Page 1

S524C20D11/20D21/80D41/80D81

1K/2K/4K/8K-bit

Serial EEPROM

Data Sheet

OVERVIEW

The S524C20D11/20D21/80D41/80D81 serial EEPROM has a 1,024/2,048/4,096/8,192-bit (128/256/512/1,024byte) capacity, supporting the standard I2C™-bus serial interface. It is fabricated using Samsung’s most

advanced CMOS technology. One of its major feature is a hardware-based write protection circuit for the entire

memory area. Hardware-based write protection is controlled by the state of the write-protect (WP) pin. Using onepage write mode, you can load up to 16 bytes of data into the EEPROM in a single write operation. Another

significant feature of the S524C20D11/20D21/80D41/80D81 is its support for fast mode and standard mode.

FEATURES

I2C-Bus Interface

• Two-wire serial interface

• Automatic word address increment

EEPROM

• 1K/2K/4K/8K-bit (128/256/512/1,024-byte)

storage area

• 16-byte page buffer

• Typical 3.5 ms write cycle time with

auto-erase function

• Hardware-based write protection for the entire

EEPROM (using the WP pin)

• EEPROM programming voltage generated

on chip

• 1,000,000 erase/write cycles

• 100 years data retention

Operating Characteristics

• Operating voltage

— 2.5 V to 5.5 V (write)

— 2.2 V to 5.5 V (read)

• Operating current

— Maximum write current: < 3 mA at 5.5 V

— Maximum read current: < 200 µA at 5.5 V

— Maximum stand-by current: < 5 µA at 3.3 V

• Operating temperature range

— – 25°C to + 70°C (commercial)

— – 40°C to + 85°C (industrial)

• Operating clock frequencies

— 100 kHz at standard mode

— 400 kHz at fast mode

• Electrostatic discharge (ESD)

— 3,000 V (HBM)

— 300 V (MM)

