Datasheet S93WD662P-2.7, S93WD662P-2.7T, S93WD662P-A, S93WD662P-AT, S93WD662P-B Datasheet (SUMMIT)

...Page 1

SUMMIT MICROELECTRONICS, Inc. • 300 Orchard City Drive, Suite 131 • Campbell, CA 95008 • Telephone 408-378-6461 • Fax 408-378-6586 • www.summitmicro.com

1

S93WD662/S93WD663

© SUMMIT MICROELECTRONICS, Inc. 2000

2013 2.0 3/21/00

Characteristics subject to change without notice

Precision Supply-Voltage Monitor and Reset Controller

With a Watchdog Timer and 4k-bit Microwire Memory

SUMMIT

MICROELECTRONICS, Inc.

FEATURES

• Precision Monitor & RESET Controller

— RESET and RESET# Outputs

— Guaranteed RESET Assertion to VCC = 1V

— 200ms Reset Pulse Width

— Internal 1.26V Reference with ±1% Accuracy

— ZERO External Components Required

• Watchdog Timer

— Nominal 1.6 Second Time-out Period

— Reset by Any Transition of CS

• Memory

— 4K-bit Microwire Memory

— S93WD662

– Internally Ties ORG Low

– 100% Compatible With all 8-bit

Implementations

– Sixteen Byte Page Write Capability

— S93WD663

– Internally Ties ORG High

– 100% Compatible With all 16-bit

Implementations

– Eight Word Page Write Capability

OVERVIEW

The S93WD662 and S93WD663 are precision power

supervisory circuits providing both active high and

active low reset outputs. Both devices incorporate a

watchdog timer with a nominal time-out value of 1.6

seconds.

Both devices have 4k-bits of E

2

PROM memory that is

accessible via the industry standard microwire bus. The

S93WD662 is configured with an internal ORG pin tied

low providing a 8-bit byte organization and the

S93WD663 is configured with an internal ORG pin tied

high providing a 16-bit word organization. Both the

S93WD662 and S93WD663 have page write capabil-

ity. The devices are designed for a minimum 100,000

program/erase cycles and have data retention in ex-

cess of 100 years.

