Page 1

DATA SH EET

Product specification

File under Integrated Circuits, IC01

1999 Jun 17

INTEGRATED CIRCUITS

SAA7327

Digital servo processor and

Compact Disc decoder with

integrated DAC for video CD

(CD7 II)

Page 2

1999 Jun 17 2

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 QUICK REFERENCE DATA

5 BLOCK DIAGRAM

6 PINNING

7 FUNCTIONAL DESCRIPTION

7.1 Decoder part

7.1.1 Principal operational modes of the decoder

7.1.2 Decoding speed and crystal frequency

7.1.3 Lock-to-disc mode

7.1.4 Standby modes

7.2 Crystal oscillator

7.3 Data slicer and clock regenerator

7.4 Demodulator

7.4.1 Frame sync protection

7.4.2 EFM demodulation

7.5 Subcode data processing

7.5.1 Q-channel processing

7.5.2 EIAJ 3 and 4-wire subcode (CD graphics)

interfaces

7.5.3 V4 subcode interface

7.6 FIFO and error corrector

7.6.1 Flags output (CFLG)

7.7 Audio functions

7.7.1 De-emphasis and phase linearity

7.7.2 Digital oversampling filter

7.7.3 Concealment

7.7.4 Mute, full-scale, attenuation and fade

7.7.5 Peak detector

7.8 DAC interface

7.8.1 Internal bitstream Digital-to-Analog Converter

(DAC)

7.8.2 External DAC interface

7.9 EBU interface

7.9.1 Format

7.10 KILL circuit

7.11 Audio features off

7.12 The VIA interface

7.13 Spindle motor control

7.13.1 Motor output modes

7.13.2 Spindle motor operating modes

7.13.3 Loop characteristics

7.13.4 FIFO overflow

7.14 Servo part

7.14.1 Diode signal processing

7.14.2 Signal conditioning

7.14.3 Focus servo system

7.14.4 Radial servo system

7.14.5 Off-track counting

7.14.6 Defect detection

7.14.7 Off-track detection

7.14.8 High-level features

7.14.9 Driver interface

7.14.10 Laser interface

7.14.11 Radial shock detector

7.15 Microcontroller interface

7.15.1 Microcontroller interface (4-wire bus mode)

7.15.2 Microcontroller interface (I2C-bus mode)

7.15.3 Decoder registers and shadow registers

7.15.4 Summary of functions controlled by decoder

registers 0 to F

7.15.5 Summary of functions controlled by shadow

registers

7.15.6 Summary of servo commands

7.15.7 Summary of servo command parameters

8 LIMITING VALUES

9 CHARACTERISTICS

10 OPERATING CHARACTERISTICS

(SUBCODE INTERFACE TIMING)

11 OPERATING CHARACTERISTICS (I2S-BUS

TIMING)

12 OPERATING CHARACTERISTICS

(MICROCONTROLLER INTERFACE TIMING)

13 APPLICATION INFORMATION

14 PACKAGE OUTLINE

15 SOLDERING

15.1 Introduction to soldering surface mount

packages

15.2 Reflow soldering

15.3 Wave soldering

15.4 Manual soldering

15.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

16 DEFINITIONS

17 LIFE SUPPORT APPLICATIONS

18 PURCHASE OF PHILIPS I2C COMPONENTS

Page 3

1999 Jun 17 3

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

1 FEATURES

• Integrated bitstream DAC with differential outputs,

operating at 96fs with 3rd order noise shaper; typical

performance of −95 dB signal-to-noise ratio (EIAJ

A-weighted)

• Separate serial input and output interfaces allow data

‘loopback’ mode for use of onboard DAC as stand-alone

DAC for digital audio signals

• Up to 2 times speed mode

• Lock-to-disc mode

• Full error correction strategy, t = 2 and e = 4

• Full subcode (CD graphics) interface

• All standard decoder functions implemented digitally on

chip

• FIFO overflow concealment for rotational shock

resistance

• Digital audio interface (EBU), audio and data

• 2 and 4 times oversampling integrated digital filter,

including fsmode

• Audio data peak level detection

• Kill interface for external DAC deactivation during digital

silence

• All SAA737x (CD7) digital servo and high-level functions

• Low focus noise

• Improved playability performance

• Automatic closed-loop gain control available for focus

and radial loops

• Pulsed sledge support

• Electronic damping of fast radial actuator during long

jump

• Microcontroller loading LOW

• High-level servo control option

• High-level mechanism monitor

• Communication may be via TDA1301/SAA7345

compatible bus or I

2

C-bus

• On-chip clock multiplier allows the use of 8.4672,

16.9344 or 33.8688 MHz crystals or ceramic

resonators.

2 GENERAL DESCRIPTION

The SAA7327 (CD7 II) is a single chip combining the

functions of a CD decoder, digital servo and bitstream

DAC, especially designed for Video CD applications.

The decoder/servo part is based on the SAA737x (CD7)

and is software compatible with this design. Extra

functions are controlled by use of ‘shadow’ registers

(see Section 7.15.3).

Supply of this Compact Disc IC does not convey an

implied license under any patent right to use this IC in any

Compact Disc application.

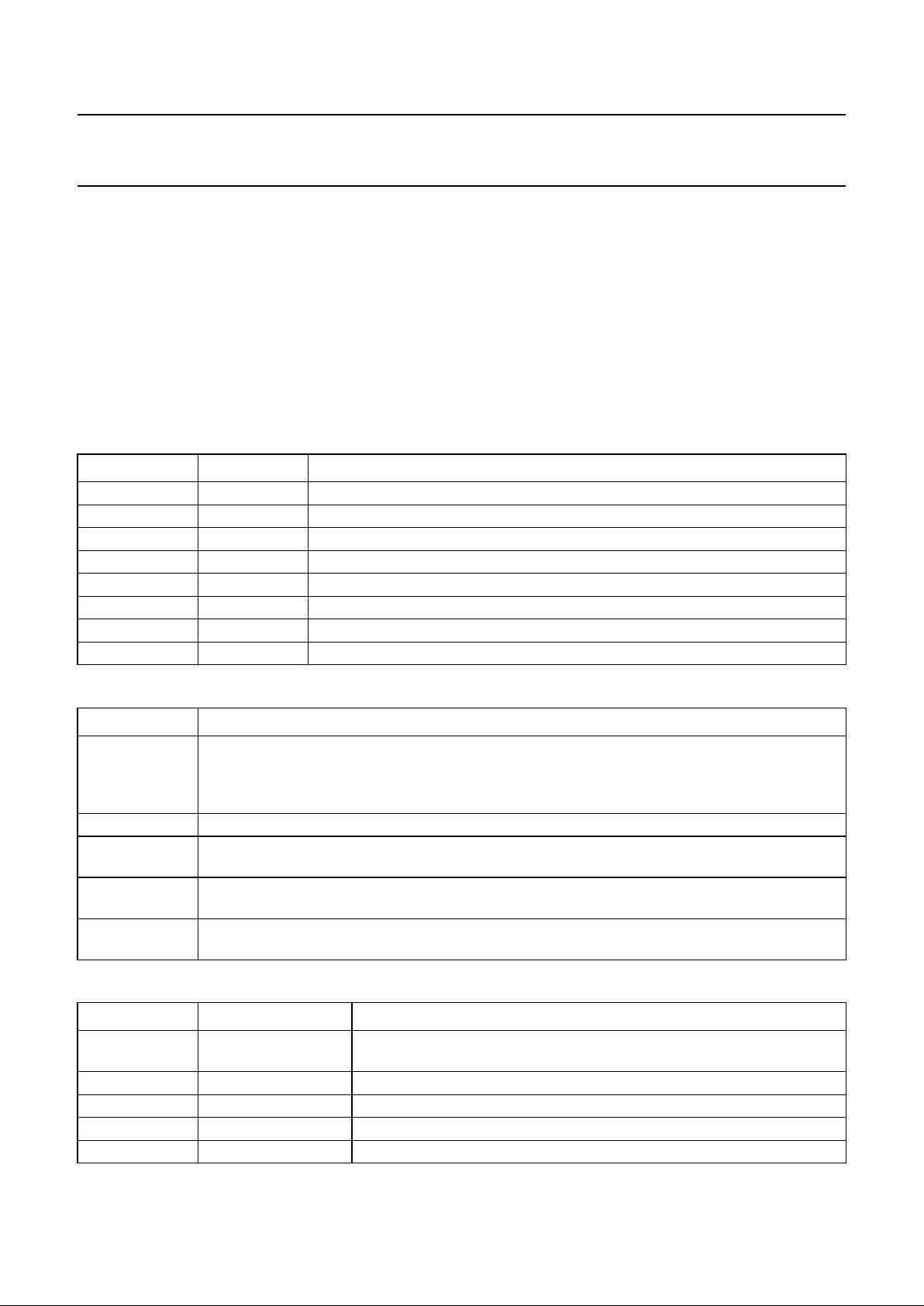

3 ORDERING INFORMATION

TYPE

NUMBER

PACKAGE

NAME DESCRIPTION VERSION

SAA7327H QFP64 plastic quad flat package; 64 leads (lead length 1.6 mm);

body 14 × 14 × 2.7 mm

SOT393-1

Page 4

1999 Jun 17 4

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

4 QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DD

supply voltage 3.0 3.3 3.6 V

I

DD

supply current n = 1 mode − 20 − mA

f

xtal

crystal frequency 8 8.4672 35 MHz

T

amb

ambient temperature −10 − +70 °C

T

stg

storage temperature −55 − +125 °C

S/N

DAC

onboard DAC signal-to-noise

ratio

1 kHz; 1fs;

EIAJ A-weighted;