Packages

• 8-pin DIP, SOP, and TSSOP

3-1

Page 2

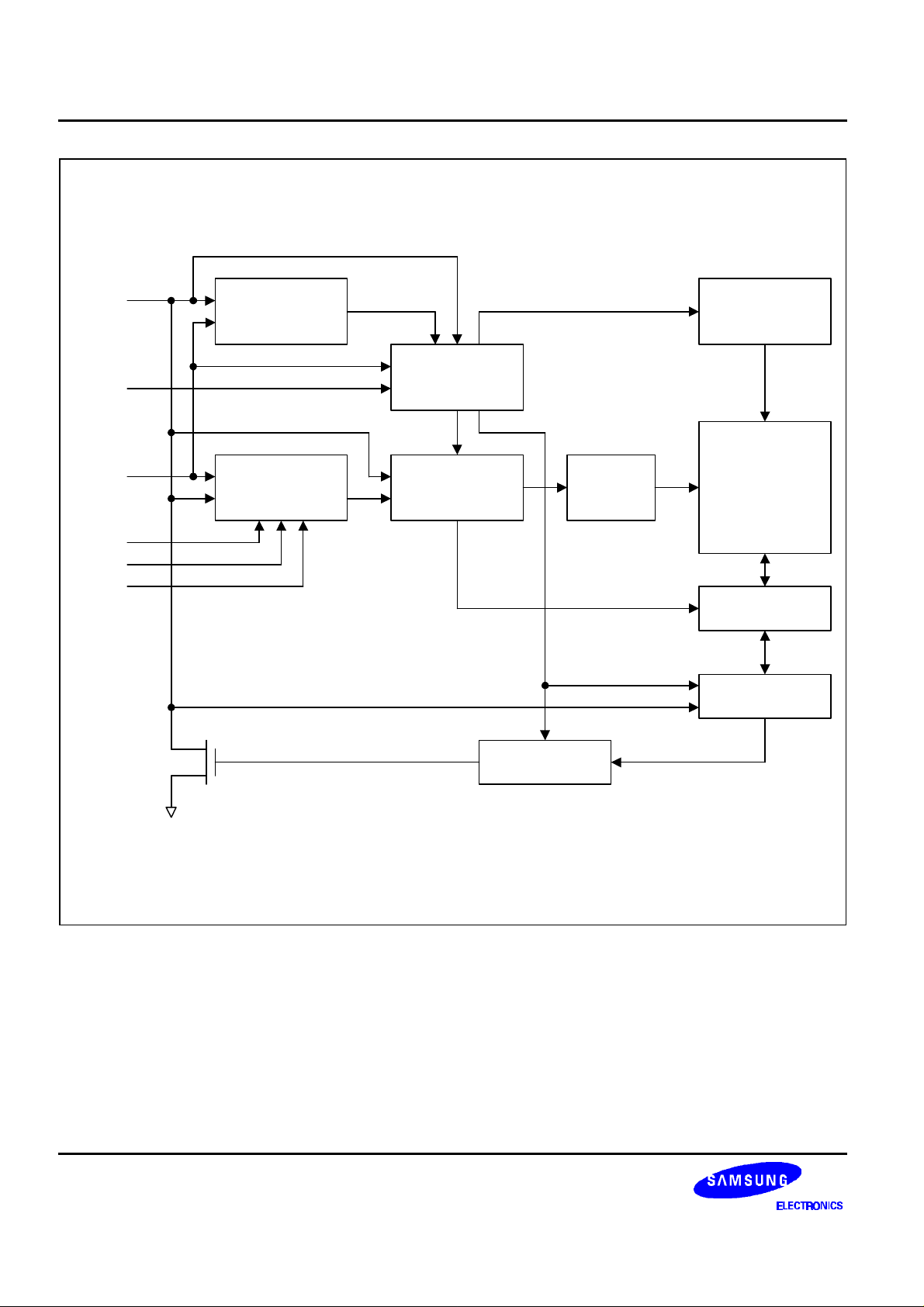

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

SDA

WP

SCL

A0

A1

A2

Start/Stop

Logic

Slave Address

Comparator

Control Logic

Word Address

Pointer

Row

decoder

HV Generation

Timing Control

EEPROM

Cell Array

128 x 8 bits

256 x 8 bits

512 x 8 bits

1024 x 8 bits

Column Decoder

Data Register

DOUT and ACK

Figure 3-1. S524C20D11/20D21/80D41/80D81 Block Diagram

3-2

Page 3

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

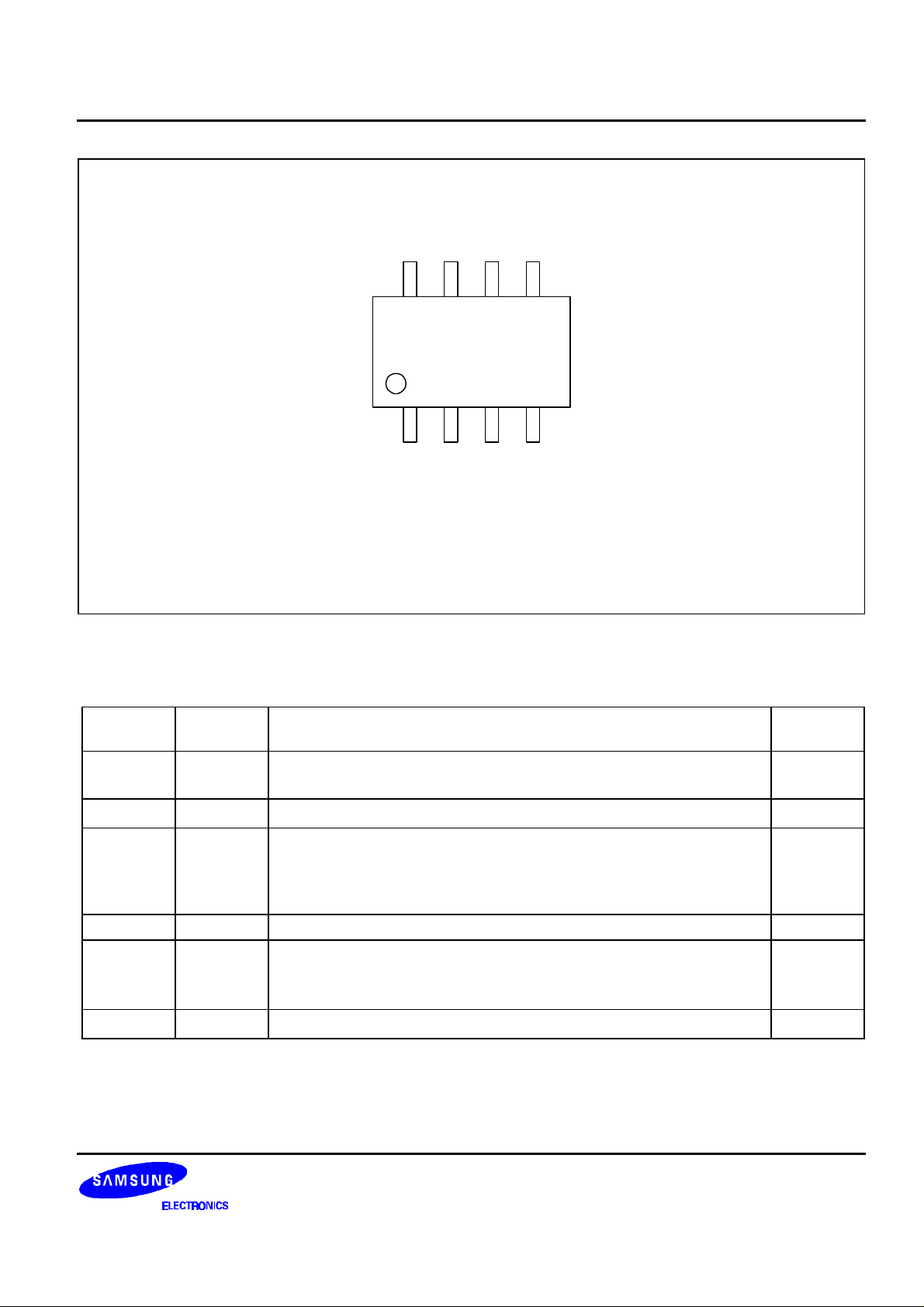

VCC WP SCL SDA

S524C20D11/20D21/

80D41/80D81

A0 A1 A2 VSS

NOTE: The S524C20D11/20D21/80D41/80D81 is available

in 8-pin DIP, SOP, and TSSOP package.

