Page 1

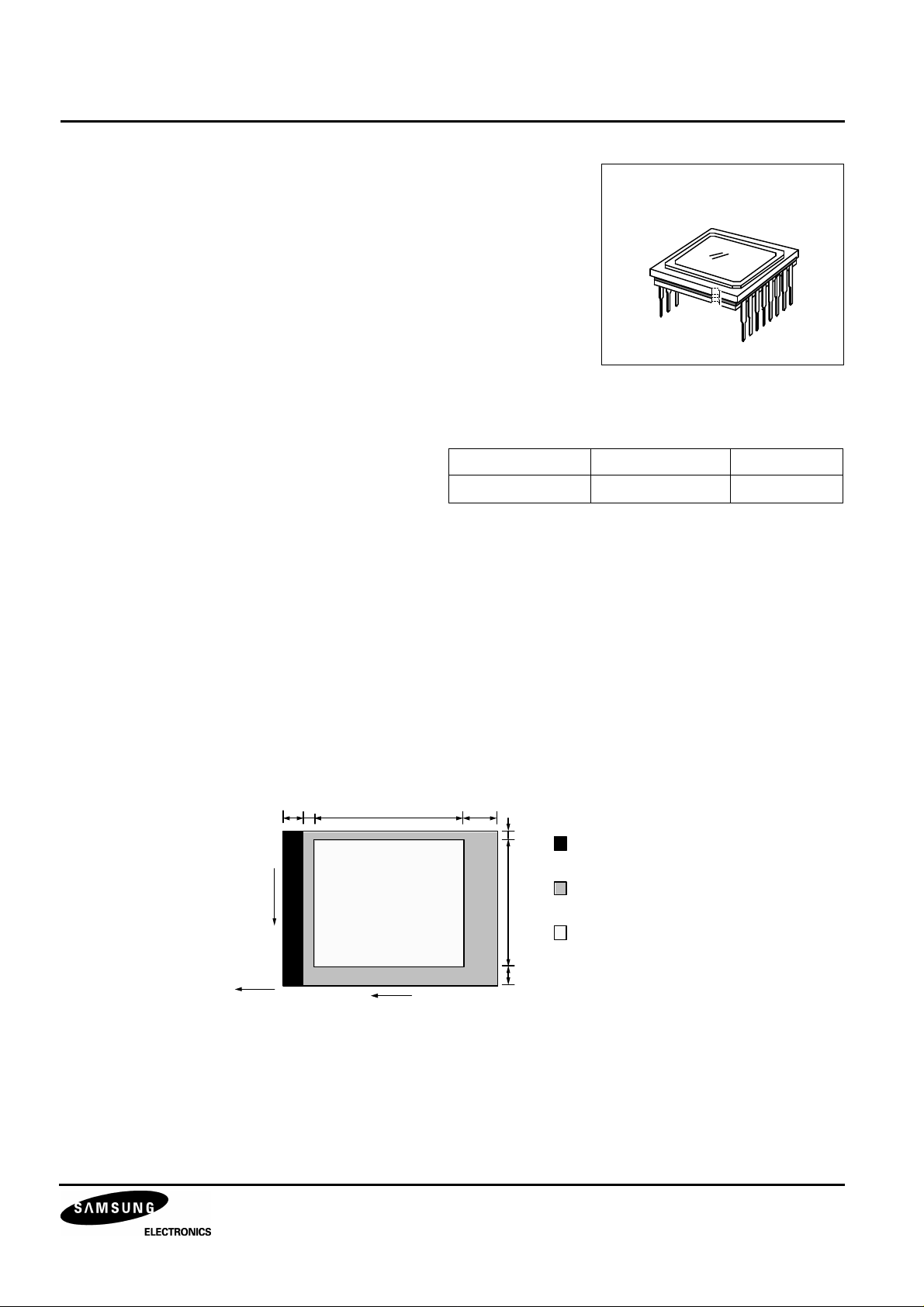

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

ORDERING INFORMATION

H-CCD

INTRODUCTION

The S5F329PW02 is an interline transfer CCD area

image sensor developed for CCIR 1/3 inch video

cameras. It can be used for door phones, surveillance

cameras, object detection and pattern recognition

FEATURES

• High Sensitivity

• Optical Size: 1/3 inch Format

• Horizontal Register: 5V Drive

• 16pin Plastic DIP Package

• Field Integration Read Out System

• No DC Bias on Reset Gate

STRUCTURE

16Pin PLASTIC-DIP

Device Package Operating

S5F329PW02-DAB0 16Pin PLASTIC-DIP

-10 °C −+55 °C

• Number of Total Pixels: 537(H) × 597(V)

• Number of Effective Pixels: 500(H) × 582(V)

• Chip Size: 6.00mm(H) × 5.10mm(V)

• Unit Pixel Size: 9.80 µm(H) × 6.30 µm(V)

• Optical Blacks & Dummies: Refer to Figure Below

Vertical 1 Line (Even Field Only)

