Page 1

Intel Corporation assumes no responsibility for the use of any circuitry other than circuitry embodied in an Intel product. No other circuit patent

licenses are implied. Information contained herein supersedes previously published specifications on these devices from Intel.

© INTEL CORPORATION, 1995 September 1995 Order Number: 272543-001

®

8XC196MH INDUSTRIAL MOTOR CONTROL

CHMOS MICROCONTROLLER

The 8XC196MH is a member of Intel’s family of 16-bit MCS® 96 microcontrollers. It is designed primarily to

control three-phase AC induction and DC brushless motors. It features an enhanced three-phase waveform

generator specifically designed for use in “inverter” motor-control applications. This peripheral provides pulsewidth modulation and three-phase sine wave generation with minimal CPU intervention. It generates three

complementary non-overlapping PWM pulses with resolutions of 0.125 µs (edge triggered) or 0.250 µs

(centered).

The 8XC196MH has two dedicated serial port peripherals, allowing less software overhead. The watchdog timer

can be programmed with one of four time options.

The 8XC196MH is available without internal memory (80C196MH), with 32 Kbytes of factory programmed

OTPROM* (83C196MH), or with 32 Kbytes of user programmable OTPROM* (87C196MH). It is available in

three packages: 84-lead PLCC, 80-lead Shrink EIAJ/QF P, and 64-lead SDIP. The 64-lead package does not

contain pins for the P5.1/INST and P6.7/PWM1 signals.

Operational characteristics are guaranteed over the temperat ure range of

– 40°C to + 85°C.

*One-Time Programmable Read-Only Memory (OTPROM) is similar to EPROM but comes in an unwindowed package and

cannot be erased. It is user programmable.

n

High Performance CHMOS 16-bit CPU

n

16 MHz Operating Frequency

n

32 Kbytes of On-chip OTPROM/RO M

n

744 Bytes of On-chip Register RAM

n

Register-to-register Archi tectu re

n

16 Prioritized Interrupt Sources

n

Peripheral Transaction Server (PTS) with 15

Prioritized Sources

n

Up to 52 I/O Lines

n

3-phase Complementary Waveform Generator

n

8-channel 8- or 10-bit A/D with Samp l e and

Hold

n

2-channel UART

n

Event Processor Array (EPA) with 2 Highspeed Capture/Com pare Mo d ules an d 4 Highspeed Compare-only Modules

n

Two Programmable 16-bit Timers with

Quadrature Countin g Input s

n

Two Pulse-width Modulator (PWM) Outputs

with High Drive Capability

n

Flexible 8- or 16-bit External Bus

n

1.75 µs 16 × 16 Multipl y

n

3 µs 32/16 Divide

n

Extended Temperature Avai lab le

n

Idle and Powerdo w n Mod es

n

Watchdog Timer

Page 2

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

2

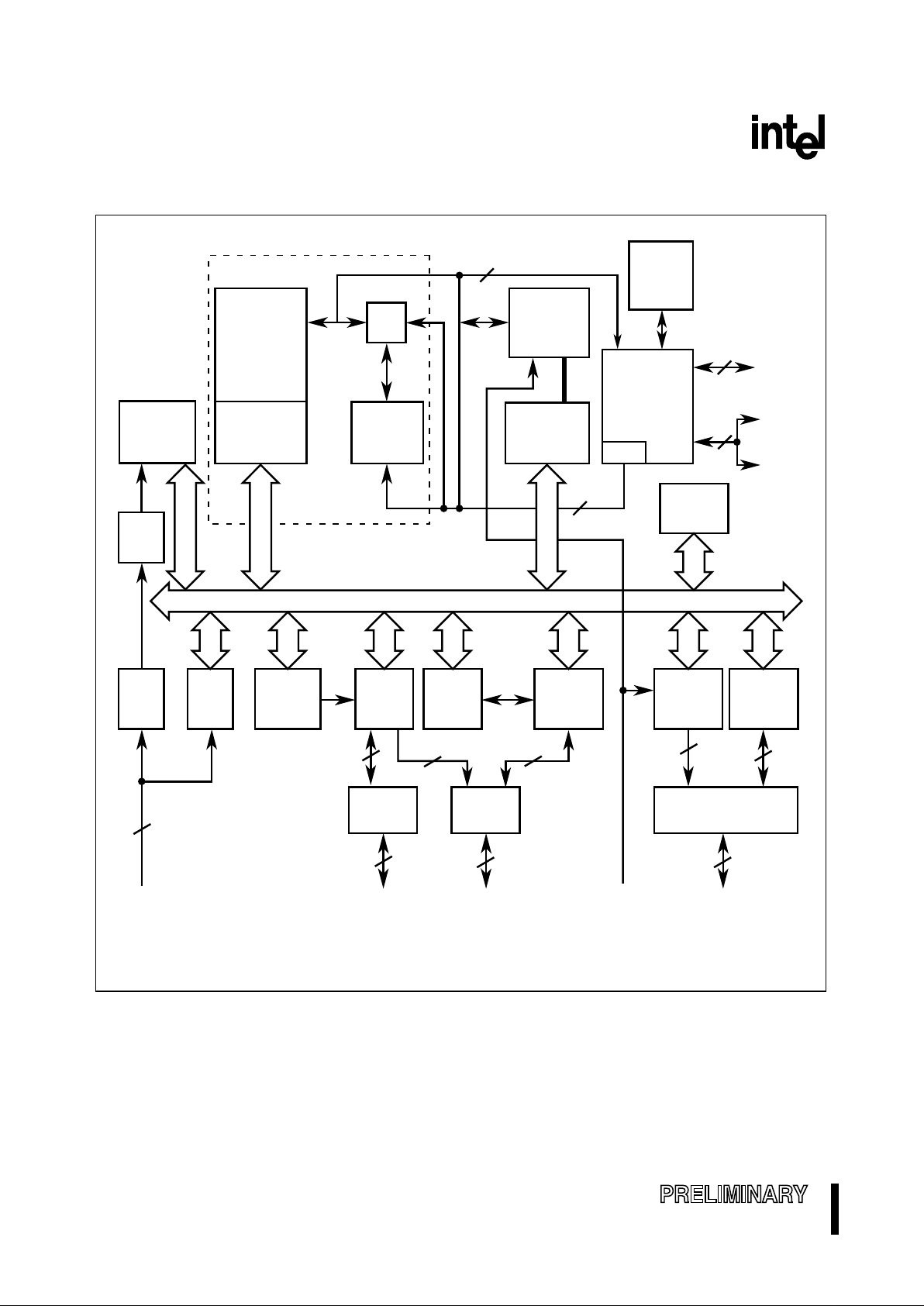

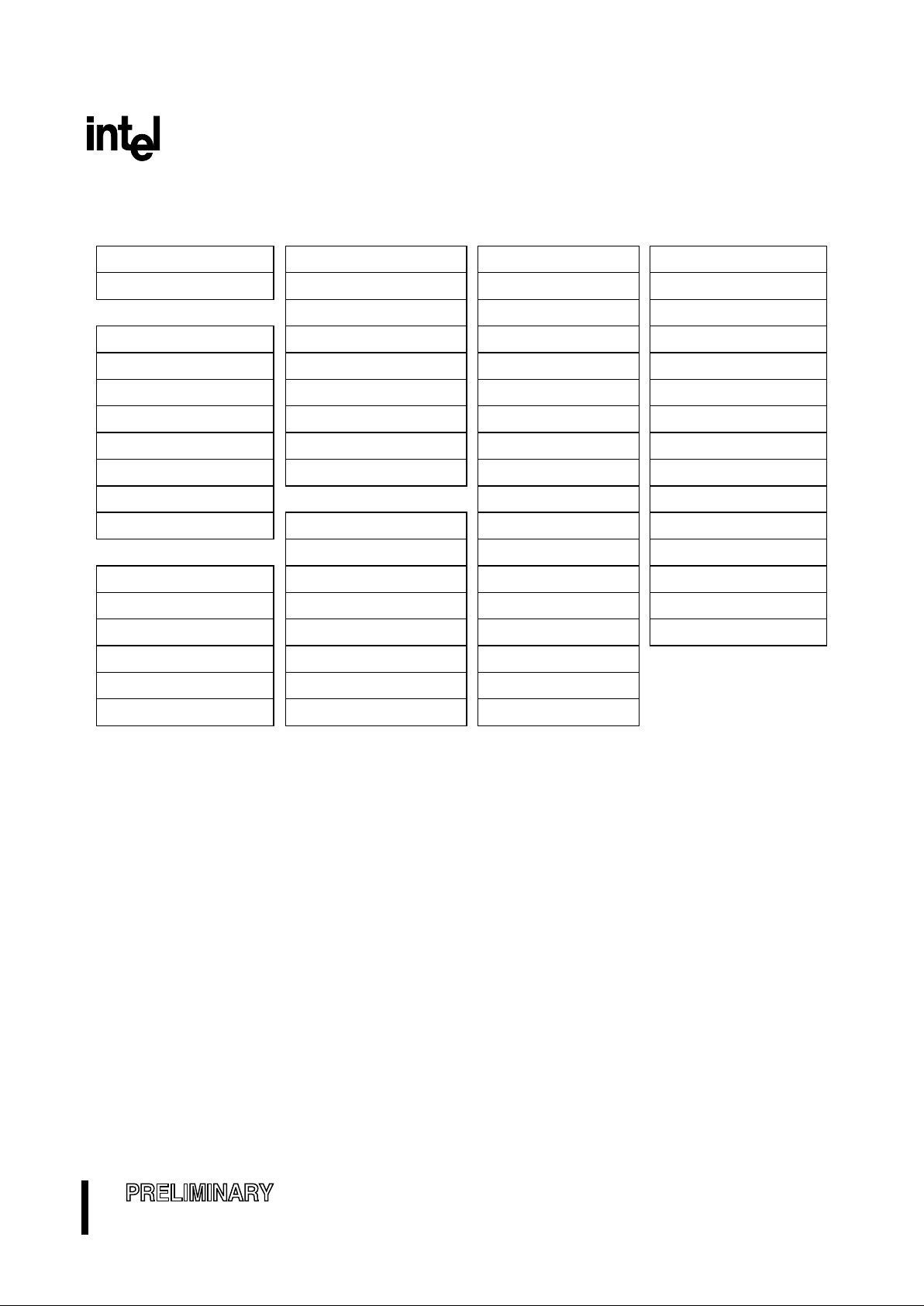

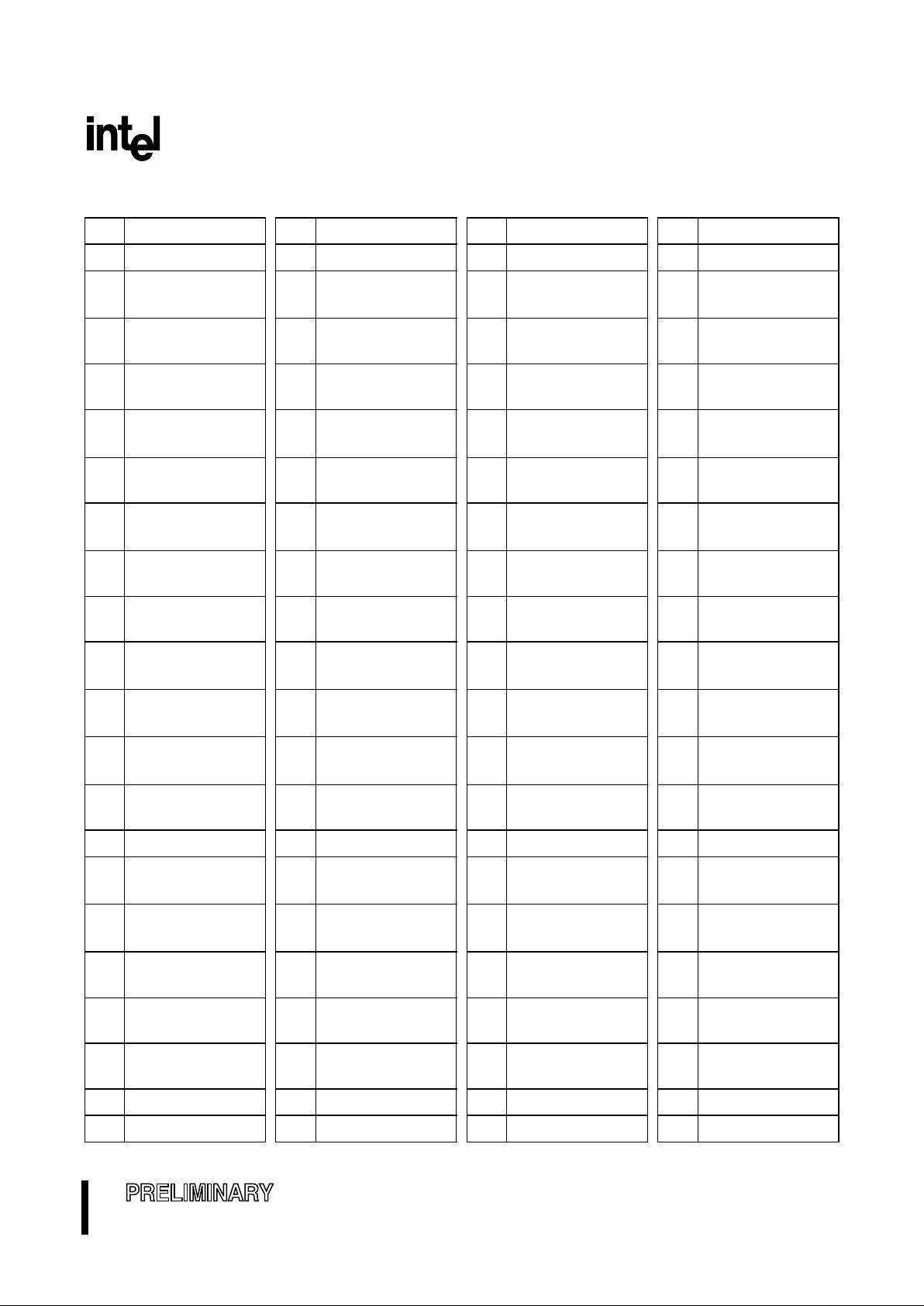

Figure 1. 8XC196MH Block Diagram

Timer 1

Timer 2

Event

Processor

Array

3-Phase

Waveform

Generator

Port 2

Microcode

Engine

RALU

CPU

Peripheral

Transaction

Server

32K

On-chip

ROM/

OTPROM

Port 4

AD15:8

Port 3

AD7:0

Port 5

Control

Signals

Interrupt

Controller

16

8

744

Byte

Register

File

Memory

Controller

Queue

Port 6

Port 6

Waveform

Generator

A2542-01

Port 2

SIO, EPA

2 Capture/Compare

4 Compare

Port 1

SIO 0

SIO 1

Port 1

Serial I/O

Baud

Rate

Generator

Port 0

A/D

Port 0

8/10-Bit

A/D

Converter

Mux

S/H

24 Bytes

CPU SFRs

Watchdog

Timer

EXTINT

PWM0

PWM1

88

4

4

26

8

6

2

8

8

Page 3

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

3

PROCESS INFORMATION

This device is manufactured on PX29.5, a CHMOS IV

process. Additional process and reliability information

is available in Intel’s

Components Quality and

Reliability

Handbook (order number 210997).

