes).

7.5.1 F

ORMAT

The digital audio output consists of 32-bit words

(‘subframes’) transmitted in bi-phasemark code (two

transitions for a logic 1 and one transition for a logic 0).

Words are transmitted in blocks of 384.

always be used for CD-ROM modes)

Table 3 32-bit digital audio output format

FUNCTION BITS DESCRIPTION

Sync 0 to 3 note 1

Auxiliary 4 to 7 not used; normally zero

Error flags 4 CFLG error and interpolation flags when selected by register A

Audio sample

Validity flag

User data

(3)

(4)

Channel status

(2)

(5)

8 to 27 first 4 bits not used (always zero); two’s complement; LSB = bit 12, MSB = bit 27

28 valid = logic 0

29 used for subcode data (Q to W)

30 control bits and category code

Parity bit 31 even parity for bits 4 to 30

Notes

1. The sync word is formed in violation of the bi-phase rule and, therefore, does not contain any data. Its length is

equivalent to 4 data bits. The 3 different sync patterns indicate the following situations:

a) Sync B: word contains left sample (start of a block, 384 words).

b) Sync M: word contains left sample (no block start).

c) Sync W: word contains right sample.

2. Left and right samples are transmitted alternately.

3. Audio samples are flagged (bit 28 = 1) if an error was detected but could not be corrected. This flag remains the same

even if data is taken after concealment.

4. Subcode bits Q to W from the subcode section are transmitted via the user data bit. This data is asynchronous with

the block rate.

5. The channel status bit is the same for both left and right words. Therefore, a block of 384 words contains 192 channel

status bits. The category code is always CD. The bit assignment is shown in Table 4.

1997 Jul 11 17

Page 18

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

Table 4 Channel status bit assignment

FUNCTION BIT DESCRIPTION

Control 0 to 3 copy of CRC checked Q-channel control bits 0 to 3; bit 2 is logic 1 when

copy permitted; bit 3 is logic 1 when recording has pre-emphasis

Reserved mode 4 to 7 always zero

Category code 8 to 15 CD: bit 8 = logic 1, all other bits = logic 0

Clock accuracy 28 and 29 set by register A:

10 = class 1 crystal (<50 ppm)

00 = class 2 crystal (<1000 ppm)

01 = class 3 crystal (>1000 ppm)

Remaining 16 to 27 and 30 to 191 always zero

7.6 S2B interface

This interface is in accordance with the

Description”

. It's a serial interface with a high level

“S2B Interface

command set for controlling a CD-ROM engine.

7.7 Audio support

Audio support consists of several parts:

• Serial data interface.

• Deemphasis control (DEEM). This signal is HIGH if the

subcode info of a track defines it to be recorded with

deemphasis.

• Kill control (KILL). This signal tests for digital silence in

the right and left channel before the digital filter.

The output is switched active LOW if silence has been

detected for at least 250 ms, if mute is active, or in

CD-ROM modes.

• Output clock for BCC-DAC applications (DACCLK).

• Oversampled output. The SAA7348 contains a

2 to 4 times oversampling IIR (Infinite

Impulse-Response) filter, and a selectable deemphasis

filter (if the de-emphasis signal is selected to come out

of DEEM then the filter is bypassed; see Table 31).

• Concealment, mute, attenuation and fade. In audio

modes a 1-sample linear interpolator becomes active if

a single sample is flagged as erroneous; left and right

channels have independent interpolators. A digital level

converter performs the following functions:

– soft mute (signal reduced to 0 in a maximum of

128 steps)

– full-scale (signal ramped back to 0 dB level)

– attenuation (signal scaled by −12 dB)

– fade (activates a 128 stage counter which allows the

signal to be scaled up or down in 0.07 dB steps)

– peak detector (measures highest audio level;

absolute level for left and right channels; the 8 MSBs

of each are output in the Q-channel data).

• Mono output selection. Either channel can be selected

to be output over both left and right channels.

7.7.1 S

ERIAL AUDIO DATA INTERFACE

The serial data interface can be switched between two

modes: Philips I2S and the EIAJ format.

In each case, the serial data is transferred through a 3-wire

interface. The I2S signal contains three components:

WCLK (word select), SCLK (serial clock) and DAC (serial

data). The polarity of WCLK and of the data can be

inverted.

The oversampling frequency and format are selected as

shown in Table 5. The serial data output is separate from

the CD-ROM output. In CD-ROM mode the DAC serial

data output pin will be muted.

Table 5 Oversampling frequency select

MODE

I2S18 4f

EIAJ 18 4f

NUMBER

OF BITS

SAMPLE FREQUENCY

18 2f

16 f

18 2f

18 f

16 4f

16 2f

16 f

s

s

s

s

s

s

s

s

s

1997 Jul 11 18

Page 19

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

7.8 CD-ROM support

The principle difference between the ACE and its

predecessors with regard to CD-ROM support is the

provision of a separate serial data pin, which removes the

need for external components. The format can be I2S or

EIAJ.

7.8.1 S

The serial data signal contains three components: WCLK

(word select), SCLK (serial clock) and DATA (serial data).

The polarity of WCLK and of the data can be inverted.

WCLK and SCLK are common with the audio serial data

output. The VALID signal is used to flag errors in either the

LSB or MSB of the 16-bit data word.

7.9 Reset

The RST pin on the SAA7348 is an active HIGH Schmitt

trigger. For a valid reset, the signal should be HIGH for a

period of 12 XTALI clock cycles, during which time the

power supply must be within specification on all power

ERIAL CD-ROM DATA INTERFACE

supply pins. To ensure that the SAA7348 resets fully it is

necessary to do one of the following:

• Connect SELPLL to DSDEN (rather than VDD). This

allows the internal clock multiplier to start immediately

after reset. Note that the internal clocks are not

guaranteed to operate at the correct frequencies for the

first 200 µs after reset. Note also that the operating

speed of the microcontroller is reduced in Idle mode

(and that baud rates change with the processor clock).