16 7 500 30

1 582 14

V-CCD

OUTPUT

Effective

Imagi ng

Area

Du mmy Pixel s

Optical Black Pixels

E ffective Pixels

1

Page 2

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

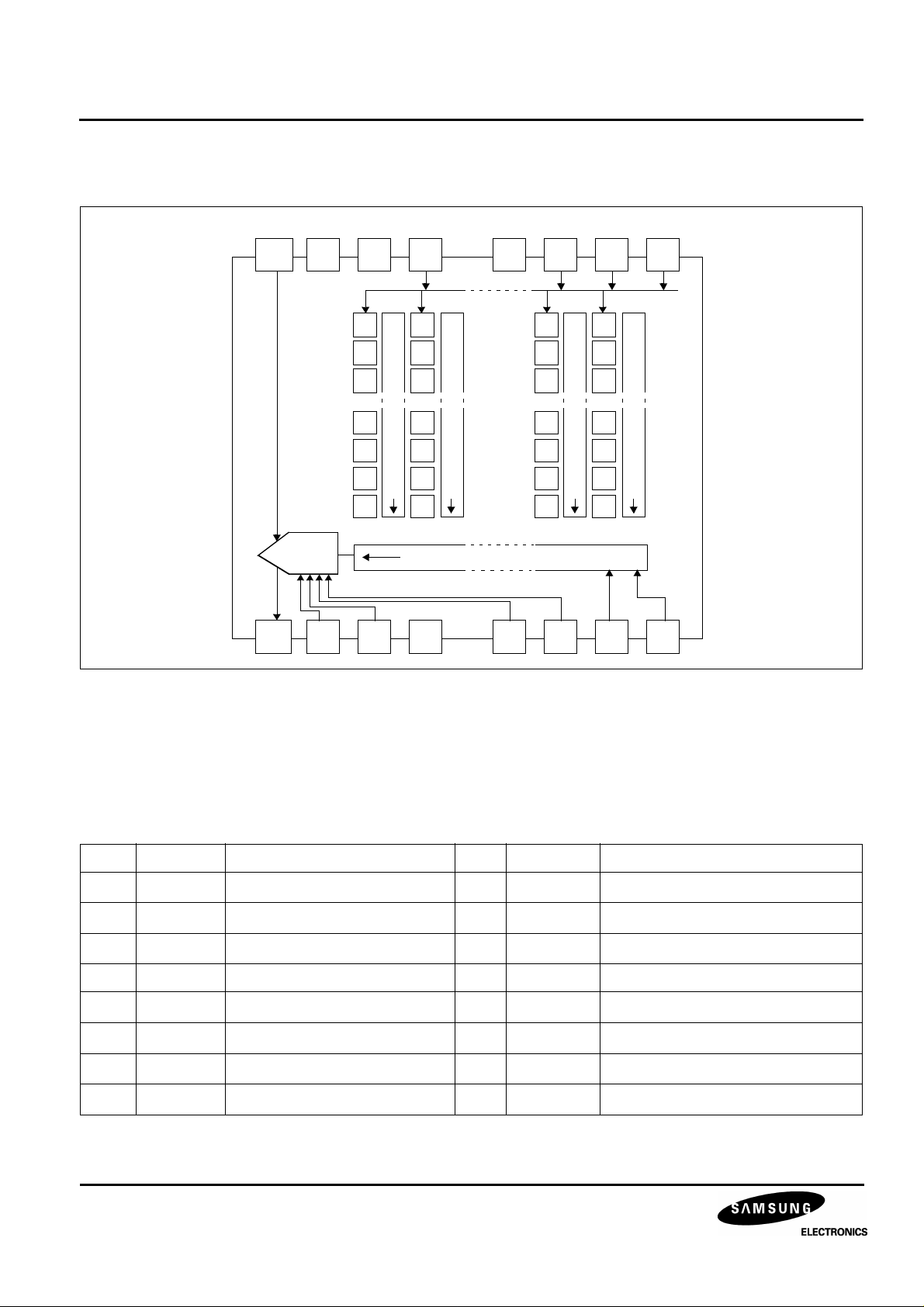

BLOCK DIAGRAM

(Top View)

8

V

DD

9 10 11 12 13 14 15 16

V

OUT

7 6 5 4 3 2 1

V

GND

V

GG

Φ

L

V

SS

V1

Vertical Shift Register CCD

Vertical Shift Register CCD

Horizontal Shift Register CCD

GND

SUB

VRD

Φ

Φ

V2

RG

Φ

V3

Vertical Shift Register CCD

Φ

H1

Vertical Shift Register CCD

Figure 1. Block Diagram

Φ

Φ

V4

H2

PIN DESCRIPTION

Table 1. Pin Description

Pin Symbol Description Pin Symbol Description

1

2

3

Φ

Φ

Φ

V4

V3

V2

Vertical CCD transfer clock 4 9

Vertical CCD transfer clock 3 10

Vertical CCD transfer clock 2 11

4 SUB Substrate voltage 12 GND Ground

5

6

Φ

V1

V

L

Vertical CCD transfer clock 1 13 VRD Reset drain voltage

Protection bias voltage 14

7 GND Ground 15

8

2

V

DD

Output AMP drain voltage 16

V

V

V

Φ

Φ

Φ

OUT

GG

SS

RG

H1

H2

Signal output

Output AMP gate voltage

Output AMP source voltage

Charge reset clock

Horizontal CCD transfer clock 1

Horizontal CCD transfer clock 2

Page 3

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

ABSOLUTE MAXIMUM RATINGS

(NOTE)