All thermal impedance data is approximate for static

air conditions at 1 watt of power dissipation. Values

will change depending on operating conditions and

the application. The Intel

Packaging

Handbook (order

number 240800) describes I ntel’s thermal impedance

test methodology.

Table 1. Thermal Characteristics

Package Type θ

JA

θ

JC

84-lead PLCC 33°C/W 11°C/W

80-lead QFP 56°C/W 12°C/W

64-lead SDIP 56°C/W N/A

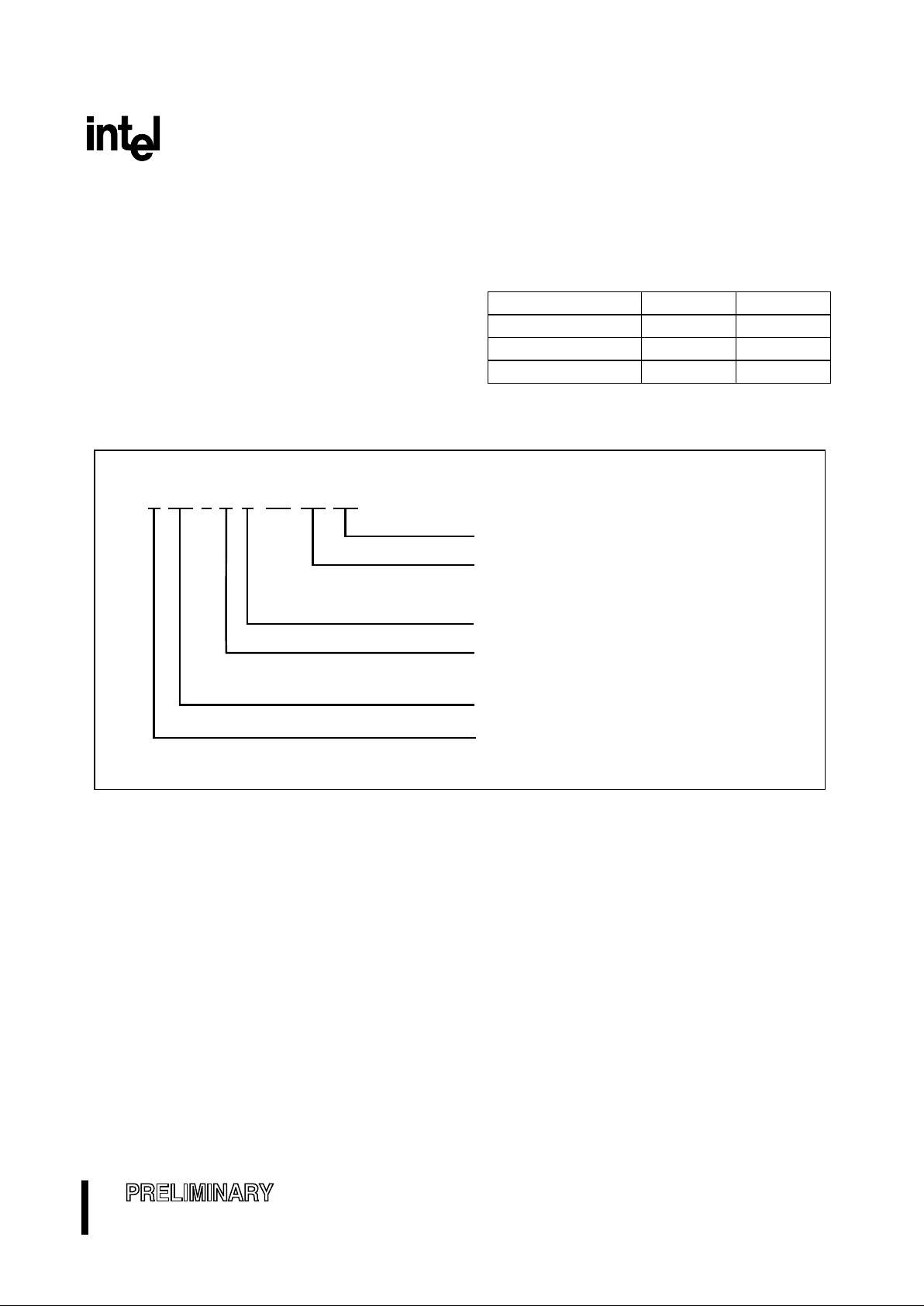

Figure 2. The 8XC196MH Family Nomenclat ure

X XX 8 X C 196 XX XX

Device Speed:

Product Family:

No Mark = 16 MHz

K

x

, Mx, N

x

CHMOS Technology

Program Memory Options:

0 = ROMless, 3 = ROM, 7 = OTPROM

Package - Type Options:

Temperature and Burn In Options:

A2759-01

D = SDIP, N = PLCC, S = QFP

No Mark = –40˚C – +85˚C Ambient

with Intel Standard Burn-In

Page 4

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

4

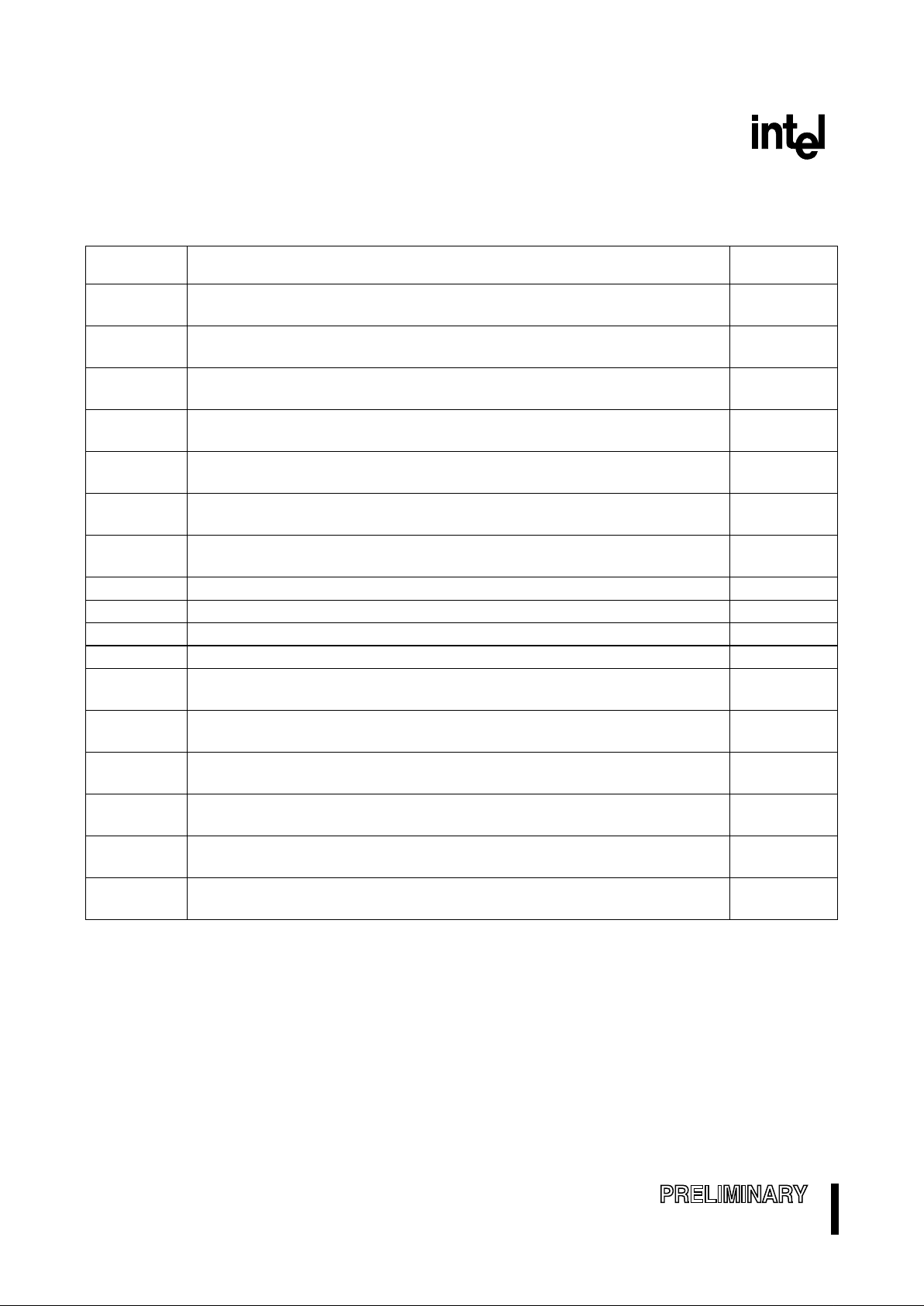

Table 2. 8XC196MH Memory Map

Address

(1)

Description Notes

0FFFFH

0A000H

External Memory

09FFFH

02080H

Internal ROM/OTPROM or External Mem ory

0207FH

0205EH

Reserved 1, 2

0205DH

02040H

PTS Vectors

0203FH

02030H

Interrupt Vectors (upper)

0202FH

02020H

ROM/OTPROM Security Key

0201FH

0201CH

Reserved 1, 2

0201BH Reserved (must contain 20H)

0201AH CCB1

02019H Reserved (must contain 20H)

02018H CCB0

02017H

02014H

Reserved

02013H

02000H

Interrupt Vectors (lower)

01FFFH

01F00H

Internal SFRs 1

1EFFH

300H

External Memory

2FFH

18H

Register RAM 3

17H

00H

CPU SFRs 1

NOTES:

1. Unless otherwise noted, write 0FFH to reserved mem ory locations and write 0 to reserved SFR bits.

2. WARNING: The contents and/or func tion of reserved locations may change with future revisions of the

device.

3. Code executed in locations 0000H to 02FFH will be forced external.

Page 5

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

5

Table 3. Signals Arranged by Fun cti onal Categ ori e s

Address & Data Programming Control Input/Output Input/Output (Cont’d)

AD15:0 AINC# P0.0/ACH0 P2.5/COMP1

CPVER P0.1/ACH1 P2.6/COMP2

Bus Control & Status PACT# P0.2/ACH2 P2.7/SCLK1#/BCLK1

ALE/ADV# PALE# P0.3/ACH3 P3.7:0

BHE#/WRH# PBUS15:0 P0.4/ACH4 P4.7:0

BUSWIDTH PMODE.3:0 P0.5/ACH5 P5.7:0

INST PROG# P0.6/ACH6/T1CLK P6.0/WG1#

READY PVER P0.7/ACH7/T1DIR P6.1/WG1

RD# P1.0/TXD0 P6.2/WG2#

WR#/WRL# Processor Control P1.1/RXD0 P6.3/WG2

EA# P1.2/TXD1 P6.4/WG3#

Power & Ground EXTINT P1.3/RXD1 P6.5/WG3

ANGND NMI P2.0/EPA0 P6.6/PWM0

V

CC

ONCE# P2.1/SCLK0#/BCLK0 P6.7/PWM1

V

PP

RESET# P2.2/EPA1

V

REF

XTAL1 P2.3/COMP3

V

SS

XTAL2 P2.4/COMP0

NOTE: The following signals are not available in the 64-pin package: P5.1, P6.7, INST, and PWM1.