• Connect SELPLL to an inverted reset signal.

The internal clock multiplier starts after reset, but during

Idle mode the microcontroller speed is normal.

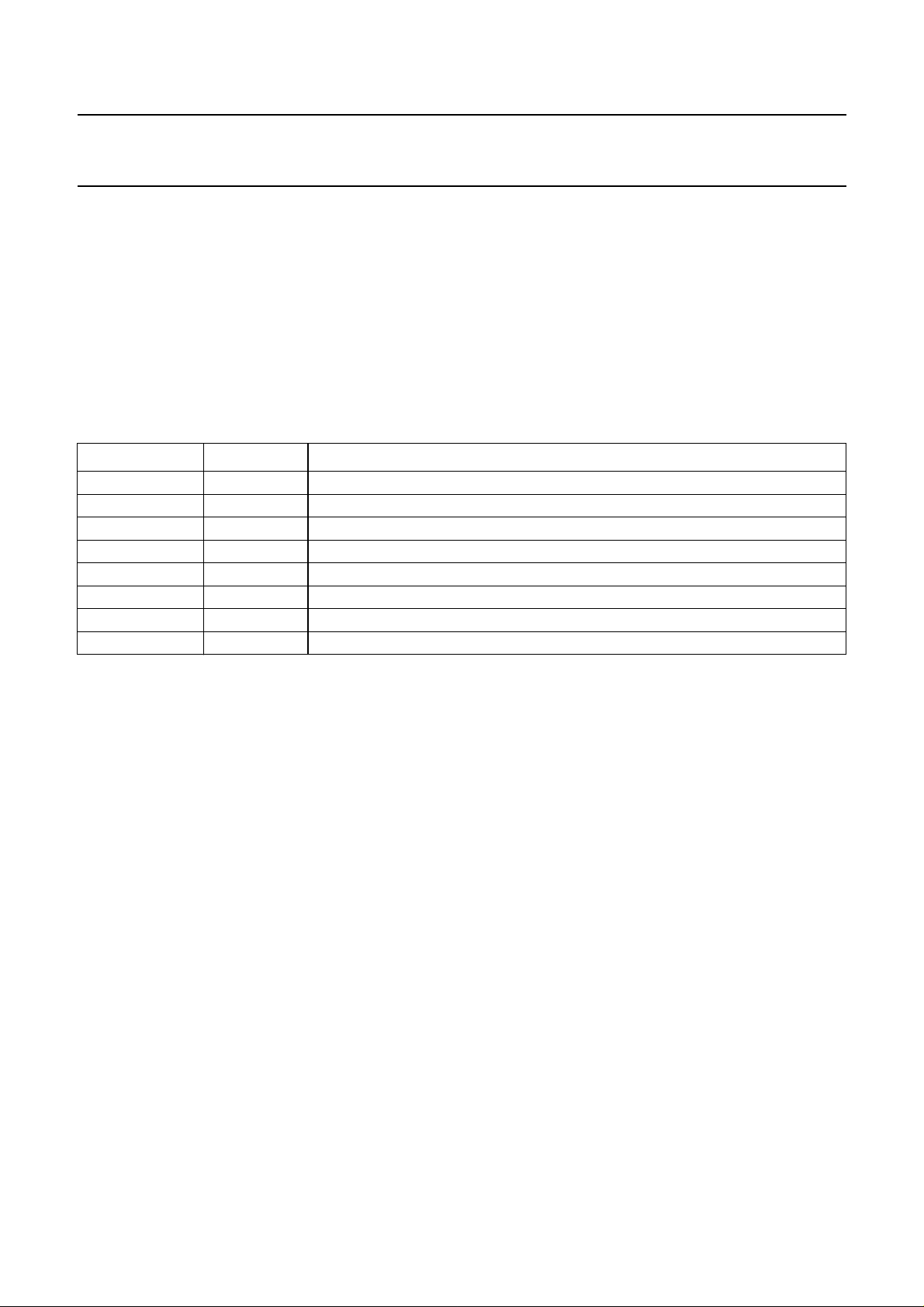

7.10 External ROM support

Since the ACE incorporates an 80C51 core it can, like any

microcontroller, run a program from external ROM.

EA pin should be tied to VSS in this case. For security

The

reasons, this pin is only sampled during reset, so a

program cannot be run partly from external ROM. Signal

relationships for external program execution are shown in

Fig.8. Timing specification can be found in Table 6.

1997 Jul 11 19

Page 20

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

Table 6 Timing specifications for external program memory search

SYMBOL PARAMETER MIN. MAX. UNIT

t

LHLL

t

AVLL

t

LLAX

t

LLPL

t

PLPH

t

PLIV

t

PXIX

t

PXIZ

t

AVIV

t

PLAZ

t

RLRH

t

WLWH

t

RLDV

t

RHDX

t

RHDZ

t

LLDV

t

AVDV

t

LLWL

t

AVWL

t

QVWX

t

WHQX

t

RLAZ

t

WHLH

ALE pulse width 60 − ns

address valid to ALE LOW 15 − ns

address hold after ALE LOW 21 − ns

ALE LOW to PSEN LOW 25 − ns

PSEN pulse width 80 − ns

PSEN LOW to valid instruction in − 65 ns

input instruction hold after PSEN 0 − ns

input instruction float after PSEN − 30 ns

address to valid instruction in − 130 ns

PSEN LOW to address float − 6ns

read pulse width 170 − ns

write pulse width 170 − ns

RD LOW to valid data in − 135 ns

data hold after RD − 50 ns

data float after RD 0 − ns

ALE LOW to valid data in − 235 ns

address to valid data in − 260 ns

ALE LOW to RD or WR LOW 80 115 ns

address valid to RD or WR LOW 115 − ns

data valid to WR transition 20 − ns

data hold to WR 20 − ns

RD LOW to address float − 0ns

RD or WR HIGH to ALE HIGH 20 40 ns

In addition to external program memory, external RAM and I/O can be accessed. Timing relationships for an external

data read are shown in Fig.9, and for an external data write in Fig.10.