Table 2. Absolute Maximum Ratings

Characteristics Symbols Min. Max. Unit

Substrate voltage SUB - GND -0.3 55 V

Supply voltage

VDD, V

OUT, VOUT

Vertical clock input voltage ΦV1, ΦV2, ΦV3, Φ

ΦV1, ΦV2, ΦV3, Φ

Horizontal clock input voltage

Voltage difference between vertical and

horizontal clock input pins

ΦH1, ΦH2 - GND

ΦV1, ΦV2, ΦV3, Φ

ΦH1, Φ

H2

ΦH1, ΦH2 - Φ

Output clock input voltage

Protection circuit bias voltage

Operating temperature

Φ

RG, ΦGG

VL - SUB

T

OPR

- GND

V4

- GND

- GND

V4

- V

V4

V4

-0.3 17 V

-10 20 V

L

-0.3 30 V

-0.3 17 V

-0.3 15 V

-0.3 17 V

-17 17 V

-0.3 15 V

-65 0.3 V

-10 55 °C

Storage temperature

NOTE: The device can be destroyed, if the applied voltage or temperature is higher than the absolute maximum rating voltage

or temperature.

T

STG

-30 80 °C

3

Page 4

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

DC CHARACTERISTICS

Table 3. DC Characteristics

Item Symbol Min. Typ. Max. Unit Remark

Output amp drain voltage

Output amp gate voltage

Output amp source voltage

V

DD

V

GG

V

SS

14.55 15.0 15.45 V

1.75 2.0 2.25 V

Ground through 680Ω V ±5%

Substrate voltage adjustment range SUB 7.0 14.5 V

Fluctuation range after substrate

voltage adjusted

Protection circuit bias voltage

Output stage drain current

∆V

V

I

SUB

L

DD

-3 3 %

V

voltage of the vertical clock waveform

VL

2.5 mA

CLOCK VOLTAGE CONDITIONS

Table 4. Clock Voltage Conditions

Item Symbol Min. Typ. Max. Unit Remark

Read-out clock voltage

Vertical transfer clock voltage

Horizontal transfer clock voltage

Charge reset clock voltage

Substrate clock voltage

V

VT

V

~ V

VH1

V

~ V

VL1

V

ΦH

V

HL

V

ΦRG

V

RGLH - VRGLL

V

ΦSUB

VH4

VL4

14.55 15.0 15.45 V High level

-0.05 0.0 0.05 V

-9.5 -9.0 -8.5 V

VVH = (V

VVL = (V

VH1

VL3

+ V

+ V

4.75 5.0 5.25 V High

-0.05 0.0 0.05 V Low

4.75 5.0 5.25 V High

0.8 V Low

20.0 23.0 25.0 V Shutter

VH2

VL4

)/2

)/2

4

Page 5

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

V

=

V

-0.3V

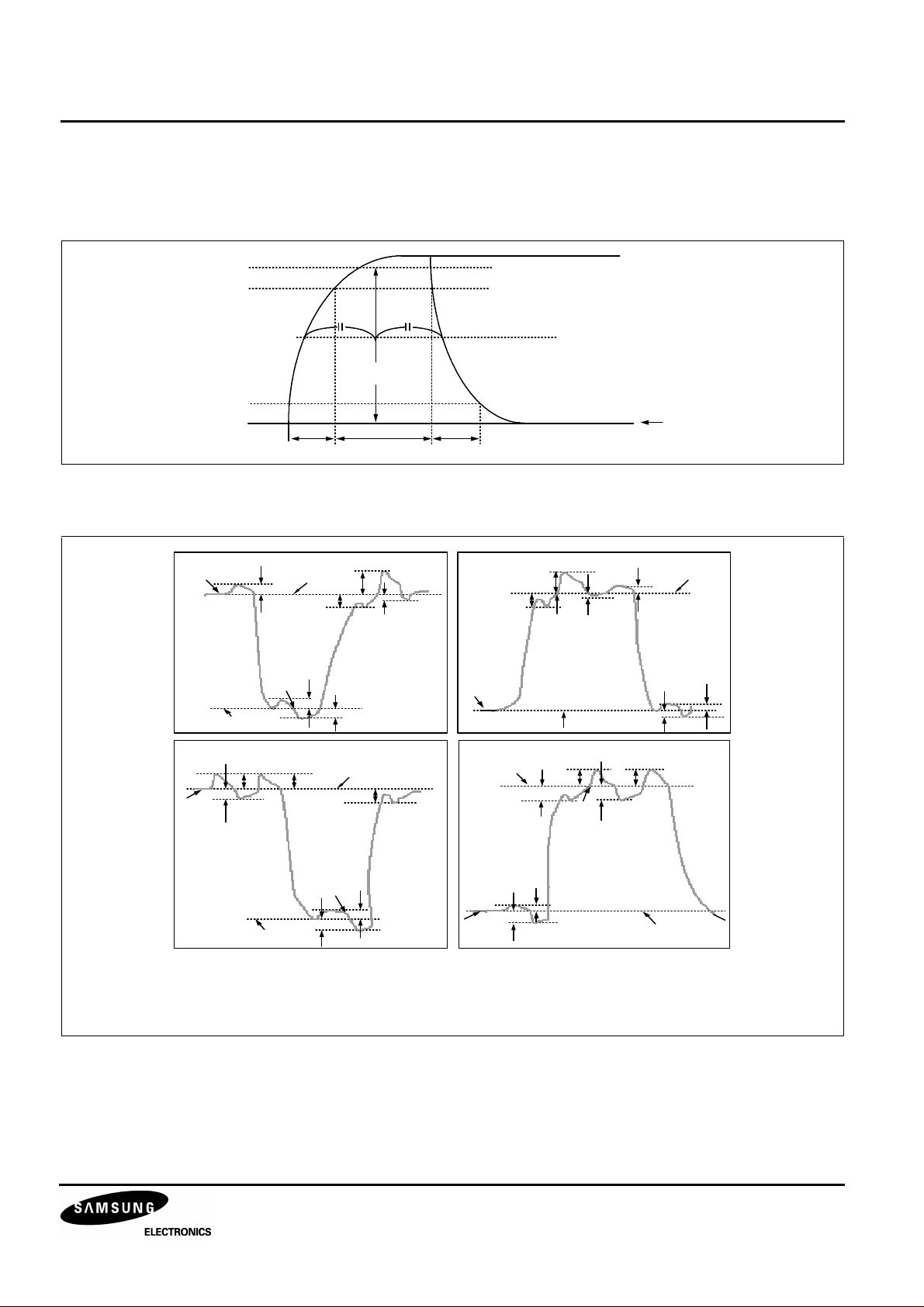

DRIVE CLOCK WAVEFORM CONDITIONS

Read Out Clock Waveform

100%

90%

V

VH1,VVH3

10%

0%

Vertical Transfer Clock Waveform

tr twh tf

0V

¥Õ

V V H 1

¥Õ

V VH2

V 1

V 2

V V H H

V V L 1

V VL

V V H H V VHH

V

VHL

V

VL

V

VH

V V H H

V V H L

V

VL H

V

V

V

V VL H

V VL 2

V VL L

VVH= (V

VV L = (V V L 3 + VV L 4)/ 2

V¥ÕV= V

¥Õ

V 3

V

V H L

V V HL

V VHH

V V H L

V

VH3

V VL 3

VL L

¥Õ

V 4

VH

VHL

V

V

V VL

VH

V VH H

VHL

V V H 4

V

VH H

V

VH

V VL H

V

VL L

V

VH H

V

VHL

V VL H

V

VL L

V

VH 1

+ V

VH 2

VL 4

)/2

V

VH H

= VVH+ 0.3V

V

VL

VVH L = VV H - 0. 3 V

VH n

- V

VL n (n = 1~4)