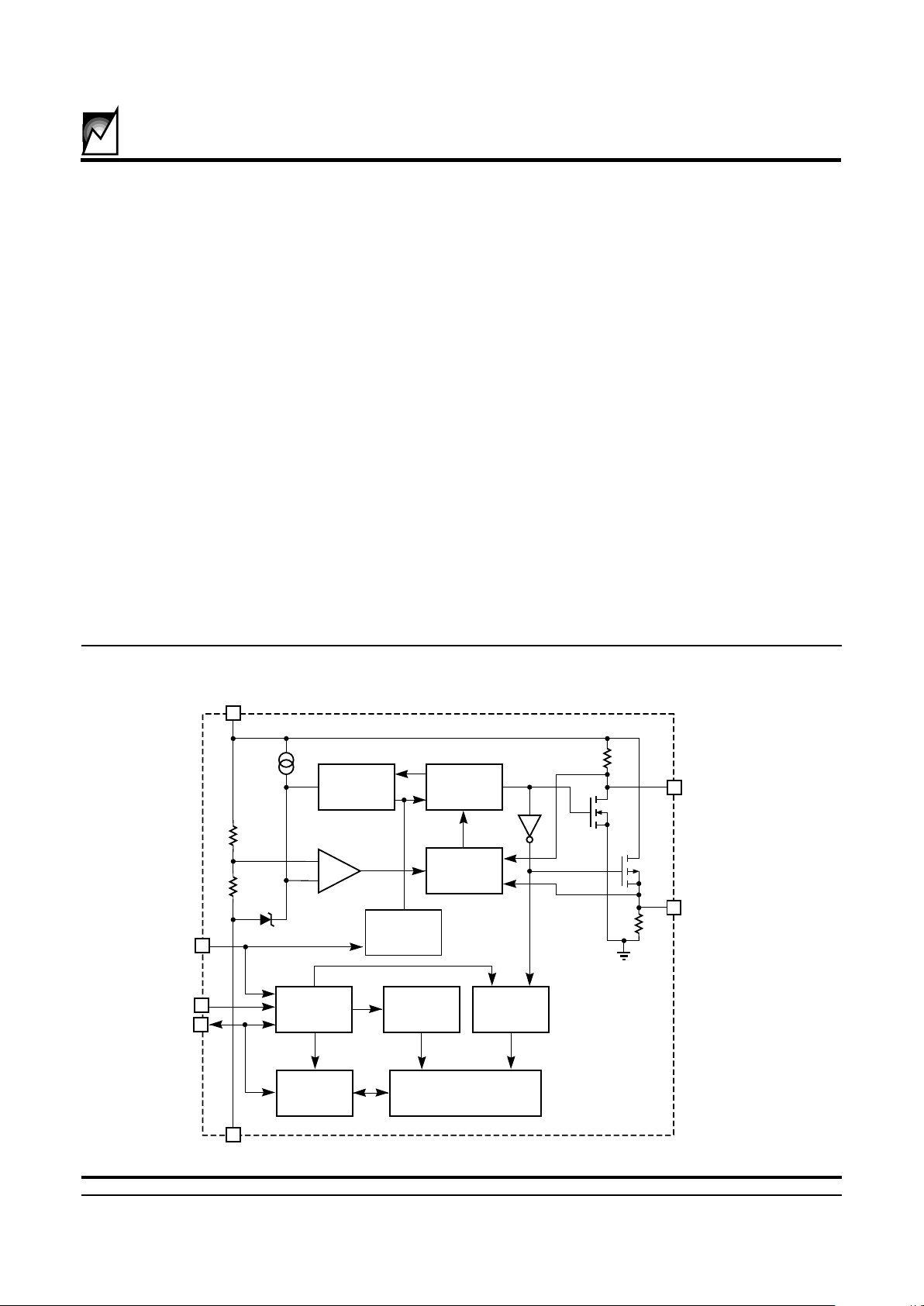

BLOCK DIAGRAM

+

–

GND

V

CC

8

5

RESET#

6

V

TRIP

RESET

PULSE

GENERATOR

5kHz

OSCILLATOR

RESET

CONTROL

MODE

DECODE

ADDRESS

DECODER

WRITE

CONTROL

DATA I/O

E2PROM

MEMORY

ARRAY

RESET

7

1.26V

SK

2

DI

3

WATCHDOG

TIMER

CS

1

2013 T BD 2.0

Page 2

2

S93WD662/S93WD663

2013 2.0 3/21/00

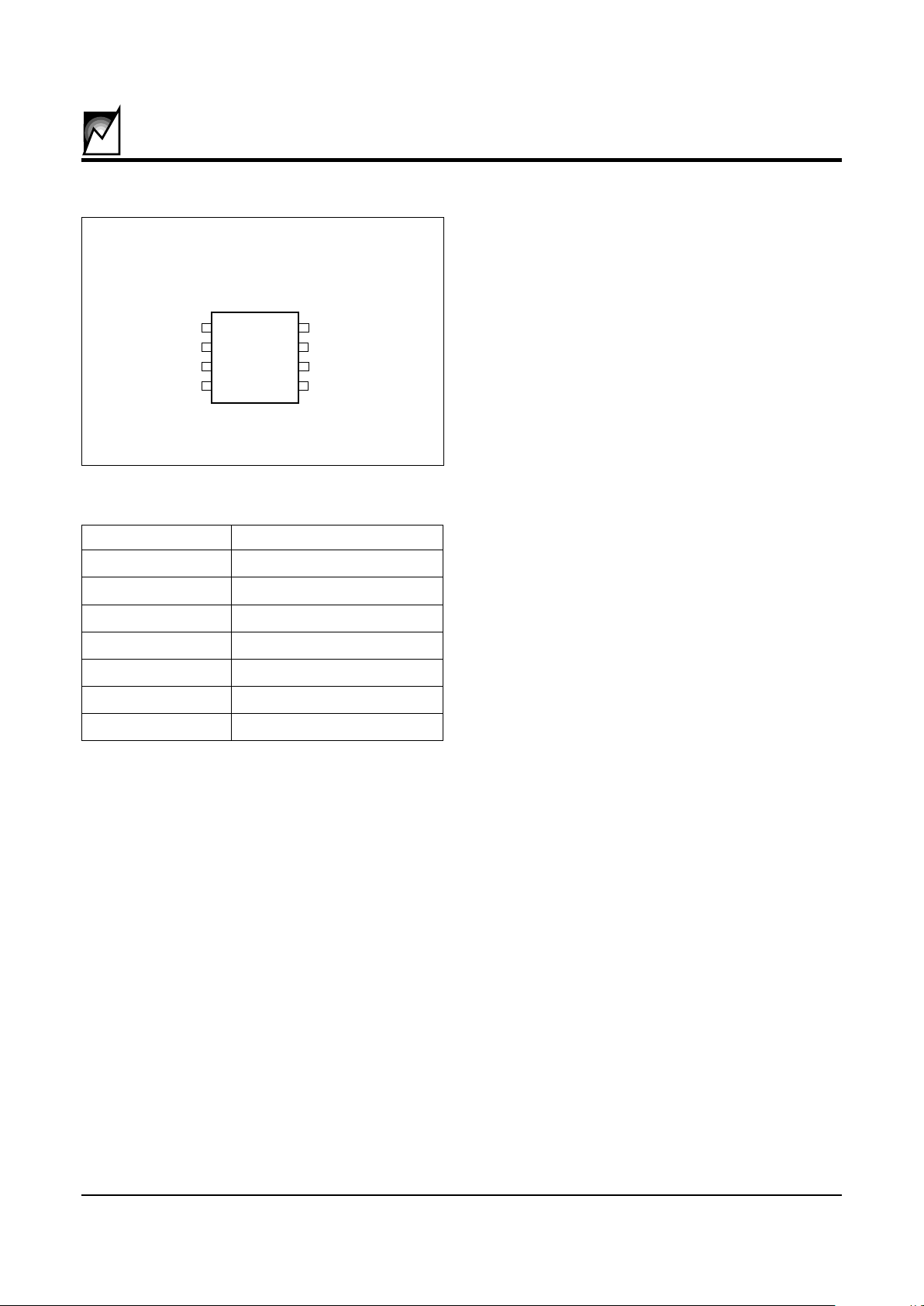

PIN FUNCTIONS

Pin Name Function

CS Chip Select

SK Clock Input

DI Serial Data Input

DO Serial Data Output

V

CC

+2.7 to 6.0V Power Supply

GND Ground

RESET/RESET# RESET I/O

PIN CONFIGURATION

DEVICE OPERATION

APPLICATIONS

The S93WD662/WD663 is ideal for applications requiring low voltage and low power consumption. This device

provides microcontroller RESET control and can be

manually resettable.