1997 Jul 11 20

Page 21

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

handbook, full pagewidth

t

LHLL

ALE

PSEN

LA0 to LA7

A8 to A15

t

AVLLtLLPL

t

LLAX

t

AVIV

t

PLAZ

t

PLIV

t

PLPH

t

PXIX

Fig.8 Timing for an external program memory fetch.

t

PXIZ

MGK502

handbook, full pagewidth

ALE

PSEN

RD

LA0 to LA7

A8 to A15

t

AVLL

t

t

AVWL

t

LLWL

LLAX

t

AVDV

t

LLDV

Fig.9 Timing for an external data read.

1997 Jul 11 21

t

RLRH

t

WHLH

t

RHDZ

MGK503

Page 22

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

handbook, full pagewidth

ALE

PSEN

WR

LA0 to LA7

A0 to A15

t

WHLH

t

AVLL

t

t

AVWL

t

LLWL

LLAX

t

WLWH

t

QVWX

t

WHQX

Fig.10 Timing for an external data write.

MGK504

1997 Jul 11 22

Page 23

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8 MICROCONTROLLER INTERFACE

This section describes the microcontroller application

registers, the memory map, the decoder registers and the

servo commands.

8.1 Microcontroller applications registers

8.1.1 CLK GENERATE REGISTER (CLKgen)

The CLK generate register is used to select clock multiplier

PLL frequencies and dividers and to switch the servo clock

between single and double frequency. The register is byte

addressable; R/W.

The on-chip clock multiplier (programmable: 4×, 6× or 8×)

allows an external 8.4672 MHz crystal to be used. This

Table 7 CLK generate register (address 0X9EH)

765 4 3 2 1 0

CLKgen.7 CLKgen.6 CLKgen.5 clock_servohi clock_seldiv2 clock_seldiv1 clock_selpll2 clock_selpll1

Table 8 Description of CLKgen bits

BIT SYMBOL DESCRIPTION

7 CLKgen.7 not used

6 CLKgen.6

5 CLKgen.5

4 clock_servohi selects single or 2 × servo clock

3 clock_seldiv2 these bits select the clock divider for the 80C51 core and servo; see Table 9

2 clock_seldiv1

1 clock_selpll2 these bits select the clock multiplier frequency; see Table 9

0 clock_selpll1

generates a single internal master clock from which all

other clock signals are derived.

Note that both the microcontroller and the servo are

designed for a 50% duty factor input clock.

For a 16× decoder speed, the internal master clock must

be 67.7376 MHz (i.e. clock multiplier set to 8×).

The 16.9344 MHz signal can be generated by setting the

clock divider to 4, resulting in a standard 50% duty factor

clock. For a 12× decoder speed, the internal master clock

must be 50.8032 MHz (i.e. clock multiplier set to 6×).

A divide factor of 3 will generate the 16.9344 MHz signal,

resulting in a 66% duty factor clock.

The clock divider values set by means of the CLKgen

register are shown in Table 9.

1997 Jul 11 23

Page 24

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

Table 9 Divider selection

MASTER

CLOCK

(MHz)

33.8688 16.9344

50.8032 16.9344

67.7376 16.9344 1

33.8688 16.9344 1

µP

CLOCK

(MHz)

REGISTER CLKgen BIT SERVO

CLOCK

01234

0000

0101

(1)

(1)

(1)

0

(1)

1

10

10

0 8.4672 4 100

1 16.9344 2 200

0 8.4672 6 100

1 16.9344 3 200

0 8.4672 8 100

1 16.9344 4 200

0 8.4672 4 100

1 16.9344 2 200

(MHz)

Note

1. The internal clock multiplier PLL operates at the same frequency for both these options.

DIVIDE

FACTOR

OVER-SPEED

SERVO

(%)

1997 Jul 11 24

Page 25

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.2 PORT SERVO REGISTER (PSR)

The Port Servo Register is the internal bus used to communicate with the servo. The register is bit addressable; R/W.

The operation of the handshake bits used for serial communications with the servo is outlined in Table 12.

Table 10 Port servo register (address 0XD8H to 0XDFH)

765 4 3 2 1 0

Tray_en Tray_pwm Srv_rdy Srv_dacc Srv_sild Srv_sicl Srv_sida Srv_intreqn

Table 11 Description of PSR bits

BIT SYMBOL ADDRESS DESCRIPTION

7 Tray_en 0XDFH signal to enable tray driver

6 Tray_pwm 0XDEH PWM signal to tray driver

5 Srv_rdy 0XDDH RDY; see Table 12

4 Srv_dacc 0XDCH DAC; see Table 12

3 Srv_sild 0XDBH SILD

2 Srv_sicl 0XDAH SICL

1 Srv_sida 0XD9H SIDA

0 Srv_intreqn 0XD8H INTREQN

Table 12 Servo serial communication handshake signals

DAC RDY DESCRIPTION

0 0 transmit register full; the microcontroller can read a byte or send a new command

0 1 idle state, transmit register empty; the microcontroller can transmit a parameter relating

to the new command

1 0 received one byte, waiting for EOT

1 1 receive register full

1997 Jul 11 25

Page 26

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.3 SERVO CONTROL REGISTER (SCR)

The Servo Control Register is used for reading and writing internal control signals. The register is byte addressable; R/W.