V

= V

V L

V L

+ 0.3V

VL H

VL L

5

Page 6

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

V

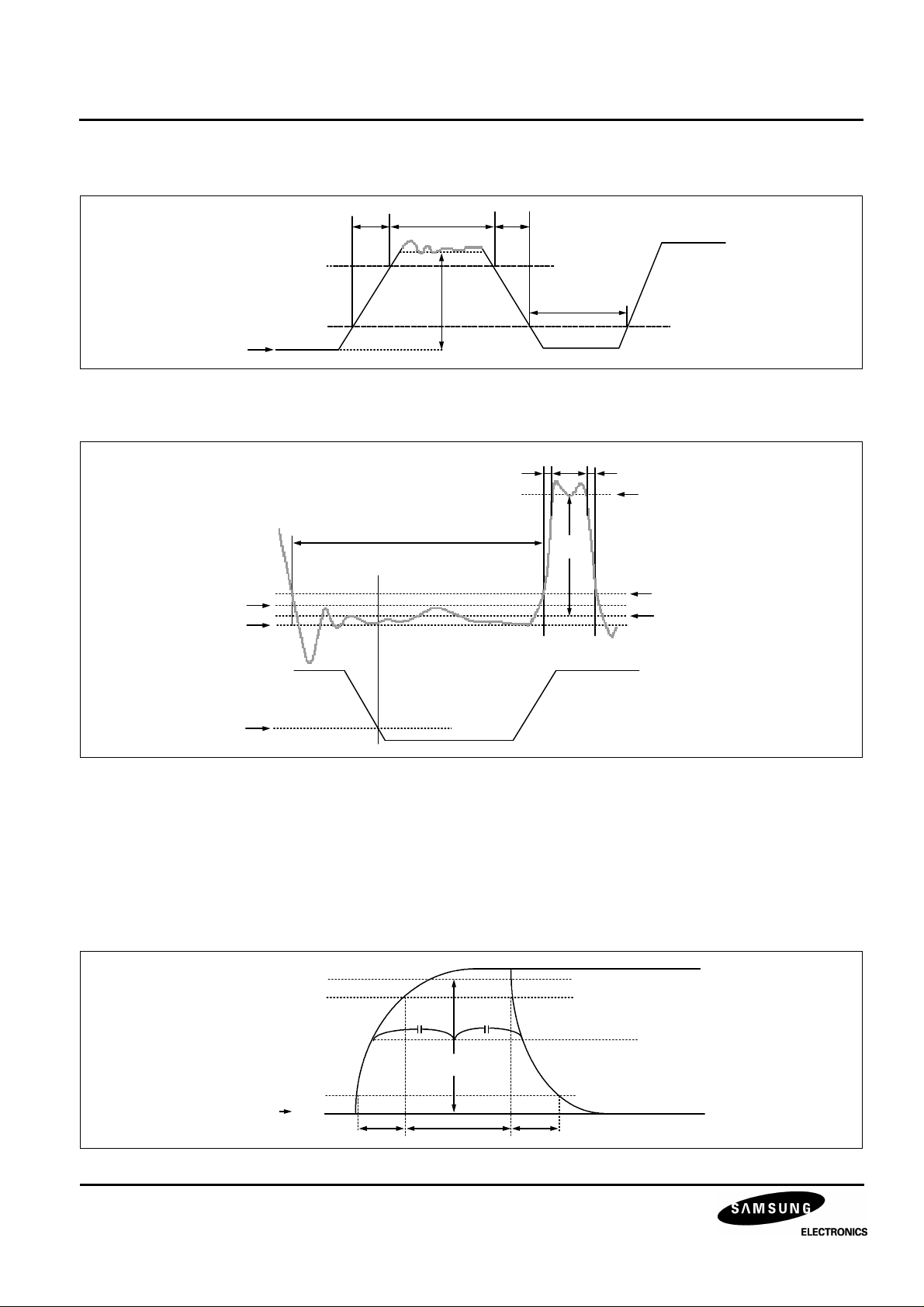

Horizontal Transfer Clock Waveform Diagram

90%

10%

HL

Reset Gate Clock Waveform Diagram

RG waveform

V

RGLH

V

RGLL

tr twh

twl

Point A

V¥Õ

tf

H

twl

twh tftr

V

RGH

V

¥Õ

RG

V

+ 0.5V

RGL

V

RGL

¥Õ

H1 waveform

10%

V

is the maximum value and V

RGLH

in the diagram about to RG rise

V

RGL

= (V

RGLH

+ V

RGLL

)/2, V

Substrate Clock Waveform

V

SU B

FRG

100%