RESET CONTROLLER DESCRIPTION

The S93WD662/WD663 provides a precision reset controller that ensures correct system operation during

brownout and power-up/-down conditions. It is configured with two open drain reset outputs: pin 7 is an active

high output and pin 6 is an active low output.

During power-up, the reset outputs remain active until

VCC reaches the V

TRIP

threshold. The outputs will continue to be driven for approximately 200ms after reaching V

TRIP

. The reset outputs will be valid so long as V

CC

is ≥ 1.0V. During power-down, the reset outputs will

begin driving active when VCC falls below V

TRIP

.

The reset pins are I/Os; therefore, the S93WD662/

WD663 can act as a stabilization circuit for an externally

applied reset. The inputs are edge triggered; that is, the

RESET input will initiate a reset time-out after detecting

a low to high transition and the RESET# input will initiate

a reset time-out after detecting a high to low transition.

Refer to the applications Information section for more

details on device operation as a debounce/reset extender circuit.

It should be noted the reset outputs are open drain.

When used as outputs driving a circuit they need to be

either tied high (RESET#) or tied to ground (RESET)

through the use of pull-up or pull-down resistors. Refer

to the applications aid section for help in determining the

value of resistor to be used. Internally these pins are

weakly pulled up (RESET#) and pulled down (RESET).

If the signals are not being used the pins may be left

unconnected.

WATCHDOG TIMER DESCRIPTION

The S93WD662/WD663 has a watchdog timer with a

nominal time-out period of 1.6 seconds. Whenever the

watchdog times out, it will generate a reset output to both

pins 6 and 7. The watchdog timer is reset by any

transition on CS.

The watchdog timer will be held in a reset state during

power-on while VCC is less than V

TRIP

. Once VCC ex-

ceeds V

TRIP

the watchdog will continue to be held in a

reset state for the t

PURST

period. After t

PURST

it will be

released and the timer will begin operation. If either

reset input is asserted the watchdog timer will be reset

and remain in the reset condition until either t

PURST

has

expired or the reset input is released, whichever is

longer.

GENERAL OPERATION

The S93WD662/WD663 is a 4096-bit nonvolatile memory

intended for use with industry standard microprocessors. The S93WD663 is organized as X16, seven 11-bit

instructions control the reading, writing and erase operations of the device. The S93WD662 is organized as

X8, seven 12-bit instructions control the reading, writing

and erase operations of the device. The device operates

on a single 3V or 5V supply and will generate on chip, the

high voltage required during any write operation.

Instructions, addresses, and write data are clocked into

the DI pin on the rising edge of the clock (SK). The DO

pin is normally in a high impedance state except when

reading data from the device, or when checking the

ready/busy status after a write operation.