Page 6

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

6

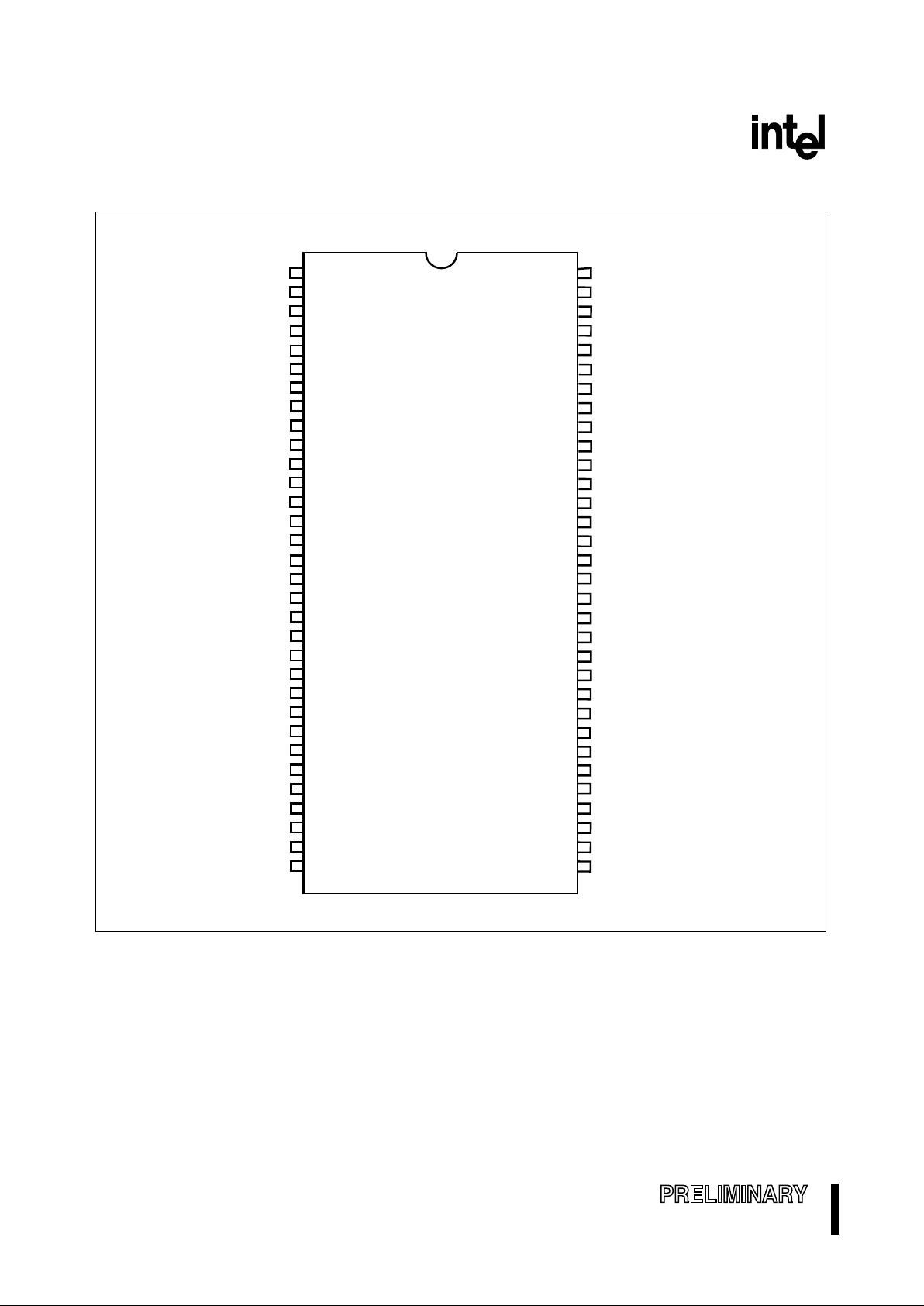

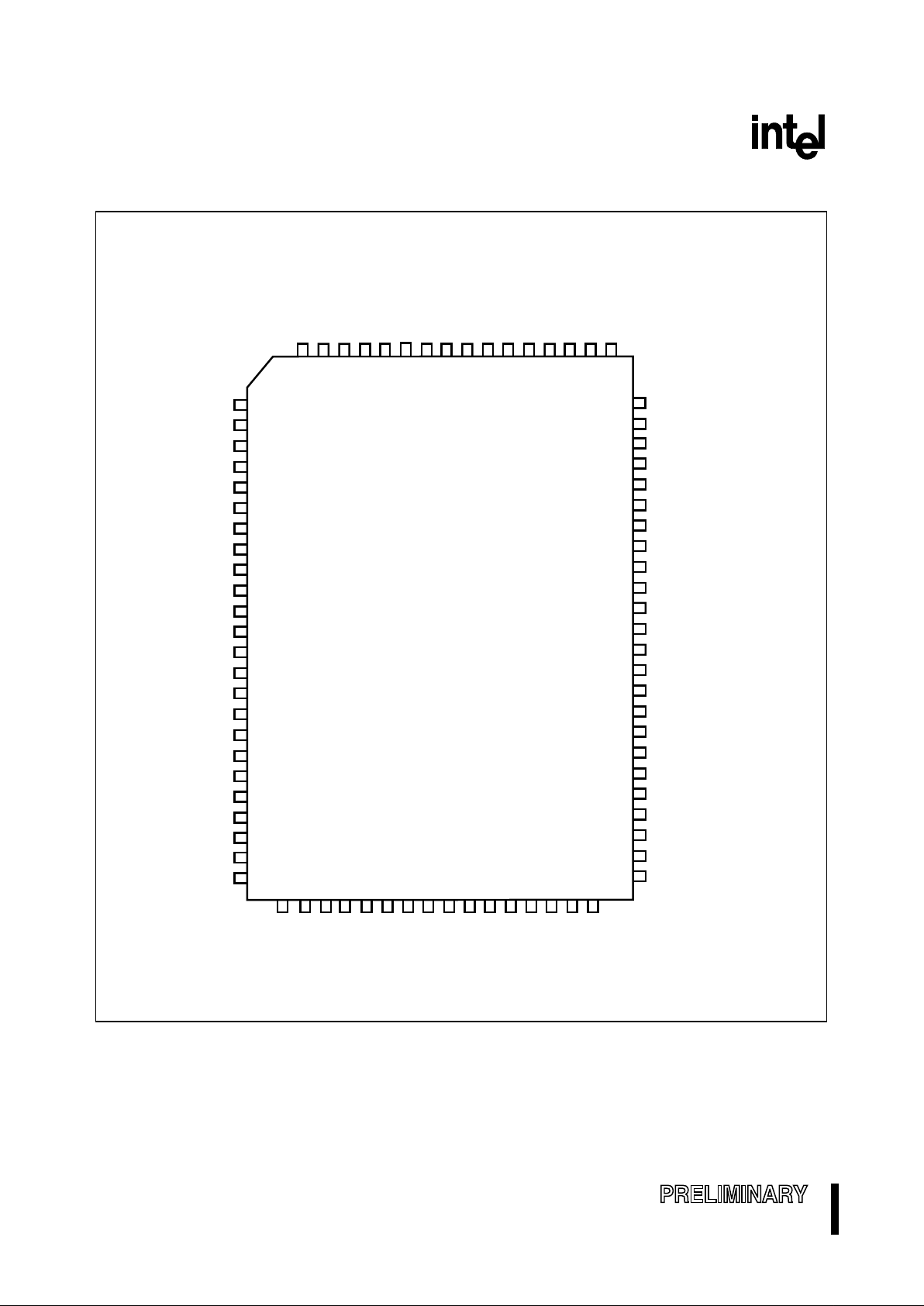

Figure 3. 8XC196MH 64-lead Shrink DIP (SDIP) Package

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

U8XC196MH

TOP VIEW

(Looking down

on component side of

PC board)