90%

10%

0%

is the minimum value of the coupling waveform in the period from Point A

RGLL

= V

RGH

- V

RGL

¥Õ

V

SU B

twhtr tf

6

Page 7

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

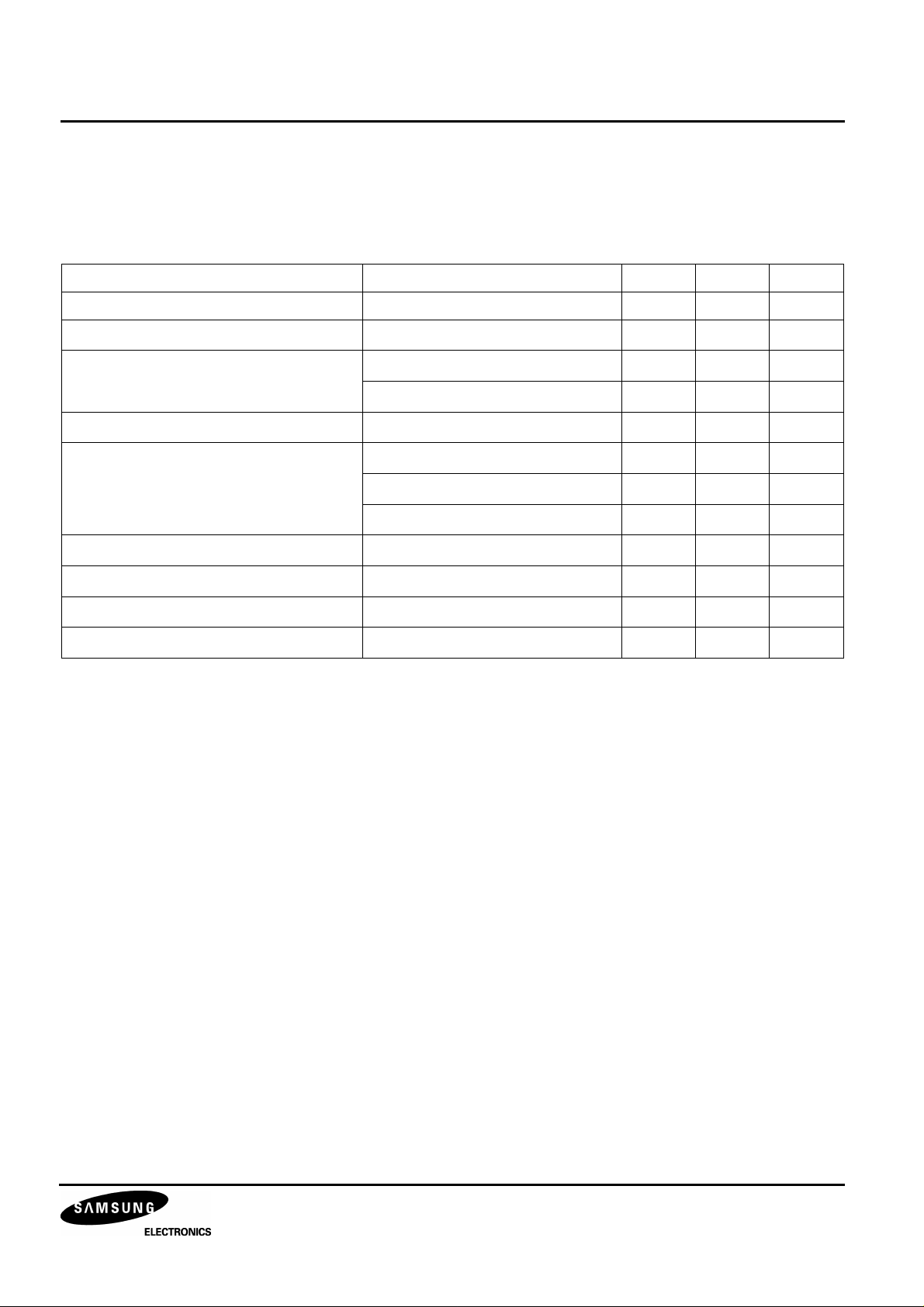

CLOCK EQUIVALENT CIRCUIT CONSTANT

Table 5. Clock Equivalent Circuit Constant

Item Symbol

Read-out clock

Vertical clock

Horizontal clock

Reset clock

Substrate clock

Φ

VH

ΦV1, Φ

ΦV3, Φ

Φ

H1

Φ

H2

Φ

RG

Φ

SUB

twh twl tr tf

Min. Typ. Max. Min. Typ. Max. Min. Typ. Max. Min. Typ. Max.