CS

SK

DI

DO

V

CC

RESET

RESET#

GND

1

2

3

4

8

7

6

5

8-Pin PDIP

or 8-Pin SOIC

2014 T PCon 2.0

Page 3

3

S93WD662/S93WD663

2013 2.0 3/21/00

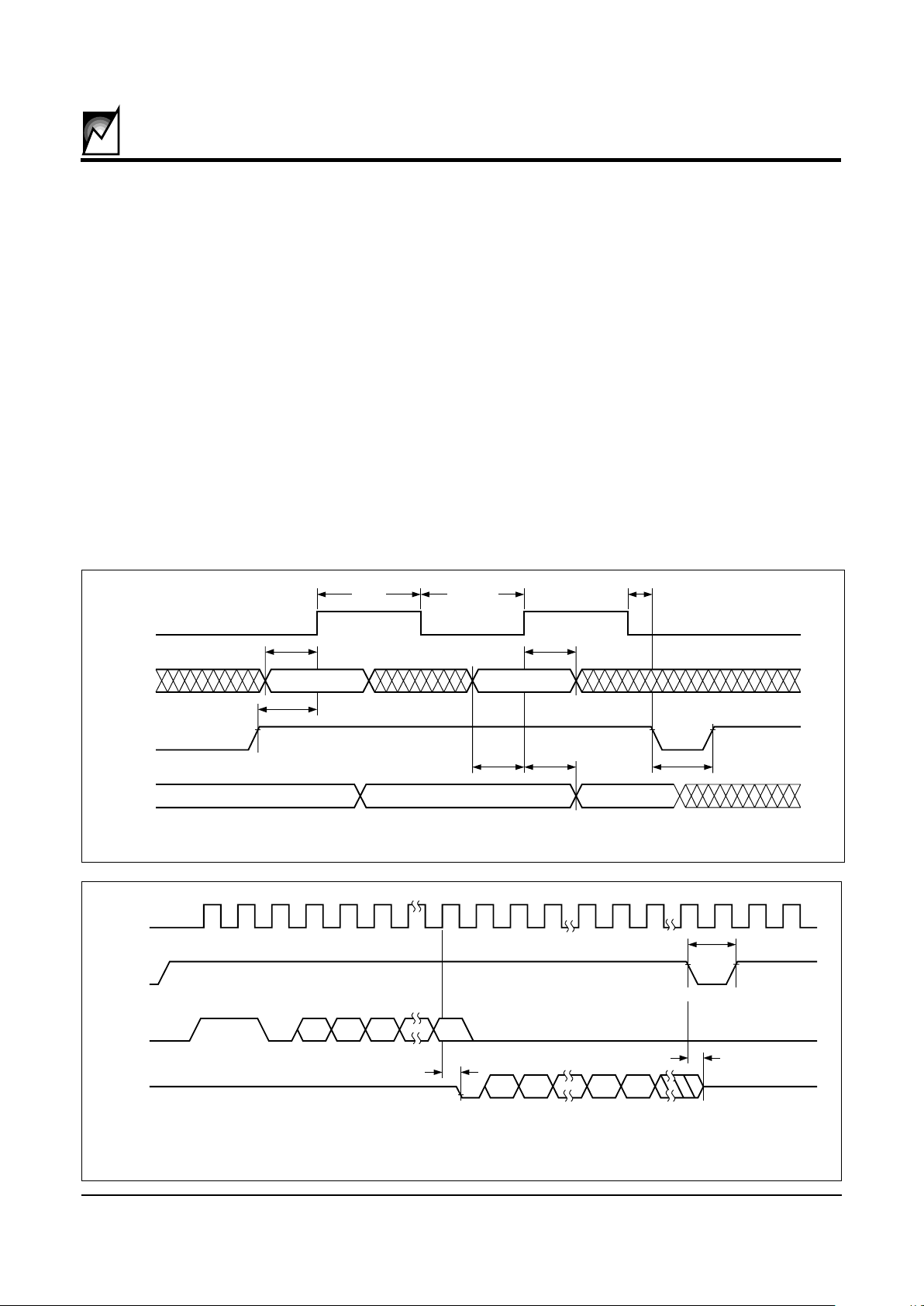

SK

2013 ILL 3 1.0

DI

CS

DO

t

DIS

t

PD0,tPD1

t

CSMIN

t

CSS

t

DIS

t

DIH

t

SKHI

t

CSH

VALID VALID

DATA VALID

t

SKLOW

The ready/busy status can be determined after the start

of a write operation by selecting the device (CS high)

and polling the DO pin; DO low indicates that the write

operation is not completed, while DO high indicates that

the device is ready for the next instruction. See the

Applications Aid section for detailed use of the ready

busy status.

The format for all instructions is: one start bit; two op

code bits and either eight (x16) or nine (x8) address or

instruction bits.

Read

Upon receiving a READ command and an address

(clocked into the DI pin), the DO pin of the S93WD662/

WD663 will come out of the high impedance state and,

will first output an initial dummy zero bit, then begin

shifting out the data addressed (MSB first). The output

data bits will toggle on the rising edge of the SK clock and

are stable after the specified time delay

(t

PD0

or t

PD1

).

Write

After receiving a WRITE command, address and the

data, the CS (Chip Select) pin must be deselected for a

minimum of 250ns (t

CSMIN

). The falling edge of CS will

start automatic erase and write cycle to the memory

location specified in the instruction. The ready/busy

status of the S93WD662/WD663 can be determined by

selecting the device and polling the DO pin.

Erase

Upon receiving an ERASE command and address, the

CS (Chip Select) pin must be deselected for a minimum

of 250ns (t

CSMIN

). The falling edge of CS will start the

auto erase cycle of the selected memory location. The

ready/busy status of the S93WD662/WD663 can be

Figure 1. Sychronous Data Timing

Figure 2. Read Instruction Timing

SK

2013 ILL4 1.0

CS

DI

DO

t

CS

STANDBY

t

HZ

HIGH-ZHIGH-Z

11 0

ANA

N–1

A

0

0

DND

N–1

D1D

0

t

PD0

Page 4

4

S93WD662/S93WD663

2013 2.0 3/21/00

determined by selecting the device and polling the DO

pin. Once cleared, the content of a cleared location

returns to a logical “1” state.

Erase/Write Enable and Disable

The S93WD662/WD663 powers up in the write disable

state. Any writing after power-up or after an EWDS

(write disable) instruction must first be preceded by the

EWEN (write enable) instruction.

Once the write instruction is enabled, it will remain enabled until power to

the device is removed, or the EWDS instruction is sent.

The EWDS instruction can be used to disable all

S93WD662/WD663 write and clear instructions, and

will prevent any accidental writing or clearing of the

device. Data can be read normally from the device

regardless of the write enable/disable status.

Erase All

Upon receiving an ERAL command, the CS (Chip Select) pin must be deselected for a minimum of 250ns

(t

CSMIN

). The falling edge of CS will start the self clocking

clear cycle of all memory locations in the device. The

clocking of the SK pin is not necessary after the device

has entered the self clocking mode. The ready/busy

status of the S93WD662/WD663 can be determined by

selecting the device and polling the DO pin. Once

cleared, the contents of all memory bits return to a

logical “1” state.

Write All

Upon receiving a WRAL command and data, the CS

(Chip Select) pin must be deselected for a minimum of

250ns (t

CSMIN

). The falling edge of CS will start the self

clocking data write to all memory locations in the device.