Figure 3-2. Pin Assignment Diagram

Table 3-1. S524C20D11/20D21/80D41/80D81 Pin Descriptions

Name Type Description Circuit

Type

A0, A1, A2

VSS

Input Input pins for device address selection. To configure a device address,

these pins should be connected to the VCC or V

of the device.

SS

– Ground pin. –

SDA I/O Bi-directional data pin for the I2C-bus serial data interface. Schmitt

trigger input and open-drain output. An external pull-up resistor must

be connected to V

Typical values for this pull-up resistor are 4.7 kΩ

CC.

(100 kHz) and 1 kΩ (400 kHz).

SCL Input Schmitt trigger input pin for serial clock input. 2

WP Input

Input pin for hardware write protection control. If you tie this pin to V

CC,

the write function is disabled to protect previously written data in the

entire memory; if you tie it to VSS, the write function is enabled.

VCC

– Single power supply. –

1

3

1

NOTE: See the following page for diagrams of pin circuit types 1, 2, and 3.

3-3

Page 4

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

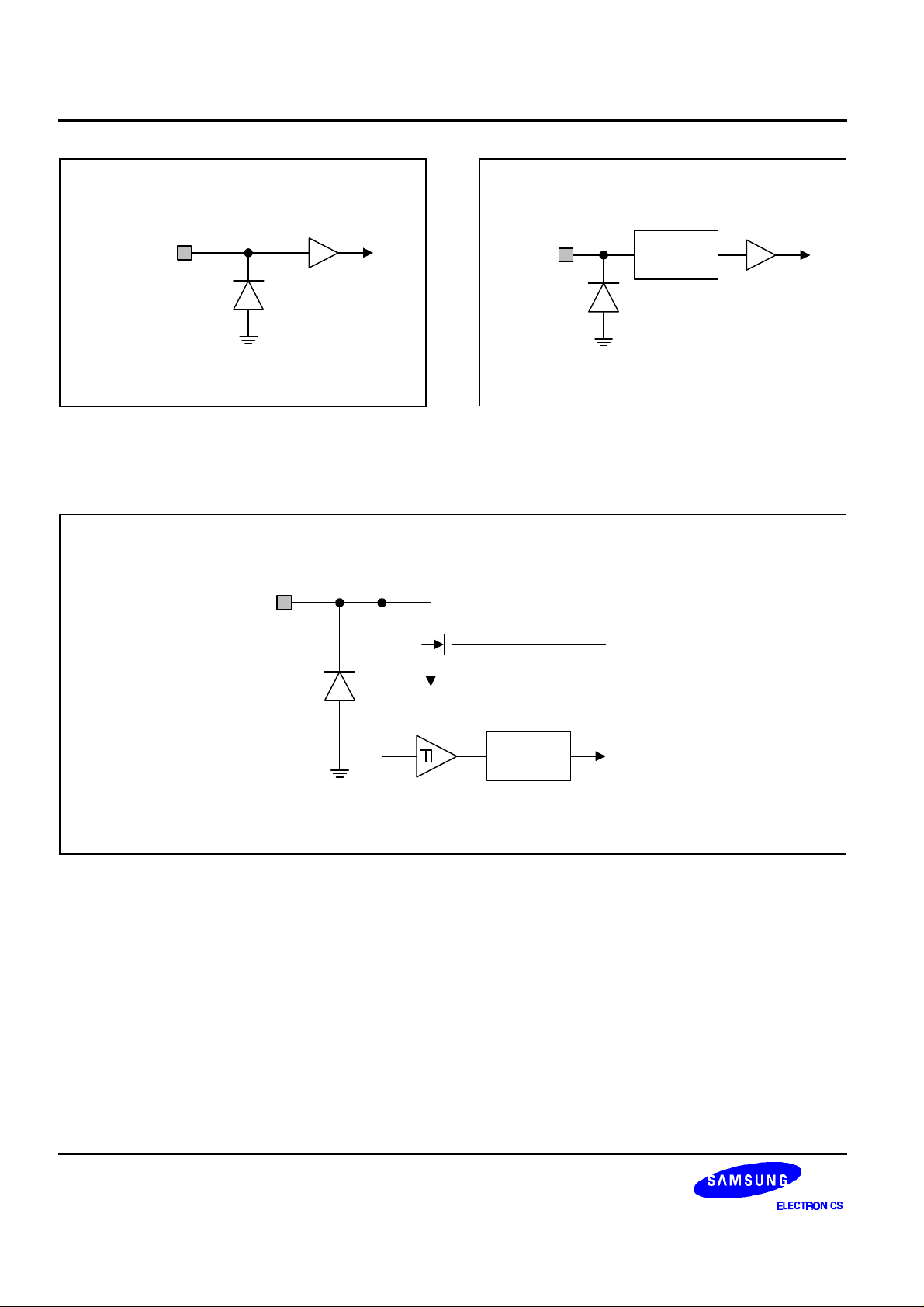

A0, A1,

A2, WP

Figure 3-3. Pin Circuit Type 1

SDA

SCL

Noise

Filter

Figure 3-4. Pin Circuit Type 2

Data Out

VSS

Noise

Filter

Figure 3-5. Pin Circuit Type 3

Data In

3-4

Page 5

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

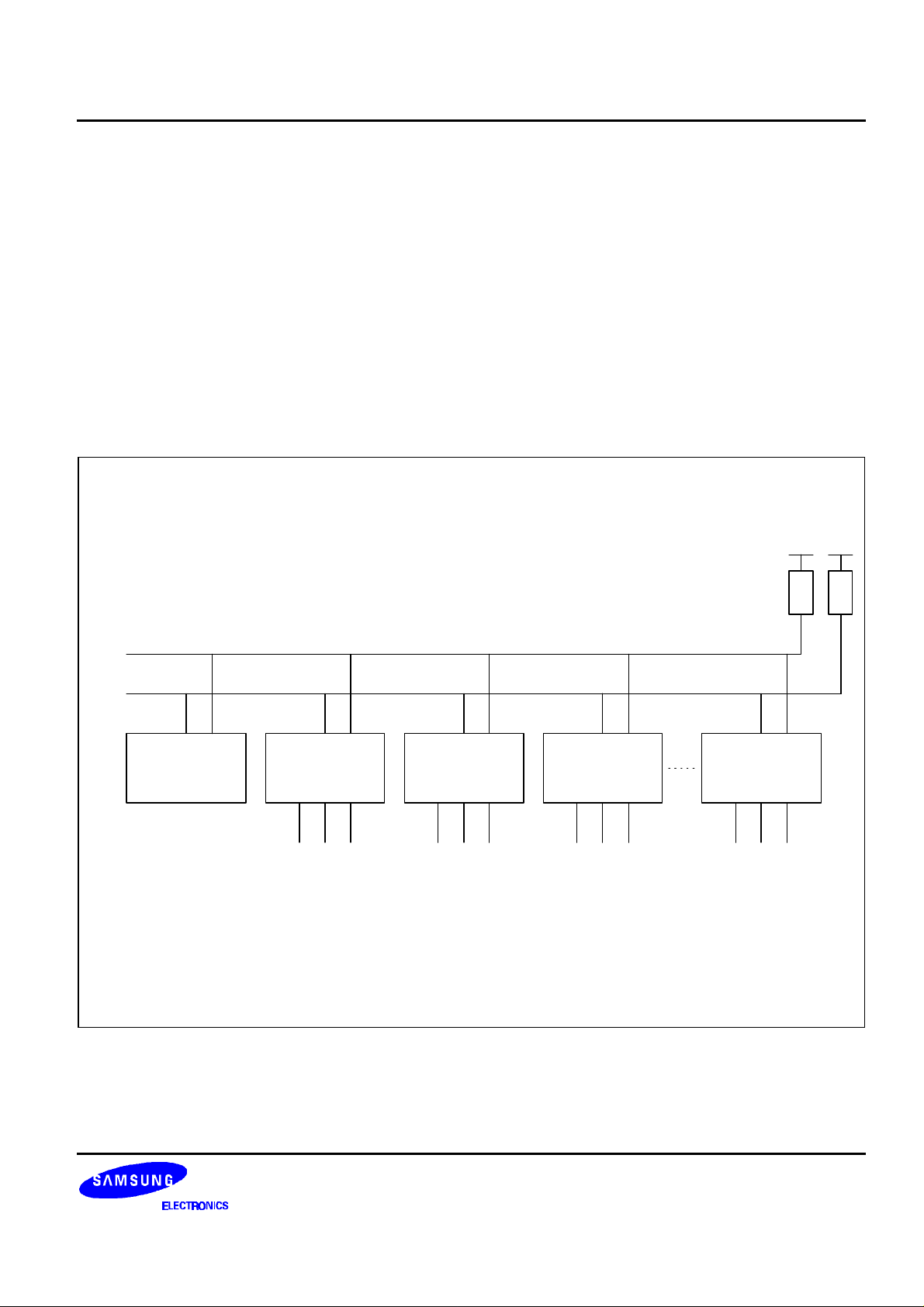

FUNCTION DESCRIPTION

I2C-BUS INTERFACE