Table 13 Servo control register (address 0XD9H)

76543210

Srv_frc_flock Srv_frc_lock Srv_otd Srv_da Srv_cl Srv_rab Srv_startup Serv_halt

Table 14 Description of SCR bits

BIT SYMBOL DESCRIPTION

7 Srv_frc_flock force_flock: coarse PLL lock indicator control; a HIGH indicates ±6% of disc speed

6 Srv_frc_lock force_lock; a HIGH indicates frequency lock

5 Srv_otd OTD controller: off-track signal generated by the controller input for the OTD

multiplexer; a HIGH indicates laser is off track

4 Srv_da DA (used only with direct decoder communication)

3 Srv_cl CL (used only with direct decoder communication)

2 Srv_rab RAB (used only with direct decoder communication)

1 Srv_startup 16 kHz pulse (start new servo processor execution sequence); pulse is latched; latch is

cleared by a write operation

0 Serv_halt servo halt; halts servo processor execution

1997 Jul 11 26

Page 27

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.4 SERVO STATUS REGISTER (STR)

The Servo Status Register holds high level status information on the servo system. The information is latched into a

register and cleared whenever the register is read. This information could be a trigger to initiate a recovery. The register

is byte addressable; read only.

Table 15 Servo status register (address 0XE9H)

7654 3210

Srv_tl1 Srv_tl0 Srv_shock Srv_hf_present Srv_FIFO_ov Srv_fock Srv_otd_inp Srv_subc

Table 16 Description of STR bits

BIT SYMBOL DESCRIPTION

7 Srv_tl1 internal servo signal; see Table 17

6 Srv_tl0 internal servo signal; see Table 17

5 Srv_shock shock: decoder status signal; Motstart2 + PLL_phase_lock + Motor-ov + FOCOK +

OTD

4 Srv_hf_present HF_present: internal decoder signal; indicates if laser spot is in a recorded area

3 Srv_FIFO_ov FIFO_OV: decoder status signal; FIFO overflow occurred

2 Srv_fock FOCOK: servo output signal; focus OK/

1 Srv_otd_inp OTD: servo output signal; laser spot on/off track

0 Srv_subc subcode found: decoder status signal; subcode present in servo buffer

OK

The Srv_tl0 and Srv_tl1 signals can be used to determine in which direction the servo is counting during a jump

execution.

Table 17 Servo jump modes

Srv_tl1 Srv_tl0 DESCRIPTION

0 0 protected mode

0 1 fast jump_1

1 0 slow jump

1 1 fast jump_2

1997 Jul 11 27

Page 28

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.5 MOTOR OUTPUT QCLV REGISTER (MOQ; address 0XF2H and 0XF3H)

The Motor Output QCLV register holds the sixteen bits of the filtered (−3 dB, 300 Hz) motor error signal. This signal is

updated at a frequency of 16.537 kHz. Address 0XF3H holds the eight most significant bits, address 0XF2H the eight

least significant bits. Refreshing rule: if the low byte is read, the high byte is locked to avoid mixing up two successive

samples. If the high byte has been read, the low byte will be refreshed. The register is byte addressable; read only.

8.1.6 P3 R

EGISTER

The P3 register is used in the same way as in the standard 80C51. It contains a second UART, however, whose input

and output pins are R

XD1

and T

respectively. Direction control is by DDROUT3 (SFR address 0XFD; see Table 25

XD1

and Section 8.1.12). The register is bit addressable; R/W.

Table 18 P3 register (address 0XB0H to 0XB7H)

76543210

WRN RDN TXD1 RXD1 INT1 INT0 TXD0 RXD0

Table 19 Description of P3 register bits

BIT SYMBOL ADDRESS DESCRIPTION

7 WRN 0XB7H WRN

6 RDN 0XB6H WDN

5 TXD1 0XB5H TXD1: serial buffer 1; transmit

4 RXD1 0XB4H RXD1: serial buffer 1; receive

3 INT1 0XB3H INT1: external Interrupt 1

2 INT0 0XB2H INT0: external Interrupt 0

1 TXD0 0XB1H TXD0: serial buffer 0; transmit

0 RXD0 0XB0H RXD0: serial buffer 0; receive

1997 Jul 11 28

Page 29

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.7 DECODER STATUS REGISTER (DSR)

The decoder status register provides decoder status information. The register is byte addressable; read only.

Table 20 Decoder status register (address 0XEBH)

765 4 3 2 1 0

Decoder_stat.7 TX_full Dec_motov Dec_pll_flock Dec_pll_lock Dec_motstop Dec_motstart_2 Dec_motstart_1

Table 21 Description of DSR bits

BIT SYMBOL DESCRIPTION

7 Decoder_stat.7 −

6 TX_full communication buffer to decoder is full

5 Dec_motov motor-overflow: decoder status signal; motor output saturates

4 Dec_pll_flock PLL_flock: decoder internal signal; can be forced by µP

3 Dec_pll_lock PLL_lock: decoder internal signal; can be forced by µP

2 Dec_motstop motstop: decoder status signal; speed <12%

1 Dec_motstart_2 motstart 2: decoder status signal; speed >50%

0 Dec_motstart_1 motstart 1: decoder status signal; speed >75%

1997 Jul 11 29

Page 30

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.8 MOTOR SETPOINT REGISTER (MSR; address

0XF9H)

The motor setpoint register is used to set the speed of the

motor in Quasi CLV mode. QCLV motor control is switched

off by making the setpoint equal 00100000. See Table 22

Table 22 Speed measurements

SFR

SETPOINT

00100000 1.8

00100010 1.9

00100011 2.0

00100101 2.1

00100111 2.2

00101000 2.3

00101010 2.4

00101100 2.5

00101101 2.6

00101111 2.7

00110000 2.8

00110010 2.9

00110011 3.0

00110101 3.1

00110111 3.2

00111000 3.3

00101010 3.4

00111100 3.5

00111110 3.6

00111111 3.7

01000000 3.8

01000010 3.9

01000011 4.0

01000101 4.1

01000111 4.2

01001001 4.3

01001011 4.4

01001100 4.5

01001110 4.6

01001111 4.7

01010001 4.8

01010010 4.9

MEASURED

SPEED

for setpoint/speed values. Note that these are measured

values. They were measured using the motor control

bread board. This bread board was hooked onto a ROM

65000 loader 12.66 application. The filter in the config

control (Cnf_filter) was switched off. A motor gain of 5 was

used. The register is byte addressable; R/W.