The clocking of the SK pin is not necessary after the

device has entered the self clocking mode. The ready/

busy status of the S93WD662/WD663 can be determined by selecting the device and polling the DO pin. It

is not necessary for all memory locations to be cleared

before the WRAL command is executed.

Page Write

93WD662 - Assume WEN has been issued. The host

will then take CS high, and begin clocking in the start

bit, write command and 9-bit byte address immediately

followed by the first byte of data to be written. The host

can then continue clocking in 8-bit bytes of data with

each byte to be written to the next higher address.

Internally the address pointer is incremented after

receiving each group of eight clocks; however, once

the address counter reaches x xxxx 1111 it will roll over

to x xxxx 0000 with the next clock. After the last bit is

clocked in no internal write operation will occur until CS

is brought low.

93WD663 - Assume WEN has been issued. The host

will then take CS high, and begin clocking in the start

bit, write command and 8-bit byte address immediately

followed by the first 16-bit word of data to be written.

The host can then continue clocking in 16-bit words of

data with each word to be written to the next higher

address. Internally the address pointer is incremented

after receiving each group of sixteen clocks; however,

once the address counter reaches xxxx x111 it will roll

over to xxxx x000 with the next clock. After the last bit

is clocked in no internal write operation will occur until

CS is brought low.

Continuous Read

This begins just like a standard read with the host

issuing a read instruction and clocking out the data

byte [word]. If the host then keeps CS high and

continues generating clocks on SK, the S93WD662/

WD663 will output data from the next higher address

location. The S93WD662/WD663 will continue

incrementing the address and outputting data so long

as CS stays high. If the highest address is reached, the

address counter will roll over to address 0000. .

CS going low will reset the instruction register and any

subsequent read must be initiated in the normal

manner of issuing the command and address.