see Figs 38 and 39

−90 −95 − dB

Page 5

1999 Jun 17 5

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

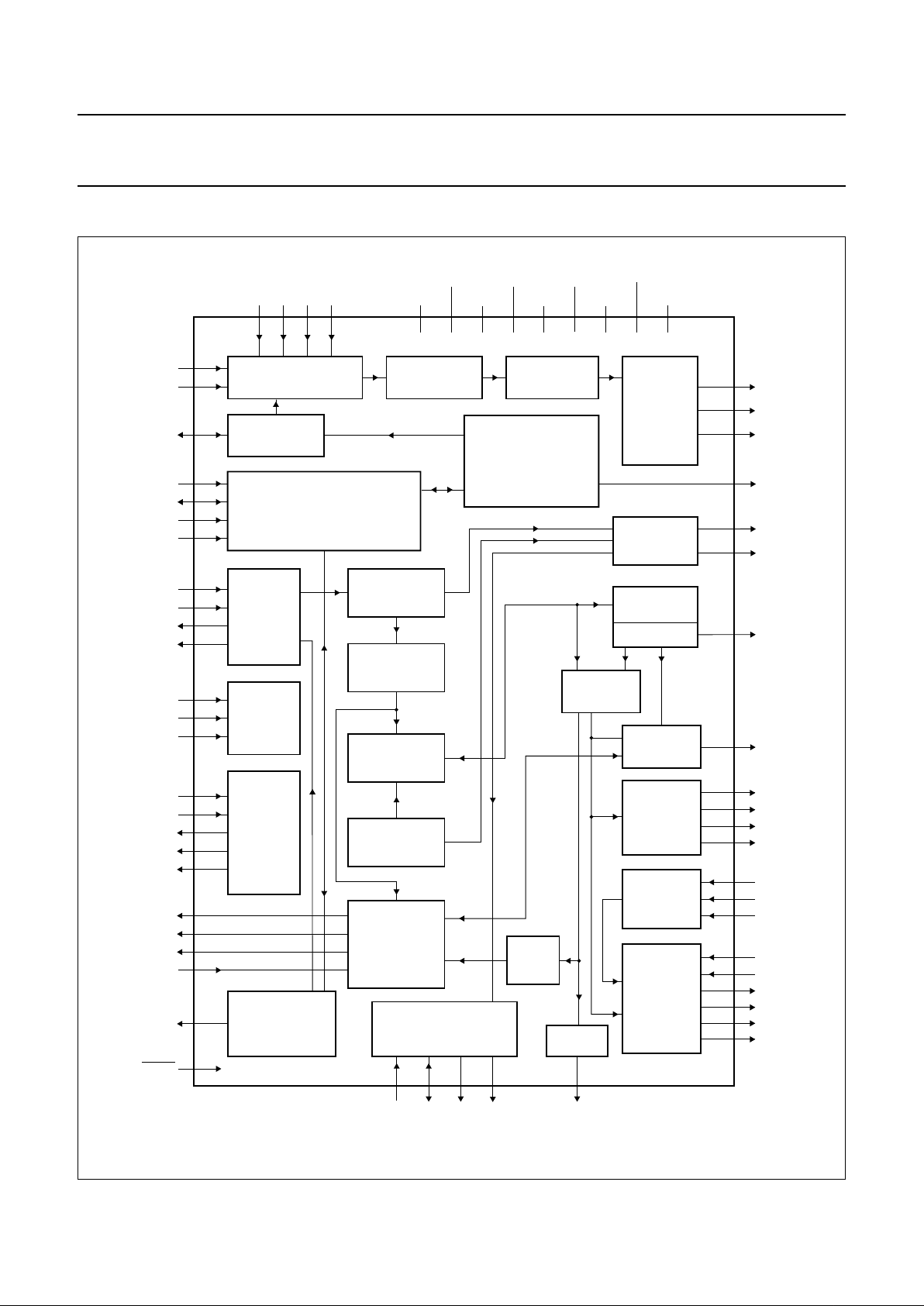

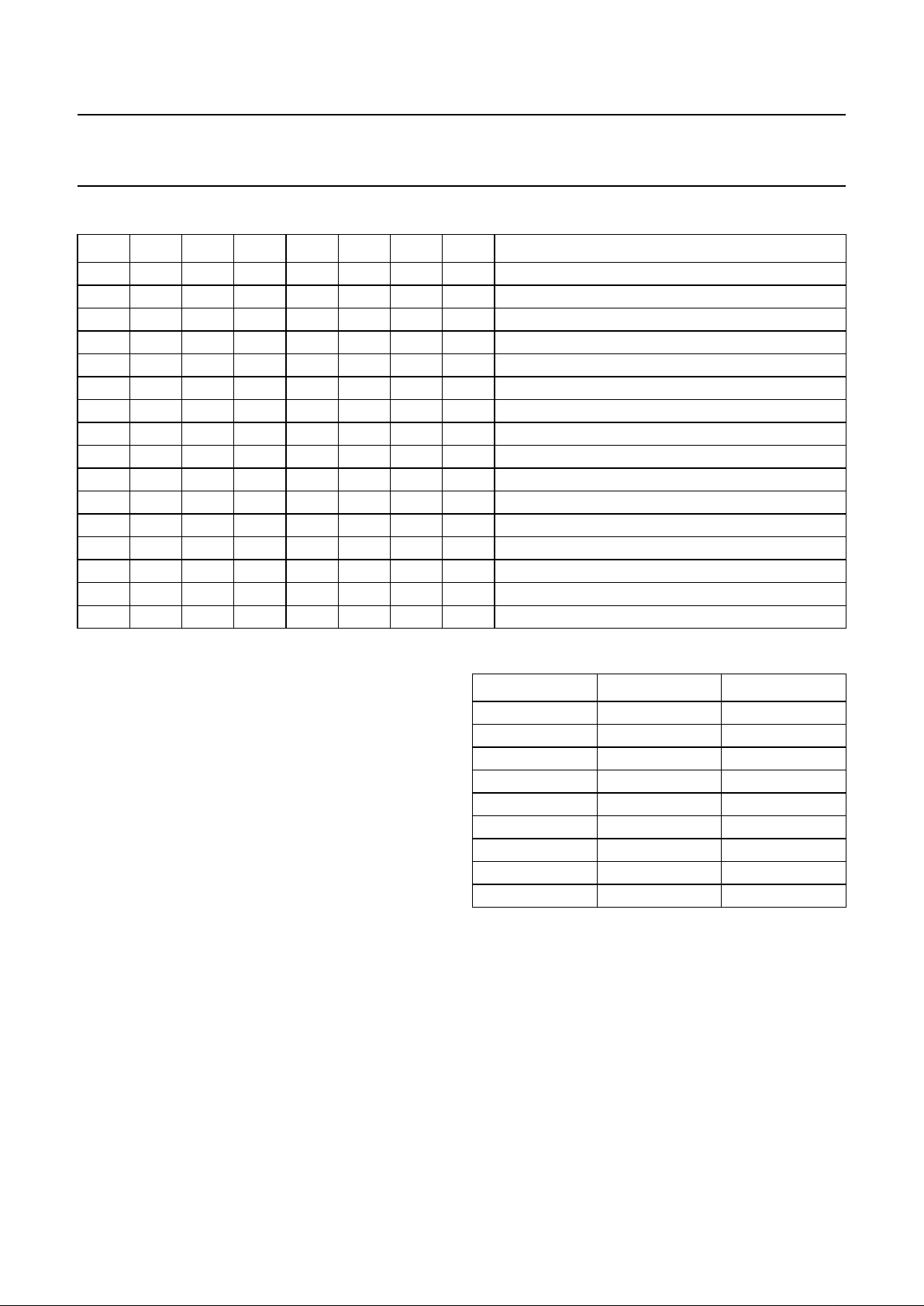

5 BLOCK DIAGRAM

Fig.1 Block diagram.

handbook, full pagewidth

DECODER

MICRO-

CONTROLLER

INTERFACE

VERSATILE PINS

INTERFACE

SUBCODE

PROCESSOR

KILL

PEAK

DETECT

SERIAL DATA

INTERFACE

TIMING

TEST

ADC

V

ref

GENERATOR

FRONT-END

DIGITAL

PLL

MOTOR

CONTROL

AUDIO

PROCESSOR

EBU

INTERFACE

ERROR

CORRECTOR

MICROCONTROLLER

INTERFACE

PRE-

PROCESSING

CONTROL

FUNCTION

CONTROL

PART

EFM

DEMODULATOR

SRAM

RAM

ADDRESSER

OUTPUT

STAGES

FLAGS

12

13

7

40

39

41

42

2

1

3

6

25

31

44

24

16

15

26

49

48

47

46

45

43

38

63 34 61 62 32

8 9 10 11 4 14 5 17 33 50 58 52 57

54

55

56

64

59

60

53

51

30

29

28

27

V

RIN

I

ref

R2

SCL

SDA

RAB

SILD

HFIN

HFREF

ISLICE

TEST1

TEST2

TEST3

SELPLL

CRIN

CROUT

CL16

CL11/4

SBSY

SFSY

SUB

RCK

STATUS

R1

D1 D2 D3 D4

V

SSA1

V

DDA2

V

SSD2

V

DDD2(C)

V

SSA2

V

DDA1

V

SSD1

V

SSD3

V

DDD1(P)

V1 V2/V3 V4 V5 KILL

EF

DATA

WCLK

SCLK

SERIAL DATA

(LOOPBACK)

INTERFACE

37

35

36

SDI

WCLI

SCLI

BITSTREAM

DAC

20

21

18

19

LP

22

RN

23

RP

LN

V

pos

V

neg

DOBM

MOTO2

MOTO1

LDON

SL

FO

RA

CFLG

RESET

SAA7327

MGS234

Page 6

1999 Jun 17 6

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

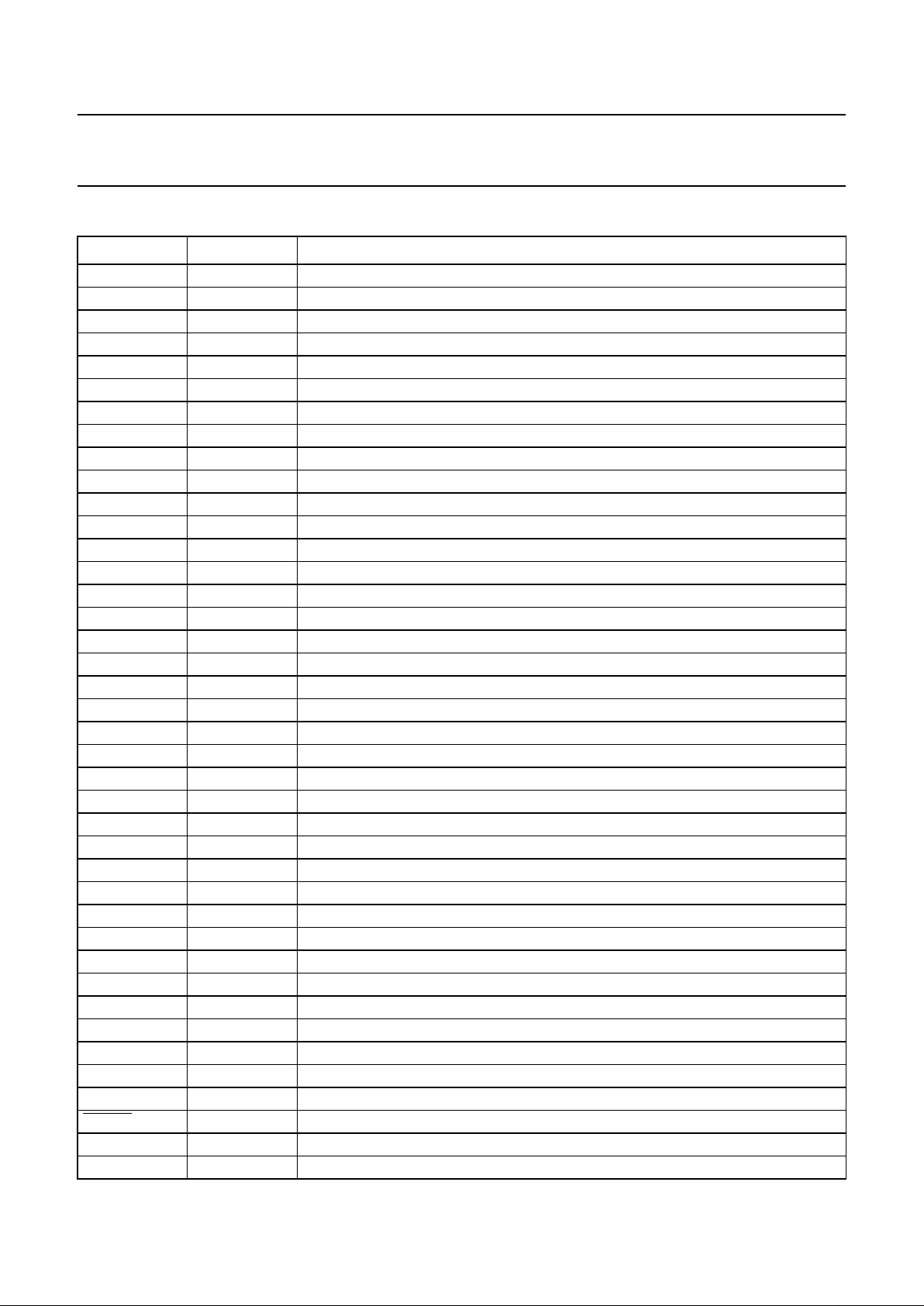

6 PINNING

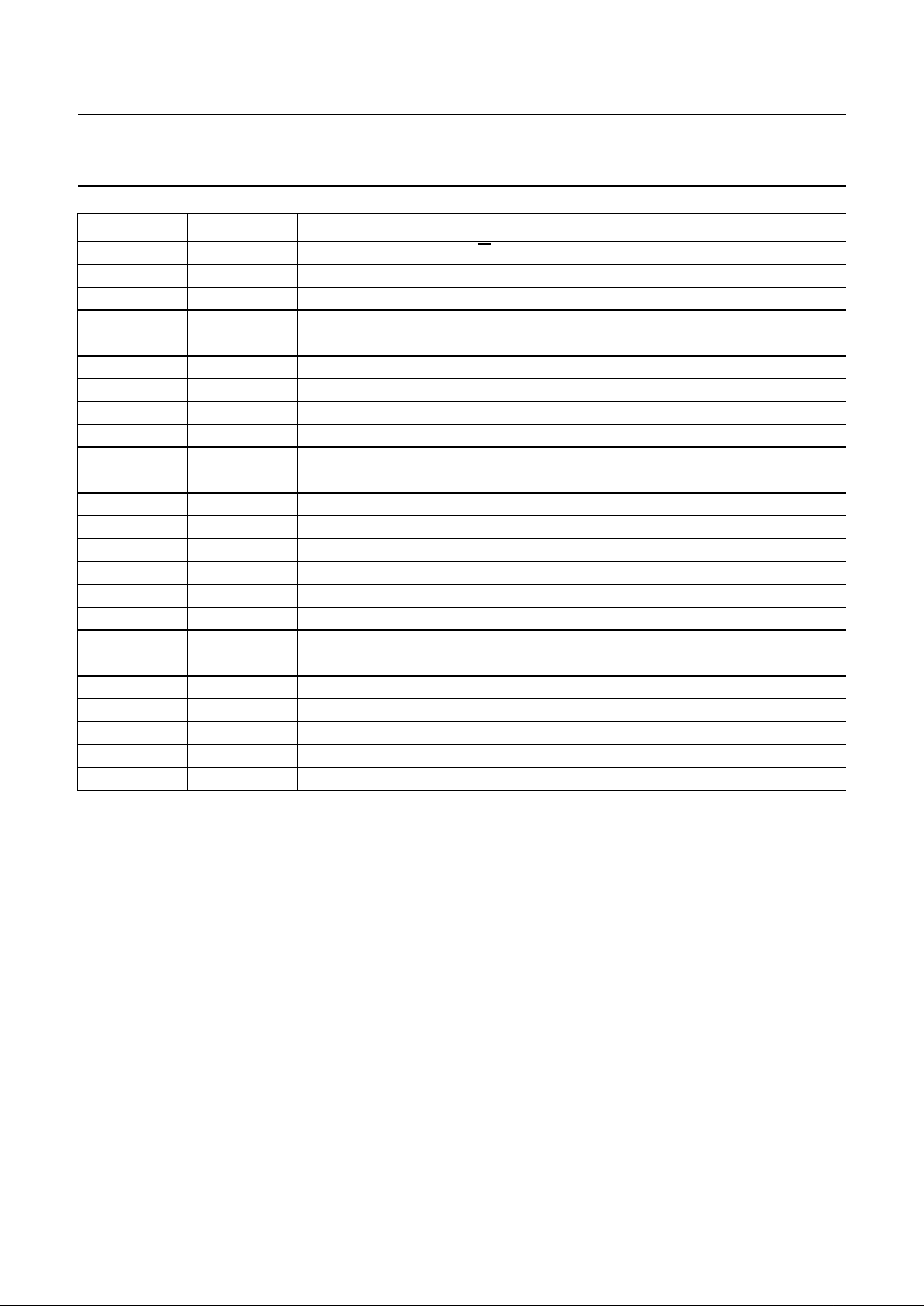

SYMBOL PIN DESCRIPTION

HFREF 1 comparator common mode input

HFIN 2 comparator signal input

ISLICE 3 current feedback output from data slicer

V

SSA1

4

(1)

analog ground 1

V

DDA1

5

(1)

analog supply voltage 1

I

ref

6 reference current output

V

RIN

7 reference voltage for servo ADCs

D1 8 unipolar current input 1 (central diode signal input)

D2 9 unipolar current input 2 (central diode signal input)

D3 10 unipolar current input 3 (central diode signal input)

D4 11 unipolar current input 4 (central diode signal input)

R1 12 unipolar current input 1 (satellite diode signal input)