SFR

SETPOINT

01010100 5.0

01010110 5.1

01010111 5.2

01011001 5.3

01011011 5.4

01011100 5.5

01011110 5.6

01011111 5.7

01100001 5.8

01100010 5.9

01100100 6.0

01100110 6.1

01100111 6.2

01101001 6.3

01101011 6.4

01101100 6.5

01101110 6.6

01101111 6.7

01110001 6.8

01110010 6.9

01110100 7.0

01110110 7.1

01110111 7.2

01111001 7.3

01111011 7.4

01111100 7.5

01111110 7.6

10000000 7.7

01111111 7.7

10000001 7.8

10000011 7.9

10000100 8.0

MEASURED

SPEED

1997 Jul 11 30

Page 31

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.9 MOTOR GAIN QCLV REGISTER (address 0XFAH)

The motor_gain_QCLV register is used to set the gain of

the motor control signal. It can be used in quasi as well as

in CLV mode. Only the 6 least significant bits are used (see

Table 23 Loop gain

GAIN

SFR SETTING

FILTER ON FILTER OFF

00000000 1 0.125

00111111 2 0.25

00111110 3 0.375

00111101 4 0.5

00111100 5 0.625

00111011 6 0.75

00111010 7 0.875

00111001 8 1

00111000 9 1.125

00110111 10 1.25

00110110 11 1.375

00110101 12 1.5

00110100 13 1.625

00110011 14 1.75

00110010 15 1.875

00110001 16 2

00110000 17 2.125

00101111 18 2.25

00101110 19 2.375

00101101 20 2.5

00101100 21 2.625

00101011 22 2.75

00101010 23 2.875

00101001 24 3

00101000 25 3.125

00100111 26 3.25

00100110 27 3.375

00100101 28 3.5

00100100 29 3.625

00100011 30 3.75

00100010 31 3.875

00100001 32 4

Table 23 for values). The actual gain depends on the filter

in the config register (Cnf_filter). If the filtering is switched

on, the gain is reduced by a factor of 8. The register is byte

addressable; R/W.

GAIN

SFR SETTING

FILTER ON FILTER OFF

00100000 33 4.125

00011111 34 4.25

00011110 35 4.375

00011101 36 4.5

00011100 37 4.625

00011011 38 4.75

00011010 39 4.875

00011001 40 5

00011000 41 5.125

00010111 42 5.25

00010110 43 5.375

00010101 44 5.5

00010100 45 5.625

00010011 46 5.75

00010010 47 5.875

00010001 48 6

00010000 49 6.125

00001111 50 6.25

00001110 51 6.375

00001101 52 6.5

00001100 53 6.625

00001011 54 6.75

00001010 55 6.875

00001001 56 7

00001000 57 7.125

00000111 58 7.25

00000110 59 7.375

00000101 60 7.5

00000100 61 7.625

00000011 62 7.75

00000010 63 7.875

1997 Jul 11 31

Page 32

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.10 DATA DIRECTION REGISTERS (DDR0, DDR2 AND DDR3)

The data direction registers are used to control the direction of data flow at the port pins (P0, P2 and P3). DDR0 controls

P0; DDR2 controls P2; DDR3 controls P3. A logic 0 written to a bit makes the relevant port an input port. A logic 1 makes

it an output port. The register is byte addressable; R/W.

Table 24 Data direction registers (address DDR0: 0XFBH; DDR2: 0XFCH; DDR3: 0XFDH); note 1

76543210

Srv_frc_flock Srv_frc_lock Srv_otd Srv_da Srv_cl Srv_rab Srv_startup Serv_halt

Table 25 Description of DDR bits

BIT SYMBOL DESCRIPTION

7 DDROUTX7 controls direction of PX.7

6 DDROUTX6 controls direction of PX.6

5 DDROUTX5 controls direction of PX.5

4 DDROUTX4 controls direction of PX.4

3 DDROUTX3 controls direction of PX.3

2 DDROUTX2 controls direction of PX.2

1 DDROUTX1 controls direction of PX.1

0 DDROUTX0 controls direction of PX.0

(1)

Note to Tables 24 and 25

1. X = 0, 2 or 3, depending on register selected (DDR0, DDR2 or DDR3).

1997 Jul 11 32

Page 33

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.11 CONFIGURATION CONTROL REGISTER (CCR)

The Config_cntrl register is used to control internal multiplexers. Note that the motor output configuration register in the

decoder is used to choose between the decoder motor control and the QCLV motor control. The register is byte

addressable; R/W.

Table 26 Description of CCR bits (address 0XFEH)

BIT

POSITION

READ WRITE

7 7 Config_cntrl.7 not used

6 6 Cnf_dac_clk_sel

5 1 Cnf_AGC_bypass AGC decoder bypass; Cnf_AGC_bypass = 1: bypass; Cnf_AGC_bypass = 0:

4 5 Cnf_lock_over Lock_over_rule; Cnf_lock_over = 1: overrules the decoder signals force_lock,

3 4 Cnf_uPotd selects OTD input; Cnf_uPotd = 1: controller; Cnf_uPotd = 0: DSICS

2 3 Cnf_sign_mag selects PWM output mode; Cnf_sign_mag = 1: sign magnitude;

1 2 Cnf_filter selects the filter in the QCLV motor control; Cnf_filter = 1: enable;

0 0 Cnf_dircom selects decoder communication mode; Cnf_dircom = 1: direct;

(1)

SYMBOL FUNCTION

selects clock to DAC; Cnf_dac_clk_sel = 1: ;

Cnf_dac_clk_sel = 0:

use AGC

force_flock

Cnf_sign_mag = 0: two’s complement

Cnf_filter = 0: disable

Cnf_dircom = 0: indirect (via the servo)

master clock

--------------------------------3

master clock

--------------------------------2

Note

1. Note that the function of bit positions 1, 2, 3, 4 and 5 depends on whether the register is being written to or read from.