Page 5

5

S93WD662/S93WD663

2013 2.0 3/21/00

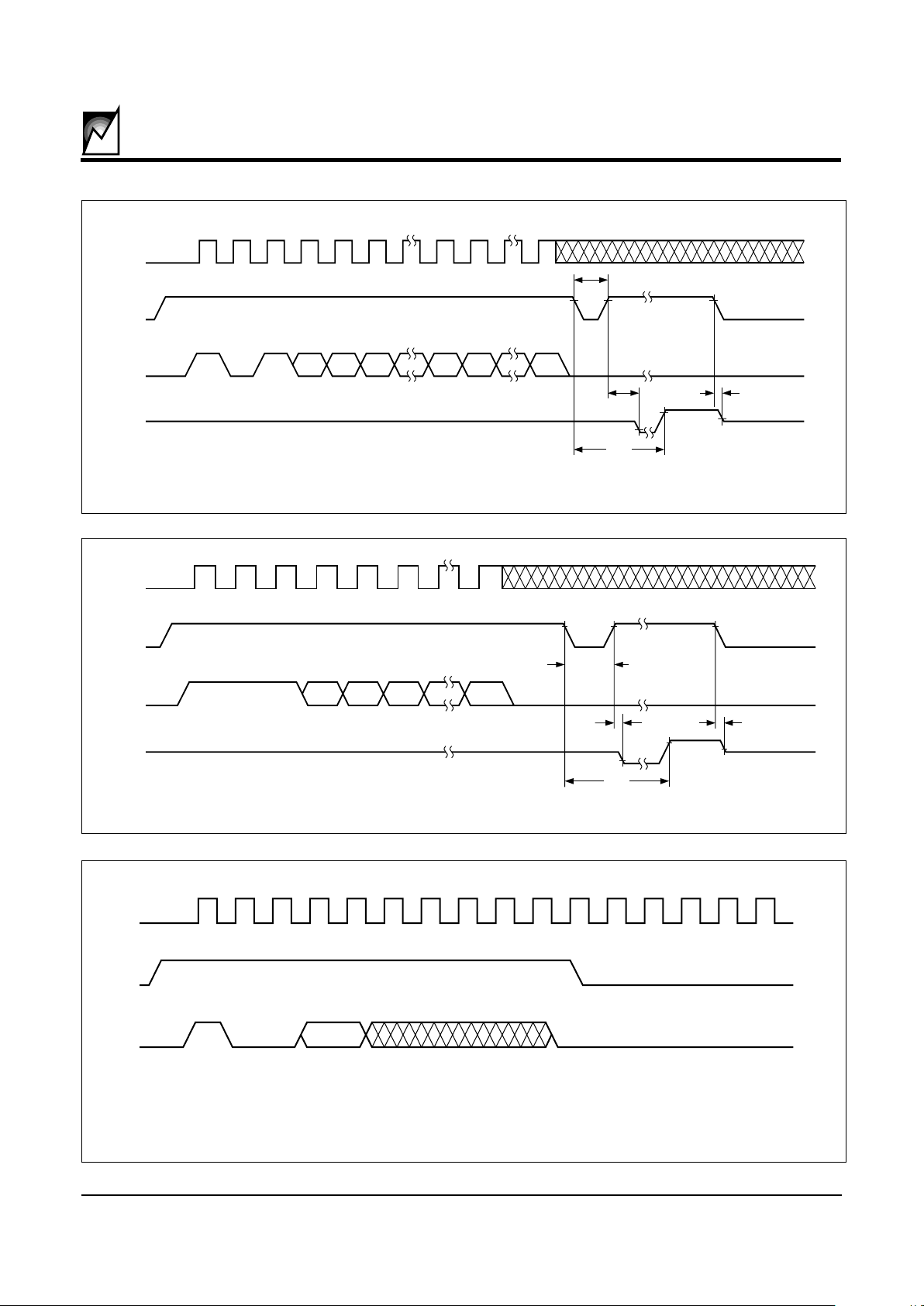

Figure 3. Write Instruction Timing

Figure 4. Erase Instruction Timing

Figure 5. EWEN/EWDS Instruction Timing

SK

2013 ILL 5 1.0

CS

DI

DO

t

CS

STANDBY

HIGH-Z

HIGH-Z

101

ANA

N-1

A

0

D

N

D

0

BUSY

READY

STATUS

VERIFY

t

SV

t

HZ

t

EW

SK

2013 ILL6 1.0

CS

DI

DO

STANDBY

HIGH-Z

HIGH-Z

1

A

N

A

N-1

BUSY READY

STATUS VERIFY

t

SV

t

HZ

t

EW

t

CS

11

A

0

SK

2013 ILL 7 1.0

CS

DI

STANDBY

10

0

*

* ENABLE=1 1

DISABLE=00

Page 6

6

S93WD662/S93WD663

2013 2.0 3/21/00

Figure 7. WRAL Instruction Timing

SK

2013 ILL 10 1.0

CS

DI

DO

t

CS

HIGH-Z

10 1

BUSY READY

STATUS VERIFY

t

SV

t

HZ

t

EW

00

STANDBY

D

O

D

N

INSTRUCTION SET

Instruction Start Opcode Address Data Comments

Bit x8 x16 x8 x16

READ 1 10 A8–A0 A7–A0 Read Address AN–A0

ERASE 1 11 A8–A0 A7–A0 Clear Address AN–A0

WRITE 1 01 A8–A0 A7–A0 D7–D0 D15–D0 Write Address AN–A0

EWEN 1 00 11xxx xxxx 11xxx xxx Write Enable

EWDS 1 00 00xxx xxxx 00xxx xxx Write Disable

ERAL 1 00 10xxx xxxx 10xxx xxx Clear All Addresses

WRAL 1 00 01xxx xxxx 01xxx xxx D7–D0 D15–D0 Write All Addresses

2013 PGM T5 1.1

Figure 6. ERAL Instruction Timing

SK

2013 ILL 8 1.0

CS

DI

DO

t

CS

HIGH-Z

HIGH-Z

10 1

BUSY READY

STATUS VERIFY

t

SV

t

HZ

t

EW

00

STANDBY

Page 7

7

S93WD662/S93WD663

2013 2.0 3/21/00

ABSOLUTE MAXIMUM RATINGS*

Temperature Under Bias ....................................................................................................................................–55°C to +125°C

Storage Temperature .........................................................................................................................................–65°C to +150°C

Voltage on any Pin with Respect to Ground

(1)

.............................................................................................–2.0V to +VCC +2.0V

VCC with Respect to Ground.................................................................................................................................. –2.0V to +7.0V

Package Power Dissipation Capability (Ta = 25°C) .............................................................................................................1.0W

Lead Soldering Temperature (10 secs) .............................................................................................................................. 300°C

Output Short Circuit Current

(2)

...........................................................................................................................................100 mA

*COMMENT

Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions outside of those listed in the operational sections of this specification is not implied. Exposure to

any absolute maximum rating for extended periods may affect device performance and reliability.

Note:

(1) The minimum DC input voltage is –0.5V. During transitions, inputs may undershoot to –2.0V for periods of less than 20 ns. Maximum DC

voltage on output pins is VCC +0.5V, which may overshoot to VCC +2.0V for periods of less than 20 ns.

(2) Output shorted for no more than one second. No more than one output shorted at a time.

(3) This parameter is tested initially and after a design or process change that affects the parameter.

(4) Latch-up protection is provided for stresses up to 100 mA on address and data pins from –1V to VCC +1V.

D.C. OPERATING CHARACTERISTICS (over recommended operating conditions unless otherwise specified)

Limits

Symbol Parameter Min. Typ. Max. Units Test Conditions

I

CC

Power Supply Current 3 mA DI = 0.0V, fSK = 1MHz

(Operating) VCC = 5.0V, CS = 5.0V,

Output Open

I

SB

Power Supply Current 50 µA CS = 0V

(Standby) Reset Outputs Open

I

LI

Input Leakage Current 2 µA VIN = 0V to V

CC

I

LO

Output Leakage Current 10 µA V

OUT

= 0V to VCC,

(Including ORG pin) CS = 0V

V

IL1

Input Low Voltage -0.1 0.8 V 4.5V-VCC<5.5V

V

IH1

Input High Voltage 2 VCC+1 V

V

IL2

Input Low Voltage 0 VCCX0.2 V 1.8V-VCC<2.7V

V

IH2

Input High Voltage VCCX0.7 VCC+1 V

V

OL1

Output Low Voltage 0.4 V 4.5V-VCC<5.5V

V

OH1

Output High Voltage 2.4 V IOL = 2.1mA

IOH = -400µA

V

OL2

Output Low Voltage 0.2 V 1.8V-VCC<2.7V

V

OH2

Output High Voltage VCC-0.2 V IOL = 1mA

IOH = -100µA

2013 PGM T3 1.1

Temperature Min Max

Commercial 0°C +70°C

Industrial -40°C +85°C

RECOMMENDED OPERATING CONDITIONS

2013 PGM T7 1.0

RELIABILITY CHARACTERISTICS

Symbol Parameter Min. Max. Units

N

END

(3)