R2 13 unipolar current input 2 (satellite diode signal input)

V

SSA2

14

(1)

analog ground 2

CROUT 15 crystal/resonator output

CRIN 16 crystal/resonator input

V

DDA2

17

(1)

analog supply voltage 2

LN 18 DAC left channel differential negative output

LP 19 DAC left channel differential positive output

V

neg

20 DAC negative reference input

V

pos

21 DAC positive reference input

RN 22 DAC right channel differential negative output

RP 23 DAC right channel differential positive output

SELPLL 24 selects whether internal clock multiplier PLL is used

TEST1 25 test control input 1 (this pin should be tied LOW)

CL16 26 16.9344 MHz system clock output

DATA 27 serial d4(1) data output (3-state)

WCLK 28 word clock output (3-state)

SCLK 29 serial bit clock output (3-state)

EF 30 C2 error flag output (3-state)

TEST2 31 test control input 2 (this pin should be tied LOW)

KILL 32 kill output (programmable; open-drain)

V

SSD1

33

(1)

digital ground 1

V2/V3 34 versatile I/O: versatile input 2 or versatile output 3 (open-drain)

WCLI 35 word clock input (for data loopback to DAC)

SDI 36 serial data input (for data loopback to DAC)

SCLI 37 serial bit clock input (for data loopback to DAC)

RESET 38 Power-on reset input (active LOW)

SDA 39 microcontroller interface data I/O line (I

2

C-bus; open-drain output)

SCL 40 microcontroller interface clock line input (I

2

C-bus)

Page 7

1999 Jun 17 7

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Note

1. All supply pins must be connected to the same external power supply voltage.

RAB 41 microcontroller interface R/

W and load control line input (4-wire bus mode)

SILD 42 microcontroller interface

R/W and load control line input (4-wire bus mode)

STATUS 43 servo interrupt request line/decoder status register output (open-drain)

TEST3 44 test control input 3 (this pin should be tied LOW)

RCK 45 subcode clock input

SUB 46 P-to-W subcode bits output (3-state)

SFSY 47 subcode frame sync output (3-state)

SBSY 48 subcode block sync output (3-state)

CL11/4 49 11.2896 or 4.2336 MHz (for microcontroller) clock output

V

SSD2

50

(1)

digital ground 2

DOBM 51 bi-phase mark output (externally buffered; 3-state)

V

DDD1(P)

52

(1)

digital supply voltage 1 for periphery

CFLG 53 correction flag output (open-drain)

RA 54 radial actuator output

FO 55 focus actuator output

SL 56 sledge control output

V

DDD2(C)

57

(1)

digital supply voltage 2 for core

V

SSD3

58

(1)

digital ground 3

MOTO1 59 motor output 1; versatile (3-state)

MOTO2 60 motor output 2; versatile (3-state)

V4 61 versatile output 4

V5 62 versatile output 5

V1 63 versatile input 1

LDON 64 laser drive on output (open-drain)

SYMBOL PIN DESCRIPTION

Page 8

1999 Jun 17 8

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Fig.2 Pin configuration.

handbook, full pagewidth

SAA7327H

MGS249

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

SBSY

SFSY

SUB

RCK

TEST3

STATUS

SILD

RAB

SCL

SDA

SCLI

SDI

WCLI

V2/V3

V

SSD1

HFREF

HFIN

ISLICE

V

SSA1

V

DDA1

I

ref

V

RIN

D1

D2

D3

D4

R1

R2

V

SSA2

CROUT

CRIN 33

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

LDONV1V5

V4

MOTO2

MOTO1

V

SSD3VDDD2(C)

SL

FO

RA

CFLG

V

DDD1(P)

DOBM

V

SSD2

CL11/4

V

DDA2

LN

LP

V

neg

V

pos

RN

RP

SELPLL

TEST1

CL16

DATA

WCLK

SCLK

EF

TEST2

KILL 49

RESET

7 FUNCTIONAL DESCRIPTION

7.1 Decoder part

7.1.1 P

RINCIPAL OPERATIONAL MODES OF THE DECODER

The decoding part supports a full audio specification and

can operate at two different disc speeds, from

single-speed (n = 1) to 2 times speed (n = 2). The factor

‘n’ is called the overspeed factor. A simplified data flow

through the decoder part is illustrated in Fig.7.

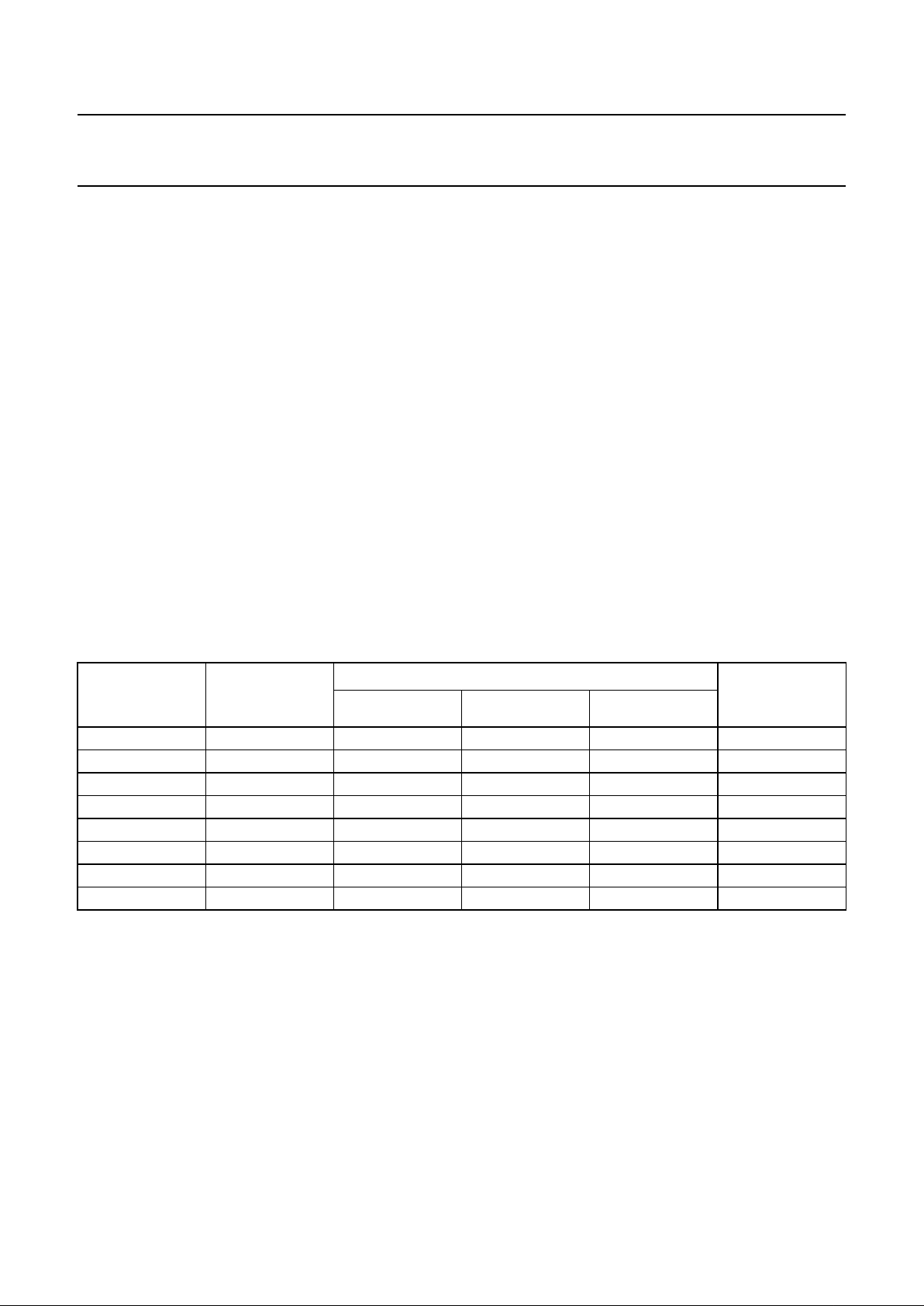

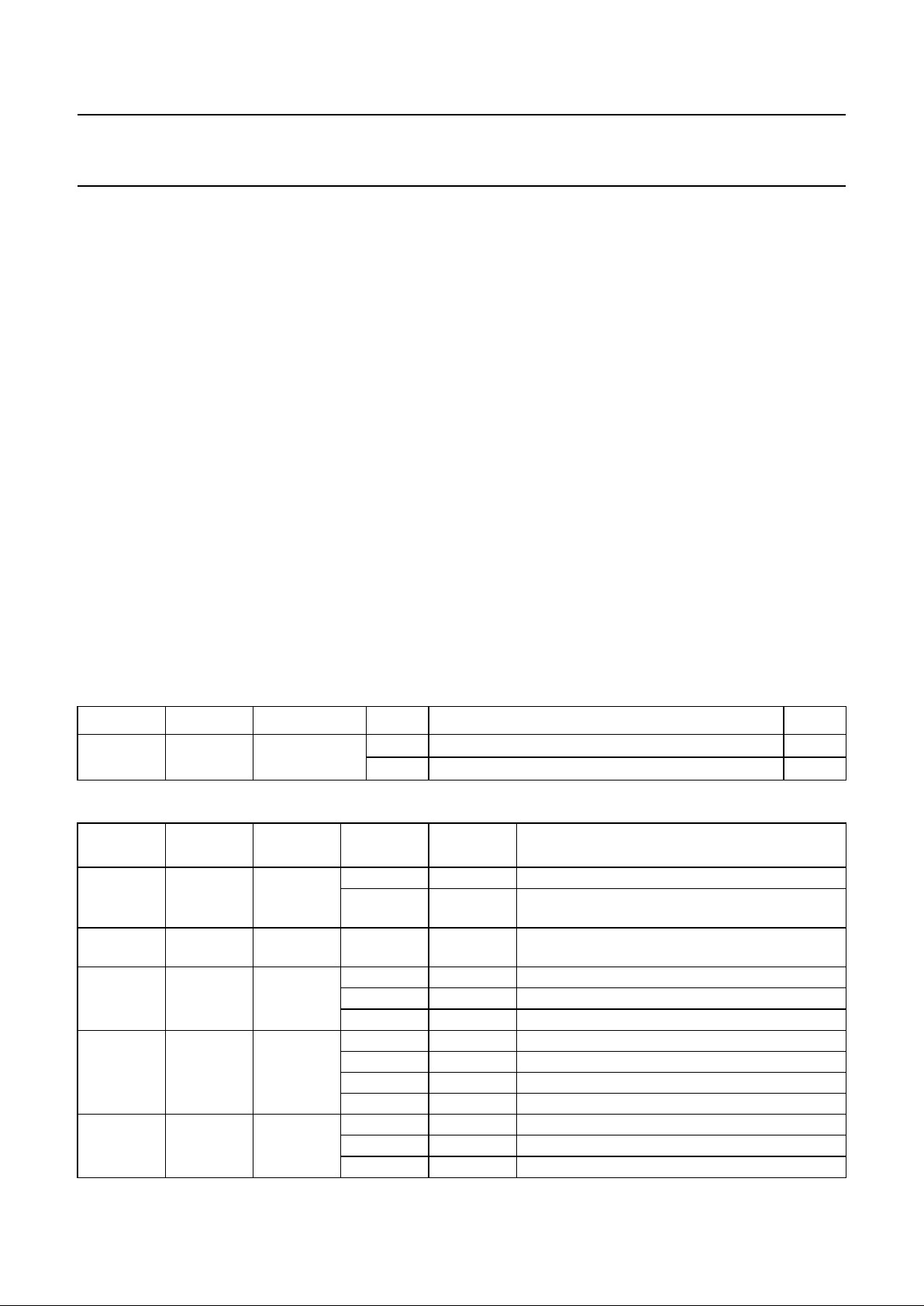

7.1.2 DECODING SPEED AND CRYSTAL FREQUENCY

The SAA7327 is a two speed decoding device, with an

internal Phase-Locked Loop (PLL) clock multiplier.

Depending on the crystal frequency used and the internal

clock settings (selectable via decoder register B), the

playback speeds shown in Table 1 are possible, where ‘n’

is the overspeed factor (1 or 2).

An internal clock multiplier is present, controlled by

SELPLL, and should only be used if a 8.4672 or

16.9344 MHz crystal, ceramic resonator or external clock

is present.

Page 9

1999 Jun 17 9

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.1.3 LOCK-TO-DISC MODE

For Electronic Shock Absorption (ESA) applications, the

SAA7327 can be put into lock-to-disc mode. This allows

Constant Angular Velocity (CAV) disc playback with

varying input data rates from the inside-to-outside of the

disc.

In the lock-to-disc mode, the FIFO is blocked and the

decoder will adjust its output data rate to the disc speed.

Hence, the frequency of the I2S-bus (WCLK and SCLK)

clocks are dependent on the disc speed. In the lock-to-disc

mode there is a limit on the maximum variation in disc

speed that the SAA7327 will follow. Disc speeds must

always be within 25% to 100% range of their nominal

value. The lock-to-disc mode is enabled/disabled by

decoder register E.

7.1.4 S

TANDBY MODES

The SAA7327 may be placed in two standby modes

selected by decoder register B (it should be noted that the

device core is still active):

• Standby 1: ‘CD-STOP’ mode; most I/O functions are

switched off

• Standby 2: ‘CD-PAUSE’ mode; audio output features

are switched off, but the motor loop, the motor output

and the subcode interfaces remain active; this is also

called a ‘Hot Pause’.

In the standby modes the various pins will have the

following values:

• MOTO1 and MOTO2: put in high-impedance, PWM

mode (standby 1 and reset: operating in standby 2); put

in high-impedance, PDM mode (standby 1 and reset:

operating in standby 2)

• SCL and SDA: no interaction; normal operation

continues

• SCLK, WCLK, DATA, EF and DOBM: 3-state in both

standby modes; normal operation continues after reset

• CRIN, CROUT, CL16 and CL11/4: no interaction;

normal operation continues

• V1, V2/V3, V4, V5 and CFLG: no interaction; normal

operation continues.