P5.6/READY

P5.4/ONCE#

EXTINT

V

SS

XTAL1

XTAL2

P6.6/PWM0

P2.7/SCLK1#/BCLK1

P2.6/COMP2/CPVER

P2.5/COMP1/PACT#

P2.4/COMP0/AINC#

P2.3/COMP3

P2.2/EPA1/PROG#

P2.1/SCLK0#/BCLK0/PALE#

P2.0/EPA0/PVER

P0.0/ACH0

P0.1/ACH1

P0.2/ACH2

P0.3/ACH3

P0.4/ACH4/PMODE.0

P0.5/ACH5/PMODE.1

V

REF

ANGND

P0.6/ACH6/T1CLK/PMODE.2

P0.7/ACH7/T1DIR/PMODE.3

P1.0/TXD0

P1.1/RXD0

P1.2/TXD1

P1.3/RXD1

P6.0/WG1#

P6.1/WG1

P6.2/WG2#

V

SS

P5.0/ALE/ADV#

V

PP

P5.3/RD#

P5.5/BHE#/WRH#

P5.2/WR#/WRL#

P5.7/BUSWIDTH

P4.6/AD14/PBUS.14

P4.5/AD13/PBUS.13

P4.7/AD15/PBUS.15

V

CC

P4.4/AD12/PBUS.12

P4.3/AD11/PBUS.11

P4.2/AD10/PBUS.10

P4.1/AD9/PBUS.9

P4.0/AD8/PBUS.8

P3.7/AD7/PBUS.7

P3.6/AD6/PBUS.6

P3.5/AD5/PBUS.5

P3.4/AD4/PBUS.4

P3.3/AD3/PBUS.3

P3.2/AD2/PBUS.2

P3.1/AD1/PBUS.1

P3.0/AD0/PBUS.0

RESET#

NMI

EA#

V

SS

V

CC

P6.5/WG3

P6.4/WG3#

P6.3/WG2

A2572-01

Page 7

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

7

Table 4. 64-lead Shrink DIP (SDI P) Pi n Assi gnme nt

Pin Name Pin Name Pin Name Pin Name

1V

SS

17 P3.7/AD7

/PBUS.7

33 P6.2/WG2# 49 P0.0/A C H0

2 P5.0/A LE/ADV# 18 P3.6/AD6

/PBUS.6

34 P6.1/WG1 50 P2.0/EPA0/PVER

3V

PP

19 P3.5/AD5

/PBUS.5

35 P6.0/WG1# 51 P2.1/SCLK0#

/BCLK0/PALE#

4 P5.3/RD# 20 P3.4/AD4

/PBUS.4

36 P1.3/RXD1 52 P2.2/EPA1

/PROG#

5 P5.5/B HE#/WRH# 21 P3.3/AD3

/PBUS.3

37 P1.2/TXD1 53 P2. 3/CO M P3

6 P5.2/W R#/WRL# 22 P3.2/AD2

/PBUS.2

38 P1.1/RXD0 54 P2.4/COMP0

/AINC#

7 P5.7/B USW I DTH 23 P3.1/AD1

/PBUS.1

39 P1.0/TXD0 55 P2. 5/CO M P1

/PACT#

8 P4.6/A D 14

/PBUS.14

24 P3.0/AD0

/PBUS.0

40 P0.7/ACH7/T1DIR

/PMODE.3

56 P2.6/COMP2

/CPVER

9 P4.5/A D 13

/PBUS.13

25 RESET# 41 P0.6/ACH6

/T1CLK/PMODE .2

57 P2.7/SCLK1#

/BCLK1

10 P4.7/AD15

/PBUS.15

26 NMI 42 ANGND 58 P6.6/PWM0

11 V

CC

27 EA# 43 V

REF

59 XTAL2

12 P4.4/AD12

/PBUS.12

28 V

SS

44 P0.5/ACH5

/PMODE.1

60 XTAL1

13 P4.3/AD11

/PBUS.11

29 V

CC

45 P0.4/ACH4

/PMODE.0

61 V

SS

14 P4.2/AD10

/PBUS.10

30 P6.5/WG3 46 P0.3/ACH3 62 EXTINT

15 P4.1/AD9/PBUS.9 31 P6.4/WG3# 47 P0.2/ACH2 63 P5.4/ONCE#

16 P4.0/AD8/PBUS.8 32 P6.3/WG2 48 P0.1/ACH1 64 P5.6/READY

Page 8

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

8

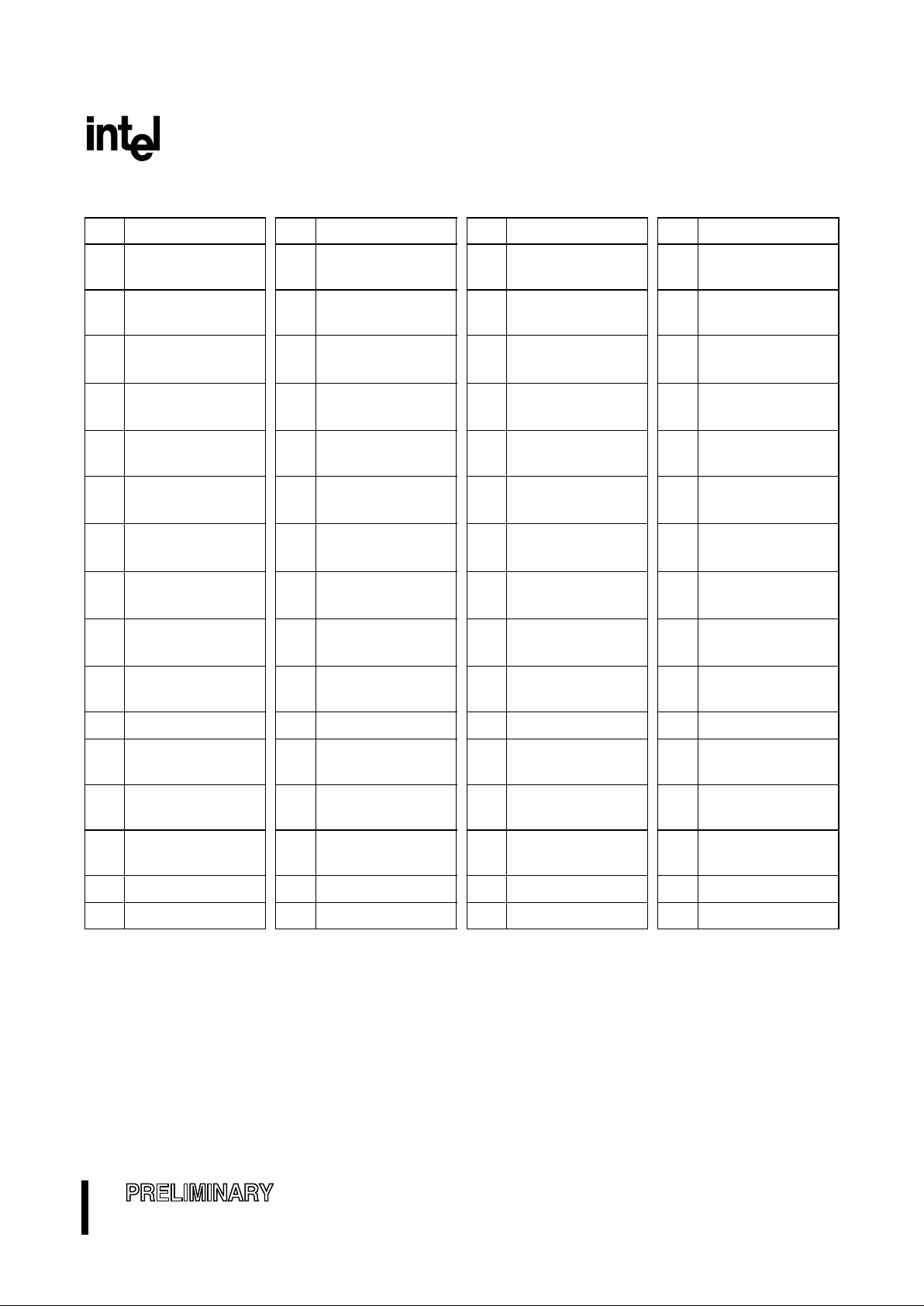

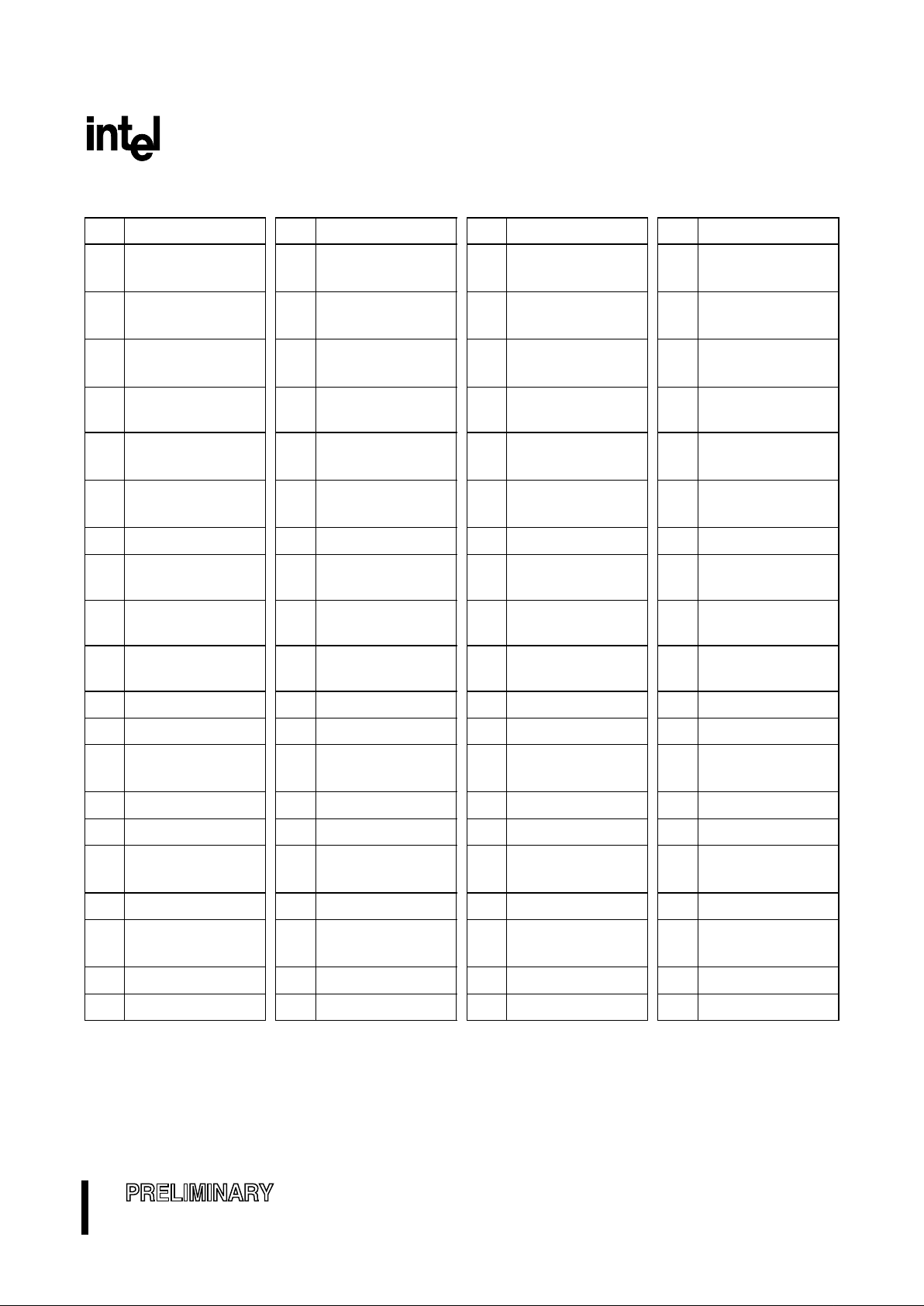

Figure 4. 8XC196MH 84-lead PLCC Package

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

11

10

987654321

84

83

82

81

80

79

78

77

76

75

P2.5/COMP1/PACT#

P2.4/COMP0/AINC#

NC

NC

P2.7/SCLK1#/BCLK1

P2.3/COMP3

P2.2/EPA1/PROG#

NC

NC

P2.1/SCLK0#/BCLK0/PALE#

P2.0/EPA0/PVER

NC

P0.0/ACH0

P0.1/ACH1

P0.2/ACH2

P0.3/ACH3

P0.4/ACH4/PMODE.0

P0.5/ACH5/PMODE.1

V

REF

ANGND

P0.6/ACH6/T1CLK/PMODE.2

P4.7/AD15/PBUS.15

P4.6/AD14/PBUS.14

VCC

P4.5/AD13/PBUS.13

NC

P4.4/AD12/PBUS.12

P4.3/AD11/PBUS.11

P4.2/AD10/PBUS.10

P4.1/AD9/PBUS.9

P4.0/AD8/PBUS.8

NC

NC

P3.7/AD7/PBUS.7

P3.6/AD6/PBUS.6

P3.5.AD5/PBUS.5

P3.4/AD4/PBUS.4

P3.3/AD3/PBUS.3

P3.2/AD2/PBUS.2

P3.1/AD1/PBUS.1

P3.0/AD0/PBUS.0

NC

P5.7/BUSWIDTH

P5.2/WR#/WRL#

NC

P5.5/BHE#/WRH#

P5.3/RD#

V

PP

P5.0/ALE/ADV#

V

SS

P5.1/INST

P5.6/READY

P5.4/ONCE#

EXTINT

V

SS

XTAL1

XTAL2

NC

NC

NC

P6.6/PWM0

P6.7/PWM1

P2.6/COMP2/CPVER

RESET#

NMI

NC

EA#

V

SS

NCVCC

P6.5/WG3

P6.4/WG3#

P6.3/WG2

V

SS

P6.2/WG2#

P6.1/WG1

P6.0/WG1#

P1.3/RXD1

P1.2/TXD1

NC

NC

P1.1/RXD0

P1.0/TXD0

P0.7/ACH7/T1DIR/PMODE.3

N8XC196MH

TOP VIEW

(Looking down

on component side of

PC board)