Endurance 100,000 Cycles/Byte

T

DR

(3)

Data Retention 100 Years

V

ZAP

(3)

ESD Susceptibility 2000 Volts

I

LTH

(3)(4)

Latch-Up 100 mA

2013 PGM T2 1.1

Page 8

8

S93WD662/S93WD663

2013 2.0 3/21/00

Limits

VCC=2.7V-4.5V VCC=4.5V-5.5V Test

SYMBOL PARAMETER Min. Max. Min. Max. UNITS Conditions

t

CSS

CS Setup Time 100 50 ns

t

CSH

CS Hold Time 0 0 ns VIL = 0.45V

t

DIS

DI Setup Time 200 100 ns VIH = 2.4V

t

DIH

DI Hold Time 200 100 ns CL = 100pF

t

PD1

Output Delay to 1 0.5 0.25 µs VOL = 0.8V

t

PD0

Output Delay to 0 0.5 0.25 µs VOH = 2.0v

t

HZ

(1)

Output Delay to High-Z 200 100 ns

t

EW

Program/Erase Pulse Width 10 10 ms

t

CSMIN

Minimum CS Low Time 0.5 0.25 µs

t

SKHI

Minimum SK High Time 0.5 0.25 µs

t

SKLOW

Minimum SK Low Time 0.5 0.25 µs

t

SV

Output Delay to Status Valid 0.5 0.25 µs CL = 100pF

SK

MAX

Maximum Clock Frequency DC 500 DC 1000 KHZ

Note:

(1) This parameter is tested initially and after a design or process change that affects the parameter.

Note:

(1) This parameter is tested initially and after a design or process change that affects the parameter.

PIN CAPACITANCE

Symbol Test Max. Units Conditions

C

OUT

(1)

OUTPUT CAPACITANCE (DO) 5 pF V

OUT

=OV

C

IN

(1)

INPUT CAPACITANCE (CS, SK, DI, ORG) 5 pF VIN=OV

2013 PGM T4 1.0

A.C. CHARACTERISTICS (over recommended operating conditions unless otherwise specified)

CL = 100pF

2013 PGM T6 1.0

Page 9

9

S93WD662/S93WD663

2013 2.0 3/21/00

Figure 8. RESET Timing Diagram

RESET CIRCUIT AC and DC ELECTRICAL CHARACTERISTICS

2.7 5 Volt-A 5 Volt-B

Symbol Parameter Min Max Min Max Min Max Unit

V

TRIP

Reset Trip Point 2.55 2.7 4.25 4.5 4.50 4.75 V

t

PURST

Power-Up Reset Timeout 130 270 130 270 130 270 ms

t

RPD

V

TRIP

to RESET Output Delay 5 5 5 µs

V

RVALID

RESET# Output Valid 1 1 1 V

t

GLITCH

Glitch Reject Pulse Width 30 30 30 ns

V

OLRS

RESET Output Low Voltage IOL=1mA 0.4 0.4 0.4 V

V

OHRS

RESET# Output High I

OH

VCC-.75 VCC-.75 VCC-.75 V

2013 PGM T1 1.1

V

CC

V

RVALID

V

TRIP

t

PURST

RESET#

RESET

2013 T fig08 2.0

t

GLITCH

t

RPD

t

PURST

t

RPD

Page 10

10

S93WD662/S93WD663

2013 2.0 3/21/00

.228 (5.80)

.244 (6.20)

.016 (.40)

.035 (.90)

.020 (.50)

.010 (.25)

x45°

.0192 (.49)

.0138 (.35)

.061 (1.75)

.053 (1.35)

.0098 (.25)

.004 (.127)

.05 (1.27) TYP.

.275 (6.99) TYP.

.030 (.762) TYP.

8 Places

.050 (1.27) TYP.

.050 (1.270) TYP.

8 Places

.157 (4.00)

.150 (3.80)

.196 (5.00)

1

.189 (4.80)

FOOTPRINT

8pn JEDEC SOIC ILL.2

.375

(9.525)

PIN 1 INDICATOR

.015 (.381) Min.

.130 (3.302)

.100 (2.54)

TYP.

.018 (.457)

TYP.

.060 ± .005

(1.524) ± .127

TYP.

.130 (3.302)

SEATING PLANE

.070 (1.778)

.0375 (0.952)

.300 (7.620)

5°-7°TYP.

(4 PLCS)

.350 (8.89)

.009 ± .002

(.229 ± .051)

0°-15°

.250

(6.350)

8pn PDIP/P ILL.3

8 Pin SOIC (Type S) Package JEDEC (150 mil body width)

8 Pin PDIP (Type P) Package

Page 11

11

S93WD662/S93WD663

2013 2.0 3/21/00

Frequently the reset controller will be deployed on a PC board that provides a peripheral function to a system.