Table 1 Playback speeds

Notes

1. The CL11 output is always a 5.6448 MHz clock if a 16.9344 MHz external clock is used and SELPLL = 0. CL11 is

available on the CL11/4 output, enabled by programming shadow register 3 (see Section 7.15.3).

2. Data capture performance is not optimized for this option.

REGISTER B SELPLL

CRYSTAL FREQUENCY (MHz) CL11

FREQUENCY

(MHz)

(1)33.8688 16.9344 8.4672

00XX 0 n = 1 −−11.2896

00XX 1 −−n = 1 11.2896

01XX 0 − n=1 − 5.6448

01XX 1 − n=1 − 11.2896

10XX 0 n = 2 −−11.2896

10XX 1 −−n = 2 11.2896

11XX 0 − n=2

(2)

− 5.6448

11XX 1 − n=2 − 11.2896

Page 10

1999 Jun 17 10

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

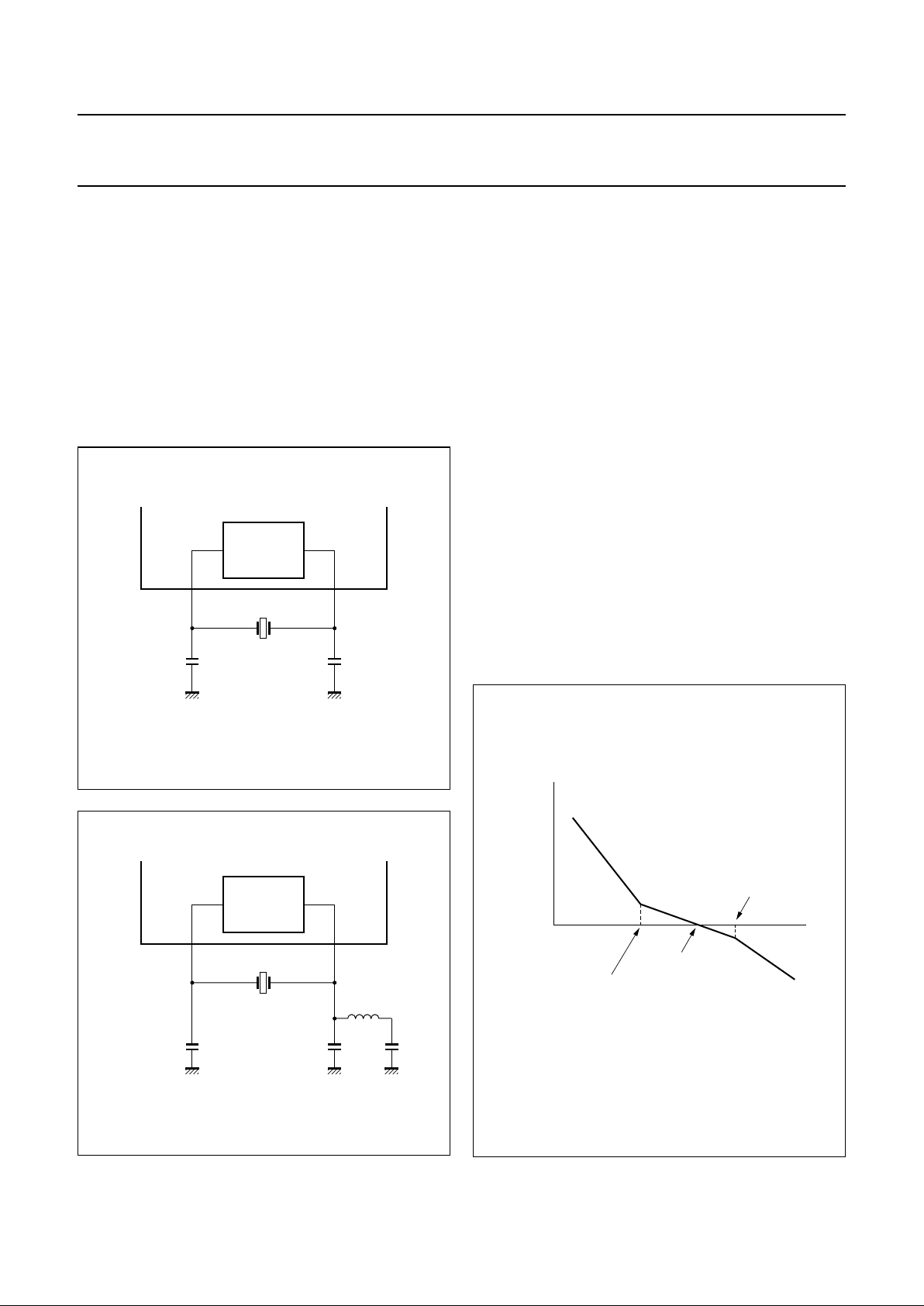

7.2 Crystal oscillator

The crystal oscillator is a conventional 2-pin design

operating between 8 and 35 MHz. This oscillator is

capable of operating with ceramic resonators and with

both fundamental and third overtone crystals. External

components should be used to suppress the fundamental

output of the third overtone crystals as shown in

Figs 3 and 4. Typical oscillation frequencies required are

8.4672, 16.9344 or 33.8688 MHz depending on the

internal clock settings used and whether or not the clock

multiplier is enabled.

Fig.3 8.4672 MHz fundamental configuration.

handbook, halfpage

OSCILLATOR

8.4672 MHz

CRIN

CROUT

SAA7327

33 pF33 pF

MGS246

Fig.4 33.8688 MHz overtone configuration.

handbook, halfpage

OSCILLATOR

33.8688 MHz

CRIN

CROUT

SAA7327

3.3 µH

1 nF10 pF10 pF

MGS247

7.3 Data slicer and clock regenerator

The SAA7327 has an integrated slice level comparator

which can be clocked by the crystal frequency clock, or

4 times the crystal frequency clock (if SELPLL is set HIGH

while using a 16.9344 MHz crystal and register 4 is set to

0XXX), or 8 times the crystal frequency clock (if SELPLL is

set HIGH while using an 8.4672 MHz crystal, and

register 4 is set to 0XXX). The slice level is controlled by

an internal current source applied to an external capacitor

under the control of the Digital Phase-Locked Loop

(DPLL).

Regeneration of the bit clock is achieved with an internal

fully digital PLL. No external components are required and

the bit clock is not output. The PLL has two registers

(8 and 9) for selecting bandwidth and equalization.

The PLL response is shown in Fig.5.

For certain applications an off-track input is necessary.

This is internally connected from the servo part (its polarity

can be changed by the foc_parm1 parameter), but may be

input via the V1 pin if selected by register C. If this flag is

HIGH, the SAA7327 will assume that its servo part is

following on the wrong track, and will flag all incoming

HF data as incorrect.

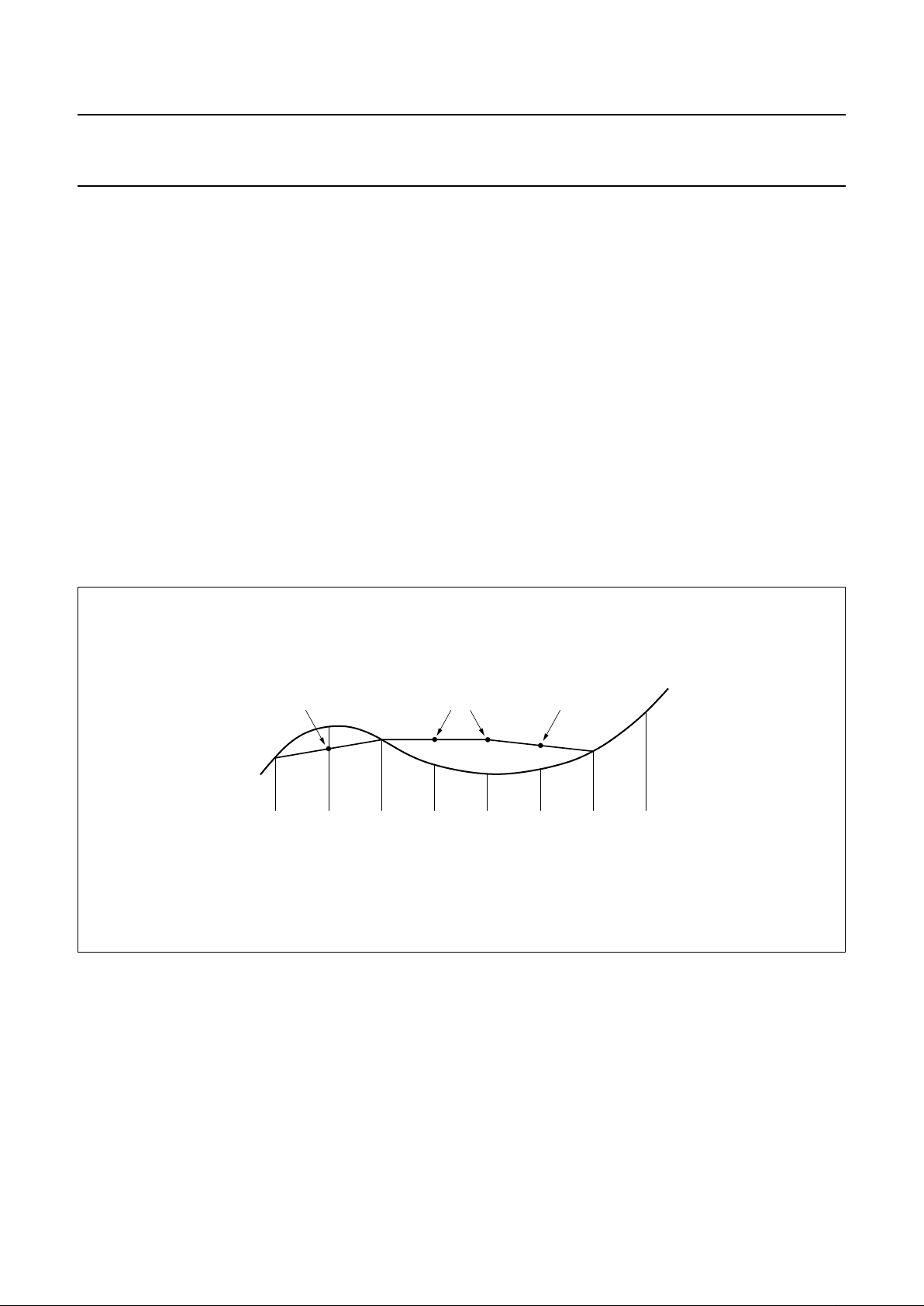

Fig.5 Digital PLL loop response.

MGS178

handbook, halfpage

f

3. PLL, LPF

2. PLL bandwidth

1. PLL integrator

PLL

loop

response

1, 2and 3 are programmable via decoder register 8.

Page 11

1999 Jun 17 11

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Fig.6 Data slicer showing typical application components (for n = 1).

47 pF

HFREF

HFIN

ISLICE

22 kΩ

2.2 kΩ

100 nF

100 nF

1 nF

HF input

crystal

clock

DQ

DPLL

V

SSA

V

SSA

V

SS

MGS179

V

DD

100 µA

100 µA

7.4 Demodulator

7.4.1 F

RAME SYNC PROTECTION

A double timing system is used to protect the demodulator

from erroneous sync patterns in the serial data.

The master counter is only reset if:

• A sync coincidence is detected; sync pattern occurs

588 ±1 EFM clocks after the previous sync pattern

• A new sync pattern is detected within ±6 EFM clocks of

its expected position.

The sync coincidence signal is also used to generate the

PLL lock signal, which is active HIGH after 1 sync

coincidence found, and reset LOW if during 61

consecutive frames no sync coincidence is found. The PLL

lock signal can be accessed via the SDA or STATUS pins

selected by decoder registers 2 and 7.

Also incorporated in the demodulator is a Run Length 2

(RL2) correction circuit. Every symbol detected as RL2 will

be pushed back to RL3. To do this, the phase error of both

edges of the RL2 symbol are compared and the correction

is executed at the side with the highest error probability.

7.4.2 EFM

DEMODULATION

The 14-bit EFM data and subcode words are decoded into

8-bit symbols.

Page 12

1999 Jun 17 12

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

Fig.7 Simplified data flow of decoder functions.

o

k, full pagewidth

SUBCODE

PROCESSOR

DIGITAL PLL

AND

DEMODULATOR

FIFO

ERROR

CORRECTOR

FADE/MUTE/

INTERPOLATE

DIGITAL

FILTER

PHASE

COMPENSATION

DE-EMPHASIS

FILTER

KILL

1

0

1

0

1

0

1

0

1

0

I2S/EIAJ BUS

INTERFACE

I2S/EIAJ

LOOPBACK

INTERFACE

WCLI

SCLI

SDI

LN

LP

RN

RP

SCLK

WCLK

DATA

EF

decoder

reg 3

V

neg

decoder reg C

decoder reg 3

reg F

decoder reg A

1

0

1: decoder reg 3 ≠ 101X

0: decoder reg 3 = 101X

(CD-ROM modes)

1: shadow reg 7 = XX1X

0: shadow reg 7 = XX0X

1: shadow reg 7 = XX1X

0: shadow reg 7 = XX0X

0: reg D = XX01

1: decoder reg A = XX0X

0: decoder reg A ≠ XX1X

V4 SUBCODE

INTERFACE

MICROCONTROLLER

INTERFACE

CD GRAPHICS

INTERFACE

EBU

INTERFACE

SBSY

SFSY

SUB

RCK

DOBM

V4

SDA

output from

data slicer

1: decoder reg 3 = XX10

(1fs mode)

0: decoder reg 3 ≠ XX10

1: no pre-emphasis detected

OR reg D = 01XX

(de-emphasis signal at V5)

0: pre-emphasis detected

AND reg D ≠ 01XX

KILL

V3

MGS180

1

0

ONBOARD

DAC

1: shadow reg 7 = XXX1

0: shadow reg 7 = XXX0

1

0

1

0

Page 13

1999 Jun 17 13

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.5 Subcode data processing

7.5.1 Q-

CHANNEL PROCESSING

The 96-bit Q-channel word is accumulated in an internal

buffer. The last 16 bits are used internally to perform a

Cyclic Redundancy Check (CRC). If the data is good, the

SUBQREADY-I signal will go LOW. SUBQREADY-I can

be read via the SDA or STATUS pins, selected via decoder

register 2. Good Q-channel data may be read from SDA.