The S524C20D11/20D21/80D41/80D81 supports the I2C-bus serial interface data transmission protocol. The twowire bus consists of a serial data line (SDA) and a serial clock line (SCL). The SDA and the SCL lines must be

connected to VCC by a pull-up resistor that is located somewhere on the bus.

Any device that puts data onto the bus is defined as the “transmitter” and any device that gets data from the bus

is the “receiver.” The bus is controlled by a master device which generates the serial clock and start/stop

conditions, controlling bus access. Using the A0,A1 and A2 input pins, up to eight S524C20D11/20D21 (four

S524C80D41, two for S524C80D81) devices can be connected to the same I2C-bus as slaves (see Figure 3-6).

Both the master and slaves can operate as transmitter or receiver, but the master device determines which bus

operating mode would be active.

V

CC

V

CC

SDA

SCL

Bus Master

(Transmitter/

Receiver)

MCU

Slave 1

S524C20D21

Tx/Rx

A0 A1 A2

To VCC or V

NOTES:

1. The A0 does not affect the device address of the S524C80D41.

2. The A0, A1 do not affect the device address of the S524C80D81.

SS

Slave 2

S524C20D21

Tx/Rx

A0 A1 A2

To VCC or V

SS

Slave 3

S524C20D21

Tx/Rx

A0 A1 A2

To VCC or V

SS

Slave 8

S524C20D21

Tx/Rx

A0 A1 A2

To VCC or V

SS

R

R

Figure 3-6. Typical Configuration (16 Kbits of Memory on the I2C-Bus)

3-5

Page 6

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

I2C-BUS PROTOCOLS

Here are several rules for I2C-bus transfers:

— A new data transfer can be initiated only when the bus is currently not busy.