1997 Jul 11 33

Page 34

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.12 A SECOND SERIAL INTERFACE

A second serial interface is implemented using the

following registers:

• SCON2: 0XC0

• SBUF2: 0XC1.

This is of course an interrupt function. Bit 6 of the

IE register is used to enable this function. Bit 6 of the

IP register is used to define this interrupt to the highest

Table 27 Servo memory map

ADDRESS (HEX) CONTENTS

0X100 time_keeper

0X101 focus_stat

0X102 rad_stat

0X103 mem_sledge1_hi

0X104 offtrack_hi_rb

0X105 offtrack_lo_rb

0X106 mem_sledge1_lo

0X107 rad_int_hi

0X108 rad_int_lo

0X109 rad_offset_hi

0X10A rad_error_gain_mem_hi

0X10B tpi_gain_hi

0X10C focus_error_mem

0X10D rad_error_mem

0X10E speed_hi

0X10F speed_lo

0X110 focus_int_hi

0X111 focus_int_lo

0X112 drop_out_code

0X113 foc_prop_mem

0X114 FOCUS_PROP_MULT

0X115 FOCUS_INT_GAIN

0X116 RAMP_MEAN_VALUE

0X117 slee_mult_mem

0X118 RAMP_HEIGTH

0X119 FE_LEVEL

0X11A timer1

0X11B acc_stat_mem

0X11C rad_prop_mult_mem

0X11D rad_error_acc_mem

priority level. The new vector address of the interrupt could

be 0033H.

8.1.13 M

Since the performance of a basic engine is largely

determined by the subcode retrieval speed, fast access to

the subcode buffer is desirable. The servo RAM is mapped

onto the AUX RAM of the microcontroller. In this way it is

possible to directly access the servo RAM registers; see

Table 27.

ADDRESS (HEX) CONTENTS

EMORY MAP ACCESS TO THE SERVO

0X11E rad_int_gain_mem

0X11F speed_mult_mem

0X120 rad_offset_lo

0X121 rad_error_gain_mem_lo

0X122 tpi_gain_lo

0X123 sp_mem_lo

0X124 sp_mem_hi

0X125 speed_setpoint

0X126 tpi_signal_mem

0X127 rad_ctrl_1_mem2

0X128 rad_ctrl_1_mem

0X129 rad_ctrl_2_mem

0X12A rad_gain_mem

0X12B stack 5

0X12C stack 4

0X12D stack 3

0X12E stack 2

0X12F stack 1

0X130 stack 0

0X131 oldcom

0X132 state_mult_mem

0X133 mem_sledge2_lo

0X134 mem_sledge2_h

0X135 RAMP_GAIN

0X136 slede_mult_mem2

0X137 FAST_SPEED

0X138 mem_sledge2_lo_lo

0X139 gain_filter2_mem_lo

0x13A gain_filter2_mem_hi

0x13B gain_filter1_mem

1997 Jul 11 34

Page 35

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

ADDRESS (HEX) CONTENTS

0x13C low_gain_mem

0x13D gain_drempel_mem

0x13E rad_ctrl_1_mem3

0x13F focus_int_mem1

0x140 interruptreg

0x141 cd6statmem

0x142 HiState

0x143 MotorStatTime

0x144 mem_sledge1_drempel_lo

0x145 mem_sledge1_drempel_hi

0x146 sledge_pulse_mem

0x147 sledge_time_ou

0x148 speed_drempel_mem

0x149 hold_mult_mem

0x14A xtra_preset

0x14B cd6subadr

0x14C cd6cmd1

0x14D cd6cmd2

0x14E asec

0x14F asecold

0x150 aframe

0x151 aframemeold

0x152 playwatchtimer

0x153 interruptmask

0x154 playwatchtimer

0x155 trackcount1

0x156 timer2

0x157 jumpwatchtime

0x158 sledge_long_brake

0x159 radwatchstat

0x15A sledge_power_mem

0x15B rad_mem_part1

0x15C StateTimerHi

0x15D StateTimerLo

ADDRESS (HEX) CONTENTS

0x15E FocusStartTime

0x15F MotorStartTime1

0x160 MotorStartTime2

0x161 RadInitTime

0x162 BrakeTime

0x163 RadialStartStat

0x164 sledge_pulse_height

0x165 focus_inject

0x166 radial_inject

0x167 detphase

0x168 oscinc

0x169 injectlevel1

0x16A injectlevel2

0x16B osc

0x16C agcgainmem

0x16D agcgainlo

0x16E focus_offset

0x16F inject_lo

0x170 offtrack_hi

0x171 oftrack_lo

0x172 not used

0x173 not used

0x174 subcode byte 0

0x175 subcode byte 1

0x176 subcode byte 2

0x177 subcode byte 3

0x178 subcode byte 4

0x179 subcode byte 5

0x17A subcode byte 6

0x17B subcode byte 7

0x17C subcode byte 8

0x17D subcode byte 9

0x17E peak level left

0x17F peak level right

1997 Jul 11 35

Page 36

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.14 DIGITAL PLL REGISTERS

The behaviour of the digital PLL can be monitored and

controlled using the following registers:

1. PLL Frequency Register (address 0XECH):

This register holds the 8 MSBs of the PLL frequency.

The register is byte addressable; read only.

2. PLL DC Offset Register (address 0XEDH):

This register holds the 8-bit asymmetry signal in two’s

complement form. The register is byte addressable;

read only.

3. PLL Jitter Register (address 0XEE):

This register holds the 8 MSBs of the 10 jitter bits.

The register is byte addressable; read only.