A2573-02

Page 9

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

9

Table 5. 84-lead PLCC Pin Assig nme nt

Pin Name Pin Name Pin Name Pin Name

1 P5.4/ONCE# 22NC 43V

SS

64 P2.0/EPA0/PVER

2 P5.6/RE ADY 23 NC 44 P6.2/WG2# 65 P2.1/SCLK0#

/BCLK0/PALE#

3 P5.1/INST 24 P3.7/AD7

/PBUS.7

45 P6.1/WG1 66 NC

4V

SS

25 P3.6/AD6

/PBUS.6

46 P6.0/WG1# 67 NC

5 P5.0/ALE/ADV# 26 P3.5/AD5

/PBUS.5

47 P1.3/RXD1 68 P2.2/EPA1

/PROG#

6V

PP

27 P3.4/AD4

/PBUS.4

48 P1.2/TXD1 69 P2. 3/CO M P3

7 P5.3/RD# 28 P3.3/AD3

/PBUS.3

49 NC 70 P2.7/SCLK1#

/BCLK1

8 P5.5/BHE#/WRH# 29 P3.2/AD2

/PBUS.2

50 NC 71 NC

9 NC 30 P3.1/AD1

/PBUS.1

51 P1.1/RXD0 72 NC

10 P5.2/WR#/WRL # 31 P3.0/AD0

/PBUS.0

52 P1.0/TXD0 73 P2. 4/CO M P0

/AINC#

11 P5.7/BUSWIDTH 32 NC 53 P0.7/ACH7

/T1DIR/PMODE. 3

74 P2.5/COMP1

/PACT#

12 P4.7/AD15

/PBUS.15

33 RESET# 54 P0.6/ACH6

/T1CLK/PMOD E.2

75 P2.6/COMP2

/CPVER

13 P4.6/AD14

/PBUS.14

34 NMI 55 ANGND 76 P6.7/PWM1

14 V

CC

35 NC 56 V

REF

77 P6.6/PWM0

15 P4.5/AD13

/PBUS.13

36 EA# 57 P0.5/ACH5

/PMODE.1

78 NC

16 NC 37 V

SS

58 P0.4/ACH4

/PMODE.0

79 NC

17 P4.4/AD12

/PBUS.12

38 NC 59 P0.3/ACH3 80 NC

18 P4.3/AD11

/PBUS.11

39 V

CC

60 P0.2/ACH2 81 XTAL2

19 P4.2/AD10

/PBUS.10

40 P6.5/WG3 61 P 0.1/ ACH1 82 XTAL1

20 P4.1/AD9/PBUS.9 41 P6.4/WG3 # 62 P0.0/ ACH0 83 V

SS

21 P4.0/AD8/PBUS.8 42 P6.3/WG 2 63 NC 84 EXTINT

Page 10

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

10

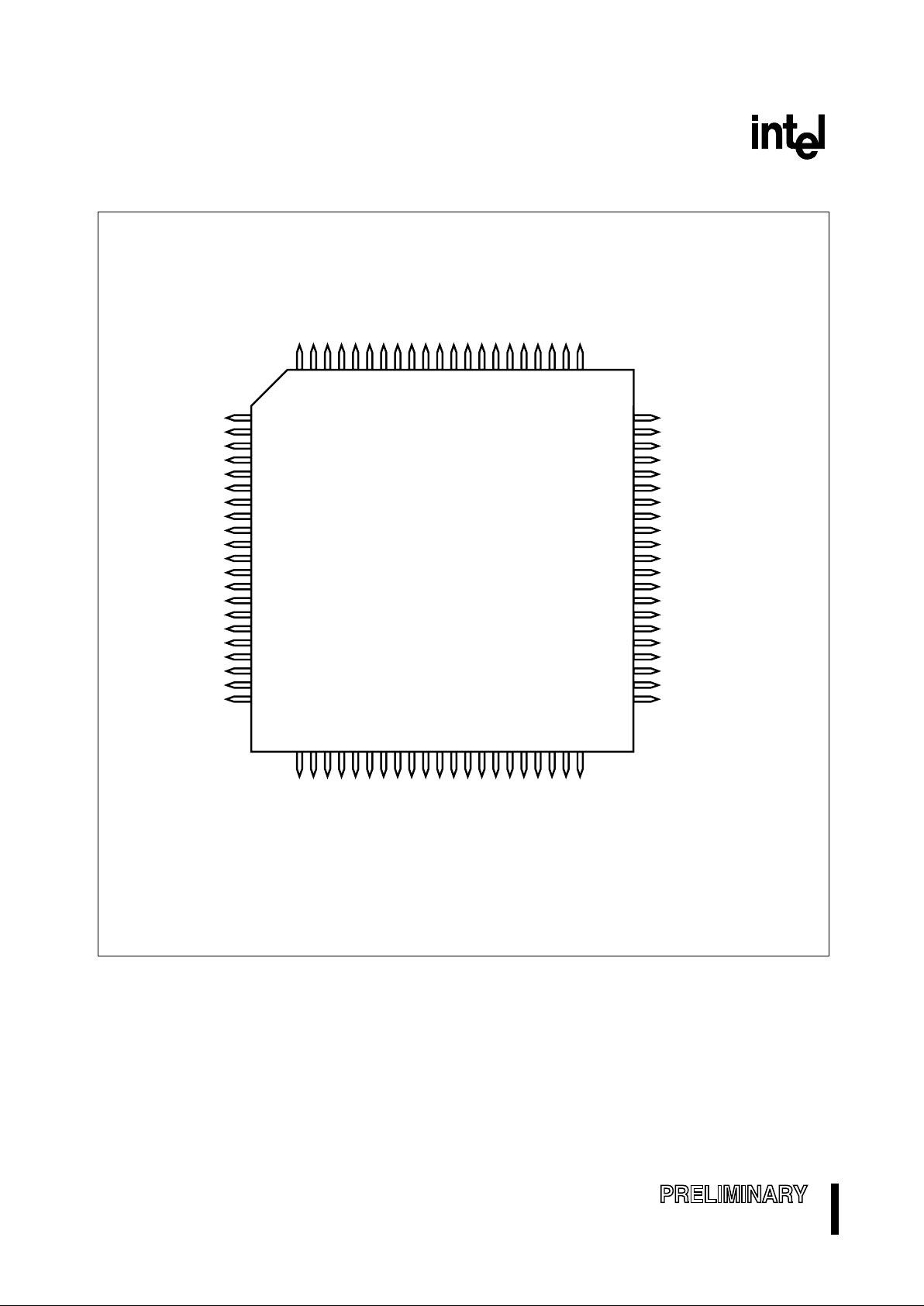

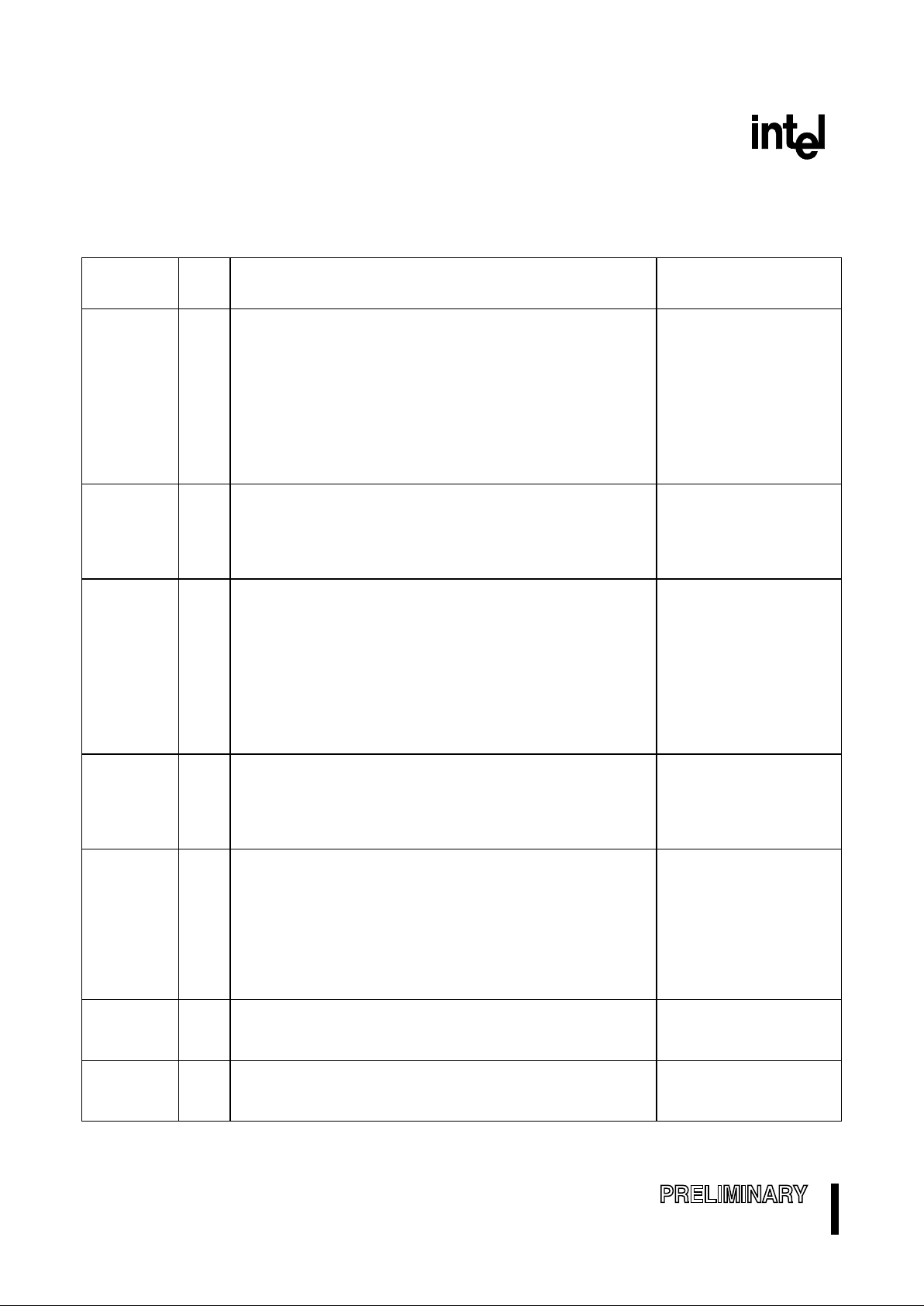

Figure 5. 8XC196MH 80-lead Shrink EIAJ/Q FP Packag e

1

2

3

4

5

6

7

8

9

10

12

17

13

14

16

18

19

11

15

20

21

24

25 26 28 2927

23

22

3938

37343230 31 33 35

36

40

42

41

43

44

45

46

47

48

49

52

53

50

51

55

54

56

57

59

58

60

61

62

63

64

65

6667

68

6973747679 77

75

72 71 70

80

78

P6.7/PWM1

P2.6/COMP2/CPVER

P2.5/COMP1/PACT#

P2.4/COMP0/AINC#

NC

NC

P2.7/SCLK1#/BCLK1

P2.3/COMP3

P2.2/EPA1/PROG#

P2.0/EPA0/PVER

NC

NC

P0.6/ACH6/T1CLK/PMODE.2

NC

P2.1/SCLK0#/BCLK0/PALE#

ANGND

P0.0/ACH0

P0.1/ACH1

P0.2/ACH2

P0.3/ACH3

P0.4/ACH4/PMODE.0

V

REF

P0.5/ACH5/PMODE.1

P0.7/ACH7/T1DIR/PMODE.3

P4.7/AD15/PBUS.15

P5.2/WR#/WRL#

P5.7/BUSWIDTH

P4.6/AD14/PBUS.14

V

CC

P4.5/AD13/PBUS.13

NC

P4.3/AD11/PBUS.11

P4.4/AD12/PBUS.12

P4.2/AD10/PBUS.10

P3.7/AD7/PBUS.7

P4.1/AD9/PBUS.9

P4.0/AD8/PBUS.8

P3.6/AD6/PBUS.6

P3.4/AD4/PBUS.4

P3.3/AD3/PBUS.3

P3.1/AD1/PBUS.1

P3.0/AD0/PBUS.0

NMI

NC

EA#

RESET#

P3.5/AD5/PBUS.5

P3.2/AD2/PBUS.2

V

SS

NC

P6.4/WG3#

P6.1/WG1

V

CC

P6.5/WG3

P6.3/WG2

V

SS

P6.2/WG2#

P1.3/RXD1

P6.0/WG1#

P1.2/TXD1

NC

NC

P1.1/RXD0

P1.0/TXD0

V

PP

P5.3/RD#

P5.1/INST

P5.0/ALE/ADV#

P5.4/ONCE#

P5.6/READY

VSSXTAL1

EXTINT

XTAL2NCNC

P6.6/PWM0

NC

P5.5/BHE#/WRH#

V

SS

S8XC196MH

TOP VIEW

(Looking down

on component side of

PC board)

A2574-01

Page 11

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

11

Table 6. 80-lead Shrink EIAJ/QFP Pin Assignment

Pin Name Pin Name Pin Name Pin Name

1 P5.2/WR#/WRL# 21 NC 41 P0.7/ACH7/T1DIR

/PMODE.3

61 P2.4/COMP0

/AINC#

2 P5.7/BUSWIDTH 22 RESET# 42 P0.6/ACH6

/T1CLK/PMODE.2

62 P2.5/COMP1

/PACT#

3 P4.7/AD15

/PBUS.15

23 NMI 43 ANGND 63 P2.6/COMP2

/CPVER

4 P4.6/AD14

/PBUS.14

24 EA# 44 V

REF

64 P6.7/PWM1

5V

CC

25 V

SS

45 P0.5/ACH5

/PMODE.1

65 P6.6/PWM0

6 P4.5/AD13

/PBUS.13

26 NC 46 P0.4/ACH4

/PMODE.0

66 NC

7NC 27V

CC

47 P0.3/ACH3 67 NC

8 P4.4/AD12

/PBUS.12

28 P6.5/WG3 48 P0.2/ACH2 68 NC

9 P4.3/AD11

/PBUS.11

29 P6.4/WG3# 49 P0.1/ACH1 69 XTAL2

10 P4.2/AD10

/PBUS.10

30 P6.3/WG2 50 P0.0/ACH0 70 XTAL1

11 P4.1/AD9/PBUS.9 31 V

SS

51 NC 71 V

SS

12 P4.0/AD8/PBUS.8 32 P6.2/WG2# 52 P2.0/EPA0/PVER 72 EXTINT

13 P3.7/AD7/PBUS.7 33 P6.1/WG1 53 P2.1/SCLK0#

/BCLK0/PALE#

73 P5.4/ONCE#

14 P3.6/AD6/PBUS.6 34 P6.0/WG1# 54 NC 74 P5.6/READY

15 P3.5/AD5/PBUS.5 35 P1.3/RXD1 55 NC 75 P5.1/INST

16 P3.4/AD4/PBUS.4 36 P1.2/TXD1 56 P2.2/EPA1

/PROG#

76 V

SS

17 P3.3/AD3/PBUS.3 37 NC 57 P2.3/COMP3 77 P5.0/ALE/ADV#

18 P3.2/AD2/PBUS.2 38 NC 58 P2.7/SCLK1#

/BCLK1

78 V

PP

19 P3.1/AD1/PBUS.1 39 P1.1/RXD0 59 NC 79 P5.3/RD#

20 P3.0/AD0/PBUS.0 40 P1.0/TXD0 60 NC 80 P5.5/BHE#/WRH#

Page 12

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

12

PIN DESCRIPTIONS

Table 7. Signal Descriptions

Signal

Name

Type Description

Multiplexed

With

ACH7

ACH6

ACH5

ACH4

ACH3:0

I Analog Channels. These pins are analog inputs to the A/D

converter.

These pins are multiplexed with the port 0 pins. While it is

possible for the pins to function simultaneously as analog and

digital inputs, this is not recommended because reading the

port while a conversion is in process can produce unreliable

conversion results.

The ANGND and V

REF

pins must be connected for the A/D

converter and the multiplexed port pins to function.

P0.7/T1DIR/PMO DE .3

P0.6/T1CLK/PMODE.2

P0.5/PMODE.1

P0.4/PMODE.0

P0.3:0

AD15:8

AD7:0

I/O Address/Data Lines. The se pins provide a multiplexed

address and data bus. During the address phase of the bus

cycle, address bits 0–15 are presented on the bus and can

be latched using ALE or ADV#. During the data phase, 8- or

16-bit data is transferred.

P4.7:0/PBUS.15:8

P3.7:0/PBUS.7:0

ADV# O Address Valid. This active-low output signal is asserted only

during external memory accesses.

ADV# indicates that valid address information is available on

the system address/data bus. The signal remains low while a

valid bus cycle is in progress and is returned high as soon as

the bus cycle completes.

An external latch can use the ADV# signal to demultiplex the

address from the address/data bus. Used with a decoder,

ADV# can generate chip-selects for external memory.

P5.0/ALE

AINC# I Auto Increment. In slave programming mode, this active-low

input signal enables the autoincrement mode. Auto increment

allows reading from or writing to sequential OTPROM

locations without requiring address transactions across the

programming bus for each read or write.

P2.4/COMP0

ALE O Address Latch En ab le. This act ive-high output signa l is

asserted only during external memory cycles.

ALE signals the start of an external bus cycle and indicates

that valid address information is available on the system

address/data bus. ALE differs from ADV# in that it is not

returned high until a new bus cycle is to begin.

An external latch can use ALE to demultiplex the address

from the address/data bus.

P5.0/ADV#

ANGND GND Analog Ground. Reference ground for the A/D convert er

and the logic used to read port 0. ANGND must be held at

nominally the same potential as V

SS

.

—

BCLK1

BCLK0

I Serial Communications Baud Clock 0 and 1. BCLK0 and 1

are alternate clock sources for the serial ports. The maximum

input frequency is F

OSC

/4.

P2.7/SCLK1#

P2.1/SCLK0#/PALE#

Page 13

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

13

BHE# O Byte High Enable. During 16-bit bus cycles, this active-low

output signal is asserted for word reads and writes and for

high-byte reads and writes to external memory. BHE#

indicates that valid data is being transferred over the upper

half of the system address/data bus.

BHE#, in conjunction with A0, selects the memory byte to be

accessed:

BHE# A0 Byte(s) Accessed

0 0 both bytes

0 1 high byte only

1 0 low byte only

P5.5/WRH#

BUSWIDTH I Bus Width. When enabled in the chip configuration register,

this active-high input signal dynamically selects the bus width

of the bus cycle in progress. When BUSWIDTH is high, a 16bit bus cycle occurs; when BUSWIDTH is low, an 8-bit bus

cycle occurs. BUSWIDTH is active during a CCR fetc h.

P5.7

COMP3

COMP2

COMP1

COMP0

O Event Processor Array (EPA) Compare Pins. These

signals are the output of the EPA compare modules. These

pins are multiplexed with other signals and may be

configured as standard I/O.

P2.3

P2.6/CPVER

P2.5/PACT#

P2.4/AINC#

CPVER O Cumulative Program Verification. This active-high output

signal indicates whether any verify errors have occurred

since the device entered programming mode. CPVER

remains high until a verify error occurs, at which time it is

driven low. Once an error occurs, CPVER remains low until

the device exits programming mode. When high, CPVER

indicates that all locations have programmed correctly since

the device entered programming mode.

P2.6/COMP2

EA# I External Access. This active-low input signal directs

memory accesses to on-chip or off-chip memory. If EA# is

low, the memory access is off-chip. If EA# is high and the

memory address is within 2000H–2FFFH, the access is to

on-chip ROM or OTPROM. Otherwise, an access with EA#

high is to off-chip memory.

EA# is sampled only on the rising edge of RESET#.

If EA# = V

EA

on the rising edge of RESET#, the device enters

the programming mode selected by PMODE.3:0.

For devices without ROM, EA# must be tied low.

—

EPA1

EPA0

I/O Event Processor Array (EPA) Input/O utpu t pins. These

are the high-speed input/output pins for the EPA

capture/compare modules. These pins are multiplexed with

other signals and may be configured as standard I/O.

P2.2/PROG#

P2.0/PVER

Table 7. Signal Descriptions (Continued)

Signal

Name

Type Description

Multiplexed

With

Page 14

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

14

EXTINT I External Interrupt. This programmable interrupt is controlled

by the WG_PROTECT re gister. This regist er cont rols

whether the interrupt is edge triggered or sampled and

whether a rising edge/high level or falling edge/low level

activates the interrupt. This interrupt vectors through memory

location 203CH. If the chip is in idle mode and if EXTINT is

enabled, a valid EXTINT interrupt brings the chip back to

normal operation, where the first action is to execute the

EXTINT service routine. After completion of the service

routine, execution resumes at the instruction following the

one that put the chip into idle mode.

In powerdown mode, a valid EXTINT interrupt

causes the

chip to return to normal operating mode. If EXTINT is

enabled, the EXTINT service routine is executed. Otherwise,

execution continues at the instruction following the IDLPD

instruction that put the chip into powerdown mode.

—

INST O Instruction Fetch. This active-high output signal is valid only

during external memory bus cycles. When high, INST

indicates that an instruction is being fetched from external

memory. The signal remains high during the entire bus cycle

of an external instruction fetch. INST is low for data

accesses, including interrupt vector fetches and chip configuration byte reads. INST is low during internal memory

fetches.

P5.1

NMI I Nonmaskable Interrupt. In normal operating mode, a rising

edge on NMI causes a vector through the NMI interrupt at

location 203EH. NMI must be asserted for greater than one

state time to guarantee that it is recognized.

In idle mode, a rising edge on NMI brings the chip back to

normal operation, where the first action is to execute the NMI

service routine. After completion of the service routine,

execution resumes at the instruction following the one that

put the chip into idle mode.

In powerdown mode, NMI causes a return to normal

operating mode only if it is tied to EXTINT.

—

ONCE# I On -ci rcu it Em ulati on. Holding this pin low while the

RESET# signal transitions from a low to a high places the

device into on-circuit emulation (ONCE) mode. ONCE mode

isolates the device from other components in the system to

allow the use of a clip-on emulator for system debugging.

This mode puts all pins except XTAL1 and XTAL2 into a highimpedance state. To exit ONCE mode, reset the device by

pulling the RESET# signal low.