— MSB is always transferred first in transmitting data.

— During a data transfer, the data line (SDA) must remain stable whenever the clock line (SCL) is High.

The I2C-bus interface supports the following communication protocols:

• Bus not busy: The SDA and the SCL lines remain High level when the bus is not active.

• Start condition: Start condition is initiated by a High-to-Low transition of the SDA line while SCL remains High

level. All bus commands must be preceded by a start condition.

• Stop condition: A stop condition is initiated by a Low-to-High transition of the SDA line while SCL remains

High level. All bus operations must be completed by a stop condition (see Figure 3-7).

~

~

SCL

~

~

SDA

Start

Condition

Data or

ACK Valid

Data

Change

Stop

Condition

Figure 3-7. Data Transmission Sequence

• Data valid: Following a start condition, the data becomes valid if the data line remains stable for the duration

of the High period of SCL. New data must be put onto the bus while SCL is Low. Bus timing is one clock

pulse per data bit. The number of data bytes to be transferred is determined by the master device. The total

number of bytes that can be transferred in one operation is theoretically unlimited.

• ACK (Acknowledge): An ACK signal indicates that a data transfer is completed successfully. The transmitter

(the master or the slave) releases the bus after transmitting eight bits. During the 9th clock, which the master

generates, the receiver pulls the SDA line low to acknowledge that it successfully received the eight bits of

data (see Figure 3-8). But the slave does not send an ACK if an internal write cycle is still in progress.

In data read operations, the slave releases the SDA line after transmitting 8 bits of data and then monitors

the line for an ACK signal during the 9th clock period. If an ACK is detected, the slave will continue to

transmit data. If an ACK is not detected, the slave terminates data transmission and waits for a stop condition

to be issued by the master before returning to its stand-by mode.

3-6

Page 7

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

Master

SCL Line

Data from

Transmitter

ACK from

Receiver

Bit 9Bit 1

ACK

Figure 3-8. Acknowledge Response From Receiver

• Slave Address: After the master initiates a Start condition, it must output the address of the device to be

accessed. The most significant four bits of the slave address are called the “device identifier”. The identifier

for the S524C20D11/20D21/80D41/80D81 is “1010B”. The next three bits comprise the addr ess of a specific

device. The device address is defined by the state of the A0, A1 and A2 pins. Using this addressing scheme,

you can cascade up to eight S524C20D11/20D21 or four S524C80D41 or two S524C80D81 on the bus (see

Table 3-2 below). The b1 for the S524C80D41 or the b1, b2 for S524C80D81 are used by the master to

select which of the blocks of internal memory (1 block = 256 words) are to be accessed. The bits are in effect

the most significant bits of the word address.

• Read/Write: The final (eighth) bit of the slave address defines the type of operation to be performed. If the

R/W bit is “1”, a read operation is executed. If it is “0”, a write operation is executed.

Table 3-2. Slave Device Addressing

Device Device Identifier Device Address R/W Bit

b7 b6 b5 b4

b3 b2 b1 b0

S524C20D11/20D21 1 0 1 0 A2 A1 A0 R/W

S524C80D41 1 0 1 0 A2 A1 B0 R/W

S524C80D81 1 0 1 0 A2 B1 B0 R/W

NOTE: The B2, B1, B0 correspond to the MSB of the memory array address word.

3-7

Page 8

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

BYTE WRITE OPERATION

In a complete byte write operation, the master transmits the slave address, word address, and one data byte to

the S524C20D11/20D21/80D41/80D81 slave device (see Figure 3-9).

Slave AddressStart Word Address Data Stop

A

C

K

A

C

K

A

C

K

Figure 3-9. Byte Write Operation

Following the Start condition, the master sends the device identifier (4 bits), the device address (3 bits), and an

R/W bit set to “0” onto the bus. Then the addressed S524C20D11/20D21/80D41/80D81 generates an ACK and

waits for the next byte. The next byte to be transmitted by the master is the word address. This 8-bit address is

written into the word address pointer of the S524C20D11/20D21/80D41/80D81.

When the S524C20D11/20D21/80D41/80D81 receives the word address, it responds by issuing an ACK and then

waits for the next 8-bit data. When it receives the data byte, the S524C20D11/20D21/80D41/80D81 again

responds with an ACK. The master terminates the transfer by generating a Stop condition, at which time the

S524C20D11/20D21/80D41/80D81 begins the internal write cycle.

While the internal write cycle is in progress, all S524C20D11/20D21/80D41/80D81 inputs are disabled and the

S524C20D11/20D21/80D41/80D81 does not respond to additional requests from the master.

3-8

Page 9

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

PAGE WRITE OPERATION

The S524C20D11/20D21/80D41/80D81 can also perform 16-byte page write operation. A page write operation is

initiated in the same way as a byte write operation. However, instead of finishing the write operation after the first

data byte is transferred, the master can transmit up to 15 additional bytes. The

S524C20D11/20D21/80D41/80D81 responds with an ACK each time it receives a complete byte of data (see

Figure 3-10).