7.5.2 EIAJ 3

AND 4-WIRE SUBCODE (CD GRAPHICS)

INTERFACES

Data from all the subcode channels (P-to-W) may be read

via the subcode interface, which conforms to EIAJ

CP-2401. The interface is enabled and configured as

either a 3 or 4-wire interface via decoder register F.

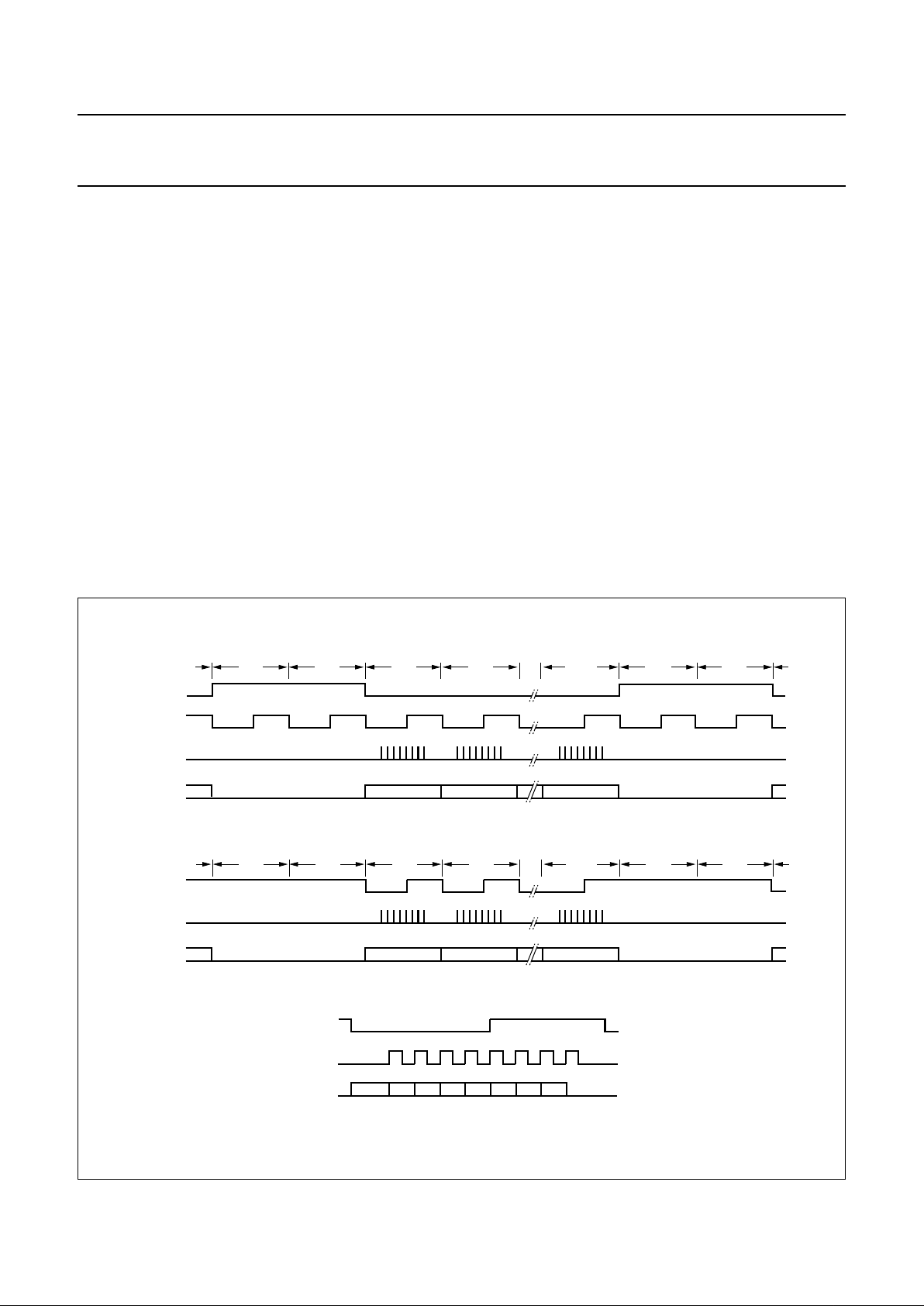

The subcode interface output formats are illustrated in

Fig.8, where the RCK signal is supplied by another device

such as a CD graphics decoder.

7.5.3 V4

SUBCODE INTERFACE

Data of subcode channels, Q-to-W, may be read via pin V4

if selected via decoder register D. The format is similar to

RS232 and is illustrated in Fig.9. The subcode sync word

is formed by a pause of (200/n) µs minimum. Each

subcode byte starts with a logic 1 followed by 7 bits

(Q-to-W). The gap between bytes is variable between

(11.3/n) µs and (90/n) µs.

The subcode data is also available in the EBU output

(DOBM) in a similar format.

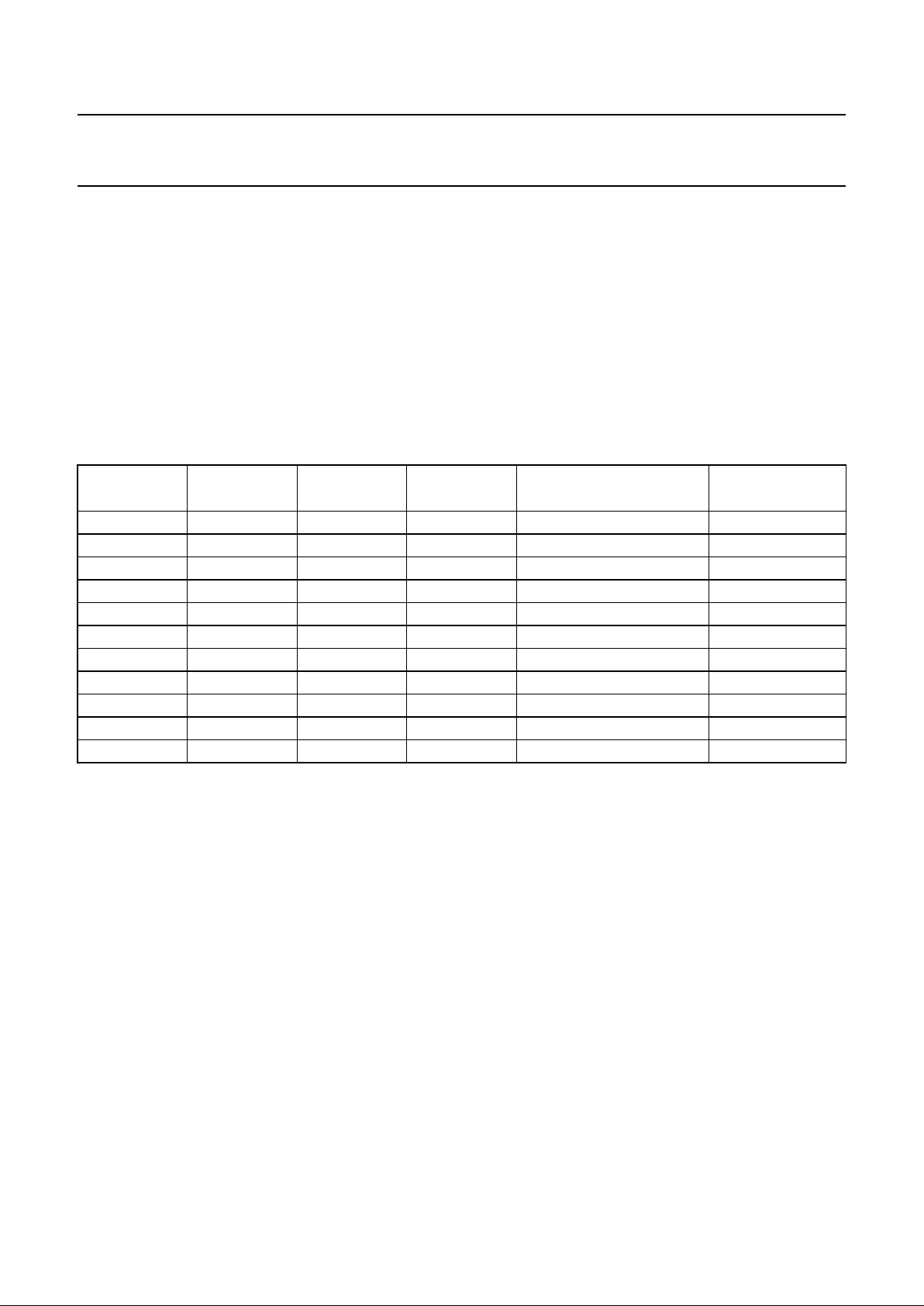

Fig.8 EIAJ subcode (CD graphics) interface format.

handbook, full pagewidth

SBSY

SFSY

RCK

SUB

SFSY

RCK

SUB

SFSY

RCK

SUB

EIAJ 4-wire subcode interface

EIAJ 3-wire subcode interface

SF0 SF1

SF2 SF3 SF97 SF0 SF1

P-W P-W P-W

P-W P-W P-W

PQRSTUVW

MBG410

SF0 SF1 SF2 SF3 SF97 SF0 SF1

Page 14

1999 Jun 17 14

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Fig.9 Subcode format and timing on pin V4.

n = disc speed.

W96 1QRSTUVW 1Q

200/n µs

min

11.3/n

µs

11.3/n µs min

90/n µs max

MBG401

7.6 FIFO and error corrector

The SAA7327 has a ±8 frame FIFO. The error corrector is

a t = 2, e = 4 type, with error corrections on both C1

(32 symbol) and C2 (28 symbol) frames. Four symbols are

used from each frame as parity symbols. This error

corrector can correct up to two errors on the C1 level and

up to four errors on the C2 level.

The error corrector also contains a flag processor. Flags

are assigned to symbols when the error corrector cannot

ascertain if the symbols are definitely good. C1 generates

output flags which are read after (de-interleaving) by C2,

to help in the generation of C2 output flags.

The C2 output flags are used by the interpolator for

concealment of uncorrectable errors. They are also output

via the EBU signal (DOBM). The EF output will flag bytes

in error in both audio and CD-ROM modes.

7.6.1 FLAGS OUTPUT (CFLG)

The flags output pin CFLG shows the status of the error

corrector and interpolator and is updated every frame

(7.35 × n kHz). In the SAA7327 chip a 1-bit flag is present

on the CFLG pin as illustrated in Fig.10. This signal shows

the status of the error corrector and interpolator.

The first flag bit, F1, is the absolute time sync signal, the

FIFO-passed subcode sync and relates the position of the

subcode sync to the audio data (DAC output). This flag

may also be used in a super FIFO or in the synchronization

of different players. The output flags can be made

available at bit 4 of the EBU data format (LSB of the 24-bit

data word), if selected by decoder register A.

Fig.10 Flag output timing diagram.

n = disc speed.

handbook, full pagewidth

F1 F2 F3 F4 F5 F6 F7 F8 F1F8

11.3/n

µs

33.9/n µs

33.9/n µs

MBG425

Page 15

1999 Jun 17 15

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Table 2 Output flags

F1 F2 F3 F4 F5 F6 F7 F8 DESCRIPTION

0XXXXXXXno absolute time sync

1XXXXXXXabsolute time sync

X 0 0 X X X X X C1 frame contained no errors

X 0 1 X X X X X C1 frame contained 1error

X 1 0 X X X X X C1 frame contained 2errors

X 1 1 X X X X X C1 frame uncorrectable

X X X 0 0 X X 0 C2 frame contained no errors

X X X 0 0 X X 1 C2 frame contained 1 error

X X X 0 1 X X 0 C2 frame contained 2 errors

X X X 0 1 X X 1 C2 frame contained 3 errors

X X X 1 0 X X 0 C2 frame contained 4 errors

X X X 1 1 X X 1 C2 frame uncorrectable

X X X X X 0 0 X no interpolations

X X X X X 0 1 X at least one 1-sample interpolation

X X X X X 1 0 X at least one hold and no interpolations

X X X X X 1 1 X at least one hold and one 1-sample interpolation

7.7 Audio functions

7.7.1 D

E-EMPHASIS AND PHASE LINEARITY

When pre-emphasis is detected in the Q-channel

subcode, the digital filter automatically includes a

de-emphasis filter section. When de-emphasis is not

required, a phase compensation filter section controls the

phase of the digital oversampling filter to ≤±1° within the

band 0 to 16 kHz. With de-emphasis the filter is not phase

linear.

If the de-emphasis signal is set to be available at V5,

selected via decoder register D, then the de-emphasis

filter is bypassed.

7.7.2 D

IGITAL OVERSAMPLING FILTER

For optimizing performance with an external DAC, the

SAA7327 contains a 2 to 4 times oversampling IIR filter.

The filter specification of the 4 times oversampling filter is

given in Table 3.

These attenuations do not include the sample-and-hold at

the external DAC output or the DAC post filter. When using

the oversampling filter, the output level is scaled −0.5 dB

down, to avoid overflow on full-scale sine wave inputs

(0 to 20 kHz).