P5.4

Table 7. Signal Descriptions (Continued)

Signal

Name

Type Description

Multiplexed

With

Page 15

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

15

P0.7

P0.6

P0.5

P0.4

P0.3:0

I Port 0. This is a high-impedance, input-only port. Port 0 pins

should not be left floating.

These pins may individually be used as analog inputs

(ACH

x

) or digital inputs (P0.x). While it is possible for the pins

to function simultaneously as analog and digital inputs, this is

not recommended because reading port 0 while a conversion

is in process can produce unreliable conversion results.

ANGND and V

REF

must be connected for port 0 and the A/D

converter to function.

ACH7/T1DIR/PMODE. 3

ACH6/T1CLK/PMODE. 2

ACH5/PMODE.1

ACH4/PMODE.0

ACH3:0

P1.3

P1.2

P1.1

P1.0

I Port 1. This is a 4-bit, bidirectional, standard I/O port that is

multiplexed with individually selectable special-function

signals. (Used as PBUS.15:12 in Auto-programming Mode.)

RXD1

TXD1

RXD0

TXD0

P2.7

P2.6

P2.5

P2.4

P2.3

P2.2

P2.1

P2.0

I/O Port 2. This is an 8-bit, bidirectional, standard I/O port that is

multiplexed with individually selectable special-function

signals. P2.6 is multiplexed with a special test mode function.

To prevent accidental entry into test modes, always configure

P2.6 as an output.

SCLK1#/BCLK1

COMP2/CPVER

COMP1/PACT#

COMP0/AINC#

COMP3

EPA1/PROG#

SCLK0#/BCLK0/PALE#

EPA0/PVER

P3.7:0 I/O Port 3. This is an 8-bit, bidirectional, memory-mapped I/O

port with open-drain outputs. The pins are shared with the

multiplexed address/data bus, which has complementary

drivers.

In programming modes, port 3 serves as the low byte of the

programming bus (PBUS).

AD7:0/PBUS.7:0

P4.7:0 I/O Port 4. This is an 8-bit, bidirectional, memory-mapped I/O

port with open-drain outputs. The pins are shared with the

multiplexed address/data bus, which has complementary

drivers.

In programming modes, port 4 serves as the high byte of the

programming bus (PBUS).

AD15:8/PBUS.15:8

P5.7

P5.6

P5.5

P5.4

P5.3

P5.2

P5.1

P5.0

I/O Port 5. This is an 8-bit, bidirectional, standard I/O port that is

multiplexed with individually selectable control signals.

Because P5.4 is multiplexed with the ONCE# function,

always configure it as an output to prevent accidental entry

into ONCE mode.

BUSWIDTH

READY

BHE#/WRH#

ONCE#

RD#

WR#/WRL#

INST

ALE/ADV#

Table 7. Signal Descriptions (Continued)

Signal

Name

Type Description

Multiplexed

With

Page 16

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

16

P6.7

P6.6

P6.5

P6.4

P6.3

P6.2

P6.1

P6.0

O Port 6. This is an 8-bit output port that is multiplexed with the

special functions of the waveform generator and PWM

peripherals. The WG_OUT register configures the pins,

establishes the output polarity, and controls whether changes

to the outputs are synchronized with an event or take effect

immediately.

PWM1

PWM0

WG3

WG3#

WG2

WG2#

WG1

WG1#

PACT# O Programming Active. In auto-programming mode, PACT#

low indicates that programming activity is occurring.

P2.5/COMP1

PALE# I Programming ALE. In slave programming mode, this active-

low input indicates that ports 3 and 4 contain a

command/address. When PALE# is asserted, data and

commands on ports 3 and 4 are read into the device.

P2.1/SCLK0#/BCLK0

PBUS.15:8

PBUS.7:0

I/O Programming Bus. In programming modes, used as a

bidirectional port with open-drain outputs to pass commands,

addresses, and data to or from the device. Used as a regular

system bus to access external memory during autoprogramming mode. When using slave programming mode,

the PBUS is used in open-drain I/O port mode (not as a

system bus). In slave programming mode, you must add

external pull-up resistors to read data from the device during

the dump word routine.

P4.7:0/AD15:8

P3.7:0/AD7:0

PMODE.3

PMODE.2

PMODE.1

PMODE.0

I Programming Mode Select. Determines the OTPROM

programming algorithm that is to be performed. PMODE is

sampled after a device reset when EA# = V

EA

and must be

stable while the device is operating.

P0.7/ACH7/T1DIR

P0.6/ACH6/T1CLK

P0.5/ACH5

P0.4/ACH4

PROG# I Programming Start. This active-low input is valid only in

slave programming mode. The rising edge of PROG# latches

data on the PBUS and begins programming. The falling edge

of PROG# ends programming.

P2.2/EPA1

PVER

O Program Verification. In programming modes, this active-

high output signal is asserted to indicate that the word has

programmed correctly. (PVER low after the rising edge of

PROG# indicates an error.)

P2.0/EPA0

PWM1:0 O Pulse Width Modulator Outpu ts. These are PWM output

pins with high-current drive capability. The duty cycle and

frequency-pulse-widths are programmable.

P6.7:6

RD# O Read. Read-signal output to external memory. RD# is

asserted only during external memory reads.

P5.3

Table 7. Signal Descriptions (Continued)

Signal

Name

Type Description

Multiplexed

With

Page 17

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

17

READY I Ready Input. This active-high input signal is used to

lengthen external memory cycles for slow memory by

generating wait states.

When READY is high, CPU operation continues in a normal

manner. If READY is low, the memory controller inserts wait

states until the READY signal goes high or until the number

of wait states is equal to the number programmed into the

chip configuration register.

READY is ignored for all internal memory accesses.

P5.6

RESET# I/O Reset. Reset input t o and open-drain output from the chip. A

falling edge on RESET# initiates the reset process. When

RESET# is first asserted, the chip turns on a pull-down

transistor connected to the RESET pin for 16 state times.

This function can also be activated by execution of the RST

instruction. In the powerdown and idle modes, asserting

RESET# causes the chip to reset and return to normal

operating mode. RESET# is a level-sensitive input.

—

RXD1

RXD0

I/O Receive Serial Data 0 and 1. In modes 1, 2, and 3, RXD0

and 1 are used to receive serial port data. In mode 0, they

function as either inputs or open-drain outputs for data.

P1.3

P1.1

SCLK1#

SCLK0#

I/O Synchronous Clock Pin 0 and 1. In mode 4, these are the

bidrectional, shift clock signals that synchronize the serial

data transfer. Data is transferred 8 bits at a time with the LSB

first. The DIR bit (SP_CON

x

.7) controls the direction of

SCLK

x

signal.

DIR = 0 The internal shift clock is output on SCLK

x

.

DIR = 1 An external shift clock is input on SCLK

x

.

P2.7/BCLK1

P2.1/BCLK0

T1CLK I External Clock. External clock for timer 1. Timer 1

increments (or decrements) on both rising and falling edges

of T1CLK. Also used in conjunction with T1DIR for

quadrature counting mode.

P0.6/ACH6/PMODE.2

T1DIR I Timer 1 External Direction. External direction (up/down) for

timer 1. Timer 1 increments when T1DIR is high and

decrements when it is low. Also used in conjunction with

T1CLK for quadrature counting mode.

P0.7/ACH7/PMODE .3

TXD1

TXD0

O Transmit Serial Data 0 and 1. In serial I/O modes 1, 2, and

3, TXD0 and 1 are used to transmit serial port data. In mode

0, they are used as the serial clock output.

P1.2

P1.0

V

CC

PWR Digital Sup ply Vo ltag e. Connect each VCC pin to the digital

supply voltage.

—

V

PP

PWR Programming Voltage. Set to 12.5 V when programming the

on-chip OTPROM. Also the timing pin for the “return from

power-down” circuit.

—

Table 7. Signal Descriptions (Continued)

Signal

Name

Type Description

Multiplexed

With

Page 18

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

18

V

REF

PWR Reference Voltage for the A/D Converter. V

REF

is also the

supply voltage to the analog portion of the A/D converter and

the logic used to read Port 0. V

REF

must be connected for the

A/D and port 0 to function.

—

V

SS

GND Digital Circui t Gro und (0 volts). Connect each VSS pin to

ground.

—

WG3

WG2

WG1

O Waveform Generator Phase 1

–3 Positive Outputs.

3-phase output signals used in motion-control applications.

P6.5

P6.3

P6.1

WG3#

WG2#

WG1#

O Waveform Generator Phase 1

–3 Negative Outputs.

Complementary 3-phase output signals used in motioncontrol applications.

P6.4

P6.2

P6.0

WR# O Write. This active-low output indicates that an external write

is occurring. This signal is asserted only during external

memory writes.

P5.2/WRL#

WRH# O Write High. During 16-bit bus cycles, this active-low output

signal is asserted for high-byte writes and word writes to

external memory.

During 8-bit bus cycles, WRH# is asserted for all write

operations.

P5.5/BHE#

WRL# O Write Low. During 16-bit bus cycles, this active-low out put

signal is asserted for low-byte writes and word writes.

During 8-bit bus cycles, WRL# is asserted for all write

operations.

P5.2/WR#

XTAL1 I Clock/Oscillator Input. Input to the on-chip oscillator

inverter and the internal cloc k generator. Also provides the

clock input for the serial I/O baud-rate generator, timers, and

PWM unit. If an external oscillator is used, connect the

external clock input signal to XTAL1 and ensure that the

XTAL1 V

IH

specification is met.

—

XTAL2 O Oscillator Output. Output of the on-chip oscillator inverter.

When using the on-chip oscillator, connect XTAL2 to an

external crystal or resonator. When using an external clock

source, let XTAL2 float.

—

Table 7. Signal Descriptions (Continued)

Signal

Name

Type Description

Multiplexed

With

Page 19

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

19

ELECTRICAL CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS*

Storage Temperature ................................ – 65°C to + 150°C

Ambient Temperature

under Bias.............................................. – 40°C to

+ 85°C

Voltage from V

PP

or EA# to

V

SS

or ANGND (Note 1) ...................... – 0.5 V to + 13.0 V

Voltage with respect to

V

SS

or ANGND (Note 1) ........................ – 0.5 V to + 7.0 V

(This includes V

PP

on ROM and CPU devices.)

Power Dissipation .......................................................... 1.5 W

(based on package heat transfer limitations, not device

power consumption)

OPERATING CONDIT I O NS*

TA (Ambient Temperature Under Bias) .........– 40°C to + 85°C

V

CC

(Digital Supply Voltage) ........ ...... ..... ..... .. 4.50 V to 5.50 V

V

REF

(Analog Supply Voltage) ....................... 4.50 V to 5.50 V

F

OSC

(Oscillator Frequency) (Note 2) ........... 8 MHz to 16 MHz

NOTES:

1. ANGND and V

SS

should be at nominally the same

potential.

2. Testing is performed down to 8 MHz, although

the device is static by design and will typically

operate below 1 Hz.

NOTICE: This data sheet contains preliminary i n formation on new products in production. It is valid for

the devices indicated in the revision history. The

specifications are subject to change without notice.

*WARNING: Stressing the device beyond the “Absolute

Maximum Ratings” may cause permanent damage. These

are stress ratings only. Operation beyond the “Operating

Conditions” is not recommended and extended exposure

beyond the “Operating Condition s” may affect device reliability.

Page 20

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

20

DC CHARACTERISTICS

Table 8. DC Characteristics over Specified Operating Conditions

Symbol Parameter Min Typ (4) M a x Units Test Conditions

V

IL

Input Low Voltage

(standard inputs (1))

– 0.5 0.3 V

CC

V

V

IL

1

Input Low Voltage

(RESET#, ports 3, 4, and

5)

– 0.5 0.8 V

V

IH

Input High Voltage

(standard inputs (1))

0.7 V

CC

VCC + 0.5 V

V

IH

1

Input High Voltage

(RESET#, ports 3, 4, and

5)

0.2 V

CC

+ 1.0 VCC + 0.5 V

V

OL

Output Low Voltage

(RESET#, ports 1, 2, 5,

P6.6, P6.7, and XTAL2)

0.3

0.45

1.5

V

V

V

I

OL

= 200 µA

I

OL

= 3.2 mA

I

OL

= 7.0 mA

V

OL

1

Output Low Voltage (ports

3, 4)

1.0 V I

OL

= 7 mA

V

OL

2

Output Low Voltage

(P6.5:0)

0.45 V I

OL

= 10 mA

V

OH

Output High Voltage

(output pins and I/O

configured as push/pull

outputs)

V

CC

– 0.3

V

CC

– 0.7

V

CC

– 1.5

V

V

V

I

OH

= – 200 µA

I

OH

= – 3.2 mA

I

OH

= – 7.0 mA

V

TH+

– V

TH–

Hysteresis voltage width

on RESET# pin

0.2 V

I

LI

Input Leakage Current

(standard inputs (1))

± 10 µA VSS < VIN < VCC – 0.3V

I

LI

1

Input Leakage Current

(port 0 – A/D inputs)

± 3µAV

SS

< VIN < V

REF

I

IH

Input High Current (NMI) 300 µA VIN = 0.7 VCC

I

IL

Input Low Current (port 2,

except P2.6)

− 70 µA VIN = 0.3 VCC

NOTES:

1. Standard input pins include XTAL1, EA#, and Ports 1 and 2 when configured as inputs.

2. Maximum current that an external device must sink to ensure test mode entry.

3. Violating these specifications during reset may cause the device to enter test modes.

4. Typical values are based on a lim ited number of sam ples and are not guarant eed. Operating conditions

for typical values are room temperature and V

REF

= VCC = 5.5 V.

5. Testing is performed down to 8 M Hz, although the device is static by design and will typically operate

below 1 Hz.

6. All voltages are referenced relative to V

SS

. When used, VSS refers to the device pin.

7. Table 9 lists the total current limits during normal (non-tr ansient conditions). The tot al current listed is the

sum of the pins listed for each specification value.