Slave Address Word Address (n)Start

A

C

K

A

C

K

Data (n)

Data (≤ n + 15) Stop

A

A

C

C

K

K

A

C

K

Figure 3-10. Page Write Operation

The S524C20D11/20D21/80D41/80D81 automatically increments the word address pointer each time it receives

a complete data byte. When one byte has been received, the internal word address pointer increments to the

next address and the next data byte can be received.

If the master transmits more than 16 bytes before it generates a stop condition to end the page write operation,

the S524C20D11/20D21/80D41/80D81 word address pointer value “rolls over” and the previously received data

is overwritten. If the master transmits less than 16 bytes and generates a stop condition, the

S524C20D11/20D21/80D41/80D81 writes the received data to the corresponding EEPROM address.

During a page write operation, all inputs are disabled and there is no response to additional requests from the

master until the internal write cycle is completed.

3-9

Page 10

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

POLLING FOR AN ACK SIGNAL

When the master issues a stop condition to initiate a write cycle, the S524C20D11/20D21/80D41/80D81 starts an

internal write cycle. The master can then immediately begin polling for an ACK from the slave device.

To poll for an ACK signal in a write operation, the master issues a start condition followed by the slave address.

As long as the S524C20D11/20D21/80D41/80D81 remains busy with the write operation, no ACK is returned.

When the S524C20D11/20D21/80D41/80D81 completes the write operation, it returns an ACK and the master

can then proceed with the next read or write operation (see Figure 3-11).

Send Write

Command

Send Stop Condition to

Initiate Write Cycle

Send Start

Condition

Send Slave Address

with R/W bit = "0"

ACK = "0" ?

Yes

Start Next

Operation

No

Figure 3-11. Master Polling for an ACK Signal from a Slave Device

3-10

Page 11

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

HARDWARE-BASED WRITE PROTECTION

You can also write-protect the entire memory area of the S524C20D11/20D21/80D41/80D81. This method of

write protection is controlled by the state of the Write Protect (WP) pin.

When the WP pin is connected to VCC, any attempt to write a value to the memory is ignored.

The S524C20D11/20D21/80D41/80D81 will acknowledge slave and word address, but it will not generate an

acknowledge after receiving the first byte of the data. Thus the write cycle will not be started when the stop

condition is generated. By connecting the WP pin to VSS, the write function is allowed for the entire memory.

These write protection features effectively change the EEPROM to a ROM in order to prevent data from being

overwritten. Whenever the write function is disabled, a slave address and a word address are acknowledged on

the bus, but data bytes are not acknowledged.

CURRENT ADDRESS BYTE READ OPERATION

The internal word address pointer maintains the address of the last word accessed, incremented by one.

Therefore, if the last access (either read or write) was to the address “n”, the next read operation would access

data at address “n+1”.

When the S524C20D11/20D21/80D41/80D81 receives a slave address with the R/W bit set to “1”, it issues an

ACK and sends the eight bits of data. The master does not acknowledge the transfer but it does generate a Stop

condition. In this way, the S524C20D11/20D21/80D41/80D81 effectively stops the transmission (see Figure 3-

12).

Slave Address DataStart

A

C

K

Stop

N

O

A

C

K

Figure 3-12. Current Address Byte Read Operation

3-11

Page 12

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

RANDOM ADDRESS BYTE READ OPERATION

Using random read operations, the master can access any memory location at any time. Before it issues the

slave address with the R/W bit set to “1”, the master must first perform a “ dummy” write operation. This operation

is performed in the following steps:

1. The master first issues a Start condition, the slave address, and the word address to be read. (This step sets

the internal word address pointer of the S524C20D11/20D21/80D41/80D81 to the desired address.)

2. When the master receives an ACK for the word address, it immediately re-issues a start condition followed

by another slave address, with the R/W bit set to “1”.

3. The S524C20D11/20D21/80D41/80D81 then sends an ACK and the 8-bit data stored at the desired address.

4. At this point, the master does not acknowledge the transmission, but generates a stop condition instead.

5. In response, the S524C20D11/20D21/80D41/80D81 stops transmitting data and reverts to its stand-by mode

(see Figure 3-13).

Slave Address Word AddressStart

A

C

K

A

C

K

Slave Address

StopStart Data (n)

A

C

K

N

O

A

C

K

Figure 3-13. Random Address Byte Read Operation

3-12

Page 13

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

SEQUENTIAL READ OPERATION

Sequential read operations can be performed in two ways: as a series of current address reads or as random

address reads. The first data is sent in the same way as the previous read mode used on the bus. The next time,

however, the master responds with an ACK, indicating that it requires additional data.

The S524C20D11/20D21/80D41/80D81 continues to output data for each ACK it receives. To stop the sequential

read operation, the master does not respond with an ACK, but instead issues a Stop condition.

Using this method, data is output sequentially with the data from address “n” followed by the data from “n+1”. The

word address pointer for read operations increments all word addresses, allowing the entire EEPROM to be read

sequentially in a single operation. After the entire EEPROM is read, the word address pointer “rolls over” and the

S524C20D11/20D21/80D41/80D81 continues to transmit data for each ACK it receives from the master (see

Figure 3-14).