Table 3 Filter specification

7.7.3 CONCEALMENT

A 1-sample linear interpolator becomes active if a single

sample is flagged as erroneous but cannot be corrected.

The erroneous sample is replaced by a level midway

between the preceding and following samples. Left and

right channels have independent interpolators. If more

than one consecutive non-correctable sample is found, the

last good sample is held. A 1-sample linear interpolation is

then performed before the next good sample (see Fig.11).

In CD-ROM modes (i.e. the external DAC interface is

selected to be in a CD-ROM format) concealment is not

executed.

PASS BAND STOP BAND ATTENUATION

0 to 9 kHz −≤0.001 dB

19 to 20 kHz −≤0.03 dB

− 24 kHz ≥25 dB

− 24 to 27 kHz ≥38 dB

− 27 to 35 kHz ≥40 dB

− 35 to 64 kHz ≥50 dB

− 64 to 68 kHz ≥31 dB

− 68 kHz ≥35 dB

− 69 to 88 kHz ≥40 dB

Page 16

1999 Jun 17 16

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.7.4 MUTE, FULL-SCALE, ATTENUATION AND FADE

A digital level controller is present on the SAA7327 which

performs the functions of soft mute, full-scale, attenuation

and fade; these are selected via decoder register 0:

• Mute: signal reduced to 0 in a maximum of 128 steps;

(3/n) ms

• Attenuate: signal scaled by −12 dB

• Full-scale: ramp signal back to 0 dB level; from mute

takes (3/n) ms

• Fade: activates a 128 stage counter which allows the

signal to be scaled up/down by 0.07 dB steps

– 128 = full-scale

– 120 = −0.5 dB (i.e. full-scale if oversampling filter

used)

–32=−12 dB

– 0 = mute.

7.7.5 PEAK DETECTOR

The peak detector measures the highest audio level

(absolute value) on positive peaks for left and right

channels. The 8 most significant bits are output in the

Q-channel data in place of the CRC bits. Bits 81 to 88

contain the left peak value (bit 88 = MSB) and

bits 89 to 96 contain the right peak value (bit 96 = MSB).

The values are reset after reading Q-channel data via

SDA.

Fig.11 Concealment mechanism.

Interpolation Hold Interpolation

MGA372

OK Error OK Error Error Error OK OK

Page 17

1999 Jun 17 17

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.8 DAC interface

7.8.1 I

NTERNAL BITSTREAM DIGITAL-TO-ANALOG CONVERTER (DAC)

The onboard bitstream DAC operates at a clock frequency of 96fs and is designed for operation with an audio input at

1fs. Optimum performance is dependent on the application circuit used and careful consideration should be given to the

recommended application circuits shown in Figs 38 and 39. The onboard DAC is controlled from shadow register 7

(see Section 7.15.3 for definition of shadow registers). This shadow register controls routing of data into the onboard

DAC and also controls the DAC output pins, which can be held at zero when the onboard DAC is not required;

see Table 4.

Table 4 Shadow register

Audio data from the decoder part of SAA7327 can be routed as described in the following two subsections.

SHADEN

SHADOW

ADDRESS

REGISTER DATA FUNCTION RESET

1 0111 (7H) control of

onboard DAC

XXX0 hold onboard DAC outputs at

zero

reset

XXX1 enable onboard DAC outputs −

XX0X use external DAC or route audio

data into onboard DAC

(loopback mode)

reset

XX1X route audio data into onboard

DAC (non-loopback mode)

−

7.8.1.1 Use onboard DAC

In this mode, shadow register 7 should be set to XX11.

This routes audio data from the decoder section of CD7 II

into the onboard DAC and enables the DAC output pins

(LN, LP, RN and RP). It should be noted that the DAC

interface format (set by decoder register 3) must be set to

16-bit 1fsmode, either I2S-bus or EIAJ format, for optimum

DAC performance to be achieved. CD-ROM mode can

also be used if interpolation is not required.

When using this mode, the serial data output pins for

interfacing with an external DAC or VCD decoder (SCLK,

WCLK, DATA and EF) are set to high-impedance.

7.8.1.2 Loopback external data into onboard DAC

The onboard DAC can also be set to accept digital audio

inputs from an external source, e.g. audio from a VCD

decoder IC. This is known as loopback mode and is

enabled by setting shadow register 7 to XX01. This

enables the serial data output pins SCLK, WCLK, DATA

and EF so that data can be routed to the external VCD

decoder (or external DAC).

The digital audio data output from the VCD decoder can

then also be input to the onboard DAC on the SAA7327 by

utilising the serial data input interface (SCLI, SDI and

WCLI).

In this mode, a wide range of data formats to the external

VCD IC can be programmed as shown in Table 4.

However, the serial inputs on the SAA7327 will always

expect the input digital audio data from the VCD IC to be

16-bit 1fs and the same data format, either I2S-bus or EIAJ,

as the serial output format (set by decoder register 3).

In fact, the onboard DAC will also accept 18-bit I2S-bus

data; in this case the 16 MSBs only will be read and the

2 LSBs discarded.

Page 18

1999 Jun 17 18

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.8.2 EXTERNAL DAC INTERFACE

Audio data from the CD10 decoder can be sent direct to an

external DAC, identical to the SAA737x series. This is

similar to the ‘loopback’ mode, but in this case the internal

DAC outputs can be held at zero i.e. shadow register 7 is

set to XX00. The SAA7327 is compatible with a wide range

of external DACs. Eleven formats are supported and are

given in Table 4. Figures 12 and 13 show the Philips

I2S-bus and the EIAJ data formats respectively. When the

decoder is operated in lock-to-disc mode, the SCLK

frequency is dependent on the disc speed factor ‘d’.

All formats are MSB first and f

s

is (44.1 × n) kHz.

The polarity of the WCLK and the data can be inverted;

selectable by decoder register 7. It should be noted that

EF is only a defined output in CD-ROM and 1fsmodes.

When using an external DAC (or when using the onboard

DAC in non-loopback mode), the serial data inputs to the

onboard DAC (SCLI, SDI and WCLI) should be left

unconnected.

Table 5 DAC interface formats

Note

1. In this mode the first 16 bits contain data, but if any of the fade, attenuate or de-emphasis filter functions are activated

then the first 18 bits contain data.

REGISTER 3

SAMPLE

FREQUENCY

NUMBER OF

BITS

SCLK (MHz) FORMAT INTERPOLATION

1010 f

s

16 2.1168 × n CD-ROM (I2S-bus) no

1011 f

s

16 2.1168 × n CD-ROM (EIAJ) no

1110 f

s

16/18

(1)

2.1168 × n Philips I2S-bus 16/18 bits

(1)

yes

0010 f

s

16 2.1168 × n EIAJ 16 bits yes

0110 f

s

18 2.1168 × n EIAJ 18 bits yes

0000 4f

s

16 8.4672 × n EIAJ 16 bits yes

0100 4f

s

18 8.4672 × n EIAJ 18 bits yes

1100 4f

s

18 8.4672 × n Philips I2S-bus 18 bits yes

0011 2f

s

16 4.2336 × n EIAJ 16 bits yes

0111 2f

s

18 4.2336 × n EIAJ 18 bits yes

1111 2f

s

18 4.2336 × n Philips I2S-bus 18 bits yes

Page 19

1999 Jun 17 19

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

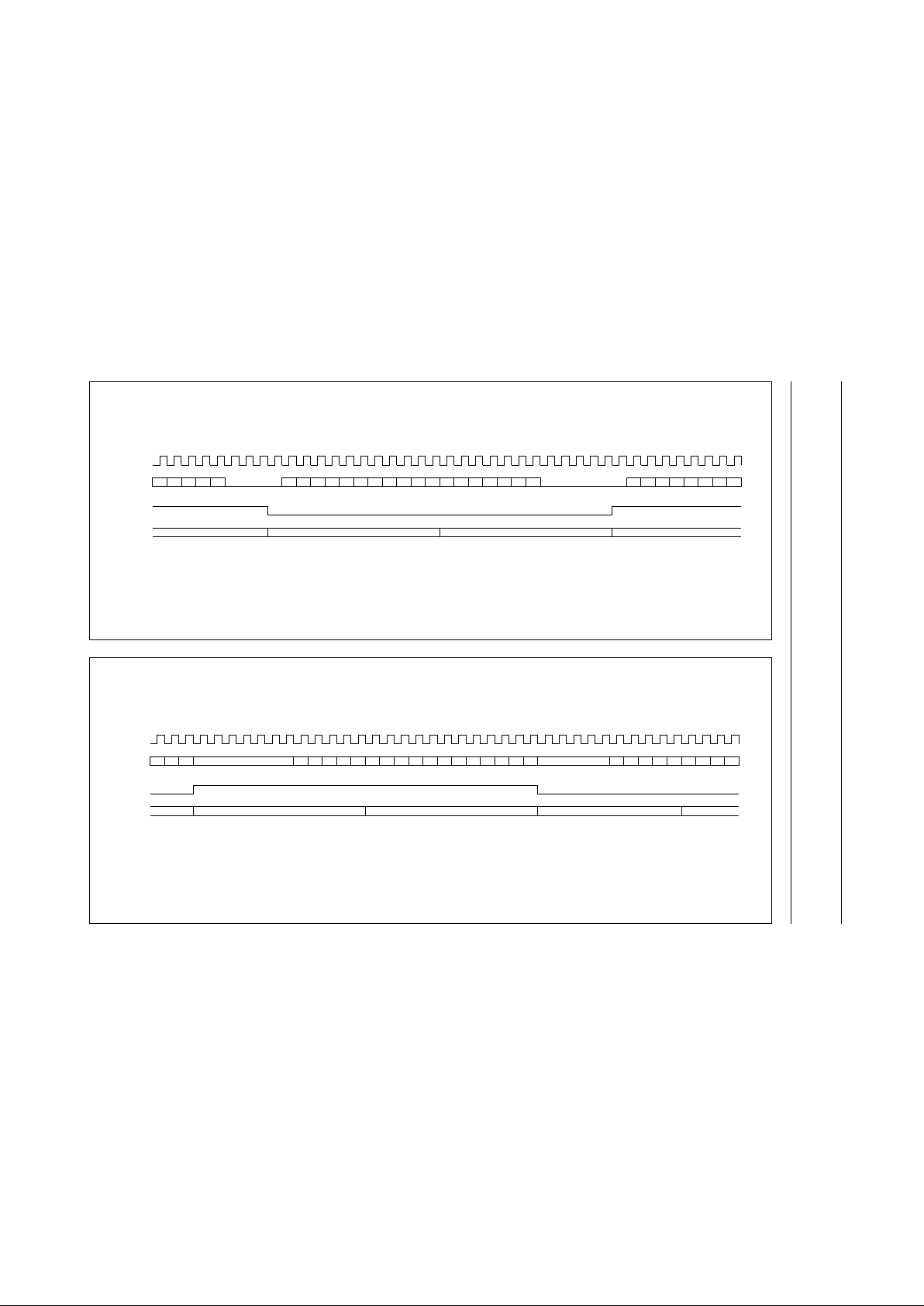

LEFT CHANNEL DATA (WCLK NORMAL POLARITY)

SCLK

15 14

15 1410DATA

WCLK

LSB error flag MSB error flag LSB error flag MSB error flag

EF

(CD-ROM

AND Ifs MODES ONLY)

01

MBG424

Fig.12 Philips I2S-bus data format (16-bit word length shown).

SCLK

17

170DATA

WCLK

0

LEFT CHANNEL DATA

MSB error flag LSB error flag MSB error flag

MBG423

EF

(CD-ROM

AND Ifs MODES ONLY)

Fig.13 EIAJ data format (18-bit word length shown).

Page 20

1999 Jun 17 20

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.9 EBU interface

The bi-phase mark digital output signal at pin DOBM is in

accordance with the format defined by the IEC958

specification. Three different modes can be selected via

decoder register A:

• DOBM pin held LOW

• Data taken before concealment, mute and fade (must

always be used for CD-ROM modes)

• Data taken after concealment, mute and fade.

7.9.1 FORMAT

The digital audio output consists of 32-bit words

(‘subframes’) transmitted in bi-phase mark code (two

transitions for a logic 1 and one transition for a logic 0).

Words are transmitted in blocks of 384. The formats are

given in Table 6.

Table 6 Format

Table 7 Description of Table 6

Table 8 Bit assignment

FUNCTION BITS DESCRIPTION

Sync 0 to 3 −

Auxiliary 4 to 7 not used; normally zero

Error flags 4 CFLG error and interpolation flags when selected by register A

Audio sample 8 to 27 first 4 bits not used (always zero) twos complement LSB = bit 12, MSB = bit 27

Validity flag 28 valid = logic 0

User data 29 used for subcode data (Q-to-W)

Channel status 30 control bits and category code

Parity bit 31 even parity for bits 4 to 30

FUNCTION DESCRIPTION

Sync The sync word is formed by violation of the bi-phase rule and therefore does not contain any data.

Its length is equivalent to 4 data bits. The 3 different sync patterns indicate the following situations:

sync B: start of a block (384 words), word contains left sample; sync M: word contains left sample

(no block start) and sync W: word contains right sample.

Audio sample Left and right samples are transmitted alternately.

Validity flag Audio samples are flagged (bit 28 = 1) if an error has been detected but was uncorrectable. This

flag remains the same even if data is taken after concealment.

User data Subcode bits Q-to-W from the subcode section are transmitted via the user data bit. This data is

asynchronous with the block rate.

Channel status The channel status bit is the same for left and right words. Therefore a block of 384 words contains

192 channel status bits. The category code is always CD. The bit assignment is given in Table 8.