2.5 0.5 0.5 µs

V2

V4

15 250 ns

37 41 38 42 12 15 10 15 ns

37 41 38 42 12 15 10 15 ns

11 15 75 79 6.5 4.5 ns

1.5 2.0 0.5 0.5 µs

Unit

7

Page 8

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

V

3¥ÕV

4

EQUIVALENT CIRCUIT PARAMETERS

Table 6. Equivalent Circuit Parameters

Item Symbol Typ. Unit Remark

Capacitance between vertical transfer clock and GND C

Capacitance between vertical transfer clocks C

C

Capacitance between horizontal transfer clock and GND

Capacitance between horizontal transfer clocks

Capacitance between reset gate clock and GND

Capacitance between substrate clock and GND

Vertical transfer clock serial resistor

R

Vertical transfer clock ground resistor

Horizontal transfer clock serial resistor

Reset gate clock serial resistor

ΦV1

C

ΦV2

ΦV12

ΦV23

C

ΦH1

ΦV1

R

ΦH1

C

C

C

C

C

R

R

, C

, C

, C

, C

ΦV13

ΦV24

, C

ΦH12

ΦRS

ΦSUB

~ R

GND

, R

ΦRS

ΦV3

ΦV4

ΦV34

ΦV41

ΦH2

ΦV4

ΦH2

1,300 pF

1,300 pF

600 pF

230 pF

120 pF

90 pF

38 pF

38 pF

10 pF

1120 pF

40 Ω

15 Ω

10 Ω

100 Ω

C¥Õ

R

¥Õ

V1

¥Õ

R

V1

C

V41

C

C¥Õ

¥Õ

V4

¥Õ

C

V12

¥Õ

V1

¥Õ

V24

V4

C¥Õ

V34

R

C

C

GND

¥Õ

C¥Õ

¥Õ

V13

V2

V3

¥Õ

V2

R

C¥Õ

R

¥Õ

V2

V23

¥Õ

V3

¥Õ

H1

¥Õ

R

H1

Φ

RS

C¥Õ

¥Õ

C

H12

H1

R

RS

Φ

R

C¥Õ

C

¥Õ

H2

¥Õ

H2

H2

RS

Φ

¥Õ

8

Page 9

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

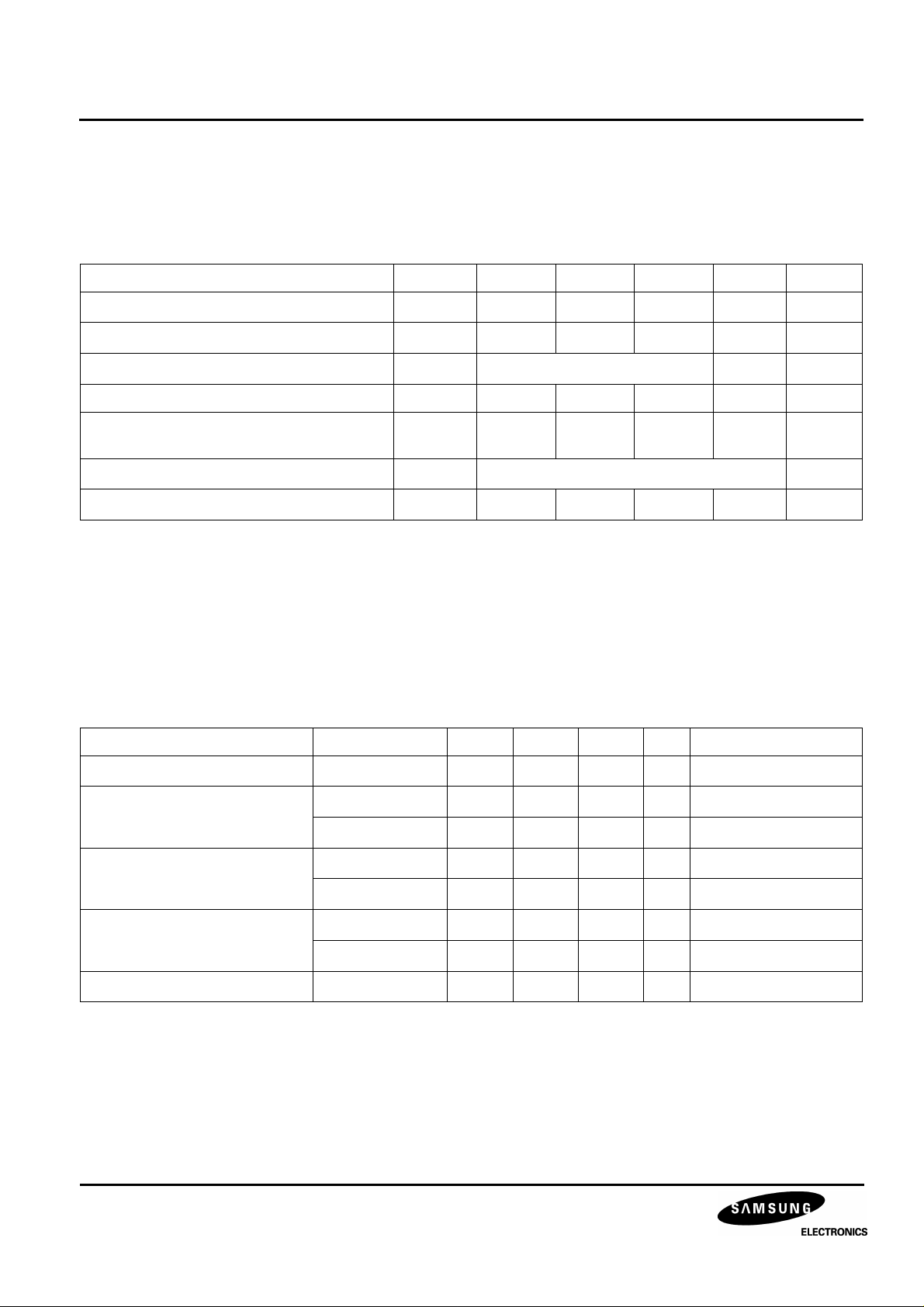

OPERATING CHARACTERISTICS

Device Temperature = 25 °C

Table 7. Operating Characteristics

Item Symbol Min. Typ. Max. Unit Remark

Sensitivity S 55 65 mV/lux 1

Saturation signal

Y

SAT

600 mV 2

Smear SM 0.005 0.012 % 3

Blooming margin BM 1,000 times 4

Uniformity U 20 % 5

Dark signal

Dark shading

(NOTE)

(NOTE)

Image lag

Flicker Y

NOTE: Test Temperature = 55 °C

D 2 mV 6

∆D 2 mV 7

Y

LAG

F

Y

0.5 % 8

2 % 9

TEST CONDITION

1. Use a light source with color temperature of 3,200K hallogen lamp and CM-500S for IR cut filter.

The light source is adjusted in accordance with the average value of Y signals indicated in each item.

2. Through the following tests the substrate voltage should be set to the value while the device condition