Page 21

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

21

I

IL

1

Input Low Current (P5.4

and P2.6 during reset) (2)

– 10 mA VIN = 0.8 V

I

IL

2

Input Low Current (ports 3,

4, and 5, except P5.4)

– 300 µA VIN = 0.8 V

I

IL

3

Input Low Current (port 1) – 300 µA VIN = 0.3 V

CC

I

OH

Output High Current (P5.4

and P2.6 during reset) (3)

– 0.2 mA 0.7 V

CC

I

OH

1

Output High Current

(P6.5:0 during reset)

– 6 – 40 µA 0.7 V

CC

I

CC

VCC Supply Current 50 70 mA XTAL1 = 16 MHz

V

CC

= 5.5 V

V

PP

= 5.5 V

V

REF

= 5.5 V

I

REF

A/D Reference Supply

Current

25mA

I

IDLE

Idle Mode Current 15 30 mA

I

PD

Powerdown Mode Current

(4)

550µA

R

RST

Reset Pull-up Resistor 6 65 kΩ

C

S

Pin Capacitance (any pin

to V

SS

)

10 pF F

TEST

= 1.0 MHz

Table 8. DC Characteristics over Specifi ed Operati ng Con ditio ns (Co n tinu ed )

Symbol Parameter Min Typ (4) M a x Units Test Conditions

NOTES:

1. Standard input pins include XTAL1, EA#, and Ports 1 and 2 when configured as inputs.

2. Maximum current that an external device must sink to ensure test mode entry.

3. Violating these specifications during reset may cause the device to enter test modes.

4. Typical values are based on a lim ited number of sam ples and are not guarant eed. Operating conditions

for typical values are room temperature and V

REF

= VCC = 5.5 V.

5. Testing is performed down to 8 M Hz, although the device is static by design and will typically operate

below 1 Hz.

6. All voltages are referenced relative to V

SS

. When used, VSS refers to the device pin.

7. Table 9 lists the total current limits during normal (non-tr ansient conditions). The tot al current listed is the

sum of the pins listed for each specification value.

Page 22

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

22

Figure 6. ICC, I

IDLE

versus Frequency

Table 9. Total Current Limits During Normal (Non -tran sien t) Co n ditio n s

Signal Names Maximu m I

OL

Limits Maxi mu m IOH Limits

Port 1 25 mA – 25 mA

Port 2, P6.6, P6.7 40 mA – 40 mA

Port 3 40 mA – 30 mA

Port 4 40 mA – 30 mA

Port 5 40 mA – 30 mA

P6.5:0 40 mA – 30 mA

A2711-01

Frequency (MHz)

I

CC

(mA)

0410

16

0

10

20

30

40

50

60

70

I

IDLE

Max

I

CC

Max

ICC Typ

I

IDLE

Typ

Page 23

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

23

EXPLANATION OF AC SYMBOLS

Each symbol consists of two pairs of letters pref ixed by “T” (for time). The characters in a pair ind icate a signal

and its condition, respectively. Symbols represent the time between the two signal/condition points. For example,

T

RHDZ

is the time between signal R (RD#) condition H (high) and signal D (Input Data) condition Z (floating). Table

10 defines the signal and condition codes.

AC CHARACTERISTICS (OVER SPECIFIED OPERA TION CONDITIONS )

Table 11 defines the AC timing specifications t hat the external memory system must meet and those that t he

8XC196MH will provide.

Table 10. AC Timing Symbol Defin i tio n s

Signals Conditions

A Address P PROG# H High

B BHE# Q Data Out L Low

D Data In R RD# V Valid

G BUSWIDTH V PVER X No Longer Valid

I T1DIR/AINC# W WR#/WRH#/WRL# Z Floating

K T1CLK X XTAL1

L ALE/ADV#/PALE# Y READY

Table 11. AC Timing Definiti ons (1)

Symbol Parameter Min Max Units Notes

F

OSC

Frequency on XTAL1 8 16 MHz 4

T

OSC

1/F

OSC

62.5 125 ns

The External Memory System Must Meet Th ese Specif icati o ns

T

AVYV

Address Valid to READY Setup 2T

OSC

– 75 ns

T

LLYV

ALE/ADV# Low to READY Setup T

OSC

– 70 ns

T

YLYH

Non READY Time No Upper Limit ns

T

LLYX

READY Hold after ALE/ADV# Low T

OSC

– 15 2T

OSC

– 40 ns 2

T

AVGV

Address Valid to BUSWIDTH Setu p 2T

OSC

– 75 ns

T

LLGV

ALE/ADV# Low to BUSWIDTH Set up T

OSC

– 60 ns

NOTES:

1. Test Conditions: Capacitive load on all pins = 100 pF, rise and fall times = 10 ns, F

OSC

= 16 MHz.

2. Exceeding the maximum specification causes additional wait states.

3. If wait states are used, add 2T

OSC

× n, where n = number of wait states.

4. Testing is performed down to 8 MHz, although the device is static by design and will typically operate

below 1 Hz.

5. Assuming back-to-back bus cycles.

6. 8-bit bus only.

Page 24

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

24

The External Memory System Must Meet These Sp ecifi cati ons (Co n tinu ed)

T

LLGX

BUSWIDTH Hold after ALE/ADV # Low T

OSC

ns

T

LHDV

ALE/ADV# High to Input Data Valid 3T

OSC

– 55 ns

T

AVDV

Address Valid to Input Data Valid 3T

OSC

– 55 ns 3

T

RLDV

RD# Active to Input Data Valid T

OSC

– 30 ns 3

T

RHDZ

End of RD# to Input Data Float T

OSC

ns

T

RXDX

Data Hold after RD# Inactive 0 ns

The 8XC196MH will Meet These Specifications

T

XHLH

XTAL1 Rising Edge to ALE Rising 20 110 ns

T

XHLL

XTAL1 Rising Edge to ALE Falling 20 110 ns

T

LHLH

ALE/ADV# Cycle Time 4T

OSC

ns 3

T

LHLL

ALE/ADV# High Period T

OSC

– 10 T

OSC

+ 10 ns

T

AVLH

Address Valid to ALE/ADV# High T

OSC

– 17 ns

T

AVLL

Address Valid to ALE/ADV# Low T

OSC

– 17 ns

T

LLAX

Address Hold after ALE/ADV# Low T

OSC

– 40 ns

T

LLRL

ALE/ADV# Low to RD# Low T

OSC

– 30 ns

T

RLRH

RD# Low Period T

OSC

– 5 T

OSC

+ 25 ns 3

T

RHLH

RD# High to ALE/ADV# High T

OSC

T

OSC

+ 25 ns 5

T

RLAZ

RD# Low to Address Float 5 ns

T

LLWL

ALE/ADV# Low to WR# Low T

OSC

– 10 ns

T

QVWH

Data Valid before WR# High T

OSC

– 23 ns

T

WLWH

WR# Low Period T

OSC

– 30 ns 3

T

WHQX

Data Hold after WR# High T

OSC

– 25 ns

T

WHLH

WR# High to ALE/ADV# High T

OSC

– 10 T

OSC

+ 15 ns 5

T

WHBX

BHE#, INST Hold after WR# High T

OSC

– 10 ns

T

WHAX

A15:8 Hold after WR# High T

OSC

– 30 ns 6

T

RHBX

BHE#, INST Hold after RD# High T

OSC

– 10 ns

T

RHAX

A15:8 Hold after RD# High T

OSC

– 30 ns 6

Table 11. AC Timing Definiti on s (1) (Continued)

Symbol Parameter Min Max Units Notes

NOTES:

1. Test Conditions: Capacitive load on all pins = 100 pF, rise and fall times = 10 ns, F

OSC

= 16 MHz.

2. Exceeding the maximum specification causes additional wait states.

3. If wait states are used, add 2T

OSC

× n, where n = number of wait states.

4. Testing is performed down to 8 MHz, although the device is static by design and will typically operate

below 1 Hz.

5. Assuming back-to-back bus cycles.

6. 8-bit bus only.

Page 25

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

25

SYSTEM BUS TIMINGS

Figure 7. System Bus Timing Diagram

XTAL1

ALE

RD#

BUS

WR#

BUS

INST

A15:8

(8-bit Bus)

Address Out

Data

Data OutAddress Out

Address Out

T

LHLL

T

OSC

Valid

A2543-01

T

XHLH

T

LHLH

T

LLRL

T

RLRH

T

RHLH

T

AVLL

T

LLAX

T

RLDV

T

RHDZ

T

RLAZ

Address Out

T

AVDV

T

LLWL

T

WLWH

T

WHLH

T

QVWH

T

WHQX

T

RHBX

T

WHBX

T

RHAX

T

WHAX

T

XHLL

T

LHDV

T

RXDX

T

AVLH

Page 26

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

26

READY TIMING (ONE WAIT STATE)

Figure 8. READY Timing Diagram (One Wait State)

A2544-01

T

AVYV

T

LLYX(Max)

Address Out

Data Out

Address Out

Data In

Address

Bus

WR#

Bus

RD#

READY

ALE

XTAL1

T

OSC

T

LHLH

+

2T

OSC

T

CLYX(Min)

T

LLYV

T

LLYX(Min)

T

CLYX(Max)

T

RLRH

+ 2T

OSC

T

RLDV

+ 2T

OSC

T

AVDV

+ 2T

OSC

T

WLWH

+ 2T

OSC

T

QVWH

+ 2T

OSC

T

RLDV

+ 2T

OSC

16 MHz 8 MHz

Page 27

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

27

BUSWIDTH TIMING

Figure 9. BUSWIDTH Timing Diagram

EXTERNAL CLOCK DRIVE

Table 12. External Clock Drive Tim ing

Symbol Parameter Min Max Units

1/T

XLXL

Oscillator Frequency 8 16 MHz

T

XLXL

Oscillator Period (T

OSC

) 62.5 125 ns

T

XHXX

High Time 22 ns

T

XLXX

Low Time 22 ns

T

XLXH

Rise Time 10 ns

T

XHXL

Fall Time 10 ns

A2545-01

Data In

BUSWIDTH

Bus

ALE

XTAL1

T

OSC

T

AVGV

T

LLGV

T

LLGX

Address Out

Page 28

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

28

Figure 10. External Clock Drive Waveforms

Figure 11. External Clock Connecti o ns

T

XHXX

T

XLXX

T

XHXL

T

XLXL

0.7 V

CC

0.8 V 0.8 V

0.7 V

CC

0.7 V

CC

T

XLXH

A2578-01

XTAL1

4.7kΩ*

8XC196 Device

XTAL2

XTAL1

External

Clock Input

Clock Driver

No Connect

V

CC

A0274-01

Note:

*Required if TTL driver is used. Not needed if CMOS driver is used.

Page 29

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

29

Figure 12. External Crystal Connectio ns

Figure 13. AC Testing Input, Output Waveforms

8XC196 Device

XTAL2

XTAL1

Quartz Crystal

C1

C2

A0273-01

V

SS

Note:

Keep oscillator components close to the chip and use

short, direct traces to XTAL1, XTAL2, and V

ss

. When

using crystals, C1=C2≈20pF. When using ceramic

resonators, consult the manufacturer for recommended

oscillator circuitry.

Test Points

2.0 V

0.8 V

AC testing inputs are driven at 3.5 V for a logic "1" and 0.45 V for

a logic "0". Timing measurements are made at 2.0 V for a logic

"1" and 0.8 V for a logic "0".

3.5 V

0.45 V

A2120-02

2.0 V

0.8 V

Page 30

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

30

Figure 14. Float Waveforms

AC CHARACTERISTICS — SERIAL PORT, SHIFT REGISTER MODE

Table 13. Serial Port Timing — Shift Reg ister Mo d e (Mode 0)

Symbol Parameter Min Max Units Notes

T

XLXL

Serial Port Clock Period

(Baud-rate

n

≥ 8002H)

(Baud-rate

n

= 8001H)

6T

OSC

4T

OSC

ns

ns 1, 2

T

XLXH

Serial Port Clock Low Period

(Baud-rate

n

≥ 8002H)

(Baud-rate

n

= 8001H)

4T

OSC

– 50

2T

OSC

– 50

4T

OSC

+ 50

2T

OSC

+ 50

ns

ns 1, 2

T

QVXH

Output Data Setup to Clock High 2T

OSC

– 50 ns

T

XHQX

Output Data Hold after Clock High 2T

OSC

– 50 ns

T

XHQV

Next Output Data Valid after Clock High 2T

OSC

+ 50 ns

T

DVXH

Input Data Setup to Clock High T

OSC

+ 50 ns

T

XHDX

Input Data Hold after Clock High 0 ns

T

XHQZ

Last Clock High to Output Float T

OSC

ns

NOTES:

1.

n

for Baud-raten signifies Serial Port 0 or 1.

2. Maximum Serial Port Mode 0 reception is with Baud-rate

n

≥ 8002H.

V

LOAD

+ 0.1 V

V

LOAD

– 0.1 V

Timing Reference

Points

V

LOAD

V

OH

– 0.1 V

V

OL

+ 0.1 V

For timing purposes, a port pin is no longer floating when a

100 mV change from load voltage occurs and begins to float

when a 100 mV change from the loading V

OH/VOL

level occurs

with I

OL/IOH

≤15 mA.