4. PLL Int Inp Register (address 0XFF):

Presets the 8 MSBs of the PLL frequency to a certain

value. The register is byte addressable; R/W.

1997 Jul 11 36

Page 37

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.1.15 DIV17 REGISTER (address 0X9FH)

This register can be used to generate the serial communication baud rate. If this method is chosen, the baud rate will be

62259 × P. The 5 LSBs of DIV17 hold the value of P. The 2 MSBs connect this baud rate generator to UART 1 or UART 2

(see Table 28). The register is byte addressable; R/W.

Table 28 Baud rate to UART connection

BIT 7 BIT 6 DESCRIPTION

0 0 baud rate generator not selected

0 1 select baud rate generator only for UART1

1 0 select baud rate generator only for UART2

1 1 select baud rate generator for UART1 and UART2

Of course in ACE it is still possible to use timers 1 and 2 to generate the baud rate. Table 29 provides an overview of

how various baud rates can be generated using timer 1, timer 2, and DIV17.

Table 29 Baud rate selection, timer based; note 1

BAUD RATE

kBAUD

1411.20 16.9344 0 XXXX

996.14 16.9344 X 1 X X 16

529.20 16.9344 2 1 X X X

498.07 16.9344 X 1 X X 8

373.55 16.9344 X 1 X X 6

264.60 16.9344 2 0 X X X

249.04 16.9344 X 1 X X 4

186.78 16.9344 X 1 X X 3

124.52 16.9344 X 1 X X 2

88.20 16.9344 1 1 0XFF X X

66.15 16.9344 1 X X 0XFFF0 X

62.26 16.9344 X 1 X X 1

44.10 16.9344 1 0 0XFF X X

33.08 16.9344 1 X X 0XFFE8 X

9.80 16.9344 1 1 0XF7 X X

Note

1. X = don’t care.

µPCLK

(MHz)

MODE SMOD

RELOAD

TIMER 1

RELOAD

TIMER 2

DIV17

(ACE)

1997 Jul 11 37

Page 38

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.2 Memory map

Table 30 Memory map

ADDRESS

LOWER ↓ 89ABCDE F

(1)

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

PO P1 P2 P3 SCON2 PSW ACC B

SP SBUF2

DPL MOTQCLVL

DPH MOTQCLVH

RSV

PCON RSV

TCON SCON1 IE IP T2CON PSR RSV RSV

TMOD SBUF RSV RSV T2MOD SCR SSR MOTSETP

TL0 RCAP2L MOTGAIN

TL1 RCAP2H DSR DDR0

TH0 TL2 PLLFREQ DDR2

TH1 TH2 PLLOFS DDR3

CLKgen PLLJITT CONFIG

DIV17 PLLINT

UPPER →

Note

1. For example, hex address A8 = IE.

1997 Jul 11 38

Page 39

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.3 Summary of the functions controlled by decoder registers 0 to F

The decoder uses 16 programmable registers, accessible under internal microcontroller control. The addresses of these

registers are given in Table 31, along with a summary of the functions performed. The INITIAL column shows the

power-on reset state.

Table 31 Decoder Registers 0 to F

REGISTER ADDRESS DATA FUNCTION INITIAL

0

(Fade and

attenuation)

1

(Motor mode)

2

(Status control)

0000 X000 mute reset

X01X attenuate −

X001 full scale −

X100 step down −

X101 step up −

0XXX DACCLK operating −

1XXX DACCLK 3-stated reset

0001 X000 motor off mode reset

X001 motor brake mode 1 −

X010 motor brake mode 2 −

X011 motor start mode 1 −

X100 motor start mode 2 −

X101 motor jump mode −

X111 motor play mode −

X110 motor jump mode 1 −

1XXX anti-windup active −

0XXX anti-windup off reset

0010 0000 status = SUBQREADY-I reset

0001 status = MOTSTART1 −

0010 status = MOTSTART2 −

0011 status = MOTSTOP −

010X status = PLL lock −

011X status = MOTOR-OV −

1X00 status = FIFO overflow −

1X01 status = shock detect −

1X10 status = latched shock detect −

1X11 status = latched shock detect reset −

(1)

1997 Jul 11 39

Page 40

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

REGISTER ADDRESS DATA FUNCTION INITIAL

3

(DAC output)

4

(Motor gain)

0011 1010 I2S-bus; CD-ROM mode −

1011 EIAJ; CD-ROM mode −

110X I

1111 I

1110 I

000X EIAJ; 16-bit; 4f

0011 EAIJ; 16-bit; 2f

0010 EIAJ; 16-bit; f

010X EIAJ; 18-bit; 4f

0111 EIAJ; 18-bit; 2f

0110 EIAJ; 18-bit; f

2

S-bus; 18-bit; 4fs mode reset

2

S-bus; 18-bit; 2fs mode −

2

S-bus; 16-bit; fs mode −

s

s

s

s

s

s

0100 X000 motor gain G = 3.2 reset

X001 motor gain G = 4.0 −

X010 motor gain G = 6.4 −

X011 motor gain G = 8.0 −

X100 motor gain G = 12.8 −

X101 motor gain G = 16.0 −

X110 motor gain G = 25.6 −

X111 motor gain G = 32.0 −

0XXX new motor control reset

1XXX standard CD6 motor control −

5

(Motor

bandwidth)

0101 XX00 motor f4 = 0.5 × n Hz reset

XX01 motor f4 = 0.7 × nHz −

XX10 motor f4 = 1.4 × nHz −

XX11 motor f4 = 2.8 × nHz −

00XX motor f3 = 0.85 × n Hz reset

01XX motor f3 = 1.71 × nHz −

10XX motor f3 = 3.42 × nHz −

6

(Motor output

configuration)