FUNCTION BITS DESCRIPTION

Control 0 to 3 copy of CRC checked Q-channel control bits 0 to 3; bit 2 is logic 1 when

copy permitted; bit 3 is logic 1 when recording has pre-emphasis

Reserved mode 4 to 7 always zero

Category code 8 to 15 CD: bit 8 = logic 1, all other bits = logic 0

Clock accuracy 28 to 29 set by register A; 10 = level I; 00 = level II; 01 = level III

Remaining 6 to 27 and 30 to 191 always zero

Page 21

1999 Jun 17 21

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.10 KILL circuit

The KILL circuit detects digital silence by testing for an

all-zero or all-ones data word in the left or right channel

prior to the digital filter. The output is switched active LOW

when silence has been detected for at least 270 ms, or if

mute is active, or in CD-ROM modes. Two modes are

available which can be selected by decoder register C:

• Pin KILL: KILL active LOW indicates silence detected on

both left and right channels

• Pin KILL: KILL active LOW indicates silence detected on

left channel. V3 active LOW indicates silence detected

on right channel.

It should be noted that when mute is active or in CD-ROM

modes the output(s) are switched LOW.

7.11 Audio features off

The audio features can be turned off (selected by decoder

register E) which affects the following functions:

• Digital filter, fade, peak detector, KILL circuit (but

outputs KILL, V3 still active) are disabled

• V5 (if selected to be the de-emphasis flag output) and

the EBU outputs become undefined.

It should be noted that the EBU output should be set LOW

prior to switching the audio features off and after switching

audio features back on a full-scale command should be

given.

7.12 The VIA interface

The SAA73727 has four pins that can be reconfigured for

different applications. One of these pins, V2/V3, can be

programmed as an input (V2) or as an output (V3). Control

of the V2/V3 pin is via shadow register 3; see Table 9:

Selection of the V2/V3 pin does not affect the function

programmed by decoder register C i.e. the V2/V3 pin can

be changed from V2 to V3 function either before or after

setting the desired function via decoder register 1100.

Selection of, for instance, a V3 function while the V2/V3

pin is set to V2 will not affect the V2 functionality.

The functions of these versatile pins is identical to the

SAA737x series. The functions of these versatile pins is

programmed by decoder registers C and D, as shown in

Table 10.

Table 9 V2/V3 configuration

Table 10 Pin applications

SHADEN ADDRESS REGISTER DATA FUNCTION RESET

1 0011 (3H) control of

V2/V3 pin

0XXX V2/V3 pin configured as V2 input reset

1XXX V2/V3 pin configured as V3 output (open-drain) −

PIN NAME

PIN

NUMBER

TYPE

REGISTER

ADDRESS

REGISTER

DATA

FUNCTION

V1 63 input 1100 XXX1 external off-track signal input

− XXX0 internal off-track signal used input may be read

via decoder status bit; selected via register 2

V2 36 input −−input may be read via decoder status bit;

selected via register 2

V3 36 output 1100 XX0X KILL output for right channel

− X01X output = 0

− X11X output = 1

V4 61 output 1101 0000 4-line motor drive (using V4 and V5)

− XX01 Q-to-W subcode output

− XX10 output = 0

− XX11 output = 1

V5 62 output 1101 01XX de-emphasis output (active HIGH)

− 10XX output = 0

− 11XX output = 1

Page 22

1999 Jun 17 22

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.13 Spindle motor control

7.13.1 M

OTOR OUTPUT MODES

The spindle motor speed is controlled by a fully integrated

digital servo. Address information from the internal

±8 frame FIFO and disc speed information are used to

calculate the motor control output signals. Several output

modes, selected by decoder register 6, are supported:

• Pulse density, 2-line (true complement output),

(1 × n) MHz sample frequency

• PWM output, 2-line, (22.05 × n) kHz modulation

frequency

• PWM output, 4-line, (22.05 × n) kHz modulation

frequency

• CDV motor mode.

7.13.1.1 Pulse density output mode

In the pulse density mode the motor output pin (MOTO1)

is the pulse density modulated motor output signal. A 50%

duty factor corresponds with the motor not actuated,

higher duty factors mean acceleration, lower mean

braking. In this mode, the MOTO2 signal is the inverse of

the MOTO1 signal. Both signals change state only on the

edges of a (1 × n) MHz internal clock signal. Possible

application diagrams are illustrated in Fig.14.

7.13.1.2 PWM output mode (2-line)

In the PWM mode the motor acceleration signal is put in

pulse-width modulation form on the MOTO1 output.

The motor braking signal is pulse-width modulated on the

MOTO2 output. The timing is illustrated in Fig.15. A typical

application diagram is illustrated in Fig.16.

Fig.14 Motor pulse density application diagrams.

MGA363 - 1

MOTO2

V

DD

V

SS

MOTO1

M

22 kΩ

10 nF

+

–

22 kΩ

10 nF

+

–

V

SS

V

SS

MOTO1

M

22 kΩ

10 nF

+

–

22 kΩ

22 kΩ

V

SS

V

DD

V

SS

22 kΩ

22 kΩ

Fig.15 2-line PWM mode timing.

rep

t = 45 µs

t 240 ns

dead

Accelerate Brake

MOTO1

MOTO2

MGA366

Page 23

1999 Jun 17 23

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.13.1.3 PWM output mode (4-line)

Using two extra outputs from the versatile pins interface, it is possible to use the SAA7327 with a 4-input motor bridge.

The timing is illustrated in Fig.17. A typical application diagram is illustrated in Fig.18.

Fig.16 Motor 2-line PWM mode application diagram.

MGA365 - 2

V

SS

+

M

MOTO1 MOTO2

10 Ω

100 nF

Fig.17 4-line PWM mode timing.

MOTO1

MOTO2

V4

V5

rep

t = 45 µs t 240 ns

dead

ovl

t = 240 ns

Accelerate Brake

MGA367 - 1

Page 24

1999 Jun 17 24

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Fig.18 Motor 4-line PWM mode application diagram.

MGA364 - 2

V

SS

+

M

MOTO1

V4

MOTO2

V5

100 nF

10 Ω

7.13.1.4 CDV/CAV output mode

In the CDV motor mode, the FIFO position will be put in

pulse-width modulated form on the MOTO1 pin [carrier

frequency (300 × d) Hz], where ‘d’ is the disc speed factor.

The PLL frequency signal will be put in pulse-density

modulated form (carrier frequency 4.23 × n MHz) on the

MOTO2 pin. The integrated motor servo is disabled in this

mode.

The PWM signal on MOTO1 corresponds to a total

memory space of 20 frames, therefore the nominal FIFO

position (half full) will result in a PWM output of 60%.

In the lock to-disc (CAV) mode the CDV motor mode is the

only mode that can be used to control the motor.

7.13.2 S

PINDLE MOTOR OPERATING MODES

The operation modes of the motor servo is controlled by

decoder register 1 (see Table 11).

In the SAA7327 decoder there is an anti-windup mode for

the motor servo, selected via decoder register 1. When the

anti-wind-up mode is activated the motor servo integrator

will hold if the motor output saturates.

7.13.2.1 Power limit

In start mode 1, start mode 2, stop mode 1 and stop

mode 2, a fixed positive or negative voltage is applied to

the motor. This voltage can be programmed as a

percentage of the maximum possible voltage, via

register 6, to limit current drain during start and stop.

The following power limits are possible; 100% (no power

limit), 75%, 50%, or 37% of maximum.

7.13.3 L

OOP CHARACTERISTICS

The gain and crossover frequencies of the motor control

loop can be programmed via decoder registers 4 and 5.

The following parameter values are possible:

• Gains: 3.2, 4.0, 6.4, 8.0, 12.8, 16, 25.6 and 32

• Crossover frequency f4: 0.5 × n Hz, 0.7 × n Hz,

1.4 × n Hz and 2.8 × nHz

• Crossover frequency f3: 0.85 × n Hz, 1.71 × n Hz and

3.42 × n Hz.

It should be noted that the crossover frequencies f3and f

4

are scaled with the overspeed factor ‘n’ whereas the gains

are not.

Page 25

1999 Jun 17 25

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.13.4 FIFO OVERFLOW

If FIFO overflow occurs during Play mode (e.g.: as a result of motor rotational shock), the FIFO will be automatically reset

to 50% and the audio interpolator tries to conceal as much as possible to minimize the effect of data loss.

Table 11 Operating modes

MODE DESCRIPTION

Start mode 1 The disc is accelerated by applying a positive voltage to the spindle motor . No decisions are involved

and the PLL is reset. No disc speed information is available for the microcontroller.

Start mode 2 The disc is accelerated as in start mode 1, however the PLL will monitor the disc speed. When the

disc reaches 75% of its nominal speed, the controller will switch to jump mode. The motor status

signals selectable via register 2 are valid.

Jump mode Motor servo enabled but FIFO kept reset at 50%, integrator is held. The audio is muted but it is

possible to read the subcode. It should be noted that in the CD-ROM modes the data, on EBU and

the I

2

S-bus is not muted.

Jump mode 1 Similar to jump mode but motor integrator is kept at zero. Used for long jumps where there is a large

change in disc speed.

Play mode FIFO released after resetting to 50%. Audio mute released.

Stop mode 1 Disc is braked by applying a negative voltage to the motor. No decisions are involved.

Stop mode 2 The disc is braked as in stop mode 1 but the PLL will monitor the disc speed. As soon as the disc

reaches 12% (or 6%, depending on the programmed brake percentage, via register E) of its nominal

speed, the MOTSTOP status signal will go HIGH and switch the motor servo to Off mode.

Off mode Motor not steered.

Fig.19 Motor servo mode diagram.

MGA362 - 2

G

f

4

fBW

3

f

Page 26

1999 Jun 17 26

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.14 Servo part

7.14.1 D

IODE SIGNAL PROCESSING

The photo detector in conventional two-stage three-beam

Compact Disc systems normally contains six discrete

diodes. Four of these diodes (three for single foucault

systems) carry the Central Aperture signal (CA) while the

other two diodes (satellite diodes) carry the radial tracking

information. The CA signal is processed into an HF signal

(for the decoder function) and LF signal (information for the

focus servo loop) before it is supplied to the SAA7327.

The analog signals from the central and satellite diodes

are converted into a digital representation using

Analog-to-Digital Converters (ADCs).

The ADCs are designed to convert unipolar currents into a

digital code. The dynamic range of the input currents is

adjustable within a given range, which is dependent on the

value of the external reference current (I

ref

) resistor and

the values programmed in shadow registers A and C.

The magnitude of the signal currents for the central

aperture diodes D1 to D4 and the radial diodes R1 and R2

are programmed separately to sixteen separate current

ranges.

The maximum input currents with an external 30 kΩ

reference current resistor are given in Table 12.

Table 12 Shadow register settings to control diode input current ranges

SHADEN BIT

SHADOW

REGISTER

ADDRESS DATA FUNCTION INITIAL

1A

signal

magnitude

control for

diodes

D1 to D4

1010 0000 (0.042).I

ref

= 1.006 µA (nom) −

0001 (0.083).I

ref

= 2.013 µA (nom) −

0010 (0.125).I

ref

= 3.019 µA (nom) −

0011 (0.167).I

ref

= 4.025 µA (nom) −

0100 (0.208).I

ref

= 5.031 µA (nom) −

0101 (0.25).I

ref

= 6.034 µA (nom) −

0110 (0.292).I

ref

= 7.044 µA (nom) −

0111 (0.333).I

ref

= 8.05 µA (nom) −

1000 (0.375).I

ref

= 9.056 µA (nom) −

1001 (0.417).I

ref

= 10.063 µA (nom) −

1010 (0.458).I

ref

= 11.069 µA (nom) −

1011 (0.5).I

ref

= 12.075 µA (nom) −

1100 (0.542).I

ref

= 13.081 µA (nom) −

1101 (0.583).I

ref

= 14.088 µA (nom) −

1110 (0.625).I

ref

= 15.094 µA (nom) −

1111 (0.667).I

ref

= 16.1 µA (nom) reset

Page 27

1999 Jun 17 27

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

1C

signal

magnitude

control for

diodes

R1 and R2

1100 0000 (0.042).I

ref

= 1.006 µA (nom) −

0001 (0.083).I

ref

= 2.013 µA (nom) −

0010 (0.125).I

ref

= 3.019 µA (nom) −

0011 (0.167).I

ref

= 4.025 µA (nom) −

0100 (0.208).I

ref

= 5.031 µA (nom) −

0101 (0.25).I

ref

= 6.034 µA (nom) −

0110 (0.292).I

ref

= 7.044 µA (nom) −

0111 (0.333).I

ref

= 8.05 µA (nom) −

1000 (0.375).I

ref

= 9.056 µA (nom) −

1001 (0.417).I

ref

= 10.063 µA (nom) −

1010 (0.458).I

ref

= 11.069 µA (nom) −

1011 (0.5).I

ref

= 12.075 µA (nom) −

1100 (0.542).I

ref

= 13.081 µA (nom) −

1101 (0.583).I

ref

= 14.088 µA (nom) −

1110 (0.625).I

ref

= 15.094 µA (nom) −

1111 (0.667).I

ref

= 16.1 µA (nom) reset

SHADEN BIT

SHADOW

REGISTER

ADDRESS DATA FUNCTION INITIAL

7.14.2 SIGNAL CONDITIONING

The digital codes retrieved from the ADCs are applied to

logic circuitry to obtain the various control signals.

The signals from the central aperture diodes are

processed to obtain a normalised focus error signal.

where the detector set-up is assumed as shown in Fig.20.

In the event of single Foucault focusing method, the signal

conditioning can be switched under software control such

that the signal processing is as follows:

The error signal, FEn, is further processed by a

proportional integral and differential (PID) filter section.

A Focus OK (FOK) flag is generated by means of the

central aperture signal and an adjustable reference level.

This signal is used to provide extra protection for the

Track-Loss (TL) generation, the focus start-up procedure

and the dropout detection.