A2579-01

Page 31

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

31

Figure 15. Serial Port Waveform — Shift Regi ster Mo de (M ode 0)

Table 14. Serial Port Timing — Mode 4

Symbol Parameter Min Max Units

T

XLXL

Serial Port Clock Period (DIR=0) 16T

OSC

131072T

OSC

ns

T

XLXX

Serial Port Clock Low Period (DIR=0/1) (T

XLXL

/2) – 30 ns

T

XHXX

Serial Port Clock High Period (DIR=0/1) (T

XLXL

/2) – 30 ns

T

XLXL

Serial Port Clock Period (DIR=1) 16T

OSC

ns

T

XHXL

Serial Clock Falling Time (DIR=1) 0 20 ns

T

XLXH

Serial Clock Rising Time (DIR=1) 0 20 ns

T

XLQV

Clock Low to Output Data Setup 7.5T

OSC

– 50 ns

T

XLQX

Output Data Hold after Clock Low 0 ns

T

XHQX

Last Output Data Hold after Clock High (DIR=1) 13.7T

OSC

ns

T

DVXX

Input Data Setup to Clock Low Invalid 0 ns

T

XHDH

Input Data Hold after Clock High 6T

OSC

ns

(In)

A2080-01

Valid

Valid

Valid Valid Valid Valid

Valid

Valid

RXD

n

(Out)

TXD

n

01 2

3

4

5

6

7

T

QVXH

T

XLXL

T

DVXH

T

XHQV

T

XHQZ

T

XHDX

T

XHQX

T

XLXH

RXD

n

Page 32

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

32

Figure 16. Serial Port Waveform — Mode 4

Figure 17. Serial Port Waveform — Clock Drive (DIR = 1)

A2550-01

TXD

n

RXD

n

SCKn#

T

XLXL

T

DVXX

T

XHDH

T

XLXX

T

XHXX

T

XHQX

T

XLQX

T

XLQV

T

XHXX

T

XLXX

T

XHXL

T

XLXL

V

IH

V

IL

SCKn#

A2582-01

T

XLXH

Page 33

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

33

BAUD-RATE CLOCK DRIVE TABLE

Figure 18. Baud-Rate Clock Drive Waveforms

Table 15. Baud Rate Clock Drive

Symbol Parameter Min Max Units

T

XLXL

Baud Rate Clock Period 4T

OSC

ns

T

XHXX

Baud Rate Clock High Time 2T

OSC

– 30 ns

T

XLXX

Baud Rate Clock Low Time 2T

OSC

– 30 ns

T

XLXH

Baud Rate Clock Rise Time 20 ns

T

XHXL

Baud Rate Clock Fall Time 20 ns

A2551-01

T

XHXX

T

XLXX

T

XHXL

T

XLXL

V

IH

T

XLXH

V

IL

BCLK

n

Page 34

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

34

A/D SAMPLE AND CONVERSION TIMES

Two parameters, sample time and conversion time,

control the time required for an A/D conversion. The

sample time is the length of time that the analog input

voltage is actually connected to the sample capacitor.

If this time is too short, the sample capacitor will not

charge completely. If the sample time is t oo long, the

input voltage may change and cause conversion

errors. The conversion time is the length of time

required to convert the analog input voltage stored on

the sample capacitor to a digital value. The

conversion time must be long enough for the

comparator and circuitry to settle and resolve the

voltage. Excessively long conversion t imes allow the

sample capacitor to discharge, degrading accuracy.

The AD_TIME register pr ograms the A/D sample an d

conversion times. Use the T

SAM

and T

CONV

specifications in Tables 16 and 18 to determine appropriate

values for SAM and CONV; otherwise, erroneous

conversion results may occur.

Use the following formulas to determ ine the S AM an d

CONV values:

where:

SAM = 1 to 7

CONV = 2 to 31

T

SAM

is the sample time, in µsec

(Tables 16 and 18)

T

CONV

is the conversion time, in µsec

(Tables 16 and 18)

F

OSC

is the XTAL1 frequency, in MHz

B is the number of bits to be converted (8 or 10)

When the SAM and CONV values are known, write

them to the AD_TIME register. Do not write to this

register while a conversion is in progres s; the results

are unpredictable.

SAM

T

SAMFOSC

2–×

8

----------------------------------------=

CONV

T

CONVFOSC

× 3–

2B×

-------------------------------------------

1–=

Page 35

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

35

AC CHARACTERISTICS — A/D CONVERTER

Table 16. 10-bit A/D Operating Conditions (1)

Symbol Description Min Max Units Notes

T

A

Ambient Temperature – 40 + 85 °C

V

CC

Digital Supply Voltage 4.5 0 5.50 V

V

REF

Analog Supply Voltage 4.50 5.50 V 2

T

SAM

Sample Time 1.0 µs3

T

CONV

Conversion Time 10.0 20.0 µs3

F

OSC

Oscillator Frequency 8 16 MHz

NOTES:

1. ANGND and V

SS

should nominally be at the same potential.

2. V

REF

must not exceed VCC by more than + 0.5 V because V

REF

supplies both the res istor ladder and the

analog portion of the converter and input port pins.

3. Program the AD_TIME register to meet the T

SAM

and T

CONV

specifications.

Table 17. 10-bit Mode A/D Characteristics Over Specified Operating Conditions (1)

Parameter Typical (3) Min Max Units (2) Notes

Resolution 1024

10

1024

10

Levels

Bits

Absolute Error 0 ± 3LSBs

Full-scale Error 0.25 ± 0.5 LSBs

Zero Offset Error 0. 2 5

± 0.5 LSBs

Nonlinearity 1.0 ± 2.0 ± 3LSBs

Differential Nonlinearity – 0.75 + 0.75 LSBs

Channel-to-channel Matching ± 0.1 0

±

1

LSBs

Repeatability ± 0.25 0 LSBs

NOTES:

1. Testing is performed with V

REF

= 5.12 V and F

OSC

= 16 MHz.

2. An

LSB

, as used here, has a value of approximately 5 mV.

3. Typical values are based on a limited number of samples and are not guaranteed. Operating conditions

for typical values are room temperature and V

REF

= VCC = 5.5 V.

4. DC to 100 KHz.

5. Multiplexer break-before-make guaranteed.

6. Resistance from device pin, through internal multiplexer, to sample capacito r.

7. These values may be exceeded if the pin current is limited to ± 2mA.

8. Applying voltage beyond these specifications will degrade the accuracy of other channels being con-

verted.

9. All conversions were performed with processor in idle mode.

Page 36

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

36

Temperature Coeff icients:

Offset

Full-scale

Differential Nonlinearity

0.009

0.009

0.009

LSB/C

LSB/C

LSB/C

Off-isolation – 60 dB 4, 5

Feedthrough – 60 dB 4

V

CC

Power Supply Rejection – 60 dB 6

Input Series Resistance 750 1.2K

Ω

4

Voltage on Analog Input Pin ANGND – 0.5 V

REF

+ 0.5 V 7, 8

Sampling Capacitor 3 pF

DC Input Leakage ± 1.0 0 ± 3

µA

Table 18. 8-bit A/D Operating Condi tion s (1)

Symbol Description Min Max Units Notes

T

A

Ambient Temperature – 40 + 85 °C

v

CC

Digital Supply Voltage 4.50 5.50 V

v

REF

Analog Supply Voltage 4.50 5.50 V 2

T

SAM

Sample Time 1.0 µs3

T

CONV

Conversion Time 7.0 20.0 µs3

F

OSC

Oscillator Frequency 8 16 MHz

NOTES:

1. ANGND and V

SS

should nominally be at the same potential.

2. V

REF

must not exceed VCC by more than + 0.5 V because V

REF

supplies both the resistor ladder and the

analog portion of the converter and input port pins.

3. Program the AD_TIME register to meet the T

SAM

and T

CONV

specifications.

Table 17. 10-bit Mode A/D Characteristics Over Speci fied O peratin g Condi tion s (1) (Cont inu ed)

Parameter Typical (3) Min Max Units (2) Notes

NOTES:

1. Testing is performed with V

REF

= 5.12 V and F

OSC

= 16 MHz.

2. An

LSB

, as used here, has a value of approximately 5 mV.

3. Typical values are based on a limited number of samples and are not guaranteed. Operating conditions

for typical values are room temperature and V

REF

= VCC = 5.5 V.

4. DC to 100 KHz.

5. Multiplexer break-before-make guaranteed.

6. Resistance from device pin, through internal multiplexer, to sample capacito r.

7. These values may be exceeded if the pin current is limited to ± 2mA.

8. Applying voltage beyond these specifications will degrade the accuracy of other channels being con-

verted.

9. All conversions were performed with processor in idle mode.

Page 37

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

37

Table 19. 8-bit Mode A/D Characteristics Over Specified Operating Conditions (1)

Parameter Typical (3) Min Max Units (2) Notes

Resolution 256

8

256

8

Levels

Bits

Absolute Error 0 ± 1LSBs

Full-scale Error

± 0.5 LSBs

Zero Offset Error ± 0.5 LSBs

Nonlinearity 0 ± 1LSBs

Differential Nonlinearity – 0.5 + 0.5 LSBs

Channel-to-channel Matching 0

±

1

LSBs

Repeatability ± 0.25 0 LSBs

Temperature Coeff icients:

Offset

Full-scale

Differential Nonlinearity

0.003

0.003

0.003

LSB/

°C

LSB/

°C

LSB/

°C

Off Isolation – 60 dB 4, 5

Feedthrough – 60 dB 4

V

CC

Power Supply Rejection – 60 dB 4

Input Series Resistance 750 1.2K Ω 6

Voltage on Analog Input Pin ANGND – 0.5 V

REF

+ 0.5 V 7, 8

Sampling Capacitor 3 pF

DC Input Leakage ± 10± 3

µA

NOTES:

1. Testing is performed with V

REF

= 5.12 V and F

OSC

= 16 MHz.

2. An

LSB

, as used here, has a value of approximately 20 mV.

3. Typical values are based on a limited number of samples and are not guaranteed. Operating conditions

for typical values are room temperature and V

REF

= VCC = 5.5 V.

4. DC to 100 KHz.

5. Multiplexer break-before-make guaranteed.

6. Resistance from device pin, through internal multiplexer, to sample capacito r.

7. These values may be exceeded if the pin current is limited to ± 2mA.

8. Applying voltage beyond these specifications will degrade the accuracy of other channels being con-

verted.

9. All conversions were performed with processor in idle mode.

Page 38

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

38

OTPROM SPECIFICATIONS

Table 20. Programming Operating Conditions

Symbol Description Min Max Units Notes

T

A

Ambient Temperature 20 30 °C

v

CC

Supply Voltage During Programming 4.50 5.50 V 3

v

REF

Reference Supply Voltage During

Programming

4.50 5.50 V 3

V

PP

Programming Voltage 12.25 12.75 V 2

V

EA

EA Pin Voltage 12.25 12.75 V 2

F

OSC

Oscillator Frequency During Auto and

Slave Mode Programming

Oscillator Frequency During Run-Time

Programming

6

6

8

12

MHz

MHz

NOTES:

1. V

CC

and V

REF

should be at nominally the same voltage during programming.

2. If V

PP

and VEA exceed the maximum specification, the device may be damaged.

3. V

SS

and ANGND should be at nominally the same potential (0 volts).

4. Load capacitance during auto and slave mode programming = 150 pF.

Table 21. AC OTPROM Programming Characteristics

Symbol Description Min Max Units

T

AVLL

Address Setup Time 0 T

OSC

T

LLAX

Address Hold Time 100 T

OSC

T

DVPL

Data Setup Time 0 T

OSC

T

PLDX

Data Hold Time 400 T

OSC

T

LLLH

PALE# Pulse Width 50 T

OSC

T

PLPH

PROG# Pulse Width (1) 50 T

OSC

T

PHLL

PROG# High to Next PALE# Low 220 T

OSC

T

PHDX

Word Dump Hold Time 50 T

OSC

T

PHPL

PROG# High to Next PROG# Low 220 T

OSC

T

LHPL

PALE# High to PROG# Low 220 T

OSC

T

PLDV

PROG# Low to Word Dump Valid 50 T

OSC

T

SHLL

RESET# High to First PALE# Low 1100 T

OSC

T

PHIL

PROG# High to AINC# Low 0 T

OSC

T

ILIH

AINC# Pulse Width 240 T

OSC

NOTE:

1. This specification is for Word Dump M ode. For programm ing pulses, use t he Modified Quick P ulse Algo-

rithm explained in the User’s Manual.

Page 39

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

39

OTPROM PROGRAMMING WAVEFORMS

Figure 19. Slave Programming Mo de Data Pro gram Mo de w ith Sing le Prog ram Pu lse

T

ILVH

PVER Hold after AINC# Low 50 T

OSC

T

ILPL

AINC# Low to PROG# Low 170 T

OSC

T

PHVL

PROG# High to PVER Valid 220 T

OSC

Table 22. DC OTPROM Programming Characteristics

Symbol Parameter Min Max Units

I

PP

VPP Supply Current (when

programming)

100 mA

NOTE: Do not apply V

PP

until VCC is stable and within specifications and the os cillator/clock has stabiliized.

Otherwise, the device may be damaged.

Table 21. AC OTPROM Programming Characteristics (Co n tinued )

Symbol Description M in Max Units

NOTE:

1. This specification is for Word Dump M ode. For programm ing pulses, use t he Modified Quick P ulse Algo-

rithm explained in the User’s Manual.

A2549-01

Data

PROG#

PALE#

PORTS 3/4

RESET#

Address/Command

PVER

Address/Command

T

PHVL

T

SHLL

T

AVLL

T

LLAX

T

LLLH

T

LHPL

T

DVPLTPLDX

T

PLPH

T

PHLL

Page 40

8XC196MH INDUSTRIAL MOTO R CONTRO L CHMO S MICRO CO NTR OLL ER

®

40

Figure 20. Slave Programming Mode i n Word Dum p with Aut oin cremen t Timin g

SLAVE PROGRAMMING MODE IN WORD DUMP WITH AUTOINCREMENT

Figure 21. Slave Programming Mode in Data Program with Repeated Program Pu lse an d Autoincremen t

A2546-01

Ver Bits/Word Dump

PROG#

PALE#

PORTS 3/4

RESET#

T

ILPL

Address/Command

AINC#

Ver Bits/Word Dump

T

PLDV

T

PHDX

T

PLDV

T

PHDX

Address

Address + 2

T

PHPL

T

SHLL

Note: P3.0 must be low ("0")

A2547-01

Data

PROG#

PALE#

PORTS 3/4

RESET#

Address/Command

PVER

Address

Address + 2

Data

Address

Data

AINC#

T

ILVH

T

PHIL

T

ILIH

Valid for

PN

Valid for P1

T

ILPL

PN

T

PHPL

P1

Page 41

8XC196MH INDUSTRIAL MOTOR CONT ROL CHM OS MICRO CO NTR OLL ER

®

41

8XC196MC/MD TO 8XC196MH DESIGN

CONSIDERATIONS

The 8XC196MH is not pin compatible with the

8XC196MC or the 8XC196MD. Be aware that signal

multiplexing sometimes differs between the

8XC196MH and the 8XC196MC/MD. For example,

P2.7 is multiplexed with COMP3 on the

8XC196MC/MD and with SCLK1# and BCLK1 on the

8XC196MH.

DATA SHEET REVISION HISTORY

This is the initial publication of this data sheet

(272543-001). Data sheets are changed as new

device information becomes available. Verify with

your local Intel sales office that you have the latest

version before finalizing a design or ordering devices.

Loading...

Loading...