Examples might be modem or network cards in a PC or a PCMCIA card in a laptop. In instances like this the peripheral

card may have a requirement for a clean reset function to insure proper operation. The system may or may not provide

a reset pulse of sufficient duration to clear the peripheral or to protect data stored in a nonvolatile memory.

The I/O capability of the RESET pins can provide a solution. The system’s reset signal to the peripheral can be fed

into the S93WD662/WD663 and it in turn can clean up the signal and provide a known entity to the peripheral’s circuits.

The figure below shows the basic timing characteristics under the assumption the reset input is shorter in duration

than t

PURST

. The same reset output affect can be attained by using the active high reset input.

When planning your resistor pull-up and pull-down values, use the following chart to help determine min. resistances.

Condition Min Typ Max Units

VCC = 1.0V, IOL=100µA 0.3 V

VCC = 1.2V, IOL=100µA 0.3 V

VCC = 3.0V, IOL=500µA 0.3 V

VCC = 3.6V, IOL=500µA 0.3 V

VCC = 4.5V, IOL=750µA 0.3 V

VCC = 1.0V, IOL=100µA 0.4 V

VCC = 1.2V, IOL=150µA 0.4 V

VCC = 3.0V, IOL=750µA 0.4 V

VCC = 3.6V, IOL=1mA 0.4 V

VCC = 4.5V, IOL=1mA 0.4 V

VCC = 1.0V, IOH=400µA VCC-0.75 V

VCC = 1.2V, IOH=800µA VCC-0.75 V

VCC = 3.0V, IOH=800µA VCC-0.5 V

VCC = 3.6V, IOH=800µA VCC-0.5 V

VCC = 4.5V, IOH=800µA VCC-0.5 V

Worst Case RESET Sink/Source Capabilities at Various VCC Levels

Parameter Symbol

RESET# Output V

OL

Voltage

RESET# Output V

OL

Voltage

RESET Output V

OH

Voltage

2013 PGM T5 1.0

RESET#

Input

RESET#

Output

RESET

Output

2013 T fig09 2.0

t

PURST

Page 12

12

S93WD662/S93WD663

2013 2.0 3/21/00

Ready/Busy StatusReady/Busy Status

Ready/Busy StatusReady/Busy Status

Ready/Busy Status

During the internal write operation the S93WD662/WD663 memory array is inaccessible. After starting the write

operation (taking CS low) the host can implement a 10ms time-out routine or alternatively it can employ a polling routine

that tests the state of the DO pin.

After starting the write, testing for the status is easily accomplished by taking CS high and testing the state of DO. If

it is low the device is still busy with the internal write. If it is high the write operation has completed.

For the polling routine the host has the option of toggling CS for each test of DO, or it can place CS high and then

intermittently test DO. SK is not required for any of these operations. Once the device is ready, it will continue to drive

DO high whenever the S93WD662/WD663 is selected. The ready state of DO can be cleared by clocking in a start

bit; this start bit can either be the beginning of a new command sequence or it can be a dummy start bit with CS returning

low before the host issues a new command.

SK

2013 ILL 13 1.0

CS

DI

DO

t

CS

HIGH-Z

HIGH-Z

STATUS CLEARED

BUSY READY

STATUS VERIFY

t

SV

t

HZ

t

EW

Page 13

13

S93WD662/S93WD663

2013 2.0 3/21/00

ORDERING INFORMATIONORDERING INFORMATION

ORDERING INFORMATIONORDERING INFORMATION

ORDERING INFORMATION

S93WD663

Base Part Number

S93WD663 = 16-bit configuration

S93WD662 = 8-bit configuration

Tape and Reel Option

Blank = Tube

T = Tape and Reel

Package

P = 8 Lead PDIP

S = 8 Lead 150mil SOIC

Operating Voltage Range

A = 4.5V to 5.5V V

TRIP

Min. @ 4.25V

B = 4.5V to 5.5V V

TRIP

Min. @ 4.50V

2.7 = 2.7V to 5.5V V

TRIP

Min. @ 2.55V

P -2.7 T

2012 ILL11 1.1

Page 14

14

S93WD662/S93WD663

2013 2.0 3/21/00

NOTICE

SUMMIT Microelectronics, Inc. reserves the right to make changes to the products contained in this publication in order to improve

design, performance or reliability. SUMMIT Microelectronics, Inc. assumes no responsibility for the use of any circuits described

herein, conveys no license under any patent or other right, and makes no representation that the circuits are free of patent

infringement. Charts and schedules contained herein reflect representative operating parameters, and may vary depending upon

a user’s specific application. While the information in this publication has been carefully checked, SUMMIT Microelectronics, Inc.

shall not be liable for any damages arising as a result of any error or omission.

SUMMIT Microelectronics, Inc. does not recommend the use of any of its products in life support applications where the failure or

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly affect its safety

or effectiveness. Products are not authorized for use in such applications unless SUMMIT Microelectronics, Inc. receives written

assurances, to its satisfaction, that: (a) the risk of injury or damage has been minimized; (b) the user assumes all such risks; and

(c) potential liability of SUMMIT Microelectronics, Inc. is adequately protected under the circumstances.

© Copyright 2000 SUMMIT Microelectronics, Inc.

Loading...

Loading...