should be kept within the range of the bias and clock conditions.

9

Page 10

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

TEST METHODS

1. Measure the light intensities (L) when the averaged illuminance output value (Y) is the standard illuminance

output value, 150mV (YA) and when half of 150mV (1/2 YA).

1

Y

---YA–

A

-----------------------------=

L

–

Y

A

).

Y

SM

-----------

Y

A

2

L

1

---

Y

A

2

1

1

----------×

-------× 100% ()×=

500

10

S

2. Adjust the light intensity to 15 times of the value with which Y is YA, then measure the averaged illuminance

output value (Y = Y

SAT

3. Adjust the light intensity to 500 times of the value with which Y is YA, then remove the read-out clock and drain

the signal in photosensors by the electronic shutter operation in all the respective horizontal blanking times with

the other clocks unchanged. Measure the maximum illuminance output value (YSM).

SM

4. Adjust the light intensity to 1,000 times of the value with which Y is YA, then inspect whether there is blooming

phenomenon or not.

5. Measure the maximum and minimum illuminance output value (Y

MAX

, Y

) when the light intensity is adjusted

MIN

to make Y to be YA.

Y

–

MAXYMIN

U

------------------------------------100%()×=

Y

A

6. Measure YD with the horizontal idling time transfer level as reference, when the device ambient temperature is

55 °C and all of the light sources are shielded.

7. Follow test method 6, measure the maximum (D

∆DD

–=

MAXDMIN

) and minimum illuminance output (D

MAX

MIN

).

10

Page 11

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

8. Adjust the light intensity of Y signal output value by strobe light to 150mV (YA), calculate by below formula with

measuring the image lag signal which is qenerated by below timing diagram.

Y

LAGYlag

FLD

SG1

Strobe

Timing

Output

150⁄()100%()×=

Light

Y Signal

Output 150mV

Y

Lag

9. Adjust the light intensity of Y signal average value to 150mV (YA), calculate by below formula with measuring

the signal differences (∆Yf [mV]) between fields.