Slave Address Data (n)Start

~

~

A

C

K

A

C

K

Data (n + x)

A

C

K

N

O

A

C

K

Figure 3-14. Sequential Read Operation

3-13

Page 14

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

ELECTRICAL DATA

Table 3-3. Absolute Maximum Ratings

(TA = 25°C)

Parameter Symbol

Supply voltage

Input voltage

Output voltage

Operating temperature

Storage temperature

Electrostatic discharge

VCC

VIN

VO

TA

T

STG

V

ESD

MM 300

Conditions Rating Unit

– – 0.3 to + 7.0 V

– – 0.3 to + 7.0 V

– – 0.3 to + 7.0 V

– – 40 to + 85

– – 65 to + 150

HBM 3000 V

Table 3-4. D.C. Electrical Characteristics

(T

= – 25°C to + 70°C (C), – 40°C to + 85°C (I), VCC = 2.2 V to 5.5 V when reading, 2.5 V to 5.5 V when writing)

A

Input low voltage

Input high voltage

Parameter Symbol

Input leakage current

Output leakage current

VIL

VIH

SCL, SDA, A0, A1, A2

ILI VIN = 0 to VCC

ILO

VO = 0 to VCC

Conditions Min Typ Max Unit

– –

0.7 V

CC

– –

– – V

0.3 V

CC

10 µA

– – 10 µA

°

C

°

C

V

Output low voltage

Supply current

Stand-by current

VOL

I

CC1

(write)

I

CC2

(write)

I

CC3

(read)

I

CC4

(read)

I

CC5

I

CC6

IOL = 3 mA, V

V

= 5.5 V, 400 kHz

CC

= 2.5 V

CC

VCC = 3.3 V, 100 kHz

V

= 5.5 V, 400 kHz

CC

V

= 3.3 V, 100 kHz

CC

V

= SDA = SCL = 5.5 V,

CC

all other inputs = 0 V

V

= SDA = SCL = 3.3 V,

CC

all other inputs = 0 V

– – 0.4 V

– – 3 mA

– – 1.5

– – 0.2

– – 0.1

– – 10 µA

– – 5

3-14

Page 15

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

Table 3-4. D.C. Electrical Characteristics (Continued)

(T

= – 25°C to + 70°C (C), – 40°C to + 85°C (I), VCC = 2.2 V to 5.5 V when reading, 2.5 V to 5.5 V when writing)

A

Parameter Symbol Conditions Min Typ Max Unit

Input capacitance

CIN

25°C, 1MHz,

– – 10 pF

VCC = 5 V, VIN = 0 V,

A0, A1, A2, SCL and WP pin

Input/output capacitance

I/O

25°C, 1MHz,

VCC = 5 V, V

= 0 V,

I/O

– – 10

C

SDA pin

Table 3-5. A.C. Electrical Characteristics

(T

= – 25°C to + 70°C (C), – 40°C to + 85°C (I), VCC = 2.2 V to 5.5 V when reading, 2.5 V to 5.5 V when writing)

A

Parameter Symbol Conditions VCC = 2.2 to 5.5 V

(Standard Mode)

VCC = 4.5 to 5.5 V

(Fast Mode)

Unit

Min Max Min Max

F

External clock frequency

Clock high time

Clock low time

Rising time

CLK

t

HIGH

t

LOW

tR

– 0 100 0 400 kHz

– 4 – 0.6 –

– 4.7 – 1.3 –

SDA, SCL – 1 – 0.3

µs

Falling time

Start condition hold time

Start condition setup time

Data input hold time

Data input setup time

Stop condition setup time

Bus free time

Data output valid from

clock low

(note)

Noise spike width

Write cycle time

NOTE: When acting as a transmitter, the S524C20D11/20D21/80D41/80D81 must provide an internal minimum delay time

to bridge the undefined period (minimum 300 ns) of the falling edge of SCL. This is required to avoid unintended

generation of a start or stop condition.