0110 XX00 motor power maximum 37% reset

XX01 motor power maximum 50% −

XX10 motor power maximum 75% −

XX11 motor power maximum 100% −

00XX MOTOS, MOTOV pins 3-state reset

01XX motor PWM mode −

10XX motor PDM mode −

11XX motor CDV mode −

(1)

−

−

−

−

−

−

1997 Jul 11 40

Page 41

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

REGISTER ADDRESS DATA FUNCTION INITIAL

7

(DAC output

control)

8

(PLL loop filter

bandwidth)

9

(PLL

equalization)

A

(EBU output)

0111 xxx0 DAC data normal value reset

xxx1 DAC data inverted value −

xx0x left channel first at DAC (WCLK normal) reset

xx1x right channel first at DAC (WCLK inverted) −

11xx stereo output at DAC reset

10xx left mono out at DAC −

01xx right mono out at DAC −

00xx both DAC channels killed −

see Table 32

1001 0111 equalization = −60 ns −

0110 equalization = −45 ns −

0101 equalization = −30 ns −

0100 equalization = −15 ns −

0011 equalization=0ns reset

0010 equalization = 15 ns −

0001 equalization = 30 ns −

0000 equalization = 45 ns −

1111 equalization = 60 ns −

1110 equalization = 75 ns −

1101 equalization = 90 ns −

1100 equalization = 105 ns −

1011 equalization = 120 ns −

1010 equalization = 135 ns −

1001 equalization = 150 ns −

1000 equalization = 165 ns −

1010 xx0x DOBM data before concealment −

xx1x DOBM data after concealment and fade reset

x1x1 DOBM off; output LOW −

x0x1 class 1 crystal (<50 ppm) −

x0x0 class 2 crystal (<1000 ppm) reset

x1x0 class 3 crystal (>1000 ppm) -

0xxx flags to DOBM off reset

1xxx flags to DOBM on −

(1)

1997 Jul 11 41

Page 42

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

REGISTER ADDRESS DATA FUNCTION INITIAL

B

(Speed control)

C

(Data slicer and

AGC control)

D

(Versatile pins

interface)

E 1110 0xxx bit controls operating speed mode, see register B reset

1011 x0xx 33.8688 MHz crystal present,

or 8.4672 MHz crystal with SELPLL set HIGH

x1xx 16.9344 MHz crystal present −

0xxx single speed mode (if register E = 0xxx)

four times speed mode (if register E = 1xxx); note 2

1xxx double speed mode (if register E = 0xxx)

eight times speed mode (if register E = 1xxx); note 2

xx00 standby 1: ‘CD-STOP’ mode reset

xx10 standby 2: ‘CD-PAUSE’ mode −

xx11 operating mode −

1100 1xxx

01xx

00xx

xx0x digital equalizer enabled −

xx1x digital equalizer disabled reset

xxx0 AGC active reset

xxx1 AGC inactive (on hold) −

1101 xx01 subcode channels Q-W at SUBQW −

xx10 SUBQW = 0 −

xx11 SUBQW = 1 reset

01xx de-emphasis signal at DEEM, no internal

10xx DEEM = 0 −

11xx DEEM = 1 reset

x0xx audio features disabled −

x1xx audio features enabled reset

xx0x lock-to-disc mode disabled reset

xx1x lock-to-disc mode enabled −

xxx0 low-stop = 0; motor brakes to 12% reset

xxx1 low-stop = 1; motor brakes to 6% −

slicer bandwidth or Hz

slicer bandwidth or Hz

slicer bandwidth or Hz

de-emphasis filter

255

--------- n

112

--------- n

27

-----n

112

--------- n

56

-----n

13

-----n

reset

reset

reset

−

−

−

−

(1)

1997 Jul 11 42

Page 43

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

REGISTER ADDRESS DATA FUNCTION INITIAL

F

(Subcode

interface)

Notes

1. The initial column shows the power-on reset state.

2. Speed can be set to (1.5×, 3×, 6× and 12×) or (2×, 4×, 8× and 16×) via the microcontroller application register

CLKgen.

Table 32 Loop filter bandwidth

REGISTER ADDRESS DATA

8

(PLL loop filter

bandwidth)

1111 x0xx subcode interface off reset

x1xx subcode interface on −

0xxx 4-wire subcode reset

1xxx 3-wire subcode −

xx10 decrease AGC gain 1 step, when AGC off (register C) −

xx10 increase AGC gain 1 step, when AGC off (register C) −

FUNCTION

INTERNAL

BANDWIDTH

(Hz)

1000 0000 1640 × n 525 × n 8400 × n −

0001 3279 × n 263 × n 16800 × n −

0010 6560 × n 131 × n 33600 × n −

0100 1640 × n 1050 × n 8400 × n −

0101 3279 × n 525 × n 16800 × n −

0110 6560 × n 263× n 33600 × n −

1000 1640 × n 2101 × n 8400 × n −

1001 3279 × n 1050 × n 16800 × n reset

1010 6560 × n 525 × n 33600 × n −

1100 1640 × n 4200 × n 8400 × n −

1101 3279 × n 2101 × n 16800 × n −

1110 6560 × n 1050 × n 33600 × n −

BANDWIDTH

(Hz)

LOW-PASS

BANDWIDTH

(Hz)

INITIAL

(1)

(1)LOOP

Note

1. The initial column shows the power-on reset state.

1997 Jul 11 43

Page 44

Philips Semiconductors Preliminary specification

All Compact Disc Engine (ACE) SAA7348GP

8.4 Summary of servo commands

The servo commands are listed in Table 33.

Table 33 Servo commands

COMMANDS CODE BYTES PARAMETERS

Write commands

Preset_Latch 81H 1 <chip_init>

Write_focus_coefs1 17H 7 <foc_parm_3> <foc_int> <ramp_incr> <ramp_height> <ramp_offset>

<FE_start> <foc_gain>

Write_focus_coefs2 27H 7 <defect_parm> <rad_parm_jump> <vel_parm2> <vel_parm1>