F

∆YfYA⁄()100% ()×=

Y

11

Page 12

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

Spectral Response

SPECTRAL RESPONSE CHARACTERISTICS

Excluding Light Source Characteristics

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

400 425 450 475 500 525 550 575 600 625 650 675 700

Wave Length (nm)

12

Figure 2. Spectral Response Characteristics

Page 13

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

APPLICATION CIRCUITS

+15V

22uH

XSUB

XV2 XV1 XSG1 XV3 XSG3 XV4

103

+

10uF/20V

FRGFH1F

H2

103

10uF/20V

1

3 4 5 6 7 8 9 102

S5C7221X01

20 19 18 17 16 15 14 13 12 11

MA110

+15V

103 103

+

105

+

10uF/20V

100K

5V

Φ

1

V4

2

Φ

V3

Φ

3

V2

SUB

4

Φ

5

V1

S5F329PW02

V

6

L

GND

7

V

8

DD

Φ

Φ

Φ

VRD

GND

V

V

16

H2

15

H1

14

RG

105

13

22K

12

11

V

SS

10

GG

9

OUT

180K

+

47/6.3V

680

27K

105

100

3.9K

KSC2757

22uH

-9V +15V

22uH

CCD Output

Figure 3. Application Circuits

13

Page 14

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

READ-OUT CLOCK TIMING CHART

Unit: [µs]

HD

V1

Odd

Field

V2

V3

2.5

Even

Field

V4

V1

V2

V3

V4

38.5

1.2 1.5 2.5 2.0

0.3

14

Figure 4. Read-out Clock Timing Chart

Page 15

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

CLOCK TIMING CHART (VERTICAL SYNC.)

FLD

VD

BLK

HD

SG1

SG2

V1

V2

V3

V4

CCD

OUT

CLP1

12345

620

625

582

581

10

1 3 5 531

15

2 4 6 2 4 6

20

25

310

582

581

315

325

320

1 3 587

330

335

340

2 4 6

82 4 6

1 3 5 7

Figure 5. Clock Timing Chart (Vertical Sync.)

15

Page 16

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

CLOCK TIMING CHART (HORIZONTAL SYNC.)

5

3

2

1

7

5

3

2

1

16

15

10

5

3

2

1

30

25

20

15

10

5

3

2

1

500

495

490

V1

V2

V3

H1

HD

BLK

H2

RS

XSHP

XSHD

V4

SUB

CLP1

Figure 6. Clock Timing Chart (Horizontal Sync.)

16

Page 17

1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA S5F329PW02

PACKAGE DIMENSIONS

2-R0.50

t = 0.25¡¾0.02

Unit: mm

8.00¡¾0.10

10.20¡¾0.10

12.40¡¾0.12

2.50

8.00¡¾0.10

10.20¡¾0.10

14.00¡¾0.12

1.30¡¾0.15

3.20¡¾0.15

1.27¡¾0.25

3.00¡¾0.50

0.46¡¾0.10

1.78¡¾0.50

12.46¡¾0.10

13.60¡¾0.12

NOTE:

1. Optical center deviation from mechanical center = ± 0.15mm for X and Y direction.

2. Optical surface height from glass lid surface = 1.3 ± 0.15mm

3. Optical surface height from package backside bottom = 1.9 ± 0.10mm

Figure 7. Package Dimensions

17

Page 18

S5F329PW02 1/3 INCH CCD IMAGE SENSOR FOR CCIR CAMERA

HANDLING INSTRUCTIONS

• Static Charge Prevention

CCD image sensors can be easily damaged by static discharge. Before handling, be sure to take the following

protective measures.

— Use non chargeable gloves, clothes or material. Also use conductive shoes.

— When handling directly, use an earth band.

— Install a conductive mat on the floor or working table to prevent generation of static electricity.

— Ionized air is recommended for discharging when handling CCD image sensor.

— For the shipment of mounted substrates, use boxes treated for the prevention of static charges.

• Soldering

— Make sure the package temperature does not exceed 80 °C.

— Solder dipping in a mounting furnace causes damage to the glass and other defects. Use a grounded 30W

soldering iron and solder each pin in less than 2 seconds. For repairs and remount, cool sufficiently.

— To dismount an imaging device, do not use a solder suction equipment. When using an electronic

disoldering tool, use a thermal controller of the zero cross on/off type and connect to ground.

• Dust and Dirt Protection

— Operate in the clean environments (around class 1000 will be appropriate).

— Do not either touch glass plates by hand or have object come in contact with glass surface. Should dirt

stick to a glass surface blow it off with an air blow (for dirt stuck through static electricity ionized air is

recommended).

— Clean with a cotton bud and ethyl alcohol if the glass surface is grease stained. Be careful not to scratch

the glass.

— Keep in case to protect from dust and dirt. To prevent dew condensation, preheat or precool when moving

to a room with great temperature differences.

— When a protective tape is applied before shipping, just before use remove the tape applied electrostatic

protection. Do not reuse the tape.

• Do not expose to strong light (sun rays) for long period, color filter are discolored.

• Exposure to high temperature or humidity will affect the characteristics. accordingly avoid storage or

usage in such conditions.

• CCD image sensors are precise optical equipment that should not be subject to mechanical shocks.

18

Loading...

Loading...