tF

t

HD:STA

t

SU:STA

t

HD:DAT

t

SU:DAT

t

SU:STO

t

BUF

tAA

tSP

tWR

SDA, SCL – 0.3 – 0.3

– 4 – 0.6 –

– 4.7 – 0.6 –

– 0 – 0 –

– 0.25 – 0.1 –

– 4 – 0.6 –

Before new

4.7 – 1.3 –

transmission

– 0.3 3.5 – 0.9

– – 100 – 50 ns

– – 10 – 10 ms

3-15

Page 16

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

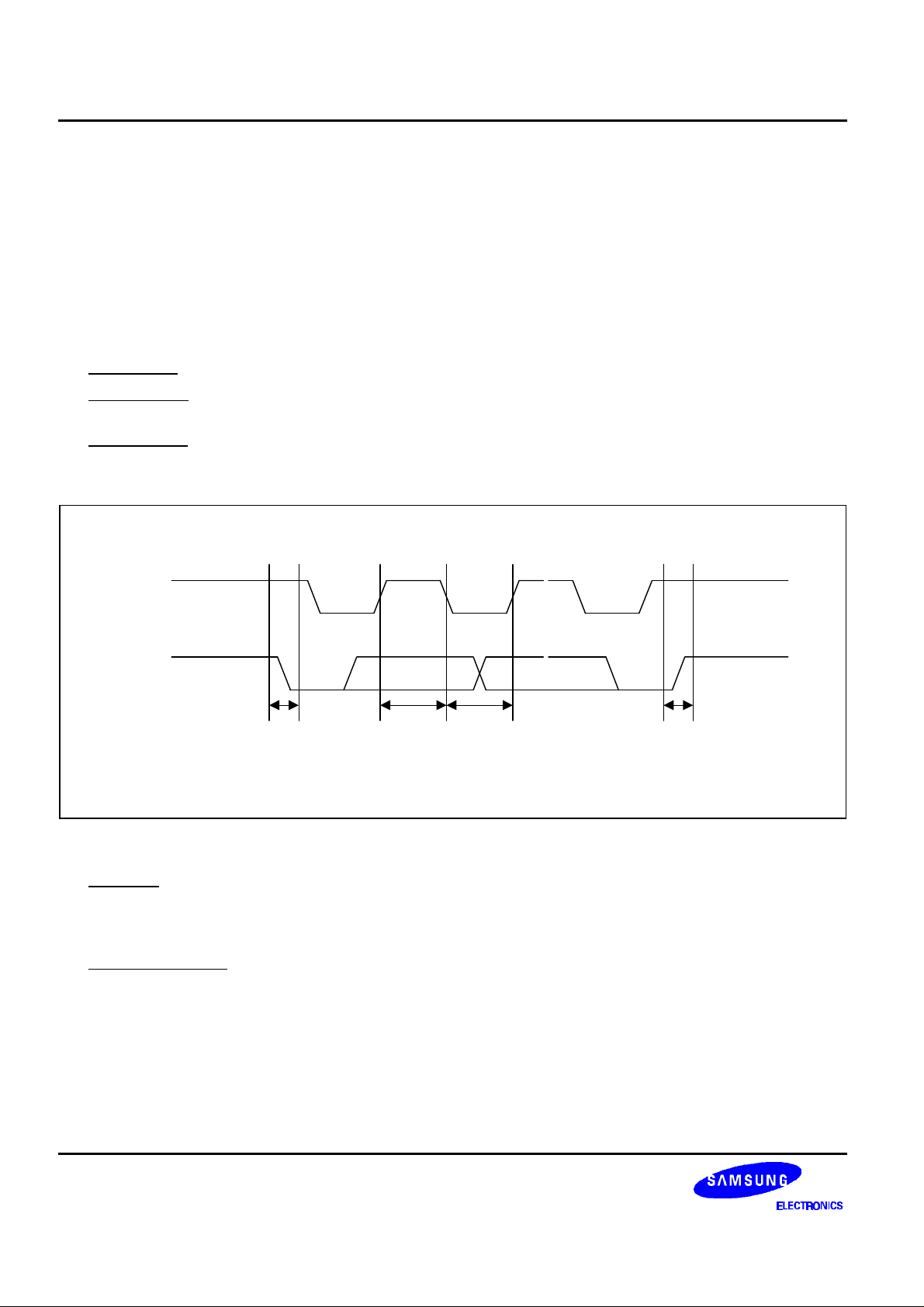

SCL

SDA In

SDA Out

tF tR

tLOW

tSU:STA tHD:STA tHD:DAT tSU:DAT tSU:STO

tHIGH

tBUFtAA

Figure 3-16. Timing Diagram for Bus Operations

~

~

SCL

SDA

WORDn

8th Bit

ACK

Stop

Condition

t

~

~

~

~

~

~

WR

Start

Condition

Figure 3-17. Write Cycle Timing Diagram

3-16

Page 17

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

CHARACTERISTIC CURVES

NOTE

The characteristic values shown in the following graphs are based on actual test measurements. They do

not, however, represent guaranteed operating values.

(Frequency = 100 kHz)

2.0

1.6

Temp = - 40 °C

1.2

ICC (mA)

0.8

0.4

Temp = - 25 °C

Temp = 0 °C

Temp = 25 °C

Temp = 70 °C

Temp = 85 °C

0

2 3 4 5 6

VCC (V)

Figure 3-18. I

(Write Current) vs. VCC

CC

3-17

Page 18

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

(Frequency = 100 kHz)

120

100

ICC (µA)

80

60

40

20

0

2 3 4 5 6

VCC (V)

Figure 3-19. I

(Read Current) vs. V

CC

Temp = - 40 °C

Temp = - 25 °C

Temp = 0 °C

Temp = 25 °C

Temp = 70 °C

Temp = 85 °C

CC

3-18

Page 19

DATA SHEET S524C20D11/20D21/80D41/80D81 SERIAL EEPROM

(Frequency = 100 kHz)

10

8

Temp = - 40 °C

6

ICC (µA)

4

2

Temp = - 25 °C

Temp = 0 °C

Temp = 25 °C

Temp = 70 °C

Temp = 85 °C

0

2 3 4 5 6

VCC (V)

Figure 3-20. I

(Stand-by Current) vs. V

CC

CC

3-19

Page 20

S524C20D11/20D21/80D41/80D81 SERIAL EEPROM DATA SHEET

(TA = 25 °C)

50

IOL (mA)

40

30

20

10

0

0 3 4 5 6

1 2

Figure 3-21. I

VOL (V)

(Output Low Voltage) vs. V

OL

VDD = 5.5 V

VDD = 5.0 V

VDD = 4.5 V

VDD = 4.0 V

VDD = 3.5 V

VDD = 3.0 V

OL

3-20

Loading...

Loading...