FE

n

D1 D2–

D1 D2+

---------------------

D3 D4–

D3 D4+

---------------------

–=

FE

n

2

D1 D2–

D1 D2+

---------------------

×=

The radial or tracking error signal is generated by the

satellite detector signals R1 and R2. The radial error

signal can be formulated as follows:

RE

s

= (R1 − R2) × re_gain + (R1 + R2) × re_offset

where the index ‘s’ indicates the automatic scaling

operation which is performed on the radial error signal.

This scaling is necessary to avoid non-optimum dynamic

range usage in the digital representation and reduces the

radial bandwidth spread. Furthermore, the radial error

signal will be made free from offset during start-up of the

disc.

The four signals from the central aperture detectors,

together with the satellite detector signals generate a track

position signal (TPI) which can be formulated as follows:

TPI = sign [(D1 + D2 + D3 + D4) − (R1 + R2) × sum_gain]

where the weighting factor sum_gain is generated

internally by the SAA7327 during initialization.

Page 28

1999 Jun 17 28

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

Fig.20 Detector arrangement.

handbook, full pagewidth

D3

D1

D2

SATELLITE

DIODE R1

SATELLITE

DIODE R2

D1

D3

D2

D4

SATELLITE

DIODE R1

SATELLITE

DIODE R2

D1

D2

D3

D4

SATELLITE

DIODE R1

SATELLITE

DIODE R2

single Foucault astigmatic focus double Foucault

MBG422

7.14.3 FOCUS SERVO SYSTEM

7.14.3.1 Focus start-up

Five initially loaded coefficients influence the start-up

behaviour of the focus controller. The automatically

generated triangular voltage can be influenced by

3 parameters; for height (ramp_height) and DC offset

(ramp_offset) of the triangle and its steepness

(ramp_incr).

For protection against false focus point detections two

parameters are available which are an absolute level on

the CA-signal (CA_start) and a level on the FEn signal

(FE_start). When this CA level is reached the FOK signal

becomes true.

If the FOK signal is true and the level on the FEn signal is

reached, the focus PID is enabled to switch on when the

next zero crossing is detected in the FEn signal.

7.14.3.2 Focus position control loop

The focus control loop contains a digital PID controller

which has 5 parameters which are available to the user.

These coefficients influence the integrating (foc_int),

proportional (foc_lead_length, part of foc_parm3) and

differentiating (foc_pole_lead, part of foc_parm1) action of

the PID and a digital low-pass filter (foc_pole_noise, part

of foc_parm2) following the PID. The fifth coefficient

foc_gain influences the loop gain.

7.14.3.3 Dropout detection

This detector can be influenced by one parameter

(CA_drop). The FOK signal will become false and the

integrator of the PID will hold if the CA signal drops below

this programmable absolute CA level. When the FOK

signal becomes false it is assumed, initially, to be caused

by a black dot.

Page 29

1999 Jun 17 29

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.14.3.4 Focus loss detection and fast restart

Whenever FOK is false for longer than approximately

3 ms, it is assumed that the focus point is lost. A fast

restart procedure is initiated which is capable of restarting

the focus loop within 200 to 300 ms depending on the

programmed coefficients of the microcontroller.

7.14.3.5 Focus loop gain switching

The gain of the focus control loop (foc_gain) can be

multiplied by a factor of 2 or divided by a factor of 2 during

normal operation. The integrator value of the PID is

corrected accordingly. The differentiating (foc_pole_lead)

action of the PID can be switched at the same time as the

gain switching is performed.

7.14.3.6 Focus automatic gain control loop

The loop gain of the focus control loop can be corrected

automatically to eliminate tolerances in the focus loop.

This gain control injects a signal into the loop which is used

to correct the loop gain. Since this decreases the optimum

performance, the gain control should only be activated for

a short time (for example, when starting a new disc).

7.14.4 R

ADIAL SERVO SYSTEM

7.14.4.1 Level initialization

During start-up an automatic adjustment procedure is

activated to set the values of the radial error gain (re_gain),

offset (re_offset) and satellite sum gain (sum_gain) for TPI

level generation. The initialization procedure runs in a

radial open loop situation and is ≤300 ms. This start-up

time period may coincide with the last part of the motor

start-up time period:

• Automatic gain adjustment: as a result of this

initialization the amplitude of the RE signal is adjusted to

within ±10% around the nominal RE amplitude

• Offset adjustment: the additional offset in RE due to the

limited accuracy of the start-up procedure is less than

±50 nm

• TPI level generation: the accuracy of the initialization

procedure is such that the duty factor range of TPI

becomes 0.4 < duty factor < 0.6 (default duty

factor = TPI HIGH/TPI period).

7.14.4.2 Sledge control

The microcontroller can move the sledge in both directions

via the steer sledge command.

7.14.4.3 Tracking control

The actuator is controlled using a PID loop filter with user

defined coefficients and gain. For stable operation

between the tracks, the S-curve is extended over 0.75 of

the track. On request from the microcontroller, S-curve

extension over 2.25 tracks is used, automatically changing

to access control when exceeding those 2.25 tracks.

Both modes of S-curve extension make use of a

track-count mechanism. In this mode, track counting

results in an ‘automatic return-to-zero track’, to avoid

major music rhythm disturbances in the audio output for

improved shock resistance. The sledge is continuously

controlled, or provided with step pulses to reduce power

consumption using the filtered value of the radial PID

output. Alternatively, the microcontroller can read the

average voltage on the radial actuator and provide the

sledge with step pulses to reduce power consumption.

Filter coefficients of the continuous sledge control can be

preset by the user.

7.14.4.4 Access

The access procedure is divided into two different modes

(see Table 13), depending on the requested jump size.

Table 13 Access modes

Note

1. Microcontroller presettable.

The access procedure makes use of a track counting

mechanism, a velocity signal based on a fixed number of

tracks passed within a fixed time interval, a velocity set

point calculated from the number of tracks to go and a user

programmable parameter indicating the maximum sledge

performance.

If the number of tracks remaining is greater than the

brake_distance then the sledge jump mode should be

activated or, the actuator jump should be performed.

The requested jump size together with the required sledge

breaking distance at maximum access speed defines the

brake_distance value.

ACCESS

TYPE

JUMP SIZE

(1)

ACCESS

SPEED

Actuator jump 1 - brake_distance decreasing

velocity

Sledge jump brake_distance - 32768 maximum

power to

sledge

(1)

Page 30

1999 Jun 17 30

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

During the actuator jump mode, velocity control with a

PI controller is used for the actuator. The sledge is then

continuously controlled using the filtered value of the radial

PID output. All filter parameters (for actuator and sledge)

are user programmable.

In the sledge jump mode maximum power (user

programmable) is applied to the sledge in the correct

direction while the actuator becomes idle (the contents of

the actuator integrator leaks to zero just after the sledge

jump mode is initiated). The actuator can be electronically

damped during sledge jump. The gain of the damping loop

is controlled via the hold_mult parameter.

Fast track jumping circuitry can be enabled/disabled via

the xtra_preset parameter.

7.14.4.5 Radial automatic gain control loop

The loop gain of the radial control loop can be corrected

automatically to eliminate tolerances in the radial loop.

This gain control injects a signal into the loop which is used

to correct the loop gain. Since this decreases the optimum

performance, the gain control should only be activated for

a short time (for example, when starting a new disc).

This gain control differs from the level initialization.

The level initialization should be performed first.

The disadvantage of using the level initialization without

the gain control is that only tolerances from the front-end

are reduced.

7.14.5 O

FF-TRACK COUNTING

The track position signal (TPI) is a flag which is used to

indicate whether the radial spot is positioned on the track,

with a margin of ±1⁄4 of the track-pitch. In combination with

the radial polarity flag (RP) the relative spot position over

the tracks can be determined.

These signals are, however, afflicted with some

uncertainties caused by:

• Disc defects such as scratches and fingerprints

• The HF information on the disc, which is considered as

noise by the detector signals.

In order to determine the spot position with sufficient

accuracy, extra conditions are necessary to generate a

Track Loss signal (TL) and an off-track counter value.

These extra conditions influence the maximum speed and

this implies that, internally, one of the following three

counting states is selected:

1. Protected state: used in normal play situations. A good

protection against false detection caused by disc

defects is important in this state.

2. Slow counting state: used in low velocity track jump

situations. In this state a fast response is important

rather than the protection against disc defects (if the

phase relationship between TL and RP of1⁄2π radians

is affected too much, the direction cannot then be

determined accurately).

3. Fast counting state: used in high velocity track jump

situations. Highest obtainable velocity is the most

important feature in this state.

7.14.6 D

EFECT DETECTION

A defect detection circuit is incorporated into the

SAA7327. If a defect is detected, the radial and focus error

signals may be zeroed, resulting in better playability.

The defect detector can be switched off, applied only to

focus control or applied to both focus and radial controls

under software control (part of foc_parm1).

The defect detector (see Fig.21) has programmable set

points selectable by the parameter defect_parm.

Fig.21 Block diagram of defect detector.

handbook, full pagewidth

DECIMATION

FILTER

FAST

FILTER

DEFECT

GENERATION

PROGRAMMABLE

HOLD-OFF

SLOW

FILTER

defect

output

sat1

sat2

+

−

MBG421

Page 31

1999 Jun 17 31

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

7.14.7 OFF-TRACK DETECTION

During active radial tracking, off-track detection has been

realised by continuously monitoring the off-track counter

value. The off-track flag becomes valid whenever the

off-track counter value is not equal to zero. Depending on

the type of extended S-curve, the off-track counter is reset

after 0.75 extend or at the original track in the 2.25 track

extend mode.

7.14.8 H

IGH-LEVEL FEATURES

7.14.8.1 Interrupt mechanism and STATUS pin

The STATUS pin is an output which is active LOW, its

output is selected by decoder register 7 to be either the

decoder status bit (active LOW) selected by decoder

register 2 (only available in 4-wire bus mode) or the

interrupt signal generated by the servo part.

8 signals from the interrupt status register are selectable

from the servo part via the interrupt_mask parameter.

The interrupt is reset by sending the read high-level status

command. The 8 signals are as follows:

• Focus lost: dropout of longer than 3 ms

• Subcode ready

• Subcode absolute seconds changed

• Subcode discontinuity detected: new subcode time

before previous subcode time, or more than 10 frames

later than previous subcode time

• Radial error: during radial on-track, no new subcode

frame occurs within time defined by playwatchtime

parameter; during radial jump, less than 4 tracks have

been crossed during time defined by jumpwatchtime

parameter

• Autosequencer state change

• Autosequencer error

• Subcode interface blocked: the internal decoder

interface is being used.

It should be noted that if the STATUS pin output is selected

via decoder register 2 and either the microcontroller writes

a different value to decoder register 2 or the decoder

interface is enabled then the STATUS output will change.

7.14.8.2 Decoder interface

The decoder interface allows decoder registers 0 to F to

be programmed and subcode Q-channel data to be read

via servo commands. The interface is enabled/disabled by

the preset latch command (and the xtra_preset

parameter).

7.14.8.3 Automatic error handling

Three Watchdogs are present:

• Focus: detects focus dropout of longer than 3 ms, sets

focus lost interrupt, switches off radial and sledge

servos, disables drive to disc motor

• Radial play: started when radial servo is on-track mode

and a first subcode frame is found; detects when

maximum time between two subcode frames exceeds

time set by playwatchtime parameter; then sets radial

error interrupt, switches radial and sledge servos off,

puts disc motor in jump mode

• Radial jump: active when radial servo is in long jump or

short jump modes; detects when the off-track counter

value decreases by less than 4 tracks between two

readings (time interval set by jumpwatchtime

parameter); then sets radial jump error, switches radial

and sledge servos off to cancel jump.

The focus Watchdog is always active, the radial

Watchdogs are selectable via the radcontrol parameter.

7.14.8.4 Automatic sequencers and timer interrupts

Two automatic sequencers are implemented (and must be

initialized after power-on):

• Autostart sequencer: controls the start-up of focus,

radial and motor

• Autostop sequencer: brakes the disc and shuts down

servos.

When the automatic sequencers are not used it is possible

to generate timer interrupts, defined by the

time_parameter coefficient.

7.14.8.5 High-level status

The read high-level status command can be used to obtain

the interrupt, decoder, autosequencer status registers and

the motor start time. Use of the read high-level status

command clears the interrupt status register, and

re-enables the subcode read via a servo command.

7.14.9 D

RIVER INTERFACE

The control signals (pins RA, FO and SL) for the

mechanism actuators are pulse density modulated.

The modulating frequency can be set to either

1.0584 MHz (DSD mode) or 2.1168 MHz; controlled via

the xtra_preset parameter. An analog representation of

the output signals can be achieved by connecting a

1st-order low-pass filter to the outputs.

Page 32

1999 Jun 17 32

Philips Semiconductors Product specification

Digital servo processor and Compact Disc decoder

with integrated DAC for video CD (CD7 II)

SAA7327

During reset (i.e. RESET pin is held LOW) the RA, FO

and SL pins are high-impedance.

7.14.10 L

ASER INTERFACE

The LDON pin (open-drain output) is used to switch the

laser off and on. When the laser is on, the output is

high-impedance. The action of the LDON pin is controlled

by the xtra_preset parameter; the pin is automatically

driven if the focus control loop is active.

7.14.11 R

ADIAL SHOCK DETECTOR

The shock detector (see Fig.22) can be switched on during

normal track following, and detects within an adjustable

frequency whether disturbances in the radial spot position

relative to the track exceed an adjustable level (controlled

by shock_level).

Every time the radial tracking error exceeds this level the

radial control bandwidth is switched to twice its original

bandwidth and the loop gain is increased by a factor of 4.

The shock detection level is adjustable in 16 steps from

0% to 100% of the traverse radial amplitude which is sent

to an amplitude detection unit via an adjustable band-pass

filter (controlled by sledge_parm1); lower corner frequency

can be set at either 0 or 20 Hz, and upper corner